Page 1

KL2612

2-Channel 125 V AC Relay Output Terminal

Configuration Instructions

Version 1.1

2006-20-23

Page 2

Datasheet for KL2612, Version 1.1

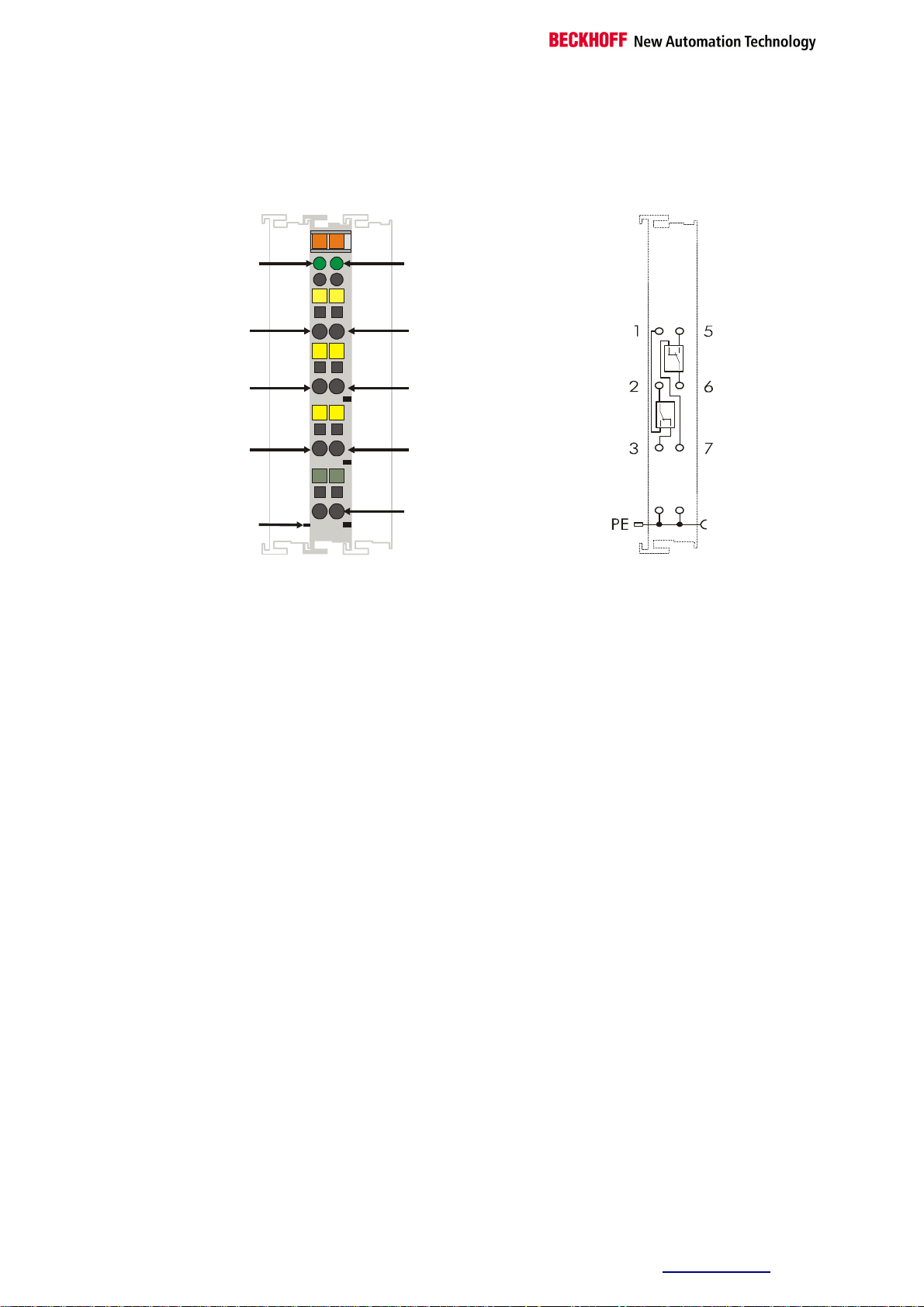

Top view

KL2612

3

7

Introduction KL2612

13

14

A

B

C

D

1

5

Signal LED2

LED display

Process data

OUT

OUT

power

contact

IN

2 6

5

6

OUT

1

2

IN

3

7

OUT

PE

PE

4

8

PE

Functional Description

The KL2612 output terminal switches two relays, each having one

changeover contact, under control of the automation device. The signal

state of the bus terminal is indicated by an LED. If the LED is on, it means

that the contact between 2 and 1 or, in the case of the second relay,

between 6 and 5, is closed. The KL2612 Bus Terminal does not have a

power contact, which means that a voltage that has been passed on

through earlier terminals via the power contacts must be fed in again after

a KL2612.

The signal LEDs indicate the operational state of the associated terminal

channel.

On: Changeover between 2-1 (6-5) closed

Off: Changeover between 2-3 (6-7) closed

Or:

A watchdog timer overflow has occurred. If no process data is handled by

the bus coupler for 100 ms, the green LED goes out and the outputs are

set to 0.

The bit-width in the process image is 2 bits.

Beckhoff™ and TwinCAT are registered trademarks of Beckhoff. Information is subject to change without notice and warranted only to the extent agreed in the terms

of contract. Beckhoff Automation GmbH, Eiserstr. 5, 33415 Verl, Germany, Phone: +49 (0) 5246 963 0, Fax.: +49 (0) 5246 963 149, http://www.beckhoff.com

Page 3

Datasheet for KL2612, Version 1.1

Technical data

Technical data KL2612

Number of outputs

Contact material

Switched voltage max.

Switched current max.

Switched power max.

with resistive load

Minimum permitted load

(approximate)

Reaction times

at rated load

Electrical isolation

K-bus current consumption

Bit width in the process

image

Service life (operating

cycles) mechanical

Operating cycles electr.

(min.)

Permitted operating

frequency at maximum

contact load

Contact resistance max. (new)

2 x change-over

Gold-clad silver alloy

125 V AC / 30 V DC

5 A

alternating voltage

0,5 A 125V AC

direct voltage

2 A 30V DC

10 µA at 10mV

Max. reaction time 4 ms

Max. release time 4 ms

max. bounce time 4 ms

500 V

60 mA

2 A

108 cycles

105 resistive load switches

at 30 V DC, 2 A

or 125 V AC, 0,5 A

20 cycles / min

< 40 mOhm

(K-bus/mains voltage)

eff

Insulation resistance (min).

Test voltage between

open contacts

Configuration

Weight approx.

Operating temperature

Storage temperature

Relative humidity

Vibrations/Shock

resistance

EMC resistance burst / ESD

Installation position

Type of protection

100 MOhm at 500 V DC

750 V (1 min. between open contacts)

No address or configuration settings

80 g

0°C ... +55°C

-25°C ... +85°C

95% without dew formation

according to IEC 68-2-6 / IEC 68-2-27

According to EN 50082 (ESD, burst) / EN 50081

any

IP20

Beckhoff™ and TwinCAT are registered trademarks of Beckhoff. Information is subject to change without notice and warranted only to the extent agreed in the terms

of contract. Beckhoff Automation GmbH, Eiserstr. 5, 33415 Verl, Germany, Phone: +49 (0) 5246 963 0, Fax.: +49 (0) 5246 963 149,

http://www.beckhoff.com

Page 4

Datasheet for KL2612, Version 1.1

i

Note

Smooth operation

Notes on the Correct Use of Relay

Terminals

It is extremely important to observe the technical specifications if fault-free

operation is to be guaranteed. Any time that the stated parameters are

exceeded, damage ranging from premature contact ageing up to fused

contacts can result.

If relays are to be used in a control system the expected operating

conditions must be analysed with great care.

Switching capacity, service life (operating cycles) and the number of

switches per minute must be considered.

Appropriate protective circuits must be used to protect the relay contacts

from excessive voltage peaks such as can occur when switching inductive

loads (contactors, motors etc.). This allows switching frequencies nearly

equal to those appropriate to resistive loads to be achieved. Arcing time

when switching DC loads are significantly longer than those for comparable

AC voltages (where there is a zero-voltage transition); melting of the

material can result.

Warning!

Service life

If the terminal is used to change the direction of inductive loads, adequate

dead-times during the switch-over must be provided, in order to avoid

temporary short-circuits.

It is the maximum values that are to be expected that are critical to

selection of the right terminal rather than the technical figures for normal

operation!

Beckhoff™ and TwinCAT are registered trademarks of Beckhoff. Information is subject to change without notice and warranted only to the extent agreed in the terms

of contract. Beckhoff Automation GmbH, Eiserstr. 5, 33415 Verl, Germany, Phone: +49 (0) 5246 963 0, Fax.: +49 (0) 5246 963 149, http://www.beckhoff.com

Loading...

Loading...