Page 1

Documentation for

EP6001 and EP6002

Serial Interface Modules (RS232 or RS422/RS485)

Version:

Date:

2.1.0

2018-10-19

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation Issue Status..............................................................................................................7

2 Product overview.......................................................................................................................................9

2.1 Module overview................................................................................................................................9

2.2 EtherCAT Box - Introduction............................................................................................................10

2.3 EP6001-0002...................................................................................................................................12

2.3.1 EP6001-0002 - Introduction............................................................................................. 12

2.3.2 EP6001-0002 – Technical data ....................................................................................... 13

2.3.3 EP6001-0002 - Process image........................................................................................ 14

2.4 EP6002-0002...................................................................................................................................16

2.4.1 EP6002-0002 - Introduction............................................................................................. 16

2.4.2 EP6002-0002 – Technical data ....................................................................................... 18

2.4.3 EP6002-0002 - Process image........................................................................................ 19

3 Mounting and connection.......................................................................................................................21

3.1 Mounting..........................................................................................................................................21

3.1.1 Dimensions ...................................................................................................................... 21

3.1.2 Fixing ............................................................................................................................... 22

3.1.3 Nut torque for connectors ................................................................................................ 23

3.1.4 Additional checks............................................................................................................. 24

3.2 EtherCAT.........................................................................................................................................25

3.2.1 EtherCAT connection....................................................................................................... 25

3.2.2 EtherCAT - Fieldbus LEDs .............................................................................................. 27

3.3 Power supply ...................................................................................................................................28

3.3.1 Power Connection ........................................................................................................... 28

3.3.2 Status LEDs for power supply ......................................................................................... 31

3.3.3 Power cable conductor losses M8 ................................................................................... 32

3.3.4 Conductor losses 7/8"...................................................................................................... 33

3.4 Signal connection ............................................................................................................................34

3.4.1 Signal connection EP6001-0002 ..................................................................................... 34

3.4.2 Signal connection EP6002-0002 ..................................................................................... 37

3.5 EP6001-0002 - Status LEDs ...........................................................................................................38

3.6 EP6002-0002 - Status LEDs ...........................................................................................................39

3.7 Cabling ............................................................................................................................................40

3.8 UL Requirements.............................................................................................................................42

3.9 ATEX notes .....................................................................................................................................43

3.9.1 ATEX - Special conditions ............................................................................................... 43

3.9.2 BG2000-0000 - EtherCAT Box protection enclosure....................................................... 44

3.9.3 ATEX Documentation ...................................................................................................... 45

4 Basics communication - EtherCAT........................................................................................................46

4.1 EtherCAT basics..............................................................................................................................46

4.2 Watchdog setting.............................................................................................................................46

EP6001 and EP6002 3Version: 2.1.0

Page 4

Table of contents

4.3 EtherCAT State Machine.................................................................................................................49

4.4 CoE interface...................................................................................................................................51

5 Commissioning/Configuration ...............................................................................................................56

5.1 EP600x-0002 - Interface modes......................................................................................................56

5.2 EP600x-0002 - Basic function principles .........................................................................................59

5.3 Insertion in the EtherCAT network...................................................................................................63

5.4 Configuration by means of the TwinCAT System Manager.............................................................66

5.5 EP600x-0002 - Selection of the interface type ................................................................................74

5.6 EP6002-0002 - sample program 1 ..................................................................................................75

5.7 EP6002-0002 - Sample program 2..................................................................................................78

5.8 EP6002-0002 - Object overview......................................................................................................81

5.9 EP6002-0002 - Object description and parameterization................................................................90

5.10 EP6001-0002 - Object overview....................................................................................................112

5.11 EP6001-0002 - Object description and parameterization..............................................................117

5.12 Restoring the delivery state ...........................................................................................................132

6 Appendix ................................................................................................................................................133

6.1 General operating conditions.........................................................................................................133

6.2 EtherCAT Box- / EtherCATPBox - Accessories ..........................................................................134

6.3 Support and Service ......................................................................................................................135

EP6001 and EP60024 Version: 2.1.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATP®, SafetyoverEtherCAT®, TwinSAFE®, XFC® and XTS® are

registered trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

EP6001 and EP6002 5Version: 2.1.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

EP6001 and EP60026 Version: 2.1.0

Page 7

1.3 Documentation Issue Status

Version Comment

2.1.0 • Chapter Notes on the documentation updated

• Structural update

• RS232 level corrected

• Chapter Mounting updated

2.0.1 • Nut torques for connectors updated

2.0.0 • Migration

• EP6001-0002 added

• Chapter Mounting updated

• Conductor losses 7/8" added

• Chapter Cabling updated

• EP6001, EP6002 Status-LEDs updated

• Chapter Signal connection added

• EP6001-0002 - Status-LEDs added

• Basics communication - EtherCAT added

• EP600x-0002 - Interface modes updated

• EP600x-0002 - Basic function principles updated

• EP600x-0002 - Choice of the interface type updated

• EP6002-0002 - Sample program 1 updated

• EP6002-0002 - Sample program 2 updated

• EP6001-0002 - Object overview added

• EtherCAT Box accessories updated

1.3.0 • Power Connection updated

1.2.0 • Description of choosing the interface type via System Manager corrected

• Object description extended

• Notes on RS485 mode extended

• Chapter EtherCAT connection updated

1.1.0 • Description of the M12 sockets corrected

• Technical data updated

1.0.0 • Extended ambient temperature range

• Sample programs added

• Special conditions for ATEX added

• Description of the power connection updated

• Overview of EtherCAT cables extended

0.1 • First preliminary version for EP6002-0002

Foreword

Firmware and hardware versions

This documentation refers to the firmware and hardware version that was applicable at the time the

documentation was written.

The module features are continuously improved and developed further. Modules having earlier production

statuses cannot have the same properties as modules with the latest status. However, existing properties

are retained and are not changed, so that older modules can always be replaced with new ones.

The firmware and hardware version (delivery state) can be found in the batch number (D-number) printed on

the side of the EtherCATBox.

EP6001 and EP6002 7Version: 2.1.0

Page 8

Foreword

Syntax of the batch number (D-number)

D: WW YY FF HH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with D no. 29 10 02 01:

29 - week of production 29

10 - year of production 2010

02 - firmware version 02

01 - hardware version 01

EP6001 and EP60028 Version: 2.1.0

Page 9

Product overview

2 Product overview

2.1 Module overview

EP600x-0002

Module Signal connection Number of channels – serial interfaces Comment

EP6001-0002 [}12]

EP6002-0002 [}16]

4 x M12 1 Narrow housing

4 x M12 2 Narrow housing

EP6001 and EP6002 9Version: 2.1.0

Page 10

Product overview

2.2 EtherCAT Box - Introduction

The EtherCAT system has been extended with EtherCAT Box modules with protection class IP67. Through

the integrated EtherCAT interface the modules can be connected directly to an EtherCAT network without an

additional Coupler Box. The high-performance of EtherCAT is thus maintained into each module.

The extremely low dimensions of only 126x30x26.5 mm (hxw xd) are identical to those of the Fieldbus

Box extension modules. They are thus particularly suitable for use where space is at a premium. The small

mass of the EtherCAT modules facilitates applications with mobile I/O interface (e.g. on a robot arm). The

EtherCAT connection is established via screened M8connectors.

Fig.1: EtherCAT Box Modules within an EtherCAT network

The robust design of the EtherCAT Box modules enables them to be used directly at the machine. Control

cabinets and terminal boxes are now no longer required. The modules are fully sealed and therefore ideally

prepared for wet, dirty or dusty conditions.

Pre-assembled cables significantly simplify EtherCAT and signal wiring. Very few wiring errors are made, so

that commissioning is optimized. In addition to pre-assembled EtherCAT, power and sensor cables, fieldconfigurable connectors and cables are available for maximum flexibility. Depending on the application, the

sensors and actuators are connected through M8 or M12connectors.

The EtherCAT modules cover the typical range of requirements for I/O signals with protection class IP67:

• digital inputs with different filters (3.0ms or 10μs)

• digital outputs with 0.5 or 2A output current

• analog inputs and outputs with 16bit resolution

• Thermocouple and RTD inputs

• Stepper motor modules

XFC (eXtreme Fast Control Technology) modules, including inputs with time stamp, are also available.

EP6001 and EP600210 Version: 2.1.0

Page 11

Fig.2: EtherCAT Box with M8 connections for sensors/actuators

Product overview

Fig.3: EtherCAT Box with M12 connections for sensors/actuators

Basic EtherCAT documentation

You will find a detailed description of the EtherCAT system in the Basic System Documentation for

EtherCAT, which is available for download from our website (www.beckhoff.com) under Downloads.

XML files

You will find XML files (XML Device Description Files) for Beckhoff EtherCAT modules on our website (www.beckhoff.com) under Downloads, in the Configuration Files area.

EP6001 and EP6002 11Version: 2.1.0

Page 12

Product overview

2.3 EP6001-0002

2.3.1 EP6001-0002 - Introduction

Fig.4: EP6001-0002

1-channel serial interface, RS232, RS422/RS485

The EP6001-0002 serial interface module allows the connection of devices with an RS232 or an RS422/

RS485 interface. The module transmits the data in a fully transparent manner to the higher-level automation

device. The active serial communication channel functions independently of the higher-level bus system in

full duplex mode at up to 115,200baud, while a 864bytes receive buffer and a 128byte send buffer are

available.

The 1-channel version has an increased end device power supply of up to 1A; the connector assignment

depends on the interface selected.

The two integrated digital inputs/outputs allow the connection of additional sensors/actuators in order, for

example, to trigger the reading process of the barcode reader or, depending on the result, to initiate an

action.

In conjunction with the TwinCAT Virtual Serial COM Driver the EP6001-0002 can be used as a normal

Windows COM interface.

EP6001 and EP600212 Version: 2.1.0

Page 13

Product overview

2.3.2 EP6001-0002 – Technical data

Technical data EP6001-0002

Fieldbus [}46]

Fieldbus connection [}25]

Nominal voltage 24VDC (-15 %/+20 %)

Data transfer channels 1

Number of digital inputs/outputs 2, 24VDC, 10µs/0.5A

Distributed clocks Data transfer rates 300...115,200Baud; 9,600Baud (8-bit, no parity, 1 stop bit)

Signal connection [}34]

Bit distortion <3%

Cable length RS232: max. 15m; RS422/RS485: approx. 1,000m

Data buffer 864-byte receive buffer, 128-byte send buffer

Sensor supply + 5VDC, 1A

Process image per channel 22 x 8-bit input,

Supply of the module electronics from the control voltage Us

Current consumption of the module

electronics

Power supply connection Power supply: 1 x M8 connector, 4-pin; downstream

Electrical isolation 500V

Special features integrated supply for the end devices 5VDC/1A

Permissible ambient temperature during

operation

Permissible ambient temperature during

storage

Vibration / shock resistance conforms to EN60068-2-6/EN 60068-2-27

EMC immunity/emission conforms to EN61000-6-2/EN 61000-6-4

Protection class IP 65/66/67 (conforms to EN 60529)

Weight app.165g

Installation position variable

Approvals [}42]

EtherCAT

2 x M8 socket (green)

preset

M12 sockets, screwable for RS232, RS422/485 or digital I/O

22 x 8-bit output,

16-bit control,

16-bit status

typical 130mA + load, e.g. 130mA + 2 x 20mA = 170mA

connection: 1 x M8 socket, 4-pin

-25…+60 °C

0 °C ... +55 °C (according to cULus, see UL requirements)

-40…+85 °C

CE, UL

EP6001 and EP6002 13Version: 2.1.0

Page 14

Product overview

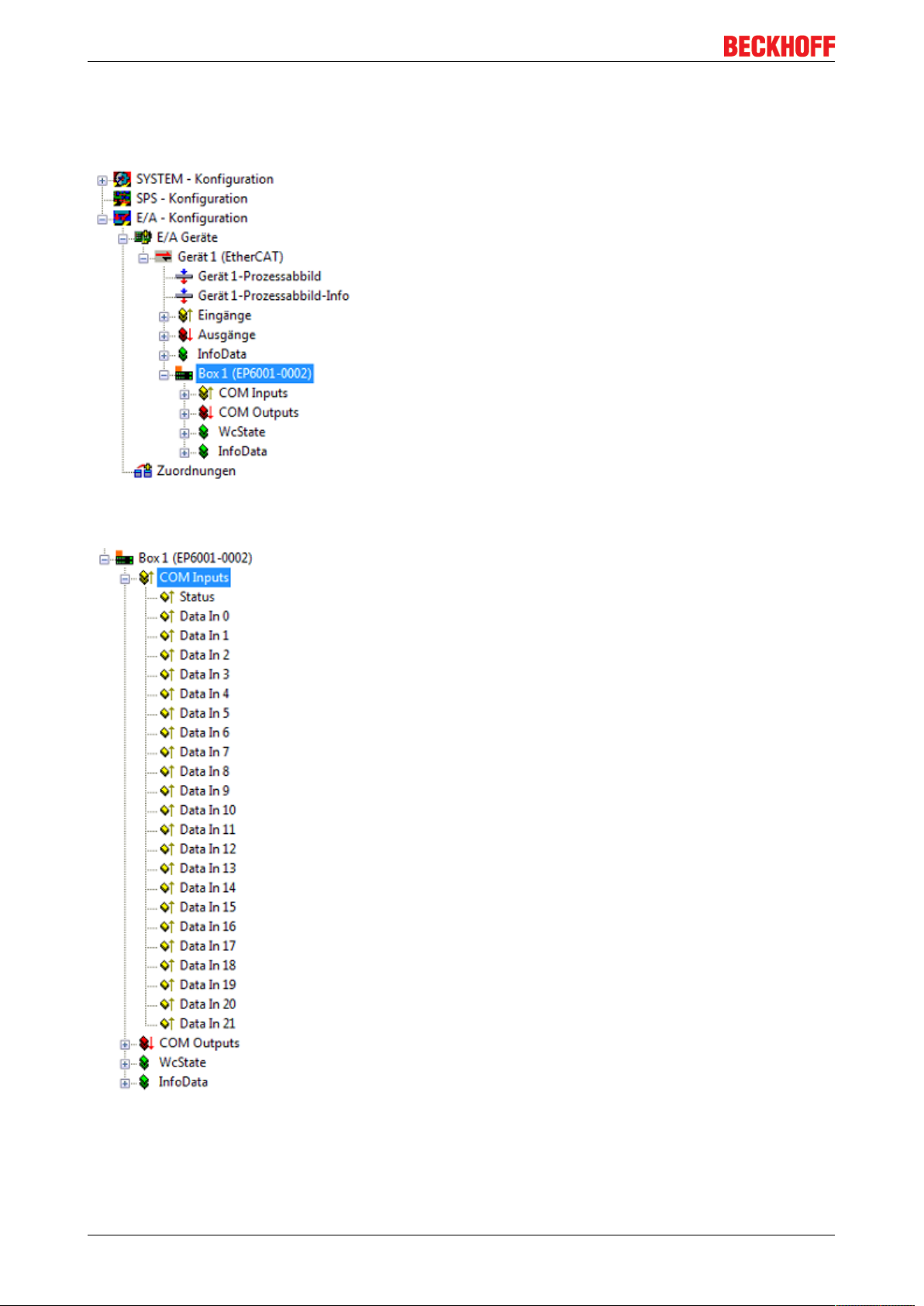

2.3.3 EP6001-0002 - Process image

The TwinCAT System Manager displays the EP6001-0002 data in a tree structure.

The tree shows:

COM inputs: Channel input data

COM outputs: Channel output data

COM Inputs

The tree shows:

Status: Status bits of the channel

Data In 0 to Data In 21: Channel input data

EP6001 and EP600214 Version: 2.1.0

Page 15

COM outputs

Product overview

The tree shows:

Status: Control bits of the channel

Data Out 0 to Data Out 21: Channel output data

EP6001 and EP6002 15Version: 2.1.0

Page 16

Product overview

2.4 EP6002-0002

2.4.1 EP6002-0002 - Introduction

Dual-channel serial interface module: RS232 or RS422/RS485

The EP6002-0002 2-channel serial interface module enables the connection of devices with an RS232 or

RS422/RS485 interface. The module transmits the data in a fully transparent manner to the higher-level

automation device. The data is transferred via the fieldbus using a simple handshake protocol. This does not

have any effect on the protocol of the serial interface. The active serial communication channel functions

independently of the higher-level bus system in full duplex mode at up to 115,200baud, while a 864bytes

receive buffer and a 128byte send buffer are available.

In connection with TwinCAT's virtual serial COM driver (see TwinCAT supplements – communication), the

EP6002 can be used as a normal Windows COM interface.

The choice of connection depends on the interface type. In the TwinCAT System Manager [}74] you can

select either the RS232 connection or the RS422/RS485 connection for each channel.

For

• RS422/RS485 use the M12 connections 1 and 3

• RS232 use the M12 connections 2 and 4

Interface modes/ operation modes

the following settings for the interfaces can be made via the CoE objects:

• RS232: point-to-point connection to an RS232 device

• RS422: 4-wire point-to-point connection to an RS422 device

• RS485:2-wire connection in bus structure to RS485 device(s)

• RS485:2-wire connection with external bridge in bus structure to RS485 device(s), monitoring of the

transmitted data

EP6001 and EP600216 Version: 2.1.0

Page 17

Quick links

Installation [}21]

Interface modes [}56]

Configuration [}63]

Sample programs [}75]

UL requirements [}42]

ATEX - Special conditions [}43]

Product overview

EP6001 and EP6002 17Version: 2.1.0

Page 18

Product overview

2.4.2 EP6002-0002 – Technical data

Technical data EP6002-0002

Fieldbus [}46]

Fieldbus connection [}25]

Data transfer channels 2 (1/1), TxD and RxD, full duplex

Data transfer rates 300...115,200Baud; 9,600Baud (8-bit, no parity, 1 stop bit)

Signal connection [}34]

Bit distortion < 3%

Cable length RS232: max. 15m; RS422/RS485: approx. 1,000m

Data buffer 864-byte receive buffer, 128-byte send buffer

Process image per channel 22 x 8-bit input,

Supply of the module electronics from the control voltage Us

Current consumption of the module

electronics

Power supply connection Power supply: 1 x M8 plug, 4-pole

Electrical isolation 500V

Permissible ambient temperature during

operation

Permissible ambient temperature during

storage

Vibration/ shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC immunity/emission conforms to EN61000-6-2/ EN61000-6-4

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Weight app.165g

Installation position variable

Approvals [}42]

EtherCAT

2 x M8 socket (green)

preset

M12 sockets for RS232 or RS422/485

22 x 8-bit output,

16-bit control,

16-bit status

typical130mA + load, e.g. 130mA + 2 x 20mA = 170mA

Onward connection: 1 x M8 socket, 4-pole

-25°C...+60°C

0°C ... +55°C (conforms to ATEX, see special conditions)

0 °C ... +55 °C (according to cULus, see UL requirements)

-40°C...+85°C

CE, cULus, ATEX

EP6001 and EP600218 Version: 2.1.0

Page 19

2.4.3 EP6002-0002 - Process image

The TwinCAT System Manager displays the EP6002-0002 data in a tree structure.

The tree shows:

• COM Inputs Channel 1: input data of the 1

channel

• COM Inputs Channel 2: input data of the 2

channel

• COM Outputs Channel 1: output data of the 1

channel

• COM Outputs Channel 2: output data of the 2

channel

Product overview

st

nd

st

nd

Table1: COM Inputs Channel 1

The tree shows:

• Status: status bits of the 1st channel

• Data In 0 to Data In 21: input data of the 1

channel

st

EP6001 and EP6002 19Version: 2.1.0

Page 20

Product overview

COM Inputs Channel 2

The data of the 2nd channel are structured identically to those of the 1st channel.

Table2: COM Outputs Channel 1

The tree shows:

• Status: Control bits of the 1st channel

• Data Out 0 to Data Out 21: output data of the

1st channel

COM Outputs Channel 2

The data of the 2nd channel are structured identically to those of the 1st channel.

EP6001 and EP600220 Version: 2.1.0

Page 21

3 Mounting and connection

3.1 Mounting

3.1.1 Dimensions

Mounting and connection

Fig.5: Dimensions of the EtherCAT Box Modules

All dimensions are given in millimeters.

Housing properties

EtherCAT Box lean body wide bodies

Housing material PA6 (polyamide)

Casting compound Polyurethane

Mounting two fastening holes Ø3mm for M3 two fastening holes Ø3mm for M3

two fastening holes Ø4.5mm for M4

Metal parts Brass, nickel-plated

Contacts CuZn, gold-plated

Power feed through max. 4A (M8)

max. 16A (7/8“)

max. 15.5A (B17 5G 1.5mm2)

Installation position variable

Protection class IP65, IP66, IP67 (conforms to EN 60529) when screwed together

Dimensions

(HxWxD)

app. 126 x 30 x 26.5mm app. 126 x 60 x 26,5mm

app. 150 x 60 x 26.5mm (without 7/8", B17)

EP6001 and EP6002 21Version: 2.1.0

Page 22

Mounting and connection

3.1.2 Fixing

Note or pointer

While mounting the modules, protect all connectors, especially the IP-Link, against contamination!

Only with connected cables or plugs the protection class IP67 is guaranteed! Unused connectors

have to be protected with the right plugs! See for plug sets in the catalogue.

Modules with narrow housing are mounted with two M3 bolts.

Modules with wide housing are mounted with two M3 bolts to the fixing holes located at the corners or

mounted with two M4 bolts to the fixing holes located centrally.

The bolts must be longer than 15 mm. The fixing holes of the modules are not threaded.

When assembling, remember that the fieldbus connectors increases the overall height. See chapter

accessories.

Mounting Rail ZS5300-0001

The mounting rail ZS5300-0001 (500 mm x 129 mm) allows the time saving assembly of modules.

The rail is made of stainless steel, 1.5 mm thick, with already pre-made M3 threads for the modules. The rail

has got 5.3 mm slots to mount it via M5 screws to the machine.

Fig.6: Mounting Rail ZS5300-000

The mounting rail is 500 mm long, that way 15 narrow modules can be mounted with a distance of 2 mm

between two modules. The rail can be cut to length for the application.

Mounting Rail ZS5300-0011

The mounting rail ZS5300-0011 (500 mm x 129 mm) has in addition to the M3 treads also pre-made M4

treads to fix 60 mm wide modules via their middle holes.

Up to 14 narrow or 7 wide modules may be mixed mounted.

EP6001 and EP600222 Version: 2.1.0

Page 23

Mounting and connection

3.1.3 Nut torque for connectors

M8 connectors

It is recommended to pull the M8 connectors tight with a nut torque of 0.4 Nm. When using the torque control

screwdriver ZB8800 is also a max. torque of 0.5Nm permissible.

Fig.7: EtherCAT Box with M8 connectors

M12 connectors

It is recommended to pull the M12 connectors tight with a nut torque of 0.6 Nm.

Fig.8: EtherCAT Box with M8 and M12 connectors

EP6001 and EP6002 23Version: 2.1.0

Page 24

Mounting and connection

7/8" plug connectors

We recommend fastening the 7/8" plug connectors with a torque of 1.5Nm.

Fig.9: 7/8" plug connectors

Torque socket wrenches

Fig.10: ZB8801 torque socket wrench

Ensure the right torque

Use the torque socket wrenches available by Beckhoff to pull the connectors tight (ZB8800,

ZB8801-0000)!

3.1.4 Additional checks

The boxes have undergone the following additional tests:

Verification Explanation

Vibration 10 frequency runs in 3 axes

5Hz < f < 60Hz displacement 0.35mm, constant amplitude

60.1Hz < f < 500Hz acceleration 5g, constant amplitude

Shocks 1000 shocks in each direction, in 3 axes

35g, 11ms

EP6001 and EP600224 Version: 2.1.0

Page 25

3.2 EtherCAT

3.2.1 EtherCAT connection

For the incoming and ongoing EtherCAT connection,

• the EtherCAT Box (EPxxxx) has two M8 sockets, marked in green

• the Coupler Box (FBB-x110) has two M12 sockets

Mounting and connection

Fig.11: EtherCAT Box: M8, 30mm housing

Fig.12: EtherCAT Box: M860mm housing (example: EP9214)

EP6001 and EP6002 25Version: 2.1.0

Page 26

Mounting and connection

Fig.13: Coupler Box: M12

Assignment

There are various different standards for the assignment and colors of connectors and cables for Ethernet/

EtherCAT.

Ethernet/EtherCAT Plug connector Cable Standard

Signal Description M8 M12 RJ45

Tx + Transmit Data+ Pin 1 Pin 1 Pin 1 yellow

Tx - Transmit Data- Pin 4 Pin 3 Pin 2 orange

Rx + Receive Data+ Pin 2 Pin 2 Pin 3 white

Rx - Receive Data- Pin 3 Pin 4 Pin 6 blue

Shield Shield Housing Shroud Screen Screen Screen

1

) colored markings according to EN 61918 in the four-pin RJ45 connector ZS1090-0003

2

) wire colors according to EN 61918

3

) wire colors

1

ZB9010, ZB9020,

ZB9030, ZB9032,

ZK1090-6292,

ZK1090-3xxx-xxxx

2

2

2

2

ZB9031 and old versions

of ZB9030, ZB9032,

ZK1090-3xxx-xxxx

orange/white

orange

blue/white

3

blue

3

3

3

TIA-568B

white/orange

orange

white/green

green

Assimilation of color coding for cable ZB9030, ZB9032 and ZK1090-3xxxx-xxxx (with

M8 connectors)

For unification the prevalent cables ZB9030, ZB9032 and ZK1090-3xxx-xxxx this means the pre assembled cables with M8 connectors were changed to the colors of EN61918 (yellow, orange, white,

blue).So different color coding exists. But the electrical properties are absolutely identical.

EtherCAT connector

The following connectors can be supplied for use in Beckhoff EtherCAT systems.

EP6001 and EP600226 Version: 2.1.0

Page 27

Mounting and connection

Name Connector Comment

ZS1090-0003 RJ45 four-pole, IP20, field-configurable

ZS1090-0004 M12, male four-pin, IP67, for field assembly

ZS1090-0005 RJ45 eight-pole, IP20, field-configurable, suitable for gigabit Ethernet

ZS1090-0006 M8 plug connector four-pole, IP67, field-configurable, for cable type ZB903x

ZS1090-0007 M8 socket four-pole, IP67, field-configurable, for cable type ZB903x

ZS1090-1006 M8 plug connector four-pole, IP67, field-configurable up to OD=6.5mm

ZS1090-1007 M8 socket four-pole, IP67, field-configurable up to OD=6.5mm

3.2.2 EtherCAT - Fieldbus LEDs

Fig.14: EtherCAT-LEDs

LED display

LED Display Meaning

IN L/A off no connection to the preceding EtherCAT module

Lit LINK: connection to the preceding EtherCAT module

flashing ACT: Communication with the preceding EtherCAT module

OUT L/A off no connection to the following EtherCAT module

Lit LINK: connection to the following EtherCAT module

flashing ACT: Communication with the following EtherCAT module

Run off Status of the EtherCAT module is Init

flashes quickly Status of the EtherCAT module is pre-operational

flashes slowly Status of the EtherCAT module is safe-operational

Lit Status of the EtherCAT module is operational

EtherCAT statuses

The various statuses in which an EtherCAT module may be found are described in the Basic System Documentation for EtherCAT, which is available for download from our website (www.beck-

hoff.com) under Downloads.

EP6001 and EP6002 27Version: 2.1.0

Page 28

Mounting and connection

3.3 Power supply

3.3.1 Power Connection

The feeding and forwarding of supply voltages is done via two M8 connectors at the bottom end of the

modules:

• IN: left M8 connector for feeding the supply voltages

• OUT: right M8 connector for forwarding the supply voltages

Fig.15: EtherCAT Box, Connectors for power supply

Fig.16: Pin assignment M8, Power In and Power Out

Table3: PIN assignment

Pin Voltage

1 Control voltage Us, +24V

2 Auxiliary voltage Up, +24V

3 GNDs* *) may be connected internally to each other depending on the module: see specific

4 GNDp*

The pins M8 connectors carry a maximum current of 4A.

Two LEDs display the status of the supply voltages.

module descriptions

DC

DC

NOTE

Don't confuse the power connectors with the EtherCAT connectors!

Never connect the power cables (M8, 24VDC) with the green marked EtherCAT sockets of the EtherCAT

Box Modules! This can damage the modules!

Control voltage Us: 24V

Power is supplied to the fieldbus, the processor logic, the inputs and the sensors from the 24VDC control

voltage Us. The control voltage is electrically isolated from the fieldbus circuitry.

DC

EP6001 and EP600228 Version: 2.1.0

Page 29

Mounting and connection

Auxiliary voltage Up 24V

DC

The Auxiliary voltage Up supplies the digital outputs; it can be brought in separately. If the load voltage is

switched off, the fieldbus functions and the power supply and functionality of the inputs are retained.

Redirection of the supply voltages

The IN and OUT power connections are bridged in the module (not IP204x-Bxxx and IE204x). The supply

voltages Us and Up can thus easily be transferred from EtherCATBox to EtherCATBox.

NOTE

Pay attention to the maximum permissible current!

Pay attention also for the redirection of the supply voltages Us and Up, the maximum permissible current

for M8 connectors of 4A must not be exceeded!

EP6001 and EP6002 29Version: 2.1.0

Page 30

Mounting and connection

Supply via EP92x4-0023 PowerBox modules

If the machine requires higher current or if the EtherCAT Box Modules are installed far away from the control

cabinet with included power supply, the usage of four cannel power distribution modules EP9214 or EP9224

(with integrated data logging, see www.beckhoff.com/EP9224) is recommended.

With these modules intelligent power distribution concepts with up to 2x16A and a maximum of 2.5mm²

cable cross-section can be realized.

Fig.17: EP92x4-0023, Connectors for Power In and Power Out

Fig.18: Pin assignment 7/8”, Power In and Power Out

EP6001 and EP600230 Version: 2.1.0

Page 31

Mounting and connection

Electrical isolation

Digital modules

In the digital input/output modules, the grounds of the control voltage (GNDs) and the auxiliary voltage

(GNDp) are connected to each other!

Check this at the documentation of each used EtherCAT Box.

Analog modules

In the analog input/output modules the grounds of the control voltage (GNDs) and the auxiliary voltage

(GNDp) are separated from each other in order to ensure electrical isolation of the analog signals from the

control voltage.

In some of the analog modules the sensors or actuators are supplied by Up - this means, for instance, that in

the case of 0...10 V inputs, any reference voltage (0...30 V) may be connected to Up; this is then available to

the sensors (e.g. smoothed 10 V for measuring potentiometers).

Details of the power supply may be taken from the specific module descriptions.

NOTE

Electrical isolation may be cancelled!

If digital and analog fieldbus boxes are connected directly via four-core power leads, the analog signals in

the fieldbus boxes may be no longer electrically isolated from the control voltage!

3.3.2 Status LEDs for power supply

Fig.19: Status LEDs for power supply

LED display

LED Display Meaning

Us (Control voltage) off The power supply voltage Us is not present

green illuminated The power supply voltage Us is present

red illuminated Because of overload (current>0.5A) the sensor supply

generated from power supply voltage Us was switched off for

all sensors fed from this.

Up (Auxiliary voltage) off The power supply voltage Up is not present

green illuminated The power supply voltage Up is present

EP6001 and EP6002 31Version: 2.1.0

Page 32

Mounting and connection

3.3.3 Power cable conductor losses M8

The ZK2020-xxxx-yyyy power cables should not exceed the total length of 15m at 4A (with continuation).

When planning the cabling, note that at 24V nominal voltage, the functionality of the module can no longer

be assured if the voltage drop reaches 6V. Variations in the output voltage from the power supply unit must

also be taken into account.

Fig.20: Power cable conductor losses

Example

8m power cable with 0.34mm² cross-section has a voltage drop of 3.2V at 4A.

EP92x4 Power Distribution Modules

With EP9214 and EP9224 Power Distribution Modules intelligent concepts for voltage supply are

available. Further information may be found under www.beckhoff.com/EP9224.

EP6001 and EP600232 Version: 2.1.0

Page 33

Mounting and connection

3.3.4 Conductor losses 7/8"

In the case of the power cables ZK2030-xxxx-yyy, a total length of 15m should not be exceeded at 16A.

When wiring, note that with a rated voltage of 24V the function of the modules can no longer be guaranteed

from a voltage drop of 6V. Variations in the output voltage from the power supply unit must also be taken

into account.

Fig.21: ZK2030-xxxx-yyy - Conductor losses

Alternatively, larger cable cross-section can be used, e.g. 2.5mm2.

EP6001 and EP6002 33Version: 2.1.0

Page 34

Mounting and connection

3.4 Signal connection

3.4.1 Signal connection EP6001-0002

RS232

Fig.22: M12 socket, A-coded

Pin Signal Connection for

1 5V

2 TxD send data

3 GND ground

4 RxD receive data

5 SHLD shield

DC

auxiliary voltage 5VDC (20mA, short-circuit proof)

RS485/RS422TX

Fig.23: M12 socket, A-coded

Pin Signal Connection for

1 Tx- send data

2 Tx+ send data

3 GND ground

4 Vcc auxiliary voltage 5VDC (20mA, short-circuit proof)

5 Shield shield

RS485 - half duplex connection

For half duplex connection under RS485 only one pair of wires is needed for data transmission.

Connect this core pair to Tx-/Tx+.

RS485 bus structure - use termination resistors

A linear bus with more than two devices can be set-up in RS485 mode. To prevent reflections during the data transmission, it is necessary to terminate the line ends of the bus cable with resistors

(120Ω).

EP6001 and EP600234 Version: 2.1.0

Page 35

RS422RX

Fig.24: M12 socket, A-coded

Pin Signal Connection for

1 Rx- receive data

2 Rx+ receive data

3 GND ground

4 Vcc auxiliary voltage 5VDC (20mA, short-circuit proof)

5 Shield shield

Mounting and connection

Digital inputs M8 and M12

The digital input modules acquire the binary control signals from the process level and transmit them to the

higher-level automation device.

The signals are connected via M8 connectors (EPxxxx-0001) or M12 connectors (EPxxxx-0002).

Fig.25: Digital inputs M8 and M12

The sensors are supplied with a common maximum current of 0.5Afrom the control voltage Us.

Light emitting diodes indicate the signal state of the inputs.

EP6001 and EP6002 35Version: 2.1.0

Page 36

Mounting and connection

Digital outputs M8 and M12

The digital output modules connect the binary control signals from the automation unit on to the actuators at

the process level.

The signals are connected via M8 connectors (EP2xxx-0001) or M12 connectors (EP2xxx-0002).

Fig.26: Digital outputs M8 and M12

The outputs are short-circuit proof and protected against inverse connection.

LEDs indicate the signal state of the outputs.

EP6001 and EP600236 Version: 2.1.0

Page 37

3.4.2 Signal connection EP6002-0002

RS485/422

Fig.27: M12 socket, A-coded

Pin Signal Connection for

1 TxD- send data

2 TxD+ send data

3 RxD- receive data

4 RxD+ receive data

5 SHLD shield

Mounting and connection

RS485 - Half Duplex Connection

For half duplex connection under RS485 only one pair of wires is needed for data transmission.

Connect this pair of wires to Tx-/Tx+.

RS485 bus set up - use terminating resistors

A linear bus with more than two devices can be set-up in RS485 mode. To prevent reflections during the data transmission, it is necessary to terminate the line ends of the bus cable with resistors

(120Ω).

RS232

Fig.28: M12 socket, A-coded

Pin Signal Connection for

1 5V

2 TxD send data

3 GND ground

4 RxD receive data

5 SHLD shield

DC

auxiliary voltage 5VDC (20mA, short-circuit proof)

EP6001 and EP6002 37Version: 2.1.0

Page 38

Mounting and connection

3.5 EP6001-0002 - Status LEDs

Fig.29: EP6001-0002 - Status LEDs

Status LEDs at the M12 connectors

Connector LED Display Meaning

M12 socket no. 1-3 RX

left

TX

right

M12 socket no.4 left LED (6) off Output A / Input A inactive

right LED (7) off Output B / Input B inactive

Power supply

off Serial port on this M12 connector not ready to receive data

green

illuminated

orange

illuminated

off Serial port on this M12 connector not ready to transmit data

green

illuminated

orange

illuminated

green

illuminated

green

illuminated

Serial port on this M12 connector ready to receive data

Serial port on this M12 connector receiving data

Serial port on this M12 connector ready to transmit data

Serial port on this M12 connector transmitting data

Output A / Input A active

Output B / Input B active

LED Display Meaning

Us off The supply voltage, Us, is not present

green

illuminated

Up off The supply voltage, Up, is not present

green

illuminated

The supply voltage, Us, is present

The supply voltage, Up, is present

EP6001 and EP600238 Version: 2.1.0

Page 39

3.6 EP6002-0002 - Status LEDs

Mounting and connection

Fig.30: EP6002-0002 - Status LEDs

Status LEDs at the M12 connectors

Connector LED Display Meaning

M12 socket no. 1-4 RX

left

TX

right

Power supply

LED Display Meaning

Us off The supply voltage, Us, is not present

Up off The supply voltage, Up, is not present

off Serial port on this M12 connector not ready to receive data

green Serial port on this M12 connector ready to receive data

orange Serial port on this M12 connector receiving data

off Serial port on this M12 connector not ready to transmit data

green Serial port on this M12 connector ready to transmit data

orange Serial port on this M12 connector transmitting data

green

illuminated

green

illuminated

The supply voltage, Us, is present

The supply voltage, Up, is present

EP6001 and EP6002 39Version: 2.1.0

Page 40

Mounting and connection

3.7 Cabling

A list of EtherCAT cables, power cables, sensor cables, Ethernet/EtherCAT connectors and fieldconfigurable connectors can be found under the following link: https://beckhoff.de/english/fieldbus_box/

ethercat_box_accessories_overview.htm?id=25525466903389

The corresponding data sheets can be found under the following link:

https://beckhoff.de/english/ethercat-box/ethercat_box_cables.htm?id=690338951657421

EtherCAT cables

Fig.31: ZK1090-3131-0xxx

For connecting EtherCAT devices, only use shielded Ethernet cables with a minimum specification of

category5 (CAT5) according to EN50173 or ISO/IEC11801.

Wiring recommendations

Detailed recommendations for EtherCAT cabling can be found in the documentation "Design recommendations for EtherCAT/Ethernet infrastructure", which is available for download from www.beckhoff.de.

EtherCAT uses four cable wires for signal transmission.

Due to automatic cable detection (auto-crossing) symmetric (1:1) or cross-over cables can be used between

EtherCAT devices from Beckhoff.

EP6001 and EP600240 Version: 2.1.0

Page 41

Power cable

Mounting and connection

Fig.32: ZK2020-3132-0xxx

Sensor cables

Fig.33: Selection of Beckhoff sensor cables

EP6001 and EP6002 41Version: 2.1.0

Page 42

Mounting and connection

3.8 UL Requirements

The installation of the EtherCAT Box Modules certified by UL has to meet the following requirements.

Supply voltage

CAUTION

CAUTION!

This UL requirements are valid for all supply voltages of all marked EtherCAT Box Modules!

For the compliance of the UL requirements the EtherCAT Box Modules should only be supplied

• by a 24 VDC supply voltage, supplied by an isolating source and protected by means of a fuse (in accordance with UL248), rated maximum 4 Amp, or

• by a 24 VDC power source, that has to satisfy NEC class 2.

A NEC class 2 power supply shall not be connected in series or parallel with another (class 2) power

source!

CAUTION

CAUTION!

To meet the UL requirements, the EtherCAT Box Modules must not be connected to unlimited power

sources!

Networks

CAUTION

CAUTION!

To meet the UL requirements, EtherCAT Box Modules must not be connected to telecommunication networks!

Ambient temperature range

CAUTION

CAUTION!

To meet the UL requirements, EtherCAT Box Modules has to be operated only at an ambient temperature

range of 0 to 55°C!

Marking for UL

All EtherCAT Box Modules certified by UL (Underwriters Laboratories) are marked with the following label.

Fig.34: UL label

EP6001 and EP600242 Version: 2.1.0

Page 43

Mounting and connection

3.9 ATEX notes

3.9.1 ATEX - Special conditions

WARNING

Observe the special conditions for the intended use of EtherCAT Box modules in potentially explosive areas – directive 94/9/EU.

• The certified components are to be installed in the BG2000-0000 protection enclosure [}44] that guarantees a protection against mechanical hazards!

• If the temperatures during rated operation are higher than 70°C at the feed-in points of cables, lines or

pipes, or higher than 80°C at the wire branching points, then cables must be selected whose temperature data correspond to the actual measured temperature values!

• Observethe permissible ambient temperature range of 0 - 55°C for the use of EtherCAT Box modules in

potentially explosive areas!

• Measures must be taken to protect against the rated operating voltage being exceeded by more than

40% due to short-term interference voltages!

• The connections of the certified components may only be connected or disconnected if the supply voltage has been switched off or if a non-explosive atmosphere is ensured!

Standards

The fundamental health and safety requirements are fulfilled by compliance with the following standards:

• EN 60079-0: 2006

• EN 60079-15: 2005

Marking

The EtherCAT Box modules certified for potentially explosive areas bear the following marking:

II 3 GEx nA II T4DEKRA 11ATEX0080 XTa: 0 - 55°C

or

II 3 GEx nA nC IIC T4DEKRA 11ATEX0080 XTa: 0 - 55°C

Batch number (D number)

The EtherCAT Box modules bear a batch number (D number) that is structured as follows:

D: WW YY FF HH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Beispiel mit Ser. Nr.: 29 10 02 01:

29 - week of production 29

10 - year of production 2010

02 - firmware version 02

01 - hardware version 01

EP6001 and EP6002 43Version: 2.1.0

Page 44

Mounting and connection

3.9.2 BG2000-0000 - EtherCAT Box protection enclosure

WARNING

Risk of electric shock and damage of device!

Bring the EtherCAT system into a safe, powered down state before starting installation, disassembly or

wiring of the modules!

ATEX

The BG2000-0000 protection enclosure has to be mounted over a single EtherCAT Box to fulfill the special

conditions according to ATEX [}43].

Installation

Put the cables for EtherCAT, power supply and sensors/actuators through the hole of the BG2000-0000

protection enclosure.

Fig.35: BG2000-0000, putting the cables

Fix the wires for EtherCAT, power supply and sensors/actuators to the EtherCAT Box.

EP6001 and EP600244 Version: 2.1.0

Page 45

Mounting and connection

Fig.36: BG2000-0000, fixing the cables

Mount the BG2000-0000 protection enclosure over the EtherCAT Box.

Fig.37: BG2000-0000, mounting the protection enclosure

3.9.3 ATEX Documentation

Notes about operation of EtherCAT Box Modules (EPxxxx-xxxx) in potentially explosive areas (ATEX)

Pay also attention to the continuative documentationNotes about operation of EtherCAT Box Modules (EPxxxx-xxxx) in potentially explosive areas (ATEX) that is available in the download area of

the Beckhoff homepage http:\\www.beckhoff.com!

EP6001 and EP6002 45Version: 2.1.0

Page 46

Basics communication - EtherCAT

4 Basics communication - EtherCAT

4.1 EtherCAT basics

Basic information on the EtherCAT fieldbus can be found in the EtherCAT system documentation.

4.2 Watchdog setting

General information on watchdog settings

The ELxxxx Terminals and EPxxxx Box Modules are equipped with a safety device (watchdog) that switches

the outputs to a safe state after a time that can be preset, for example in the case of interrupted process data

traffic, or to OFF, for example depending on device and setting.

The EtherCAT Slave Controller (ESC) has two watchdogs:

• SM watchdog (default: 100 ms)

• PDI watchdog (default: 100 ms)

SM Watchdog (SyncManagerWatchdog)

The SyncManager watchdog is reset after each successful EtherCAT process data communication with the

terminal/box. If no EtherCAT process data communication takes place with the terminal/box for longer than

the set and activated SM watchdog time, e.g. in the event of a line interruption, the watchdog is triggered and

the outputs are set to FALSE. The OP status of the terminal/box is unaffected by this. The watchdog is only

reset after a successful EtherCAT process data access. Set the monitoring time as specified below.

The SyncManager watchdog monitors correct and timely process data communication with the ESC from the

EtherCAT side.

PDI watchdog (process data watchdog)

If no PDI communication with the EtherCAT slave controller (ESC) takes place for longer than the set and

activated PDI watchdog time, this watchdog is triggered.

PDI (Process Data Interface) is the internal interface between the ESC and local processors in the EtherCAT

slave, for example. The PDI watchdog can be used to monitor this communication for failure.

The PDI watchdog monitors correct and timely process data communication with the ESC but from the

application side.

The SM and PDI watchdogs should be set separately for each slave in the TwinCAT System Manager:

EP6001 and EP600246 Version: 2.1.0

Page 47

Basics communication - EtherCAT

Fig.38: EtherCAT tab --> Advanced settings --> Behavior --> Watchdog

Comments:

• The multiplier applies to both watchdogs.

• Each watchdog has its own timer setting, which together with the multiplier results in a time.

• Important: The multiplier/timer setting is loaded into the slave on start-up, if the corresponding

checkbox is ticked. If the checkbox is not ticked, no download takes place, and the ESC setting

remains unchanged.

Multiplier

Both watchdogs receive their pulses from the local terminal/box clock, divided by the watchdog multiplier.

1/25 MHz * (watchdog multiplier + 2) = 100µs (for default setting of 2498 for the multiplier)

The standard setting of 1000 for the SM watchdog corresponds to a release time of 100 ms.

The value in multiplier + 2 corresponds to the number of basic 40ns ticks representing a watchdog tick.

The multiplier can be modified in order to adjust the watchdog time over a larger range.

Example "Set SM watchdog"

This checkbox enables manual setting of the watchdog times. If the outputs are set and the EtherCAT

communication is interrupted, the SM watchdog is triggered after the set time and the outputs are deleted.

This setting can be used for adapting a terminal to a slower EtherCAT master or long cycle times. The

default SM watchdog setting is 100 ms. The setting range is from 0 to 65535. Together with a multiplier in a

range from 1 to 65535, this covers a watchdog period of 0 to ~170 seconds.

Calculation

Multiplier = 2498 → watchdog base time = 1 / 25MHz * (2498 + 2) = 0.0001seconds = 100µs

SM watchdog = 10000 → 10000 * 100µs = 1second watchdog monitoring time

EP6001 and EP6002 47Version: 2.1.0

Page 48

Basics communication - EtherCAT

CAUTION

Caution! Unintended behavior of the system is possible!

The function for switching off of the SM watchdog via SM watchdog = 0 is only implemented in terminals

from version -0016. In previous versions this operating mode should not be used.

CAUTION

Caution! Damage to the equipment and unintended behavior of the system is possible!

If the SM watchdog is activated and a value of 0 is entered the watchdog switches off completely. This is

watchdog deactivation! Outputs are then NOT set to a safe state, in the event of an interruption in communication!

Outputs in SAFEOP

Watchdog monitoring is activated by default. It sets the outputs in the module to a safe state (e.g.

OFF), depending on the SAFEOP and OP settings, and depending on the device and its settings. If

this is prevented due to deactivation of watchdog monitoring in the module, outputs can be switched

or remain set in device state SAFEOP.

EP6001 and EP600248 Version: 2.1.0

Page 49

Basics communication - EtherCAT

4.3 EtherCAT State Machine

The state of the EtherCAT slave is controlled via the EtherCAT State Machine (ESM). Depending upon the

state, different functions are accessible or executable in the EtherCAT slave. Specific commands must be

sent by the EtherCAT master to the device in each state, particularly during the bootup of the slave.

A distinction is made between the following states:

• Init

• Pre-Operational

• Safe-Operational and

• Operational

• Boot

The regular state of each EtherCAT slave after bootup is the OP state.

Fig.39: EtherCAT State Machine

Init

After switch-on the EtherCAT slave in the Init state. No mailbox or process data communication is possible.

The EtherCAT master initializes sync manager channels 0 and 1 for mailbox communication.

Pre-Operational (Pre-Op)

During the transition between Init and Pre-Op the EtherCAT slave checks whether the mailbox was initialized

correctly.

In Pre-Op state mailbox communication is possible, but not process data communication. The EtherCAT

master initializes the sync manager channels for process data (from sync manager channel 2), the FMMU

channels and, if the slave supports configurable mapping, PDO mapping or the sync manager PDO

assignment. In this state the settings for the process data transfer and perhaps terminal-specific parameters

that may differ from the default settings are also transferred.

Safe-Operational (Safe-Op)

During transition between Pre-Op and Safe-Op the EtherCAT slave checks whether the sync manager

channels for process data communication and, if required, the distributed clocks settings are correct. Before

it acknowledges the change of state, the EtherCAT slave copies current input data into the associated DPRAM areas of the EtherCAT slave controller (ECSC).

EP6001 and EP6002 49Version: 2.1.0

Page 50

Basics communication - EtherCAT

Mailbox and process data communication is possible in the Safe-Op state, but the slave keeps its outputs in

the safe state. However, the input data are cyclically updated.

Operational (Op)

Before the EtherCAT master switches the EtherCAT slave from Safe-Op to Op it must transfer valid output

data.

In the Op state the slave copies the output data of the masters to its outputs. Process data and mailbox

communication is possible.

Boot

In the Boot state the slave firmware can be updated. The Boot state can only be reached via the Init state.

In the Boot state mailbox communication via the file access over EtherCAT (FoE) protocol is possible, but no

other mailbox communication and no process data communication.

EP6001 and EP600250 Version: 2.1.0

Page 51

Basics communication - EtherCAT

4.4 CoE interface

General description

The CoE interface (CANopen over EtherCAT) is used for parameter management of EtherCAT devices.

EtherCAT slaves or the EtherCAT master manage fixed (read only) or variable parameters which they

require for operation, diagnostics or commissioning.

CoE parameters are arranged in a table hierarchy. In principle, the user has read access via the fieldbus.

The EtherCAT master (TwinCAT System Manager) can access the local CoE lists of the slaves via

EtherCAT in read or write mode, depending on the properties.

Different CoE parameter types are possible, including string (text), integer numbers, Boolean values or larger

byte fields. They can be used to describe a wide range of features. Examples of such parameters include

manufacturer ID, serial number, process data settings, device name, calibration values for analog

measurement or passwords.

Organization takes place on 2 levels by means of hexadecimal numbering: the (main) index is named first,

then the subindex. The value ranges are:

• Index 0 to 65535

• Subindex: 0…255

A parameter localized in this way is normally written as 0x8010:07, with preceding "0x" to identify the

hexadecimal numerical range and a colon between index and subindex.

The relevant ranges for EtherCAT fieldbus users are:

• 0x1000: This is where fixed identity information for the device is stored, including name, manufacturer,

serial number etc., plus information about the current and available process data configurations.

• 0x8000: This is where the operational and functional parameters for all channels are stored, such as

filter settings or output frequency.

Other important ranges are:

• 0x4000: In some EtherCAT devices the channel parameters are stored here (as an alternative to the

0x8000 range).

• 0x6000: Input PDOs ("input" from the perspective of the EtherCAT master)

• 0x7000: Output PDOs ("output" from the perspective of the EtherCAT master)

Availability

Not every EtherCAT device must have a CoE list. Simple I/O modules without dedicated processor

usually have no variable parameters and therefore no CoE list.

If a device has a CoE list, it is shown in the TwinCAT System Manager as a separate tab with a listing of the

elements:

EP6001 and EP6002 51Version: 2.1.0

Page 52

Basics communication - EtherCAT

Fig.40: CoE-Online tab

The CoE objects from 0x1000 to 0x1600, which are available in the example device "EL2502", can be seen

in the above figure; the subindices from 0x1018 are expanded.

Data management

Some parameters, particularly the setting parameters of the slave, are configurable and writeable. This can

be done in write or read mode

• via the System Manager (figure above) by clicking. This is useful for commissioning of the system/

slaves. Click on the row of the index to be parameterized and enter a value in the SetValue dialog.

• from the control system/PLC via ADS, e.g. through function blocks from the TcEtherCAT.lib library This

is recommended for modifications while the system is running or if no System Manager or operating

staff are available.

Data management

If CoE parameters on the slave are changed online, this is saved fail-safe in the device (EEPROM)

in Beckhoff devices. This means that the changed CoE parameters are still retained after a restart.

The situation may be different with other manufacturers.

Startup list

Startup list

Changes in the local CoE list of the terminal are lost if the terminal is replaced. If a terminal is replaced with a new Beckhoff terminal, it will have the factory settings. It is therefore advisable to link

all changes in the CoE list of an EtherCAT slave with the Startup list of the slave, which is processed whenever the EtherCAT fieldbus is started. In this way a replacement EtherCAT slave can

automatically be parameterized with the specifications of the user.

If EtherCAT slaves are used which are unable to store local CoE values permanently, the Startup

list must be used.

Recommended approach for manual modification of CoE parameters

• Make the required change in the System Manager. The values are stored locally in the EtherCAT slave

EP6001 and EP600252 Version: 2.1.0

Page 53

Basics communication - EtherCAT

• If the value is to be stored permanently, enter it in the Startup list. The order of the Startup entries is

usually irrelevant.

Fig.41: Startup list in the TwinCAT System Manager

The Startup list may already contain values that were configured by the System Manager based on the ESI

specifications. Additional application-specific entries can be created.

Online/offline directory

While working with the TwinCAT System Manager, a distinction has to be made whether the EtherCAT

device is "available", i.e. switched on and linked via EtherCAT and therefore online, or whether a

configuration is created offline without connected slaves.

In both cases a CoE directory is visible according to the figure "CoE-Online tab", but the connectivity is

displayed as offline/online.

• If the slave is offline

◦ the offline list from the ESI file is displayed. In this case modifications are not meaningful or

possible.

◦ the configured status is shown under Identity

◦ no firmware or hardware version is displayed, since these are features of the physical device.

◦ Offline is shown in red

EP6001 and EP6002 53Version: 2.1.0

Page 54

Basics communication - EtherCAT

Fig.42: Offline list

• If the slave is online

◦ the actual current slave directory is read. This may take several seconds, depending on the size

and cycle time.

◦ the actual identity is displayed

◦ the firmware and hardware version of the equipment according to the electronic information is

displayed.

◦ Online is shown in green

Fig.43: Online list

EP6001 and EP600254 Version: 2.1.0

Page 55

Basics communication - EtherCAT

Channel-based order

The CoE directory is located in EtherCAT devices that usually encompass several functionally equivalent

channels. e.g. a 4-channel 0 – 10 V analog input terminal also has 4 logical channels and thus 4 identical

sets of parameter data for the channels. In order to avoid having to list each channel in the documentation,

the placeholder "n" tends to be used for the individual channel numbers.

In the CoE system 16 indices, each with 255 subindices, are generally sufficient for representing all channel

parameters. The channel-based order is therefore arranged in 16

dec

/10

steps. The parameter range

hex

0x8000 exemplifies this:

• Channel 0: parameter range 0x8000:00 ... 0x800F:255

• Channel 1: parameter range 0x8010:00 ... 0x801F:255

• Channel 2: parameter range 0x8020:00 ... 0x802F:255

• …

This is generally written as 0x80n0. Detailed information on the CoE interface can be found in the EtherCAT

system documentation on the Beckhoff website.

EP6001 and EP6002 55Version: 2.1.0

Page 56

Commissioning/Configuration

5 Commissioning/Configuration

5.1 EP600x-0002 - Interface modes

Via CoE objects the following settings can be done for the interfaces:

Parameterization

The module is parameterized via the CoE - Online tab (with a double-click on the corresponding object). Only the mandatory parameters for the respective interface mode are specified here. Further

settings may be possible.

RS232: point-to-point connection to an RS232 device

Direct connection to an RS232 end device, full duplex data transmission (default setting).

Fig.44: Point-to-point connection to an RS232 device

The following CoE objects must be set

Index Name Meaning Data type Flags Setting

F800:0n Interface type Ch n 0x00 RS232 BIT1 RW 0x00 (0

0x01 RS485/422

(default)

dec

RS422: 4-wire point-to-point connection to an RS422 device

Direct connection to an RS422 end device, full duplex data transmission.

Data can be transmitted in full duplex in RS422 mode. Only point-to-point connections can be established.

Fig.45: 4-wire point-to-point connection to an RS422 device

The following CoE objects must be set

Index Name Meaning Data type Flags Setting

F800:0n Interface type

Ch n

0x00 RS232 BIT1 RW 0x01

0x01 RS485/422

(1

dec

)

)

Index Name Meaning Data type Flags Setting

80n0:07 Enable point-to-

point connection (RS422)

Channel n

0

The module is used in a bus structure in accordance with the RS485

bin

standard.

1

The module is used for a point-to-point connection (RS422).

bin

BOOLEAN RW 1

bin

EP6001 and EP600256 Version: 2.1.0

Page 57

Commissioning/Configuration

RS485: 2-wire connection in bus structure to RS485 device(s)

Bus structure, half duplex data transmission

Fig.46: 2-wire connection in bus structure to RS485 device(s)

The following CoE objects must be set

Index Name Meaning Data type Flags Setting

F800:0n Interface type

Ch n

Index Name Meaning Data type Flags Setting

80n0:06 Enable half du-

plex

channel n

0x00 RS232 BIT1 RW 0x01

(1

0x01 RS485/422

0

Full duplex: transmitted data are monitored. The bit has no effect in

bin

RS232 and RS422 mode

1

Half duplex: The reception of the data transmitted by the box itself is

bin

suppressed

BOOLEAN RW 1

dec

bin

(default)

)

Index Name Meaning Data type Flags Setting

80n0:07 Enable point-to-

point connection (RS422)

Channel n

0

The module is used in a bus structure in accordance with the RS485

bin

standard.

1

The module is used for a point-to-point connection (RS422).

bin

BOOLEAN RW 0

bin

Deactivated receive driver

The receive driver is deactivated during the transmission procedure. The transmitted data are not

monitored!

RS485: 2-wire connection with external bridge in bus structure to RS485 device(s)

Bus structure, half duplex data transmission with diagnosis of the transmitted data

Fig.47: 2-wire connection with external bridge in bus structure to RS485 device(s)

The following CoE objects must be set

Index Name Meaning Data type Flags Setting

F800:0n Interface type

Ch n

0x00 RS232 BIT1 RW 0x01

(1

0x01 RS485/422

dec

)

Index Name Meaning Data type Flags Setting

80n0:06 Enable half du-

plex

channel n

0

Full duplex: transmitted data are monitored. The bit has no effect in

bin

RS232 and RS422 mode

1

Half duplex: The reception of the data transmitted by the box itself is

bin

suppressed

BOOLEAN RW 0

bin

EP6001 and EP6002 57Version: 2.1.0

Page 58

Commissioning/Configuration

Index Name Meaning Data type Flags Setting

80n0:07 Enable point-to-

point connection (RS422)

Channel n

0

The module is used in a bus structure in accordance with the RS485

bin

standard.

1

The module is used for a point-to-point connection (RS422).

bin

BOOLEAN RW 0

bin

Activated receive driver (from firmware version 03)

The receive driver remains activated during the transmission procedure. The transmitted data are

monitored! A conditional diagnosis of the line is thus possible. If there is a discrepancy between the

transmitted data and the monitored data, it may be assumed that a further receiver also cannot receive these data flawlessly. In this case, check the bus line!

Also see about this

2 Configuration by means of the TwinCAT System Manager [}70]

EP6001 and EP600258 Version: 2.1.0

Page 59

Commissioning/Configuration

5.2 EP600x-0002 - Basic function principles

The EP6002-0002 2-channel serial interface module enables the connection of two devices with an RS232

or RS485/RS422 interface. The EP6001-0002 1-channel serial interface module enables the connection of

one device with an RS232 or RS485/RS422 interface and in addition the connection of digital inputs/outputs.

EP6002-0002 - two configurable interfaces

The module has two physical interfaces, which can each be configured as RS232 or RS422/485.

Interface 1 of the EP6002-0002

• RS232 on M12 socket 1 or

• RS422/485 on M12 socket 2

Interface 2 of the EP6002-0002

• RS232 on M12 socket 3 or

• RS422/485 on M12 socket 4

The receive buffer has 864bytes, the send buffer 128bytes. The factory setting of the module is 9600baud,

8data bits, 1stop bit, no parity.

No hardware flow control takes place; however, software flow control is possible via XON, XOFF.

EP6001-0002 - One configurable interface

The module has one physical interface, which can be configured as RS232 or RS422/485. In addition, the

box allows the connection of digital inputs/outputs on M12 socket 4.

Interface 1 of the EP6001-0002

• RS232 on M12 socket 1 or

• RS485/422TX on M12 socket 2 or

• RS422RX on M12 socket 3

Communication between PLC and EP600x-0002

Communication takes place

• as with a COM port using the virtual serial COM driver or

• via control word and status word

Sending data

You can transmit up to 22bytes of data to the module in one cycle via DataOut0 ... DataOut21.

• Set the Output Length parameter in the control byte to the number of bytes to be transmitted.

• Toggle the Transmit Request bit in the control byte.

• The module acknowledges the data transmission in the status byte via the Transmit Accepted

parameter.

Receiving data

If the module toggles the Receive Request bit in the status byte, there are new receive data

• Read the Input Length parameter from the status byte. It contains the number of bytes to be received.

• The data are provided in DataOut0 ... DataOut21. The first datum is contained in DataIn0.

• After reading the data, acknowledge this by toggling the Receive Request bit in the control byte.

The module only makes new data available after that.

EP6001 and EP6002 59Version: 2.1.0

Page 60

Commissioning/Configuration

Interface level

The EP600x-0002 module operates at RS232 level with respect to GND or with differential RS485/422 level.

Fig.48: Level of RS232, RS485/RS422 interfaces

Process data

As delivered, 22bytes of user data and 1 control/status word are transferred.

Parameterization via CoE (index 0x80n0)

0x80n0 [}91] Parameterization via CoE

The parameterization of the module can be set in the CoE (CAN over EtherCAT) list.

Parameterization via the CoE list (CAN over EtherCAT)

Please note the following general CoE notes when using/manipulating the CoE parameters: - Keep

a startup list if components have to be replaced - Differentiation between online/offline dictionary,

existence of current XML description - Use "CoE reload" for resetting changes

The following CoE settings are possible from object 0x8000 of the EP6002-0002 and are shown here in the

default settings:

EP6001 and EP600260 Version: 2.1.0

Page 61

Fig.49: EP6002-0002 - CoE settings on object 0x8000 (default)

Commissioning/Configuration

Process data description

The process data are generated from CoE objects 0x6000 (Inputs) [}107] and 0x7000 (Outputs) [}109] and

are described in chapter Object description and parameterization [}90].

Transfer rates

The EP boxes have a process image of 22bytes of user data. It possible to transmit or receive these

22bytes every second cycle at the most.

The data is transferred from the EP box to the controller in the first cycle. In the second cycle, the controller

must acknowledge that it has accepted the data.

Therefore, if the cycle time is 10ms, 50times 22bytes can be transmitted per second.

With a set data frame of 8N1, each transmitted byte consists of a start bit, eight data bits and a stop bit. This

is equivalent to 10bits per user byte.

With the above mentioned settings, a continuous data transfer rate of:

• 50[1/s] x 22[bytes] x 10[bits] = 11000 bps

can be achieved.

The next lower baud rate is 9600baud. Accordingly, continuous transfer at a maximum baud rate of 9600

can be secured with a cycle time of 10ms.

If only low quantities of data are to be transmitted or received sporadically (e.g. bar code scanner) the baud

rate can also be set higher, or the cycle time can be enlarged.

If the controller cannot collect the data quickly enough from the EP box, the data will be stored intermediately

in the internal buffer of the EP box. The buffer for received data has a size of 864bytes. If this is exhausted,

all further data will be lost.