Beckett CG50 User Manual

COMMERCIAL PRODUCTS

GAS-FIRED

Fire, Explosion and Asphyxiation Hazards

Failure to follow these instructions exactly could lead to fi re or explosion and result in

death, severe personal injury or property damage.

Do not store or use gasoline or other fl ammable vapors and liquids in the vicinity of this or any other appliance.

1.

What to do if you smell gas:

2.

- Do not try to light any appliance.

- Do not touch any electrical switch.

- Do not use any phone in your building. Immediately call your gas supplier from a telephone outside the building.

- Follow the gas supplier’s instructions.

- Call the fi re department if you cannot contact your supplier.

Installation and service must be performed by a qualifi ed installer, service agency, or the gas supplier.

3.

2

Contents

General Information ....................................................4

Hazard Defi nitions .........................................................................4

Professional Installer’s Responsibility ...........................................5

Pre-installation Checklist ........................................... 5

Indoor Installation .......................................................................... 5

Combustion Air Supply .................................................................. 5

Clearances .................................................................................... 5

Fuel Gas Supply ........................................................................... 5

Flue Vent System .......................................................................... 5

Electrical Supply ............................................................................ 7

Verify Burner Components ............................................................ 7

Verify Firing Input Range ............................................................... 7

Verify Burner Air Tube Assembly ...................................................7

Mount the Burner ....................................................... 10

Connect Gas Piping .................................................. 10

Gas Trains ................................................................................... 11

Wire the Burner .......................................................... 14

Sequence of Operation ............................................. 14

Prepare the Burner for Start-up ............................... 17

Start-up Checklist ....................................................................... 17

Start the Burner ........................................................ 18

Burner Start Procedure ...............................................................18

Initial Air Settings .........................................................................18

Optional Modulation Linkage Adjustment Instructions ................20

Adjustment Procedure .................................................................20

Modulation Control ......................................................................22

Verify Input Firing Rate ................................................................ 23

Estimating Rate ........................................................................... 24

Clocking a Gas Meter ..................................................................24

Uncorrected Flow Rate ...............................................................24

Pressure Correction ....................................................................24

Temperature Correction ..............................................................24

BTU’s and MBH...........................................................................24

Check Operation and Safety Controls .........................................26

Use Test Instruments to Set Combustion ....................................27

Recommended Combustion Test Sequence ...............................27

Maintenance and Service.......................................... 28

Annual Maintenance ..................................................................28

Appliance ....................................................................................28

Gas Supply Piping .......................................................................29

Installation Area ........................................................................... 29

Adjust the Burner for Proper Combustion ..................................29

Flame Safeguard .........................................................................29

Manual Shutdown for Long Periods ............................................29

Ignition Reliability ........................................................................29

Propane Restrictor Description ..................................................31

Installation ..................................................................................31

For the Operator ..........................................................................33

Replacement Parts .................................................... 34

Limited Warranty Information .................................. 36

CG15, CG25, CG50 Burner Manual

3

Section: General Information

General Information

Hazard Defi nitions

Indicates a hazardous

situation which, if not

avoided, will result in death or serious injury.

Indicates a hazardous

situation, which, if not

avoided, could result in death, or serious

injury.

Used with the safety

alert symbol, indicates a

hazardous situation, which, if not avoided,

may result in minor or moderate injury.

Within the boundaries of the hazard warning, there will

be information presented describing consequences if the

warning is not headed and instructions on how to avoid

the hazard.

Used to address practices not related

to personal injury.

Owner’s Responsibility

Failure to follow these instructions,

misuse, or incorrect adjustment of

the burner could lead to equipment

malfunction and result in asphyxiation,

explosion or fi re.

Contact a professional, qualifi ed service agency for the

installation, adjustment, and service of your gas burning

system. Thereafter, have your equipment adjusted and

inspected at least annually to ensure reliable operation.

This work requires technical training, trade experience,

licensing or certifi cation in some states and the proper

use of special combustion test instruments.

Please carefully read and comply with the following

instructions:

See the front cover for ‘What to do if you smell gas’.

y

Never store or use gasoline or other fl ammable liquids

y

or vapors near this burner or appliance.

Never attempt to burn garbage or refuse in this

y

appliance.

Never attempt to light the burner/appliance by throwing

y

burning material into the appliance.

Never attempt to burn any fuel not specifi ed and

y

approved for use in this burner.

Never restrict the air inlet openings to the burner or

y

the combustion air ventilation openings in the room.

To the Owner:

Thank you for purchasing a Beckett burner for use

with your heating appliance. Please pay attention to

the Safety Warnings contained within this instruction

manual. Keep this manual for your records and

provide it to your qualifi ed service agency for use

in professionally setting up and maintaining your

burner.

Your CG series gas burner will provide years of

effi cient operation if it is professionally installed and

maintained by a qualifi ed service technician. If at

any time the burner does not appear to be operating

properly, immediately contact your qualifi ed

service agency for consultation.

We recommend annual inspection/service of

your gas heating system by a qualifi ed service

agency.

Frozen Plumbing and

Water Damage Hazard

If the facility is unattended in severely cold weather,

burner primary control safety lockout, heating system

component failures, power outages or other electrical

system failures could result in frozen plumbing and

water damage in a matter of hours. For protection,

take preventive actions such as having a security

system installed that operates during power outages,

senses low temperature and initiates an effective

action. Consult with your heating contractor or

security agency.

4

Section: Pre-installation Checklist

Professional Installer’s Responsibility

Follow these instructions

exactly

Failure to follow these instructions could

lead to equipment malfunction and result

in asphyxiation, explosion or fi re.

Please read all instructions before proceeding. Follow

y

all instructions completely.

This equipment must be installed, adjusted, and

y

started by a qualifi ed service agency that is licensed

and experienced with all applicable codes and

ordinances and responsible for the installation and

commissioning of the equipment.

y

The installation must comply with all local codes and

ordinances having jurisdiction and the latest edition of

the National Fuel Gas Code ANSI Z223.1 (NFPA 54)

and CAN1-B149.1 in Canada.

Concealed damage – If you discover

damage to the burner or controls

during unpacking, notify the carrier at once and fi le the

appropriate claim forms.

High altitude installations – Accepted industry practice

requires no derate of burner capacity up to 2000 feet

above sea level. For altitudes higher than 2000 feet,

derate the burner capacity 2% for each 1000 feet above

the 2000 feet.

50 Hz motors – The burner ratings, air settings and other

adjustments are based on 60 Hz motors at 3450 rpm.

Derate fi ring capacity 20% when using 50 Hz motors.

Consult factory for specifi c application data.

Pre-installation Checklist

Combustion Air Supply

The burner requires combustion air and ventilation air

for reliable operation. Assure that the building and/or

combustion air openings comply with the latest edition of

the National Fuel Gas Code ANSI Z223.1 (NFPA 54).

For appliance/burner units in confi ned spaces, the room

must have an air opening near the top of the room, plus

one near the fl oor, each with a free area at least one

square inch per 1000 Btu/hr input for all fuel-burning

equipment in the room.

For Canadian installations, refer to latest edition of CAN1B149.1 standard.

If there is risk of the space being under negative pressure,

or of exhaust fans or other devices depleting available

air for combustion and ventilation, the appliance/burner

should be installed in an isolated room provided with

outside combustion air.

Clearances

With the burner installed in the appliance, there must be

adequate space in front of and on the sides of the burner

to allow access and operation. Verify that the clearance

dimensions comply with local codes and with the appliance

manufacturer’s recommendations.

Fuel Gas Supply

Verify that the gas supply piping complies with all applicable

local codes and the latest edition of the National Fuel Gas

Code ANSI Z223.1 (NFPA 54).

Insure that the supply gas pipe size is capable of providing

at least the minimum pressure required to the burner gas

train inlet at the burner’s full capacity rating. Refer to

Table 1.

Indoor Installation

Protect against Dust and

Moisture

Wet or dusty environments could lead to blocked air

passages, corrosion damage to components, impaired

combustion performance and result in asphyxiation,

explosion or fi re.

This burner is designed for clean, dry installations.

y

Electrical controls are not protected against rain or

y

sprayed liquids.

Keep the installation clear of dust, dirt, corrosive

y

vapors, and moisture.

Protective covers and more frequent maintenance

y

may be required.

CG15, CG25, CG50 Burner Manual

Flue Vent System

The fl ue gas vent system must be in good condition

and must comply with National Fuel Gas Code ANSI

Z223.1 (NFPA 54) and all other applicable codes having

jurisdiction for vent construction, capacity, and sizing.

5

Section: Pre-installation Checklist

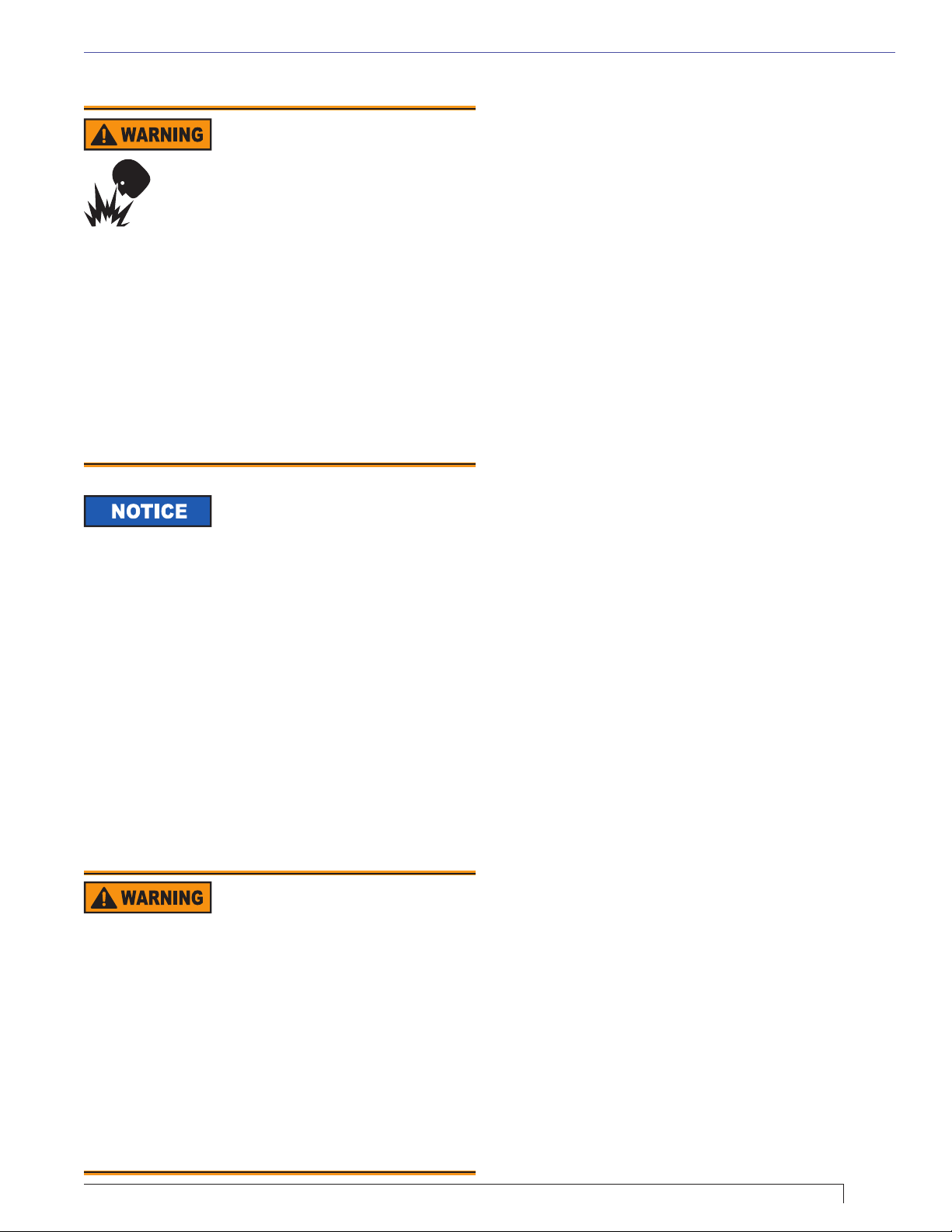

Table 1 – Burner Specifi cations

CG15 CG25 CG50

Input Firing Range†:

High Fire (Max.)

High Fire (Min.)

Low Fire (Max.)

Low Fire (Min.)

Fuel:

Natural Gas

Propane (LP)

Gas Train:

Standard

Options

Gas Train Inlet Pressure:

Minimum

Maximum

Manifold to Furnace

Pressure Drop:**

Highest High Fire

Lowest High Fire

Firing Modes Available: Low Fire Start

Standard Flame

Safeguard:

Low Fire Start

High / Low

Modulation

Flame Detector:

Standard UV UV UV

Airfl ow Proving Switch: Standard Standard Standard

Gas Pressure Switches: Standard High and Low Standard High and Low Standard High and Low

Ignition: Direct Ignition of Main Flame Direct Ignition of Main Flame Direct Ignition of Main Flame

Motor:

HP

RPM

Standard Voltage

Motor FLA

Optional Voltages

Weight: 125 lbs. 145 lbs. 165 lbs.

Dimensions: Refer to Figures 4 & 5.

*See manufacturer’s nameplate settings for specifi

** See Figures 14A, 14B, & 14C.

† Canada High Fire rate is reduced to accomodate 25% reserve air.

USA Canada USA Canada USA Canada

1,500 MBH

800 MBH

560 MBH

350 MBH

0.6 Specifi c Gravity Typical

1.53 Specifi c Gravity Typical

UL Listed / CSD-1 confi guration

IRI, FM

3.7” WC*

10 PSI

3.7” WC

2.7” WC

High/Low

Modulation

RM7897A

RM7897C

RM7897C

1/2HP

3450 RPM

120 volt, 1 ph, 60 Hz

6.4 Amps @120 volt AC

208/230v, 1 ph, 60 Hz

208/230v, 3 ph, 60 Hz

460v, 3 ph, 60 Hz

575v, 3 ph, 60 Hz

1,370 MBH

800 MBH

560 MBH

350 MBH

c minimum gas pressure requirements.

2,700 MBH

1,300 MBH

990 MBH

550 MBH

0.6 Specifi c Gravity Typ.

1.53 Specifi c Gravity Typ.

UL Listed / CSD-1 confi guration

IRI, FM

3.5” WC*

10 PSI

3.5” WC

2.5” WC

High/Low

Modulation

RM7897C

RM7840L

3/4 HP

3450 RPM

120 volt, 1 ph, 60 Hz

10.4 Amps @120 volt AC

208/230v, 1 ph, 60 Hz

208/230v, 3 ph, 60 Hz

460v, 3 ph, 60 Hz

575v, 3 ph, 60 Hz

2,300 MBH

1,300 MBH

990 MBH

550 MBH

5,000 MBH

2,000 MBH

1,400 MBH

730 MBH

0.6 Specifi c Gravity Typ.

1.53 Specifi c Gravity Typ.

UL Listed / CSD-1 confi guration

IRI, FM

3.5” WC*

10 PSI

3.5” WC

2.5” WC

High/Low

Modulation

RM7897C

RM7840L

2 HP

3450 RPM

208/230v, 1 ph, 60 Hz

13.4 Amps @230 volt AC

208/230v, 3 ph, 60 Hz

460v, 3 ph, 60 Hz

575v, 3 ph, 60 Hz

4,000 MBH

2,000 MBH

1,400 MBH

730 MBH

Figure 1 - Burner Label Location

General Model Information

Serial Number,

Including Date Code

Rating Information

Approval Agency Symbols

Fuel

6

R.W. Beckett Construction

& Setting Data

R.W. Beckett Specifi cation

Number and Revision

Boiler Manufacturer and

Model, When Applicable

Additional Codes

Test For Gas Pipe Leaks

Leaking gas could result in asphyxiation, explosion,

or fi re hazard.

The gas supply piping must be absolutely leak-free.

y

Pressure test the gas piping with air that is at least

y

three times greater than the gas pressure being

used.

Verify that there are no leaks before proceeding.

y

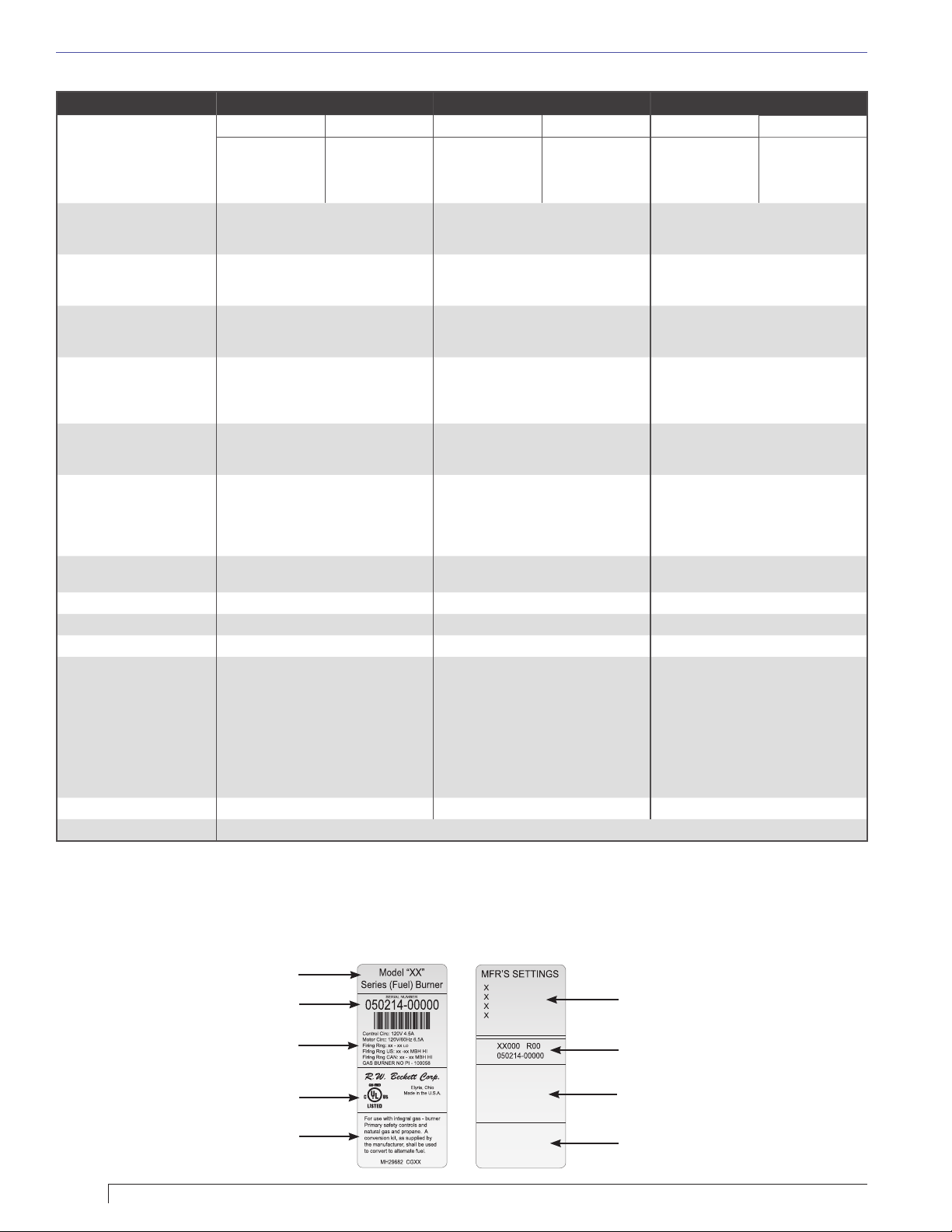

Figure 2 - Minimum Combustion Chamber Dimensions

Minimum Inside Dimensions (inches)

Burner

Model

CG15.1S 15 16 42 7

CG15.2S 16 17 45 8

CG15.3S 17 18 47 8

CG15.4S 18 19 50 9

CG25.1S 19 20 45 9

CG25.2S 20 21 48 10

CG25.3S 21 22 50 10

CG25.4S 22 23 52 11

CG25.5S 23 25 55 11

CG50.1S 21 23 55 10

CG50.2S 22 24 58 11

CG50.3S 24 26 62 12

CG50.4S 25 27 65 12

CG50.5S 27 29 70 13

Width

‘W’

Height

‘H’

Length

‘L’ at Min

H & W*

Dimensions shown are for cast

iron sectional boilers with uptakes

between sections. For minimum dimensions of other

furnace types consult R. W. Beckett Corporation.

Burner

Head

Centerline

to fl oor ‘A’

Section: Pre-installation Checklist

Electrical Supply

Check the nameplate on the burner to verify that the

power connections available are correct for the burner.

Refer to Figure 1. All power must be supplied through

fused disconnect switches and comply with the latest

edition of National Electric Code NFPA 70 (Canada CSA

C22.1) and all other local or applicable codes.

Verify Burner Components

Burner model can be checked from burner carton or rating

label on burner.

Flange mounting arrangement (Includes high-temperature

gasket and/or fi ber rope for pressure fi ring).

Verify Firing Input Range

Refer to appliance manufacturer’s instructions (if available)

for the fi ring input range. Otherwise the maximum

recommended fi ring range for the burner depends on the

length and width of the fi ring chamber and the distance

from the burner center to the chamber fl oor. Verify that the

chamber dimensions are at least as large as the minimum

values given in Figure 2. If the appliance dimensions are

smaller, reduce the fi ring rate accordingly.

Flames are shaped by their furnaces

and by its fl ue locations. Increased

height and width can decrease the length requirement.

When shaping is too severe fl ames impinge on the walls.

Impingement causes CO and carbon deposits and may

damage the wall. Maintaining these minimum dimensions

should prevent impingement, but smaller furnaces may

be acceptable depending upon the results of applications

testing. We recommend factory testing of all new burner/

furnace combinations by the furnace manufacturer and/or

R. W. Beckett Corp.

The volume of the furnace also

infl uences the combustion process.

R. W. Beckett Corp. recommends at least 1 cubic foot of

furnace volume for each 150,000 BTU/Hr of fi ring rate.

Verify Burner Air Tube Assembly

The information in this section may be disregarded if

○

the burner supplied by the appliance manufacturer is

a matched component.

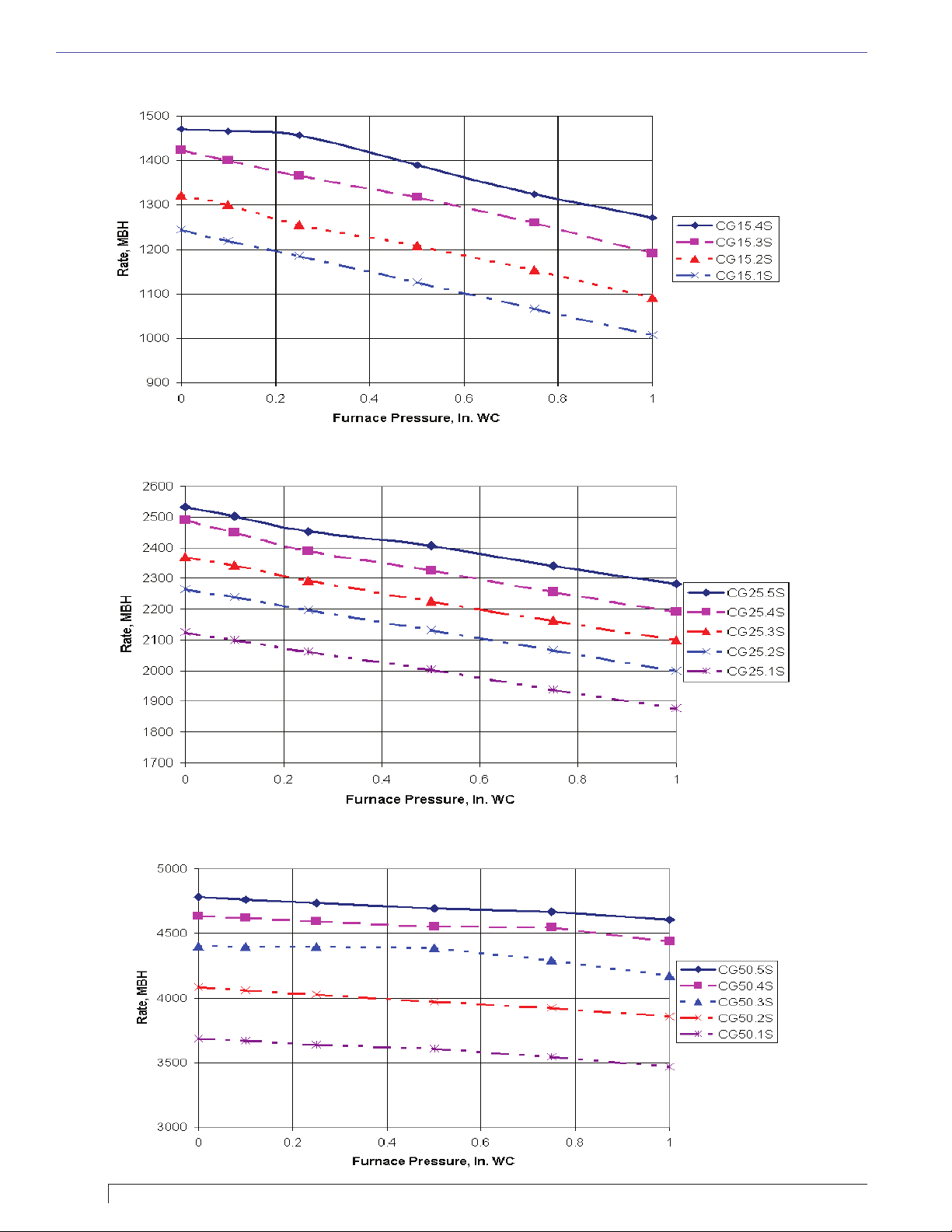

Maximum fi ring capacity depends on the furnace

○

pressure. Use the charts shown in Figure 3A, Figure

3B, and Figure 3C, to verify the correct burner

confi guration for the input rate.

CG15, CG25, CG50 Burner Manual

Refer to Figures 4 & 5 to verify the air tube assembly

○

length and mounting insertion dimensions.

7

Section: Pre-installation Checklist

Figure 3A - Maximum Capacity (at 3% O2) vs Furnace Pressure - CG15, 60Hz.

Figure 3B - Maximum Capacity (at 3% O2) vs Furnace Pressure - CG25, 60Hz.

Figure 3C - Maximum Capacity (at 3% O2) vs Furnace Pressure - CG50, 60Hz.

8

Section: Pre-installation Checklist

Figure 4 - Burner Dimensions

DIM. A

O.D.

Model Dim. A Dim. B Dim. C Dim. D Dim. E Dim. F Dim. G Dim. H O.D. Pipe Thread

CG15 20.8 9.4 32.7 13.7 5.2 18.4 6.2 10.8 5.6 1-1/4 NPT

CG25 20.9 9.3 33.2 13.4 6.8 17.8 6.7 12.6 6.9 2 NPT

CG50 24.4 10.5 33.6 13.5 7.5 17.4 6.7 14.6 7.7 2-1/2 NPT

DIM. B

DIM. D

DIM. E

DIM. F

DIM. C

DIM. G

DIM. H

NOTE: All dimensions are in inches.

Figure 5 - Panel and Modulating Valve Dimensions

16.00

2.9

6.00

12.4

DIM. A

FEMALE PIPE THREAD

CG15, CG25, CG50 Burner Manual

DIM. B

Model Dim. A Dim. B Pipe Thread

CG15 5.12 11.75 1-1/4 NPT

CG25 5.12 11.75 2 NPT

CG50 5.81 13.25 2-1/2 NPT

*Dimensions are in inches

9

Section: Mount the Burner & Connect Gas Piping

Mount the Burner

Mount the burner to the appliance. The burner specifi ed

for packaged equipment will have a fl ange welded for the

required insertion. Follow the appliance manufacturer’s

instructions for mounting.

In the absence of instructions, or for retrofi ts, make sure

that the air tube insertion dimension, measured along the

side of the air tube from the welded fl ange to the end of

burner air tube, is correct.

Protect the Air Tube from

Overheating

Overheating could cause damage to the air tube and

other combustion components leading to equipment

malfunction and impaired combustion performance.

The end of the air tube must not extend into the

y

combustion chamber unprotected unless it has

been factory-tested and specifi ed by the appliance

manufacturer.

The end of the air tube should be set back ¼” from

y

fl ush with the refractory inside wall to prevent damage

from overheating.

Refer to the instructions outlined in this section for

y

methods of additional protection.

If this dimension cannot be achieved, protect the

○

end of the air tube by installing a suitable ceramic

refractory material such as a refractory mill board

capable of withstanding at least 2300 degrees F. The

entry hole diameter in the appliance should be 1”

larger than the air tube to facilitate ease of installation

and provide adequate protection.

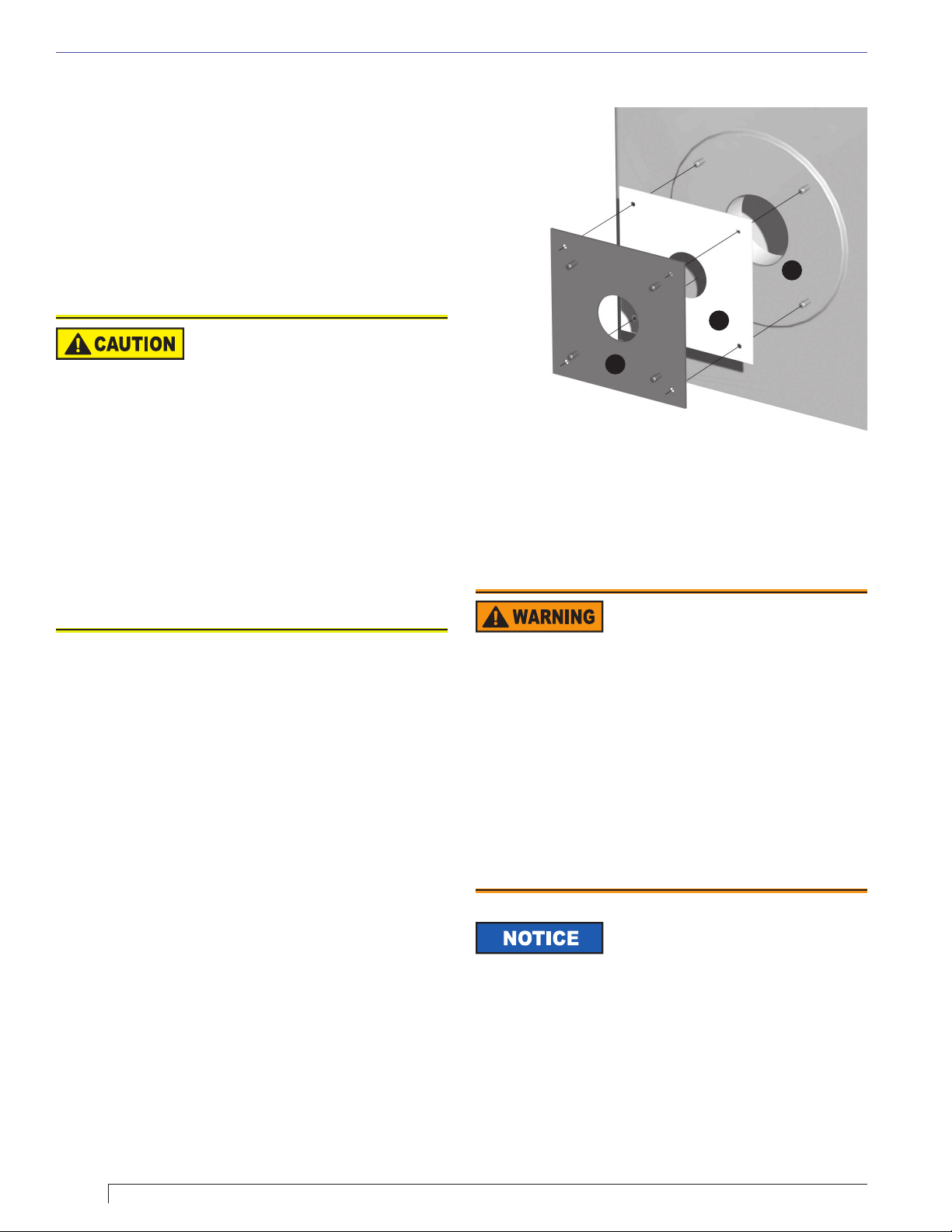

Referring to Figure 6, if the front plate opening (C)

○

in the boiler is larger than the burner fl ange bolt

circle, then a custom mounting plate (A) of at least

1/4” thickness must be used with a suitable hightemperature refractory material anchored on the fi re-

side. A suitable high-temperature gasket (B) must be

used for an effective seal.

Attach the plate and gasket to the boiler and tighten

○

the mounting nuts or bolts securely.

Verify that the air tube is ¼” back from fl ush (see

○

Figure 2), and there is nothing blocking the fl ame

zone that could cause fl ame impingement.

Figure 6 - Custom Mounting Plate

C

B

A

Key:

A = Burner mounting fl ange

B = Gasket

C = Appliance mounting plate

Connect Gas Piping

Do Not Use Tefl on Tape on

Gas Piping

Damage to gas valve cutoff seals and valve bodies

could cause gas leaks and result in asphyxiation,

explosion or fi re.

Pieces of tape can be cut loose during installation and

y

lodge in gas valves causing cutoff seal problems.

Te fl on tape ‘lubricates’ pipe threads, allowing iron

y

pipes to penetrate too deeply into aluminum valve

bodies causing distortion and leakage.

Use only pipe sealant compounds that are resistant to

y

the gas being used.

All gas piping installation must

comply with the latest edition of the

National Fuel Gas Code ANSI Z223.1 (NFPA 54) and

other applicable local codes.

The gas supply system must be sized to deliver at

least the minimum required pressure to the gas train

inlet. Contact your local gas utility for verifi cation of gas

pressures, allowable pressure drops, and any local piping

code requirements. Refer to Figure 7 for an illustration of

a gas piping layout and refer to Table 2 for pipe sizing.

10

Install a Drip Leg in Gas

Supply Piping

Foreign matter could lodge in gas valve

cutoff seals, resulting in gas leak-through,

explosion or fi re.

Install a full-size drip leg or dirt pocket in the piping

directly ahead of the main shutoff valve to capture foreign

matter.

Gas Trains

Gas Leaks and Explosion

Hazards

Section: Connect Gas Piping

Pressure Drop curves of Figures 14A, 14B, and 14C are

correct for both propane and natural gas. That is also

why a gas train adjusted for the burner’s natural gas

requirements will be correctly adjusted for its propane

requirements. R. W. Beckett provides the same pressure

regulating safety shutoff valve in the gas train (usually a

Honeywell V4944B) for both natural gas and propane.

The valve is marked for natural gas due to its primary

usage in a pressure range normally used by natural gas

appliances. It is safe and effective for propane usage in

this design application.

Optional – Gas trains for IRI and FM are available and

must be specifi ed when ordering a burner.

Provide Over-pressure Protection

CSD-1 requires that if gas pressure entering the building

exceeds the rating of any gas train component an

overpressure protection device must be installed.

Standard – An Underwriters Laboratories (UL) listed

gas train is standard for the CG10 gas burner. This

confi guration also meets CSD-1 requirements. See

Figures 8A and 8B for typical component layout.

Propane (LP) – When the correct propane restrictor is

added to a burner’s gas pipe assembly it changes the

burner’s gas pressure drop so that the propane pressure

drop is equal to the natural gas pressure drop of the same

BTU fi ring rate. That is why the Manifold to Furnace

Figure 7 - Typical Gas Piping Layout

Verify – Verify that the train components are not damaged

and all piping and fi ttings are clean inside and out. The

gas train is normally shipped as components and must be

assembled and installed at the site.

Vent Lines – Install vent lines to any gas valve component

that requires atmospheric air pressure to balance a

diaphragm. Vent lines must be run to the outdoors, with

the termination point away from fresh air intakes and

windows. The terminal opening must be fi tted with a wire

mesh screen to block insects and other contaminants

from entering the vent and must be mounted in such a

position that water, ice, dirt, or any other foreign matter

cannot infi ltrate and block the vent piping. Make sure the

fi nal assembly is anchored securely.

ABBREV.

ITEM DESCRIPTION

HGPS

HIGH GAS PRESSURE SWITCH

LGPS

LOW GAS PRESSURE SWITCH

MSC

MAIN SHUTOFF COCK

MLTC

MAIN LEAK TEST COCK

PG

PRESSURE GAUGE

S

STRAINER

SSOV1

SAFETY SHUTOFF VALVE #1

TC

TEST COCK

U

UNION

2PRV

TWO POSITION REGULATING VALVE

METER

REGULATOR

GAS UTILITY PIPING

PG

U

CG15, CG25, CG50 Burner Manual

DRIP LEG

FACILITY PIPING

S

(IF USED)

MSC

LGPS

U

SSOV1

TC

2PRV

GAS TRAIN BURNER

TC

MLTC

U

HGPS

BURNER

TC

11

Loading...

Loading...