Page 1

www.basler.com

+1 618.654.2341 (USA)

info@basler.com

INTRODUCTION

Six-input BE3 temperature relays use resistance

temperature detectors (RTDs) to monitor remote

temperatures. When any of six monitored temperatures

exceeds a preset limit, the corresponding LED indicator

lights, the TRIP LED lights, and the relay output operates.

BE3 temperature relays are available for use with 10 Ω

copper or 100 Ω platinum RTDs.

SPECIFICATIONS

Operating Power

All units require externa l oper a ting pow er.

Nominal Voltage: 120 Vac, ±25%, 45 to 65 Hz, 2 VA

240 Vac, ±25%, 45 to 65 Hz, 2 VA

24 Vdc, ±20%, galvanically

isolated, <3 W

RTD Inputs

The RTD inputs accommodate two- or three-wire RTDs.

Depending on the style number of the relay, the RTD inputs

accept either 10 Ω copper or 100 Ω platinum RTDs.

Style 5J5X1: 10 Ω copper RTDs

Style 5K5X1: 100 Ω platinum RTDs

The temperature measurement range of each input is 0 to

200°C.

Metering Output

Range: 0 to 1 mAdc

Burden: 5 kΩ maximum

Setpoints

Range: 50 to 100% (±3%) of input

temperature range

Repeatability: Greater than 0.5% of full span

Differential: Fixed at 2%

Outputs

Relay Type: S.P.D.T.

AC Rating: 250 V, 5 A, non-resistive,

1200 VA

DC Rating: 125 V, 1 A, resistive, 120 W

Mechanical Life: 5 million operations

Temperature

Operating Temperature: 0°C (32°F) to 60°C (140°F)

Functional Temperature: –25°C (–13°F) to 70°C (158°F)

Storage Temperature: –40°C (–40°F) to 85°C (185°F)

Temperature Coefficient: 0.03% per °C (300 ppm/°C )

Humidity

Relative Humidity: 95% non-condensing

Model

Physical

Mounting: DIN rail 1.38” by 0.29” (35 mm by

Case: Complies with IEC 529, DIN

Case Material: Complies with UL 94VO

Weight: 1.32 lb (0.59 kg)

Size: 3.94” wide (100 mm)

Agency

cULus listed to UL 508 and CSA C22.2 No. 14

CE compliant

GOST-R certified per the relevant standards of Gosstandart

of Russia

BE3-49R - 6 Inputs

7.5 mm)

40050, BS 5490

OPERATION

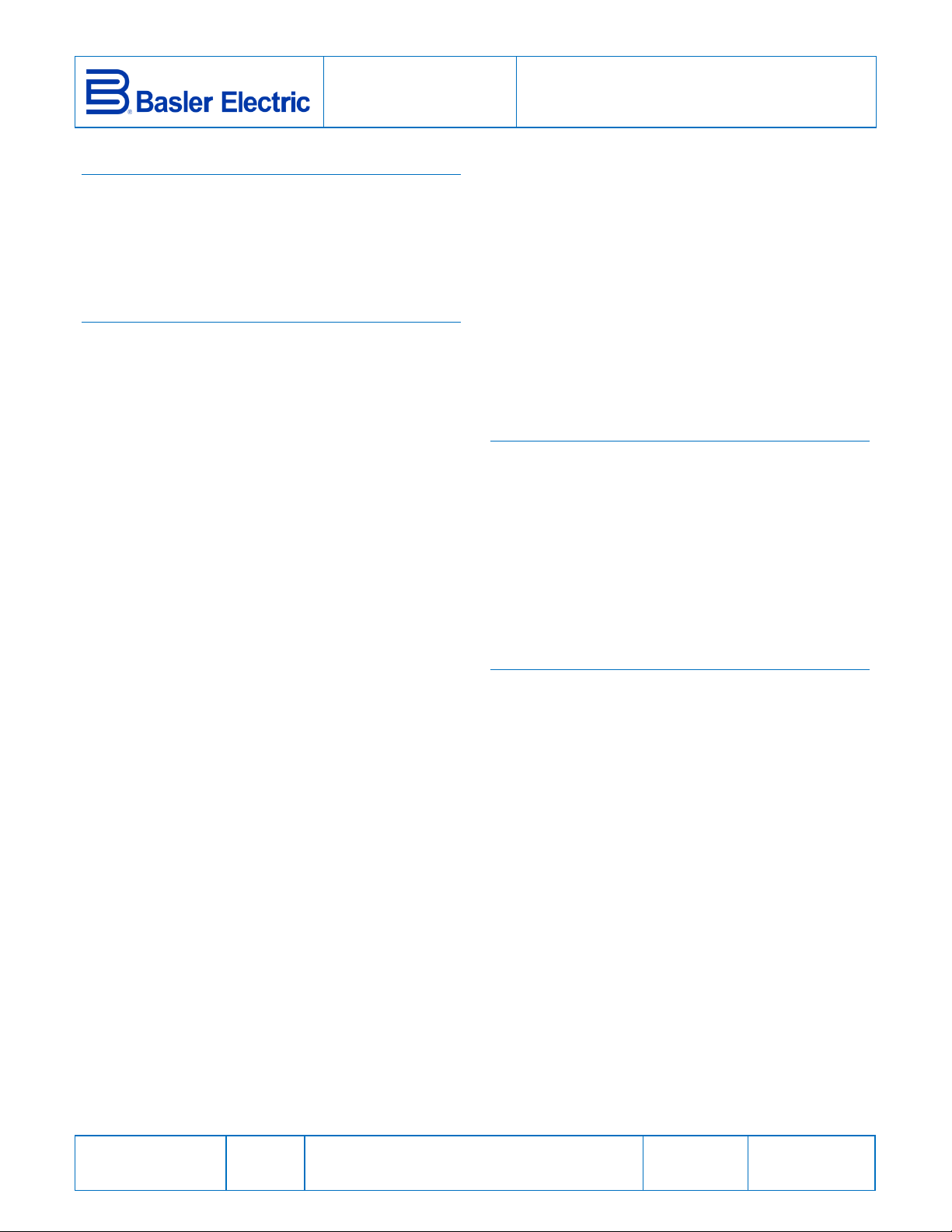

Six temperatures are monitored through RTDs connected to

the BE3 temperature relay. RTD connections are labeled A,

B, C, D, E, and F. One front-panel contr ol lab ele d SET is

used to adjust the trip level for all six RTDs. The setpoint is

adjustable from 50 to 100% (±3%) of the RTD temperature

range. When any RTD temperature exceeds the setpoint,

the TRIP LED lights, and the relay output energizes. Each

RTD has a corresponding LED to identify which RTD has

exceeded the temperature setpoint. For example, if the

temperature of RTDs B and C exceeds the trip level, the B,

C, and TRIP LEDs light and the relay output energizes. A

green LED labeled AUX indicates the power supply status.

INSTALLATION

BE3 temperature relays are designed for mount ing on

standard DIN rails that comply with DIN-EN 50022.

Mounting involves hooking the top edge of the cutout on the

base of the case over one edge of the DIN rail. The opposite

side of the cutout containing the release clip is then pushed

over the opposite side of the DIN rail. To remove or

reposition the relay, lever the release clip and move the

relay as required. BE3 relays should be installed in a dry,

vibration-free location where the ambient temperature does

not exceed the operating temperature range. Connections to

the relay should be made using wire that meets applicable

codes and is properly sized for the application. Figure 1

illustrates the terminal connections for the BE3-49R

temperature relay.

A burden resistor must be installed across all unused RTD

inputs that are not connected to an actual RTD. For units

with style number 5JXXX, it is suggested that a 10 Ω resistor

be connected across any unused RTD inputs. For units with

style number 5JXXX, it is suggested that a 100 Ω resistor be

connected across any unused RTD inputs. The minimum

power rating for the burden resistors is ¼ W.

Publication

9320500991

Revision

D

Instructions

Date

03/14

Copyright

2014

Page 2

CALIBRATION

Proper calibration requires a precision decade resistance

box with 1% accuracy or better. While calibrating the relay,

burden resistors must be connected across the remaining,

open RTD inputs. A temperature and resistance crossreference table for your RTDs is also needed. Use the

following procedure to calibrate your relay.

1. Adjust the SET control fully counterclockwise.

2. Connect the decade resistance box to RTD input A and

connect a 10 Ω (style 5JXXX) or 100 Ω (style 5KXXX)

burden resistor across the remaining RTD inputs. The

burden resistor power rating should be ¼ W or greater.

Apply nominal external operating power to the relay.

FIGURES

3. Set the decade resistance box at the value that

corresponds to the desired temperature setpoint.

4. Slowly adjust the SET control clockwise until the A and

TRIP LEDs light and the output relay energizes.

MAINTENANCE

BE3 relays are solid-state devices that require no

maintenance. In the event that your relay requires repair,

contact Basler Electric, Highland, IL, USA for return

authorization.

ORDERING INFORMATION

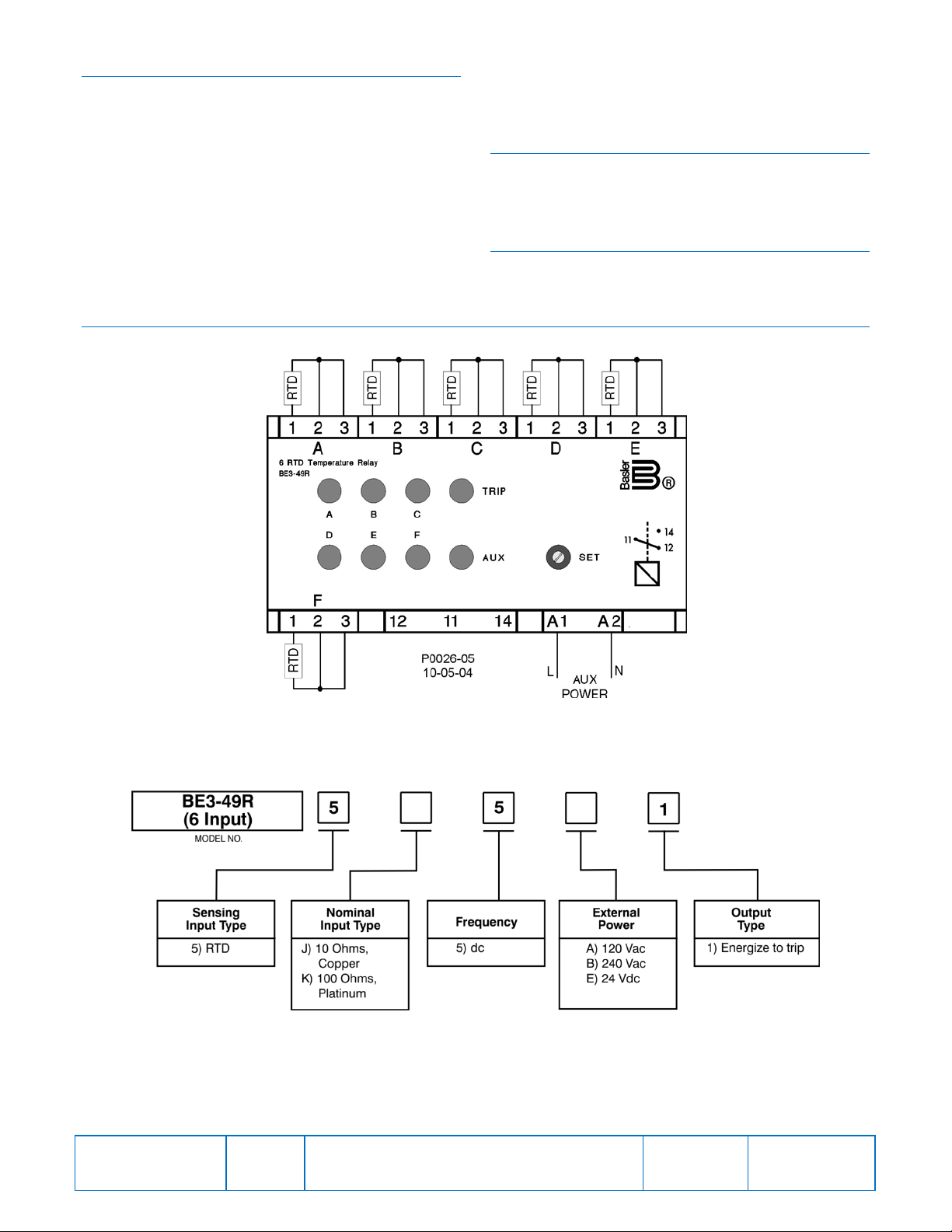

Figure 2 shows the BE3 temperature relay style chart.

Figure 1. BE3-49R - 6 Input Connections

Figure 2. BE3-49R - 6 Input Style Number Identification Chart

Publication

9320500991

Revision

D

Instructions

Date

03/14

Page

2 of 2

Loading...

Loading...