Page 1

INSTRUCTION MANUAL

FOR

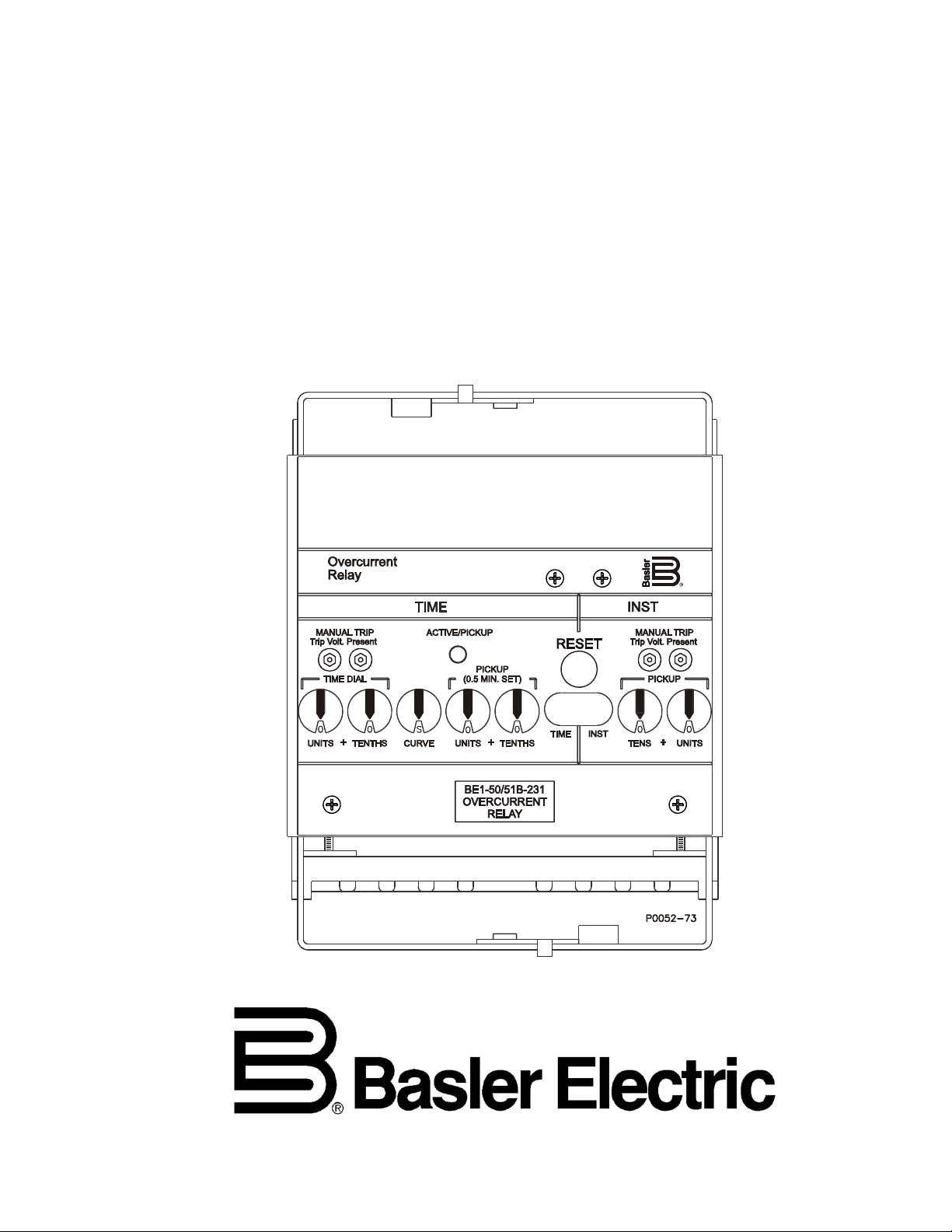

OVERCURRENT RELAY

BE1-50/51B-231

Publication: 9252000895

Revision: C 12/11

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the BE1-50/51B-231

Overcurrent Relay. To accomplish this, the following information is provided:

General Information and Specifications

Controls and Indicators

Functional Description

Installation and Maintenance

Testing

WARNING!

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

9252000895 Rev C BE1-50/51B-231 Introduction i

Page 4

First Printing: January 2007

Printed in USA

© 2007-2011 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

December 2011

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use,

subject to return on request, and with the mutual understanding that it will not

be used in any manner detrimental to the interest of Basler Electric.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual

provide data for every possible contingency regarding installation or operation. The availability and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii BE1-50/51B-231 Introduction 9252000895 Rev C

Page 5

REVISION HISTORY

The following information provides a historical summary of the changes made to this instruction manual

(9252000895). Revisions are listed in reverse chronological order.

Manual

Revision and Date

C, 12/11

B, 12/08

A, 03/08

—, 01/07

Made changes to reflect that a new connection plug is included with

the relay.

Updated year of IEEE C37.90 specifications in Section 1.

Improved description of Locator H (Active/Pickup LED) in Table 2-1.

Removed notes about hard-wiring relay case to ground since relay is

a direct replacement, i.e. not shipped with a case.

Updated Storage statement in Section 4.

Modified Figure 5-2, Target Operational Test Setup.

In Section 5, Testing, removed list of required tools and removed

steps about disconnecting and re-connecting relay terminal wires.

Modified Target Test so that TIME and INST targets can be verified

independently from each other.

Minor text edits throughout manual.

Updated front panel drawings to show new target reset button.

Initial release

Change

9252000895 Rev C BE1-50/51B-231 Introduction iii

Page 6

iv BE1-50/51B-231 Introduction 9252000895 Rev C

Page 7

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • CONTROLS AND INDICATORS ........................................................................................ 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

SECTION 5 • TESTING ............................................................................................................................ 5-1

APPENDIX A • TIME CHARACTERISTIC CURVES ................................................................................ A-1

9252000895 Rev C BE1-50/51B-231 Introduction v

Page 8

vi BE1-50/51B-231 Introduction 9252000895 Rev C

Page 9

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

Introduction ............................................................................................................................................ 1-1

Features ................................................................................................................................................. 1-1

Advantages ........................................................................................................................................ 1-2

Specifications ......................................................................................................................................... 1-2

Current Sensing Input ........................................................................................................................ 1-2

Time Overcurrent (51) Element .......................................................................................................... 1-2

Instantaneous Overcurrent (50) Element ........................................................................................... 1-4

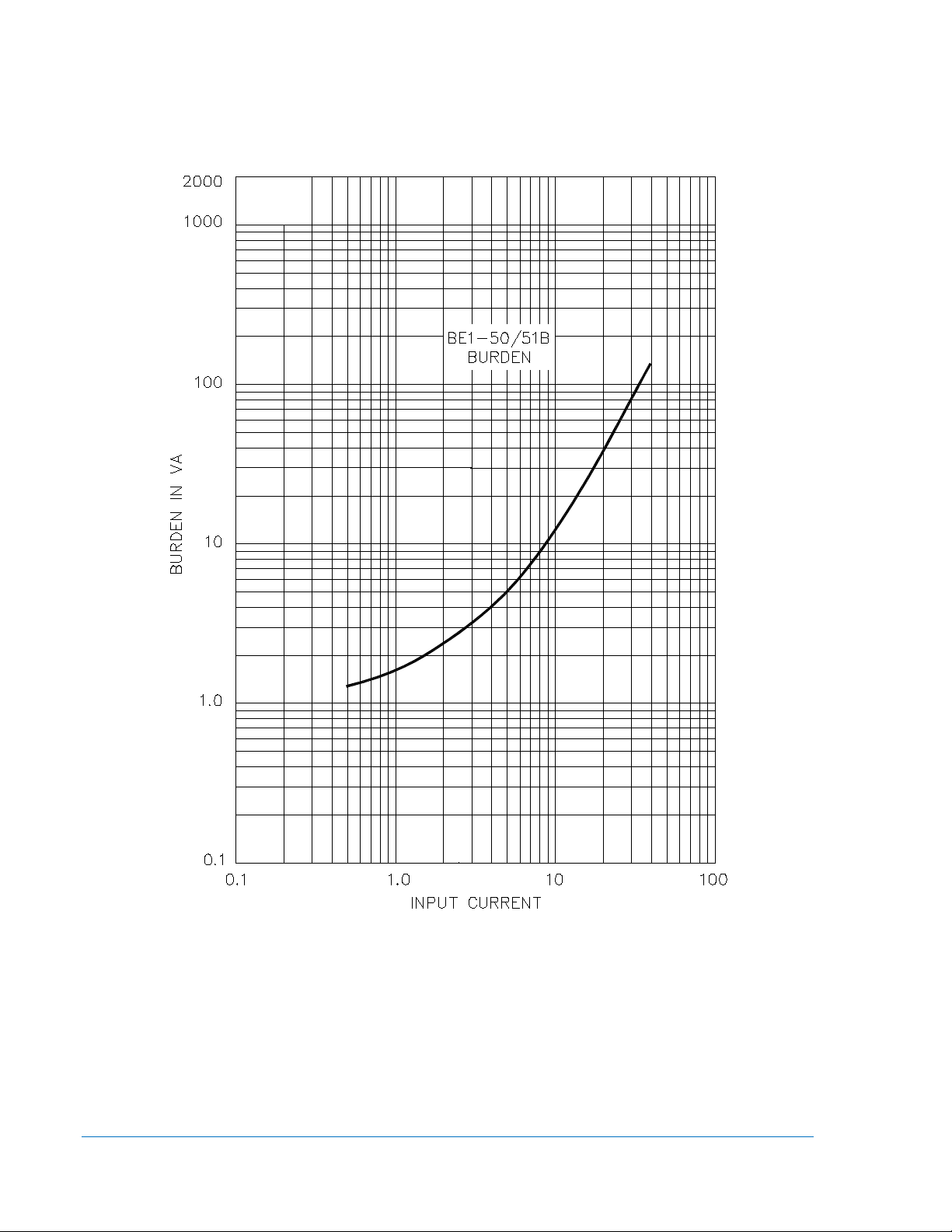

Burden ................................................................................................................................................ 1-6

Frequency Response ......................................................................................................................... 1-6

Transient Response ........................................................................................................................... 1-6

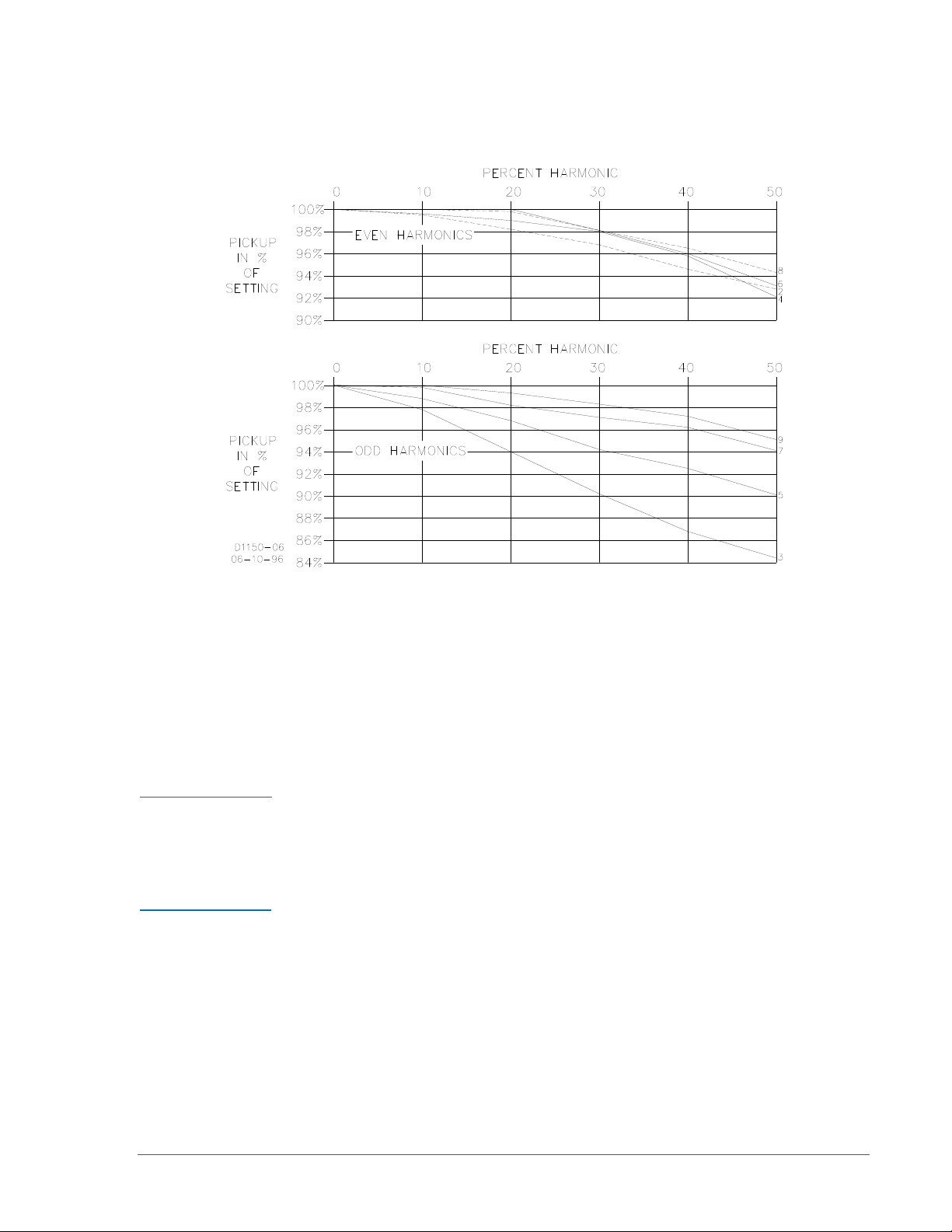

Harmonic Response ........................................................................................................................... 1-7

Target Indicators ................................................................................................................................ 1-7

Output Contacts ................................................................................................................................. 1-7

Type Tests .......................................................................................................................................... 1-7

Environment ....................................................................................................................................... 1-8

GOST-R Certification ......................................................................................................................... 1-8

Physical .............................................................................................................................................. 1-8

Figures

Figure 1-1. Integrating Reset Characteristic Curve ................................................................................... 1-4

Figure 1-2. Instantaneous Characteristic Curves

Figure 1-3. Harmonic Rejection

Figure 1-4. Burden Characteristics

...................................................................................... 1-5

................................................................................................................. 1-7

............................................................................................................ 1-6

Tables

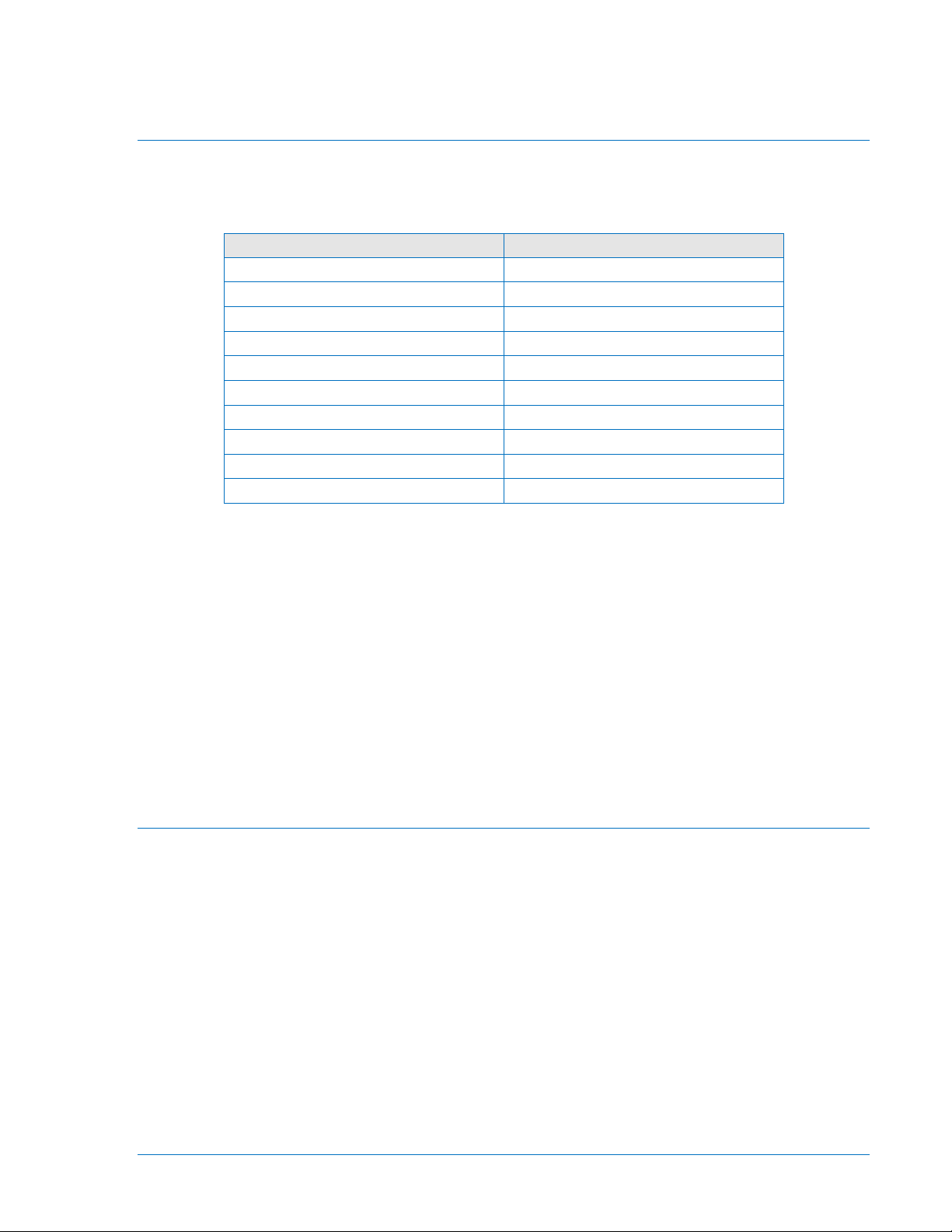

Table 1-1. GE IAC Relays Suitable for Direct Replacement ..................................................................... 1-1

Table 1-2. Time Characteristic Curve Constants with SW3-3 Open (Off)

Table 1-3. Time Characteristic Curve Constants with SW3-3 Closed (On)

................................................. 1-3

.............................................. 1-3

9252000895 Rev C BE1-50/51B-231 General Information i

Page 10

ii BE1-50/51B-231 General Information 9252000895 Rev C

Page 11

SECTION 1 • GENERAL INFORMATION

Introduction

BE1-50/51B-231 protective relays are direct replacements for General Electric, IAC relays. The BE150/51B-231 has a 5 ampere current sensing input. Compatible IAC model numbers are listed in

Table 1-1.

Table 1-1. GE IAC Relays Suitable for Direct Replacement

IAC Model Number Curve Type

12IAC51A∗∗∗A

12IAC51B∗∗∗A

12IAC53A∗∗∗A

12IAC53B∗∗∗A

12IAC55A∗∗∗A

12IAC55B∗∗∗A

12IAC66A∗∗∗A

12IAC66B∗∗∗A

12IAC77A∗∗∗A

12IAC77B∗∗∗A

∗ Any digit covering all pickup ranges except 50 Hz models.

Inverse

Inverse with Instantaneous

Very Inverse

Very Inverse with Instantaneous

Short Time

Short Time with Instantaneous

Long Time

Long Time with Instantaneous

Extremely Inverse

Extremely Inverse with Instantaneous

To replace an existing IAC relay, perform the following steps.

1. Select the desired relay settings on your new BE1-50/51B-231 relay.

2. Remove the existing IAC relay.

3. Attach the cover adapter to the existing case.

4. Insert the new relay.

5. Install the new Basler Electric connection plug.

6. Install the new Basler Electric cover.

Basler Electric BE1-50/51B-231 protective relays are self-powered, microprocessor-based, nondirectional phase or ground relays that monitor the magnitude of a single-phase ac current to provide

accurate instantaneous and time overcurrent protection for 60 Hz power systems. Each model covers 15

popular time characteristics, a wide range of pickup settings, and field selectable instantaneous or

integrating reset.

Features

A wide range of pickup settings and front panel selectable time characteristics permit applications

involving coordination with fuses, reclosers, cold load pickup, motor starting, and fixed time requirements.

Also, an integrating reset function is available to simulate the disk reset of electromechanical relays.

BE1-50/51B-231 overcurrent relays have the following standard features.

• Independent time and instantaneous elements

• A secure method to manually trip the breaker at the relay front panel

• Direct reading front panel controls

• Minimum pickup setting for safety during installation

• Time characteristics extend to a pickup multiple of 40

• Rugged draw-out construction with steel case

• Gravity latching targets retain indication without power

• Built-in accuracy eliminates internal adjustments

• Minimum transient overreach

• Field selectable characteristic curve selection similar to either GE IAC or ABB type curves

• Field selectable instantaneous or integrating reset

• Field selectable 0.0, 0.1, 0.2, or 0.3 second, fixed, instantaneous delay

9252000895 Rev C BE1-50/51B-231 General Information 1-1

Page 12

Internal switches provide for selecting instantaneous element delays of 0.0, 0.1, 0.2, or 0.3 second,

characteristic curve group selection for either GE IAC or ABB type curves, and instantaneous or

integrating reset characteristics. Switch location and description is provided in Section 2.

Advantages

BE1-50/51B-231 overcurrent relays have many advantages over other overcurrent relays. The primary

advantages are:

• Time characteristics are defined by equations and graphs

• Field selectable time characteristics

• Very low burden extends the linear range of the CTs

• Self powered from the sensed current

• Continuous automatic calibration

BE1-50/51B-231 overcurrent relays may be tested without removing the relay from the case. Shorting

contacts are provided for all current inputs when the connection plugs or relay chassis is removed from

the relay case.

Specifications

BE1-50/51B-231 electrical and physical specifications are listed in the following paragraphs.

Current Sensing Input

Continuous Current.................... 14 Aac

One Second Rating ................... 400 Aac

Time Overcurrent (51) Element

Setting the TIME PICKUP control at the minimum pickup setting places the relay in the most sensitive

state and may be used as a safety setting.

Pickup

Setting Range ............................ 0.5 to 15.9 Aac

Setting Increment ....................... 0.1 Aac

Accuracy .................................... ±2%, ±25 milliamperes at or above 0.5 ampere setting

Dropout

Dropout occurs at 95% of pickup value.

Timing Range

0.0 to 9.9 seconds in 0.1 second steps.

Timing Accuracy

The timing accuracy is the sum of ±1 cycle, ±2%. This accuracy applies to the range of 1.3 to 40 times tap

and is for a given measured multiple of tap. The measurement of the multiple of tap has an accuracy that

is the sum of ±2%, ±25 milliamperes.

Timing Accuracy Example

PU setting .................................. 5 amperes

Current Applied .......................... 6.5 amperes

+ Multiple Tolerance .................. 6.655 amperes

– Multiple Tolerance .................. 6.345 amperes

Time Curve ................................ E

Time Dial .................................... 5.0

Minimum time dial

using 6.655 amperes ............... 46.5470 seconds

Maximum time dial

using 6.345 amperes ............... 61.3968 seconds

Curve time using 6.5 amperes ... 53.1800 seconds

1-2 BE1-50/51B-231 General Information 9252000895 Rev C

Page 13

Curve Characteristics

KBD

CM

AD

T

N

T

++=

-

Nine inverse time functions and one fixed time function can be selected by the front-panel Curve switch.

Characteristic curves for the inverse and definite time functions are defined by the following equation.

Where: TT = time to trip in seconds

D = time dial setting

M = multiple of pickup setting

A, B, C, N, K = constants for the particular curve

Time characteristic curve constants are listed in Tables 1-2 and 1-3. Constants have been selected to

conform to the characteristics of electromechanical relays over a range of pickup multiples from 1.3 to 40.

Values of the constants are provided for use in computer relay setting software. Timing accuracy is ±1

cycle, ±2 percent of time to trip.

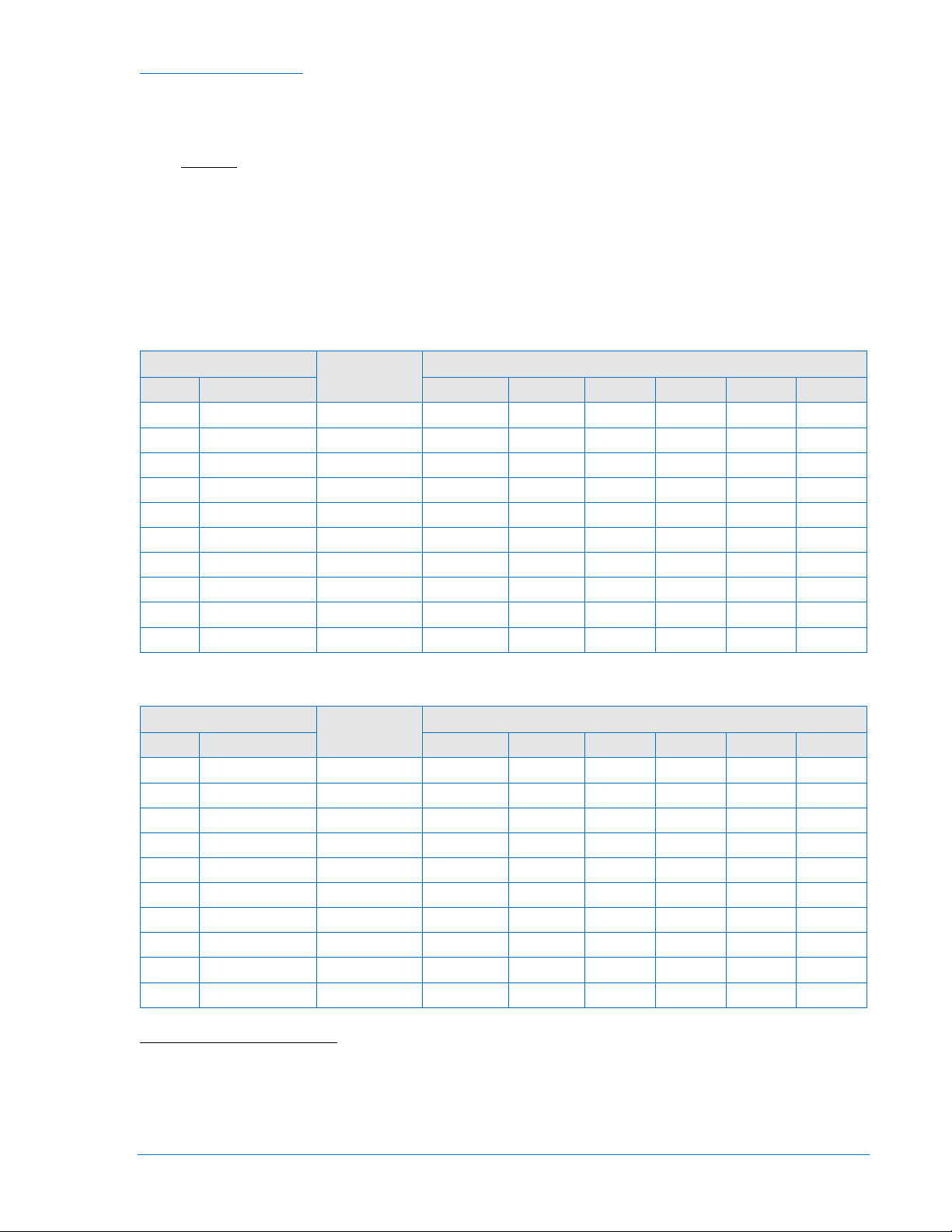

Table 1-2. Time Characteristic Curve Constants with SW3-3 Open (Off)

Curve Type ∗

BE1 Similar To A B C N K R

Figure

Number †

Constants

S ABB CO-2 A-1 0.2663 0.03393 1.000 1.2969 0.028 0.500

L ABB CO-5 A-2 5.6143 2.18592 1.000 1.000 0.028 15.750

D ABB CO-6 A-3 0.4797 0.21359 1.000 1.5625 0.028 0.875

M ABB CO-7 A-4 0.3022 0.12840 1.000 0.5000 0.028 1.750

I ABB CO-8 A-5 8.9341 0.17966 1.000 2.0938 0.028 9.000

V ABB CO-9 A-6 5.4678 0.10814 1.000 2.0469 0.028 5.500

E ABB CO-11 A-7 7.7624 0.02758 1.000 2.0938 0.028 7.750

B BS142-B ‡ A-8 1.4638 0.00000 1.000 1.0469 0.028 3.250

C BS142-C ‡ A-9 8.2506 0.00000 1.000 2.0469 0.028 8.000

F None § N/A 0.0000 1.00000 0.000 0.0000 0.000 1.000

Table 1-3. Time Characteristic Curve Constants with SW3-3 Closed (On)

Curve Type ∗

BE1 Similar To A B C N K R

Figure

Number †

Constants

S GE IAC 55 A-10 0.0286 0.0208 1.000 0.9844 0.028 0.0940

L GE IAC 66 A-11 2.3955 0.00002 1.000 0.3125 0.028 7.8001

D ABB CO-6 A-3 0.4797 0.21359 1.000 1.5625 0.028 0.8750

M ABB CO-7 A-4 0.3022 0.12840 1.000 0.5000 0.028 1.7500

I GE IAC 51 A-12 0.2747 0.1042 1.000 0.4375 0.028 0.8868

V GE IAC 53 A-13 4.4309 0.0991 1.000 1.9531 0.028 5.8231

E GE IAC 77 A-14 4.9883 0.0129 1.000 2.0469 0.028 4.7742

B BS142-B ‡ A-8 1.4636 0.00000 1.000 1.0469 0.028 3.2500

C BS142-C ‡ A-9 8.2506 0.00000 1.000 2.0469 0.028 8.0000

F None § N/A 0.0000 1.00000 0.000 0.0000 0.000 1.0000

Notes for Tables 1-2 and 1-3

∗ BE1 Curve Types: S: Short InverseV: Very Inverse

L: Long InverseE: Extremely Inverse

D: Definite TimeB: BS142 Very Inverse

M: Moderately Inverse C: BS142 Extremely Inverse

I: Inverse F: Fixed Time Delay

9252000895 Rev C BE1-50/51B-231 General Information 1-3

Page 14

† Figure numbers refer to the characteristic curves located in Appendix A, Time Characteristic Curves.

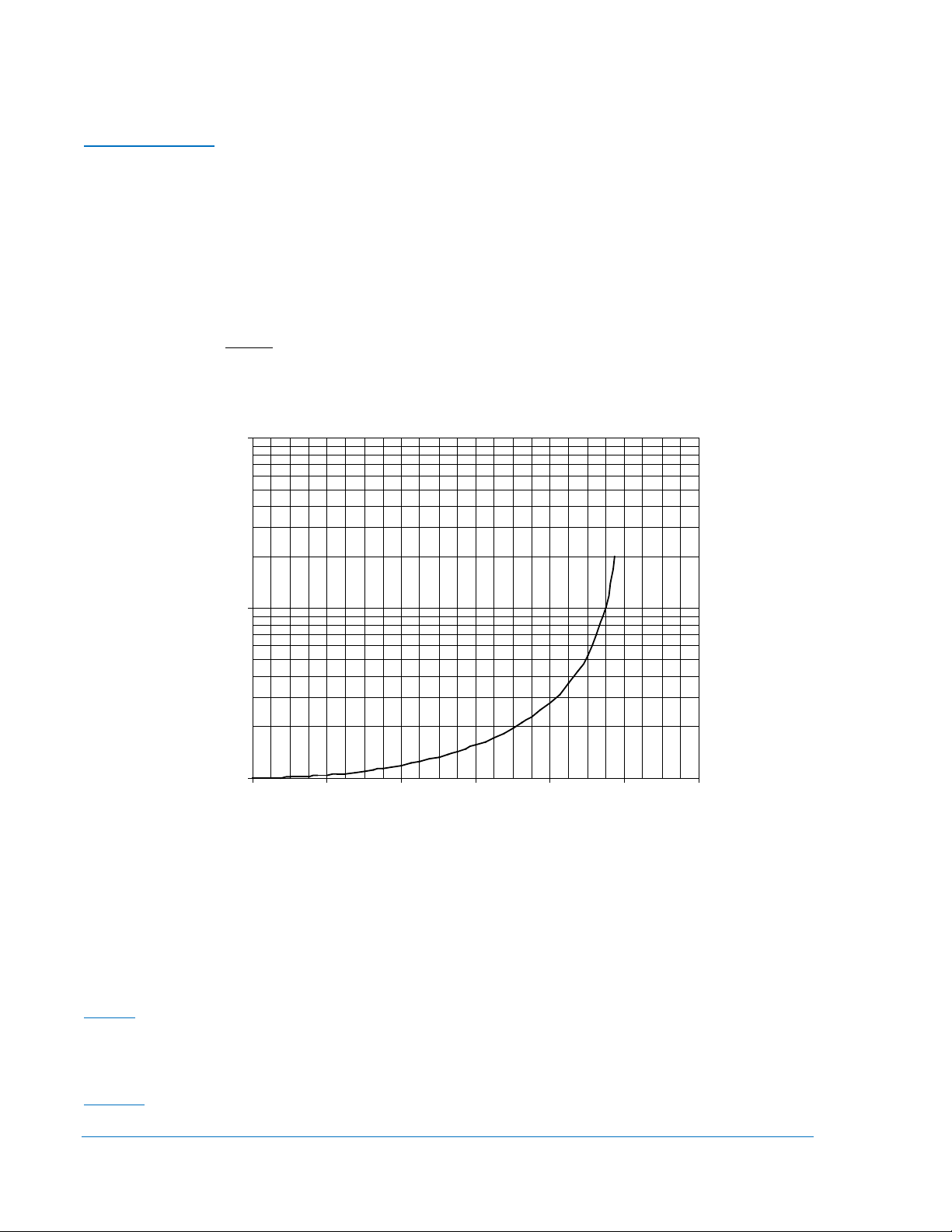

1M

RD

T

2

R

−

=

Where:

M = Current in multiples of PICKUP setting during reset

1.0

10.0

100.0

0.000 0.200 0.400 0.600 0.800 1.000 1.200

Multiple of Pickup

xRD (Seconds)

P0046-11

Vertical axis xRD (Seconds) is applicable for all curves and is derived from

multiplying the constant R for the curve selected times D (the Time Dial setting).

‡ Curves B and C are defined in British Standard BS142 and IEC Standard IEC 255-4.

§ Fixed time delay, adjustable from 0.1 to 9.9 seconds.

Integrating Reset

Reset begins when the current drops below 95% of pickup. Integrating reset simulates the disk reset of

electromechanical relays. BE1-50/51B-231 relays provide the integrating reset function even when input

current falls to zero.

Integrating reset characteristics are defined by the following equation and shown in Figure 1-1. Equation

constants are provided in Tables 1-2 or 1-3.

Integrating Reset Equation:

TR = Time to reset in seconds

R = Constant for the particular curve

D = TIME DIAL setting

Figure 1-1. Integrating Reset Characteristic Curve

Instantaneous Overcurrent (50) Element

Setting the INST PICKUP control at the minimum pickup setting places the relay in the most sensitive

state and may be used as a safety setting.

Pickup

Setting Range ............................ 1 to 99 Aac

Setting Increment ....................... 1 Aac

Accuracy .................................... ±2%, ±25 milliamperes at or above 1.0 ampere setting

Dropout

Dropout occurs at 95% of pickup value.

1-4 BE1-50/51B-231 General Information 9252000895 Rev C

Page 15

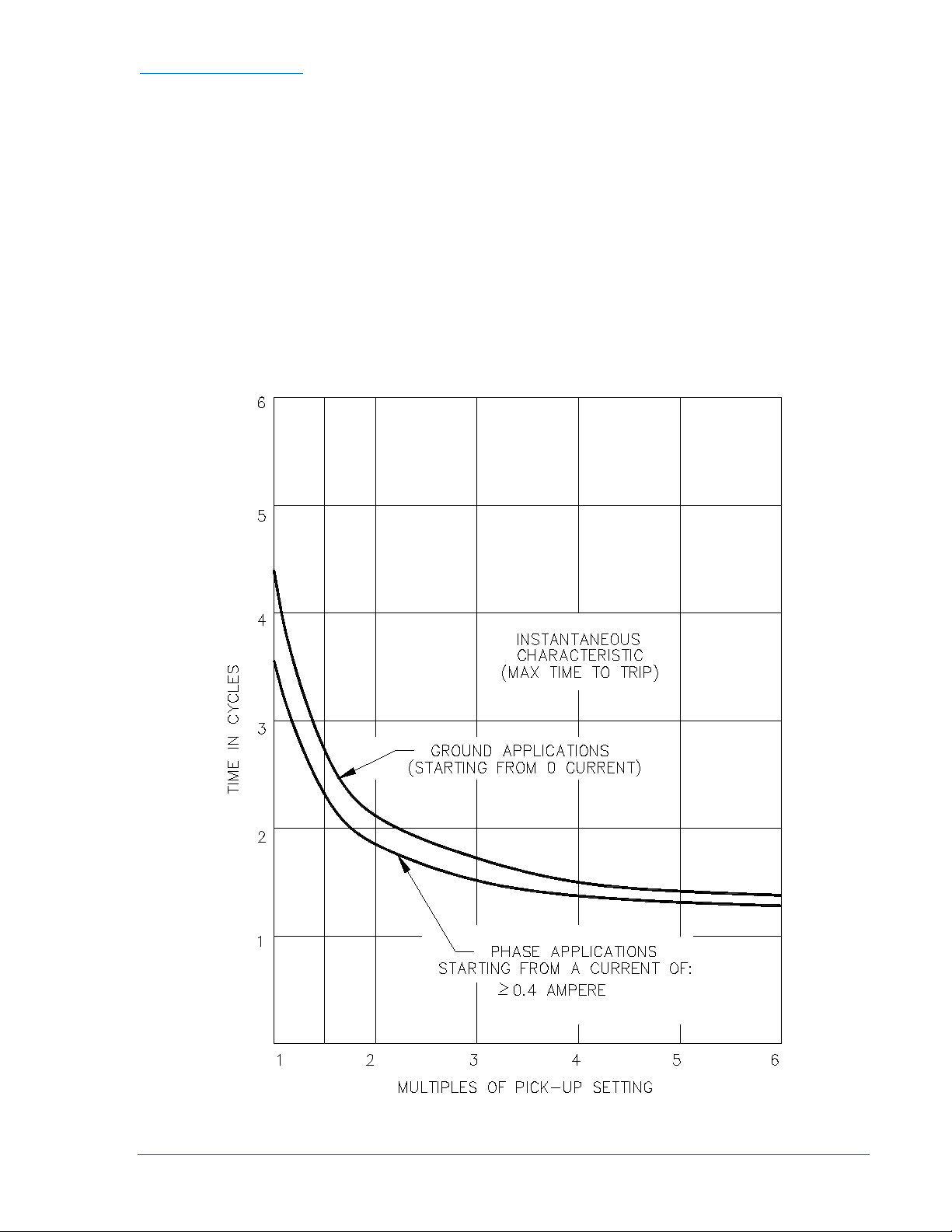

Curve Characteristics

P0048-10

Instantaneous characteristic curves are similar to standard electromechanical instantaneous units.

However, the time to trip for applications where the initial current through the relay is less than 0.4

ampere may be slightly longer. This may occur on a very lightly loaded circuit or when the relay is

providing ground protection and is connected to measure neutral current.

instantaneous characteristic curves for maximum time to trip.

An additional fixed delay of 0.1, 0.2, or 0.3 second may be added with internal switches SW3-1 and

SW3-2. This delay applies to both phase and ground applications. Closing switch SW3-1 provides an

additional delay of 0.2 second. Closing switch SW3-2 provides an additional delay of 0.1 second. Closing

both SW3-1 and SW3-2 provides an additional delay of 0.3 second. Section 2 illustrates the location of

SW3.

The instantaneous element in BE1-50/51B-231 relays may be set lower than the instantaneous element

in ABB relays and still have the same reach. This is because the BE1-50/51B-231 instantaneous element

effectively eliminates the fault current transient overreach components. When calculating BE1-50/51B231 relay instantaneous element settings, calculate the symmetrical value without any adder for transient

overreach.

Figure 1-2 shows the

Figure 1-2. Instantaneous Characteristic Curves

9252000895 Rev C BE1-50/51B-231 General Information 1-5

Page 16

Burden

P0048-11

Burden is non-linear. Figure 1-3 illustrates the device burden.

At 0.5 amperes .......................... 4.8 Ω

At 5.0 amperes .......................... 0.2 Ω

Figure 1-3. Burden Characteristics

Frequency Response

A change of ±5 Hz from the nominal 60 Hz current causes <0.5% change in the current required for

pickup.

Transient Response

<10% overreach with system time constants up to 40 ms.

1-6 BE1-50/51B-231 General Information 9252000895 Rev C

Page 17

Harmonic Response

Figure 1-4 shows that a relay set for 1 ampere pickup would pick up at 0.96 amperes with a current

containing 40% seventh harmonic. This corresponds to a 10:1 rejection ratio. Other conditions may be

evaluated in the same manner.

Figure 1-4. Harmonic Rejection

Target Indicators

Gravity latched, manually reset targets indicate that current of 0.2 amperes or greater was present in the

trip circuit. Target coil resistance is less than 0.1 ohms and operate time is less than one millisecond. See

Output Contacts for maximum current rating.

Output Contacts

Output contacts are surge protected and rated as follows.

Resistive Ratings

120/240 Vac ............................... Make 30 amperes for 0.2 seconds, carry 7 amperes for 2 minutes, 3

amperes continuously, and break 5 amperes.

125/250 Vdc ............................... Make 30 amperes for 0.2 seconds, carry 7 amperes for 2 minutes, 3

amperes continuously, and break 0.3 ampere.

Inductive Ratings

120/240 Vac, 125/250 Vdc ........ Make and carry 30 amperes for 0.2 seconds, carry 7 amperes for 2

minutes, 3 amperes continuously, and break 0.3 ampere. (L/R = 0.04).

Type Tests

Isolation ..................................... IEEE C37.90-2005

Transient Surge ......................... IEEE C37.90.1-2004

Radiated Interference ................ IEEE C37.90.2-2004

Electrostatic Discharge .............. IEEE C37.90.3-2006

Vibration ..................................... IEC 255-21-1

Shock and Bump ....................... IEC 255-21-2

9252000895 Rev C BE1-50/51B-231 General Information 1-7

Page 18

Environment

Operating Temperature ............. –40°C to 70°C (–40°F to158°F)

Storage Temperature................. –50°C to 70°C (–58°F to 158°F).

GOST-R Certification

GOST-R certified per the relevant standards of Gosstandart of Russia.

Physical

Weight ........................................ 6.1 lb (2.77 kg)

1-8 BE1-50/51B-231 General Information 9252000895 Rev C

Page 19

SECTION 2 • CONTROLS AND INDICATORS

TABLE OF CONTENTS

SECTION 2 • CONTROLS AND INDICATORS ........................................................................................ 2-1

Introduction ............................................................................................................................................ 2-1

Figures

Figure 2-1. Front Panel Controls and Indicators ....................................................................................... 2-1

Figure 2-2. Location of SW3

Tables

Table 2-1. BE1-50/51B-231 Controls and Indicators (Refer to Figures 2-1 and 2-2) ................................ 2-3

...................................................................................................................... 2-2

9252000895 Rev C BE1-50/51B-231 Controls and Indicators i

Page 20

ii BE1-50/51B-231 Controls and Indicators 9252000895 Rev C

Page 21

SECTION 2 • CONTROLS AND INDICATORS

Introduction

Figure 2-1 illustrates the front panel controls and indicators of the BE1-50/51B-231. Figure 2-2 illustrates

the location of switch SW3. Both illustrations have lettered call-outs that correspond to the control and

indicator descriptions provided in Table 2-1.

Figure 2-1. Front Panel Controls and Indicators

9252000895 Rev C BE1-50/51B-231 Controls and Indicators 2-1

Page 22

P0053-50

SW3

Figure 2-2. Location of SW3

2-2 BE1-50/51B-231 Controls and Indicators 9252000895 Rev C

Page 23

Table 2-1. BE1-50/51B-231 Controls and Indicators (Refer to Figures 2-1 and 2-2)

Locator Control or Indicator Function

A INST MANUAL TRIP

Test Points

B INST PICKUP

Selectors

C Targets

D TIME PICKUP

Selectors

E CURVE Selector

F TIME DIAL Selectors

G TIME MANUAL TRIP

Test Points

When shorted, the test points (jacks) provide a secure means to

manually trip the controlled breaker. Jacks accept a standard 0.08

inch diameter phone tip plug.

Two switches (TENS and UNITS) to select pickup current in

amperes. Changing switch selectors while the relay is in service

may cause tripping.

Red target indicators latch when the trip circuit current is greater

than 0.2 amperes. One target each for TIME and INST.

Two switches (UNITS and TENTHS) to select pickup current in

amperes. Changing switch selectors while the relay is in service

may cause tripping.

Ten position selector switch to select one of nine inverse functions

or one fixed time function.

Two selector switches (UNITS and TENTHS) to select the desired

characteristic curve. A setting of 0.0 results in instantaneous

operation without any intentional delay. A setting of 9.9

corresponds to the typical time provided by an electromechanical

relay at its maximum dial setting.

When shorted, the test points provide a secure means to manually

trip the controlled breaker. Jacks accept a standard 0.08 inch

diameter phone tip plug.

H ACTIVE/PICKUP LED

I Target RESET Button

SW3 SW3-1

SW3-2

SW3-3

SW3-4

This bicolor LED indicates the level of current sensed by the relay.

A green LED indicates that the relay is active but not picked up.

The LED changes to red when the sensed current exceeds the

time overcurrent pickup setting. The LED changes from red to

green when the sensed current decreases below 95% of the time

overcurrent pickup setting.

Note: A minimum of 0.5 A is required to light the LED. The LED

may not turn green (active) before turning red (picked up) at the

0.5 A pickup setting.

Linkage extends through back of front cover to reset both gravity

latched target indicators.

SW3-1 provides an additional instantaneous delay of 0.2 second

when closed (ON). Closing both SW3-1 and SW3-2 provides an

additional instantaneous delay of 0.3 second.

SW3-2 provides an additional instantaneous delay of 0.1 second

when closed (ON). Closing both SW3-2 and SW3-1 provides an

additional instantaneous delay of 0.3 second.

SW3-3 provides selection of GE IAC type curves or ABB type

curves. Closing switch SW3-3 (ON) selects GE IAC type curves

(refer to Table 1-3). Opening switch SW3-3 (OFF) selects ABB

type curves (refer to Table 1-2).

SW3-4 provides selection of either instantaneous or integrating

reset characteristics. Closing SW3-4 (ON) selects integrating reset

characteristics. Opening SW3-4 (OFF) selects instantaneous reset

characteristics.

9252000895 Rev C BE1-50/51B-231 Controls and Indicators 2-3

Page 24

2-4 BE1-50/51B-231 Controls and Indicators 9252000895 Rev C

Page 25

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

General .................................................................................................................................................. 3-1

Functional Description ........................................................................................................................... 3-1

Sensing Input ..................................................................................................................................... 3-1

Power Supply ..................................................................................................................................... 3-1

Instantaneous Signal .......................................................................................................................... 3-1

Time Signal ........................................................................................................................................ 3-1

Microprocessor ................................................................................................................................... 3-1

Power-Off Sensing ............................................................................................................................. 3-1

Outputs ............................................................................................................................................... 3-2

Figures

Figure 3-1. Functional Block Diagram ....................................................................................................... 3-2

9252000895 Rev C BE1-50/51B-231 Functional Description i

Page 26

ii BE1-50/51B-231 Functional Description 9252000895 Rev C

Page 27

SECTION 3 • FUNCTIONAL DESCRIPTION

General

BE1-50/51B-231 Overcurrent Relays are microprocessor based non-directional relays that measure ac

current to provide secure and reliable instantaneous and time overcurrent protection for power systems.

Functional Description

Sensing Input

Single phase ac current from system current transformers (CT) is brought into the Overcurrent Relay at

terminals 5 and 6. Refer to Figure 3-1 to follow the functional description. The input current is applied to

internal power and signal CTs.

Power Supply

Current from the power CT is rectified, filtered, and supplied to all relay internal circuitry for operating

power. A precision +5 Vdc supply also serves as a reference for automatic calibration.

Instantaneous Signal

Current from the signal CT is rectified and applied to the instantaneous scaling resistors controlled by the

INST PICKUP selector switches. The analog voltage of the instantaneous input signal developed across

the scaling resistors is filtered and applied to the multiplexor (MUX).

Time Signal

Current from the signal CT is also rectified and applied to the time scaling resistors controlled by the TIME

PICKUP selector switches. The analog voltage of the time input signal is also filtered and applied to the

multiplexor.

Microprocessor

Operating power from the power supply is applied to the microprocessor supervisor circuit. When the

microprocessor is active and executing code, the ACTIVE/PICKUP LED is green. When the input current

falls below an acceptable level, the supervisor circuit interrupts the microprocessor, halts further

operation, and turns OFF the ACTIVE/PICKUP LED. A microprocessor watchdog feature resets the

microprocessor program when the program flow is interrupted.

Information from the TIME DIAL selector switches, the TIME CURVE selector switch, INST DELAY

switches, and RESET CHAR switch is also applied to the microprocessor. The microprocessor uses

these inputs to set the operating parameters.

When the microprocessor is ready for analog information from the multiplexor, microprocessor control

signals cause the multiplexor to route the desired input through to the output. The output is converted

from an analog value to a digital value and applied to the microprocessor.

The microprocessor performs the program operations based on the inputs and the internal software

program. When the sensed current exceeds the TIME PICKUP setting, the ACTIVE/PICKUP LED turns

from green to red. The 50/51 contact is closed in accordance with the TIME characteristic equation or if

the sensed current exceeds the INST PICKUP setting.

Power-Off Sensing

Power-off sensing circuits measure the voltage across a capacitor at power-down and at power-up. These

circuits determine how long power has been removed based on the difference voltage and the circuit RC

time constant. This provides information for the integrating reset function even when power has been

entirely removed.

9252000895 Rev C BE1-50/51B-231 Functional Description 3-1

Page 28

Outputs

Instantaneous and Timed

System circuit breakers controlled by the output contacts can be manually tripped by applying a short

across the TIME or INST MANUAL TRIP front panel test points. Current flow in the trip circuit is indicated

by the operation of the target. The targets will not operate without adequate operating power for the relay.

WARNING!

Trip circuit voltage is present at the front panel test points. When shorting the

test points, use insulated jumpers to avoid contact with these voltages.

Figure 3-1. Functional Block Diagram

3-2 BE1-50/51B-231 Functional Description 9252000895 Rev C

Page 29

SECTION 4 • INSTALLATION

TABLE OF CONTENTS

SECTION 4 • INSTALLATION .................................................................................................................. 4-1

General .................................................................................................................................................. 4-1

Factory Settings ..................................................................................................................................... 4-1

Installation .............................................................................................................................................. 4-1

Application Coordination ........................................................................................................................ 4-1

Connections ........................................................................................................................................... 4-3

Maintenance........................................................................................................................................... 4-4

Storage ................................................................................................................................................... 4-4

Figures

Figure 4-1. Coordination Timing Diagram ................................................................................................. 4-2

Figure 4-2. AC Input Connections

Figure 4-3. DC Control Connections

............................................................................................................. 4-3

......................................................................................................... 4-4

9252000895 Rev C BE1-50/51B-231 Installation i

Page 30

ii BE1-50/51B-231 Installation 9252000895 Rev C

Page 31

SECTION 4 • INSTALLATION

KBD

CM

AD

T

N

Trip

++

−

=

( )

0280202758.0

110

276247

09382

.

.

.

+×+

−

×

=

110806124

.

seconds 0.209=

General

When not shipped as part of a control or switchgear panel, the relays are shipped in sturdy cartons to

prevent damage during transit. Immediately upon receipt of a relay, check the model and part number

against the requisition and packing list to see that they agree. Visually inspect the relay for damage that

may have occurred during shipment. If there is evidence of damage, immediately file a claim with the

carrier and notify the Regional Sales Office, or contact the Sales Representative at Basler Electric,

Highland, Illinois.

Proper operation of the relay may be confirmed by performing the operational test procedure of Section 5.

If the relay won't be installed immediately, store the relay in its original shipping carton in a moisture and

dust-free environment.

Factory Settings

Factory settings for the internal switches of SW3 are as follows:

• SW3-1 — OFF (0.0 additional fixed delay for the instantaneous element).

• SW3-2 — OFF (0.0 additional fixed delay for the instantaneous element).

• SW3-3 — ON (General Electric, IAC type characteristic curves).

• SW3-4 — ON (Integrating reset characteristics).

Installation

Select the desired relay settings before putting the relay into service. Changing pickup current settings

while the relay is in service may cause tripping. Perform the following procedures to install the BE150/51B-231 relay.

• Select the desired relay settings on your new BE1-50/51B-231 relay.

• Remove the existing IAC relay.

• Use the four screws provided and attach the cover adapter to the existing case.

• Insert the new relay and close the cradle latches locking the relay into the case.

• Install the new Basler Electric connection plug.

• To install the cover, position the interlocking bracket at the top of the new Basler Electric cover into

the mating receptacle at the top of the cover adapter plate. Secure the captive fastener at the bottom

of the cover.

Application Coordination

In a typical application coordination scheme, a BE1-50/51B-231 is being used to provide primary

protection for a radial distribution feeder. An electromechanical overcurrent relay with extremely inverse

timing provides protection for the transformer and bus. To improve coordination with the

electromechanical relay, the BE1 relay with integrating reset characteristic has the time characteristic

curve E (extremely inverse) selected (SW3-3 set to OFF) and the TIME DIAL set to 2.0. The feeder

reclosing relay is set for two reclose attempts at 3 and 15 seconds after the initial trip. If a permanent fault

occurs (magnitude ten times pickup), calculate the feeder breaker trip time for each of the three

operations. Refer to Section 1 for characteristic curve constants.

From the time characteristic curve equation.

524815

=

9252000895 Rev C BE1-50/51B-231 Installation 4-1

.

−

++

.

028005516.0

Page 32

From the reset characteristic curve equation.

1M

RD

T

2

Reset

−

=

seconds 15.5

10

27.75

2

−=

−

×

=

( )( )

Rewind Full

Time RewindTrip Full

T

Occurence This Trip

=

( )( )

15.5

30.209

T

B

=

( )( )

15.5

11.960.209

T

C

=

seconds 0.161TC=

M = 0 if current goes to zero.

Negative result indicates reset time.

Results: Full trip = 0.209 seconds and full reset = 15.5 seconds if current goes to zero.

In Figure 4-1,

T

= 0.209 seconds (relay was at reset).

A

T

= value < TA because rewind has not gone to zero.

B

T

= value < TA because rewind has not gone to zero.

C

Figure 4-1. Coordination Timing Diagram

Equation for time to trip during rewind (before relay is reset).

Second Operation

seconds 0.040TB=

Third Operation

4-2 BE1-50/51B-231 Installation 9252000895 Rev C

Page 33

Connections

Typical ac input and dc control connections are shown in Figures 4-2 and 4-3. Refer to the block diagram

in Section 3 for relay internal connections.

Figure 4-2. AC Input Connections

9252000895 Rev C BE1-50/51B-231 Installation 4-3

Page 34

Figure 4-3. DC Control Connections

Maintenance

BE1-50/51B-231 overcurrent relays require no preventive maintenance. However, periodic checks should

be performed according to scheduled practices. A recommended periodic test is provided in Section 5. If

the relay fails to function properly, contact the Technical Sales Support Department of Basler Electric.

Storage

This device contains long-life electrolytic capacitors. For devices that are not in service (spares in

storage), the life of these capacitors can be maximized by energizing the device for 30 minutes once per

year.

4-4 BE1-50/51B-231 Installation 9252000895 Rev C

Page 35

SECTION 5 • TESTING

TABLE OF CONTENTS

SECTION 5 • TESTING ............................................................................................................................ 5-1

General .................................................................................................................................................. 5-1

Dielectric Test ........................................................................................................................................ 5-1

Operational Test Procedure ................................................................................................................... 5-1

Test Equipment Required................................................................................................................... 5-1

Test Procedure ................................................................................................................................... 5-3

Setting the Relay .................................................................................................................................... 5-5

Periodic Tests ........................................................................................................................................ 5-5

General ............................................................................................................................................... 5-5

Periodic Test ...................................................................................................................................... 5-5

Figures

Figure 5-1. Pickup and Timing Test Setup ................................................................................................ 5-2

Figure 5-2. Target Operational Test Setup

................................................................................................ 5-2

9252000895 Rev C BE1-50/51B-231 Testing i

Page 36

ii BE1-50/51B-231 Testing 9252000895 Rev C

Page 37

SECTION 5 • TESTING

General

Dielectric testing, operational testing, and periodic testing are described in the following paragraphs.

Dielectric Test

In accordance with IEC 255-5 and IEEE C37.90-2005, one-minute dielectric (high potential) tests may be

performed as follows:

All circuits to ground: 2,828 Vdc or 2,000 Vac

Input to output circuits: 2,828 Vdc or 2,000 Vac

Output contacts are surge protected.

Operational Test Procedure

The following procedures verify operation of relays BE1-50/51B-231. The test setup of Figures 5-1 and

5-2 are intended primarily as an illustration of the principles involved. Other test setups known to be

capable of testing with the stated and implied tolerances (including equipment specifically designed for

testing relays) may be used.

Test Equipment Required

• Current source with a range from 0 to 20 Aac (sensing input current)

• AC or DC voltage source (target operation)

• Timer or counter

CAUTION

To ensure proper timing during testing, before each test, remove the current

from the unit for R times D seconds (refer to Section 1, Specifications, Time

Reset for R and D definitions).

9252000895 Rev C BE1-50/51B-231 Testing 5-1

Page 38

Figure 5-1. Pickup and Timing Test Setup

Figure 5-2. Target Operational Test Setup

5-2 BE1-50/51B-231 Testing 9252000895 Rev C

Page 39

NOTE

Observe all applicable electrostatic discharge (ESD) precautions when

When testing TIME overcurrent functions, INST PICKUP settings of 00 will

affect the calibration of the TIME functions. TIME PICKUP settings of 00 also

affect INST functions.

Test Procedure

The following tests are performed to verify functionality of the BE1-50/51B-231 overcurrent relay. The

TIME and INST output contact terminals are strapped together. Therefore it is necessary to disconnect

specific wires during the TIME and INST pickup tests. This verifies the proper functionality of the TIME

and INST elements.

NOTE

handling the relay draw-out assembly.

TIME Pickup Test

Perform preliminary setup:

• Connect test setup as shown in Figure 5-1.

• Insure that SW3 switches are set: SW3-1 to OFF, SW3-2 to OFF, SW3-3 to ON and SW3-4 to

ON.

• Set TIME DIAL to 0.0.

• Set CURVE to S

• Set TIME PICKUP to 0.5.

• Set INST PICKUP to 90.

Step 1. Slowly increase current to terminals 5 and 6. PICKUP LED should turn RED at a maximum input

current of 0.550 ampere.

Step 2. Decrease input current until PICKUP LED turns GREEN then OFF.

Step 3. Set TIME PICKUP to 2.2.

Step 4. Slowly increase current to terminals 5 and 6. PICKUP LED should change from GREEN to RED

at an input current of 2.131 to 2.269 amperes.

Step 5. Decrease input current until PICKUP LED turns OFF.

INST Pickup Test

Perform preliminary setup:

• Connect test setup as shown in Figure 5-1.

• Insure that SW3 switches are set: SW3-1 to OFF, SW3-2 to OFF, SW3-3 to ON, and SW3-4 ON.

• Set TIME DIAL to 0.0.

• Set CURVE to S

• Set TIME PICKUP to 15.9.

• Set INST PICKUP to 01.

Step 1. Slowly increase current to terminals 5 and 6. INST contacts should close at an input current of

0.955 to 1.045 amperes.

Step 2. Decrease input current until INST output contacts open.

Step 3. Set INST PICKUP to 08.

Step 4. Slowly increase current to terminals 5 and 6. INST contacts should close at an input current of

7.815 to 8.185 amperes.

Step 5. Decrease input current until INST output contacts open.

9252000895 Rev C BE1-50/51B-231 Testing 5-3

Page 40

Time Dial Test

Perform preliminary setup:

• Connect test setup as shown in Figure 5-1.

• Insure that SW3 switches are set: SW3-1 to OFF, SW3-2 to OFF, SW3-3 to ON, and SW3-4 ON.

• Set TIME DIAL to 4.5.

• Set CURVE to S

• Set TIME PICKUP to 1.0.

• Set INST PICKUP to 90.

Step 1. Prepare to apply 1.5 amperes input current to terminals 5 and 6 and record the elapsed time from

when current is applied until TIME output contacts close.

Step 2. Apply the current (step from 0 to 1.5 amperes) and record the elapsed time. Elapsed time should

be 0.345 to 0.424 seconds. (This tolerance is greater than ±2 % because it is the accumulation of

both pickup and timing tolerances.)

Step 3. Remove input current.

Target Test

Perform preliminary setup:

• Connect test setup as shown in Figure 5-2.

• Insure that SW3 switches are set: SW3-1 to OFF, SW3-2 to OFF, SW3-3 to ON, and SW3-4 ON.

• Set TIME DIAL to 4.5.

• Set CURVE to S

• Set TIME PICKUP to 1.0.

• Set INST PICKUP to 90.

Step 1. Set voltage source to provide a target current of 1.0 ampere.

Step 2. Apply 5 amperes input current to terminals 5 and 6. Check that the TIME target operates.

Step 3. Remove input current and reset target.

Step 4. Set TIME PICKUP to 15.9 and set INST PICKUP to 01.

Step 5. Set voltage source to provide a target current of 1.0 ampere.

Step 6. Apply 5 amperes input current to terminals 5 and 6. Check that the INST target operates.

Step 7. Remove input current and reset target.

Manual Trip Test

Perform preliminary setup:

• Connect test setup as shown in Figure 5-2.

• Insure that SW3 switches are set: SW3-1 to OFF, SW3-2 to OFF, SW3-3 to ON, and SW3-4 ON.

• Set TIME DIAL to 4.5.

• Set CURVE to S

• Set TIME PICKUP to 1.0.

• Set INST PICKUP to 01.

WARNING!

Trip circuit voltage is present at the front panel test points. When shorting the

test points, use insulated jumpers to avoid contact with these voltages.

Step 1. Set voltage source to provide a target current of 1.0 ampere.

Step 2. Apply 0.9 ampere input current to terminals 5 and 6. (0.9 ampere provides input power but stays

below pickup.)

Step 3. Connect a jumper between TIME MANUAL TRIP test points. Check that TIME target operates.

Step 4. Connect a jumper between INST MANUAL TRIP test points. Check that INST target operates.

Step 5. Reset targets.

5-4 BE1-50/51B-231 Testing 9252000895 Rev C

Page 41

Integrating Reset Test

Perform preliminary setup:

• Connect test setup as shown in Figure 5-1.

• Insure that SW3 switches are set: SW3-1 to OFF, SW3-2 to OFF, SW3-3 to ON, and SW3-4 ON.

• Set TIME DIAL to 9.9.

• Set CURVE to V.

• Set TIME PICKUP to 1.0.

• Set INST PICKUP to 90.

Step 1. Set voltage source to provide a target current of 1.0 ampere.

Step 2. Read all of Step 3 before beginning Step 3.

Step 3. Apply 4.0 amperes input current to terminals 5 and 6. After the unit trips, remove the input current

for 29 ±0.25 seconds, then reapply the 4.0 amperes input current. Record the elapsed time from

the re-application of input current to the output retrip.

Result: Elapsed time should be 2.08 ±0.4 seconds.

Setting the Relay

Select the desired relay settings before putting the relay into service. Changing pickup current settings

while the relay is in service may cause tripping.

Periodic Tests

General

All relays should be tested periodically to identify and correct any problems that are found.

Single phase relays such as the BE1-50/51B-231 are normally used in groups of four (three phase and

ground) on the protected circuit. This relay scheme allows each unit to be withdrawn one at a time for

testing purposes without losing protection. Only three are required at any one time to sense all types of

faults on a grounded wye system. Refer to Figures 5-1 and 5-2 for recommended test setups.

Periodic Test

Periodic testing should consist of the following procedures.

Step 1. Verify that the instantaneous pickup is within ±2% of the value set on the dials. Pickup occurs

when the INST output contacts close.

Step 2. Verify that the time pickup is within ±2% of the value set on the dials. Pickup occurs when the

LED turns GREEN then RED.

Step 3. Verify that the time to trip for the curve and time dial settings at a multiple of six is the same as

the time given on the characteristic curve. Refer to Section 1 for the characteristics curves.

Step 4. Verify that the time to trip for the instantaneous element at a pickup multiple of 2 is not greater

than the time given on the instantaneous characteristic curve. Refer to Section 1 for the

instantaneous characteristic curve.

Step 5. Verify that the targets operate with one ac ampere of trip current in the trip circuits and that they

can be reset using the RESET BUTTON.

9252000895 Rev C BE1-50/51B-231 Testing 5-5

Page 42

5-6 BE1-50/51B-231 Testing 9252000895 Rev C

Page 43

APPENDIX A • TIME CHARACTERISTIC CURVES

TABLE OF CONTENTS

APPENDIX A • TIME CHARACTERISTIC CURVES ................................................................................ A-1

Time Characteristic Curves .................................................................................................................... A-1

Figures

Figure A-1. Time Characteristic Curve, S-Short Inverse (SW3-3 OFF, Similar to ABB CO-2) ................. A-1

Figure A-2. Time Characteristic Curve, L-Long Inverse (SW3-3 OFF, Similar to ABB CO-5)

Figure A-3. Time Characteristic Curve, D-Definite Time (Similar to ABB CO-6)

Figure A-4. Time Characteristic Curve, M-Moderately Inverse (Similar to ABB CO-7)

Figure A-5. Time Characteristic Curve, I-Inverse (SW3-3 OFF, Similar to ABB CO-8)

Figure A-6. Time Characteristic Curve, V-Very Inverse (SW3-3 OFF, Similar to ABB CO-9)

Figure A-7. Time Characteristic Curve, E-Extremely Inverse (SW3-3 OFF, Similar to ABB CO-11)

Figure A-8. Time Characteristic Curve, BS142-B (BS142 Very Inverse)

Figure A-9. Time Characteristic Curve, BS142-C (BS142 Extremely Inverse)

Figure A-10. Time Characteristic Curve, S2-Short Inverse (SW3-3 ON, Similar to GE IAC 55)

Figure A-11. Time Characteristic Curve, L2-Long Inverse (SW3-3 ON, Similar to GE IAC 66)

Figure A-12. Time Characteristic Curve, I2-Inverse (SW3-3 ON, Similar to GE IAC 51)

Figure A-13. Time Characteristic Curve, V2-Very Inverse (SW3-3 ON, Similar to GE IAC 53)

Figure A-14. Time Characteristic Curve, E2-Extremely Inverse (SW3-3 ON, Similar to GE IAC 77)

.................. A-2

...................................... A-3

............................. A-4

........................... A-5

................. A-6

........ A-7

.................................................. A-8

......................................... A-9

............. A-10

.............. A-11

........................ A-12

.............. A-13

..... A-14

9252000895 Rev C BE1-50/51B-231 Time Characteristic Curves i

Page 44

ii BE1-50/51B-231 Time Characteristic Curves 9252000895 Rev C

Page 45

APPENDIX A • TIME CHARACTERISTIC CURVES

Time Characteristic Curves

Figures A-1 through A-14 illustrate the time characteristic curves that are programmed into the nonvolatile

memory of this relay.

Figure A-1. Time Characteristic Curve, S-Short Inverse

(SW3-3 OFF, Similar to ABB CO-2)

9252000895 Rev C BE1-50/51B-231 Time Characteristic Curves A-1

Page 46

Figure A-2. Time Characteristic Curve, L-Long Inverse

(SW3-3 OFF, Similar to ABB CO-5)

A-2 BE1-50/51B-231 Time Characteristic Curves 9252000895 Rev C

Page 47

Figure A-3. Time Characteristic Curve, D-Definite Time

(Similar to ABB CO-6)

9252000895 Rev C BE1-50/51B-231 Time Characteristic Curves A-3

Page 48

Figure A-4. Time Characteristic Curve, M-Moderately Inverse

(Similar to ABB CO-7)

A-4 BE1-50/51B-231 Time Characteristic Curves 9252000895 Rev C

Page 49

Figure A-5. Time Characteristic Curve, I-Inverse

(SW3-3 OFF, Similar to ABB CO-8)

9252000895 Rev C BE1-50/51B-231 Time Characteristic Curves A-5

Page 50

Figure A-6. Time Characteristic Curve, V-Very Inverse

(SW3-3 OFF, Similar to ABB CO-9)

A-6 BE1-50/51B-231 Time Characteristic Curves 9252000895 Rev C

Page 51

Figure A-7. Time Characteristic Curve, E-Extremely Inverse

(SW3-3 OFF, Similar to ABB CO-11)

9252000895 Rev C BE1-50/51B-231 Time Characteristic Curves A-7

Page 52

Figure A-8. Time Characteristic Curve, BS142-B

(BS142 Very Inverse)

A-8 BE1-50/51B-231 Time Characteristic Curves 9252000895 Rev C

Page 53

Figure A-9. Time Characteristic Curve, BS142-C

(BS142 Extremely Inverse)

9252000895 Rev C BE1-50/51B-231 Time Characteristic Curves A-9

Page 54

Figure A-10. Time Characteristic Curve, S2-Short Inverse

(SW3-3 ON, Similar to GE IAC 55)

A-10 BE1-50/51B-231 Time Characteristic Curves 9252000895 Rev C

Page 55

Figure A-11. Time Characteristic Curve, L2-Long Inverse

(SW3-3 ON, Similar to GE IAC 66)

9252000895 Rev C BE1-50/51B-231 Time Characteristic Curves A-11

Page 56

Figure A-12. Time Characteristic Curve, I2-Inverse

(SW3-3 ON, Similar to GE IAC 51)

A-12 BE1-50/51B-231 Time Characteristic Curves 9252000895 Rev C

Page 57

Figure A-13. Time Characteristic Curve, V2-Very Inverse

(SW3-3 ON, Similar to GE IAC 53)

9252000895 Rev C BE1-50/51B-231 Time Characteristic Curves A-13

Page 58

Figure A-14. Time Characteristic Curve, E2-Extremely Inverse

(SW3-3 ON, Similar to GE IAC 77)

A-14 BE1-50/51B-231 Time Characteristic Curves 9252000895 Rev C

Page 59

Page 60

®

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com, info@basler.com

Phone +1 618.654.2341 Fax +1 618.654.2351

Loading...

Loading...