Bard WH184-A, WH242-A, WH242-B, WH242-C, WH301-A Specifications

...

THE WALL-MOUNTTM HEAT PUMPS - WH (60HZ)

WH-Series Refrigerant 22 60Hz

Heating Capacities: 18,800 to 58,000 BTUH

Cooling Capacities: 19,000 to 56,500 BTUH

The Bard Wall-Mount Heat Pump is a self-contained energy efficient heating and

cooling system, which is designed to offer maximum indoor comfort at a minimal

cost without using valuable indoor floor space or outside ground space. This unit is

the ideal product for versatile applications such as: new construction, modular

offices, school modernization, telecommunication structures, portable structures or

correctional facilities. Factory or field installed accessories are available to meet

specific job requirements.

Engineered Features

Aluminum Finned Copper Coils:

Grooved tubing and enhanced louvered

fin for maximum heat transfer and

energy efficiency.

Twin Blowers:

Move air quietly. Most models feature

multispeed blower motors providing

airflow adjustment for high and low static

operation. Motor overload protection is

standard on all models.

Heat Pump Compressor:

Reciprocating compressor designed to

withstand higher compressor ratios and

longer operation than normal air

conditioning compressors. Equipped

with crankcase heater and dual

discharge muffler. Standard on all 2, 2½,

3 and 3½ ton models.

Scroll compressor designed for

increased efficiency, quieter operation

and improved reliability for longer life.

Eliminates need for crankcase heater

and suction accumulator. Standard on

all 1½, 4 and 5 ton models.

Galvanized 20 Gauge Zinc Coated

Steel Cabinet:

Cleaned, rinsed, sealed and dried

before the polyurethane primer is

applied. The cabinet is handsomely

finished with a baked on, beige textured

enamel, which allows it to withstand

1000 hours of salt spray tests per ASTM

B117-03.

Electrical Components:

Are easily accessible for routine

inspection and maintenance through a

right side, service panel opening.

Features a lockable, hinged access

cover to the circuit breaker or pull

disconnect switch.

Electric Heat Strips:

Features an automatic limit and thermal

cut-off safety control. Heater packages

are factory or field installed for all 1½

through 5 ton models. Features easy

slide-in field assembly with various

BTUH outputs.

Condenser Fan and Motor

Shroud Assembly:

Slide out for easy access.

One Inch, Disposable Air Filters:

Are standard equipment. Optional one

inch washable filters available and

filter racks permit the addition of 2"

pleated filter. Factory or field installed.

Solid State Electronic Heat Pump

Control:

Provides efficient 30, 60 or 90 minute

defrost cycle. A thermistor sensor,

speed up terminal for service and 10

minute defrost override are standard on

the electronic heat pump control.

High Pressure Switch:

Is built-in with a lockout circuit that

resets from the room thermostat.

Five Minute Compressor Time

Delay:

Short cycle protection is standard. Built

into the heat pump control.

Suction Accumulator:

Protects the reciprocating compressor

from refrigerant flood back and prevents

damage to the compressor bearing

surfaces. Not required on scroll

compressor applications.

Emergency Heat Circuit:

Permits continuous operation of the

system.

Barometric Fresh Air Damper:

Standard on all units. Allows up to 25%

outside fresh air.

Built-in Circuit Breakers:

Standard on all electric heat versions of

single and three phase (230/208 volt)

equipment. Toggle disconnects are

standard on all electric heat versions of

three phase (460 volt) equipment.

Slope Top:

Standard feature for water run-off.

Full Length Mounting Brackets:

Built into cabinet for improved

appearance and easy installation.

NOTE: Bottom mounting bracket

included to assist in installation.

Top Rain Flashing:

Standard feature on all models.

Ventilation System Packages

All packages are designed

to meet your specific

ventilation requirements

utilizing one of six

ventilation options for the

product. The ventilation

package is mounted within

the unit eliminating the

need for an exterior

mounted hood or damper

assembly on the unit. All

assemblies can be factory

installed, installed in the

field at time of installation

or as a retrofit system after

installation.

• Standard - Barometric

Fresh Air Damper

• Optional - Motorized

Fresh Air Damper

• Optional - Blank off Plate

• Optional - Commercial

Room Ventilator w/Exhaust

• CRV - Spring Return

• CRVP - Power Return

• Optional - Economizer

with Exhaust

• Optional - Energy

Recovery Ventilator

• Complies with efficiency requirements of ASHRAE/IESNA 90.1-2004.

• Certified to ARI Standard 390-2003 for SPVU (Single Package Vertical Units).

• Commercial Product - Not intended for Residential application.

Form No. S3210-206

Supersedes S3210-106

Page 1 of 12

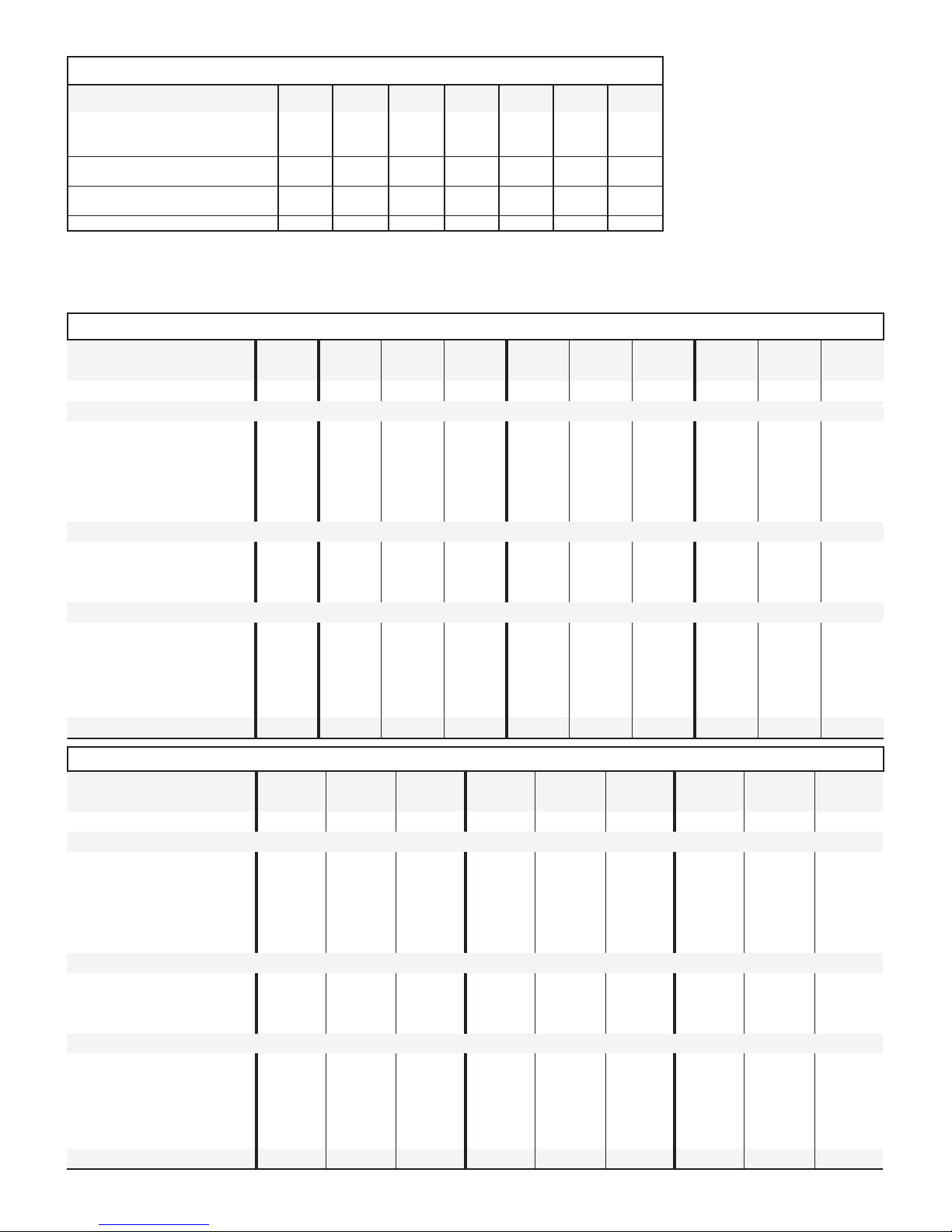

Capacity and Efficiency Ratings

SLEDOM 481HW 242HW 103HW 163HW 124HW 384HW 206HW

HUTBgnilooC

REE

1

2

REES

3

POC

2

POC

2

FPSH

3

HUTB)F74(gnitaeHpmeThgiH

1

HUTB)F71(gnitaeHpmeTwoL

1

004,81006,32000,03006,53005,14000,74005,65

01.902.907.800.907.800.907.8

00.1105.0100.0100.0100.0105.0102.01

000,81002,32000,82004,43000,14000,64000,85

08.200.300.309.200.300.300.3

000,01000,21006,51000,91000,32000,82000,53

08.109.109.109.100.201.200.2

06.606.606.606.608.600.700.7

1 Capacity is certified in accordance with ARI Standard 390-2003 and tested in accordance with ARI Standard 210/240-2003.

2 EER = Energy Efficiency Ratio, COP = Coefficient of Performance and are certified in accordance with ARI Standard 390-2003.

3 SEER =

Seasonal Energy Efficiency Ratio, HSPF = Heating Seasonal Performance Factor and are tested in accordance with ARI Standard 210/240-2003.

All ratings based on fresh air intake being 100% closed (no outside air introduction).

Specifications 1-1/2 through 3 Ton

SLEDOM A-481HW A-242HW B-242HW C-242HW A-103HW B-103HW C-103HW A-163HW B-163HW C-163HW

ZH06--gnitaRlacirtcelE 1-802/032 1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064

egnaRegatloVgnitarepO352-791352-791352-791605-414352-791352-791605-414352-791352-791605-414

AtiucriC--rosserpmoC

egatloV802/032802/032802/032064802/032802/032064802/032802/032064

spmAdaoLdetaR8.8/0.70.11/0.016.7/9.69.30.41/9.217.8/

tnerruCnoitceleStiucriChcnarB0.010.110.80.40.410.010.50.710.110.6

spmArotoRkcoL54/5465/6515/1

epyTrosserpmoCllorcS.piceR.piceR.piceR.piceR.piceR.piceR.piceR.piceR.piceR

resnednoC&rotoMnaF

MPR-PH--rotoMnaF5701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/1

spmA--rotoMnaF2.

MFC/AID--naF0061-"810061-"810061-"810061-"810002-"020002-"020002-"020002-"020091-"020091-"02

rotaropavE&rotoM

DPS/MPR/PH--rotoMrewolB1-0011-6/11-0011-6/11-0011-6/12-0011-3/12-0011-3/12-0011-3/12-0011-3/12-0011-3/12-0011-3/12-0011-3/1

spmA--rotoMrewolB0.10.10.11.12.22.21.12.22.21.1

.P.S.E&gnilooCMFC

)lioCteW-detaR(retliF/w

.DTS)sehcni(seziSretliF1x52x611x52x611x52x611x52x611x03x611x03

.SBL--thgieWgnippihS

12.12.14.15.15.14.15.15.14.1

4.-0562.-0082.

003 003 003 003 563 563 563 083 083 083

55257/5786/864369/6957/5704

-0082.-0084.-00014.-00014.-00013.-00113.-00113.-0011

1.88.40.71/3.615.01/8.92.5

x611x03x611x03x611x03x611x03x61

Specifications 3-1/2 through 5 Ton

SLEDOM A-124HW B-124HW C-124HW A-384HW B-384HW C-384HW A-206HW B-206HW C-206HW

ZH06--gnitaRlacirtcelE 1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064

egnaRegatloVgnitarepO352-791352-791605-414352-791352-791605-414352-791352-791605-414

AtiucriC--rosserpmoC

egatloV802/032802/032064802/032802/032064802/032802/032064

spmAdaoLdetaR4.02/3.811.31/2.211.66.12/8.027.21/3.212.66.92

tnerruCnoitceleStiucriChcnarB0.120.410.78.129.215.60.030.020.9

spmArotoRkcoL201/20119/1924/24131/1311

epyTrosserpmoC.piceR.piceR.piceRllorcSllorcSllorcSllorcSllorcSllorcS

resnednoC&rotoMnaF

DPS/MPR/PH--rotoMnaF2-058-3/12-058-3/12-058-3/12-058-3/12-058-3/12-058-3/12-058-3/12-058-3/12-058-3/1

oMnaF5.25.23.15.25.23.15.25.23.1

Form No. S3210-206

Supersedes S3210-106

Page 2 of 12

spmA--rot

MFC/AID--naF0572-"420572-"420572-"420572-"420572-"420572-"420572-"420572-"420572-"42

rotaropavE&rotoM

DPS/MPR/PH--rotoMrewolB2-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/1

spmA--rotoMrewolB3.33.39.13.33.39.13.33.39.1

.P.S.E&gnilooCMFC

)lioCteW-detaR(retliF/w

.DTS)sehcni(seziSretliF1x03x021x03x021x03x021x03x021x03x021x03x021x03x021x03x

.SBL--thgieWgnippihS

3.-00413.-00413.-00412.-05

015 015 015 015 015 015 015 015 015

/9.521.02/5.616.8

9/1964961/961731/73126/26

512.-05512.-05513.-00713.-00713.-0071

021x03x02

Ventilation System Packages

Bard Wall-Mounts are designed to provide optional ventilation packages to meet all of your ventilation and indoor air quality requirements. All

units are equipped with a barometric fresh air damper as the standard ventilation package. All ventilation packages can be built-in at the

factory, or field-installed at a later date.

BAROMETRIC FRESH AIR DAMPER - BFAD STANDARD

The barometric fresh air damper is a standard feature on all models. It is installed on the inside of the service door

and allows outside ventilation air, up to 25% of the total airflow rating of the unit, to be introduced through the air

inlet openings and to be mixed with the conditioned air. The damper opens during blower operation and closes

when the blower is off. Adjustable blade stops allow different amounts of outside air to be introduced into the

building and can be easily locked closed if required.

Barometric Fresh Air Damper

Motorized Fresh Air Damper

Commercial Room Ventilator

Economizer

BLANK OFF PLATE - BOP OPTIONAL

A blank off plate is installed on the inside of the service door. It covers the air inlet openings which restricts any

outside air from entering into the unit. The blank off plate should be utilized in applications where outside air is not

required to be mixed with the conditioned air.

MOTORIZED FRESH AIR DAMPER - MFAD OPTIONAL

The motorized fresh air damper is internally mounted behind the service door and allows outside ventilation air, up to

25% of the total airflow rating of the unit, to be introduced through the air inlet openings and to be mixed with the

conditioned air. The two position damper can be fully open or closed. The damper blade is powered open by a

24VAC motor with spring return on power loss. The damper can be controlled by indoor blower operation or can be

field connected to be managed based on building occupancy.

NOTE: The above vent systems are intake only without built-in exhaust capability. Building will likely require separate

field installed barometric relief or mechanical exhaust elsewhere within the conditioned space. Balancing dampers in

the return air grille may be required to achieve specified amount of outdoor air intake.

COMMERCIAL ROOM VENTILATOR - CRV OPTIONAL

The built-in commercial room ventilator is internally mounted behind the service door and allows outside

ventilation air, up to 50% of the total airflow rating of the unit, to be introduced through the air inlet openings.

It includes a built-in exhaust air damper.

The commercial room ventilator (CRV) is a simple and innovative approach to improving the indoor air quality by

providing fresh air intake and exhaust capability through the CRV. The damper can be easily adjusted to control the

amount of fresh air supplied into the building. The CRV can be controlled by indoor blower operation or field

controlled based on room occupancy. Two versions available (except on 1.5 and 2-Ton models). The CRV and

CRVS are power open - spring return on power loss, and CRVP is power open and power close. Complies with

ANSI/ASHRAE Standard 62.1 “Ventilation for Acceptable Indoor Air Quality.”

ECONOMIZER - EIFM OPTIONAL

The built-in economizer system is internally mounted behind the service door and allows outdoor air to be

introduced through the air inlet openings. The amount of outdoor air varies in response to the system controls and

settings defined by the end user. It includes a built-in exhaust air damper. The economizer is designed to provide

“free cooling” when outside air conditions are cool and dry enough to satisfy cooling requirements without running

the compressor. This in turn provides lower operating costs, while extending the life of the compressor.

Standard Features:

• One Piece Construction - Easy to install with no mechanical linkage adjustment required.

• Exhaust Air Damper - Built in with positive closed position. Provides exhaust air capability to prevent

pressurization of tight buildings.

• Actuator Motor - 24 volt, power open, spring return with built in torque limiting switch.

• Proportioning Type Control - for maximum “free cooling” economy and comfort.

• Moisture Eliminator & Prefilter - permanent, washable aluminum construction.

• Enthalpy Control - adjustable to monitor outdoor temperature and humidity.

• Minimum Position Potentiometer - adjustable to control minimum damper blade position for ventilation

purposes.

• Mixed Air Sensor - to monitor outside and return air to automatically modulate damper position.

WALL-MOUNT ENERGY RECOVERY VENTILATOR - WERV OPTIONAL

The wall-mount energy recovery ventilator (WERV) is a highly innovative approach to meeting indoor air quality

ventilation requirements as established by ANSI/ASHRAE Standard 62.1. The WERV allows from 200 to 450 CFM

(depending upon model) of fresh air and exhaust through the unit while maintaining superior indoor comfort and

Energy Recovery Ventilator

humidity levels. In most cases this can be accomplished without increasing equipment sizing or operating costs.

Heat transfer efficiency is up to 67% during summer and 75% during winter conditions.

The WERV consists of a unique “rotary energy recovery cassette” that provides effective sensible and latent heat

transfer capabilities during summer and winter conditions. Various control schemes are addressed including limiting

ventilation during building occupancy only.

The WERV is designed to be internally mounted behind the service door in the WA, WH or WL model wall-mount

units. It can be built-in at the factory or field installed as an option. WERV-*3C and WERV-*5C can be

independently adjusted for intake and exhaust rates.

Manufactured under U.S. Patent Nos. 5,485,878; 5,301,744;

5,002,116; 4,924,934; 4,875,520; 4,825,936; 6,310,330.

Form No. S3210-206

Supersedes S3210-106

Page 3 of 12

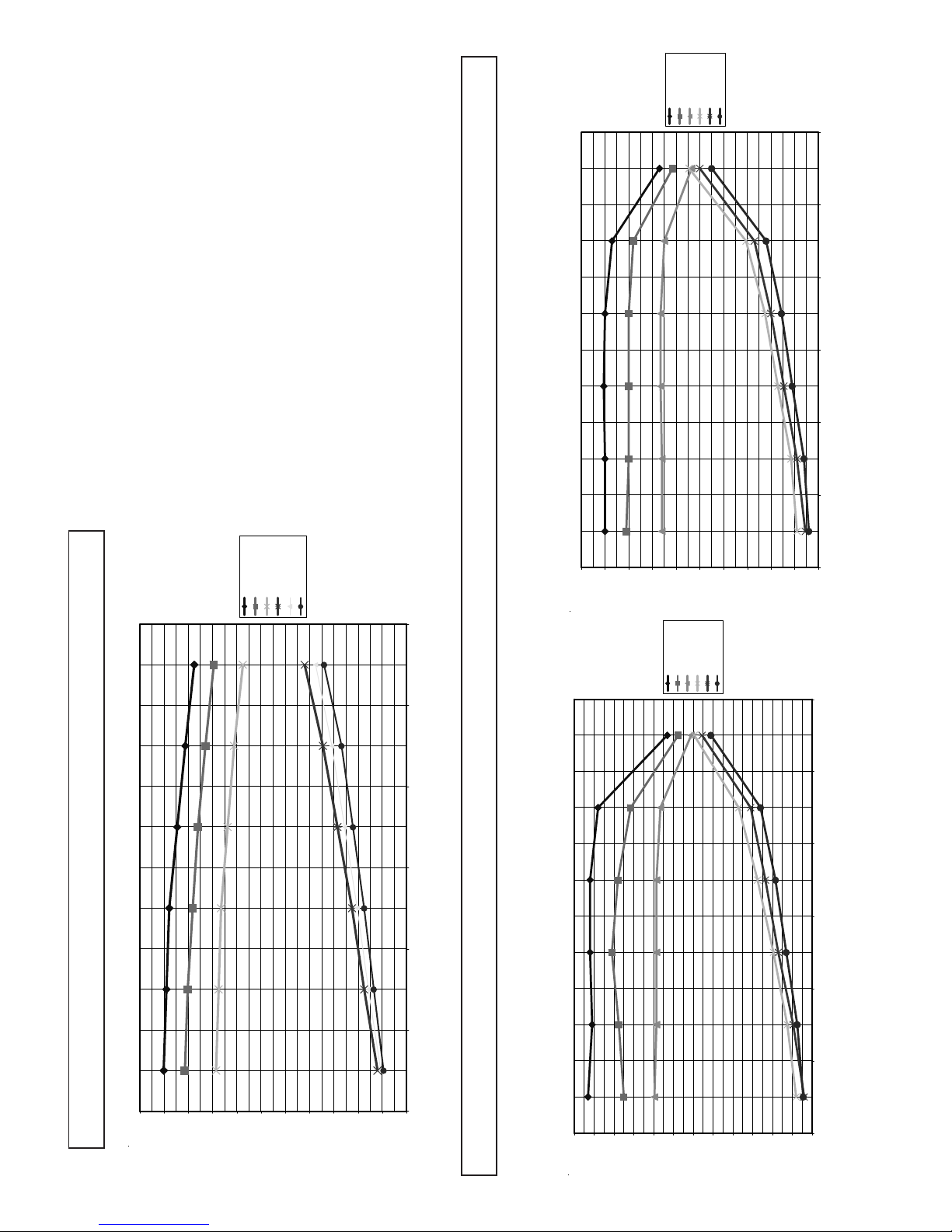

0

100

200

300

400

500

600

700

800

900

1000

ABCDEF

Vent Position

Airflow (cfm)

Total Air 0 ESP

Total Air .15 ESP

Total Air .3 ESP

Vent Air 0 ESP

Vent Air .15 ESP

Vent Air .3 ESP

WH30 & WH36 LOW SPEED TOTAL AND VENTILATION AIRFLOW

Total Air 0 ESP

Total Air .15 ESP

Total Air .3 ESP

Vent Air 0 ESP

Vent Air .15 ESP

Vent Air .3 ESP

Total Air 0 ESP

Total Air .15 ESP

Total Air .3 ESP

Vent Air 0 ESP

Vent Air .15 ESP

Vent Air .3 ESP

Vent Position

Vent Position

WH18 & WH24 TOTAL AND VENTILATION AIRFLOW

400

500

600

700

800

900

1000

Commercial Room Ventilator Performance Data - CRV-2

Form No. S3210-206

Supersedes S3210-106

Page 4 of 12

1100

Airflow (cfm)

ABCDEF

ABCDEF

0

100

200

300

Commercial Room Ventilator Performance Data - CRVS-3 and CRVP-3

WH30 & WH36 HIGH SPEED TOTAL AND VENTILATION AIRFLOW

1200

1100

1000

900

600

700

800

400

500

Airflow (cfm)

300

0

100

200

Loading...

Loading...