Bard FH085D36D, FH110D48D, FH110D60D, FLF085D36D, FLR085D36D Installation Instructions Manual

...

OIL FURNACE

INSTALLATION INSTRUCTIONS

MODELS

FH085D36D FH110D48D FH110D60D

FLF085D36D FLR085D36D FLF110D48D

FLR110D48D FLR140D60D FC085D36D

WARNING

READ ALL INSTRUCTIONS CAREFULL Y BEFORE BEGINNING THE

INSTALLATION.

THIS INST ALLATION MUST COMPLY WITH THESE INSTRUCTIONS AND

THE REQUIREMENTS OF ALL GOVERNING CODES AND ORDINANCES FOR

THE INST ALLATION LOCATION.

IT IS THE RESPONSIBILITY OF INSTALLER TO KNOW AND UNDERSTAND

ALL OF THESE REQUIREMENTS.

F AILURE TO DO SO COULD CREATE A HAZARD RESULTING IN PROPER TY

DAMAGE, BODIL Y INJURY OR DEATH.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE V APORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

IMPORTANT NOTICE

THIS FURNACE IS NOT INTENDED FOR USE AS A CONSTRUCTION

HEA TER. USE OF THIS FURNACE DURING CONSTRUCTION AND FINISHING

PHASES OF A STRUCTURE IS CONSIDERED AS "OPERA TION IN A

CORROSIVE A TMOSPHERE" AND "UNUSUAL, NEGLIGENT OR IMPROPER

USE" AND AS SUCH ARE CONSIDERED EXCLUSIONS BY THE BARD

MANUFACTURING COMPANY LIMITED W ARRANTY.

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

Manual: 2100-392A

Supersedes:

File: VOL. I, TAB 3

Date: 12-17-01

Copyright 2001

CONTENTS

Getting Other Information and Publications

Installation and Operating Instructions

Equpment Selection ...............................................2

Locating the Furnace..............................................2

Duct Work...............................................................6

Installing a Cooling Unit..........................................6

Wiring ...............................................................6

Oil Line Piping ........................................................8

Beckett AFG Oil Burner..........................................8

Beckett “CleanCut” Oil Pump .................................9

Beckett Solid State Igniter ......................................9

Beckett R7184B Primary Control............................9

Beckett R7184B Primary Operational Guide ........10

Burner Set up and Adjustments ........................... 11

Burner Nozzle and Electrode Adjustments...........14

Ventilation and Combustion Air ............................14

Louvers and Grilles...............................................18

Venting .............................................................18

Thermostat ...........................................................18

Fan & Limit Control...............................................18

T ABLES

Table 1 Minimum Clearances ............................. 2

Table 2 Dimensions Lo-Boy Models .................. 3

T able 3 Dimensions Hi-Boy Models .................... 4

T able 4 Dimensions Counterflow Models............ 5

Table 5 Electrical Data ........................................ 7

Table 6 Furnace Data ........................................11

Table 7 Correlation of % of CO

Reserve Air .......................................... 13

Table 8 No. 2 Fuel Oil Efficiency Chart ............. 13

T able 9 Recommended Start-Up Settings ........ 13

T able 10 Round Duct Sizing ............................... 14

Table 1 1 Sq.Ft. Required as

Unconfined Space................................ 15

Table 12 Minimum Ventilation Openings............. 16

Table 13 Temperature Rise Ranges, Limit

Control Settings, and

Heating Blower Speeds........................ 19

Table 14 Filter Sizes for Gas Furnaces............... 20

, O2 and

2

Filters

Hi-Boy Models – Filter Locations & Removal

and Replacement Procedures ..............................20

Counterflow Models – Filter Locations ...............21

Lo-Boy Models – Filter Locations .......................22

Maintenance

Lubrication ............................................................23

Inspect Air Filter....................................................23

Final Inspeciton and Test......................................23

Service Hints ........................................................23

Combination Combustion Chamber/Burner

Mounting System..................................................24

To Remove Burner Only .......................................24

To Remove Entire Combustion Chamber

Mounting System..................................................24

Common Causes of Trouble.................................26

Care of Finish .......................................................26

Cleaning of Furnace .............................................26

Blower System Resistance Curves ................ 27-30

Wiring Diagrams............................................. 31-33

FIGURES

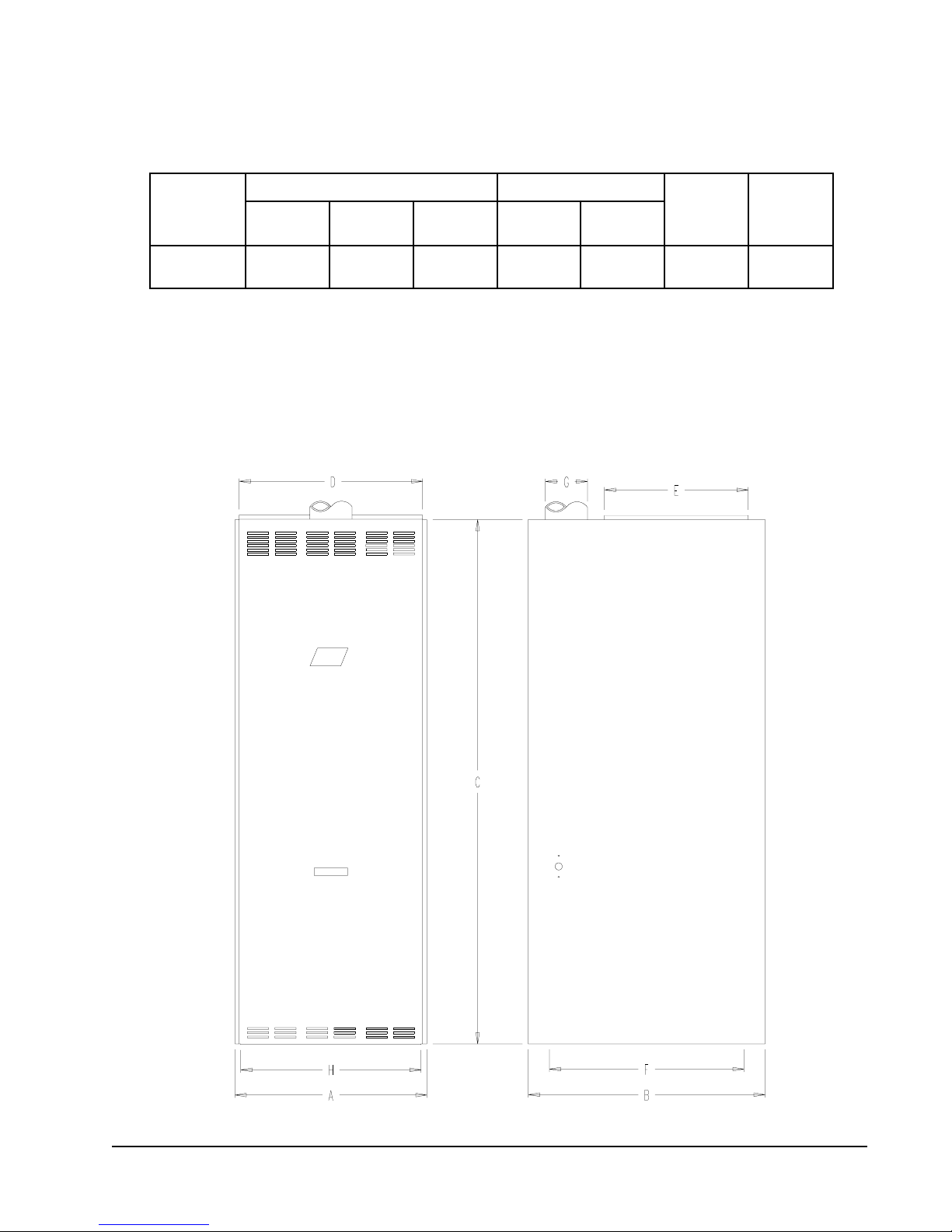

Figure 1 Lo-Boy Models Dimensions ............... 3

Figure 2 Hi-Boy Models Dimensions................ 4

Figure 3 Counterflow Models Dimensions ....... 5

Figure 4 Typical Installation Requirement

Front Flue .......................................... 7

Figure 5 T ypical Single Inside

Tank Installation................................. 8

Figure 6 Pressure Gauge Connection to

Pressure Gauge Port....................... 12

Figure 7 Electrode Adjustments..................... 14

Figure 8 All Air From Inside Building.............. 15

Figure 9 All Air From Outdoors ...................... 16

Figure 10 All Air From Outdoors Through

Ventilated Attic................................. 17

Figure 11 All Air From Outdoors - Inlet Air

From Ventilated Crawl Space and

Outlet Air to Ventilated Attic............. 17

Figure 12 Typical Installation of 16x25x1

Filter Rack........................................ 20

Figure 13 Typical Installation of 20x25x1

Filter Rack........................................ 20

Figure 14 Filter Installation - Counterflow

Models ............................................. 21

Figure 15 Filter Installation - Lo-Boy Models ... 24

Figure 16A Removal of Burner Only .................. 20

Figure 16B Removal of Entire Combustion

Chamber Mounting System ............. 25

i

GETTING OTHER INFORMA TION and PUBLICATIONS

These publications can help you install the furnace. You

can usually find these at your local library or purchase

them directly from the publisher. Be sure to consult

current edition of each standard.

National Fuel Gas Code ........... ANSI Z223.1/NFPA54

National Electrical Code ......................ANSI/NFPA 70

Standard for the Installation .............. ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air...................... ANSI/NFPA 90B

Heating and Air Conditioning Systems

Standard for Chimneys, Fireplaces, Vents ... NFPA 211

and Solid Fuel Burning Appliances

Load Calculation for .......................... ACCA Manual J

Residential Winter and Summer Air Conditioning

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACC A Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

Duct Design for Residential .............. ACCA Manual D

Winter and Summer Air Conditioning

and Equipment Selection

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-392

Page 1

INST ALLATION and OPERATING INSTRUCTIONS

EQUIPMENT SELECTION

An accurate heating load calculation must be conducted

using American Society of Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE) or Air

Conditioning Contractors of America (ACCA) manuals.

Do not add a large safety factor above the calculated

value. If the calculated heating load requirement

exceeds the heating capacity rating of a given model,

use only the next larger size available. Never increase

by any more than absolutely necessary based upon

available equipment heating capacities. Always select

based upon heat capacity (output), never use input

capacities.

NOTE: It is the personal responsibility and

obligation of the purchaser to contract a

qualified installer to assure that installation

is adequate and is in conformance with

governing codes and ordinances.

LOCATING THE FURNACE

When installing the furnace be sure to provide adequate

space for easy service and maintenance. Locate the

furnace as close to the chimney as practical, giving

consideration to the accessibility of the oil burner,

controls, and blower for service. Allow a minimum of

24 inches at front of furnace for servicing oil burner.

Allow adequate room for filter and blower

maintenance. Clearance from combustible material as

stated on the furnace and repeated in Table 1 must be

maintained. For damp basement installations, a raised

concrete pad is recommended. This will help keep the

bottom of the furnace dry and reduce rusting.

An oil burner must have a generous supply of

combustion air to operate properly. The flow of

combustion and ventilating air must not be obstructed

from reaching the furnace. See “Ventilation and

Combustion Air” section.

The furnace area must be kept clear and free of

combustible materials, gasoline and other flammable

vapors and liquids.

This unit is not designed for mobile home or trailer

installations. Always install furnace in a level position.

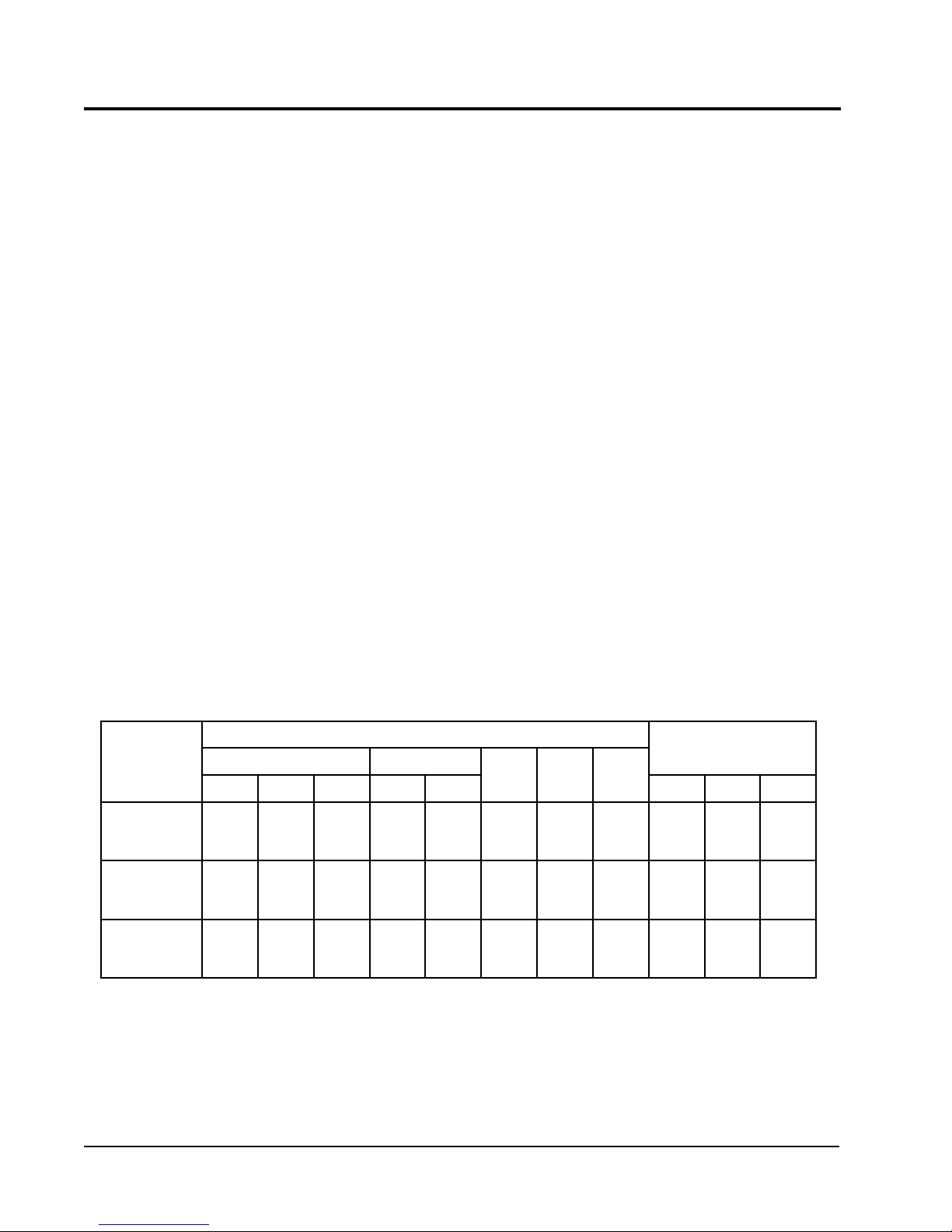

TABLE 1

MINIMUM CLEARANCES

sehcnI--secnaraelCnoitallatsnImuminiM

1

ledoM

D63D580HF

D84D011HF

D06D011HF

D84D011FLF

D84D011RLF

D63D580CF

j

C

NC

*

**

4

4

4

D63D580FLF

6

D63D580RLF

6

6

6

D06D041RLF

6

6

For the first three (3) feet from plenum. After three (3) feet, no clearance required.

Combustible flooring

Noncombustible floor

Maintained on one side or the other to achieve filter access and/or blower service.

Floor must be noncombustible. For furnace only installation can be installed on combustible

flooring only when installed on special base part no. CFB7 available from factory. When air

conditioning coil cabinet DCB23-22 is used then use special base part no. CFB23.

1

1

1

0

81

0

81

81

1

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

tcuD

2

2

2

2

2

2

2

2

2

eulF

epiProolFtnorFkcaBsediSpoTsediStnorFkcaBsediS

9

9

9

9

9

9

9

9

9

C

C

C

CN

CN

CN

CN

CN

**

CN

ecivreSmuminiM

secnaraelCecanruFmunelP

42

42

42

42

42

42

42

42

42

---

---

---

42

42

42

42

42

---

---

---

---

*

81

81

*

81

*

81

*

81

*

---

Manual 2100-392

Page 2

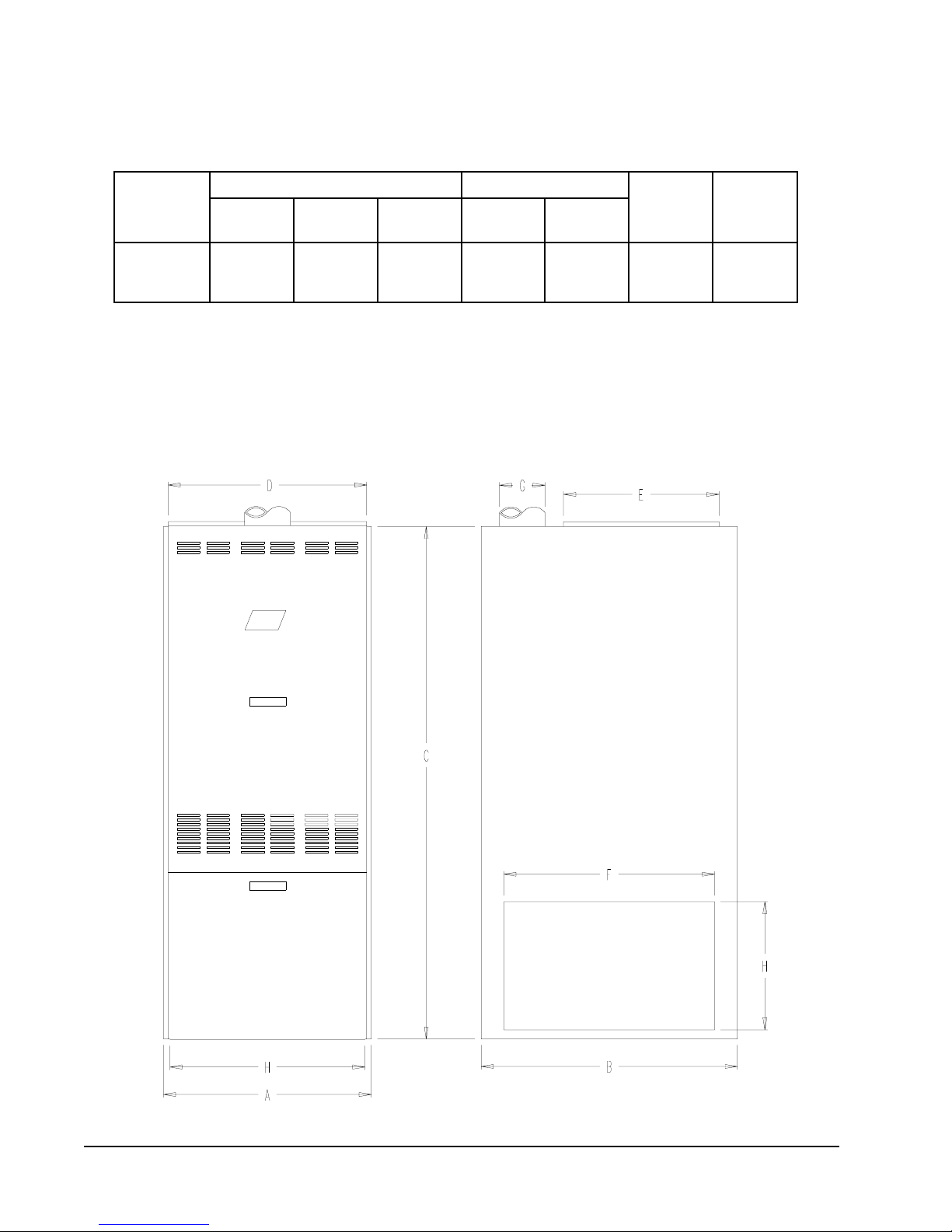

TABLE 2

LO-BOY MODELS

DIMENSIONS (INCHES)

munelP

tenibaC

ledoM

rebmuN

D63D580FLF

D63D580RLF

D84D011RLF

D84D011RLF

D06D041RLF62050502x5261x52raeR68/5-34---1x52x021

j

Washable type filter 1” nom. thickness

A

32

32

32

32

B

htdiW

C

htpeD

4/1-74

4/1-74

4/1-74

4/1-74

thgieH

4/1-04

4/1-04

4/1-44

4/1-44

ExD

sgninepOnoitcennoCeulFsretliFriA

FxD

ylppuS

02x22

02x22

02x22

02x22

nruteRnoitacoL

61x22

61x22

61x22

61x22

G

tnorF

raeR

tnorF

raeR

HJ

.aiD

6

6

6

6

eziS

---

43

---

83

4/1-5

--4/1-5

---

1

.oN

desU

1x02x61

1

1x02x61

1

1x02x02

1

1x02x02

1

FIGURE 1

LO-BOY MODELS DIMENSIONS

MIS-1345

Manual 2100-392

Page 3

TABLE 3

HI-BOY MODELS

DIMENSION (INCHES)

tenibaCsgninepOmunelP

ledoM

rebmuN

D63D580HF

D84D011HF

D06D011HF

A

htdiW

32

32

32

j

Washable type filter

k

Left or right side return air option. Must be cut in by installer.

B

htpeD

2/1-13

2/1-13

2/1-13

C

thgieH

65

06

06

ExD

ylppuS

02x22

02x22

02x22

2

HxF

nruteR

41x32

41x32

41x32

G

.aiDeulF

6

6

6

1

eziSretliF

52x61

52x61

52x02

FIGURE 2

HI-BOY MODELS DIMENSIONS

Manual 2100-392

Page 4

MIS-1346

TABLE 4

COUNTERFLOW MODELS

DIMENSION (INCHES)

tenibaCsgninepOmunelP

ledoM

rebmuN

D63D580CF322/1-926502x2291x816

A

htdiW

j

Washable type filter

k

Left or right side return air option. Must be cut in by installer.

B

htpeD

C

thgieH

ExD

2

nruteR

HxF

ylppuS

G

.aiDeulF

FIGURE 3

COUNTERFLOW MODELS DIMENSIONS

1

eziSretliF

02x01

02x51

MIS-1344

Manual 2100-392

Page 5

DUCT WORK

The air distribution system should be designed and

installed in conformance with manuals published by Air

Conditioning Contractors of America (ACCA) as set

forth in Manual D, or ASHRAE publications.

IMPORTANT

When a furnace is installed so that supply

ducts carry air circulated by the furnace to

areas outside the space containing the

furnace, the return air must also be handled

by a duct(s) sealed to the furnace casing and

terminating outside the space containing the

furnace This is to prevent drawing possible

hazardous combustion products into the

circulated air.

INSTALLING A COOLING UNIT

When the furnace is used in connection with a cooling

unit*, the furnace shall be installed parallel with or on

the upstream side of the cooling unit to avoid

condensation in the heating element. With a parallel

flow arrangement, the dampers or other means used to

control flow of air shall be adequate to prevent chilled

air from entering the furnace, and if manually operated,

must be equipped with means to prevent operation of

either unit, unless the damper is in the full heat or cool

position.

* A cooling unit is an air conditioning coil, heat

pump coil or chilled water coil.

When installing a cooling unit above an FH or FL

(below on an FC) series furnace, the coil must be

spaced far enough from the furnace outlet to assure

proper operation of the furnace. Bard supplied coils,

when used with Bard supplied coil cabinets, are

automatically positioned.

For top discharge FH and FL models, when coils are

installed without using Bard coil cabinets or coils of

another brand are used, the coil drain pan should be

located a minimum of two (2) inches above the top of

the furnace cabinet. If a greater clearance is specified

by the coil manufacturer then it would apply.

INADEQUATE SUPPLY AIR and/or RETURN

AIR DUCT SYSTEMS

Short cycling because of limit control operation can be

created by incorrectly designed or installed supply and/

or return air duct systems.

The duct systems must be designed using ASHRAE or

ACCA design manuals and the equipment CFM and

external static pressure ratings to insure proper air

delivery capabilities.

On replacement installations, particularly if equipment

is oversized, the duct systems can easily be undersized.

Modifications may be required to assure that the

equipment is operating within the approved

temperature rise range when under full rated input

conditions, and that no short cycling on limit controls is

occurring.

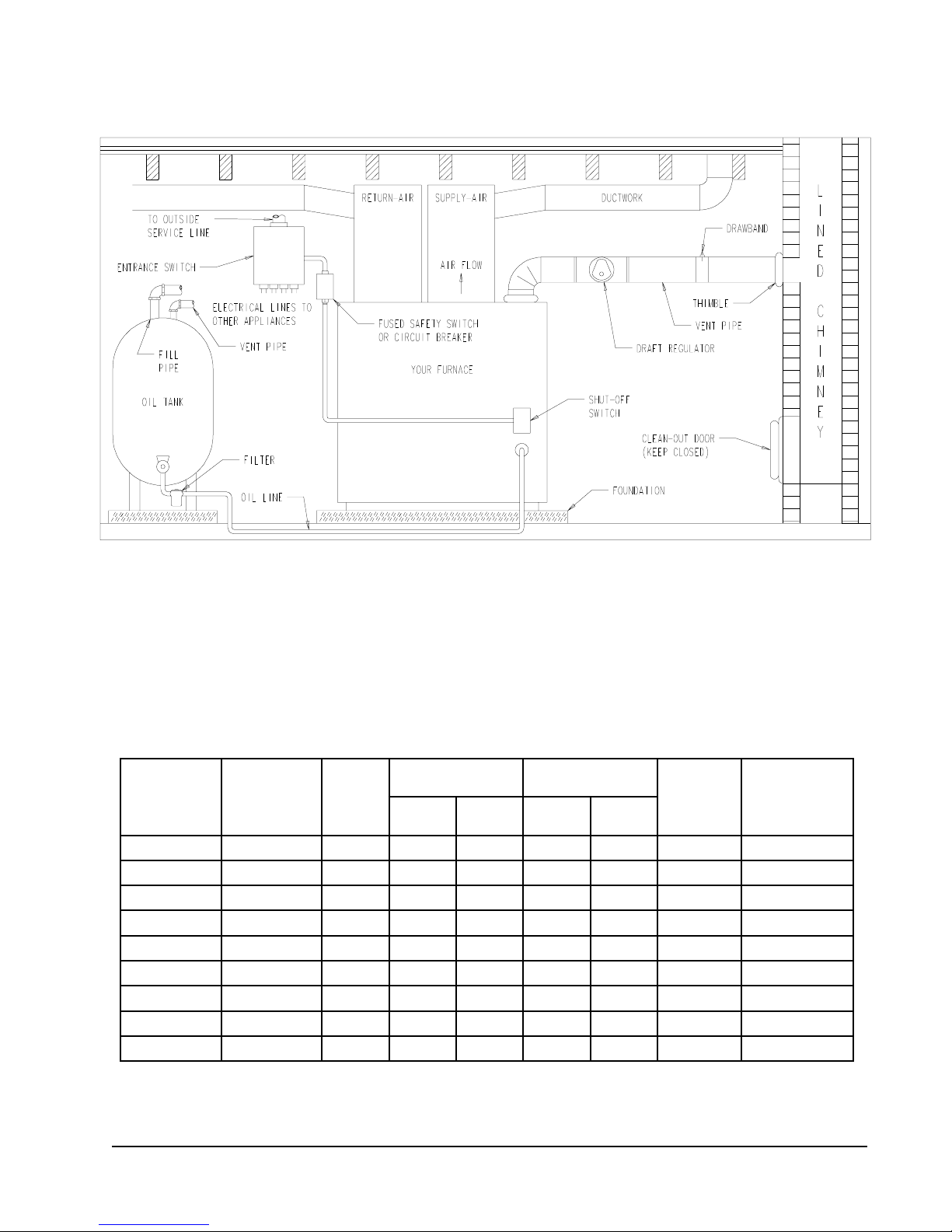

INSTALLING THE FURNACE

A typical installation is shown in Figure 4. All parts of

the furnace installation (furnace, oil tank and piping

systems, combustion and ventilation air, venting, etc.)

must comply with NFPA31, Installation of Oil Burning

Equipment -- latest edition. This drawing shows the

typical connecting parts needed to correctly install this

furnace. Make sure that all parts of the heating system

comply with the local codes.

Check the furnace and your load calculation to verify

that the unit is properly sized. (Refer to Equipment

Selection” section on Page 2.)

The correct size of unit needed may be substantially

smaller than the unit being replaced due to home

improvements and technology advancements since the

initial installation.

WIRING

FACTORY WIRING

All units are fully factory wired. Multispeed blowers

are factory wired on high speed for cooling/manual fan

operation. Heating speeds are wired for the largest

input and may need lower speed for field installed low

input nozzle. If replacement wire is necessary, use 105

degrees C minimum. See electrical data, Table 5.

NOTE: If drain pan is anything other than a steel pan

particular attention must be given to the

installation instructions for the coil to make

sure it is acceptable for use with these oil

furnaces having maximum outlet air

temperature of 200° F.

See CFM versus static pressure tables on pages 23-26

for additional information.

Manual 2100-392

Page 6

FIELD WIRING

All wiring must conform to the National Electrical

Code and all local codes. A separate fuse or breaker

should be used for the furnace.

FIGURE 4

TYPICAL INSTALLATION REQUIREMENTS

FRONT FLUE LO-BOY MODEL SHOWN

NOTE: The chimney must be lined with a high temperature noncorrosive material that complies with the local

codes, or in their absence with Standard for Chimneys and Vents, NFPA211. Also see section on Venting

in these instructions.

TABLE 5

ELECTRICAL DATA

rotoMrewolBrotoMrenruB

latoT

ledoMHP-ZH-stloV

spmA

D63D580HF1-06-5112.93/15.77/17.15151

D84D011HF1-06-5112.212/15.017/17.16102

D06D011HF1-06-5112.414/35.217/17.19102

D63D580FLF1-06-5113.713/16.57/17.15151

D63D580RLF1-06-5113.713/16.57/17.15151

D84D011FLF1-06-5112.212/15.017/17.16102

D84D011RLF1-06-5112.212/15.017/17.16102

D06D041RLF1-06-5112.414/35.217/17.19102

D63D580CF1-06-5113.73/16.57/17.15151

PHALFPHALF

MIS-1335

emiT.xaM

muminiM

tiucriC

yticapmA

esuFyaleD

RCAHro

rekaerBtiucriC

Manual 2100-392

Page 7

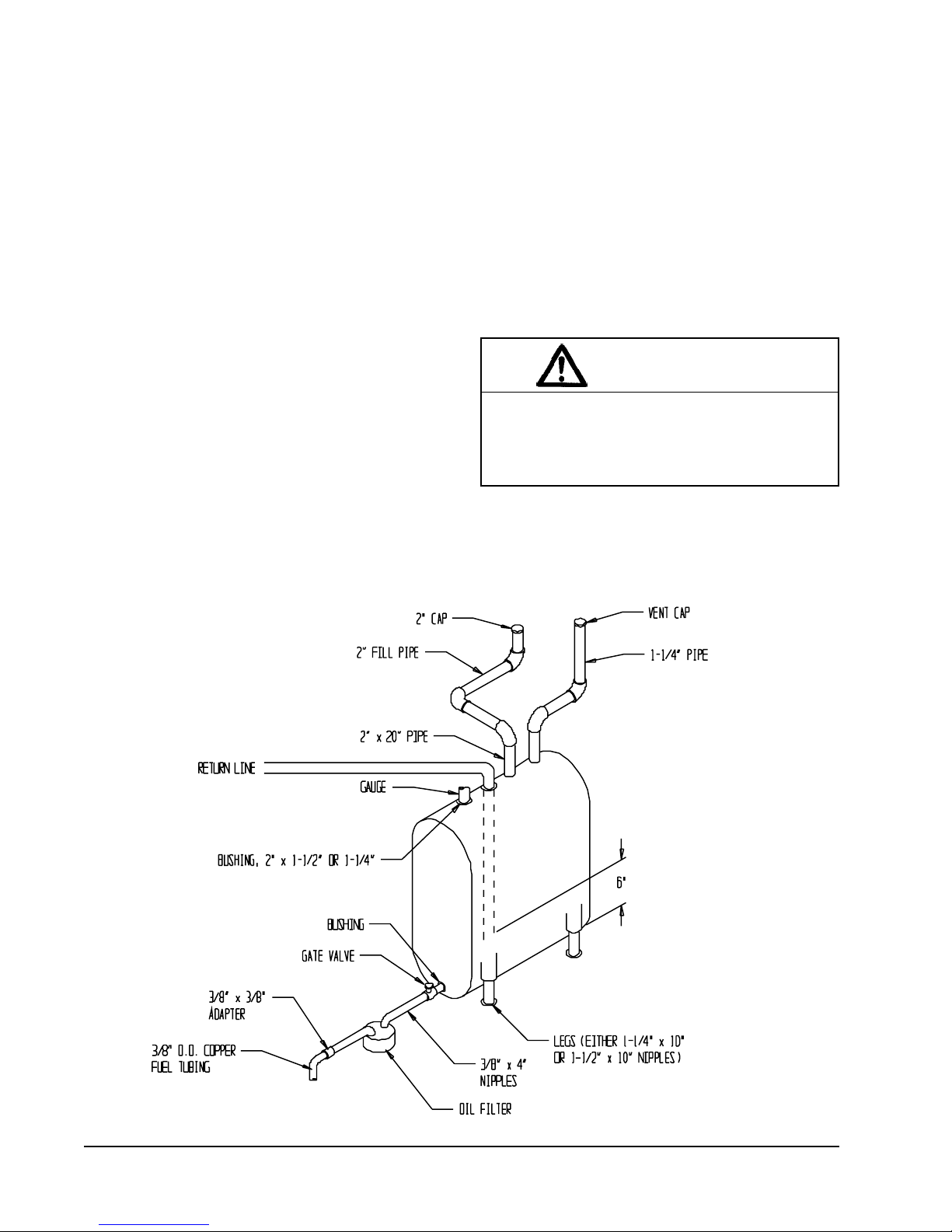

OIL LINE PIPING

First determine whether the pipe system is to be a single

line system or a two line system. All connections must

be absolutely air tight or you will have a malfunction of

the burner. When installing the piping, a good oil filter

should be installed close to the burner. A single line

system is recommended for gravity feed.

A typical single inside tank installations shown in

Figure 5. For installation details for this and other tank

configurations, refer to NFPA31 -- latest edition. All

tank and pipe setups must comply with NFPA31.

BECKETT AFG OIL BURNER

This furnace is equipped with a high static Beckett AFG

oil burner which is designed to produce adequate draft

in nearly any vertically vented application. The burner

employs the latest time tested controls of the highest

quality. The controls consist of a high voltage Beckett

solid state igniter, a Beckett “CleanCut” oil pump with

an integral solenoid valve, and a Beckett R7184B

primary control.

These controls were selected for their proven high

quality, dependability, and serviceability. With proper

maintenance this burner assembly will provide many

years of reliable service.

All units are shipped with the oil burner installed, and

with high rate oil nozzle installed designed for use with

No. 1 or No. 2 fuel oil. Inspect firepot refractory

before firing to be sure it has not been jarred out of

position in shipment. Burner air tube must not

extend beyond inside surface of firepot. Burner

head should be centered on the combustion chamber

opening. See Figures 16A and 16B.

WARNING

Never attempt to use gasoline in your furnace.

Gasoline is more combustible than fuel oil and

could result in a serious explosion causing

damage, injury or death.

FIGURE 5

TYPICAL SINGLE INSIDE TANK INSTALLATION

Manual 2100-392

Page 8

MIS-1340

The following is a detailed explanation of each control

included in the Becket AFG Oil Burner, how each

operates, how to set up the burner, and how to

troubleshoot problems should they occur.

BECKETT “CLEANCUT” OIL PUMP

This oil pump is equipped with an oil solenoid valve

installed in the pump housing. This feature provides

quick cutoffs resulting in reduction in smoke after the

burner shuts down. This is a time proven pump design

and is capable of both one and two pipe systems. This

pump requires a pre-purge style primary control such as

the R7184B primary. All installation and set up

instructions are outlined in the “Oil Pump

Specification” section of the installation instructions

manual.

As an improved service feature Bard Manufacturing has

installed a brass tee fitting next to the oil line output of

the pump for installing a pressure gauge to ensure the

correct pump pressure. Refer to the “Burner Set Up and

Adjustment” section in the manual.

BECKETT SOLID STATE IGNITER

This igniter differs from the traditional iron core

transformer in that it produces a 14,000 volt spark

instead of a 10,000 volt spark of the iron core

transformer. This hotter spark provides for cleaner,

faster ignitions. Being solid state technology this

igniter is less susceptible to problems caused by voltage

variations. It also has a greater ability to ignite cold

and/or inconsistent oil. The solid state igniter is wired

to the primary control the same as a standard iron core

transformer.

BECKETT R7184B PRIMARY CONTROL

The R7184B Interrupted Electronic Oil Primary is a

line voltage, safety rated, interrupted ignition oil

primary control for residential oil burners. The R7184B

used with a cad cell flame sensor, operates the oil

burner and oil valve. The primary controls fuel oil,

senses flame, controls ignition spark and is designed to

notify a remote alarm circuit before going into lockout

when equipped with a flame monitoring system.

This primary control, though it possesses the latest

technology, is a very simple control to operate and

provides additional troubleshooting features to ease

service and reduce down time. Once the features and

operation of this control are understood the service

person will find it a welcomed addition. In an effort to

help in the transition to the R7184B primary control the

operational guide is provided following on Page 10.

Manual 2100-392

Page 9

Loading...

Loading...