WALL MOUNTED

INSTALLATION

INSTRUCTIONS

PACKAGED HEAT PUMP

Models:

WH301, WH361

© Copyright 2003

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914. . .Moving ahead just as planned.

Manual No.: 2100-193O

Supersedes: 2100-193N

File: Volume III, Tab 17

Date: 05-04-07

Manual 2100-193O

Page 1 of 26

CONTENTS

G

etting Other Information and Publications

For more information,

contact these publishers ........................................3

Wall Mount General Information

Heat Pump Wall Mount Model Nomenclature ........ 4

Shipping Damage .................................................. 4

General ............................................................. 4

Duct Work ...................................................... 4 & 8

Filters ............................................................. 8

Fresh Air Intake ...................................................... 8

Condensate Drain .................................................. 8

Installation Instructions

Wall Mounting Information ..................................... 9

Mounting the Unit................................................... 9

Top Outlet Only ...................................................... 9

Wiring — Main Power .......................................... 15

Wiring — Low Voltage Wiring............................... 15

Low Voltage Connections .................................... 15

Optional Outdoor Thermostat Applications .......... 17

Thermostat Indicator ............................................ 19

Start Up

Important Installer Note........................................ 20

Crankcase Heaters .............................................. 20

Service Hints ........................................................20

Sequence of Operation ........................................20

Pressure Service Ports ........................................ 21

Defrost Cycle ....................................................... 21

Troubleshooting

Solid State Heat Pump Control

Troubleshooting Procedures ................................ 22

Checking Temperature Sensor Outside

Unit Circuit ........................................................... 23

Fan Blade Setting Dimensions ............................ 24

Removal of Fan Shroud ....................................... 24

Refrigerant Charge .............................................. 24

Pressure Tables ................................................... 25

Optional Accessories ...........................................26

Figures

Figure 1 Unit Dimensions ................................... 6

Figure 2 Fresh Air Damper Assembly ................. 8

Figure 3 Mounting Instructions ......................... 10

Figure 4 Electric Heat Clearance ...................... 11

Figure 5 Attaching Top Outlet to Unit ................ 12

Figure 6 Top Outlet Model Mounted ................. 12

Figure 7 Wall-Mounting Instructions ................. 13

Figure 8 Wall-Mounting Instructions ................. 13

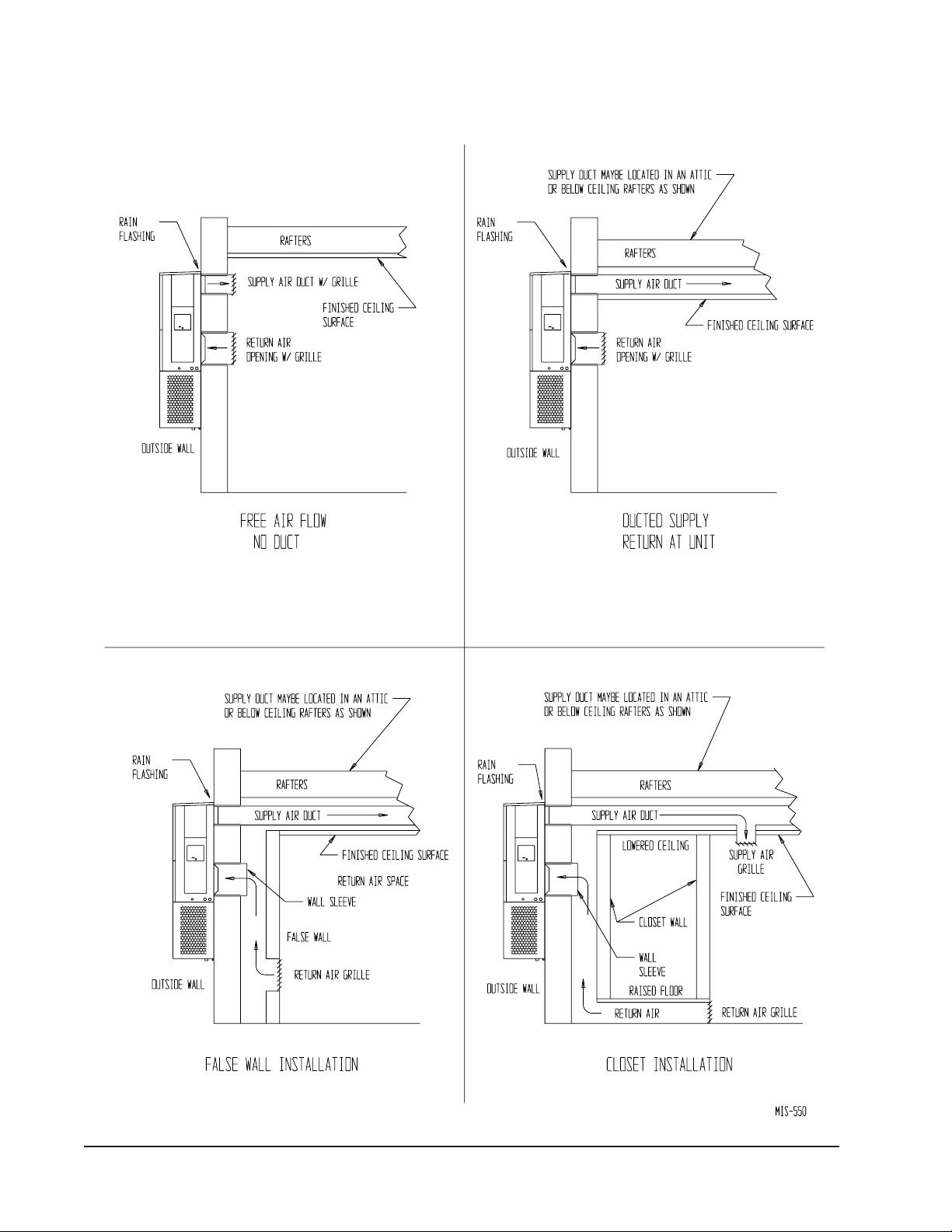

Figure 9 Common Wall-Mounting Installations . 14

Figure 10 Low Voltage Wiring ............................. 16

Figure 11 Compressor Cutoff

Thermostat Wiring .............................. 17

Figure 12 Compressor Cutoff

Thermostat Wiring .............................. 17

Figure 13 Electric Heat Hold-Off Wiring ..............18

Figure 14 Electric Heat Hold-Off Wiring ..............18

Figure 15 Start Up Label ..................................... 20

Figure 16 Defrost Control Board ......................... 21

Figure 17 Fan Blade Setting ...............................24

Tables

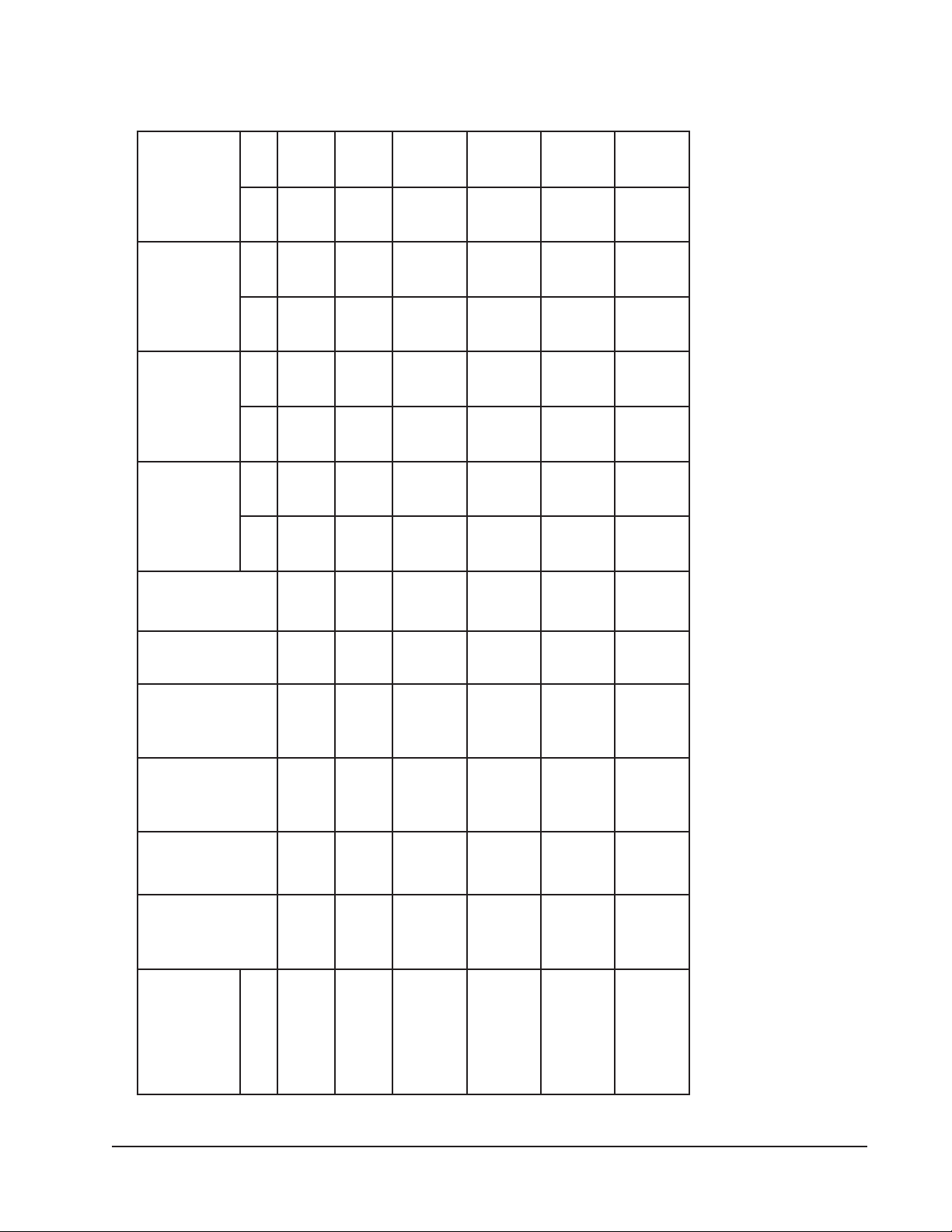

Table 1 Electric Heat Table ................................5

Table 2 Dimensions of Basic Unit ......................6

Table 3 Electrical Specifications ........................ 7

Table 4 Operating Voltage Range ...................15

Table 5 Thermostat Wire Size ......................... 16

Table 6 Wall Thermostat .................................. 19

Table 7 Troubleshooting .................................. 22

Table 8 Fan Blade Dimensions ....................... 24

Table 9 Suction Line Temperatures ................. 24

Table 10 Indoor Blower Performance ................ 24

Table 11 CFM and ESP..................................... 24

Table 12 Maximum ESP of Operation

Electric Heat Only ............................... 24

Table 13 Cooling Pressures .............................. 25

Table 14 Heating Pressures ..............................25

Table 15 Optional Accessories .......................... 26

Manual 2100-193O

Page 2 of 26

Getting Other Information and Publications

These publications can help you install the air

conditioner or heat pump. You can usually find these at

your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code ....................... ANSI/NFPA 70

Standard for the Installation ............... ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air ........................ ANSI/NFPA 90B

Heating and Air Conditioning Systems

Load Calculation for ............................. ACCA Manual J

Residential Winter and Summer Air Conditioning

Duct Design for Residential ................ACCA Manual D

Winter and Summer Air Conditioning and Equipment

Selection

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue NW

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manufactured under the following U.S. patent numbers:

5,485,878; 5,301,744; 5,002,116; 4,924,934;

4,875,520; 4,825,936

Manual 2100-193O

Page 3 of 26

WALL MOUNT GENERAL INFORMATION

HEAT PUMP WALL MOUNT MODEL NOMENCLATURE

WH 36 1 A 10 X X X X X A

MODEL NUMBER

CAPACITY

30 - 2½ Ton

36 - 3 Ton

VENTILATION OPTIONS

X - Barometric Fresh Air Damper (Standard)

B - Blank-off Plate

M - Motorized Fresh Air Damper

V - Commercial Room Ventilator - Motorized with Exhaust

E - Economizer (Internal - Fully Modulating with Exhaust

R - Energy Recovery Ventilator - with Exhaust

NOTE: For 0 KW and circuit breakers (230/208 Volt) or pull disconnects (460 Volt) applications, insert 0Z in the KW field of model number.

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be checked

for external signs of shipping damage. If damage is

found, the receiving party must contact the last carrier

immediately, preferably in writing, requesting inspection

by the carrier’s agent.

REVISIONS

VOLTS & PHASE

A - 230/208/60/1

B - 230/208/60/3

C - 460/60/3

KW

COLOR OPTIONS

X - Beige (Standard)

1 - White

2 - Mesa Brown

4 - Buckeye Gray

5 - Desert Brown

8 - Dark Bronze

FILTER OPTIONS

X - 1-Inch Throwaway (Standard)

W- 1-Inch Washable

P - 2-Inch Pleated

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Page 3 for information on codes and

standards.

COIL OPTIONS

X - Standard

1 - Phenolic Coated Evaporator

2 - Phenolic Coated Condenser

3 - Phenolic Coated Evaporator

and Condenser

OUTLET OPTIONS

X - Front (Standard)

T - Top on WH30 and WH36

Models

CONTROL

MODULES

Size of unit for a proposed installation should be based

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

on heat loss calculations made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Association for

the Installation of Air Conditioning and Ventilating

Systems of Other Than Residence Type, NFPA No. 90A,

and Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

The unit is designed for use with or without duct work.

should adhere to local codes.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method to

install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

heat pump system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

DUCT WORK

Any heat pump is more critical of proper operating

charge and an adequate duct system than a straight air

conditioning unit. All duct work, supply and return,

must be properly sized for the design airflow

requirement of the equipment. Air Conditioning

Contractors of America (ACCA) is an excellent guide to

proper sizing. All duct work or portions thereof not in

the conditioned space should be properly insulated in

order to both conserve energy and prevent condensation

or moisture damage.

Manual 2100-193O

Page 4 of 26

UTB

TABLE 1

ELECTRIC HEAT TABLE

1-0421-8023-0423-8023-0641-0421-8023-0423-8023-064

sledoMA-103HWB-103HWC-103HWA-163HWB-163HWC-163HW

WKAUTBAUTBAUTBAUTBAUTBAUTBAUTBAUTBAUTBA

51 5.26002151.4500483

016.14031432.63006526.14031432.6300652

58.02560711.81008218.02560711.8100821

64.41005025.21063512.7574024.41005025.21063512.757402

510.81002152.63002152.13004830.8100215

97.12006037.81030328.01007037.12006037.81030328.0100703

Manual 2100-193O

Page 5 of 26

TABLE 2

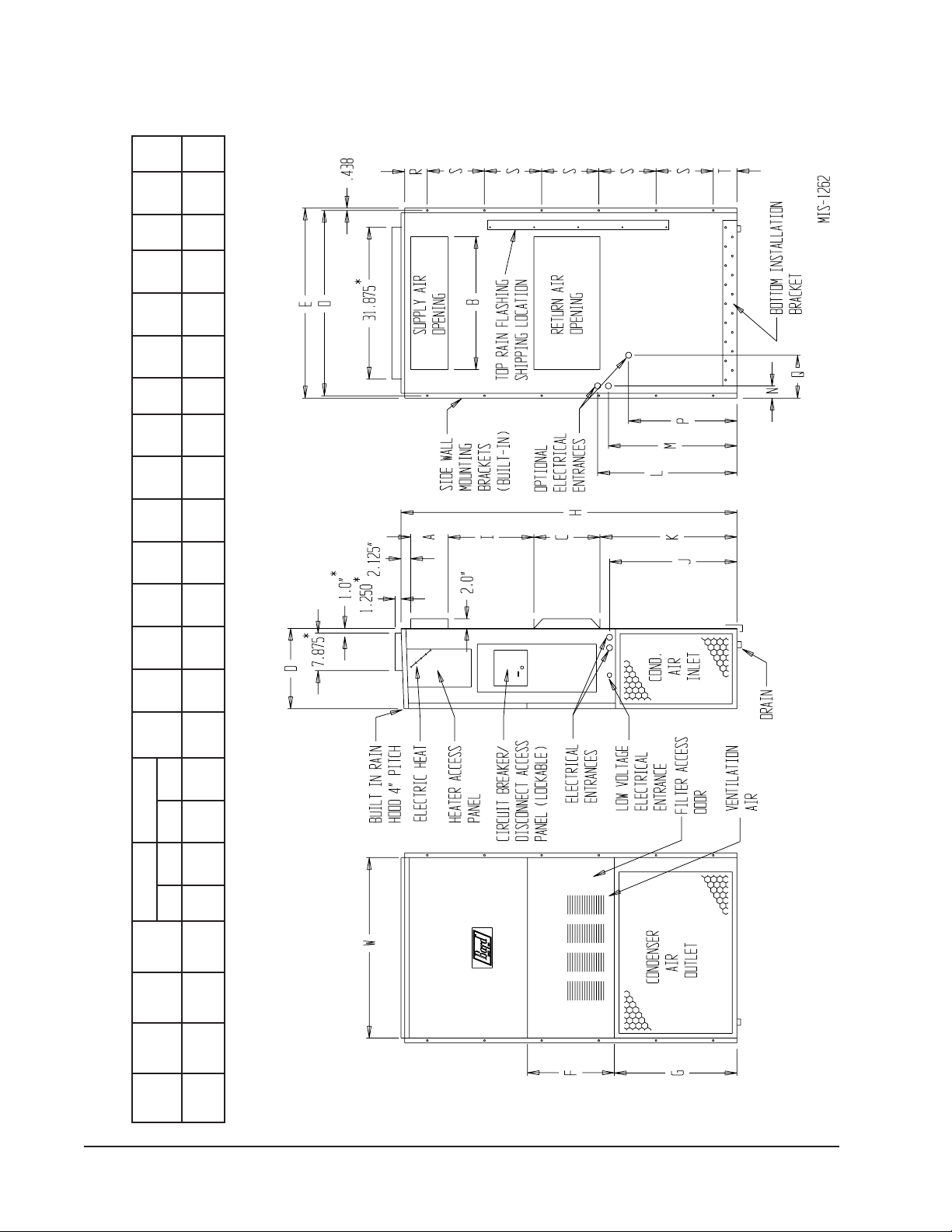

FIGURE 1

UNIT DIMENSIONS

EFGIJKLMNOPQRSTABCB

DIMENSIONS OF BASIC UNIT (NOMINAL)

ylppuSnruteR

thgieH

)H(

htpeD

)D(

htdiW

)W(

ledoM

Manual 2100-193O

Page 6 of 26

03HW

FRONT VIEW BACK VIEWSIDE VIEW

002.83521.71365.0788.788.7288.3188.7200.0405.8157.5239.7157.6257.8252.9200.7257.291.9357.2241.991.400.2100.5

OPTIONAL TOP OUTLET (FACTORY INSTALLED ONLY) FOR WH30 AND WH36 MODELS ONLY.

63HW

*

2

---

---

---

---

---

---

---

---

eziSeriW

dnuorG

01

---

---

01

---

---

---

---

---

---

---

---

---

---

---

---

---

01

01

---

---

---

01

01

---

---

---

---

---

---

---

---

---

---

---

---

rewoPdleiF

eziSeriW

---

2

---

esuFlanretxE

tiucriCro

mumixaM

rekaerB

---

1

---

eriW

eriW

tiucriC

---

ATKCBTKCATKCBTKCATKCBTKCATKCBTKC

---

eziS

01

eziS

8

rekaerB

530508

yticapmA

muminiM

tiucriC

4

dnuorG

2

rewoP

TABLE 3

dleiF

2

lanretxE

roesuF

mumixaM

1

ELECTRICAL SPECIFICATIONS

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

210101

210101

025203

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

010101

01

8

520405

---

---

---

---

---

---

---

---

------

---

---

---

---

---

---

---

---

---

41

210101

41

210101

8

51

025203

---

01

--8

---

03

---

05

---

62

---

05

01

8

8

4

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

01

01

04

01

--6

---

03

---

06

---

62

---

35

01

8

6

4

060809

6

6

06

06

25

35

8

4

---

---

---

---

---

---

---

---

---

---

010101

01

888

520405

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

01

41

41

51

05

4

yticapmA

muminiM

tiucriC

42

.oN

detaR

111

dnAstloV

esahP

stiucriC

rewoP

dleiF

Z0A-,00A-103HW

91

05

67

111

1-802/032

50A-

Z0B-,00B-103HW

ledoM

3 01A-

01

91

111

42

62

723597

1

1

1

1-802/032

73

64

3-802/032

02

837405

38

2r

2ro1

111

o1

3-802/032

3-064

60B-

60C-

Z0C-,0

0C-103HW

3 90B-

3 90C-

50A-

Z0A-,00A-163HW

5 51C-

3 01A-

60B-

Z0B-,00B-163HW

5 51A-

11

0252

62

1

111

1

3-064

60C-

Z0C-,00C-163HW

5 51C-

5 51B-

3 90B-

3 90C-

National Electric Code (latest revision), Article 310 for power conductor sizing.

1 Maximum size of the time delay fuse or HACR type circuit breaker for protection of field wiring conductors.

2 Based on 75° copper wire. All wiring must conform to the National Electrical Code and all local codes.

3 Maximum KW that can operate with heat pump on these "Minimum Circuit Ampacity" values are to be used for sizing the field power conductors. Refer to the

power conductor sizing.

4 These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electrical Code (latest version), Article 310 for

310 regarding Ampacity Adjustment Factors when more than three conductors are in a raceway.

Not available on dehumidification models.

5

CAUTION: When more than one field power conductor circuit is run through one conduit, the conductors must be derated. Pay special attention to note 8 of table

Not available in top outlet version.

Manual 2100-193O

Page 7 of 26

Refer to Table 12 for maximum static pressure available

for duct design.

Design the duct work according to methods given by the

Air Conditioning Contractors of America (ACCA).

When duct runs through unheated spaces, it should be

insulated with a minimum of one inch of insulation.

Use insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect the

duct work to the equipment in order to keep the noise

transmission to a minimum.

A 1/4 inch clearance to combustible material for the

first three (3) feet of duct attached to the outlet air frame

is required. See Wall Mounting Instructions and

Figures 3, 4, 7 & 8 for further details.

Ducts through the walls must be insulated and all joints

taped or sealed to prevent air or moisture entering the

wall cavity.

FRESH AIR INTAKE

All units are built with fresh air inlet slots punched in

the service panel.

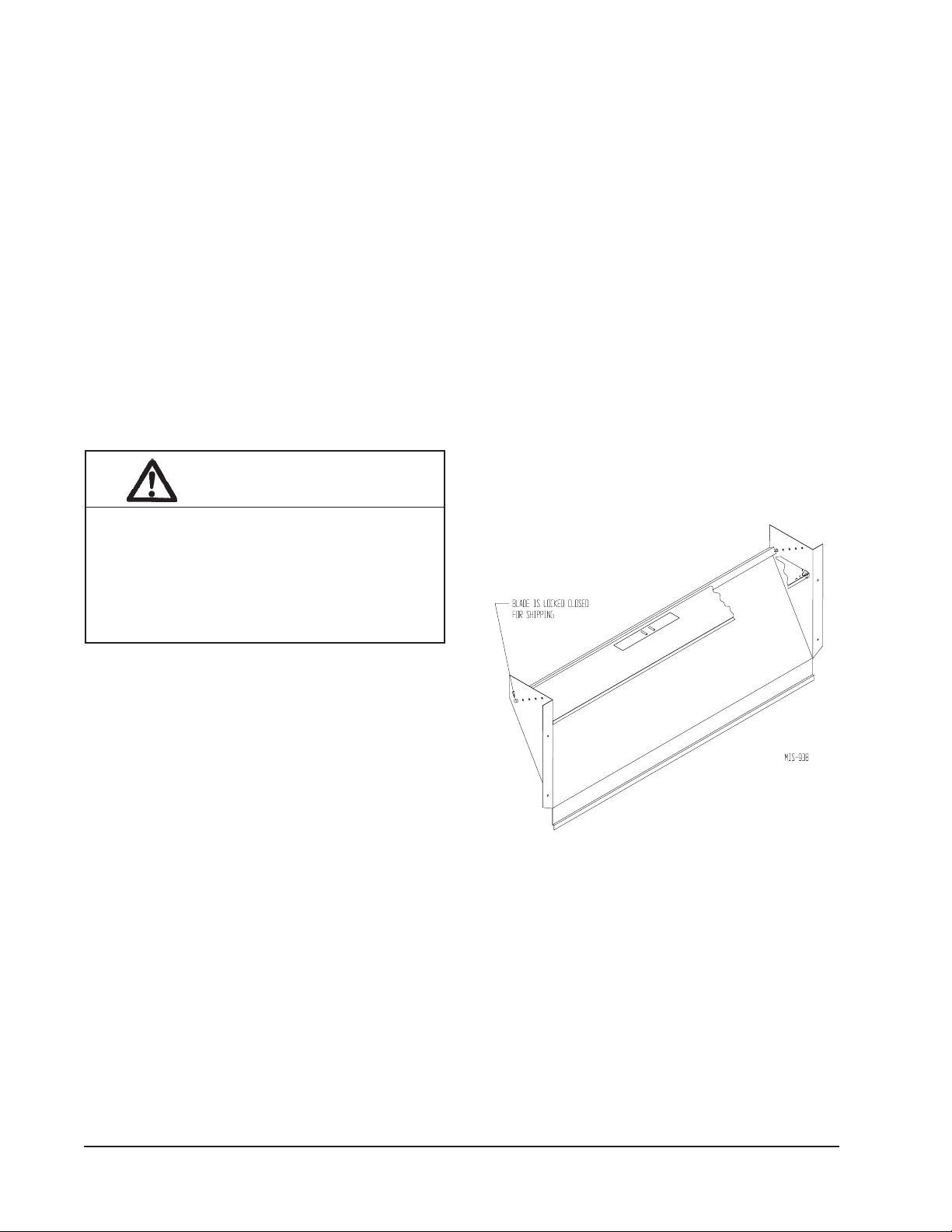

If the unit is equipped with a fresh air damper assembly,

the assembly is shipped already attached to the unit.

The damper blade is locked in the closed position. To

allow the damper to operate, the maximum and

minimum blade position stops must be installed. See

Figure 2.

All capacity, efficiency and cost of operation

information as required for Department of Energy

“Energyguide” Fact Sheets is based upon the fresh air

blank-off plate in place and is recommended for

maximum energy efficiency.

The blank-off plate is available upon request from the

factory and is installed in place of the fresh air damper

shipped with each unit.

CAUTION

Some installations may not require any

return air duct. A metallic return air grille is

required with installations not requiring a

return air duct. The spacing between

louvers on the grille shall not be larger than

5/8 inches.

Any grille that meets the 5/8 inch louver criteria may be

used. It is recommended that Bard Return Air Grille Kit

RG-2 through RG-5 or RFG-2 through RFG-5 be

installed when no return duct is used. Contact

distributor or factory for ordering information. If using

a return air filter grille, filters must be of sufficient size

to allow a maximum velocity of 400 fpm.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

FILTERS

A 1-inch throwaway filter is supplied with each unit.

The filter slides into position making it easy to service.

This filter can be serviced from the outside by removing

the service door. A 1-inch washable filter and a 2-inch

pleated filter are also available as optional accessories.

The internal filter brackets are adjustable to

accommodate the two inch filter by loosening two

screws in each bracket assembly and sliding the brackets

apart to the required width and retightening the four

screws.

FIGURE 2

FRESH AIR DAMPER ASSEMBLY

CONDENSATE DRAIN

A plastic drain hose extends from the drain pan at the

top of the unit down to the unit base. There are

openings in the unit base for the drain hose to pass

through. In the event the drain hose is connected to a

drain system of some type, it must be an open or vented

type system to assure proper drainage.

Manual 2100-193O

Page 8 of 26

INSTALLATION INSTRUCTIONS

WALL MOUNTING INFORMATION

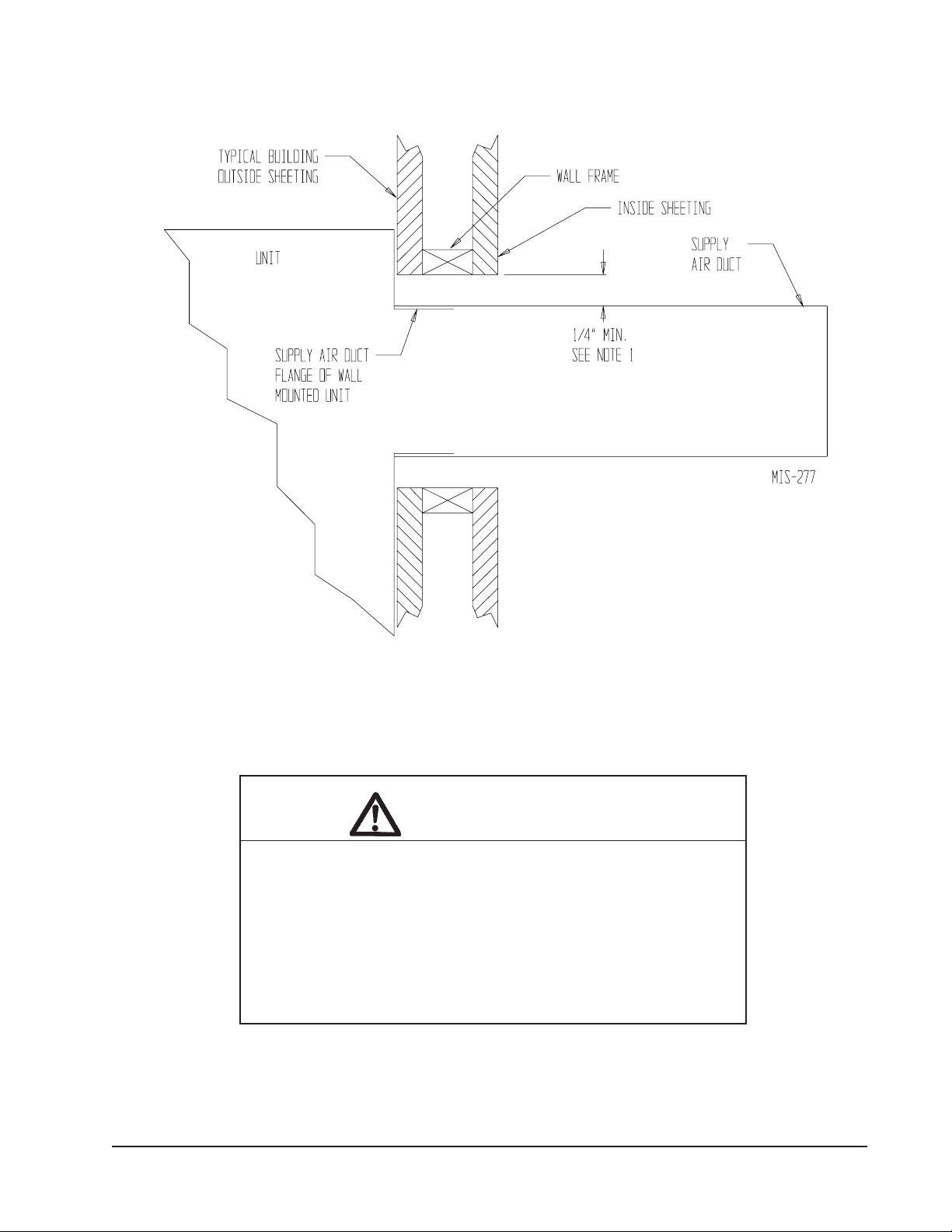

1. Two holes, for the supply and return air openings,

must be cut through the wall as shown in Figure 3.

2. On wood-frame walls, the wall construction must be

strong and rigid enough to carry the weight of the

unit without transmitting any unit vibration.

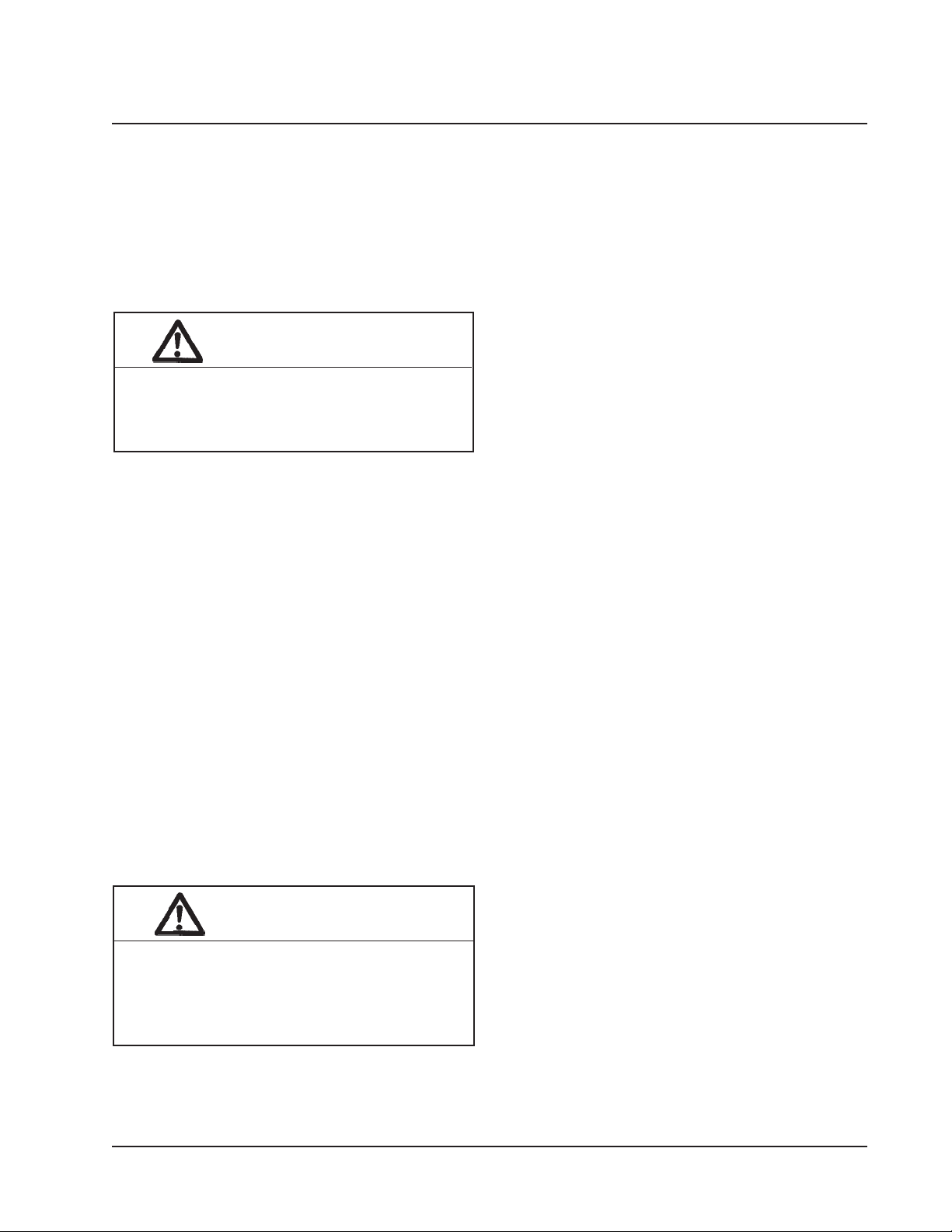

WARNING

Fire hazard can result if 1/4 inch clearance

to combustible materials for supply air duct

is not maintained. See Figure 3.

3. Concrete block walls must be thoroughly inspected

to insure that they are capable of carrying the

weight of the unit installed.

MOUNTING THE UNIT

1. These units are secured by wall mounting brackets

which secure the unit to the outside wall surface at

both sides. A bottom mounting bracket is provided

for ease of installation, but is not required.

2. The unit itself is suitable for “0” inch clearance, but

the supply air duct flange and the first 3 feet of supply

air duct require a minimum of 1/4 inch clearance to

combustible material. If a combustible wall, use a

minimum of 28½" x 8½" dimensions for sizing.

However, it is generally recommended that a 1-inch

clearance is used for ease of installation and

maintaining the required clearance to combustible

material. The supply air opening would then be

30" x 10". See Figures 3, 4, 7 and 8 for details.

3. Locate and mark lag bolt locations and bottom

mounting bracket location. See Figure 3.

4. Mount bottom mounting bracket, if used.

5. Hook top rain flashing under back bend of top. Top

rain flashing is shipped secured to the back of the unit

on the right side.

6. Position unit in opening and secure with 5/16 lag

bolts; use 7/8 inch diameter flat washers on the lag

bolts.

7. Secure rain flashing to wall and caulk across entire

length of top. See Figure 3.

8. For additional mounting rigidity, the return air and

supply air frames or collars can be drilled and

screwed or welded to the structural wall itself

(depending upon wall construction). Be sure to

observe required clearance if combustible wall.

9. On side-by-side installations, maintain a minimum of

20 inches clearance on right side to allow access to

heat strips and control panel and to allow proper

airflow to the outdoor coil. Additional clearance may

be required to meet local or national codes.

TOP OUTLET ONLY

1. Remove airframe angles from the back of the unit.

2. Coat angles with two 1/8" beads of silicone as shown.

Silicone is shipped in the control panel. See Figure 5.

3. Secure angles to the top of the unit with 14 screws

provided. Use prepunched holes provided. Do not

relocate. See Figure 5.

4. After installation of duct work, seal around airframe

and duct work to provide a rain tight seal.

5. It is strongly recommended, but not required, that this

unit be installed under a soffit area large enough to

shield the top of the unit. See Figure 6.

WARNING

Failure to provide the 1/4 inch clearance

between the supply duct and a combustible

surface for the first 3 feet of duct can result

in fire.

Manual 2100-193O

Page 9 of 26

FIGURE 3

MOUNTING INSTRUCTIONS

Manual 2100-193O

Page 10 of 26

FIGURE 4

ELECTRIC HEAT CLEARANCE

Side section view of supply air duct for wall mounted unit showing 1/4" clearance to combustible surfaces.

WARNING

A minimum of 1/4" clearance must be maintained between the

supply air duct and combustible materials. This is required for

the fist three (3) feet of ducting.

It is important to insure that the 1/4" minimum spacing is

maintained at all points.

Failure to do this could result in overheating the combustible

material and may result in a fire.

Manual 2100-193O

Page 11 of 26

FIGURE 5

ATTACHING TOP OUTLET AIRFRAMES TO UNIT

FIGURE 6

UNIT WITH TOP OUTLET MOUNTED UNDER OVERHANG

Manual 2100-193O

Page 12 of 26

FIGURE 7

WALL-MOUNTING INSTRUCTIONS

SEE FIGURE 3 – MOUNTING INSTRUCTIONS

FIGURE 8

WALL-MOUNTING INSTRUCTIONS

SEE UNIT DIMENSIONS, FIGURE 1,

FOR ACTUAL DIMENSIONS

SEE FIGURE 1 FOR

DUCT DIMENSIONS

Manual 2100-193O

Page 13 of 26

FIGURE 9

COMMON WALL-MOUNTING INSTALLATIONS

Manual 2100-193O

Page 14 of 26

WIRING — MAIN POWER

Refer to the unit rating plate for wire sizing information

and maximum fuse or “HACR Type” circuit breaker

size. Each outdoor unit is marked with a “Minimum

Circuit Ampacity”. This means that the field wiring

used must be sized to carry that amount of current.

Depending on the installed KW of electric heat, there

may be two field power circuits required. If this is the

case, the unit serial plate will so indicate. All models

are suitable only for connection with copper wire. Each

unit and/or wiring diagram will be marked “Use Copper

Conductors Only”. These instructions must be adhered

to. Refer to the National Electrical Code (NEC) for

complete current carrying capacity data on the various

insulation grades of wiring material. All wiring must

conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75ºC

copper) for all models, including the most commonly

used heater sizes. Also shown are the number of field

power circuits required for the various models with

heaters.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or “HACR Type” circuit breaker that is to

be used with the equipment. The correct size must be

used for proper circuit protection and also to assure that

there will be no nuisance tripping due to the momentary

high starting current of the compressor motor.

The disconnect access door on this unit may be locked to

prevent unauthorized access to the disconnect. To

convert for the locking capability, bend the tab located

in the bottom left hand corner of the disconnect opening

under the disconnect access panel straight out. This tab

will now line up with the slot in the door. When shut, a

padlock may be placed through the hole in the tab

preventing entry.

If no motorized vent option is used, nine (9) wires

should be run from the thermostat subbase to the 24V

terminal board in the unit. A nine (9) conductor, 18

gauge copper color-coded thermostat cable is

recommended. If a motorized vent option is used,

terminal O1 on the unit low voltage terminal block will

also be used. This requires a ten (10) conductor

thermostat cable to be run. The connection points are

shown in Figure 10.

LOW VOLTAGE CONNECTIONS

These units use a grounded 24 volt AC low voltage

circuit.

The "R" terminal is the hot terminal and the "C"

terminal is grounded.

"G" terminal is the fan input.

"Y" terminal is the compressor input for cooling and

heat pump.

"B/W1" terminal is the reversing valve input. The

reversing valve must be energized for heating mode.

"R" terminal is 24 VAC hot.

"C" terminal is 24 VAC grounded.

"L" terminal is compressor lockout output. This

terminal is activated on a high or low pressure trip by the

electronic heat pump control. This is a 24 VAC output.

"W2" terminal is second stage heat (if equipped).

"01" terminal is the ventilation input. This terminal

energizes any factory installed ventilation option.

"E" terminal is the emergency heat input. This terminal

energizes the emergency heat relay.

WIRING — LOW VOLTAGE WIRING

230/208V, 1 phase and 3 phase equipment dual primary

voltage transformers. All equipment leaves the factory

wired on 240V tap. For 208V operation, reconnect from

240V to 208V tap. The acceptable operating voltage

range for the 240 and 208V taps are shown in Table 4:

TABLE 4

OPERATING VOLTAGE RANGE

PATEGNAR

V042612-352

V802781-022

NOTE: The voltage should be measured at the

field power connection point in the

unit and while the unit is operating at

full load (maximum amperage

operating condition.)

LOW VOLTAGE CONNECTIONS

FOR DDC CONTROL

Fan Only Energize G

Cooling Mode Energize Y, G

Heat Pump Heating Energize Y, G, B

2nd Stage Heating Energize G, W2, Y, B/W1

(if employed)

Ventilation Energize G, O1

Emergency Heat Energize B, W2, E, G

Manual 2100-193O

Page 15 of 26

FIGURE 10

LOW VOLTAGE WIRING

Manual 2100-193O

Page 16 of 26

TABLE 5

THERMOSTAT WIRE SIZE

remrofsnarT

AVALFeguaGeriW

553.2

mumixaM

ecnatsiD

teeFnI

eguag02

eguag81

eguag61

eguag41

eguag21

54

06

001

061

052

OPTIONAL OUTDOOR THERMOSTAT

APPLICATIONS

Thus, not requiring the optional compressor cut-off

thermostat or the electric heat cut-off thermostat option.

Since most equipment at the time of manufacture is not

designated for any specific destination of the country and

are installed in areas not approaching the lower outdoor

temperature range, outdoor thermostats are not factory

installed as standard equipment, but are offered as an

option. There are also different applications for applying

outdoor thermostats. The set point of either type of outdoor

thermostat application is variable with geographic region

and sizing of the heating equipment to the individual

structure. Utilization of the heating Application Data, and

the heat loss calculation of the building are useful in

determining the correct set points.

Temperature and Humidity Controller #8403-060, along

with the Outdoor Sensor option Part #8403-061, can be

used to:

•Limit minimum outdoor temperature for cooling option.

• Limit minimum outdoor temperature for heat pump option.

•Inhibit electric heat operation for heat pumps above

selected outdoor temperature.

FIGURE 11

COMPRESSOR CUTOFF THERMOSTAT WIRING

4 & 10KW 1 PH — 6 & 9KW 3 PH

OPTIONAL COMPRESSOR CUTOFF

THERMOSTAT (See Figures 11 and 12)

Heat pump compressor operation at outdoor temperatures

below 0°F are neither desirable nor advantageous in term

of efficiency. An outdoor thermostat can be applied to

take the mechanical heating (compressor) off line, and

send the (compressor) signal to energize electric heat in

its place (to make electric heat first stage heating). This

can also be applied to bank the quantity of available

electric heat. For example: A heat pump operates with

10KW second stage heat – once the outdoor thermostat

has switched then operates 15KW without the compressor

as first stage heat.

NOTE: The additional LAB (low ambient bypass) relay is

required to prevent heater operation during low

temperature cooling operation.

FIGURE 12

COMPRESSOR CUTOFF THERMOSTAT WIRING

15KW 1 PH & 3 PH

Manual 2100-193O

Page 17 of 26

ELECTRIC HEAT HOLD-OFF (See Figures 13

and 14)

In other applications, it is desirable to disable the

operation of the electric heat until outdoor temperatures

have reached a certain design point. This won't allow

the electric heat to come on as second stage heating

unless the outdoor temperature is below the set point of

the outdoor thermostat. This is done to maximize

ELECTRIC HEAT HOLD-OFF WIRING

4 & 10KW 1 PH — 6 & 9KW 3 PH

efficiency by utilizing the heat pump to bring the

conditioned space temperature up, rather than cycling on

the electric heat due a second stage call for heat from the

thermostat on start-up coming off a night setback

condition or someone increasing the thermostat set

point. (NOTE: Some programmable thermostats do

have a built-in time delay for pulling in second stage

heat when coming off setback conditions.)

FIGURE 13

Manual 2100-193O

Page 18 of 26

FIGURE 14

ELECTRIC HEAT HOLD-OFF WIRING

15KW 1 PH & 3 PH

TABLE 6

WALL THERMOSTAT

tatsomrehTserutaeFetanimoderP

850-3048

)1511D0225HT(

060-3048

)544-0211(

taehegats2,loocegats2

elbammargorP-noNcinortcelE

revoegnahclaunaMrootuA

taehegats3,loocegats2

cinortcelEelbammargorP

revoegnahclaunaMrootuA

tatsidimuHni-tliubhtiw

Manual 2100-193O

Page 19 of 26

START UP

IMPORTANT INSTALLER NOTE

For improved start-up performance, wash the indoor

coil with a dishwashing detergent.

FIGURE 15

START UP LABEL

IMPORTANT

CRANKCASE HEATERS

All units are provided with some form of compressor

crankcase heat.

All single and three phase models have an insertion

well-type heater located in the lower section of the

compressor housing. This is a self-regulating type

heater that draws only enough power to maintain the

compressor at a safe temperature.

Some form of crankcase heat is essential to prevent

liquid refrigerant from migrating to the compressor,

causing oil pump out on compressor start up and

possible valve failure due to compressing a liquid.

The decal in Figure 15 is affixed to all outdoor units

detailing start up procedure. This is very important.

Please read carefully.

SERVICE HINTS

1. Caution owner/operator to maintain clean air filters at

all times. Also, not to needlessly close off supply

and return air registers. This reduces airflow through

the system, which shortens equipment service life as

well as increasing operating costs.

2. Switching to heating cycle at 75°F or higher outside

temperature may cause a nuisance trip of the remote

reset high pressure switch. Turn thermostat off then

on to reset the high pressure switch.

3. The heat pump wall thermostats perform multiple

functions. Be sure that all function switches are

correctly set for the desired operating mode before

trying to diagnose any reported service problems.

4. Check all power fuses or circuit breakers to be sure

they are the correct rating.

5. Periodic cleaning of the outdoor coil to permit full

and unrestricted airflow circulation is essential.

SEQUENCE OF OPERATION

COOLING – Circuit R-Y makes at thermostat pulling

in compressor contactor, starting the compressor and

outdoor motor. The G (indoor motor) circuit is

automatically completed on any call for cooling

operation or can be energized by manual fan switch on

subbase for constant air circulation.

THESE PROCEDURES MUST BE

FOLLOWED AT INITIAL START UP

AND AT ANY TIME POWER HAS

BEEN REMOVED FOR 12 HOURS

OR LONGER.

TO PREVENT COMPRESSOR DAMAGE

WHICH MAY RESULT FROM THE PRESENCE

OF LIQUID REFRIGERANT IN THE

COMPRESSOR CRANKCASE:

1. Make certain the room thermostat is in the

"off" position (the compressor is not to

operate).

2. Apply power by closing the system

disconnect switch. This energizes the

compressor heater which evaporates the

liquid refrigerant in the crankcase.

3. Allow 4 hours or 60 minutes per poind of

refrigerant in the system as noted on the

unit rating plate, whichever is greater.

4. After properly elapsed time, the thermostat

may be set to operate the compressor.

5. Except as required for safety while

servicing. Do not open system

disconnect switch.

HEATING – A 24V solenoid coil on reversing valve

controls heating cycle operation. Two thermostat

options, one allowing “Auto” changeover from cycle to

cycle and the other constantly energizing solenoid coil

during heating season and thus eliminating pressure

equalization noise except during defrost, are to be used.

On “Auto” option, a circuit is completed from R-W1

and R-Y on each heating “on” cycle, energizing

reversing valve solenoid and pulling in compressor

contactor starting compressor and outdoor motor. R-G

also make starting indoor blower motor. Heat pump

heating cycle now in operation. The second option has

no “Auto” changeover position, but instead energizes

the reversing valve solenoid constantly whenever the

system switch on subbase is placed in “Heat” position,

the “B” terminal being constantly energized from R. A

thermostat demand for heat completes R-Y circuit

pulling in compressor contactor starting compressor and

outdoor motor.

R-G make starting indoor blower motor.

7961-061

Manual 2100-193O

Page 20 of 26

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on all

units so that the system operating pressures can be

observed. Pressure tables can be found on Page 25

covering all models. It is imperative to match the

correct pressure table to the unit by model number.

DEFROST CYCLE

The defrost cycle is controlled by temperature and time

on the solid state heat pump control. See Figure 16.

When the outdoor temperature is in the lower 40° F

temperature range or colder, the outdoor coil

temperature is 32° F or below. This coil temperature is

sensed by the coil temperature sensor mounted near the

bottom of the outdoor coil. Once coil temperature

reaches 30° F or below, the coil temperature sensor

sends a signal to the control logic of the heat pump

control and the defrost timer will start.

After 60 minutes at 30° F or below, the heat pump

control will place the system in the defrost mode.

During the defrost mode, the refrigerant cycle switches

back to the cooling cycle, the outdoor motor stops,

electric heaters are energized, and hot gas passing

through the outdoor coil melts any accumulated frost.

When the temperature rises to approximately 57° F, the

coil temperature sensor will send a signal to the heat

pump control, which will return the system to heating

operations automatically.

If some abnormal or temporary condition such as a high

wind causes the heat pump to have a prolonged defrost

cycle, the heat pump control will restore the system to

heating operation automatically after 10 minutes.

The heat pump defrost control board has an option of 30,

60 or 90-minute setting. All models are shipped from

the factory on the 60-minute pin. If special

FIGURE 16

DEFROST CONTROL BOARD

circumstances require a change to another time, remove

the wire from the 60 minute terminal and reconnect to

the desired terminal. The manufacturer's

recommendation is for 60 minute defrost cycles. Refer

to Figure 16.

There is a cycle speed up jumper on the control. This

can be used to reduce the time between defrost cycle

operation without waiting for time to elapse.

Use a small screwdriver or other metallic object, or

another 1/4 inch QC, to short between the SPEEDUP

terminals to accelerate the HPC timer and initiate

defrost.

Be careful not to touch any other terminals with the

instrument used to short the SPEEDUP terminals. It

may take up to 10 seconds with the SPEEDUP terminals

shorted for the speedup to be completed and the defrost

cycle to start.

As soon as the defrost cycle kicks in remove the

shorting instrument from the SPEEDUP terminals.

Otherwise the timing will remain accelerated and run

through the 1-minute minimum defrost length sequence

in a matter of seconds and will automatically terminate

the defrost sequence.

There is an initiate defrost jumper (sen jump) on the

control that can be used at any outdoor ambient during

the heating cycle to simulate a 0° coil temperature. This

can be used to check defrost operation of the unit

without waiting for the outdoor ambient to fall into the

defrost region.

By placing a jumper across the SEN JMP terminals (a 1/4

inch QC terminal works best) the defrost sensor mounted

on the outdoor coil is shunted out and will activate the

timing circuit. This permits the defrost cycle to be

checked out in warmer weather conditions without the

outdoor temperature having to fall into the defrost region.

In order to terminate the defrost test the SEN JMP

jumper must be removed. If left in place too long the

compressor could stop due to the high

pressure control opening because of

high pressure condition created by

operating in the cooling mode with

outdoor fan off. Pressure will rise

fairly fast as there is likely no actual

frost on the outdoor coil in this

artificial test condition.

There is also a 5-minute compressor

time delay function built into the HPC.

This is to protect the compressor from

short cycling conditions. In some

instances it is helpful to the service

technician to override or speed up this

timing period, and shorting out the

SPEEDUP terminals for a few seconds

can do this.

Manual 2100-193O

Page 21 of 26

TROUBLESHOOTING

SOLID STATE HEAT PUMP CONTROL

TROUBLESHOOTING PROCEDURE

1. Turn on AC power supply to indoor and outdoor

units.

2. Turn thermostat blower switch to “Fan On” – the

indoor blower should start. (If it doesn't, troubleshoot

indoor unit and correct problem).

TROUBLESHOOTING

MOTPMYSSESUACELBISSOPKCEHCOTTAHWRIAPERROKCEHCOTWOH

ezigrenetonseod

rotomroodtuonaF

nurtonseod

gnitaehrognilooc(

ezigreneton

)ylnognitaeh(

otniogtonlliwtinU

tsorfed

)ylnognitaeh(

tsorfedfo

)ylnognitaeh(

Manual 2100-193O

Page 22 of 26

rotcatnocrosserpmoC

)gnitaehrognilooc(

evitcefed

.tcerroc

)tsorfedgnirudtpecxe

seodevlavgnisreveR

tuoemoctonlliwtinU

evitcefed

evitcefed

evitcefed

evitcefed

evitcefed

gniriwtiucriclortnoC,tinutanoitcennocRrofkcehC

tuokcolrosserpmoC.1

.2

trohsrosserpmoC

noitcetorpelcyc

lortnocpmuptaeH

evitcefedrotcatnoCliocdetrohsroneporofkcehC

tongnisahprewoP

evitcefedrotoMdetrohsroneporofkcehC

roticapacrotoM

lortnocpmuptaeH

evlavgnisreveR

evitcefedliocdionelos

lortnocpmuptaeH

rosneserutarepmeT

lortnocpmuptaehro

rosneserutarepmeT

lortnocpmuptaehro

TABLE 7

gnidniw

C-Bdna

3. Turn thermostat blower switch to “Auto” position.

Indoor blower should stop.

4. Set system switch to heat or cool. Adjust thermostat

to call for “Heat” or “Cool” – the indoor blower,

compressor and outdoor fan should start.

NOTE: If there was no power to 24 volt transformer, the

compressor and outdoor fan motor will not start

for 5 minutes. This is because of the compressor

short cycle protection.

C-RneewtebV42dna

neewtebV42rofkcehC

hgihssorcakcehC

.hctiwserusserp

elbissoprehtollakcehC

560-0012launaM.sesuac

gnidniwrotom

)CN-moC(lortnocpmup

pudeepsssorcarepmuJ

.etunimenonihtiw

.1

lortnocpmuptaehnoC-1L

.2

C-CCneewtebV42rofkcehC

lortnocpmuptaehnoC-Ydna

esahpnoDELderrofkcehC

).ylnostinuesahp3(.rotinom

kcehC.gnitarroticapackcehC

.roticapacdetrohsroneporof

taehnoyalernafssorcakcehC

liocdetrohsroneporofkcehCliocdionelosecalpeR

C-VRneewtebV42rofkcehC

.1

.2

rosneserutarepmettcennocsiD

.1

ssorcarepmujdnadraobmorf

nesdnaslanimretpudeeps

dluohssihT.slanimretpmuj

.2

ahguorhtogottinuehtesuac

.etunimenonihtiwelcyctsorfed

.1

esuacdluohssihT.slanimret

tsorfedfotuoemocottinueht

.2

lortnocpmuptaeh

.hctiws

sdnoces01retfarepmuj

lortnocpmuptaehecalpeR

rotcatnocecalpeR

rotomecalpeR

roticapacecalpeR

lortnocpmuptaehecalpeR

gniriwtiucriclortnockcehC

lortnocpmuptaehecalpeR

rosneserutarepmet

.lortnocpmuptaehecalper

.rosneserutarepmret

.lortnocpmuptaehecalper

rewopottinuroodtuootnoitcennocRnuR

tatsomrehtnrutC-LneewtebegatlovonfI

erusserphgihteserotniaganodnaffo

tonlliwdnaneposihctiwserusserphgihfI

.hctiwsersserphgihecalper,teser

pudeepsrepmuj,C-CCneewtebegatlovonfI

dluohsrewopsdnoces01nihtiwdnalanimret

pudeepsevomeR.C-CCneewtebraeppa

.tinuehtotsdaelrewopowthctiwS

ecalper,elcyctsorfedhguorhtseogtinufI

,elcyctsorfedhguorhtogtonseodtinufI

ecalper,elcyctsorfedfotuosemoctinufI

,elcyctsorfedfotuoemoctonseodtinufI

CHECKING TEMPERATURE SENSOR

OUTSIDE UNIT CIRCUIT

1. Disconnect temperature sensor from board and from

outdoor coil.

2. Use an ohmmeter and measure the resistance of the

sensor. Also use ohmmeter to check for short or

open.

3. Check resistance reading to chart of resistance use

sensor ambient temperature. (Tolerance of part is

± 10%.)

4. If sensor resistance reads very low, then sensor is

shorted and will not allow proper operation of the

heat pump control.

5. If sensor is out of tolerance, shorted, open or reads

very low ohms then it should be replaced.

TEMPERATURE "F" VS. RESISTANCE "R" OF TEMPERATURE SENSOR

FR FR FR FR

0.52-

0.42-

0.32-

0.22-

0.12-

0.02-

0.91-

0.81-

0.71-

0.61-

0.51-

0.41-

0.31-

0.21-

0.11-

0.01-

0.9-

0.8-

0.7-

0.6-

0.5-

0.4-

0.3-

0.2-

0.1-

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0.01

0.11

0.21

178691

990091

585381

813771

982171

784561

409951

925451

553941

473441

675931

659431

605031

912621

980221

801811

272411

575011

010701

475301

062001

46079

18939

80019

93188

17358

99628

12108

23677

03257

01927

07607

70586

81466

99346

94426

56506

54785

0.31

0.41

0.51

0.61

0.71

0.81

0.91

0.02

0.12

0.22

0.32

0.42

0.52

0.62

0.72

0.82

0.92

0.03

0.13

0.23

0.33

0.43

0.53

0.63

0.73

0.83

0.93

0.04

0.14

0.24

0.34

0.44

0.54

0.64

0.74

0.84

0.94

0.05

58965

48255

04635

15025

41505

82094

09574

00264

55844

45534

59224

77014

89893

75783

25673

38563

84553

54543

47533

43623

32713

04803

68992

75192

55382

77572

32862

29062

38352

69642

03042

48332

85722

05122

16512

98902

53402

69891

0.35

0.25

0.35

0.45

0.55

0.65

0.75

0.85

0.95

0.06

0.16

0.26

0.36

0.46

0.56

0.66

0.76

0.86

0.96

0.07

0.17

0.27

0.37

0.47

0.57

0.67

0.77

0.87

0.97

0.08

0.18

0.28

0.38

0.48

0.58

0.68

0.78

0.88

47391

76881

57381

98971

43471

48961

74561

22161

01751

01351

12941

44541

77141

02831

47431

73131

01821

29421

38121

38811

19511

70311

13011

26701

10501

74201

00001

0679

6259

9929

7709

2688

3568

9448

0528

7508

9687

6867

0.98

0.09

0.19

0.29

0.39

0.49

0.59

0.69

0.79

0.89

0.99

0.001

0.101

0.201

0.301

0.401

0.501

0.601

0.701

0.801

0.901

0.011

0.111

0.211

0.311

0.411

0.511

0.611

0.711

0.811

0.911

0.021

0.121

0.221

0.321

0.421

7057

4337

5617

0007

0486

3866

1356

3836

9326

8906

1695

7285

7965

0755

6445

6235

8025

4905

2894

3784

7674

3664

2654

4644

7634

4724

2814

3904

6004

1293

8383

7573

8763

1063

6253

2543

Manual 2100-193O

Page 23 of 26

FAN BLADE SETTING DIMENSIONS

Shown in Figure 17 are the correct fan blade setting

dimensions for proper air delivery across the outdoor

coil.

The suction line temperatures in Table 9 are based upon

80ºF dry bulb/67ºF wet bulb (50 percent R.H.)

temperature and rated airflow across the evaporator

during cooling cycle.

Any service work requiring removal or adjustment in the

fan and/or motor area will require that the dimensions

below be checked and blade adjusted in or out on the

motor shaft accordingly.

FIGURE 17

FAN BLADE SETTING

TABLE 8

FAN BLADE DIMENSION

ledoMAnoisnemiD

103HW

163HW

"52.1

REMOVAL OF FAN SHROUD

1. Disconnect all power to unit.

2. Remove the screws holding both grilles, one on each

side of unit, and remove grilles.

3. Remove screws holding fan shroud to condenser and

bottom – nine (9) screws.

4. Unwire condenser fan motor.

5. Slide complete motor, fan blade, and shroud assembly

out the left side of the unit.

6. Service motor/fan as needed.

7. Reverse steps to reinstall.

REFRIGERANT CHARGE

The correct system R-22 charge is shown on the unit

rating plate. Optimum unit performance will occur with

a refrigerant charge resulting in a suction line

temperature (6 inches from compressor) as shown in

Table 9.

TABLE 9

SUCTION LINE TEMPERATURES

detaR

ledoM

103HW001,185-6556-36

163HW001,115-9486-66

wolfriA

DOF59

erutarepmeT

DOF28

erutarepmeT

TABLE 10

INDOOR BLOWER PERFORMANCE

CFM AT 230 VOLTS

163HW,103HW

.P.S.E

HnI2O

0./059539/593,1513,1

1./039519/043,1072,1

2./019588/582,1091,1

3./558038/502,1001,1

4./008557/011,1000,1

5./------/500,1078

6./------/------

deepSwoLdeepShgiH

/lioCyrDlioCteW/lioCyrDlioCteW

TABLE 11

CFM AND ESP

j

detaR

ledoM

103HW

163HW

Rated CFM and ESP on high speed tap

MFC

000,1

001,1

j

detaR

PSE

03.

03.

003,1-039

053,1-039

TABLE 12

MAXIMUM ESP OF OPERATION

ELECTRIC HEAT ONLY

teltuOtnorFteltuOpoT

woL

ledoM

00A

103HW

50A

163HW

01A

51A

00B

103HW

60B

163HW

90B

51B

00C

103HW

60C

163HW

90C

51C

Values shown are for units equipped with standard 1"

throwaway filter or 1" washable filter. Derate ESP by

.15 for 2" pleated filter.

deepS

05.

04.

53.

53.

05.

04.

53.

53.

05.

05.

03.

03.

hgiH

deepS

05.

05.

04.

04.

05.

05.

54.

54.

05.

05.

04.

04.

woL

deepS

05.

04.

52.

AN

05.

AN

03.

AN

05.

AN

53.

AN

05.

05.

04.

AN

05.

AN

04.

AN

05.

AN

54.

AN

dednemmoceR

egnaRwolfriA

hgiH

deepS

Manual 2100-193O

Page 24 of 26

TABLE 13

COOLING PRESSURE (PSI) – OUTDOOR TEMPERATURE °F

AIR TEMPERATURE ENTERING OUTDOOR COIL °F

riAnruteR

ledoM

103HW

163HW

erutarepmeTerusserP5708580959001501011511

BDged57

BWged26

BDged08

BWged76

BDged58

BWged27

BDged57

BWged26

BDged08

BWged76

BDged58

BWged27

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

67

87

08

532

942

362

18

38

58

142

552

962

88

09

29

052

462

972

96

17

37

012

622

242

37

67

87

612

232

842

97

18

48

322

042

652

18

38

48

58

78

772

192

503

913

333

78

88

09

19

39

482

892

213

723

39

59

79

89

001

492

803

323

833

353

57

67

87

08

28

752

372

092

603

323

08

28

48

58

78

462

182

792

413

68

88

09

29

49

372

092

803

523

243

88

743

49

143

653

101

863

38

933

98

133

843

59

063

TABLE 14

HEATING PRESSURE (PSI) – OUTDOOR TEMPERATURE °F

AIR TEMPERATURE ENTERING OUTDOOR COIL °F

riAnruteR

ledoM

103HW07

163HW07

erutarepmeTerusserP050151025203530454055506

o

o

ediSwoL

ediSwoL

12

52

82

23

63

93

34

74

15

55

95

ediShgiH

341

841

351

951

561

271

081

881

791

702

712

22

52

82

13

43

83

24

64

05

55

06

ediShgiH

541

251

951

761

771

681

791

802

022

332

642

Low side pressure ± 2 psig

High side pressure ± 5 psig

Tables are based upon rated CFM (airflow) across the evaporator coil and should be found under section titled

“Refrigerant Charge” on Page 24 in manual. If there is any doubt as to correct charge being in the system, the

charge should be removed, system evacuated and recharged to serial plate instructions

.

36

76

822

932

56

07

062

572

Manual 2100-193O

Page 25 of 26

TABLE 15

OPTIONAL ACCESSORIES

LEDOMNOITPIRCSED

50A-03HWHEsegakcaPretaeH 1 X

01A-03HWHEsegakcaPretaeH 1 X

50A-63HWHEsegakcaPretaeH 1 X

01A-63HWHEsegakcaPretaeH 1 X

51A-63HWHEsegakcaPretaeH 1 X

60B-30HWHEsegakcaPretaeH 1 XX

90B-30HWHEsegakcaPretaeH 1 XX

51B-30HWHEsegakcaPretaeH 1 X

60C-30HWHEsegakcaPretaeH 1 XX

90C-30HWHEsegakcaPretaeH 1 XX

51C-30HWHEsegakcaPretaeH 1 XX

3-POBetalPffOknalB

3-DAFBrepmaDriAhserFcirtemoraB XXXXXX

3-DAFMrepmaDriAhserFdezirotoM XXXXXX

3-VRCtsuahxEhtiwrotalitneVlaicremmoC XXXXXX

3-MFIEtsuahxEhtiwrezimonocE

WH301-A

XXXXXX

XXXXXX

WH301-B

WH301-C

WH361-A

WH361-B

WH361-C

3-HMC)CPL(lortnoCerusserPwoL

7-HMC)CAL(lortnoCtneibmAwoL XXXXXX

9-HMCCPL+CAL XXXXXX

A41-HMC)TDO(tatsomrehTroodtuO XXXXXX

51-CMC)KS(tiKtratSXX

10-DPMWtiKrekaerBtiucriCXX

Manual 2100-193O

Page 26 of 26

A3A-VREWrotalitneVyrevoceRygrenEXXXX

A3C-VREWrotalitneVyrevoceRygrenEXX

XXXXXX

A50-BCMWtiKrekaerBtiucriCX

B30-BCMWtiKrekaerBtiucriCX

A60-BCMWtiKrekaerBtiucriCX

X

Loading...

Loading...