Bacharach MGS-250 Quick Start Guide

GAS DETECTOR

INSTALLATION GUIDE

P/N: 6490-9004

Revision 0

January 25, 2016

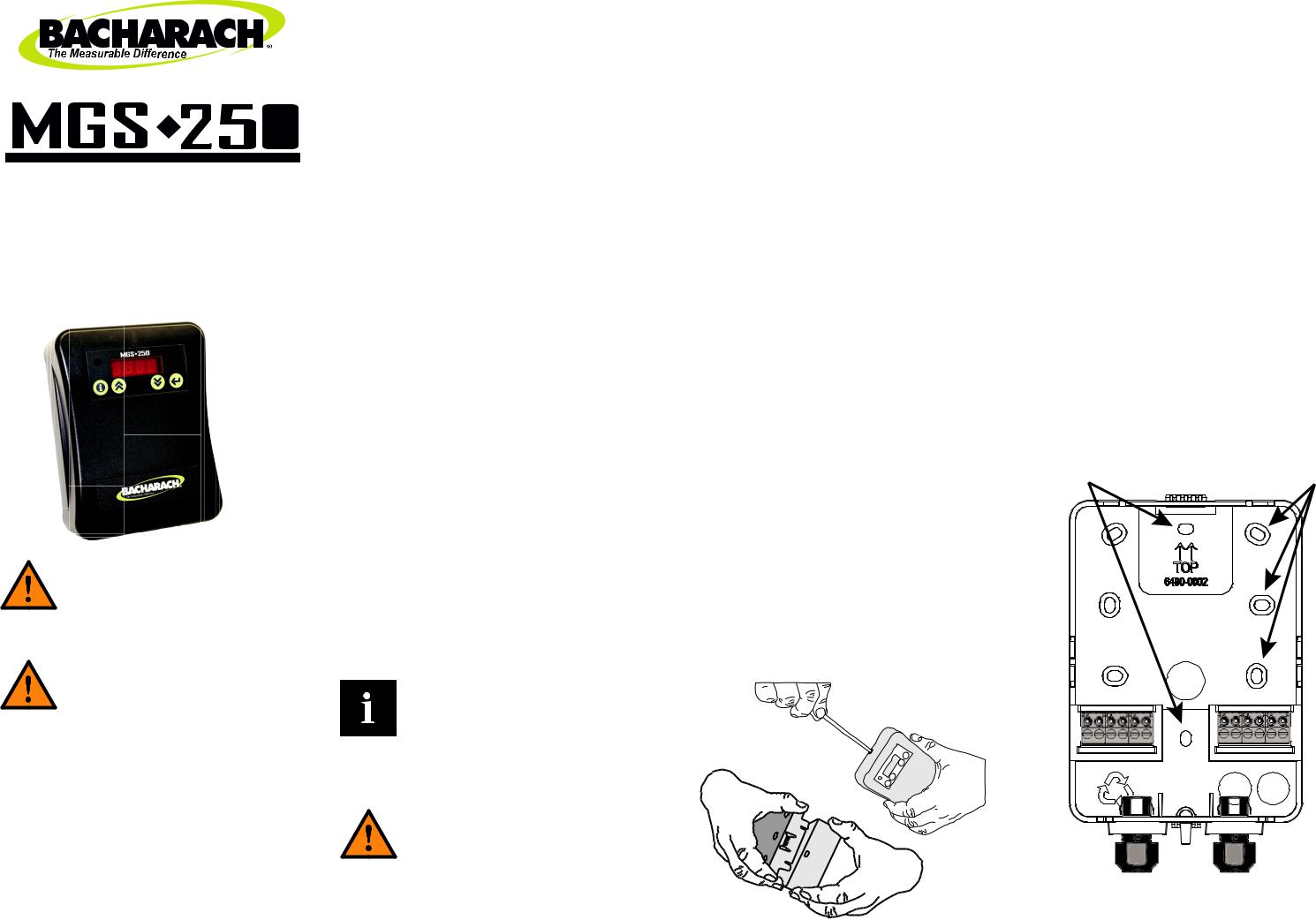

Sensor

Housing

CAUTION: DO NOT MOUNT the

MGS-250 in an area that may contain flammable liquids or vapors. Operation of electrical equipment in such an area constitutes a safety hazard.

WARNING: Strictly follow the instructions in the Gas Detector Manual (part number 6490-9000) available at www.MyBacharach.com.

1: OPERATING AREA AND CONDITIONS

The Bacharach MGS-250 is an instrument for the continuous monitoring of refrigerant gases.

The instrument is powered by 24V AC or DC. The output signal can be selected as either voltage or current. The on-board relay can be used to switch alarm devices.

2: SAFETY INSTRUCTIONS

USER MANUAL: Before using this equipment, carefully read and strictly follow the User Manual (part number 6490-9000). The user must fully understand and strictly observe the instructions. Use the equipment only for the purposes listed and under the conditions specified in those documents.

CODE COMPLIANCE: Comply with all local and national laws, rules and regulations associated with this equipment.

GENUINE PARTS: Use only genuine Bacharach spare parts and accessories, otherwise proper functioning of the equipment may be impaired.

TECHNICIAN USE ONLY: This unit must be installed by a suitably qualified technician who will install this unit in accordance with these instructions and the standards in their particular industry/country. Operators of the unit should be aware of the regulations and standards in their industry/country for the operation of this unit. These notes are only intended as a guide and the manufacturer bears no responsibility for the installation or operation of this unit.

Failure to install and operate the unit in accordance with these instructions and with industry guidelines may cause serious injury including death and the manufacturer will not be held responsible in this regard.

SAFE MOUNTING: This monitor must be connected by a marked, suitably located and easily reached switch or circuit-breaker as means of disconnection.

3: SPECIFICATIONS

Weight |

6.3 oz |

180 g |

|

and |

|||

4.0” x 5.5” x 1.5” |

102 x 140 x 37 mm |

||

Dimensions |

|||

|

|

||

|

|

|

|

Temperature |

-22° to 104° F |

-30° to 40° C |

|

Rating |

|||

|

|

||

|

|

|

|

Enclosure |

ABS plastic; UL ammability |

||

|

rating of 94V-0 |

||

|

|

||

Approvals |

CE, UL/CSA/IEC/EN 61010-1 |

||

|

|

|

|

NOTE: When installed in areas that may be subjected to water spray, the optional splash guard (P/N: 6900-0001) should be used in conjunction with the MGS-250. Weight and dimensions (above) do not include optional splash guard.

4: MOUNTING

IMPORTANT: Do not apply caulking or other material around the gas detector base. The gas detector relies on air exchange through the spaces between the base and the gas detector housing. Do not obstruct the small gap around the housing and the base with any material.

4: MOUNTING (CONTINUED)

ACCESSIBILITY: The mounting location of the monitor should allow it to be easily accessible for visual monitoring and servicing.

VIBRATION FREE LOCATION: Do NOT mount the MGS-250 directly to vibrating machinery as the vibrations may degrade the gas detector’s performance.

PLACEMENT GUIDELINES: The MGS-250 should be installed plumb and level and securely fastened to a rigid mounting surface.

WATER SPRAY: When installed in areas that may be subjected to water spray, the optional splash guard (P/N: 6900-0001) should be used in conjunction with the MGS-250.

ENVIRONMENTAL CONSIDERATIONS: Carefully consider the full range of environmental conditions to which the instruments will be exposed.

TARGET GAS CONSIDERATIONS: The physical data of the gas or vapor to be detected must be observed.

APPLICATION CONSIDERATIONS: The specifics of the application (for example, possible leaks, air movement/draft, etc.) must be observed.

ACCESSIBILITY CONSIDERATIONS: The degree of accessibility required for maintenance purposes must be granted.

ACCESSORY CONSIDERATIONS: The types of optional and accessory equipment that will be used with the system must be kept in mind.

ELECTRONIC CONSIDERATIONS: The system contains sensitive electronic components that can be easily damaged. Do not touch nor disturb any of these components.

Mount the MGS-250 according to the above considerations, product dimensions (see Section 3), maximum wiring lengths (see Section 5), and the corresponding mounting dimensions shown in the illustrations that follow.

To open the housing as received use a flat blade screwdriver and depress the top latch. While pushing the latch, grasp the back edge of the housing near the latch and pull the back away.

4: MOUNTING (CONTINUED)

When mounted, the housing is simply opened by pressing the top latch with a suitable screwdriver or other flat blade. With the top latch depressed pull the housing apart by grasping the sides and pulling straight out. With the housing separated the mounting base with terminal blocks will be visible.

STEP 1: Open the housing.

STEP 2: Position the base to the pre-determined (acceptable) mounting location. Use the gas detector base to mark the mounting locations as needed. The hole pattern on the back plate is sized to mount the gas detector onto various electrical junction boxes. The other holes may be used as needed to mount the gas detector to other structures, or onto a wall.

STEP 3 - FOR WALL MOUNT: Attach the MGS-250 base to the mounting surface using two #6 screws (provided) through two of the mounting holes, being careful not to over-tighten the screws.

STEP 3 - FOR JUNCTION BOX MOUNT: Attach the MGS-250 base to the junction box (using mounting hardware provided with your junction box) through the two junction box holes.

STEP 4: Unless you are ready to wire the device, carefully snap the cover onto the base unit.

Junction Box |

NOTE: Use #6 |

Flat Surface |

Mounting |

screw or smaller for |

Mounting Holes |

Holes (2 Places) |

wall mounting. |

(6 Places) |

|

|

|

|

|

caulkingor sealant on or |

MGS-250 or its base. |

|

|

|

|

|

NOT apply |

aroundthe |

|

|

|

|

|

DO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cable Gland |

|

(Optional) or |

Cable Gland |

Blanking Plug |

(Installed) |

(Not Shown) |

Loading...

Loading...