Baby Lock BL500A User Manual [nl]

“IMPORTANT SAFETY INSTRUCTIONS”

“Read all instructions before using.”

When using a sewing machine, basic safety precautions should always be taken,

including the following:

DANGER – To reduce the risk of electric shock:

● The sewing machine should never be left unattended while plugged in. Always unplug the sewing machine from the electrical outlet immediately after using and before

cleaning.

● Always unplug before changing the light bulb. Replace bulb with same type rated 120V 15 watts for 120V model or rated 240V 15 watts for 220-240V model.

WARNING – To reduce the risk of burns, fire, electric shock, or injury:

● Do not allow this sewing machine to be used as a toy. Close attention is necessary when the sewing machine is used by or near children.

● Use this sewing machine only for its intended use as described in this manual. Use only accessories recommended by the manufacturer as contained in this manual.

● Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return the

sewing machine to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

● Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing machine and foot control free from the accumulation of lint,

dust, and loose cloth.

● Never drop or insert any object into any opening.

● Do not use outdoors.

● Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

● To disconnect, turn the main switch to the symbol “O” position which represents off, then remove plug from outlet.

● Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

● Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

● Always use the proper needle plate. The wrong plate can cause the needle to break.

● Do not use bent needles.

● Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

● Turn off power to the machine by flipping the ON/OFF switch to the symbol “O” before making any adjustments in the needle area, such as threading the needle,

changing the needle, threading the bobbin or changing the presser foot etc.

● Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when making any other user servicing adjustments mentioned in the

instruction manual.

● This sewing machine is not intended for use by young children or infirm persons without supervision.

● Young children should be supervised to ensure that they do not play with this sewing machine.

CAUTION For U.S.A. only– This appliance has a polarized plug (one blade wider than the other) to reduce the risk of electric shock, this plug

is intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

“SAVE THESE INSTRUCTIONS”

“This sewing machine is intended for household use.”

FOR USERS IN THE UK, EIRE, MALTA

AND CYPRUS ONLY

IMPORTANT

● In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying the mark, rating as marked on plug.

● Always replace the fuse cover. Never use plugs with the fuse cover omitted.

● If the available electrical outlet is not suitable for the plug supplied with this equipment, you should contact your authorized retailer to obtain the correct lead.

FOR USERS IN AC INPUT 220-240V

COUNTRIES AND MEXICO

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety . Children should be supervised to ensure that they

do not play with the appliance.

CONGRATULATIONS ON CHOOSING

A BABY LOCK SEWING MACHINE

Your machine is one of the finest sewing machines available for home use.

To fully enjoy all the features incorporated into it, we suggest that you study this booklet.

PLEASE READ BEFORE USING YOUR SEWING MACHINE

For safe operation

● Be sure to watch the placement of your hands in relation to the needle while sewing. Do not touch moving parts such as the balance wheel, thread take-up or needle

while the machine is operating.

● Remember to turn off the power switch and unplug the cord when:

●

Operation is completed

●

Replacing or removing the needle or any other parts

●

A power failure occurs during use

●

Maintaining the machine

●

Leaving the machine unattended

● Do not place anything on the foot controller.

● Plug the machine directly into the wall outlet. Do not use extension cords.

For a longer service life

● When storing your sewing machine, avoid direct sunlight and high humidity locations. Do not store the sewing machine beside a space heater, iron, or other hot

objects.

● Use only neutral soaps or detergents to clean the case. Benzene, thinner, and scouring powders can damage the case and machine, and should never be used.

● Do not drop or hit the machine.

● Always consult the operation manual when replacing any accessories, including: the presser feet, needle or other parts to assure correct installation.

For repair or adjustment

In the event that a malfunction occurs or adjustment is required, first follow the troubleshooting table in the back of the operation manual to inspect and adjust the machine

yourself. If the problem persists, please consult your nearest authorized Baby Lock service center.

For additional product information and update, or to find your nearest Baby Lock dealer, visit our website at www.babylock.com

CONTENTS

Accessories .......................................................................1

Machine Features..............................................................2

Before You Begin ..............................................................3

Power Cord and Foot Controller ...............................3

Power Switch ............................................................3

Thread Tension Dial..................................................3

Hand Wheel ..............................................................3

Stitch Length Regulator ............................................3

Reverse Stitch Lever.................................................3

Presser Foot Lift Lever..............................................4

Knee Lift....................................................................4

Presser Foot Pressure Adjustment Dial....................4

Fabric Extension Table .............................................4

Thread Cutter Button ................................................5

Needle Stop Position Button.....................................5

Light Switch...............................................................5

Feed Dog Adjustment Knob......................................5

Changing Needles and Light Bulb...................................6

Changing the Needle ................................................6

Changing the Feed Pin .............................................6

Changing Light Bulbs................................................6

Threading...........................................................................7

Bobbin Winding.........................................................7

Bobbin Insertion ........................................................9

Upper Threading .....................................................10

Using the Needle Threader.....................................10

Using the Spool Net ................................................11

Stitch Samples and Needle Chart..................................12

Stitch Samples ........................................................12

Thread Tension.......................................................12

Changing Presser Feet ...................................................13

Changing Presser Feet (Zipper Foot) .....................13

Presser Feet ...........................................................13

Basic Sewing ...................................................................14

Basic Sewing ..........................................................14

Pin Feeding (for hard-to-handle fabrics) .................14

Rolled Hem Foot .....................................................15

Zipper Foot..............................................................16

Invisible Zipper Foot................................................17

1/4” Foot..................................................................17

Quilting Foot............................................................18

Walking Foot ...........................................................18

Seam Guide ............................................................19

Caring for Your Machine ................................................20

Cleaning the Machine .............................................20

Lubrication Points ...................................................20

Trouble Shooting ............................................................21

Accessories

1234

5678

9 101112

13 14 15 16

17 18

19 20

No. Part Name Part Code

1 Cover XA0917-056

2 Medium Screwdriver XC9541-051

3 Small Screwdriver XC9542-051

4 Cleaning Brush X59476-051

5 Knee Lift XA0830-051

6 Needles and Case 1 Size 9

(ORGAN HLX5) 2 Size 11

1 Size 14 X80805-151

1 Size 16

1 Ballpoint Needle

7 Feed Pin 138483-051

8 Feed Pin Changer XC1407-051

9 General Purpose Foot XA1425-001

10 Bobbin (5) 100376-051

11 Spool Cap XA2111-050

12

Flex Reaction Foot (on machine)

13 Rolled Hem Foot X57138-101

14 Zipper Foot 112797-001

15 Invisible Zipper Foot 148475-001

16 1/4” Foot XA7258-001

17 Quilting Foot XA7255-301

18 Walking Foot XA7253-001

19 Seam Guide XA7256-001

20 Foot Controller XC6658-151

21 Fabric Extension Table XC3117-051

22

Spool Cone Holder (on machine)

23 Spool Net XA5523-050

136021-001

XA0679-050

21 22

23

Note

(FOR U.S.A only)

Foot controller: Model P

This foot controller is used for sewing machine model

BL500A.

1

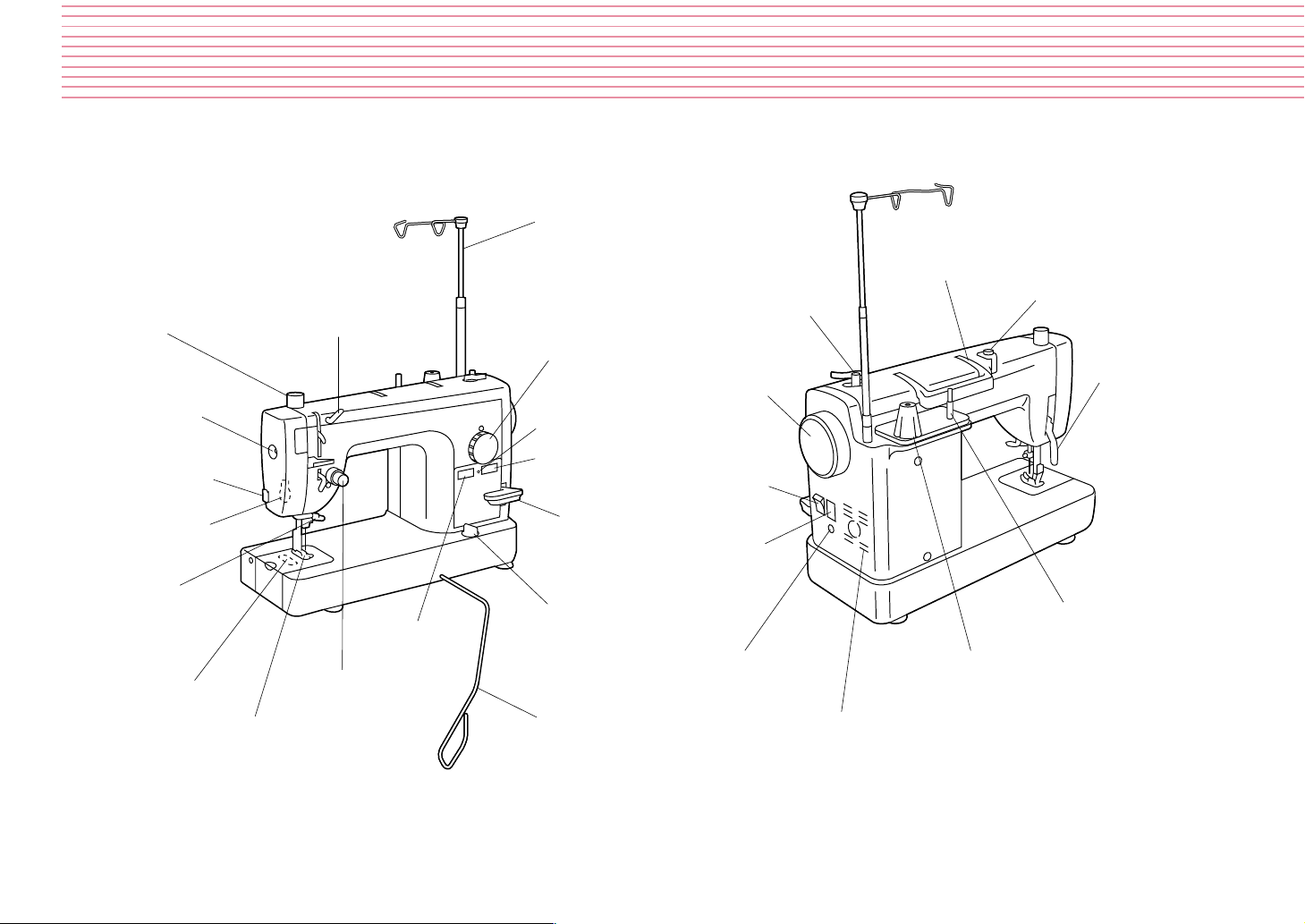

Machine Features

Thread Guide Bar

(Page 7)

Presser Foot Pressure

Adjustment Dial (Page 4)

Light Switch

(Page 5)

Thread Trimmer

Sewing Area

Light (Page 6)

Needle Threader

(Page 10 and 11)

Quick Bobbin

Thread Device (Page 9)

Three Hole

Thread Guide (Page 10)

Thread Tension Dial

(Page 3 and 12)

Feed Dogs

(Page 5 and 14)

Thread Cutter

Button (Page 5)

Stitch Length

Regulator (Page 3)

Indicator Lamp

Needle Stop Position

Button (Page 5)

Reverse Stitch

Lever (Page 3)

Feed Dog Adjustment

Knob (Page 5)

Foot Controller Jack

(Page 3)

Knee Lift

(Page 4)

Bobbin Winder

(Page 7)

Hand Wheel

(Page 3)

Power Switch

(Page 3)

Power Socket

(Page 3)

Air Vents

Handle

Spool Cone Holder

(Page 7)

Thread Guide for

Bobbin Winding (Page 7)

Presser Foot

Lift Lever (Page 4)

Spool Pin

(Page 7)

2

Before You Begin (1)

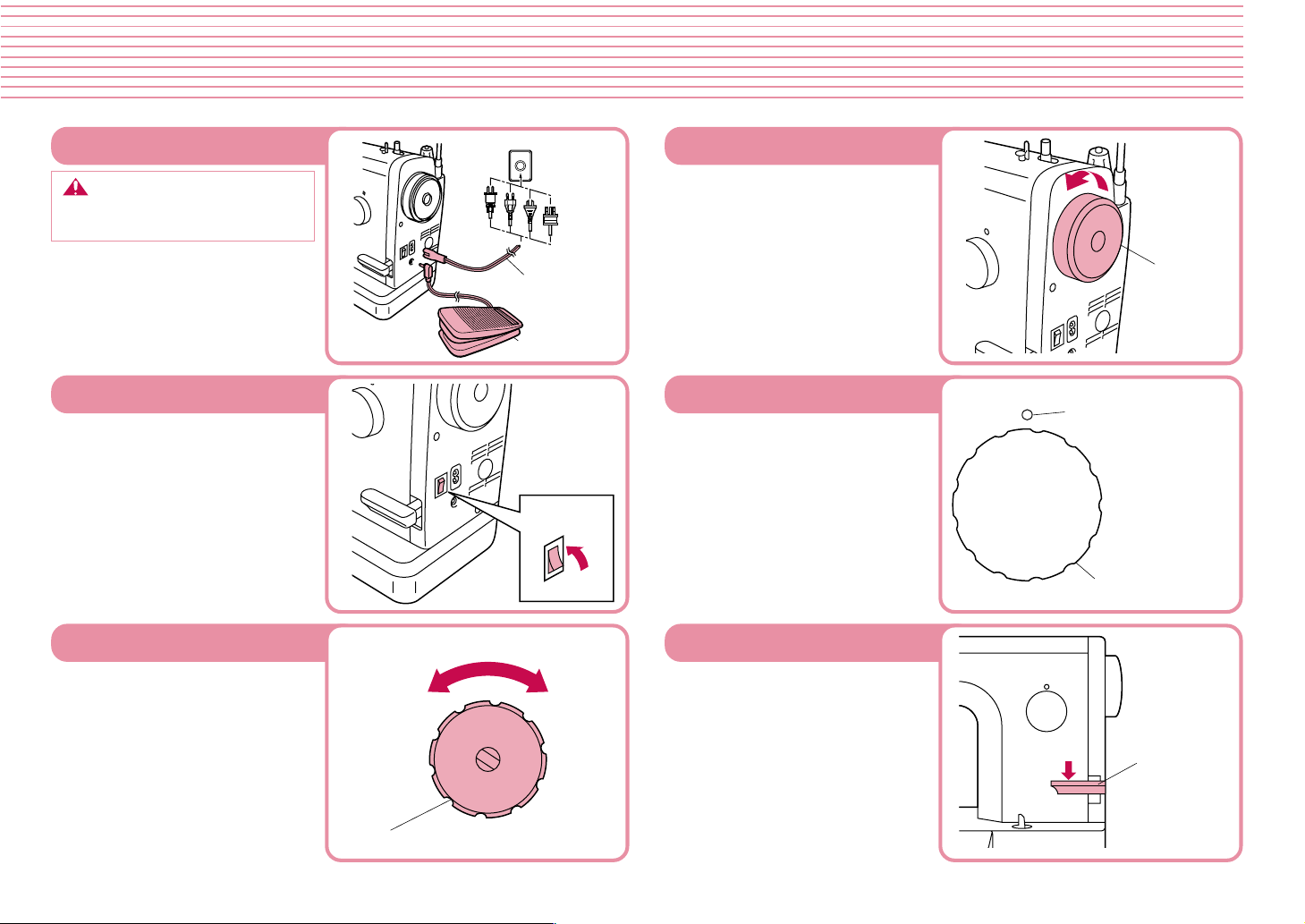

Power Cord and Foot Controller

Note

Please use common household

current.

● Plug in cord.

● Plug foot controller into machine.

Power Switch

● Flip power switch to “I” position to

turn on.

● To switch power off, flip switch to

“O” position.

Thread Tension Dial

Power Cord

Foot Controller

Power Switch

I

O

Upper Thread Tension

Hand Wheel

● Position needle using hand

wheel.

✽ Always turn hand wheel towards

you.

Stitch Length Regulator

● Adjust desired stitch length using

stitch length regulator dial.

Reverse Stitch Lever

Stitch Length

Reference Mark

1

7

6

2

3

4

5

Stitch Length Regulator

Hand Wheel

Lower number

= shorter stitches

Higher number

= longer stitches

● When tighter thread tension is

desired, turn the tension dial to

the right. Upper and bobbin

threads will meet on right side of

the fabric.

When looser thread tension is de-

●

sired, turn tension dial to the left.

Upper and lower threads will then

meet on wrong side of fabric.

Loosen Tighten

Tension Block

● Sewing in reverse is possible

when the reverse stitch lever is in

the lowered position.

✽ Make sure to push the lever all

the way down when reverse sewing is desired.

✽ When the feed adjustment dial is

set between 5-7mm, the reverse

stitch length is always 5 mm.

Reverse Stitch

Lever

3

Presser Foot Lift Lever

● Lowering the presser foot lift lever lowers the sewing foot down

onto the fabric and engages the

thread tension function.

✽ When working with heavy fabrics

or other fabrics that don’t slide

easily under the foot, raise the

presser foot lever to position the

fabric.

Presser Foot

Lift Lever

Presser Foot Pressure

Adjustment Dial

● Turning the pressure adjustment

dial raises and lowers the pressure indicator needle as the

amount of pressure on the

presser foot changes.

See also: “Feed Dog Adjustment

Knob” on page 5.

Presser Foot Pressure Adjustment Dial

Knee Lift

● Using the convenient knee lift to

lift and lower the presser foot

easily, leaving both your hands

free.

Setting up the knee lift.

✽ Push the knee lift bar all the way

into the socket.

✽ When knee lift is not in use, it

can rest at the bottom of the fabric extension table.

4

Knee Lift

Fabric Extension Table

Knee Lift

✽ See “Thread Tension” on page

12.

✽ Coordinate the color coding for

proper foot pressure and feed

dog settings.

Pressure Indicator

Needle

Fabric Extension Table

●

Lower table feet and attach fabric extension table as shown in the below diagram.

2

Hole

Guide pin

Stopper

3

1

Table legs

3

2

Hook

Before You Begin (2)

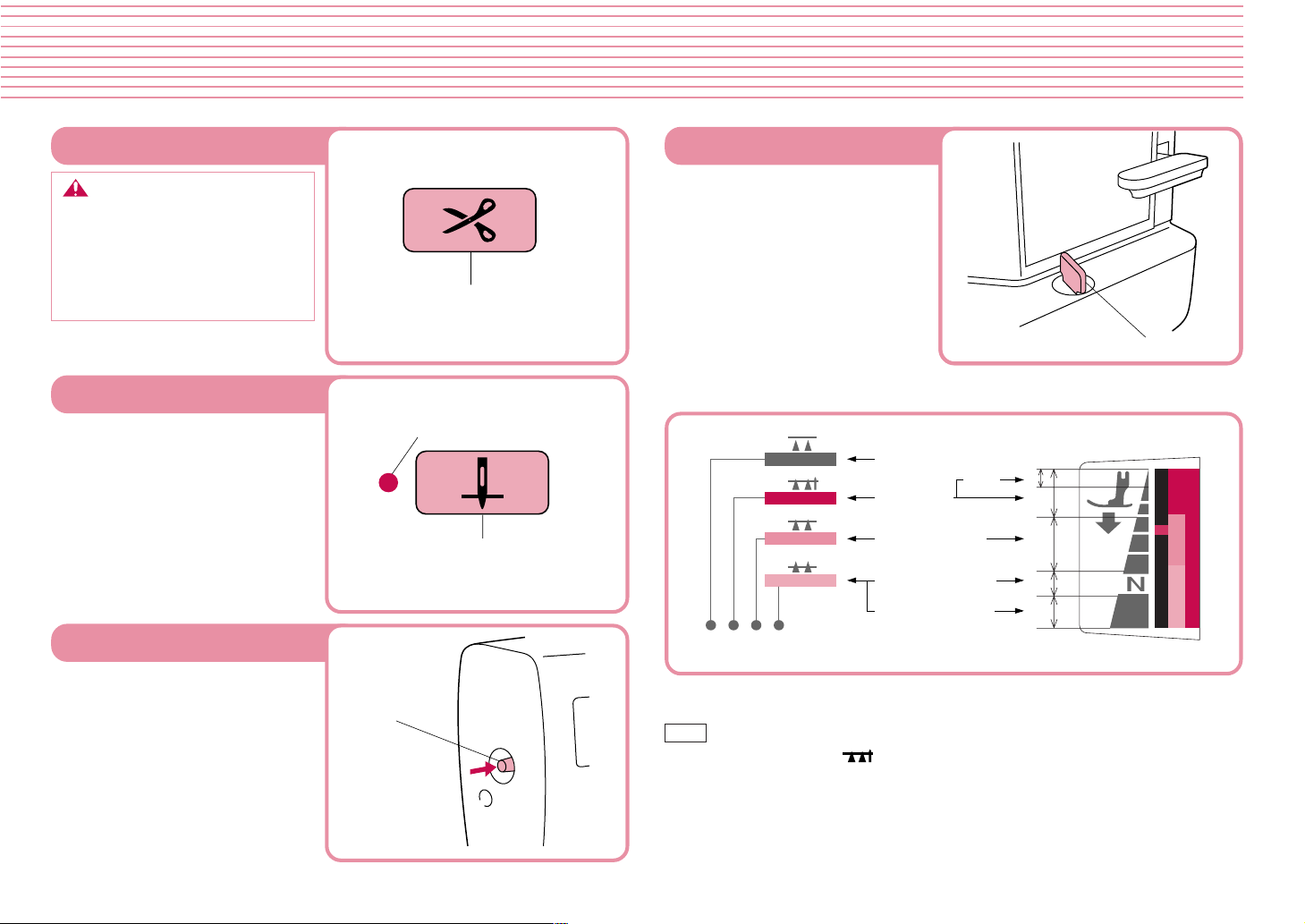

Thread Cutter Button

Note

When the machine stops due to

jammed threads and so forth, do not

step on the foot controller, turn the

power off and move the needle with the

hand wheel, check the situation. Otherwise broken needles could result.

●

The thread cutter trims upper and

bobbin threads at the end of seams.

✽ Press with the presser lever down.

Needle Stop Position Button

●

When indicator lamp is lit up, the

machine will stop sewing with the

needle lowered through the fabric.

● When indicator lamp is off, the

needle position when sewing

stops, will be random.

● If the safety mechanism is activated, for example if the thread

becomes tangled, the red lamp

flashes.

Light Switch

Feed Dog Adjustment Knob

● Height of feed dogs can be adjusted to coincide with fabric

weights.

Thread Cutter Button

Feed Dog Adjustment Knob

Foot Pressure and Feed Dog Position

Indicator Lamp

(Feed Dogs Down)

Velvet

(Pin Feeding)

Lightweight Fabrics

Needle Stop Position Button

Middleweight Fabrics

Heavyweight Fabrics

● Push light switch to turn the light

over the sewing area on and off.

Light Switch

Select one of four feed dog positions according to your needs.

Note

✽ If a setting other than

✽ Coordinate the color coding for proper foot pressure and feed dog settings.

is selected, the pin feed mechanism will not operate.

5

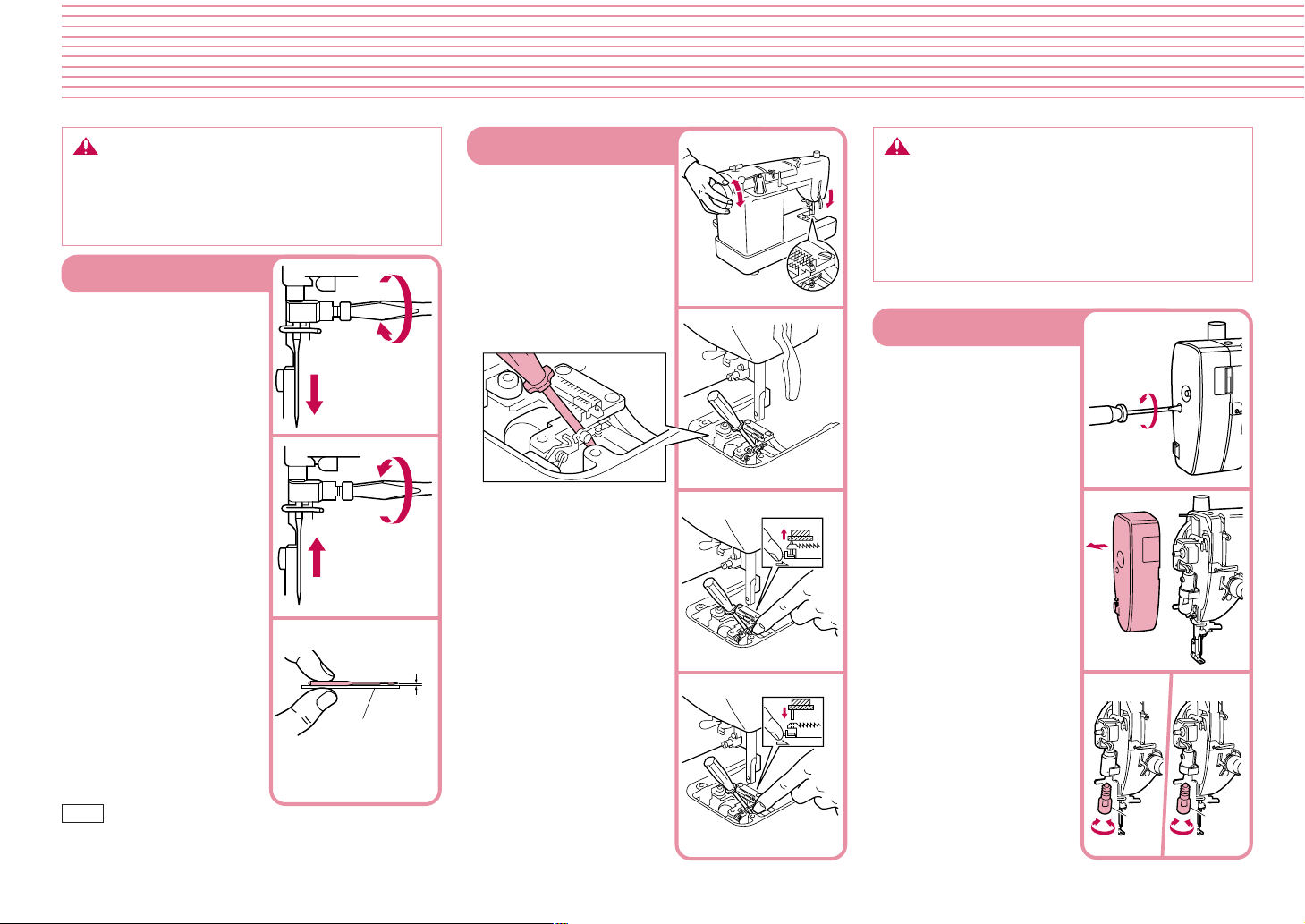

Changing Needles and Light Bulb

Light

Bulb

Note

Please make sure power is off before carrying out

the following operations. There is a chance of injury

if the machine accidentally starts running during

this operation.

Changing the Needle

1 Turn the sewing ma-

chine off. Raise needle

to highest position using hand wheel, and

lower presser foot.

2 Loosen screw with

screwdriver, and remove needle.

3 Hold the needle with

the flat side to the right,

and insert the needle as

far as it will go. Make

sure needle is screwed

in tightly.

✽ If the needle is not ad-

equately inserted or the

screw is loose, this may

break the needle or

cause a breakdown and

the needle threader will

not work.

✽ Check needles on a flat

surface to make sure

they are not bent.

Note

HLX5 needles should be used; however, Schmetz 130/

705H may also be used under normal circumstances.

6

Screwdriver

The needle should lay

parallel to a surface.

Flat surface

Lay needle on

a flat surface

(such as the needle

plate or a plate

of glass).

Changing the Feed Pin

1

Set the feed dogs to “velvet” position. (See page 5.)

2

Remove needle, presser

foot and needle plate.

3

Lower presser foot and

turn hand wheel until feed

pin is in its highest position.

4

Insert small screwdriver (included) as shown in diagram.

5 While holding spring

with fingertip, lower the

feed pin changer onto

the needle to pick it up.

Attach new feed pin to

6

feed pin changer, lower

and attach while holding

spring with fingertip.

7 Remove screwdriver.

8 Re-attach needle plate,

needle and presser foot.

Note

Please make sure power is off before carrying out

the following operation. The glass plate over the

light bulb will be hot immediately after using the

machine, therefore it is advisable to wait until the

light bulb has had a chance to cool down before

changing bulbs.

Changing Light Bulbs

1 Turn off power.

2 Remove screw from

head.

3 Remove bulb housing.

4 Unscrew bulb and re-

move.

5 Screw in new bulb.

Sewing Light:

See page 20.

6 Re-attach bulb housing

and tighten screw.

Screwdriver

230V

120V

Light

Bulb

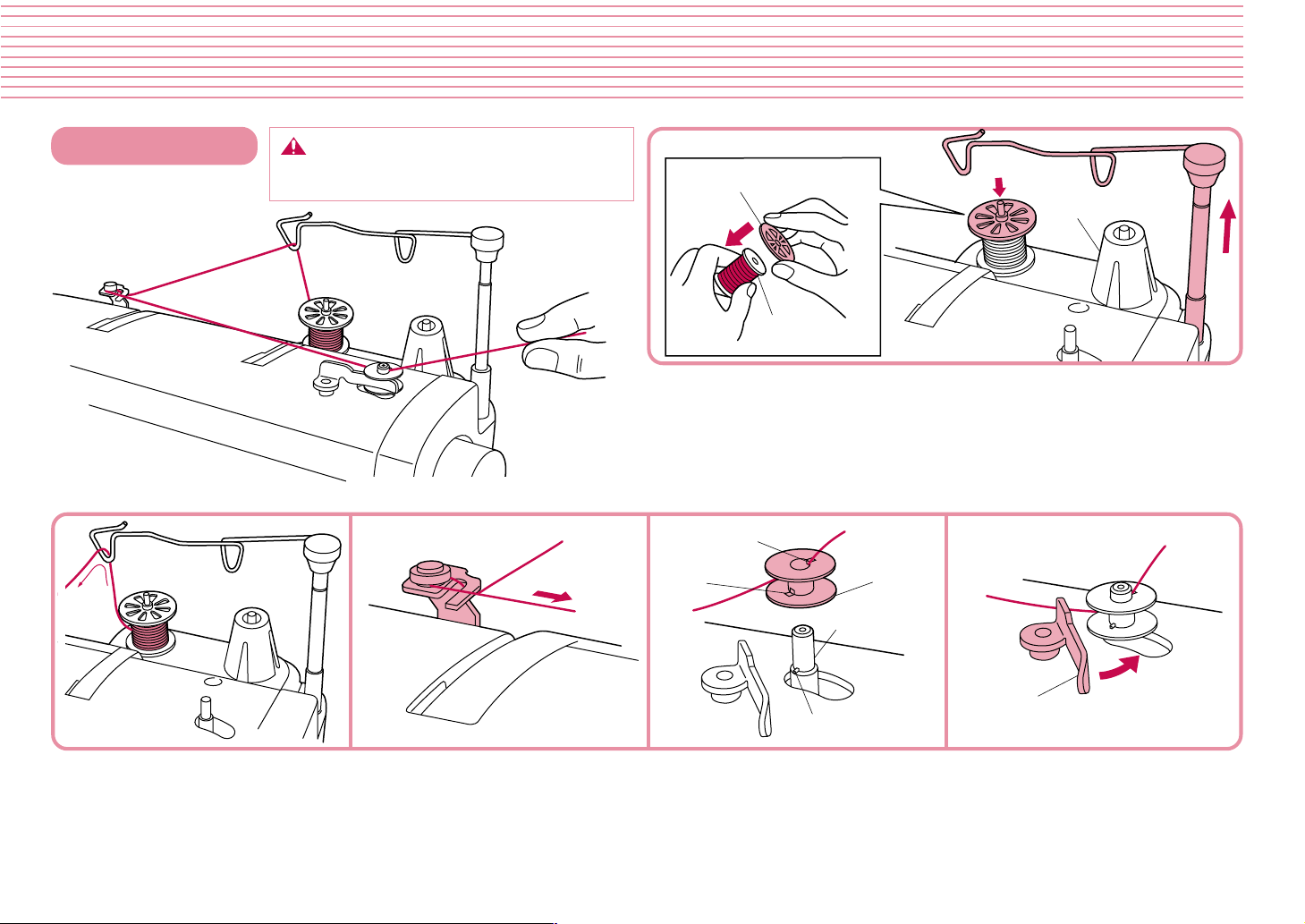

Threading (1)

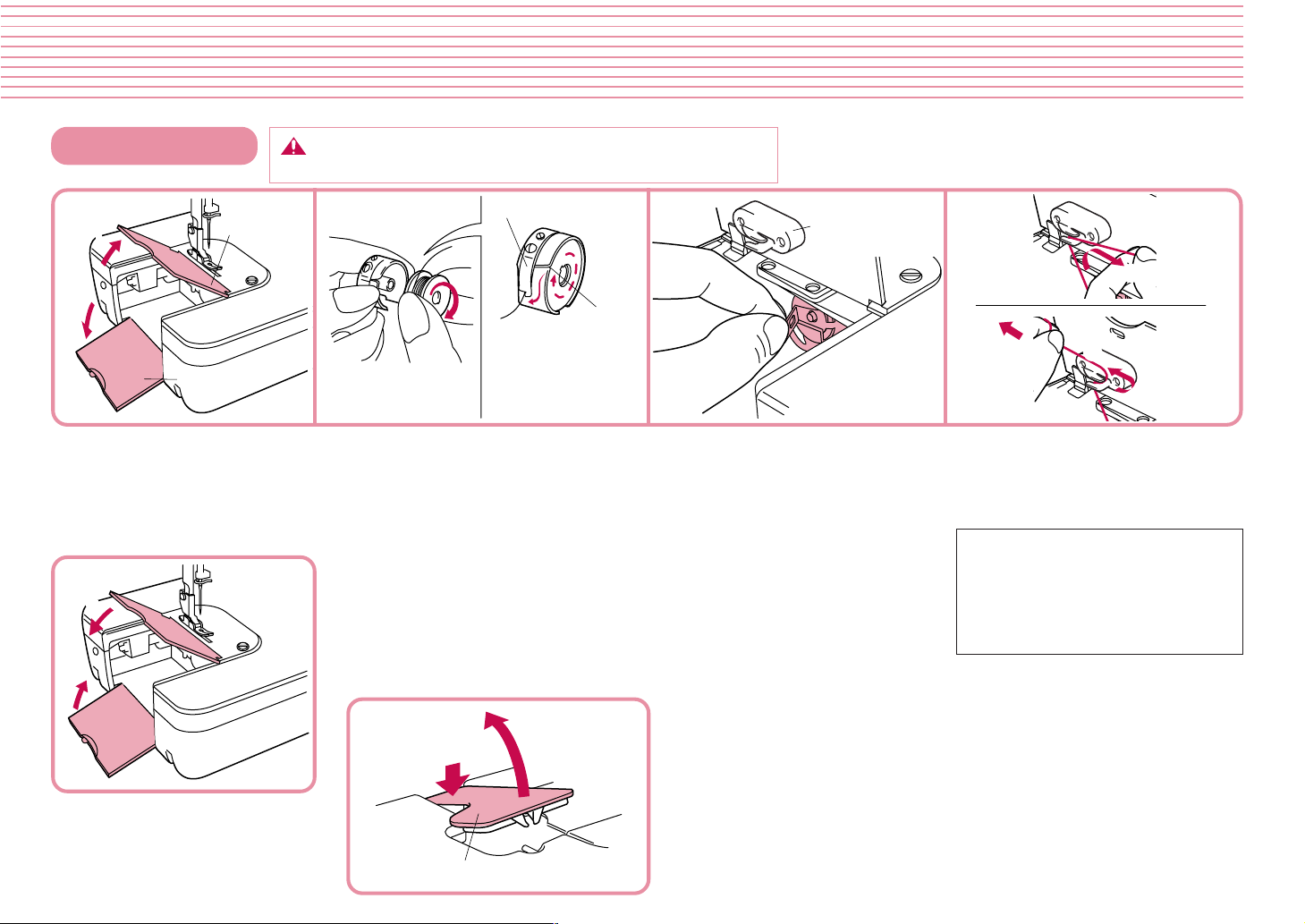

Bobbin Winding

4

3

Note

Do not move bobbin winding clutch while machine

is running.

3

2

5 - 0: See the following illustrations.

1

✽1

Spool Cap

Spool of Thread

1 Raise the thread guide bar all the way.

2 Mount a spool thread on the spool pin.

✽1 Use spool cap when using parallel-wound thread.

✽2 Use spool cone holder to stabilize cone shaped spools of thread.

Thread Notch 1

Thread Notch 2

Bobbin

Bobbin Winder

Shaft

2

✽2

Spool Cone Holder

1

3 Pass the thread through the triangu-

lar hole.

4 Pass thread through bobbin winding

thread guide as shown in drawing.

Guide Pin

5 Run thread through top thread notch

1, and align bottom thread notch 2 of

the bobbin with guide pin on bobbin

winder shaft.

Bobbin Winding Clutch

6 Press bobbin winding clutch up

against empty bobbin. If the bobbin

stop does not slide easily between

the top and bottom of the bobbin,

check that the bobbin is seated properly with the guide pin (5) inserted

into the lower notch.

7

✽

Place the thread end so that it does

not protrude from the bobbin.

While holding the end of the thread, step on

the foot controller for a few seconds. Once

enough thread has wound itself around the

bobbin to hold itself in place, release the

foot controller and trim the excess thread.

Continue to wind the bobbin while pressing

down on the foot controller.

8

Release the foot controller to stop

winding process when bobbin is full.

Bobbin Winding Clutch

9

Manually move bobbin winding clutch

back to original position.

0 Cut thread and remove bobbin.7

8

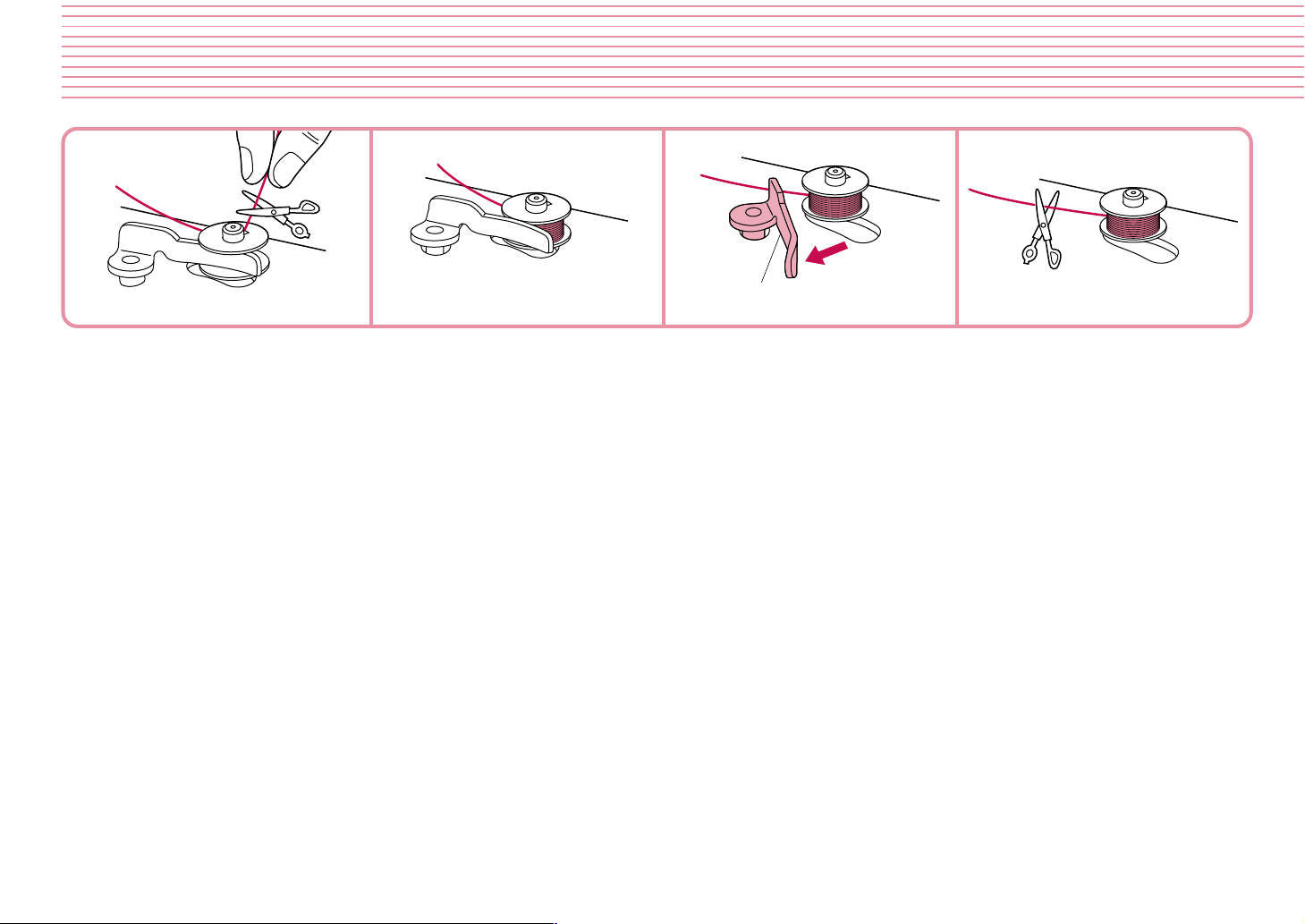

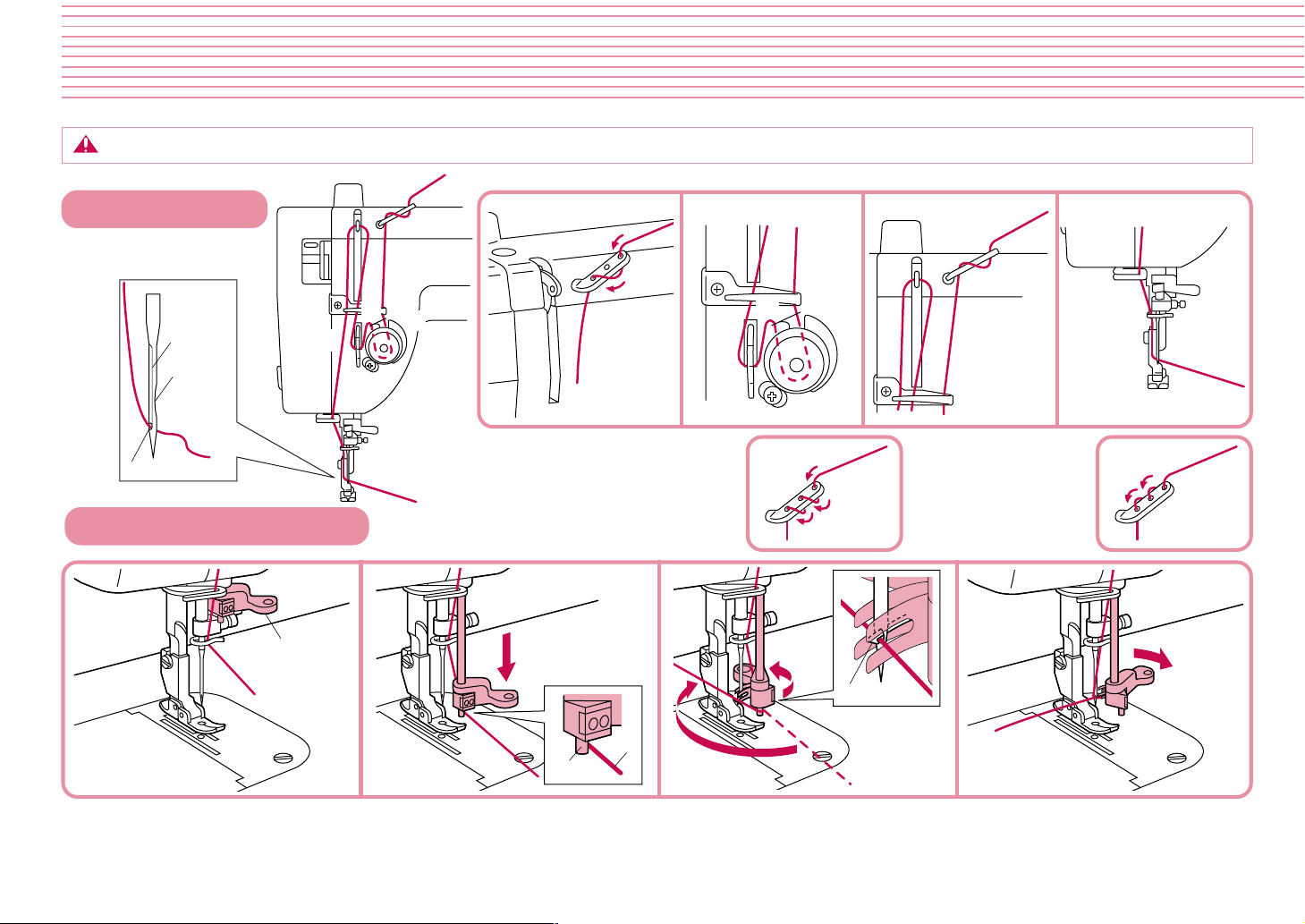

Bobbin Insertion

CAUTION – Moving parts –

To reduce risk of injury, switch power off before servicing. Open covers.

1

Needle Plate

2

Bobbin Door

1 Lift needle plate and open bob-

bin door.

2

1

5 Lower slide plate and close bob-

bin door, following numbers

2 above in order.

Latch Spring

Thread Notch

✽ Bobbin should be

positioned so it

winds to the left.

2 Put bobbin into the bobbin case.

✽ Run thread through thread notch and under

latch spring, so that a length of thread is exposed.

✽ Always use the bobbin case that was sup-

plied with this machine. A secondary bobbin case can be ordered from your dealer.

● When the fabric extension table is set in place

1

Bobbin Thread Setting Cover

Quick Bobbin

Thread Device

Pull the latch lever of the bobbin case

3

out and push the bobbin case into the

shuttle race and release the latch lever.

✽ If the latch lever is not set securely on

the hook, it may fly off during sewing

and cause lower thread breakage.

Rotate the hand wheel one full rotation towards you to check that the

bobbin case is set securely.

Open the bobbin thread setting cover

beforehand, then set the bobbin

thread in place. (You can set the bobbin thread in place without removing

the fabric extension table.)

1

3

2

4 Pass the thread through the quick

bobbin thread device in the order

2, pull in the direction of the arrow

3, then cut the thread.

★

Quick Bobbin Thread Device

This device cuts the bobbin thread end

to an appropriate length after the bobbin has been replaced and holds it at

that length, so the operation of pulling

out the thread can not be skipped.

1

9

Threading (2)

Note

Please turn off the power before using needle threader. Accidentally stepping on the foot controller during this operation could cause bodily injury or damage to the machine.

Upper Threading

8

Long

Groove

Depression

Thread

Needle Hole

5

9

0

Using the Needle Threader

Automatic

Needle

Threader

7

6

4

A

2

1

3

1

5

●

Make sure thread take-up lever is in

highest position and presser foot is up.

✽

When using polyester thread or thread

that tangles or breaks, run the thread

through all Three Hole of the thread guide.

Thread

Pin

2

4

6

1

2

3

Hook

✽

Pull the thread to

the left and check

that it is caught on

the hook.

7

8

✽ If the thread is still

tangles or breaks, run

the thread through the

holes backwards as

shown in diagram.

9

0

A

1 Rotate hand wheel towards you until

needle is in the highest position, and

lower presser foot.

2 Take thread in your left hand, and

10

gently pull it forward.

3 Lower needle threader.

Pull thread along the right side of the pin.

✽

✽

Do not force the needle threader lower

than the eye of the needle. Be sure that

the needle is in the highest position.

4 Turn the needle threader lever all

the way in the direction of

when the hook extends from the

needle hole, pull the thread in the direction of

2 to catch it on the hook.

1 and

While holding the thread gently, return

5

the needle threader lever to the right. As

you do this the hook that has caught the

thread will move as well, pulling a loop

of thread through the eye of the needle.

Loading...

Loading...