Page 1

AutoView

®

1000R

AutoView

Installer/User Guide

®

2000R

Page 2

INSTRUCTIONS

This symbol is intended to alert the user to the presence of important operating and

maintenance (servicing) instructions in the literature accompanying the appliance.

DANGEROUS VOLTAGE

This symbol is intended to alert the user to the presence of uninsulated

dangerous voltage within the product’s enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to persons.

POWER ON

This symbol indicates the principal on/off switch is in the on position.

POWER OFF

This symbol indicates the principal on/off switch is in the off position.

PROTECTIVE GROUNDING TERMINAL

This symbol indicates a terminal which must be connected to earth ground

prior to making any other connections to the equipment.

Page 3

AutoView® 1000R

AutoView® 2000R

Installer/User Guide

Avocent, the Avocent logo, The Power of Being There,

AutoView, AVWorks, Outlook and OSCAR are trademarks or

registered trademarks of Avocent Corporation or its affiliates.

All other marks are the property of their respective owners.

© 2003 Avocent Corporation. All rights reserved.

Page 4

USA Notification

Canadian Notification

Japanese Approvals

Warning: Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les

limites applicables aux appareils numériques de la classe A prescrites dans le Règlement

sur le brouillage radioélectrique édicté par le Ministère des Communications du Canada.

Taiwanese Approvals

Agency Approvals

EN55022 Class A, EN55024, EN61000-3-3, FCC15 Class A, VCCI Class A, IEC950,

EN60950, UL 1950/60950 third edition, CSA C22.2 No. 950, E-E011-02-2836 (A),

CNS 13438

Page 5

Table of Contents

Chapter 1: Product Overview

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2: Installation

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rack Mounting Your AutoView 1000R/2000R . . . 10

Installing the AutoView 1000R/2000R . . . . . . . . . . 11

Adding Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3: Local Port Operation

Controlling Your System at the Local Port . . . . . . 19

Viewing and Selecting Ports and Servers . . . . . . . . 19

Navigating OSCAR . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring OSCAR . . . . . . . . . . . . . . . . . . . . . . . . 22

Assigning Server or Serial Device Names . . . . . . . 23

Assigning Device Types . . . . . . . . . . . . . . . . . . . . . . 25

Changing the Display Behavior . . . . . . . . . . . . . . . 26

Controlling the Status Flag . . . . . . . . . . . . . . . . . . . 27

Broadcasting to Servers . . . . . . . . . . . . . . . . . . . . . . 29

Using Scan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting Console Security . . . . . . . . . . . . . . . . . . . . .32

Setting the Keyboard Country Code . . . . . . . . . . . . 34

Managing Server Tasks Using OSCAR . . . . . . . . .35

Viewing and Disconnecting User Connections . . .36

Running System Diagnostics . . . . . . . . . . . . . . . . . 37

Resetting Your PS/2 Keyboard and Mouse . . . . . . 39

Displaying Version Information . . . . . . . . . . . . . . . 40

Chapter 4: Terminal Operations

Configuring the Terminal Applications Menu . . . 45

Appendices

Appendix A: FLASH Upgrades . . . . . . . . . . . . . . . . 49

Appendix B: Using AVRIQ-SRL Modules . . . . . . . 53

Appendix C: Unshielded Twisted Pair

(UTP) Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Appendix D: Technical Specifications . . . . . . . . . . 60

Appendix E: Sun Advanced Key Emulation . . . . . 62

Appendix F: Technical Support . . . . . . . . . . . . . . . 64

Page 6

Page 7

1

Product Overview

Contents

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Page 8

Page 9

Chapter 1: Product Overview 3

Chapter 1: Product Overview

Features and Benefits

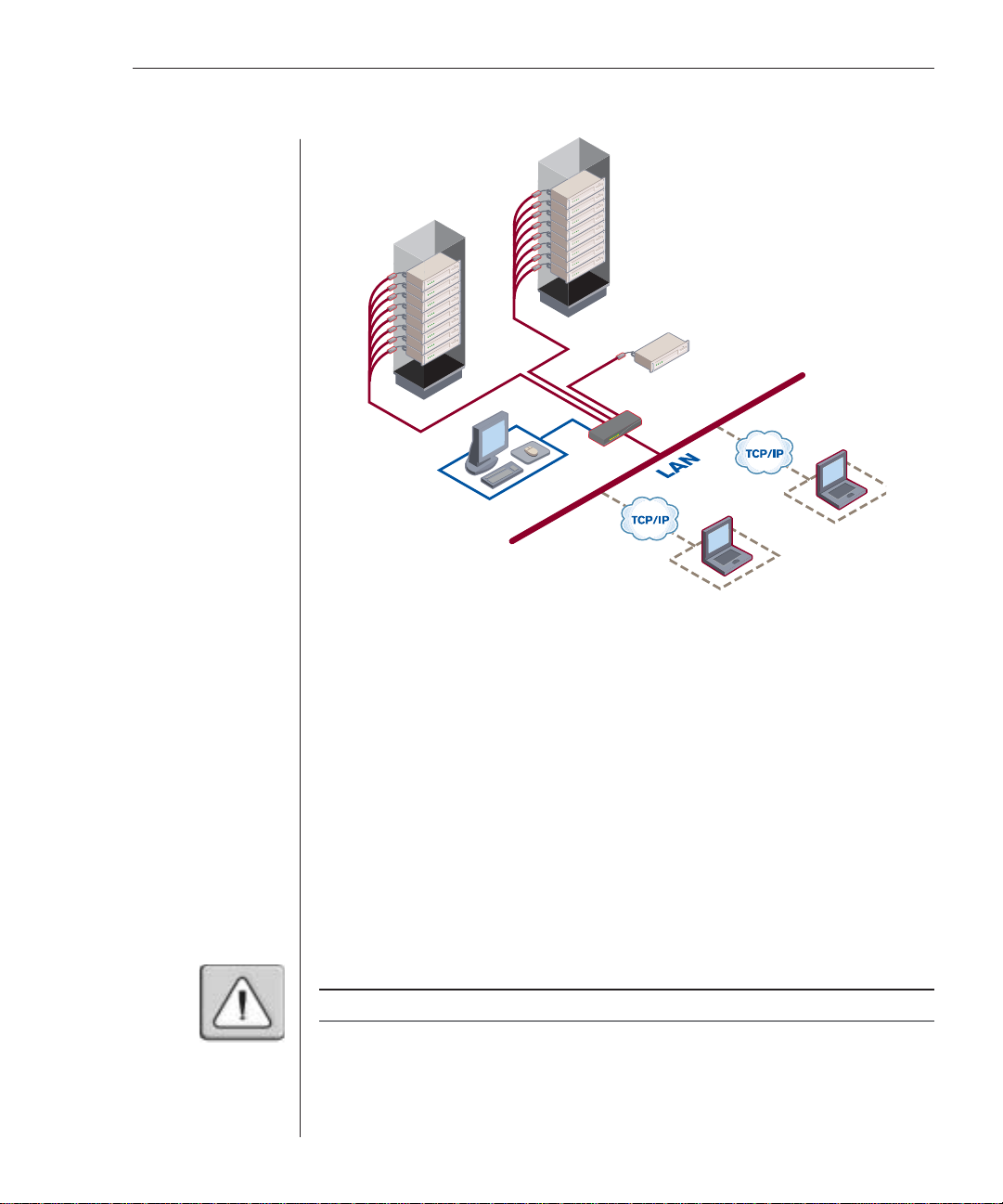

The Avocent AutoView® 1000R and 2000R model switches combine analog and

digital technology to provide flexible, centralized control of data center

servers. This solution delivers secure digital access and flexible server

management from anywhere at any time.

NOTE: Throughout the documentation you will see the word “ appliance” used generically to

describe the AutoView 1000R/2000R switch.

The AutoView 1000R/2000R consists of a rack mountable keyboard, video and

mouse ( KVM) switch configurable for analog (local) and digital (remote)

connectivity. Each AutoView 1000R/2000R has 16 Avocent Rack Interface

( ARI) ports for connecting devices and operating over standard LAN

connections. Access servers or serial devices across a 100BaseT Ethernet

connection or directly through a local port on the AutoView 1000R/2000R for

analog KVM connectivity and administration. Video resolutions through the

local port can be up to 1600 x 1280 with an end-to-end cable length of up to 15

meters (50 feet). Remote users can achieve video resolution of up to

1280 x 1024 with a cable length of up to 10 meters (32 feet) between the

AutoView 1000R/2000R and the server.

Number

of

AutoView 1000R

servers

Digital

users

Analog

user

LAN

16

AutoView 2000R

LAN

16

Figure 1.1: AutoView 1000R/2000R Model Comparison

1

2

1

1

AVRIQ and AVRIQ-SRL (serial) modules

The AVRIQ and AVRIQ-SRL (serial) modules with CAT 5 design dramatically

reduce cable clutter, while providing optimal digital display resolution and

video settings. The built-in memory of the AVRIQ simplifies configuration by

assigning and retaining unique server names or Electronic ID ( EID) numbers

for each attached server. This integrated intelligence enhances security and

prevents unauthorized access to a server through module manipulation. The

AVRIQ is powered directly from the server and provides Keep Alive

functionality even if the AutoView 1000R/2000R is not powered.

Page 10

4 AutoView 1000R/ AutoView 2000R Installer/User Guide

The AVRIQ-SRL (serial) module is a DCE device that provides the primary

interface between a serial device and the AutoView 1000R/2000R appliance. It

provides VT100 terminal emulation, break suppression and port history in a

convenient module format. The AVRIQ-SRL is compatible with the ARI ports of

the AutoView 1000R/2000R appliance. See Appendix B for more information on

the AVRIQ-SRL module.

Access via network connection

No special software or drivers are required on the attached computers. Remote

users access the AutoView 1000R/2000R and all attached systems via Ethernet

from a PC running AVWorks

™

. This software resides on the user’s PC only. User

PCs can be located anywhere a valid network connection exists. The AutoView

1000R/2000R can be configured on a separate network from your data network,

allowing access to your servers even if your applications network is down.

Point and click control with AVWorks software

The AVWorks software is a cross-platform management application that allows

you to view and control the AutoView 1000R/2000R and all attached servers.

The AVWorks software provides secure authentication, data transfers and

username/ password storage. By utilizing a browser interface for navigation

with an intuitive split-screen interface, this software provides you with a single

point of access for your entire system. From here, you can manage the

AutoView 1000R/2000R, install a new AutoView 1000R/2000R or launch a video

session to a system server. Multiple servers can be accessed by one user; each

additional computer’s video will appear in a separate program window.

NOTE: Throughout the documentation and AVWorks user interface, you will see the word

“ appliance” used generically to describe the AutoView 1000R/2000R sw itch .

Page 11

Chapter 1: Product Overview 5

AVRIQ

Modules

Rack

AVRIQ

Modules

Rack

of

Servers

Analog Connection

of

Servers

Critical Server

AutoView 2000R

IP Connections

Figure 1.2: Example AutoView 2000R Configuration

Safety Precautions

To avoid potential video and/or keyboard problems when using Avocent products:

• If the building has 3-phase AC power, ensure that the computer and monitor

are on the same phase. For best results, they should be on the same circuit.

To avoid potentially fatal shock hazard and possible damage to equipment,

please observe the following precautions:

• Do not use a 2-wire extension cord in any Avocent product confi guration.

• Test AC outlets at the computer and monitor for proper polarity and grounding.

• Use only with grounded outlets at both the computer and monitor. When

using a backup Uninterruptible Power Supply (UPS), power the computer,

the monitor and the appliance off the supply.

NOTE: The AC inlet is the main disconnect.

Page 12

6 AutoView 1000R/ AutoView 2000R Installer/User Guide

Rack mount safety considerations

• Elevated Ambient Temperature: If installed in a closed rack assembly, the

operation temperature of the rack environment may be greater than room

ambient. Use care not to exceed the rated maximum ambient temperature

of the appliance.

• Reduced Air Flow: Installation of the equipment in a rack should be such

that the amount of airfl ow required for safe operation of the equipment is

not compromised.

• Mechanical Loading: Mounting of the equipment in the rack should be such

that a hazardous condition is not achieved due to uneven mechanical loading.

• Circuit Overloading: Consideration should be given to the connection of

the equipment to the supply circuit and the effect that overloading of

circuits might have on overcurrent protection and supply wiring. Consider

equipment nameplate ratings for maximum current.

• Reliable Earthing: Reliable earthing of rack mounted equipment should be

maintained. Pay particular attention to supply connections other than

direct connections to the branch circuit (for example, use of power strips).

UTP cables

The AutoView 1000R/2000R will function correctly with any combination of

CAT 5, CAT 5e and CAT 6 cables.

NOTE: Throughout this manual, the generic term “CAT 5” refers to any CAT cable used by the

AutoView 1000R/2000R appliance.

Page 13

2

Installation

Contents

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rack Mounting Your AutoView 1000R/2000R . . . 10

Installing the AutoView 1000R/2000R . . . . . . . . . . 11

Adding Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Page 14

Page 15

Chapter 2: Installation 9

Chapter 2: Installation

The AutoView 1000R/2000R appliance requires that the AVWorks software be

installed prior to use. AVWorks software allows you to view and control a

server attached to the AutoView 1000R/2000R appliance, configure and

maintain the system and prevent unauthorized access to the appliance via

IP connection.

NOTE: The local port does not require the AVWorks software for operation. The local port

uses the On-Screen Confi guration and Activity Reporting interface (OSCAR®). For more

information, see Chapter 3.

The AutoView 1000R/2000R appliance uses Ethernet networking

infrastructure and TCP/IP protocol to transmit keyboard, video and mouse

information between operators and connected computers. Although 10BaseT

Ethernet may be used, a dedicated, switched 100BaseT network provides

improved performance.

Getting Started

Before installing your AutoView 1000R/2000R appliance, refer to the following

lists to ensure you have all items that shipped with the appliance as well as

other items necessary for proper installation.

Supplied with the AutoView 1000R/2000R

The following items are supplied with your appliance:

• AutoView 1000R or AutoView 2000R appliance

• Power cord

• Rack mounting kit

• One straight-through null modem serial cable

• AutoView 1000R/2000R Installer/User Guide

• AVWorks Installer/User Guide

• AVWorks CD

• AutoView 1000R/2000R and AVWorks Quick Installation Guide

Additional items needed

The following are additional items needed to use your appliance:

• One AVRIQ per attached server or switch

• One AVRIQ-SRL per attached serial device

• One CAT 5 patch cable per server or serial device (4-pair UTP, up to

10 meters)

Page 16

10 AutoView 1000R/ AutoView 2000R Installer/User Guide

Setting up your network

The AutoView 1000R/2000R appliance uses IP addresses to uniquely identify

the appliances and the computers running AVWorks software. The AutoView

appliance supports both BootP (a subset of DHCP) and static IP addressing.

Avocent recommends that IP addresses be reserved for each appliance and

that they remain static while the appliances are connected to the network.

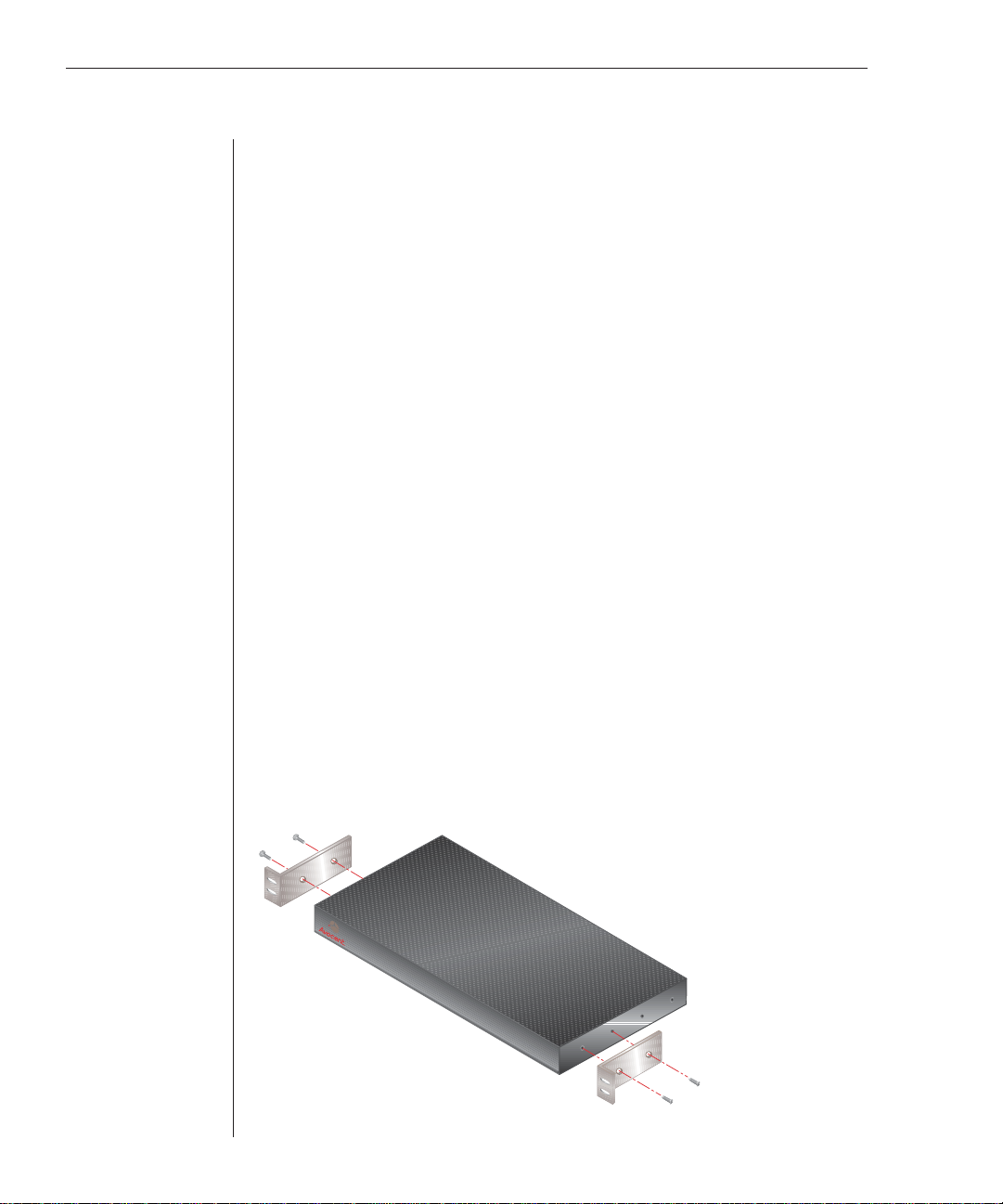

Rack Mounting Your AutoView 1000R/2000R

Your AutoView 1000R/2000R appliance ships with rack mounting brackets for

easy integration into your rack. Before installing the appliance and other

components in the rack cabinet (if not already installed), stabilize the rack in a

permanent location. Install your equipment starting at the bottom of the rack

cabinet, then work to the top. Avoid uneven loading or overloading of

rack cabinets.

To install the 1U switch mounting bracket:

1. Line up the holes in the “long side” of the kit’s side brackets with the

screw holes in the switch.

2. With a Phillips screwdriver, fasten the mounting brackets to the switch

using two 8/32 ” x 1//2 ” pan head screws on each side.

3. Attach the four cage nuts or clip nuts to the rack mounting fl ange of the

rack cabinet so that the nuts are positioned on the inside of the rack.

4. Mount the switch assembly to the rack cabinet by matching the holes in

the “short side” of each bracket to an appropriate set of matching holes on

your rack cabinet. Next, insert the combination hex head screws through

the slots in the bracket and the holes in the mounting rail, then into the

cage nuts or clip nuts.

Figure 2.1: AutoView 1000R/2000R Horizontal Installation

Page 17

Chapter 2: Installation 11

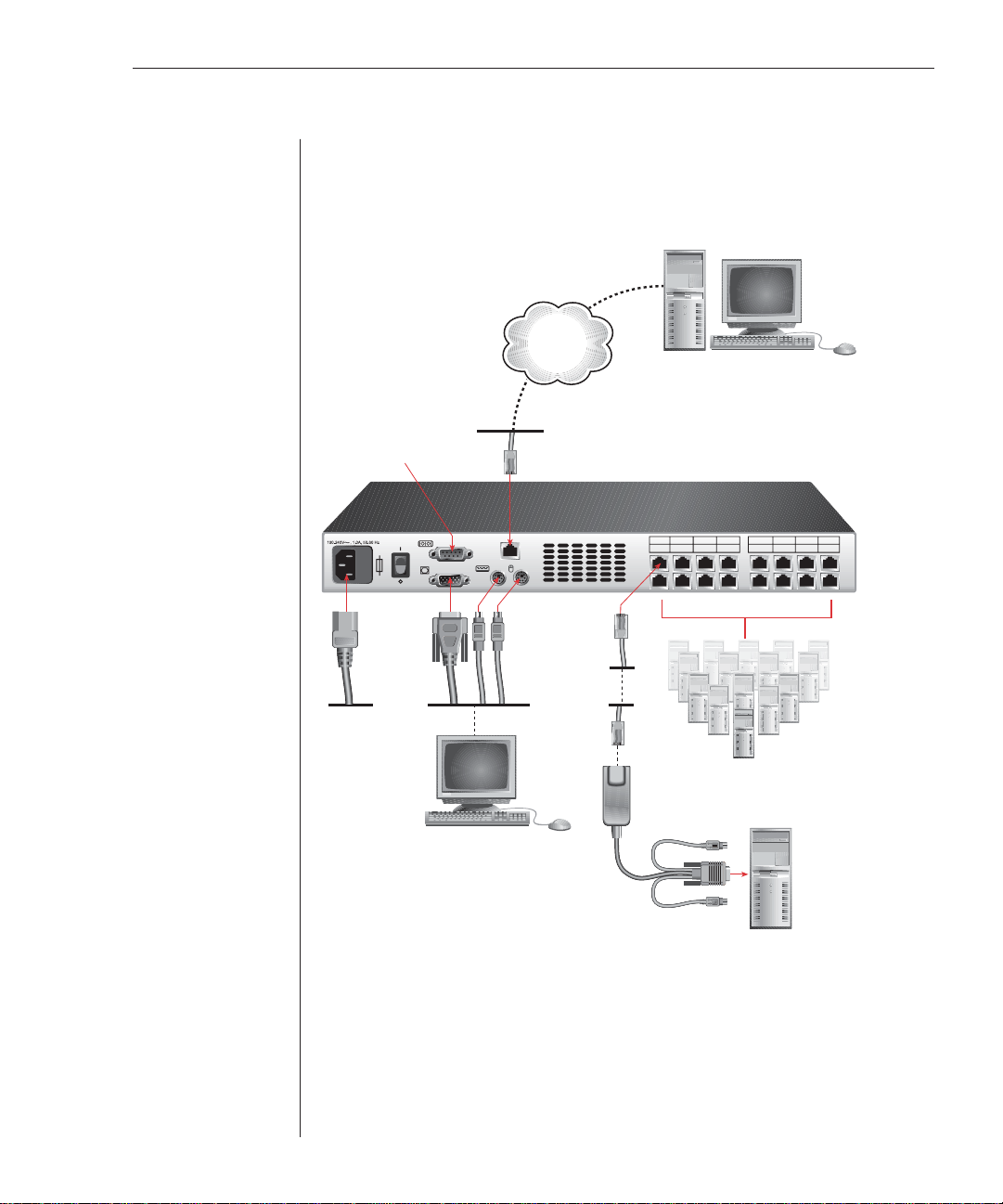

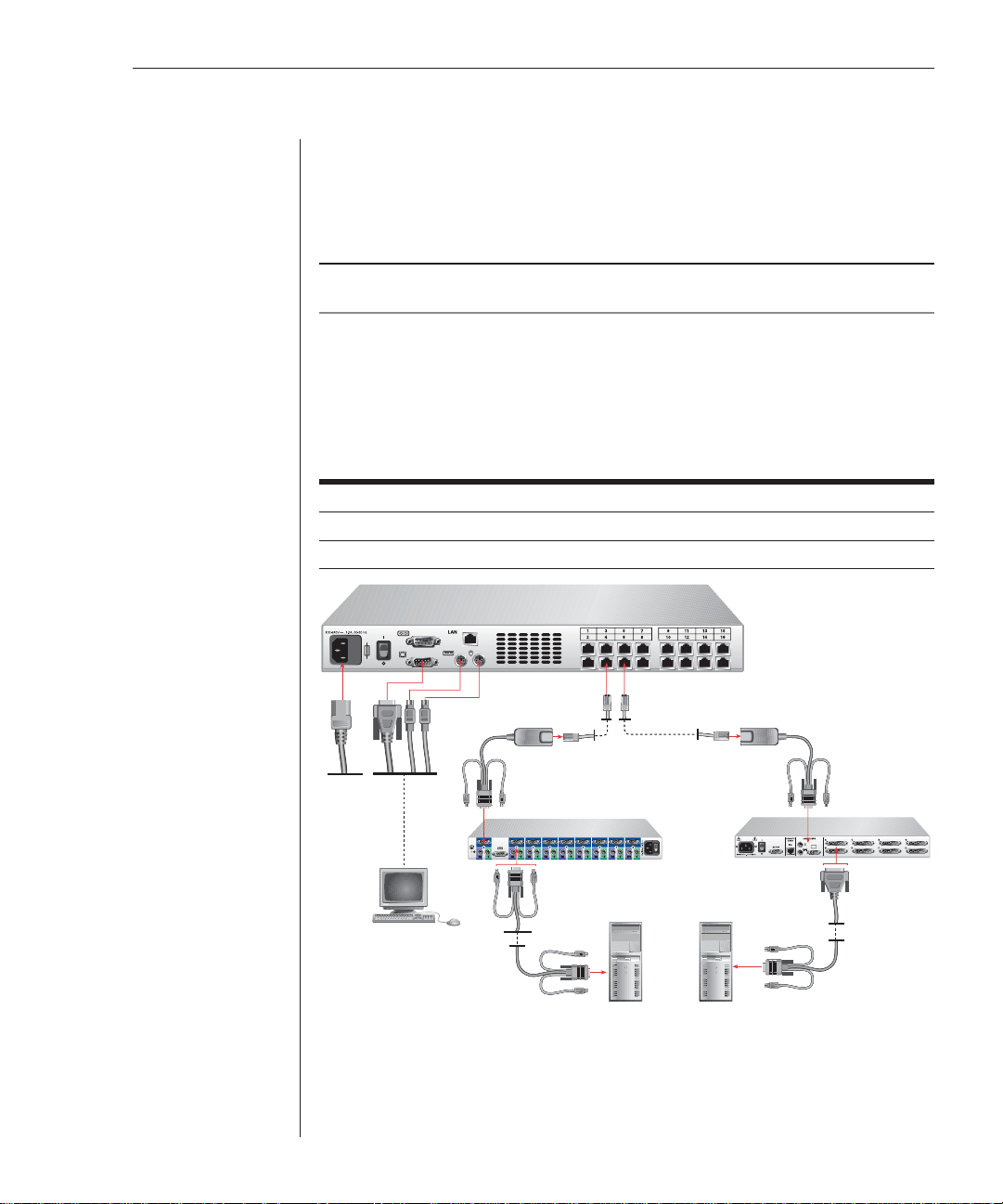

Installing the AutoView 1000R/2000R

Figure 2.2 illustrates one possible configuration for your AutoView 1000R/

2000R appliance. Follow the detailed set of procedures following Figure 2.2 to

successfully install your appliance.

Network

One user for the AutoView 1000R

or two users for the AutoView 2000R

Confi guration Port

for updating

fi rmware

LAN

AutoView1000R/2000R Appliance

1357 9111315

2468 10121416

KVM

ARI Ports 1-16

Connections

Power

Cord

CAT 5

Cable

Servers 2-16

Local User

AVRIQ Module

PS/2, USB, Sun and serial modules

are available

Figure 2.2: Basic AutoView 1000R/2000R Configuration

Remote User

Server 1

Page 18

12 AutoView 1000R/ AutoView 2000R Installer/User Guide

CAUTION: To reduce the risk of electric shock or damage to your equipment -

- Do not disable the power cord grounding plug. The grounding plug is an important

safety feature.

- Plug the power cord into a grounded (earthed) outlet that is easily accessible at all times.

- Disconnect the power from the appliance by unplugging the power cord from either the

electrical outlet or the appliance.

To install the AutoView 1000R/2000R hardware:

1. Connect a terminal or PC running terminal emulation software (such as

HyperTerminal

appliance using an RS-232 DB9 null modem cable. The terminal should

be set to 9600 baud, 8 bits, 1 stop bit, no parity and no fl ow control.

2. Plug the supplied power cord into the back of the appliance and then into

an appropriate power source.

3. When you turn on the power, the Power indicator on the front of the

appliance will blink for 30 seconds while performing a self-test.

Approximately 10 seconds after it stops blinking, press the Enter key to

access the main menu.

®

)to the confi guration port on the back panel of the

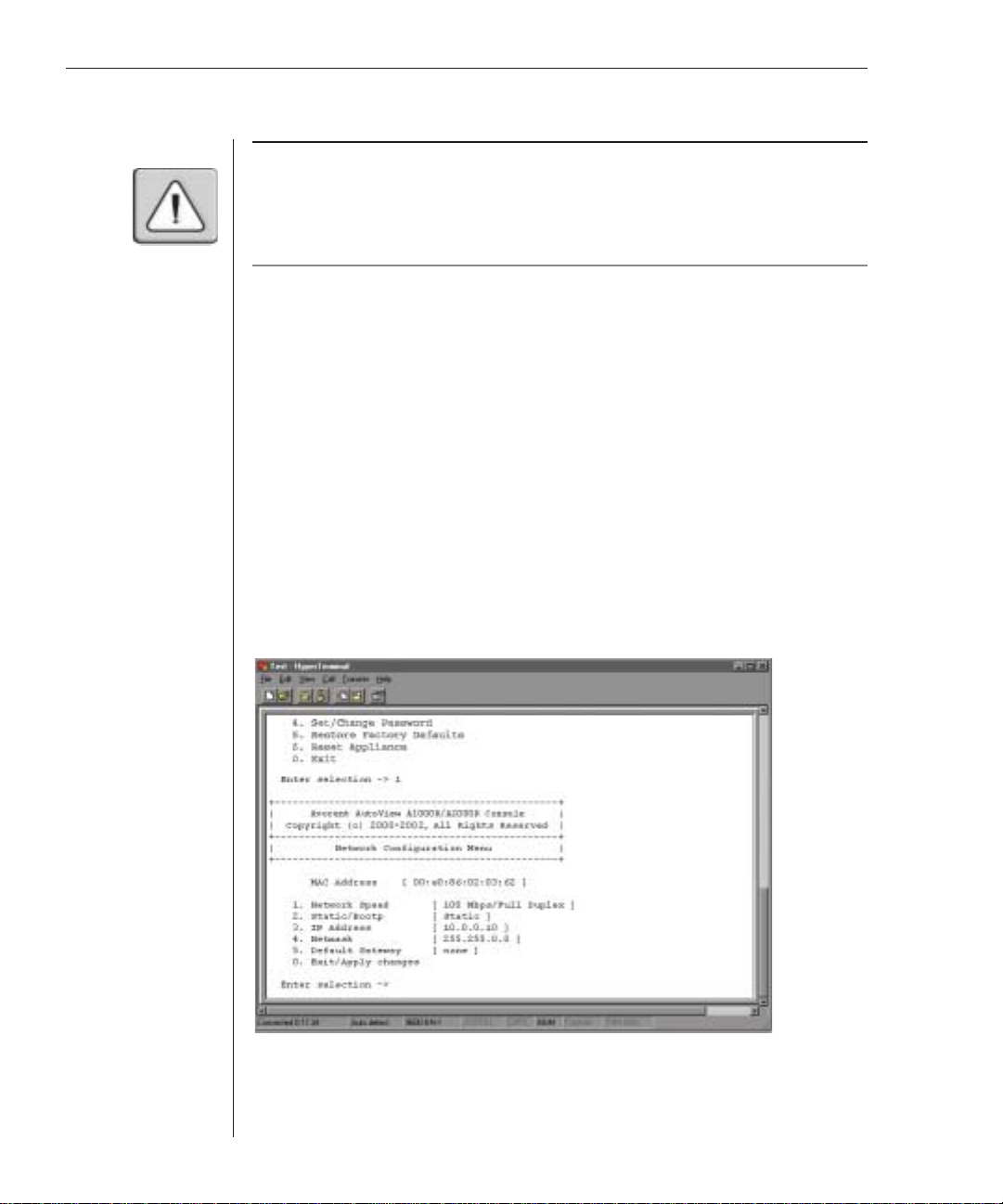

To confi gure the AutoView 1000R/2000R hardware:

1. You will see the Terminal Applications menu with six options. Select

option 1, Network Confi guration.

Figure 2.3: Network Configuration Menu

Page 19

Chapter 2: Installation 13

2. Select option 1 from the Network Confi guration menu to set your network

speed. When possible, you should set your connection manually without

relying on the auto negotiate feature. Once you enter your selection, you

will be returned to the Network Confi guration menu.

3. Select option 2 and specify if you are using a static or BootP IP address.

Use a static IP address for ease of confi guration. If you are using a BootP

address, please confi gure your BootP server to provide an IP address to the

appliance, skip step 4 and continue to the next procedure.

4. Select options 3-5 from the Terminal Applications menu, in turn, to fi nish

confi guring your appliance for IP address, netmask and default gateway.

Once this is completed, type a Ø to return to the main menu.

To adjust the mouse acceleration:

Before a server can be connected to the AutoView 1000R/2000R, an adjustment

to mouse acceleration must be made. Use the default Microsoft

®

Windows

PS/2 mouse driver for all Microsoft Windows systems attached to the appliance.

®

For Microsoft Windows NT

®

(using default drivers):

1. From the desktop, select Start - Settings - Control Panel - Mouse. The

Mouse Properties dialog box will appear.

2. Click on the Motion tab.

3. Set the Pointer speed to Slow. You will need to set this for any Windows

NT user account that will be accessing the Windows NT system through

the appliance.

4. Set Acceleration to None for mouse sync.

For Microsoft Windows 2000/Windows XP (using default drivers):

1. From the desktop, select Start -Settings -Control Panel -Mouse. The Mouse

Properties dialog box will appear.

2. Click on the Motion tab.

3. Set the speed setting to the default of 50%.

4. If you are using Windows 2000, click the Mouse tab and set Acceleration to

None for mouse sync.

-orIf you are using Windows XP, click the Pointer Options tab and check the

Enhance pointer precision checkbox.

Page 20

14 AutoView 1000R/ AutoView 2000R Installer/User Guide

To connect an AVRIQ module to each server:

1. Locate the AVRIQ modules for your AutoView 1000R/2000R appliance.

2. Attach the appropriately color-coded ends to the keyboard (violet),

monitor (blue) and mouse (green) ports on the fi rst server you will be

connecting to the appliance.

3. Attach one end of the CAT 5 cabling that will run between your AVRIQ and

AutoView 1000R/2000R appliance to the RJ-45 connector on the

AVRIQ module.

4. Connect the other end of the CAT 5 cable to the desired ARI port on the

back of your AutoView 1000R/2000R appliance.

5. Repeat steps 2-4 for all servers you wish to attach.

NOTE: When connecting a Sun AVRIQ module, you must use a multi-sync monitor to

accommodate Sun computers that support both VGA and sync-on-green or composite sync.

See Appendix B for more information on the AVRIQ-SRL module.

To connect serial devices to the AutoView 1000R/2000R appliance:

1. Locate an AVRIQ-SRL module.

2. Attach the AVRIQ-SRL 9-pin serial connector to the serial port of the

device to be connected to your AutoView 1000R/2000R appliance.

3. Attach one end of the CAT 5 cable to the RJ-45 connector on the AVRIQSRL module. Connect the other end of the CAT 5 cable to the desired ARI

port on the back of your AutoView 1000R/2000R appliance.

NOTE: The AVRIQ-SRL module is a DCE device and only supports VT100 terminal emulation.

4. Connect the power supply to the power connector on your AVRIQ-SRL.

The cable expander can be used to power up to four AVRIQ-SRL modules

from a single power supply.

5. Connect the AVRIQ-SRL power supply to an appropriate AC wall outlet.

Power up your serial device.

To connect an AVRIQ-PEM:

1. Locate the AVRIQ-PEM module.

2. Attach one end of a CAT 5 cable to the IN port on the AVRIQ-PEM module.

3. Connect the other end of the CAT 5 cable to the desired ARI port on the

back of your AutoView 1000R/2000R appliance.

4. Attach one end of another CAT 5 cable to one of the eight ports on the

AVRIQ-PEM module.

Page 21

Chapter 2: Installation 15

5. Connect the other end of the CAT 5 cable to the appropriate AVRIQ

module for the server you want to connect to the appliance.

6. Repeat steps 4-5 for all servers you wish to attach. Up to eight servers may

be attached to the AutoView 1000R/2000R appliance through the

AVRIQ-PEM module.

NOTE: When a server is connected using an AVRIQ-PEM and is in use, other servers

connected through that AVRIQ-PEM cannot be accessed by other users.

Adding a legacy KVM switch

You can add your legacy switches to the AutoView 1000R/2000R appliance for

better integration into your existing configuration. In a cascaded system, each

ARI port will accommodate up to 24 servers.

Legacy Switch Support

Legacy Product Model Numbers

OutLook

AutoView AV200-4, AV200-8, AV400-4, AV400-8, AV416, AV424

®

ES 140ES, 180ES, 280ES, 1160ES, 2160ES, 4160ES

AutoView 1000R

Appliance

KVM Connections

AVRIQ

Power

Cord

Local User

Figure 2.4: AutoView 1000R Configuration with a Legacy KVM Switch

Module

Outlook ES Switch

CAT 5 Cable

Server 1 Server 1

PS/2, USB, Sun and

Serial are available

AVRIQ Module

AutoView

200/400

Switch

Page 22

16 AutoView 1000R/ AutoView 2000R Installer/User Guide

To add a legacy KVM switch:

1. Mount the legacy switch into your rack cabinet. Locate a length of CAT 5

cabling to connect your appliance to the AVRIQ for your legacy switch.

2. Attach one end of the CAT 5 cabling to the RJ-45 connector on the AVRIQ.

3. Connect the other end of the CAT 5 cable to a port on the back of your

AutoView 1000R/2000R.

4. Attach the keyboard, monitor and mouse connectors of the AVRIQ to a

user port on your legacy cascade switch.

5. Connect the servers to your Avocent cascade switch according to the

instructions included with the device.

6. Power cycle the legacy switch to enable the cascade code.

7. Repeat steps 2-5 for all cascade switches you want to attach to

your appliance.

To connect the network and turn on your AutoView 1000R/2000R:

1. Connect your network cable from the LAN port on the rear of the

AutoView 1000R/2000R appliance to your network.

2. The components in the AutoView 1000R/2000R system may be turned on

in any order. However, since the AVRIQ modules are powered by the

servers, turn on the servers fi rst and then turn on all attached systems for

the most effi cient startup.

Adding Servers

While you can configure the entire AutoView 1000R/2000R system through

either the OSCAR or AVWorks interfaces, we recommend first adding server

names to OSCAR at the local analog station prior to adding or discovering the

appliance in AVWorks at the remote digital station.

To add server names:

1. Launch OSCAR at the local analog station and input all server names. You

can also customize OSCAR as well as access the AutoView 1000R/2000R

from the local analog station. See Chapter 3 for detailed instructions on

OSCAR setup and confi guration.

2. After you install AVWorks on each remote digital station, launch AVWorks

and click Add New Appliance to add the new AutoView 1000R/2000R. The

server names you entered in OSCAR will now display in AVWorks for all

servers/AVRIQ modules that are powered up and online. AVRIQ modules

that are offl ine can be added later using the resync feature. See the

AVWorks Installer/User Guide that ships with your appliance.

Page 23

3

Local Port Operation

Contents

Controlling Your System at the Local Port . . . . . . 19

Viewing and Selecting Ports and Servers . . . . . . . . 19

Navigating OSCAR . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring OSCAR . . . . . . . . . . . . . . . . . . . . . . . . 22

Assigning Server or Serial Device Names . . . . . . . 23

Assigning Device Types . . . . . . . . . . . . . . . . . . . . . . 25

Changing the Display Behavior . . . . . . . . . . . . . . . 26

Controlling the Status Flag . . . . . . . . . . . . . . . . . . . 27

Broadcasting to Servers . . . . . . . . . . . . . . . . . . . . . . 29

Using Scan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting Console Security . . . . . . . . . . . . . . . . . . . . .32

Setting the Keyboard Country Code . . . . . . . . . . . . 34

Managing Server Tasks Using OSCAR . . . . . . . . .35

Viewing and Disconnecting User Connections . . .36

Running System Diagnostics . . . . . . . . . . . . . . . . . 37

Resetting Your PS/2 Keyboard and Mouse . . . . . . 39

Displaying Version Information . . . . . . . . . . . . . . . 40

Page 24

Page 25

Chapter 3: Local Port Operation 19

Chapter 3: Local Port Operation

Controlling Your System at the Local Port

The AutoView 1000R/2000R includes a local port on the back of the appliance

that allows you to connect a monitor and a PS/2 keyboard and mouse for direct

local access. The appliance uses OSCAR, Avocent’s On-Screen Configuration

and Activity Reporting interface, which utilizes intuitive menus to configure

your system and select computers.

NOTE: Acceleration must be set to None for mouse sync on servers. See Installing the

AutoView 1000R/2000R in Chapter 2 for more information.

Viewing and Selecting Ports and Servers

Use the OSCAR Main dialog box to view, configure and control servers in the

AutoView 1000R/2000R system. You may view your servers by name, port or

by the unique Electronic ID number ( EID) embedded in each AVRIQ. You will

see an OSCAR-generated port list by default when you first launch OSCAR.

The Port column indicates the ARI port to which a server is connected. If you

connect a legacy KVM switch to the appliance, the port numbering displays the

ARI port first, then the switch port to which the server is connected. For

example, in Figure 3.1, all the servers except Darrell, Ebert and Edmond are

connected to legacy switches.

To access the Main dialog box:

Press Print Screen to launch OSCAR. The Main dialog box appears.

Figure 3.1: Example of Configured Main Dialog Box

NOTE: You can also press the Control key twice within one second to launch OSCAR. You can

use this key sequence in any place you see Print Screen throughout this installer/ user guide.

Page 26

20 AutoView 1000R/ AutoView 2000R Installer/User Guide

Viewing the status of your appliance

The status of the servers in your system is indicated in the right columns of the

Main dialog box. The following table describes the status symbols.

OSCAR Status Symbols

Symbol Description

(green circle) Server connected, powered up and the AVRIQ is online.

Connected server is powered down or is not operating properly an d the

AVRIQ is offl ine.

Connected switch is online.

Connected switch is offl ine or is not operating properly.

(yellow circle) The designated AVRIQ is being upgraded. When this symbol

displays, do not cycle power to the appliance or connected servers and do not

disconnect AVRIQ modules.

inoperable and require the AVRIQ to be returned to the factory for repair.

(green letter) The AVRIQ is being accessed by the indicated user channel, which

displays in the monitor icon. The local user letter may change, depending on the

availability of a video channel.

Doing so may render the module permanently

(black letter) AVRIQ is blocked by the indicated user channel. For instance, in

Figure 3.1, user B is viewing Forester, but is blocking access to Acton, Barrett

and Edie which are connected to the same AVRIQ chain.

Selecting servers

Use the Main dialog box to select servers. When you select a server, the appliance

reconfigures the keyboard and mouse to the proper settings for that server.

To select servers:

Double-click the server name, EID or port number.

-or-

If the display order of your server list is by port (Port button is depressed), type

the port number and press Enter.

-or-

If the display order of your server list is by name or EID number (Name or EID

button is depressed), type the first few characters of the name of the server or

the EID number to establish it as unique and press Enter.

Page 27

Chapter 3: Local Port Operation 21

To select the previous server:

Press Print Screen and then Backspace. This key combination toggles you

between the previous and current connections.

To disengage the user from a server:

Press Print Screen and then Alt+Ø. This leaves the user in a free state, with no

server selected. The status flag on your desktop displays Free.

Soft switching

Soft switching is the ability to switch servers using a hotkey sequence. You can soft

switch to a server by pressing Print Screen and then typing the first few

characters of its name or number. If you have set a Screen Delay Time and you

press the key sequences before that time has elapsed, OSCAR will not display.

To confi gure servers for soft switching:

1. Press Print Screen to launch OSCAR. The Main dialog box appears.

2. Click Setup - Menu. The Menu dialog box appears.

3. For Screen Delay Time, type the number of seconds of delay desired

before the Main dialog box is displayed after Print Screen is pressed.

4. Click OK.

To soft switch to a server:

1. To select a server, press Print Screen. If the display order of your server list

is by port (Port button is depressed), type the port number and press Enter.

-orIf the display order of your server list is by name or EID number (Name or

EID button is depressed), type the fi rst few characters of the name of the

server or the EID number to establish it as unique and press Enter.

2. To switch back to the previous server, press Print Screen then Backspace.

Navigating OSCAR

This table describes how to navigate OSCAR using the keyboard and mouse.

OSCAR Navigation Basics

This Keystroke Does This

Print Screen Opens OSCAR. Press Print Screen twice to send the Print

Screen keystroke to the currently selected AVRIQ module.

F1 Opens the Help screen for the current dialog box.

Page 28

22 AutoView 1000R/ AutoView 2000R Installer/User Guide

OSCAR Navigation Basics (continued)

This Keystroke Does This

Escape Closes the current dialog box without saving changes and returns

to the previous one. If the Main dialog box is displayed, pressing

Escape closes OSCAR and displays a status fl ag if status fl ags

are enabled. See Controlling the Status Flag in this chapter for

more information. In a message box, it closes the pop-up box and

returns to the current dialog box.

Alt Opens dialog boxes, selects or checks options and executes

actions when used with underlined or other designated letters.

Alt+X Closes the current dialog box and returns to the previous one.

Alt+O Selects the OK button, then returns to the previous dialog box.

Single-click, Enter In a text box, it selects the text for editing and enables the Left

and Right Arrow keys to move the cursor. Press Enter again to

quit the edit mode.

Enter Completes a switch in the Main dialog box and exits OSCAR.

Print Screen, Backspace Toggles back to previous selection. Print Screen, Alt+Ø

immediately disengages user from a server; no server is selected.

Status fl ag displays Free. (This only applies to the Ø on the

keyboard and not the keypad.)

Print Screen, Pause Immediately turns on screen saver mode and prevents access to that

specifi c console, if it is password protected.

Up/Down Arrows Moves the cursor from line to line in lists.

Right/Left Arrows Moves the cursor between columns. When editing a text box,

these keys move the cursor within the column.

Page Up/Page Down Pages up and down through Name and Port lists and Help pages.

Home/End Moves the cursor to the top or bottom of a list.

Backspace Erases characters in a text box.

Delete Deletes current selection in the scan list or characters in a text box.

Shift-Del Deletes from the current selection to the end of the list when

editing a scan list.

Numbers Type from the keyboard or keypad.

Caps Lock Disabled. Use the Shift key to change case.

Configuring OSCAR

You can configure your AutoView 1000R/2000R system from the Setup menu

within OSCAR. Select the Names button when initially setting up your

appliance to identify servers by unique names. Select the other setup features

to manage routine tasks for your servers from the OSCAR menu.

Page 29

Chapter 3: Local Port Operation 23

Setup Features to Confi gure OSCAR

Feature Purpose

Menu Change the server listing between numerically by port or EID number and

alphabetically by name

Change the Screen Delay Time before OSCAR displays after pressing Print Screen

Flag Change display, timing, color or location of the status fl ag

Broadcast Simultaneously send mouse movements and keystrokes to multiple servers

Scan Set up a custom scan pattern for up to 16 servers

Security Set passwords to restrict server access

Enable the screen saver

Keyboard Set the keyboard country code to send to Sun servers

Devices Identify the appropriate number of ports on an attached cascade switch

Names Identify servers by unique names

To access the Setup menu:

1. Press Print Screen to launch OSCAR. The Main dialog box appears.

2. Click Setup. The Setup dialog box appears.

Figure 3.2: Setup Dialog Box

Assigning Server or Serial Device Names

Use the Names dialog box to identify individual servers or serial devices by

name rather than by port number. The Names list is always sorted by port

order. You can toggle between displaying the name or the EID number of each

AVRIQ. Names are stored in the AVRIQ, so even if you move the module/

server/serial device to another ARI port, the name and configuration will be

recognized by the appliance.

NOTE: If a server or serial device is turned off, its respective AVRIQ will not appear in the

Names list.

Page 30

24 AutoView 1000R/ AutoView 2000R Installer/User Guide

To access the Names dialog box:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Setup - Names. The Names dialog box appears.

Figure 3.3: Names Dialog Box

NOTE: If new AVRIQ modules are discovered by the AutoView 1000R/2000R, the on-screen list

will be automatically updated. The mouse cursor will change into an hourglass during the update. No

mouse or keyboard input will be accepted until the list update is complete.

To assign names to servers or serial devices:

1. In the Names dialog box, select a server or serial device name or port

number and click Modify. The Name Modify dialog box appears.

Figure 3.4: Name Modify Dialog Box

2. Type a name in the New Name box. Names of servers or serial devices may

be up to 15 characters long. Legal characters include: A-Z, a-z, Ø-9, space

and hyphen.

3. Click OK to transfer the new name to the Names dialog box. Your selection

is not saved until you click OK in the Names dialog box.

4. Repeat steps 1-3 for each server or serial device in the system.

Page 31

Chapter 3: Local Port Operation 25

5. Click OK in the Names dialog box to save your changes.

-orClick X or press Escape to exit the dialog box without saving changes.

NOTE: If an AVRIQ has not been assigned a name, a combination of the EID and port is used

as the default name.

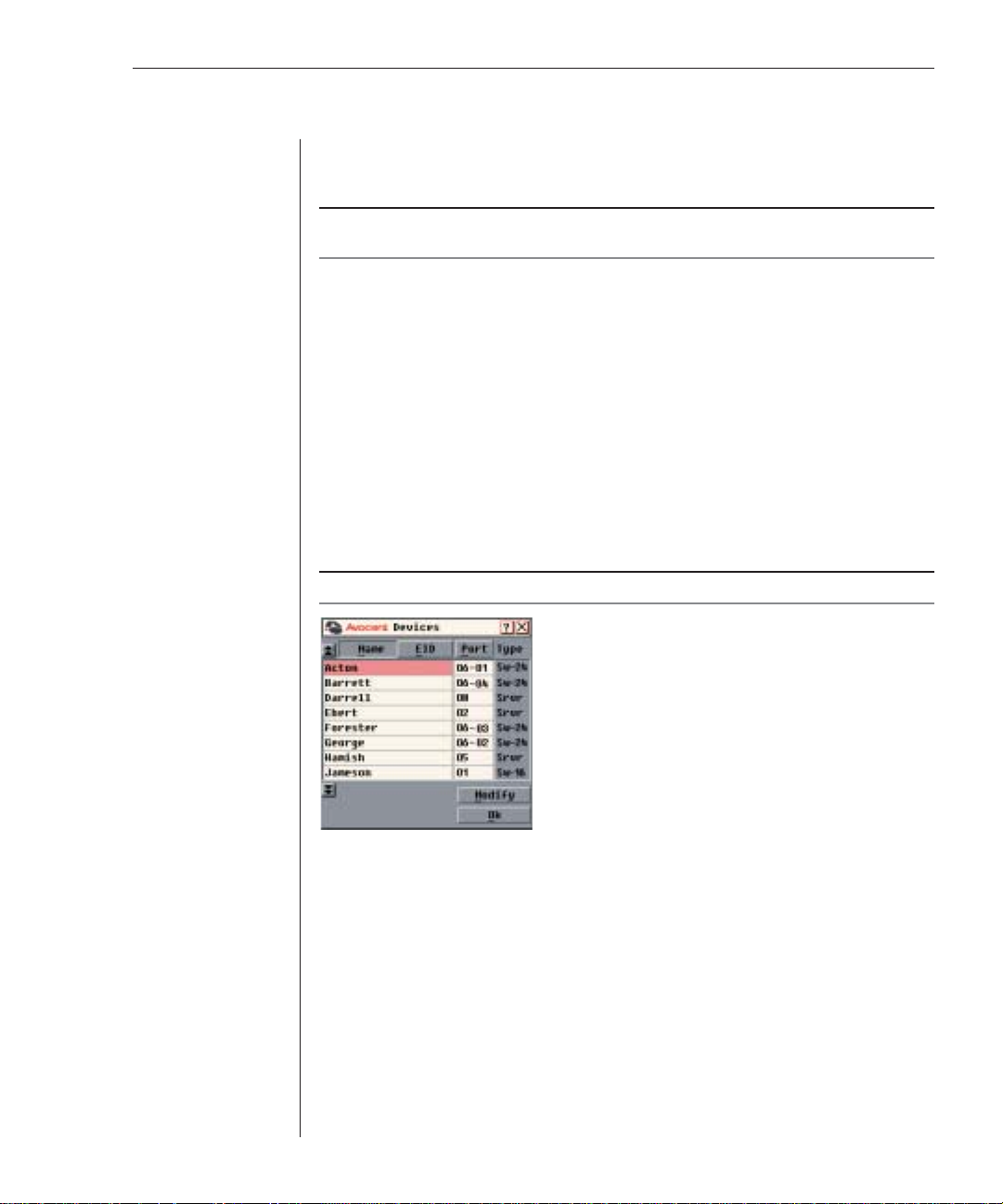

Assigning Device Types

While the appliance automatically discovers cascade switches attached to

your appliance, you will need to specify the number of ports on the cascade

switch through the Devices dialog box. You will see an Sw-24 appear in the

Type category for the cascade switch. Select the switch from the list and the

Modify button appears, allowing you to assign the appropriate number of

ports to it.

To access the Devices dialog box:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Setup - Devices. The Devices dialog box appears.

NOTE: The Modify button will only be available if a confi gurable switch is selected.

Figure 3.5: Devices Dialog Box

When the AutoView 1000R/2000R appliance discovers a cascade switch, you

will notice the numbering format change from being an ARI port only to [ARI

port]-[switch port] to accommodate each server under that switch.

For example, if a switch is connected to ARI port 6, each server connected to it

would be numbered sequentially. The server using ARI port 6, switch port 1

would be 06-01, the server using ARI port 6, switch port 2 would be 06-02, and

so on.

Page 32

26 AutoView 1000R/ AutoView 2000R Installer/User Guide

To assign a device type:

1. In the Devices dialog box, select the desired port number.

2. Click Modify. The Device Modify dialog box appears.

Figure 3.6: Device Modify Dialog Box

3. Choose the number of ports supported by your switch and click OK.

4. Repeat steps 1–3 for each port requiring a device type to be assigned.

5. Click OK in the Devices dialog box to save settings.

NOTE: Changes made in the Device Modify dialog box are not saved until you click OK in the

Devices dialog box.

Changing the Display Behavior

Use the Menu dialog box to change the display order of servers and set a Screen

Delay Time for OSCAR. The display order setting alters how servers will display

in several screens including the Main, Devices and Broadcast dialog boxes.

To access the Menu dialog box:

1. Press Print Screen to launch OSCAR. The Main dialog box appears.

2. Click Setup - Menu in the Main dialog box. The Menu dialog box appears.

Figure 3.7: Menu Dialog Box

Page 33

Chapter 3: Local Port Operation 27

To choose the default display order of servers:

1. Select Name to display servers alphabetically by name.

-orSelect EID to display servers numerically by EID number.

-orSelect Port to display servers numerically by port number.

2. Click OK.

To set a Screen Delay Time for OSCAR:

1. Type in the number of seconds (Ø-9) to delay OSCAR display after you

press Print Screen. Entering Ø will instantly launch OSCAR with no delay.

2. Click OK.

Setting a Screen Delay Time allows you to complete a soft switch without

OSCAR displaying. To perform a soft switch, see Soft switching in this chapter.

Controlling the Status Flag

The status flag displays on your desktop and shows the name or EID number

of the selected server or the status of the selected port. Use the Flag dialog box

to configure the flag to display by server name or EID number, or to change

the flag color, opacity, display time and location on the desktop.

OSCAR Status Flags

Flag Description

Flag type by name

Flag type by EID number

Flag indicating that the user has been disconnected from all systems

Flag indicating that broadcast mode is enabled

To access the Flag dialog box:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Setup - Flag. The Flag dialog box appears.

Page 34

28 AutoView 1000R/ AutoView 2000R Installer/User Guide

Figure 3.8: Flag Dialog Box

To determine how the status fl ag is displayed:

1. Select Name or EID to determine what information will be displayed.

2. Select Displayed to show the fl ag all the time or select Timed to display the

fl ag for only fi ve seconds after switching.

3. Select a fl ag color in Display Color. The following fl ag colors are available:

• Flag 1 - Grey fl ag with black text

• Flag 2 - White fl ag with red text

• Flag 3 - White fl ag with blue text

• Flag 4 - White fl ag with violet text

4. In Display mode, select Opaque for a solid color fl ag or select Transparent

to see the desktop through the fl ag.

5. To position the status fl ag on the desktop:

a. Click Set Position to gain access to the Position Flag screen.

b. Left-click on the title bar and drag to the desired location.

c. Right-click to return to the Flag dialog box.

Figure 3.9: Position Flag

NOTE: Changes made to the fl ag position are not saved until you click OK in the Flag dialo g box.

6. Click OK to save settings.

-orClick X to exit without saving changes.

Page 35

Chapter 3: Local Port Operation 29

Broadcasting to Servers

The local user can simultaneously control multiple servers in a system, to

ensure that all selected servers receive identical input. You can choose to

broadcast keystrokes and/or mouse movements independently.

NOTE: You can broadcast to as many as 16 servers at a time, one server per ARI port.

To access the Broadcast dialog box:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Setup - Broadcast. The Broadcast dialog box appears.

Figure 3.10: Broadcast Dialog Box

NOTE: Broadcasting Keystrokes - The keyboard state must be identical for all servers receiving

a broadcast to interpret keystrokes identically. Specifi cally, the Caps Lock and Num Lock modes

must be the same on all keyboards. While the appliance attempts to send keystrokes to the

selected servers simultaneously, some servers may inhibit and thereby delay the transmission.

NOTE: Broadcasting Mouse Movements - For the mouse to work accurately, all systems

must have identical mouse drivers, desktops (such as identically placed icons) and video

resolutions. In addition, the mouse must be in exactly the same place on all screens. Because

these conditions are extremely diffi cult to achieve, broadcasting mouse movements to multiple

systems may have unpredictable results.

To broadcast to selected servers:

1. From the Broadcast dialog box, select the mouse and/or keyboard

checkboxes for the servers that are to receive the broadcast commands.

-orPress the Up or Down Arrow keys to move the cursor to the target server.

Then press Alt+K to select the keyboard checkbox and/or Alt+M to select

the mouse checkbox. Repeat for additional servers.

2. Click OK to save the settings and return to the Setup dialog box. Click X or

press Escape to return to the Main dialog box.

3. Click Commands. The Commands dialog box appears.

Page 36

30 AutoView 1000R/ AutoView 2000R Installer/User Guide

4. Click the Broadcast Enable checkbox to activate broadcasting.

5. From the user station, type the information and/or perform the mouse

movements you want to broadcast.

To turn broadcasting off:

From the Commands dialog box, clear the Broadcast Enable checkbox.

Using Scan Mode

In scan mode, the appliance automatically scans from port to port ( server to

server). You can select up to 16 servers from a list of all servers attached to

your appliance. You can display the list by either the server’s name or EID

number by pressing the appropriate button.

NOTE: Scanning is only available to the local user.

To add servers to the scan list:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Setup - Scan. The Scan dialog box appears.

Figure 3.11: Scan Dialog Box

3. The dialog box contains a listing of all servers attached to your appliance.

Click the checkbox next to the servers you wish to scan.

-orDouble-click on a server’s name or port.

-orPress Alt and the number of the server you wish to scan. You can select up

to 16 servers.

4. In the Scan Time box, type the number of seconds (from 3-99) of desired

time before the scan moves to the next server in the sequence.

5. Click OK.

Page 37

Chapter 3: Local Port Operation 31

To remove a server from the scan list:

1. In the Scan dialog box, deselect the checkbox next to the server to

be removed.

-orDouble-click on the server’s name or port.

-orClick the Clear button to remove all servers from the scan list.

2. Click OK.

To start the scan mode:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands. The Commands dialog box appears.

Figure 3.12: Commands Dialog Box

3. Select Scan Enable in the Commands dialog box.

4. Click X to close the Commands dialog box.

NOTE: Scanning will begin as soon as the scan button is checked.

To cancel scan mode:

1. Select a server if OSCAR is open.

-orMove the mouse or press any key on the keyboard if OSCAR is not open.

Scanning will stop at the currently selected server.

-orIf OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands. The Commands dialog box appears.

3. Clear Scan Enable.

Page 38

32 AutoView 1000R/ AutoView 2000R Installer/User Guide

Setting Console Security

OSCAR enables you to set security on your local port console. You can establish a

screen saver mode that engages after your console remains unused for a specified

Inactivity Time. Once engaged, your console will remain locked until you press any

key or move the mouse. You will then need to type in your password to continue.

Use the Security dialog box to lock your console with password protection, set

or change your password and enable the screen saver.

NOTE: If a password has been previously set, you will have to enter the password before you

can access the Security dialog box.

To access the Security dialog box:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Setup - Security. The Security dialog box appears.

Figure 3.13: Security Dialog Box

To set or change the password:

1. Single-click and press Enter or double-click in the New text box.

2. Type the new password in the New text box and press Enter.

Passwords must contain both alpha and numeric characters, are case

sensitive and may be up to 1 2 characters long. Legal characters are: A-Z,

a-z, Ø-9, space and hyphen.

3. In the Repeat box, type the password again and press Enter.

4. Click OK to change your password, and then close the dialog box.

NOTE: If you should lose or forget your password, yo u will need to return your switch to have it

reset to the factory default settings. See Appendix F: Technical Support for contact information.

To password protect your console:

1. Set your password as described in the previous procedure.

2. Select Enable Screen Saver.

Page 39

Chapter 3: Local Port Operation 33

3. Type the number of minutes for Inactivity Time (from 1-99) to delay

activation of password protection and the screen saver feature.

4. For Mode, select Energy if your monitor is E

NERGY STAR

®

compliant;

otherwise select Screen.

CAUTION: Monitor damage can result from the use of Energy mode with monitors not

compliant with E

NERGY STAR

®

.

5. (Optional) Click Test to activate the screen saver test which lasts 10

seconds then returns you to the Security dialog box.

6. Click OK.

To log in to your console:

1. Press any key or move the mouse.

2. The Password dialog box appears. Type your password, then click OK.

3. The Main dialog box appears if the password was entered properly.

To remove password protection from your console:

1. From the Main dialog box, click Setup - Security; the Password dialog box

appears. Type your password, then click OK.

2. In the Security dialog box, single-click and press Enter or double-click in

the New box. Leave the box blank. Press Enter.

3. Single-click and press Enter or double-click in the Repeat box. Leave the

box blank. Press Enter.

4. Click OK to eliminate your password.

To enable the screen saver mode with no password protection:

1. If your console does not require a password to gain access to the Security

dialog box, proceed to step 2.

-orIf your console is password protected, see the previous procedure, then go

to step 2.

2. Select Enable Screen Saver.

3. Type the number of minutes for Inactivity Time (from 1–99) to delay

activation of the screen saver.

4. Choose Energy if your monitor is E

NERGY STAR

®

compliant; ot herwise

select Screen.

Page 40

34 AutoView 1000R/ AutoView 2000R Installer/User Guide

CAUTION: Monitor damage can result from the use of Energy mode with monitors not

compliant with ENERGY STAR®.

5. (Optional) Click Test to activate the screen saver test which lasts 10

seconds then returns you to the Security dialog box.

6. Click OK.

NOTE: Activation of the screen saver mode disconnects the user from a server; no server is

selected. The status fl ag displays Free.

To exit the screen saver mode:

Press any key or move your mouse. The Main dialog box appears and any

previous server connection will be restored.

To turn off the screen saver:

1. In the Security dialog box, clear Enable Screen Saver.

2. Click OK.

To immediately turn on the screen saver:

Press Print Screen, then press Pause.

Setting the Keyboard Country Code

NOTE: Using the keyboard code that supports a language different from that of your AutoView

1000R/2000R fi rmware will cause incorrect keyboard mapping.

Sun servers may use key mappings for non-US keyboards. By default,

AutoView 1000R/2000R appliances send the US keyboard country code to Sun

and USB modules attached to servers, and the code is applied to the servers

when they are powered up or rebooted. Codes are then stored in the

AVRIQ modules.

Issues may arise when you use the US keyboard country code with a keyboard

of another country. For example, the Z key on a US keyboard is in the same

location as the Y key on a German keyboard. Sun servers will interpret

pressing the Y key on a German keyboard as the Z key when the US keyboard

country code is used.

The Keyboard command enables you to send a different keyboard country

code than the default US setting. The specified country code is sent to all

servers attached to the AutoView 1000R/2000R appliances when they are

powered up or rebooted, and the new code is stored in the AVRIQ modules.

NOTE: If an AVRIQ module is moved to a different server, the keyboard country code will need to

be reset.

Page 41

Chapter 3: Local Port Operation 35

See Appendix E for information on emulating certain Sun keys using a PS/2

keyboard and special considerations for Japanese and Korean Sun

USB keyboards.

NOTE: Only local users can view or change keyboard country code settings.

To set the keyboard country code for Sun servers:

1. If OSCAR is not activated, press Print Screen. The Main dialog box

will appear.

2. Click Setup - Keyboard. The Keyboard dialog box appears.

Figure 3.14: Keyboard Dialog Box

3. Select a country code and click OK.

4. Reboot the Sun servers. After rebooting, each Sun server will request the

country code setting stored in the AVRIQ modules.

NOTE: If you wish to reboot the servers by power-cycling them, you must wait 90 seconds

before rebooting. A soft reboot may be performed without waiting 90 seconds.

Managing Server Tasks Using OSCAR

You can manage your AutoView 1000R/2000R system from the Commands

menu within OSCAR including engaging the scan and broadcast modes,

managing user connections, running diagnostics and updating your firmware.

Commands to Manage Routine Tasks for Your Servers

Feature Purpose

Broadcast Enable Begin broadcasting to your servers. Confi gure a server list for

broadcasting under the Setup dialog box.

Scan Enable Begin scanning your servers. Set up a server list for scanning in the

Setup dialog box.

User Status View and disconnect users.

Page 42

36 AutoView 1000R/ AutoView 2000R Installer/User Guide

Commands to Manage Routine Tasks for Your Servers (continued)

Feature Purpose

Run Diagnostics Validate the integrity of your system including memory, fi r m ware

CRCs, Comm interfaces, switch controller, local and remote video

and AVRIQ modules.

AVRIQ Status Simultaneously upgrade multiple AVRIQ modules.

Reset PS/2 Re-establish operation of PS/2 keyboard and mouse.

Display Versions View version information for the appliance as well as view and

upgrade fi rmware for individual AVRIQ modules.

To access the Commands menu:

1. Press Print Screen to launch OSCAR. The Main dialog box appears.

2. Click Commands. The Commands dialog box appears.

Figure 3.15: Commands Dialog Box

Viewing and Disconnecting User Connections

You can view and disconnect users through the User Status dialog box. The

username (U) will always be displayed; however, you can display either the

server name or EID number to which a user is connected. If there is no user

currently connected to a channel, the user field will be blank and the server

field will display Free.

NOTE: The local user can be disconnected by a remote user via the AVWorks software. See

the AVWorks Installer/User Guide for additional information.

To view current user connections:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands - User Status. The User Status dialog box appears.

Page 43

Chapter 3: Local Port Operation 37

Figure 3.16: User Status Dialog Box

To disconnect a user:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands - User Status. The User Status dialog box appears.

3. Click the letter corresponding to the user to disconnect. The Disconnect dialog

box will appear.

Figure 3.17: Disconnect Dialog Box

4. Click OK to disconnect the user and return to the User Status dialog box.

-orClick X or press Escape to exit the dialog box without disconnecting a user.

NOTE: If the User Status list has changed since it was last displayed, the mouse cursor will

turn into an hourglass as the list is automatically updated. No mouse or keyboard input will be

accepted until the list update is complete.

Running System Diagnostics

You can validate the integrity of your system through the Run Diagnostics

command. This command checks the main board functional sub-systems

( memory, communications, switch control and the video channels) for each

system controller. When you select the Run Diagnostics command, you will

Page 44

38 AutoView 1000R/ AutoView 2000R Installer/User Guide

receive a warning indicating that all users (remote and local) will be

disconnected. Click OK to confirm and begin the test.

The Diagnostics dialog box appears. The top section of the dialog box displays

the hardware tests. The bottom portion divides the tested AVRIQ modules into

three categories: online, offline or suspect.

NOTE: An AVRIQ may appear to be offl ine while it is being upgraded.

Next to each item to be tested, you will see a pass (green circle) or fail (red x)

symbol appear to the left of each item as that test finishes. A symbol will also

display to the left of the LAN connection to indicate if it is (green) or is not

(red) accessible and functional. The following table details each of the tests.

Diagnostic Test Details

Test Description

Memory Tests Reports on the condition of the main board RAM

Firmware CRCs Valid a t e s t h e c u r r e n t fi rmware images stored in the system’s FLASH

Comm Interfaces Verifi es that inter-board communication sub-systems are

accessible and functional

Switch Controller test

Local and Remote Video Verifi es that all the video channel sub-systems are accessible

LAN Connection test Verifi es that the LAN connection is accessible and functional

On-line AVRIQs Indicates the total number of currently connected and powered

Offl ine AVRIQs Indicates the number of AVRIQ modules that have been connected

Suspect AVRIQs Indicates the number of AVRIQ modules that have been detected,

Verifi es the switch matrix controller is accessible and functional

and functional

AVRIQ modules

successfully in the past and are apparently powered down

but are either unavailable for connection or have dropped packets

during the ping tests

To run diagnostic tests:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands - Run Diagnostics. A warning message appears

indicating that all users will be disconnected.

3. Click OK to begin diagnostics.

-orClick X or press Escape to exit the dialog box without running a

diagnostic test.

4. All users are disconnected and the Diagnostics dialog box displays.

Page 45

Chapter 3: Local Port Operation 39

Figure 3.18: Diagnostics Dialog Box

5. As each test is fi nished, a pass or fail symbol appears. The test is complete

when the last test’s symbol displays.

6. (Optional) If you have any Offl ine AVRIQ modules, you can click the Clear

button to remove them from the list.

7. (Optional) If you have any Suspect AVRIQ modules, you can click the

Display button. The Suspect AVRIQs dialog box appears.

Figure 3.19: Suspect AVRIQs Dialog Box

Make a note of each AVRIQ module in the list. In Figure 3.19, the fi rst

AVRIQ (Sw-4) is attached to channel 4 of a cascade switch, the second (???)

is non-communicative and the third (Srvr) is attached directly to a server.

You may want to troubleshoot each of these AVRIQ modules.

Resetting Your PS/2 Keyboard and Mouse

If your PS/2 keyboard or mouse locks up, you may be able to re-establish

operation of these peripherals by issuing a reset command. The reset command

sends a key sequence to the server which causes the mouse and keyboard

settings to be sent to the appliance. With communication re-established between

the server and the appliance, functionality is restored to the user.

Page 46

40 AutoView 1000R/ AutoView 2000R Installer/User Guide

NOTE: This function is for Microsoft Windows-based computers only. Resetting the PS/2 on a

computer running any other operating system may require that you reboot that computer.

To reset the PS/2 mouse and keyboard values:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands - Reset PS/2. A message box displays requesting that you

confi rm the reset. Click OK.

a. A message appears indicating that the mouse and keyboard have

been reset.

b. Click X to close the message box.

-orClick X or press Escape to exit without sending a reset command to

the PS/2 mouse and keyboard.

Displaying Version Information

OSCAR enables you to display the AutoView 1000R/2000R and AVRIQ

firmware versions. For optimum performance, keep your firmware current.

For more information, see Appendix A.

To display version information:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands - Display Versions. The Version dialog box appears. The

top half of the box lists the sub-system versions in the appliance.

Figure 3.20: Version Dialog Box

3. Click Digital to view the Digitizer unit fi rmware versions. The Digital

Version dialog box appears. The top section identifi es the Digitizer subsystem versions. The center section identifi es the current network

settings. Click X or press Escape to return to the Version dialog box.

Page 47

Chapter 3: Local Port Operation 41

Figure 3.21: Digital Version Dialog Box

4. Click AVRIQ (see Figure 3.20) to view individual AVRIQ version

information. The AVRIQ Selection dialog box appears.

Figure 3.22: AVRIQ Selection Dialog Box

5. Select an AVRIQ to view and click the Version button. The AVRIQ Version

dialog box appears. For more information on loading fi rmware, see

Appendix A.

Figure 3.23: AVRIQ Version Dialog Box

6. Click X to close the AVRIQ Version dialog box.

Page 48

42 AutoView 1000R/ AutoView 2000R Installer/User Guide

Page 49

4

Terminal Operations

Contents

Configuring the Terminal Applications Menu . . . 45

Page 50

Page 51

Chapter 4: Terminal Operations 45

Chapter 4: Terminal Operations

Each individual AutoView 1000R/2000R may be configured at the appliance

level through the configuration port on the back of the appliance. All terminal

commands are accessed through a terminal or PC running terminal

emulation software.

Configuring the Terminal Applications Menu

The AutoView 1000R/2000R Terminal Applications menu features seven

selections: Network Configuration, Firmware Management, Enable Debug

Messages, Set/Change Password, Restore Factory Defaults, Reset Appliance

and Exit.

To access the Terminal Applications menu:

1. Connect a terminal or PC running terminal emulation software (such as

HyperTerminal) to the Confi guration port on the back panel of the

AutoView 1000R/2000R using a RS-232 DB9 null modem cable. The

terminal should be set to 9600 baud, 8 bits, 1 stop bit, no parity and no fl ow

control. The terminal may be connected at any time, even when the

appliance is powered.

2. Press any key to access the main menu.

Network Configuration

The AutoView 1000R/2000R appliance is configured for network access

through the Network Configuration option. When it is selected, you will have

access to the addressing that allows the AutoView 1000R/2000R to be

positioned in your network. For more information, see Installing the AutoView

1000R/2000R in Chapter 2.

Firmware Management

This menu option contains the FLASH Download command. The FLASH

Download selection allows you to keep your AutoView 1000R/2000R firmware

current with upgrades available from Avocent. For more information, see

Appendix A: FLASH Upgrades.

CAUTION: Do not cycle power to the AutoView 1000R/2000R appliance or connected

servers, and do not disconnect AVRIQ modules during a FLASH upgrade. Doing so may

render the module permanently inoperable and require the AVRIQ modules to be returned to

the factory for repair.

Page 52

46 AutoView 1000R/ AutoView 2000R Installer/User Guide

Enable Debug Messages

This menu option allows you to configure the AutoView 1000R/2000R to display

messages regarding the status of the AutoView 1000R/2000R. Once you select the

level of detail to receive, the AutoView 1000R/2000R will begin to display

information on your terminal screen. When you are finished viewing, press any

key to exit this mode.

Set/Change Password

The AutoView 1000R/2000R can be set to a secure mode where the Terminal

Applications menu cannot be accessed without first entering a password.

To activate security:

1. Select the Set/Change Password menu option. You will be prompted with

the option to continue. Enter a Y.

2. Type a password for this AutoView 1000R/2000R and press Enter. This

password must be a minimum of 5 characters and can be up to a

maximum of 12 characters (10 are visible). The password must consist of a

combination of alpha and numeric characters.

3. You will be prompted to re-type the password. Once you complete this

step, security will be active and you will not be able to access AutoView

1000R/2000R terminal operations without the password.

To change the password:

1. Select the Set/Change Password menu option.

2. You will be prompted to type the old password and a new one.

3. Re-enter the new password to verify.

NOTE: This password places your AutoView 1000R/2000R terminal in a secure mode. This

password should be guarded like any network password and care should be taken to avoid

forgetting or misplacing it. There are no means for recovering a lost password.

Restore Factory Defaults

This menu option will restore the network configuration and security

configuration to the default settings.

Reset Appliance

This menu option allows you to execute a soft reset of the

AutoView 1000R/2000R.

Exit

This menu selection will return you to the ready prompt.

Page 53

Appendices

Contents

Appendix A: FLASH Upgrades . . . . . . . . . . . . . . . . 49

Appendix B: Using AVRIQ-SRL Modules . . . . . . . 53

Appendix C: Unshielded Twisted Pair

(UTP) Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Appendix D: Technical Specifications . . . . . . . . . . 60

Appendix E: Sun Advanced Key Emulation . . . . . 62

Appendix F: Technical Support . . . . . . . . . . . . . . . 64

Page 54

Page 55

Appendices 49

Appendices

Appendix A: FLASH Upgrades

The AVRIQ is unavailable while an upgrade is in progress. When an upgrade

is initiated, any current connection to the server via the AVRIQ will be

terminated. If you are using AVWorks software, a server experiencing an

AVRIQ firmware update may not display, or may display as disconnected. The

server will appear normally when the FLASH update is completed.

Upgrading the AutoView 1000R/2000R

The AutoView 1000R/2000R appliance FLASH upgrade feature allows you to

upgrade your appliance with the latest firmware available. To perform this

update you will need a TFTP server. If you don’t already have a TFTP server,

there are several you can download from the Internet.

Next, you will need to visit http://www.avocent.com/support and download the

latest FLASH firmware from Avocent. Save the FLASH upgrade file to the

appropriate directory on the TFTP server. Once this is complete, the following steps

will upload the new FLASH file.

CAUTION: Disconnecting an AVRIQ during a fi rmware update or cycling power will render the

module inoperable and require the AVRIQ to be returned to the factory for repair.

To upload a new FLASH fi le:

1. Connect a terminal or PC running terminal emulation software (such as

HyperTerminal) to the confi guration port on the back panel of the

AutoView 1000R/2000R. The terminal should be set to 9600 baud, 8 bits, 1

stop bit, no parity and no fl ow control.

2. Connect the LAN port on the AutoView 1000R/2000R to an Ethernet hub

that is also connected to the PC being used as the TFTP server.

3. Launch both the server software and the terminal emulation software.

4. Verify that the AutoView 1000R/2000R is turned on. After approximately 40

seconds, the AutoView 1000R/2000R will send out a message, Avocent

AutoView 1000R/2000R Ready__Press any key to continue. Press any key to

access the main menu. The AutoView 1000R/2000R main menu appears.

5. Get the IP address of the TFTP server. If using the SolarWinds TFTP

server, it appears in the lower right-hand corner of the server’s pane.

Otherwise, extract it from the OS tools (may be OS-dependent):

a. Right-click on Network Neighborhood.

b. Select Properties.

c. Select the Protocols tab.

Page 56

50 AutoView 1000R/ AutoView 2000R Installer/User Guide

d. Select TCP/IP protocol.

e. Select Properties and note the IP address.

6. Assign the IP address in the AutoView 1000R/2000R, if needed:

a. In the HyperTerminal window, type 1 to select Network Confi guration.

b. Note the AutoView 1000R/2000R IP address. The fi rst three numbers

must be the same as in the server’s IP address from step 5. The last

number must be different. If the AutoView 1000R/2000R IP address is

not correct, change it as follows: type 3 to select IP address, then enter

the correct address.

c. Type Ø to exit the Network Confi guration menu. If you changed the IP

address, wait per the directions on the screen.

7. From the main menu, type 2 to select Firmware Management. The current

version of your fi rmware displays in the Firmware Management screen.

8. From the Firmware Management menu, type 1 to select FLASH Download.

9. Type the IP address of the TFTP server and press Enter.

10. Type the name of the FLASH fi le and press Enter.

11. Confi rm the TFTP download by typing y or yes and pressing Enter.

12. The AutoView 1000R/2000R will verify the fi le you downloaded is valid.

Next you will be prompted to confi rm the upgrade. Type y or yes and Enter.

13. The AutoView 1000R/2000R will begin the FLASH upgrade process. On-

screen indicators will display the upgrade process. When the upload is

complete, the AutoView 1000R/2000R will reset and upgrade the

internal sub-systems.

CAUTION: Do not cycle power to the AutoView 1000R/2000R during this process. A

loss of power might render the appliance inoperable and require the appliance be returned to

the factory for repair. This upgrade may take up to 10 minutes to complete.

14. Once the upgrade is complete, the startup message from step 4 will appear

on the terminal screen.

Upgrading the AVRIQ firmware

NOTE: During an OSCAR-initiated upgrade, the AVRIQ status indicator in the Main dialog box

will be yellow.

The AVRIQ modules can be upgraded individually or simultaneously.

To simultaneously upgrade multiple AVRIQs:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands - AVRIQ Status. The AVRIQ Status dialog box appears.

Page 57

Appendices 51

Figure A.1: AVRIQ Status Dialog Box

3. Select one or more types of modules to upgrade. Click Upgrade.

NOTE: If your AVRIQ modules are already upgraded to the latest version of fi rmware, the

Upgrade button will not appear in the AVRIQ Status dialog box.

Figure A.2: AVRIQ Upgrade Dialog Box

4. The AVRIQ Upgrade dialog box appears. Click OK to initiate the upgrade

and return to the AVRIQ Status dialog box.

To upgrade AVRIQ fi rmware individually:

1. If OSCAR is not open, press Print Screen. The Main dialog box will appear.

2. Click Commands - Display Versions. The Version dialog box appears.

Figure A.3: Version Dialog Box

Page 58

52 AutoView 1000R/ AutoView 2000R Installer/User Guide

3. Click AVRIQ to view individual module version information. The AVRIQ

Selection dialog box appears.

Figure A.4: AVRIQ Selection Dialog Box

4. Select an AVRIQ to upgrade and click the Version button. The AVRIQ

Version dialog box appears.

Figure A.5: AVRIQ Version Dialog Box

5. Click the Load Firmware button. The AVRIQ Load dialog box appears.

Figure A.6: AVRIQ Load Dialog Box

6. Click OK to initiate the upgrade and return to the AVRIQ Status dialog box.

NOTE: During an upgrade, the AVRIQ status indicator in the Main dialog box will be yellow.

The selected AVRIQ module is unavailable while an upgrade is in progress. When an upgrade

is initiated, any current connection to the server via an AVRIQ or serial device via an AVRIQSRL will be terminated.

Page 59

Appendices 53

Appendix B: Using AVRIQ-SRL Modules

The AVRIQ-SRL module is a serial-to-VGA converter which permits VT100capable devices to be viewed from the AutoView 1000R/2000R local port or by

using the AVWorks software. The actual serial data is not accessed, but is

merely displayed. All serial data coming from the target device is displayed in

a VT100 window, placed into a video buffer and sent to the AutoView 1000R/

2000R appliance as though it came from a VGA server. Likewise, keystrokes

entered on a keyboard are sent to the attached device as though they were

typed upon a VT100 terminal.

AVRIQ-SRL module modes

The following modes can be accessed from the AVRIQ-SRL module:

• On-Line - This mode enables you to send and receive serial data.

• History - This mode enables you to review serial data.

• Confi guration - This mode enables you to specify communication parameters, the appearance of the serial data, key combinations for specifi c

actions and macros.

Configuring the AVRIQ-SRL

NOTE: The AVRIQ-SRL module is a DCE device and only supports VT100 terminal emulation.

Pressing Ctrl-F8 will activate the Configuration Screen, which contains menu

items that allow you to configure your AVRIQ-SRL module.

NOTE: When the Confi guration Screen is active, pressing Enter saves changes and returns you

to the previous screen. Pressing Esc returns you to the previous screen without saving changes.

Within the Configuration Screen, you can modify the following options:

• Baud Rate - This option allows you to specify the serial port communications speed in bits per second (BPS). Available options are 300, 1200, 2400,

9600, 19200, 34800, 57600 or 115200. The default value is 9600.

• Parity - This option allows you to specify the serial port communications

parity. Available options are EVEN, ODD or NONE. The default value

is NONE.

• Flow Control - This option allows you to specify the type of serial fl ow

control. Available options are NONE, XOn/XOff (software) and RTS/CTS

(hardware). The default value is NONE. If you select a baud rate of 115200,

the only available fl ow control is RTS/CTS (hardware).

Page 60

54 AutoView 1000R/ AutoView 2000R Installer/User Guide