Page 1

Rewinder Specifications

Height:

Width:

Depth:

Weight:

Hub

Diameters:

Rewind

Speed:

Operating

Temperature:

Storage

Temperature:

Relative

Humidity:

8.5 inches (210 mm)

12 inches (305 mm) with disks attached

10 inches (255 mm)

10 inches (255 mm)

10.9 lb. (5 kg)

3 inches (76 mm Rewinder P/N M093503)

4 inches (102 mm Rewinder P/N M093502)

1 inches (25 mm – optional kit)

3 inches (76 mm – optional kit)

Coreless (optional kit)

1 to 12 inches per second

(25 mm to 305 mm)

40F to 110F (4 C to 43C)

15F to 120F (-9 C to 49C)

Operating and Storage:

5% to 90% non-condensing

Supply Specifications

OPERATING INSTRUCTIONS

These instructions explain how to set up and use the

Monarch 935 Rewinder.

To use multiple core sizes, order Rewinder M093502 and

optional Core Kit P/N 1244 76 which includes a 1”core, a 3”

core, and a spindle and bale for coreless operation.

Unpacking the Rewinder

After unpacking the rewinder, yo u should have the rewinder,

power supply with cord, the b ase, four Phillips screws, two

supply guide disks, two core holders, and a retainer with

thumbscrew. Keep the box and packaging material in case

the rewinder ever needs repair.

Assembling the Rewinder

To assemble the rewinder, you need a Phillips screwdriver.

1. Line up the holes in the base with the holes in the

bottom of the rewinder.

2. Use the four Phillips screws to attach the base to the

rewinder. The lower pin prevents the pick-up arm from

being assembled on the wrong side of the shaft.

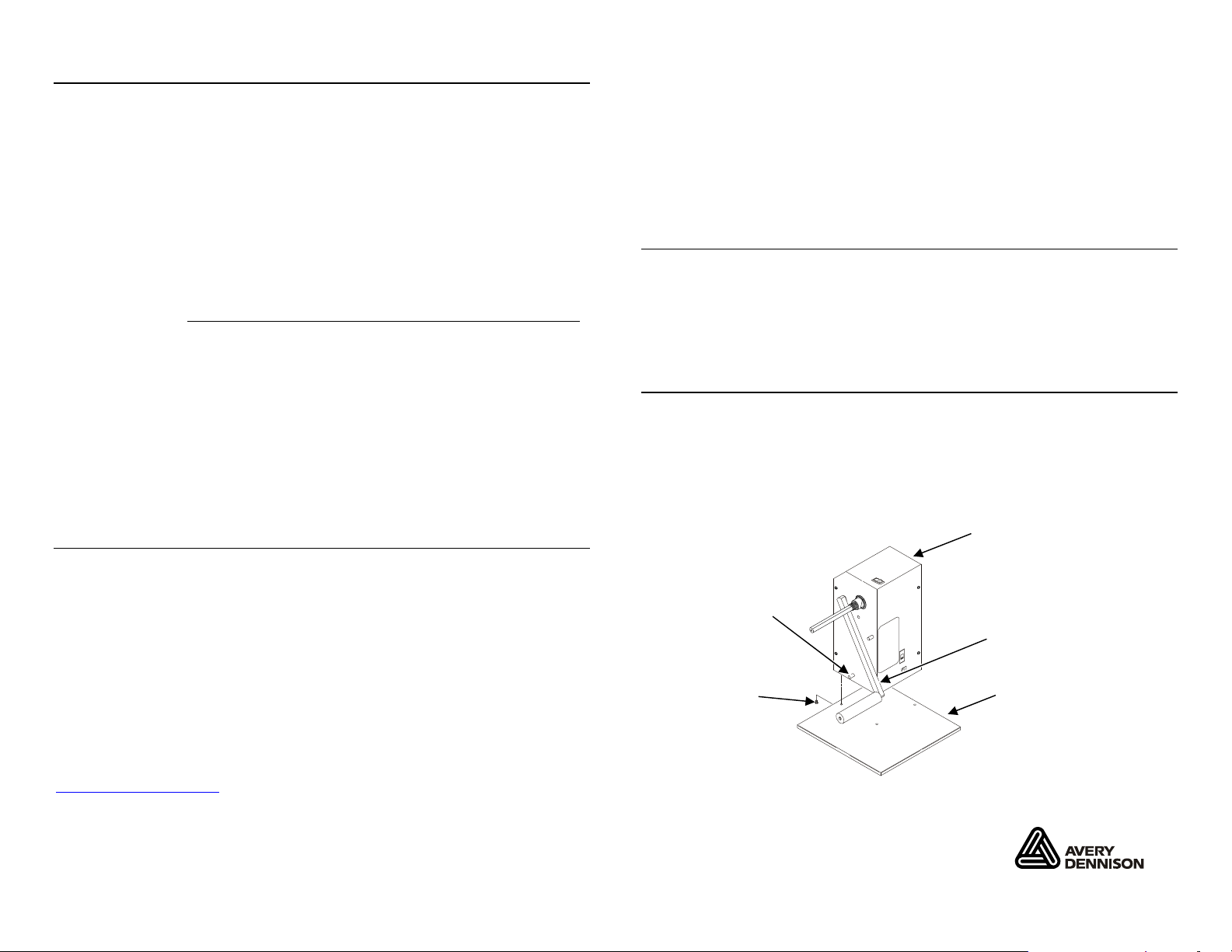

Rewinder

Supply

Thickness:

Supply

Width:

Coreless

0.005 inches to 0.012 inches

(0.13 mm to 0.30 mm)

1.2 inches to 4.125 inches

(30 mm to 105 mm)

1200 inches (30,480 mm)

Maximum:

For supplies, service or assistance, call toll free:

1-800-543-6650 (In the U.S.A.)

1-800-387-4740 (In Canada)

www.monarch.com

Pin

Pick-up arm

Phillips

Screw

Base

CAUTION: Do not lift or carry the rewinder using

the pick-up arm.

Monarch and 935 are trademarks of Avery Dennison

Retail Information Services LLC.

TC0935OI Rev. AF 10/10 2007 Avery Dennison Corp. All rights reserved.

Page 2

Setting Up the Rewinder

The rewinder includes either 3 inc h or 4-inch core holders

standard. The optional Core Kit (PN1244 76) includes 1-inch

and 3-inch core holders, a spindle and bale for coreless

operation. Order the Core Kit to match the core sizes you

need.

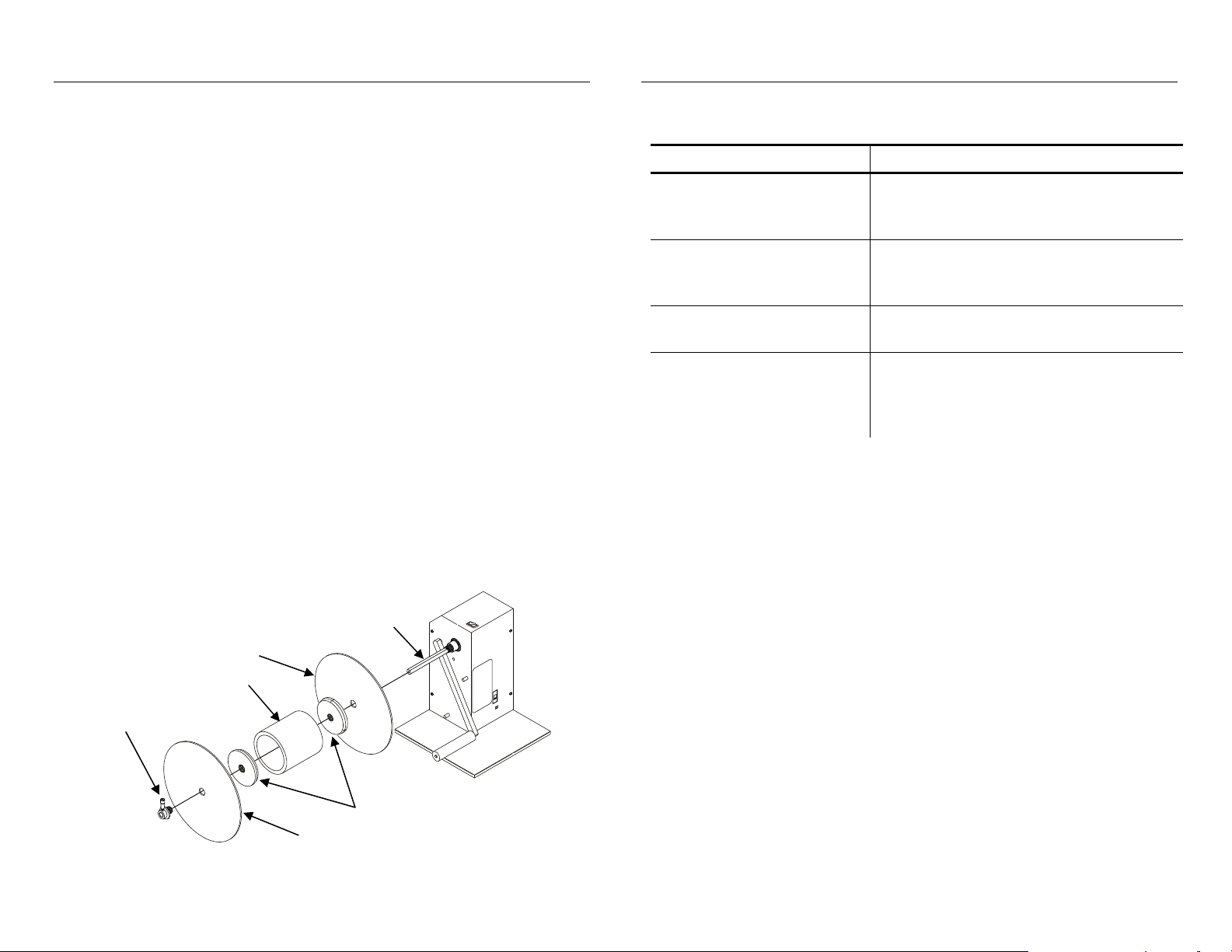

1. Slide a disk onto the shaft. Make sure the disk rests on

the small ridge on the s haft.

2. Select the core holder with the small metal clips on the

edge.

3. Slide and thread the core holder onto the shaft with the

beveled edge towards the empty core.

Note: The shaft is threaded and only the core holder wi th

the metal clips threads onto the shaft.

4. Slide an empty core onto the shaft. Make sure it rests

firmly on the core holder.

5. Slide the outer disk onto the retainer. Make sure the

disk rests on the small ri dge on the retainer. Thread the

retainer into the core holde r, tighten and slide onto the

shaft. Make sure the beveled edge of the core holder

fits into the empty core.

6. Align and tighten the thumbscrew with the flat on the

shaft to the outer disk. Do not push the outer disk in

too far.

Troubleshooting

Use the following table to c orrect some minor problems that

may occur.

Problem Action

Rewinder feeds

supply, instead of

rewinding.

The core does not stay

on the core holder.

Supply is pinched

when rewinding.

Rewinder is pulling too

hard on supply or

supply perforations are

breaking.

Note: Disable the printer’s backfe ed option when using the

rewinder; poor image place ment and/or supply

errors may occur.

Make sure the direction switch is

set properly.

Make sure the inside core holder

is the one with the small me tal

clips on the edge.

Make sure the outer disk has not

been pushed in too far.

Make sure the supply is fed

under the pick-up arm and then

attached to the empty core or

coreless adapter.

Shaft

Disk

Empty Core

Retainer

Thumbscrew

Core Holders

Outer Disk

2 7

Page 3

Removing the Supply

Connecting the Cables

1. Loosen the thumbscrew on the ou ter disk.

2. Remove the outer disk and core ho lder.

3. Remove the roll of rewound supplies.

Setting Up for Coreless Operation

The rewinder includes 3 inch or 4-inch core holders

standard. Set up is the same when using the optiona l core

holders for 1-inch or 3-inch operation, see “Setting Up the

Rewinder.”

Note: The maximum number of inches to rewind with the

coreless adapter is 1200.

For coreless operation:

1. Slide a disk onto the shaft. Make sure the disk rests on

the small ridge on the s haft.

2. Remove the bale from the coreless adapter. Slide the

threaded end of the coreless adapter onto the shaft.

3. Tighten the coreless adapter onto the shaft.

4. Place less than 0.5-inch of supply onto the adapter and

slide the bale onto the adapt er. Make sure the short end

of the bale is on the top.

5. Wind a few labels onto the adapt er.

6. Turn on the rewinder.

When finished rewinding, remove the bale and slide the roll

of rewound supplies off the shaft.

1. Plug the power supply into the inlet.

2. Plug the power cable into the power supply.

OFF

ON

Direction

Switch

Power

Inlet

Power Cable

3. Plug the other end of the cable into a grounded electrical

outlet.

4. Turn on the rewinder.

6 3

Page 4

Using the Rewinder

The rewinder can be set for inside (l abels wound in) or

outside (labels wound out) wind ing.

If the full roll of supply was wound face out, it sho uld be

rewound face out; if the full roll of supply was wound face in,

it should be rewound face in.

The winding direction switch is located directly above the

power inlet.

For outside winding:

1. Slide the direction switch t o the lower position.

2. Position and align the rewinder with the printer.

3. Thread the supply as shown.

Direction

Switch

Power

Inlet

Rewinder

Printer

Note: Feed the supply under the pick-up arm.

4. Tape the supply to the empty c ore.

5. Turn on the rewinder.

For inside winding:

1. Slide the direction switch to the upper position.

2. Position and align the rewinder with the printer.

3. Thread the supply as shown.

Rewinder

Note: Feed the supply under the pick-up arm.

4. Tape the supply to the empty c ore.

5. Turn on the rewinder.

Printer

4 5

Loading...

Loading...