Page 1

User Manual

Model 676 - LOKPRINT™

Machine Configuration 2 over 1, 1 over 1 & 2 over 0

AVERY DENNISON

Manual Edition 3.0

20 August 2004

Manual Part Number 371389

Page 2

This page intentionally blank

User Manual Model 676 LOKPRINT®

Page 3

Contents

Scope 1

Introduction................................................................................................................................ 1

Safety Issues / Warnings 1

Caution.......................................................................................................................................1

Warranty Information 2

Description / Specifications 3

Printer Description..................................................................................................................... 3

Printer Specification .................................................................................................................. 5

Personal Computer Specifications ............................................................................................. 6

Customer Responsibility 7

Location of Printer ..................................................................................................................... 7

AC Power Line .......................................................................................................................... 9

Printer Unpacking / Installation 9

Unpacking.................................................................................................................................. 9

Inventory of Components......................................................................................................... 10

Fuse Configuration................................................................................................................... 11

Installing the Power Cord ........................................................................................................ 12

Installing the PC Interface Cable ............................................................................................. 12

Installing the PC Software ....................................................................................................... 12

TCB Dip Switch S2 Settings.................................................................................................... 12

Printer Operation 13

Loading Stock .......................................................................................................................... 13

Butt Splice ............................................................................................................................... 14

Web Guides ............................................................................................................................. 14

Print Head Operation ............................................................................................................... 15

Installing Ink Ribbon ............................................................................................................... 17

Splices...................................................................................................................................... 18

Control Panel Operation 19

Printer Controls........................................................................................................................ 19

Indicator Lights........................................................................................................................ 20

Display Modes ......................................................................................................................... 22

User Manual Model 676 LOKPRINT® Scope •••• iii

Page 4

Adjustments 32

Feed Roller Pressure ................................................................................................................ 32

Sensors..................................................................................................................................... 32

Sensor Adjustments: ................................................................................................................ 32

Machine Set Up Sequence ....................................................................................................... 33

Maintenance 34

Cleaning................................................................................................................................... 34

Print Head Handling ................................................................................................................ 35

Print Head Replacement .......................................................................................................... 36

Lubrication Procedure.............................................................................................................. 39

Electrical Trouble Shooting 40

Power Up / Sign On / Communications ................................................................................... 40

Stock / Ink Advance................................................................................................................. 42

Print ......................................................................................................................................... 43

Mechanical Trouble Shooting 44

Stock ........................................................................................................................................ 44

Ink............................................................................................................................................ 45

Print ......................................................................................................................................... 45

Appendix A 46

Error Messages ........................................................................................................................ 46

Appendix B 47

Software Upgrade Chip Placement Positions........................................................................... 47

Front Panel Diagnostic Descriptions........................................................................................ 49

Appendix C 50

Printhead Life Extension.......................................................................................................... 50

Printhead Fail Modes ............................................................................................................... 51

Printhead Cleaning Procedure.................................................................................................. 52

Printhead Installation and Removal Procedures....................................................................... 53

Electrical Assembly Drawings 54

Machine Wiring ....................................................................................................................... 54

Electrical System Schematic.................................................................................................... 55

Motherboard Power Connectors .............................................................................................. 56

Mechanical Assembly Drawings 57

Unwind Assembly Drawing ..................................................................................................... 58

Unwind Parts List .................................................................................................................... 59

Web Guide Assembly Drawing................................................................................................ 60

Web Guide Parts List ............................................................................................................... 61

Drive Assembly Drawing......................................................................................................... 62

Drive Parts List ........................................................................................................................ 63

Top - Printhead Assembly Drawing......................................................................................... 64

iv •••• Scope User Manual Model 676 LOKPRINT®

Page 5

Top - Printhead Parts List ........................................................................................................ 65

Bottom – Printhead Assembly Drawing................................................................................... 66

Bottom – Printhead Parts List .................................................................................................. 67

Ink Unwind / Rewind Assembly Drawing................................................................................ 68

Ink Unwind / Rewind Parts List............................................................................................... 69

Web Tension Guide Assembly Drawing.................................................................................. 70

Web Tension Guide Parts List ................................................................................................. 71

Drive Belt Routing Drawing .................................................................................................... 72

User Manual Model 676 LOKPRINT® Scope •••• v

Page 6

Page 7

Scope

Introduction

This user manual was arranged for the person who is going to operate the machine.

The information is arranged in the order that is needed to install and operate the

machine. It starts with general information, then to unpacking the crate, installing the

stock and ink ribbon, printer operation, control panel operation, and finally care and

maintenance of the printer.

We at AVERY DENNISON hope that you will come to appreciate the efforts and

quality that has gone into producing your AVERY DENNISON 676LKP Printer and

wish to remind you that you are our number one priority. We welcome any

constructive comments or criticisms so that we may continue to offer you the best

printer in the industry for years to come.

Safety Issues / Warnings

Caution

This machine has some pinch points. All of these areas have been well guarded and

it is recommended that the safety features of this machine are never altered or

defeated.

User Manual Model 676 LOKPRINT® Scope •••• 1

Page 8

Warranty Information

Limited Warranty

AVERY DENNISON extends the following warranties to the original purchaser of a

AVERY DENNISON 676LKP that has been installed and operated using

recommended procedures and operating conditions.

Parts

Parts found defective in material or workmanship will be replaced at no charge for a

period of six months following the machine's shipment date. Parts damaged by

negligence, abuse, or normal wear are not covered. AVERY DENNISON 676LKP

parts classed as normal wear items include print heads, feed and platen rollers, and

knife blades.

Service

Service to replace defective parts as defined above, shall be provided at no charge for

a period of six months following the shipment date.

When ordering machines and supplies in the U.S.A., reference all correspondence to

the address below.

AVERY DENNISON

One Wilcox Street

Sayre, Pa. 18840

Call: 1-800-967-2927 or (570) 888-6641

Fax: (570) 888-5230

For spare parts, requests for service or technical support

AVERY DENNISON

One Wilcox Street

Sayre, Pa. 18840

Call: 1-800-967-2927 or (570) 888-6641

Fax: (570) 888-5230

For parts and service in other countries please contact your local AVERY

DENNISON supplier.

AVERY DENNISON reserves the right to incorporate any modifications or

improvements in the machine system and machine specifications which it considers

necessary and does not assume any obligation to make said changes in equipment

previously sold.

2 •••• Warranty Information User Manual Model 676 LOKPRINT®

Page 9

Description / Specifications

Printer Description

The AVERY DENNISON MODEL 676 LKP THERMAL PRINTER (Figure 1) is

an electronic printer that can print on noncoated polyester stocks. The printer is

available as a 2 station single sided printer, a 2 over 1- two-sided printer and as a 1

over 1 - two-sided printer. The printer interfaces to a computer or a main frame

system that allows for computer input or even design of a label with AVERY

DENNISON’S PCMate Plus's “FORMATTER” program. The printer can generate a

complete label printed on one side, with two colors on the top, two sided with either

two colors on top with a third on the bottom, or one color on top with a second color

on the bottom.

• Design your own labels on a PC

• Computer interface = IBM Compatible

• Mainframe direct interface

• RS232 9 Pin D shell female Serial interface connector

Figure 1 - AVERY DENNISON MODEL 676LKP LABEL

PRINTER

User Manual Model 676 LOKPRINT® Description / Specifications •••• 3

Page 10

4 •••• Description / Specifications User Manual Model 676 LOKPRINT®

Page 11

Printer Specification

Print method: Narrow web thermal transfer printer

Speed – 3,4, and 5 IPS (76.2, 101.6, and 127mm/second) – w/ Lokprint II, 5” only

Label Size Min: 1.062" (27mm) web x 1" (25.4mm) feed

Max: 2.0" (51mm) web x 1.0" (25.4 mm) feed

2.0" (50.8mm) web x 5.0" (127 mm) feed

Cutting No cutter included on printer

Print Area Min: None

Max: up to 2" (50.8mm) web x up to 13.875" (352.4 mm) feed

Resolution 300 DPI x 300 DPI

Fonts

recommended

for 676LKP

printers

Logos No restriction on number or size per tag (up to maximum image area)

Care Symbols Full Ginetex Care Symbol set and full NAFTA / ASTM Care Symbol Set

Justification Left, Right, and Center field selectable

Stock Support for blank sublimation fabric only

Interface AVERY DENNISON PCL via RS232 serial port - 9 pin D-shell

Control Panel Push-button printer function with 2 Line x 24 Character International LCD Backlit Display

Dimensions 17.0" (431.8mm) high x 33" (838.2mm) wide with 10” O.D. supply roll (30” (762mm) printer

Weight 107 Lbs. (48.5Kg.) Shipping Weight = 130 Lbs. (58.9Kg.)

Electrical 90-132 / 180-265 VAC 50-60Hz 10Amp 1 Ph User selectable through AC entry fuse config.

Temperature

Humidity 5% to 90% non-condensing

- Resident in the printer and tested in Lokprint applications: Swiss 721Bold, Swiss 721 Heavy,

Swiss 721 black condensed, Swiss 721 Medium.

- Tested, must be ordered as an option: Swiss 721 BT 0003

- 7pt up to 96pt (300 DPI),

- All rotations 0°, 90°, 180°, 270°

All rotations 0°, 90°, 180°, 270°

Fully Scaleable

All rotations 0°, 90°, 180°, 270°

only) x 20.0" (508.0mm) deep

41°F (5°C) to 104°F (40°C)

User Manual Model 676 LOKPRINT® Description / Specifications •••• 5

Page 12

Other Features - Downloading of information while machine is operating

- Sequenced Fields

- Time/Date Stamping (Both month/day/year and day/month/year format)

- Life Counts

- Operator adjustable: strobe, cut position, print position, baud rate, and buffer size

- Error Detection of: stock out, ink out, print head open, feed open, full stacker, stacker jam,

and print head over-temperature

- Display: labels left to be cut and stacked in a batch, batch ID, total life inches, total life

cuts

- Self Diagnostics

Ink Ribbon AVERY DENNISON high energy dye sublimation

Options - PCMate Plus w/Formatter – 800264 on 3 ½” disks or 800264CD on CD disk

- Spare Parts Kit – 370016 for all head configurations

- International Hardware Kit - 370014

Personal Computer Specifications

This specification describes the hardware and application software requirements for

the Personal Computer that is used to download to the AVERY DENNISON 676

LKP Printer.

The AVERY DENNISON AVERY DENNISON 676 LKP Printer uses a Windows

version of “PcMate Plus / Formatter”. This application will create the tag or label

formats (layouts) then fill and transfer data to the printer through the serial port of the

computer.

“PcMate Plus / Formatter ” Requires the following;

• IBM® PC or compatible

• Microsoft Windows® 98 2nd edition or higher

(Including Win 2000, ME, NT, and XP)

• 64 Megabytes RAM

• 1 Gigabyte Hard Drive

• Pentium or Pentium Type processor - 400 Mhz or higher

• 3-1/2" floppy drive and CD Rom

DISK DRIVES: You will need a hard disk with at least 100 megabytes of free disk

space to store the PCMate Plus program. Additional space will be required to store

formats, batches, etc.

Refer to your specific software package for proper installation procedures.

6 •••• Description / Specifications User Manual Model 676 LOKPRINT®

Page 13

Customer Responsibility

Location of Printer

The printer weighs approximately 250 Lbs (113.4 Kg) and requires a table of

sufficient quality and strength to handle this load while the printer is operating.

AVERY DENNISON recommends an industrial type worktable having the

approximate dimensions of 96" (245.8cm) wide to 30" (76.2Ccm) deep to 32"

(81.3cm) high. Refer to Figure 2.

Figure 2 - Recommended Workstation Layout.

The location of the AVERY DENNISON 676 LKP printer should be based on

human factors. The printer should be located in an area that maintains optimum flow

of your product while providing for the operator’s comfort. AVERY DENNISON

has taken significant steps to ensure that the operator controls and operations are

easily accessible. This goal can only be met, however, if the printer is also located

with human factors in mind. These include the height of the printer, the space around

the printer, and the accessibility to the printer.

The AVERY DENNISON 676 LKP printer is a high-resolution 300 DPI thermal

printer. While AVERY DENNISON has designed the printer to be reasonably quiet,

it is recommended to locate the printer in an area where printing and cutting

repetitious noise is acceptable.

The AVERY DENNISON 676 LKP printer is designed to operate in conjunction

with the AVERY DENNISON Lokprint™ II box and either an Ultrasonic Finisher, a

Cold Knife Finisher or a Rewind Unit.

User Manual Model 676 LOKPRINT® Customer Responsibility •••• 7

Page 14

The unit should always be operated with the cover closed to minimize the amount of

dust and dirt in the machine.

8 •••• Customer Responsibility User Manual Model 676 LOKPRINT®

Page 15

AC Power Line

AVERY DENNISON requires that the electric service be 10 Amps @ 115VAC or 10

Amps @ 230VAC. This will allow the computer and any additional support or

service equipment to be plugged into the same service.

Any electrical service which is supplying a AVERY DENNISON printer or

peripheral equipment connected to a AVERY DENNISON printer should follow

standard electrical code practices including proper grounding and neutral

requirements.

The AVERY DENNISON printer was designed to operate in an industrial setting for

extended periods of time; however, the printer is controlled by a microprocessor

which is very sensitive to brownouts or power spikes. For this reason as well as the

minimum recommended current supply, AVERY DENNISON recommends that a

separate “clean” service be installed or reserved for the exclusive use of the AVERY

DENNISON printer and it’s peripherals.

Printer Unpacking / Installation

Unpacking

The AVERY DENNISON printer is shipped in a large cardboard box that may be

difficult to move by hand.

DO NOT REMOVE THE PRINTER FROM THE PACKAGE OR UNPACK

IN THE SHIPPING / RECEIVING DEPARTMENT.

NOTE: Unpacking in the shipping / receiving department is not recommended for

the following reasons.

First: The box in which your AVERY DENNISON printer was shipped allows the

printer to be moved with a forklift, forkcart or handcart. Because of the

weight of the printer, it is easier and safer to use one of these devices to

move the printer to its intended installation location.

Second: Leaving the printer in the crate while it is being moved within your

facility will help to protect the printer during the movements to this new

location. Once the printer has reached its intended location you should

begin the unpacking process.

Open the box from top by removing the two (2) banding straps and cutting the tape

seam on top of the printer. (See Figure 3).

Remove the plastic over the printer.

Remove all the smaller loss items from in and around the printer.

There is a sleeve to lift the printer from the box for easy removal.

Lift the printer onto the table.

User Manual Model 676 LOKPRINT® Printer Unpacking / Installation •••• 9

Page 16

Inspect the machine for shipping damage. If obvious damage is discovered, contact

AVERY DENNISON for further instructions - in the U.S.A. at (570) 888-6641. In

countries other than the U.S.A. please contact your local AVERY DENNISON

supplier.

Figure 3 - Shipping Box.

Save the shipping materials to relocate the unit or return to factory for service.

Inventory of Components

The following list shows the additional parts (pieces) that should be included in your

AVERY DENNISON 676 shipping crate. If anything is missing, notify AVERY

DENNISON immediately - in the U.S.A. at (570) 888-6641. In countries other than

the U.S.A. please contact your local AVERY DENNISON supplier.

- AVERY DENNISON 676 LKP "User's Manual"

- A quick-disconnect power cord

- A serial communications cable with adapter

- Optional software ordered to drive the printer.

- Tool kit

NOTE: Some of the above parts may be inside the envelope that contains the tool

kit.

AVERY DENNISON 676LKP TOOL KIT (#371391)

241149 Anti-Static Gloves (2)

241132 Anti-Static Wrist Strap

921309 Hex Key Set

101330 9/64” Ball Driver

921304 5/32” Ball Driver

921364 3/16" Long Ball Driver

351156 Chip Removal Tool

371389 676LKP Users Manual

921353 Phillips Head Screwdriver

921338 T-T Printer Cleaning Kit

10 •••• Printer Unpacking / Installation User Manual Model 676 LOKPRINT®

Page 17

Fuse Configuration

Location of 115V Text

Location of 230V Text

A

The main fuse(s) on the AVERY DENNISON 676 LKP are located inside the AC

power entry receptacle. The entry has a fuse drawer that holds the fuse(s) and selects

the appropriate line voltage. If the number in the window DOES NOT match the AC

line intended to be supplied to the printer, DO NOT plug the power cord in. Re

configure as follows:

1) Using a flat blade screwdriver, open the AC entry by lifting the tab just above the

voltage indicator window.

WARNING: Attempting to open the AC entry with the AC power cord inserted into

2) Remove the red fuse drawer.

3) Remove all fuses and the fuse jumper if it is present.

4) Insert into the fuse drawer the correct number and style of fuses and fuse jumper

for your application.

Configuration Number One: Line voltage between the range of

90 - 132VAC @ 50 - 60Hz 1 Ph

1) Install one 921167 - 10.0A 250V Fast Acting 1/4 x 1 1/4"

2) Install one Fuse Jumper

See Figure FUSE1

Configuration Number Two: Line voltage between the range of

1) Install two 921168 10.0A 250V Fast Acting 5 x 20MM

it will cause damage to the AC entry.

180 - 265VAC @ 50 - 60Hz 1 Ph

FUSE 1 FUSE 2

Fuse Jum per

One 1/4 x 1 1/4" Fuse Far Side

NOTE: The fuse jumper must be removed to install both 5 x

20mm fuses.

The fuses must be between points A and B as shown not B and C.

See Figure FUSE2

5 x 20 m m fuse

FRONT FRONT

Location of 115V Text

B

Location of 230V Text

Two 5 x 20MM Fuses One Each Side

5) Reinsert the fuse drawer into the AC entry with the desired voltage up.

6) Close the AC entry and verify the correct voltage is now visible.

C

User Manual Model 676 LOKPRINT® Printer Unpacking / Installation •••• 11

Page 18

Installing the Power Cord

A power cord is shipped with each printer. The cord for 115-volt printers will use

the standard three-prong plug used in the U.S.A. A 230-volt printer and some other

115-volt configurations must have the receptacle end of the connector removed and

the proper plug installed. It is the customers’ responsibility to have the plug and

alteration work done by a certified electrician. AVERY DENNISON supplies

printers to many countries with many variations. Therefore we leave this to the

customer to make the proper selection for their country.

Installing the PC Interface Cable

The 676 requires a 9-pin RS232 cable. This cable is provided with the printer. If the

cable was not found it can be ordered from AVERY DENNISON (Part no. 351124).

The male end of the cable should be connected to the 9-pin D-shell female connector

that is located on the right side of the printer. The female end of the cable is made to

fit a 9-pin male RS232 connector on the back of the PC.

Installing the PC Software

The software to drive the AVERY DENNISON family of printers is covered in

separate documentation. The “Formatter” software to create formats for the AVERY

DENNISON 676 printer is a Windows application. The original software “Selfform”

will not create formats for the 676. The new "PCMate" package is capable of making

formats for all AVERY DENNISON control printers.

PCMate Plus Ver. 3.21.32 will support the 676LKP. Lower versions may not contain

the test drivers.

The printer is also capable of operating directly from a mainframe when using the

RS232 interface and AVERY DENNISON's PCL command language.

TCB Dip Switch S2 Settings

DIP SWITCH # DEFINITION 676 LOKPRINT™

8 LOKPRINT™ OFF

7 UNUSED OFF

6 UNUSED OFF

5 STACKER OFF

4 MACHINE

TYPE

3 MACHINE

TYPE

2 UNUSED OFF

1 300 DPI ON

ON

ON

12 •••• Printer Unpacking / Installation User Manual Model 676 LOKPRINT®

Page 19

Printer Operation

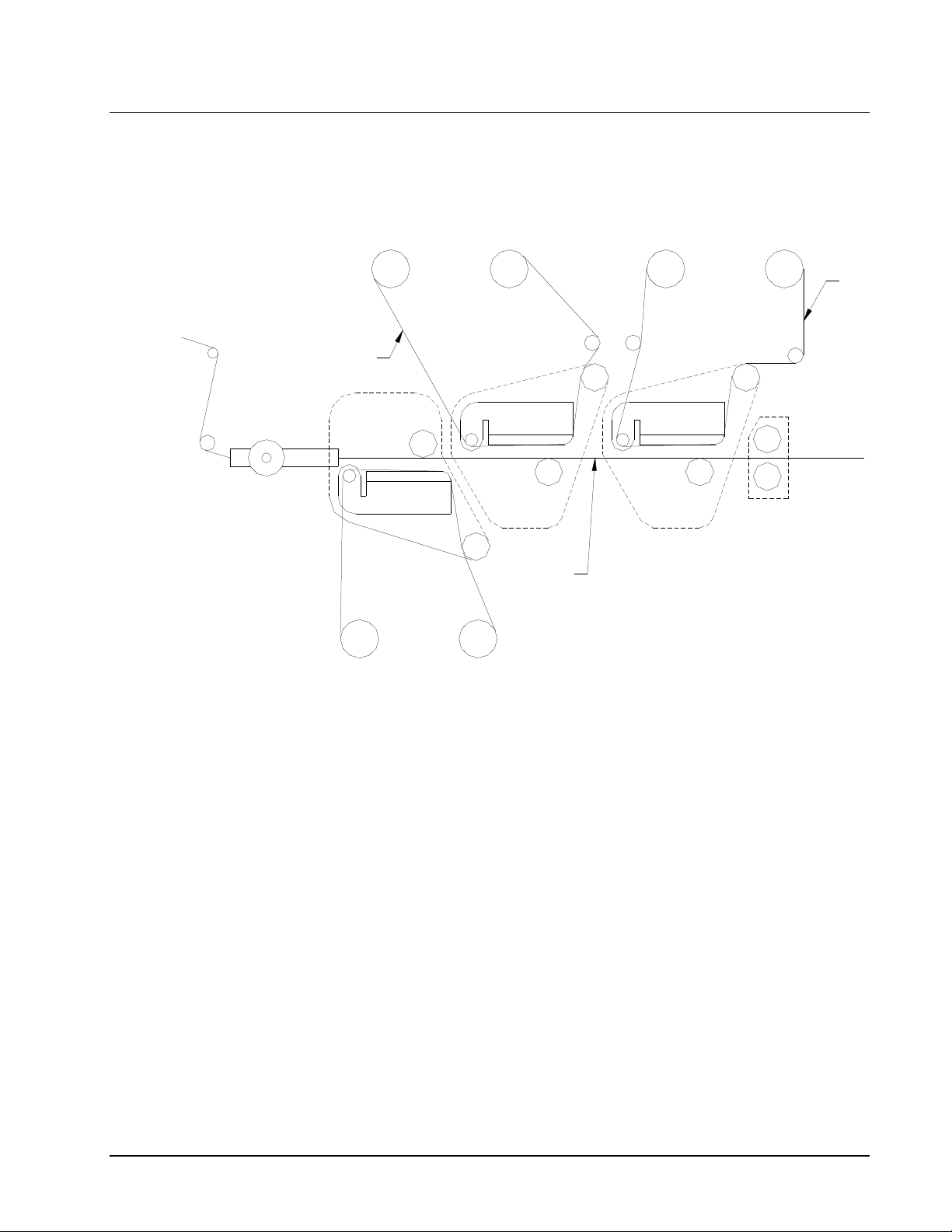

Loading Stock

FABRIC

SUPPLY

HEAD 2

INK

TAKE-UP

HEAD 2

SUPPLY

HEAD 3

TAKE-UP

HEAD 3

INK

WEB GUIDE

SUPPLY

HEAD 1

HEAD 1

TAKE-UP

HEAD 1

HEAD 2

STOCK

HEAD 3

DRIVE / AUX

Figure 4 - LOKPRINT® Threading Diagram

Loading Stock For The First Time

1) Adjust the unwind width wider than the roll of stock to be loaded. Set the stock

roll on the unwind between the guides with the stock unwinding from the top

clockwise. Adjust the unwind width down to the stock size with the outer guide

contacting the roll. Turn the knob an additional ½ turn clockwise. This will

activate the constant backpressure device.

2) Adjust the web guides to a width wider than the stock.

3) Remove the tape or pull the glued end of the stock loose from the supply roll of

stock. Pull off about 2 feet (.5 m) of stock to thread it through the printer.

NOTE: If the material was glued to the core, cut off all material that has glue on any

surface.

4) Open the hinged cover to the machine.

5) Open all print heads that are in use by pulling the release knob and then rotating

the print heads into the open latched position. The print stations have a pin in

the rear to hold them open.

User Manual Model 676 LOKPRINT® Printer Operation •••• 13

Page 20

Butt Splice

6) Open the feed rollers by rotating the feed pressure knob counterclockwise.

7) After looping the leading edge of the stock over the decurler slide it through the

web guides. Keep the stock in the center, as the printer is center justified.

8) As the stock exits the web guides, continue to slide the stock through the print

stations.

9) Once the stock reaches the feed rollers it maybe necessary to hold the feed

pressure knob open in order to pass between the rollers.

10) Check that the stock is centered and tracking straight through the printer. Adjust

as needed.

11) Allow feed to close (spring loaded). Close the printheads that are in use. Do not

run a station closed that is not in use. This will cause premature head failure.

12) Rewind any loose stock back onto the supply roll.

13) Adjust the web guides on the decurler down to the edges of the stock without

deforming the stock.

NOTE: DO NOT RUN BUTT SPLICES THROUGH THE PRINT STATIONS

The AVERY DENNISON 676 LKP has been designed keeping the operators need to

change supplies quickly and often in mind. Re threading the stock is quicker than

butt splicing is. If however you have determined a butt splice is necessary, after

loading a new roll of stock onto the unwind tape the free ends together. Remove all

slack by rotating the supply roll counterclockwise. To prolong print head life it is

highly recommended that all hand splices be advanced beyond the print stations

before printing is resumes. This can best be accomplished by using the stock

presently in the print stations to manually pull the new stock through and into the

stacker. Once the butt splice is in the stacker close the feed rollers and those print

stations needed for the format.

NOTE: Whenever stock of a different type or width is put on the printer, a sample

run should be performed. If the print quality / position is acceptable, you

can immediately begin your production run. If the print quality / position

needs to be optimized, refer to the Adjustments section and perform the

procedure needed to make the necessary improvement.

Web Guides

The AVERY DENNISON 676 LKP printer has been designed with the operators'

needs in mind. Therefore there are only two sets of web guides in the printer that

need to be changed as the width of the rolls change for various width stocks. Neither

of these adjustments require a tool.

The first guide is on the unwind itself. A knob located on the front of the unwind

adjusts the width of the guides on the unwind while maintaining center justification.

To increase the width, turn the knob counter clockwise - to decrease the width, turn

the knob clockwise. Adjust the unwind width wider than the roll of stock to be

loaded. Set the stock roll on the unwind between the guides with the stock

unwinding from the top clockwise. Adjust the unwind width down to the stock size

14 •••• Printer Operation User Manual Model 676 LOKPRINT®

Page 21

with the outer guide contacting the roll. Turn the knob an additional ½ turn

clockwise. This will activate the constant backpressure device.

The second set of guides are located on the decurler just to the left of the stock

registration funnel. Once a stock is loaded and tracking straight through the machine

adjust this set of web guides down to the edges of the stock without deforming the

stock. If a large distance is to be covered - loosen the plastic thumb screw and slide

the collar into the new position - then retighten the thumbscrew. Fine adjustments of

the stocks web position can be made by simply moving the collar as a set in or out. If

the guides are too tight, the stock will have rolled up edges.

CENTER

FRAME

REAR

WEB GUIDE

PRESSURE ASSEMBLY

373093 (NEW)

SHOULDER BOLT

989995 (NEW)

8-32 NUT

990069 (NEW)

Print Head Operation

The print head modules are to be opened and closed for threading of stock and ink.

The unit must also be opened to clean the head and for print head replacement. Later

in the manual, under separate headings, cleaning and replacement will be covered.

For clarity the print stations have been assigned numbers one through three from left

to right. The far-left print station prints the back, it is print station number one. The

center and right print stations print on the top, they are stations two and three. Each

print station has an interlock switch that prevents the printer from running with any or

all print stations in the open position if that print station is assigned in the format

being printed. If a print station is open, the display will read HEAD OPEN

STATION X.

WARNING: DO NOT TOUCH THE PRINT HEAD WITHOUT WEARING THE

To open the print heads for threading supplies or cleaning pulling the release knob

and then rotating the print head into the open latched position (see figure 5). The top

two print stations have a pin in the rear to hold them open. The bottom print station

will remain open via gravity - however it has a hole in the rear to hold the print head

in a slightly open position to act as a bridge when one is threading stock.

ANTI-STATIC GLOVES AND THE ANTI-STATIC WRIST STRAP.

User Manual Model 676 LOKPRINT® Printer Operation •••• 15

Page 22

Figure 5 - Print Head Open / Closed

To close the head again pull the release knob and then rotate the print head into the

closed latched position (see figure 5).

16 •••• Printer Operation User Manual Model 676 LOKPRINT®

Page 23

Installing Ink Ribbon

The ink ribbon comes pre-packaged in a plastic bag. For best results, leave the ink

ribbon wrapped in this bag until you are ready to use it in the printer. Use the

procedure and diagram below for loading the ink.

TAKE-UP

HEAD 1

TAKE-UP

HEAD 2

HEAD 2

STOCK

FABRIC

WEB GUIDE

SUPPLY

HEAD 1

SUPPLY

HEAD 2

INK

HEAD 1

SUPPLY

HEAD 3

HEAD 3

TAKE-UP

HEAD 3

DRIVE / AUX

INK

Figure 6

1) Unwrap the ink ribbon and put it on the ink-ribbon supply arbor for the print

station to be loaded (Figure 6) by pressing it on to the arbor when the three slots

are lined up.

2) Make sure the ink ribbon comes off the roll in the direction shown and is threaded

as illustrated (Figure 6).

NOTE: A new ink ribbon has a leader that makes it easier to use when threading the

ribbon through the print area.

3) Place an empty ink-ribbon take-up core on the ink-ribbon take-up arbor for the

print station to be loaded. The ink take-up core must be at least as wide as the ink

supply.

4) Open the print head to the print station being loaded.

5) After starting the leader off the supply roll - pull enough ink off to thread though

the print station and onto the take up core. The adhesive on the supply roll of ink

will be used to fasten the leader to the take up core.

NOTE: Make sure that the ink-ribbon take-up core and the ink-ribbon supply roll

are both against the ink backer plate so that the ink ribbon tracks straight

through the print station.

User Manual Model 676 LOKPRINT® Printer Operation •••• 17

Page 24

Splices

The sonic splices were dropped because they were damaging print heads and would

not pull through the web guides.

The new splice tape will not damage the printer, but will NOT print. The new splice

may cause a sensor error on the SS Finisher. However, they will sonically cut.

18 •••• Printer Operation User Manual Model 676 LOKPRINT®

Page 25

Control Panel Operation

Printer Controls

Start

- Starts the printer

- ON LINE light must be GREEN

(Batches downloaded to be printed)

Feed

- FEED and START must both be used

- Feed will stop when the buttons are released

- Labels between print station one and the knife will be cut and stacked as

finished labels

- Stock moves through in one continuous strip

- Stock moves through without printing

- Ink will advance, ink save on print station two will automatically be

activated.

- The print heads must be latched in the down position.

User Manual Model 676 LOKPRINT® Control Panel Operation •••• 19

Page 26

Indicator Lights

Test

- TEST and START must both be used

- Test will stop when the buttons are released

- Labels between print station one and the knife will be cut and stacked as

finished labels

- Stock moves through in one continuous strip

- Stock moves through with test pattern printing

- The ink will advance with the stock.

- The print heads must be latched in the down position.

Stop

- The stop button will stop the printer at the end of the current label being

printed.

The AVERY DENNISON 676 has three Indicator lights. These lights are used along

with the LCD display to tell the operator the current status of the printer.

On Line

OFF

- Has not been powered on.

- Is in its power - up sequence.

- Failed the system test

After Power Up Sequence:

- Printer is running.

20 •••• Control Panel Operation User Manual Model 676 LOKPRINT®

Page 27

ORANGE

- System is operational

- Ready for batches to be downloaded

GREEN

- Batches to print, ready to start

Sensor

GREEN = "C" SENSOR

- Printer is stopped, - light is on, - sensor is positioned over a web sensor

mark

- Flashing light while the printer is running, - the sensor is in-line with the

registration HOLES

ORANGE = REFLECTIVE SENSOR

- Flashing light while the printer is running, - the sensor is in-line with the

registration PRINTED MARKS

Error

ORANGE

- System inter-lock triggered, display for error LCD Display

The LCD display is a 2 line, 24 character, with back lighting feature for easy

readability. The first line of the display, in most cases, will be a prompt or question the second line is the response.

User Manual Model 676 LOKPRINT® Control Panel Operation •••• 21

Page 28

Display Modes

R E A D Y F O R B A T C H E S

6 7 6 / 3 0 0 / L O K P R I N T I I

B A T C H I D

P C L 0 0 1 1 0

There are four (4) main mode levels that are selected and modified using the

following function keys:

Use the MODE ↓ key to move through the main mode screens shown below:

Pressing the EXIT / Up arrow button will put the user at one of these two screens.

HOME SCREEN

OR

Q U A N T I T Y

Press the MODE / Down arrow button will cycle the panel through the following

main screens.

PRINTER ADJUSTMENTS

P R E S S E N T E R F O R

P R I N T / C U T P O S I T I O N S

PRINTHEAD ADJUSTMENTS

P R E S S E N T E R F O R

P R I N T H E A D S E T U P

CALIBRATE SENSORS

P R E S S E N T E R F O R

C A L I B R A T I N G S E N S O R S

LIFE COUNTS / VERSIONS

P R E S S E N T E R F O R

L I F E C O U N T S / V E R S I O N S

22 •••• Control Panel Operation User Manual Model 676 LOKPRINT®

Page 29

SETUP SCREEN

P R E S S E N T E R F O R

F E A T U R E S E T U P

VERIFIER SETUP SCREEN

P R E S S E N T E R F O R

V E R I F I E R S E T U P

POWER UP DIAGNOSTICS

D I A G N O S T I C T E S T 1

This screen is displayed while the Front Panel is initializing and waiting for the

Thermal Control Board (TCB) response. While this screen is displayed the code will

check the functionality of the LED's and the display. Each state of the LED's will be

checked - (red, green, amber and off). The LCD is checked by writing a character to

the display, checking for communications and then reading the character back and

comparing with the code. If an error occurs, the code will halt the diagnostic test and

blink the ERROR LED.

The keypad is also checked during DIAGNOSTIC TEST 1. Each key is tested to see

if it is stuck on. If a fault condition is detected, the test is halted and the screen will

display the first error key found with the following display:

( B U T T O N N A M E ) K E Y S T U C K

The (BUTTON NAME) will be one of the push button names on the front panel START, FEED, TEST, STOP, EXIT, MODE, <YES, NO>, OR ENTER.

When the code has finished the above tests, the code will attempt to communicate

with the Control Board (TCB).

D I A G N O S T I C T E S T # # #

T C B V E R S I O N 0 0 . 0 0

This screen will be updated with diagnostic numbers as the TCB and AT go through

different stages of PowerPC initialization.

The diagnostic test screen will also be displayed when the Diagnostic tests that are

runable from the front panel are being executed.

Once the diagnostic tests are complete, the Front Panel should display the HOME

screen.

User Manual Model 676 LOKPRINT® Control Panel Operation •••• 23

Page 30

HOME SCREEN

T P A T T E R N

R E A D Y F O R B A T C H E S

6 7 6 / 3 0 0

OR

B A T C H I D

P C L 0 0 1 1 0

When the printer is powered up and all initializations are complete, if there aren’t any

Batches to print, the "HOME" screen will be "READY FOR BATCHES" and the

model and print head density.

When there are Batches to be printed, the "HOME" screen will be the

"BATCH ID QTY" screen. The Batch ID / Batch Qty screen displays the

currently cutting batch ID and labels remaining to be cut.

Note: Look into suppressing leading zeros on batch quantity.

When the Batch Id / Qty screen is the home screen and the user presses the EXIT

button the Model and DPI are displayed briefly before the Batch Id / Qty screen is

shown.

If the printer is performing a FEED or a TEST pattern, the screen will show

"FEEDING" or "PRINTING TEST PATTERN" respectively on line two, the top line

will be blank

F E E D I N G

P R I N T I N G T E S

Q U A N T I T Y

Pressing the MODE / Down Arrow key will take the user to the "PRINT / CUT

POSITIONS" screen.

Pressing the EXIT / Up Arrow key will take the user back to the "HOME" screen.

24 •••• Control Panel Operation User Manual Model 676 LOKPRINT®

Page 31

PRINT / CUT POSITIONS

P R E S S E N T E R F O R

P R I N T / C U T P O S I T I O N S

This screen follows the Batch ID / Batch Qty screen if there are batches to print,

otherwise it follows the “Ready for batches” / Model DPI “HOME” screen.

Pressing ENTER will take the user to the PRINTER ADJUSTMENTS screens.

Pressing the MODE / Down Arrow key will take the user to the "PRINTHEAD

SETUP" screen.

Pressing the EXIT / Up Arrow key will take the user back to the "HOME" screen.

PRINTER ADJUSTMENTS

P R E S S E N T E R T O

P R I N T C H E C K O U T F O R M A T

This screen is the first screen under PRINTER ADJUSTMENTS. Pressing ENTER

will cause the printer to print the checkout format. The printer will setup to do the

checkout format and start printing. The front panel will remain on this screen so the

user can use the MODE / Down Arrow key to get to the printer adjustments. When

the EXIT / Up Arrow key is pressed the printer stops printing the checkout format

and goes back to what it was doing before the checkout was requested.

Pressing the MODE / Down Arrow key will take the user to the first screen of this

group. Pressing the EXIT / Up Arrow key will take the user back to the "HOME"

screen.

P R I N T P O S I T I O N S T A T I O N 1

V A L U E : ± X X N E W V A L U E : ± Y Y

Station 1 not used.

P R I N T P O S I T I O N S T A T I O N 2

V A L U E : ± X X N E W V A L U E : ± Y Y

This screen follows the first screen under PRINTER ADJUSTMENTS. This screen

allows the print position of station 2 to be adjusted.

The <YES / NO> buttons are used to change the print value.

The value is displayed in a positive / negative format. The value ranges for XX and

YY can be from a -9 to a +9

Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the HOME .

User Manual Model 676 LOKPRINT® Control Panel Operation •••• 25

Page 32

P R I N T P O S I T I O N S T A T I O N 3

V A L U E : ± X X N E W V A L U E : ± Y Y

This screen follows the second screen under PRINTER ADJUSTMENTS. This

screen allows the print position of station 3 to be adjusted.

The <YES / NO> buttons are used to change the print value.

The value is displayed in a positive / negative format. The value ranges for XX and

YY can be from a -9 to a +9

Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the HOME .

S T A T I O N 2 D O T S H I F T

V A L U E : ± X X N E W V A L U E : ± Y Y

This screen follows the CHANGE CUT POSITION screen. This screen allows the

print position of station 2 to be adjusted in the WEB direction.

The <YES / NO> buttons are used to change the shift value.

The value is displayed in a positive / negative format. The value ranges for XX and

YY can be from a -16 to a +16 dots. (One dot is 1/300")

Pressing the MODE / Down Arrow key will take the user to the first screen under

PRINTER ADJUSTMENTS.

Pressing the EXIT / Up Arrow key will take the user back to the HOME.

PRINTHEAD SETUP

P R E S S E N T E R F O R

P R I N T H E A D S E T U P

This screen follows the PRINT POSITIONS screen.

Pressing ENTER will take the user to the PRINTHEAD SETUP screens.

Pressing the MODE / Down Arrow key will take the user to the "LIFE COUNTS /

VERSIONS" screen.

Pressing the EXIT / Up Arrow key will take the user back to the "HOME" screen.

C H A N G E S T R O B E S T A T I O N 2

V A L U E : ± X X N E W V A L U E : ± Y Y

This screen follows strobe adjust for station 1. This screen allows the user to adjust

the strobe for station 2. The <YES / NO> buttons are used to change the print value.

The value is displayed in a positive / negative format. The value ranges for X and Y

can be from a -7 to a +7. Pressing ENTER will change the CURRENT STROBE

value to the NEW STROBE value.

Pressing the MODE / Down Arrow key will take the user to the next screen. Pressing

the EXIT / Up Arrow key will take the user back to the HOME screen.

26 •••• Control Panel Operation User Manual Model 676 LOKPRINT®

Page 33

C H A N G E S T R O B E S T A T I O N 3

V A L U E : ± X X N E W V A L U E : ± Y Y

This screen follows strobe adjust for station 2. This screen allows the user to adjust

the strobe for station 3. The <YES / NO> buttons are used to change the print value.

The value is displayed in a positive / negative format. The value ranges for X and Y

can be from a -7 to a +7. Pressing ENTER will change the CURRENT STROBE

value to the NEW STROBE value.

Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the HOME screen.

H E A D C A T E G O R Y S T A T I O N 2

V A L U E : ± X X N E W V A L U E : ± Y Y

This screen follows HEAD CATEGORY STATION 1. The screen allows the user to

enter the head category for station 2. The <YES / NO> buttons are used to change

the head category value. The value ranges from 1 to 8. Pressing ENTER will change

the head category value to the new value. See the section “PRINTHEAD

REPLACEMENT” for instructions on setting the head category.

Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the HOME screen.

H E A D C A T E G O R Y S T A T I O N 3

V A L U E : ± X X N E W V A L U E : ± Y Y

This screen follows HEAD CATEGORY STATION 2. The screen allows the user to

enter the head category for station 3. The <YES / NO> buttons are used to change

the head category value. The value ranges from 1 to 8. Pressing ENTER will change

the head category value to the new value. See the section “PRINTHEAD

REPLACEMENT” for instructions on setting the head category.

Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the HOME screen.

S T A T I O N A C T I V A T I O N 2 3

C L O S E H E A D S P R E S S E N T E R

This screen follows HEAD CATEGORY STATION3. The screen allows the user to

configure the printer for the number of heads in the system. The numbers ’2’, ’3’

stand for stations 2 and 3. If the number appears on the screen then it means that

station is activated. If the number doesn’t appear on the screen then that station is

not activated and the printer will not print, look for ink out, or look for head open on

that print station.

The printer determines if a head is in the system by checking the head open switch

when the ‘Enter’ button is pressed. If the user would like to disable a station that is

User Manual Model 676 LOKPRINT® Control Panel Operation •••• 27

Page 34

in the machine for reasons of convenience then they can just open the head for that

station and press enter.

If the operating system has been changed or TCBSETUP has been used to reinitialize the machine it will show all print stations active as the default. If it is a 1/1

printer that doesn’t have station 3 installed then the user will have to come to this

screen and press ‘Enter’ to deactivate station 3, otherwise the printer will show INK

OUT STATION3 errors when it is run.

Pressing the MODE / Down Arrow key will take the user to the first screen under

PRINTHEAD SETUP.

Pressing the EXIT / Up Arrow key will take the user back to the HOME screen.

LIFE COUNTS / VERSIONS

P R E S S E N T E R F O R

L I F E C O U N T S / V E R S I O N S

This screen follows the CALIBRATE SENSORS screen.

Pressing ENTER will take the user to the Life Count and Operating system version

number Screens.

Pressing the MODE / Down Arrow key will take the user to the SETUP screen.

Pressing the EXIT / Up Arrow key will take the user back to the "HOME" screen.

L A B E L C O U N T E R : 0 0 0 0 0 0

P R E S S E N T E R T O R E S E T

This screen is the first screen under LIFE COUNTS / VERSIONS.

This screen shows total labels since last counter reset.

Pressing the ENTER key will reset the counter.

Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the HOME screen.

T O T A L L A B E L S P R O D U C E D

0 0 0 0 0 0 0 0 0 0

This screen follows the LABEL COUNTER screen. This screen displays the total

labels since the factory. This counter is NOT resettable by the user.

Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the "HOME" screen.

T O T A L I N C H E S O F S T O C K

0 0 0 0 0 0 0 0 0 0

This screen follows the TOTAL LABELS SINCE FACTORY screen. This screen

displays the total inches since the factory. This value is NOT resettable by the user.

Pressing the MODE / Down Arrow key will take the user to the next screen. Pressing

the EXIT / Up Arrow key will take the user back to the HOME screen.

28 •••• Control Panel Operation User Manual Model 676 LOKPRINT®

Page 35

C O N T R O L L E R V E R S I O N

T C B 1 0 9 3 4

This screen follows the FRONT PANEL VERSION screen.

This screen shows operating system version for the controller (TCB).

Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the HOME screen.

I M A G E R V E R S I O N

U S A 1 9 . 0 1

This screen follows the controller version number screen.

This screen shows operating system version for the imager (AT).

Pressing the MODE / Down Arrow key will take the user to the first screen under

Counts / Version.

Pressing the EXIT / Up Arrow key will take the user back to the HOME screen.

FEATURE SETUP SCREEN

P R E S S E N T E R F O R

F E A T U R E S E T U P

This screen follows the LIFE COUNT \ VERSIONS screen.

Pressing ENTER shows the first screen under setup.

Pressing the MODE / Down Arrow key will take the user to the PRINT / CUT

POSITIONS screen.

Pressing the EXIT / Up Arrow key will take the user back to the HOME screen.

C U T T E R I S E N A B L E D

P R E S S E N T E R T O D I S A B L E

OR

C U T T E R I S D I S A B L E D

P R E S S E N T E R T O E N A B L E

This screen is the first screen of SETUP. This screen allows the cutter to be enabled

or disabled. Pressing ENTER will toggle from ENABLED to DISABLED and vice

versa. Pressing the MODE / Down Arrow key will take the user to the next screen.

Pressing the EXIT / Up Arrow key will take the user back to the "HOME" screen.

E M U L A T I O N M O D E : N O N E

N E W E M U L A T I O N M O D E : 6 3 0

This screen follows the CUTTER ENABLE / DISABLE screen. This screen allows

the EMULATION MODE to be changed. Use the <YES and NO> keys to move

between NONE, 630, and 650 modes. Pressing ENTER will update the emulation

mode with the selection after new emulation mode. Pressing the MODE / Down

Arrow key will take the user to the next screen. Pressing the EXIT / Up Arrow key

will take the user back to the "HOME" screen.

User Manual Model 676 LOKPRINT® Control Panel Operation •••• 29

Page 36

D E F A U L T T R A N S F E R T Y P E 1

V A L U E : X X X N E W V A L U E : Y Y Y

Station 1 not used.

D E F A U L T T R A N S F E R T Y P E 2

V A L U E : X X X N E W V A L U E : Y Y Y

This screen follows the DEFAULT TRANSFER TYPE1 screen IF emulation mode is

something other than none. This screen allows the DEFAULT TRANSFER TYPE to

be changed. This transfer type is used when the printer is in 630 or 650 emulation

mode for print station 2. The 630 and 650 do not send valid 676 transfer types in

their PCL code. This default is used for those formats. Use the <YES and NO> keys

change the number value at the cursor position. Pressing ENTER will update the

current position with the selection and move the cursor to the next position. All three

positions must be entered. (I.e. 053 for type 53). After ENTER is pressed on the last

digit the TRANSFER TYPE on the top line will be updated. Pressing the MODE /

Down Arrow key will take the user to the next screen. Pressing the EXIT / Up Arrow

key will take the user back to the "HOME" screen.

D E F A U L T T R A N S F E R T Y P E 3

V A L U E : X X X N E W V A L U E : Y Y Y

This screen follows the DEFAULT TRANSFER TYPE2 screen IF emulation mode is

something other than none. This screen allows the DEFAULT TRANSFER TYPE to

be changed. This transfer type is used when the printer is in 630 or 650 emulation

mode for print station 3. The 630 and 650 do not send valid 676 transfer types in

their PCL code. This default is used for those formats. Use the <YES and NO> keys

change the number value at the cursor position. Pressing ENTER will update the

current position with the selection and move the cursor to the next position. All three

positions must be entered. (I.e. 053 for type 53). After ENTER is pressed on the last

digit the TRANSFER TYPE on the top line will be updated. Pressing the MODE /

Down Arrow key will take the user to the next screen. Pressing the EXIT / Up Arrow

key will take the user back to the "HOME" screen.

L A N G U A G E : X X X X X X

N E W L A N G U A G E : Y Y Y Y Y Y

This screen follows the "DEFAULT TRANSFER TYPE" screen. This screen allows

the front panel display language to be changed. Use the <YES and NO> keys to

move between the supported languages on the pr1nter. Any number of front panel

languages can be stored on the Flash Disk Module (dependent on available space). If

no additional languages other than the default are available on the printer XXXXXX

and YYYYYY will be the same value. Pressing ENTER will update the display

language with the selection. Pressing the MODE / Down Arrow key will take the

user to the "PROTOCOL" screen. Pressing the EXIT / Up Arrow key will take the

user back to the "HOME" screen.

Warning: Mis-matched communication protocols may result in the inability to

communicate with the printer and / or loss of data.

30 •••• Control Panel Operation User Manual Model 676 LOKPRINT®

Page 37

P R O T O C O L : X X X X X X

N E W P R O T O C O L : Y Y Y Y Y Y

This screen follows the LANGUAGE screen. This screen allows the

communications protocol to be changed between the supported types. Use the <YES

and NO> keys to move between the supported protocols – RTS / CTS is considered

hardware handshaking and XON / XOFF is considered to be software. Pressing

ENTER will update the communications protocol with the selection. Pressing the

MODE / Down Arrow key will take the user to the next screen. Pressing the EXIT /

Up Arrow key will take the user back to the "HOME" screen.

B A U D R A T E : X X X X X X

N E W B A U D R A T E : Y Y Y Y Y Y

This screen follows the PROTOCOL screen. This screen allows the serial

communications speed to be changed. Use the <YES and NO> keys to move

between the supported speeds – typical is 9600 dependent on serial communication

cable length. Pressing ENTER will update the communications speed with the

selection. Pressing the MODE / Down Arrow key will take the user to the

“CHANGE DATE AND TIME” screen. Pressing the EXIT / Up Arrow key will

take the user back to the "HOME" screen.

C H A N G E D A T E A N D T I M E

0 3 / 1 4 / 0 0 1 2 : 0 5 P M

This screen follows the “BAUD RATE” screen. This screen allows the system date

and time to be changed. When this screen appears, the first digit of the month will be

blinking. (The date is shown in US format, MM/DD/YY.) Pressing the <YES and

NO> keys will change the digit up and down respectively. Pressing ENTER will

move to the next digit. Only the digits and the A or P in AM or PM can be changed.

When all changes are complete, pressing the MODE / Down Arrow key will take the

user to the “INKSAVE ENABLE / DISABLE” screen, and pressing the EXIT / Up

Arrow key will take the user back to the “HOME” screen. If an illegal date or time is

entered, this screen will be re-displayed with the original date or time. A valid date

and time must be entered before the user can go on.

User Manual Model 676 LOKPRINT® Control Panel Operation •••• 31

Page 38

Adjustments

Feed Roller Pressure

General

The rubber pressure roller is supported by an eccentric shaft mounted in bearings

located in vertical slots in the front and rear mounting plates of the drive module.

This roller is mounted in an extension spring controlled arm so no pressure

adjustment is required.

Sensors

Sensor Identification:

Stock Out

A micro switch located on the back of the unwind will detect when the stock core is

lifted when the stock is consumed and stop the printer. AVERY DENNISON stocks

are fastened to the supply core and will lift the core at the end of the roll. Supplies

that do not have this feature will fail to stop the printer.

Ink Out

Optical sensors located on each print station’s ink unwind arbor allow the printer to

monitor the availability of ink.

Feed Open

A micro switch on the back of the feed module will detect the position of the feed

module pressure knob and only allow the printer to operate with the feed pressure

knob closed.

Sensor Adjustments:

All the micro switches and optical sensors in your 676 LKP printer were calibrated at

the time your printer was manufactured, however from time to time it may become

necessary to readjust / recalibrate due to the large variety of stocks and inks that can

be run on the machine.

Stock Out

With a full roll of stock loaded on the unwind with the unwind web guides properly

adjusted you should heard the switch click as you raise and lower the roll. If not the

switch bail is adjusted by carefully bending it as needed.

32 •••• Adjustments User Manual Model 676 LOKPRINT®

Page 39

Feed Open

If the switch is in need of adjustment - first check and adjust as needed the feed

pressure as it will affect the switch adjustment. With the machine rear cover

removed while opening and closing the feed pressure knob you should heard the

switch clicking. If not, the switch bail is adjusted by carefully bending it as needed.

Machine Set Up Sequence

1) Power off the printer, remove the media and ink and thoroughly clean it from the

unwind to the stock exit using alcohol and a clean soft cloth. The print heads

should be cleaned as per the Print Head Cleaning instruction section in the manual.

2) Load a full roll of an average width media and ink on the printer.

3) Power on the printer. After passing diagnostics tests the front panel should display

READY FOR BATCHES if not then resolve any remaining error conditions.

4) Arrow down to the PRINT / CUT POSITIONS mode and press enter. Cycle

through all the prints, cut, and station two dot shift values to get a feel for their

present settings.

5) Cycle back to the beginning of the Printer Adjustment and press enter at Print

Checkout Format.

6) If all three print stations or stations two and three are present, adjust station

number two by moving the dots with the dot shift on the front panel so that the

tracking line on the front of the label becomes one continuous line.

The machine is now ready for production formats at which time the operator should

need only to fine-tune the prints and strobes via the front panel.

User Manual Model 676 LOKPRINT® Adjustments •••• 33

Page 40

Maintenance

Cleaning

Print Head Cleaning

CAUTION: TURN OFF THE POWER TO THE PRINTER BEFORE

NEVER REMOVE THE HEAD FROM THE PRINTER EXCEPT FOR

Supplies:

- Always use clean supplies when cleaning the head.

- Never use anything abrasive to the head.

- NEVER use anything metallic on or near the printhead.

STARTING ANY CLEANING.

REPLACEMENT.

The Anti-static wrist strap (which must contact the skin and be

tight) and anti-static gloves must be worn at all times when

handling a print head to avoid damaging the print head.

- Alcohol and a cotton swab are the recommended items to use when cleaning the

printhead.

RECOMMEND AVERY DENNISON "MASTER CLEANING KIT" # 921338

Procedure:

-The Printhead should be cleaned every two to four hours of continuous usage. A

good cleaning of the print head after eight to twelve hours of continuous usage

should be done. This cleaning must be done with the print head in the printer.

- Apply a liberal amount of alcohol to a swab.

- Rub the swab across the print line of the printhead to remove the build-up.

- The platen roller and feed rollers should also be cleaned with alcohol to remove ink

and card dust build-up.

34 •••• Maintenance User Manual Model 676 LOKPRINT®

Page 41

Clean Platen Roller

You may determine if the printhead has been adjusted properly by performing a test

pattern as documented elsewhere in this manual. A properly adjusted print head will

produce an even grid of chevrons when the test pattern is performed. Before making

any judgments as to the quality of the printhead, it is absolutely necessary to

ensure that the platen roller and the printhead are clean of all debris. Clean the

platen roller located immediately beneath the print head with a clean cloth and a

small amount of alcohol. Be careful not to damage the platen roller while cleaning.

If the roller is worn, replace the roller.

Supplies:

- Always use clean supplies when cleaning the sensor and light bar.

- Never use anything abrasive to the sensor and light bar.

- NEVER use an alcohol-based solution when cleaning the sensor or light bar.

- Dry air or a cotton swab are the AVERY DENNISON recommended items to use

when cleaning the sensor and light bar.

Print Head Handling

Warning

Print heads can be damaged easily, and are subject to premature failure if not cleaned

on a regular basis. Please follow the procedures carefully to help ensure print head

life and print quality.

Thermal print heads are very sensitive and must be handled with care to help ensure

longer print head life. Because print heads may be damaged through a number of

ways, AVERY DENNISON has developed the following procedures;

Handling

Static discharge is very detrimental to thermal print heads. To avoid contacting print

heads with a static charge, follow these simple procedures:

- All print heads should be kept in original anti-static bags until they are

placed in the machine.

- The 676 LKP printer is supplied with an anti-static wrist strap. Locate the

strap - it must be worn at all times when handling the print heads.

- Do not touch any terminals extending from the print head or the print line.

- Anti-static gloves are provided with your machine upon installation and

extras may be ordered from AVERY DENNISON. These gloves must

be worn at all times when handling the print head. If an anti-static glove

is not available, make absolutely certain to thoroughly wash and dry your

hands before handling the print head. Oils from your hands can

contaminate the print line and quickly destroy the printing elements.

User Manual Model 676 LOKPRINT® Maintenance •••• 35

Page 42

Print Head Replacement

NEVER REMOVE THE PRINT HEAD FROM THE PRINTER EXCEPT FOR

REPLACEMENT.

TURN OFF THE POWER TO THE PRINTER BEFORE STARTING ANY

ELECTRONIC COMPONENT REPLACEMENT.

NOTE: The Anti-static wrist strap (which must contact the skin and be tight) and

anti-static gloves must be worn at all times when handling a print head to

avoid damaging the print head.

1) Review the Printhead Handling Procedure Sheet packaged with each print head to

determine if any procedures have changed before beginning this procedure.

2) Remove the media and ink from the machine for easy print head removal.

3) Unplug the cables that connect to the print head. Unplug the cable by firmly, but

gently pulling it out.

4) Loosen (2) 6-32 Phillips screws visible through holes in the upper print head

holder. Slide the head toward unwind end of printer.

NOTE: Screws are fitted with washers.

6-32 PHILLIPS SCREWS

5) Place your hand (with static gloves on) underneath the print line of the print head

and pull down guiding screws through keyhole slots. This will remove the print

head assembly from the mount plate. You may need to "help" the print head out

by pushing on the heat sink with your left hand.

6) Remove the two print head mount screws located on the top of the print head with

a Phillips head screwdriver.

36 •••• Maintenance User Manual Model 676 LOKPRINT®

Page 43

7) Remove the old printhead carefully from the heat sink.

HEAT SINK

PRINTHEAD

8) Place the new print head onto the heat sink.

9) Replace the two print head mount screws. Be sure that the head is resting flat on

the heat sink before tightening these screws.

10) Replace the print head assembly in the printer, sliding screw / washer (Paragraph

4) into the holes in the mount plate. Make sure that the screw / washer slides all

the way to the front of the holder. Tighten screws.

HEAD TOUCHES

11) Reconnect the print head cable connectors, making sure that the connectors are

seated tightly.

NOTE: If the cable is not connected correctly, the print head will be destroyed when

the machine is powered on. Check to see that the cable is tight by observing

from underneath the print head. The cable’s connectors should be inside of

the connectors located on the print head.

12) Replace the media and ink and double-check your work. Power the machine on

and make sure that no adverse effects are noted. Before printing - the printhead

category must be set to match the new printheads mean resistance as labeled

on the head itself.

A) On the front panel arrow down to PRINT HEAD SETUP using the

MODE button and press ENTER.

B) Arrow down to HEAD CATEGORY for the print station you

replaced the head in.

User Manual Model 676 LOKPRINT® Maintenance •••• 37

Page 44

C) Using the left (<YES) or right (NO>) arrow key set the HEAD

CATEGORY as called out in the PRINTHEAD CATEGORY

CHART below.

D) Press the ENTER key to enter the value. The printer must be turned

off and back on for the change to take effect.

PRINTHEAD CATEGORY CHART

MEAN

RESISTANCE

obtained from

printhead label

PRINTHEAD

CATEGORY

entered in front panel

for print station

containing head

1190 – 1243 1

1244 - 1295 2

1296 – 1348 3

1349 - 1400 4

1401 – 1453 5

1454 - 1505 6

1506 – 1558 7

1559 – 1610 8

13) As a final test of the print head installation, run a test pattern to check the print

quality. You should observe an even grid of chevrons. If you do not see such a

grid, make sure both the front and the back printheads are moved all the way to

the right.

38 •••• Maintenance User Manual Model 676 LOKPRINT®

Page 45

Lubrication Procedure

General

The 676 series printers are factory equipped with either composition bearings not

requiring lubrication, pre-lubricated bronze bearings, or pre-lubricated needle

bearings. Periodic cleaning of the printer and removal of dust will greatly enhance

the length of the time the printer will function.

Composition (Iglide) Bearings

1) If field replacement of an assembly fitted with a plastic bearing is performed, a

single drop of spindle oil should be applied to assist in bearing break-in.

2) If, after long use, a plastic bearing starts to "squeak", disassemble the component

containing the bearing and lightly abrade the shaft surface. Clean the bearing

(dust or old oil) with alcohol, re-lubricate with 1 drop of light oil and reassemble.

No other printer lubrication should be required in normal use.

User Manual Model 676 LOKPRINT® Maintenance •••• 39

Page 46

Electrical Trouble Shooting

Power Up / Sign On / Communications

Problem Probable Cause Corrective Action

Machine fails to power up

with no light present in

the AC power switch.

2) Lack of power to machine. 2) Check that both ends of the power cord are

3) Missing or blown fuse(s) 3) Check that the fuse(s) located inside the AC

Machine fails to power up

with light present in the

AC power switch.

2) Thermal Control Board

Front panel displays no text

or nothing at all.

1) Incorrect power voltage. 1) Confirm that the AC entry is configured for the

line voltage intended to be applied to the

machine. Failure to do so can damage the

machine's internal power supply. Refer to the

"Fuse Configuration".

plugged in securely.

2A) Confirm that the outlet the machine is plugged

into has power.

entry are present and intact. Replace as needed.

Refer to the "Fuse Configuration".

1) Unconnected cable / connector

inside machine.

unplugged from the Mother Board

1) Front panel cable unplugged. 1) Power off and remove the power cord from the

1) Power off and remove the power cord from the

AC entry. Remove the back cover and inspect

the cables and connectors to and from the power

supply. Refer to the "Electrical System

Schematic".

2) Power off and remove the power cord from the

AC entry. Remove the back cover and reseat the

Thermal Control Board.

AC entry. Remove the back cover and inspect

the cable and connectors to and from the front

panel. Refer to the "Electrical System

Schematic".

40 •••• Electrical Trouble Shooting User Manual Model 676 LOKPRINT®

Page 47

Problem Probable Cause Corrective Action

Front panel does not

complete diagnostics test 2.

Machine does not receive

batches.

2) Machine not powered on or has

3) Data sent to wrong printer. 3) In PCMate change to the printer the data is

4) Configuration incorrect in

5) Faulty Thermal Control Board. 5) Replace Thermal Control Board.

6) Jumpers not configured

1) One or more PC board(s)

unplugged from the Mother

Board.

1) Serial communications cable

loose or unconnected.

not completed diagnostics tests.

PCMate.

correctly.

1) Power off and remove the power cord from the

AC entry. Remove the back cover and reseat the

offending board.

1) Check and secure both ends of the serial cable

with the thumbscrews.

2) Power machine on and wait until machine

displays "Ready for batches". Re-download

data.

intended to be sent.

4) Re configure PCMate for AVERY DENNISON

PCL printer as per your PCMate manual.

6) Contact AVERY DENNISON Service.

User Manual Model 676 LOKPRINT® Electrical Trouble Shooting •••• 41

Page 48

Stock / Ink Advance

Problem Probable Cause Corrective Action

Stock does not advance

when the start button is

depressed.

2) An interlock condition exists. 2) Determine the number and type of interlock(s)

3) Feed motor unplugged or faulty. 3) Check feed motor cable and or replace feed

4) Thermal Control Board

5) Feed roller not gripping stock. 5) Adjust the feed pressure. Refer to "Mechanical

6) Feed rollers bound. 6) With power off check that all rollers turn freely.

7) Stock bound. 7) With the print head and feed open check that the

Ink does not advance when

the start button is

depressed.

1) No batches to be printed. 1) Download batch (if batch downloaded uses the

same format as a previously downloaded batch

the machine with start automatically).

by reading the front panel display. As each is

corrected the number of errors will decrease

(Example "Error 901 Stock Out" reload stock).

motor.

4) Check Thermal Control Board / AT board

unplugged or faulty.

1) No batches to be printed. 1) Download batch (if batch downloaded uses the

connection and or replace Thermal Control

Board.

Adjustment Of Feed Roller Pressure".

stock will pull through the printer with little to no

resistance.

same format as a previously downloaded batch

the machine with start automatically).

2) An interlock condition exists. 2) Determine the number and type of interlock(s)

by reading the front panel display. As each is

corrected the number of errors will decrease

(Example "Error 901 Stock Out" reload stock).

3) Ink motor unplugged or faulty. 3) Check ink motor cable and or replace ink motor.

4) Thermal Control Board

unplugged or faulty.

5) Ink roller bound. 5) With power off check that all rollers and arbors

6) Ink bound. 6) With the print head open check that the ink will

4) Check Thermal Control Board / AT board

connection and or replace Thermal Control

Board.

turn freely.

pull through the printer with little to no

resistance.

42 •••• Electrical Trouble Shooting User Manual Model 676 LOKPRINT®

Page 49

Print

Problem Probable Cause Corrective Action

Machine advances stock

but does not print.

2) Print head faulty. 2) Replace print head.

3) Head Driver Board unplugged or

Print registration is off in

the feed direction.

2) Field(s) position incorrect in the

3) Bound platen roller. 3) Check that the platen roller turns freely on it's

Print registration is off in

the web direction.