Page 1

RTM-ATCA-7350

Installation and Use

P/N: 6806800H30G

September 2014

Page 2

©

Copyright 2014 Artesyn Embedded Technologies, Inc.

All rights reserved.

Trademarks

Artesyn Embedded Technologies, Artesyn and the Artesyn Embedded Technologies logo are trademarks and service marks of

Artesyn Embedded Technologies, Inc.© 2014 Artesyn Embedded Technologies, Inc. All other product or service names are the

property of their respective owners.

Intel® is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

Java™ and all other Java-based marks are trademarks or registered trademarks of Oracle America, Inc. in the U.S. and other countries.

Microsoft®, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

Microsoft Corporation.

PICMG®, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

Industrial Computer Manufacturers Group.

UNIX® is a registered trademark of The Open Group in the United States and other countries.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Artesyn assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Artesyn reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Artesyn to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

an Artesyn website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Artesyn.

It is possible that this publication may contain reference to or information about Artesyn products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Artesyn intends to announce such Artesyn products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Artesyn.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Artesyn Embedded Technologies Artesyn Embedded Technologies

Marketing Communications

2900 S. Diablo Way, Suite 190

Tempe, Arizona 85282

Lilienthalstr. 17-19

85579 Neubiberg/Munich

Germany

Page 3

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1 Overview of RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4.1 Supported Board Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.4.2 Board Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 Hardware Preparation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Unpacking and Inspecting RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3 Environmental and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4 Module Installation and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.4.1 Ejector Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.4.2 ESD Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.5 Installation Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5.1 Wearing the ESD-Preventive Wrist Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5.2 Removing Filler Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.6 Installing and Replacing Daughter Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.6.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.6.2 Preparations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.6.3 GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.6.3.1 Installation Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.6.3.2 Installing the GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.6.3.3 Replacing the GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.6.4 FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.6.4.1 Installation Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.6.4.2 Installing the FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.6.4.3 Replacing the FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.7 Installing and Removing the RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

RTM-ATCA-7350 Installation and Use (6806800H30G)

3

Page 4

2.7.1 Installing RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.7.2 Removing RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.8 Connecting External Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.8.1 Connecting KVM Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.8.2 Connecting Network Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.8.3 Connecting Optical Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3 Controls, LEDs and Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.2 Face Plate Connectors and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.2.1 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.2.2 Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.2.2.1 RTM-ATCA-7350 Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.3 Zone 3 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.3.1 P30 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.3.2 P31 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.3.3 P32 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.3 Daughter Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.3.1 GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.3.2 FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

A Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

A.1 Artesyn Embedded Technologies - Embedded Computing Documentation . . . . . . . . . . . . . . . . 67

A.2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 5

List of Tables

Table 1-1 Mechanical Specifications of RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 1-2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 1-3 Product Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 1-4 Available Board Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 2-1 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 2-2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 3-1 Indicators on the RTM-ATCA-7350 Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 3-2 USB Port Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 3-3 VGA Port Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 3-4 PIN 30 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 3-5 PIN 31 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 3-6 PIN 32 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 4-1 Indicators Provided by the GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 4-2 Indicators Provided by the FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table A-1 Artesyn Embedded Technologies - Embedded Computing Publications . . . . . . . . . . . . . . . 67

Table A-2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

RTM-ATCA-7350 Installation and Use (6806800H30G)

5

Page 6

List of Tables

6

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 7

List of Figures

Figure 2-1 Wearing the ESD-Preventive Wrist Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 2-2 Removing the Filler Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 2-3 Structure of RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 2-4 Installing the GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 2-5 Installing RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 2-6 Removing RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 2-7 Connecting the KVM Cables to RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 2-8 Connecting the Network Cables to RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 2-9 Connecting the Optical Fibers to RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 3-1 Face Plate of RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 3-2 Structure of RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 3-3 Connectors and Indicators of RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 3-4 RTM-ATCA-7350 Front Plate USB Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 3-5 RTM-ATCA-7350 Front Plate VGA Port Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 4-1 Block Diagram of RTM-ATCA-7350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 4-2 GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 4-3 FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

RTM-ATCA-7350 Installation and Use (6806800H30G)

7

Page 8

List of Figures

8

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 9

About this Manual

Overview of Contents

This manual is intended for the users who install and configure the RTM-ATCA-7350 of the

server blade. The user must be a professional engineer in the server device field, who has been

trained and is able to identify danger levels when operating the device.

This manual describes the structure, appearance, functions, technical specifications,

precautions, and installation procedure of the RTM-ATCA-7350. In addition, it also provides

information of the components supported by the RTM-ATCA-7350 and describes how to

install and replace the components.

This manual is divided into the following chapters and appendix.

Chapter 1, Introduction, on page 15 gives an overview of the features of the product,

standard compliances, mechanical data, and ordering information.

Chapter 2, Hardware Preparation and Installation, on page 19 outlines the installation

requirements, hardware accessories, and installation procedures.

Chapter 3, Controls, LEDs and Connectors, on page 47 describes external interfaces of the

board. This include connectors and LEDs.

Chapter 4, Functional Description, on page 61 includes a block diagram and functional

description of major components of the product.

Appendix A, Related Documentation, on page 67 provides a listing of related product

documentation, manufacturer’s documents, and industry standard specifications.

Abbreviations

This document uses the following abbreviations:

Abbreviation Definition

ACA Australian Communications Authority

BIOS Basic Input Output System

BMC Baseboard Management Controller

CMOS Complementary Metal Oxide Semiconductor

DIMM Dual Inline Memory Module

ECC Error Checking and Correcting

RTM-ATCA-7350 Installation and Use (6806800H30G)

9

Page 10

About this Manual

Abbreviation Definition

EIA Electronics Industries Association

EMC Electromagnetic Compatibility

ESD Electro-Static discharge

FBD Fully Buffer DIMM

FC Fiber Channel

FCC Federal Communications Commission

FRU Field Replaceable Unit

GE Gigabit Ethernet

IEC International Electrotechnical Commission

IPMB Intelligent Platform Management BUS

IPMC Intelligent Platform Management Controller

IPMI Intelligent Platform Management Interface

About this Manual

10

KVM Keyboard, Video, and Mouse

OOS Out of Service

PCI Peripheral Component Interconnect

RTM Rear Transition Module

SCSI Small Computer System Window

SDR Sensor Data Record

SEL System Event Log

ShMC Shelf Management Controller

SOL Serial Over LAN

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 11

Conventions

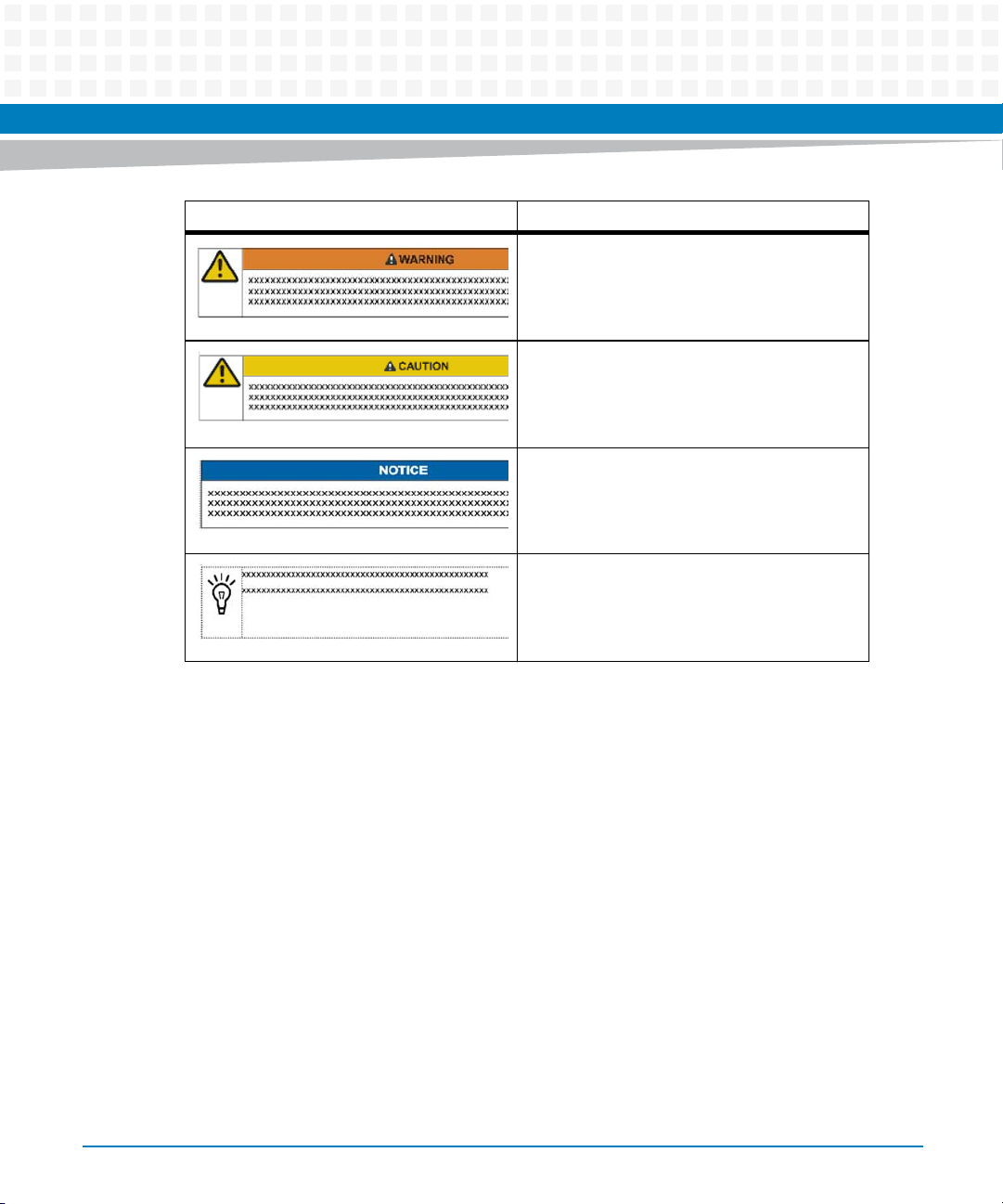

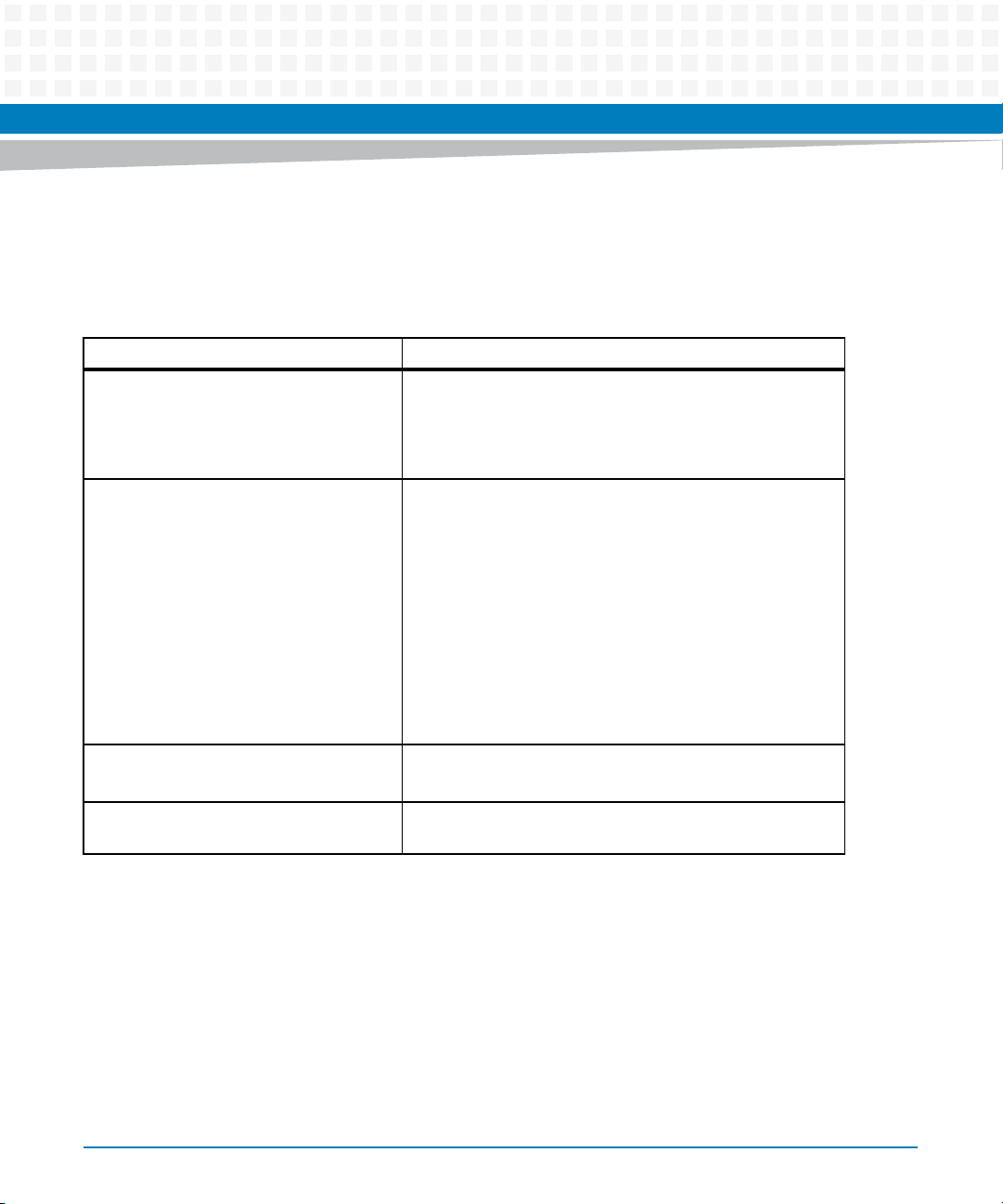

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related

Courier + Bold Used to characterize user input and to separate

Reference Used for references and for table and figure

About this Manual

(digits are 0 through F), for example used for

addresses and offsets

elements or commands in body text

it from system output

descriptions

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

[text] Notation for software buttons to click on the

... Repeated item for example node 1, node 2, ...,

.

.

.

.. Ranges, for example: 0..4 means one of the

| Logical OR

RTM-ATCA-7350 Installation and Use (6806800H30G)

screen and parameter description

node 12

Omission of information from

example/command that is not necessary at the

time being

integers 0,1,2,3, and 4 (used in registers)

11

Page 12

About this Manual

Notation Description

About this Manual

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury

Indicates a hazardous situation which, if not

avoided, may result in minor or moderate injury

Indicates a property damage message

No danger encountered. Pay attention to

important information

12

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 13

About this Manual

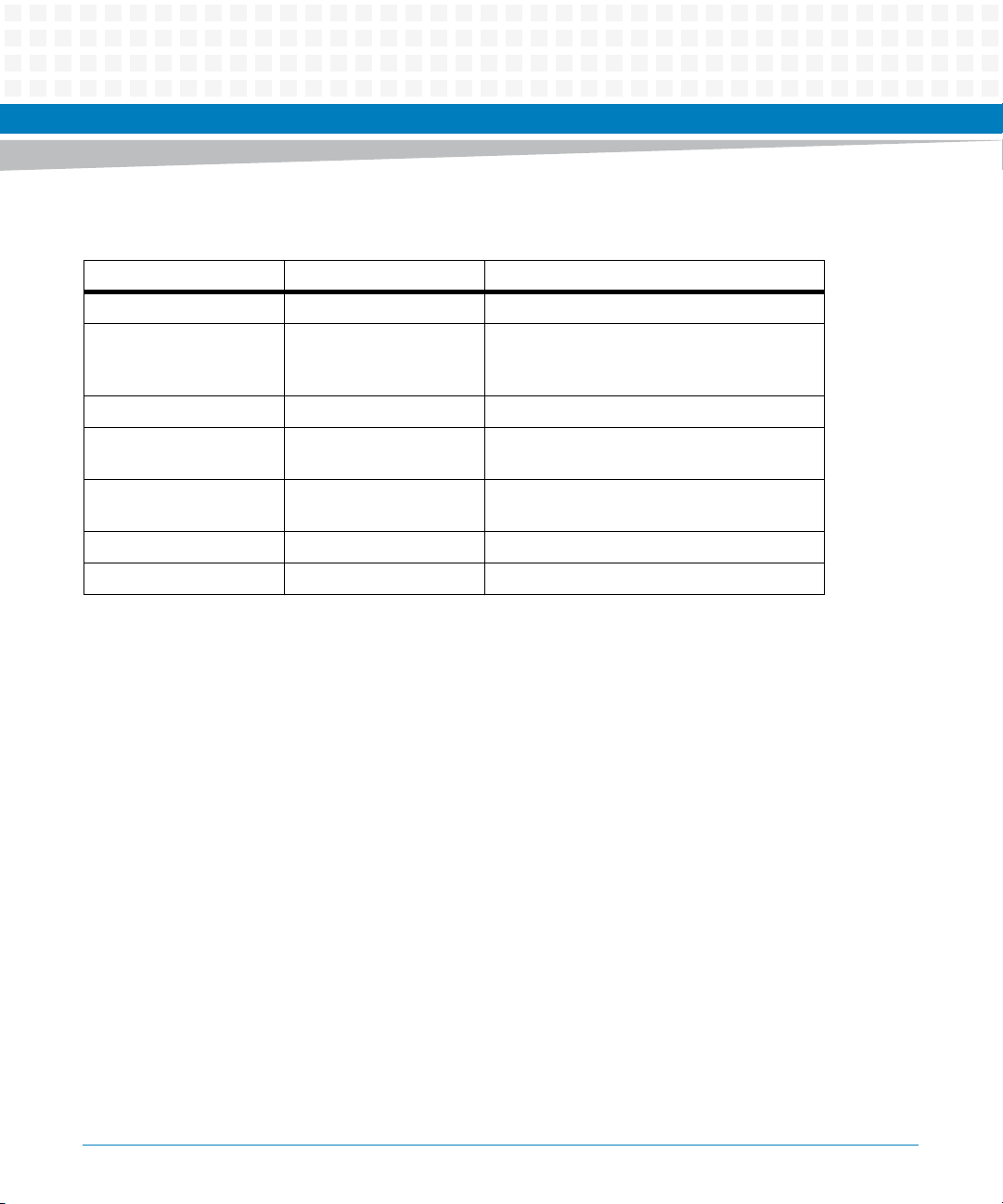

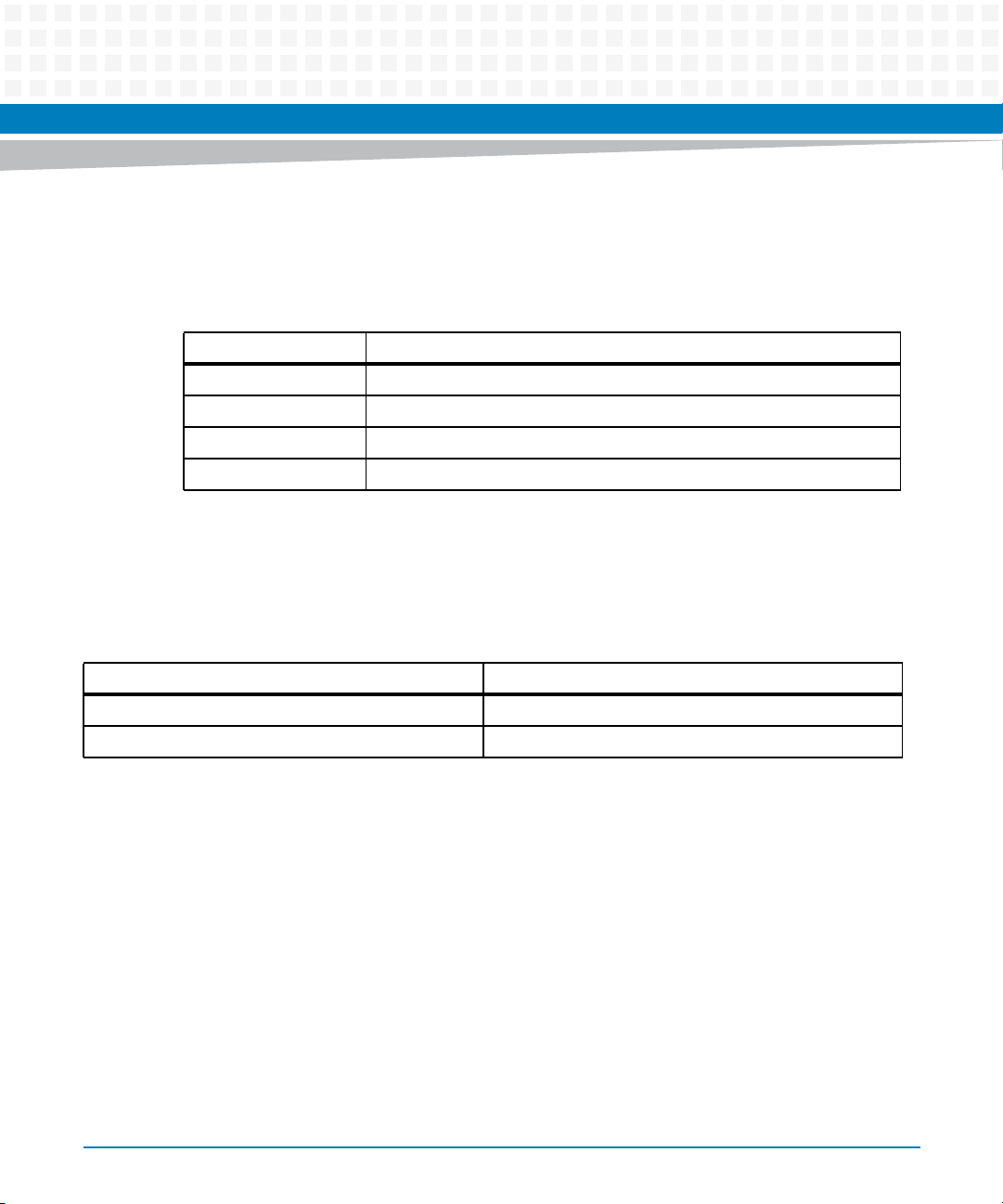

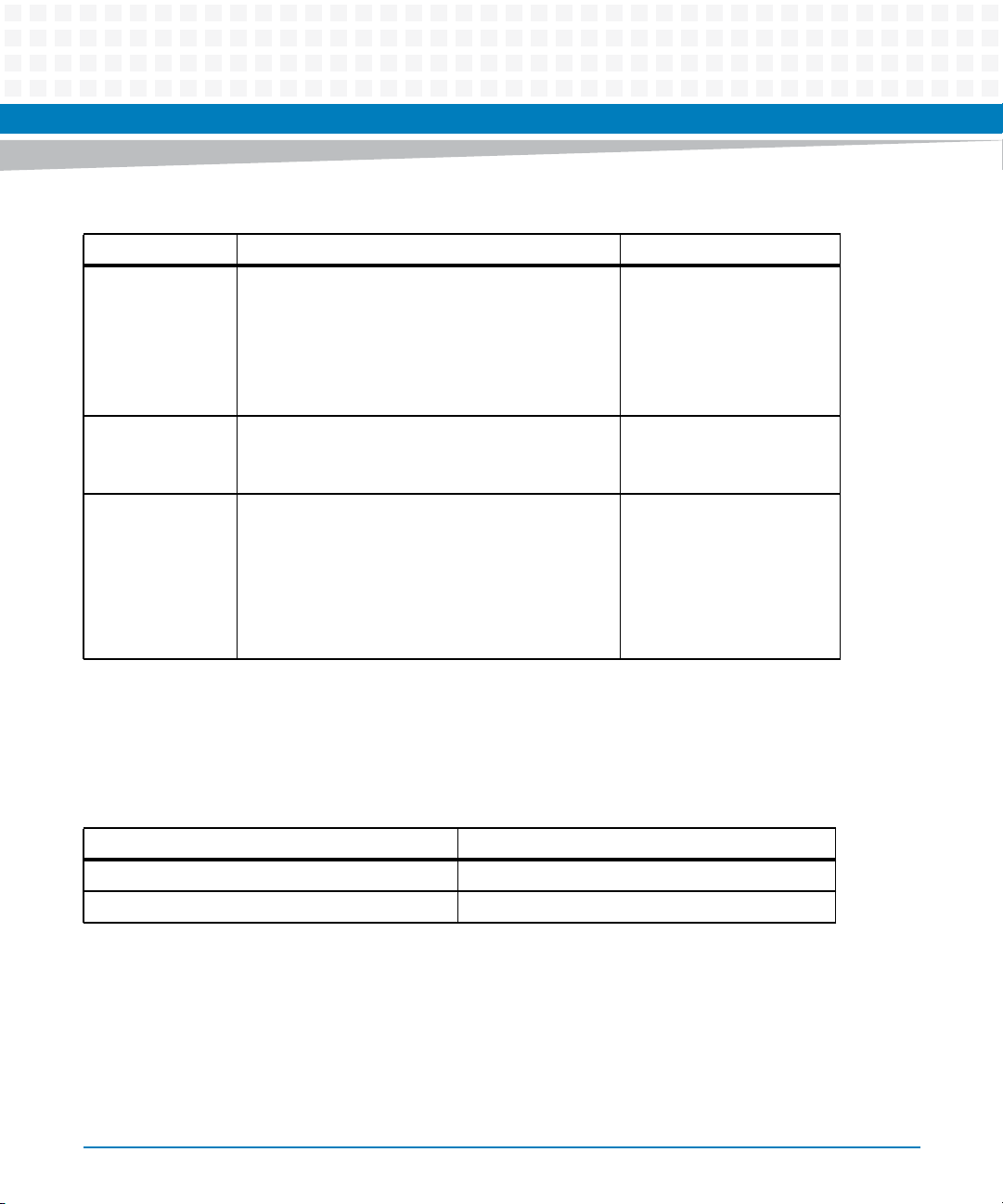

Summary of Changes

Part Number Publication Date Description

6806800H30A March 2008 First edition

6806800H30B August 2008 Added Backplane Connectors (zone 3) to

Chapter 3, Controls, LEDs and Connectors, on

page 47.

6806800H30C January 2009 Third edition

6806800H30D November 2009 Updated Section Installing RTM-ATCA-7350 on

page 37.

6806800H30E November 2009 Updated Section Installing RTM-ATCA-7350 on

page 37.

6806800H30F February 2010 Updated Standard Compliances on page 16

6806800H30G September 2014 Re-branded to Artesyn template.

RTM-ATCA-7350 Installation and Use (6806800H30G)

13

Page 14

About this Manual

About this Manual

14

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 15

Introduction

1.1 Overview of RTM-ATCA-7350

The ATCA-7350 Rear Transition Module (RTM) of the server blade (hereinafter referred to as

RTM-ATCA-7350) must work with the server blade ATCA-7350. RTM-ATCA-7350 provides

external interfaces for the connected server blade.

RTM-ATCA-7350 provides the following functions:

RTM-ATCA-7350 provides two daughter card connectors. RTM-ATCA-7350 supports the

following daughter cards:

– Gigabit Ethernet (GE) daughter card

– Fiber Channel (FC) daughter card

The daughter cards provide external interfaces for the server blade.

As a manageable module of the server blade, RTM-ATCA-7350 is managed by the

Intelligent Platform Management Controller (IPMC) of the server blade.

Chapter 1

The IPMC monitors the working status of RTM-ATCA-7350. In addition, the Field

Replaceable Unit (FRU) data is stored in the EEPROMs on the RTM itself and the daughter

cards.

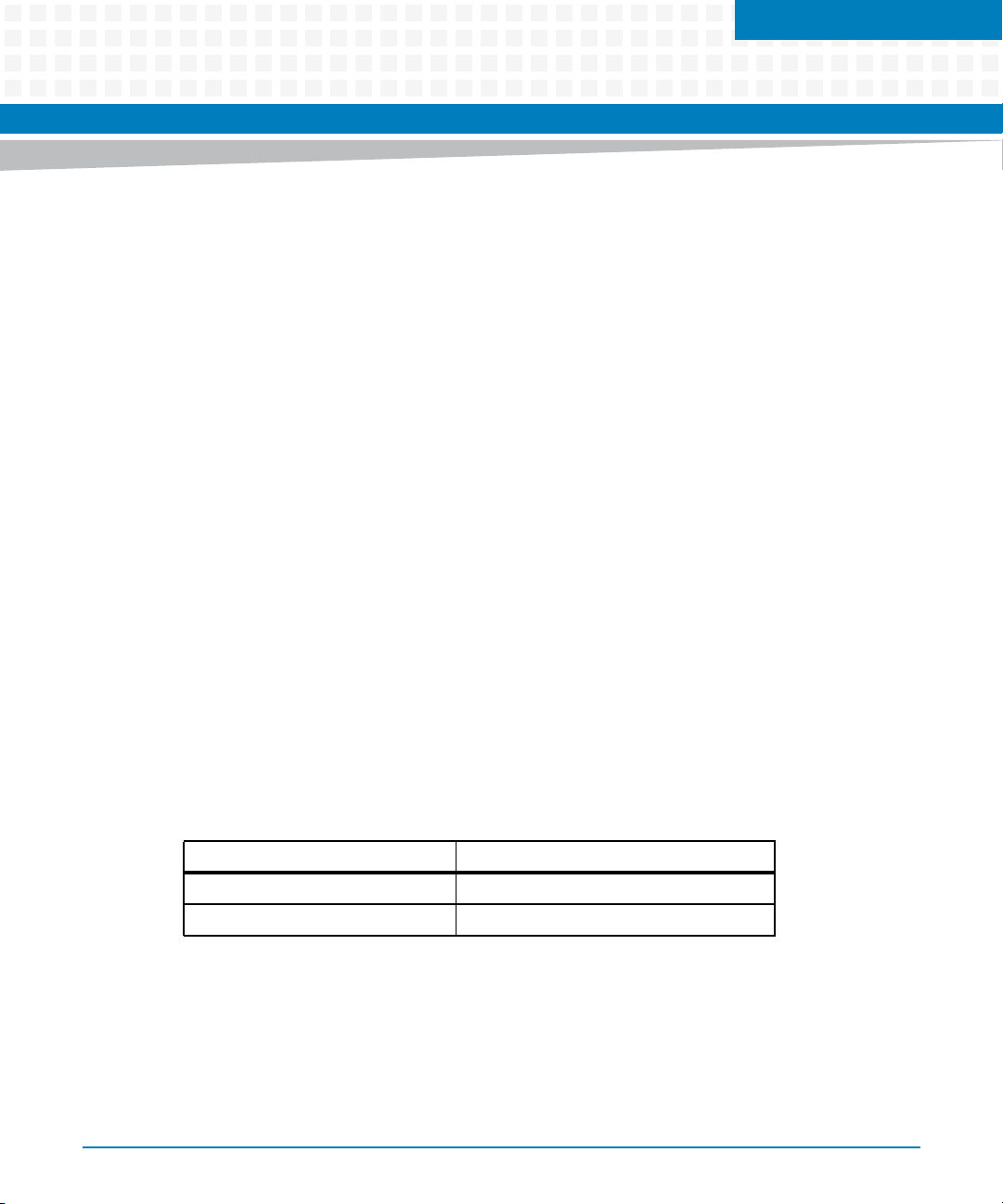

1.2 Mechanical Data

The following table lists the mechanical specifications of RTM-ATCA-7350.

Table 1-1 Mechanical Specifications of RTM-ATCA-7350

Item Specification

Maximum weight 0.76 kg

Length x width x height 322.3 mm x 70 mm x 29 mm

RTM-ATCA-7350 Installation and Use (6806800H30G)

15

Page 16

Introduction

1.3 Standard Compliances

The product is designed to meet the following standards.

Table 1-2 Standard Compliances

Standard Description

UL 60950-1

EN 60950-1

IEC 60950-1

CAN/CSA C22.2 No 60950-1

CISPR 22

CISPR 24

EN 55022

EN 55024

FCC Part 15

Industry Canada ICES-003

VCCI Japan

AS/NZS CISPR 22

EN 300 386

NEBS Standard GR-1089 CORE

NEBS Standard GR-63-CORE

ETSI EN 300019 series

1

PICMG

1. Some PICMG requirements are not fully met. Refer ATCA-7350/RTM-ATCA-7350 Release Notes for more information.

3.0 Defines mechanics, blade dimensions, power distribution,

Legal safety requirements

EMC requirements (legal) on system level (predefined

Artesyn Embedded Technologies)

Environmental requirements

power and data connectors, and system management

1.4 Ordering Information

When ordering board variants or board accessories, use the order numbers given on the

following pages.

16

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 17

1.4.1 Supported Board Models

The following table explains the product nomenclature used for the available board variants.

Table 1-3 Product Nomenclature

Order Number Description

RTM-ATCA-7350 RTM FOR THE ATCA-7350 BLADE WITH 10G FABRIC SUPPORT (ROHS 5/6)

RTM-ATCA-7350-GE RTM FOR THE ATCA-7350 BLADE WITH 2 GE INTERFACES (ROHS 5/6)

RTM-ATCA-7350-2GE RTM FOR THE ATCA-7350 BLADE WITH 4 GE INTERFACES (ROHS 5/6)

RTM-ATCA-7350-FC RTM FOR THE ATCA-7350 BLADE WITH 2 FC INTERFACES (ROHS 5/6)

1.4.2 Board Accessories

As of the printing date of this manual, the following board accessories were available.

Introduction

Table 1-4 Available Board Accessories

Board Accessories Order Number

Gigabit Ethernet (GE) daughter card MEZC-RTM-7150-GE

Fiber Channel (FC) daughter card

1. Optical modules for the FC daughter card must be obtained separately. Recommended modules are:

FINISAR FTRJ8519P1BNL-HW

FINISAR FTRJ8519P2BNL-HW

RTM-ATCA-7350 Installation and Use (6806800H30G)

1

MEZC-RTM-7150-FC

17

Page 18

Introduction

18

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 19

Hardware Preparation and Installation

2.1 Overview

This chapter describes:

Unpacking and inspecting RTM-ATCA-7350

Precautions during the operation

Preparations before installation

Installation procedure

Installing and replacing daughter cards

Connection of external cables

Removal procedure

Chapter 2

2.2 Unpacking and Inspecting RTM-ATCA-7350

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product or electronic components, make sure that your are working in an

ESD-safe environment.

Shipment Inspection

To inspect the shipment, perform the following steps.

1. Verify that you have received all items of your shipment:

Printed Quick Start Guide

RTM-ATCA-7350

Any optional items ordered

2. Check for damage and report any damage or differences to the customer service.

RTM-ATCA-7350 Installation and Use (6806800H30G)

19

Page 20

Hardware Preparation and Installation

3. Remove the desiccant bag shipped together with the blade and dispose of it

according to your country’s legislation.

The product is thoroughly inspected before shipment. If any damage occurred during

transportation or any items are missing, please contact our customer's service immediately.

2.3 Environmental and Power Requirements

The following environmental and power requirements are applicable to the board.

2.3.1 Environmental Requirements

Table 2-1 Environmental Requirements

Requirement Operating Non-Operating

Temperature +5ºC (41ºF) to +40ºC (104ºF) (normal operation)

according to NEBS Standard GR-63-CORE

-5ºC to +55ºC (short term operation) according to

NEBS Standard GR-63-CORE

Temp. Change +/- 0.25ºC/min or 15ºC/h (59ºF/h) according to

NEBS Standard GR-63-CORE

Rel. Humidity 5% to 85% non-condensing according to Artesyn -

internal environmental requirements

Altitude <= 4000m

20

RTM-ATCA-7350 Installation and Use (6806800H30G)

-40ºC (-40ºF) to +70ºC

(158ºF) (may be further

limited by installed

accessories)

+/- 0.25ºC/min or 15ºC/h

(59ºF/h)

5% to 85% non-condensing

according to Artesyn internal environmental

requirements

Page 21

Hardware Preparation and Installation

Table 2-1 Environmental Requirements (continued)

Requirement Operating Non-Operating

Vibration 1.0g from 5 to 100 Hz and back to 5 Hz at a rate of

0.1 octave/minute

Shock Half-sine, 11 m/Sec, 30mSec/sec

Free Fall 1,200 mm (Packaged) /all

2

5-20 Hz @ 0.01 g2/Hz

20-200 Hz @ -3.0 dB/octave

Random 5-20 Hz @ 1

2

3

/Sec

m

Random 20-200 Hz @ -3

2

m/Sec

Blade level packaging

Half-sine, 6 mSec at 180

2

m/Sec

edges and corners

1.0m (Packaged) per ETSI

300 019-2-2 (Blade level

packaging)

25mm (unpackaged) per

GR-63-CORE

2.3.2 Power Requirements

Table 2-2 Power Requirements

Requirement Operating

Power supply Provided by the server blade

Maximum power consumption 14.2 W

RTM-ATCA-7350 Installation and Use (6806800H30G)

21

Page 22

Hardware Preparation and Installation

2.4 Module Installation and Removal

Personal Injury

Power and communication cables

Touching power and communication cables that are energized may cause injuries.

Make sure that the cables cannot be touched while the product is operating.

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product or electronic components, make sure that your are working in an

ESD-safe environment.

22

Module Damage

If the blade is not fully aligned with the interface in the backplane, too much force may twist the

pins on the blade or backplane.

Do not exert too much force when you insert the blade.

Note the following points at the time of installing RTM-ATCA-7350:

Make sure that you wear an electrostatic discharge (ESD)-preventive wrist strap to prevent

the static electricity from hurting you or damaging the device.

Keep your personal objects such as your clothes away from RTM-ATCA-7350. To prevent

the static electricity on clothing, you need to put on antistatic clothing.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 23

RTM-ATCA-7350 is installed in the slot paired with the server blade slot at the back side of

the shelf. RTM-ATCA-7350 is powered from the payload power of the front board. You

should install RTM-ATCA-7350 before payload power of the front board is turned on. Hot

swap of the RTM-ATCA-7350 while under power is not supported.

Hold the ejector handles and the face plate when you insert or remove RTM-ATCA-7350.

Do not touch the components inside of the blades.

Keep the blade vertical when you install RTM-ATCA-7350. Align the blade with the slot and

then insert it in the shelf.

2.4.1 Ejector Handles

RTM-ATCA-7350 is powered by the server blade in the slot paired with the RTM-ATCA-7350

slot. RTM-ATCA-7350 does not support hot swap. As shown in Figure 3-1, the face plate of

RTM-ATCA-7350 provides an upper and a lower ejector handles. The ejector handles help to

insert, remove, fasten, power on, and power off RTM-ATCA-7350.

Hardware Preparation and Installation

2.4.2 ESD Prevention

Static electricity may hurt you or damage the device. To minimize the damage, pay attention

to the following points:

Before you operate the device, wear the ESD-preventive wrist strap. Both terminals of the

ESD-preventive wrist strap must contact well. One terminal touches your bare skin, and

the other is inserted in the jack at the front or back side of the shelf. For details on how to

wear the ESD-preventive wrist strap, refer Wearing the ESD-Preventive Wrist Strap on page

24.

Avoid moving your body as much as possible. Movement gathers static electricity around

you.

Do not touch the solder point, pin, or bare circuit.

Do not leave the device in the place where others can operate it.

Install the device at once after you take it out of the antistatic package. If you need to lay

down the device, place it back in the antistatic package. Do not lay the device on the shelf

or cabinet.

Monitor the temperature and humidity of the equipment room. Warm air decreases the

humidity and increases the static electricity in the room.

RTM-ATCA-7350 Installation and Use (6806800H30G)

23

Page 24

Hardware Preparation and Installation

2.5 Installation Preparations

The installation preparations process includes:

check the installation environment

wear the ESD-preventive wrist strap

remove the blank filler panels

unpack and check the RTM-ATCA-7350 suite

2.5.1 Wearing the ESD-Preventive Wrist Strap

Module Damage

Electrostatic discharge can damage circuits or shorten their life.

The ESD-preventive wrist strap prevents only the static electricity on your body from

damaging the blade. To prevent the static electricity on your clothes, it is recommended to

wear the antistatic clothes. Additionally, you have to make sure that the cabinet and shelf

are properly grounded - for details, refer to the corresponding system documentation.

24

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 25

Hardware Preparation and Installation

To wear the ESD-preventive wrist strap, proceed as follows:

1. Wrap the ESD-preventive wrist strap around your wrist, as shown in the figure

below.

2. Fasten the latch. Make sure that the ESD-preventive wrist strap well touches your

bare wrist.

3. Insert the grounding terminal of the ESD-preventive wrist strap in the jack of the

cabinet or shelf.

Figure 2-1 Wearing the ESD-Preventive Wrist Strap

RTM-ATCA-7350 Installation and Use (6806800H30G)

25

Page 26

Hardware Preparation and Installation

2.5.2 Removing Filler Blades

After a filler blade is removed, place it in the equipment room or other moisture-proof and dustproof places.

You should install a blank filler blade in the slot after removing the blade. Otherwise, it may effect

the ventilation, heat dissipation, electromagnetic shielding and dust prevention of the shelf.

If this is the first installation for the shelf, the blade is fully configured and the shelf is not powered

on, you can remove all the filler blades. Then, install blades in the slots in order. This document

takes the first installation as an example.

If you want to install multiple blades in the shelf that is powered on, you can remove a filler blade

and then install a blade one by one.

If the slot is occupied with a filler blade you have to remove it first.

26

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 27

Hardware Preparation and Installation

To remove the filler blade, proceed as follows:

1. As shown in step 1 of the figure below, use a screwdriver to anticlockwise loosen

the two captive screws on a filler blade.

2. As shown in step 2 of the figure below, remove the filler blade.

Figure 2-2 Removing the Filler Blade

2.6 Installing and Replacing Daughter Cards

RTM-ATCA-7350 Installation and Use (6806800H30G)

27

Page 28

Hardware Preparation and Installation

2.6.1 Precautions

Incorrect installation or removal of additional devices or modules may damage the product or

the additional devices or modules.

Before installing or removing additional devices or modules, read the respective

documentation.

Personal Injury

Power and communication cables

Touching power and communication cables that are energized may cause injuries.

Make sure that the cables cannot be touched while the product is operating.

28

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product or electronic components, make sure that your are working in an

ESD-safe environment.

Do not exert too much force when you insert the blade.

If the blade is not fully aligned with the interface in the backplane, too much force may twist the

pins on the blade or backplane.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 29

Note the following points at the time of installing or replacing components:

Make sure that you wear an electrostatic discharge (ESD)-preventive wrist strap to prevent

the static electricity from hurting you or damaging the device.

Keep the area where the components reside clean and keep the components away from

the heat-generating devices, such as radiators.

Ensure that your sleeves are tightened or rolled up above the elbow. For safety purpose, it

is not recommended to wear jewelry, watch, glasses with metal frame, or clothes with

metal buttons.

Do not exert too much force, or insert or remove the components forcibly. Avoid damage

to the components or plug-ins, for example, the pins are bent or get short circuit.

2.6.2 Preparations

Before you install or replace a component, make the following preparations

Hardware Preparation and Installation

Confirming the feasibility of the operation

– There are available spare parts of the component to be installed or replaced in the

equipment warehouse. When the available spare parts are in short supply, contact

Artesyn technical support for help in time.

– Make sure that the new component is in good condition, without defects such as

oxidation, chemical corrosion, missing component, or transportation damage.

– By reading this document, you are familiar with how to install and replace the

component and master the skills required by the operation.

Checking the environment

Make sure that the shelf, power supply, temperature, and humidity meet the operating

requirements of the blades and components. For details, refer to ATCA-7350 Installation

and Use Manual and other related documents.

Preparing spare parts and tools

– Prepare the component to be installed or replaced.

When you hold or transport the component, use the special antistatic package. In

addition, you need to tidy, record, and repair the component during routine

maintenance.

RTM-ATCA-7350 Installation and Use (6806800H30G)

29

Page 30

Hardware Preparation and Installation

– Prepare the cross screwdriver, screws, plastic supports, cooling gel, and ESD-

preventive wrist strap.

The supplier provides a list of tools and negotiates with you to decide the tool

provider.

Confirming installation or changing positions

Confirm the positions of the cabinet, the shelf, and the slot where RTM-ATCA-7350 is

installed. Then, stick a label on the face plate of RTM-ATCA-7350 to avoid wrong

operation.

Others

If a serious problem occurs and cannot be solved when you install or replace the

component, contact Artesyn for technical support.

2.6.3 GE Daughter Card

This manual considers the GE daughter card providing two external Ethernet interfaces as an

example, and describes how to install the daughter card on and remove it from RTM-ATCA-

7350.

30

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 31

2.6.3.1 Installation Positions

When the GE daughter card is used with the RTM-ATCA-7350 it can be installed on the

daughter card connector J1, J2. The default position as used on the RTM-ATCA-7350-GE is

position J2.

Figure 2-3 Structure of RTM-ATCA-7350

Hardware Preparation and Installation

RTM-ATCA-7350 Installation and Use (6806800H30G)

31

Page 32

Hardware Preparation and Installation

2.6.3.2 Installing the GE Daughter Card

To install the GE daughter card, proceed as follows.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap on page 24.

2. Lay RTM-ATCA-7350 where the GE daughter card is to be installed on the antistatic

desktop.

3. As shown in step 1 of the figure below, insert two plastic supports vertically in the

holes used to fasten the GE daughter card.

4. As shown in step 2 of the figure below, at the back side of RTM-ATCA-7350, use a

screwdriver to clockwise fasten the two screws used to fix the plastic supports.

5. Take the GE daughter card out of the antistatic package.

32

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 33

Hardware Preparation and Installation

6. Insert the GE daughter card in RTM-ATCA-7350 by facing the daughter card at an

angle of 45° to the RTM. Align the daughter card connector with the connector on

RTM-ATCA-7350, and the daughter card positioning holes with the plastic supports

on RTM-ATCA-7350. Exert even power downwards until the daughter card

connector is fully inserted into the connector on RTM-ATCA-7350 and the daughter

card is fastened by the plastic latches. See step 3 in the figure below.

Figure 2-4 Installing the GE Daughter Card

RTM-ATCA-7350 Installation and Use (6806800H30G)

33

Page 34

Hardware Preparation and Installation

7. Insert RTM-ATCA-7350 with the GE daughter card installed in the shelf. For more

information refer, Installing RTM-ATCA-7350 on page 37.

After installation, check if RTM-ATCA-7350 can be powered on and work normally. Use the

network cable to connect RTM-ATCA-7350 to the external network. Check if the network is

connected properly and monitor whether the network port indicator is normal.

2.6.3.3 Replacing the GE Daughter Card

To replace the GE daughter card, proceed as follows.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap on page 24.

2. Remove the RTM-ATCA-7350 whose GE daughter card is to be replaced. For more

information refer, Removing RTM-ATCA-7350 on page 40.

34

3. Open the plastic latches fastening the GE daughter card.

4. Exert even force upwards until the daughter card connector is removed from the

connector on RTM-ATCA-7350. Remove the daughter card by facing the daughter

card at an angle of 45° to the RTM.

5. Place the removed GE daughter card in an antistatic package.

6. Take the new GE daughter card out of the antistatic package.

7. Insert the GE daughter card in RTM-ATCA-7350 by facing the daughter card at an

angle of 45° to the RTM. Align the daughter card connector with the connector on

RTM-ATC A-7350, and the daughter card positioning holes with the plastic supports

on RTM-ATCA-7350. Exert even power downwards until the daughter card

connector is fully inserted into the connector on RTM-ATCA-7350 and the

daughter card is fastened by the plastic latches.

8. Install RTM-ATCA-7350 whose GE daughter card is replaced. For more information

refer, Installing RTM-ATCA-7350 on page 37.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 35

After replacement, check if RTM-ATCA-7350 can be powered on and work normally. Use the

network cable to connect RTM-ATCA-7350 to the external network. Check if the network is

connected properly and monitor whether the network port indicator is normal.

2.6.4 FC Daughter Card

This section describes how to install the daughter card on and remove it from RTM-ATCA-7350.

2.6.4.1 Installation Positions

When the FC daughter card is used with the RTM-ATCA-7350 it can be installed on the

daughter card connector J1. The RTM-ATCA-7350 provides space for one FC daughter card.

Use of the FC daughter card excludes use of the GE daughter card.

2.6.4.2 Installing the FC Daughter Card

Hardware Preparation and Installation

To install the FC daughter card, proceed as follows.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap on page 24.

2. Lay RTM-ATCA-7350 where the FC daughter card is to be installed on the antistatic

desktop.

3. Insert two plastic supports vertically in the holes used to fasten the FC daughter

card.

4. At the back side of RTM-ATCA-7350, use a screwdriver to clockwise fasten the two

screws used to fix the plastic supports.

5. Take the FC daughter card out of the antistatic package.

RTM-ATCA-7350 Installation and Use (6806800H30G)

35

Page 36

Hardware Preparation and Installation

6. Insert the FC daughter card in RTM-ATCA-7350 by facing the daughter card at an

angle of 45° to the RTM. Align the daughter card connector with the connector on

RTM-ATC A-7350, and the daughter card positioning holes with the plastic supports

on RTM-ATCA-7350. Exert even power downwards until the daughter card

connector is fully inserted into the connector on RTM-ATCA-7350 and the

daughter card is fastened by the plastic latches.

7. Insert RTM-ATCA-7350 with the FC daughter card installed in the shelf. For more

information refer, Installing RTM-ATCA-7350 on page 37.

After installation, check if RTM-ATCA-7350 can be powered on and work normally. Use the

optical fiber to connect RTM-ATCA-7350 to the external storage system. Check if RTM-ATCA7350 can transmit data normally and monitor whether the FC status indicator is normal.

2.6.4.3 Replacing the FC Daughter Card

36

To replace the FC daughter card, proceed as follows.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap on page 24.

2. Remove the RTM-ATCA-7350 whose FC daughter card is to be replaced. For more

information refer, Removing RTM-ATCA-7350 on page 40.

3. As shown in step 1 of the figure below, open the plastic latches fastening the FC

daughter card.

4. Exert even force upwards until the daughter card connector is removed from the

connector on RTM-ATCA-7350. As shown in step 2 of the figure below, remove the

daughter card by facing the daughter card at an angle of 45° to the RTM.

5. Place the removed FC daughter card in an antistatic package.

6. Take the new FC daughter card out of the antistatic package.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 37

Hardware Preparation and Installation

7. Insert the FC daughter card in RTM-ATCA-7350 by facing the daughter card at an

angle of 45° to the RTM. Align the daughter card connector with the connector on

RTM-ATCA-7350, and the daughter card positioning holes with the plastic supports

on RTM-ATCA-7350. Exert even power downwards until the daughter card

connector is fully inserted into the connector on RTM-ATCA-7350 and the daughter

card is fastened by the plastic latches. See step 3 in the figure above.

8. Install RTM-ATCA-7350 whose FC daughter card is replaced. For more information

refer, Installing RTM-ATCA-7350 on page 37.

After replacement, check if RTM-ATCA-7350 can be powered on and work normally. Use the

optical fibre to connect RTM-ATCA-7350 to the external storage system. Check if RTM-ATCA7350 can transmit data normally and monitor whether the FC status indicator is normal.

2.7 Installing and Removing the RTM-ATCA-7350

2.7.1 Installing RTM-ATCA-7350

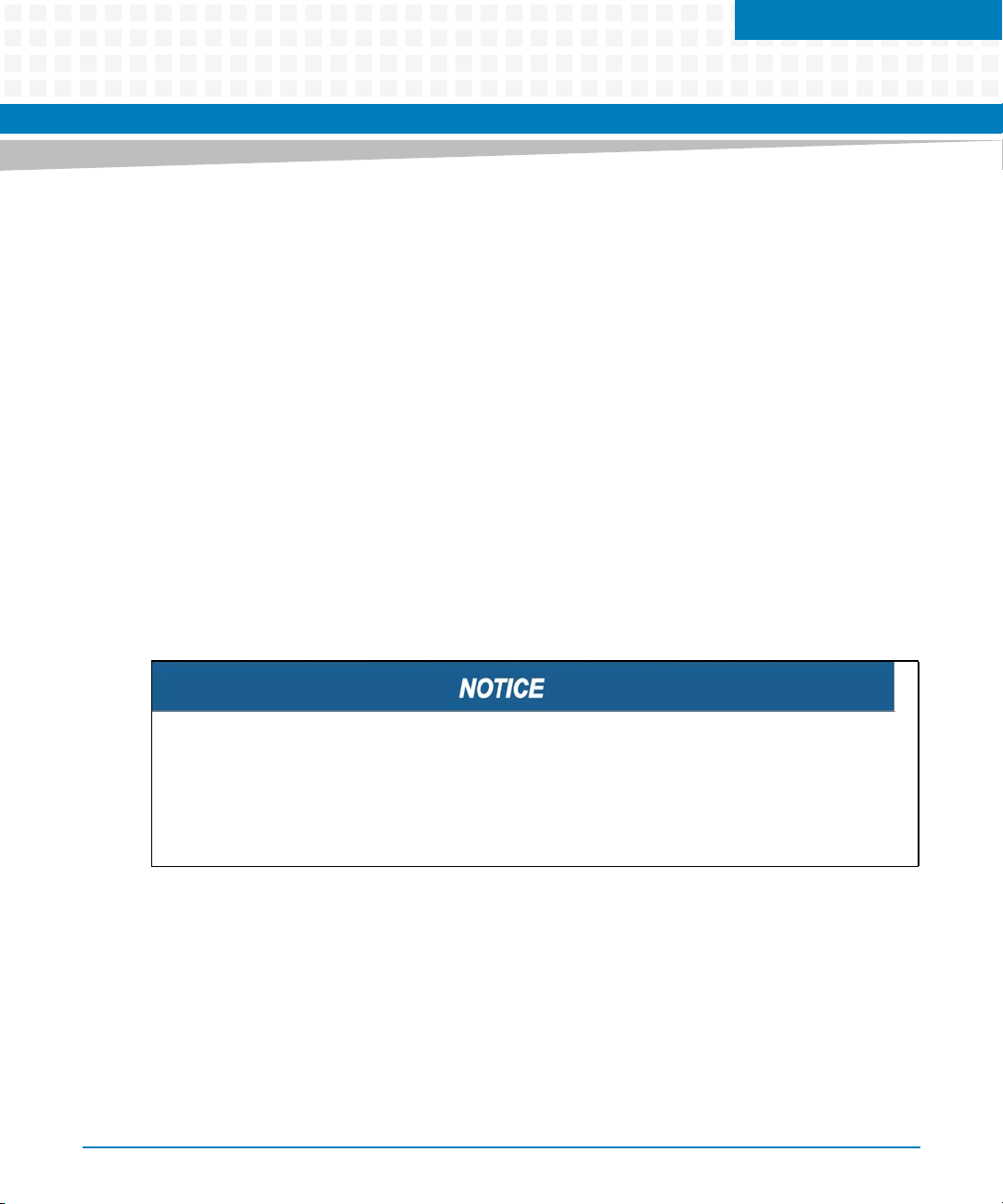

Product Damage

You can install RTM-ATCA-7350 into a system if the front blade is already installed or if it is not

installed. In case the front blade is already installed, its payload has to be powered down first.

RTM-ATCA-7350 Installation and Use (6806800H30G)

37

Page 38

Hardware Preparation and Installation

Installation Procedure with Installed Front Blade

The following procedure describes the installation of RTM-ATCA-7350. It assumes that your

system is powered on. If your system is powered off, you can disregard the blue LED and thus

skip the respective step. In this case it is a purely mechanical installation. The same applies to

an installation without an installed front blade. In this case disregard the LEDs and skip the

respective step.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap on page 24.

2. Unlatch the lower handle of the front blade outward by squeezing the lever and the

latch together and turning the handle outward only enough to unlatch the handle

from the face plate, that means until you feel a resistance. Do not rotate the handle

fully outward.

The blue LED blinks indicating that the shelf manager is informed about the desire

of the blade to power down the payload of the front blade and the power-down

process is ongoing.

38

3. Wait until the blue LED of the front blade is permanently ON. A permanently

switched ON LED indicates that the payload of the front blade has been powered

down.

4. Remove the front blade. For instructions on how to remove the blade, refer to

Removing the ATCA-7350 in ATCA-7350 Installation and Use manual.

5. Take RTM-ATCA-7350 out of the antistatic package.

6. Fully open the upper and lower ejector handles of the RTM.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 39

Hardware Preparation and Installation

7. Align the upper and lower sides of RTM-ATCA-7350 with the guide rails (the edges

of the slot). Slide RTM-ATCA-7350 along the guide rails until the positioning pins of

RTM-ATCA-7350 are inserted in the positioning holes in the shelf.

Figure 2-5 Installing RTM-ATCA-7350

8. Make sure that the ejector handles are fastened to the beam. Close the upper and

lower ejector handles inwards until the inner sides of the ejector handles are

attached to the face plate.

9. Use the screwdriver to fasten the captive screws clockwise to fix RTM-ATCA-7350.

The LEDs of the RTM are off now.

10.Insert the main blade. For instructions on how to install the main blade, refer to

Installing the ATCA-7350 in a Powered Shelf in ATCA-7350 Installation and Use manual.

RTM-ATCA-7350 Installation and Use (6806800H30G)

39

Page 40

Hardware Preparation and Installation

11.Close the handles of the front blades. The LEDs; OOS LED, Blue LED, and healthy

LED of RTM are on.

12.Wait until the blue LED on the RTM is OFF.

A switched off blue LED indicates that the payload of the RTM has become active.

2.7.2 Removing RTM-ATCA-7350

Product Damage

You should power off the front blade before removing RTM-ATCA-7350.

40

To remove RTM-ATCA-7350, proceed as follows:

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap on page 24.

2. Unlatch the lower handle outward by squeezing the lever and the latch together

and turning the handle outward only enough to unlatch the handle from the face

plate, that means until you feel a resistance. Do not rotate the handle fully outward.

The blue LED blinks indicating that the shelf manager is informed about the desire

of the blade to power down the payload of both the front blade and the RTM and

the power-down process in ongoing.

3. Wait until the blue LED of the RTM is permanently ON. A permanently switched ON

LED indicates that the payload of the RTM has been powered down.

4. As shown in step 2 of the figure below, use the screwdriver to unfasten the captive

screws of the RTM anticlockwise.

5. As shown in step 1 of the figure below, fully open the upper and lower ejector

handles.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 41

Hardware Preparation and Installation

6. As shown in step 3 of the figure below, remove RTM-ATCA-7350 along the guide

rails.

7. Place RTM-ATCA-7350 in the antistatic package.

Figure 2-6 Removing RTM-ATCA-7350

2.8 Connecting External Cables

After RTM-ATC A-7350 is installed in the shelf, you can connect the keyboard, video, and mouse

(KVM) cables.

RTM-ATCA-7350 Installation and Use (6806800H30G)

41

Page 42

Hardware Preparation and Installation

If RTM-ATCA-7350 is configured with the GE daughter card or FC daughter card, it provides the

external GE network ports or external FC interfaces. Network cables or optical fibers can be

connected to RTM-ATCA-7350. You can choose to use one or more daughter cards according

to actual applications.

Refer Daughter Cards on page 62, for the functions of the daughter cards of RTM-ATCA-7350.

Cable Damage

There is a back cable trough at the back side of the shelf. You need to arrange and identify

all cables and then bind and fasten them in the back cable through after connecting them.

If you use excessive force when installing cables, the cables may be damaged.

Do not exert too much force when you insert or remove the cables. Do not twist or tear the

cables in any condition.

2.8.1 Connecting KVM Cables

The figure below shows the method of connecting the Keyboard, Video, Mouse (KVM) cables

to RTM-ATCA-7350 when connecting PS/2 compatible keyboard and mouse using a PS/2-USB

converter. USB based keyboard and mouse can also be attached to the RTM by using a USB hub.

Product Damage

You have to use matching interfaces for the KVM cables.

Use a PS/2-USB converter when connecting to PS/2 based keyboard and mouse cables.

Use a USB hub when connecting to USB based keyboard and mouse cables.

42

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 43

Hardware Preparation and Installation

Figure 2-7 Connecting the KVM Cables to RTM-ATCA-7350

2.8.2 Connecting Network Cables

Electromagnetic Radiation

Make sure that the cable and connectors of the network cable are with shielding function and

that both ends of the shielded layer of the network cable are grounded. It is recommended that

the network cable is grounded through the metal cover of the network port connector.

When RTM-ATCA-7350 is configured with the GE daughter card, it provides two external

Ethernet interfaces with 10/100/1000M Base-T auto-negotiation. Network cables are used to

connect RTM-ATCA-7350 to the external network.

RTM-ATCA-7350 Installation and Use (6806800H30G)

43

Page 44

Hardware Preparation and Installation

The figure below shows the method of connecting the network cables to RTM-ATCA-7350.

Figure 2-8 Connecting the Network Cables to RTM-ATCA-7350

2.8.3 Connecting Optical Fibers

When RTM-ATCA-7350 is configured with the FC daughter card, it provides two external 2G FC

interfaces. Optical fibers are used to connect RTM-ATCA-7350 to the external Storage Area

Network (SAN) storage system. Optical modules for the FC daughter cards must be obtained

separately. Recommended modules are FINISAR FTRJ8519P1BNL-HW, FINISAR

FTRJ8519P2BNL-HW.

44

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 45

Hardware Preparation and Installation

As shown in steps 1 and 2 in the figure below, insert the optical module in the FC interface and

then insert the optical fibers in the optical module.

Figure 2-9 Connecting the Optical Fibers to RTM-ATCA-7350

RTM-ATCA-7350 Installation and Use (6806800H30G)

45

Page 46

Hardware Preparation and Installation

46

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 47

Controls, LEDs and Connectors

3.1 Overview

This chapter describes:

Face plate connectors

Face plate LEDs

Rear panel connectors

Chapter 3

RTM-ATCA-7350 Installation and Use (6806800H30G)

47

Page 48

Controls, LEDs and Connectors

3.2 Face Plate Connectors and LEDs

The following figure shows the face plate of RTM-ATCA-7350 without daughter cards installed.

Figure 3-1 Face Plate of RTM-ATCA-7350

48

You need to install a filler blade in the position that is not occupied by the face plate of the

daughter card.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 49

3.2.1 LEDs

The face plate of RTM-ATCA-7350 provides the following indicators:

Out of service (OOS) indicator

In service (IS) indicator

Hotswap (H/S) indicator

The GE daughter card provides the network port indicators and the FC daughter card provides

the FC status indicators. You can monitor these indicators to diagnose the current status of

RTM-ATCA-7350.

The following table lists the indicators on the RTM-ATCA-7350 face plate.

Table 3-1 Indicators on the RTM-ATCA-7350 Face Plate

Indicator Color Meaning Description

Controls, LEDs and Connectors

OOS Red or amber Service status

indicator

IS Red, green or

amber

H/S Blue Hot swap indicator Off: RTM-ATCA-7350 is in activated state.

In service indicator The IS LED is off when the payload processor

The RTM-ATCA-7350 turns the red LED on

when transitioning from FRU M3 to M4 state

if in local control state. It is the responsibility

of the application to change the status of the

LED via IPMI command.

The RTM-ATCA-7350 turns the LED off when

transitioning from FRU state M6 to M1 if in

local control state.

starts running.

Payload Management software is

responsible for controlling the IS LED.

On: RTM-ATCA-7350 is inserted, but in

deactivated state or not powered on.

1

Blinking at the long blink rate

7350 is requesting activation.

Blinking at the short blink rate

7350 is requesting deactivation.

: RTM-ATCA-

2

: RTM-ATCA-

RTM-ATCA-7350 Installation and Use (6806800H30G)

49

Page 50

Controls, LEDs and Connectors

Table 3-1 Indicators on the RTM-ATCA-7350 Face Plate (continued)

Indicator Color Meaning Description

ATN Amber Attention indicator The ATN LED is set to off when the payload

processor starts running.

Payload Management software is responsible for

controlling the ATN LED.

1. Blinking at the long blink rate means that the indicator is on for 900 ms and then off for 100 ms alternatively.

2. Blinking at the short blink rate means that the indicator is on for 100 ms and then off for 900 ms alternatively.

50

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 51

3.2.2 Connectors

RTM-ATCA-7350 provides two daughter card connectors, as shown in the following figure.

Figure 3-2 Structure of RTM-ATCA-7350

Controls, LEDs and Connectors

RTM-ATCA-7350 Installation and Use (6806800H30G)

51

Page 52

Controls, LEDs and Connectors

In the above figure:

Label Description

1 Daughter card connector J2

2 Daughter card connector J1

3.2.2.1 RTM-ATCA-7350 Face Plate

Face plate of the RTM-ATCA-7350 provides:

One USB interface

One VGA DB15 Port

OOS indicator

IS indicator

52

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 53

Controls, LEDs and Connectors

ATN indicator

H/S indicator

Figure 3-3 Connectors and Indicators of RTM-ATCA-7350

RTM-ATCA-7350 Installation and Use (6806800H30G)

53

Page 54

Controls, LEDs and Connectors

3.2.2.1.1 USB Port

RTM-ATCA-7350 provides a single port USB connector on the face plate. The USB port is

compliant to the USB 1.1 specification. The following USB Port Pin Assignment table describes

the pinout information.

Figure 3-4 RTM-ATCA-7350 Front Plate USB Connector Pinout

Table 3-2 USB Port Pin Assignment

Pin Pin Name Description

1 +5V +5V Power Supply, Max 500mA each port.

2 Data- Differential Data transmitting pair.

3Data+

4 GROUND Ground, connected to the logic GND of ATCA-7350.

54

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 55

3.2.2.1.2 VGA Port

ATCA-7350 provides its VGA output port through RTM-ATCA-7350. The VGA port on RTMATCA-7350 use a DB15 female connector with a signal definition compatible to the standard

VGA plug.

Figure 3-5 RTM-ATCA-7350 Front Plate VGA Port Pinout

Controls, LEDs and Connectors

Table 3-3 VGA Port Pin Assignment

Pin Pin Name Description

1 RED Analog red video output signal.

2 GREEN Analog green video output signal.

3 BLUE Analog blue video output signal.

4 RESERVED1 Reserved.

5 RESERVED2 Reserved on RTM-ATCA-7350.

6 GROUND1 Connected to the logic ground of RTM-ATCA-7350.

7 GROUND2 Connected to the logic ground of RTM-ATCA-7350.

8 RESERVED3 Reserved on RTM-ATCA-7350.

9 RESERVED4 Reserved, Connected to 5VCC on RTM-ATCA-7350 through a

10 GROUND3 Connected to the logic ground of RTM-ATCA-7350.

11 RESERVED5 Reserved.

RTM-ATCA-7350 Installation and Use (6806800H30G)

PTC resistor.

55

Page 56

Controls, LEDs and Connectors

Table 3-3 VGA Port Pin Assignment (continued)

Pin Pin Name Description

12 DDC DATA DDC data pin for CRT.

13 HS Horizontal sync for Monitor.

14 VS Vertical sync for Monitor.

15 DDC CLK DDC pin SCL for CRT.

3.3 Zone 3 Connectors

Zone 3 is composed of three connectors, P30, P31, and P32. The three connectors are used to

connect RTMs with RTM-ATCA-7350s. Zone 3 defines the following signals:

USB (USB)

VGA

IPMC SMBus

Power (VCC 12VDC, VSBY 5V5)

PCI-E Channels

General control signals (RTM PRESENT, RTM RST, LEDs)

Fabric channel port 0, port 1, port 2, port 3 for the ATCA-7350

3.3.1 P30 Pinout

P30 uses a common 2mm HM connector. P31 uses a half-height ZD connector. P32 uses a ZD

connector.

Refer to the PICMG specification for the location of the connectors.

The following table shows the P30 pinout. PinA1 on the server blade side is on the top of the

connector while the server blade is placed top side upwards and the face plate is left.

56

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 57

Controls, LEDs and Connectors

RTM_EN0_ and RTM_EN_ are signals that indicate the RTM is firmly inserted.

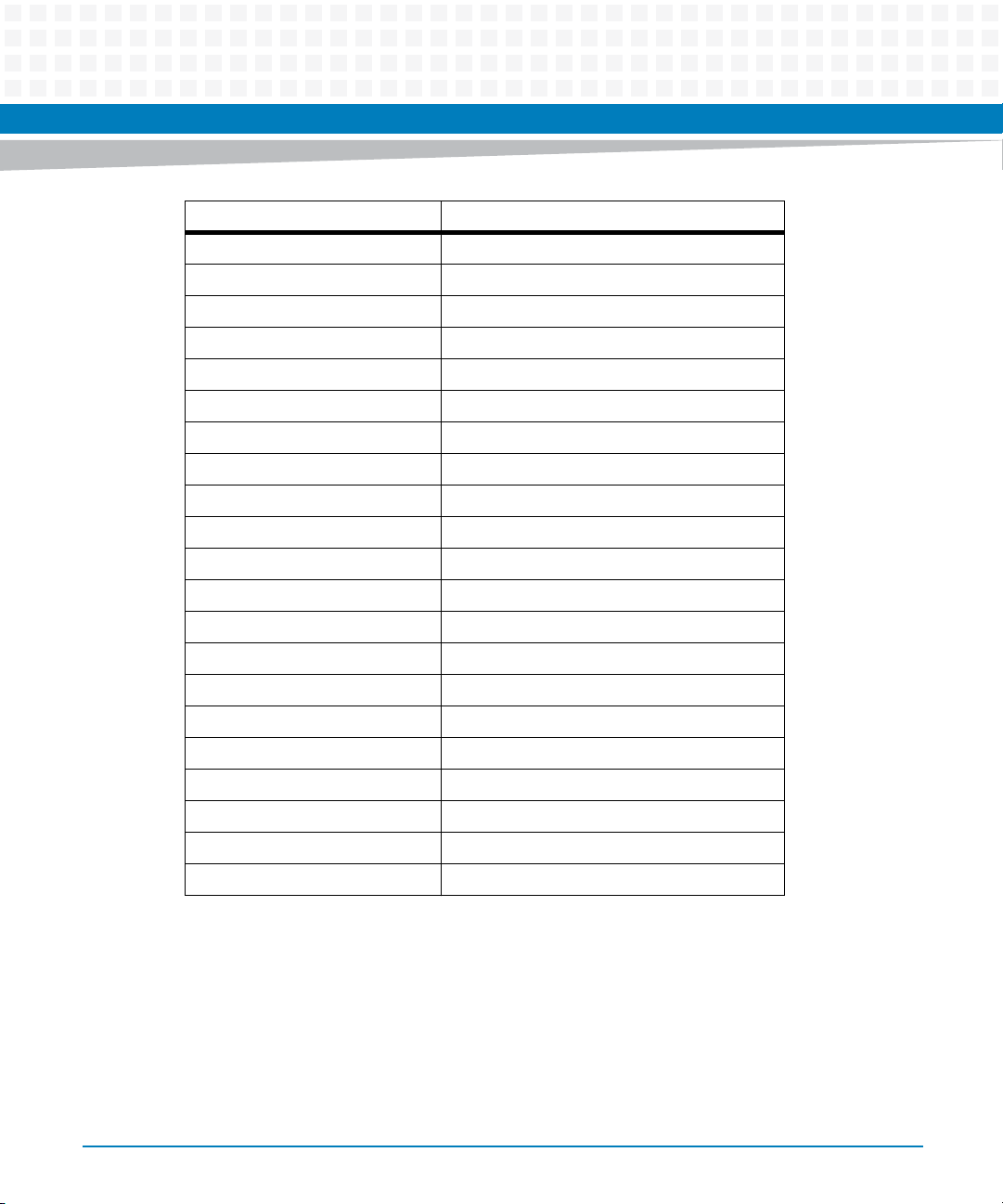

Table 3-4 PIN 30 Pinout

HM A B C D E

1 VSB5V RTM_EN0 GND RTM_OOSR_ RTM_HEALTHY_G_

2 VSB5V RTM_HOTSPWAP_ GND RTM_HEALTHY_R RTM_OOSY_

3 +12V RTM_TOP_EJECTOR_GND RTM_SDA RTM_SCL

4 +12V RT;_EPROM_WE GND VGA_RED CPLD_RTM_TDI

5 +12V RTM_BOT_EJECTOR_GND VGA_BLUE RTM_JTAG_TDO

6 +12V RTM_KBCLK GND VGA_GREEN CPLD_RTM_TCK

7 +12V RTM_MSDAT GND VGA_HS CPLD_RTM_TMS

8 +12V RTM_MSCLK GND VGA_VS CPLD_RTM_TRST

9 +12V RTM_KBDAT GND VGA_DDCCLK RTM_PWR_GOOD

10 +12V RTM_USB_P GND VGA_DDCDAT RTM_LM80_INT_

11 +12V RTM_USB_N GND RTM_SBY_RST RTM_EN_

3.3.2 P31 Pinout

P31 is used for port1 and port2 signals of the Fabric interface, and the PCIE signals from MCH.

PinA1 on the sever board side is on the top of the connector, and on the left column of the P31

connector while the server board is placed top side upwards and the front panel is on the left.

Table 3-5 PIN 31 Pinout

ZD1 A B C D

1 RTM_SYSLED_G_RESERVED GND RTM_SYSLED_R_RESERVED GND

2 RTM_FC2_TX2_HRTM_FC2_TX2_L GND RTM_FC1_TX2_HRTM_FC1_TX2_L GND

3 RTM_FC2_RX2_HRTM_FC2_RX2_L GND RTM_FC1_RX2_HRTM_FC1_RX2_L GND

RTM-ATCA-7350 Installation and Use (6806800H30G)

57

Page 58

Controls, LEDs and Connectors

Table 3-5 PIN 31 Pinout (continued)

ZD1 A B C D

4 RTM_FC2_TX1_HRTM_FC2_TX1_L GND RTM_FC1_TX1_HRTM_FC1_TX1_L GND

5 RTM_FC2_RX1_HRTM_FC2_RX1_L GND RTM_FC1_RX1_HRTM_FC1_RX1_L GND

6 RTM_PE7_PRS

NT_R_

7 RTM_EXP7_RXP3RTM_EXP7_RXN3 GND MCH_EXP7_RXP2MCH_EXP7_RXN2 GND

8 RTM_EXP7_RXP2RTM_EXP7_RXN2 GND MCH_EXP7_RXP1MCH_EXP7_RXN1 GND

9 RTM_EXP7_RXP1RTM_EXP7_RXN1 GND MCH_EXP7_RXP0MCH_EXP7_RXN0 GND

10 RTM_EXP7_RXP0RTM_EXP7_RXN0 GND RTM_PCIE7_CL

RTM_PE7_RST_ GND MCH_EXP7_RXP3MCH_EXP7_RXN3 GND

RTM_PCIE7_CLK_NGND

K_P

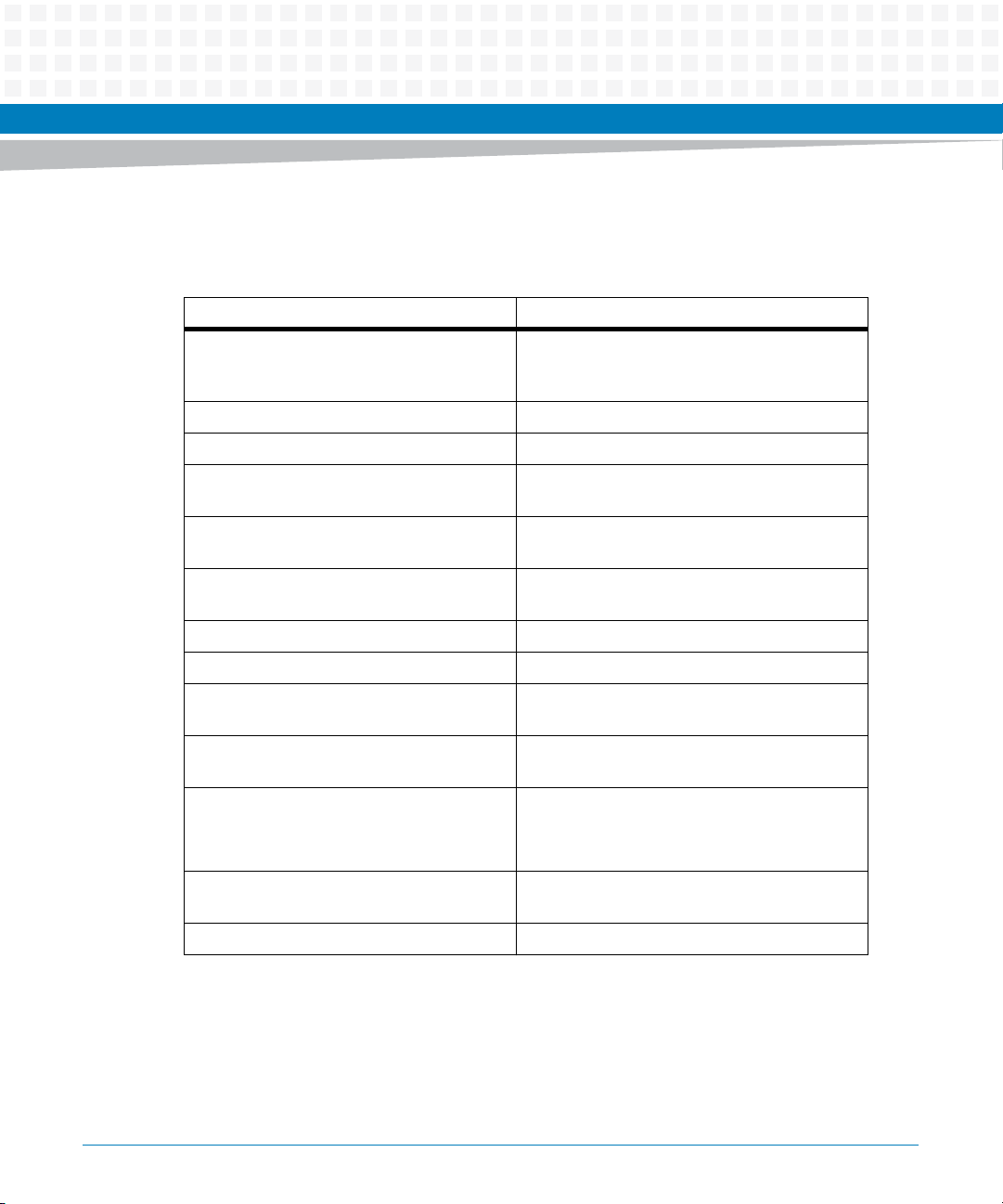

3.3.3 P32 Pinout

P32 is used for port1 and port4 signals of the Fabric interface, and the PCIE signals from front

board.

PinA1 on the server board side is on the top of the connector, and on the left column of the P32

connector while the server board is placed top side upwards and the front panel is on the left.

Table 3-6 PIN 32 Pinout

ZD2 A B C D E F G H

1 RTM_PE

_SDA

2 RTM_EX

P6_RXP

1

58

RTM_PE

_SCL

RTM_EX

P6_RXN

1

GNDMCH_E

XP6_RX

P1

GNDMCH_E

XP6_RX

P0

MCH_E

XP6_RX

N1

MCH_E

XP6_RX

N0

GNDRTM_EX

P6_RXP

3

GNDRTM_EX

P6_RXP

2

RTM-ATCA-7350 Installation and Use (6806800H30G)

RTM_EX

P6_RXN

3

RTM_EX

P6_RXN

2

GNDMCH_E

XP6_RX

P3

GNDMCH_E

XP6_RX

P2

MCH_E

XP6_RX

N3

MCH_E

XP6_RX

N2

GN

D

GN

D

Page 59

Controls, LEDs and Connectors

Table 3-6 PIN 32 Pinout (continued)

ZD2 A B C D E F G H

3 RTM_EX

P6_RXP

0

RTM_EX

P6_RXN

0

GNDRTM_PC

IE6_CLK

_P

RTM_PC

IE6_CLK

_N

GNDRTM_EX

P5_RXP

3

RTM_EX

P5_RXN

3

GNDMCH_E

XP5_RX

P3

MCH_E

XP5_RX

N3

GN

D

4 RTM_EX

P5_RXP

1

5 RTM_EX

P5_RXP

0

6 RTM_EX

P4_RXP

1

7 RTM_EX

P4_RXP

0

8 RTM_PE

6_PRSN

T_R_

9 RTM_FC

2_TX3_

H

10 RTM_FC

2_RX3_

H

RTM_EX

P5_RXN

1

RTM_EX

P5_RXN

0

RTM_EX

P4_RXN

1

RTM_EX

P4_RXN

0

RTM_PE

5_PRSN

T_R_

RTM_FC

2_TX3_

L

RTM_FC

2_RX3_

L

GNDMCH_E

XP5_RX

P1

GNDMCH_E

XP5_RX

P0

GNDMCH_E

XP4_RX

P1

GN

MCH_E

D

XP4_RX

P0

GNDRTM_PE

4_PRSN

T_

GNDRTM_FC

1_TX3_

H

GNDRTM_FC

1_RX3_

H

MCH_E

XP5_RX

N1

MCH_E

XP5_RX

N0

MCH_E

XP4_RX

N1

MCH_E

XP4_RX

N0

RTM_PE

5_WAKE

_

RTM_FC

1_TX3_

L

RTM_FC

1_RX3_

L

GNDRTM_EX

P5_RXP

2

GNDRTM_PC

IE4_CLK

_P

GNDRTM_EX

P4_RXP

3

GNDRTM_EX

P4_RXP

2

GNDRTM_PE

6_RST_

GNDRTM_FC

2_TX0_

H

GNDRTM_FC

2_RX0_

H

RTM_EX

P5_RXN

2

RTM_PC

IE4_CLK

_N

RTM_EX

P4_RXN

3

RTM_EX

P4_RXN

2

RTM_PE

5_RST_GND

RTM_FC

2_TX0_

L

RTM_FC

2_RX0_

L

GNDMCH_E

XP5_RX

P2

GNDRTM_PC

IE5_CLK

_P

GNDMCH_E

XP4_RX

P3

GNDMCH_E

XP4_RX

P2

RTM_PE

4_RST_

GNDRTM_FC

1_TX0_

H

GNDRTM_FC

1_RX0_

H

MCH_E

XP5_RX

N2

RTM_PC

IE5_CLK

_N

MCH_E

XP4_RX

N3

MCH_E

XP4_RX

N2

RTM_PE

4_WAKE

_

RTM_FC

1_TX0_

L

RTM_FC

1_RX0_

L

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

GN

D

RTM-ATCA-7350 Installation and Use (6806800H30G)

59

Page 60

Controls, LEDs and Connectors

60

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 61

Functional Description

4.1 Overview

This chapter describes:

Block diagram

Daughter cards

4.2 Block Diagram

The following block diagram shows the main components of RTM-ATCA-7350 and how they

interact/connect.

Figure 4-1 Block Diagram of RTM-ATCA-7350

Chapter 4

RTM-ATCA-7350 Installation and Use (6806800H30G)

61

Page 62

Functional Description

4.3 Daughter Cards

RTM-ATCA-7350 provides two daughter card connectors, you can choose one or two GE

daughter cards (single slot) or one FC daughter card (dual slot).

4.3.1 GE Daughter Card

The GE daughter card provides two external Ethernet interfaces; 10/100/1000M Base-T autonegotiation and RJ-45 interface. The RTM-ATCA-7350 can host one or two GE daughter cards,

thus providing up to four external Ethernet interfaces.

The following figure shows the GE daughter card.

Figure 4-2 GE Daughter Card

62

Indicators

The GE daughter card provides two network port indicators. You can monitor these indicators

to diagnose the current status of the external Ethernet interfaces.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 63

The following table lists the two network port indicators provided by the GE daughter card.

Table 4-1 Indicators Provided by the GE Daughter Card

Indicator Color Meaning Description

Functional Description

Network port indicator Green Network port working

Amber

state

4.3.2 FC Daughter Card

The FC daughter card provides two 2G FC interfaces; FC-AL, FC-SW, point to point, and 1G/2G

auto-negotiation. The RTM-ATCA-7350 can host one FC daughter card. Use of the FC daughter

card excludes use of the GE daughter card.

Optical modules are used to provide the optical interfaces at the face plate. See Connecting

Optical Fibers on page 44 for installing the optical modules. Optical modules for the FC

daughter card must be obtained separately. Recommended modules are FINISAR

FTRJ8519P1BNL-HW. FINISAR FTRJ8519P2BNL-HW.

Off: The network port does

not work.

Green on: The network port is

in Link state.

Amber blinking: The network

port is in Active state and is

transmitting data.

RTM-ATCA-7350 Installation and Use (6806800H30G)

63

Page 64

Functional Description

The following figure shows the FC daughter card.

Figure 4-3 FC Daughter Card

64

Indicators

The FC daughter card provides the RUN and ALM indicators. You can monitor these indicators

to diagnose the current status of the external FC interfaces.

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 65

The following table lists the two indicators provided by the FC daughter card.

Table 4-2 Indicators Provided by the FC Daughter Card

Indicator Color Meaning Description

Functional Description

ALM Amber FC interface working

state

RUN Green

Green on and amber on: RTM-ATCA-7350 is in

the power-on process.

Green off and amber blinking: Signal

synchronization is lost.

Green off and amber on: The interfaces are

obtaining signals.

Green on and amber off: The interfaces are ready

for processing signals.

Green blinking and amber blinking: A fault

occurs in the firmware.

RTM-ATCA-7350 Installation and Use (6806800H30G)

65

Page 66

Functional Description

66

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 67

Appendix A

A Related Documentation

A.1 Artesyn Embedded Technologies - Embedded

Computing Documentation

The publications listed below are referenced in this manual. You can obtain electronic copies of

Artesyn Embedded Technologies - Embedded Computing publications by contacting your

local Artesyn sales office. For released products, you can also visit our Web site for the latest

copies of our product documentation.

1. Go to www.artesyn.com/computing/support/product/technical-documentation.php.

2. Under FILTER OPTIONS, click the Document types drop-down list box to select the type of

document you are looking for.

3. In the Search text box, type the product name and click GO.

Table A-1 Artesyn Embedded Technologies - Embedded Computing Publications

Document Title and Source Publication Number

ATCA-7350 Installation and Use 6806800G59

ATCA-7350: Control via IPMI, Programmer's Reference 6806800H29

MESC-RTM-7150-FC Installation Information 6806800F90

MESC-RTM-7150-GE Installation Information 6806800F89

ATCA-7X50-HDDx-SAS/SATA Installation Information 6806800E28

ATCA-7x50-MEM Installation Information 6806800E27

ATCA-7350/RTM-ATCA-7350 Release Notes 6806800H69

RTM-ATCA-7350 Installation and Use (6806800H30G)

67

Page 68

Related Documentation

A.2 Related Specifications

For additional information, refer to the following table for related specifications. As an

additional help, a source for the listed document is provided. Please note that, while these

sources have been verified, the information is subject to change without notice.

Table A-2 Related Specifications

Organization Document Title

Intel

developer.intel.com/design/servers/ipmi

PICMG

picmg.org/specifications.stm

Platform Management FRU Information Storage Definition

v1.0

IPMI Specification v1.5

PICMG 3.0 Revision 2.0 Advanced TCA Base Specification

68

RTM-ATCA-7350 Installation and Use (6806800H30G)

Page 69

Page 70

Artesyn Embedded Technologies, Artesyn and the Artesyn Embedded Technologies logo are trademarks and service marks of Artesyn Embedded Technologies, Inc.

All other product or service names are the property of their respective owners.

©

2014 Artesyn Embedded Technologies, Inc.

Loading...

Loading...