Page 1

PrAMC-7311

Installation and Use

P/N: 6806800P34D

June 2014

Page 2

©

Copyright 2014 Artesyn Embedded Technologies, Inc.

All rights reserved.

Trademarks

Artesyn Embedded Technologies, Artesyn and the Artesyn Embedded Technologies logo are trademarks and service marks of

Artesyn Embedded Technologies, Inc.© 2014 Artesyn Embedded Technologies, Inc. All other product or service names are the

property of their respective owners.

Intel® is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

Java™ and all other Java-based marks are trademarks or registered trademarks of Oracle America, Inc. in the U.S. and other countries.

Microsoft®, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

Microsoft Corporation.

PICMG®, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

Industrial Computer Manufacturers Group.

UNIX® is a registered trademark of The Open Group in the United States and other countries.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Artesyn assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Artesyn reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Artesyn to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

an Artesyn website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Artesyn.

It is possible that this publication may contain reference to or information about Artesyn products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Artesyn intends to announce such Artesyn products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Artesyn.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Artesyn Embedded Technologies Artesyn Embedded Technologies

Marketing Communications

2900 S. Diablo Way, Suite 190

Tempe, Arizona 85282

Lilienthalstr. 17-19

85579 Neubiberg/Munich

Germany

Page 3

Contents

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.3 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2 Hardware Preparation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.2 Unpacking and Inspecting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3 Environmental and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.2 Thermal Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.3.3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4 Module Installation and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3 Controls, LEDs and Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.2 Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.3 Face Plate Connectors and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.3.1 Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.3.2 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.4 Platform Controller Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

PrAMC-7311 Installation and Use (6806800P34D)

3

Page 4

Contents

Contents

Contents

4.5 I350-AM4 Quad Port Gigabit Ethernet Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.6 DDR3 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.7 USB Accessed SD card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.8 Module Management Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5 Address Mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.2 Memory Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.2.1 System Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.2.2 Flash Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3 I/O Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.4 PCI Device Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.5 GPIO Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.6 SMBus Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.7 Interrupt Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6 Basic Input Output System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.1 BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Connecting to a Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3 Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.4 Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.5 Legend Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.5.1 Field Help Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.5.2 General Help Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.6 Boot Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.7 Advanced Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.7.1 Selecting Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.7.2 Boot Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.7.3 ACPI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.7.4 Processor Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.7.5 Processor Power Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.7.6 Peripheral Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.7.7 HDD Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.7.8 Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4

PrAMC-7311 Installation and Use (6806800P34D)

Page 5

Contents

6.7.9 System Agent Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.7.10 Graphics Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.7.11 PEG Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.7.12 South Bridge Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.7.13 South Bridge PCI Express Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.7.14 PCI Express Root Port 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.7.15 South Bridge USB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.7.16 South Bridge Serial IRQ Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.7.17 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.7.18 LPC Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.7.19 SMBIOS Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.7.20 Management Engine Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.7.21 Thermal Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.7.22 Intel Fast Flash Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.8 IPMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.9 Security Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.10 Boot Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.11 Exit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

6.12 Updating the BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

6.13 BIOS Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

A Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

A.1 Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

A.2 Mechanics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

A.3 During or After Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

A.4 During Boot-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.5 During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

B Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.1 Artesyn Embedded Technologies - Embedded Computing Documentation . . . . . . . . . . . . . . .123

B.2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

PrAMC-7311 Installation and Use (6806800P34D)

5

Page 6

Contents

Contents

Contents

6

PrAMC-7311 Installation and Use (6806800P34D)

Page 7

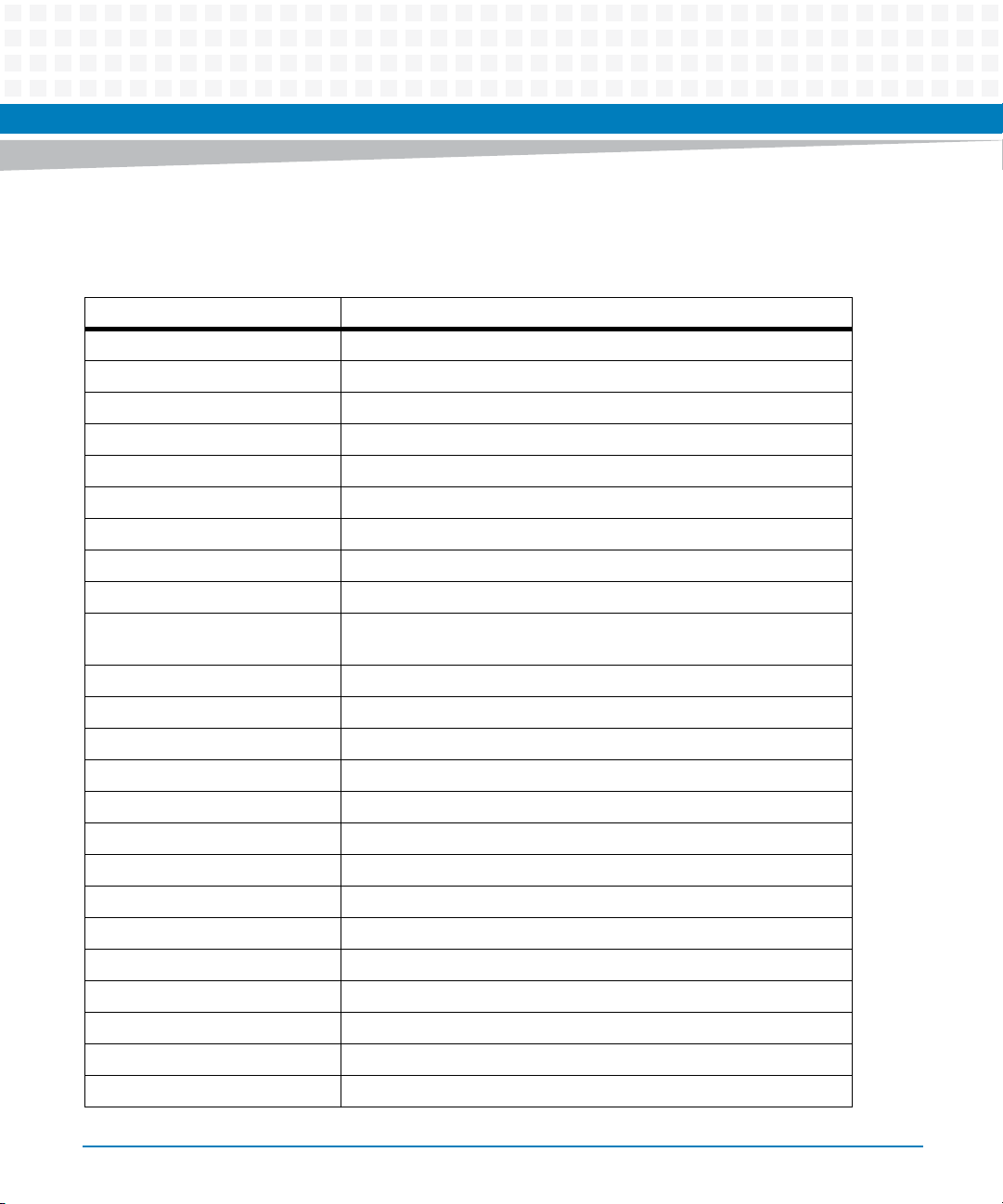

List of Tables

Table 1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 1-2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 1-3 Available Board Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 2-1 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 2-2 DC System Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 3-1 Face Plate LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 5-1 Memory Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 5-2 FWH Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 5-3 I/O Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 5-4 PCI Device Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 5-5 GPIO Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 5-6 SMBus Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 5-7 Interrupt Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 6-1 Serial Port Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 6-2 Main Menu Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 6-3 Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 6-4 Legend Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 6-5 Advanced Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 6-6 Boot Configuration Options Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 6-7 ACPI Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 6-8 Processor Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 6-9 Processor Power Management Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 6-10 Peripheral Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 6-11 HDD Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 6-12 Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 6-13 DMI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 6-14 Intel VT-d Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 6-15 Graphics Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 6-16 PEG Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 6-17 South Bridge Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 6-18 South Bridge PCI Express Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 6-19 PCI Express Root Port 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Table 6-20 South Bridge USB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 6-21 South Bridge USB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 6-22 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 6-23 South Bridge USB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

PrAMC-7311 Installation and Use (6806800P34D)

7

Page 8

List of Tables

Table 6-24 SMBIOS Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Table 6-25 ME Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 6-26 Thermal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Table 6-27 CPU Thermal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Table 6-28 Platform Thermal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Table 6-29 Intel Fast Flash Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Table 6-30 IPMI Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Table 6-31 Security Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Table 6-32 Exit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Table 6-33 Example BIOS Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Table B-1 Artesyn Embedded Technologies - Embedded Computing Publications . . . . . . . . . . . . . .123

Table B-2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

8

PrAMC-7311 Installation and Use (6806800P34D)

Page 9

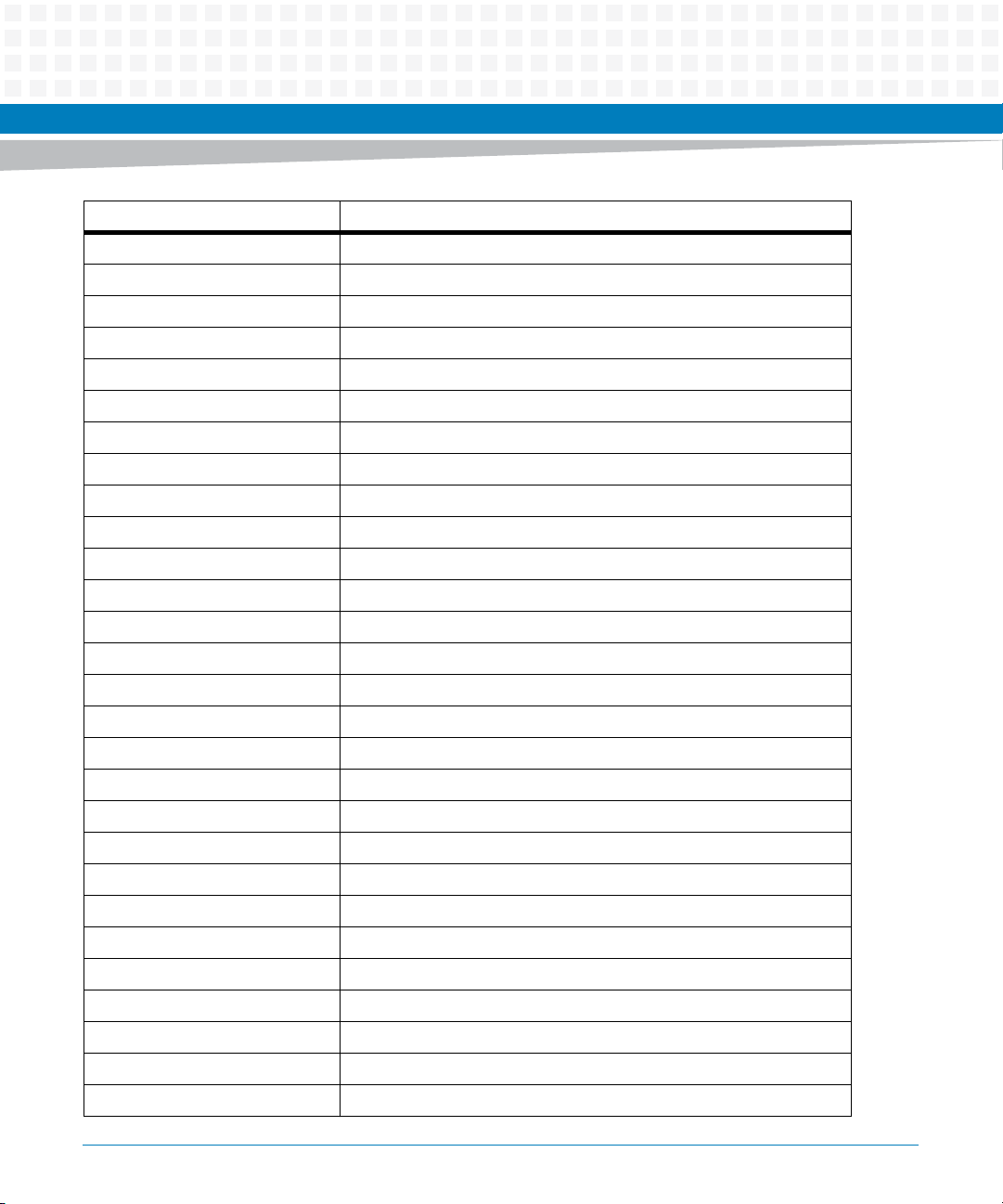

List of Figures

Figure 1-1 Mid-Size AMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 1-2 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 3-1 Mechanical Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 3-2 Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 3-3 Serial Console RJ45 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 3-4 Ethernet Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 3-5 USB Micro-B Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 4-1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 5-1 System Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 5-2 Flash Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 6-1 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 6-2 General Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 6-3 Boot Features menu options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 6-4 Advanced Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 6-5 Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 6-6 Boot Configuration Options Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 6-7 ACPI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 6-8 Processor Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 6-9 Processor Power Management Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 6-10 Peripheral Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 6-11 HDD Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 6-12 Memory Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 6-13 System Agent Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 6-14 System Agent Configuration - Intel VT-d Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 6-15 Graphics Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 6-16 PEG Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 6-17 South Bridge Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 6-18 South Bridge PCI Express Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 6-19 PCI Express Root Port 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 6-20 South Bridge USB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 6-21 South Bridge Serial IRQ Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 6-22 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 6-23 LPC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 6-24 SMBIOS Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 6-25 ME Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 6-26 Thermal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

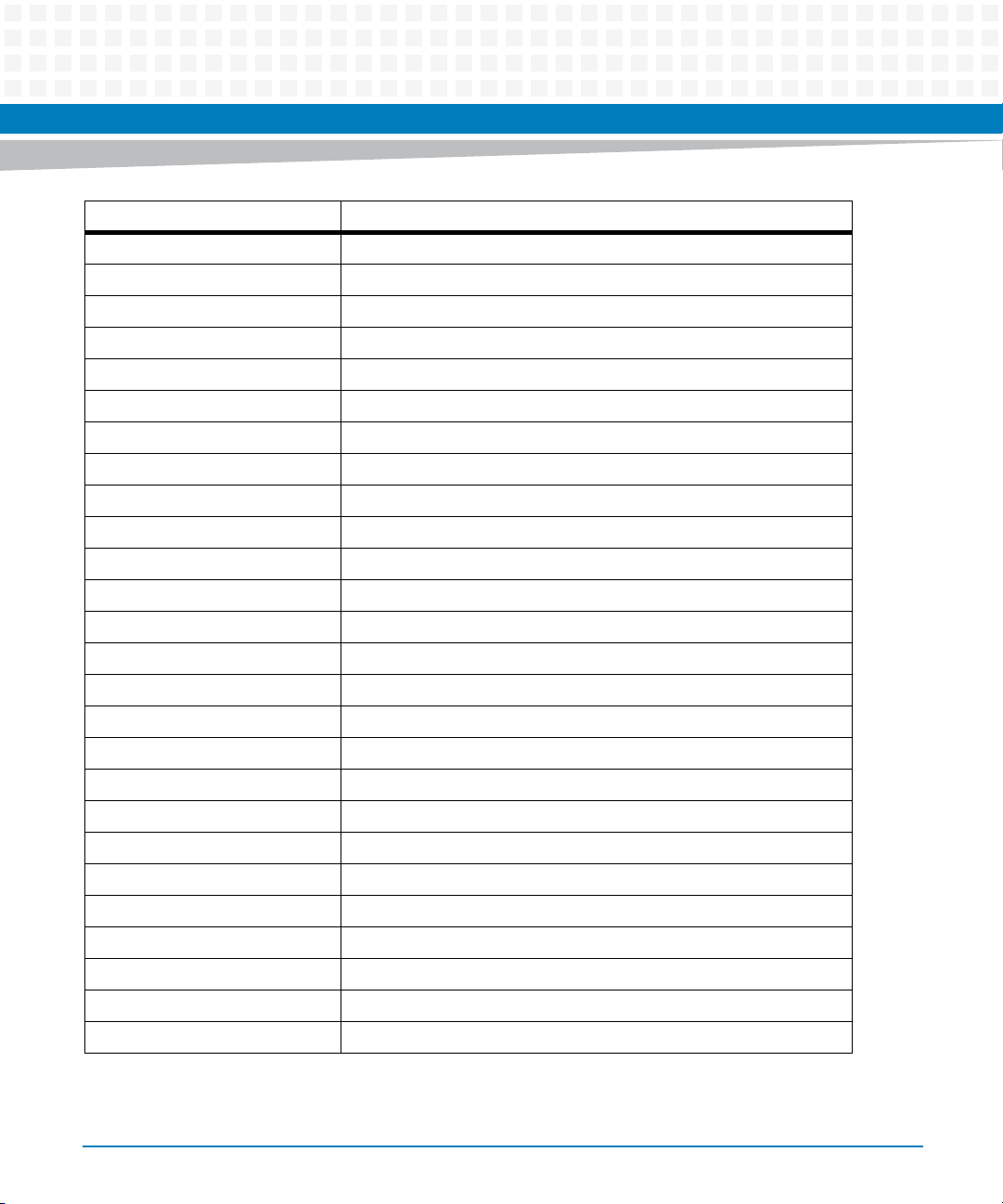

PrAMC-7311 Installation and Use (6806800P34D)

9

Page 10

List of Figures

Figure 6-27 Thermal Configuration-CPU Thermal Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 6-28 Platform Thermal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 6-29 Intel Fast Flash Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 6-30 IPMI Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 6-31 Post Watch Dog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 6-32 IPMI SEL Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 6-33 Security Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 6-34 Boot Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 6-35 Exit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10

PrAMC-7311 Installation and Use (6806800P34D)

Page 11

About this Manual

Overview of Contents

This manual is divided into the following chapters and appendices.

Safety Notes on page 17 describes the safety information which has to be regarded.

Sicherheitshinweise on page 21 provides a German translation of the chapter "Safety

Notes”.

Introduction on page 27 gives a brief overview of the product features, standard safety

compliances and ordering information.

Hardware Preparation and Installation on page 33 includes a procedure for unpacking the

product, environmental and power requirements, configuration information, additional

required equipment, and installation instructions.

Controls, LEDs and Connectors on page 41 describes the board layout, face plate LEDs, and

connectors.

Functional Description on page 47 includes a block diagram and a functional description of

major components.

Address Mapping on page 51 provides a description of the different devices that are

memory-mapped on the product, detailing the address range, description and size of the

devices.

Basic Input Output System on page 61 provides an overview of the BIOS plus a description of

the menu items and how to use them to configure the product.

Troubleshooting on page 117 provides a hint list for detecting possible errors.

Related Documentation on page 123 provides a listing of related product documentation,

manufacturer’s documents and industry standard specifications.

PrAMC-7311 Installation and Use (6806800P34D)

11

Page 12

About this Manual

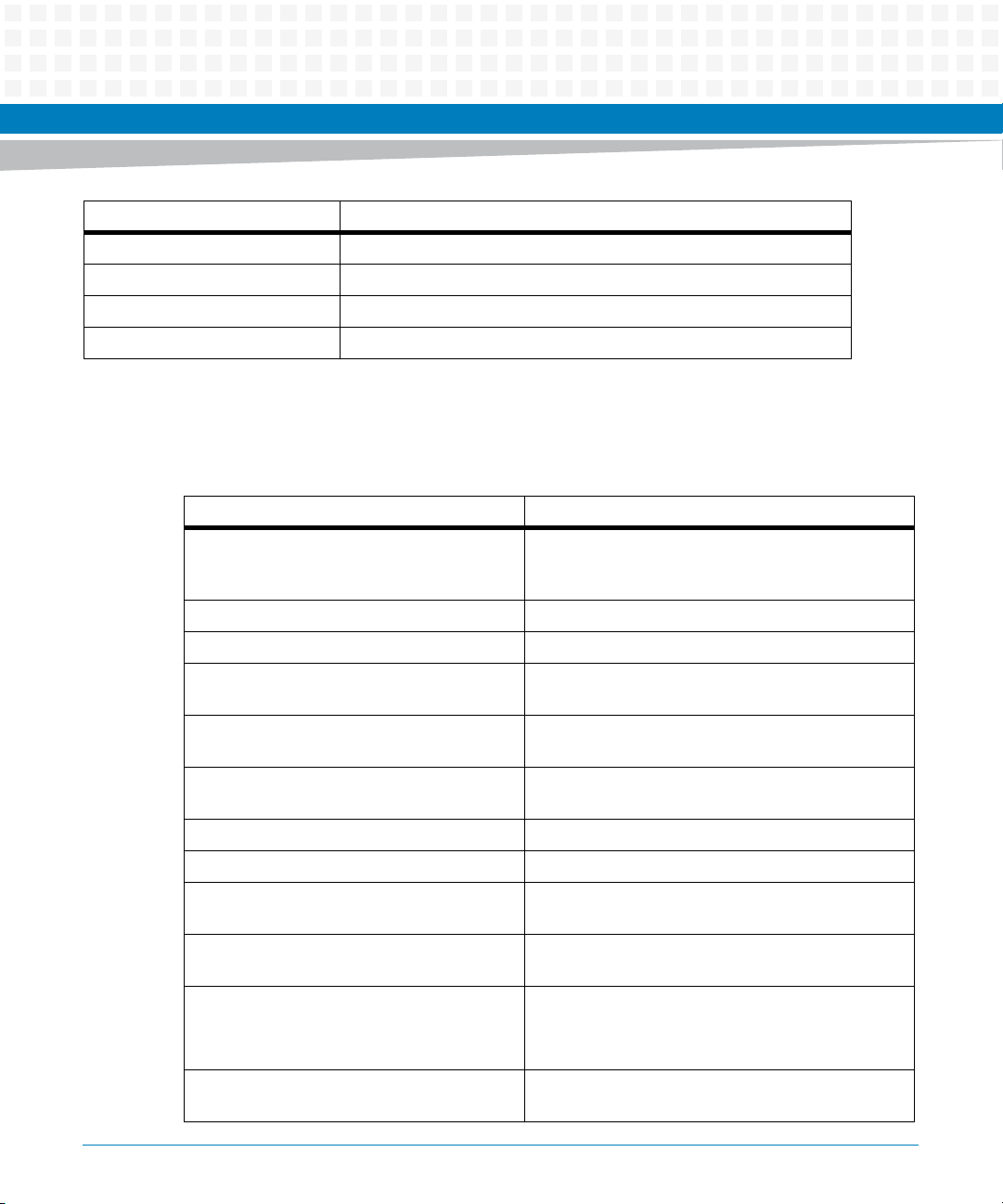

Abbreviations

This document uses the following abbreviations:

Abbreviation Definition

AHCI Advanced Host Controller Interface

AMC Advanced Mezzanine Card

ANSI American National Standards Institute

ATA Advanced Technology Attachment

ATAPI Advanced Technology Attachment Packet Interface

AVR Automatic Voltage Regulation

BIOS Basic Input Output System

CDROM Compact Disk Read Only Memory

CFM Cubic Feet per Minute

About this Manual

CISPR Comité Internationale Spécial des Perturbations

Radioelectrotechnique

CMOS Complementary Metal-Oxide Semiconductor

CPU Central Processing Unit

CR Console Redirection

DC Direct Current

DID Device Identifier

DMA Direct Memory Access

DOS Disk Operating System

DRAM Dynamic Random Access Memory

EDMA Enhanced Direct Memory Access

EHCI Enhanced Host Controller Interface

EISA Extended Industry Standard Architecture

EMC Electromagnetic Compatibility

EMV Elektromagnetische Verträglichkeit

EN European Norm

12

PrAMC-7311 Installation and Use (6806800P34D)

Page 13

Abbreviation Definition

ESCD Extended System Configuration Data

ESD Electrostatic Discharge

ETH Ethernet

ETSI European Telecommunications Standards Institute

FAE Field Application Engineer

FCC Federal Communications Commission

FRU Field Replaceable Unit

FSB Front Side Bus

FWH Firmware Hub

GHz Gigahertz

GPIO General Purpose Input Output

About this Manual

HS Hot Swap

I/O Input Output

ID Identifier

IDE Integrated Drive Electronics

IEC International Electrotechnical Commission

IICH Integrated I/O Controller Hub

IMCH Integrated Memory Controller Hub

IP Internet Protocol

IPMB Intelligent Platform Management Bus

IPMC Intelligent Platform Management Controller

IRQ Interrupt Request

IS In Service

ISA Industry Standard Architecture

LCT Laser Communication Terminal

LED Light Emitting Diode

LV Low Voltage

MCH Memory Controller Hub

PrAMC-7311 Installation and Use (6806800P34D)

13

Page 14

About this Manual

Abbreviation Definition

MMC Module Management Controller

MSI Messaged Signaled Interrupts

MTRR Memory Type Range Registers

NEBS Network Equipment Building Standards

NMI Non-Maskabke Interrupt

NSI North South Interface

NVRAM Non-Volatile Random Access Memory

OHCI Open Host Controller Interface

OOS Out Of Service

OS Operating System

PATA Parallel Advanced Technology Attachment

PC Personal Computer

About this Manual

PCB Printed Circuit Board

PCH Platform Controller Hub

PCI Peripheral Component Interconnect

PCI-E Peripheral Component Interconnect Express

POST Power-On Self Test

RN Release Notes

RTC Real Time Clock

SATA Serial Advanced Technology Attachment

SELV Safety Extra Low Voltage

SIU Serial Interface Unit

SMBus System Management Bus

TDP Thermal Dissipation Power

TPE Twisted-Pair Ethernet

UART Universal Asynchronous Receiver-Transmitter

14

PrAMC-7311 Installation and Use (6806800P34D)

Page 15

Abbreviation Definition

UL Underwriters Laboratories Incorporated

USB Universal Serial Bus

VCCI Voluntary Control Council for Interference

WDT Watchdog Timer

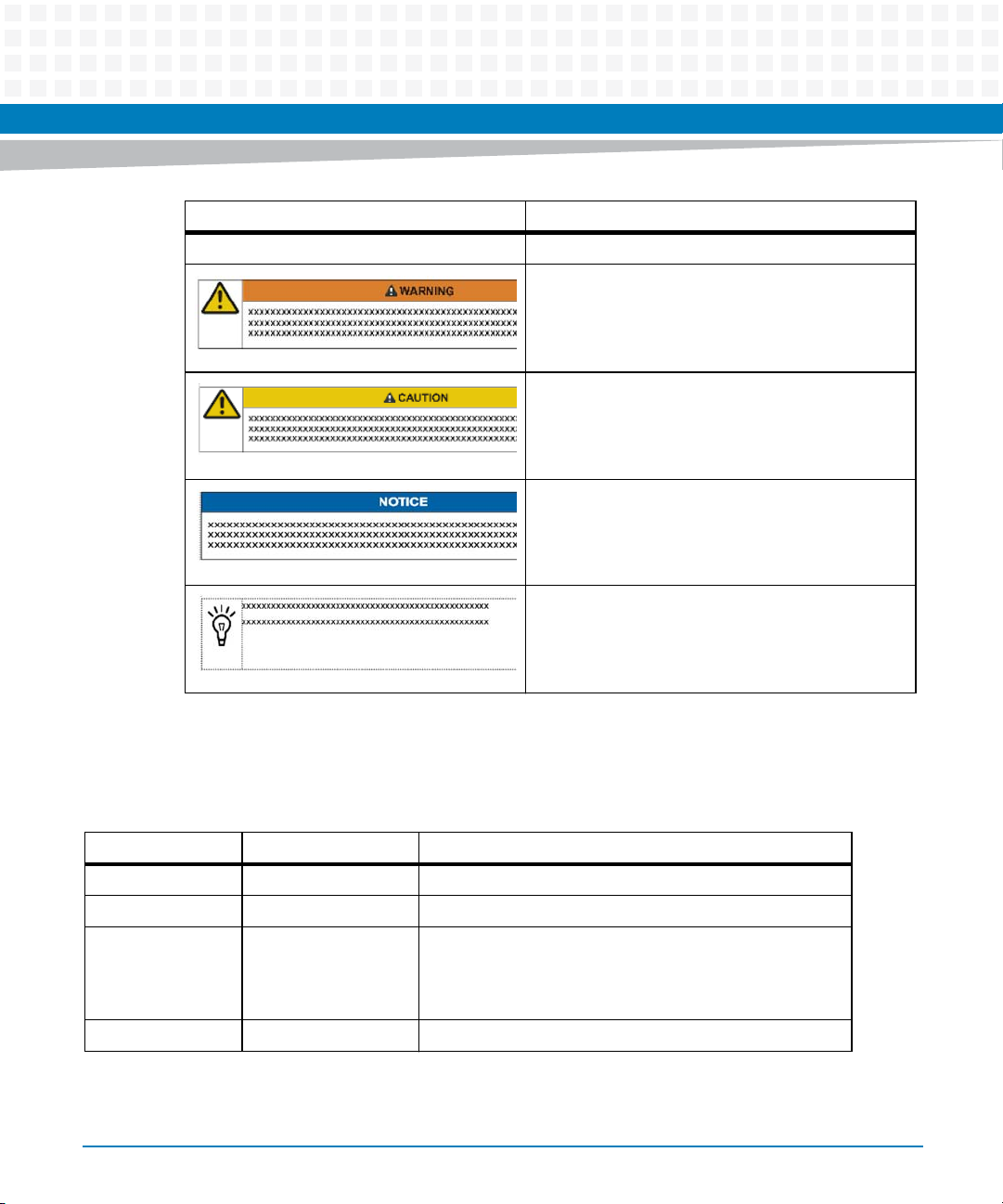

Conventions

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are

0 through F), for example used for addresses and

offsets

About this Manual

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related elements

or commands in body text

Courier + Bold Used to characterize user input and to separate it

from system output

Reference Used for references and for table and figure

descriptions

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

[text] Notation for software buttons to click on the screen

and parameter description

... Repeated item for example node 1, node 2,..., node

12

.

.

.

.. Ranges, for example: 0..4 means one of the integers

Omission of information from example/command

that is not necessary at the time being

0,1,2,3, and 4 (used in registers)

PrAMC-7311 Installation and Use (6806800P34D)

15

Page 16

About this Manual

Notation Description

| Logical OR

About this Manual

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury

Indicates a property damage message

No danger encountered. Pay attention to important

information

Summary of Changes

This manual has been revised and replaces all prior editions.

Part Number Publication Date Description

6806800P34A September 2012 Initial version

6806800P34B December 2012 Updated Standard Compliances on page 29.

6806800P34C February 2013 Updated Figure "Face Plate" on page 42, Connec tors on page

42, Figure 3-1 on page 41, Figure 3-3 on page 43, Figure

3-4 on page 43, Figure 3-5 on page 44 , Table "Face Plate

LEDs" on page 44 and Figure 6-35 on page 112.

6806800P34D June 2014 Re-branded to Artesyn.

16

PrAMC-7311 Installation and Use (6806800P34D)

Page 17

Safety Notes

This section provides warnings that precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed during all phases of

operation, service, and repair of this equipment. You should also employ all other safety

precautions necessary for the operation of the equipment in your operating environment.

Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

Artesyn intends to provide all necessary information to install and handle the product in this

manual. Because of the complexity of this product and its various uses, we do not guarantee

that the given information is complete. If you need additional information, ask your Artesyn

representative.

The product has been designed to meet the standard industrial safety requirements. It must

not be used except in its specific area of office telecommunication industry and industrial

control.

Only personnel trained by Artesyn or persons qualified in electronics or electrical engineering

are authorized to install, remove or maintain the product.

The information given in this manual is meant to complete the knowledge of a specialist and

must not be used as replacement for qualified personnel.

Keep away from live circuits inside the equipment. Operating personnel must not remove

equipment covers. Only factory authorized service personnel or other qualified service

personnel may remove equipment covers for internal subassembly or component replacement

or any internal adjustment.

Do not install substitute parts or perform any unauthorized modification of the equipment or

the warranty may be voided. Contact your local Artesyn representative for service and repair

to make sure that all safety features are maintained.

EMC

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

PrAMC-7311 Installation and Use (6806800P34D)

17

Page 18

Safety Notes

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense. Changes or

modifications not expressly approved by Artesyn Embedded Technologies could void the

user's authority to operate the equipment. Board products are tested in a representative

system to show compliance with the above mentioned requirements. A proper installation in

a compliant system will maintain the required performance. Use only shielded cables when

connecting peripherals to assure that appropriate radio frequency emissions compliance is

maintained.

Operation

Product Damage

Surface of the Product

High humidity and condensation on the product surface causes short circuits.

Do not operate the product outside the specified environmental limits. Make sure the product

is completely dry and there is no moisture on any surface before applying power.

Overheating and Product Damage

Operating the product without forced air cooling may lead to overheating and thus damage of

the product.

When operating the product, make sure that forced air cooling is available in the shelf.

Data Corruption

If power to the blade is removed while the BIOS is still updating changes to the flash, the

changes will not be saved, and worse, the flash may be corrupted.

Whenever you select the Exit Saving Changes option to save changes to BIOS setup and exit,

do not power the blade down before BIOS reboots.

Product Damage or Loss of Regulatory Compliance

The serial port is meant for development/debug/craft purpose only.

The serial cable is not meant to be connected during normal field operation. The PrAMC-7311

has not been qualified for regulatory compliance with the serial cable connected.

18

PrAMC-7311 Installation and Use (6806800P34D)

Page 19

System Malfunction

Incorrect BIOS settings can cause the system to malfunction.

To rectify mistakes use <F2> on the keyboard to return to setup and restore the system

defaults by pressing <F9>. Alternatively you can press <F2> to return to the BIOS setup and go

to the Exit menu and select Load setup Defaults.

Installation

Damage of the Product and Additional Devices and Modules

Incorrect installation or removal of additional devices or modules may damage the product or

the additional devices or modules.

Before installing or removing additional devices or modules, read the respective

documentation.

Safety Notes

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product or electronic components, make sure that your are working in an

ESD-safe environment.

Product Damage

Incorrect installation of the product can cause damage of the product.

Only use handles when installing/removing the product to avoid damage/deformation to the

face plate and/or PCB.

Damage to the Product/Backplane or System Components

Bent pins or loose components can cause damage to the product, the backplane, or other

system components.

Therefore, carefully inspect the product and the backplane for both pin and component

integrity before installation.

PrAMC-7311 Installation and Use (6806800P34D)

19

Page 20

Safety Notes

Artesyn Embedded Technologies and our suppliers take significant steps to ensure there are

no bent pins on the backplane or connector damage to the boards prior to leaving the factory.

Bent pins caused by improper installation or by inserting boards with damaged connectors

could void the Artesyn Embedded Technologies warranty for the backplane or boards.

Cabling and Connectors

Product Damage

The RJ-45 connector(s) on the face plate are either twisted-pair Ethernet (TPE) or E1/T1/J1

interfaces. Connecting an E1/T1/J1 line to an Ethernet connector may damage the product.

Make sure that TPE connectors near your working area are clearly marked as network

connectors.

Verify that the length of an electric cable connected to a TPE bushing does not exceed 100

m.

Make sure the TPE bushing of the product is connected only to safety extra low voltage

circuits (SELV circuits).

If in doubt, ask your system administrator.

Battery

This product utilizes a lithium battery which can only be replaced by qualified service

personnel.

Caution: Risk of explosion if the battery is replaced by an incorrect type. Dispose of used

batteries according to the instructions.

Environment

Always dispose of used AMCs, system components and RTMs according to your country’s

legislation and manufacturer’s instructions.

20

PrAMC-7311 Installation and Use (6806800P34D)

Page 21

Sicherheitshinweise

Dieses Kapitel enthält Hinweise, die potentiell gefährlichen Prozeduren innerhalb dieses

Handbuchs vorrangestellt sind. Beachten Sie unbedingt in allen Phasen des Betriebs, der

Wartung und der Reparatur des Systems die Anweisungen, die diesen Hinweisen enthalten

sind. Sie sollten außerdem alle anderen Vorsichtsmaßnahmen treffen, die für den Betrieb des

Produktes innerhalb Ihrer Betriebsumgebung notwendig sind. Wenn Sie diese

Vorsichtsmaßnahmen oder Sicherheitshinweise, die an anderer Stelle diese Handbuchs

enthalten sind, nicht beachten, kann das Verletzungen oder Schäden am Produkt zur Folge

haben.

Artesyn Embedded Technologies ist darauf bedacht, alle notwendigen Informationen zum

Einbau und zum Umgang mit dem Produkt in diesem Handbuch bereit zu stellen. Da es sich

jedoch um ein komplexes Produkt mit vielfältigen Einsatzmöglichkeiten handelt, können wir

die Vollständigkeit der im Handbuch enthaltenen Informationen nicht garantieren. Falls Sie

weitere Informationen benötigen sollten, wenden Sie sich bitte an die für Sie zuständige

Geschäftsstelle von Artesyn.

Das System erfüllt die für die Industrie geforderten Sicherheitsvorschriften und darf

ausschließlich für Anwendungen in der Telekommunikationsindustrie und im Zusammenhang

mit Industriesteuerungen verwendet werden.

Einbau, Wartung und Betrieb dürfen nur von durch Artesyn ausgebildetem oder im Bereich

Elektronik oder Elektrotechnik qualifiziertem Personal durchgeführt werden. Die in diesem

Handbuch enthaltenen Informationen dienen ausschließlich dazu, das Wissen von

Fachpersonal zu ergänzen, können dieses jedoch nicht ersetzen.

Halten Sie sich von stromführenden Leitungen innerhalb des Produktes fern. Entfernen Sie auf

keinen Fall Abdeckungen am Produkt. Nur werksseitig zugelassenes Wartungspersonal oder

anderweitig qualifiziertes Wartungspersonal darf Abdeckungen entfernen, um Komponenten

zu ersetzen oder andere Anpassungen vorzunehmen.

Installieren Sie keine Ersatzteile oder führen Sie keine unerlaubten Veränderungen am Produkt

durch, sonst verfällt die Garantie. Wenden Sie sich für Wartung oder Reparatur bitte an die für

Sie zuständige Geschäftsstelle von Artesyn Embedded Technologies. So stellen Sie sicher, dass

alle sicherheitsrelevanten Aspekte beachtet werden.

PrAMC-7311 Installation and Use (6806800P34D)

21

Page 22

Sicherheitshinweise

EMV

Das Produkt wurde in einem Artesyn Standardsystem getestet. Es erfüllt die für digitale Geräte

der Klasse A gültigen Grenzwerte in einem solchen System gemäß den FCC-Richtlinien

Abschnitt 15 bzw. EN 55022 Klasse A. Diese Grenzwerte sollen einen angemessenen Schutz

vor Störstrahlung beim Betrieb des Produktes in Gewerbe- sowie Industriegebieten

gewährleisten.

Das Produkt arbeitet im Hochfrequenzbereich und erzeugt Störstrahlung. Bei

unsachgemäßem Einbau und anderem als in diesem Handbuch beschriebenen Betrieb können

Störungen im Hochfrequenzbereich auftreten.

Wird das Produkt in einem Wohngebiet betrieben, so kann dies mit grosser Wahrscheinlichkeit

zu starken Störungen führen, welche dann auf Kosten des Produktanwenders beseitigt werden

müssen. Änderungen oder Modifikationen am Produkt, welche ohne ausdrückliche

Genehmigung von Artesyn durchgeführt werden, können dazu führen, dass der Anwender die

Genehmigung zum Betrieb des Produktes verliert. Boardprodukte werden in einem

repräsentativen System getestet, um zu zeigen, dass das Board den oben aufgeführten EMVRichtlinien entspricht. Eine ordnungsgemässe Installation in einem System, welches die EMVRichtlinien erfüllt, stellt sicher, dass das Produkt gemäss den EMV-Richtlinien betrieben wird.

Verwenden Sie nur abgeschirmte Kabel zum Anschluss von Zusatzmodulen. So ist

sichergestellt, dass sich die Aussendung von Hochfrequenzstrahlung im Rahmen der erlaubten

Grenzwerte bewegt.

Warnung! Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im Wohnbereich

Funkstörungen verursachen. In diesem Fall kann vom Betreiber verlangt werden,

angemessene Maßnahmen durchzuführen.

Betrieb

Beschädigung des Produktes

Hohe Luftfeuchtigkeit und Kondensat auf der Oberfläche des Produktes können zu

Kurzschlüssen führen.

Betreiben Sie das Produkt nur innerhalb der angegebenen Grenzwerte für die relative

Luftfeuchtigkeit und Temperatur. Stellen Sie vor dem Einschalten des Stroms sicher, dass sich

auf dem Produkt kein Kondensat befindet.

22

PrAMC-7311 Installation and Use (6806800P34D)

Page 23

Überhitzung und Beschädigung des Produktes

Betreiben Sie das Produkt ohne Zwangsbelüftung, kann das Produkt überhitzt und schließlich

beschädigt werden.

Bevor Sie das Produkt betreiben, müssen Sie sicher stellen, dass das Shelf über eine

Zwangskühlung verfügt.

Fehlerhafter Datenbestand

Wenn sie die Spannungsversorgung des Produkts abschalten, während das BIOS die Daten im

Flash aktualisiert, werden die Änderungen nicht gespeichert oder die Daten im Flash können

beschädigt werden.

Wenn Sie die Option Exit Saving Changes benutzen, um BIOS Änderungen zu speichern, sollten

Sie deshalb immer warten bis das BIOS einen Neustart durchgeführt hat, bevor Sie die

Spannungsversorgung des Produkts abschalten.

Schäden am Produkt oder Verlust der Sicherheitszulassung

Das Anschließen eine Kabels an die serielle Schnittstelle ist nur für Entwicklungs- und

Debugzwecke und nicht für den Betrieb im Feld bestimmt.

Das Produkt wurde nicht für den Betrieb mit angeschlossenem seriellen Kabel zugelassen.

Sicherheitshinweise

Störung des Systembetriebs

Falsche BIOS Einstellungen können den Systembetrieb stören.

Sie können fehlerhafte Einstellungen korrigieren, indem Sie mit der <F2> Taste ins BIOS

zurückkehren und mit der <F9> Taste die Werkseinstellungen wiederherstellen. Alternativ

können Sie mit <F2> ins BIOS zurückkehren und im Exit Menü den Eintrag Load Setup Defaults

auswählen.

Installation

Beschädigung des Produktes und von Zusatzmodulen

Fehlerhafte Installation von Zusatzmodulen, kann zur Beschädigung des Produktes und der

Zusatzmodule führen.

Lesen Sie daher vor der Installation von Zusatzmodulen die zugehörige Dokumentation.

PrAMC-7311 Installation and Use (6806800P34D)

23

Page 24

Sicherheitshinweise

Beschädigung von Schaltkreisen

Elektrostatische Entladung und unsachgemäßer Ein- und Ausbau des Produktes kann

Schaltkreise beschädigen oder ihre Lebensdauer verkürzen.

Bevor Sie das Produkt oder elektronische Komponenten berühren, vergewissern Sie sich, daß

Sie in einem ESD-geschützten Bereich arbeiten.

Beschädigung des Produktes

Fehlerhafte Installation des Produktes kann zu einer Beschädigung des Produktes führen.

Verwenden Sie die Handles, um das Produkt zu installieren/deinstallieren. Auf diese Weise

vermeiden Sie, dass das Face Plate oder die Platine deformiert oder zerstört wird.

Beschädigung des Produktes, der Backplane oder von System Komponenten

Verbogene Pins oder lose Komponenten können zu einer Beschädigung des Produktes, der

Backplane oder von Systemkomponenten führen.

Überprüfen Sie daher das Produkt sowie die Backplane vor der Installation sorgältig und stellen

Sie sicher, dass sich beide in einwandfreien Zustand befinden und keine Pins verbogen sind.

24

PrAMC-7311 Installation and Use (6806800P34D)

Page 25

Sicherheitshinweise

Artesyn Embedded Technologies und unsere Zulieferer unternehmen größte Anstrengungen

um sicherzustellen, dass sich Pins und Stecker von Boards vor dem Verlassung der

Produktionsstätte in einwandfreiem Zustand befinden. Verbogene Pins, verursacht durch

fehlerhafte Installation oder durch Installation von Boards mit beschädigten Steckern kann die

durch Artesyn Embedded Technologies gewährte Garantie für Boards und Backplanes

erlöschen lassen.

Kabel und Stecker

Beschädigung des Produktes

Bei den RJ-45 Steckern, die sich an dem Produkt befinden, handelt es sich entweder um

Twisted-Pair-Ethernet (TPE) oder um E1/T1/J1-Stecker. Beachten Sie, dass ein versehentliches

Anschließen einer E1/T1/J1-Leitung an einen TPE-Stecker das Produkt zerstören kann.

Kennzeichnen Sie deshalb TPE-Anschlüsse in der Nähe Ihres Arbeitsplatzes deutlich als

Netzwerkanschluss.

Stellen Sie sicher, dass die Länge eines mit Ihrem Produkt verbundenen TPE-Kabels 100 m

nicht überschreitet.

Das Produkt darf über die TPE-Stecker nur mit einem Sicherheits-Kleinspannungs-

Stromkreis (SELV) verbunden werden.

Umweltschutz

Entsorgen Sie alte Batterien und/oder Blades/Systemkomponenten/RTMs stets gemäß der in

Ihrem Land gültigen Gesetzgebung und den Empfehlungen des Herstellers.

PrAMC-7311 Installation and Use (6806800P34D)

25

Page 26

Sicherheitshinweise

26

PrAMC-7311 Installation and Use (6806800P34D)

Page 27

Introduction

1.1 Features

The PrAMC-7311 is designed as a hot-swappable, high-performance and low-power dual-core

processor AMC module and can be used as a processing and system controller module as

defined in the Micro Telecom Computing Architecture (μTCA) standard. The module works in

conjunction with an AMC carrier card and extends the processing power and functionalities of

the carrier card. It is based on the Intel Core i7-2655LE processor and the Intel QM67 chipset

and offers powerful processing capability with low power consumption, large memory

capacity, USB2.0 port Connected SD card, and high I/O bandwidth via face plate and rear AMC

fabric I/O interfaces.

It is available as a mid-size AMC module.

Table 1-1 Features

Feature Description

Chapter 1

Processor Intel Core i7-2655LE LV processor (4 MB L3 cache) 2.2 GHz

Memory Support for dual channel DDR3-1333 registered memory and for 2 Gbit

/ 4 Gbit SDRAMs for 4 GB / 8 GB capacity, 4Gbit dual -die SDRAMS for 16GB

capacity

Quad Gigabit Ethernet

(SerDes)

1 Gbit Fast Ethernet Intel i350-AM4 (PCIe x4)

USB 2.0 Based SD card Optional 2GB MicroSD card

PCIe Interface One PCIe x8 interface

SATA Interface Two Gen 2 SATA channels via AMC fabric I/O interface

RS-232 Port Face plate RJ-45 port

Core Chip Intel BD82QM67 Platform Controller Hub (PCH)

MMC Renesas H8S/2472 microcontroller

Form Factor Single width mid-size AMC (73.5 mm x 181.5 mm)

Intel i350-AM4 (PCIe x 4) Dual 1 Gbit SerDes interface via AMC fabric I/O

interface, Supports PXE boot

Face plate RJ-45 port

Supports PXE boot

Configurable as two PCIe x4 interfaces

Supported via AMC fabric I/O interface

Implementing Pigeon Point MMC firmware

PrAMC-7311 Installation and Use (6806800P34D)

27

Page 28

Introduction

Figure 1-1 Mid-Size AMC

28

PrAMC-7311 Installation and Use (6806800P34D)

Page 29

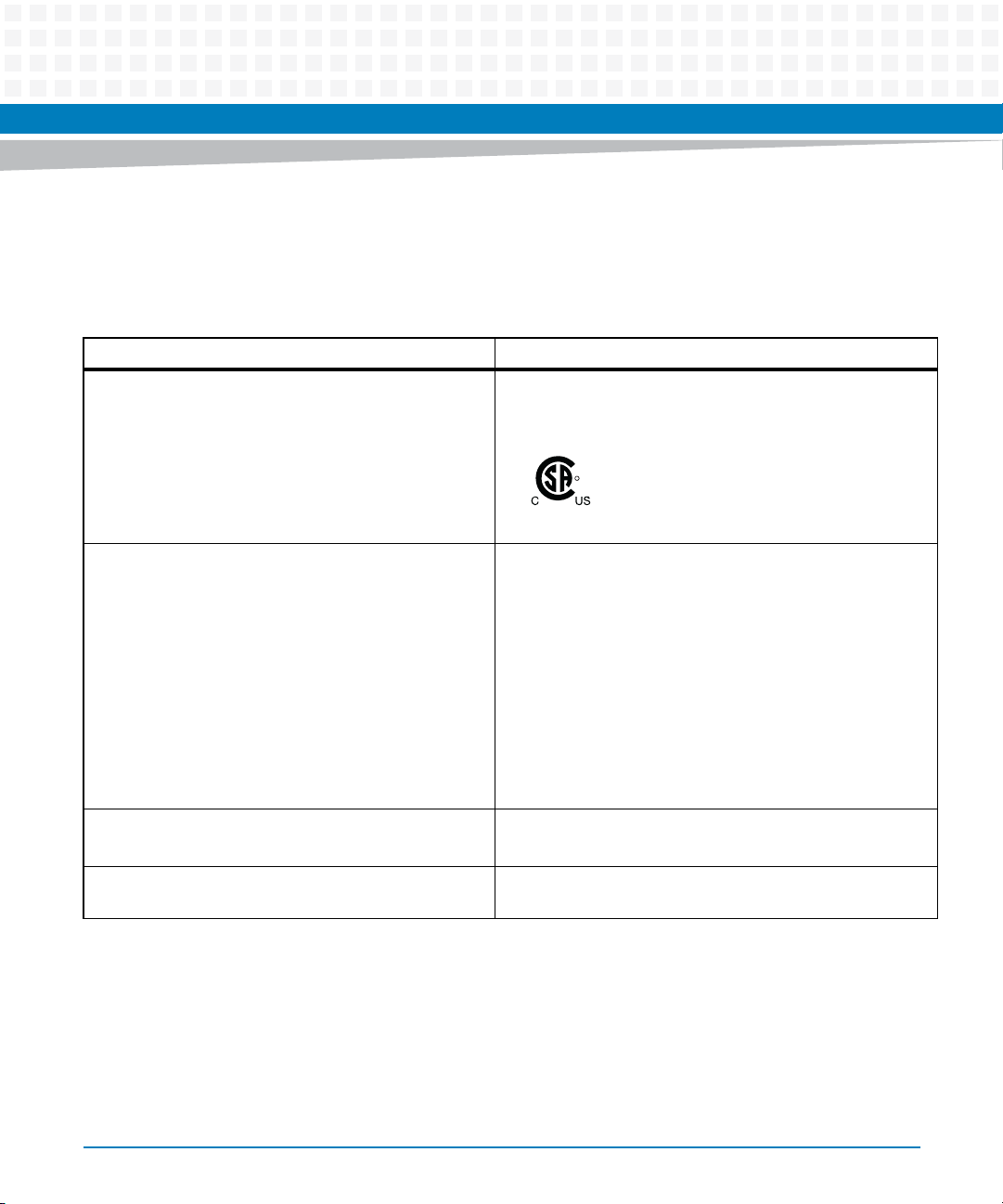

1.2 Standard Compliances

This product meets the following standards.

Table 1-2 Standard Compliances

Standard Description

Introduction

UL 60950-1(2nd edition)

EN 60950-1(2nd edition)

IEC 60950-1(2nd edition)

CAN/CSA C22.2 No 60950-1(2nd edition)

CISPR 22

CISPR 24

EN 55022

EN 55024

FCC Part 15

Industry Canada ICES-003

VCCI Japan(tested but not submitted to agency)

AS/NZS CISPR 22(tested but not submitted to agency)

EN 300 386

NEBS Standard GR-1089 CORE

NEBS Standard GR-63-CORE

ETSI EN 300019 series

AMC.0 Defines mechanics, blade dimensions, power distribution,

Legal safety requirements (Reference CSA file LR 49303)

Isolation is functional insulation only complying with 60950-

1 clause 5.3.4c

R

LR 49303

EMC requirements (legal) on system level (predefined

Artesyn system)

Environmental requirements

power and data connectors, and system management

PrAMC-7311 Installation and Use (6806800P34D)

29

Page 30

Introduction

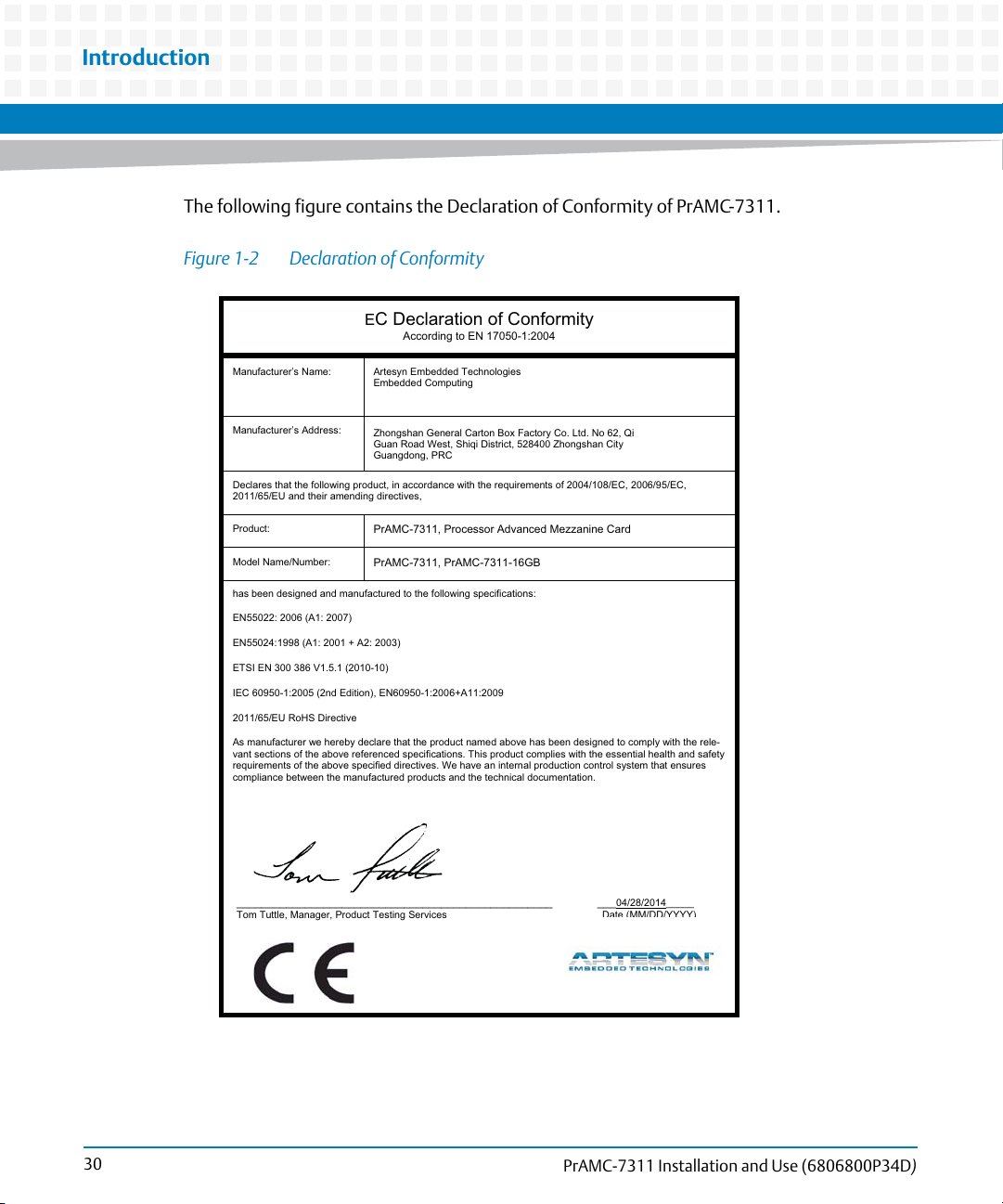

The following figure contains the Declaration of Conformity of PrAMC-7311.

Figure 1-2 Declaration of Conformity

E

C Declaration of Conformity

According to EN 17050-1:2004

Manufacturer’s Name:

Manufacturer’s Address:

Declares that the following product, in accordance with the requirements of 2004/108/EC, 2006/95/EC,

2011/65/EU and their amending directives,

Product:

Model Name/Number:

has been designed and manufactured to the following specifications:

EN55022: 2006 (A1: 2007)

EN55024:1998 (A1: 2001 + A2: 2003)

ETSI EN 300 386 V1.5.1 (2010-10)

IEC 60950-1:2005 (2nd Edition), EN60950-1:2006+A11:2009

2011/65/EU RoHS Directive

As manufacturer we hereby declare that the product named above has been designed to comply with the rele-

vant sections of the above referenced specifications. This product complies with the essential health and safety

requirements of the above specified directives. We have an internal production control system that ensures

compliance between the manufactured products and the technical documentation.

___________________________________________________ ___

Tom Tuttle, Manager, Product Testing Services Date (MM/DD/YYYY)

Artesyn Embedded Technologies

Embedded Computing

Zhongshan General Carton Box Factory Co. Ltd. No 62, Qi

Guan Road West, Shiqi District, 528400 Zhongshan City

Guangdong, PRC

PrAMC-7311, Processor Advanced Mezzanine Card

PrAMC-7311, PrAMC-7311-16GB

04/28/2014_____

30

PrAMC-7311 Installation and Use (6806800P34D)

Page 31

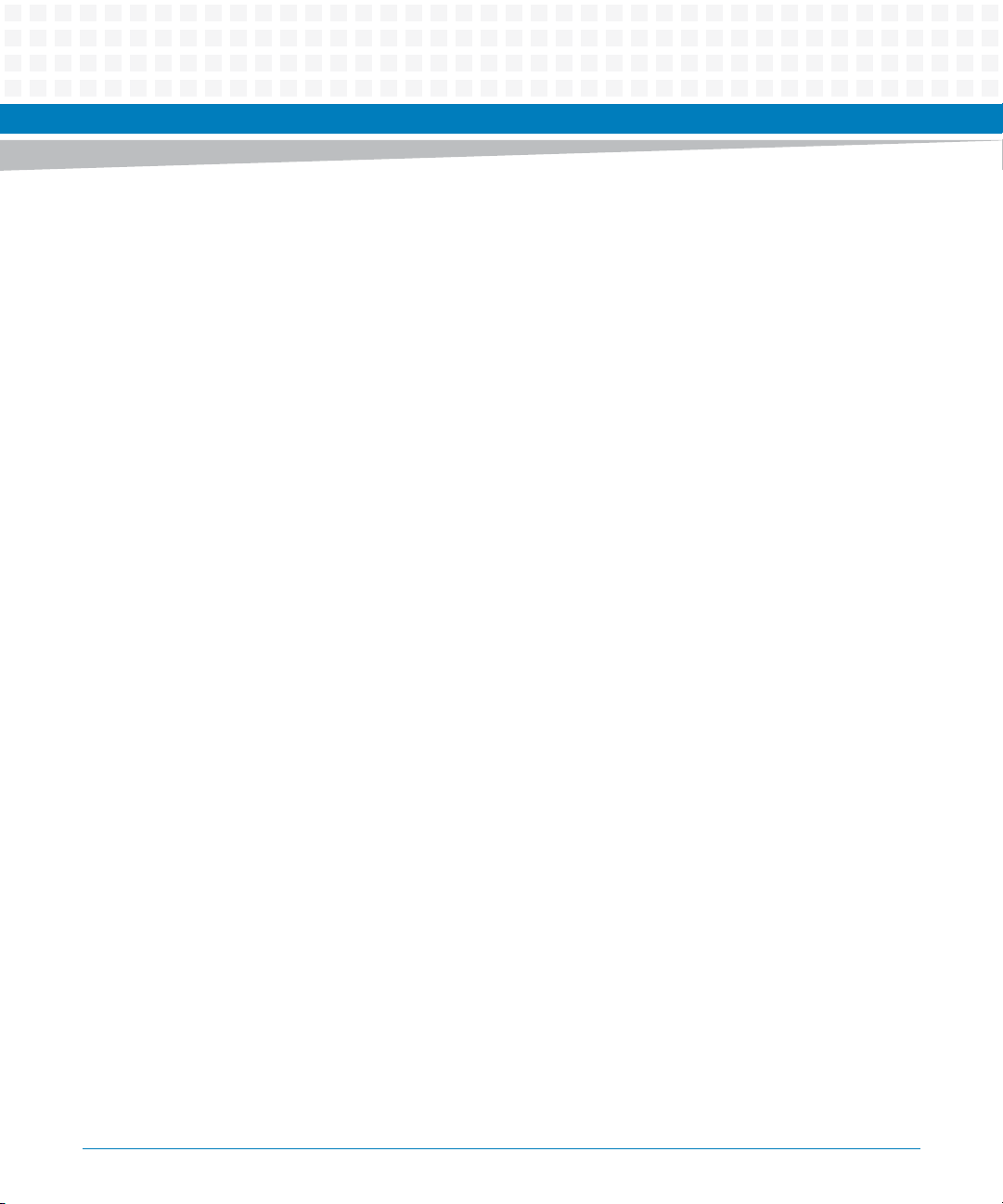

1.3 Ordering Information

When ordering board variants, use the order numbers given in the following table.

Table 1-3 Available Board Variants

Order Number Assembly Number Description

PrAMC-7311 0106810M01C AMC with Intel Core i7 processor, 4GB

PrAMC-7311-16GB 0106810M03B AMC with Intel Core i7 processor, 16GB

Introduction

DDR3- mid size

DDR3- mid size

PrAMC-7311 Installation and Use (6806800P34D)

31

Page 32

Introduction

32

PrAMC-7311 Installation and Use (6806800P34D)

Page 33

Hardware Preparation and Installation

2.1 Overview

In this chapter you can find information on the following topics:

Unpacking and inspecting the module

Environmental and power requirements

Configuring the module

Installing module accessories

Module installation and removal

2.2 Unpacking and Inspecting the Module

Chapter 2

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the blade can damage circuits

or shorten their life.

Before touching the blade or electronic components, make sure that your are working in an

ESD-safe environment.

Shipment Inspection

To inspect the shipment, perform the following steps.

1. Verify that you have received all items of your shipment:

PrAMC-7311 module

Any optional items ordered

2. Check for damage and report any damage or differences to the customer service.

PrAMC-7311 Installation and Use (6806800P34D)

33

Page 34

Hardware Preparation and Installation

3. Remove the desiccant bag shipped together with the module and dispose of it

according to your country’s legislation.

The blade is thoroughly inspected before shipment. If any damage occurred during

transportation or any items are missing, please contact our customer's service immediately.

2.3 Environmental and Power Requirements

The following environmental and power requirements are applicable to the blade.

2.3.1 Environmental Requirements

34

You must make sure that the blade, when operated in your particular system configuration,

meets the environmental requirements specified below.

Operating temperatures refer to the temperature of the air circulating around the blade and not

to the component temperature.

Blade Damage

High humidity and condensation on the blade surface causes short circuits.

Do not operate the blade outside the specified environmental limits. Make sure the blade is

completely dry and there is no moisture on any surface before applying power.

PrAMC-7311 Installation and Use (6806800P34D)

Page 35

Hardware Preparation and Installation

Table 2-1 Environmental Requirements

Requirement Operating Non-Operating

Temperature +0 ºC (32 °F) to +55 ºC (131 °F) (normal

operation) according to NEBS Standard GR63-CORE

Temp. Change +/- 0.25 ºC/min according to NEBS Standard

GR-63-CORE

Rel. Humidity 5% to 90% non-condensing according to

Artesyn-internal environmental

requirements

Vibration 0.1 g from 5 to 200 Hz and back to 5 Hz at a

rate of 0.25 octave/minute

Shock Half-sine, 11 m/Sec, 30 mSec/Sec

Free Fall - 1,200 mm/all edges and corners

2

-40 ºC (-40 °F) to +70 ºC (158 °F) (may be

further limited by installed accessories)

+/- 0.25 ºC/min

5% to 95% non-condensing according to

Artesyn-internal environmental

requirements

5-20 Hz at 0.01 g

20-200 Hz at -3.0 dB/octave

Random 5-20 Hz at 1 m

Random 20-200 Hz at -3 m/Sec

Blade level packaging

Half-sine, 6 mSec at 180 m/Sec

1.0 m (packaged) per ETSI 300 019-2-2

(Blade level packaging)

100 mm (unpacked) per GR-63-CORE

2

/Hz

2

/Sec

2.3.2 Thermal Requirements

3

2

2

The minimum airflow requirements for the AdvancedTCA platforms are 13 CFM for the 2.2 GHz

PrAMC-7311 module platforms. This is with a maximum operating temperature limit of 55 °C

(131 °F).

Contact your Artesyn sales representative for current information on the detailed thermal

information including airflow and resistance of the PrAMC-7311.

PrAMC-7311 Installation and Use (6806800P34D)

35

Page 36

Hardware Preparation and Installation

2.3.3 Power Requirements

Make sure that the module is used on an approved AdvancedTCA carrier board in an

AdvancedTCA shelf connected to -48 VDC up to -60 VDC, for use in a restricted access area only

by trained personnel. All circuits are safety-extra-low-voltage (SELV) under normal operating

conditions, and are not subject to over voltages/transients.

Table 2-2 DC System Power Requirements

Feature Value

Rated voltage 12 VDC

Operating voltage 10 VDC to 14 VDC

Input current 5 A at 12 V

Power dissipation 30 W (Typical)

60 W (max)

36

The module provides two independent power inputs according to the AdvancedTCA

specification.

PrAMC-7311 Installation and Use (6806800P34D)

Page 37

Hardware Preparation and Installation

2.4 Module Installation and Removal

This section describes how to install and remove an AMC module.

Damage of Circuits

Electrostatic discharge and incorrect product installation and removal can damage circuits or

shorten their life.

Before touching the product or electronic components, make sure that you are working in an

ESD-safe environment.

Product Malfunctioning

Incorrect product installation and removal can result in product malfunctioning.

When plugging the product in or removing it, do not press on the face plate but use the handles.

Limitization of Operating Temperature Range

Installing AMC modules with small operating temperature ranges onto the blade may further

restrict the operating temperature range of the blade.

Make sure that the operating temperature of any installed AMC modules and the blade as a

bundle are within allowed limits.

Installation Procedure

The following describes how to install an AMC module into an AMC bay of the base board. The

installation procedure assumes that the AMC module is being hot-inserted, that means the

base board is powered. The procedure for the cold insertion, that means the base board is not

powered, is the same, except that you need not wait for the blue LED indications to proceed.

1. Make sure you are in an ESD-safe environment.

2. Identify the AMC bay to be used for the installation.

3. If the required AMC bay is occupied by an AMC filler panel, you will need to remove

the filler panel before proceeding with the installation procedure. The removal

procedure for the filler panel is the same as described in the Removal procedure

which follows immediately after this procedure. Ignore steps that mention the blue

LED.

PrAMC-7311 Installation and Use (6806800P34D)

37

Page 38

Hardware Preparation and Installation

4. Ensure that AMC module handle is in the extracted position: pulled outward, away

from the face plate.

5. Using your thumb, apply equal and steady pressure on the face plate as necessary

to carefully slide the AMC module into the guides rails.

6. Continue to gently push the module along the guide rails till the module is fully

engaged with the connector. Avoid using excessive force during this operation.

7. Wait for the blue LED to glow. The blue LED glows when the AMC module is

completely engaged with the connector.

8. Press module handle inwards toward the face plate to lock the AMC module on

AMC bay.

9. Wait for the blue LED to perform a series of long blinks. The blue LED blinks when

the handle is locked in position indicating module detection and activation by the

carrier board.

38

10.Observe blue LED status/activity. The module is fully installed when the blue LED

stops blinking and stays OFF.

Removal Procedure

The following describes how to remove an AMC module from the base board. The procedure

assumes that the base board is powered. If it is not powered, the steps regarding the blue LED

can be ignored and skipped.

1. Make sure you are in an ESD safe environment.

2. Remove any cables that are connected to the AMC module face plate connectors.

3. Gently pull the module latch outward, approximately 3 mm from its locked

position.

PrAMC-7311 Installation and Use (6806800P34D)

Page 39

Hardware Preparation and Installation

4. Wait for the blue LED to first perform short blinks, and then glow persistently.

Data Loss

Removing the blade with the blue LED still blinking causes data loss.

Wait until the blue LED is permanently illuminated, before removing the blade.

5. Once the blue LED glows persistently, gently pull the AMC module handle outward

to disconnect the module from the AMC connectors. Continue to gently slide the

module outward along the guide rails.

Poor Shelf Cooling and EMC Compliance Violation

An empty AMC bay may result in poor shelf cooling and strong EMC radiation and thus lead to

EMC compliance violation.

Therefore, always cover empty or unused AMC bays with a filler panel.

6. Install AMC filler panel.

PrAMC-7311 Installation and Use (6806800P34D)

39

Page 40

Hardware Preparation and Installation

40

PrAMC-7311 Installation and Use (6806800P34D)

Page 41

Controls, LEDs and Connectors

3.1 Overview

This chapter describes:

Mechanical layout of the module

Face plate connectors and LEDs

3.2 Board Layout

The following figure provides an overview of the mechanical layout of the module

components.

Figure 3-1 Mechanical Layout

Chapter 3

PrAMC-7311 Installation and Use (6806800P34D)

41

Page 42

Controls, LEDs and Connectors

3.3 Face Plate Connectors and LEDs

The following figure shows the face plates of the PrAMC-7311 modules.

Figure 3-2 Face Plate

3.3.1 Connectors

The following connectors are available on the face plate.

Serial - RJ45

Ethernet

USB

42

PrAMC-7311 Installation and Use (6806800P34D)

Page 43

Controls, LEDs and Connectors

The serial interface COM can be used to connect a console. You can find its signal description in

the following figure.

Figure 3-3 Serial Console RJ45 Connector Pinout

The Ethernet interface ETH is used to establish an Ethernet connection. You can find its signal

description in the following figure.

Figure 3-4 Ethernet Connector Pinout

PrAMC-7311 Installation and Use (6806800P34D)

43

Page 44

Controls, LEDs and Connectors

The USB 2.0 interface USB can be used to connect other USB devices. You can find its signal

description in the following figure.

Figure 3-5 USB Micro-B Connector Pinout

3.3.2 LEDs

Figure 3-2 shows the LEDs on the face plate.

The meaning of the LEDs is described in the following table.

Table 3-1 Face Plate LEDs

Name Color Description

OOS Red Out Of Service

This LED is controlled by higher layer software, such as middleware or

applications.

The IPMC turns this LED on when the payload gets activated and turns

it off when the payload gets de-activated.

IS Green In Service

This LED is controlled by higher layer software, such as middleware or

applications.

The IPMC turns this LED off when the payload gets either activated or

de-activated.

44

PrAMC-7311 Installation and Use (6806800P34D)

Page 45

Table 3-1 Face Plate LEDs (continued)

Name Color Description

HS Blue FRU State Machine

During module installation:

Permanently blue: On-board IPMC powers up.

Blinking blue: Module communicates with shelf manager.

OFF: Module is active.

During module removal:

Blinking blue: Module notifies shelf manager of its desire to deactivate.

Permanently blue: Module is ready to be extracted.

ACT type Green ACTIVITY type

Blinking: When Packets are Txed/Rxed

Off: No Activity

Link status Yellow Link status

On: Link

Off: No Link

Controls, LEDs and Connectors

PrAMC-7311 Installation and Use (6806800P34D)

45

Page 46

Controls, LEDs and Connectors

46

PrAMC-7311 Installation and Use (6806800P34D)

Page 47

Functional Description

4.1 Overview

The main components of the PrAMC-7311 are:

Intel Core

Intel BD82QM67 PCH (Platform Controller Hub)

Intel i350-AM4 Gigabit Ethernet Controller (Quad Port)

4GB DDR3 memory (Supports 1333,1066 with ECC)

USB Accessed SD card

They are described in more detail in the following sections.

™

i7-2655LE Processor (Central Processing Unit)

Chapter 4

PrAMC-7311 Installation and Use (6806800P34D)

47

Page 48

Functional Description

4.2 Block Diagram

The following figure provides an overview of the main function blocks of the PrAMC-7311 and

how they are interconnected.

Figure 4-1 Block Diagram

AMC Front Panel AMC Edge

RJ45

Integrated

Mag & LEDs

MicroUSB

Type-B

Connector

RJ45

Connector

text

text

MicroSD

Connector

text

text

text

text

text

2 GB DDR3 SDRAM

9 x 2Gb x 8

64- bit + 8-bit ECC

text

text

text

text

text

2 GB DDR3 SDRAM

9 x 2Gb x 8

64- bit + 8-bit ECC

UART

UART

Interface

1G Ethernet

PCH SMBus

SPD

text

text

USB2240

USB Flash

Media

Controller

LP47N 217N

LP47N 217N

DDR3, 72 bit

1066/1333

PCH SMBus

SPD

DDR3, 72 bit

1066/1333

SMBus to OnBoard Device

USB0

USB1

Port80

On- Board Power

Flash

E2PROM

DDR3

Channel A

DDR3

Channel B

LPC

Isolation

Isolation

Hot- Swap Switch,LEDs

SPI

Intel

Powerville i350

QUAD 1G

SPI

Eth Controller

X4 PCIe

PEG

Intel

Core i7- 2655LE

Sandy Bridge

Clock

Intel

BD82 QM67

Cougar Point

PCH

FDI DMI

Latch

On Board

Power

Conversion

Power monitoring

Signals from PCH

Isolation

Buffer

Power monitoring

boot Control

LPC

SOL UART

Power &

Status

Signals

Power Control

Signals

1G Ethernet SERDES

1G Ethernet SERDES

SM bus for SOL

XDP

Local PCIe Clock

SATA

SATA

X4 PCIe

X4 PCIe

signals

Isolation

Boot

Seletion

Logic

BIOS

Latch

MMC

Renesas

H8S/ 2472

Payload Enable

Power

sequence

Control &

Monitoring

Logic

(UCD 90160)

To UCD90160

SPI Flash

AT25DF 641A

64Mbit

SPI Flash

AT25DF 641A

64Mbit

SM bus for SOL

I2C

PS0/PS1/ GA[2:0]

I2C3

AMC Port 0

AMC Port 1

AMC Port 2

AMC Port 3

AMC Port 4-7

AMC Port 8-11

IPMB-

AMC_ Enable

3.3 V Mgmt

Temp

Sensor

FRU/SDR

L

12V

48

PrAMC-7311 Installation and Use (6806800P34D)

Page 49

Functional Description

4.3 CPU

The PrAMC-7311 uses the high performance and low power Core™ i7-2655LE Processor

operating with a 2.2 GHz core frequency. Please see the Intel documentation for details

regarding this device.

4.4 Platform Controller Hub

The PrAMC-7311 utilizes the Intel BD82QM67 PCH (Platform Controller Hub). Please see Intel

documentation for details regarding this device.

4.5 I350-AM4 Quad Port Gigabit Ethernet Controller

The PrAMC-7311 uses the Intel i350-AM4 Quad Port Gigabit Ethernet Controller to provide 1

Gigabit Copper interface to Front Panel (RJ45 With integrated Magnetics) two 1000base-BX

SERDES interfaces to the AMC fabric interface. The Gigabit Ethernet Controller resides on PCI

Express Interface of the Intel i7-2655LE CPU.

Please see Intel documentation for details regarding this device.

4.6 DDR3 Memory

The PrAMC-7311 uses 18 Samsung K4B2G0846D-HCH9 devices to provide 4GB of ECC

protected DDR3 memory supporting 1333 MT/s operation.

The PrAMC-7311-16GB uses 18 micron MT41J1G8THE-15E devices to provide 16GB of ECC

protected DDR3 memory supporting 1066 MT/s operation..

4.7 USB Accessed SD card

The PrAMC-7311 supports an optional MicroSD card which serves as Persistent memory for the

purposes of Storing an OS and local storage. The MicroSD card is accessed through the

USB2240 controller which is connected to the USB 0 port of the PCH.

PrAMC-7311 Installation and Use (6806800P34D)

49

Page 50

Functional Description

4.8 Module Management Controller

The PrAMC-7311 provides the Module Management Controller (MMC) based on the

H8S/2472, an 16-bit RISC micro controller of the AVR family from Renesas.

The following are the key features:

H8S/2472 micro controller implementing Pigeon Point MMC firmware

Supports IPMB interface via the AMC fabric I/O interface

Supports LPC(LPC to Serial) interface with QM67 PCH, and Header for it's own

programming

Controls power on signal for the module

Controls Status and Health of the module with the help of sensors and Signals

50

PrAMC-7311 Installation and Use (6806800P34D)

Page 51

Address Mapping

5.1 Overview

The information in this chapter might be helpful for developing your own operating system.

5.2 Memory Address Mapping

The following table shows the memory range of the PrAMC-7311.

Table 5-1 Memory Range

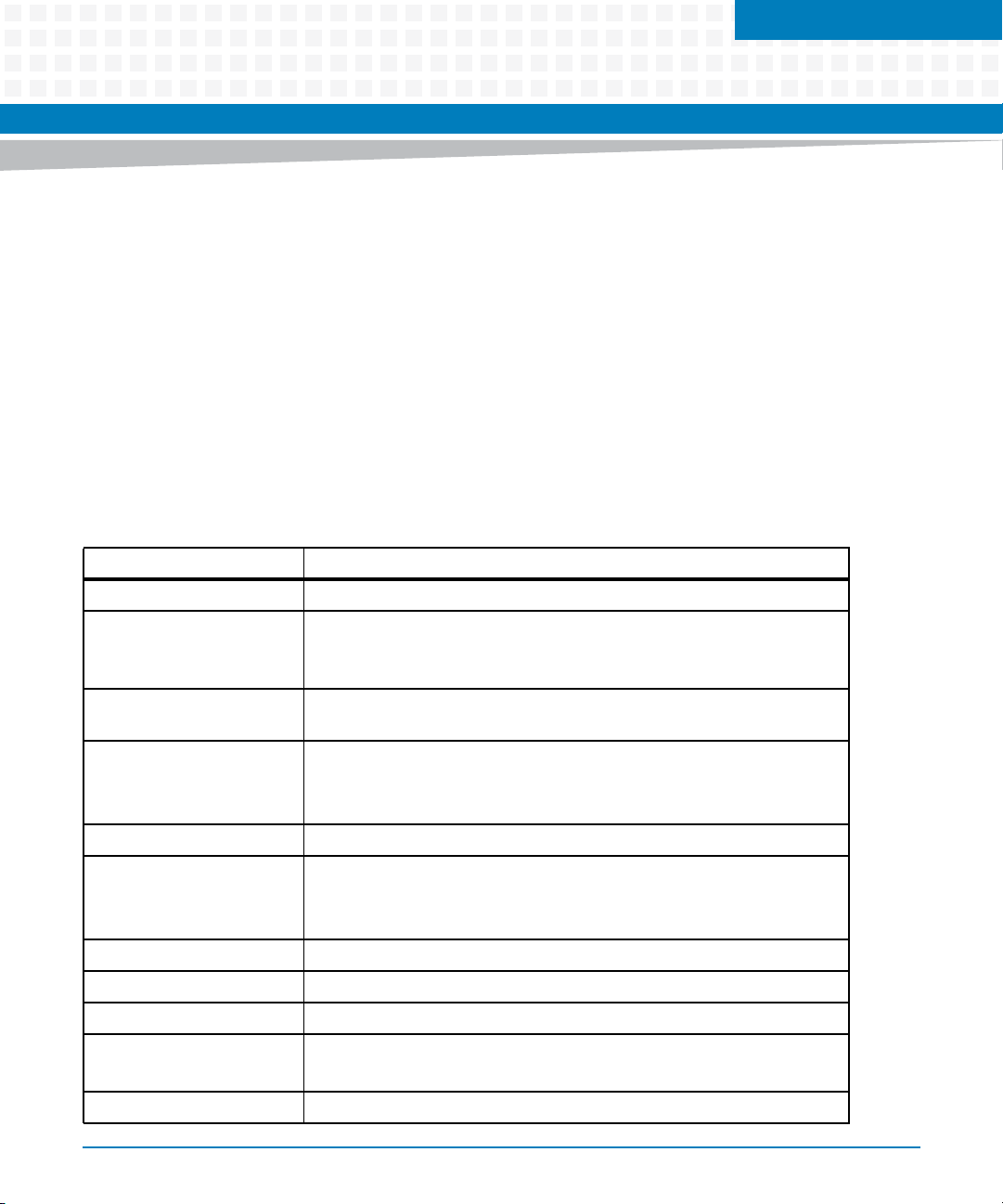

Base Address Size Device