Page 1

COMX-P1022 COM Express Module

Installation and Use

P/N: 6806800M04C

July 2014

Page 2

©

Copyright 2014 Artesyn Embedded Technologies, Inc.

All rights reserved.

Trademarks

Artesyn Embedded Technologies, Artesyn and the Artesyn Embedded Technologies logo are trademarks and service marks of

Artesyn Embedded Technologies, Inc.© 2014 Artesyn Embedded Technologies, Inc. All other product or service names are the

property of their respective owners.

Intel® is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

Java™ and all other Java-based marks are trademarks or registered trademarks of Oracle America, Inc. in the U.S. and other countries.

Microsoft®, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

Microsoft Corporation.

PICMG®, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

Industrial Computer Manufacturers Group.

UNIX® is a registered trademark of The Open Group in the United States and other countries.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Artesyn assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Artesyn reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Artesyn to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

an Artesyn website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Artesyn.

It is possible that this publication may contain reference to or information about Artesyn products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Artesyn intends to announce such Artesyn products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Artesyn.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Artesyn Embedded Technologies Artesyn Embedded Technologies

Marketing Communications

2900 S. Diablo Way, Suite 190

Tempe, Arizona 85282

Lilienthalstr. 17-19

85579 Neubiberg/Munich

Germany

Page 3

Contents

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.3 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.3.1 COMX-P1022 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.3.2 Heat Spreader Mechanical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.3.3 Cooler Mechanical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.4 Board Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.5 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.5.1 Supported Board Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.5.2 Board Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2 Hardware Preparation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1 Environmental and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1.2 Thermal Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.1.3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2 Unpacking and Inspecting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.3 Preparing the Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4 Installing and Removing the Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.5 Installing the MicroSD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.6 Installing and Removing the Heat Spreader/Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.7 Installing and Removing the Module on the Carrier Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3 Controls, LEDs, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.1 Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.2 Connectors and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

3

Page 4

Contents

Contents

Contents

3.2.1 COM Express Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.2 Default Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.2.2.1 DIP Switch Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.2.2.2 Boot Location Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.2.2.3 SPI CS0 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.2.2.4 SDHC Write-protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.2.3 System Status LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.2.4 JTAG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.2.5 GPIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.2 Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.3 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.3.1 SDRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.3.2 SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.3.3 SPI Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.3.4 EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.4 Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.5 Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.6 I2C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.6.1 I2C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.6.2 I2C EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.6.3 I2C Device - Thermal Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.6.4 SODIMM SDP EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.6.5 RTC and Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.6.6 USB Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.6.7 PCA9545. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.6.8 TFP410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.7 Reset Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.8 Interrupt Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.9 JTAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.10 GPIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.11 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.12 PCI Express . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 5

Contents

4.13 Ethernet (eTSEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.14 SATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.15 SSI (Synchronous Serial Interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.16 DIU (Display Interface Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.17 UART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5 Maps and Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.1 Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.2 IRQ Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.3 Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6 Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1 Upgrade Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1.1 Host Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1.2 Upgrade MicroSD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.1.3 Upgrade SPI Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7 Operating System and Driver Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.1 Supported Operating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.2 Supported Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

A Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1 Artesyn Embedded Technologies - Embedded Computing Documentation . . . . . . . . . . . . . . . . 81

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

5

Page 6

Contents

Contents

Contents

6

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 7

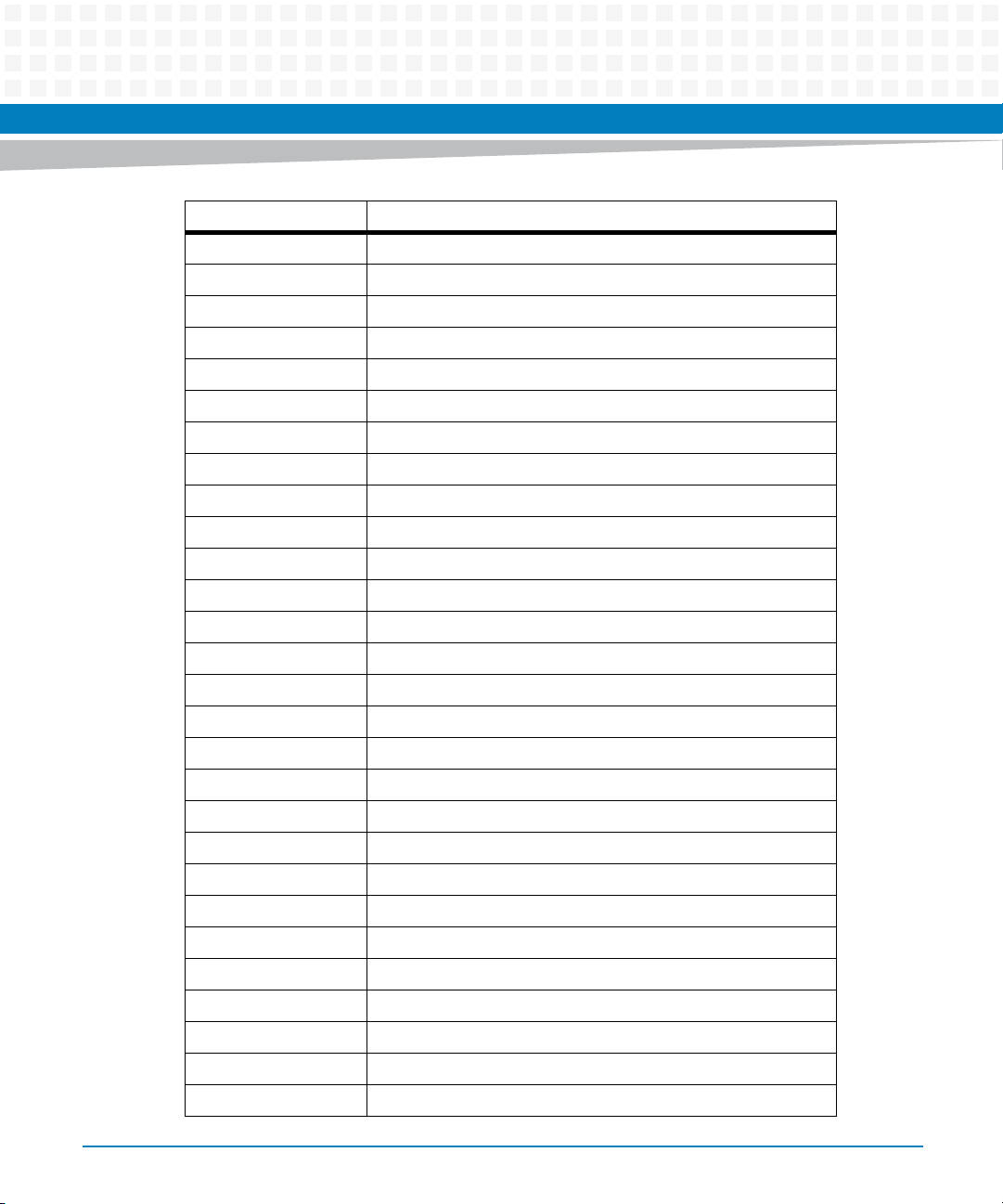

List of Tables

Table 1-1 COMX-P1022 Features Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 1-2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 1-3 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 1-4 Available Board Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 1-5 Available Board Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 2-1 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 2-2 Critical Temperature Spots for COMX-P1022 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 2-3 Board Power Supply Current Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 3-1 COM Express Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 3-2 Configure I2CMUX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 3-3 Boot Location Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 3-4 SPI CS0 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 3-5 SDHC Write-protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3-6 System LED Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3-7 CPU Debug (P1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 3-8 GE PHY Debug (Test Point14-19) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 3-9 GPIO Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 4-1 I2C#1 Address Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 4-2 I2C#2 Address Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 4-3 PCA955 Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 4-4 GPIO Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 5-1 Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 5-2 IRQ Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 7-1 Driver Controller Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table A-1 Artesyn Embedded Technologies - Embedded Computing Publications . . . . . . . . . . . . . . . 81

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

7

Page 8

List of Tables

8

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 9

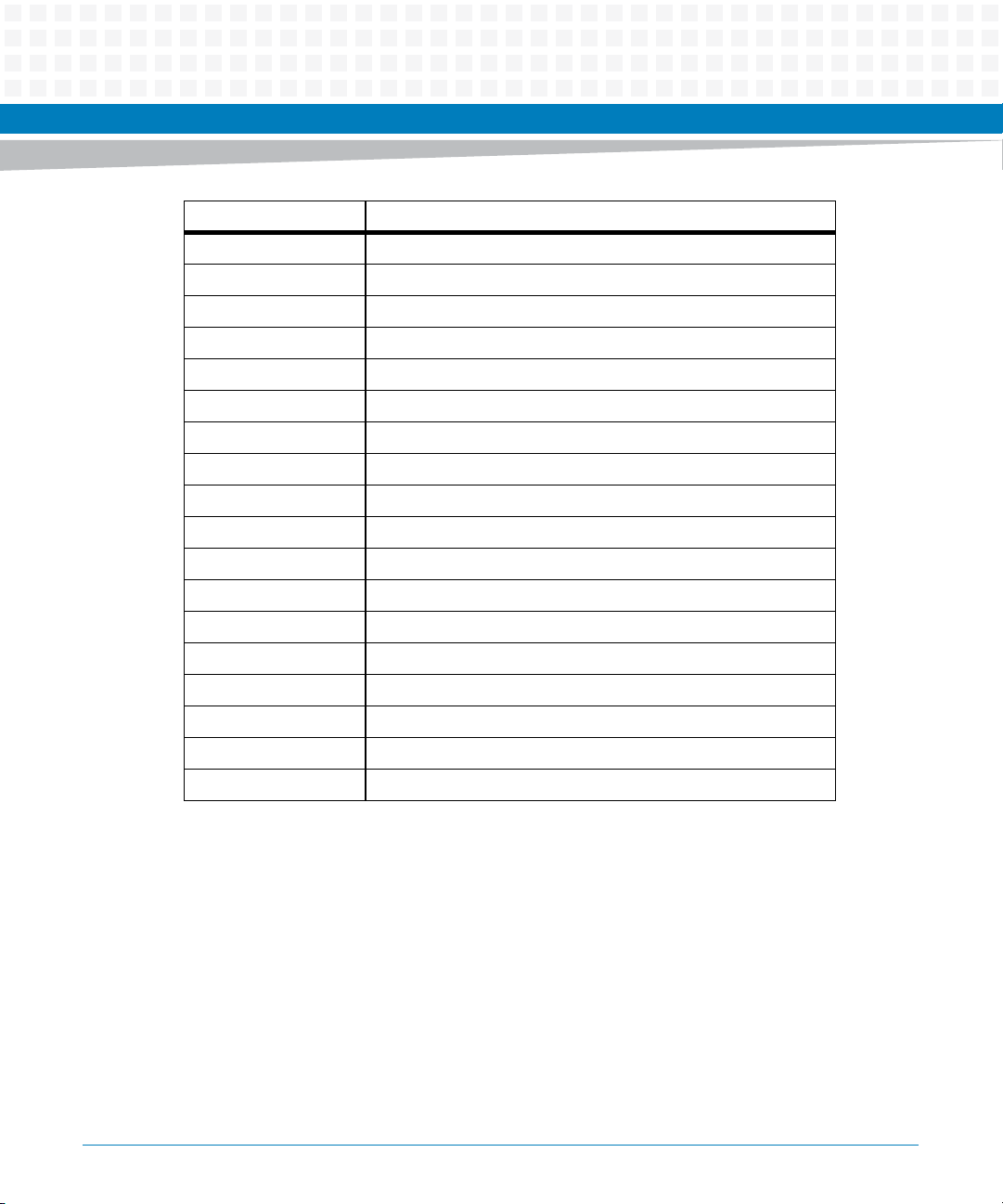

List of Figures

Figure 1-1 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 1-2 COMX-P1022 Mechanical Dimensions (Top and Side View) . . . . . . . . . . . . . . . . . . . 26

Figure 1-3 Heat Spreader Mechanical Dimensions (Front and Side View) . . . . . . . . . . . . . . . . . 28

Figure 1-4 Cooler Mechanical Dimensions (Front and Side View) . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 1-5 Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2-1 MicroSD Card Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 3-1 COMX-P1022 COM Express Module Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 3-2 COMX-P1022 COM Express Module Components (Rear View) . . . . . . . . . . . . . . . . . 44

Figure 4-1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 4-2 P1022 Processor Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 4-3 SPI Area for U-boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 4-4 Reset Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 4-5 Interrupt Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

9

Page 10

List of Figures

10

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 11

About this Manual

Overview of Contents

This manual is divided into the following chapters and appendices.

Safety Notes summarizes the safety instructions in the manual.

Sicherheitshinweise is a German translation of the Safety Notes chapter.

Introduction gives an overview of the features of the product, standard compliances,

mechanical data, ordering information, and board identification.

Hardware Preparation and Installation outlines the installation requirements, hardware

accessories, switch settings, and installation procedures.

Controls, LEDs, and Connectors describes external interfaces of the board. This includes

connectors and LEDs.

Functional Description includes a block diagram and functional description of major

components of the product.

Firmware Upgrade describes the procedures in upgrading the firmware.

Operating System and Driver Support lists the drivers and operating systems supported by

the product.

Related Documentation provides a listing of related product documentation,

manufacturer’s documents, and industry standard specifications.

Abbreviations

This document uses the following abbreviations:

Abbreviation Definition

AAmps

BGA Ball Grid Array

COM Communications

COM-E Computer-on-Module Express

COP Common On-chip Processor

CPU Central Processing Unit

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

11

Page 12

About this Manual

Abbreviation Definition

CRC Cyclic Redundancy Check

DDR Double Data Rate

oC Degrees Celsius

DRAM Dynamic Random Access Memory

DUART Dual Universal Asynchronous Receiver/Transmitter

ECC Error Correction Code

EEPROM Electrically Erasable Programmable Read-Only Memory

EPROM Erasable Programmable Read-Only Memory

F/W Firmware

GB Giga Bytes

GbE Gigabit Ethernet

Gbit Gigabit

About this Manual

12

RGMII Reduce Gigabit Media Independent Interface

H/W Hardware

I/O Input/Output

IEEE Institute of Electrical and Electronics Engineers

I2C Inter IC

JTAG Joint Test Access Group

KB Kilo Bytes

LED Light Emitting Diode

MB Mega Bytes

Mbit Megabit

MBLT Multiplexed Block Transfer

Mbps Megabits Per Second

MHz Megahertz

MTBF Mean Time Between Failure

OS Operating System

PCI-X Peripheral Component Interconnect -X

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 13

Abbreviation Definition

PIC Programmable Interrupt Controller

PLL Phase-Locked Loop

POR Power-On Reset

PRD Product Requirements Document

RAM Random Access Memory

RGMII Reduced Gigabit Media Independent Interface

ROM Read-Only Memory

RTBI Reduced Ten Bit Interface

RTC Real-Time Clock

RTM Rear Transition Module

SATA Serial AT Attachment

About this Manual

SDRAM Synchronous Dynamic Random Access Memory

SMT Surface Mount Technology

SODIMM Small-Outline Dual In-line Memory Module

S/W Software

USB Universal Serial Bus

V Volts

W Watts

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

13

Page 14

About this Manual

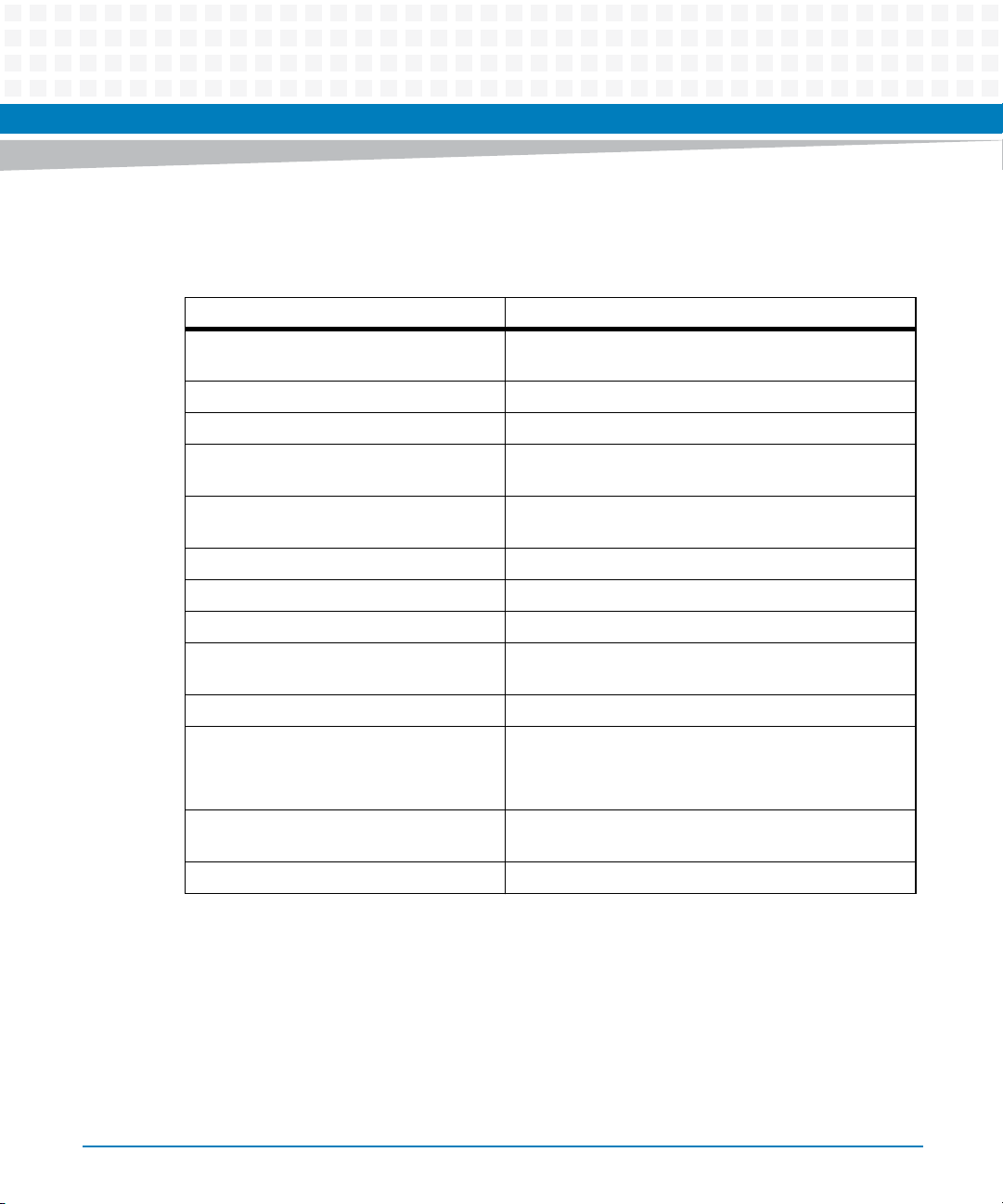

Conventions

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are 0

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related elements or

Courier + Bold Used to characterize user input and to separate it from

Reference Used for references and for table and figure descriptions

File > Exit Notation for selecting a submenu

About this Manual

through F), for example used for addresses and offsets

commands in body text

system output

14

<text> Notation for variables and keys

[text] Notation for software buttons to click on the screen and

parameter description

... Repeated item for example node 1, node 2, ..., node 12

.

.

.

.. Ranges, for example: 0..4 means one of the integers

| Logical OR

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Omission of information from example/command that

is not necessary at the time being

0,1,2,3, and 4 (used in registers)

Page 15

Notation Description

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury

Indicates a property damage message

No danger encountered. Pay attention to important

information

About this Manual

Summary of Changes

The table below lists all the revisions implemented in this manual.

Part Number Publication Date Description

6806800M04A September 2011 GA Version

6806800M04B February 2012 Updated Table "COM Express Connector Pinout"

on page 45.

6806800M04C July 2014 Re-branded to Artesyn.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

15

Page 16

About this Manual

About this Manual

16

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 17

Safety Notes

This section provides warnings that precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed during all phases of

operation, service, and repair of this equipment. You should also employ all other safety

precautions necessary for the operation of the equipment in your operating environment.

Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

Artesyn Embedded Technologies intends to provide all necessary information to install and

handle the product in this manual. Because of the complexity of this product and its various

uses, we do not guarantee that the given information is complete. If you need additional

information, ask your Artesyn Embedded Technologies representative.

The product has been designed to meet the standard industrial safety requirements. It must

only be used in its specific area of office telecommunication industry, industrial control, and

development. It must not be used in safety critical components, life supporting devices or on

aircraft.

Only personnel trained by Artesyn Embedded Technologies or persons qualified in electronics

or electrical engineering are authorized to install, remove or maintain the product. The

information given in this manual is meant to complete the knowledge of a specialist and must

not be used as replacement for qualified personnel.

Keep away from live circuits inside the equipment. Operating personnel must not remove

equipment covers. Only factory authorized service personnel or other qualified service

personnel is allowed to remove equipment covers for internal subassembly or component

replacement or any internal adjustment.

This product operates with dangerous voltages that can cause injury or death. Use extreme

caution when handling, testing, and adjusting this equipment and its components.

Operation

Product Damage

High humidity and condensation on surfaces cause short circuits.

Do not operate the product outside the specified environmental limits. Make sure the product

is completely dry and there is no moisture on any surface before applying power.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

17

Page 18

Safety Notes

Installation

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product make sure that your are working in an ESD-safe environment or

wear an ESD wrist strap or ESD shoes. Hold the product by its edges and do not touch any

components or circuits.

Damage of the Product and Additional Devices and Modules

Incorrect installation or removal of additional devices or modules damages the product or the

additional devices or modules.

Before installing or removing additional devices or modules, read the respective

documentation and use appropriate tools.

Pin Damage

Forcing the module into the system may damage the connector pins.

If the module hangs during insertion, pull it out and insert it again.

Environment

Environmental Damage

Improperly disposing of used products may harm the environment.

Always dispose of used products according to your country’s legislation and manufacturer’s

instructions.

18

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 19

Sicherheitshinweise

This section provides a German translation of the Safety Notes.

Dieses Kapitel enthält Hinweise, die potentiell gefährlichen Prozeduren innerhalb dieses

Handbuchs vorrangestellt sind. Beachten Sie unbedingt in allen Phasen des Betriebs, der

Wartung und der Reparatur des Systems die Anweisungen, die diesen Hinweisen enthalten

sind. Sie sollten außerdem alle anderen Vorsichtsmaßnahmen treffen, die für den Betrieb des

Systems innerhalb Ihrer Betriebsumgebung notwendig sind. Wenn Sie diese

Vorsichtsmaßnahmen oder Sicherheitshinweise, die an anderer Stelle diese Handbuchs

enthalten sind, nicht beachten, kann das Verletzungen oder Schäden am System zur Folge

haben.

Artesyn Embedded Technologies ist darauf bedacht, alle notwendigen Informationen zum

Einbau und zum Umgang mit dem System in diesem Handbuch bereit zu stellen. Da es sich

jedoch bei dem System um ein komplexes Produkt mit vielfältigen Einsatzmöglichkeiten

handelt, können wir die Vollständigkeit der im Handbuch enthaltenen Informationen nicht

garantieren. Falls Sie weitere Informationen benötigen sollten, wenden Sie sich bitte an die für

Sie zuständige Geschäftsstelle von Artesyn Embedded Technologies.

Das Produkt erfüllt die für die Industrie geforderten Sicherheitsvorschriften und darf

ausschließlich für Anwendungen in der Telekommunikationsindustrie, im Zusammenhang mit

Industriesteuerungen und in der Entwicklung verwendet werden. Es darf nicht in

sicherheitskritischen Anwendungen, lebenserhaltenden Geräten oder in Flugzeugen

verwendet werden.

Einbau, Wartung und Betrieb dürfen nur von durch Artesyn Embedded Technologies

ausgebildetem oder im Bereich Elektronik oder Elektrotechnik qualifiziertem Personal

durchgeführt werden. Die in diesem Handbuch enthaltenen Informationen dienen

ausschließlich dazu, das Wissen von Fachpersonal zu ergänzen, können dieses jedoch nicht

ersetzen.

Halten Sie sich von stromführenden Leitungen innerhalb des Systems fern. Entfernen Sie auf

keinen Fall die Systemabdeckung. Nur werksseitig zugelassenes Wartungspersonal oder

anderweitig qualifiziertes Wartungspersonal darf die Systemabdeckung entfernen, um

Systemkomponenten zu ersetzen oder andere Anpassungen vorzunehmen.

Installieren Sie keine Ersatzteile oder führen Sie keine unerlaubten Veränderungen am System

durch, sonst verfällt die Garantie. Wenden Sie sich für Wartung oder Reparatur bitte an die für

Sie zuständige Geschäftsstelle von Artesyn Embedded Technologies. So stellen Sie sicher, dass

alle sicherheitsrelevanten Aspekte beachtet werden.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

19

Page 20

Sicherheitshinweise

Artesyn Embedded Technologies und unsere Zulieferer unternehmen größte Anstrengungen

um sicherzustellen, dass sich Pins und Stecker von Boards vor dem Verlassen der

Produktionsstätte in einwandfreiem Zustand befinden. Verbogene Pins, verursacht durch

fehlerhafte Installation oder durch Installation von Boards mit beschädigten Steckern kann die

durch Artesyn Embedded Technologies gewährte Garantie für Boards und Backplanes

erlöschen lassen.

Dieses Produkt wird mit gefährlichen Spannungen betrieben, die zu Verletzungen und Tod

führen können. Seien Sie im Umgang mit dem Produkt und beim Testen und Anpassen des

Produktes und seiner Komponenten äußerst vorsichtig.

Betrieb

Beschädigung des Systems

Hohe Luftfeuchtigkeit und Kondensat auf den Oberflächen der Produkte kann zu

Kurzschlüssen führen.

Betreiben Sie die Produkte nur innerhalb der angegebenen Grenzwerte für die relative

Luftfeuchtigkeit und Temperatur und stellen Sie vor dem Einschalten des Stroms sicher, dass

sich auf den Produkten kein Kondensat befindet.

System Installation

Beschädigung von Schaltkreisen

Elektrostatische Entladung und unsachgemäßer Ein- und Ausbau des Produktes kann

Schaltkreise beschädigen oder ihre Lebensdauer verkürzen.

Bevor Sie das Produkt oder elektronische Komponenten berühren, vergewissern Sie sich, daß

Sie in einem ESD-geschützten Bereich arbeiten.

Beschädigung des Produktes und der Zusatzmodule

Fehlerhafter Ein- oder Ausbau von Zusatzmodulen führt zu Beschädigung des Produktes oder

der Zusatzmodule.

Lesen Sie deshalb vor dem Ein- oder Ausbau von Zusatzmodulen die Dokumentation und

benutzen Sie angemessenes Werkzeug.

20

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 21

Umweltschutz

Umweltverschmutzung

Falsche Entsorgung der Produkte schadet der Umwelt.

Entsorgen Sie alte Produkte gemäß der in Ihrem Land gültigen Gesetzgebung und den

Empfehlungen des Herstellers.

Sicherheitshinweise

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

21

Page 22

Sicherheitshinweise

22

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 23

Introduction

1.1 Features

COMX-P1022 COM Express Module is a COM Express module based on the Freescale P1022

processor and derivative processors P1013. COM Express is an industry-standard embedded

computer module defined by PICMG.

The following table summarizes the features of COMX-P1022 COM Express Module.

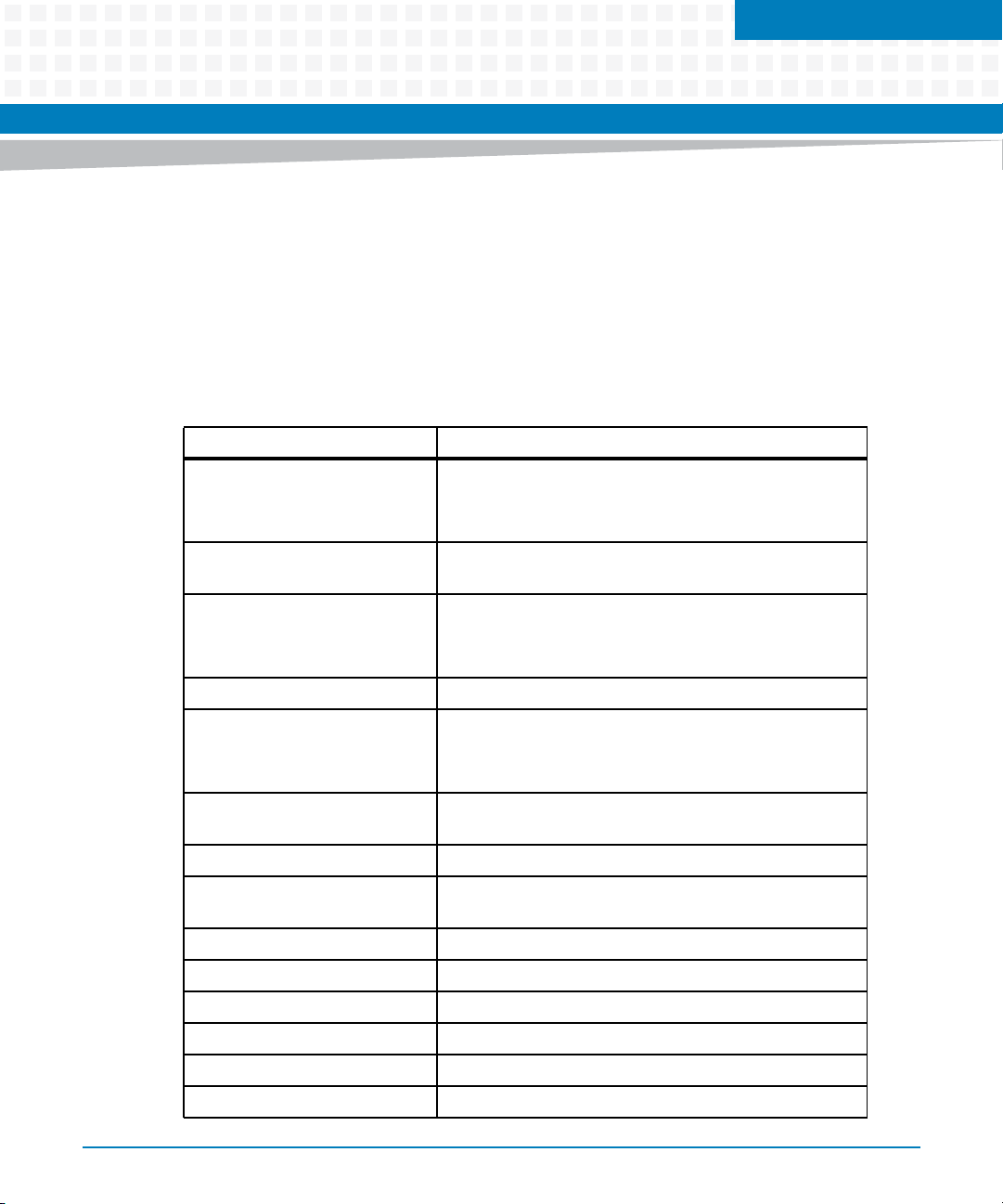

Table 1-1 COMX-P1022 Features Summary

Function Features

Processor Freescale Power PC

Memory Supports 2GB DDR3 667MT/s DDR3+ECC arranged in

Chapter 1

– P1022: 1.066 GHz dual core

– P1013: Single core

two ranks on one slot

SD Card 2 GB MicroSD Card on module

SDHC signals routed to the COM-E connector

Storage for bootloader and OS

UART Two UARTs

Video Supports up to 1280x1024@60 HZ

24bpp display color depth

Supports DVI and LVDS interfaces

Ethernet Broadcom BCM5482 supports two 10/100/1000BASE-T

ports.

USB Four USB2.0 ports routed to the COM-E connector

PCI Express Two x1 PCI-E 1.0 and one x2 PCI-E 1.0 (@2.5 GT/s) ports

routed to the COM-E connectors.

Boot Loader TBD

I2C Four ports

RTC M41ST85WMX6TR

JTAG JTAG connector on module

Audio I2S/SSI interface

SATA Two SATA ports routed to the COM-E connectors

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

23

Page 24

Introduction

1.2 Standard Compliances

This product meets the following standards:

Table 1-2 Standard Compliances

Standard Description

UL/CSA 60950-1

EN 60950-1

IEC 60950-1 CB Scheme

FCC 47 CFR Part 15 Subpart B (US),

Class A

EN55022 Class A (EU)

AS/NZS CISPR 22 Class A

(Australia/New Zealand)

VCCI Class A (Japan)

Legal safety requirements

EMC requirements (legal) on system level (predefined

Artesyn system)

24

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 25

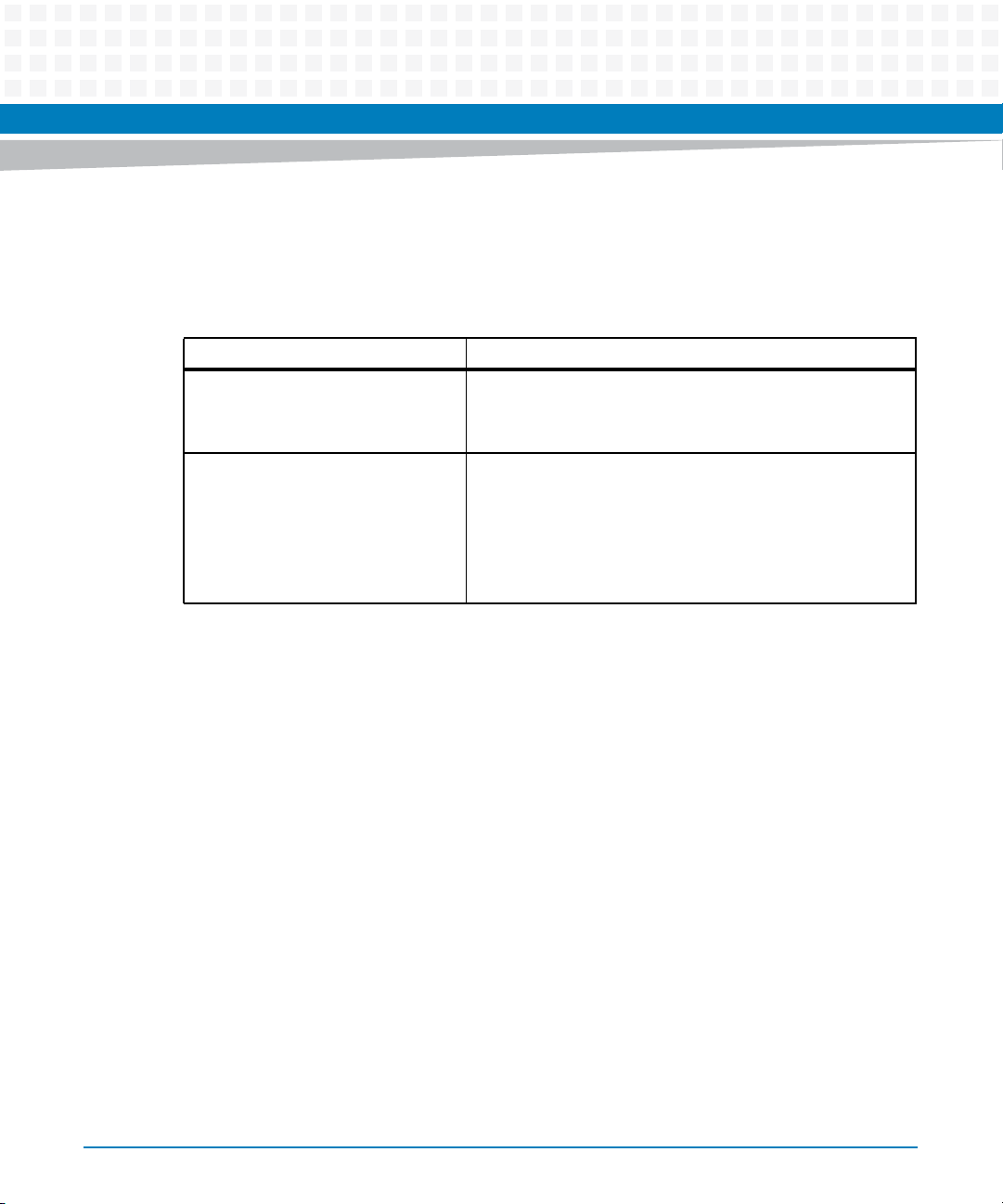

Figure 1-1 Declaration of Conformity

E

C Declaration of Conformity

According to EN 17050-1:2004

Manufacturer’s Name:

Manufacturer’s Address:

Declares that the following product, in accordance with the requirements of 2004/108/EC, 2006/95/EC,

2011/65/EU and their amending directives,

Product:

Artesyn Embedded Technologies

Embedded Computing

Zhongshan General Carton Box Factory Co. Ltd. No 62, Qi

Guan Road West, Shiqi District, 528400 Zhongshan City

Guangdong, PRC

COM Express Form Factor System-on-Chip device

Introduction

Model Name/Number:

has been designed and manufactured to the following specifications:

EN55022:2006 (A1: 2007) Class A

EN55024: 1998 (A1: 2001 + A2: 2003)

IEC 60950-1 (2nd Edition) +A1:2009

2011/65/EU RoHS Directive

As manufacturer we hereby declare that the product named above has been designed to comply with the rele-

vant sections of the above referenced specifications. This product complies with the essential health and safety

requirements of the above specified directives. We have an internal production control system that ensures

compliance between the manufactured products and the technical documentation.

___________________________________________________ ___07/15/2014______

COMX-P1022

Tom Tuttle, Manager, Product Testing Services Date (MM/DD/YYYY)

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

25

Page 26

Introduction

1.3 Mechanical Data

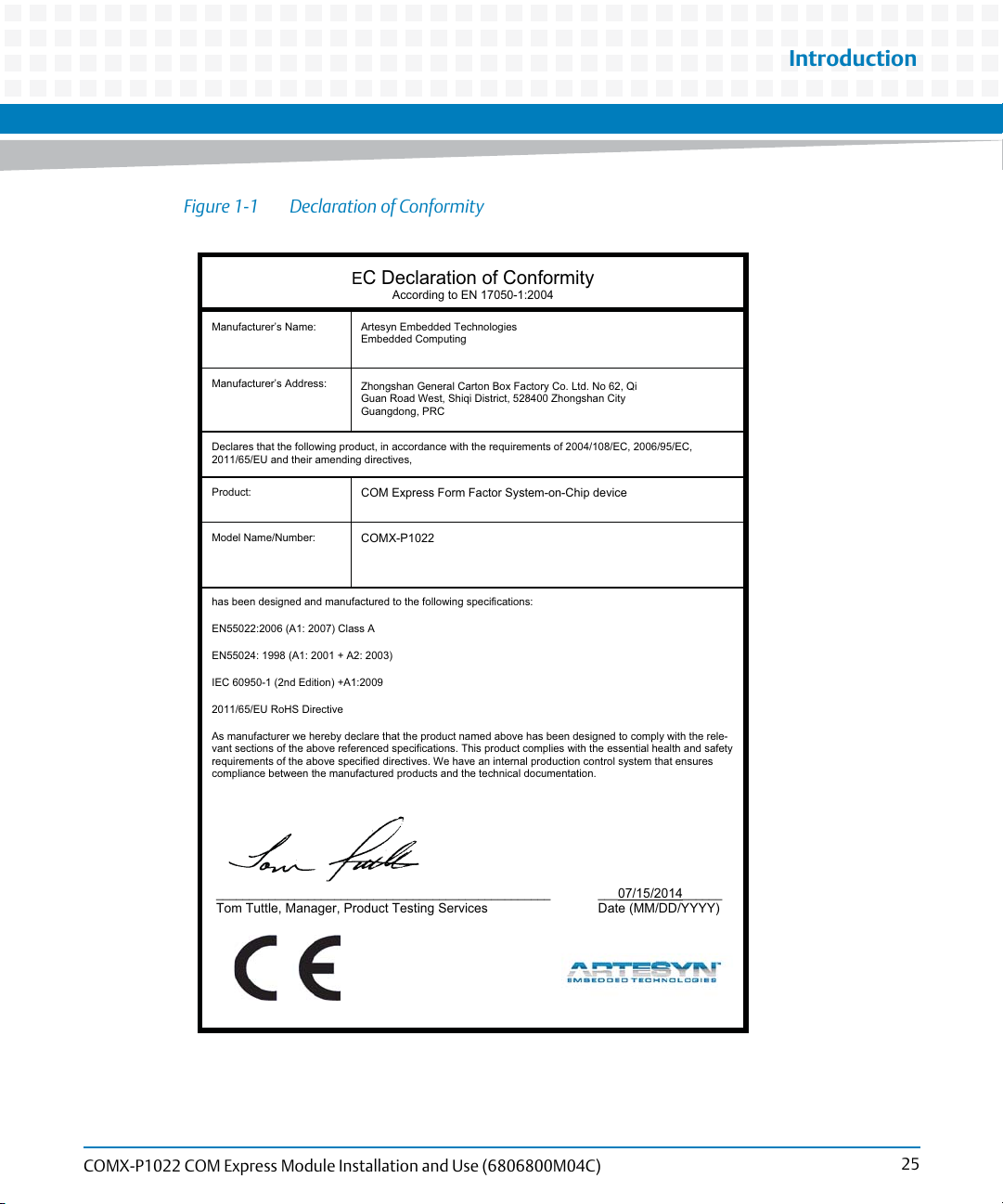

1.3.1 COMX-P1022 Mechanical Data

Figure 1-2 COMX-P1022 Mechanical Dimensions (Top and Side View)

2.7 HOLE

WITH 6 PAD

BOTH SIDE

2PL91.00

89.10

84.00

19.61

2PL4.00

0.00

6.50

0.00

3PL4.00

13.59

42.93

42.54

57.14

2PL80.00

91.00

90.95

95.00

95.00

43.18

20.32

PIN 1

2.67

2.00

26

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 27

Table 1-3 Mechanical Data

Feature Value

Dimensions COM Express basic form factor: 95 mm x 95 mm

Weight 70.0 g

Introduction

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

27

Page 28

Introduction

1.3.2 Heat Spreader Mechanical Data

Figure 1-3 Heat Spreader Mechanical Dimensions (Front and Side View)

95.00

10.00

30.50

20.00

11.50

95.00

28

11.00

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 29

1.3.3 Cooler Mechanical Data

Figure 1-4 Cooler Mechanical Dimensions (Front and Side View)

Introduction

95.00

10.00

30.50

20.00

11.50

95.00

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

23.50

29

Page 30

Introduction

1.4 Board Identification

This section shows the serial number and its location on the board.

Figure 1-5 Serial Number Location

Serial Number

1.5 Ordering Information

1.5.1 Supported Board Models

The following table lists the product variants that are available upon release of this publication.

Table 1-4 Available Board Variants

Order Number Description

COMX-P1022 P1022 COM Module

30

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 31

Table 1-4 Available Board Variants (continued)

Order Number Description

COMX-P1022-2G-KIT P1022 COM Module with 2 GB memory and heatsink

For availability of other variants, consult your local Artesyn sales representative.

1.5.2 Board Accessories

The following table lists the board accessories that are available upon release of this

publication.

Table 1-5 Available Board Accessories

Order Number Description

COMX-P1022-HSP Heat spreading plate

Introduction

COMX-P1022-HTSNK Heatsink

For availability of other board accessories, consult your local Artesyn sales representative.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

31

Page 32

Introduction

32

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 33

Hardware Preparation and Installation

2.1 Environmental and Power Requirements

2.1.1 Environmental Requirements

The following table lists the environmental requirements that the board must meet when

operated in your particular system configuration.

Operating temperatures refer to the temperature of the air circulating around the board and

not to the component temperature.

Chapter 2

Product Damage

High humidity and condensation on surfaces cause short circuits.

Do not operate the system outside the specified environmental limits. Make sure the

product is completely dry and there is no moisture on any surface before applying power.

Table 2-1 Environmental Requirements

Requirement Operating Non-Operating

Temp Cycle Class -40°C to 85°C:500 cycles

Temperature 0°C to 60°C -40°C to 85°C

Humidity 10% to90% (non-condensing)

Vibration 0.01g2/Hz @ 5-500Hz (Random Vibration)

Shock 20G peak 11ms (half sine)

Altitude -60 to 4000m ASL

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

33

Page 34

Hardware Preparation and Installation

2.1.2 Thermal Requirements

Table 2-2 Critical Temperature Spots for COMX-P1022

Heat Dissipation Power

Component Identifier

CPU-P1022 6 Tjmax = 125

SODIMM Tcmax = 85

(W)

Maximum Allowable

Temperature (°C)

Contact your Artesyn sales representative for current information on the detailed thermal

information including airflow and resistance of the module.

System Overheating

Cooling Vents

Improper cooling can lead to system damage and can void the manufacturer's warranty.

To ensure proper cooling and undisturbed airflow through the system do not obstruct the

ventilation openings of the system. Make sure that the fresh air supply is not mixed with hot

exhaust from other devices.

34

Personal Injury

During operation, hot surfaces may be present on the heat sinks and the components of the

product.

To prevent injury from hot surface do not touch any of the exposed components or

heatsinks on the product when handing. Use the handle and face plate, where applicable, or

the board edge when removing the product from the enclosure.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 35

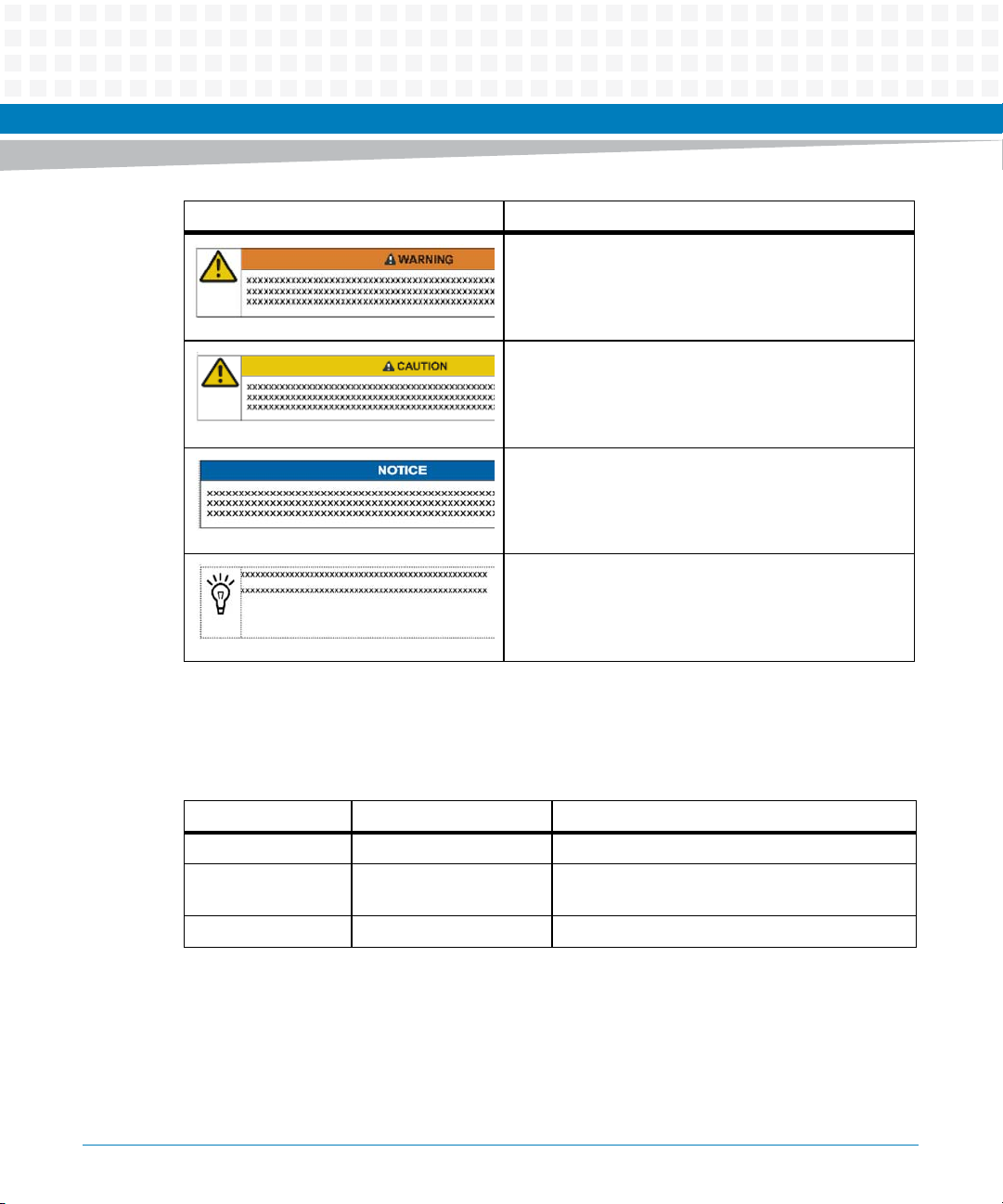

2.1.3 Power Requirements

Table 2-3 Board Power Supply Current Requirements

0.75V 1.0V 1.2V 1.5V 1.8V 2.5V 3.3V

CPU(P1022) 6000 1000 100 200

DDR3 600 4400

USB PHY(3315) 55

USB HUB(2514) 415

GE PHY BCM5482 260 88

DS90C385 493

TFP410PAP 250

Hardware Preparation and Installation

74LVCH32244A x2 120

Total 23.17W 0.45W 6W 3.12W 8.1W 0.5W 5W

2.2 Unpacking and Inspecting the Module

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten its life.

Before touching the product make sure that you are working in an ESD-safe environment or

wear an ESD wrist strap or ESD shoes. Hold the product by its edges and do not touch any

components or circuits.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

35

Page 36

Hardware Preparation and Installation

Shipment Inspection

1. Verify that you have received all items of your shipment:

Printed Quick Start Guide and Safety Notes

COMX-P1022 COM Express Module

2. Check for damage and report any damage or differences to customer service.

3. Remove the desiccant bag shipped together with the product.

Environmental Damage

Improperly disposing of used products may harm the environment.

Always dispose of used products according to your country’s legislation and manufacturer’s

instructions.

2.3 Preparing the Installation Environment

Before you install or replace components, pay attention to the following:

Wear an ESD-preventive wrist strap to prevent the static electricity from damaging the

device.

Keep the area where the components reside clean and keep the components away from

heat-generating devices, such as radiator.

Ensure that your sleeves are tightened or rolled up above the elbow. For safety purposes,

it is not recommended to wear jewelry, watch, glasses with metal frame, or clothes with

metal buttons.

Do not exert too much force, or insert or remove the components forcibly. Avoid damage

to the components or plug-ins.

36

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 37

Hardware Preparation and Installation

Confirm the feasibility of the operation

There are available spare parts of the components to be installed or replaced in the

equipment warehouse. When the available spare parts are lacking, contact Artesyn

Embedded Technologies for help in time. For details on how to get help from Artesyn

Embedded Technologies, visit http://www.artesyn.com/computing/.

Make sure that the new components are in good condition, without defects such as

oxidation, chemical corrosion, missing components, or transportation damage.

By reading this document, you are familiar with how to install and replace the component

and master the skills required by the operation.

Check the environment

Make sure that the power supply, temperature, and humidity meet the operating

requirements for the board and its components. For details, refer to the respective system

documentation.

Prepare the parts and the tools

Prepare the components to be installed or replaced.

When you hold or transport the components, use the special antistatic package. Prepare

the cross screwdriver, screws, plastic supports, cooling gel, and ESD-preventive wrist

strap.

Confirm installation or changing position

Confirm the position where COMX-P1022 COM Express Module will be installed.

If a serious problem occurs and cannot be solved when you install or replace the

component, contact Artesyn for technical support.

2.4 Installing and Removing the Memory Module

There is one 204-pin SODIMM slot on the COMX-P1022 COM Express Module.

Pin Damage

Forcing the module into the system may damage connector pins.

If the module hangs during insertion, pull it out and insert it again.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

37

Page 38

Hardware Preparation and Installation

Installing a Memory Module

1. Wear the ESD-preventive wrist strap.

2. Lay the COM-E module where the SODIMM is to be installed on the anti-static

desktop.

3. Take the SODIMM out of the anti-static package, holding it by the edges.

4. Line up the notch located on the row of the metal pins at the bottom of the module

with the key in the SODIMM slot on the COM-E module.

5. Insert the SODIMM in a slantwise position or at a 45-degree angle to slide the

memory module into place.

38

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 39

Hardware Preparation and Installation

6. Press down on the memory module against the COM-E module until you hear it

snap into place. The module must be properly aligned before you press it down into

its final position. You can remove the module from the socket and reinstall it if you

cannot press it down into its final position.

Removing a Memory Module

1. Wear the ESD-preventive wrist strap.

2. Release the module from the slot by pushing the spring latches on either side of the

module outward.

3. Lift the module from the COM-E Module.

Damage of the Product and Additional Devices and Modules

Incorrect installation or removal of additional devices or modules damages the product or

the additional devices or modules.

Before installing or removing additional devices or modules, read the respective

documentation and use appropriate tools.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

39

Page 40

Hardware Preparation and Installation

2.5 Installing the MicroSD Card

COMX-P1022 COM Express Module has an on-module MicroSD card slot with a 2 GB MicroSD

card installed.

Figure 2-1 MicroSD Card Slot

40

Installing the MicroSD Card

1. Insert the MicroSD card to the MicroSD socket.

2. Make sure that the metallic contact point of the MicroSD card and the MicroSD

socket are lined up correctly.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 41

Hardware Preparation and Installation

2.6 Installing and Removing the Heat Spreader/Cooler

Installing the Heat Spreader/Cooler

1. Check the thermal interface material pads on the heat spreader/cooler. Make sure

the pads are aligned to their corresponding components on the COMX-P1022 COM

Express module.

2. Align the standoffs of the heat spreader/cooler with the screw holes on the COMX-

P1022 COM Express module.

3. Hold the heat spreader/cooler and COMX-P1022 COM Express module.

4. From the backside of COMX-P1022 COM Express module, use two screws to fasten

the module to the heat spreader/cooler through two internal mounting holes.

Removing the Heat Spreader/Cooler

1. Loosen and remove the two pieces of screws that attach the heat spreader/cooler

to the COMX-P1022 COM Express module.

2. While holding the edges, pull the heat spreader/cooler from the COMX-P1022 COM

Express module.

2.7 Installing and Removing the Module on the Carrier Board

The assembled COM Express module with the attached heat spreader/ cooler is attached to a

carrier board.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

41

Page 42

Hardware Preparation and Installation

Installing the COM Express Module on the Carrier Board

1. Line up the board-to-board connector of the COMX-P1022 COM Express Module

assembly with the board-to-board connector of the carrier board.

2. Make sure that the interconnectors are properly aligned and that the bottom

surface of the COMX-P1022 COM Express Module have contact with the four

standoffs on carrier board.

3. From the topside of the COMX-P1022 COM Express Module assembly, locate the

screw holes on heat spreader/cooler.

4. Use the screws to fasten the COMX-P1022 COM Express Module assembly to the

carrier board.

Removing the COM Express Module from the Carrier Board

1. From the topside of the COMX-P1022 COM Express Module assembly, locate the

four screws that connect the COMX-P1022 COM Express Module assembly to the

carrier board.

2. Loosen and remove the screws.

3. While holding the edges, pull the COMX-P1022 COM Express Module from the

carrier board.

42

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 43

Controls, LEDs, and Connectors

3.1 Board Layout

Figure 3-1 COMX-P1022 COM Express Module Components

Chapter 3

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

43

Page 44

Controls, LEDs, and Connectors

Figure 3-2 COMX-P1022 COM Express Module Components (Rear View)

3.2 Connectors and Switches

3.2.1 COM Express Connector

The following two tables provide the pin out for the Freescale type COM-E module.

44

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 45

Controls, LEDs, and Connectors

The first column shows the default signal names while the succeeding columns show the

differences in values.

Table 3-1 COM Express Connector Pinout

Row A Row B Row C Row D

A1 GND B1 GND C1 GND (FIXED) D1 GND (FIXED)

A2 GBE0_MDI3- B2 GBE0_ACT# C2 GBE1_ACT# D2 GBE2_ACT#

A3 GBE0_MDI3+ B3 1588_CLK_OUT C3 GBE1_MDI3- D3 GBE2_MDI3-

A4 GBE0_LINK100#B4 1588_PULSE_OUT1C4 GBE1_MDI3+ D4 GBE2_MDI3+

A5 GBE0_LINK1000#B5 1588_PULSE_OUT2C5 GBE1_LINK100# D5 GBE2_LINK100

#

A6 GBE0_MDI2- B6 1588_ALARM_OUT1C6 GBE1_MDI2- D6 GBE2_MDI2-

A7 GBE0_MDI2+ B7 1588_ALARM_OUT2C7 GBE1_MDI2+ D7 GBE2_MDI2+

A8 GBE0_LINK# B8 1588_TRIG_IN1 C8 GBE1_LINK1000# D8 GBE2_LINK100

0#

A9 GBE0_MDI1- B9 1588_TRIG_IN2 C9 GBE1_MDI1- D9 GBE2_MDI1-

A10 GBE0_MDI1+ B10 1588_CLK_IN C10 GBE1_MDI1+ D10 GBE2_MDI1+

A11 GND B11 GND C11 GND (FIXED) D11 GND (FIXED)

A12 GBE0_MDI0- B12 PWRBTN# C12 GBE1_MDI0- D12 GBE2_MDI0-

A13 GBE0_MDI0+ B13 SMB_CK C13 GBE1_MDI0+ D13 GBE2_MDI0+

A14 GBE0_CTREF B14 SMB_DAT C14 GBE1_LINK# D14 GBE2_LINK#

A15 SUS_S3# B15 SMB_ALERT# C15 DDI1_PAIR6+/RSV

D/User Display

A16 SATA0_TX+ B16 SATA1_TX+ C16 DDI1_PAIR6-

/RSVD/User

Display

A17 SATA0_TX- B17 SATA1_TX- C17 CE_PB12/LGPL0 D17 CE_PA0/LCLK0

A18 SUS_S4# B18 SUS_STAT# C18 CE_PB13/LGPL1 D18 CE_PA1/LCLK1

A19 SATA0_RX+ B19 SATA1_RX+ C19 NC D19 NC

D15 IRQ_OUT_B

D16 IRQ_IN0

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

45

Page 46

Controls, LEDs, and Connectors

Table 3-1 COM Express Connector Pinout (continued)

Row A Row B Row C Row D

A20 SATA0_RX- B20 SATA1_RX- C20 NC D20 NC

A21 GND B21 GND C21 GND D21 GND

A22 SATA2_TX+ B22 SATA3_TX+ C22 NC D22 NC

A23 SATA2_TX- B23 SATA3_TX- C23 NC D23 NC

A24 SUS_S5# B24 PWR_OK C24 DDI1_HPD/RSVD/

User Display

A25 SATA2_RX+ B25 SATA3_RX+ C25 DDI1_PAIR4+/RSV

D/User Display

A26 SATA2_RX- B26 SATA3_RX- C26 DDI1_PAIR4-

/RSVD/User

Display

A27 BATLOW# B27 WDT C27 DDI1_AUX+/RSVD

/User Display

A28 (S)ATA_ACT# B28 AC/HAD_SDIN2 C28 DDI1_AUX-

/RSVD/User

Display

A29 AC/HAD_SYNC B29 AC/HAD_SIN1 C29 DDI1_PAIR5+/RSV

D/User Display

A30 AC/HAD_RST# B30 AC/HAD_SIN0 C30 DDI1_PAIR5-

/RSVD/User

Display

A31 GND B31 GND C31 GND D31 GND

A32 AC/HAD_BITCLKB32 SPKR C32 U0_TXD D32 DDI1_PAIR2+/R

D24 CE_PA2/LCS0_B

D25 CE_PA3/LCS1_B

D26 DDI1_PAIR0+/R

SVD/User

Display

D27 DDI1_PAIR0-

/RSVD/User

Display

D28 CE_PB18/LAD0

0

D29 DDI1_PAIR1+/R

SVD/User

Display

D30 DDI1_PAIR1-

/RSVD/User

Display

SVD/User

Display

A33 AC/HAD_SDOUTB33 I2C_CK C33 U0_RXD D33 DDI1_PAIR2-

/RSVD/User

Display

A34 BIOS_DIS0# B34 I2C_DAT C34 U0_CTS D34 CE_PB19/LAD0

1

46

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 47

Controls, LEDs, and Connectors

Table 3-1 COM Express Connector Pinout (continued)

Row A Row B Row C Row D

A35 THERMTRIP# B35 THRM# C35 U0_RTS D35 CE_PB20/LAD0

2

A36 USB6- B36 USB7- C36 U1_TXD D36 DDI1_PAIR3+/R

SVD/User

Display

A37 USB6+ B37 USB7+ C37 U1_RXD D37 DDI1_PAIR3-

/RSVD/User

Display

A38 USB_6_7_OC# B38 USB_4_5_OC# C38 U1_CTS D38 TDM_CLK_Tx0/

SSI_TCK0/User

Defined

A39 USB4- B39 USB5- C39 U1_RTS D39 TDM_CLK_Rx0/

SSI_RCK0/User

Defined

A40 USB4+ B40 USB5+ C40 MDIO1 (clause 22) D40 TDM_TxD0/SSI

_TXD0/User

Defined

A41 GND B41 GND C41 GND D41 GND

A42 USB2- B42 USB3- C42 U2_TXD/User

Defined

A43 USB2+ B43 USB3+ C43 U2_RXD/User

Defined

A44 USB_2_3_OC# B44 USB_0_1_OC# C44 U2_CTS/User

Defined

A45 USB0- B45 USB1- C45 U2_RTS/User

Defined

A46 USB0+ B46 USB1+ C46 U3_TXD/User

Defined

D42 TDM_RxD0/SSI

_RXD0/User

Defined

D43 TDM_TxFS0/SSI

_TFS0/User

Defined

D44 TDM_RxFS0/SSI

_RFS0/User

Defined

D45 SSI_TCK1/TDM

_CLK_Tx1/User

Defined

D46 SSI_RCK1/TDM

_CLK_Rx1/User

Defined

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

47

Page 48

Controls, LEDs, and Connectors

Table 3-1 COM Express Connector Pinout (continued)

Row A Row B Row C Row D

A47 VCC_RTC B47 EXCD1_PERST# C47 U3_RXD/User

Defined

D47 SSI_TXD1/TDM

_TxD1/User

Defined

A48 EXCD0_PERST# B48 EXCD1_CPPE# C48 U3_CTS/User

Defined

A49 EXCD0_CPPE# B49 SYS_RESET# C49 U3_RTS/User

Defined

A50 LPC_SERIRQ B50 CB_RESET# C50 MDC1 (clause 22) D50 SSI_RFS1/TDM_

A51 GND B51 GND C51 GND D51 GND

A52 NC B52 NC C52 SERDES_RX16+ D52 SERDES_TX16+

A53 NC B53 NC C53 SERDES_RX16- D53 SERDES_TX16-

A54 SD_DATA0 B54 SD_CMD C54 TYPE0# D54 TYPE3#

A55 SERDES_TX4+ B55 SERDES_RX4+ C55 SERDES_RX17+ D55 SERDES_TX17+

A56 SERDES_TX4- B56 SERDES_TX4- C56 SERDES_RX17- D56 SERDES_TX17-

A57 GND B57 SD_WP C57 TYPE1# D57 TYPE2#

A58 NC B58 NC C58 NC D58 NC

A59 NC B59 NC C59 NC D59 NC

A60 GND B60 GND C60 GND D60 GND (FIXED)

A61 NC B61 NC C61 NC D61 NC

D48 SSI_RXD1/TDM

_RxD1/User

Defined

D49 SSI_TFS1/TDM_

TxFS1/User

Defined

RxFS1/User

Defined

A62 NC B62 NC C62 NC D62 NC

A63 SD_DATA1 B63 SD_CD# C63 MDIO2 (clause 22

or 45)

A64 NC B64 NC C64 GND D64 LP_TAMPER_DE

A65 NC B65 NC C65 NC D65 NC

A66 GND B66 WAKE0# C66 NC D66 NC

A67 SD_DATA2 B67 WAKE1# C67 CE_PA12 / LAD00 D67 GND

48

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

D63 MDC2 (Clause

45)

T_BAT

Page 49

Controls, LEDs, and Connectors

Table 3-1 COM Express Connector Pinout (continued)

Row A Row B Row C Row D

A68 SERDES_TX0+ B68 SERDES_RX0+ C68 NC D68 NC

A69 SERDES_TX0- B69 SERDES_RX0- C69 NC D69 NC

A70 GND B70 GND C70 GND (FIXED) D70 GND (FIXED)

A71 LVDS_A0+ B71 LVDS_B0+ C71 NC D71 NC

A72 LVDS_A0- B72 LVDS_B0- C72 NC D72 NC

A73 LVDS_A1+ B73 LVDS_B1+ C73 DDI1_CTRLDATA/

RSVD/User

Display

A74 LVDS_A1- B74 LVDS_B1- C74 NC D74 NC

A75 LVDS_A2+ B75 LVDS_B2+ C75 NC D75 NC

A76 LVDS_A2- B76 LVDS_B2- C76 GND D76 GND

A77 LVDS_VDD_EN B77 LVDS_B3+ C77 CE_PA13 / LGPL2 D77 CE_PA14 /

A78 LVDS_A3+ B78 LVDS_B3- C78 NC D78 NC

A79 LVDS_A3- B79 LVDS_BKLT_EN C79 NC D79 NC

A80 GND B80 GND C80 GND (FIXED) D80 GND

A81 LVDS_A_CK+ B81 LVDS_B_CK+ C81 CE_PA15 / LGPL3 D81 CE_PA20

A82 LVDS_A_CK- B82 LVDS_B_CK- C82 CE_PA16 / LGPL4 D82 CE_PA21

A83 LVDS_I2C_CK B83 LVDS_BKLT_CTRL C83 IRQ01 D83 CE_PA18

A84 LVDS_I2C_DAT B84 VCC_5V_SBY C84 GND D84 GND

A85 SD_DATA3 B85 VCC_5V_SBY C85 IRQ02 D85 CE_PA19

A86 KBD_RST# B86 VCC_5V_SBY C86 CE_PA17 /

IRQ_IN3

A87 KBD_A20GATE B87 VCC_5V_SBY C87 GND D87 GND

D73 DDI1_CTRLCLK/

RSVD/User

Display

LWE0_B

D86 CE_PA24

A88 SERDES_CK_REF+B88 SPI_CS1# C88 CE_PA25 / GPI0 D88 CE_PA29 /

GPO0

A89 SERDES_CK_REF-B89 VGA_RED C89 CE_PA26 / GPI1 D89 CE_PA30 /

GPO1

A90 GND B90 GND C90 GND (FIXED) D90 GND

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

49

Page 50

Controls, LEDs, and Connectors

Table 3-1 COM Express Connector Pinout (continued)

Row A Row B Row C Row D

A91 SPI_CS0# B91 VGA_GRN C91 CE_PA27 / GPI2 D91 CE_PA31 /

GPO2

A92 SPI_MISO B92 VGA_BLU C92 CE_PA28 / GPI3 D92 CE_PB0

A93 SD_CLK B93 VGA_HSYNC C93 GND D93 GND

A94 SPI_CLK B94 VGA_VSYNC C94 CE_PB1 D94 CE_PB8

A95 SPI_MOSI B95 VGA_I2C_CK C95 CE_PB2 D95 CE_PB9

A96 GND B96 VGA_I2C_DAT C96 GND D96 GND

A97 VCC_12V B97 CE_PB31 C97 CE_PB3 D97 CE_PB21

A98 VCC_12V B98 CE_PA22 C98 SPI_CS2# D98 CE_PB22

A99 VCC_12V B99 CE_PA23 C99 SPI_CS3# D99 CE_PB23

A100 GND B100 GND C100 GND (FIXED) D100 GND (FIXED)

A101 VCC_12V B101 VCC_12V C101 SGMII_CLK+ D101 CE_PB29

A102 VCC_12V B102 VCC_12V C102 SGMII_CLK- D102 CE_PB30

A103 VCC_12V B103 VCC_12V C103 GND D103 GND

A104 VCC_12V B104 VCC_12V C104 VCC_12V D104 VCC_12V

A105 VCC_12V B105 VCC_12V C105 VCC_12V D105 VCC_12V

A106 VCC_12V B106 VCC_12V C106 VCC_12V D106 VCC_12V

A107 VCC_12V B107 VCC_12V C107 VCC_12V D107 VCC_12V

A108 VCC_12V B108 VCC_12V C108 VCC_12V D108 VCC_12V

A109 VCC_12V B109 VCC_12V C109 VCC_12V D109 VCC_12V

A110 GND B110 GND C110 GND D110 GND

50

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 51

3.2.2 Default Switch Settings

Switches that are not mentioned should always be switched OFF.

3.2.2.1 DIP Switch Setting

Table 3-2 Configure I2CMUX

S1_23 Description

Controls, LEDs, and Connectors

OFF SPI ON MODULE

ON SPI ON CARRIER

3.2.2.2 Boot Location Configuration

Table 3-3 Boot Location Configuration

S4_14 S4_23 S5_14 S5_23 Description

ON ON ON ON BOOT FROM PCIE 1

ON ON ON OFF BOOT FROM PCIE 2

ON ON OFF ON RESERVED

ON ON OFF OFF RESERVED

ON OFF ON ON BOOT FROM DDR

ON OFF ON OFF BOOT FROM PCIE 3

ON OFF OFF ON BOOT FROM SPI

ON OFF OFF OFF *BOOT FROM SDHC

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

51

Page 52

Controls, LEDs, and Connectors

Table 3-3 Boot Location Configuration (continued)

S4_14 S4_23 S5_14 S5_23 Description

OFF ON ON ON BOOT FROM 8BIT

OFF ON ON OFF RESERVED

OFF ON OFF ON BOOT FROM 8BIT

OFF ON OFF OFF RESERVED

OFF OFF ON ON BOOT FROM 16BIT NOR

OFF OFF ON OFF BOOT FROM 8BIT NOR

OFF OFF OFF ON BOOT FROM 16BIT NOR

NANDFLASH SMALL PAGE

NANDFLASH LARGE PAGE

FLASH

FLASH

FLASH

OFF OFF OFF OFF BOOT FROM 16BIT NOR

3.2.2.3 SPI CS0 Configuration

Table 3-4 SPI CS0 Configuration

S1_23 Description

OFF SPI ON MODULE

ON SPI ON CARRIER

FLASH

52

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 53

Controls, LEDs, and Connectors

3.2.2.4 SDHC Write-protect

Table 3-5 SDHC Write-protect

S3_14 SDHC WP ON CARRIER S3_23 SDHC WP ON MODULE

OFF Write protect OFF Write protect

ON Write ON Write

3.2.3 System Status LEDs

LEDs indicate the status of the power and the CPU before any software is run.

Table 3-6 System LED Status

Location Status

D1 CPU Core Power OK(1.0V)

D2 DDR3 Power OK(1.5V)

D3 3.3V Power OK

D4 2.5V Power OK

D5 1.2V Power OK

D6 1.8V Power OK

D9 CPU in Sleep state

D10 1.0V_SW Power OK

D11 1.0V_SW_IO Power OK

D12 3.3V_SW Power OK

D13 2.5V_SW Power OK

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

53

Page 54

Controls, LEDs, and Connectors

3.2.4 JTAG

COMX-P1022 supports JTAG method for CPU and GE PHY debugging.

Table 3-7 CPU Debug (P1)

Pin Signal Pin Signal

1 JTAG_TDO 2 NC

3 JTAG_TDI 4 COP_TRST#

5 COP_RUNSTOP 6 COP_VSENSE

7 JTAG_TCK 8 P_CKSTP_IN#

9 JTAG_TMS 10 NC

11 COP_SRST# 12 GND

13 COP_HRST# 14 NC

15 P_CKSTP_OUT# 16 GND

Table 3-8 GE PHY Debug (Test Point14-19)

Test Point Signal

TP2 JTAG_GE_TDI

TP3 JTAG_GE_TDO

TP4 JTAG_GE_TCK

TP5 JTAG_GE_TMS

TP6 JTAG_GE_TRST#

3.2.5 GPIO

Table 3-9 GPIO Description

GPIO FUNCTION

TRIG_OUT /GPIO3_21 SATA_ACT#

54

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 55

Table 3-9 GPIO Description (continued)

GPIO FUNCTION

IRQ11/ GPIO3_13 WATCHDOG

TRIG_IN/GPIO3_20 LVDS_ENABLE

UDE1_B/GPIO3_17 LVDS_ENAVDD

POWER_OK/GPIO3_19 LVDS_PWM

IRQ6/GPIO2_31 MUX_I2C

IRQ7/ GPIO3_9 GPI0

IRQ8/ GPIO3_10 GPI1

IRQ9/ GPIO3_11 GPI2

IRQ10/ GPIO3_12 GPI3

MCP0_B/GPIO3_14 GPO0

MCP1_B/GPIO3_15 GPO1

Controls, LEDs, and Connectors

UDE0_B/GPIO3_16 GPO2

READY_P1/GPIO3_22 GPO3

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

55

Page 56

Controls, LEDs, and Connectors

56

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 57

Functional Description

4.1 Block Diagram

Figure 4-1 Block Diagram

Chapter 4

4.2 Processor

COMX-P1022 COM Express Module supports the Freescale P1022 processor and compatible

with the P1013 processor. P1022 includes the following features:

Dual e500v2 Core, 533MHz to 1.066 GHz clock frequency

Power consumption of less than 6 W at 1.066 GHz

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

57

Page 58

Functional Description

32 KB instruction and 32 KB data first-level cache (L1) for each core

256 KB second-level cache (L2) with ECC

64 bit DDR2/DDR3 controller with ECC supports data rate of up to 667 Mbps per pin

31x31 mm 689-pin wirebond power-BGA

45 nm SOI process technology

Each e500 core complex contains a separate 32-KB, eight-way set associative level 1 (L1)

instruction and data caches to provide the execution units and registers rapid access to

instructions and data. The 32 KB cache is divided into eight ways and 128 sets, so there is a

total of 1024 blocks. The size of each block is eight words (32 bytes).

Figure 4-2 P1022 Processor Block Diagram

4.3 Memory

P1022 supports 64-bit DDR2/DDR3 SDRAM memory controller with ECC.

The COM-E module supports a 2GB dual-rank DDR3 with ECC SO-UDIMM memory modules

which can be run at 667MHz.

58

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 59

4.3.1 SDRAM

COMX-P1022 COM Express Module only supports 2 GB DDR3 667 MT/s DDR3+ECC arranged in

two ranks in one slot.

4.3.2 SD Card

COMX-P1022 COM Express Module has a microSD card slot on-module with a 2 GB SD card

installed. The SD card stores the Bootloader and the Operating System.

The eSDHC acts as a bridge, passing host bus transactions to SD/MMC cards by sending

commands and performing data accesses to or from the cards. It handles the SD/MMC

protocol at the transmission level.

4.3.3 SPI Flash

Functional Description

COMX-P1022 COM Express Module has an SPI socket on-module with a 4 MB SPI Flash installed.

The U-Boot is installed in the SPI flash on module.

The flash was divided into 3 areas: configure data, U-boot, and Environment argument area.

Figure 4-3 SPI Area for U-boot

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

59

Page 60

Functional Description

4.3.4 EEPROM

COMX-P1022 COM Express Module uses two 256x8(2 Kb) I2C EEPROM for boot up

configuration.

4.4 Video

COMX-P1022 COM Express Module supports the following:

DVI

LV DS

4.5 Audio

COMX-P1022 supports an I2S/SSI interface to COM-Express.

4.6 I2C

4.6.1 I2C Bus

There are two I2C buses included in P1022 (I2C#1 and I2C#2).

I2C input clock is equal to platform frequency / 2, which is 266MHz. The desired I2C SCL

frequency is 400KHz so the clock divisor is 667.

There is one device attached to I2C#1 and 5 devices attached to I2C#2. The following tables

describe the I2C buses and devices:

Table 4-1 I2C#1 Address Distribution

IIC1 ADDRESS

EEPROM 0XA0

60

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 61

Table 4-2 I2C#2 Address Distribution

IIC2 ADDRESS

ADT7461 0X98

DDR3 0XA6 0X66 0x36

RTC 0XD0

IIC MUX 0XE0

TFP410 0X72

4.6.2 I2C EEPROM

The I2C EEPROM AT24C02B is located on I2C#1. It is used for board information storage (such

as MAC Address, board ID etc) or for other purposes.

The EEPROM provides 2048 bits of serial electrically erasable and programmable read-only

memory (EEPROM) organized as 256 words of 8 bits each. The device address is 0xA0, it can be

accessed only at I2C#1.

Functional Description

AT24C02 support SEQUENTIAL READ and page write.

Sequential reads are initiated by either a current address read or a random address read. After

the microcontroller receives a data word, it responds with an acknowledge. As long as the

EEPROM receives an acknowledge, it will continue to increment the data word address and

serially clock out sequential data words. When the memory address limit is reached, the data

word address will "roll over" and the sequential read will continue.

AT24C02's 32K EEPROM was internally organized with 32 pages of 8 bytes each. A page write is

initiated the same as a byte write, but the microcontroller does not send a stop condition after

the first data word is clocked in. Instead, after the EEPROM acknowledges receipt of the first

data word, the microcontroller can transmit up to seven more data words.

4.6.3 I2C Device - Thermal Sensor

The thermal sensor ADT7461 is a dual-channel digital thermometer and under/over

temperature alarm, intended for use in PCs and thermal management systems. It is located on

I2C#2. The device address is 0x98. It is designed for monitoring P1022 processor temperature.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

61

Page 62

Functional Description

The ADT7461 can accurately measure the temperature of a remote thermal diode to ±1°C and

the ambient temperature to ±3°C. The temperature measurement range defaults to 0°C to

+127°C, but can be switched to a wider measurement range of?55°C to +150°C. The ADT7461

communicates over a 2-wire serial interface compatible with system management bus

(SMBus) standards. An ALERT output signals when the on-chip or remote temperature is out of

range. The THERM output is a comparator output that allows on/off control of a cooling fan.

The ALERT output can be reconfigured as a second THERM output, if required.

By default, u-boot should mask THERM and ALERT output, set the temperature measurement

range to 0°C to +127°C. And u-boot should provide u-boot commands for setting operation

mode, and getting the monitoring temperature.

4.6.4 SODIMM SDP EEPROM

The SODIMM SDP EEPROM is connected to I2C#2. I2C address for SDP EEPROM of memory

module is 0xA6 and 0x66.

Commonly the memory module information on SDP EEPROM can be used to configure the

memory controller. But in this case, we use fix parameters to configure the memory controller,

so the BSP won't read the SDP EEPROM.

4.6.5 RTC and Watchdog Timer

The RTC/WDT M41ST85W is located on I2C#2, and the device address is 0xD0.

The M41ST85W is a combination Serial Real-Time Clock, Microprocessor Supervisor, and

NVRAM Supervisor. It is built in a low power CMOS SRAM process and has a 64-byte memory

space with 44 bytes of NVRAM and 20 memory-mapped RTC registers. The RTC registers are

configured in binary coded decimal (BCD) format. The M41ST85W has 512-bit, static CMOS

SRAM organized as 64 words by 8 bits. A built-in 32.768 kHz oscillator and 8 bytes of the SRAM

are used for the clock/calendar function and are configured in binary coded decimal (BCD)

format. An additional 12 bytes of RAM provide status/control of Alarm, Watchdog and Square

Wave functions. Addresses and data are transferred serially via a two line, bi-directional I2C

interface. The built-in address register is incremented automatically after each WRITE or READ

data byte. The M41ST85W can detect power failures and automatically switches to the battery

supply when a power failure occurs. The energy needed to sustain the SRAM and clock

operations can be supplied by a small lithium button-cell supply when a power failure occurs.

62

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

Page 63

4.6.6 USB Hub

There is one USB2514 located on I2C#2, and the device address is 0x58.

USB2514 is a USB hub controller IC with 4 downstream ports for embedded USB solutions. The

4-port hub is fully compliant with the USB 2.0 Specification and will attach to an upstream port

as a Full-Speed Hub or as a Full-/High-Speed Hub, and High Speed (if operating as a High-Speed

Hub) downstream devices on all of the enabled downstream ports.

The SMSC Hub must be configured in order to correctly function when attached to a USB host

controller. There are three principal ways to configure the hub: SMBus, EEPROM, or by internal

default setting. In all cases, the configuration method will be determined by the CFG_SEL2,

CFG_SEL1 and CFG_SEL0 pins immediately after RESET_N negation.

In SMBus case, the CFG_SEL1 and CFG_SEL0 pins must be 01, so the Hub can be configured as

an SMBus slave for external download of user-defined descriptors.

The USB Hub can work well even without any configuration. So U-boot doesn't need to access

the USB Hub registers through I2C bus unless special requirements are need.

Functional Description

4.6.7 PCA9545

The PCA9545 is a quad bi-directional translating switch controlled via the I2C bus. The SCL/SDA

upstream pair fans out to four downstream pairs, or channels. Any individual SCx/SDx channel

or combination of channels can be selected, determined by the contents of the programmable

control register. Four interrupt inputs, INT0 to INT3, one for each of the downstream pairs, are

provided, but in this case, they are not used.

COMX-P1022 COM Express Module Installation and Use (6806800M04C)

63

Page 64

Functional Description

PCA9545's i2c address is E0. There is only a control register in PCA9545 that can be read or

written via I2C#1.

Table 4-3 PCA955 Register

Bit Name Description

0 BO 0: Channel 0 disable

1 B1 0: Channel 1 disable

2 B2 0: Channel 2 disable

1: Channel 0 enable

1: Channel 1 enable

1: Channel 2 enable

3 B3 0: Channel 3 disable

4.6.8 TFP410

There is one TFP410 located on I2C#2, and the device address is 0x70.

The TFP410 is a DVI-compliant digital transmitter that is used in digital host monitor systems

to T.M.D.S. encode and serialize RGB pixel data streams. TFP410 supports resolutions from

VGA to UXGA and can be controlled in two ways: 1) configuration and state pins or 2) the

programmable I2C serial interface.

The host in a digital display system, usually a PC or consumer electronics device, contains a

DVI-compatible transmitter such as the TI TFP410 that receives 24-bit pixel data along with

appropriate control signals. The TFP410 encodes the signals into a high speed, low voltage,

differential serial bit stream optimized for transmission over a twisted-pair cable to a display

device. The display device, usually a flat-panel monitor, requires a DVI compatible receiver like

the TI TFP401 to decode the serial bit stream back to the same 24-bit pixel data and control

signals that originated at the host. This decoded data can then be applied directly to the flat

panel drive circuitry to produce an image on the display. Since the host and display can be

separated by distances up to 5 meters or more, serial transmission of the pixel data is preferred

64

1: Channel 3 enable