Artesyn Centellis 4100 Installation

Centellis 4100

Installation and Use

P/N: 6806800D82E

April 2015

©

Copyright 2014 - 2015 Artesyn Embedded Technologies, Inc.

All rights reserved.

Trademarks

Artesyn Embedded Technologies, Artesyn and the Artesyn Embedded Technologies logo are trademarks and service marks of

Artesyn Embedded Technologies, Inc.© 2014 Artesyn Embedded Technologies, Inc. All other product or service names are the

property of their respective owners.

Intel® is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

Java™ and all other Java-based marks are trademarks or registered trademarks of Oracle America, Inc. in the U.S. and other countries.

Microsoft®, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

Microsoft Corporation.

PICMG®, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

Industrial Computer Manufacturers Group.

UNIX® is a registered trademark of The Open Group in the United States and other countries.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Artesyn assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Artesyn reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Artesyn to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

an Artesyn website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Artesyn.

It is possible that this publication may contain reference to or information about Artesyn products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Artesyn intends to announce such Artesyn products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Artesyn.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Artesyn Embedded Technologies Artesyn Embedded Technologies

Marketing Communications

2900 S. Diablo Way, Suite 190

Tempe, Arizona 85282

Lilienthalstr. 17-19

85579 Neubiberg/Munich

Germany

Contents

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1 System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.1.1 Shelf. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1.1.2 Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.1.3 Shelf Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.1.4 Node Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.1.5 Hub Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.1.6 Rear Transition Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.1.7 AMC Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.1.8 Power Entry Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.1.9 Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.1.10 Air Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.2 System Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.3 Shelf Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.4 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1.5 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.2 Site Planning Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.2.1 Receiving and Unpacking the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.2.2 Site and Installation Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2.2.3 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

2.2.3.1 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

2.2.3.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2.2.4 Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2.2.5 Mounting Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2.2.6 Airflow Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Centellis 4100 Installation and Use (6806800D82E)

3

Contents

Contents

Contents

2.2.7 Acoustic Noise Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2.3 Site Planning Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3 System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.2 Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.2.1 Type Label Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.2.2 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.2.3 Tools You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.3.1 Installing the System in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.3.2 Ground System/Bonding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.3.3 Powering-Up the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.4 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.4.1 Powering Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.4.2 Removing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4 FRU Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.2 Installing RTMs, Blades and Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.2.1 Module Installation and Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.2.1.1 Installing the RTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.2.1.2 Removing the RTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

4.2.2 Node Blade Installation and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

4.2.2.1 Installing the Node Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4.2.2.2 Removing the Node Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.2.3 Installing and Removing the Shelf Manager Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

4.2.3.1 Non-Powered System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

4.2.3.2 Powered System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

4.2.4 Installing and Removing Alarm Board ATCA-A100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

4.2.4.1 Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

4.2.4.2 Non-Powered System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

4.2.4.3 Powered System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4.3 Unused Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4

Centellis 4100 Installation and Use (6806800D82E)

Contents

4.4 Installing Power Entry Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4.5 Installing Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

4.6 Installing an Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

4.6.1 Replacing the Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

4.6.2 Cleaning the Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

4.6.3 Storing the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

5 Non-Field-Replaceable Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

5.2 Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

5.2.1 Base Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

5.2.2 Fabric Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

5.2.3 Update Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

5.2.4 Synchronization Clock Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

5.3 Shelf Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

6 Configuring and Operating the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.2 Network Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

6.2.1 Default VLAN Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

6.2.2 Slot Numbers and Slot Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

6.2.3 Shelf Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

6.2.3.1 Setting the Shelf Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

6.2.3.2 Shelf Address Reading Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

6.2.4 IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

6.2.4.1 Shelf Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

6.2.4.2 Hub Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

6.2.4.3 Node Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

6.2.5 Restoring Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

6.3 Accessing System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

6.4 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

6.4.1 Supported Operating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

6.4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

6.4.3 Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Centellis 4100 Installation and Use (6806800D82E)

5

Contents

Contents

Contents

6.5 Power Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

6.5.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

6.5.2 Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

6.5.2.1 Low Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

6.5.2.2 High Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

6.5.2.3 Power Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

6.5.3 PEM Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

6.5.3.1 Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

6.5.3.2 Power Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

6.6 Cooling Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

6.7 Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

6.7.1 Cold Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

6.7.1.1 Heartbeat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

6.7.1.2 Data Replication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

6.7.1.3 HPI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

6.7.2 System Start-Up Behavior and Dependencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

6.7.2.1 Shelf Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

6.7.2.2 Hub Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

6.7.2.3 System Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

6.7.3 Redundancy Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

6.7.3.1 Shelf Manger Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

6.7.3.2 Shelf Manager Takeover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

6.7.3.3 Shelf Manager Failover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

6.7.3.4 Shelf Manager Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

6.7.3.5 Shelf Manager Extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

6.8 Blade Insertion and Extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

6.8.1 Power-On After Blade Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

6.8.2 Power-Down Before Blade Extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

A Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

A.1 Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

A.1.1 Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

A.1.2 After Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

A.1.3 Blower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

6

Centellis 4100 Installation and Use (6806800D82E)

Contents

B Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

B.1 Artesyn Embedded Technologies - Embedded Computing Documentation . . . . . . . . . . . . . . .209

Centellis 4100 Installation and Use (6806800D82E)

7

Contents

Contents

Contents

8

Centellis 4100 Installation and Use (6806800D82E)

List of Tables

Table 1-1 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 1-2 Ordering Information Excerpt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 2-1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 2-2 Critical Temperature Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 2-3 System Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 2-4 Dimensions and Weight of System and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 6-1 Slot Numbering and Slot Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Table 6-2 Shelf IP Connectivity Record #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

Table 6-3 Shelf IP Connectivity Record #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

Table 6-4 Hub Blade IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Table 6-5 Access to System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Table 6-6 Software Available on System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Table 6-7 Available Software Upgrade Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Table 6-8 Start up Dependencies of the Shelf Manager and the Hub Blade . . . . . . . . . . . . . . . . . . . . . 196

Table B-1 Artesyn Embedded Technologies - Embedded Computing Publications . . . . . . . . . . . . . .209

Centellis 4100 Installation and Use (6806800D82E)

9

List of Tables

10

Centellis 4100 Installation and Use (6806800D82E)

List of Figures

Figure 1-1 System Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 1-2 System Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 1-3 Slot Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 1-4 AdvancedTCA System Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 1-5 Shelf Management Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 1-6 Declaration of Comformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 2-1 Hot Spot Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 2-2 Hot Spot Air Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 2-3 Hot Spot Power Entry Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 2-4 Rack Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 2-5 Shelf Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 2-6 Planning Checklist 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 2-7 Planning Checklist 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 3-1 Rack Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 3-2 Grounding Lugs at the System's Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 4-1 ATCA-M100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 4-2 Jumper Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 4-3 Rotary Switch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 4-4 PEM Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 5-1 Location of Internal Components (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Figure 5-2 Location of Zones on a Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 5-3 Base Interface: Dual Star Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Figure 5-4 Fabric Interface with a Dual Star Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Figure 5-5 Update Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 5-6 Shelf Configuration Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Figure 6-1 ATCA-F120 Switch Management Fabric Interface Bridge Configuration . . . . . . . .166

Figure 6-2 ATCA-F120 Switch Management Base Interface Bridge Configuration . . . . . . . . . 167

Figure 6-3 Dual Star Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 6-4 IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Figure 6-5 IP Address Scheme for the Out-Of-Band Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Figure 6-6 Power Entry Modules Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Figure 6-7 Functional Block Diagram of a PEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Figure 6-8 Four-PEM Shelf Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Figure 6-9 Shelf Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Figure 6-10 Block Diagram of a Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 6-11 System Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

Centellis 4100 Installation and Use (6806800D82E)

11

List of Figures

Figure 6-12 Shelf Manager Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 6-13 Link Failover after Active Shelf Manager Failover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Figure 6-14 Blade Power-On After Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Figure 6-15 Blade Power-Down Before Extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

12

Centellis 4100 Installation and Use (6806800D82E)

About this Manual

Overview of Contents

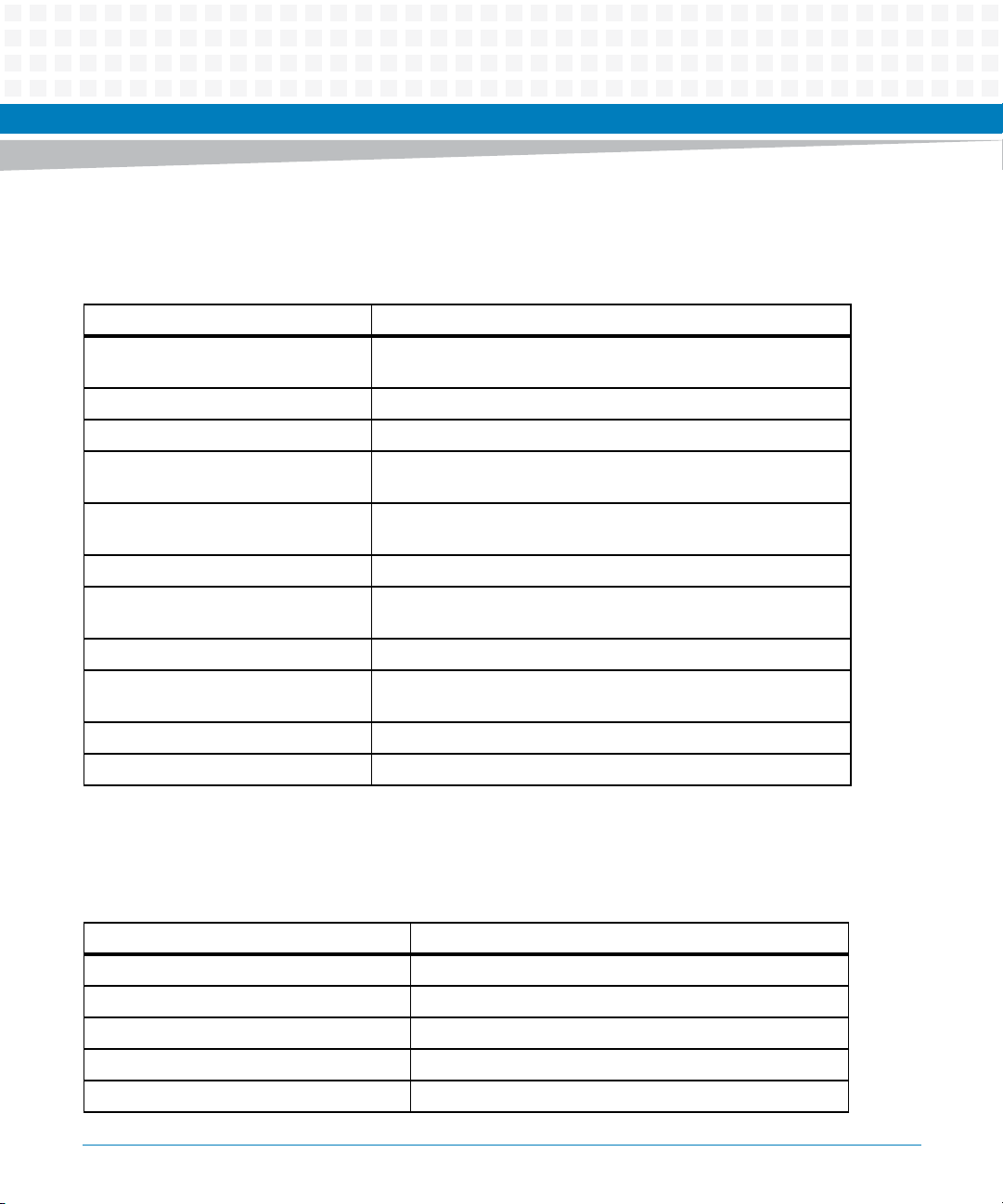

This Installation and Use manual is organized as follows:

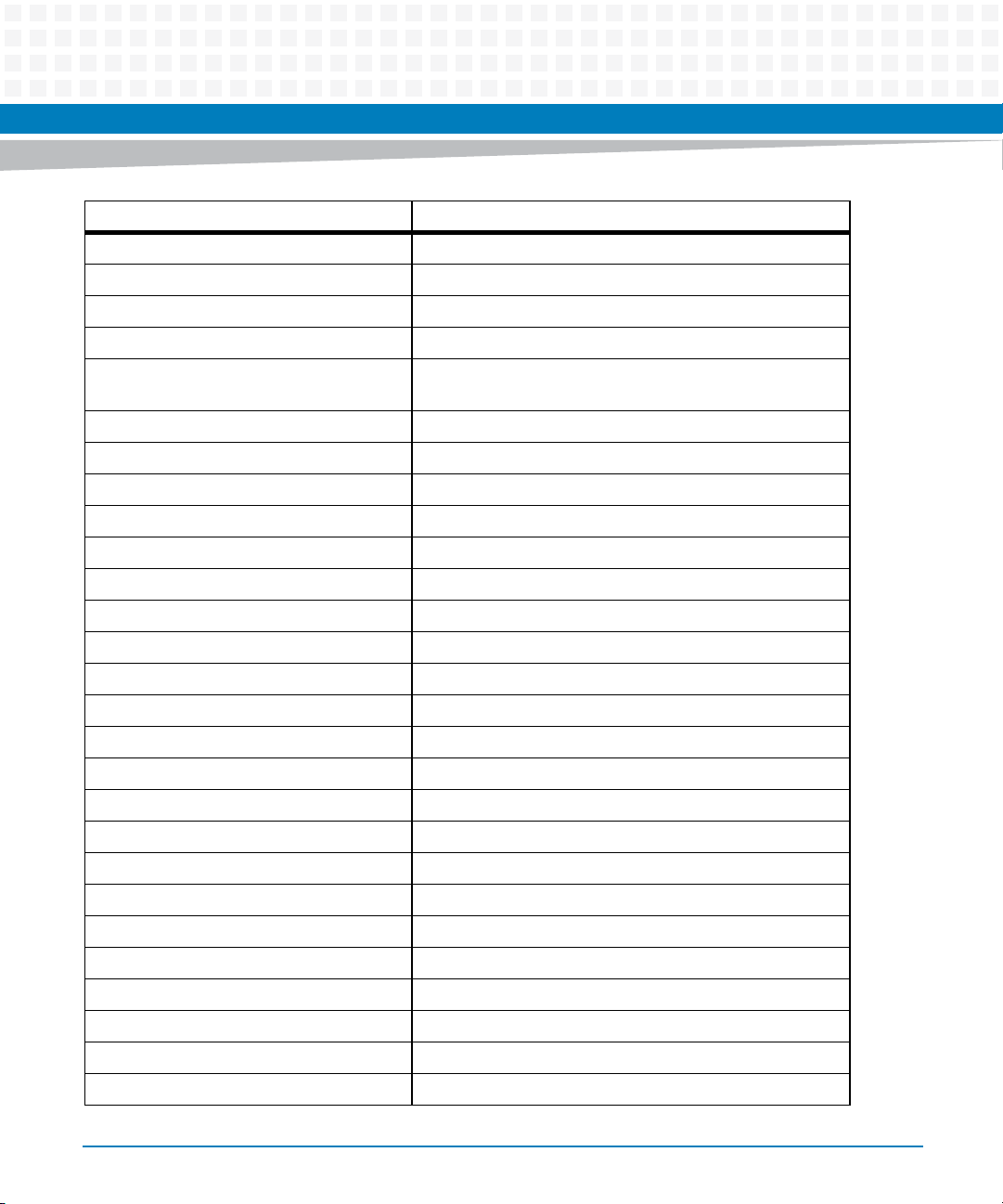

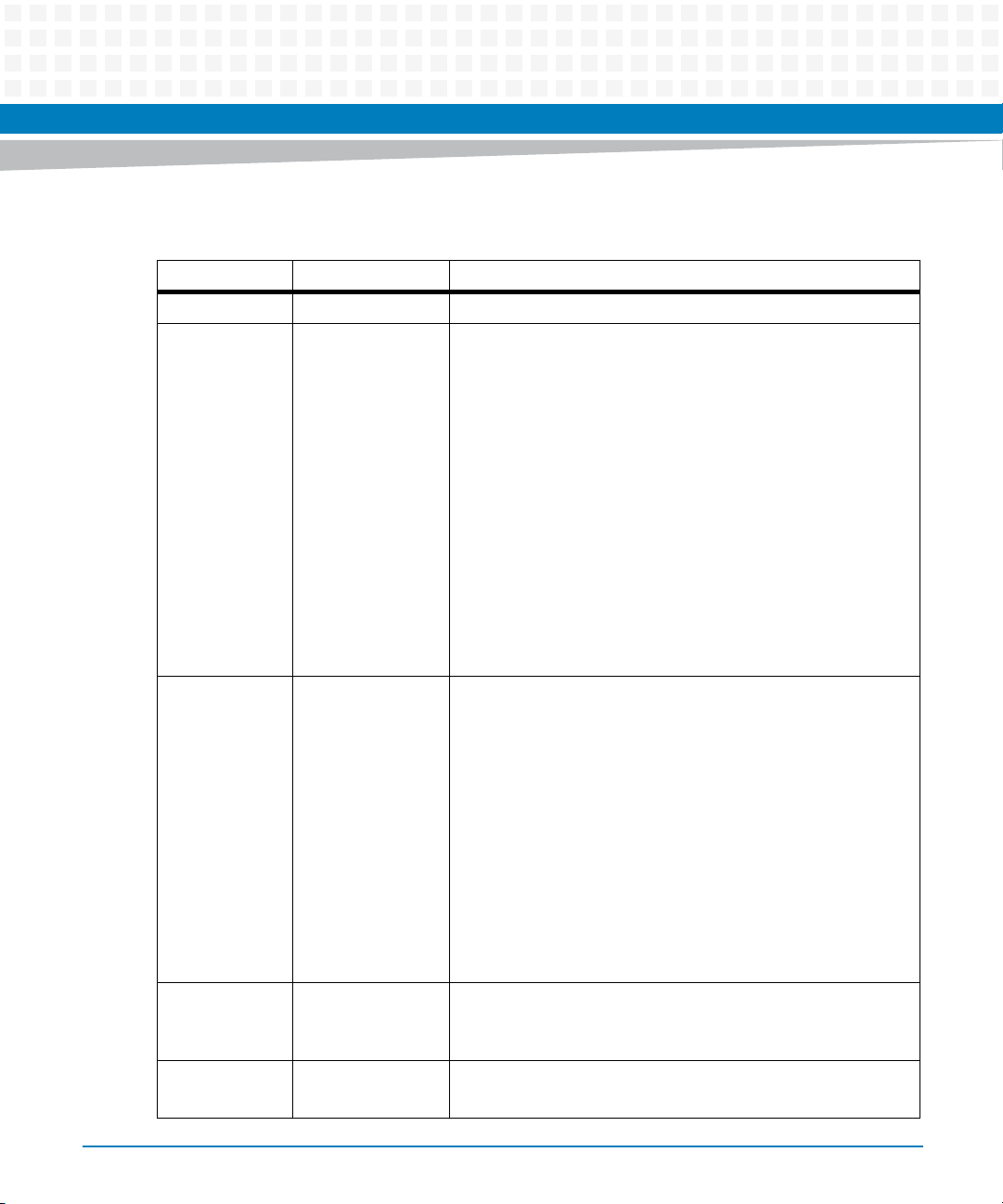

Chapter Description

About this Manual Lists all conventions and abbreviations used in this manual and

outlines the revision history

Safety Notes Describes the safety information which has to be regarded

Sicherheitshinweise Translation of the chapter "Safety Information" to German

System Overview Provides an overview of the features of the system and lists order

numbers

Site Preparation Provides site plannning considerations and checklists, describes

the requirements and conditions

System Installation Describes how to install and run the system

FRU Installation Describes how to install and replace blades, RTMs, power

components, blowers, and air filter

Non-Field-Replaceable Units Describes backplane

Configuring and Operating the

System

Troubleshooting This chapter helps you to solve problems which may occur

Related Documentation Lists related documentation and specifications

Describes how to access the system and how to configure the

system (network configuration, redundancy)

Abbreviations

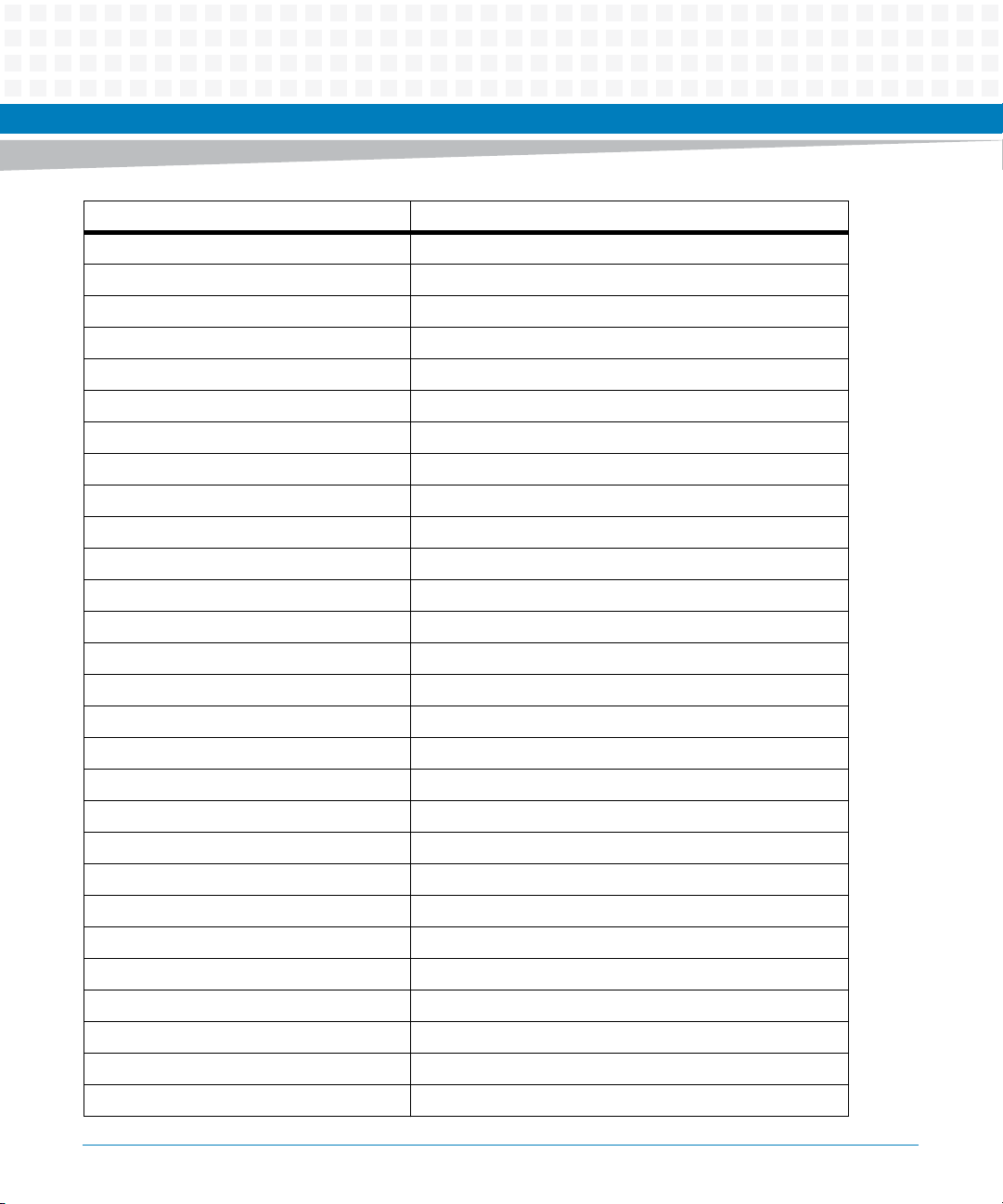

This document uses the following abbreviations:

Abbreviation Definition

AdvancedTCA Advanced Telecom Computing Architecture

AMC AdvancedTCA Mezzanine Card

ANSI American National Standards Institute

ARP Address Resolution Protocol

ARTM AdvancedTCA Rear Transition Module

Centellis 4100 Installation and Use (6806800D82E)

13

About this Manual

Abbreviation Definition

ATCA Advanced Telecommunications Computing Architecture

AWG American Wire Gauge

BBS Basic Blade Services

CGL Carrier Grade Linux

CISPR Comité International Spécial des Perturbations

Radioélectriques

CO Central Office

CPU Central Processing Unit

DC Direct Current

DHCP Dynamic Host Configuration Protocol

EMC Electromagnetic Compatibility

EMI Electromagnetic Interference

About this Manual

EMV Elektromagnetische Vertraeglichkeit

EN European Norm

ESD Electrostatic Discharge

ETSI European Telecommunication Standards Institute

FAE Field Application Engineers

FCC Federal Communications Commission

FCU Firmware Upgrade Utility

FRU Field Replaceable Unit

FUMI Firmware Update Management Instrument

GmbH Gesellschaft mit beschraenkter Haftung

HA High Availability

HPI Hardware Platform Interface

HS Hot Swap

ID Identifier

IEC International Electric Code

IEEE Institute of Electrical and Electronics Engineers

14

Centellis 4100 Installation and Use (6806800D82E)

Abbreviation Definition

I/O Input / Output

IP Internet Protocol

IPM Intelligent Platform Management

IPMB Intelligent Platform Management Bus

IPMC Intelligent Platform Management Controller

IPMI Intelligent Platform Management Interface

LED Light Emitting Diode

MMC Mezzanine Management Controller

NAE National Academy of Engineering

NEBS Network Equipment Building System

NEC National Electric Code

About this Manual

OEM Original Equipment Manufacturer

OOB Out-of-band

OS Operating System

PCI Peripheral Component Interconnect

PEM Power Entry Module

PICMG PCI Industrial Computer Manufacturers Group

PMC PCI Mezzanine Card

RAM Random Access Memory

RMCP Remote Management Control Protocol

RoHS Restriction of Certain Hazardous Substances

ROM Read-Only Memory

RTM Rear Transition Module

SAF Service Availability Forum

SCSI Small Computer System Interface

SELV Safety Extra Low Voltage

SGA Shelf Geographical Address

ShM Shelf Manager

Centellis 4100 Installation and Use (6806800D82E)

15

About this Manual

Abbreviation Definition

ShMC Shelf Management Controller

SSH Secure Shell

SW Ethernet Switch

TDM Time-Division Multiplexing

TNV-2 Telecom Network Voltages without overvoltage

TPE Twisted-Pair Ethernet

UL Underwriters Laboratories

USB Universal Serial Bus

VCCI Voluntary Control Council for Interference

VLAN Virtual Local Area Network

WEEE Waste from Electrical and Electronic Equipment

About this Manual

Conventions

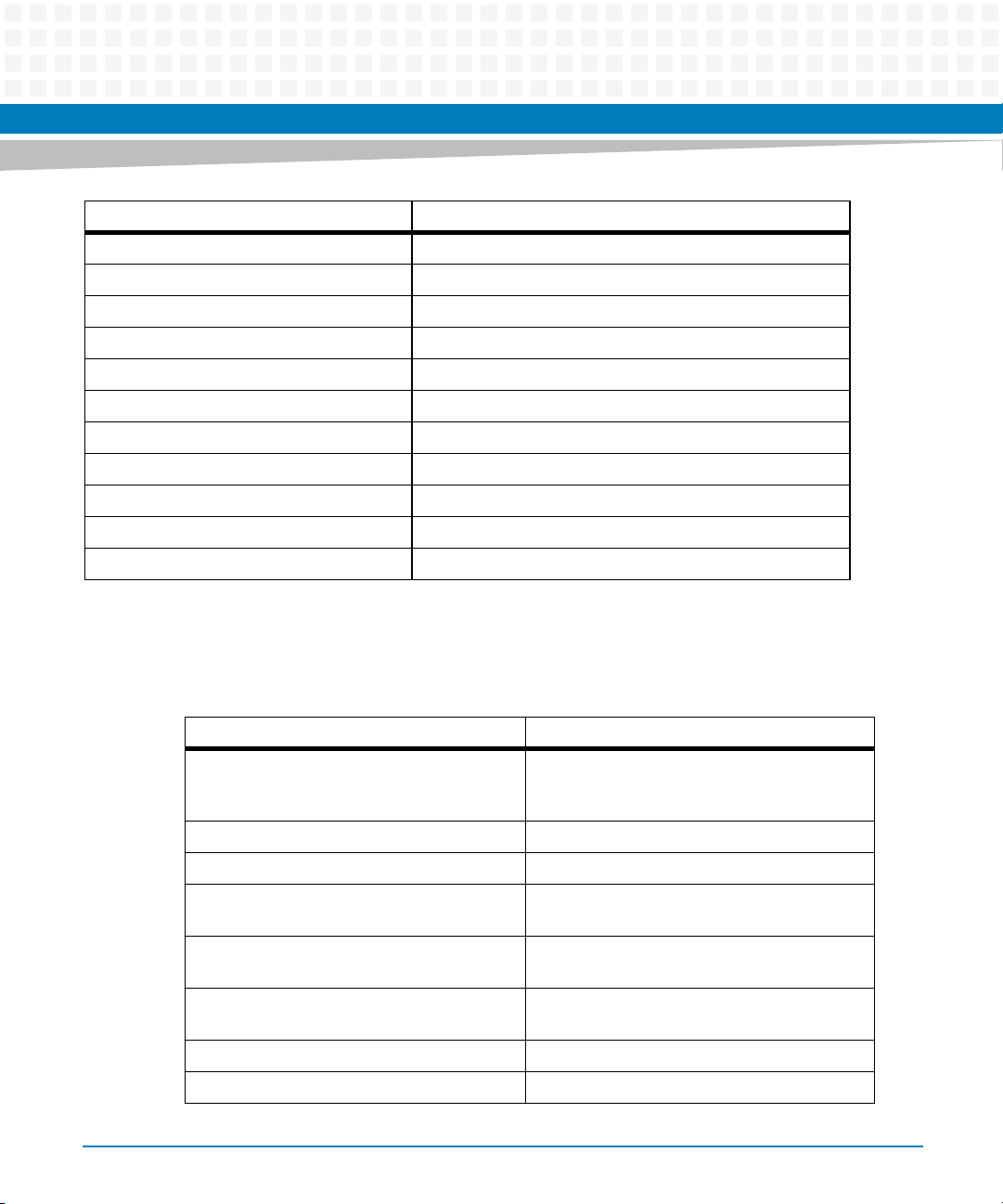

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related

Courier + Bold Used to characterize user input and to separate

Reference Used for references and for table and figure

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

16

(digits are 0 through F), for example used for

addresses and offsets

elements or commands in body text

it from system output

descriptions

Centellis 4100 Installation and Use (6806800D82E)

About this Manual

Notation Description

[text] Notation for software buttons to click on the

screen and parameter description

... Repeated item for example node 1, node 2, ...,

node 12

.

.

.

.. Ranges, for example: 0..4 means one of the

| Logical OR

Omission of information from

example/command that is not necessary at the

time being

integers 0,1,2,3, and 4 (used in registers)

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury

Indicates a hazardous situation which, if not

avoided, may result in minor or moderate

injury

Indicates a property damage message

No danger encountered. Pay attention to

important information

Centellis 4100 Installation and Use (6806800D82E)

17

About this Manual

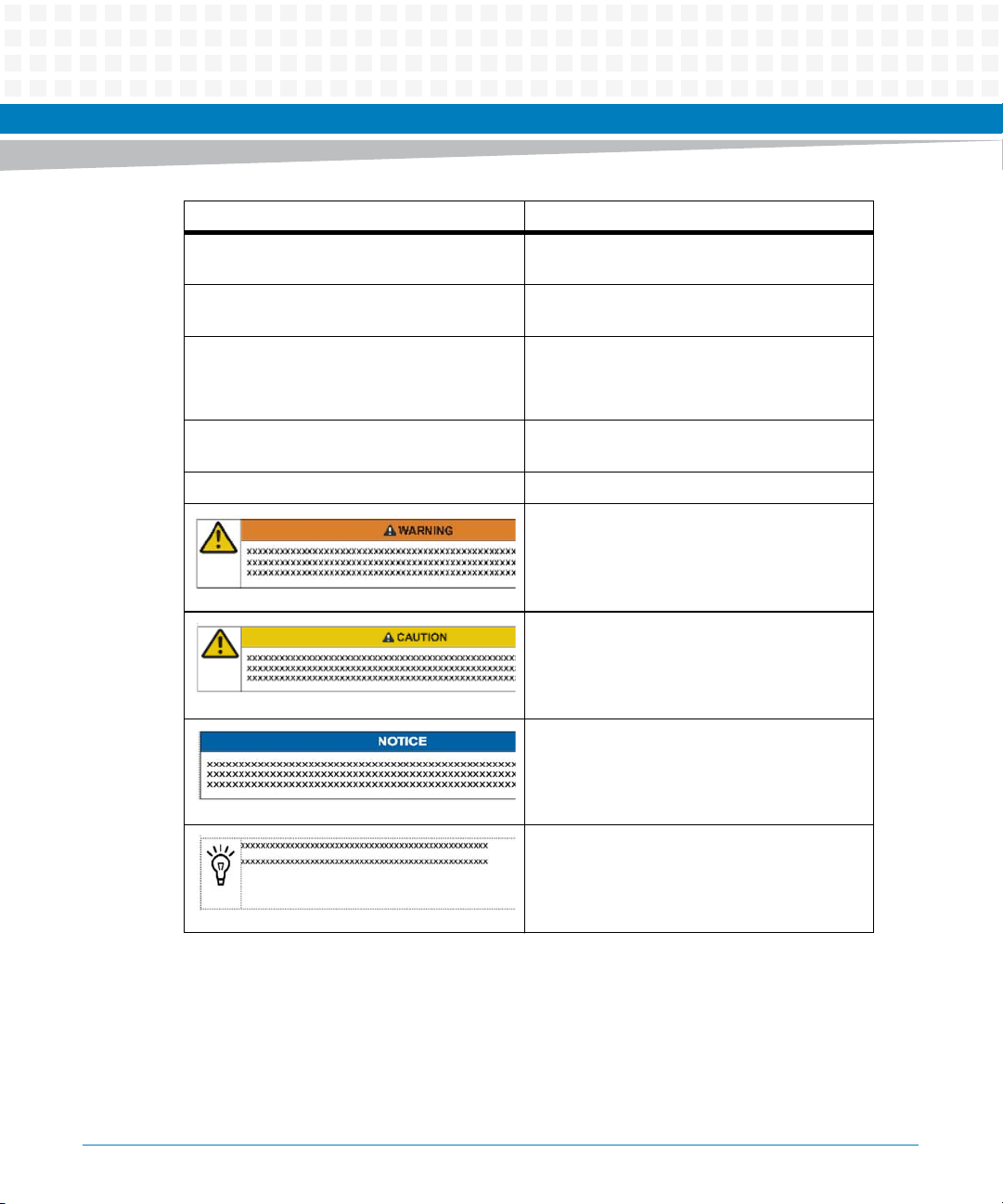

Summary of Changes

Order No. Date Description

6806800D82A October 2007 Preliminary Installation and Use

6806800D82B February 2008 Deleted German translation of safety notes in text

About this Manual

Added Figure "System Rear View" on page 51

Updated Ordering Information on page 63

Added Table "Critical Temperature Limits" on page 69

Added Figure "Hot Spot Air Inlet" on page 70, Figure "Hot Spot Air

Outlet" on page 71, and Figure "Hot Spot Power Entry Module"

on page 72

Updated Powering-Up the System on page 89

Added Before Installation on page 116

Updated Installing Power Entry Modules on page 126

Updated Installing Blowers on page 142

Updated chapter Chapter 6, Configuring and Operating the

System, on page 165

Editorial changes

18

6806800D82C July 2008 Added Figure "Declaration of Comformity" on page 62

Added Shelf Configuration on page 164

Changed heat dissipation values in Airflow Requirements on page

76 and Cooling Subsystem on page 191

Added Shelf Configuration on page 164

Corrected torque for feed cable connection

Replaced Figure "PEM Location" on page 126 and Figure "Power

Entry Modules Location" on page 186

Replaced Figure "Block Diagram of a Blower" on page 193

Deleted all occurrences of SNMP

Deleted glossary

Editorial changes

6806800D82D July 2010 Corrected the wire size defined for the PEM power

wiring in Requirements on page 81 and Installing the System in a

Rack on page 84

6806800D82E April 2015 Re-branded to Artesyn template.

Updated Table 2-4 on page 73.

Centellis 4100 Installation and Use (6806800D82E)

Safety Notes

This section provides warnings that precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed during all phases of

operation, service, and repair of this equipment. You should also employ all other safety

precautions necessary for the operation of the equipment in your operating environment.

Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

Artesyn Embedded Technologies - Embedded Computing intends to provide all

necessary information to install and handle the product in this manual. Because of the

complexity of this product and its various uses, we do not guarantee that the given

information is complete. If you need additional information, ask your Artesyn Embedded

Technologies - Embedded Computing representative.

The product has been designed to meet the standard industrial safety requirements. It must

only be used in its specific area of office telecommunication industry, industrial control, and

development. It must not be used in safety critical components, life supporting devices or on

aircraft.

Only personnel trained by Artesyn Embedded Technologies - Embedded Computing or

persons qualified in electronics or electrical engineering are authorized to install, remove or

maintain the product. The information given in this manual is meant to complete the

knowledge of a specialist and must not be used as replacement for qualified personnel.

Keep away from live circuits inside the equipment. Operating personnel must not remove

equipment covers. Only factory authorized service personnel or other qualified service

personnel may remove equipment covers for internal subassembly or component replacement

or any internal adjustment.

Do not install substitute parts or perform any unauthorized modification of the equipment or

the warranty may be voided. Contact your local Artesyn Embedded Technologies -

Embedded Computing representative for service and repair to make sure that all safety

features are maintained.

Centellis 4100 Installation and Use (6806800D82E)

21

Safety Notes

General

Danger of Injuries

At the system's rear there are sharp pins which can cause injuries.

Be careful when handling the system.

EMC

The product has been tested and found to comply with the limits for a Class A digital device in

this system, pursuant to part 15 of the FCC Rules, EN 55022 Class A respectively. These limits

are designed to provide reasonable protection against harmful interference when the product

is operated in a commercial, business or industrial environment.

The product generates and uses radio frequency energy and, if not installed properly and used

in accordance with this user's documentation, may cause harmful interference to radio

communications. Operating the product in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his own

expense. To ensure proper EMC shielding, operate the system only with free slots populated

with filler blades.

Grounding

To ensure the system is properly grounded, each of the system's parts contact the EMI gasket.

The system contains gaskets at the shelf and module level.

The shelf is also fitted with ESD contacts. Please take care for proper ESD protection of the

operator.

This is a Class A product based on the standard of the Voluntary Control Council for

Interference by Information Technology Interference (VCCI). If this equipment is used in a

domestic environment, radio disturbance may arise. When such trouble occurs, the user may

be required to take corrective actions.

22

Centellis 4100 Installation and Use (6806800D82E)

System Installation

System Damage

To avoid system damage verify that the system environment meets the environmental and

power requirements given in this manual before installing the system.

Before you begin to set up and cable your new system, consider these guidelines:

Restricted access area: Install the system only in a restricted access area.

Installation codes: This unit must be installed in accordance with the National Electrical

Code, Articles 110.16, 110.17, and 110.18 and the Canadian Electrical Code, Section 12.a

Overcurrent protection: A readily accessible listed branch circuit overcurrent protective

device must be incorporated into the building wiring. For appropriate AWG rating of the

overcurrent protection device see NEC Table 310.16 and other national regulations.

The protective bonding conductor depends on your power distribution topology. Make

sure that you use an appropriate protective bonding conductor regarding the rating of the

branch circuit protection.

Safety Notes

Install the system safely. Make sure that cables and cords are out of the way.

Make sure that the set-up is comfortable for users.

Centellis 4100 Installation and Use (6806800D82E)

23

Safety Notes

System Damage

Environmental contamination can impair system operation.

Locate the system in a stable area free of excess movement and jarring and free of dust, smoke,

and electrostatic discharge (ESD). Make sure that the temperature does not exceed the

operating temperature given in the environmental requirements in this manual and allow

room for proper air flow for cooling.

Personal Injury or System Damage

The system is supplied by a TNV-2 voltage. This voltage is considered hazardous.

Make sure that the external power supply meets the relevant safety standards. Ensure that

TNV-2 is separated from dangerous voltages (mains) through double or reinforced insulation.

System Overheating

Inproper cooling leads to blade damage.

To ensure proper cooling always operate the system in a horizontal position. Furthermore,

keep clear at least 6 cm adjacent to the cooling vents on the chassis front and back side. For

detailed information refer to Site Planning Considerations on page 65.

Personal or System Damage

Unstable system installation in a rack can cause the rack to topple over.

Therefore, if your system is the only one in the rack, make sure to mount the system in the

lowest part of the rack. If other systems are installed in one rack, start with the heaviest

component at the bottom.

If the rack is equipped with stabilizing devices, make sure that they are installed and extended

so that the rack is secure. Then proceed to mount or service the system.

Personal Injury or System Damage

When pulling the system out of the rack, it can fall down and cause injuries.

Pull out the system cautiously.

Personal Injury or System Damage

The system is heavy and if you carry it on your own you can hurt your back.

To prevent injury, keep your back straight and have two people lift the system or use additional

lifting equipment.

24

Centellis 4100 Installation and Use (6806800D82E)

System Damage

During the course of handling, shipping, and assembly, pins, shrouds and mounting screws,

blowers and other items can become loose or damaged.

Do not operate a damaged shelf, this can cause damage to devices that interfere with it.

Electrical Hazard

The caution label on the system's rear near the grounding studs shows that you have to create

an earth connection because there may be a high leakage current which is considered as

hazardous.

High leakage current can cause injuries. Therefore, it is essential that you create an earth

connection before connecting the PEM.

Warning, due to the high leakage current an earth connection is essential before connecting

to a telecommuncation network.

Always ensure that the system is properly grounded.

Safety Notes

System Damage

Wrong jumper settings can make the shelf in-operable. Therefore, never change the settings

of the jumpers.

Blade and RTM Installation

Damage of Circuits

Electrostatic discharge and incorrect RTM or blade installation and removal can damage

circuits or shorten their life.

Before touching the RTM, blade or electronic components, make sure that you are working in

an ESD-safe environment.

Installation Sequence of RTMs and AdvancedTCA Blades

If you are going to install an RTM and an AdvancedTCA blade you have to regard the following

Centellis 4100 Installation and Use (6806800D82E)

25

Safety Notes

sequence:

First install the RTM, then install the matching AdvancedTCA blade. Otherwise the blades and

RTMs will be damaged.

Blade or System Damage

Installing a blade in the wrong slot causes blade or system damage. Only install blades in the

designated slots.

Damage of RTM and Front Blade

Removing the RTM from the system while the playload of the front blade is powered up may

damage the front blade and RTM.

Whenever removing the RTM from the system, you have to power down the playload of the

front blade first.

RTM Malfunctioning

Incorrect RTM installation and removal can result in RTM malfunctioning.

When plugging the RTM in or removing it, do not press on the face plate but use the handles.

RTM Damage

Installing the RTM with other blades than the ones designed for it may damage the RTM and

the front blade.

Only install the RTM with the correct front blade.

Data Loss

Removing the RTM with the system power on and the blue LED on the front blade still flashing

causes data loss.

Before removing the RTM from a powered system, power down the slot by opening the lower

handle of the front blade and wait until the blue LED is permanently ON.

Blade Malfunctioning

Incorrect blade installation and removal can result in blade malfunctioning.

Make sure that the blade is connected to the system backplane via all assembled connectors

and that power is available on all zone 1 power pins.

26

Centellis 4100 Installation and Use (6806800D82E)

Operation

System Overheating

Cooling vents

Inproper cooling can lead to blade and system damage.

To ensure proper cooling and undisturbed airflow through the system always operate the

system in a horizontal position and keep clear at least 60 mm at the back and 60 mm to each

side of the system. Do not obstruct the ventilation openings at the top, sides and back of the

system. Keep the fresh air intake at the bottom front side of the chassis completely clear, and

ensure that fresh air supply is not mixed with hot exhaust from other devices.

To ensure proper air flow within the system make sure that all slots are populated with either

filler blades, blades or dummy blades.

Product Damage

High humidity and condensation on blade surfaces causes short circuits.

Do not operate the system outside the specified environmental limits. Make sure the system is

completely dry and there is no moisture on any surface before applying power. Do not start the

system below 0ºC.

Safety Notes

Injury

Caution: this unit has four -48V to -60 V DC feeders. All must be disconnected to de-energize

the system. To reduce the risk of injury, disconnect the feeders when removing power from the

system.

System Damage

Air Filter

Air contamination can pollute the air filter and obstruct the air intake of the system which may

cause system overheating and component damage.

To guarantee proper airflow through the system the air filter has to be replaced at least every

six months. Artesyn Embedded Technologies - Embedded Computing recommends to

replace the air filter every 90 days. Filter replacement frequency depends on the environment

the system is subjected to.

Air filters should be cleaned at least every 90 days or sooner, depending on the conditions of

the environment. Because central offices vary in physical location and cleanliness, check your

air filters every week after you first install your system. In a dusty environment, a filter may

Centellis 4100 Installation and Use (6806800D82E)

27

Safety Notes

need cleaning more often than a filter in a cleaner environment. Check the filters frequently

until you have a good idea of how often it needs cleaning. Based on your findings, establish a

regular cleaning schedule and keep a log to record the date of each filter cleaning or

replacement.

This equipment is designed to permit the connection of the earthed conductor of the DC

supply circuit to the earthing conductor at the equipment. If this connection is made, all of the

following conditions must be met:

This equipment shall be connected directly to the DC supply system earthing electrode

conductor or to a bonding jumper from an earthing terminal bar or bus to which the DC

supply system earthing electrode conductor is connected.

This equipment shall be located in the same immediate area (such as, adjacent cabinets)

as any other equipment that has a connection between the earthed conductor of the same

DC supply circuit and the earthing conductor, and also the point of earthing of the DC

system. The DC system shall not be earthed elsewhere.

The DC supply source shall be located within the same premises as this equipment.

Switching or disconnecting devices shall not be in the earthed circuit conductor between

the DC source and the point of connection of the earthing electrode conductor.

French translation: Cet appareil est conçu pour permettre le raccordement du conducteur relié

à la terre du circuit d'alimentation c.c. au conducteur de terre de l'appareil. Pour ce

raccordement, toutes les conditions suivantes doivent être respectées:

Ce matériel doit être raccordé directement au conducteur de la prise de terre du circuit

d'alimentation c.c. ou à une tresse de mise à la masse reliée à une barre omnibus de terre

laquelle est raccordée à l'électrode de terre du circuit d'alimentation c.c.

Les appareils dont les conducteurs de terre respectifs sont raccordés au conducteur de

terre du même circuit d'alimentation c.c. doivent être installés à proximité les uns des

autres (p.ex., dans des armoires adjacentes) et à proximité de la prise de terre du circuit

d'alimentation c.c. Le circuit d'alimentation c.c. ne doit comporter aucune autre prise de

terre.

La source d'alimentation du circuit c.c. doit être située dans la même pièce que le matériel.

- Il ne doit y avoir aucun dispositif de commutation ou de sectionnement entre le point de

raccordement au conducteur de la source d'alimentation c.c. et le point de raccordement

à la prise de terre.

28

Centellis 4100 Installation and Use (6806800D82E)

System Overheating

If you reduce the blower speed the system temperature will rise.

Constantly control the system temperature once you have reduced the blower speed.

While operating the system ensure that the environmental and power requirements are met.

Loss of Safety Approval for ATCA-715/7105/717/7107 and the System

If you use the ACC/CABLE/RJ45/DSUB in applications other than maintenance and if you use it

with devices not providing a protection according to EN 60950-1, you loose the safety

approval of the blade.

Therefore, only use the ACC/CABLE/RJ45/DSUB for maintenance and with devices providing a

protection according to EN 60950-1.

Injuries or Short Circuits

Blade or Power Supply

In case the ORing diodes of the blade fail, the blade may trigger a short circuit between input

line A and input line B so that line A remains powered even if it is disconnected from the power

supply circuit (and vice versa).

To avoid damage or injuries, always check that there is no more voltage on the line that has

been disconnected before continuing your work.

Safety Notes

Expansion

System Overload

To avoid an overload of the system check the total power consumption of all components

installed (see the technical specification of the respective components). Ensure that any

individual output current of any source stays within its acceptable limits (see the technical

specification of the respective source).

Loss of Safety Compliance

Using of Additional Plug-in Blades

By using additional plug-in blades it may be possible that the system may be no more

compliant to safety and EMC regulations.

The system integrator has to ensure that the compliancy is guaranteed.

Centellis 4100 Installation and Use (6806800D82E)

29

Safety Notes

Exchanging PEMs

Personal Injury through Electric Shock and Burning

Touching the PEM power input terminals with metallic objects on your hands, wrists, or

hanging from your neck may lead to serious injuries like burns or amputations. Do not wear any

metallic attire or commodity on your hands, wrists, or hanging from your neck when working

at the power input terminals or power input cables. Be extremely careful when you use

electrically conductive tools near the PEMs.

Short Circuits or Personal Injury

Ensure that the power feeds you plan to remove or attach are powered off and cannot be

switched on while you are working.

Ensure that all power input lines are not energized.

Short Circuit and Electric Shock

To avoid short circuits and electric shock, the power lugs must not be energized before

removing the screws. It is essential to ensure that the power lugs are not energized before

loosening the screws. Be careful with the used tools in order to prevent a short circuit.

Personal Injury

PEMs will get hot. Touching a hot PEM can cause injuries.

Let the PEM cool down before pulling it out with bare hands.

PEM Damage

Applying reversal power causes damage to the electrolytic capacitors of the filter. Therefore,

only switch on the breakers if no red light is visible.

Exchanging Blowers

System Overheating

Running the system with less than three blowers may damage the system. Do not operate the

system with less than three blowers.

30

Centellis 4100 Installation and Use (6806800D82E)

System Damage

Operating the system with the blower cover open for more than 30 seconds may damage the

system.

When replacing a blower, make sure to open the blower cover only immediately before the

replacement, perform the replacement without delays, and close it immediately after the

replacement.

When a blower is taken out of operation, the system manager will compensate for the loss by

increasing the speed of the remaining blowers.

Personal Injury

Rotating Blowers

Inserting tools or fingers into operational blowers may cause injuries.

Blowers become exposed when the blower tray is pulled. Keep clear of the blowers as long as

they are rotating.

When the blower is removed, extreme care should be taken while handling the blower itself.

The centrifugal forces will make the unit difficult to handle.

Safety Notes

Cabling

Personal Injury

The cabling should follow existing cable paths using existing or similar cable fastenings.

Never change the system's cabling as delivered by Artesyn. Check proper function of the

system after cabling extensions. To avoid injuries always ensure that cables are securely

installed so that nobody can trip over them.

Personal Injury through Electric Shock

Touching contacts and cables during system operation can cause injuries through electric

shock.

To avoid electric shock make sure that contacts and cables of the system cannot be touched

while the system is operating. If in doubt concerning cabling, ask your local Artesyn

representative.

Cable Damage

Folding the fiber cable damages the cable and inhibits the data transmission. Therefore, make

sure you do not fold the cable.

Centellis 4100 Installation and Use (6806800D82E)

31

Safety Notes

RJ-45 Connector

System Damage

RJ-45 connectors on blades are either twisted-pair Ethernet (TPE) or E1/T1/J1 network

interfaces. Connecting an E1/T1/J1 line to an Ethernet connector may damage your system.

Make sure that TPE connectors near your working area are clearly marked as network

connectors.

Verify that the length of an electric cable connected to a TPE bushing does not exceed 100

meters.

Make sure the TPE bushing of the system is connected only to safety extra low voltage

circuits (SELV circuits).

If in doubt, ask your system administrator.

32

Centellis 4100 Installation and Use (6806800D82E)

Loading...

Loading...