Artesyn ATCA-F120 Installation

ATCA-F120

Installation and Use

P/N: 6806800D06J

August 2014

©

Copyright 2014 Artesyn Embedded Technologies, Inc.

All rights reserved.

Trademarks

Artesyn Embedded Technologies, Artesyn and the Artesyn Embedded Technologies logo are trademarks and service marks of

Artesyn Embedded Technologies, Inc.© 2014 Artesyn Embedded Technologies, Inc. All other product or service names are the

property of their respective owners.

Intel® is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

Java™ and all other Java-based marks are trademarks or registered trademarks of Oracle America, Inc. in the U.S. and other countries.

Microsoft®, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

Microsoft Corporation.

PICMG®, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

Industrial Computer Manufacturers Group.

UNIX® is a registered trademark of The Open Group in the United States and other countries.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Artesyn assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Artesyn reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Artesyn to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

an Artesyn website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Artesyn.

It is possible that this publication may contain reference to or information about Artesyn products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Artesyn intends to announce such Artesyn products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Artesyn.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Artesyn Embedded Technologies Artesyn Embedded Technologies

Marketing Communications

2900 S. Diablo Way, Suite 190

Tempe, Arizona 85282

Lilienthalstr. 17-19

85579 Neubiberg/Munich

Germany

Contents

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4.1 Supported Blade Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4.2 Blade Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 Hardware Preparation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 Unpacking and Inspecting the Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3 Environmental and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.4 Installing Rear Transition Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.5 Configuring the Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.6 Blade Installation and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.6.1 Installing the Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.6.2 Removing the Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.7 AMC Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.7.1 Supported AMC Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.7.1.1 AMC Bay B4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.7.1.2 AMC Bay B1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.7.2 AMC Module Installation and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.8 Configuring and Setting Up the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3 Controls, LEDs and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.2 Blade Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3 Face Plate Connectors and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.3.1 Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.3.1.1 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ATCA-F120 Installation and Use (6806800D06J)

3

Contents

Contents

Contents

3.3.1.2 Ethernet Management Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.3.1.3 AMC Module Ethernet Access Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.3.1.4 Ethernet Base Channel Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.3.2 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.4 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.3 Central Processing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.4 Main Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.5 Glue Logic FPGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.5.1 General Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.5.2 Watchdog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.6 Boot and User Flashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.6.1 Boot Flashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.6.2 User Flashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.7 Fabric Channel Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.8 Base Channel Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.9 Base Interface Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.9.1 Port Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.9.2 Shelf Manager Cross Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.10 Intelligent Peripheral Management Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.10.1 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.10.2 Available IPMI Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.10.3 Watchdog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5 U-Boot Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.2 Accessing U-Boot via the Serial Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.3 Selecting Boot Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.3.1 Configuring U-Boot for Network Boot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.3.2 Configuring U-Boot to Boot from RAM Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.3.3 Configuring U-Boot to Boot from Flash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4

ATCA-F120 Installation and Use (6806800D06J)

Contents

5.4 Selecting the Boot Flashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.5 Using the Persistent Memory Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5.6 Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.7 Linux Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5.8 Power-On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.8.1 POST Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.8.2 Controlling the Execution of the POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.9 ATCA-F120 Specific U-Boot Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.10 ATCA-F120-Specific U-Boot Environment Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.11 Updating U-Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

A Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

A.1 Artesyn Embedded Technologies - Embedded Computing Documentation . . . . . . . . . . . . . . . 107

A.2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

ATCA-F120 Installation and Use (6806800D06J)

5

Contents

Contents

Contents

6

ATCA-F120 Installation and Use (6806800D06J)

List of Tables

Table 1-1 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 1-2 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 1-3 Blade Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 1-4 Available Blade Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 2-1 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 2-2 Critical Temperature Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 2-3 DC System Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 2-4 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 2-5 AMC Bay B4 - Port Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 2-6 AMC Bay B1- Port Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 3-1 Serial Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 3-2 Ethernet Management Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3-3 AMC Module Ethernet Interface Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 3-4 Base Channel Extension Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 3-5 Face Plate LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 4-1 Main Features of Fabric Channel Interface Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 4-2 FIX 1 Ethernet Port Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 4-3 FIX 2 Ethernet Port Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 4-4 Base Channel Switch Port Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 4-5 Base Interface Extension - Port Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 4-6 On-Board Memory of IMC, ISC0/1 and MMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 4-7 IPMI Sensors Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 5-1 Physical Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 5-2 Linux Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 5-3 POST Result Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 5-4 Post Results in SYS FW PROGRESS IPMI Sensor Reading Data . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 5-5 SYS FW PROGRESS IPMI Sensor - POST Error Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 5-6 POST Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 5-7 Environment Variable post_control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 5-8 ATCA-F120 Specific U-Boot Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 5-9 ATCA-F120 Specific U-Boot Environment Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table A-1 Artesyn Embedded Technologies - Embedded Computing Publications . . . . . . . . . . . . . . 107

Table A-2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

ATCA-F120 Installation and Use (6806800D06J)

7

List of Tables

8

ATCA-F120 Installation and Use (6806800D06J)

List of Figures

Figure 1-1 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-1 Critical Temperature Spots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2-2 On-Board Configuration Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-3 Location of AMC Bays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 2-4 AMC Module B4 Interconnection Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 3-1 Mechanical Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 3-2 Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 3-3 Location of Serial Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 3-4 Location of Ethernet Management Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 3-5 Location of AMC Module Ethernet Management Interface Connector . . . . . . . . . . 55

Figure 3-6 Location of Base Channel Extension Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 3-7 Face Plate LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 3-8 Location of AdvancedTCA Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 3-9 P30 Connector Pinout (Columns A to D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 3-10 P30 Connector Pinout (Columns E to H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 3-11 P31 Connector Pinout (Columns A to D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 3-12 P31 Connector Pinout (Columns E to H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 3-13 P32 Connector Pinout (Columns A to D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 3-14 P32 Connector Pinout (Columns E to H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 4-1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 4-2 On-Board Routing of Fabric Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 4-3 On-Board Routing of Base Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 4-4 Shelf Manager Cross Connection via Update Channel . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 4-5 Shelf Manager Cross Connection via Base Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 4-6 IPMI Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 4-7 Location of IPMI Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

ATCA-F120 Installation and Use (6806800D06J)

9

List of Figures

10

ATCA-F120 Installation and Use (6806800D06J)

About this Manual

Overview of Contents

This manual is divided into the following chapters and appendices.

Chapter 1, Introduction, on page 17 describes the main features of the ATCA-F120.

Chapter 2, Hardware Preparation and Installation, on page 23 describes installation

prerequisites including the blade installation itself.

Chapter 3, Controls, LEDs and Connectors, on page 47 describes external interfaces of the

blade. This includes connectors and LEDs.

Chapter 4, Functional Description, on page 65 describes in more detail functional blocks of

the blade. This includes a block diagram, description of the main components used and so

on.

Chapter 5, U-Boot Firmware, on page 87 describes the main features of the on-board boot

firmware U-boot and how to work with it.

Appendix A, Related Documentation provides links to further ATCA-F120-related

documentation

Safety Notes on page 109 lists safety notes applicable to the blade

Sicherheitshinweise on page 115 is the German translation of the previous English safety

notes (this had to be included for legal reasons)

Abbreviations

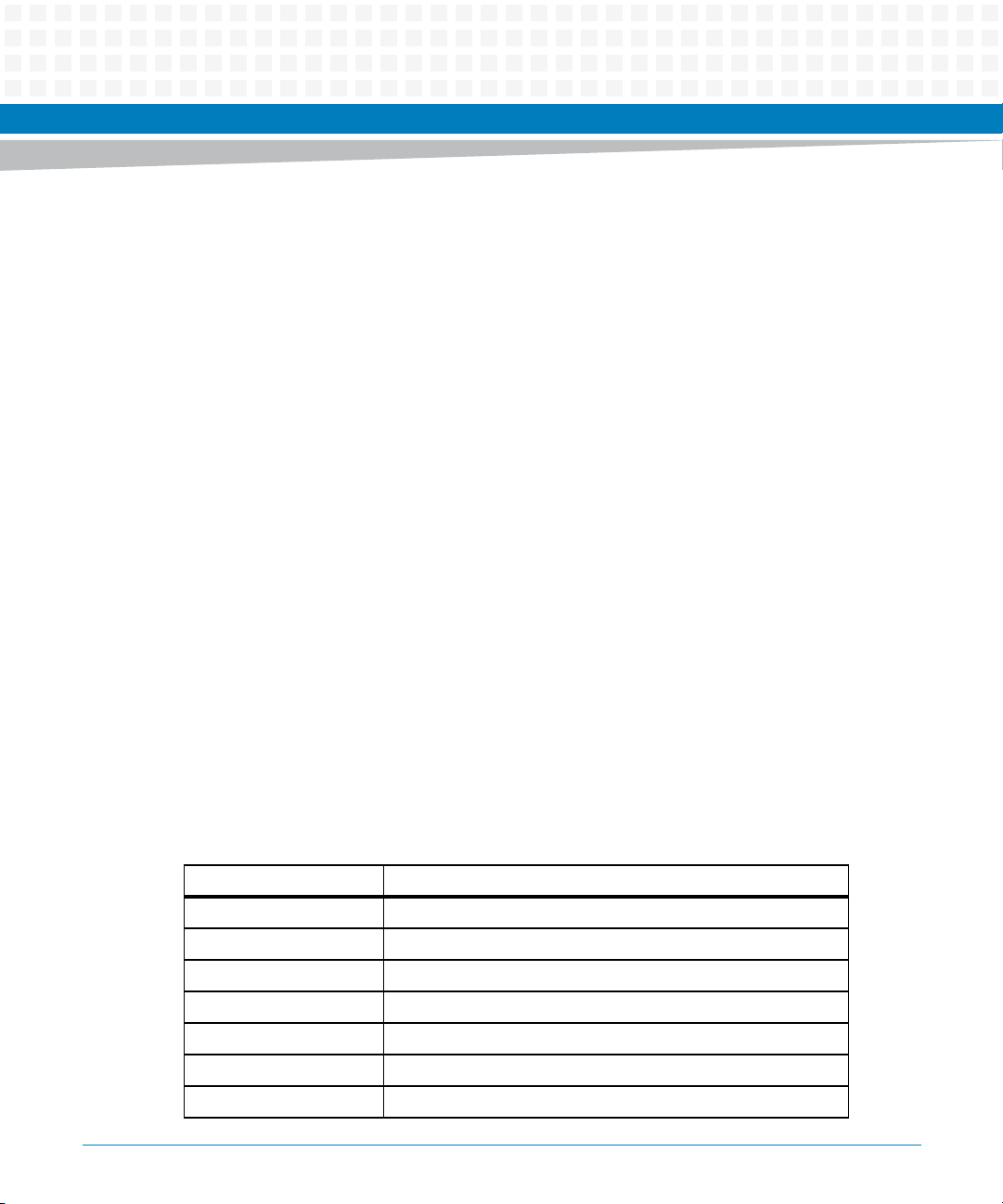

This document uses the following abbreviations:

Abbreviation Description

ACL Access Control List

ADC Analog-to-Digital Conversion

AMC Advanced Mezzanine Card

BBS Basic Blade Service

BT Block Transfer

CoS Classes of Service

DDR Double Data Rate

ATCA-F120 Installation and Use (6806800D06J)

11

About this Manual

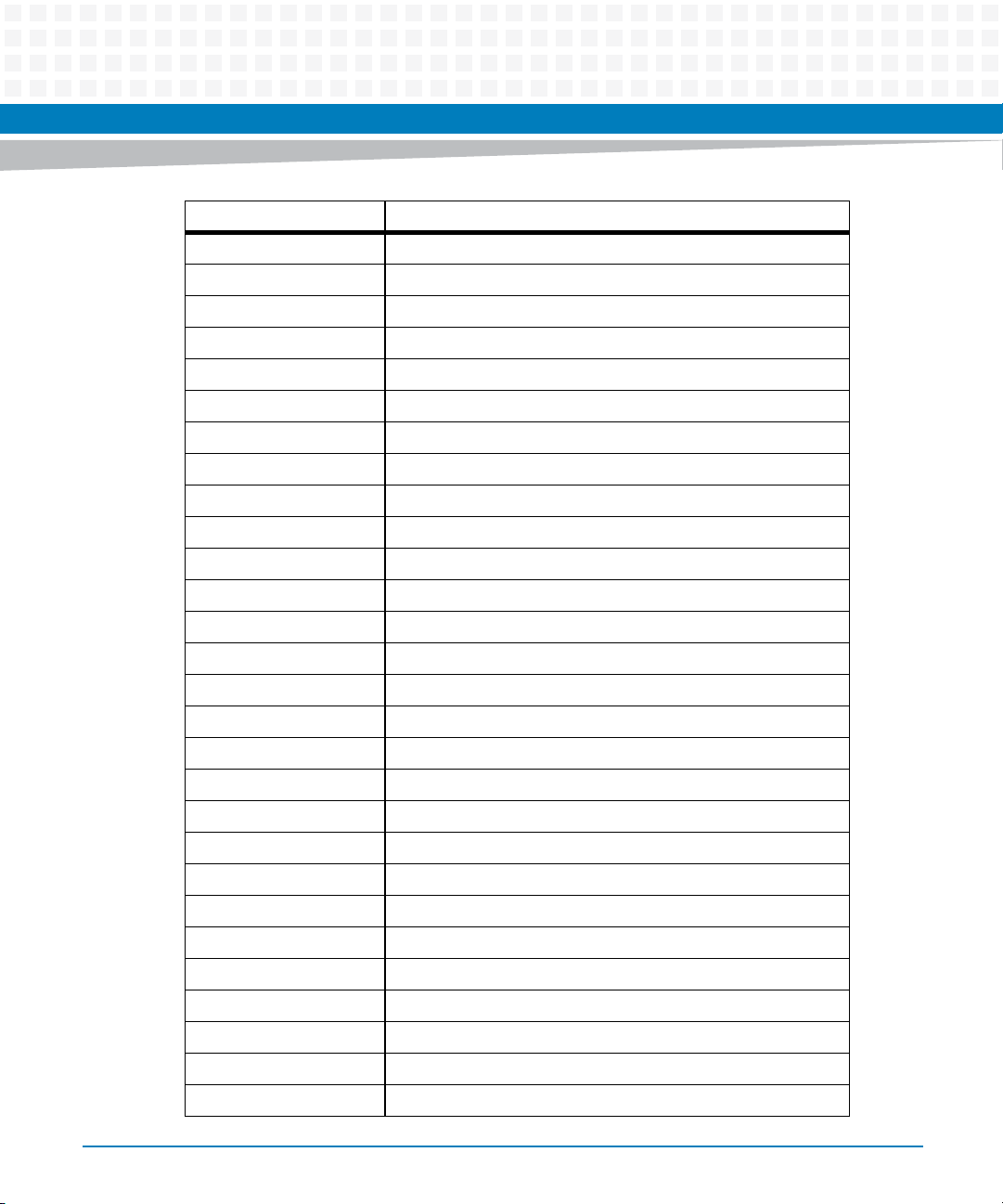

Abbreviation Description

ECC Embedded Communications Computing

EMC Electromagnetic Compatibility

EMV Elektromagnetische Verträglichkeit

ESD Electrostatic Discharge

ETSI European Telecommunications Standards Institute

FIFO First In, First Out

FPGA Field Programmable Gate Array

FRU Field Replaceable Unit

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronics Engineers

IMC IPMC Master Controller

IPMC Intelligent Peripheral Management Controller

About this Manual

12

IPMI Intelligent Platform Management Interface

ISC IPMC Slave Controller

MMC Mezzanine Management Controller

NEBS Network Equipment-Building System

OEM Original Equipment Manufacturer

OOS Out Of Service

PCB Printed Circuit Board

PCI Peripheral Component Interconnect

PICMG PCI Industrial Computer Manufacturers Group

PMC PCI Mezzanine Card

POST Power-On Self-Test

RTM Rear Transition Module

RoHS Restriction of Hazardous Substances Directive

SDRAM Synchronous Dynamic Random Access Memory

SDRs Sensor Data Record

SELV Safety Extra Low Voltage Circuits

ATCA-F120 Installation and Use (6806800D06J)

Abbreviation Description

SERDES Serializer/Deserializer

SGMII Serial Gigabit Media Independent Interface

SPI Serial Peripheral Interface

SRAM Static Random Access Memory

STP Shielded Twisted Pair

ShM Shelf Manager

TPE Twisted-Pair Ethernet

VLAN Virtual Local Area Network

Conventions

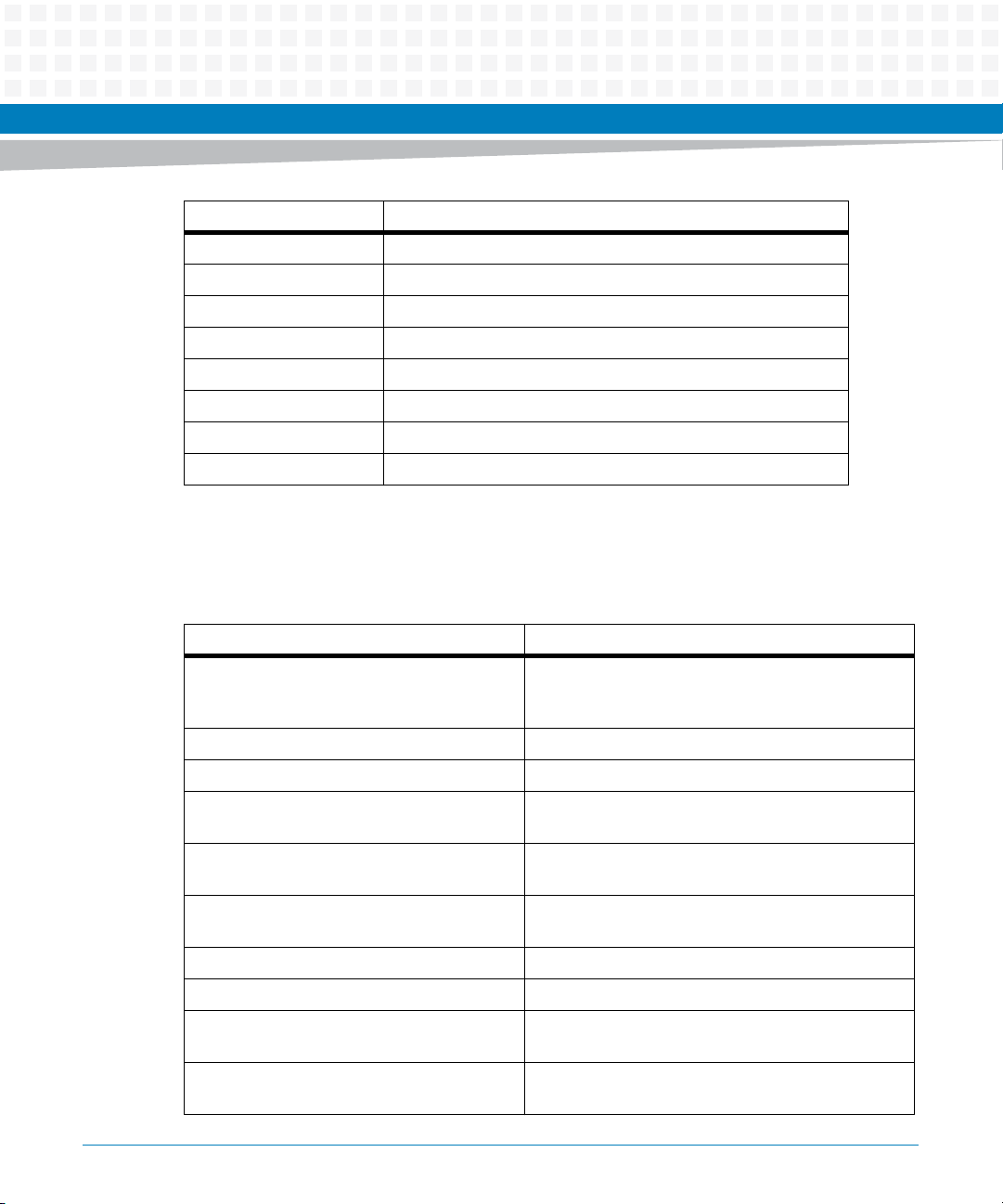

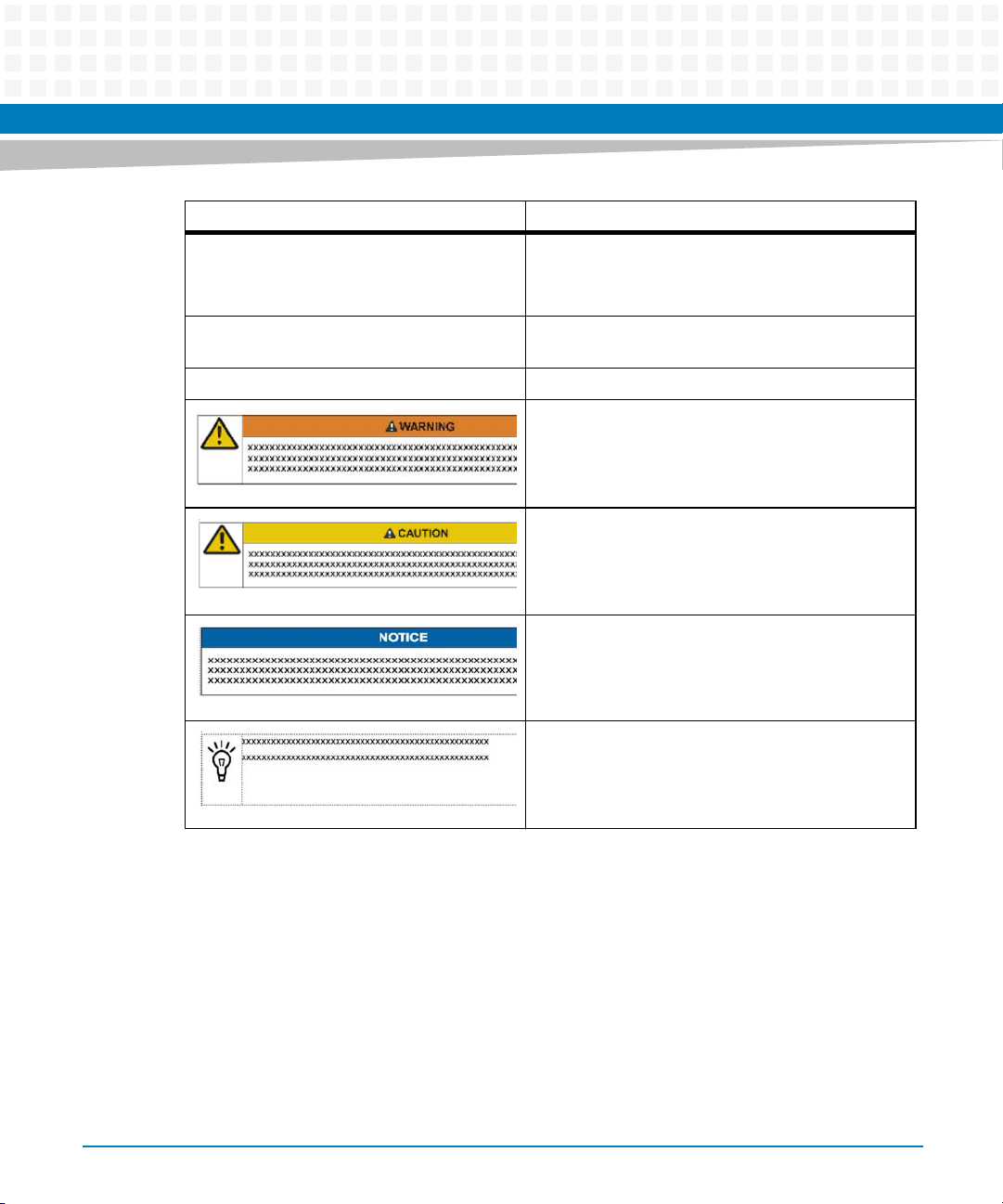

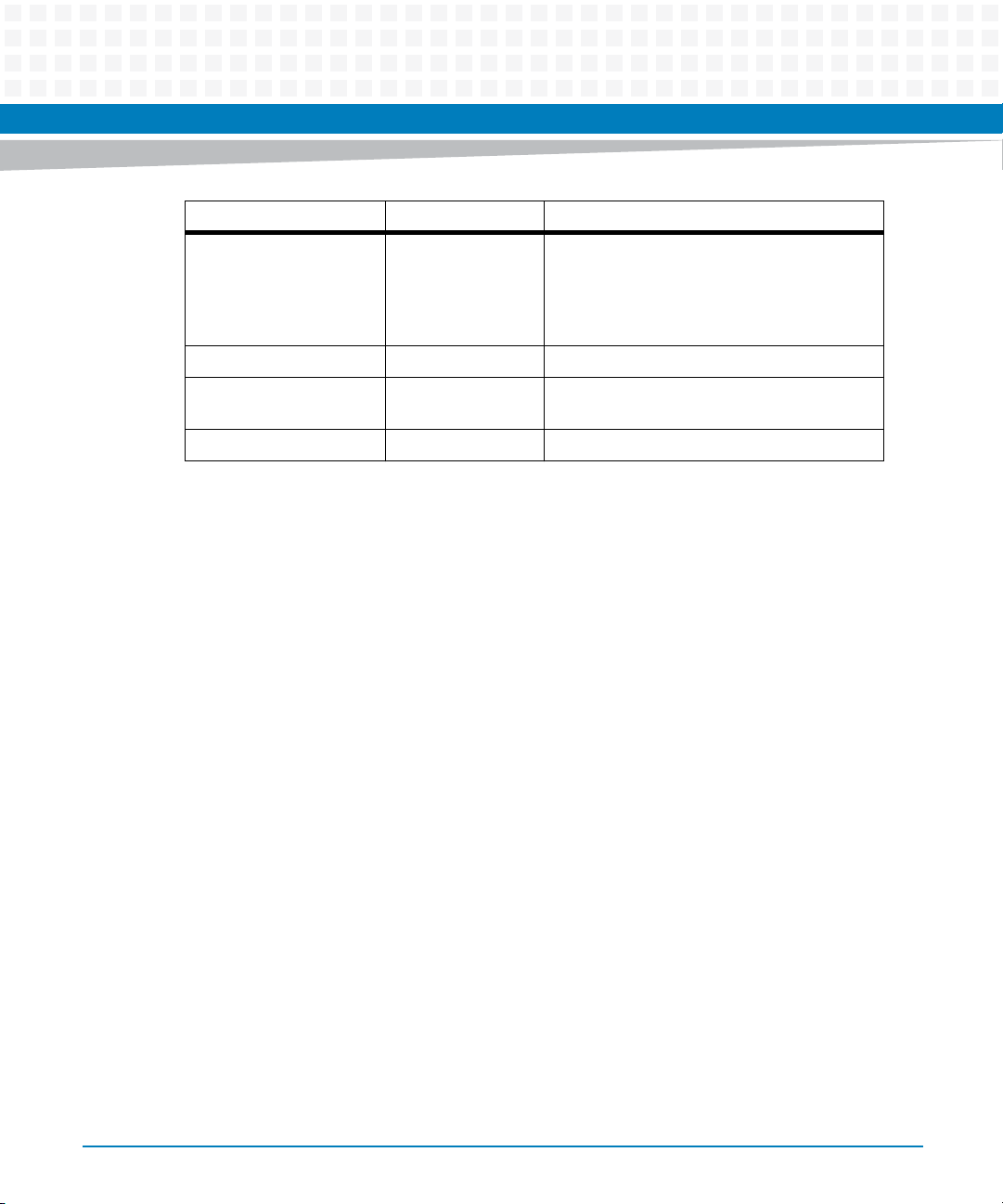

The following table describes the conventions used throughout this manual.

About this Manual

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related elements

Courier + Bold Used to characterize user input and to separate it

Reference Used for references and for table and figure

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

[text] Notation for software buttons to click on the screen

... Repeated item for example node 1, node 2, ..., node

ATCA-F120 Installation and Use (6806800D06J)

0 through F), for example used for addresses and

offsets

or commands in body text

from system output

descriptions

and parameter description

12

13

About this Manual

Notation Description

About this Manual

.

.

.

.. Ranges, for example: 0..4 means one of the integers

| Logical OR

Omission of information from example/command

that is not necessary at the time being

0,1,2,3, and 4 (used in registers)

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury

Indicates a property damage message

No danger encountered. Pay attention to important

information

14

ATCA-F120 Installation and Use (6806800D06J)

Summary of Changes

This manual has been revised and replaces all prior editions.

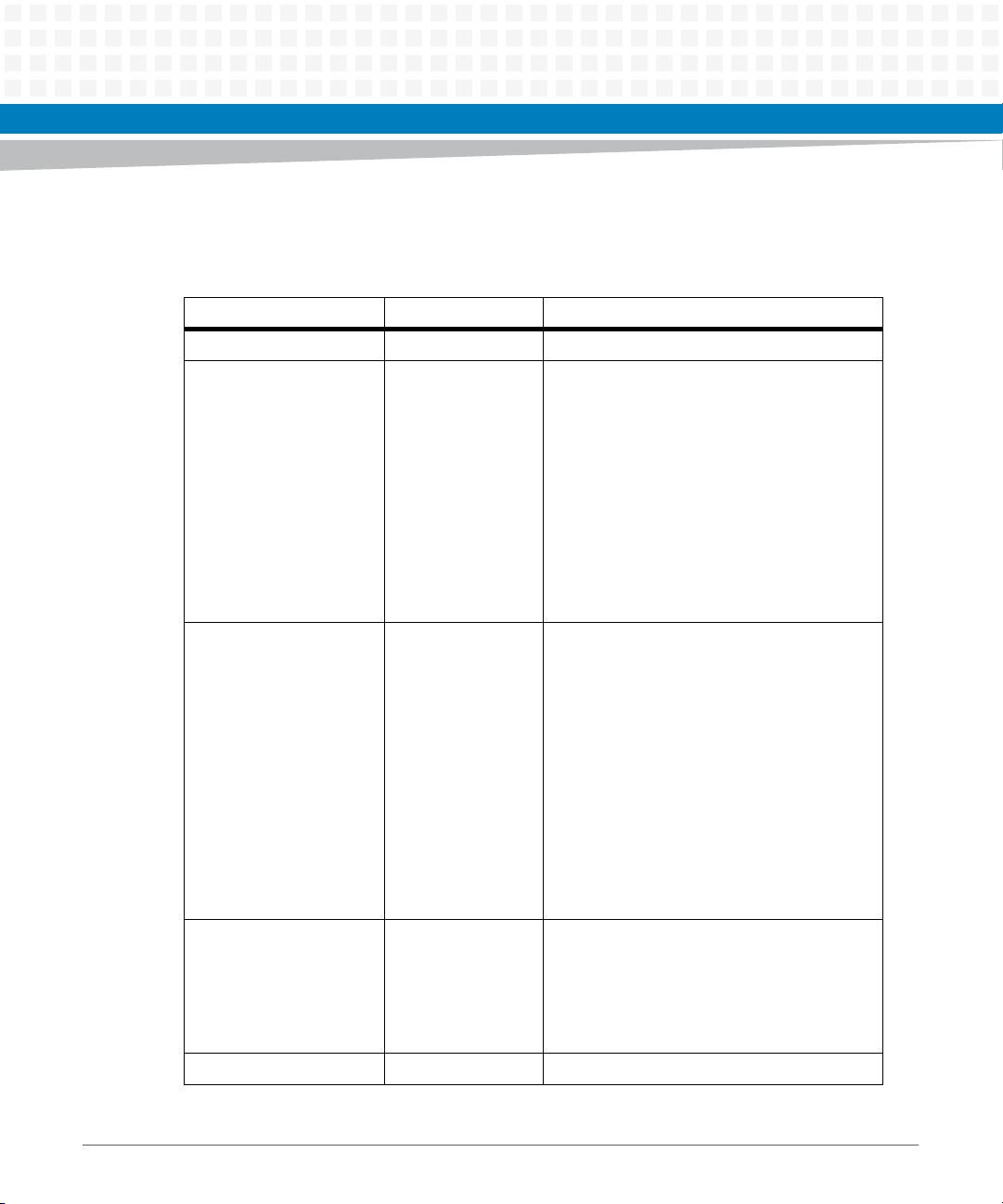

Part Number Publication Date Description

6806800D06A April 2007 First draft (DA release version)

6806800D06B September 2007 EA version

About this Manual

Changes made compared to previous version

include: updated standard requirements,

updated power requirements, updated

environmental requirements, enhanced

block diagram figures (fabric and base

interface connections as well as shelf

manager cross-connection figures), updated

IPMI sensor list, added blackplane connector

pinouts, added section: "Boot and User

Flashes", added figure which shows the

location of on-board switches.

6806800D06C December 2007 Added mechanical data, in section

6806800D06D February 2008 Added note regarding environmental

6806800D06E February 2008 Corrected wrong year on titlepage

ATCA-F120 Installation and Use (6806800D06J)

"Environmental Requirements" added

description of critical temperature spots;in

section "Power Requirements" updated table

"DC System Power Requirements". in figure

"AMC Module B4 Interconnection Scheme"

included AdvancedTCA update channel

number AND AMC port number to avoid

confusion between the term "port" used in

different contexts (AMC port and ATCA

update channel port) ; updated

Sensors Overview" table; added sections

"FPGA" and "Central Processing Unit"; updated

"U-Boot Firmware" section;

variables to section "U-Boot"; corrected main

memory size in section "Main Features";

changed manual to Emerson style (logo,

etc.); added "Declaration of Conformity" to

section "Standard Compliances"

""IPMI

15

About this Manual

Part Number Publication Date Description

6806800D06F February 2009 Updated on-board configuration switch

6806800D06G December 2012 Updated Standard Compliances on page 18.

6806800D06H November 2013 Updated Table "ATCA-F120 Specific U-Boot

6806800D06J August 2014 Re-branded to Artesyn template.

About this Manual

description (described additional serial

interface routing option towards RTM);

enhanced U-Boot upgrade description; added

references to RTM-ATCA-F120-OPT

Environment Variables" on page 101.

16

ATCA-F120 Installation and Use (6806800D06J)

Introduction

1.1 Features

The ATCA-F120 is an AdvancedTCA™ switch blade as defined in the PICMG 3.0 Revision 2

AdvancedTCA Base Specification and PICMG 3.1 Revision 1.0 Specification Ethernet/Fiber Channel

for AdvancedTCA Systems.

The blade provides the following Ethernet interfaces:

15 1000BaseT base channel interfaces via backplane

15 10G-BX4/1000BX fabric channel interfaces via backplane

SERDES interface via update channel

One 1000Base-T management interface via face plate

One Base Channel extension interface via face plate

One 1000BaseT face plate interface which connects to AMC bay B1

Chapter 1

Optional Rear Transition Module (RTM)

Further features of the ATCA-F120 are the following:

Freescale MPC8548E PowerQUICC III CPU

At least 512 MBytes DDR2 SDRAM main memory with ECC support

Dual boot flashes of 32 MBytes each

Two NAND flashes with a size of two GBytes each

Real-time clock

Serial interface via face plate

Serial interface via Update Channel (connection to second ATCA-F120 in the system)

Support for two AMC bays

AMC and backplane support for Clock Generator Module

On-board IPMC

ATCA-F120 Installation and Use (6806800D06J)

17

Introduction

1.2 Standard Compliances

This blade, when installed in a compliant shelf, meets the following standards.

Table 1-1 Standard Compliances

Standard Description

UL 60950-1

EN 60950-1

IEC 60950-1

CAN/CSA C22.2 No 60950-1

CISPR 22

CISPR 24

EN 55022

EN 55024

FCC Part 15

Industry Canada ICES-003

VCCI Japan

AS/NZS CISPR 22

EN 300 386

NEBS Standard GR-1089 CORE

NEBS Standard GR-63-CORE

ETSI EN 300019 series

PICMG 3.0 Rev. 2.0 AdvancedTCA Base Specification.

PICMG 3.1 Rev. 1.0 AdvancedTCA Ethernet/Fibre Channel Specification.

Legal safety requirements

EMC requirements (legal) on system level (predefined

Artesyn system)

Environmental requirements

Defines mechanics, blade dimensions, power

distribution, power and data connectors, and system

management

18

PICMG AMC.0 R2.0 Advanced

Mezzanine Card Base Specification

Defines mechanics, interfaces etc. of Advanced

Mezzanine Cards.

ATCA-F120 Installation and Use (6806800D06J)

Introduction

To fulfill the requirements of Telcordia GR-1089,R4-14, use Shielded Twisted Pair (STP) cables

grounded at both ends to connect to the Ethernet ports.

The product has been designed to meet the directive on the restriction of the use of certain

hazardous substances in electrical and electronic equipment (RoHS) Directive 2011/65/EU.

ATCA-F120 Installation and Use (6806800D06J)

19

Introduction

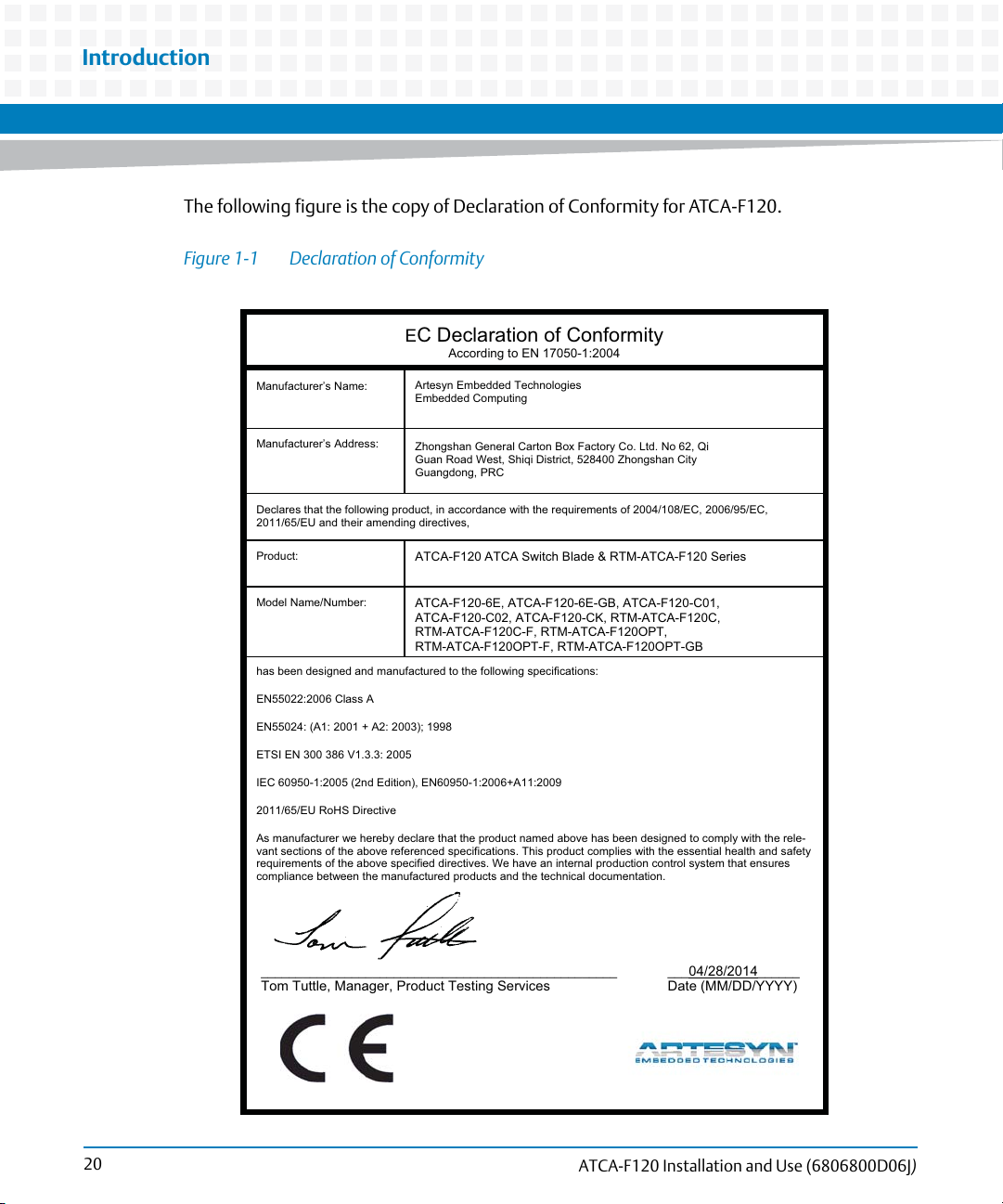

The following figure is the copy of Declaration of Conformity for ATCA-F120.

Figure 1-1 Declaration of Conformity

E

C Declaration of Conformity

According to EN 17050-1:2004

Manufacturer’s Name:

Manufacturer’s Address:

Declares that the following product, in accordance with the requirements of 2004/108/EC, 2006/95/EC,

2011/65/EU and their amending directives,

Product:

Model Name/Number:

has been designed and manufactured to the following specifications:

EN55022:2006 Class A

EN55024: (A1: 2001 + A2: 2003); 1998

ETSI EN 300 386 V1.3.3: 2005

IEC 60950-1:2005 (2nd Edition), EN60950-1:2006+A11:2009

2011/65/EU RoHS Directive

As manufacturer we hereby declare that the product named above has been designed to comply with the rele-

vant sections of the above referenced specifications. This product complies with the essential health and safety

requirements of the above specified directives. We have an internal production control system that ensures

compliance between the manufactured products and the technical documentation.

Artesyn Embedded Technologies

Embedded Computing

Zhongshan General Carton Box Factory Co. Ltd. No 62, Qi

Guan Road West, Shiqi District, 528400 Zhongshan City

Guangdong, PRC

ATCA-F120 ATCA Switch Blade & RTM-ATCA-F120 Series

ATCA-F120-6E, ATCA-F120-6E-GB, ATCA-F120-C01,

ATCA-F120-C02, ATCA-F120-CK, RTM-ATCA-F120C,

RTM-ATCA-F120C-F, RTM-ATCA-F120OPT,

RTM-ATCA-F120OPT-F, RTM-ATCA-F120OPT-GB

20

___________________________________________________ ___

04/28/2014

______

Tom Tuttle, Manager, Product Testing Services Date (MM/DD/YYYY)

ATCA-F120 Installation and Use (6806800D06J)

1.3 Mechanical Data

The following table provides details on the blade’s mechanical data.

Table 1-2 Mechanical Data

Data Type Value

Dimensions (width x height x depth) 30 mm x 351 mm x 312 mm

Weight 2.3 Kg

1.4 Ordering Information

This section provides details on available blade variants and accessories.

Introduction

1.4.1 Supported Blade Models

As of writing this guide, the following blade variants were available. Consult your local Artesyn

sales representative for further variants that may be available.

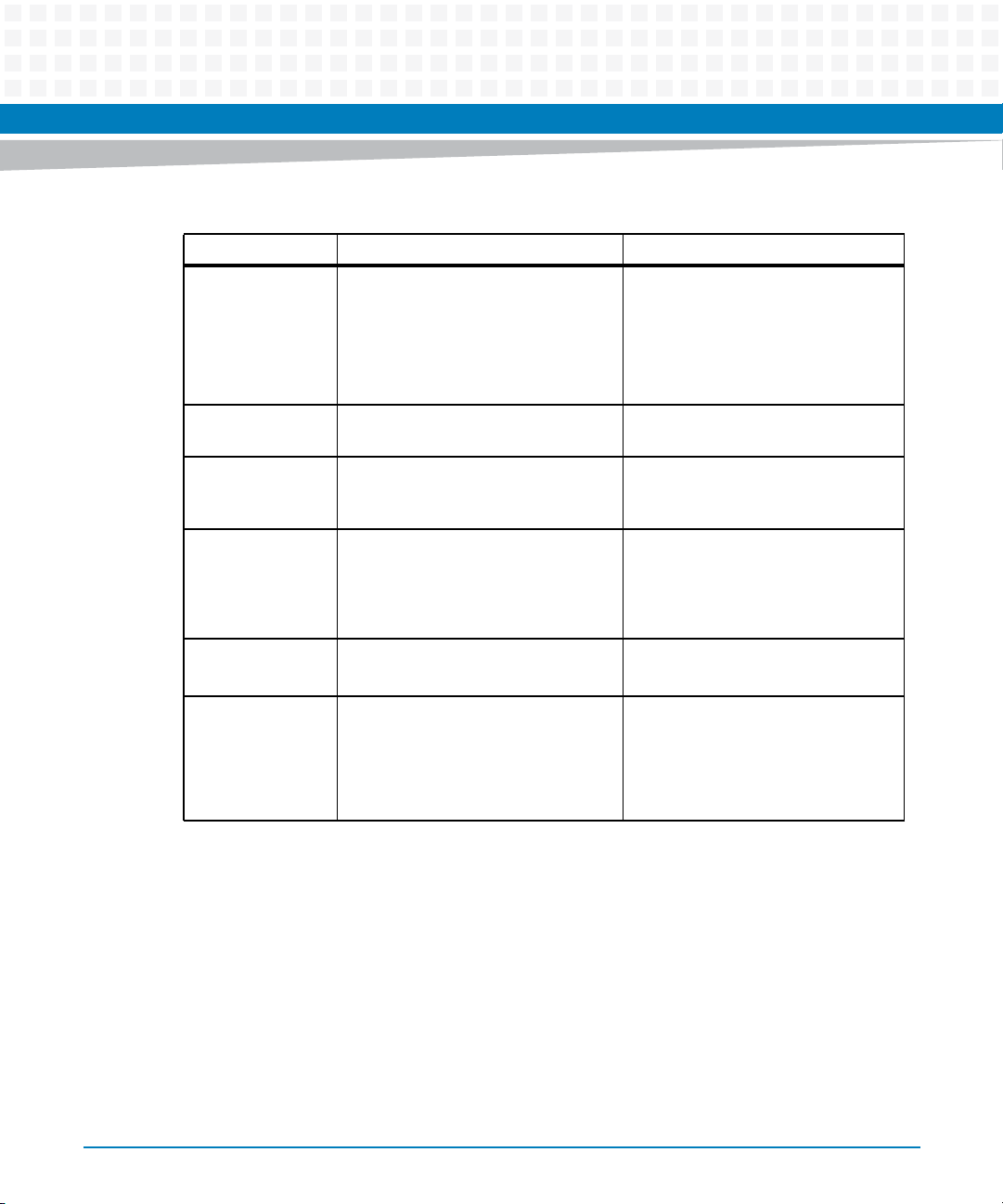

Table 1-3 Blade Variants

Blade Variant Description

ATCA-F120-6E ATCA-F120 equipped with 512 MBytes main memory. 6E

RoHS compliant.

ATCA-F120 Installation and Use (6806800D06J)

21

Introduction

1.4.2 Blade Accessories

As of the printing date of this manual, the following blade accessories were available.

Table 1-4 Available Blade Accessories

Accessory Description

RTM-ATCA-F120C Rear Transition Module (RTM) with copper uplinks. It provides access to:

Four 10 Gigabit Ethernet Fabric Channel uplinks via CX4 connectors

Four 1 Gigabit Ethernet Base Channel interfaces via RJ-45 connectors

Two 10 Gigabit Ethernet Base Channel uplinks via CX4 connectors

Four 1 Gigabit Ethernet Fabric Channel interfaces via RJ-45

Two RJ-45 telecom clocking interface connectors for inter-shelf

The RTM is 6E RoHS compliant.

connectors

clocking configurations

RTM-ATCA-F120OPT

The main features of this RTM are:

Four 10 Gigabit Ethernet Fabric Channel uplinks via SFP+ connectors

Two 10 Gigabit Ethernet Base Channel uplinks via SFP+ connectors

Four 1 Gigabit Ethernet Base Channel interfaces via SFP connectors

Two 1 Gigabit Ethernet Fabric Channel interfaces via SFP connectors

Two RJ-45 telecom clocking interface connectors for inter-shelf

clocking configurations

One serial RS-232 interface for accessing the base blade

On-board mezzanine management controller (MMC) compliant to

IPMI 2.0

22

ATCA-F120 Installation and Use (6806800D06J)

Hardware Preparation and Installation

2.1 Overview

This chapter provides all the information that you need in order to install the ATCA-F120 incl.

accessories into your AdvancedTCA system. For completeness purposes and because of the

similarity with the installation procedures, the respective removal procedures are also given in

this chapter. The structure of this chapter reflects the sequence of the main steps that you will

typically take in order to install the ATCA-F120 and accessories into your AdvancedTC A system.

These main steps and their sequence are:

1. Unpack and inspect the blade

2. Make sure environmental and power requirements are met

3. If applicable, install Rear Transition Module (RTM)

4. Configure the ATCA-F120

5. Install the ATCA-F120

Chapter 2

6. If applicable, install AMC modules

2.2 Unpacking and Inspecting the Blade

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the blade can damage

circuits or shorten their life.

Before touching the blade or electronic components, make sure that your are working in an

ESD-safe environment.

Shipment Inspection

To inspect the shipment, perform the following steps.

1. Verify that you have received all items of your shipment:

Printed "Getting Started" guide

ATCA-F120 blade

ATCA-F120 Installation and Use (6806800D06J)

23

Hardware Preparation and Installation

Any optional items ordered

2. Check for damage and report any damage or differences to the customer service.

3. Remove the desiccant bag shipped together with the blade and dispose of it

according to your country’s legislation.

The blade is thoroughly inspected before shipment. If any damage occurred during

transportation or any items are missing, please contact our customer's service immediately.

2.3 Environmental and Power Requirements

The following environmental and power requirements are applicable to the blade.

2.3.1 Environmental Requirements

You must make sure that the blade, when operated in your particular system configuration,

meets the environmental requirements specified below.

Operating temperatures refer to the temperature of the air circulating around the blade, and

not to component temperatures.

If you integrate the blade in your own, non-Artesyn, system, please contact your local sales

representative for further safety information.

Blade Damage

High humidity and condensation on the blade surface causes short circuits.

Do not operate the blade outside the specified environmental limits. Make sure the blade is

completely dry and there is no moisture on any surface before applying power.

Do not operate the blade below -5°C.

24

ATCA-F120 Installation and Use (6806800D06J)

Hardware Preparation and Installation

Table 2-1 Environmental Requirements

Requirement Operating Non-Operating

Temperature +5ºC (41°F) to +40ºC (104°F): normal

operation according to NEBS

Standard GR-63-CORE

-5ºC (23°F) to +55ºC (131°F):

exceptional operation according to

NEBS Standard GR-63-CORE

Temp. Change +/- 0.25ºC/min according to NEBS

Standard GR-63-CORE

Rel. Humidity 5% to 90% non-condensing according

to Artesyn-internal environmental

requirements

Vibration 0.1g from 5 to 100 Hz and back to 5

Hz at a rate of 0.1 octave/minute

Shock Half-sine, 11 m/Sec, 30 mSec/sec

Free Fall 1,200 mm/all edges and corners

-40ºC (-40°F) to +70ºC (158°F) - may

be further limited by installed

accessories

+/- 0.25ºC/min

5% to 95% non-condensing according

to Artesyn-internal environmental

requirements

5-20 Hz at 0.01 g

20-200 Hz at -3.0 dB/octave

Random 5-20 Hz at 1 m

Random 20-200 Hz at -3 m/Sec

2

Blade level packaging

Half-sine, 6 mSec at 180 m/Sec

1.0m (packaged) per ETSI 300 019-22 (blade level packaging)

100mm (unpackaged) per GR-63CORE

2

/Hz

2

/Sec

3

2

2

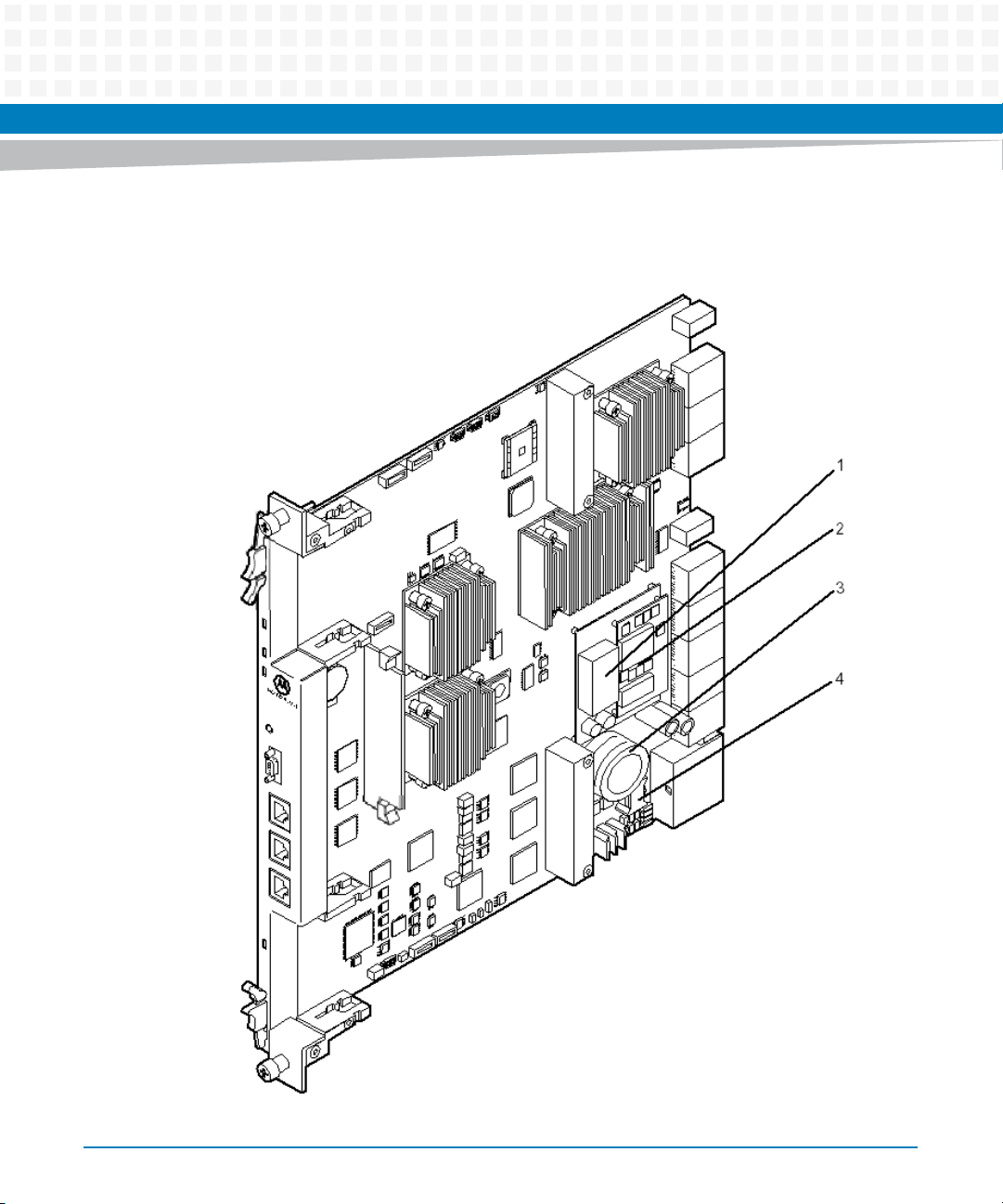

During the safety qualification of this blade, the following on-board locations were identified

as critical with regards to the maximum temperature during blade operation. To guarantee

proper blade operation and to ensure safety, you have to make sure that the temperatures at

the locations specified in the following are not exceeded. If not stated otherwise, the

temperatures should be measured by placing a sensor exactly at the given locations. For your

convenience all temperature spots are shown in a figure that provides a detailed view of the

blade.

ATCA-F120 Installation and Use (6806800D06J)

25

Hardware Preparation and Installation

Figure 2-1 Critical Temperature Spots

26

ATCA-F120 Installation and Use (6806800D06J)

Hardware Preparation and Installation

Table 2-2 Critical Temperature Limits

Temperature in

Location Temperature in Celsius

1 85°C 185°F Top center of DC/DC converter used

2 100°C 212°F PCB surface of main DC/DC

3 105°C 221°F Big capacitor, margin which faces

4 90°C 194°F Top center of filter coil

Fahrenheit Description

for management power

converter

the DC/DC converter

2.3.2 Power Requirements

Make sure that the blade is used in an AdvancedTCA shelf connected to -48VDC up to -60VDC,

according to Telecommunication Network Voltage (TNV-2). A TNV-2 circuit is a circuit whose

normal operating voltages exceed the limits for a safety-extra-low-voltage (SELV) under

normal operating conditions, and which is not subject to over-voltages from

telecommunication networks.

Table 2-3 DC System Power Requirements

Feature Value

Rated voltage -48VDC to -60VDC

Operating voltage -40.0VDC to -72VDC

Input current max. 5.0A@40V

Power dissipation max. 200W

ATCA-F120 Installation and Use (6806800D06J)

US and Canada: -48VDC

US and Canada: -40.0 to -60VDC

The tested blade was a ATCA-F120 blade, including two

installed AMC modules (35W each), and an RTM-ATCAF120-COP (30W).

27

Hardware Preparation and Installation

2.4 Installing Rear Transition Modules

As of writing this guide, the following rear transition module (RTM) were available: RTM-ATCAF120C and RTM-ATCA-F120-OPT

The RTMs are not hot-swappable. Before you install them, you must make sure that either no

front blade is installed in the respective slot, or that the front blade is powered-down. For

further details about the RTM installation refer to the Installation and Use guide of the

respective RTM.

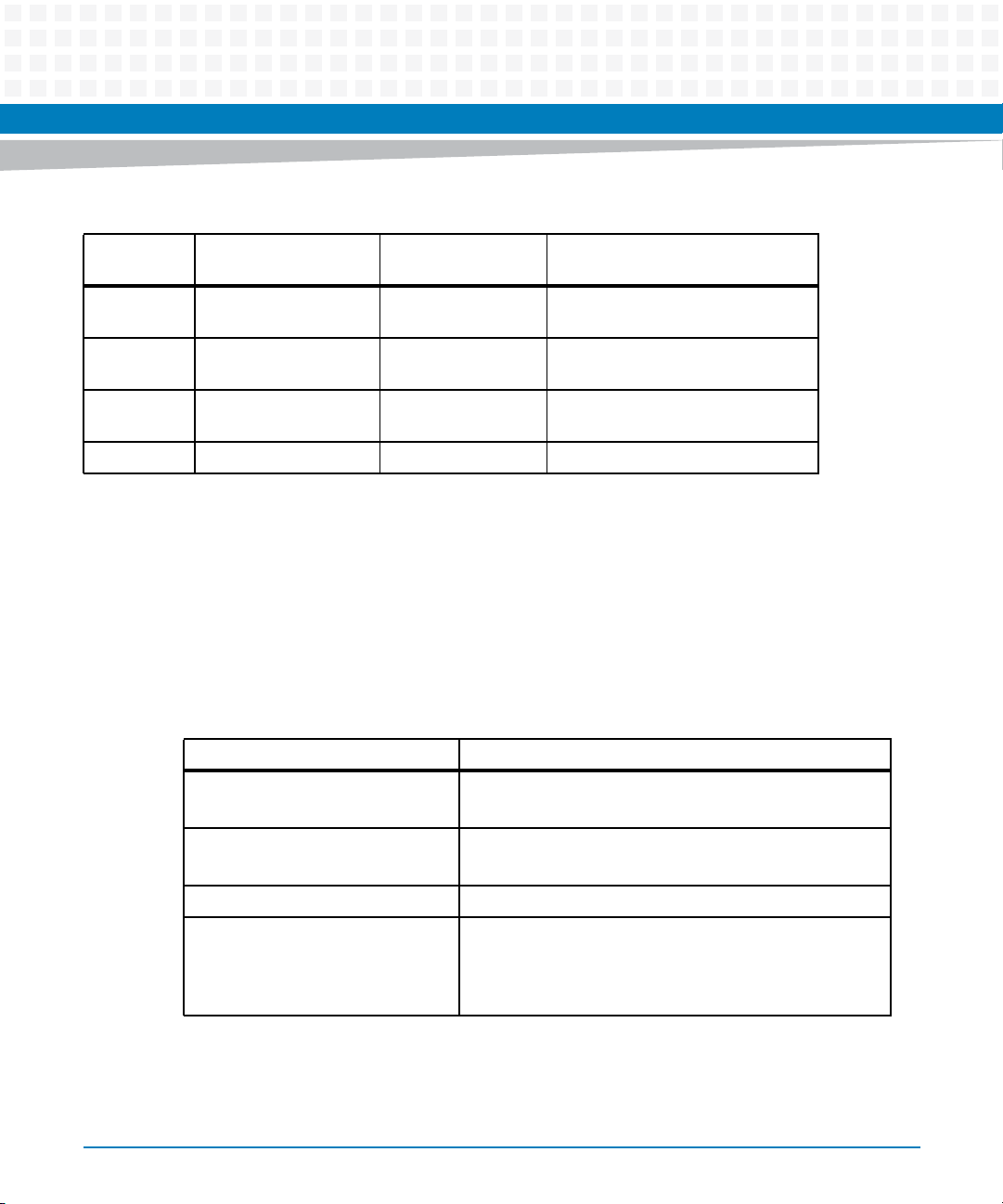

2.5 Configuring the Blade

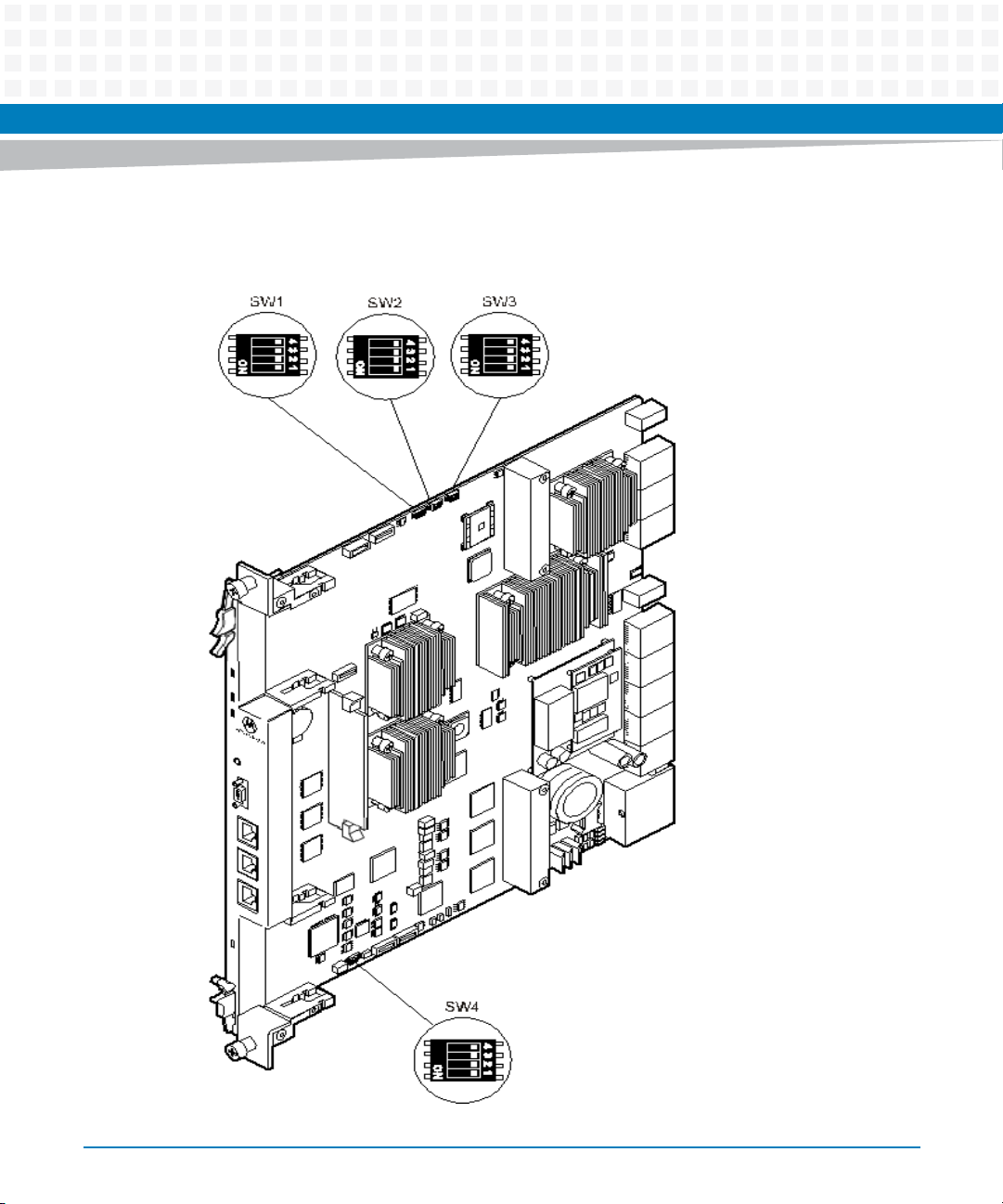

The blade provides the configuration switches SW1, SW2, SW3 and SW4. Their location is

shown in the following figure. The switch settings shown in the figure correspond to the

default settings. The switches are displayed as the small white squares.

28

ATCA-F120 Installation and Use (6806800D06J)

Figure 2-2 On-Board Configuration Switches

Hardware Preparation and Installation

ATCA-F120 Installation and Use (6806800D06J)

29

Hardware Preparation and Installation

Blade Malfunction

Switches marked as 'reserved' might carry production-related functions and can cause the

blade to malfunction if their setting is changed.

Therefore, do not change settings of switches marked as 'reserved'. The setting of switches

which are not marked as 'reserved' has to be checked and changed before blade installation.

Blade Damage

Setting/resetting the switches during operation can cause blade damage.

Therefore, check and change switch settings before you install the blade.

Table 2-4 Switch Settings

Switch Description

SW1-1 Selects whether the shelf manager (ShM) is accessed through Base

Channel port 1 or Update channel port 0. For details refer to Shelf

Manager Cross Connection on page 78.

Note that this switch setting can be overwritten via IPMI.

OFF: ShM is accessed through Update Channel port 0 (default)

ON: ShM is accessed through Base Channel port 1

SW1-2 Reserved (default: OFF)

SW1-3 Reserved (default: OFF)

SW1-4 Reserved (default: OFF)

SW2-1 and SW2-2 Serial interface routing

SW2-1 OFF and SW2-2 OFF (default): Serial interface of CPU is routed to

the F120 face blade and serial interface at RTM is disabled

SW2-1 ON and SW2-2 OFF: serial interface of CPU is routed to theRTM’s

face plate and serial interface of IPMC is routed to the F120 face plate (for

debugging only)

Other switch settings: Reserved

SW2-3 User flash #1 write protection. See User Flashes on page 69 and Memory

Map on page 95 for further details.

OFF: User flash #1 write-enabled (default)

ON: User flash #2 write-protected

30

ATCA-F120 Installation and Use (6806800D06J)

Loading...

Loading...