Ariston GENUS HE 35 Plus Instructions

GENUS HE 35 Plus

BFFi

Installation and

Servicing

Instructions

Type C Boilers

G.C.N: 47-116-57 (35 kW)

LEAVE THESE

INSTRUCTIONS WITH THE

END-USER

GENUS

HE 35

Plus

Country of destination

GB

IE

2

1. General Information

2. Control Panel

3. How to Use

4. Anti-Frost Device

5. Maintenance

6. Trouble Shooting

7. Filling Instructions

8. Time Clock

8.1 Setting the Mechanical Clock

8.2 Setting the Digital Clock

9. General Information for the Installer

9.1 Overall View

10. Installation

10.1 Delivery

10.2 Reference Standards

10.3 Siting the Appliance

10.4 Clearances

10.5 Overall View

10.6 Mounting the Appliance

10.7 Electrical Connection

10.8 Gas Connection

10.9 Water Connections

11. Connecting the Flue

11.1 Fitting the Coaxial Flue (Ø 60/100 mm Horizontal)

11.2 Fitting the Coaxial Flue (Ø 60/100 mm Vertical)

11.3 Fitting the 5” Flue (Ø 80/125 mm - Vertical)

11.4 Fitting the Twin Pipe (Ø 80/80 mm)

12. Electrical Connections

13.

Electrical System Diagrams

14. Water Circuit Diagrams

15. Commissioning

15.1 Initial Preparation

15.2 Completion

15.3 Removal and Fitting of the Case - Servicing

15.4 Pressurisation

15.5 Commissioning

15.6 Settings

15.7 Operating Faults

TABLE OF CONTENTS

16. Gas Convertion

17. Maintenance

18. Servicing Instructions

18.1 Replacement of Parts

18.2 To Gain General Access

18.2.1 Removing the front panel

18.2.2 Removing the control panel

18.3 Access to the Control System

18.3.1 Removing the main PCB

18.3.2 Removing the display PCB

18.3.3 Removing the fuses

18.3.4 Removing the time clock

18.4 Access to the Combustion Chamber

18.4.1 Removing the combustion chamber front panel

18.4.2 Removing the air gas assembly

18.4.3 Removing the burner

18.4.4 Removing the detection electrode

18.4.5 Removing the ignition electrode

18.4.6 Removing the fan

18.4.7 Removing the gas valve

18.4.8 Removing the heat exchanger

18.4.9 Removing the spark generator

18.5 Access to the Water Circuit

18.5.1 Drain down

18.5.2 Removing the 3 way valve

18.5.3 Removing the heating return filter

18.5.4 Removing the by-pass

18.5.5 Removing the pressure relief valve (3 bar)

18.5.6 Removing the pressure relief valve (7 bar)

18.5.7 Removing the temperature & pressure relief

valve (7 bar)

18.5.8 Removing & cleaning the condensate trap

18.5.9 Removing the pressure gauge

18.5.10 Removing the pump

18.5.11 Removing the heating expansion vessel

18.5.12 Removing the DHW expansion vessel

18.5.13 Removing the overheat thermostat

18.5.14 Removing the temperature sensors (N.T.C’s)

18.5.15 Removing the tank temperature sensor

18.5.16 Removing the water pressure gauge

18.5.17 Removing the flow switch

18.5.18 Removing the DHW temperature sensor

18.5.19 Removing the non return valve

18.5.20 Removing the plate heat exchanger

18.5.21 Removing the tank

19. Fault Finding Guide

20. Short Spares List

21. Technical Information

3

These instructions are suitable for the GENUS HE 35 Plus boilers :

Do not forget the Log Book!

MTS supports Benchmark, the heating industry code to ensure the correct installation, commissioning and servicing of

domestic central heating systems.

To The Householder

Make sure you have a completed Log Book for your boiler. This provides a record of the commissioning of your boiler.

It contains important information about your particular installation that may be required by service engineers. The Log Book will

also provide contact details for the installer should you need guidance in the use of this appliance or if there are any problems.

As with your car, your boiler will work more reliably and efficiently if regularly serviced. We recommend an annual service

check. The service history of the appliance will be recorded on the Log Book.

In the unlikely event of any problems with your boiler or system you should first contact your installer. If your installer cannot

resolve the problem he should telephone our national service helpline.

A charge may be made if MTS Service is called out to resolve a non-product related fault.

Your statutory rights are not affected.

CUSTOMER CARE

MTS, as a leading manufacturer of domestic and commercial water heating appliances is committed to providing high quality

products and a high quality after sales service.

Advice on installation or servicing can also be obtained by contacting the MTS Technical and Customer Service Departments

at High Wycombe.

TECHNICAL DEPARTMENT CUSTOMER SERVICE DEPARTMENT

Tel: 0870 241 8180 Tel: 0870 600 9888

Fax: 01494 459775 Fax: 01494 459775

GUARANTEE

The manufacturer’s guarantee is for 2 years from the date of purchase. The guarantee is invalidated if the appliance is not

installed in accordance with the recommendations made herein or in a manner not approved by the manufacturer. To assist us

in providing you with an efficient after sales service, please return the guarantee registration card enclosed with the boiler

without delay.

CAUTION

In the United Kingdom, installation, start-up, adjustments and maintenance, must be performed by a competent person only, in

accordance with the current Gas Safety (Installation & Use) Regulations and the instructions provided.

In the Republic of Ireland, the installation and initial start up of the appliance must be carried out by a Competent Person in

accordance with the current edition of I.S.813 “Domestic Gas Installations”, the current Buidling Regulations, reference should

also be made to the current ETCI rules for electrical installation.

All CORGI registered installers carry a CORGI ID card, and have a registration number. Both should be recorded in

your boiler Log Book. You can check your installer is CORGI registered by calling CORGI direct on:- (01256) 372300.

Improper installation may cause damage or injury to individuals, animals and personal property for which the manufacturer will

not be held liable. To ensure efficient and safe operation it is recommended that the boiler is serviced annually by a competent

person.

If it is known that a fault exists on the appliance, it must not be used until the fault has been corrected by a competent person.

To The Installer

As part of the commissioning of this appliance it is vital that the Log Book is completed and given to the Householder. Please

ensure that your customer is aware of the importance of keeping the Log Book safe as a record of the installation and the

appliance service history.

Please ensure that your customer is aware of the correct operation of the system, boiler and controls.

MTS recommend the use of protective clothing, when installing and working on the appliance i.e. gloves.

This instruction booklet is especially designed for appliances installed in the UK and the Republic of Ireland

1. GENERAL INFORMATION

4

2. CONTROL PANEL

* Warning the flue analysis mode must only be selected by a qualified service engineer.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

6

12

36

37

30

26

32

29

33

34

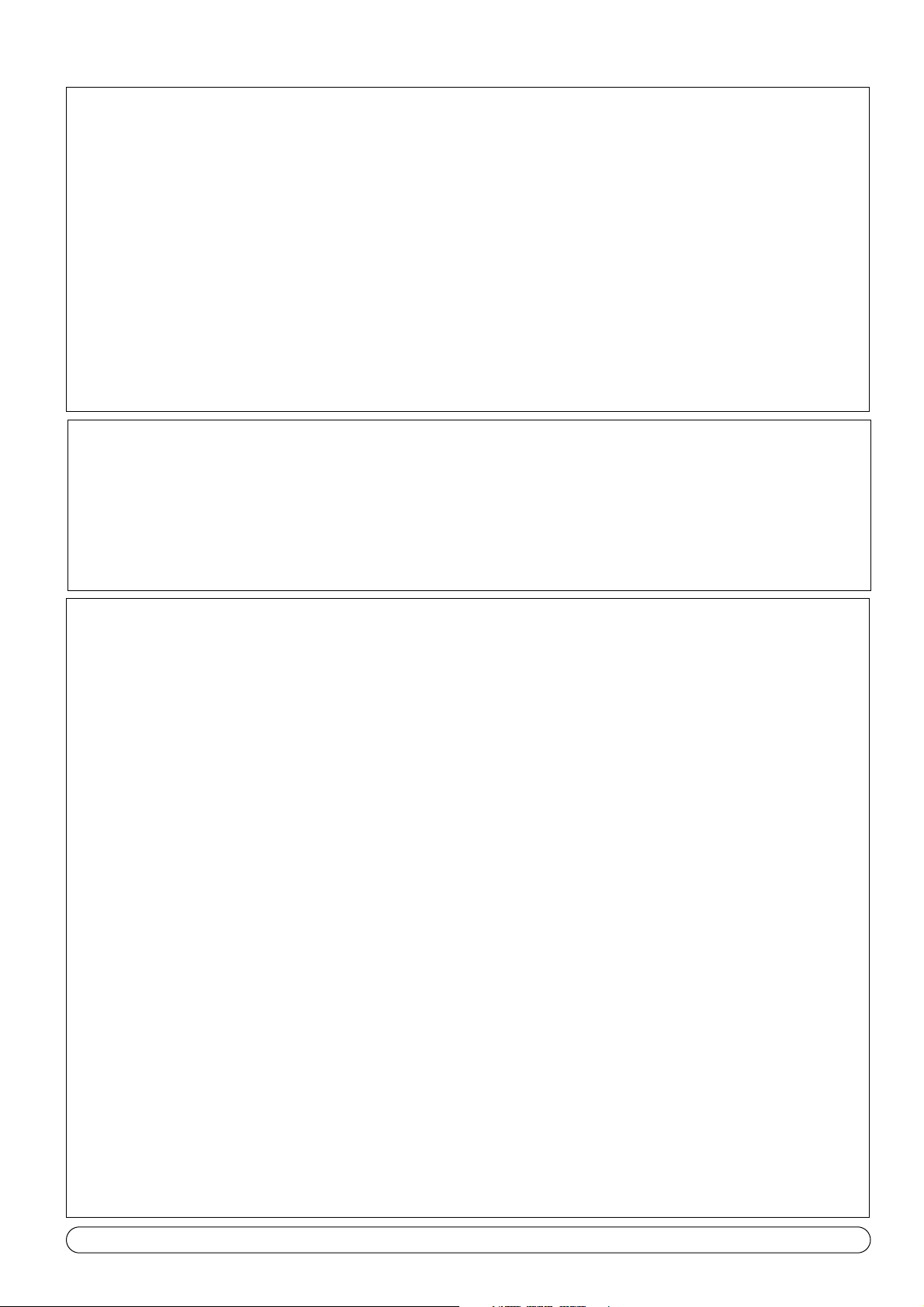

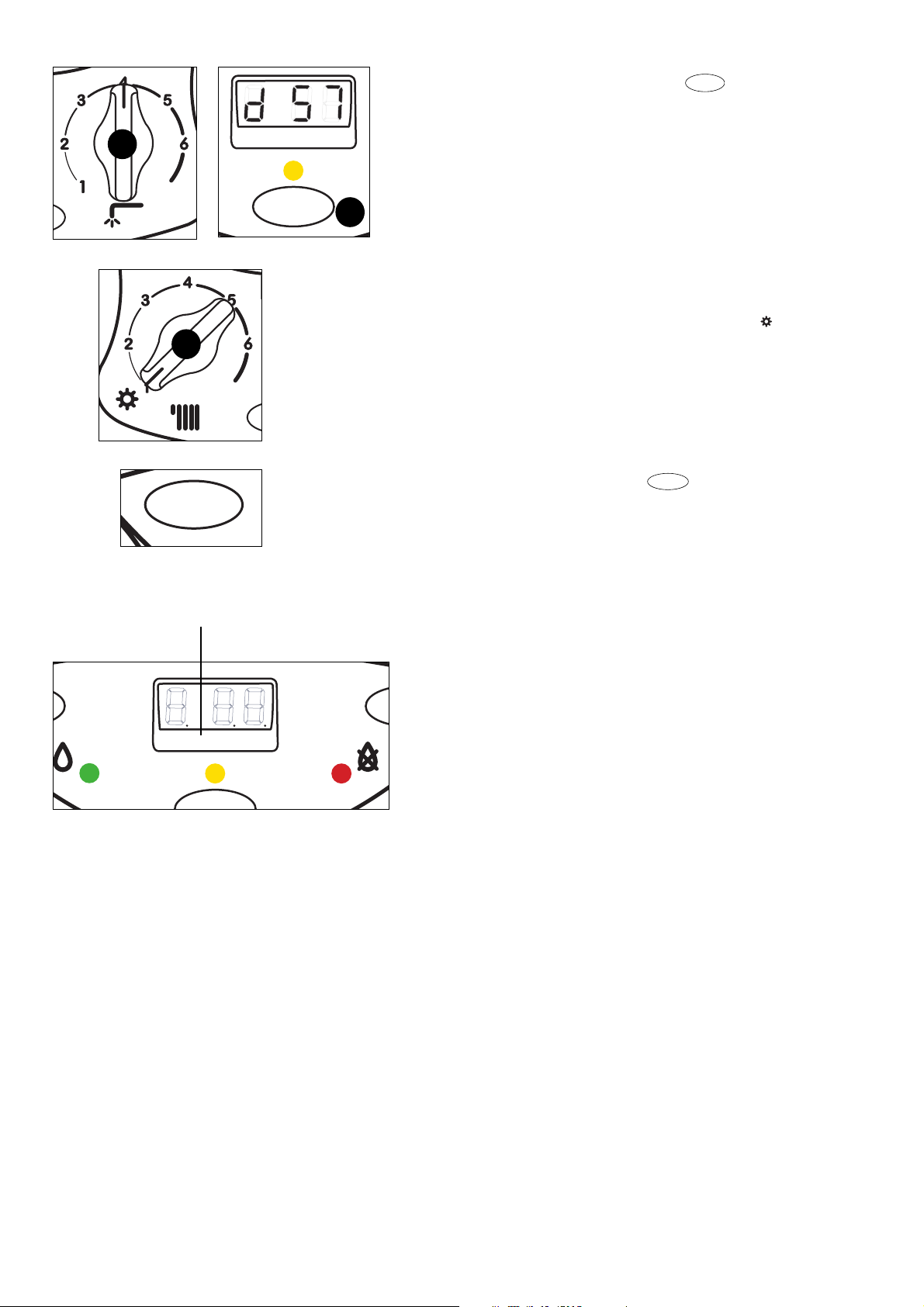

Control panel (Fig. 2.1)

26. - On/off push button

27. - Reset push button

28. - domestic hot water function and COMFORT tank on/off button

29. - burner operation green indicator light

30. - red indicator lock-out light

31. - yellow indicator - Comfort button

32. - Central Heating control knob

stop/mini/maxi

33. - DHW control knob /mini/maxi

34. - Increasing button +

35. - Reducing button -

36. - Menu button

37. - Pressure gauge

46. - Time clock

48. - Display

35

27

28

31

48

46

FIG. 2.1

USER INSTRUCTIONS

Connecting bracket

Taps shown in Open position (Fig. 2.2)

39 : Gas service tap

40 : Water service tap

41 : Central heating flow isolating valve

42 : Central heating return isolating valve

43 & 44: Filling taps

45 : Filling loop

Fig. 2.2

41

42

43

44

45

39

40

ON/OFF

1

24

2

23

3

22

4

12

5

6

7

9

8

9

10

21

20

I

19

18

17

16

6

15

11

14

12

13

COMFORT

RESET

5

3. HOW TO USE

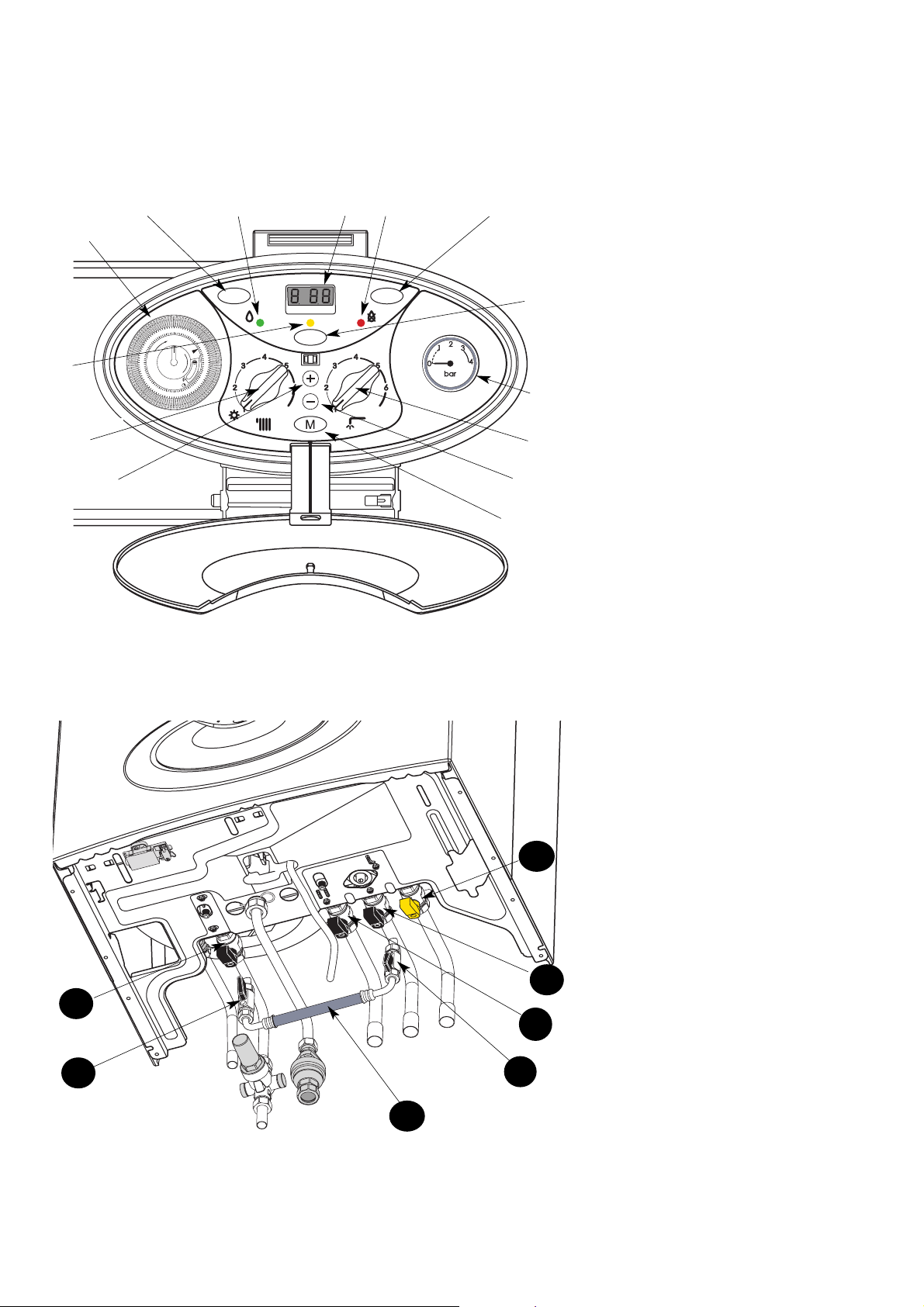

Switching on

1. Check that the pressure in heating system is

adequate, i.e. the pressure gauge 37 shows 1

bar minimum and 1.5 bar maximum.

2. Check that the gas service tap 39 (Fig. 3.1) is

opened (Figs. 3.2 and 3.3) and that the mains

power is on, On/Off push button 26 Power

ON.

The boiler is now ready to use.

Note : If the boiler has been turned off for some

time, the presence of air in the gas pipe

may result in a lockout.

FIG. 3.2

FIG. 3.3

GAS COCK CLOSED

GAS COCK OPEN

FIG. 3.1

26

27

30

32

32

32

39

Ignition procedure

Press the button 26, the electronic control unit will ignite the

burner without any manual intervention (only when there is a

demand for Domestic hot water or heating). If the burner does not

ignite within the safety period, the screen will display error code A01

and the warning light 30 will come on.

To reinitialise the ignition system, press the button 27.

If ignition fails again, verify that the gas tap is open before calling a

qualified technician.

RESET

ON/OFF

Summer and winter operation

The boiler produces hot water for heating and Domestic hot water.

Winter operation means the production of hot water for heating and

the production of Domestic hot water. Summer operation means the

production of Domestic hot water only. The boiler control panel

allows selection of winter or summer operation.

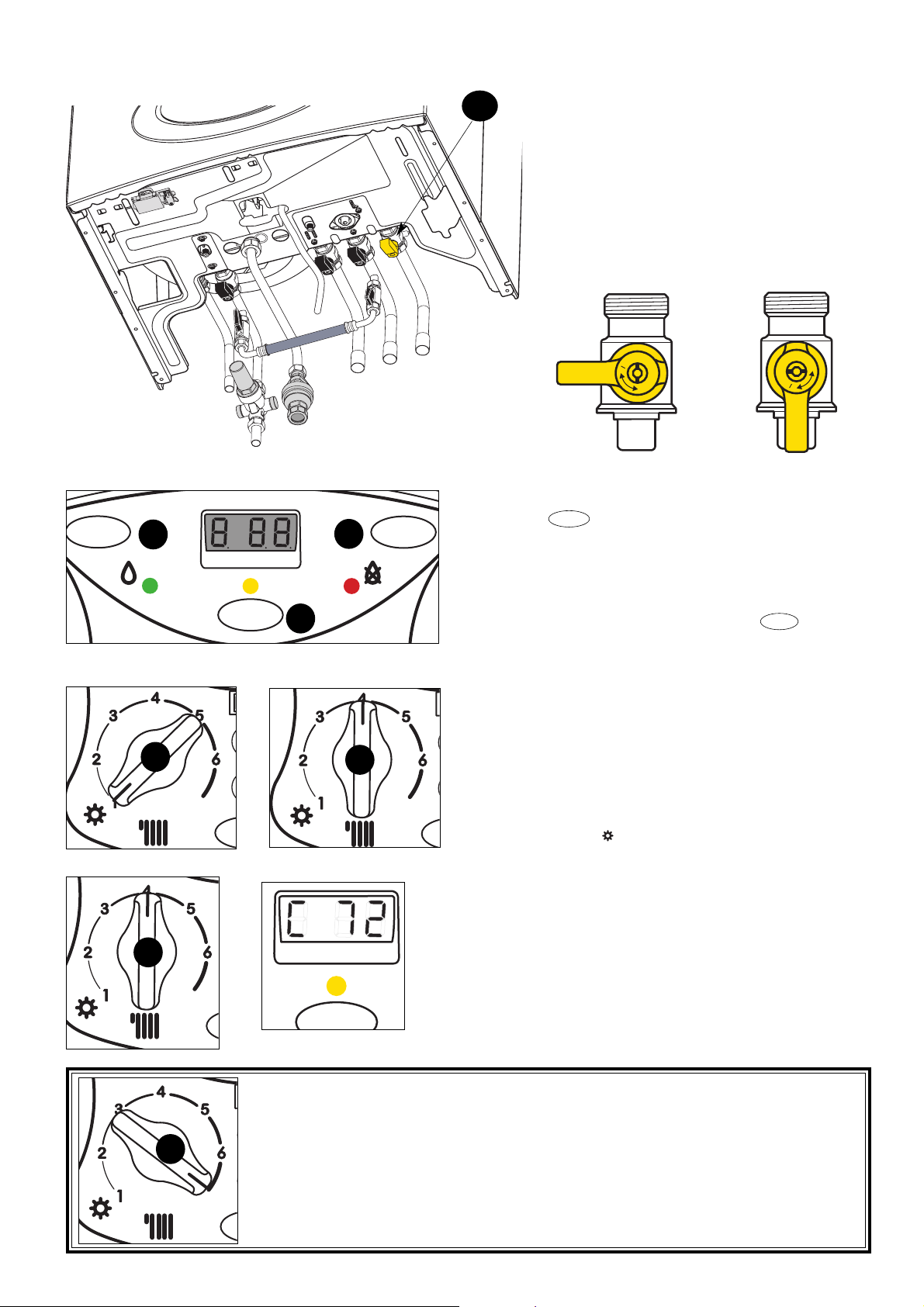

Keep the knob 32 in the position to select summer operation. To

select winter operation, turn the knob 32 to a position between the

minimum value and the maximum value.

Heating temperature control

To adjust the heating water temperature, use the knob 32, position

the pointer between the minimum and maximum values; the

temperature obtained can vary between 42°C and 82°C or 25°C and

75°C.

The heating command is activated by a mechanical programmer, or

the room thermostat or a remote unit.

Installation with regulation by external temperature

(Only activated if the external sensor is installed)

In this case, by turning the knob 32, it is possible to change the heating outlet temperature and

therefore the ambient temperature of your home. When the knob is turned, the display indicates

P6 and the heating outlet temperature can be varied by - 20 °C to 20 °C.

However, the boiler can be controlled by the timeswitch, a Clima Manager remote control or a

room thermostat.

As soon as the desired temperature is reached, the burner is switched off and the circulation

pump stops or goes into post-circulation mode.

32

ON/OFF

COMFORT

RESET

+

+

COMFORT

6

The boiler is fitted with a device, which in the event that the water

temperature falls below 8

o

C the pump activates and runs until a

temperature of 18

o

C is attained. In the event that the water

temperature falls below 3

o

C, the diverter valve switches to Domestic

Hot Water and the burner fires on minimum power until a temperature

of 33

o

C is attained.s

This device is only activated when the boiler is operating perfectly and

- the system pressure is sufficient;

- the boiler is powered electrically;

- gas is available.

Schedule an annual maintenance check-up for the boiler with a CORGI

registered Service Engineeer in the UK and with a competent person

as described in I.S.813 for IE.

Correct maintenance always results in savings in the cost of running

the system.

4. ANTI-FROST DEVICE

5. MAINTENANCE

33

32

R

Afficheur gauche

Afficheur droit

28

Regulation of Domestic hot water

To obtain Domestic hot water, press the button COMFORT 28

(yellow LED comes on)

To adjust the Domestic hot water temperature in winter or summer

operation, use the knob 33. It is possible to determine the temperature of

water stored in the tank between 40°C and 70°C.

COMFORT

Interruption of heating

To interrupt heating, turn the knob 32 to the sun position .

The boiler will continue to operate in the summer position to provide

Domestic hot water only.

Switch-off procedure

To switch the boiler off, press the button 26. Close the gas tap

located under the boiler and move the boiler external power supply switch

to the OFF position.

ON/OFF

Display: display of current operations

During operation of the boiler, in other words when it is performing its

normal functions, the left side of the display shows a series of characters

referring to the operations, as indicated below:

0

No heating command

C

Heating

c

pump in post-circulation mode for heating

d

Domestic hot water

h

Pump in post-circulation mode for Domestic hot water

b

Tank reheating

On the right, the display shows (2 characters):

- in heating mode: heating installation output temperature

- in Domestic hot water distribution mode: drawing-off temperature.

- in tank reheating mode: tank temperature or drawing-off temperature.

ON/OFF

COMFORT

7

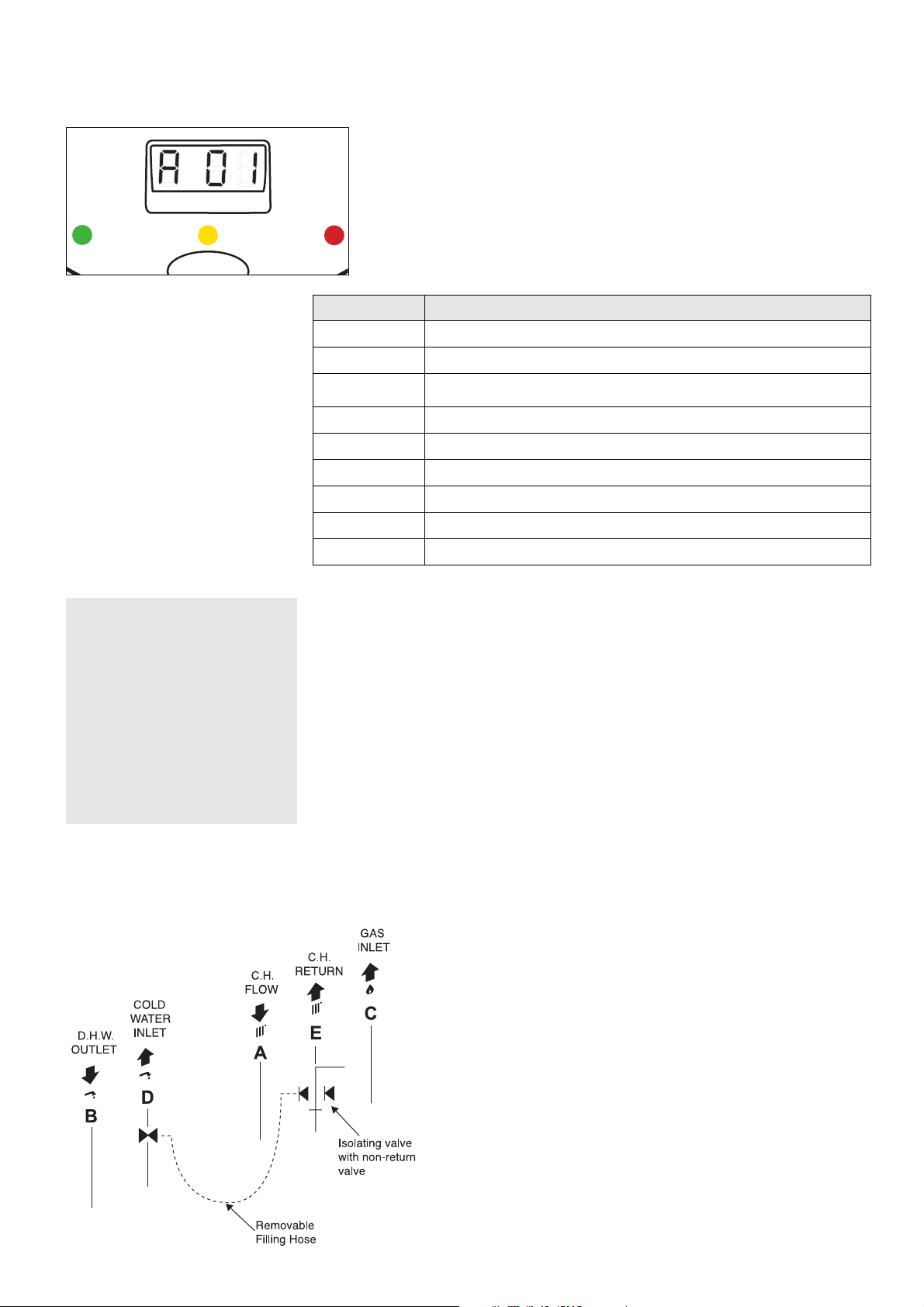

AFFICHEUR CAUSE

A01

Three ignition attempts

A03

The output temperature exceeds 105°C during operation

A07

Too many flame separations over a period during operation

A17

Input water circulation fault

A18

No water circulation

A33

Fan problem

A97

Electronic control problem

A98

Electronic control problem

A99

Electronic control problem

6. TROUBLE SHOOTING

7. FILLING INSTRUCTIONS

A method for initially filling the system and replacing lost water

during servicing and initial filling (in accordance with current Water

Regulations), is provided as an integral part of the connection kit

(see Fig. 3.1).

To fill the system and replace lost water it is necessary to proceed

as follows:

- Switch off the power to the boiler;

- Ensure that the flexible hose is connected to both the cold

water inlet connection and the C.H. flow connection;

- Open the black lever on the valve for the C.H. flow connection

and slowly open the black handle on the valve for the cold water

inlet until water is heard passing through the valves;

- Once the pressure gauge 37 (Fig. 2.1) reads between 1 and

1.5 bar close the levers on both the cold water connection and the

C.H. flow connection

- Switch the power to the boiler back on.

N

OTE: THE FLEXIBLE HOSE MUST BE REMOVED ONCE THE SYSTEM HAS

BEEN FILLED

.

FIG. 7.1

CONDITIONS FOR STOPPAGE OF THE BOILER

This boiler is fitted with safety devices which are activated in certain situations

and cause the boiler to stop operating.

There are two types of stoppage:

- Operating failure (A)

- Safety stop (E)

OPERATING STOPPAGE "A"

This type of stoppage is displayed in the form of a number preceded by a

letter (A) as shown in the following table.

To clear this type of stoppage, press the reset button (Reset).

In the table, each error code is associated with the problem causing it to

appear.

In the case of error

A 02

, before

calling a qualified technician, check

the pressure gauge to see if the

water pressure in the appliance is 1

bar. If necessary, restore the

pressure using the filling valve

located under the boiler and perform

an ON/OFF operation by pressing

the button. If the pressure falls

frequently in the appliance, have a

plumber check for water leaks.

N.B. Warning! The boiler is always

connected to an electrical supply.

IMPORTANT

If this type of failure occurs too often,

call an approved after sales technical

service. For safety reasons, the

boiler will only allow 5 reignition

attempts in 15 minutes (pressing of

the RESET button). After the fifth

attempt, the boiler goes into safety

shutdown mode E 99.

This is therefore not a problem in the

case of sporadic or isolated

stoppages.

SAFETY SHUTDOWN “E”

In the event of a safety shutdown, indicated by display of the letter E followed by a

number, there is no need to take action. The boiler will automatically attempt to reset and

restart. If this does not occur, call a qualified technician. Switch off the boiler as described

in the previous paragraph, close the gas tap and move the external electrical supply

switch to the OFF position.

Antilocking of pump and three-way valve

To prevent locking of the components, the appliance performs a self-test every 24 hours:

the pump starts up for 3 seconds and the diverting valve is operated.

8

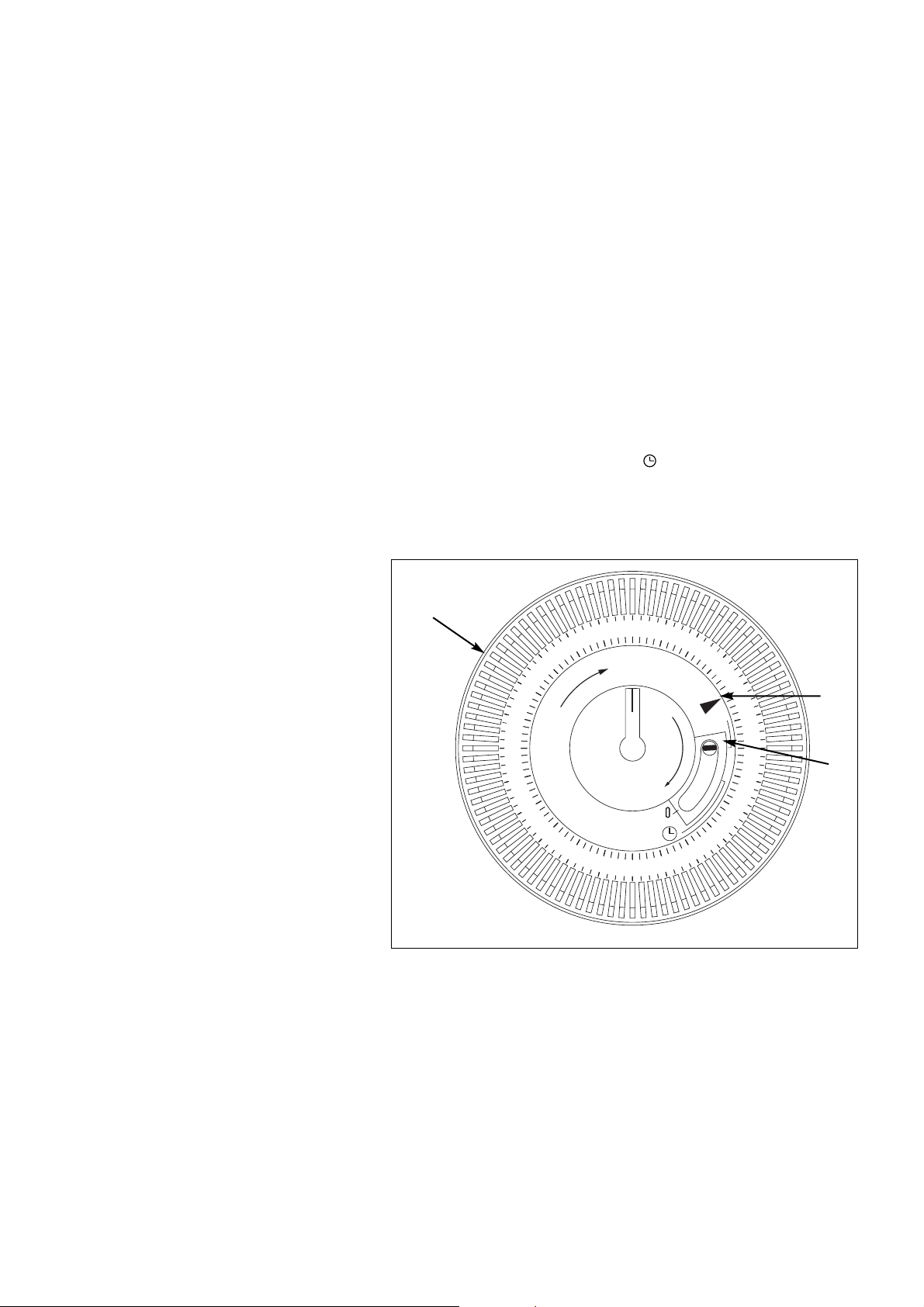

8. TIME CLOCK

1. General layout

The mechanical clock covers a 24 hour period. Each tappet

represents 15 minutes A (Fig 8.1). An override switch is located on

the clock B (Fig 8.1).

2. To set the time

To set the time of day, grasp the outer edge of the dial and turn

slowly clockwise until the correct time is lined up with the arrow C

(Fig. 8.1).

3. To Set the "On" and "Off" times

The clock uses a 24hours system. e.g. 8 = 8.00 am and

18 = 6.00 pm "ON" periods are set by sliding all tappets between

the "ON" time and the "OFF" time to the outer edge of the dial.The

tappets remaining at the centre of the dial are the "OFF" periods.

4. For operation

Put the selector switch B to the symbol to control the central

heating by the clock. Put the switch B to «I» to select permanent

operation or to «0» to turn the central heating off permanently.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

6

12

A

C

B

8.1 Setting the Mechanical Clock

FIG. 8.1

1

12

6

13

24

14

23

15

22

16

21

20

I

19

18

17

2

3

4

5

6

7

9

8

9

10

11

12

9

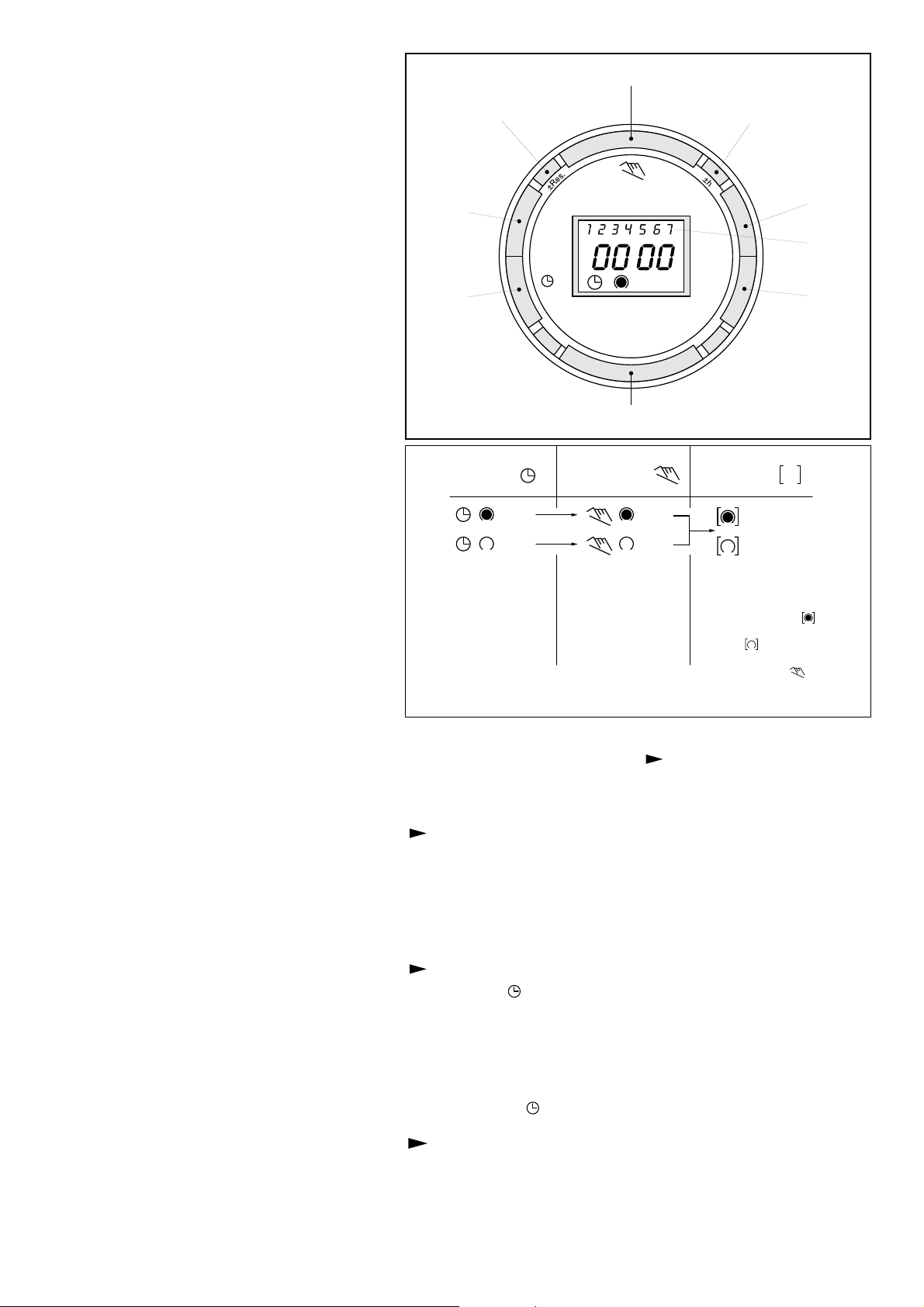

Operating the time switch

The step marked with the symbol “ ” are necessary to carry out a

switching program.

Preparing for Operation

Activate the “Res” switch (=RESET) to reset the time switch to its

default setting (activate using a pencil or similar pointed instrument).

Do this:

- every time you wish to “reset” the time switch

- to erase all switching times and the current time of day.

After approximately two seconds the following display appears:

Enter current time and weekday

- Keep the “ ” key pressed down

During the summer time period press the +/- 1h key once.

Enter the hour using the “h” key

Enter the minutes using the “m” key

Enter the day using the “Day” key

1 = “Monday”..............7 = Sunday

- Release the “ ” key.

Entering the switching times

You have 20 memory Iocations available. Each switching time takes

up one memory location.

Keep pressing the “Prog” key until a free memory location is shown in

the display “– –:– –”.

8.2 Setting the Digital Clock

Reset

Manual switch

Summer and

winter time

setting

Enter

switching

times

Imput

time

Automatic Manual Continuous

Operation Operation Operation

= ON = ON = Continuously ON

= OFF = OFF = Continuously OFF

The switching If the current You can only

times corres- switching mode is return to automatic

pond to the changed manually, mode from the

program the next switching continuously-ON

entered. time will be and continuously-

carried out auto- OFF switching

matically again modes by

according to the pressing the " "

entered switching key.

program.

.

g

o

r

P

Day

Enter

weekday/s

h

m

Enter

the hours

Week-

days

flash

Enter

minutes

10

Programme ON or OFF with the “ ” key:

“ ”= OFF; “ ”= ON

Enter the hour using “h”

Enter the minutes using “m”

If a switching command is to be carried out every day (1 2 3 4 5 6

7) then store using the “ ” key, otherwise select the day(s) it is to

be carried out by using the “Day” key.

When the day seIection is left bIank, the programmed switching

instruction operates at the same time every day

1 2 3 4 5 6 = Monday – Saturday

1 2 3 4 5 = Monday – Friday

6 7 =Saturday – Sunday

Selection of single days: 1 = Mon. .............. 2 =Tues.

Save the switching time with the “ ” key.

The time switch enters the automatic operating mode and displays

the current time of day.

Begin any further entry of a switching time with the “Prog” switch. If

your entry is incomplete, the segments not yet selected will blink in

the display. After programming is completed, and you return the

time clock to the current time display with the “ ” key, the time

clock will not activate any switching instruction required for the

current time. You may need to manually select the desired

switching state with the “ ” key. Thereafter, as the unit

encounters further switching instructions in the memory in real time,

it will correctly activate all subsequent switching instructions.

Manual Override Switch “ ”

With the “ ” you can change the current setting at any time. The

switching program already entered is not altered.

Reading the programmed switching times

Pressing the “Prog” key displays the programmed switching times until

the first free memory location appears in the display “– – : – –”.

If you now press the “Prog” key once again, the number of free memory

Iocations will be displayed, e.g. “18”. If all memory locations are

occupied, the display “00” appears.

Changing the programmed switching times

Press the “Prog” key repeatedly until the switching time you want to

change is displayed. You can now enter the new data. See point

“Entering the switching times”.

Notes on storing switching times:

If you end your entry of the switching times by pressing the “Prog” key,

then the switching time you have entered will be stored and the next

memory location displayed.

In addition, a complete switching command is stored automatically

after around 90 seconds provided no other key is pressed. The time

switch then enters the automatic operating mode and displays the

current time again.

Deleting individual switching times

Press the “Prog” key repeatedly until the switching time you wish to

delete is shown in the display. Then set to “– –” using the “h” or “m” key

and keep the “ ” key pressed down for around 3 seconds. The

switching time is now erased and the current time is displayed.

AM / PM time display

If you press the “+/-1h” and “h” keys at the same time, the time display

switches into the AM/PM mode.

11

Read the instructions and recommendations in these Installation and Servicing Instructions carefully to ensure proper installation,

use and maintenance of the appliance.

Keep this manual in a safe place. You may need it for your own reference while Servicing Technicians or your installer may need

to consult it in the future.

This is a combined appliance for the production of central heating (C.H.) and domestic hot water (D.H.W.).

This appliance must be used only for the purpose for which it is designed.

The manufacturer declines all liability for damage caused by improper or negligent use.

No asbestos or other hazardous materials have been used in the fabrication of this product.

Before connecting the appliance, check that the information shown on the data plate and the Technical Information (Section 21)

comply with the electric, water and gas mains of the property. You will find the data plate on the reverse of the control panel.

Do not install this appliance in a damp environment or close to equipment which spray water or other liquids.

Do not place objects on the appliance.

Do not allow children or inexperienced persons to use the appliance without supervision.

If you smell gas in the room, do not turn on or off light switches, use the telephone or any other object which might cause

sparks.

Open doors and windows immediately to ventilate the room.

Shut the gas mains tap (at or adjacent to the gas meter) or the valve of the gas cylinder and call your Gas Supplier immediately.

If you are going away for a long period of time, remember to shut the mains gas tap or the gas cylinder valve.

Always disconnect the appliance either by unplugging it from the mains or turning off the mains switch before cleaning the

appliance or carrying out maintenance.

In the case of faults or failure, switch off the appliance and turn off the gas tap. Do not tamper with the appliance.

For repairs, call your local Authorised Servicing Agent and request the use of original spare parts. For in-guarantee repairs

contact MTS (GB) Limited.

Check the following at least once a year:

1 - Check the seal of water connections, replacing the gaskets if necessary.

2 - Check the seal of the gas connections, replacing the gaskets if necessary.

3 - Check the general condition of the appliance and of the combustion chamber visually.

4 - Visual check of the combustion: clean burners if necessary.

5 - With reference to point 3, dismantle and clean the combustion chamber if necessary.

6 - With reference to point 4, dismantle and clean the injectors if necessary.

7 - Visual check of the primary heat exchanger:

- check for overheating of the exchangers fins;

- clean the exhaust side of the exchanger and fan if necessary.

8 - Regulate the gas pressure, ignition pressure, partial flame, maximum flame.

9 - Check proper operation of the heating safety system:

- maximum safety temperature;

- maximum safety pressure.

10 - Check the proper operation of the gas safety system:

- gas or flame safety device;

- gas valve safety device.

11 - Check that the electrical connections have been made in compliance wit h the instructions shown in the Installation

Instructions.

12 - Check the efficiency of the hot water supply (flow and temperature).

13 - Check pressure in the Domestic Expansion Vessel and top up as necessary.

14 - Check manually by turning the test knob the Temperature & Pressure Relief Valve.

15 - Check manually by turning the test knob the Expansion Relief Valve.

16 - Check discharge pipes from both the central heating and domestic hot water for obstructions.

17 - Check general operation of the appliance.

18 - Check the exhaust system for the combustion products.

19 - Check all unvented domestic hot water controls and systems

NOTE: These checks are not exhaustive

9. GENERAL INFORMATION FOR THE INSTALLER

INSTALLER INSTRUCTIONS

12

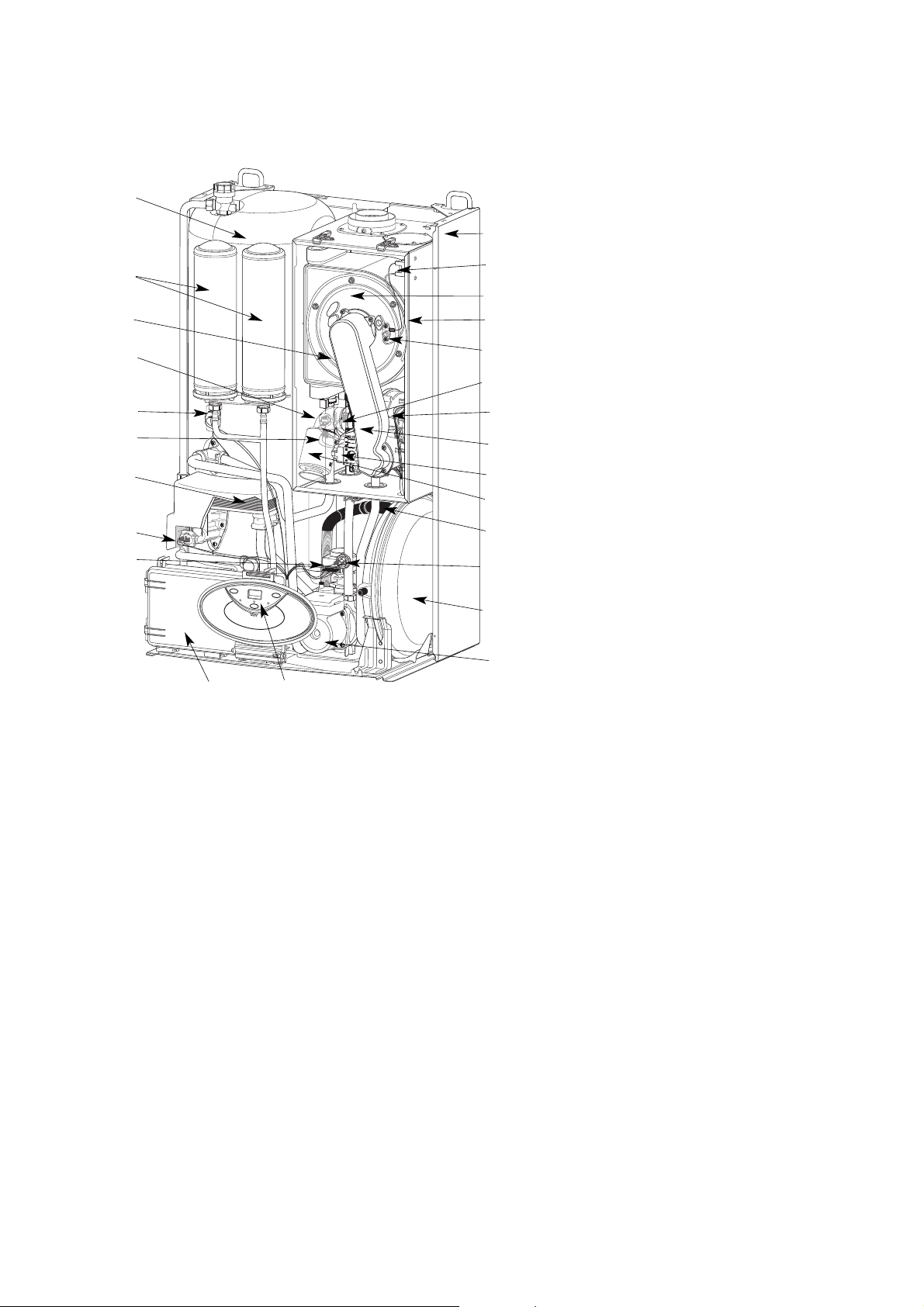

9.1 OVERALL VIEW

1

2

3

4

5

6

8

10

11

13

14

7

15

16

18

12

19

17

9

21

20

22

23

24

25

FIG. 9.1

1. - sheet steel casing

2. - pressurised expansion tank

3.- sealed casing

4. - burner/exchanger assembly

5. - 24 V fan

6. - air/gas connection assembly

7. - ignition electrodes

8. - flame detection electrode

9. - stainless steel Domestic hot water tank

10. - circulation pump

11.- electronic control unit

12. - ignition transformer

13.- overheat cut-off

14. - gas valve

15. - tank sensor

16. - heating outlet sensor

17. - heating return sensor

18.- distributor valve

19. - stainless steel plate Domestic hot water

exchanger

20. - Domestic hot water flow rate controller

21. - Domestic hot water sensor

22. - silencer

23. - siphon

24. - Domestic hot water expansion cylinder

25. - pressure switch

13

The technical information and instructions provided herein below are

intended for the installer / Servicing Technician so that the unit may be

installed and serviced correctly and safely.

There will be two items:

1 - The fully assembled boiler

2 - A separately boxed connection kit

WATER REGULATIONS

In GB it is necessary to comply with the Water Supply (Water Fittings)

Regulations 1999, for Scotland, The Water Bylaws 2000, Scotland. The

Genus 30 Plus is an approved product under the Water Regulations.

To comply with the Water Regulations, you attention is drawn to The Water

Regulations guide published by the Water Regulations Advisory Scheme

(WRAS) gives full details of the requirements.

In IE, the requirements given in the current edition of I.S.813 and the

current Building Regulations must be followed.

BUILDING REGULATIONS

These are a statutory document and take priority over all other regulations

and recommendations. The installation of an unvented hot water storage

cylinder is classified as a "Controlled Service" and Regulation G3 applies.

To meet the requirements of the Regulation, installation of an unvented

system should be undertaken by a "competent installer".

All installations of unvented hot water storage systems having a capacity of

more than 15 litres should be notified to the relevant Local Authority by

means of Building Notice or by the submission of full plans. It is important

to note that it is a criminal offence to install an unvented hot water storage

system without notifying the Local Authority.

The installation of this appliance must be in accordance with the

relevant requirements of the Local Building Regulations, the current

I.E.E. Wiring Regulations, the bylaws of the local water authority, in

Scotland, in accordance with the Building Standards (Scotland)

Regulation and Health and Safety document No. 635 “Electricity at work

regulations 1989” and in the Republic of Ireland with the current edition

of I.S. 813, the Local Building Regulations (IE).

C.O.S.H.H.

Materials used in the manufacture of this appliance are non-hazardous

and no special precautions are required when servicing.

Installation should also comply with the following British Standard

Codes of Practice:

10. INSTALLATION

10.2 Reference Standards

10.1 Delivery

BS 7593 Treatment of water in domestic hot water

central heating systems

BS 5546 Installation of hot water supplies for

domestic purposes

BS 5440-1 Flues

BS 5440-2 Air supply

BS 5449 Forced circulation hot water systems

BS 6798 Installation of gas fired hot water boilers

of rated input not exceeding 60kW

BS 6891 Installation of low pressure gas pipe up to

28mm

BS 7671 IEE wiring regulations

BS 7074 Specification for expansion vessels

BS 5482 Installation of L.P.G.

10.3 Siting the Appliance

14

and in the Republic of Ireland in accordance with the following

Codes of Practice:

WARNING!!

The addition of anything that may interfere with the normal

operation of the appliance without express written permission of

the manufacturer or his agent could invalidate the warranty. In GB

this could also infringe the GAS SAFETY(Installation and Use)

REGULATIONS.

In the Republic of Ireland the installation and initial start up of the

appliance must be carried out by a Competent Person in

accordance with the current edition of I.S.813 “Domestic Gas

Installations”, the current Building Regulations, reference should

also be made to the current ETCI rules for electrical installation.

The appliance may be installed in any room or indoor area,

although particular attention is drawn to the requirements of the

current I.E.E. Wiring Regulations, in Scotland, the electrical

provisions of the Building Regulations applicable in Scotland, and

in the Republic of Ireland, the current edition of I.S.813, with

respect to the installation of the combined appliance in a room

containing a bath or shower. The location of the boiler in a room

containing a bath or shower should only be considered if there is

no alternative.

Where a room-sealed appliance is installed in a room

containing a bath or shower reference should be made to the

relevant requirements.

In GB this is the current I..E.E. WIRING REGULATIONS and

BUILDING REGULATIONS. In IE reference should be made to

the current edition of I.S.813 and the current ETCI rules.

If the boiler is to be sited into a timber framed building, reference

must be made to the current edition of the Institution of Gas

Engineers Publication IGE/UP/7 (Gas Installations in Timber

Framed Housing).

The location must permit adequate space for servicing and air

circulation around the appliance as indicated in Section 10.4.

The location must permit the provision of an adequate flue and

termination.

For unusual locations special procedures may be necessary.

BS 6798-1987 gives detailed guidance on this aspect.

A compartment used to enclose the appliance must be designed

specifically for this purpose. No specific ventilation requirements

are needed for the installation within a cupboard.

This appliance is not suitable for outdoor installation.

I.S. 813 Domestic Gas Installations

The following BS Standards give valuable information;

BS 5546 Installation of hot water supplies for

domestic purposes

BS 5449 Forced circulation hot water systems

BS 7074 Specification for expansion vessels

BS 7593 Treatment of water in domestic hot water

central heating systems

15

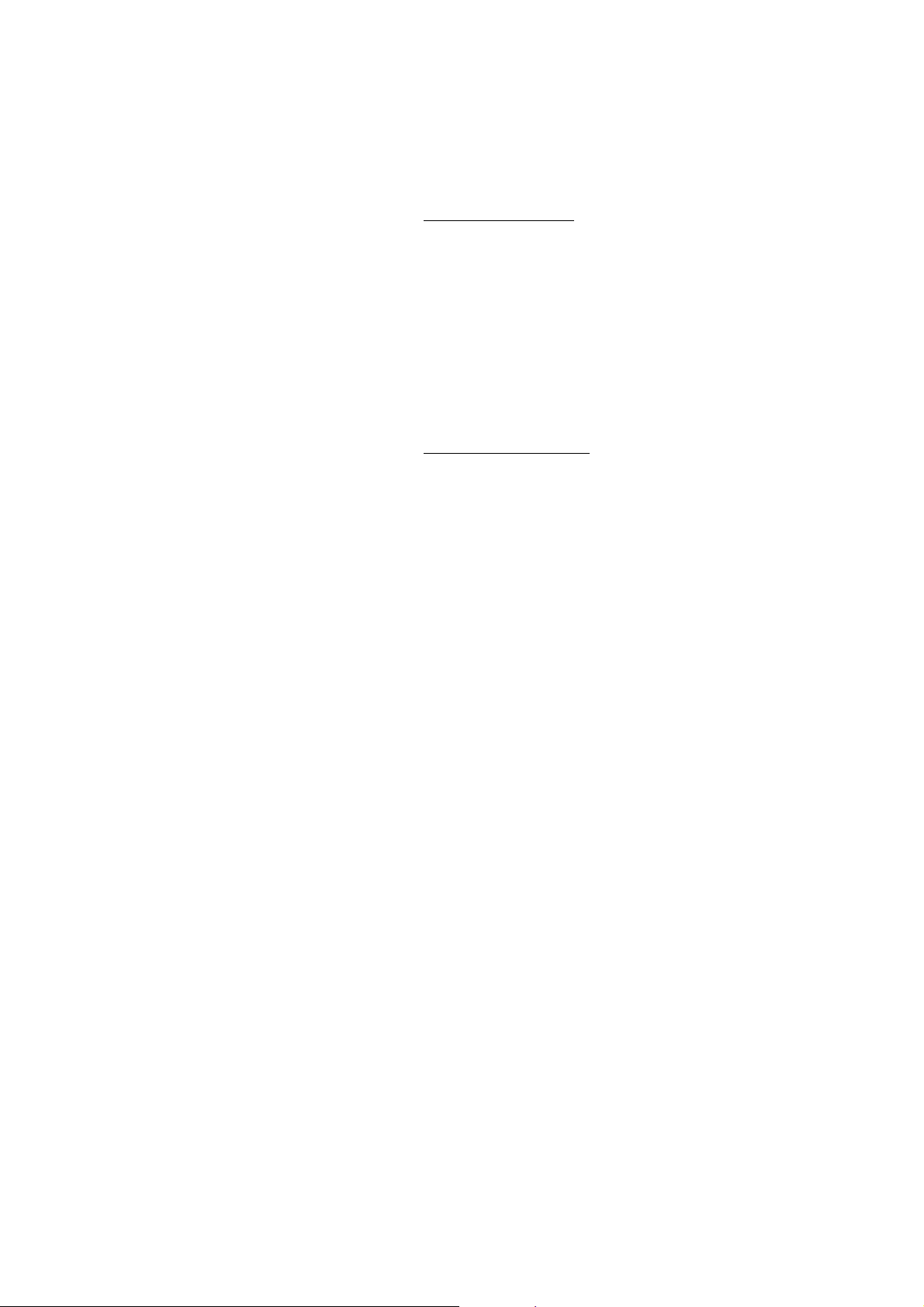

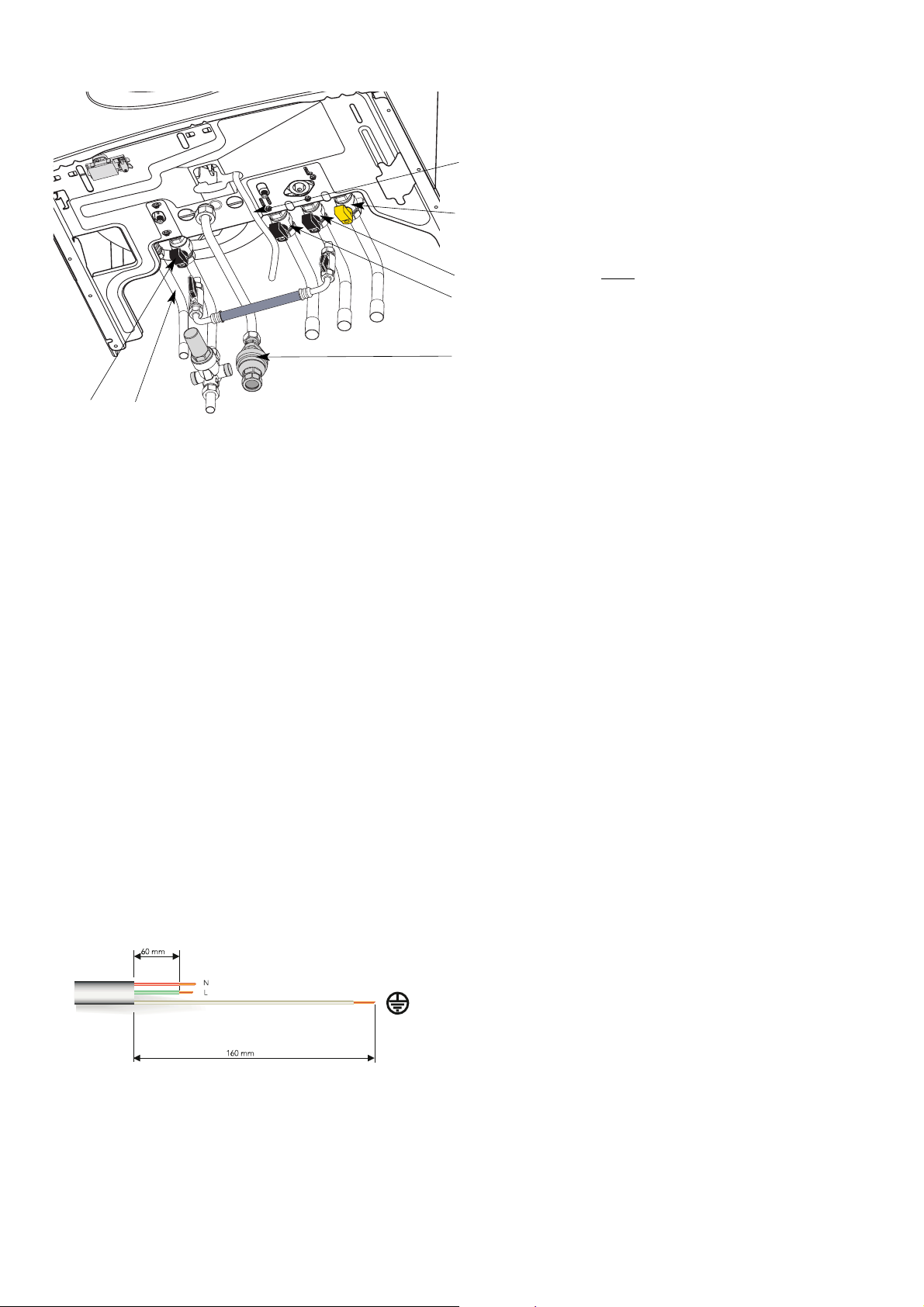

10.5 Overall Dimensions

FIG. 10.1

The type C appliances (in which the combustion circuit,

air vent intake and combustion chamber are air-tight

with respect to the room in which the appliance is

installed) can be installed in any type of room.

Secondary ventilation is not required with this boiler. The

boiler must be installed on a solid, non-combustible,

permanent wall to prevent access from the rear.

In order to allow for access to the interior of the boiler for

maintenance purposes, the boiler must be fitted with a

clearance of 450 mm in front 400 mm below the boiler and

200mm above the boiler, and installed in compliance with the

clearance requirements indicated in Fig. 10.1.

Legend:

39 = Gas service tap

40 = Heating return

41 = Heating flow

42 = Water service tap

43 = Tank hot water flow

38 = Water tank

discharge valve

44 = Central heating

discharge valve

10.4 Clearances

195

500

180

470

950

450mm minimum for

servicing purposes

595

317

135

54

43

42

54 145

172 54

80

38

41

44

40

39

280

925

57

188

16

After removing the boiler from its packaging, remove the

template from the separate box containing the connection

kit. N

OTE: Pay particular attention to any test water that

may spill from the appliance.

Place the template in the position the appliance is to be

mounted and after ensuring it is hanging squarely, use it to

drill the holes for the hanging bracket, connection kit and

flue pipe(s) NB: For further information relating to the flue

installation please refer to Section 11 F

LUE CONNECTION. (If

the appliance is to be fitted on a wall of combustible

material, the wall must

be protected by a sheet of fireproof

material).

If the appliance is to be fitted into a timber framed building,

guidance should be sought from the Institute of Gas

Engineers document R

EF: IGE/UP/7.

10.6.1. Drill the wall and plug using those supplied with

the connections kit, position the hanging bracket and

secure with the wall bolts supplied, assembl the

connection kit and secure to the wall. N

OTE: It is highly

recommended that a spirit level be used to position the

appliance to ensure that it is perfectly level.

10.6.2. Position the appliance on the hanging bracket

and connect the connection kit to the boiler connections.

(see also Sections 10.8 Gas Connections, 10.9 Water

Connections & F

IG.10.2).

For safety purposes, have a competent person carefully

check the electrical system in the property, as the

manufacturer will not be held liable for damage caused by

the failure to earth the appliance properly or by anomalies

in the supply of power. Make sure that the residential

electrical system is adequate for the maximum power

absorbed by the unit, which is indicated on the rating plate.

In addition, check that the section of cabling is appropriate

for the power absorbed by the boiler.

The boiler operates with alternating current, as indicated in

the Technical Information table (Section 21), where the

maximum absorbed power is also indicated. Make sure

that the connections for the neutral and live wires

correspond to the indications in the diagram. The

appliance electrical connections are situated on the

reverse of the control panel (see the Servicing Instructions

Section 18 for further information).

Important!

In the event that the power supply cord must be changed,

replace it with one with the same specifications. Make the

connections to the terminal board located within the control

panel, as follows:

- The yellow-green wire should be connected to the

terminal marked with the earth symbol; make sure to reuse the ferrule mounted on the other supply cord;

- The blue wire should be connected to the terminal

marked “N”;

- The brown wire should be connected to the terminal

marked “L”.

Note: The diagrams for the electrical system are indicated

in Section 13.

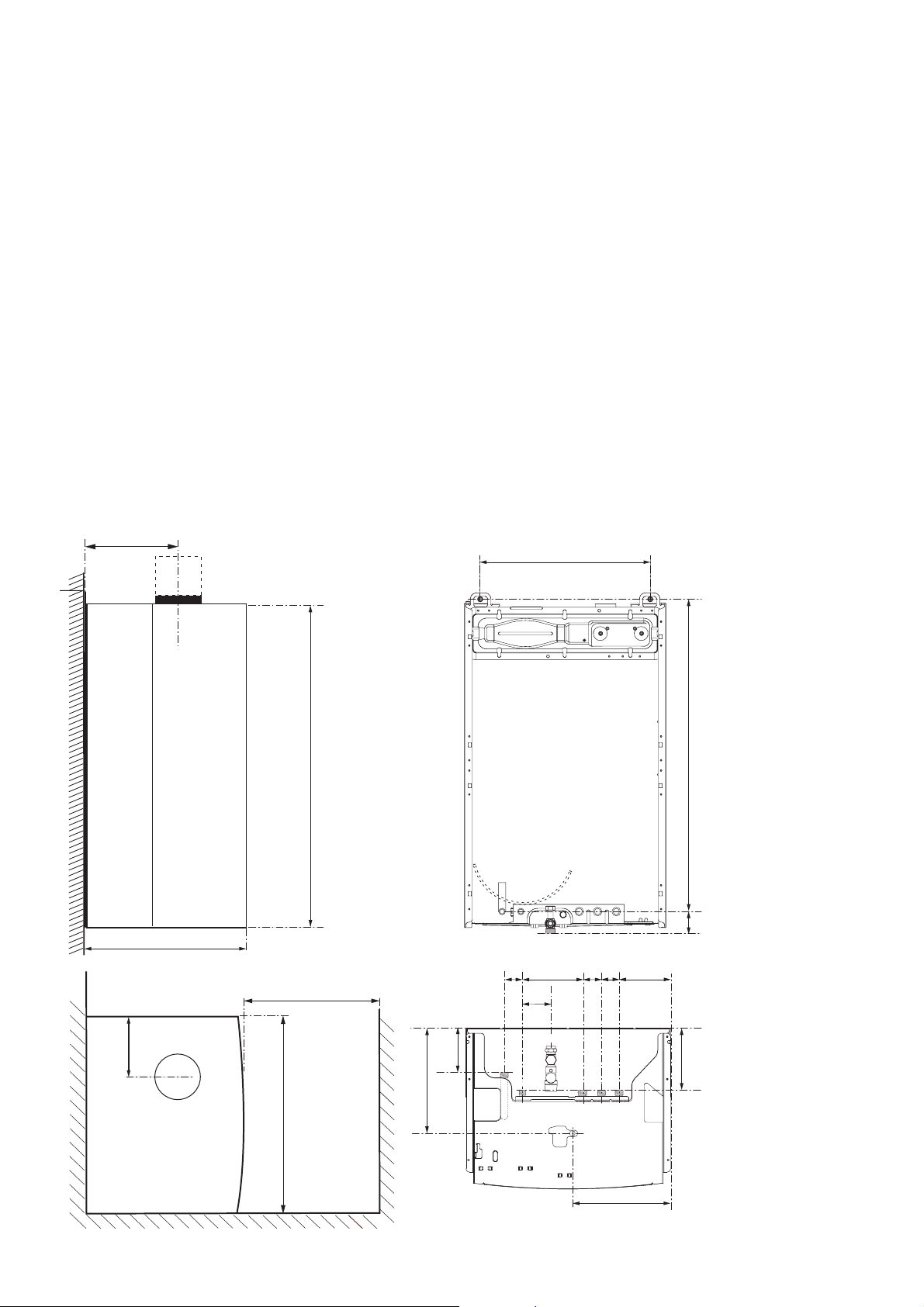

FIG. 10.3

10.7 Electrical Connection

10.6 Mounting the Appliance

Legend:

39 = Gas service tap

40 = Heating return

41 = Heating flow

42 = Water service tap

43 = Tank hot water flow

38 = Water tank valve

44 = Heating valve

FIG. 10.2

39

40

41

38

44

42

43

17

10.8 Gas Connection

Warning, this appliance must be earthed.

External wiring must be correctly earthed, polarised and in

accordance with relevant regulations / rules. In GB this is the

current I.E.E. WIRING REGULATIONS. In IE reference should be

made to the current edition of the ETCI rules. This boiler is supplied

for connection to a 220 - 240 V~ 50 Hz supply.

The supply must be fused at 3 A.

The method of connection to the electricity supply must facilitate

complete electrical isolation of the appliance, by the use of a fused

double pole isolator having a contact separation of at least 3 mm in

all poles or alternatively, by means of a 3 A fused three pin plug

and unswitched shuttered socket outlet both complying with BS

1363.

The point of connection to the Electricity supply must be readily

accessible and adjacent to the appliance unless the appliance is

installed in a bathroom when this must be sited outside the

bathroom.

The local gas region contractor connects the gas meter to the

service pipe.

The gas installation should be in accordance with the relevant

standards. In GB this is BS6891 and in IE this is the current edition

of I.S.813.

The connection the the appliance is a 22 mm copper tail located at

the rear of the gas service cock (Fig. 10.2).

If the gas supply for the boiler serves other appliances ensure that

an adequate supply is available both to the boiler and the other

appliances when they are in use at the same time.

Pipe work must be of an adequate size. Pipes of a smaller size than

the boiler inlet connection should not be used.

Central Heating

Detailed recommendations are given in BS 6798:1987 and BS

5449-1:1990, the following notes are given for general

guidance.

Pipe Work:

Copper tubing to BS EN 1057:1996 is recommended for water

pipes. Jointing should be either with capillary soldered or

compression fittings.

Where possible pipes should have a gradient to ensure air is

carried naturally to air release points and water flows naturally

to drain taps.

The appliance has a built-in automatic air release valve,

however it should be ensured as far as possible that the

appliance heat exchanger is not a natural collecting point for air.

Except where providing useful heat, pipes should be insulated

to prevent heat loss and avoid freezing.

Particular attention should be paid to pipes passing through

ventilated spaces in roofs and under floors.

By-pass:

The appliance includes an automatic by-pass valve, which

protects the main heat exchanger in case of reduced or

interrupted water circulation through the heating system, due to

the closing of thermostatic valves or cock-type valves within the

system.

10.9 Water Connections

18

System Design:

This boiler is suitable only for sealed systems.

Drain Cocks:

These must be located in accessible positions to permit the

draining of the whole system. The taps must be at least 15 mm

nominal size an manufactured in accordance with BS 2870:1980.

Safety Valve Discharge (Primary Water):

The discharge should terminate facing downwards on the exterior

of the building in a position where discharging (possibly boiling

water & steam) will not create danger or nuisance, but in an easily

visible position, and not cause damage to electrical components

and wiring.

The discharge must not be over an entrance or a window or any

other type of public access.

Mains Water Feed - Central Heating:

There must be no direct connection to the mains water supply

even through a non-return valve, without the approval of the Local

Water Authority, and must be in accordance with water supply

regulations. Your attention is drawn to, for GB: Guidance G24.2

and recommendation R24.2 of the water regulations guide and for

IE: the current edition of I.S.813.

Filling:

A temporary method for initially filling the system and replacing

lost water during servicing and initial filling (complying to current

water regulations and byelaws) is provided. The flexible hose

must be removed once the system has been filled.

Domestic Hot Water

Storage Discharge Pipe Work

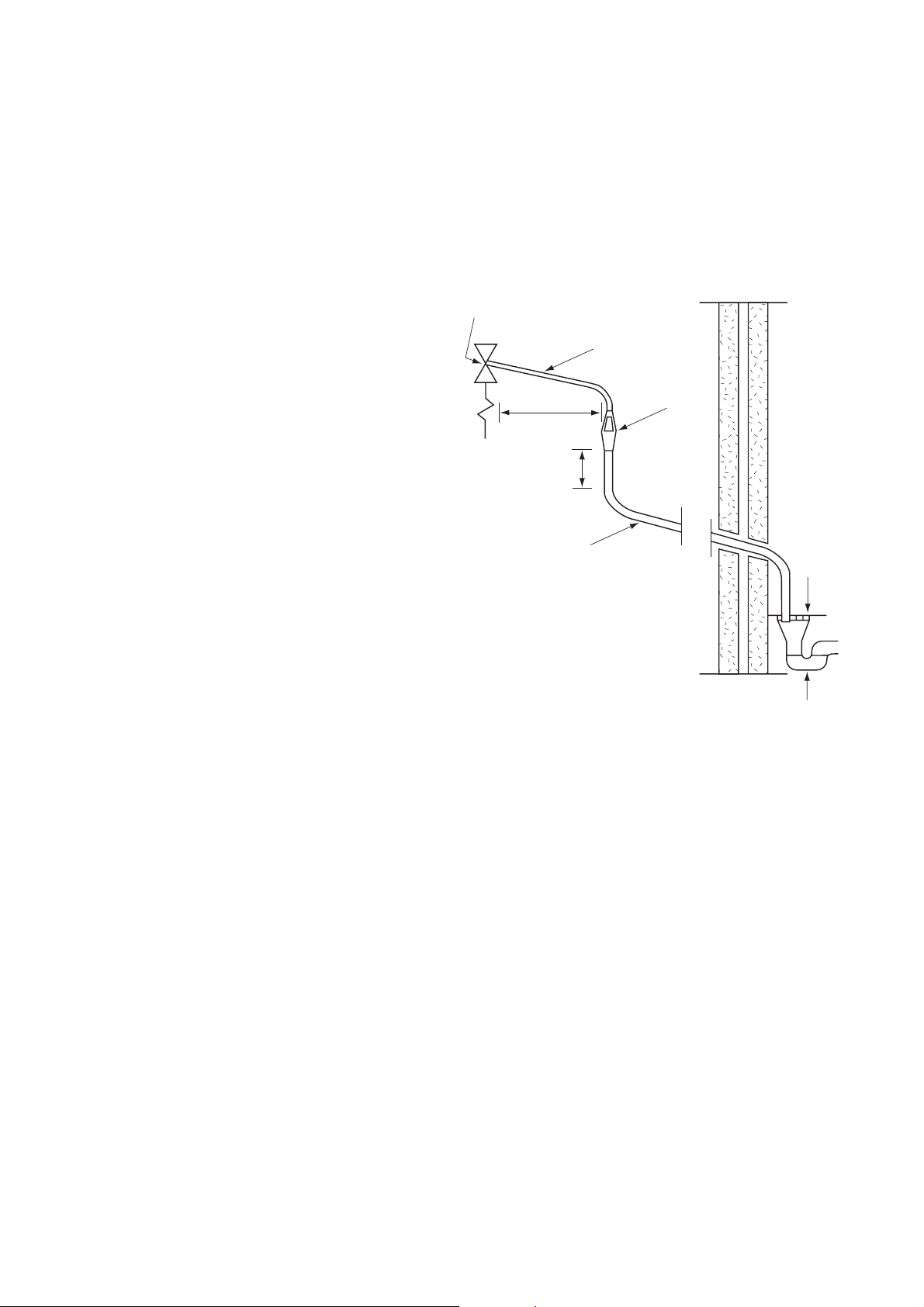

1) The tundish must be installed directly below the discharge outlet

connection of the boiler. The tundish must also be in a position visible

to the occupants, and positioned away from any electrical devices.

The discharge pipe from the tundish should terminate outside in a

safe place where there is no risk to persons in the vicinity of the

discharge and to be of metal.

2) Discharge pipes from the temperature & pressure relief and

expansion relief valve are joined together within the appliance.

3) The pipe diameter must be at least one pipe size larger than the

nominal outlet size of the safety device unless it's total equivalent

hydraulic resistance exceeds that of a straight pipe 9m long.

i.e. Discharge pipes between 9m and 18m equivalent resistance

length should be at least 2 sizes larger than the nominal outlet size of

the safety device. Between 18 m and 27 m at least 3 sizes larger, and

so on.

Bends must be taken into account in calculating the flow resistance.

See fig. 10.4 (page 19) and Table 1 (page 20).

4) The discharge pipe must have a vertical section of pipe at least 300 m

in length, below the tundish before any elbows or bends in the

pipework.

5) The discharge pipe must be installed with a continuous fall.

6) The discharge must be visible at both the tundish and the final point of

discharge, but where this is not possible or practically difficult; there

should be clear visibility at one or other of these locations. Examples

of acceptance are:

i) Ideally below a fixed grating and above the water seal in a trapped

gully.

ii) Downward discharges at a low level; i.e. up to 100 mm above

external surfaces such as car parks, hard standings, grassed areas etc.

These are acceptable providing that where children may play or

otherwise come into contact with discharges, a wire cage or similar

guard is positioned to prevent contact, whilst maintaining visibility.

19

iii) Discharges at high level; I.e. into a metal hopper and metal down

pipe with the end of the discharge pipe clearly visible (tundish visible or

not).

Or onto a roof capable of withstanding high temperature discharges of

water 3 m from any plastic guttering systems that would take such a

discharge (tundish visible).

iv) Where a single pipe serves a number of discharges, such as in

blocks of flats, the number served should be limited to not more than 6

systems so that any installation can be traced reasonably easily.

Fig.10.4

The single common discharge pipe should be at least one pipe size large

than the largest individual discharge pipe to be connected.

If unvented hot water storage systems are installed where discharges

from safety devices may not be apparent I.e. in dwellings occupied by

the blind, infirm or disabled people, consideration should be given to

the installation of an electronically operated device to warn when

discharge takes place.

Note: The discharge will consist of scalding water and steam. Asphalt,

roofing felt and non-metallic rainwater goods may be damaged by such

discharges.

Warning

The outlet from the temperature & pressure relief valve must not be

used for any other purpose.

The temperature & pressure relief valve must not be removed in any

circumstances. Any of the above will totally invalidate the warranty.

Note

The discharge from the central heating and domestic hot water systems

may be joined together after the tundish.

Air Release Points:

These must be fitted at all high points where air naturally collects

and must be sited to facilitate complete filling of the system.

The appliance has an integral sealed expansion vessel to

accommodate the increase of water value when the system is

heated.

Temperature & pressure

relief valve

Metal discharge pipe (D1) from

temperature & pressure relief valve.

to tundish.

Tundish

500 mm Max.

300 mm

Min.

Metal discharge pipe (D2) from tundish

with continuous fall. See Table 2 and worked

example.

Discharge below

fixed grating.

(see page 6 for

alternative points

of discharge).

Fixed grating

Trapped gulley

20

It can accept up to 7l (1.5 gal) of expansion water. If the heating circuit

has an unusually high water content, calculate the total expansion and

add an additional sealed expansion vessel with adequate capacity.

Domestic Water:

The domestic water must be in accordance with the relevant

recommendation of BS 5546:1990. Copper tubing to BS EN

1057:1996 is recommended for water carrying pipe work and must be

used for pipe work carrying drinking water. The domestic hot water

temperature should be be adjusted to trip at 60˚C. This temperature

will prevent the formation of limescale in hard water areas.

Note: This appliance is capable of producing domestic hot water of

up to 70˚C. For extra security against scalding a thermostatic

blending valve may be installed on the domestic hot water

outlet.

Secondary Return

:

The secondary return connection can be used as an option. A Non

Return Valve (not supplied) must be fitted to prevent back flow and a

Bronze Pump will be needed in conjunction with a Pipe Thermostat to

circulate the hot water (neither of which are supplied).

Worked Example:

The example below is for a G 1/2 Temperature & Pressure Relief valve

with a discharge pipe (D2) having 4 no. elbows and length of 7 m from the

Tundish to the point of discharge.From Table 1

Maximum resistance allowed for a straight length of 22 mm copper

discharge pipe (D2) from G 1/2 T & P valve is 9m.

Subtract the resistance for 4 no. 22 mm elbows at 0.8m each = 3.2 m.

Therefore the maximum permitted length equates to: 5.8 m.

As 5.8m is less than the actual length of 7 m therefore calculate the next

largest size.

Maximum resistance allowed for a straight length of 28 mm pipe (D2) from

G 1/2 T & P valve equates to: 18 m.

Subtract the resistance for 4 no. 28 mm elbow at 1.0m each = 4 m.

Therefore the maximum permitted length equates to: 14 m

As the actual length is 7 m, a 28 mm (D2) copper pipe will be satisfactory.

Table 1. Sizing of copper discharge pipe “D2” for

common temperature valve outlet sizes.

Valve outlet size Minimum size of

discharge pipe D1*

G 1/2 15 mm 22 mm

G 3/4 22 mm 28 mm

G 1 28 mm 35 mm

Minimum size of

discharge pipe D2*

from tundish

28 mm

35 mm

35 mm

42 mm

42 mm

54 mm

Maximum

resistance allowed,

expressed as a

length of pipe (i.e.

no elbow or bends)

Up to 9 m

Up to 18 m

Up to 27 m

Up to 9 m

Up to 18 m

Up to 27 m

Up to 9 m

Up to 18 m

Up to 27 m

Resistance created

by each elbow or

bend

0.8 m

1.0 m

1.4 m

1.0 m

1.4 m

1.7 m

1.4 m

1.7 m

2.3 m

21

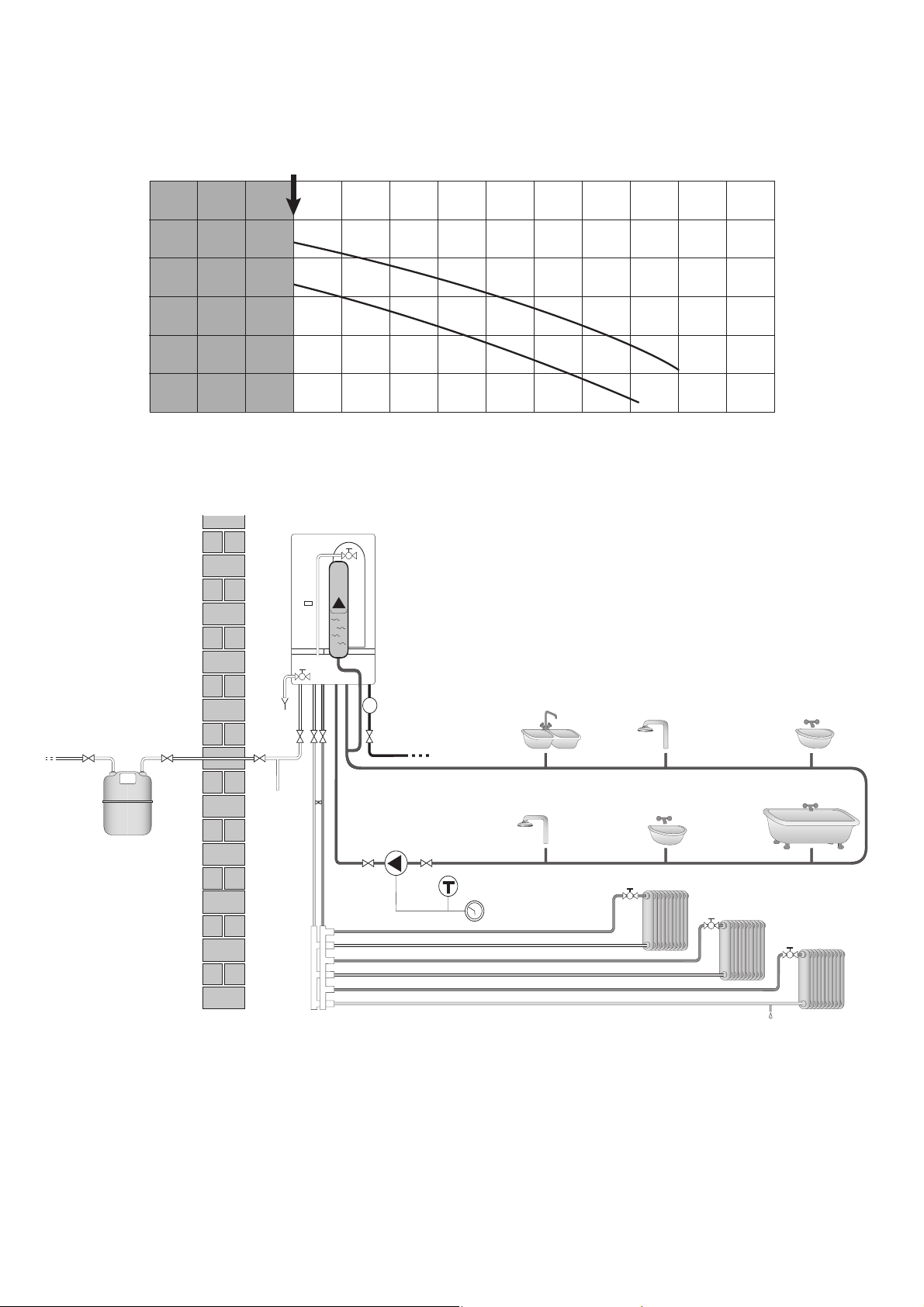

Operating Pressure

Fig. 10.5

A - Gas Inlet

B - C.H. Return

C - C.H. Flow

D - D.H.W. Secondary Return

E - D.H.W. Flow

F - C.W. Inlet

1 - Gas Meter Inlet Cock

2 - Gas Meter

3 - Gas Meter Outlet Cock

4 - Internal Gas Cock

5 - Appliance Gas Inlet Cock

6 - Cold Water Inlet Cock

7 - D.H.W. Expansion Vessel

8 - Cock

9 - Secondary Return Pump

10 - Thermostat

11 - Time Control Clock

12 - T&P Valve

13 - Tundish

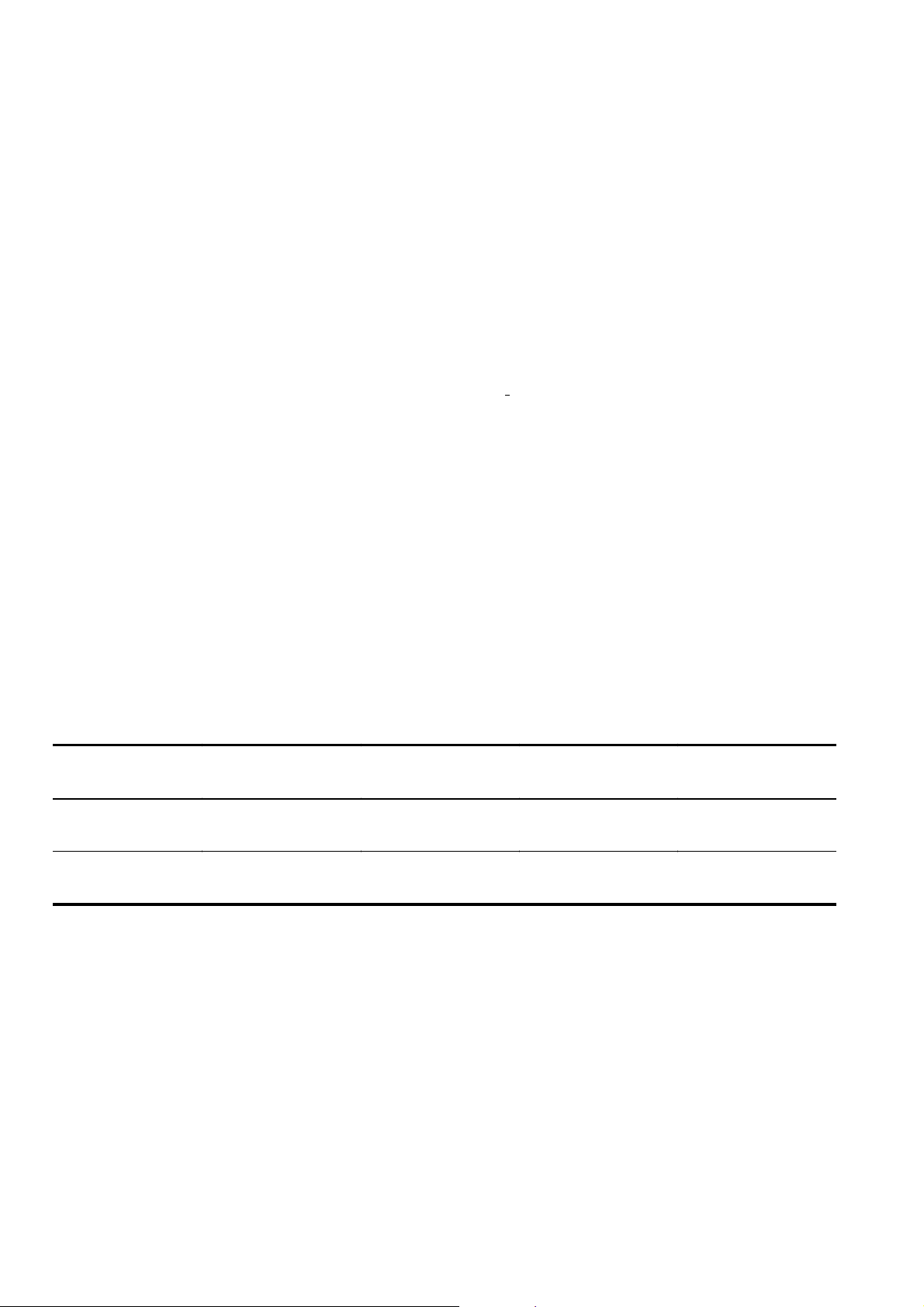

Residual Head of the Boiler ΔT = 20oC

Fig. 10.6

m/H2O

mCE

Minimum flow (thermostatic valves closed)

6

5

4

3

2

1

GV

PV

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

l/h

16

7

12

BC D E F

A

13

31

2

5

4

Other

Users

Pressure

V

Reducing Valve

6

Cold Water Inlet

9

8

8

10

11

Drain Tap

(at lowest point)

Loading...

Loading...