Page 1

Model type:

ATD104EX

Commercial code:

27636

Page 2

General notes

Technical Documentation guidelines

----------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------

You can find herewith some generic information to simplify cunsulting of technical documentation:

1. Models of same range share the same exploded views, which report the richest set of spare parts:generally, a model does not

necessarly have a related spare part for each particular shown on exploded views.

2. Some spare parts can not be represented directly on the exploded views (instruction booklets, specific kit, etc...). You can find

those codes in the spare parts list with the same reference of particular where spares are installed or with references 099, 999.

Instruction booklets, once managed, appear with 000 reference.

3. On the higher right site of each exploded view there is a serial number which indicates the beginning of the production of

certain range:some models might have more than an exploded view for a given category, each distinguished by a different serial

no.and linked to another spare parts list, In this case, serial no. is required to supply the right spare part code. Exploded view to be

considered is the one with a more recent serial no. but previous than the one of the model that needs assistance.

4.Exploded views might require further updates even after publishing. Addition of new spares will go on following the already

existing numeration references. Revision number of an exploded view is shown into last four digits of serial number into upper

right hand corner.

5.The spare parts list associated to an exploded view shows related codes of spares managed for a certain model; for each spare

part other informations are available:

REF: reference no of spare into a table; SUBSTITUTE: list of spare(s) which can replace a code but that keeps same functional

characteristics

INDUSTRIAL CODE: list of variables of a model (shown into model label) where such spare is used; NOTICE: code of

information(s) to refer to complete technical intervention, track for changes or to find correct spare part code.

6. Some notices, into a same section are generic therefore cannot be directly linked to a spare part. In order to assist a model in

the best way as possible, it is helpful to pay attention to all notices and constantly verify documentation updates

7.Technical documentation cover shows model name and its commercial codes

mod.ATD104EX page 2

Page 3

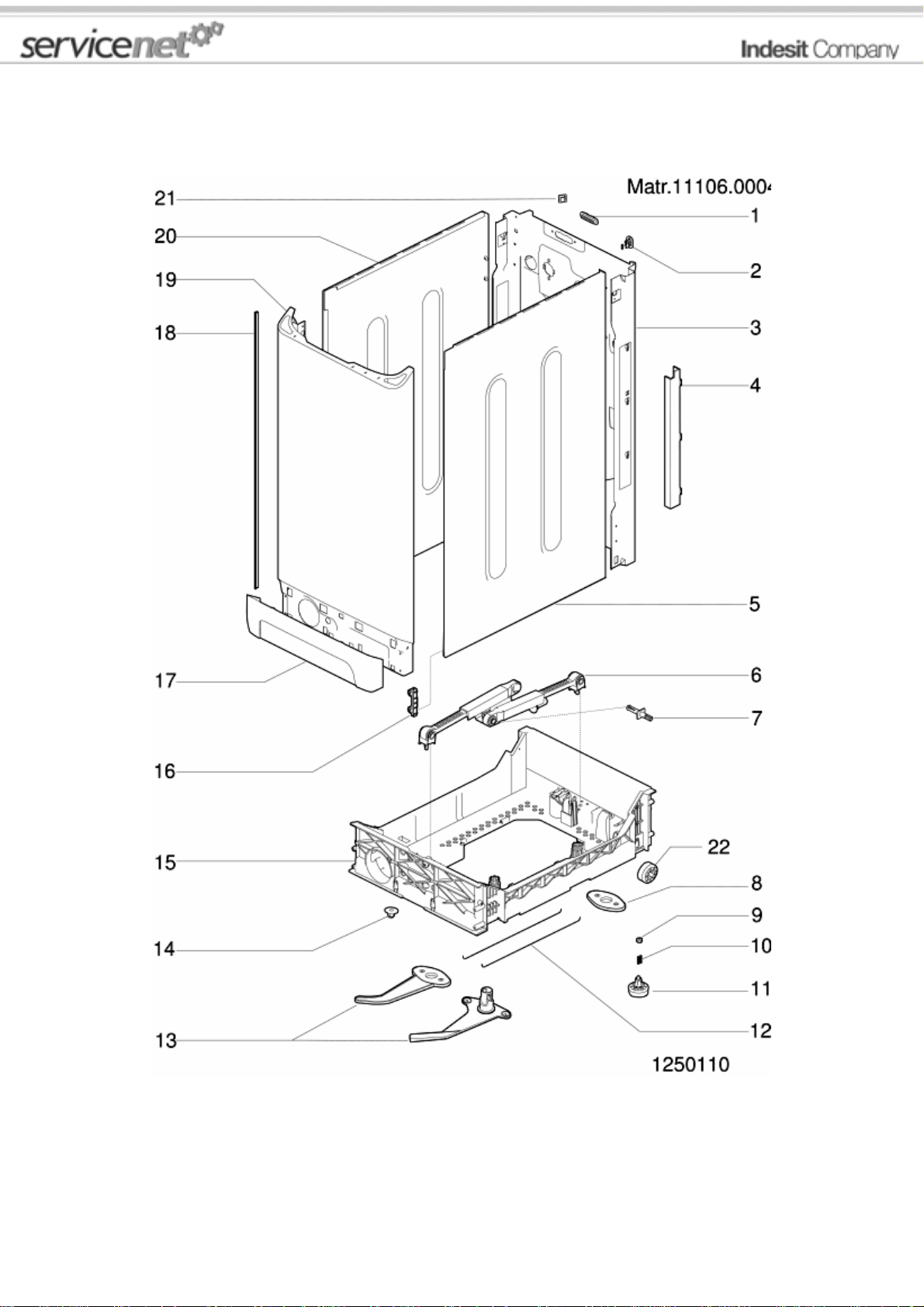

1250110 Exploded views

mod.ATD104EX page 3

Page 4

1250110 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

000 C00088296 user instructions booklet gb-f-d-it

000 C00088297 user instructions booklet se-fi-no-

000 C00088298 user instructions booklet rus-hu-cs

001 C00083909 испыт.заглушка машины tl

002 C00064205 блок направляющий для

003 C00083784 панель задняя, модели с n1040278

003 C00091893 панель задняя top ph2002 n1040288

003 C00094067 2 x C00097841 панель задняя, модели с n1040309

1 x C00098566

003 C00098566 панель задняя, модели с n1040309

n1040336

003 C00112632 панель задняя tl evoii n1040336

004 C00083901 защитное присп./направляющая

005 C00083774 1 x C00084913 side panel right top ph2001

006 C00083787 1 x C00196002 амортизатор 120n top ph2001

007 C00055037 расширитель n1040414

007 C00118593 расширитель

008 C00083792 кулачок каретки tlph2001

009 C00083788 гайка опоры

010 C00059869 пружина опоры d =11 mm h =

011 C00083789 опора top ph2001

012 C00083791 штырь каретки tl ph2001

013 C00083793 рычаг кулачка + каретка

014 C00083786 гайка ro-mob m6 d.28 1.5top

015 C00083785 1 x C00093539 опора верхней панели корпуса

016 C00083780 блок боковины тумбы ph2001

017 C00087059 плинтус ph2001 atd

018 C00065071 профиль боковины

019 C00085462 1 x C00117345 передняя панель top ph2001

020 C00083776 1 x C00084913 side panel left top ph2001

021 C00041575 крючок самоклеящийся

022 C00091071 заднее колесико панели n1040271

mod.ATD104EX page 4

Page 5

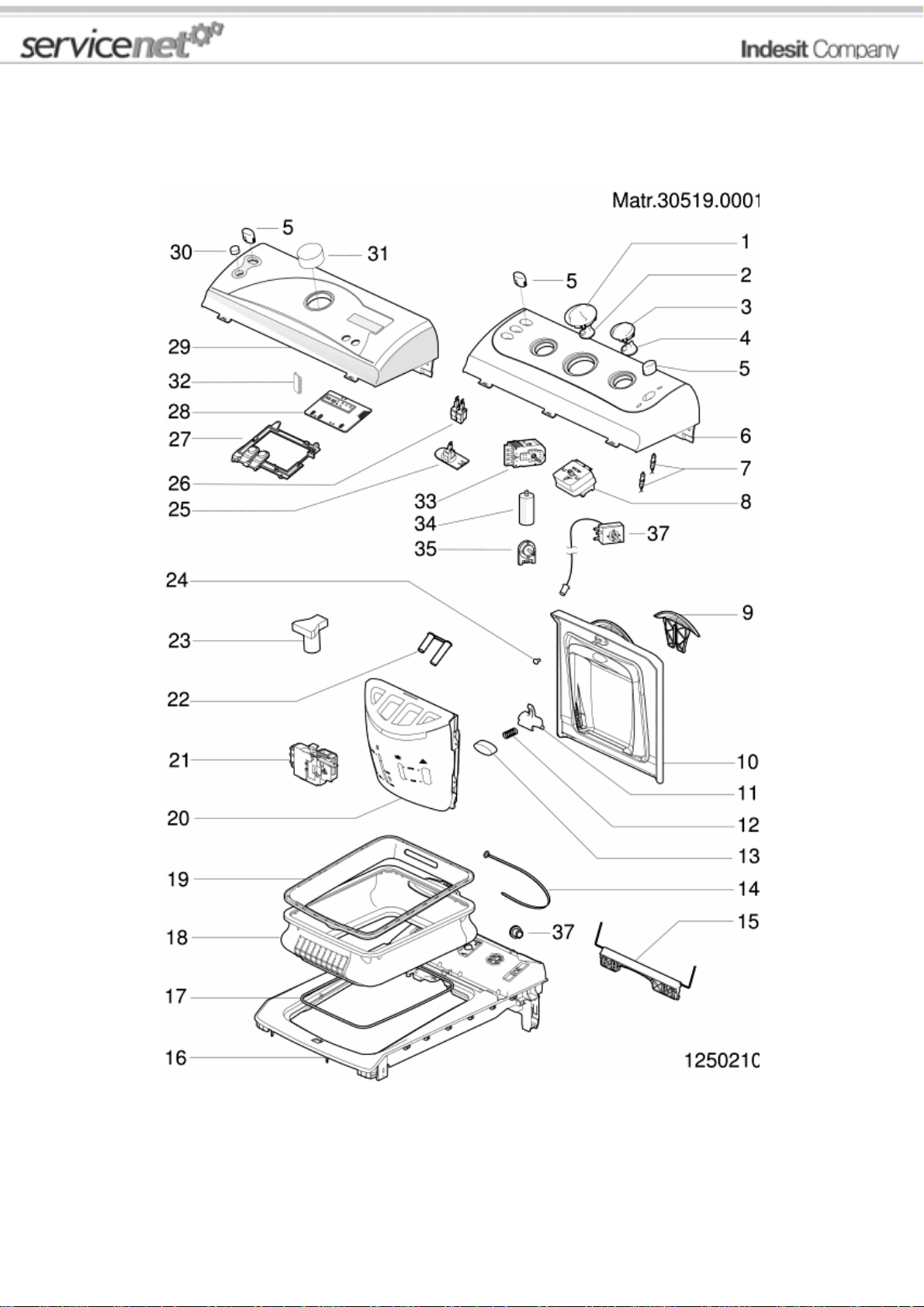

1250210 Exploded views

mod.ATD104EX page 5

Page 6

1250210 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

004 C00083804 опора рукоятки tl ph2001

005 C00087066 клавиша выключателя вкл/выкл

009 C00087070 ручка крышки ariston tl2001

010 C00087069 1 x C00085608 крышка ariston bremb tl2001 N1040346

011 C00083918 рычаг разблокировки дозатора

012 C00083922 пружина крюка дозатора tl

013 C00084983 1 x C00116868 бел.расцепл.кнопка дозатора 27

014 C00031331 зажим труба

015 C00087073 пружин.опора tl ariston 2001

016 C00087074 опора крышки tl ariston 2001 N1040346

017 C00057933 заднее кольцо натяж.

018 C00085611 1 x C00111495 диафрагма tl ph2001 N1040346

n1040330

019 C00083924 1 x C00116866 бел.диафрагмен.защита 27 tl

020 C00084343 1 x C00116869 белый дозатор 27 tl ph2001

021 C00085610 микрозамедлитель n1040332

021 C00111494 микрозамедлитель tl evoii n1040332

022 C00084359 крышка сифона tl ph2001

024 C00083893 винт 4x12 tc-t15 tl ph2001

025 C00087067 1 x C00143095 переключатель bitron 16

026 C00063971 однополюсный выключатель

026 C00076577 замык.кнопка огр.хода

027 C00087061 рама дисплея

028 C00087062 1 x C00090832 дисплей lcd ewm20 sw1.72 без

029 C00088299 приборный щиток atd104ex

030 C00087064 клавиша выключателя start

031 C00087063 рукоятка tl2001 ariston

032 C00088295 модуль eeprom дисплей

034 C00082331 шумопоглощающ. фильтр

mod.ATD104EX page 6

Page 7

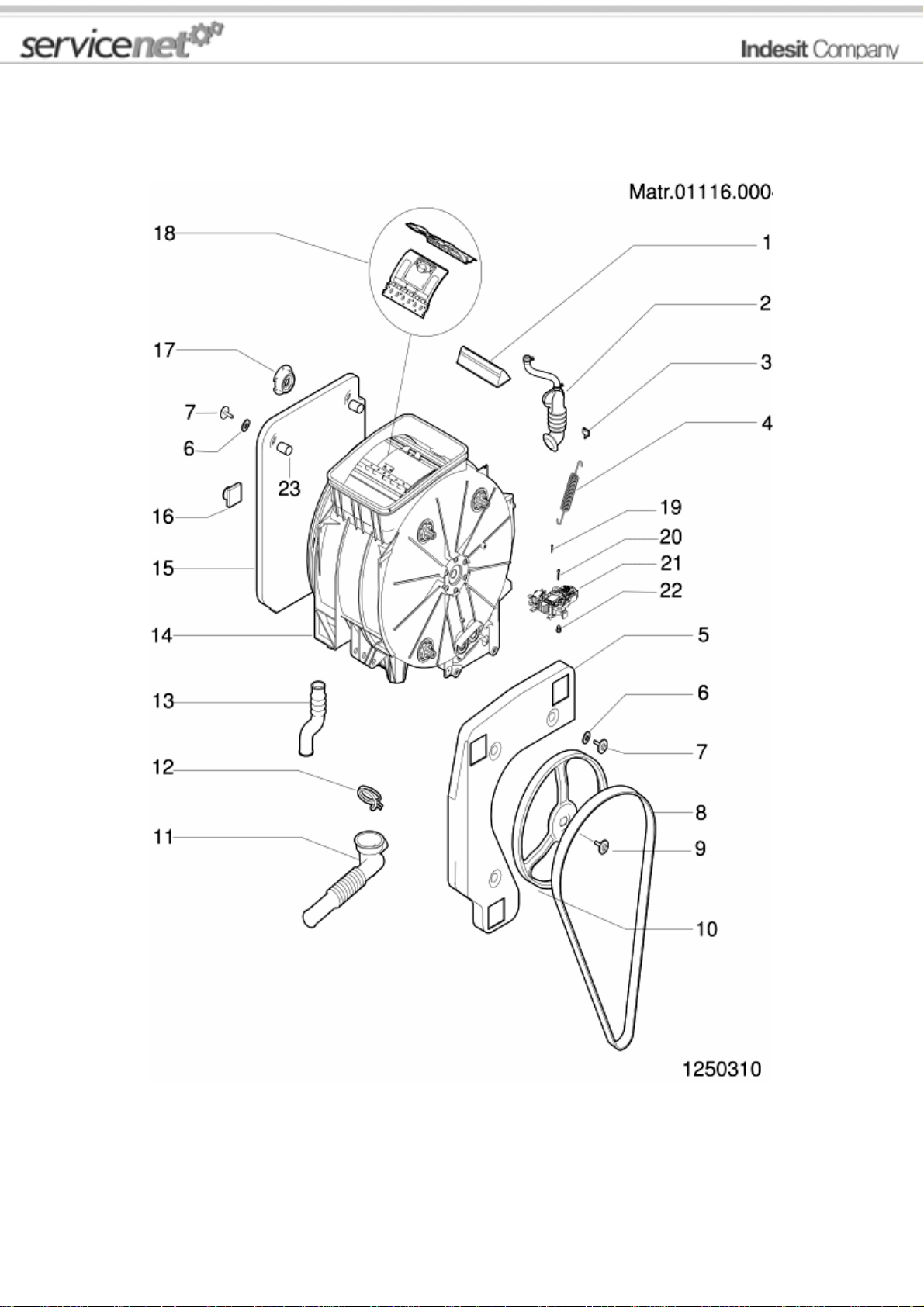

1250310 Exploded views

mod.ATD104EX page 7

Page 8

1250310 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

001 C00051504 перемещающ.устр.

001 C00083894 перемещ.устр.белья с весом tl

002 C00085471 вытяжная труба tl ph2001 n1040336

002 C00112602 шланг для спуска пара в сборе n1040336

003 C00065320 зажимное кольцо для опоры

004 C00083798 пружина ванны tl ph2001

004 C00085463 передн.пружина ванны tl ph2001

005 C00083794 правый противовес tl ph2001

006 C00041605 шайба чашеобразная

007 C00083797 винт sw. 8x27 tc-t30tl ph2001

008 C00083910 упругий ремень pvel 1213h8 tl

009 C00065076 1 x C00064786 винт ведомого шкива torx

010 C00083912 ведомый шкив d280 tl ph2001

011 C00083898 труба ванны-фильтр tl ph2001 n1040332

011 C00111502 трубка бак-насос oko tl evoii n1040332

012 C00074054 хомут соедин. шланга между

013 C00055328 труба сбора моющ.средства n1040332

014 C00083805 1 x C00110148 пластмассовая ванна n1040324

1 x C00110152

014 C00110152 1 x C00111409 пластмассовая ванна 600/1000 n1040324

1 x C00111505 n1040332

n1040340

014 C00111505 пластмассовая ванна 600/1000 tl n1040332

015 C00083896 левый противовес tl ph2001

016 C00055303 заглушка противошумная

017 C00087966 опора подшипника в сборе

018 C00080691 комплект болтов tl n1040245

018 C00083895 залив.отверстие n1040245

n1040344

018 C00112743 1 x C00252375 отверстие для загрузки n1040245

n1040344

019 C00087948 винт 6x12 tc-t30 блокировка

020 C00055316 винт

021 C00087950 1 x C00118932 блок барабана tl2002

022 C00087947 втулка блокировки барабана

mod.ATD104EX page 8

Page 9

1250310 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

099 C00064550 держатель сливных шлангов

099 C00065871 заглушка упаковки

099 C00081629 герметик dow corn 7091

099 C00085574 комплект упаковки tl ph2001 n1040278

099 C00091902 комплект упаковки tl ph2002

mod.ATD104EX page 9

Page 10

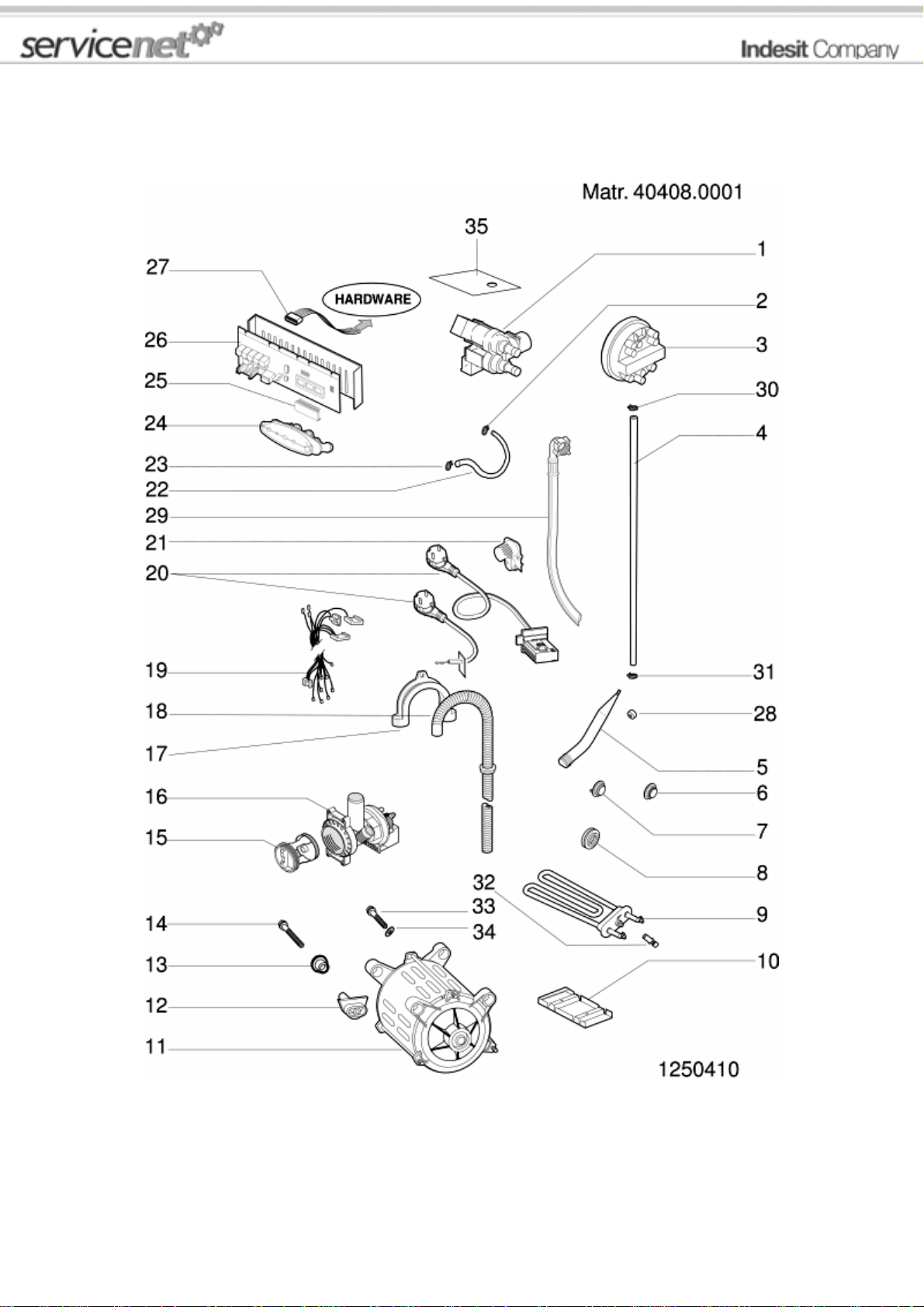

1250410 Exploded views

mod.ATD104EX page 10

Page 11

1250410 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

001 C00083940 двухходовой электроклапан 1e- n1040301

n1040309

001 C00096350 1 x C00116159 электроклапан 1e2u p.2.5 n1040301

n1040309

n1040321

002 C00061959 клемма

003 C00083903 реле давления 1+1 ур. tl ph2001 n1040332

003 C00111493 реле давления 1+1 ур. tl evoii n1040332

004 C00083897 трубка реле давления tl ph2001

005 C00051555 воздухоуловитель n1040332

005 C00092173 воздушный фильтр-ловушка n1040332

007 C00083915 температурный зонд ntc elth tl

009 C00083906 нагрев. сопротивл. 1750w-230v n1040324

009 C00110148 сопротивление нагрева 1700 вт- n1040324

010 C00055322 дефлектор n1040324

011 C00098677 коллекторный

011 C00116645 1 x C00196549 щетка двигателя ceset тип 6170

012 C00083911 гайка ph2001

013 C00083914 втулка штыря двигателя tl

014 C00084333 винт m8x35 tc-t30

015 C00045027 насосный фильтр askoll/plaset

016 C00083942 сливной насос askoll 230 tl n1040332

016 C00111409 1 x C00141862 сливной насос tl evoii n1040332

017 C00036145 1 x C00019902 держатель сливного шланга

018 C00051563 сливная труба

019 C00087928 проводка дисплея, блокировка n1040288

n1040301

019 C00096451 электропроводка дисплея n1040301

n1040332

019 C00111571 проводка дисплей- осн. плата n1040332

020 C00083907 кабель питания 3x1,0 l=1500 tl n1040288

020 C00091633 кабель питания 3x1 schuko

021 C00083944 решетка выпускной трубы tl n1040336

022 C00083939 1 x C00093620 трубка от распредел. клапана к n1040309

022 C00087068 1 x C00093621 соединит. трубка электромагн. n1040309

mod.ATD104EX page 11

Page 12

1250410 Spare parts list

Ref. Code С сер.№ По Substitute Description Notice Industrial

022 C00097841 трубка электр. распред. клапана n1040309

023 C00054734 клеммник

024 C00083941 распределитель tl

025 C00088294 eeprom atd104ex программа

026 C00084838 1 x C00093157 электр. модуль без eeprom univ. n1040237

n1040321

027 C00066292 съемный зажим lb2000

027 C00084566 1 x C00095669 серийный ключ lb2000-pc e top

027 C00084943 1 x C00099862 серийный кабель lb2000 - pc n1040211

n1040317

028 C00078221 соединитель губчатый 40x5x30

029 C00051556 1 x C00003070 труба подающая

1 x C00005572

030 C00051541 клавиша

031 C00061958 клемма d=32,7

035 C00109798 1 x C00116161 защита электроклапана tl n1040321

mod.ATD104EX page 12

Page 13

Notices

N1040346: Elimination of leakage between upper top and cover on TL.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

This modification is applied only after having checked for the absence of distortion or breakage of the components that jointly

ensure a watertight seal (cover, top, diaphragm, etc.).

The modification consists in raising the diaphragm to obtain greater interference between diaphragm and cover inner panel.

PROCEDURE:

Remove the nine screws located under the diaphragm, remove the plastic protection, and raise the diaphragm, positioning it inside

the loading port.

After drying the supporting surface apply a strip of approximately 1.2 mm of adhesive expanded rubber, replacement P/N 066834

which has been previously prepared by cutting it in half lengthwise.

n1040061: Trouble-shooting.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Intervention procedure on 2000 washing machines

1. Reading the error code

The fault on the appliance is signalled via:

1. the continuous rotation of the selector knob

2. the action, for the first 4', of the electrovalve and the drain pump

3. the door becomes unlocked

4. the led flashes:

the number of flashes indicates the fault code; the code should be read as follows:

· each fast flash (2/3 flashes of the led very close together) represents one code value

· the fault code is evaluated by counting the number of flashes occurring at 3/4" intervals from one another

· stop counting when the washing machine waits the equivalent of approximately 8/9" between flashes

· the procedure is repeated by the appliance cyclically

E.g.: F03

mod.ATD104EX page 13

Page 14

(FIGURE NT 00)

2. Autotest

Should the washing machine not be signalling an error, you can check it using a serial key and using a particular autotest cycle,

which is to be activated as follows:

1. bring the washing machine to reset position (coloured ball) for at least 5" and wait until the led flashes on reset mode

2. insert the hardware key into the serial outlet

3. position the switch situated on the key in TEST position

4. wait for the door to lock and for the selector to start turning

5. position the switch situated on the key in PC position

the appliance will carry out the following cycle:

· selector moves on up to position 0 (12h if the appliance has a delay, programme 1 if it has no delay)

· loads the wash electrovalve for approx. 10"

· loads the pre-wash electrovalve for approx. 10"

· loads the wash electrovalve and pre-wash electrovalve at the same time until the pressure switch is on full

· heats up to 30° and moves the motor in both directions

· selector moves on for 9 notches

· drains and spins

· the selector knob stops on one of the reset positions

· STOP

The test cycle can be repeated as many times as you wish following the same procedures

The test cycle can be interrupted by positioning the selector knob on one of the reset positions.

3. Intervention in the event of a Fault

In the event of a fault, the procedure to go by is as follows:

F01: Triac Short circuit

Overhaul CNE

mod.ATD104EX page 14

Page 15

Replace Card

F02: Blocked Motor, Short-circuited/Open Tachometry

Overhaul CNE

Overhaul Motor connector

Control CNE Continuity/Motor Connector

Control Motor Windings

Control Tachometry Windings

Replace Card

F03: Open/Short-Circuited NTC Found

Overhaul CNA

Control NTC Wiring

Control CNA/NTC Wiring Continuity

Replace NTC

Replace Card

F04: Overflow and Pressure Switch Empty found at the same time (Pressure Switch stuck on Empty)

Overhaul CN1

Overhaul Pressure Switch Contacts

Control CN1/Pressure Switch Continuity

Replace Pressure Switch

Replace Card

F05: Blocked Pump or Pressure Switch stuck on Empty Found

Overhaul CNF (pump connector)

Overhaul Pump Connector

Control Pump Filter

Control Pump Windings

Change Pump

Replace Card

F06: Selector Error (a part no. cannot be found)

Overhaul CND (selector connector)

Overhaul Selector Connector

Control Selector/CND Continuity

Control Selector Motor

Replace Selector

Replace Card

F07: Resistance Relay Stuck

Overhaul CN1

Overhaul CN1

Overhaul Resistance Connection

Replace Card

Overhaul Resistance Connection

Replace Card

F08: Resistance Missing or Pressure Switch stuck on Full Found

Overhaul CN1

Overhaul Resistance Connection

Overhaul Pressure Switch Connection

Replace Resistance

Replace Pressure Switch

Replace Card

F09: Machine Setup Error Found

mod.ATD104EX page 15

Page 16

Control Microprocessor Version

Ask for EEPROM Spare Part indicating Microprocessor version

F10: Pressure Switch Empty and Full or neither Empty nor Full Pressure Switch Found

Overhaul CN1

Overhaul Pressure Switch Wiring

Control CN1/Pressure Switch Continuity

Replace Pressure Switch

Replace Card

F11: Pump Feedback Missing

Overhaul CN1

Overhaul CNF

Overhaul Pump Connector

Overhaul Pressure Switch Connector

Control Pump Windings

Replace Pump

Replace Card

F12 SPECIFIC FOR LVB2000 INDESIT EVOLUTION / DIALOGIC.

F12: Lack of Display card-Main Card Communication

1. Check the effectiveness of contacts on CNC Connector Card

2. Overhaul 8-way connector on Display card

3. Check continuity of CNC-CN 8 way connector

4. Replace Main Card

5. Replace Display Card

F13: NTC wiring harness disconnected from the dryer system

1. Check the efficiency of the terminals on the CNA connector board

2. Check NTC wiring harness

3. Check the wiring harness continuity of the CNA / NTC connectors

4. Replace NTC

5. Replace terminal board

F14: Dryer connector open or not connected

1. Check the efficiency of the terminals on the CNI connector board

2. Overhaul CN1

3. Overhaul connector connection

4. Replace the board.Merloni Elettrodomestici

F15: Dryer connector is always active

1. Check the efficiency of the terminals on the CNI connector board

2. Overhaul connector connection

3. Overhaul the pressure sensor connection

4. Replace the connector

5. Replace pressure sensor

6. Replace the board

F16: Non-functioning basket block

1. Go over connector card CNC

2. Go over connector basket block

3. Control Continuity of cabling CNC / basket block and basket block supply

4. Replace basket block

5. Replace card

N.B.From Fault F01 to fault F11

mod.ATD104EX page 16

Page 17

These are shown by LEDs in stand by/on in LVB2000 machines Ariston/Indesit.

From fault F01 to fault F12

These are shown in a display located on the instrument panel of LVB2000 ma-chines

Evolution Indesit.

From fault F01 to fault F15

Are those that are indicated according to the version via LED stand by/on or

display positioned on the Wash Dry machine Ariston/Indesit panel.

4. Replacing the card

Should you have to replace the card:

· retrieve the EEPROM from the old card

· reassemble the EEPROM onto the new replacement card (without EEPROM)

In the event, and only in this case:

· an F02 has been detected

· the above-mentioned checks have been carried out and no problems have been detected on the wiring or to the motor

· the card fitted onto the washing machine is a 12 or 20 version (the version is indicated by a label on the module-containing box

with SW20 or SW12)

you should:

· fit on a new card (version 32 or above)

· fit on an updated EEPROM to request from the assistance service centre, stating the code (e.g. 80xxxxx0000 or 46xxxxx0000),

the serial number and the washing machine model.

n1040211: Serial cable to connect the hardware key with the PC.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

To connect the hardware key: LB2000 with the personal computer,you must use

a serial cable, pin to pin 9 pin F/F, to garantee the availability, it was

decided to manage it as a spare part.

The SAT code of the cable (length 2m) is 084943.

n1040237: BREMBATE TOP LOADER ELECTRONIC CARD

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

On all the top loaders produced in the Brembate establishment that are concerned with the current notice, it is advisable to

retrieve the box card that is found in the assisted machine, in the case of the substitution of the electronic card.

In the event that it is decided to substitute both the box + module, it is imperative to shear off the two small central sterns of the

same box.

mod.ATD104EX page 17

Page 18

n1040242: Power card with welded eeprom.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial number 20304.0001, IDC power card with welded eeprom is used to ensure the perfect connection of all parts, in the

Comunanza, Teverola and Brembate factories.

To replace the module with welded eeprom, it will be necessary to use the eeprom indicated in the SAT document of the model

concerned.

To replace the module on a unit with welded eeprom both the SAT module and the eeprom are required, because the latter cannot

be reused.

n1040245: Brembate washing machine basket doors re

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

For all washing machine models produced in the Brembate factory and relevant to this note, in replacing the loading mouth code

083895/112743/252375 proceed as follows:

-remove the 18 rivets (9 on the right, 9 on the left) hooking the two doors to the loading mouth on the machine;

-take replacement part 083895/112743/252375 and carry out the same operation described in the previous point;

-hook the two new doors and the new loading mouth on the basket of the machine using the nut and bolts kit code 080691

(formed of 18 screws + 18 washers + 18 nuts);

-use silicone (SAT code 081629) for hooking the loading mouth on the basket.

n1040271: Introduction of wheel on Brembate TOP washing machines

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The central rear wheel on top-load washing machines, relevant to this note, produced in the Brembate factory has been eliminated

with introduction of the small wheel for movement.

This modification has introduced the rear wheel assembly Sat code 091071, eliminating the trolley bar Sat code 083791 and the

trolley cam Sat code 083792 (Sat codes 083791 and 083792 will continue to be regularly managed by the replacement parts

warehouse).

Three feet are now used instead of four.

The mobile support still remains Sat code 083785.

The new mechanism can also be fitted to premodification machines.

The image n1040271.1 shows the situation with the new mechanism, and image n1040271.2 the situation with the

premodification mechanism.

mod.ATD104EX page 18

Page 19

n1040278: New packing kit on Brembate TOP washing machines

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial no. 21022.0001, a new packing kit Sat code 091902 (in place of Sat code 085574) and a new rear panel Sat code

091893 (in place of Sat code 083784) have been introduced on top-load washing machines produced in the Brembate factory.

This modification has introduced the packing hole cover Sat code 065871 and the drain tube support code 064550.

n1040288: Power supply cable + moulded filter on top-load Brembate WMs

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial number 30224.0001, all top-load washing machines produced in the Brembate factory have been equipped with a

new power supply cable with moulded filter and new rear panels with a specific opening for fixing the new cable.

The new power supply cables are:

Sat code 091632 Power supply cable 3x1 schuko 1.5m+capacitance filter;

Sat code 091633 Power supply cable 3x1 schuko 1.5m+inductive filter;

Sat code 091641 Power supply cable l=2550mm ag +capacitance filter;

Sat code 091635 Power supply cable uk 3x1 l=1950mm+capacitance filter;

Sat code 091634 Power supply cable uk 3x1 l= 1950mm + inductive filter;

Sat code 091689 Power supply cable l=2550mm ag +inductive filter.

mod.ATD104EX page 19

Page 20

The new rear panels are:

Sat code 094067 - premodification Sat code 091893 (used for few months in place of code 083784, see N1040278);

Sat code 094068 - premodification Sat code 093623 (specific for the Hotpoint WMTL80UK model, commercial code 28749).

To use premodified wirings on modified products perform the connection to the terminal block of the new cable as shown in fig.

1 - 1D.

The wiring diagrams indicated in the Documentation remain the same.

n1040301: Modification of solenoid valves and wiring on Brembate TOP LOAD washing machines

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial number 30609.0001, the top-load washing machines affected by this note have been equipped with the solenoid valve

with coil rast 2.5 Sat code 096350 in place of 083940.

This modification does not affect model WMTL80UK commercial code 28749, which has been equipped with solenoid valves

Sat code 096350 (1E2U) and 096349 (1E1U) in place of 083940 (1E2U) and 093546 (1E1U).

The wiring harnesses have been modified therefore both the premodification and new ones will be managed; the wiring diagrams

are unchanged.

The Sat codes are given below:

Sat code new 096426 premodification 087487;

Sat code new 096427 premodification 087703;

Sat code new 096428 premodification 088098;

Sat code new 096429 premodification 088127;

Sat code new 096431 premodification 088292;

Sat code new 096432 premodification 090240;

Sat code new 096433 premodification 088027;

Sat code new 096434 premodification 091648;

mod.ATD104EX page 20

Page 21

Sat code new 096436 premodification 091651;

Sat code new 096437 premodification 091649;

Sat code new 096438 premodification 091652;

Sat code new 096440 premodification 091653;

Sat code new 096452 premodification 093540;

Sat code new 096441 premodification 090610;

Sat code new 096451 premodification 087928;

Sat code new 096444 premodification 091650;

Sat code new 096445 premodification 091654.

The models affected by this modification are:

26376 WT60FR

26867 WT62EX

26377 WT62TFR

26450 WT6IT

26454 WT5IT

26451 WT4IT

26894 WT52CSI

26865 WT40EX

26866 WT50EX

28672 WT124FR

28075 WT120EX

26868 WT82EXP

26379 WT82TFR

26452 WAT6IT

26453 WAT8IT

27872 W4608TLCSI

26899 WT100CSI

26869 WT102EXP

27728 WT102TFR

28670 WT92FR

28671 WT112FR

28314 WAT10IT

27873 W4610TLCSI

28669 WT80FR

26897 WT80CSI

26970 WT67EU

27143 AT82IT

28491 AT125FR

29395 AT110FR

27122 AT85FR

29388 AT95FR

29182 AT109FR

27142 AT62IT

28749 WMTL80UK

29393 ATD102FR

27148 ATD120EX

27125 ATD120FR

29394 ATD122FR

27636 ATD104EX

27145 ATD104IT

27144 ATD84IT

26898 WT90CSI

27635 AT84EX

28074 AT104EX

27726 AT84EO

27684 AT84AG

mod.ATD104EX page 21

Page 22

The wiring diagrams are unchanged.

n1040309: Modification of rear panels on TOP LOADING washing machines.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial no. 30912.0001, the system used for fixing the loading solenoid valve (spare part code 096350) to the rear panel has

been modified on Top Loading washing machines, rotating its position by 90°.

The solenoid valve (spare part code 096350) has been modified with the 45° rotation of a coil; the Replacements Warehouse will

continue to manage this part with the same code. When replacing on premodification machines, fit the coils as shown in figure

N1040309FIG3-1 and on modified machines, as shown in figure N1040309FIG3-2; to rotate the coil, lift it using a screwdriver

and then refit according to the inserts on the plastic.

Replacement codes of the parts affected by this modification (see figure N1040309FIG1):

FIG1 A - PREMODIFICATION STRUCTURE

solenoid valve tube/distributor assembly: premodification 083939;

solenoid valve tube/distributor assembly: premodification 087068;

rear panel: premodification 094067.

FIG1 B - NEW STRUCTURE

solenoid valve tube/distributor assembly: new 097841;

solenoid valve tube/distributor assembly: new 097841;

rear panel: new 098566.

Replacement codes of the parts affected by the modification to WMTL80UK (see figure N1040309FIG2):

FIG2 A - PREMODIFICATION STRUCTURE

solenoid valve tube/distributor assembly: premodification 093620;

solenoid valve tube/distributor assembly: premodification 093621;

rear panel: premodification 094068.

FIG2 B - NEW STRUCTURE

solenoid valve tube/distributor assembly: new 097832;

solenoid valve tube/distributor assembly: new 097832;

rear panel: new 098567.

Premodification panels will be managed by the Replacements Warehouse while stocks last; when replacing with new ones on

premodification appliances the new tubes must also also be used.

When using the new panels on appliances before serial no. 30609.0001, fitted with solenoid valve code 083940, rotate the coil

45° and follow the instructions given above for code 096350, paying attention during the wiring phase to keep the cables away

from the bowl support spring.

mod.ATD104EX page 22

Page 23

n1040321: Plastic protecion for solenoid valve.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

All top-load washing machines produced from September 2003 to February 2004 (from serial no. 30900.0000 to 40300.0000)

mod.ATD104EX page 23

Page 24

have been equipped with a plastic protection Service code 109798 (shown in N1040321FIG1), to prevent water from damaging

the solenoid valve and electronic card.

n1040324: Modification of heater fixing system on top-load washing machines.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

mod.ATD104EX page 24

Page 25

From serial number 40506.0001, the fixing system of the heater to the tank has been modified on all top-load washing machines

affected by this note, with the introduction of a metal retainer (image N1040322FIG1 reference NEW) in place of deflector

Service code 055322.

The modification has involved both heater and tanks. Given below are the Service codes of the new and old items concerned:

-PLASTIC TANK FOR 600-1000 RPM MACHINES: new 110152, premodification 083805;

-PLASTIC TANK FOR 1200 RPM MACHINES: new 110153, premodification 092023;

-HEATER: new 110148, premodification 083906.

n1040332: 'Evizzazione' of top-load washing machines produced in Brembate

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial no. 40628.0001, the following items have been modified on all top-load washing machines affected by this note:

PLASTIC TANK

800/1000 rpm machines: premodification 110152 - new 111505

1200 rpm machines: premodification 110153 - new 111573

PUMP BOWL TUBE

premodification 083898 - new 111502 (OKO PUMP BOWL TUBE)

AIR TRAP

premodification 051555 - new 092173

mod.ATD104EX page 25

Page 26

MICRO DELAY DEVICE

premodification 085610 - new 111494

DRAIN PUMP

premodification 083942 - new 111409

PRESSURE SWITCH

premodification 087499 - new 111514

premodification 087704 - new 111516

premodification 083903 - new 111493

WIRING

ELIMINATION OF DETERGENT RECOVERY TUBE code 055328

The modification has involved the introduction of a new industrial code with final 30.

Given below is the list of affected models with related industrial codes and spare part codes of modified wirings:

WT60FR (91263760000 - 91263760030):

Wiring: premodification 096426 - new 111515

WT62TFR (91263770000 - 91263770030):

Wiring: premodification 096427 - new 111517

WT6IT (91264500000 - 91264500030):

Wiring: premodification 096428 - new 111523

WT4IT (91264510000 - 91264510030):

Wiring: premodification 096429 - new 111529

WAT6IT (91264520030 - 91264520000):

Wiring: premodification 096434 - new 111538

WAT8IT (91264530030 - 91264530000):

Wiring: premodification 096434 - new 111538

WT5IT (91264540030 - 91264540000):

Wiring: premodification 096428 - new 111523

WT40EX (91268650030 - 91268650000):

Wiring: premodification 096432 - new 111515

WT50EX (91268660130 - 91268660100):

Wiring: premodification 096433 - new 111529

WT62EX (91268670230 - 91268670200):

Wiring: premodification 096427 - new 111517

WT82EX (91268680130 - 91268680100):

Wiring: premodification 096434 - new 111538

WT102EX (91268690130 - 91268690100):

Wiring: premodification 096434 - new 111538

WT52CSI (91268940130 - 91268940100):

Wiring: premodification 096431 - new 111551

WT80CSI (91268970130 - 91268970100):

Wiring: premodification 096437 - new 111555

WT90CSI (91268980130 - 91268980100):

Wiring: premodification 096444 - new 111561

WT100CSI (91268990130 - 91268990100):

Wiring: premodification 096434 - new 111538

WT67EU (91269700030 - 91269700000):

Wiring: premodification 096437 - new 111555

AT62IT (91271420030 - 91271420000):

Wiring: premodification 096440 - new 111568

AT82IT (91271430030 - 91271430000):

Wiring: premodification 096438 - new 111569

mod.ATD104EX page 26

Page 27

ATD84IT (91271440030 - 91271440000):

Wiring: premodification 096451 - new 111571

ATD104IT (91271450030 - 91271450000):

Wiring: premodification 096451 - new 111571

ATD120EX (91271480130 - 91271480100):

Wiring: premodification 096451 - new 111571

AT50EX (91272040130 - 91272040100):

Wiring: premodification 088264 - new 111505

AT84EX (91276350130 - 91276350100):

Wiring: premodification 096445 - new 111580

ATD104EX (91276360130 - 91276360100):

Wiring: premodification 096451 - new 111571

AT64EX (91276740030 - 91276740000):

Wiring: premodification 088264 - new 111579

AT84AG (91276840030 - 91276840000):

Wiring: premodification 096445 - new 111580

AT84EO (91277260030 - 91277260000):

Wiring: premodification 096445 - new 111580

WT102TFR (91277280030 - 91277280000):

Wiring: premodification 096434 - new 111538

AT64EO (91277540030 - 91277540000):

Wiring: premodification 088264 - new 111579

AT50AG (91277630030 - 91277630000):

Wiring: premodification 088264 - new 111579

W46.08TLCSI (91278720030 - 91278720000):

Wiring: premodification 096434 - new 111538

W46.10TLCSI (91278730030 - 91278730000):

Wiring: premodification 096434 - new 111538

AT104EX (91280740030 - 91280740000):

Wiring: premodification 096445 - new 111580

WT120EX (91280750030 - 91280750000):

Wiring: premodification 096434 - new 111538

WAT10IT (91283140030 - 91283140000):

Wiring: premodification 096434 - new 111538

AT125FR (91284910030 - 91284910000):

Wiring: premodification 096438 - new 111569

WT80FR (91286690030 - 91286690000):

Wiring: premodification 096436 - new 112221

WT92FR (91286700030 - 91286700000):

Wiring: premodification 096434 - new 111538

WT112FR (91286710030 - 91286710000):

Wiring: premodification 096434 - new 111538

WT124FR (91286720030 - 91286720000):

Wiring: premodification 096434 - new 111538

WMTL80UK (91287490030 - 91287490000):

Wiring: premodification 096542 - new 112231

AT109FR (91291820030 - 91291820000):

Wiring: premodification 096438 - new 111569

AT95FR (91293880030 - 91293880000):

Wiring: premodification 096438 - new 111569

ATD102FR (91293930030 - 91293930000):

Wiring: premodification 096441 - new 112235

ATD122FR (91293940030 - 91293940000):

Wiring: premodification 096451 - new 111571

AT110FR (91293950030 - 91293950000):

Wiring: premodification 096438 - new 111569

WT100FR (91305060030 - 91305060000):

mod.ATD104EX page 27

Page 28

Wiring: premodification 096436 - new 112221

WT118FR (91305080030 - 91305080000):

Wiring: premodification 096434 - new 111538

AT8EIT (91306100030 - 91306100000):

Wiring: premodification 096438 - new 111569

WT119FR (91319910030 - 91319910000):

Wiring: premodification 096434 - new 111538

n1040336: Elimination of vent from rear panel of top-load washing machines.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial no. 40825.0001, the vent tube has been modified with the elimination of the vent from the rear panel of all top-load

washing machines affected by this note (see photo N1040336FIG1).

Given below are the codes of the modified items:

- Vent tube: premodification 085471 new 112602;

- Rear panel: premodification 098566 new 112632;

- Vent grid code 083944 has been eliminated.

n1040340: TUB ASSEMBLY 111505 - 111573 (EVO II) ON EVOI TOP LOADING APPLIANCES

mod.ATD104EX page 28

Page 29

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Given below are the instructions to install the new EVOII Top Loading tubs (codes 111505 and 111573) on EVOI Top Loading

washing machines produced before serial no. 40628.0001 (see note n1040332).

Please note that:

the EVOI Top Loading range tubs (spare part codes 110152-110153) are no longer managed as spare parts and have been

replaced as follows:

if you order code 110152 (EVOI T.L. 600-1000 RPM TUB) you will receive in its place:

- 111505: EVOII T.L. 600-1000 RPM TUB

- 111409: EVOII T.L. DRAIN PUMP

if you order code 110153 (EVOI T.L. 1200 RPM TUB) you will receive in its place:

- 111573: EVOII T.L. 1200 RPM TUB-BASKET ASSEMBLY

- 111409: EVOII T.L. DRAIN PUMP

Proceed as follows:

1) Replace the EVOI DRAIN PUMP with the new EVOII DRAIN PUMP - 111409;

2) Eliminate the DETERGENT RECOVERY TUBE (the new tub and new pump are not provided with the corresponding hole);

3) Do not remove the VENT TUBE that is on the appliance (the one on the new EVOII tub-basket assembly is no longer provided

with the vent on the rear panel).

Given below are the models affected:

26376 - WT60FR

26377 - WT62TFR

26450 - WT6IT

26451 - WT4IT

26452 - WAT6IT

26453 - WAT8IT

26454 - WT5IT

26865 - WT40EX

26866 - WT50EX

26867 - WT62EX

26868 - WT82EX

26869 - WT102EX

26894 - WT52CSI

26897 - WT80CSI

26898 - WT90CSI

26899 - WT100CSI

26970 - WT67EU

27142 - AT62IT

27143 - AT82IT

27144 - ATD84IT

27145 - ATD104IT

27148 - ATD120EX

27204 - AT50EX

27635 - AT84EX

27636 - ATD104EX

27674 - AT64EX

27684 - AT84AG

27726 - AT84EO

27728 - WT102TFR

27754 - AT64EO

mod.ATD104EX page 29

Page 30

27763 - AT50AG

27872 - W46.08TLCSI

27873 - W46.10TLCSI

28074 - AT104EX

28075 - WT120EX

28314 - WAT10IT

28491 - AT125FR

28669 - WT80FR

28670 - WT92FR

28671 - WT112FR

28672 - WT124FR

28749 - WMTL80UK

29182 - AT109FR

29388 - AT95FR

29393 - ATD102FR

29394 - ATD122FR

29395 - AT110FR

30506 - WT100FR

30508 - WT118FR

30610 - AT8EIT

31991 - WT119FR

n1040344: Modification of loading port on Top Loading washing machines.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The loading port with replacement P/N 112743 has been installed on the models affected by the current bulletin from serial

number 41119.0001; the new port is not interchangeable with premodification P/N 083895.

The commercial code and the code of affected models are given below.

26376WT60FR

26377WT62TFR

26451WT4IT

26452WAT6IT

26453WAT8IT

26454WT5IT

26865WT40EX

26866WT50EX

26867WT62EX

26868WT82EX

26869WT102EX

26894WT52CSI

26897WT80CSI

26898WT90CSI

26899WT100CSI

26970WT67EU

27145ATD104IT

27636ATD104EX

27728WT102TFR

27763AT50AG

27872W46.08TLCSI

mod.ATD104EX page 30

Page 31

28074AT104EX

28314WAT10IT

28670WT92FR

28749WMTL80UK

30506WT100FR

30610AT8EIT

33194AVTL62EU

33195AVTL82EU

33196AVTL83EU

33198AVTL104EU

33686AVTL60AG

33738AVTL60EO

33739AVTL84EO

33807AVTL62IT

33915WITL85FR

33916WITL88FR

33917WITL90FR

33918WITL100FR

33969AVTL108FR

34265WITP82EU

34266WITP102EU

34267WITL105EU

34269WITE87EU

34280WITL85EU

n1040414: Введен новый упругий стопор амортизатора на машинах с верхней загрузкой

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Начиная с серийного номера 50213.0001, введен расширительный элемент C00118593 вместо C00055037.

Новый элемент может использоваться и на предыдущих версиях машин, к которым относится настоящее сообщение.

mod.ATD104EX page 31

Page 32

Electric schemes and links

Cod. ce042500

mod.ATD104EX page 32

Page 33

Legend

Legend: ce042500

AQS Aquastop electrovalve Mzbn/MTA zbn timer motor

B Buzzer N Neutral or Terminal Board

BC Blocco Cesto NC Spin cycle exclusion

BF Terminal board contact, motor fan and dryer P Pressure switch

BP Buzzer P1 1st level pressure cut-off switch

C Condensator P2 2nd level pressure cut-off switch

CA Condensator PA High speed potentiometer

DV Switching device PB Low speed potentiometer

EF/CL Electro-Valve Cold Water / Bleach PL Pure Wool

EF/L Electro-Valve Cold Water / Wash PM Motor Thermoprotector

EF/P Electro-Valve Cold Water / Prewash PR Timer programmer or Pressure switch

ER Exclude Heating Element PS Drain pump

ET Thermostat disactivation R Heating element

EV Electrovalve RE Relay

EVA Dryer electrovalve RR Heating element

EVC Hot water electrovalve RV Speed regulator

EVF Elettrovalvola acqua fredda Ras/RA Dryer heating element

EVL Wash electrovalve S LED

EVP Pre Wash electrovalve SL Line LED

FA Antijamming filter SO Door LED

FD Delicate drying cycle thermostat SR Heating LED

FE Strong drying cycle thermostat ST Temperature selector

FRT Thermofusible Heating Element SV Speed Selector for Spin

I Inverter T Timer contacts

I1..2..3.. Switches/switching devices TA Drying timer contacts

IA Switch On/Off TB Low Temperature Thermostat

IC Switch N.C. - 1/2 Load TC Spider wheel earth

ID Switch display TFL Flange earth

IE Water Saving Device TG Main earth

IF Switch - Spin Reduction TH Thermostat

IP Door switch TH1 1st temperature thermostat

IR Line switch TH2 2nd temperature thermostat

IS Water-stop TH3 3rd temperature thermostat

mod.ATD104EX page 33

Page 34

L Line or Lamp THF Operating thermostat

LB Low Level THR Adjustable thermostat

LN Normal Level TM Motor earth

LS Pilot lamp TMB Main cabinet earth

M Earth-symbol TMP Motor thermal protector

MC Spin cycle motor TMS Thermostop

MI MOTOR WITH PULLEY TP Thermal protector

ML Wash cycle motor TPS Drain pump earth

MO Terminal Board TR Heating element earth

MP Door dip-switch TS Safety thermostat

MR Thermal Lock TT Timer earthing connection

MT Timer motor TTH Earthing Thermostat

MV Motor fan TV Tank earth

MV -Ras Dryer heating element ZBN Timer

mod.ATD104EX page 34

Page 35

Electric schemes and links

Cod. lg049500

mod.ATD104EX page 35

Page 36

Legend

Legend: lg049500

AQS Aquastop electrovalve Mzbn/MTA zbn timer motor

B Buzzer N Neutral or Terminal Board

BC Blocco Cesto NC Spin cycle exclusion

BF Terminal board contact, motor fan and dryer P Pressure switch

BP Buzzer P1 1st level pressure cut-off switch

C Condensator P2 2nd level pressure cut-off switch

CA Condensator PA High speed potentiometer

DV Switching device PB Low speed potentiometer

EF/CL Electro-Valve Cold Water / Bleach PL Pure Wool

EF/L Electro-Valve Cold Water / Wash PM Motor Thermoprotector

EF/P Electro-Valve Cold Water / Prewash PR Timer programmer or Pressure switch

ER Exclude Heating Element PS Drain pump

ET Thermostat disactivation R Heating element

EV Electrovalve RE Relay

EVA Dryer electrovalve RR Heating element

EVC Hot water electrovalve RV Speed regulator

EVF Elettrovalvola acqua fredda Ras/RA Dryer heating element

EVL Wash electrovalve S LED

EVP Pre Wash electrovalve SL Line LED

FA Antijamming filter SO Door LED

FD Delicate drying cycle thermostat SR Heating LED

FE Strong drying cycle thermostat ST Temperature selector

FRT Thermofusible Heating Element SV Speed Selector for Spin

I Inverter T Timer contacts

I1..2..3.. Switches/switching devices TA Drying timer contacts

IA Switch On/Off TB Low Temperature Thermostat

IC Switch N.C. - 1/2 Load TC Spider wheel earth

ID Switch display TFL Flange earth

IE Water Saving Device TG Main earth

IF Switch - Spin Reduction TH Thermostat

IP Door switch TH1 1st temperature thermostat

IR Line switch TH2 2nd temperature thermostat

IS Water-stop TH3 3rd temperature thermostat

mod.ATD104EX page 36

Page 37

L Line or Lamp THF Operating thermostat

LB Low Level THR Adjustable thermostat

LN Normal Level TM Motor earth

LS Pilot lamp TMB Main cabinet earth

M Earth-symbol TMP Motor thermal protector

MC Spin cycle motor TMS Thermostop

MI MOTOR WITH PULLEY TP Thermal protector

ML Wash cycle motor TPS Drain pump earth

MO Terminal Board TR Heating element earth

MP Door dip-switch TS Safety thermostat

MR Thermal Lock TT Timer earthing connection

MT Timer motor TTH Earthing Thermostat

MV Motor fan TV Tank earth

MV -Ras Dryer heating element ZBN Timer

mod.ATD104EX page 37

Page 38

Electric schemes and links

Cod. se105400

mod.ATD104EX page 38

Page 39

Legend

Legend: se105400

AQS Aquastop electrovalve Mzbn/MTA zbn timer motor

B Buzzer N Neutral or Terminal Board

BC Blocco Cesto NC Spin cycle exclusion

BF Terminal board contact, motor fan and dryer P Pressure switch

BP Buzzer P1 1st level pressure cut-off switch

C Condensator P2 2nd level pressure cut-off switch

CA Condensator PA High speed potentiometer

DV Switching device PB Low speed potentiometer

EF/CL Electro-Valve Cold Water / Bleach PL Pure Wool

EF/L Electro-Valve Cold Water / Wash PM Motor Thermoprotector

EF/P Electro-Valve Cold Water / Prewash PR Timer programmer or Pressure switch

ER Exclude Heating Element PS Drain pump

ET Thermostat disactivation R Heating element

EV Electrovalve RE Relay

EVA Dryer electrovalve RR Heating element

EVC Hot water electrovalve RV Speed regulator

EVF Elettrovalvola acqua fredda Ras/RA Dryer heating element

EVL Wash electrovalve S LED

EVP Pre Wash electrovalve SL Line LED

FA Antijamming filter SO Door LED

FD Delicate drying cycle thermostat SR Heating LED

FE Strong drying cycle thermostat ST Temperature selector

FRT Thermofusible Heating Element SV Speed Selector for Spin

I Inverter T Timer contacts

I1..2..3.. Switches/switching devices TA Drying timer contacts

IA Switch On/Off TB Low Temperature Thermostat

IC Switch N.C. - 1/2 Load TC Spider wheel earth

ID Switch display TFL Flange earth

IE Water Saving Device TG Main earth

IF Switch - Spin Reduction TH Thermostat

IP Door switch TH1 1st temperature thermostat

IR Line switch TH2 2nd temperature thermostat

IS Water-stop TH3 3rd temperature thermostat

mod.ATD104EX page 39

Page 40

L Line or Lamp THF Operating thermostat

LB Low Level THR Adjustable thermostat

LN Normal Level TM Motor earth

LS Pilot lamp TMB Main cabinet earth

M Earth-symbol TMP Motor thermal protector

MC Spin cycle motor TMS Thermostop

MI MOTOR WITH PULLEY TP Thermal protector

ML Wash cycle motor TPS Drain pump earth

MO Terminal Board TR Heating element earth

MP Door dip-switch TS Safety thermostat

MR Thermal Lock TT Timer earthing connection

MT Timer motor TTH Earthing Thermostat

MV Motor fan TV Tank earth

MV -Ras Dryer heating element ZBN Timer

mod.ATD104EX page 40

Loading...

Loading...