Aprilaire 8140, 8140NC Installation Manual

Model 8140 and 8140NC

Fresh Air Ventilator

Installation and Operating Instructions

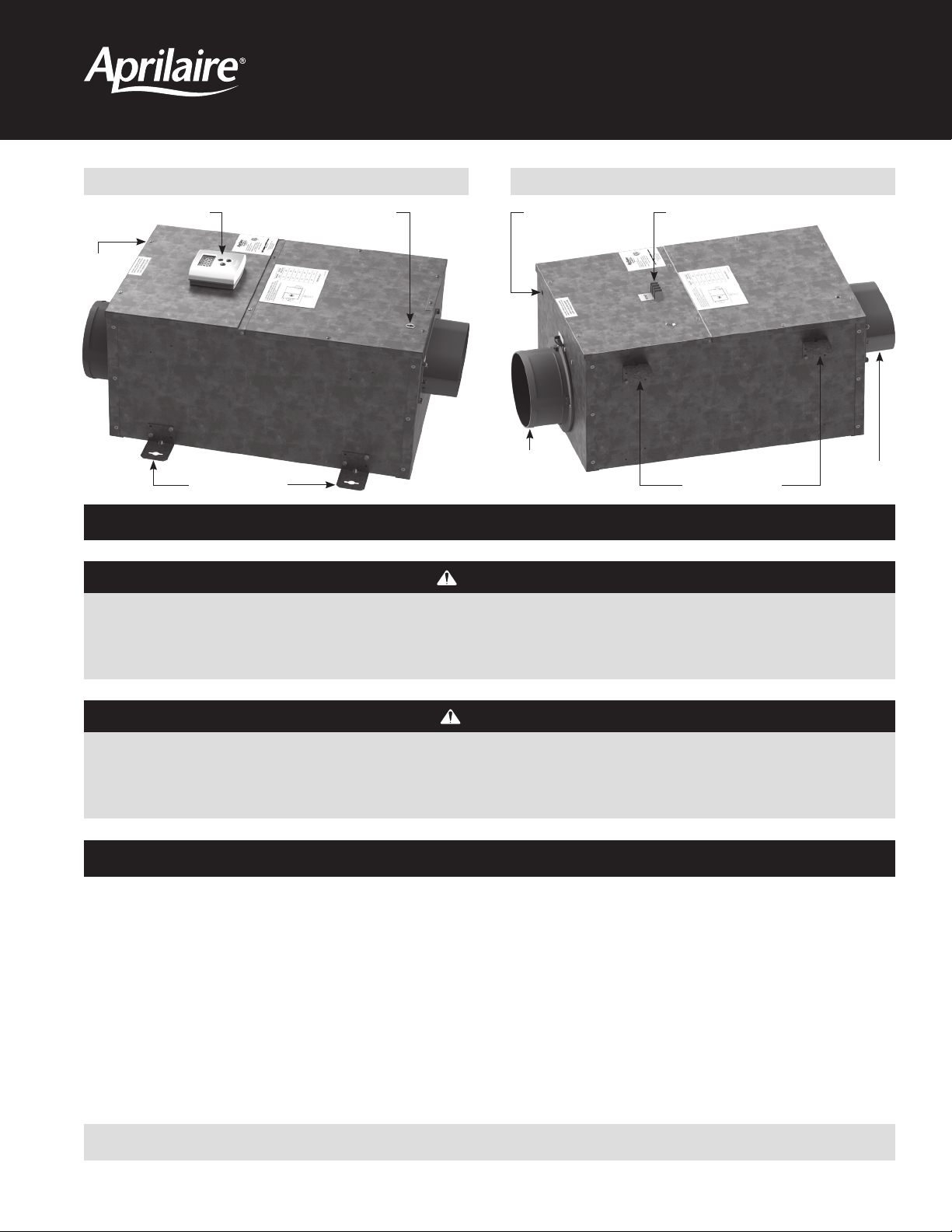

MODEL 8140 FRESH AIR VENTILATOR MODEL 8140NC FRESH AIR VENTILATOR

VENTILATION CONTROLLER

FILTER

COVER

BRACKET LOCATION

WALL MOUNT

INLET COLLAR AND

NORMALLY CLOSED

POWER DAMPER

VENTILATION TERMINALSLOW PRESSURE PORTHIGH PRESSURE PORT

JOIST MOUNT

BRACKET LOCATION

SAFETY INSTRUCTIONS

WARNING

1. 120 Volts may cause serious injury from electric shock. Disconnect electrical power before starting installation or servicing. Leave power

disconnected until installation/service is completed.

2. Sharp edges may cause serious injury from cuts. Use care when cutting plenum openings and handling duct work.

OUTLET

COLLAR

CAUTION

1. Read all instructions before beginning installation.

2. Improper installation may cause property damage or injury. Installation, service, and maintenance must be performed by a qualified service

technician.

TABLE OF CONTENTS

Safety Instructions ...............................................1

Introduction and Compliance Statement ...........................2

Specifications ...................................................2

Install Electrical Outlet............................................2

Ventilator Location and Orientation................................3

Mount the Ventilator .............................................3

Mount Intake Hood ..............................................4

Install Ductwork .................................................4

Model 8140NC – Wiring to Various Controls ........................5

Model 8140NC – Test Mode .......................................6

Model 8140NC – Sequence of Operation ...........................6

Model 8140 – Wiring the Control to the HVAC System ...............6

Model 8140 – Connecting the Control to the Ventilator ..............7

Model 8140 – Operation ..........................................7

Model 8140 – Test Mode ..........................................8

Measure Delivered Airflow ........................................8

Model 8140 – Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Model 8140 – Rater/Inspector Verification .........................10

Model 8140 – Sequence of Operation .............................10

Filter Cleaning...................................................11

Internal Schematics ..............................................11

Limited Warranty ...............................................12

READ AND SAVE THESE INSTRUCTIONS

10012996 B2208006B 7.19

English 1

INTRODUCTION AND COMPLIANCE STATEMENT

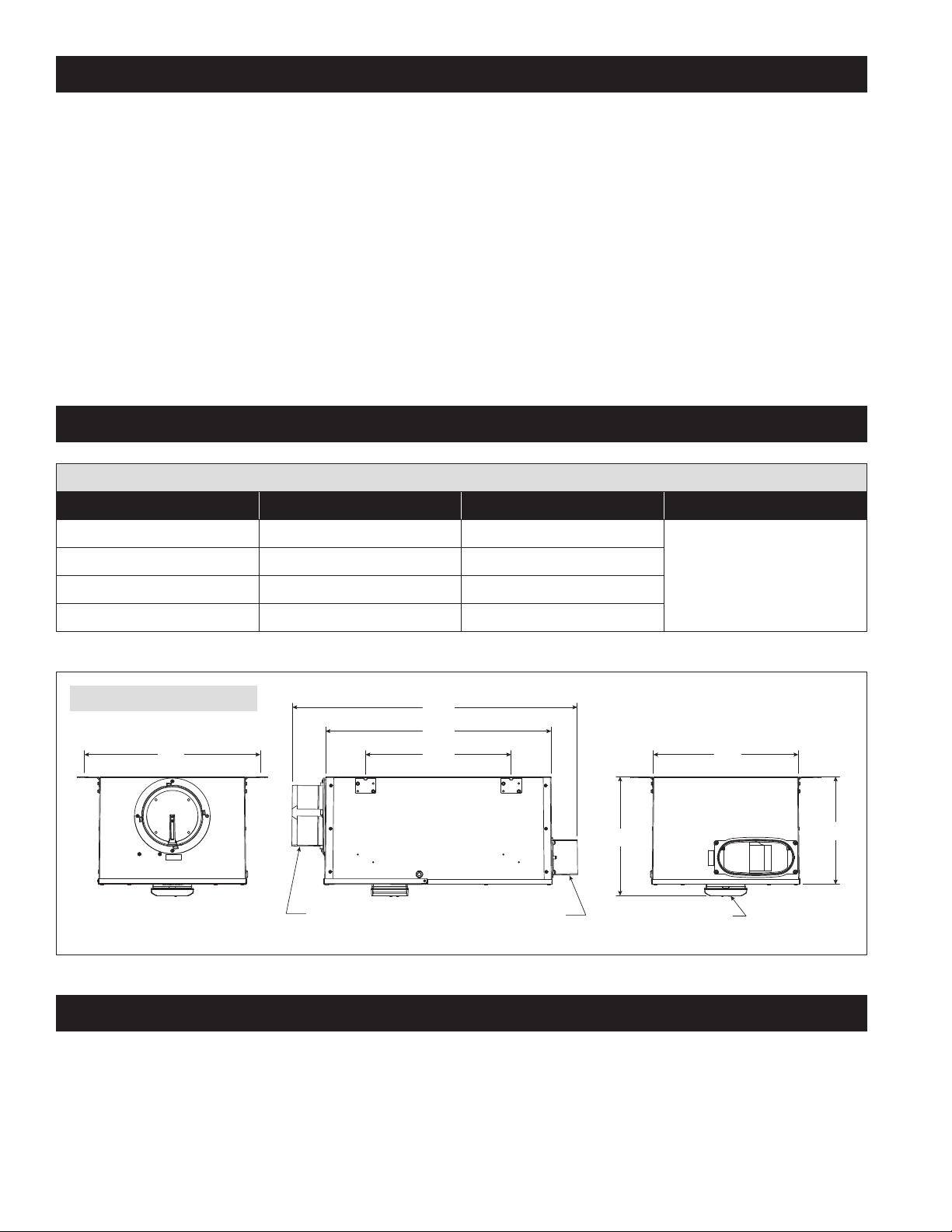

27. 75

10.50

FOR 6" DIAMETER DUCT

FOR 6" DIAMETER DUCT

The Model 8140 and 8140NC Fresh Air Ventilators are designed to bring in precisely the right amount of outdoor air into today’s efficiently designed

homes. Duct the inlet of the ventilator to an outdoor air intake and duct the discharge to the HVAC system, then simply plug the unit in, set the

amount of needed ventilation and select the desired temperature limits.

Temperature limits are set on the control to avoid bringing in outdoor air during the hottest or coldest period of the day. The built in control will

automatically compensate for the ventilation time that is missed by bringing in additional outdoor air during milder periods of the day. Compliance

with the requirements of ASHRAE 62.2-2010 is met as the control adds ventilation time as needed to account for the fractional on-time and

effectiveness of the ventilation schedule. The control will also ensure that ventilation occurs no less than one hour of every four. When properly

installed and set, the Model 8140 and 8140NC Fresh Air Ventilators will meet the mechanical ventilation requirements of:

Energy Star Certified Homes, Version 3

EPA Indoor airPLUS, Version 1

2012 & 2015 International Residential Code (IRC)

2012 & 2015 International Energy Conservation Code (IECC)

California Energy Commission Title 24

SPECIFICATIONS

TABLE 1 – SPECIFICATIONS

External Static Pressure ("w.c.) Airflow (CFM) Efficacy (CFM/watt) Voltage

0.0 250 4.5

0.2 205 3.8

0.4 165 3.1

0.6 125 2.1

FIGURE 1 – DIMENSIONS (INCHES)

17.15

INLET: ROUND COLLAR

22.13

14.00

OUTLET: OVAL COLLAR

120 VAC

1 phase

60 Hz

14.31

11.60

CONTROL NOT INCLUDED

ON MODEL 8140NC

90-2299

INSTALL ELECTRICAL OUTLET

Install a standard NEMA 5-15 receptacle suitable for the location, near where the ventilator will be installed. The ventilator comes equipped with a

6-foot power cord with a standard 3-prong plug.

2 English

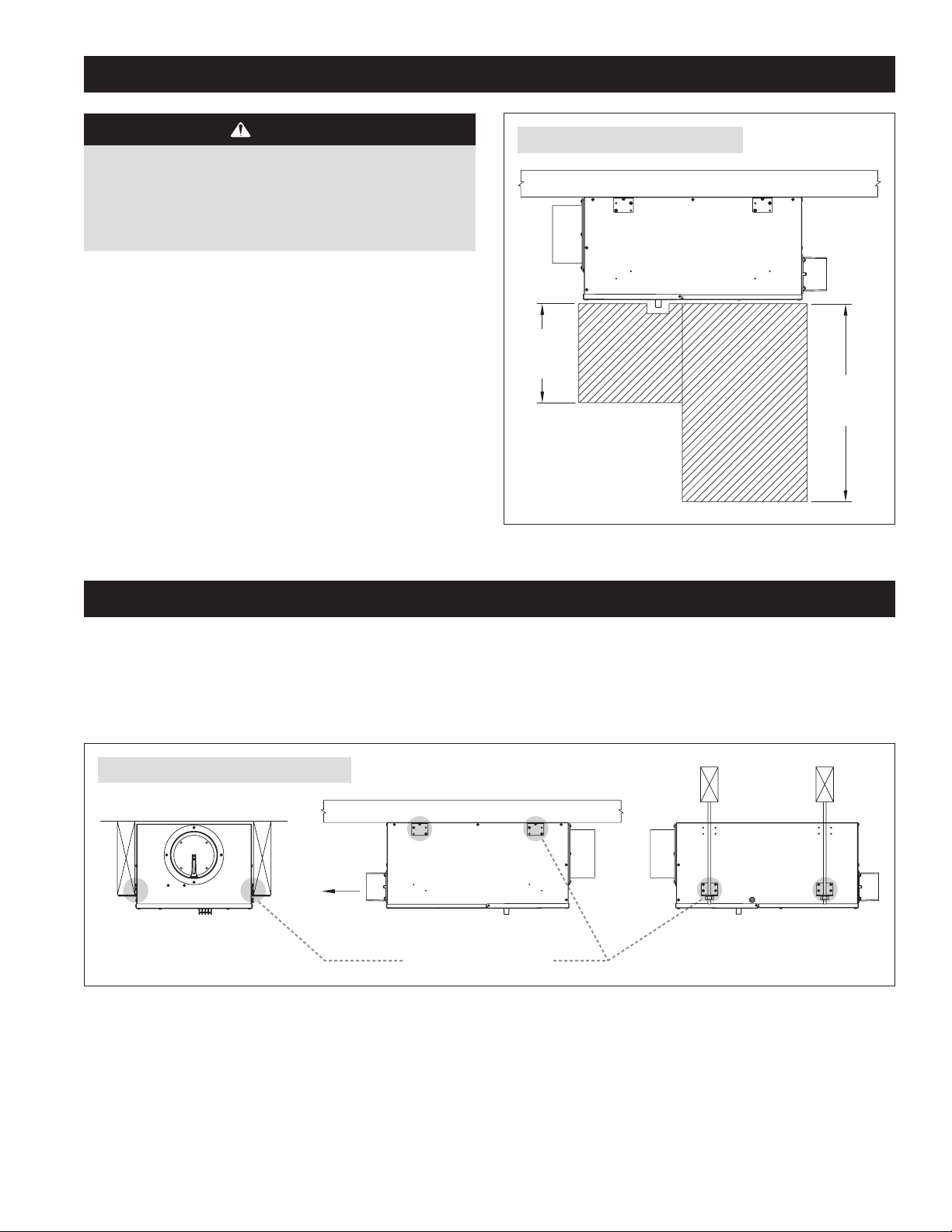

VENTILATOR LOCATION AND ORIENTATION

CAUTION

1. Mount the blower with the lowest, exposed moving parts at

least 8 feet (2.4 m) above floor or grade level.

2. Mount the blower at least 3.3 feet (1.0 m) from any accessible

opening of the duct.

Choose a location for the ventilator that is within 6 feet of the outlet

into which the ventilator will be plugged. Allow space for filter removal

and service as shown in FIGURE 2.

The ventilator can be mounted in any orientation.

FIGURE 2 – CLEARANCES FOR SERVICING

10"

FILTER

ACCESS

24"

MOTOR

ACCESS

90-2241

MOUNT THE VENTILATOR

1. Install the mounting brackets, using the supplied #8 x 1/2" screws, to the side of the housing as shown in FIGURE 3. Use the holes nearest the

covers for mounting to floor joists or hanging from rafters. Use the holes near the bottom of the unit for mounting to a flat wall or ceiling surface.

2. Secure the ventilator into joists or a strong platform and screw into place using the #10 x 3/4" screws provided. The ventilator weighs

approximately 25 pounds, so do not secure it into drywall alone.

FIGURE 3 – MOUNTING BRACKET POSITIONING

AIR FLOW

MOUNTED TO THE JOIST HUNG FROM THE JOIST

MOUNTED TO WALL OR FLOOR JOISTS

MOUNTING BRACKET LOCATIONS

90-2241

English 3

MOUNT INTAKE HOOD

Install a weather tight hood with a bird screen.

Cut a hole in the exterior wall that is large enough to fit 6" insulated flexible duct through with minimal compression of the insulation. Pull the duct

through the hole and attach the flex duct to the collar of the hood. Use metal foil tape or a plastic zip-tie to secure the duct to the collar. Pull the

insulation and vapor barrier over the duct and tape it to the collar.

IMPORTANT: The end of the insulation must be sealed to prevent condensation from forming inside the insulation. If a plastic zip-tie is used to

secure the insulation to the hood collar, also tape the end to seal it against condensation problems.

Press the hood against the outside wall and secure in place with screws; seal around the perimeter of the hood with caulk.

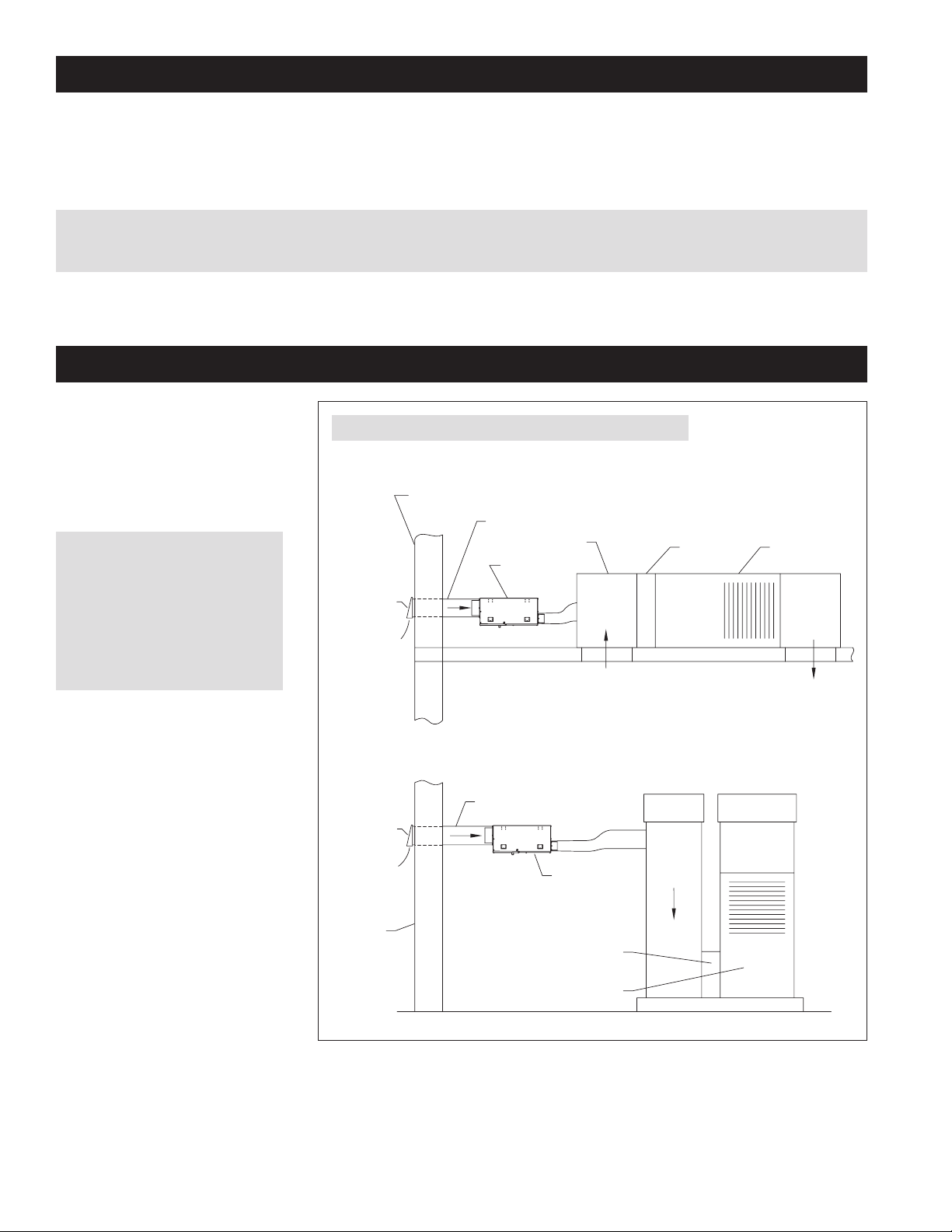

INSTALL DUCTWORK

Install 6" diameter flexible, insulated duct

from the round inlet collar of the unit to the

intake hood and from the oval outlet collar

of the unit to the HVAC system. Duct the

outlet of the ventilator to the return side of

the HVAC system (refer to FIGURE 4).

IMPORTANT: The end of the

insulation must be sealed to prevent

condensation from forming inside

the insulation. If a plastic zip-tie is

used to secure the insulation to the

hood collar, also tape the end to seal

it against condensation problems.

FIGURE 4 – DUCTING IN UPFLOW AND HORIZONTAL HVAC SYSTEMS

TYPICAL ATTIC INSTALLATION

GABLE END WALL, BAND JOIST, OR PORCH SOFFIT

FRESH AIR INTAKE DUCT

RETURN MIXING BOX

FRESH AIR

INTAKE HOOD

WITH SCREEN

FRESH AIR

FRESH AIR

VENTILATOR

AIR FLOW

FILTER

FURNACE/AIR

HANDLER

4 English

FRESH AIR

INTAKE HOOD

WITH SCREEN

FRESH AIR

OUTSIDE

WALL

90-2241

TYPICAL BASEMENT INSTALLATION

FRESH AIR INTAKE DUCT

FRESH AIR

VENTILATOR

AIR FLOW

FILTER

FURNACE/AIR HANDLER

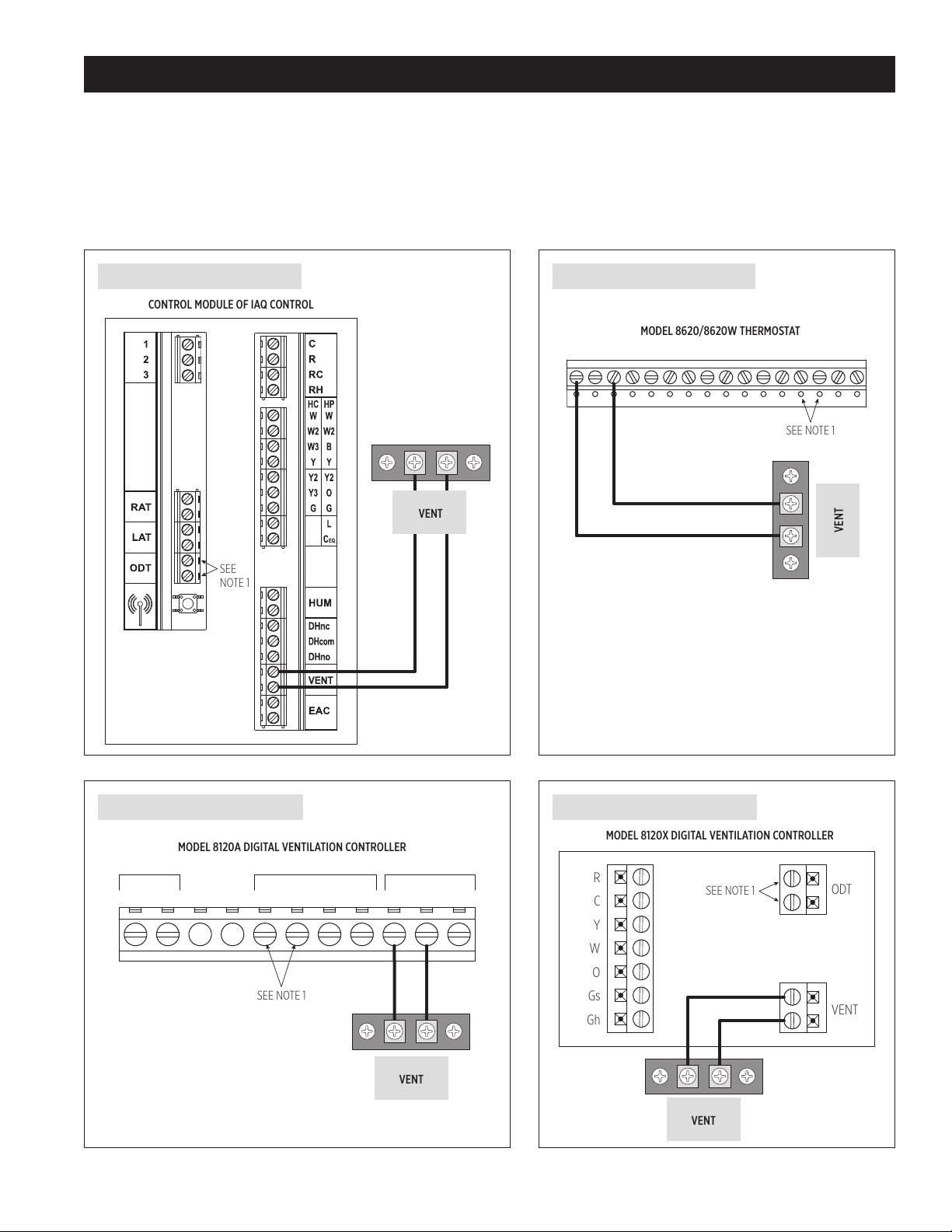

MODEL 8140NC – WIRING TO VARIOUS CONTROLS

CONTROL MODULE OF IAQ CONTROL

VENT

SEE

NOTE 1

MODEL 8120A DIGITAL VENTILATION CONTROLLER

VENT

SEE NOTE 1

MODEL 8620/8620W THERMOSTAT

VENT

SEE NOTE 1

R

C

Y

W

O

Gs

Gh

ODT

VENT

MODEL 8120X DIGITAL VENTILATION CONTROLLER

VENT

SEE NOTE 1

Suggested Controls:

• Aprilaire IAQ Control Models 8910, 8910W or 8920W

• Aprilaire Thermostat Models 8620 or 8620W

• Model 8120A or 8120X Digital Ventilation Controller

Select the diagram that corresponds to the control to be used. Wire the controls to the HVAC equipment and any other IAQ accessory in accordance

with the literature provided with the control.

FIGURE 5 – WIRING TO IAQ CONTROL

FIGURE 6 – WIRING TO THERMOSTAT

C I2

I1 Y

O/B RC

Y2 W2

RG

L T2

S2

W

T1

S1

FIGURE 7 – WIRING TO MODEL 8120A

NOT

CR VENTODT GfUSED

NOTE 1: An outdoor temperature sensor must be installed to use outdoor temperature limits for ventilation control.

FIGURE 8 – WIRING TO MODEL 8120X

OUTPUTSINPUTSPOWER

GW

English 5

MODEL 8140NC – TEST MODE

CONTROL

MOUNTING

PLATE

VENTILATION CONTROL

RCYWG

RCYWG

THERMOSTAT

WIRE NUT

(FIELD

SUPPLIED)

R

C

Y

W

O

GS

GH

FURNACE

R & C = 24 VAC

Y = COOLING

W = HEAT

GS = FAN INPUT

GH = FAN OUTPUT

VENT

ODT

After all ducting and wiring is complete, plug in the ventilator, restore power to the HVAC system and make sure the switch controlling the outlet into

which the ventilator is plugged (if applicable) is turned on.

1. Use the installed control to complete a circuit between the VENT terminals on the 8140NC.

2. Verify that the ventilator blower starts and that the integral damper opens.

3. If the ventilator has been wired to turn on the HVAC blower with ventilation, verify that the blower is on.

4. Measure the airflow (CFM) that the installed ventilator is delivering. See MEASURE DELIVERED AIRFLOW section on page 8.

5. Using the instructions provided with the installed control, adjust the ventilation settings as required.

MODEL 8140NC – SEQUENCE OF OPERATION

Refer to the installation manual provided with the control that is wired to the Model 8140NC.

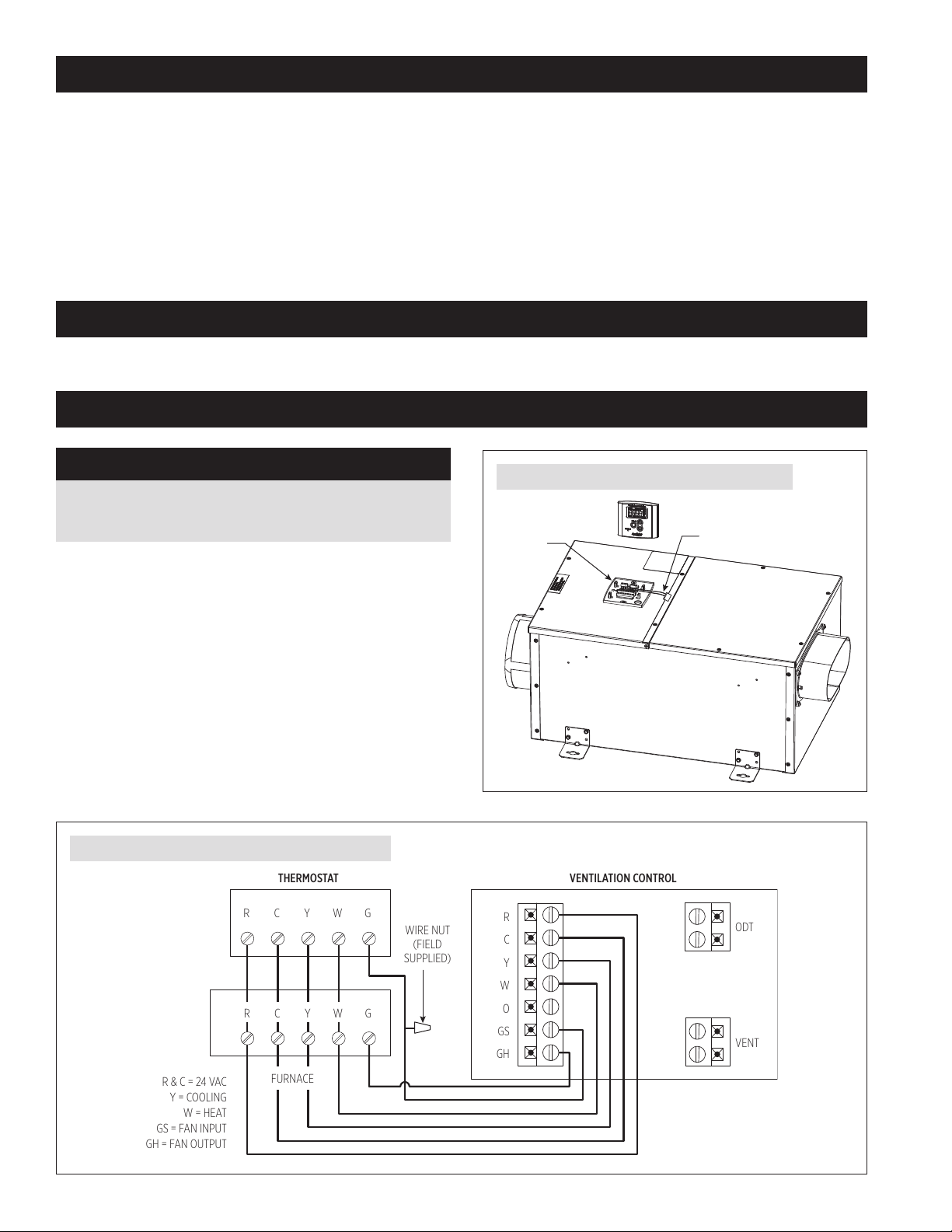

MODEL 8140 – WIRING THE CONTROL TO THE HVAC SYSTEM

NOTICE

Disconnect power to HVAC system during wiring to avoid

electrical shorts.

1. Remove the control from the mounting plate as shown in FIGURE 9.

Set control aside in a safe place until all wiring has been completed.

2. Run a 6-conductor (min.) cable (for furnace/AC applications) or a

7-conductor (min.) cable between the control and the HVAC system.

3. Wire to the HVAC system in accordance with FIGURE 10 if installed in

a furnace/AC application or FIGURE 11 if installed with a heat pump.

FIGURE 10 – WIRING VENTILATION CONTROL TO A FURNACE

FIGURE 9 – REMOVE CONTROL FROM MOUNTING PLATE

CONTROL

CONTROL CONNECTOR

90-2299

6 English

VENTILATION CONTROL

RCYW1G

RCYWG

HEAT PUMP THERMOSTAT

WIRE NUT

(FIELD

SUPPLIED)

O

R & C = 24 VAC

Y = COMPRESSOR

W1 = 1st STAGE AUX. HEAT

O = REV. VALVE, COOLING

GS = FAN INPUT

GH = FAN OUTPUT

R

C

Y

W

O

GS

GH

VENT

ODT

HEAT PUMP

O

FIGURE 11 – WIRING VENTILATION CONTROL TO A HEAT PUMP

CONTROL BACK CONTROL FRONTCONTROL MOUNTING PLATE

MIN/

HR

CODE

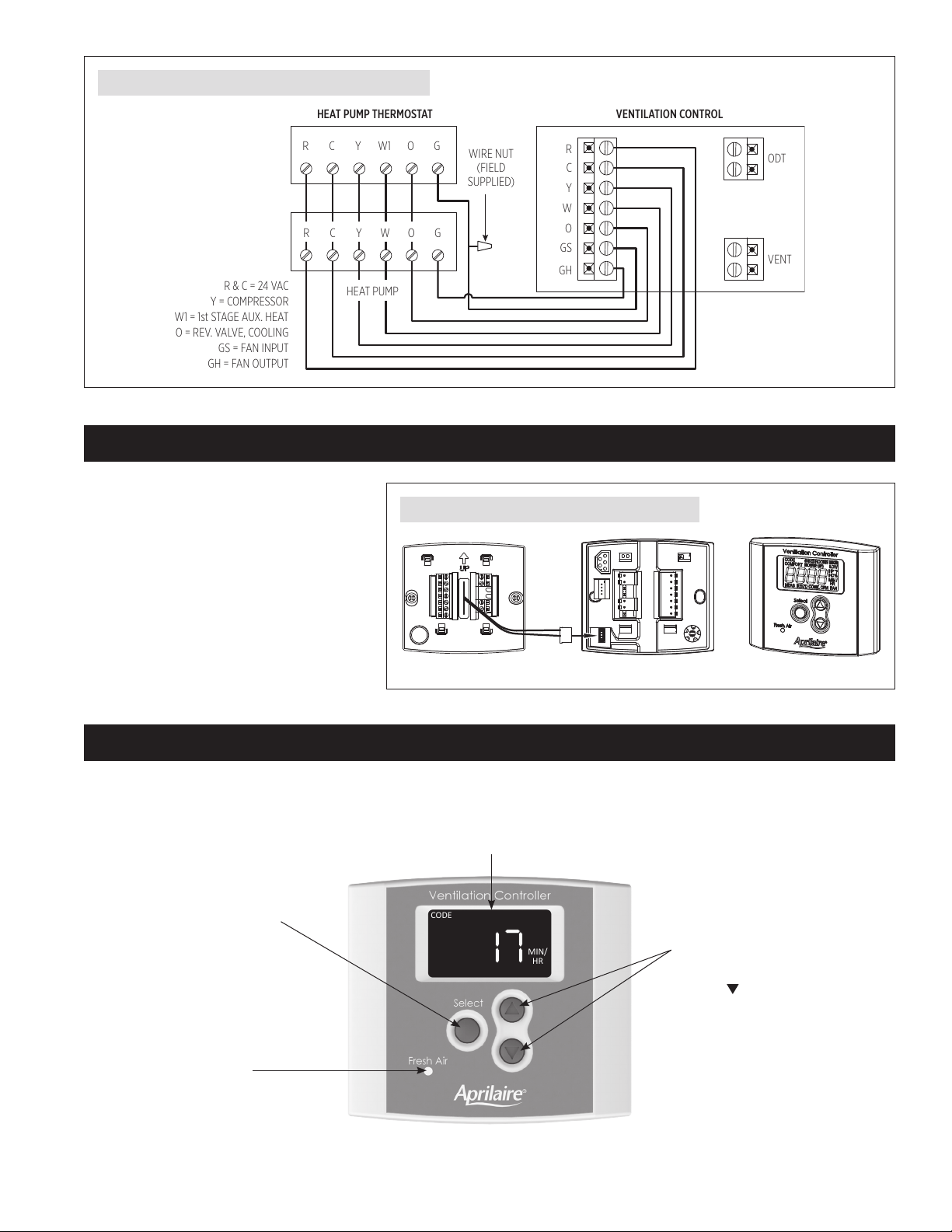

MODEL 8140 – CONNECTING THE CONTROL TO THE VENTILATOR

Plug the Control Connector into the back of the

control at the location shown in FIGURE 12. Route

the connector wire through the channels in the

control and reattach the control to the mounting

plate. Restore power to the HVAC system and plug

in the ventilator when complete.

FIGURE 12 – PLUG THE CONTROL INTO THE VENTILATOR

MODEL 8140 – OPERATION

The display will appear faint normally; the first press of any button will turn on the display at full power.

Shows the ventilation time setting (minutes/hr), mode of operation

(Code or Comfort) and whether the HVAC fan has been turned on when ventilating.

Use for Rater/Inspector Verification.

Press and hold for 5 seconds to

enter Test Mode or Set Up Menu.

Lights green when ventilating.

90-2291

Use to override the calculated ventilation

time setting (6 – 60 minutes/hr). Press

and hold to turn ventilation OFF.

To return to the calculated setting, go

completely through the Set Up Menu.

English 7

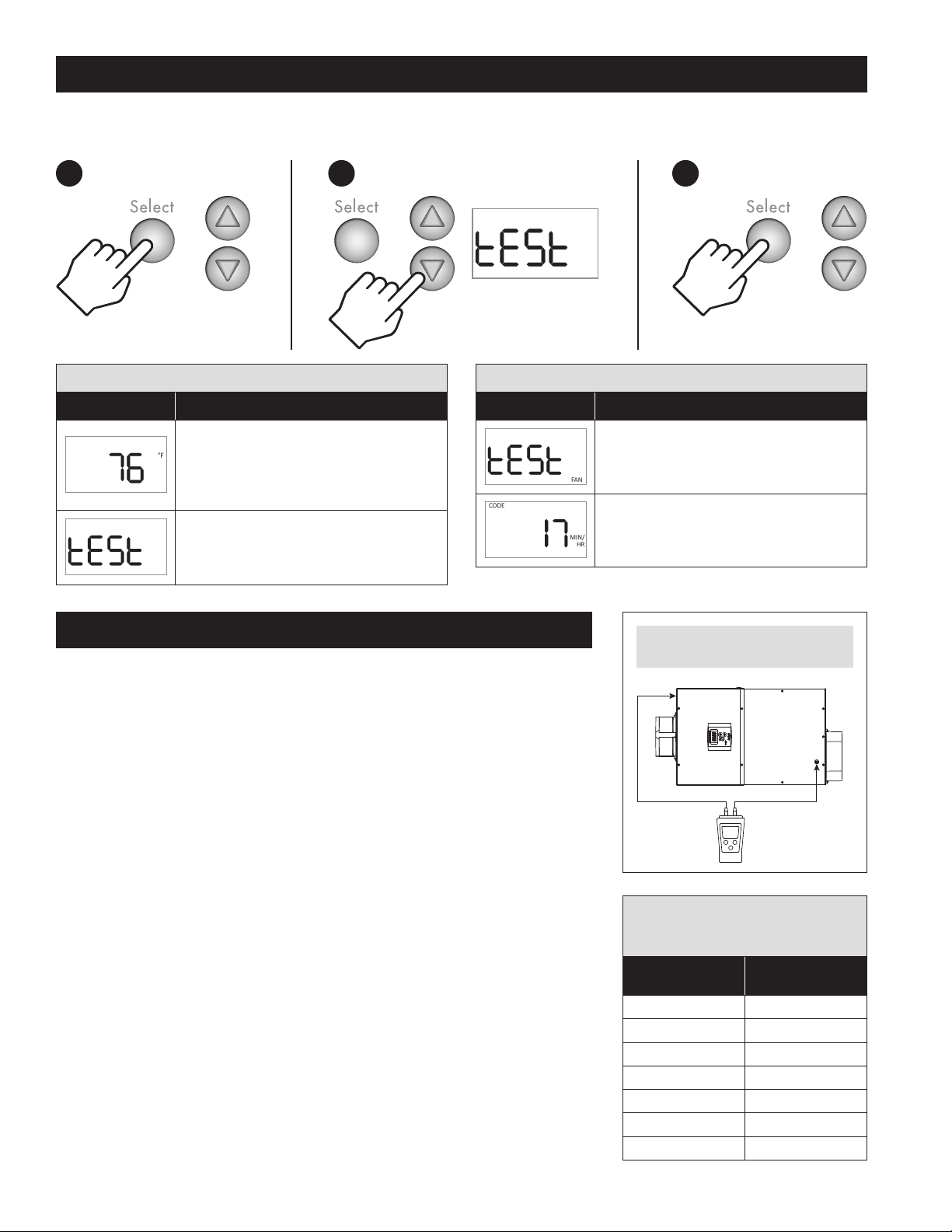

MODEL 8140 – TEST MODE

2 3

HP°FHC

1

MEASURED REQ’D CONT CFM

FAN

MIN/

HR

CODE

After wiring and set up have been completed, Test Mode can be used to verify that all components in the ventilation system function and that wiring

to the HVAC system fan is correct.

Hold for 5 seconds.

TABLE 2 – MODEL 8140 TEST MODE MENU

Test Sequence Description

Shows outdoor temperature or ----°F if no

separate outdoor temperature sensor has been

%

installed. Model 8140 installations do not require a

separate sensor – outdoor temperature is measured

by the control's on-board sensor.

tESt shows on the display, the green Fresh Air LED

will light and either the damper will open or the

power ventilator will turn on depending on what

has been wired to the VENT terminals.

TABLE 2 – MODEL 8140 TEST MODE MENU

Test Sequence Description

After 15 seconds, the HVAC fan will turn on if it has

been wired and set up to do so. The display will

show FAN along with tESt.

After 45 seconds Test Mode automatically

completes and the display returns to the operating

display.

MEASURE DELIVERED AIRFLOW

1. Make sure the ventilator is plugged in and wired to an external control (Model 8140NC) or that

the integral control is wired to the HVAC system (Model 8140).

2. Use 1/4" flexible tubing to attach a pressure gauge set to " w.c. (sometimes shown as “in. w.g.”

or “in. H2O”) to the inlet and outlet pressure ports on the ventilator. The pressure gauge should

have as small a range as possible to get a meaningful measurement – a range of 1.0" w.c. should

be sufficient. Connect the high or “+” port of the gauge to the outlet pressure port on the

ventilator, and the low or “-“ port of the gauge to the inlet pressure port on the ventilator. See

FIGURE 13.

3. Model 8140NC – Turn on the ventilator using the installed control for the Model 8140NC. This

can be done by temporarily changing the ventilation setting to 60 minutes/hour or you can

simply place a jumper between the VENT terminals of the ventilator.

Model 8140 – Turn on the ventilator by using the “Up” button to increase the ventilation setting

to 60 MIN./HR.

4. Use the label on the cover of the ventilator, or TABLE 3, to convert the pressure reading to

delivered airflow. If the pressure reading false between listed values, either use the lower value

or interpolate between values: CFM = Lower Value + [(Higher Value – Lower Value) * 10 *

(Pressure Reading – Lower Value Pressure)]. The following is an example:

a. Measured Pressure Reading is 0.34" w.c.

b. Table 2 lists 205 CFM @ 0.3" w.c. and 175 @ 0.4" w.c.

c. Either use 175 CFM or interpolate:

CFM = 175 + [(205-175) * 10 * (0.34-0.3)] = 175 + [(30) * 10 * (.04)] = 175 + 12 = 187 CFM

Interpolating will demonstrate higher delivered airflow, but requires a calculation to be done.

FIGURE 13 – MEASURE PRESSURE AT

INLET AND OUTLET PRESSURE PORTS

Lo

INLET

Hi

-

+

90-2354

TABLE 3 – DELIVERED AIRFLOW

CORRESPONDING TO MEASURED PRESSURE

AT VENTILATOR PRESSURE PORTS

Measured Pressure

(" w.c.)

0.1 250

0.2 230

0.3 205

0.4 175

0.5 145

0.6 110

0.7 70

Delivered Airflow

(CFM)

OUTLET

8 English

Loading...

Loading...