Page 1

User Guide

BTS Master™ MT8220T

High Performance Handheld Base Station Analyzer

Appendix A provides a list of supplemental documentation for the

BTS Master features and options. The documentation set is

available as PDF files on the Anritsu website.

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

http://www.anritsu.com

Part Number: 10580-00366

Published: June 2018

Copyright 2018 Anritsu Company

Revision: L

Page 2

Page 3

Table of Contents

Chapter 1—General Information

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Contacting Anritsu for Sales and Service . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Instrument Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Available Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Calibration and Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4 Instrument Care and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . 1-5

Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

ESD Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

RF Input Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5 Secure Environment Workplace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

BTS Master Memory Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Erase All User Files in Internal Memory . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Recommended Usage in a Secure Environment . . . . . . . . . . . . . . . . . 1-9

Chapter 2—Instrument Overview

2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Turning On the BTS Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Instrument Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Fan Inlet and Exhaust Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Front Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-4 Interface Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Touch Screen Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Symbols and Icons on the Title Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Symbols and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Display Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Touch Screen Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-5 Data Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Text Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Numeric Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Selection Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2-6 Mode Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2-7 Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2-8 Soft Carrying Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

MT8220T UG PN: 10580-00366 Rev. L Contents-1

Page 4

Table of Contents (Continued)

2-9 Tilt Bail Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Chapter 3—Quick Start

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Connect the Input Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Editing and Entering Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Selecting the Analyzer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3 Set the Measurement Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Using Start and Stop Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Entering Center Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Selecting Signal Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Setting Measurement Frequency Bandwidth . . . . . . . . . . . . . . . . . . . 3-3

3-4 Set the Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting Amplitude Reference Level and Scale . . . . . . . . . . . . . . . . . . . 3-4

Setting Amplitude Range and Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Reference Level Offset for External Loss or External Gain . . . . . . . . . . 3-5

3-5 Set the Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-6 Setting Up Limit Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Simple Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Limit Line Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Complex Limit Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-7 Setting Up Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-8 Selecting a Measurement Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-9 Saving Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-10 Anritsu PC Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-11 External Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Chapter 4—File Management

4-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Managing Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

File Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Save Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Recall Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Copy Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Delete Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-3 File Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Contents-2 PN: 10580-00366 Rev. L MT8220T UG

Page 5

Table of Contents (Continued)

4-4 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Save Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

File Type Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Save Location Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Save On... Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Recall Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Copy Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Delete Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Chapter 5—System Operation

5-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 System Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

System Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

System Options 2/2 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Power-On Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Display Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Brightness Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Reset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-4 Preset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-5 Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-6 Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Chapter 6—GPS

6-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Activating the GPS Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-3 Resetting GPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4 Saving and Recalling Traces with GPS Information . . . . . . . . . . . . . . . . . . 6-3

Saving Traces with GPS Information. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Recalling GPS Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-5 GPS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Chapter 7—Anritsu Tool Box

7-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2 Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-3 Anritsu Software Tool Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

MT8220T UG PN: 10580-00366 Rev. L Contents-3

Page 6

Table of Contents (Continued)

7-4 Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Line Sweep Tools (LST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Master Software Tools (MST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

easyTest Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

easyMap Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Wireless Remote Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Chapter 8—Web Remote Control

8-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

LAN Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Connection to a Wireless Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-3 Web Remote Control Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

User Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Capture Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Capture Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

File List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Device Management (not as Administrator) . . . . . . . . . . . . . . . . . . . . . 8-8

Device Management (Administrator) . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Logout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Appendix A—Measurement Guides

A-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Appendix B—Error Messages

B-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B-2 Self Test or Application Self Test Error Messages . . . . . . . . . . . . . . . . . . B-1

B-3 Operation Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Appendix C—LAN and DHCP

C-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C-2 LAN Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C-3 Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Ethernet Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

C-4 ipconfig Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

C-5 Ping Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Contents-4 PN: 10580-00366 Rev. L MT8220T UG

Page 7

Table of Contents (Continued)

Appendix D—Glossary of Terms

D-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

D-2 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Index

MT8220T UG PN: 10580-00366 Rev. L Contents-5

Page 8

Contents-6 PN: 10580-00366 Rev. L MT8220T UG

Page 9

Chapter 1 — General Information

1-1 Introduction

The BTS Master User Guide is part of a set of manuals that describe all of the instrument

functions and their use. This manual covers the instrument overview, system functions and

other common features, along with a brief guide to basic measurement concepts and setups.

Instrument operations are explained in various document types as listed below.

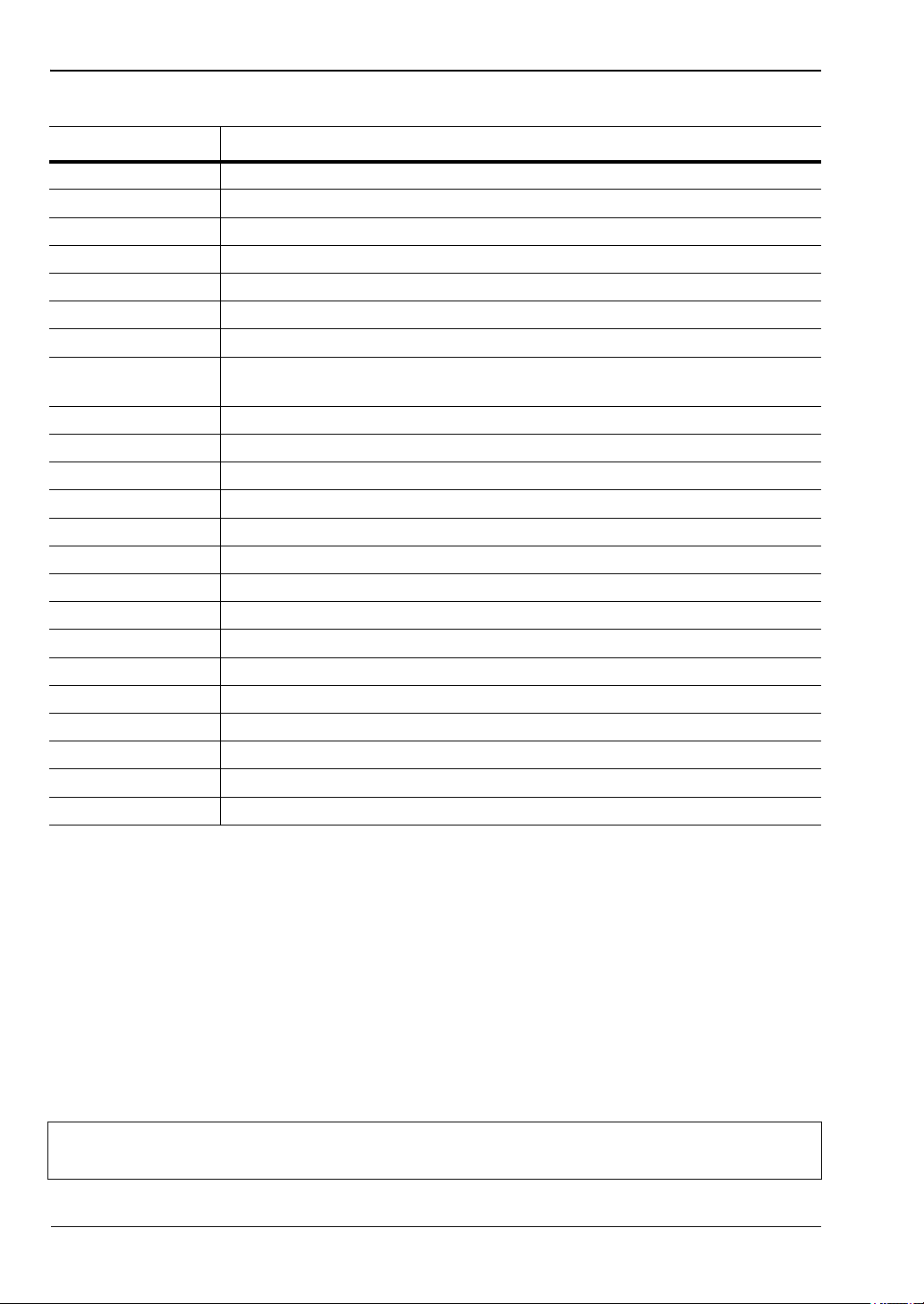

Additional Documentation

Document Part Number Description (Required Option)

10100-00065 Important Product Information, Compliance, and Safety Notices

Spectrum Analyzer Measurement Guide

Bias-Tee (Option 10)

IQ Waveform Capture (Option 24)

10580-00349

10580-00230 Cable and Antenna Analyzer Measurement Guide

10580-00232

10580-00234

10580-00235

10580-00236

10580-00240

10580-00280

10580-00367 Programming Manual

10580-00368 Maintenance Manual

Interference Analyzer (Option 25)

Channel Scanner (Option 27)

Zero-Span IF Output (Option 89)

Gated Sweep (Option 90)

Coverage Mapping (Option 431)

Signal Generators Measurement Guide

Vector Signal Generator (Option 23)

3GPP Signal Analyzer Measurement Guide

GSM/GPRS/EDGE Measurements (Option 880)

W-CDMA/HSPA+ Measurements (Option 881)

TD-SCDMA/HSPA+ Measurements (Option 882)

LTE/LTE-A FDD/TDD Measurements (Option 883)

LTE 256QAM Demodulation Measurements (Option 886)

NB-IoT Measurements (Option 887)

3GPP2 Signal Analyzer Measurement Guide

CDMA/EV-DO Measurements (Option 884)

WiMAX Signal Analyzer Measurement Guide

WiMAX Fixed/Mobile Measurements (Option 885)

Power Meter Measurement Guide

Internal Power Meter

High-Accuracy Power Meter (Option 19)

PIM Master User Guide

PIM Analyzer (requires PIM Master MW82xxA)

MT8220T UG PN: 10580-00366 Rev. L 1-1

Page 10

1-2 Instrument Description General Information

Document Part Number Description (Required Option)

CPRI LTE RF Analyzer and BBU Emulator Measurement Guide

CPRI LTE RF Measurements (Option 752; requires Option 759)

10580-00415

10580-00434

11410-00698

a.The obsolete Option 751 is functionally identical to the combined Options 752 and 759.

Read the Handheld Instruments Product Information, Compliance, and Safety Guide

(PN: 10100-00065) for important safety, legal, and regulatory notices before operating the

equipment. For additional information and literature covering your product, visit the product

page of your instrument and select the Library tab:

http://www.anritsu.com/en-US/test-measurement/products/mt8220t

PIM over CPRI Measurements (Option 754; requires Option 752)

CPRI BBU Emulation Nokia/ALu LTE (Option 760; requires

Option 752)

RET Device Test Nokia/ALu (Option 761; requires Option 760)

OBSAI LTE RF Analyzer Measurement Guide

OBSAI LTE RF Measurements (Option 753; requires Option 759)

BTS Master Technical Data Sheet

Performance Specifications, Instrument Options and Accessories

a

Contacting Anritsu for Sales and Service

To contact Anritsu, visit the following URL and select the services in your region:

http://www.anritsu.com/contact-us.

1-2 Instrument Description

The MT8220T BTS Master is an integrated multi-functional base station test tool that

eliminates the need to carry and to learn to use multiple test sets. The measurement

capabilities include: spectrum analyzer smart measurements, precision return loss, VSWR,

cable loss, distance-to-fault, two port gain/loss, one-port and two-port magnitude and phase,

interference analysis, spectrogram, and power meter.

RF, advanced demodulation, and over-the-air (OTA) measurements can be applied to

GSM/GPRS/EDGE, W-CDMA/HSPA+, TD-SCDMA/HSPA+, LTE FDD/TDD, CDMA/EV-DO,

and WiMAX Fixed/Mobile signals.

Additional capabilities include a Vector Signal Generator (VSG), GPS location information,

and enhanced external frequency reference oscillator accuracy.

The MT8220T model has cable and antenna analysis (400 MHz to 6.0 GHz), spectrum

analysis (150 kHz to 7.1 GHz), and an internal power meter (10 MHz to 7.1 GHz). The cable

and antenna analysis is performed by a Vector Network Analyzer that is designed to make

accurate vector-corrected 1-port and 1-path, 2-port magnitude and phase measurements from

400MHz to 6GHz.

1-2 PN: 10580-00366 Rev. L MT8220T UG

Page 11

General Information 1-2 Instrument Description

The MT8220T is also a synthesizer-based spectrum analyzer that provides quick and

accurate measurement results. Measurements can be easily made by using the main

instrument functions: frequency, span, amplitude, and bandwidth. Dedicated keys for

one-button measurements of field strength, channel power, occupied bandwidth, Adjacent

Channel Power Ratio (ACPR), and Carrier to Interference Ratio (C/I) make the handheld

MT8220T the ideal choice for the field. A familiar calculator-type keypad allows for fast data

entry.

In transmitter analyzer mode, the MT8220T displays 6 markers and the marker table in

Code Domain Power and Codogram displays. In Spectrum Analyzer mode, a full range of

marker capabilities (such as peak, center, and delta functions) are provided for faster, more

comprehensive analysis of displayed signals. Upper and lower multi-segmented limit lines

are available to create quick, simple pass/fail measurements. A menu option provides for an

audible alert when a limit value is exceeded.

Time and date stamping of measurement data is automatic. The internal memory provides

for storage and recall of traces and measurement setups. The bright daylight-viewable,

high-resolution, color liquid crystal display (LCD) provides easy viewing in a variety of

lighting conditions. The MT8220T is capable of approximately 2.5 hours of continuous

operation from a fully charged battery and can be operated from a 12 VDC source, which also

simultaneously charges the battery.

Several PC-based software programs are available free-of-charge from Anritsu. Refer to

Chapter 7 for a brief overview.

• Anritsu Master Software Tools (MST) provides a convenient means for storing

measurement data. Master Software Tools can also convert measurements from the

display into several graphic formats. Master Software Tools supports all of the options

that are provided with the instrument.

• Line Sweep Tools (LST) can be used with Cable & Antenna measurements to create

reports, view and organize data, analyze historical data, edit markers and limit lines,

rename traces and trace analysis.

• easyMap Tools is used to create maps for coverage and interference mappings.

Additional information for specific software programs is available under the software’s

Help menu.

Measurements may be stored in internal memory, on a USB flash drive, or a

FAT32-formatted external disk. Stored measurements can be downloaded to a PC by using

the included USB and Ethernet cables. After being stored, the graphic trace can then be

displayed, scaled, or enhanced with markers and limit lines. Historical graphs can be overlaid

with current data by using the PC mouse in a drag-and-drop fashion. The underlying data

can be extracted and used in spreadsheets or for other analytical tasks.

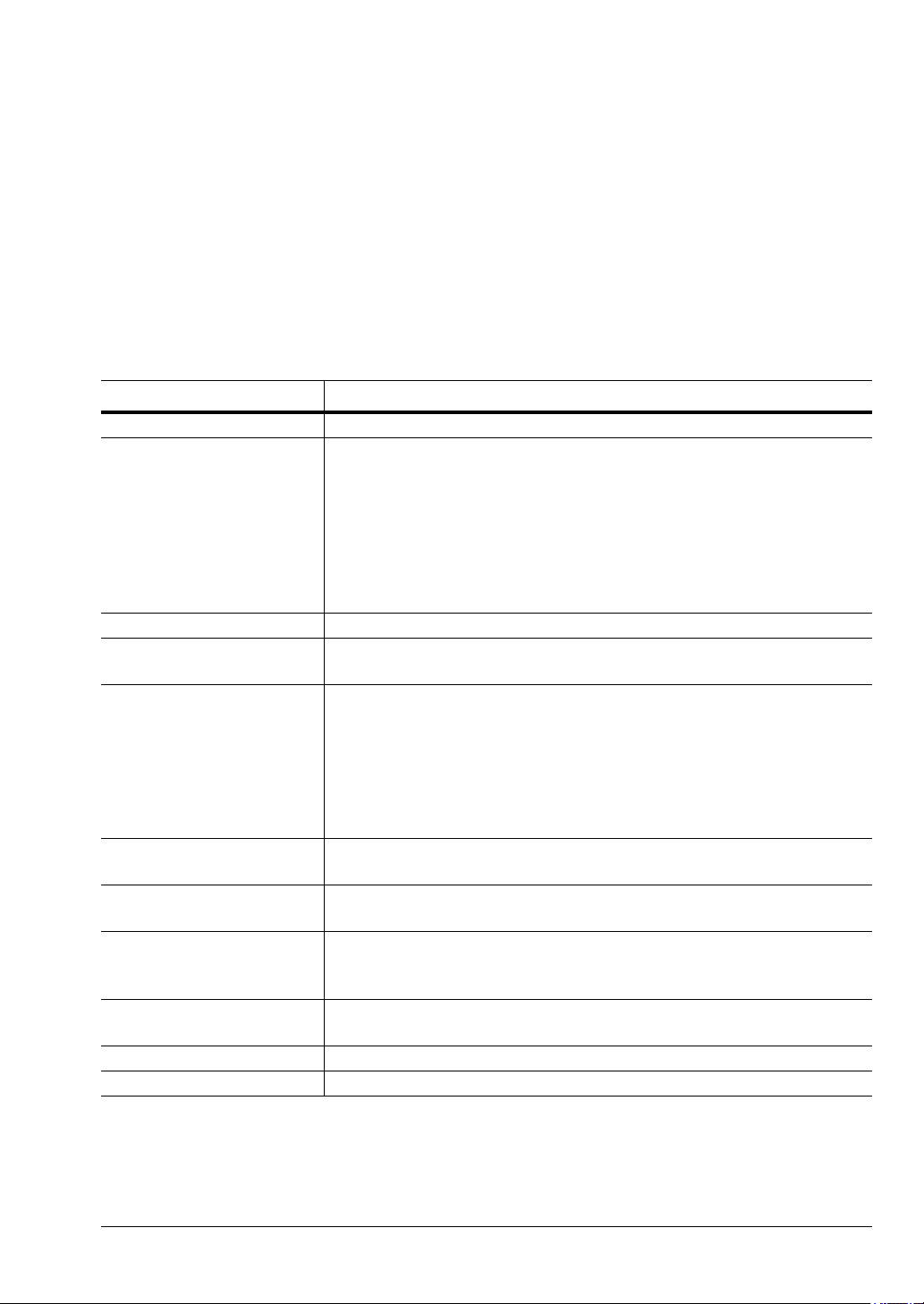

Available Options

Available options for the BTS Master are listed in Table 1-1.

Table 1-1. Available Options

Option Description

MT8220T-0010 Bias-Tee

MT8220T-0019 High-Accuracy Power Meter (sensor not included)

MT8220T UG PN: 10580-00366 Rev. L 1-3

Page 12

1-3 Calibration and Verification General Information

Tab le 1-1 . Available Options

Option Description

MT8220T-0023 Vector Signal Generator

MT8220T-0024 I/Q Waveform Capture

MT8220T-0025 Interference Analyzer

MT8220T-0027 Channel Scanner

MT8220T-0089 Zero-Span IF Output

MT8220T-0090 Gated Sweep

MT8220T-0098 Standard Calibration to ISO17025 and ANSI/NCSL Z540-1

MT8220T-0099 Premium Calibration to ISO17025 and ANSI/NCSL Z540-1 (provides

everything included with Option 98 plus test report and uncertainty data)

MT8220T-0431 Coverage Mapping

MT8220T-0752 CPRI LTE RF Measurements (requires Option 759)

MT8220T-0753 OBSAI LTE RF Measurements (requires Option 759)

MT8220T-0754 PIM over CPRI Measurements (requires Option 752)

MT8220T-0759 RF over Fiber Hardware (requires Option 752 or 753)

MT8220T-0760 CPRI BBU Emulation Nokia/ALu LTE (requires Option 752)

MT8220T-0761 RET Device Test Nokia/ALu (requires Option 760)

MT8220T-0880 GSM/GPRS/EDGE Measurements

MT8220T-0881 W-CDMA/HSPA+ Measurements

MT8220T-0882 TD-SCDMA/HSPA+ Measurements

MT8220T-0883 LTE/LTE-A FDD/TDD Measurements

MT8220T-0884 CDMA/EV-DO Measurements

MT8220T-0885 WiMAX Fixed/Mobile Measurements

MT8220T-0886 LTE 256QAM Demodulation Measurements (requires Option 883)

MT8220T-0887 NB-IoT Measurements

1-3 Calibration and Verification

The MT8220T loads factory calibration data during start-up, eliminating the need for daily

calibration checks. In W-CDMA mode, an additional automatic calibration is performed as

the internal temperature of the MT8220T changes (to ensure the best possible measurement

results). The Cable and Antenna Analyzer mode requires calibration standards for OPEN,

SHORT, and LOAD (OSL), which are sold separately.

Although the MT8220T does not require daily field calibration, Anritsu recommends an

annual calibration and performance verification by local Anritsu service centers. Contact

information for Anritsu Service Centers is available at http://www.anritsu.com/contact-us.

Note

1-4 PN: 10580-00366 Rev. L MT8220T UG

Anritsu recommends allowing the instrument to warm up to typical operation

temperature (approximately 15 minutes) before calibrating.

Page 13

General Information 1-4 Instrument Care and Preventive Maintenance

1-4 Instrument Care and Preventive Maintenance

BTS Master care and preventive maintenance consist of cleaning the unit and inspecting and

cleaning the RF connectors on the instrument and all accessories. Clean the BTS Master with

a soft, lint-free cloth dampened with water or water and a mild cleaning solution.

Caution To avoid damaging the display or case, do not use solvents or abrasive cleaners.

Connector Care

Clean the RF connectors and center pins with a cotton swab dampened with denatured

alcohol. Visually inspect the connectors. The fingers of N(f) connectors and the pins of N(m)

connectors should be unbroken and uniform in appearance. If you are unsure whether the

connectors are undamaged, gauge the connectors to confirm that the dimensions are correct.

Visually inspect the test port cables. Test port cables should be uniform in appearance, not

stretched, kinked, dented, or broken.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the

Type-N connectors. The recommended torque is 12 lbf·in to 15 lbf· in (1.36 N ·m to 1.70 N·m).

Inadequate torque settings can affect measurement accuracy. Over-tightening connectors can

damage the cable, the connector, the instrument, or all of these items.

Visually inspect connectors for general wear, cleanliness, and for damage such as bent pins or

connector rings. Repair or replace damaged connectors immediately. Dirty connectors can

limit the accuracy of your measurements. Damaged connectors can harm the instrument.

Connection of cables carrying an electrostatic potential, excess power, or excess voltage can

damage the connector, the instrument, or both.

Connecting Procedure

1. Carefully align the connectors. The male connector center pin must slip concentrically

into the contact fingers of the female connector

2. Push connectors straight together. Do not twist or screw them together. A slight

resistance can usually be felt as the center conductors mate.

3. To tighten, turn the connector nut, not the connector body. Major damage can occur to

the center conductor and to the outer conductor if the connector body is twisted.

4. If you use a torque wrench, initially tighten by hand so that approximately 1/8 turn or

45 degrees of rotation remains for the final tightening with the torque wrench.

Relieve any side pressure on the connection (such as from long or heavy cables) in order

to assure consistent torque. Use an open-end wrench to keep the connector body from

turning while tightening with the torque wrench.

Do not over-torque the connector.

Disconnecting Procedure

1. If a wrench is needed, use an open-end wrench to keep the connector body from turning

while loosening with a second wrench.

2. Complete the disconnection by hand, turning only the connector nut.

3. Pull the connectors straight apart without twisting or bending.

MT8220T UG PN: 10580-00366 Rev. L 1-5

Page 14

1-4 Instrument Care and Preventive Maintenance General Information

ESD Caution

The MT8220T, like other high performance instruments, is susceptible to ESD (electrostatic

discharge) damage. Coaxial cables and antennas often build up a static charge, which may

damage the MT8220T input circuitry (if allowed to discharge by connecting directly to the

MT8220T without previously discharging the static charge). MT8220T operators must be

aware of the potential for ESD damage and take all necessary precautions.

Operators should exercise practices outlined within industry standards such as JEDEC-625

(EIA-625), MIL-HDBK-263, and MIL-STD-1686, which pertain to ESD and ESDS devices,

equipment, and practices. Because these apply to the MT8220T, Anritsu Company

recommends that any static charges that may be present be dissipated before connecting

coaxial cables or antennas to the MT8220T. This may be as simple as temporarily attaching a

short or load device to the cable or antenna prior to attaching to the MT8220T. Remember

that the operator may also carry a static charge that can cause damage. Following the

practices outlined in the above standards ensures a safe environment for both personnel and

equipment.

RF Input Warning

The BTS Master is a sensitive measuring instrument designed to measure low power levels.

Avoid damaging this sensitive circuitry by observing the maximum input levels printed on

the instrument connector labeling and specified in the product technical data sheet.

Typical maximum input is +30 dBm (±50 VDC) and could be less if additional features, such

as a preamplifier, are in use. Be sure to review the product technical data sheet or Anritsu

website for recommended components and accessories that can help you protect your

instrument. These include a variety of adapters, attenuators, filters, and RF detection

accessories.

1-6 PN: 10580-00366 Rev. L MT8220T UG

Page 15

General Information 1-4 Instrument Care and Preventive Maintenance

Battery

Compartment Door

Battery Replacement

The battery can be replaced without the need for any tools. The battery compartment is

located on the lower left side of the instrument, with the measurement display facing you.

Slide the battery door down, towards the bottom of the instrument. To remove the battery

pack, pull straight out on the battery lanyard.

Figure 1-1. Battery Compartment Door

Warning

The battery that is supplied with the BTS Master may need charging before use. The battery

can be charged while it is installed in the BTS Master by using either the AC-DC adapter or

the 12-Volt DC adapter, or outside the BTS Master with the optional Dual Battery Charger.

Refer to “Symbols and Indicators” on page 2-9 for a description of battery symbols.

Caution

Note

To avoid damage, use only Anritsu approved batteries, adapters, and chargers

with this instrument.

When using the Automotive Adapter, always verify that the supply is rated for a

minimum of 60 Watts at 12 VDC, and that the socket is clear of any dirt or debris. If

the adapter plug becomes hot to the touch during operation, discontinue use

immediately.

Use only Anritsu Company approved batteries, adapters, and chargers with this

instrument. Anritsu recommends removing the battery for long-term storage of the

instrument.

MT8220T UG PN: 10580-00366 Rev. L 1-7

Page 16

1-5 Secure Environment Workplace General Information

1-5 Secure Environment Workplace

This section details the types of memory in the BTS Master, how to delete stored user files in

internal memory, and recommended usage in a secure environment workplace.

BTS Master Memory Types

The instrument contains non-volatile disk-on-a-chip memory, EEPROM, and volatile DRAM

memory. The instrument is also supplied with an external USB flash drive. The instrument

does not have a hard disk drive or any other type of volatile or non-volatile memory.

Disk-On-A-Chip (DOC): DOC is used for storage of instrument firmware, factory calibration

information, user measurements, setups, and .jpg screen images. User information stored on

the DOC is erased by the master reset process described below.

EEPROM: This memory stores the model number, serial number, and calibration data for the

instrument. Also stored here are the user-set operating parameters such as frequency range.

During the master reset process, all operating parameters stored in the EEPROM are set to

standard factory default values.

RAM Memory: This is volatile memory used to store parameters needed for the normal

operation of the instrument along with current measurements. This memory is reset

whenever the instrument is restarted.

External USB Flash Drive (not included with the instrument): This memory may be selected

as the destination for saved measurements and setups for the instrument. The user can also

copy the contents of the internal disk-on-chip memory to the external flash memory for

storage or data transfer. The external Flash USB can be reformatted or sanitized using

software on a PC.

Refer to Chapter 4, “File Management” for additional information on saving and copying files

to the USB flash drive.

Erase All User Files in Internal Memory

Perform a Master Reset:

1. Turn the instrument on.

2. Press the Shift button, then the System (8) button.

3. Press the System Options submenu key.

4. Press the Reset key, then the Master Reset key.

A message box will be displayed to warn the user that all settings will be returned to

factory default values and all user files will be deleted. This is a standard file deletion

and does not involve overwriting existing information.

5. Press the Enter button to complete the master reset.

6. The instrument will reboot and the reset is complete.

1-8 PN: 10580-00366 Rev. L MT8220T UG

Page 17

General Information 1-5 Secure Environment Workplace

Recommended Usage in a Secure Environment

Set the BTS Master to save files to the external USB Flash drive:

1. Attach the external Flash drive and turn the instrument on.

2. Press the Shift button, then the File (7) button.

3. Press the Save submenu key.

4. Press the Change Save Location submenu key, then select the USB drive using the

rotary knob, Up/Down arrow keys, or the touch screen.

5. Press the Set Location key.

The external USB drive is now the default location for saving files.

Not all after-market USB drives are compatible with the instrument. Many drives

come with a second partition that contains proprietary firmware. This partition must

Note

be removed. Only one partition is allowed. Refer to the individual manufacturer for

instructions on how to remove it. You might also try reformatting a drive that

contains a single partition using FAT32 format.

MT8220T UG PN: 10580-00366 Rev. L 1-9

Page 18

1-5 Secure Environment Workplace General Information

1-10 PN: 10580-00366 Rev. L MT8220T UG

Page 19

Chapter 2 — Instrument Overview

On/Off Button

2-1 Introduction

This chapter provides an overview of the Anritsu MT8220T BTS Master. It describes the

instrument front panel, touch screen display, and the connector panel. For detailed

information on the instrument’s test and measurement functions, refer to one of the Anritsu

user documents listed in Appendix A.

2-2 Turning On the BTS Master

The Anritsu BTS Master is capable of approximately three hours of continuous operation

from a fully charged, field-replaceable battery (refer to “Battery Replacement” on page 1-7).

The instrument can also be operated from a 12 VDC source (which will simultaneously charge

the battery). This can be achieved with either the Anritsu AC-DC Adapter or the Automotive

Power Adapter. Both items are included as standard accessories.

When using the Automotive Power Adapter, always verify that the supply is rated

Caution

for a minimum of 60 Watts at 12 VDC and that the socket is clear of any dirt or

debris. If the adapter plug becomes hot to the touch during operation, discontinue

use immediately.

To turn on the MT8220T, press the green On/Off button on the front panel (see Figure 2-1).

The instrument takes approximately 60 seconds to complete power-up and to load the

application software. At the completion of this process, the instrument is ready for use.

Figure 2-1. MT8220T On/Off Button

MT8220T UG PN: 10580-00366 Rev. L 2-1

Page 20

2-3 Instrument Front Panel Instrument Overview

1

4

11

5

6

3

2

7

8

9

10

12

2-3 Instrument Front Panel

The BTS Master uses a touch screen and keypad for data input. See Figure 2-2. The five

bottom menu keys and up to eight submenu keys on the right side of the display are touch

screen keys. The menu and submenu keys vary depending on the current operation mode and

instrument function selected. Refer to “Mode Selector” on page 2-14.

1, 11 Fan Ports

2 Instrument Settings Summary (menu shortcuts)

3 Touch Screen Submenu Keys (Active Menu or Active Function Block)

4 Menu Button

5 Speaker

6 Power LED and Battery Charge LED

7 On/Off Button

8 Enter Key and Arrow Keys

9 Rotary Knob

10 Number Keypad (includes Shift and Esc)

12 Touch Screen Main Menu Keys

Figure 2-2. BTS Master Front Panel and Interface Screen

2-2 PN: 10580-00366 Rev. L MT8220T UG

Page 21

Instrument Overview 2-3 Instrument Front Panel

Fan Inlet and Exhaust Ports

Keep the fan inlet and exhaust ports clear of obstructions at all times for proper ventilation

and cooling of the instrument. For port locations, see Figure 2-2.

LED Indicators

Power LED

The Power LED is located above the On/Off button. The LED is solid green when the

instrument is on, and blinks slowly when the unit is off but is connected to an external power

source.

Charge LED

The Charge LED is located above the On/Off button. The LED blinks slowly when the battery

is charging and is solid green when the battery is fully charged.

Front Panel Keys

The numeric keypad, rotary knob, and the four arrow keys can all be used to change the value

of the currently selected parameter.

Numeric Keypad

Keys 0 through 9 are used for numeric input, with an alternate function printed in blue above

each of the keys. Press the Shift key, then a numeric key, to access the instrument menu or

function indicated by the key label.

Some of the alternate functions associated with the numeric keypad are not available in all

measurement modes. Refer to the Measurement Guides listed in Appendix A.

Decimal Key

Press this key when entering decimal values.

+/– Key

Press this key to change the sign of numbers that are entered with the number keys. Press

three keys, Shift, then Decimal, then +/–, to save a JPEG image of the current display screen.

Shift Key

Pressing the Shift key followed by a number key executes the function that is indicated in

blue above the number key. When the Shift key is active, its icon is displayed at the far right

of the title bar, above the sweep window.

Figure 2-3. Shift Key Icon in Title Bar

MT8220T UG PN: 10580-00366 Rev. L 2-3

Page 22

2-3 Instrument Front Panel Instrument Overview

Esc Key

Press this key to cancel the parameter change being made and exit the current menu

function, if applicable.

Arrow Keys

The four arrow keys are used to scroll through a list and highlight the item you wish to select,

or to change the value of the currently selected parameter. The arrow keys can also be used to

move markers. The rotary knob performs similar functions.

Enter Key

Press this key to apply a parameter value or instrument setting you have entered, or to select

a highlighted item from a list.

Rotary Knob

Turn the rotary knob to change numerical values, scroll through selectable items in a list, or

to move markers. Values or items may be within a dialog box or an edit window.

Menu Key

The Menu key displays a grid of shortcut icons for installed measurement modes and

user-selected menus and setup files. See Figure 2-4. Press one of the icons in the top rows to

switch to the corresponding application. These icons are system-generated and cannot be

moved or deleted. Only the Esc key and the application icons are functional in the Menu

screen.

Figure 2-4. Menu Key Screen

2-4 PN: 10580-00366 Rev. L MT8220T UG

Page 23

Instrument Overview 2-3 Instrument Front Panel

Shortcut icons displayed in the top rows of the Menu screen vary with the

Note

instrument model, firmware version, and installed options. Help for the Menu

screen is available by pressing the icon in the lower right corner of the display.

An alternative to the Menu key is to press Shift, then the Mode (9) key to display the Mode

Selector list box. Refer to “Mode Selector” on page 2-14.

User-Created Shortcuts

To create a shortcut to any submenu key or main menu key, press and hold the key until a

grid appears, showing the open locations on the Menu screen where you can place the new

shortcut. Press one of the cells in the displayed grid to place the shortcut. See Figure 2-5.

Figure 2-5. Placement Grid for User-Created Shortcuts

To create a shortcut to a setup file (.stp), press Recall under the File menu, then press and

hold the desired file name until a grid is displayed. Select the display location of the new

shortcut as described above.

MT8220T UG PN: 10580-00366 Rev. L 2-5

Page 24

2-3 Instrument Front Panel Instrument Overview

User-defined shortcuts remain on the Menu screen until deleted. To delete or move a shortcut

icon, press the Menu key, then press and hold the shortcut until the Customize Button dialog

appears. See Figure 2-6. Press the appropriate button to delete or move the shortcut icon.

Figure 2-6. Customize Button Dialog

Press Esc to close the dialog without deleting or moving the shortcut. Also use Esc to exit the

Menu screen.

2-6 PN: 10580-00366 Rev. L MT8220T UG

Page 25

Instrument Overview 2-4 Interface Screen

1 2 3 4 6 75

10

11

8

9

2-4 Interface Screen

Figure 2-7 illustrates the BTS Master interface screen in Spectrum Analyzer mode, with

touch screen menu keys, title bar, and measurement settings and results around the graph

area, or sweep window.

Many of the measurement settings displayed to the left and the top of the sweep window are

actually touch screen shortcuts that you can press to bring up the corresponding menu.

1 Real Time Clock

2 Data Summary, Active Marker Values

3 Current Location Data, Latitude and Longitude Using GPS

4 Shortcut to the Save Submenu

5 Measurement Display or Measurement Grid or Sweep Window

6 Battery Charge Indicator

7 Instrument Mode (shortcut to Current Measurement Submenu)

8 Submenu Keys or Active Function Block

9 Main Menu Keys

10 Optional Data Window (also location of Marker Table)

11 Instrument Settings Summary (shortcuts to Menus and Submenus)

Figure 2-7. Spectrum Analyzer Display

MT8220T UG PN: 10580-00366 Rev. L 2-7

Page 26

2-4 Interface Screen Instrument Overview

Touch Screen Keys

Main Menu Touch Screen Keys

There are five main menu keys horizontally arranged along the bottom of the interface

screen. These keys give access to the instrument’s test and measurement functions, which are

documented in the applicable Measurement Guide. Refer to Appendix A.

Different operation or measurement modes may display different main menu keys. To switch

to another mode, press the Menu key, or press Shift followed by the Mode (9) key.

Note

Submenu Touch Screen Keys

Most of the instrument setup, control, and measurement functions are performed through the

use of the submenu keys along the right side of the display. The key labels change as

measurement settings and instrument setup parameters change. The current submenu title

is displayed at the top of the submenu key block, which consists of up to eight touch screen

keys. See Figure 2-7 on page 2-7.

The instrument model and installed options determine what measurement modes

are available. Refer to Table1-1 onpage1-3.

Symbols and Icons on the Title Bar

Figure 2-8. Title Bar with Icons

The instrument title bar displays the system date and time. When GPS is on and is tracking

satellites, its icon is followed by latitude and longitude coordinates.

Press the storage icon to open the touch screen keyboard for saving measurements, setups,

limit lines, or screen display JPEG files. This shortcut to the “Save” on page 4-10 is

equivalent to pressing Shift and File (7), then Save. Refer to “Save Dialog Box” on page 4-3.

Press the camera icon to save a JPEG image of the current screen display.

The battery symbol indicates the charge remaining in the battery. The colored section inside

the symbol changes size and color with the charge level. See Table 2-1 on page 2-9. The

Battery Charge LED (adjacent to the On/Off button) flashes when the battery is charging,

and remains on steady when the battery is fully charged.

Use only Anritsu-approved batteries, adapters, and chargers with this instrument.

Caution

The Shift icon is displayed after the Shift key is pressed, and it remains displayed until

another button is pressed.

2-8 PN: 10580-00366 Rev. L MT8220T UG

Anritsu Company recommends removing the battery for long-term storage of the

instrument.

Page 27

Instrument Overview 2-4 Interface Screen

Shift

Symbols and Indicators

The following symbols, icons, and indicators convey the instrument status or condition on the

display. The colors shown here are in the standard or default display mode.

Table 2-1. Symbols and Icons

Symbol Description

Green: Battery is 30 % to 100 % charged.

Yellow: Battery is 10 % to 30 % charged.

Red: Battery is 0 % to 10 % charged.

Green with Black Plug body: Battery is fully charged and

external power is applied.

Lightning Bolt: Battery is being charged (any color symbol).

Red Plug body: External power is applied, and no battery is

installed, or battery has lost communications with the instrument.

Storage Icon: Tap the floppy disk icon to display the Save screen

and menu.

Camera Icon: Saves a JPEG image of the current screen display.

Shift Key Icon: This icon is displayed between the battery symbol

and the submenu keys after the Shift key has been pressed, and

until another key is pressed.

GPS Icon: This icon is displayed right after the date and time

when GPS is available. Refer to Chapter 6, “GPS” for details.

Power Button with Power LED and Charge LED: This is a

physical button with LED indicators. It is located near the numeric

keypad.

MT8220T UG PN: 10580-00366 Rev. L 2-9

Page 28

2-4 Interface Screen Instrument Overview

Black on White Night Vision

Color on WhiteHigh Contrast

Display Settings

The Display Settings submenu lets you adjust the screen brightness level and control the

auto-dimming function. Refer to “Brightness Settings Menu” on page 5-8.

You can also turn off the display entirely, as described in “Display Settings Menu”

on page 5-7. To turn the display back on, press any key (except the Power button) three times

in rapid succession.

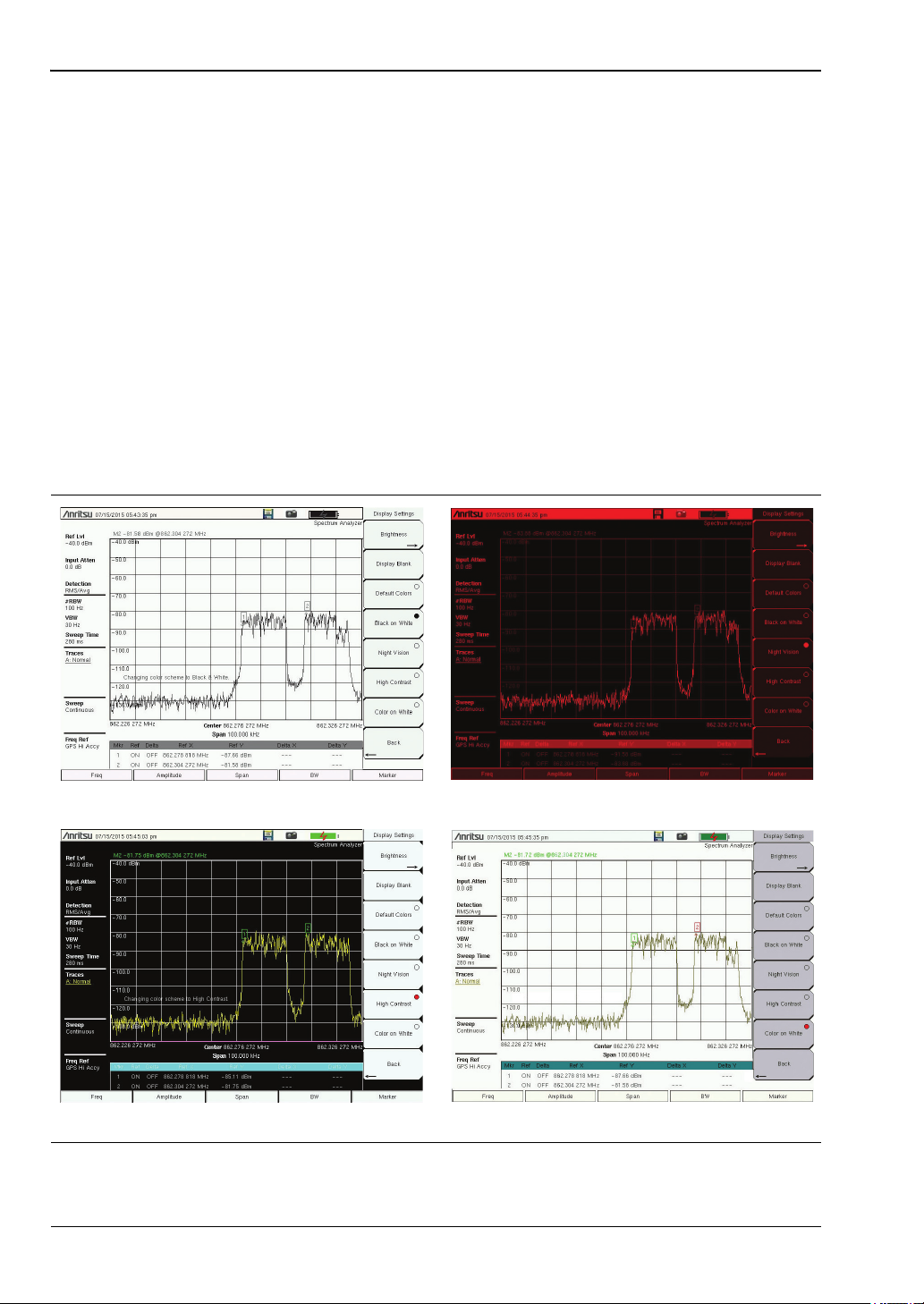

In addition to the default display colors shown in Figure 2-7 on page 2-7, you can select

different color schemes to suit the ambient lighting conditions. See Figure 2-9. Some color

settings may not be available in all measurement modes.

Black on White — used for printing and viewing in broad daylight conditions

Night Vision — optimized for nighttime viewing

High Contrast — used in challenging viewing conditions

Color on White — used for printing and viewing in broad daylight conditions

Figure 2-9. Display Color Settings

2-10 PN: 10580-00366 Rev. L MT8220T UG

Page 29

Instrument Overview 2-4 Interface Screen

Touch Screen Calibration

Calibration optimizes the response of touch input. It is recommended if the instrument does

not respond as expected when you press the touch screen.

The Calibrate Touch Screen submenu key is in the “System Menu” on page 5-3. When pressed,

a message box is displayed with instructions for calibration. See Figure 2-10. Press Enter to

begin calibration, or press Esc to cancel. Alternatively, you can press 1 while the message box

is displayed to use the arrow keys for navigation. Refer to “Disable Touch Screen to Use

Arrow Navigation”.

Figure 2-10. Touch Screen Calibration Message Box

During calibration, press the crosshairs in sequence as they appear on the screen. The

process takes less than one minute.

Calibrate Touch Screen Shortcut

Another way to access touch screen calibration is to press Shift, then 0 (zero). This displays

the touch screen calibration message box shown in Figure 2-10. The shortcut can be used if

your touch inputs do not correspond to the appropriate locations on the screen to such an

extent that you cannot access the Calibrate Touch Screen submenu key.

Disable Touch Screen to Use Arrow Navigation

If the touch screen is not functioning, you can use Arrow Navigation to simulate pressing the

touch screen main menu keys and submenu keys. From the touch screen calibration message

box (see Figure 2-10), press 1 to display the arrow navigation message box, illustrated in

Figure 2-11. Press 1 again to enter the arrow navigation mode, or press Esc to cancel.

Figure 2-11. Arrow Navigation Message Box

In arrow navigation mode, a red border highlights the currently selected key (see Figure 2-12

on page 2-12). Use the arrow keys to move the red selection box, then press the Menu key to

activate the highlighted key. Only the main menu keys and submenu keys can be activated

using Arrow Navigation. This feature does not move the red selection box into other areas of

the touch screen, like the display title bar, sweep window, or the instrument settings area on

the left.

MT8220T UG PN: 10580-00366 Rev. L 2-11

Page 30

2-4 Interface Screen Instrument Overview

To save a measurement in arrow navigation mode, press Shift then File (7). Use the arrow

keys to move the red selection box to the Save Measurement As submenu key. This submenu

key must be used because the arrow navigation mode cannot be used to change data in popup

windows in the measurement display. File names are determined by the current setting of the

Save Measurement As submenu key. Refer to “Save Measurement As” on page 4-10.

You can save a JPEG image of the current display screen by pressing Shift, followed by

Decimal, then +/–. The JEPG image shows screen data, but does not contain the additional

measurement information that accompanies a saved measurement in a *.spa measurement

file.

To return to normal touch entry mode, reboot the instrument (turn power Off, then On). If

your touch screen has been damaged, refer to “Contacting Anritsu for Sales and Service”

on page 1-2.

Figure 2-12. Arrow Navigation Example

2-12 PN: 10580-00366 Rev. L MT8220T UG

Page 31

Instrument Overview 2-5 Data Entry

2-5 Data Entry

User input can be in the form of numeric values for instrument or measurement settings,

selected values from a preset list, or alphanumeric text when entering file names, for

example. To view or change a parameter value, access the appropriate submenu by pressing

one of the five main menu keys along the bottom of the interface screen, then navigating

through the touch screen submenus.

Other instrument functions are accessible from the numeric keypad, when used in

combination with the Shift key. Refer to “Numeric Keypad” on page 2-3. Some of the

parameter settings displayed on the left of the interface screen or under the title bar are

touch screen shortcuts to related submenus.

Depending on the measurement mode, refer to the associated Measurement Guide listed in

Appendix A for a description of available menus and submenus.

Text Entry

When an instrument function requires you to enter text, such as a name for a measurement

or setup file you wish to save, a touch screen keyboard is displayed. See Figure 2-13. Digits

can be entered using the touch screen keyboard or the front panel keypad. The left and right

arrow keys move the insertion point in the file name edit box.

Refer to “Save Dialog Box” on page 4-3 for information on saving files.

Figure 2-13. Touch Screen Keyboard

MT8220T UG PN: 10580-00366 Rev. L 2-13

Page 32

2-6 Mode Selector Instrument Overview

Numeric Values

To modify a numeric parameter setting that is displayed on a submenu touch screen key,

press the key to make it active. The display color of the currently set value changes to red.

Use the rotary knob, arrow keys, or the numeric keypad to change the value. When entering a

value from the keypad, the submenu typically shows the selectable units. Press the desired

unit or press Enter to complete the entry.

Selection Lists

Some parameters and instrument functions are selectable from a pop-up list. These list boxes

display the available selections, and value limits if applicable. Use the arrow keys or the

rotary knob to scroll through the list and highlight the desired entry. You can also use the

touch screen to make your selection.

To apply the selection, press Enter. To exit the selection list without making a change, press

the Escape (Esc) key.

2-6 Mode Selector

To change to another operation or measurement mode, press Shift, then the Mode (9) key to

display the Mode Selector list box, illustrated in Figure 2-14. Use the directional arrow keys

or the rotary knob to highlight the desired mode, then press Enter to switch to the selected

application. The measurement modes available for selection depend on the options that are

installed and activated on your instrument.

An alternate method of selecting a measurement mode is through the use of the “Menu Key”

on page 2-4.

Figure 2-14. Mode Selector List Box

2-14 PN: 10580-00366 Rev. L MT8220T UG

Page 33

Instrument Overview 2-7 Connector Panel

1 2

15

3 4 5 6 7 8

14 13 12 11 10

9

2-7 Connector Panel

The BTS Master connector panel is illustrated in Figure 2-15.

1 Fan Exhaust Port

2 Spectrum Analyzer RF In / VNA PORT 2

3 Ext (External) Trigger In

4 IF Out 140 MHz (Option 89)

5 Ref In

6 Ref Out 10 MHz

7 RF Output / VNA PORT 1

8 Attachment for Locking Hardware

9 SFP Optical Module Connectors (Option 759)

10 External Power

11 LAN Ethernet

12 USB Interface, Type A

13 USB Interface, Type Mini-B

14 Headset Jack

15 GPS Antenna Connector

Figure 2-15. Test Panel Connectors for the MT8220T

Spectrum Analyzer RF In / VNA PORT 2

This is a 50 Type-N female connector. The maximum input is +30 dBm at ±50 VDC.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the

Type-N connector. Do not overtighten the connector. The recommended torque is 12 lbf·in to

15 lbf·in (1.36 N·m to 1.70 N·m).

MT8220T UG PN: 10580-00366 Rev. L 2-15

Page 34

2-7 Connector Panel Instrument Overview

Ext Trigger In

A TTL signal that is applied to the External Trigger 50 female BNC input connector causes a

single sweep to occur. In the Spectrum Analyzer mode, it is used in zero span, and can be used

to cause triggering to occur on the selected edge of the signal, either rising or falling. After the

sweep is complete, the resultant trace is displayed until the next trigger signal arrives. To

prevent damage to your instrument, do not use pliers or a wrench to tighten the BNC

connector. Do not overtighten the connector.

IF Out 140 MHz (Option 89)

This 50 BNC connector is for Zero Span 140 MHz IF Output with Option 89. To prevent

damage to your instrument, do not use pliers or a wrench to tighten the BNC connector. Do

not overtighten the connector.

Ext Ref In

The External Reference In port is a 50 BNC female connector that provides for input of an

external frequency reference. Refer to your Technical Data Sheet for valid frequencies. To

prevent damage to your instrument, do not use pliers or a wrench to tighten the BNC

connector. Do not overtighten the connector.

Ref Out 10 MHz

The External Reference Out port is a 50 BNC female connector that provides 10 MHz at

0 dBm to –7 dBm. To prevent damage to your instrument, do not use pliers or a wrench to

tighten the BNC connector. Do not overtighten the connector.

RF Out / VNA PORT 1

This is a 50 Type N female connector. The maximum input is +23 dBm at ±50 VDC.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the

Type-N connector. Do not overtighten the connector. The recommended torque is 12 lbf·in to

15 lbf·in (1.36 N·m to 1.70 N·m).

Optical SFP (Option 759)

The optical transceiver port is used to connect the instrument to the fiber optic CPRI or

OBSAI link between a Radio Frequency Module (RFM) and a Base Band Module (BBM). The

two SFP ports are present only when Option 759 (RF over Fiber hardware) is installed. Refer

to the BTS Master Technical Data Sheet for transceiver part numbers and specifications.

Option 759 requires either Option 752 (CPRI LTE RF Measurements) or

Note

Option 753 (OBSAI LTE RF Measurements). The combination of Option 759 and

Option 752 is functionally identical to obsolete Option 751.

2-16 PN: 10580-00366 Rev. L MT8220T UG

Page 35

Instrument Overview 2-7 Connector Panel

External Power

This is a 2.1 mm by 5.5 mm barrel connector, 12 to 15 VDC, < 5.0 A. The external power

connector is used to power the unit and for battery charging. A green flashing indicator light

near the power switch shows that the instrument battery is being charged by the external

charging unit. The indicator is steadily illuminated when the battery is fully charged.

When using the AC Adapter, always use a three-wire power cable that is

Warning

connected to a three-wire power outlet. If power is supplied without proper

grounding, the user is at risk of receiving a severe or fatal electric shock.

LAN Connection

The RJ48C connector is used to connect the BTS Master to a local area network (LAN).

Integrated into this connector are two LEDs. The amber LED shows the presence of a

10 Mbit/s LAN connection when On, and a 100 Mbit/s LAN connection when Off. The green

LED flashes to show that LAN traffic is present. For additional information about the LAN

connection, Ethernet connection, and DHCP, refer to Appendix C.

USB Interface – Type A

The BTS Master can also be a USB Host and allow power sensors and USB memory devices

to be connected to the instrument for storing measurements, setups, and files.

USB Interface – Type Mini-B

The 5-pin mini-B USB 2.0 interface can be used to connect the MT8220T BTS Master directly

to a PC. The first time the MT8220T is connected to a PC, the normal USB device detection by

the computer operating system will take place. The CD-ROM that shipped with the

instrument contains a driver for Windows XP that is installed when Master Software Tools is

installed. Drivers are not available for earlier versions of the Windows operating system.

During the driver installation process, place the CD-ROM in the computer drive and specify

that the installation wizard should search the CD-ROM for the driver.

Note

For proper detection, Master Software Tools should be installed on the PC prior to

connecting the BTS Master to the USB port.

Headset Jack

The 3-wire headset jack provides audio output from the built-in AM/FM/SSB demodulator

and from other sounds generated by the instrument. The jack accepts a 3.5 mm 3-wire

miniature phone plug such as those commonly used with cellular telephones.

GPS Antenna Connector

The GPS antenna connection on the BTS Master is type SMA(F). Selectable +3 VDC or

+5 VDC antenna power. To prevent damage to your instrument, do not use pliers or a plain

wrench to tighten the SMA connector. Do not overtighten the connector. The recommended

torque is 8 lbf·in (0.9 N·m or 90 N·cm).

The MT8220T BTS Master includes a passive GPS antenna (2000-1733-R) which can be

connected for acquiring GPS location data.

MT8220T UG PN: 10580-00366 Rev. L 2-17

Page 36

2-8 Soft Carrying Case Instrument Overview

2-8 Soft Carrying Case

The instrument can be operated while in the soft carrying case. On the back of the case is a

storage pouch for accessories and supplies. Inside the pouch is a D-ring that can be used to

securely attach a small accessory.

To install the instrument into the soft carrying case:

1. The front panel of the case is secured with hook-and-loop fasteners. Fully close the

front panel of the case. When closed, the front panel supports the shape of the case

while you are inserting the BTS Master.

2. Place the soft carrying case face down on a stable surface, with the front panel fully

closed and laying flat.

3. Fully open the zippered back of the case.

4. Insert the instrument face down into the case, taking care that the connectors are

properly situated in the case top opening. You may find it easier to insert the

connectors first, then pull the corners over the bottom of the BTS Master.

Figure 2-16. Soft Carrying Case

5. Close the back panel and secure with the zipper.

The soft carrying case includes a detachable shoulder strap, which can be connected to the

D-rings on the corners of the case, as required for comfort or convenience. Using one upper

corner and one lower corner holds the bottom of the instrument close to your chest and allows

hands-free operation.

Two zippers provide access around the back of the case. The zipper closer to the

front of the case opens the case back, and allows access to install and remove the

Note

2-18 PN: 10580-00366 Rev. L MT8220T UG

instrument. The zipper closer to the back of the case opens a support panel that

can be used to provide support for improved stability and air flow while the

instrument is in the case. The support panel angle is adjustable. This support

panel also contains the storage pouch.

Page 37

Instrument Overview 2-9 Tilt Bail Stand

2-9 Tilt Bail Stand

The attached tilt bail can be used for desktop operation when the instrument is not installed

in the soft case. The tilt bail provides a backward tilt for improved stability and air flow.

To deploy the tilt bail, pull the bottom of the tilt bail away from the back of the instrument.

To store the tilt bail, push the bottom of the bail towards the back of the instrument and snap

the bail into the clip on the back of the instrument.

Figure 2-17. Tilt Bail Housed and Extended

MT8220T UG PN: 10580-00366 Rev. L 2-19

Page 38

2-9 Tilt Bail Stand Instrument Overview

2-20 PN: 10580-00366 Rev. L MT8220T UG

Page 39

Chapter 3 — Quick Start

3-1 Introduction

This chapter is intended to assist you in your first use of the MT8220T BTS Master. The

purpose of this chapter is to provide a starting point for basic measurement setups. This

chapter describes general instrument setup, including: instrument mode, frequency,

bandwidth, amplitude, span, limit lines, and markers. After measurements are taken, refer to

“Managing Files” on page 4-1 for a description of saving, recalling, and deleting measurement

files. For more detailed information about specific measurements, refer to the measurement

descriptions in the measurement guides for the specific instrument mode and analyzer

technology (such as Cable & Antenna, Spectrum Analyzer, WiMAX, or 3GPP). Refer to

Appendix A, “Measurement Guides”, for a list of these measurement guides and their Anritsu

part numbers.

An example of a measurement available with Option 25, Interference Analyzer is shown in

Figure 3-1. The spectrogram displays power at frequency for a specified time period. Refer to

the Spectrum Analyzer Measurement Guide for additional information.

Figure 3-1. Spectrogram Example

MT8220T UG PN: 10580-00366 Rev. L 3-1

Page 40

3-2 Measurement Setup Quick Start

3-2 Measurement Setup

Connect the Input Source

Connect the input signal or antenna to the RF In connector on the top of the instrument. For

connector descriptions, refer to Figure 2-15 on page 2-15.

Editing and Entering Values

• Parameter values that are ready for editing are displayed in red on the submenu key.

After changing the value, press Enter or the appropriate unit terminator key to set the

new value.

• Some submenu keys have toggled parameter values (On / Off, Low / High, On/Large/Off).

On these submenu keys, the current value is underlined. Press the submenu key to

toggle the value.

• Use the Arrow keys, numeric keypad, or rotary knob to change submenu key values,

to select list box options, or to enter filenames.

Selecting the Analyzer Mode

The instrument Analyzer Modes are also referred to as Measurement Modes or Applications.

To switch to a different mode:

1. Press the Menu button on the instrument front panel.

2. Press the desired screen icon. Refer to “Menu Key” on page 2-4.

Alternatively, you can:

1. Press Shift followed by the Mode (9) key on the numeric keypad to display the Mode

Selector list of installed applications (refer to “Mode Selector” on page 2-14).

2. Use the directional Arrow keys or the rotary knob to highlight the desired mode. The

left and right Arrow keys skip to the top and bottom of the list, respectively.

3. Press Enter.

To exit without changing the selection, press Esc.

3-2 PN: 10580-00366 Rev. L MT8220T UG

Page 41

Quick Start 3-3 Set the Measurement Frequency

3-3 Set the Measurement Frequency

Using Start and Stop Frequencies

The submenu keys and the frequency settings are displayed on the left and right edges of the

graph in the seep window.

1. Press the Freq main menu key.

2. Press the Start Freq submenu key.

3. Enter the desired start frequency. When entering a frequency by using the keypad, the

submenu key labels change to frequency units: GHz, MHz, kHz, and Hz. Press the

appropriate unit key. Pressing the Enter key has the same affect as pressing the MHz

submenu key.

4. Press the Stop Freq submenu key.

5. Enter the desired stop frequency.

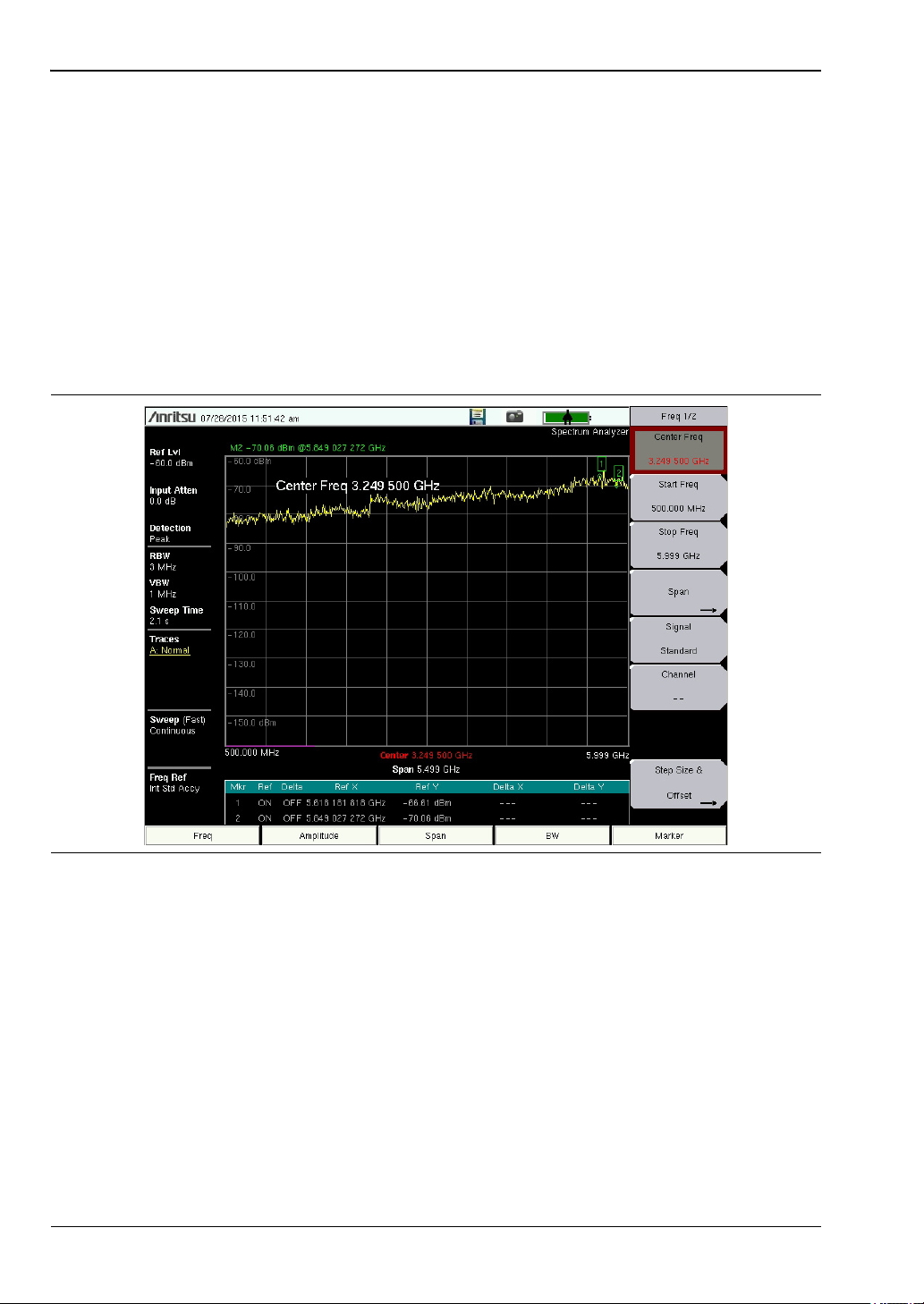

Entering Center Frequency

1. Press the Freq main menu key.

2. Press the Center Freq submenu key. This key is usually selected automatically.

3. Enter the desired center frequency by using the keypad, the arrow keys, or the rotary

knob. When entering a frequency by using the keypad, the submenu key labels change

to frequency units: GHz, MHz, kHz, and Hz. Press the appropriate unit key. Pressing

the Enter key has the same affect as pressing the MHz submenu key.

Selecting Signal Standard

1. Press the Freq main menu key.

2. Press the Signal Standard submenu key. The Signal Standards dialog opens. You can

enter channel numbers instead of frequencies.

3. Highlight a signal standard and press Enter or the rotary knob to select.

4. Press the Channel submenu key to change the channel value in the Channel Editor.

Note The signal standards list can be updated via Master Software Tools.

Setting Measurement Frequency Bandwidth

Spectrum Analyzer and Interference Analysis Mode

1. Press the BW main menu key to display the BW menu.

• Press the RBW or the VBW submenu key (or both) to manually change values.

• Set RBW and VBW automatically by pressing the Auto RBW submenu key or the

Auto VBW submenu key.

2. Press the VBW/Average Type submenu key to toggle between Linear averaging

(arithmetic mean) and Logarithmic averaging (geometric mean).

MT8220T UG PN: 10580-00366 Rev. L 3-3

Page 42

3-4 Set the Amplitude Quick Start

3. Press the RBW/VBW submenu key to change the ratio of resolution bandwidth to video

bandwidth.

4. Press the Span/RBW submenu key to change the ratio of span width to resolution

bandwidth.

3-4 Set the Amplitude

Press the Amplitude main menu key to display the Amplitude menu.

Setting Amplitude Reference Level and Scale

Spectrum Analyzer and Interference Analysis Modes

To change the current measurement units, press the Units submenu key and select the

required units from the submenu keys that are presented. Press the Back submenu key to

return to the Amplitude menu.

1. Press the Reference Level submenu key and use the Up/Down arrow keys or the keypad

to change the reference level. Press Enter to set the reference level value.

2. Press the Scale submenu key and use the Up/Down arrow keys or the keypad to enter

the desired scale. Press Enter to set the scale value.

The Scale parameter cannot be changed when linear units are selected (Watts or

Volts).

Note

Press the Amplitude submenu key and select Auto Atten coupling of the attenuator

setting and the reference level to help ensure that harmonics and spurs are not

introduced into the measurements. Attenuator Functions are described in the

Spectrum Analyzer Measurement Guide.

Setting Amplitude Range and Scale

This setting applies to most demodulator modes of instrument operation. The Spectrum

Analyzer mode and Cable & Antenna modes has no equivalent to Auto Range. For other

analyzer modes, consult the individual measurement guides in Appendix A.

1. Press the Adjust Range submenu key to set an optimal reference level based on the

measured signal.

To have the instrument continually set the optimal reference level, press the

Auto Range submenu key so that On is selected.

2. Press the Scale submenu key.

3. Enter the desired scale units by using the keypad, the Arrow keys, or the rotary knob.

Press the Enter key to set. The y-axis scale is automatically renumbered.

3-4 PN: 10580-00366 Rev. L MT8220T UG

Page 43

Quick Start 3-5 Set the Span

Reference Level Offset for External Loss or External Gain

To obtain accurate measurements, compensate for any external attenuation or gain by using

the RL Offset submenu. The compensation factor is in dB. External attenuation can be

created by using an external cable or an external high power attenuator, external gain is

typically from an amplifier.

To adjust the reference level for either gain or loss, press the RL Offset submenu key and

enter a positive dB value and then press the appropriate submenu key (dB External Gain or

dB External Loss). The new RL Offset value will be displayed on the instrument and reference

level is adjusted.

3-5 Set the Span

Spectrum Analyzer, Interference Analysis, and Power Meter Modes

1. Press the Span main menu key or press the Freq main menu key followed by the Span

submenu key.

2. To select full span, press the Full Span submenu key. Selecting full span overrides any

previously set Start and Stop frequencies.

3. For a single frequency measurement, press the Zero Span submenu key.

Note

To quickly move the span value up or down, press the Span Up 1-2-5 or

Span Down 1-2-5 submenu keys These keys facilitate a zoom-in, zoom-out

feature in a 1-2-5 sequence.

MT8220T UG PN: 10580-00366 Rev. L 3-5

Page 44

3-6 Setting Up Limit Lines Quick Start

3-6 Setting Up Limit Lines

Press the Shift key then the Limit (6) key on the numeric keypad to display the Limit menu.

Simple Limit Line

Spectrum Analyzer and Interference Analysis Modes

1. Press the Shift key and then the Limit (6) key.

2. Press the Limit (Upper / Lower) submenu key to select the desired limit line, Upper or

Lower.

3. Activate the selected limit line by pressing the On Off submenu key so that On is

underlined.

4. Press the Limit Move submenu key to display the Limit Move menu. Press the

Move Limit submenu key to adjust the limit line.

5. Press the Back submenu key to return to the Limit menu.

6. If necessary, press the Set Default Limit submenu key to redraw the limit line in view.

Limit Line Envelope

Spectrum Analyzer and Interference Analysis Modes

1. Press the Shift key and then the Limit (6) key.

2. Press the Limit (Upper / Lower) submenu key to select the desired limit line, Upper or

Lower.

3. Press the Limit Envelope submenu key to display the Limit Envelope menu.

4. Press the Create Envelope submenu key to create an envelope around the

measurement.

5. Press Upper Points or Lower Points submenu key to change the number of segments in

the envelope.

6. Press the Upper Shape or Lower Shape submenu key to toggle between square and

sloped limit envelope.

7. Adjust the Upper or Lower Offset to move the limit line closer to (a smaller value) or

further away from the trace.

Complex Limit Lines

Spectrum Analyzer and Interference Analysis Modes

When building some complex limit lines, you can create either the right or left half of the limit

line and then build the remainder by pressing the Limit Advanced submenu key and then

pressing the Limit Mirror submenu key. The complete set of Limit menus is described in the

Spectrum Analyzer Measurement Guide (refer to Appendix A).

3-6 PN: 10580-00366 Rev. L MT8220T UG

Page 45

Quick Start 3-7 Setting Up Markers

3-7 Setting Up Markers

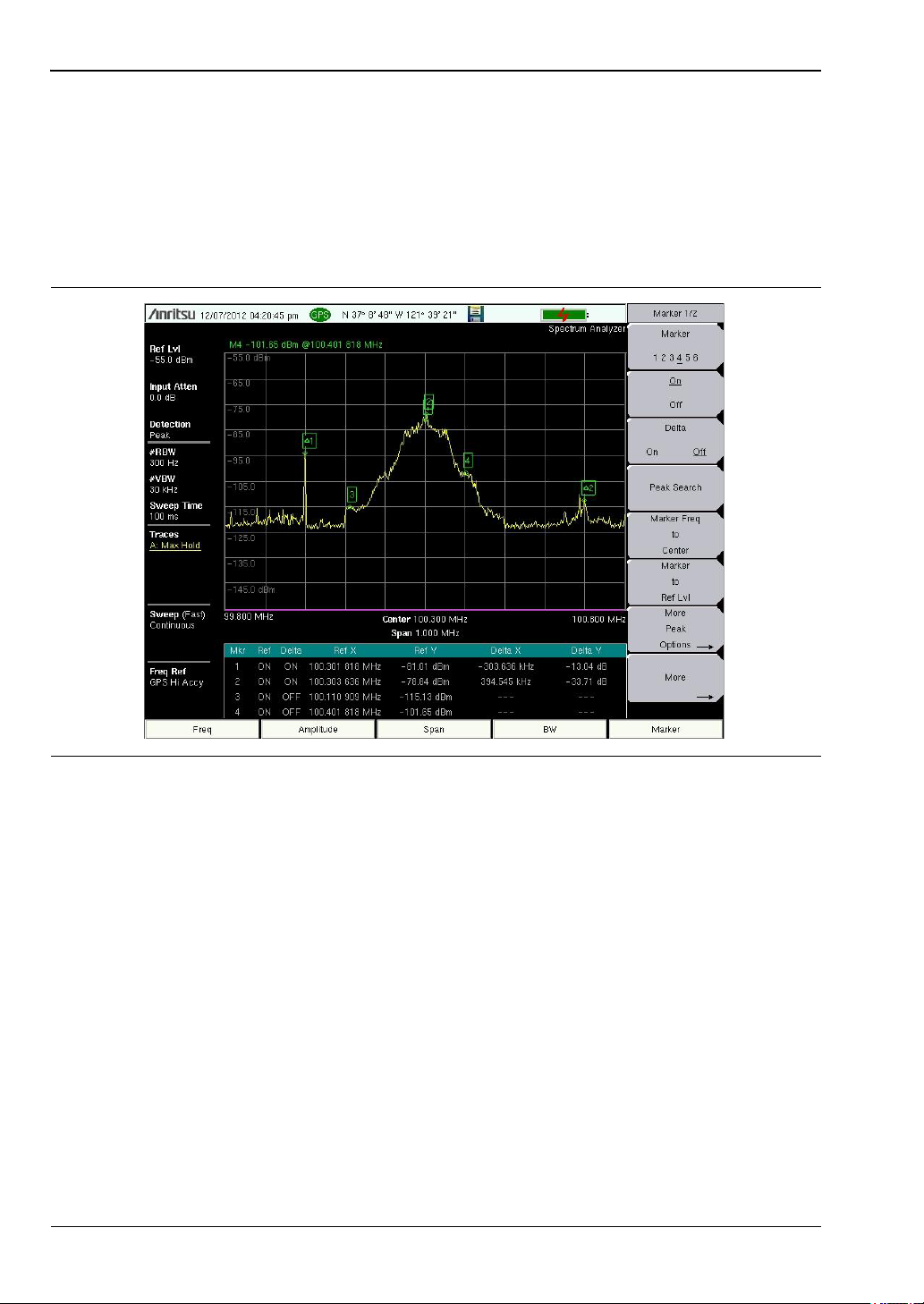

Press the Marker main menu key to display the Marker menu. See Figure 3-2. Touch a

marker number or the Marker button to activate that marker. After a marker is active, other

submenu keys can be used to place the marker. Refer to the Measurement Guides in

Appendix A for more details.

1. Press the Marker submenu key. Press the desired marker number. The selected marker

number is displayed in the sweep window and is also underlined on the Marker

submenu key.

2. Press the On Off submenu key (if necessary) so that On is underlined. The selected

marker is displayed in red, ready to be moved.

3. Use the rotary knob, an Arrow key, or the touch screen to place the marker on the

desired frequency.

Note that when a marker is active, you can drag your finger across the sweep window

horizontally (at any level) to move the marker. Also, when a marker is active and the

Marker menu is displayed, you can type a frequency to place the active marker at a

point of interest.

4. Press the Peak Search submenu key to move the active marker to the highest signal

amplitude that is currently displayed on screen. For additional marker movements,

press the More Peak Options submenu key. Refer to the Spectrum Analyzer

Measurement Guide for more details.

5. Repeat Step 1 and Step 2 to activate and move multiple markers.

Selecting, Activating, and Placing a Delta Marker:

When a delta marker is On, its position data is relative to its reference marker. For example,

Delta Marker 3 displays x-axis and y-axis data relative to Marker 3. This reference