Page 1

Series

MS278XB

High Performance Signal Analyzer

Operation Manual

Software Version 4.xx

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

P/N: 10410-00273

Revision: D

Copyright 2007 Anritsu Company

Printed: July 2007

Page 2

Page 3

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and workmanship for

three years from the date of shipment.

Anritsu’s obligation covers repairing or replacing products which prove to be defective during the warranty period.

Buyers shall prepay transportation charges for equipment returned to Anritsu for warranty repairs. Obligation is

limited to the original purchaser. Anritsu is not liable for consequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear. Also, the warranty

does not apply to defects resulting from improper or inadequate maintenance by the Buyer, unauthorized

modification or misuse, or operation outside of the environmental specifications of the product. No other warranty is

expressed or implied, and the remedies provided herein are the Buyer’s sole and exclusive remedies.

DISCLAIMER OF WARRANTY

DISCLAIMER OF WARRANTIES. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, ANRITSU

COMPANY AND ITS SUPPLIERS DISCLAIM ALL WARRANTIES, EITHER EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, WITH REGARD TO THE SOFTWARE PRODUCT. THE USER ASSUMES THE ENTIRE

RISK OF USING THE PROGRAM. ANY LIABILITY OF PROVIDER OR MANUFACTURER WILL BE LIMITED

EXCLUSIVELY TO PRODUCT REPLACEMENT.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES. TO THE MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, IN NO EVENT SHALL ANRITSU COMPANY OR ITS SUPPLIERS BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING,

WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS

OF BUSINESS INFORMATION, OR ANY OTHER PECUNIARY LOSS) ARISING OUT OF THE USE OF OR

INABILITY TO USE THE SOFTWARE PRODUCTS, EVEN IF ANRITSU COMPANY HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES AND JURISDICTIONS DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

TRADEMARK ACKNOWLEDGMENTS

Windows, Windows XP, Microsoft Paint, Microsoft Word, Microsoft Access, Microsoft Excel, Microsoft PowerPoint,

and Visual Studio are all registered trademarks of Microsoft Corporation.

Acrobat Reader is a registered trademark of Adobe Corporation.

MATLAB is a registered trademark of The MathWorks Corporation.

NI is a trademark of the National Instruments Corporation.

Signature is a trademark of Anritsu Company.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers as a guide for the

proper installation, operation and maintenance of Anritsu Company equipment and computer programs. The

drawings, specifications, and information contained herein are the property of Anritsu Company, and any

unauthorized use or disclosure of these drawings, specifications, and information is prohibited; they shall not be

reproduced, copied, or used in whole or in part as the basis for manufacture or sale of the equipment or software

programs without the prior written consent of Anritsu Company.

UPDATES

Updates, if any, can be downloaded from the Documents area of the Anritsu web site at:

http://www.us.anritsu.com

Page 4

END-USER LICENSE AGREEMENT FOR ANRITSU SOFTWARE

IMPORTANT-READ CAREFULLY: This End-User License Agreement (EULA) is a legal agreement between you

(either an individual or a single entity) and Anritsu for the Signature software product identified above, which

includes computer software and associated media and printed materials, and may include “online” or electronic

documentation (“SOFTWARE PRODUCT” or “SOFTWARE”). By receiving or otherwise using the SOFTWARE

PRODUCT, you agree to be bound by the terms of this EULA.

SOFTWARE PRODUCT LICENSE

The SOFTWARE PRODUCT is protected by copyright laws and international copyright treaties, as well as other

intellectual property laws and treaties. The SOFTWARE PRODUCT is licensed, not sold.

1. GRANT OF LICENSE. This EULA grants you the following rights:

a. You may use ONE copy of the Software Product identified above only on the hardware product (Signature Signal

Analyzer and its internal computer) which it was originally installed. The SOFTWARE is in “use” on a computer

when it is loaded into temporary memory (for example, RAM) or installed into permanent memory (for example, hard

disk, CD-ROM, or other storage device) of that computer. However, installation on a network server for the sole

purpose of internal distribution to one or more other computer(s) shall not constitute “use.”

b. Solely with respect to electronic documents included with the SOFTWARE, you may make an unlimited number of

copies (either in hardcopy or electronic form), provided that such copies shall be used only for internal purposes and

are not republished or distributed to any third party.

2. OWNERSHIP. Except as expressly licensed to you in this Agreement, Anritsu retains all right, title, and interest in

and to the SOFTWARE PRODUCT; provided, however, that, subject to the license grant in Section 1.a and Anritsu's

ownership of the underlying SOFTWARE PRODUCT, you shall own all right, title and interest in and to any

Derivative Technology of the Product created by or for you.

3. COPYRIGHT. All title and copyrights in and to the SOFTWARE PRODUCT (including but not limited to any

images, photographs, animations, video, audio, music, text, and “applets” incorporated into the SOFTWARE

PRODUCT), the accompanying printed materials, and any copies of the SOFTWARE PRODUCT are owned by

Anritsu or its suppliers. The SOFTWARE PRODUCT is protected by copyright laws and international treaty

provisions. Therefore, you must treat the SOFTWARE PRODUCT like any other copyrighted material except that you

may make one copy of the SOFTWARE PRODUCT solely for backup or archival purposes. You may not copy any

printed materials accompanying the SOFTWARE PRODUCT.

4. DESCRIPTION OF OTHER RIGHTS AND LIMITATIONS.

a. Limitations on Reverse Engineering, Decompilation, and Disassembly. You may not reverse engineer, decompile, or

disassemble the SOFTWARE, except and only to the extent that such activity is expressly permitted by applicable law

notwithstanding this limitation.

b. Rental. You may not rent or lease the SOFTWARE PRODUCT.

c. Software Transfer. You may permanently transfer all of your rights under this EULA, provided that you retain no

copies, you transfer all of the SOFTWARE PRODUCT (including the Signature Signal Analyzer, all component parts,

the media and printed materials, any upgrades, this EULA, and, if applicable, the Certificate of Authenticity), and the

recipient agrees to the terms of this EULA.

d. Termination. Without prejudice to any other rights, Anritsu may terminate this EULA if you fail to comply with the

terms and conditions of this EULA. In such event, you must destroy all copies of the SOFTWARE PRODUCT.

5. U.S. GOVERNMENT RESTRICTED RIGHTS. THE SOFTWARE PRODUCT AND DOCUMENTATION ARE

PROVIDED WITH RESTRICTED RIGHTS. USE, DUPLICATION, OR DISCLOSURE BY THE GOVERNMENT IS

SUBJECT TO RESTRICTIONS AS SET FORTH IN SUBPARAGRAPH (C)(1)(II) OF THE RIGHTS IN TECHNICAL

DATA AND COMPUTER SOFTWARE CLAUSE AT DFARS 252.227-7013 OR SUBPARAGRAPHS (C)(1) AND (2) OF

THE COMMERCIAL COMPUTER SOFTWARE-RESTRICTED RIGHTS AT 48 CFR 52.227-19, AS APPLICABLE.

MANUFACTURER IS ANRITSU COMPANY, 490 JARVIS DRIVE, MORGAN HILL, CALIFORNIA 95037-2809.

The Signature software is copyright © 2007, Anritsu Company. All rights are reserved by all parties.

Page 5

Page 6

Page 7

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Company uses the

following symbols to indicate safety-related information. For your own safety, please read the information

carefully before operating the equipment.

Symbols Used in Manuals

Danger: This indicates a very dangerous procedure that could result in

serious injury or death, or loss related to equipment

malfunction, if not performed properly.

Warning: This indicates a hazardous procedure that could result in

light-to-severe injury or loss related to equipment

malfunction, if proper precautions are not taken.

Caution: This indicates a hazardous procedure th at could re sult in loss

related to equipment malfunction if proper precautions are

not taken.

Safety Symbols Used on Equipment and in Manuals

The following safety symbols are used inside or on the equipment near operation locations to provide

information about safety items and operation precautions. Ensure that you clearly understand the meanings of

the symbols and take the necessary precautions before operating the equipment. Some or all of the following

five symbols may or may not be used on all Anritsu equipment. In addition, there may be other labels attached

to products that are not shown in the diagrams in this manual.

This indicates a prohibited operation. The prohibited operation is indicated symbolically in or near

the barred circle.

This indicates a compulsory safety precaution. The required operation is indicated symbolically in or

near the circle.

This indicates a warning or caution. The contents are indicated symbolically in or near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

MS278XB OM Safety-1

Page 8

For Safety

Warning: Always refer to the operation manual when working near

locations at which the alert mark, shown on the left, is

attached. If the operation, etc., is performed without heeding

the advice in the operation manual, there is a risk of

personal injury. In addition, the equipment performance may

be reduced.

Moreover, this alert mark is sometimes used with other

marks and descriptions indicating other dangers.

Warning: When supplying power to this equipment, connect the

accessory 3-pin power cord to a 3-pin grounded power

outlet. If a grounded 3-pin outlet is not available, use a

conversion adapter and ground the green wire, or connect

the frame ground on the rear panel of the equipment to

ground. If power is supplied without grounding the

equipment, there is a risk of receiving a severe or fatal

electric shock.

Warning: This equipment can not be repaired by the operator. D

attempt to remove the equipment covers or to disassemble

internal components. Only qualified service technicians with

a knowledge of electrical fire and shock hazards should

service this equipment. There are high-voltage parts in this

equipment presenting a risk of sev ere injury or fatal electric

shock to untrained personnel. In addition, there is a risk of

damage to precision components.

Warning: Use two or more people to lift and move this equipment, or

use an equipment cart. There is a risk of back injury if this

equipment is lifted by one person.

Caution: Electrostatic Discharge (ESD) can damage the highly

sensitive circuits in the instrument. ESD is most likely to

occur as test devices are being connected to, or

disconnected from, the instrument’s front and rear panel

ports and connectors. You can protect the instrument and

test devices by wearing a static-discharge wristband.

Alternatively, you can ground yourself to discharge any static

charge by touching the outer chassis of the grounded

instrument before touching the instrument’s front and rear

panel ports and connectors. Avoid touching the test port

center conductors unless you are properly grounded and

have eliminated the possibility of static discharge.

o not

Repair of damage that is found to be caused by electrostatic

discharge is not covered under warranty.

Safety-2 MS278XB OM

Page 9

Table of Contents

Chapter 1—General Information

1-1 About this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Associated Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

RF/Analog Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Digital Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Software Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

External Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Identification Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Cleaning the Touch Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Operating System Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Antivirus Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Windows Updates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Operating System Backup and Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Replacing the Line Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Internal Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Chapter 2—Preparation for Use

2-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-4 Unpacking the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Initial Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Package Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-5 Assembly (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Rack Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-6 Power On Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Instrument Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Warm-up Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Instrument Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

MS278XB OM i

Page 10

Table of Contents (Continued)

2-7 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

BIOS Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Windows XP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

User Installed Applications and Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Desktop Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Directory Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Security Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Remote Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Computer Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Third Party Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Hard Disk Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Analyzer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Installing Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Customizing the Tool Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-8 Remote Interface Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

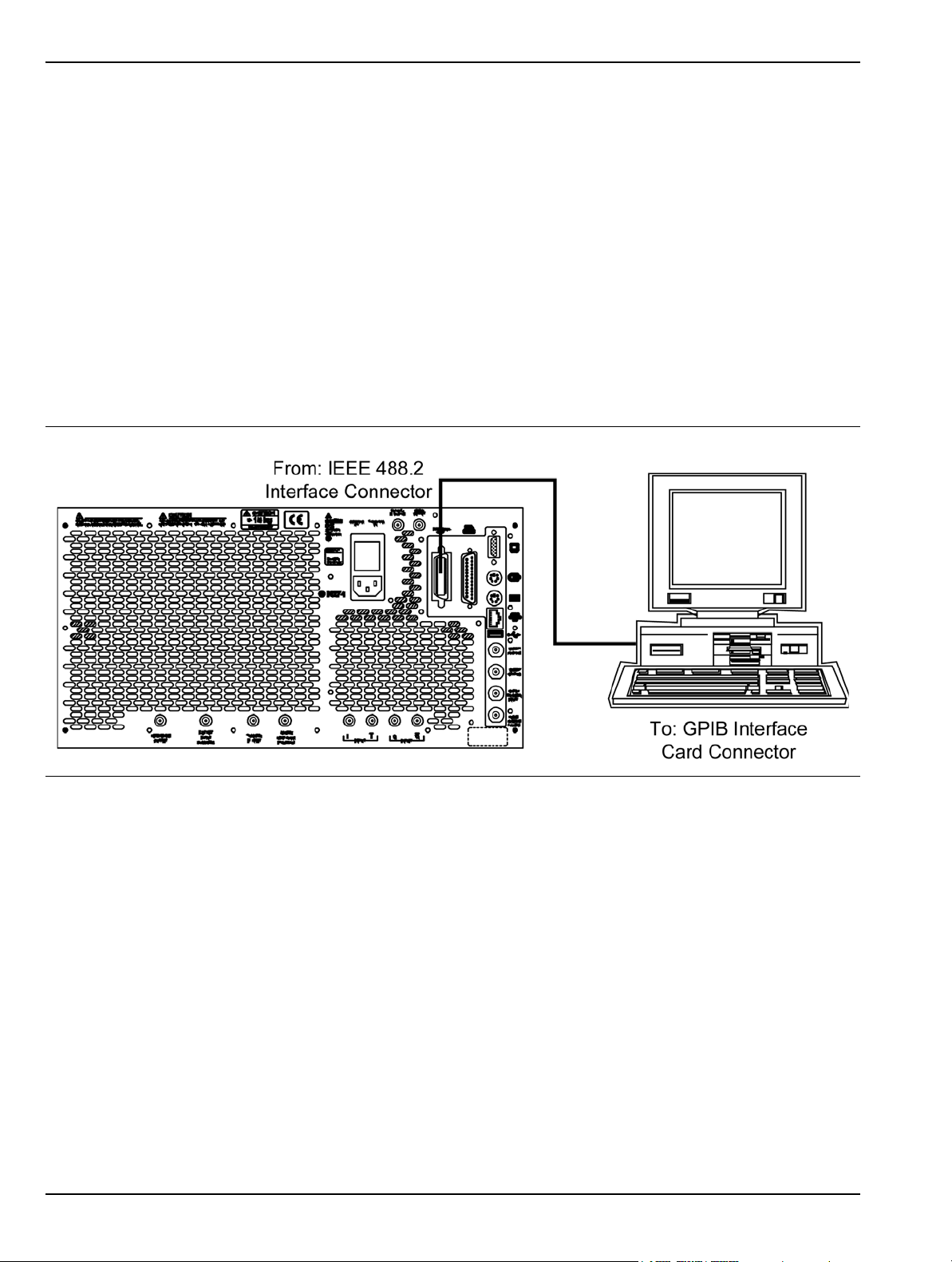

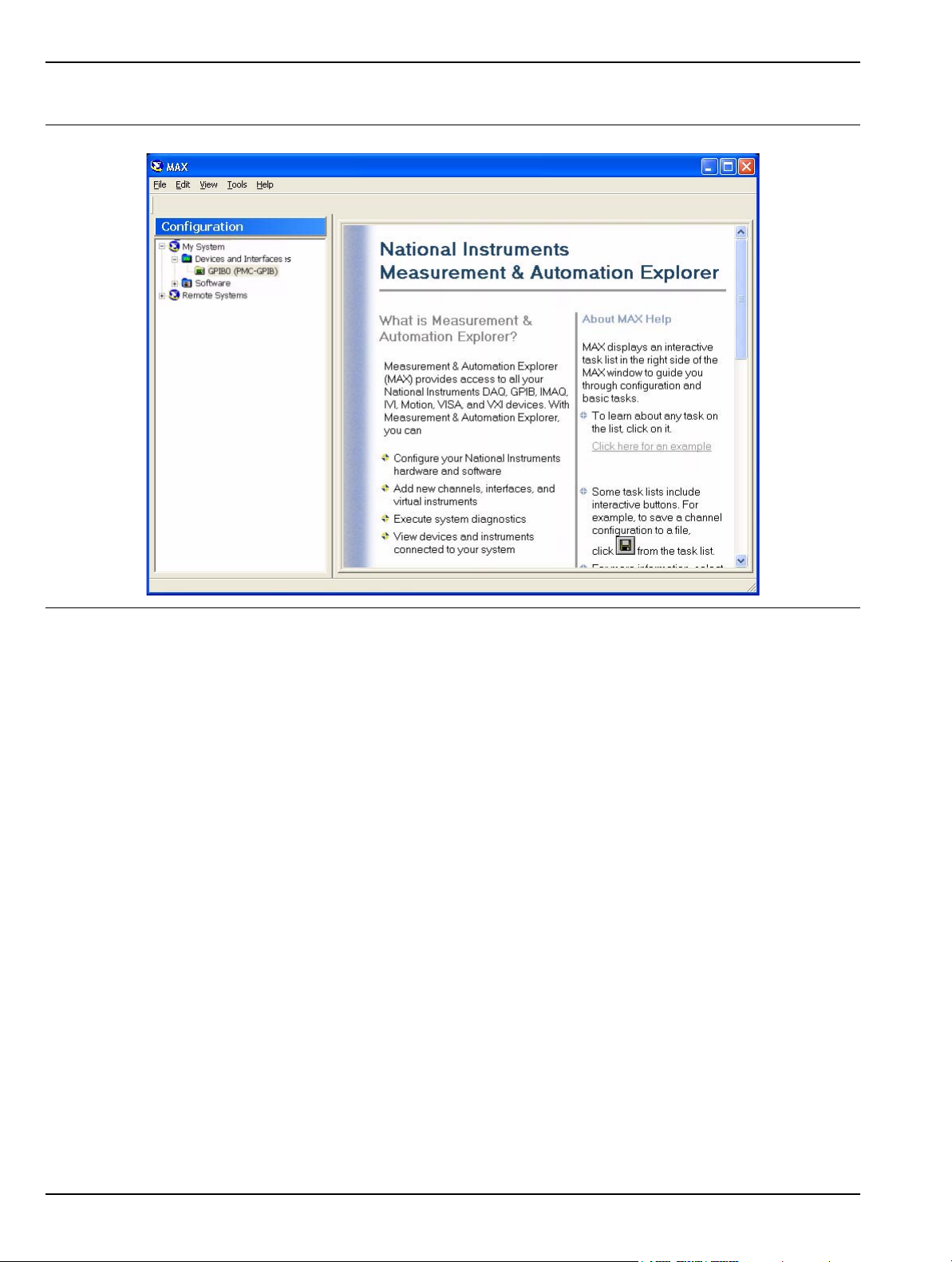

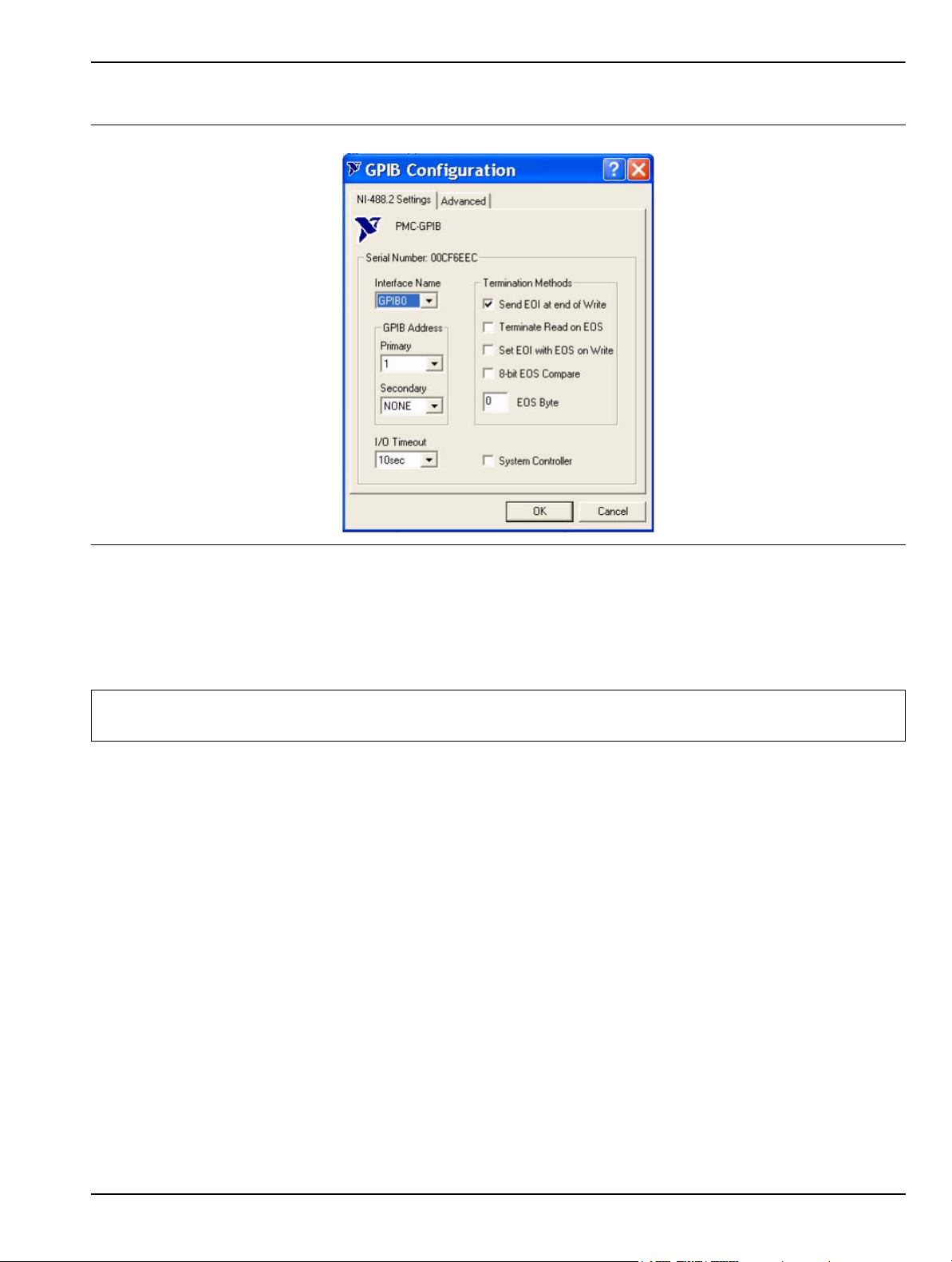

GPIB Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

GPIB Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

GPIB Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

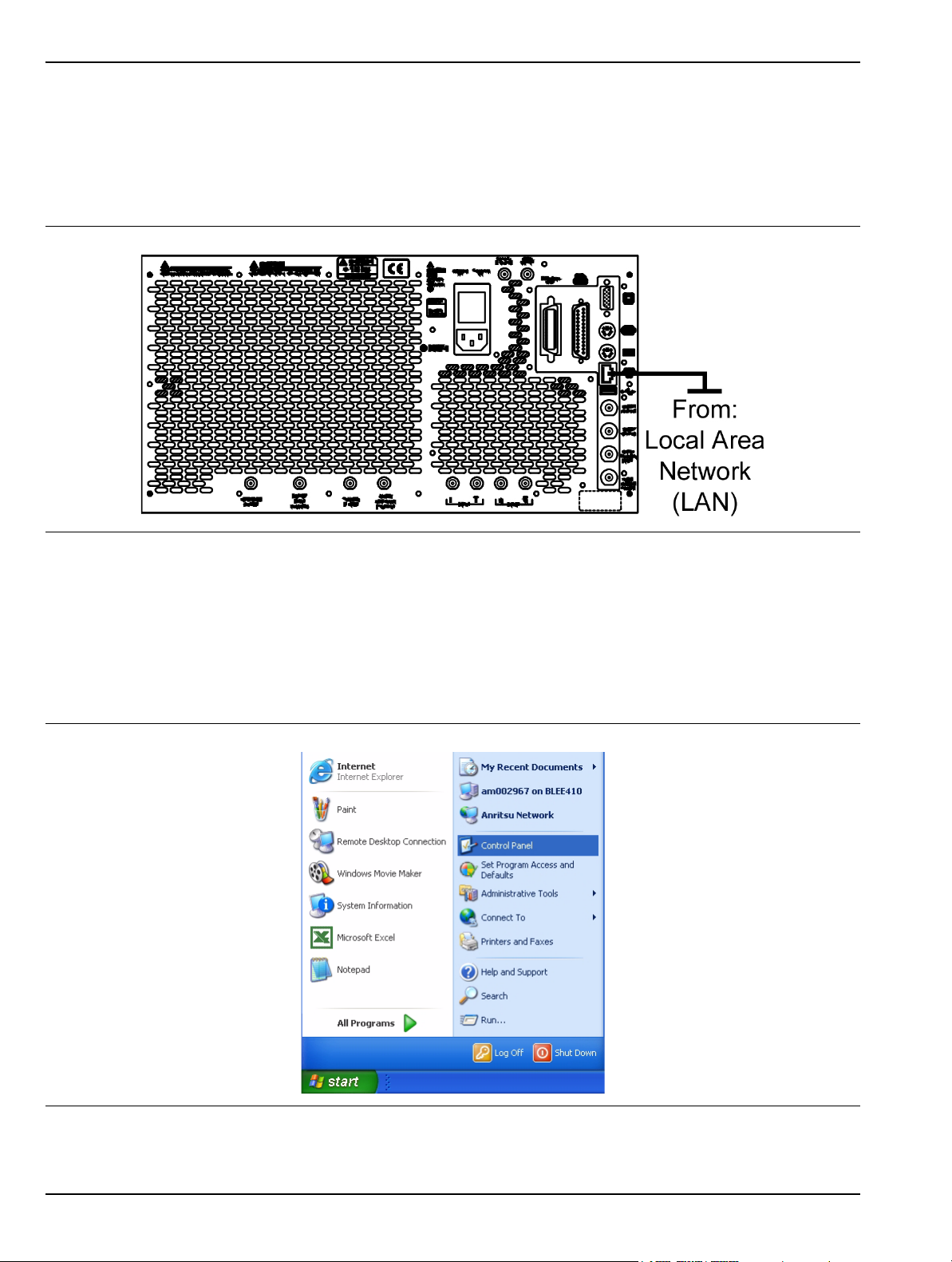

LAN Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Network Interface Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-9 Connecting External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Connecting an External Keyboard or Mouse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Connecting an External Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Connecting an External Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Connecting an External USB Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2-10 Preparation for Storage/Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Preparation for Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Preparation for Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Use a Suitable Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Protect the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Cushion the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Seal the Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Address the Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Chapter 3—Instrument Overview

3-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

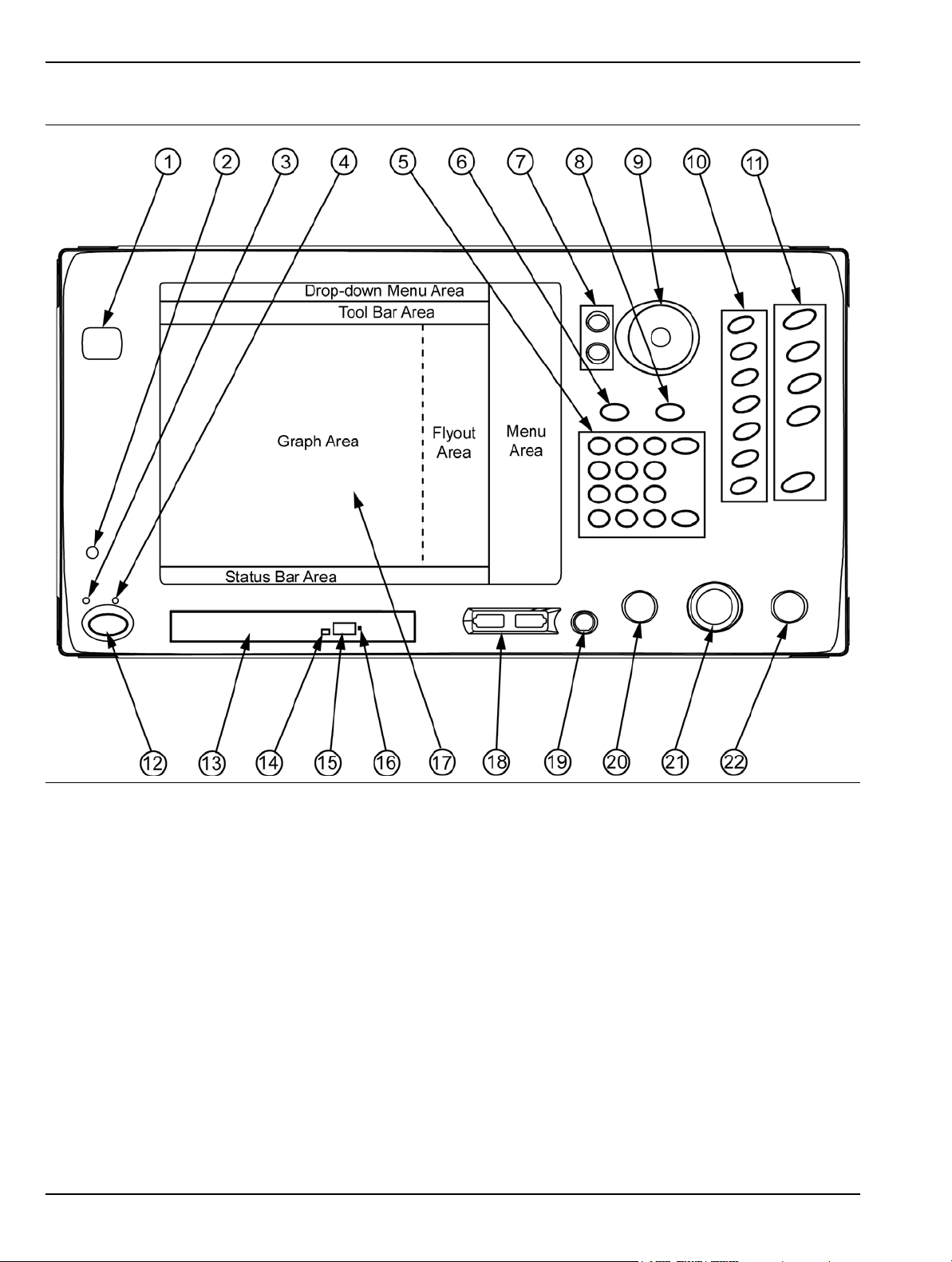

3-2 Front Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Front Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

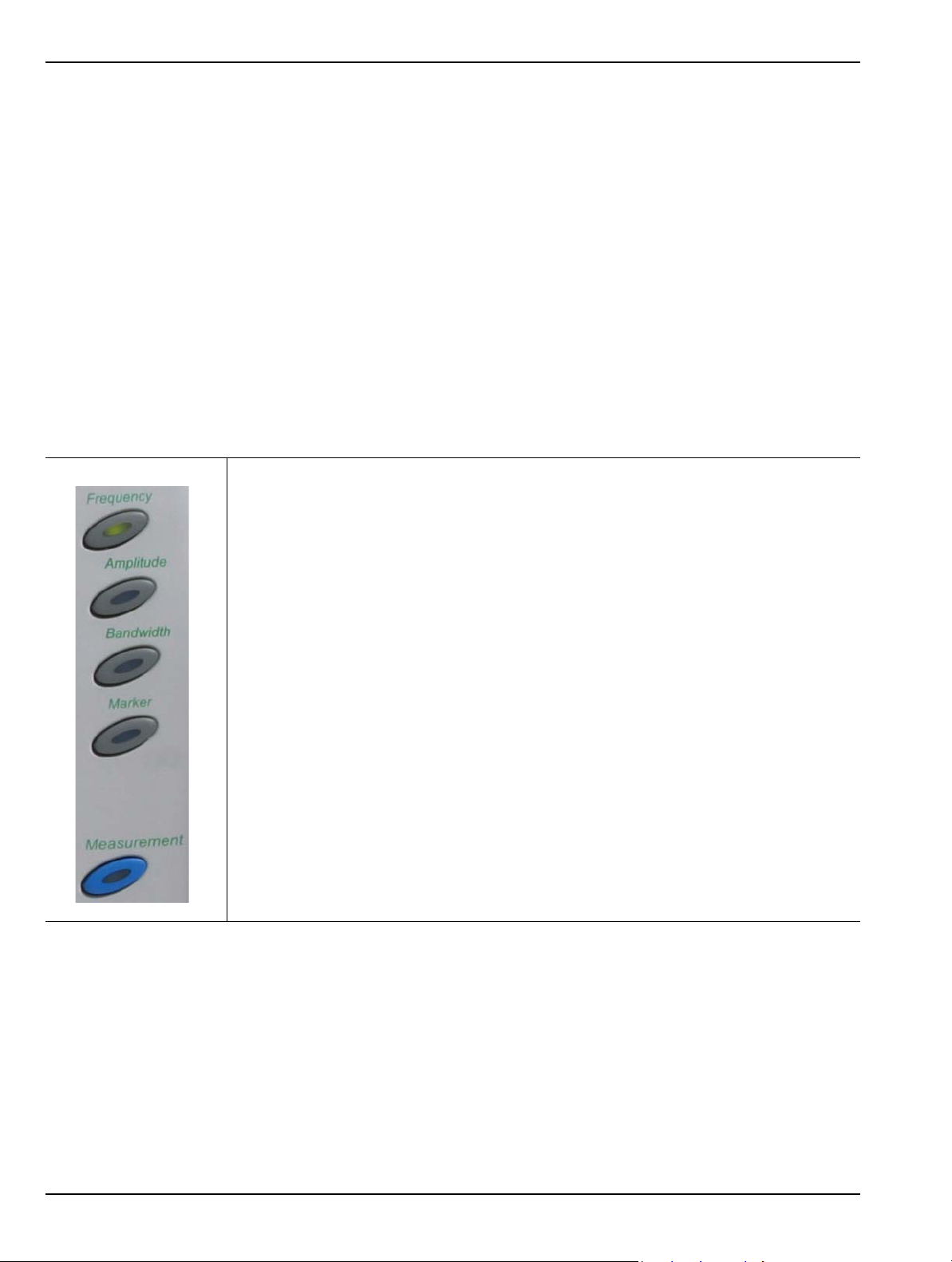

Major Function Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Minor Function Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

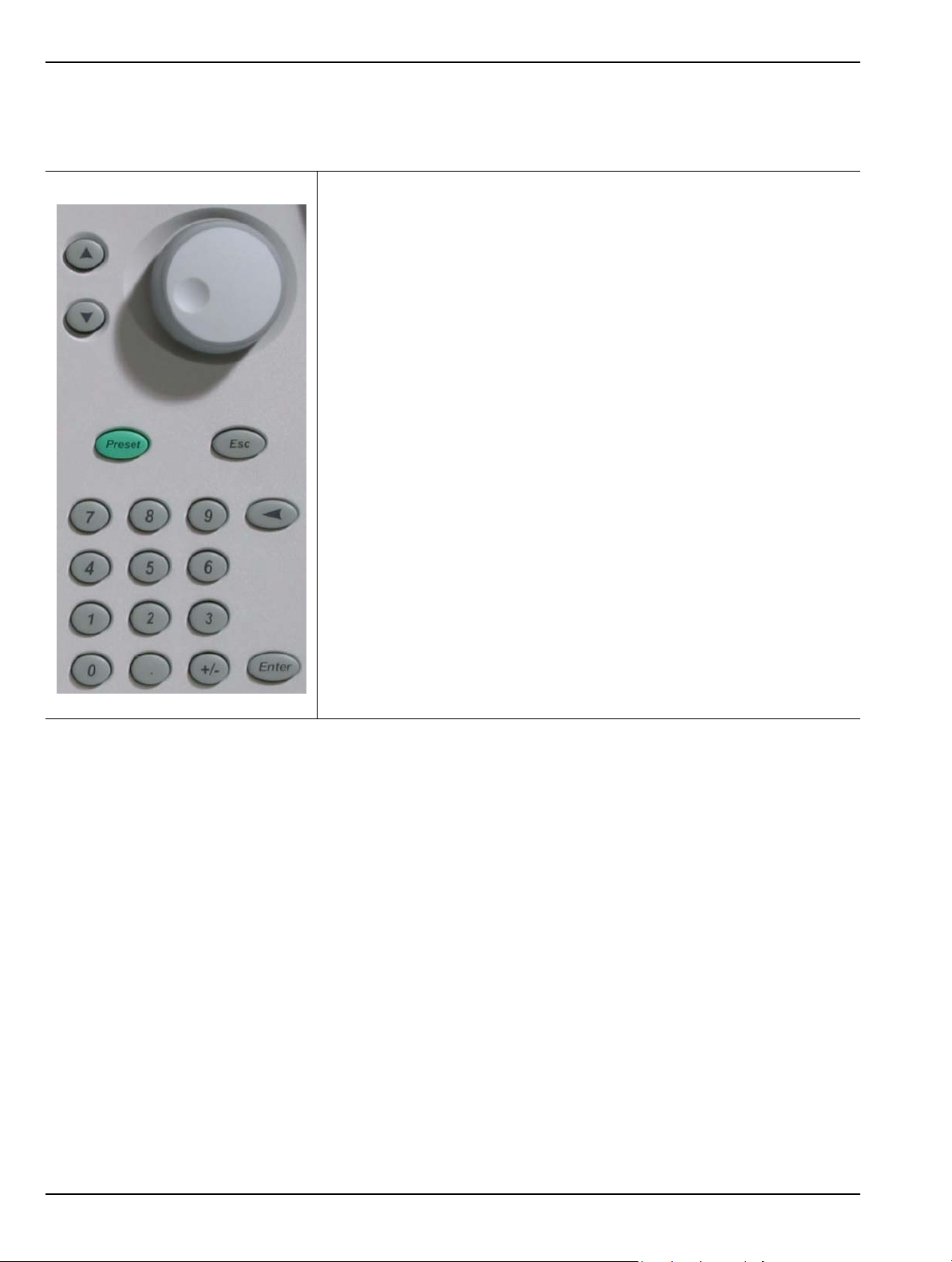

Numeric and Cursor Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

DVD-ROM/CD-RW Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Manually Ejecting the DVD-ROM/CD-RW Drive Tray . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

ii MS278XB OM

Page 11

Table of Contents (Continued)

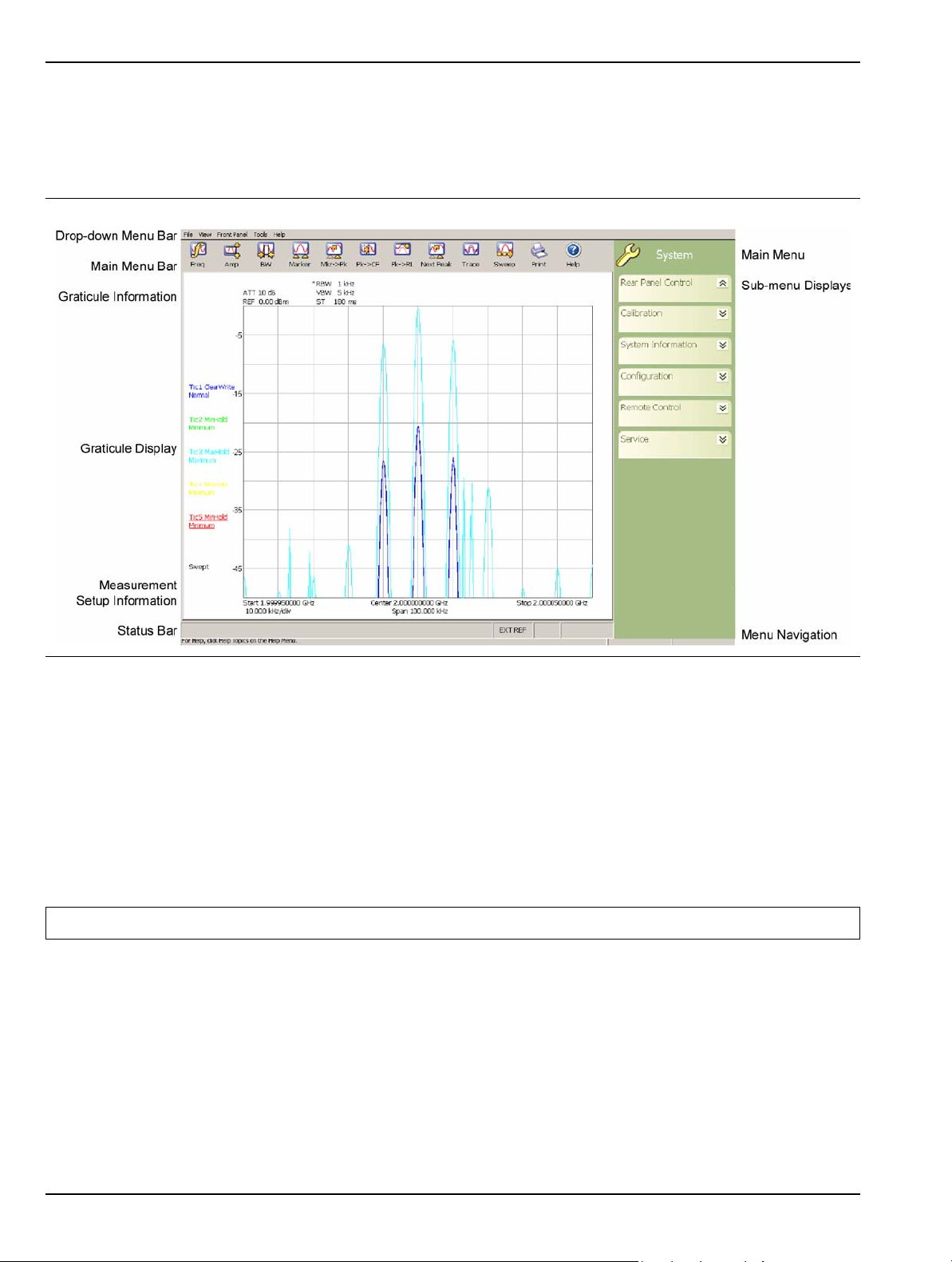

3-3 Graphical User Interface Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

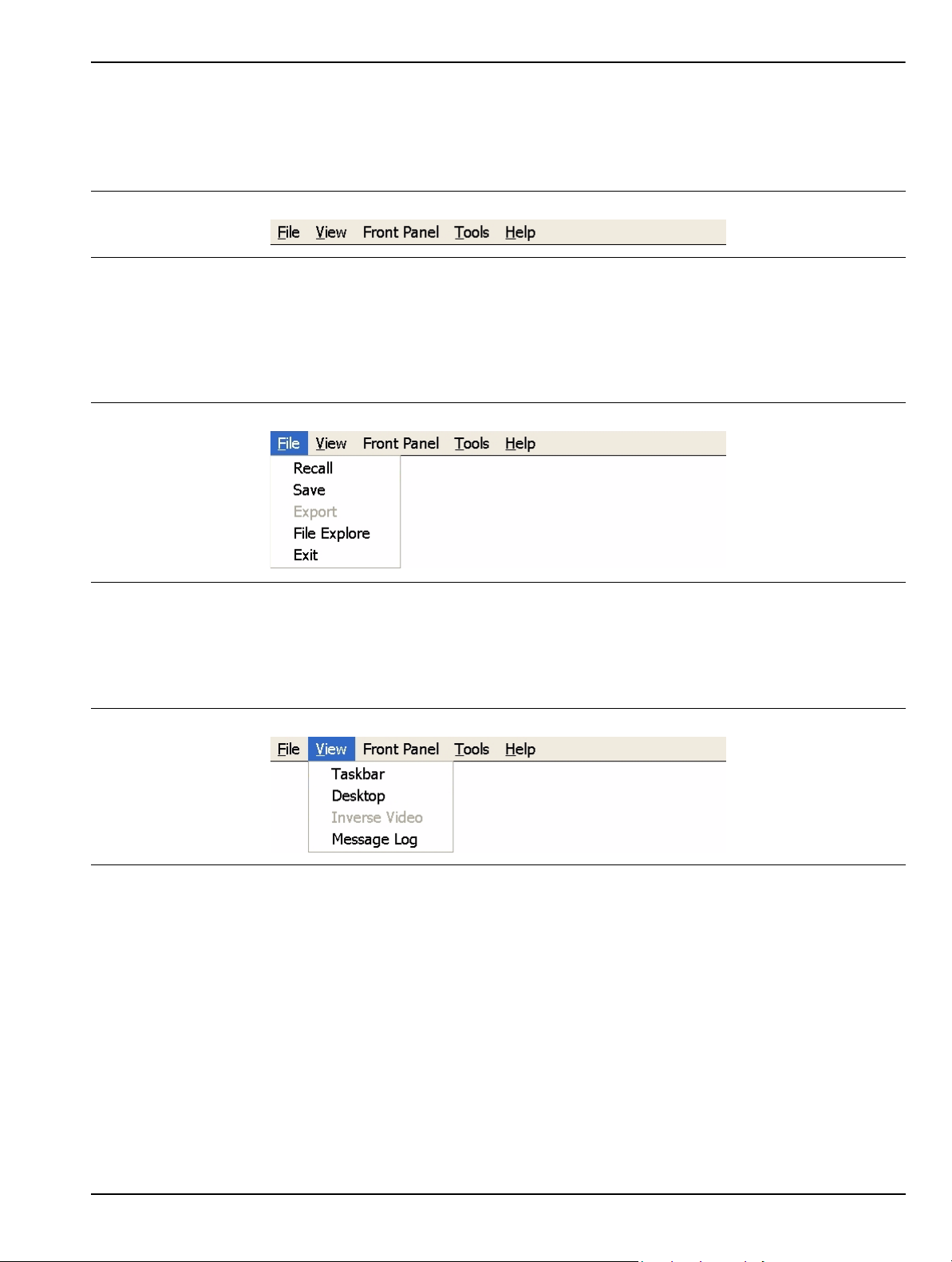

Drop-down Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

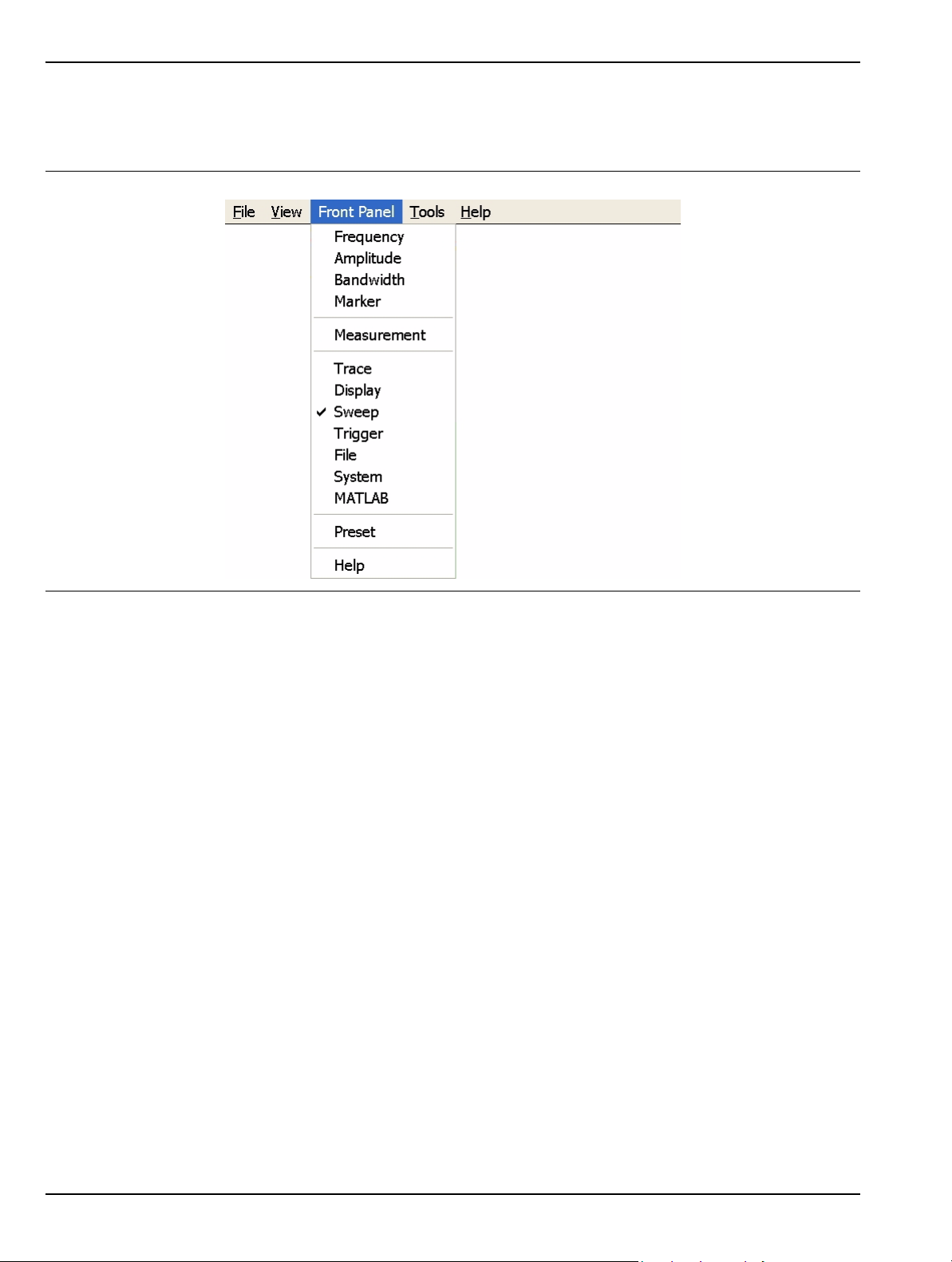

Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

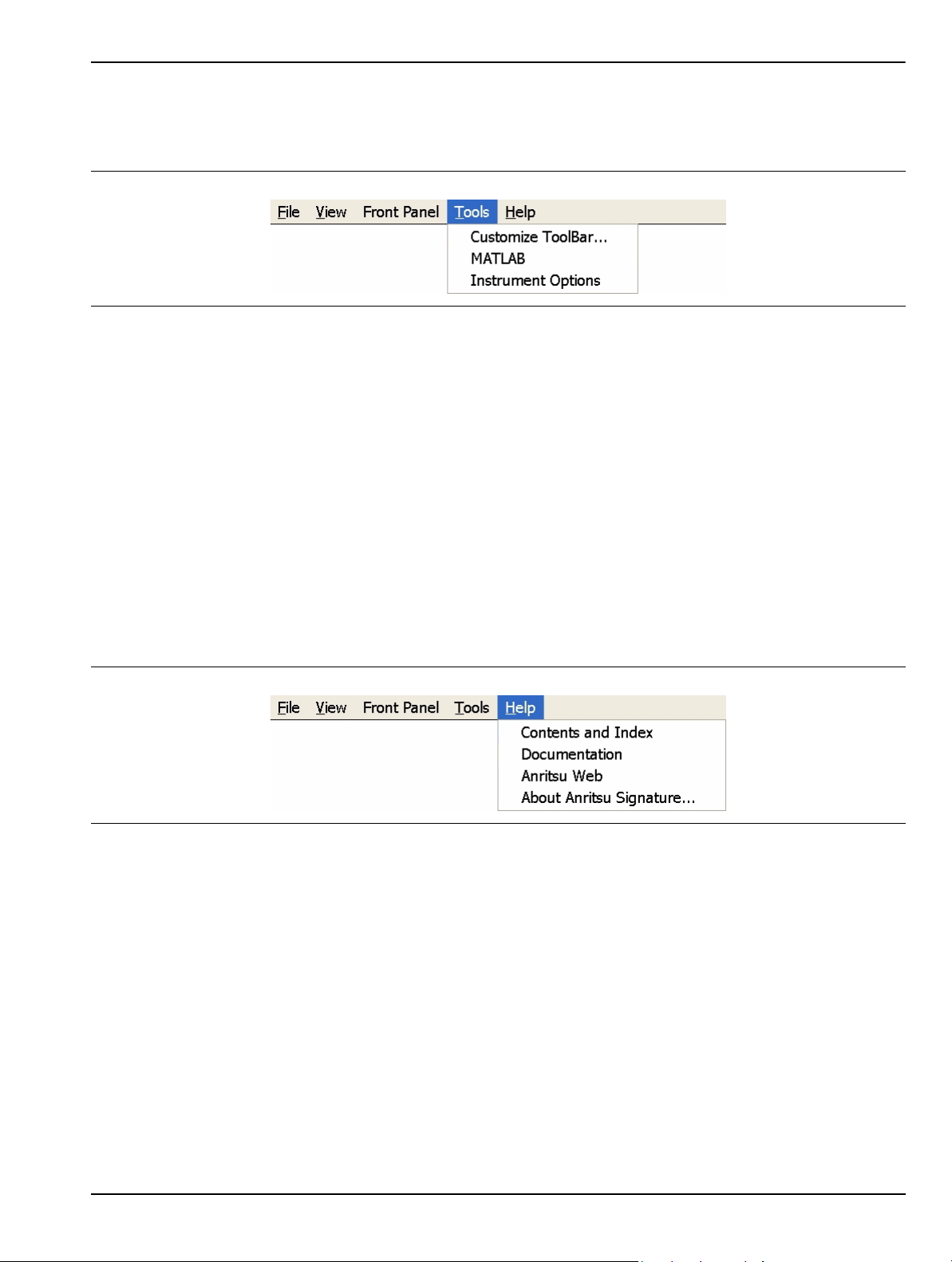

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

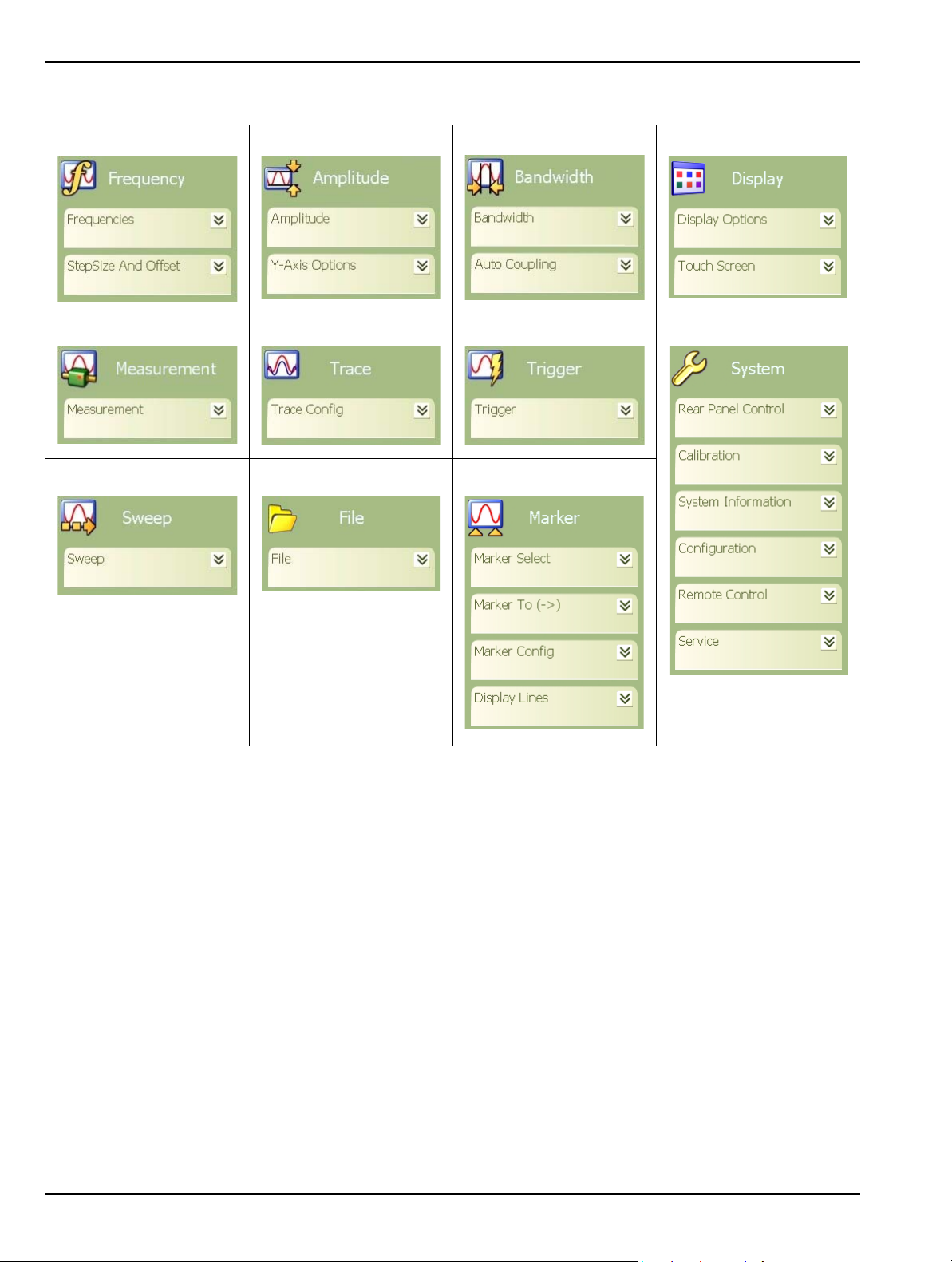

Main Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

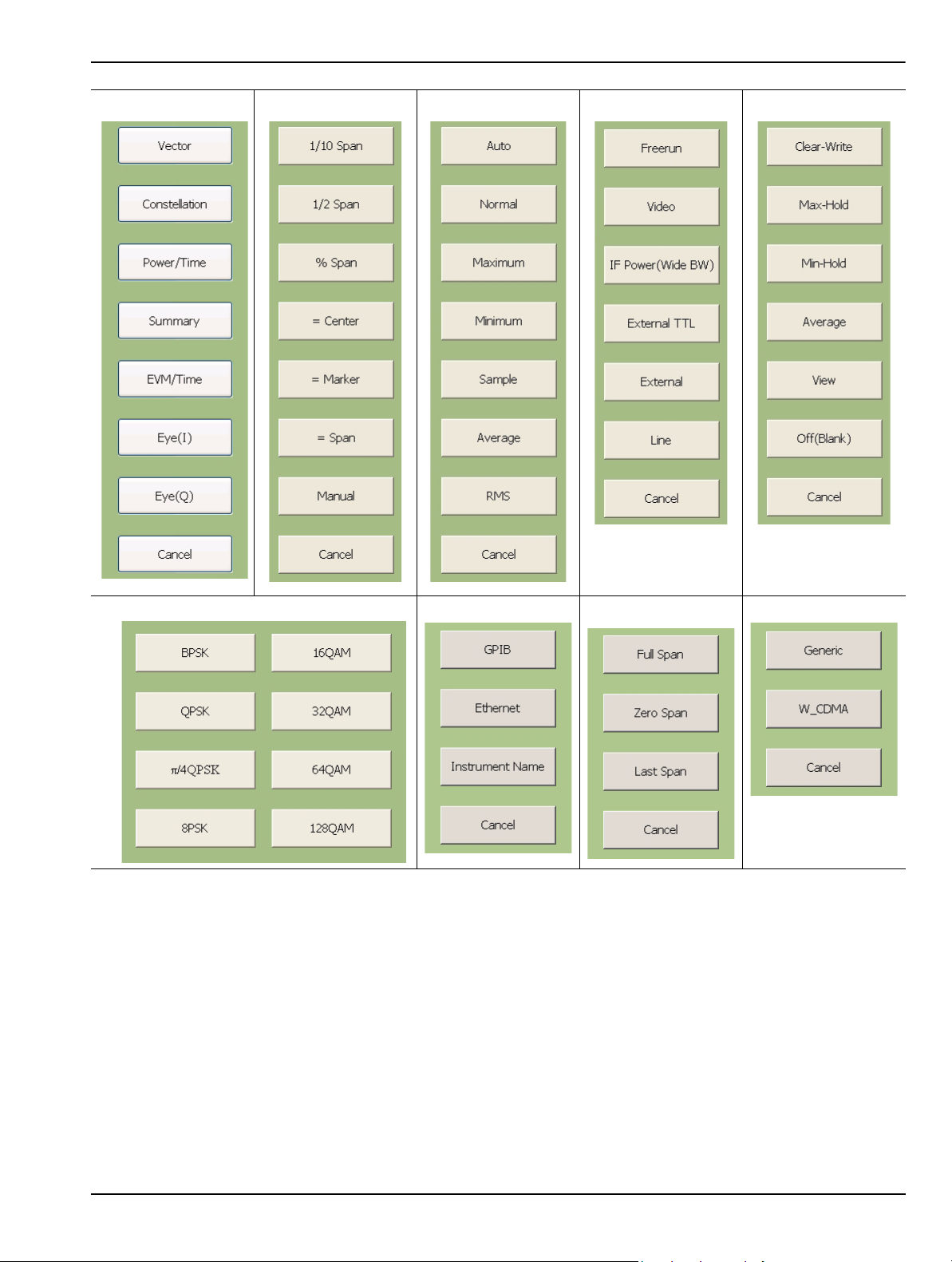

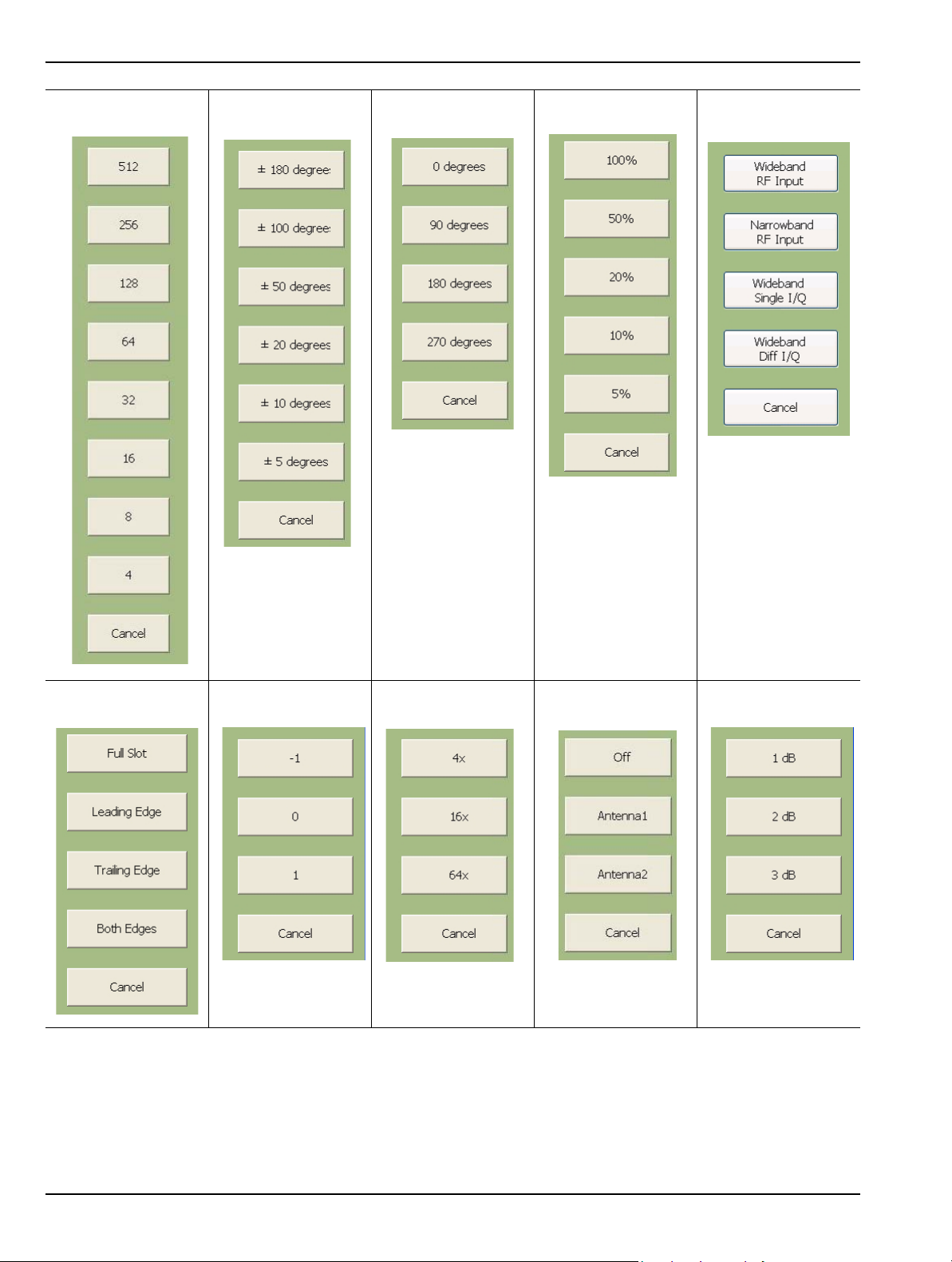

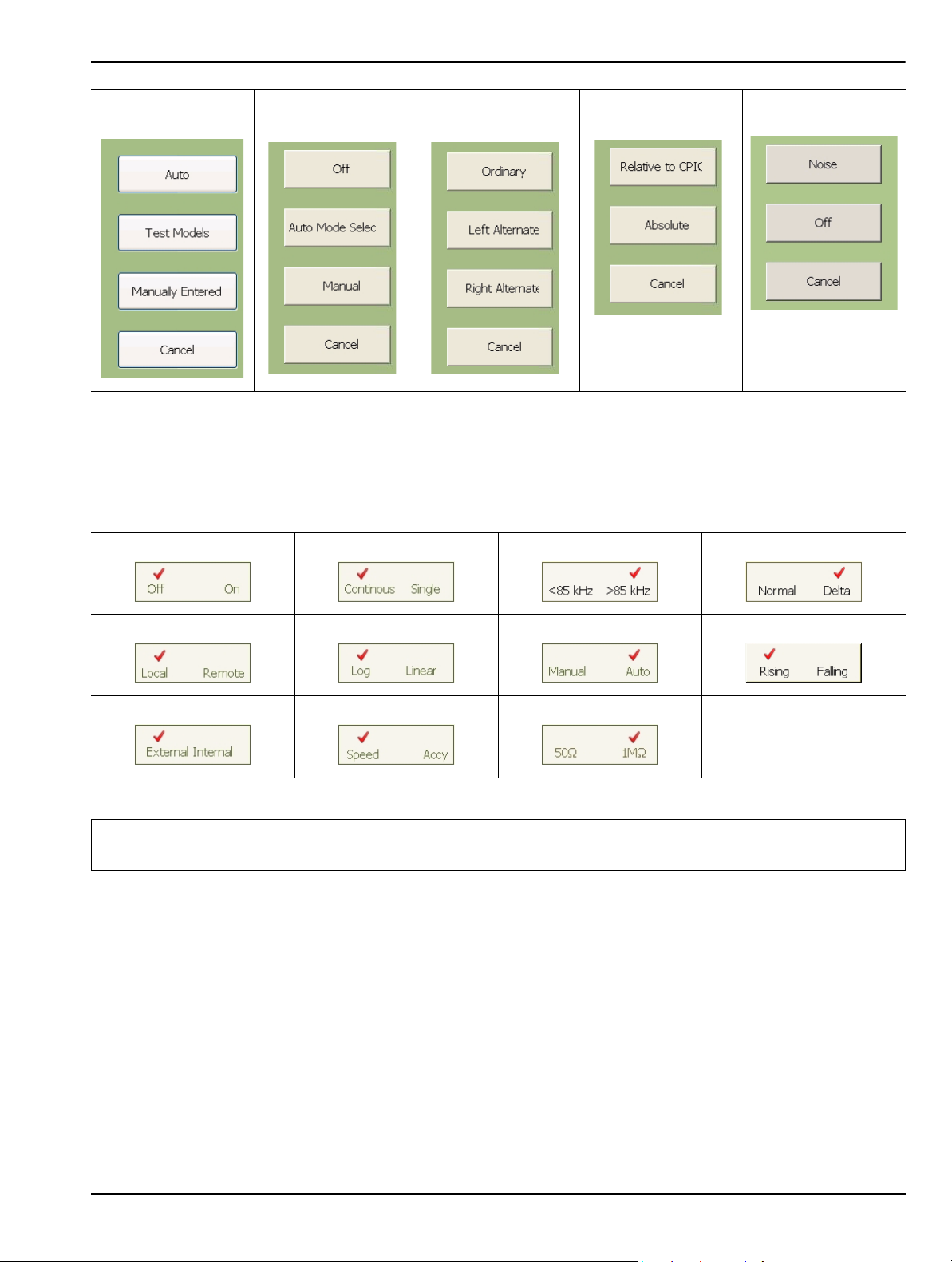

Sub-menu Trees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Entering Data and Fly-out Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Toggle Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

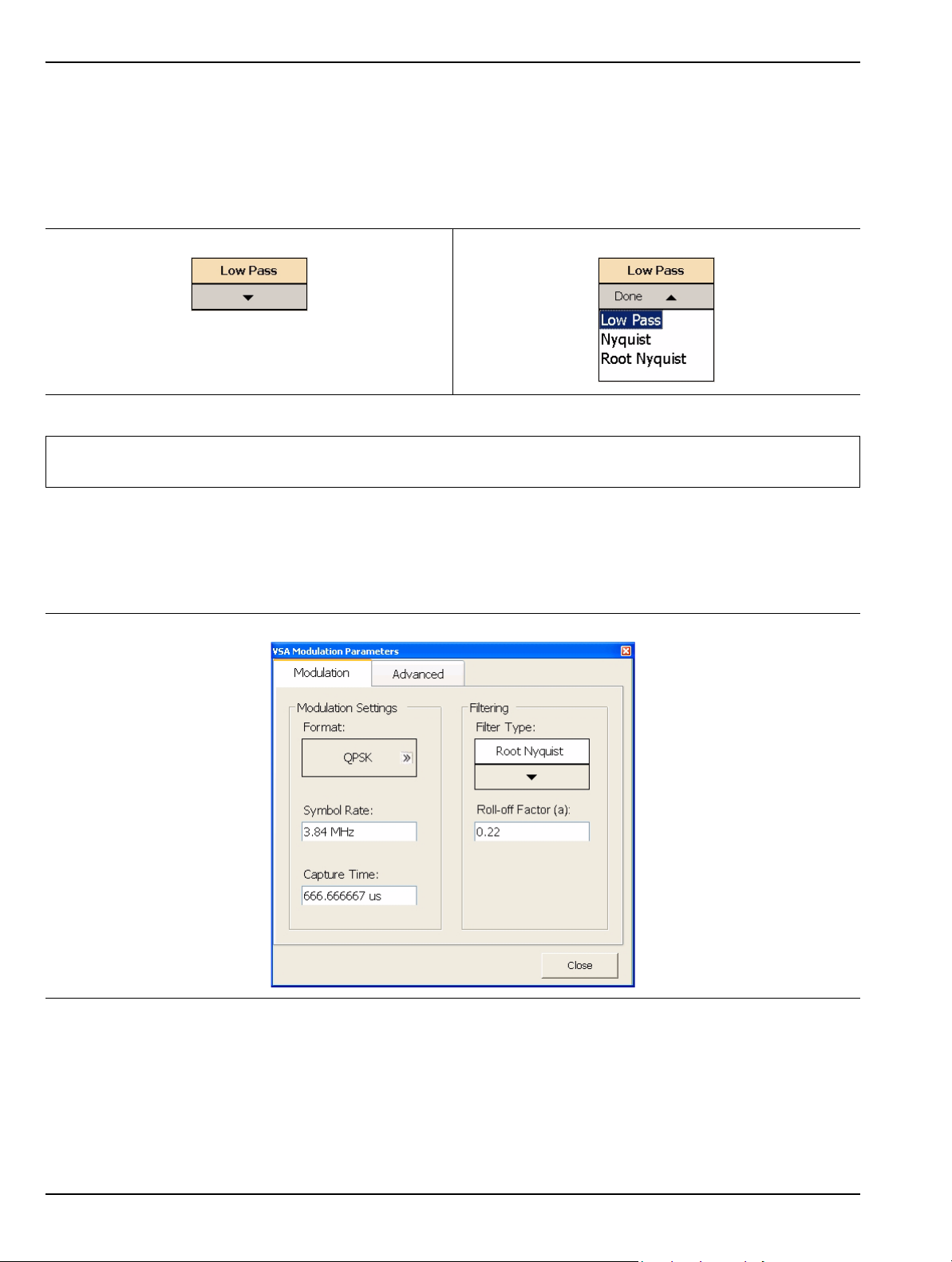

Drop-down Selection Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Parameter Entry and Measurement Setup Dialogs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Alpha-Numeric Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Graticule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Spectral Analysis Graticule Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Data Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Vector Signal Analysis Graticule Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Instrument Messages and Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

General Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Warning Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Calibration Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

External Keyboard Hot-key Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

3-4 Instrument Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Changing Setups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Calibration State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Instrument Preset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

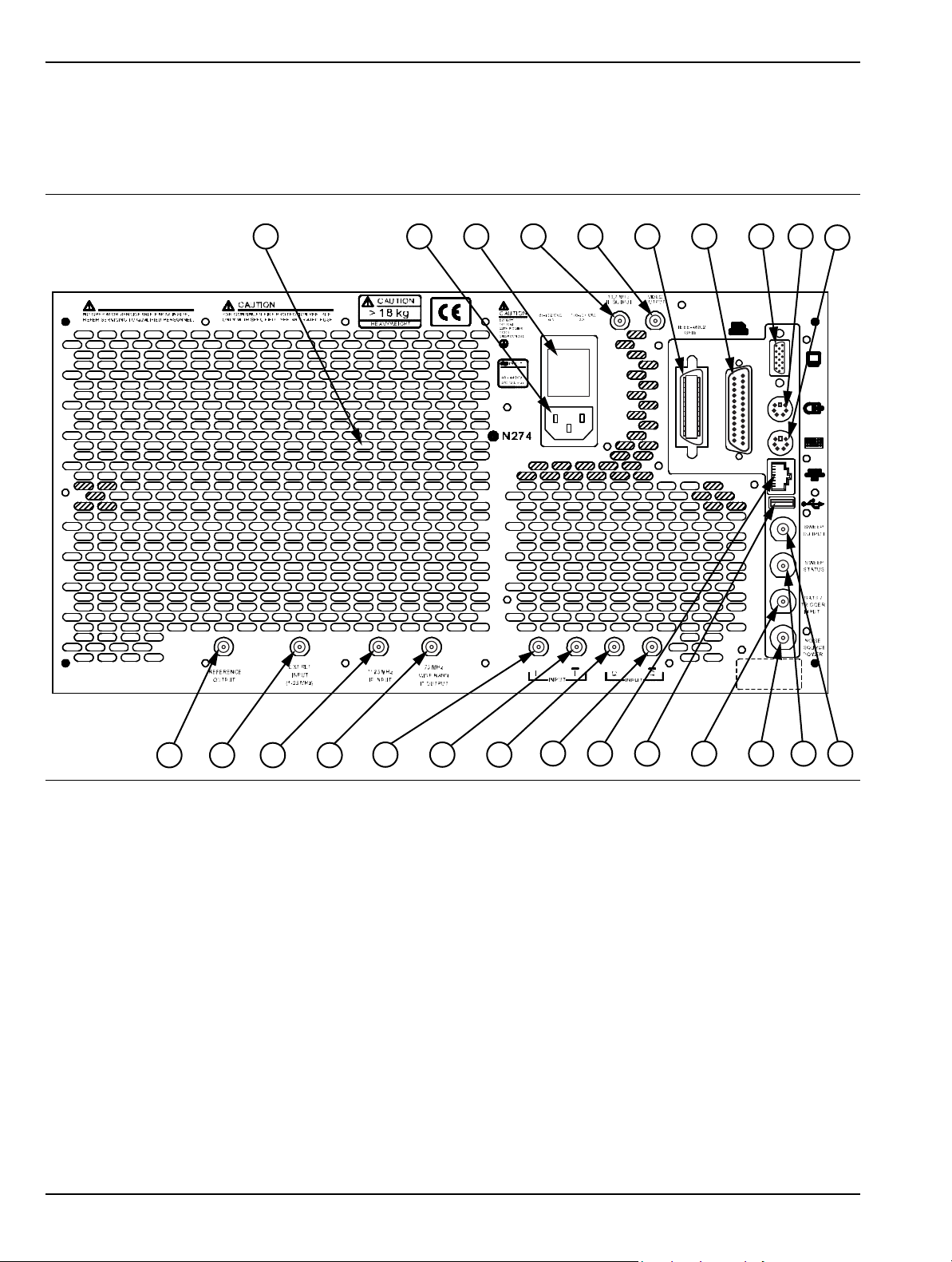

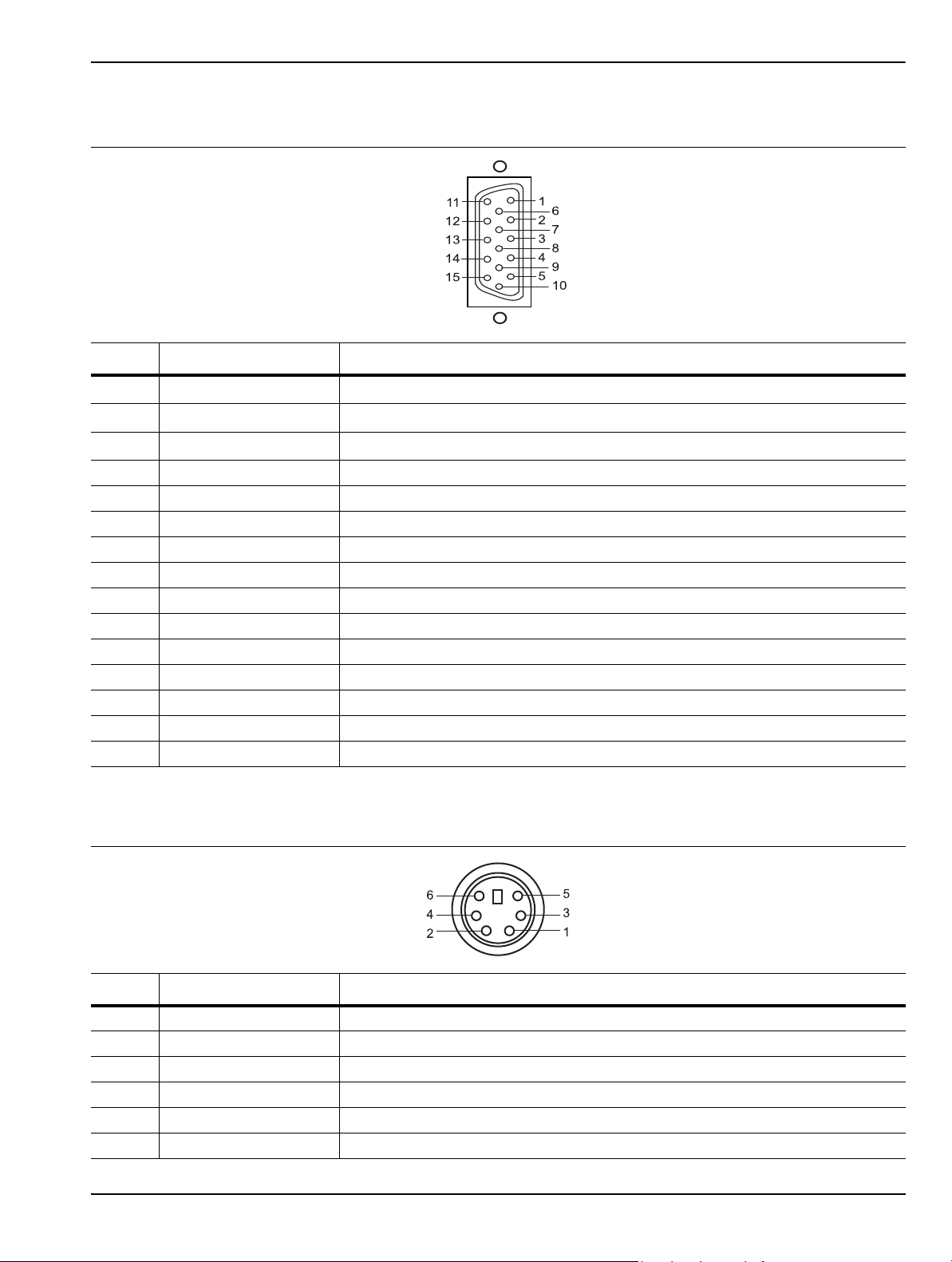

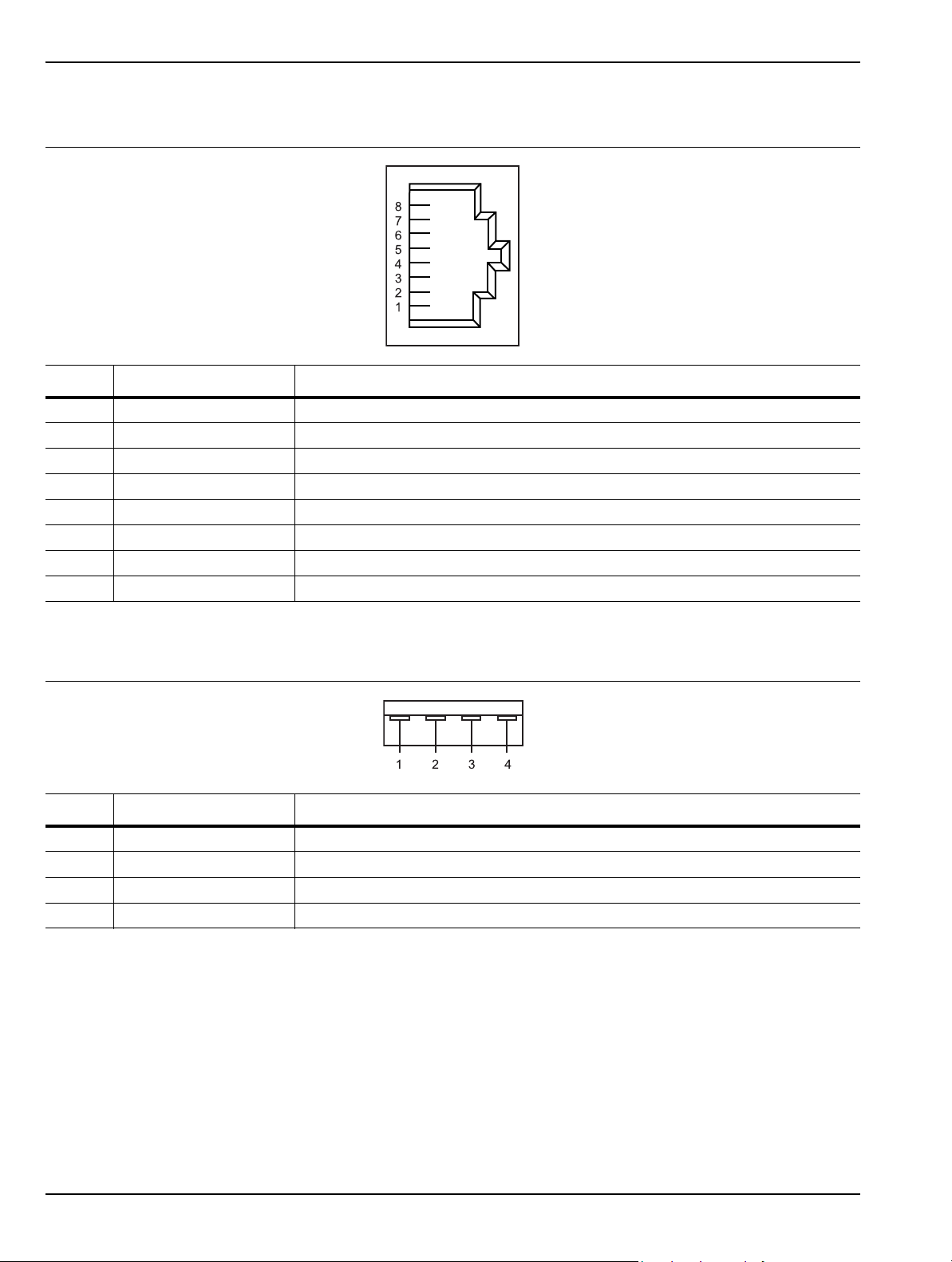

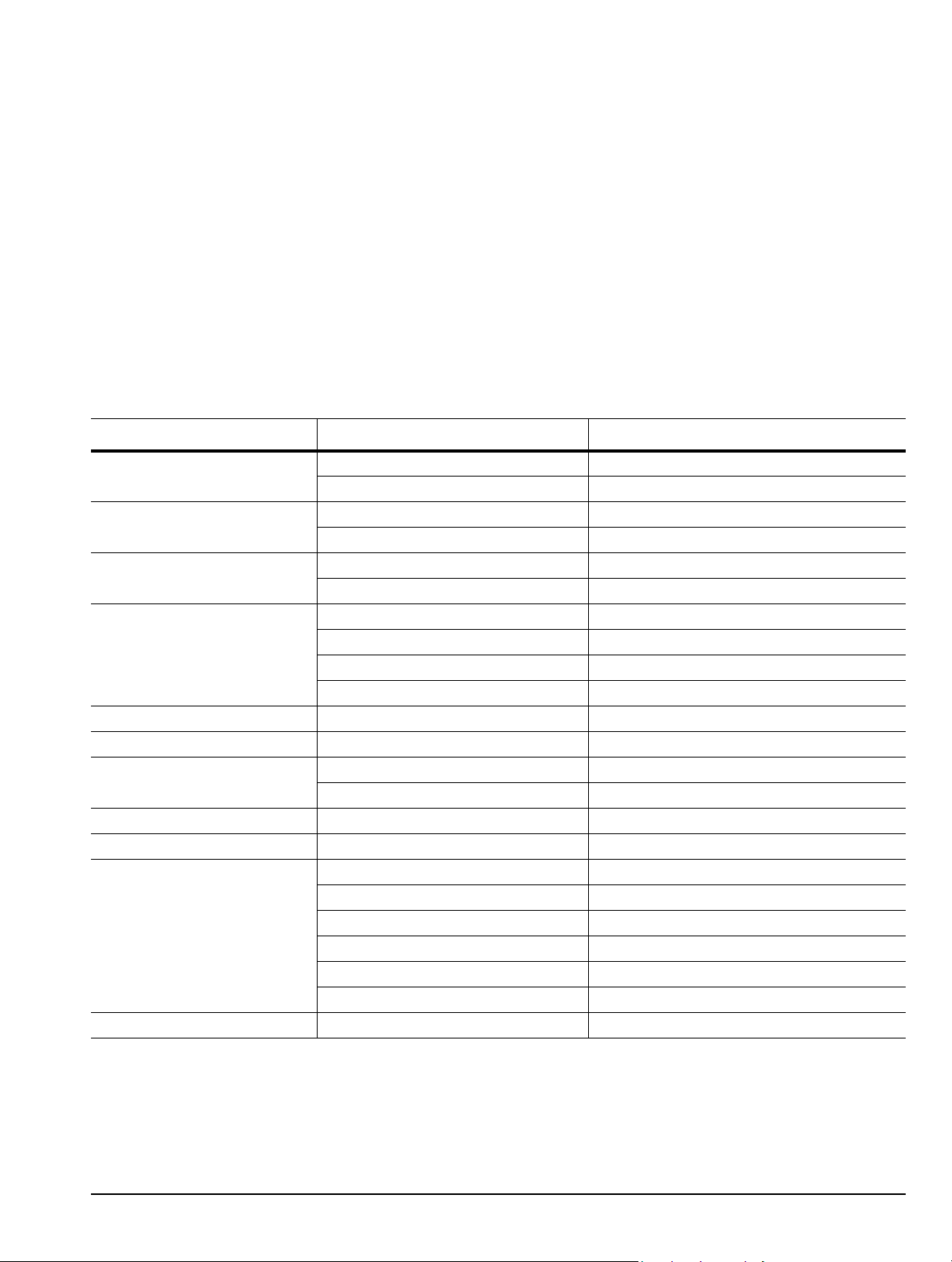

3-5 Rear Panel and Connector Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Chapter 4—Front Panel Menus

4-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Quick Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

MS278XB OM iii

Page 12

Table of Contents (Continued)

4-3 Menu Archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Frequency Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Frequencies Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Step Size and Offset Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Amplitude Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Amplitude Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Y-Axis Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Bandwidth Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Bandwidth Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Auto Coupling Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Marker Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Marker Select Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Marker to (–>) Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Marker Config Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Display Lines Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Measurement Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Measurement Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Trace Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Trace Config Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Display Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Display Options Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Touch Screen Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Sweep Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Sweep Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Trigger Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Trigger Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

System Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Rear Panel Control Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Calibration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

System Information Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

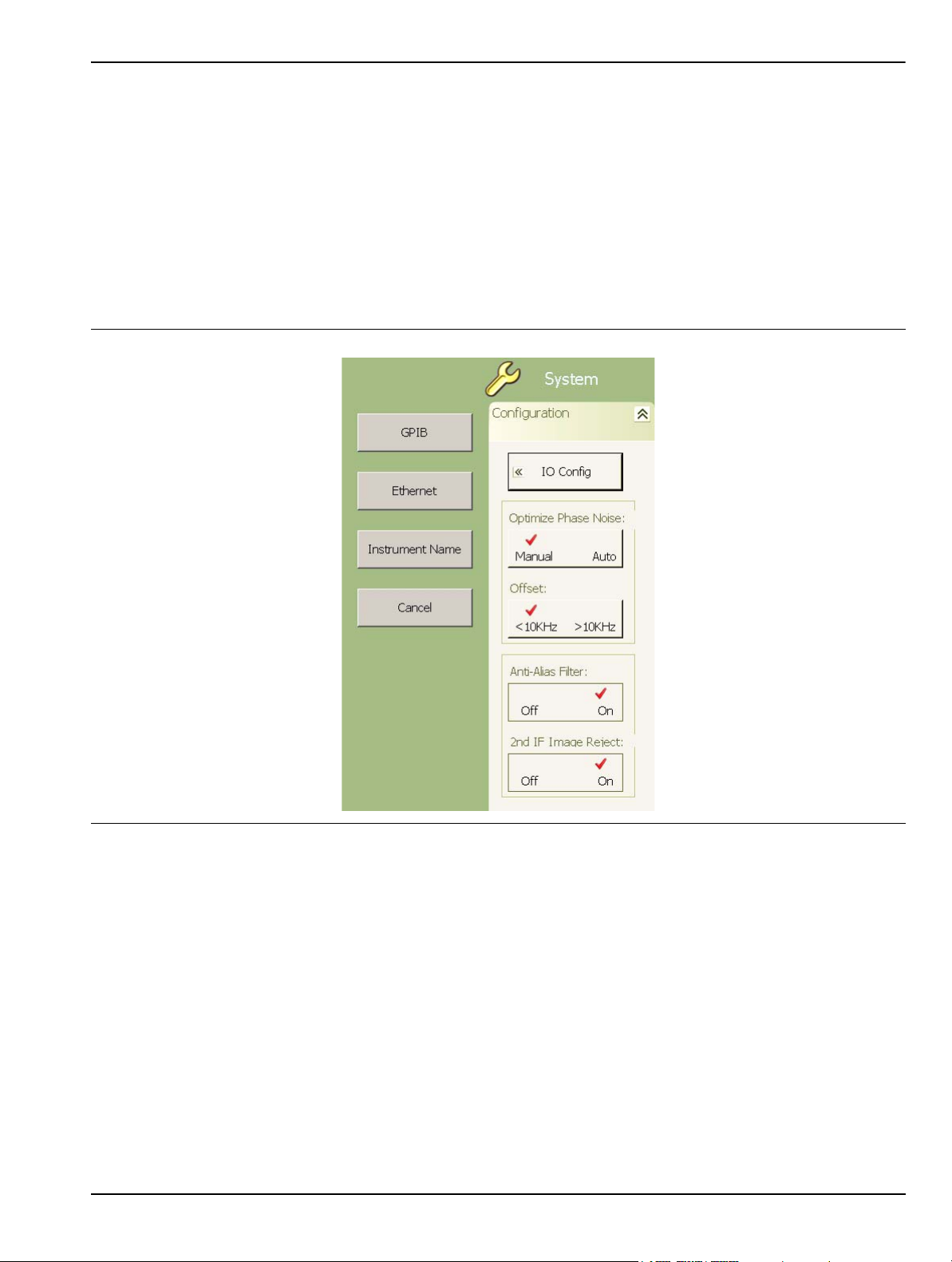

Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Remote Control Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

File Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

iv MS278XB OM

Page 13

Table of Contents (Continued)

4-4 Parameter Entry and Measurement Setup Dialog Archive. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Occupied Bandwidth Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Channel Power Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Adjacent Channel Power (ACP) Setup Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Multicarrier Channel Power Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

CCDF Setup Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Spectrum Mask Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

VSA Modulation Parameters Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

WCDMA Graph Type Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

WCDMA Setup Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

TPC Limit Edge Definition Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Channel Table Editor Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Customize Tool Bar Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Options Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

MATLAB Setup Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Chapter 5—Measurements

5-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Basic Measurement Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Setting the Center Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Setting the Frequency Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Setting the Start and Stop Frequencies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Setting the Reference Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Setting the Input Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Setting the Scale/Div . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Setting the Resolution Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Setting the Video Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Setting the Sweep Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Setting the Bandwidth Coupling Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Setting Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Setting Trace Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Configuring the Triggering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5-3 Measurement Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Measuring a CW Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Measuring Harmonics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Displaying Wide Band FFT Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Displaying Narrow Band FFT Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Measuring a Pulse in the Time Domain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Displaying Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Displaying Trace Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Measuring Phase Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5-4 RF Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

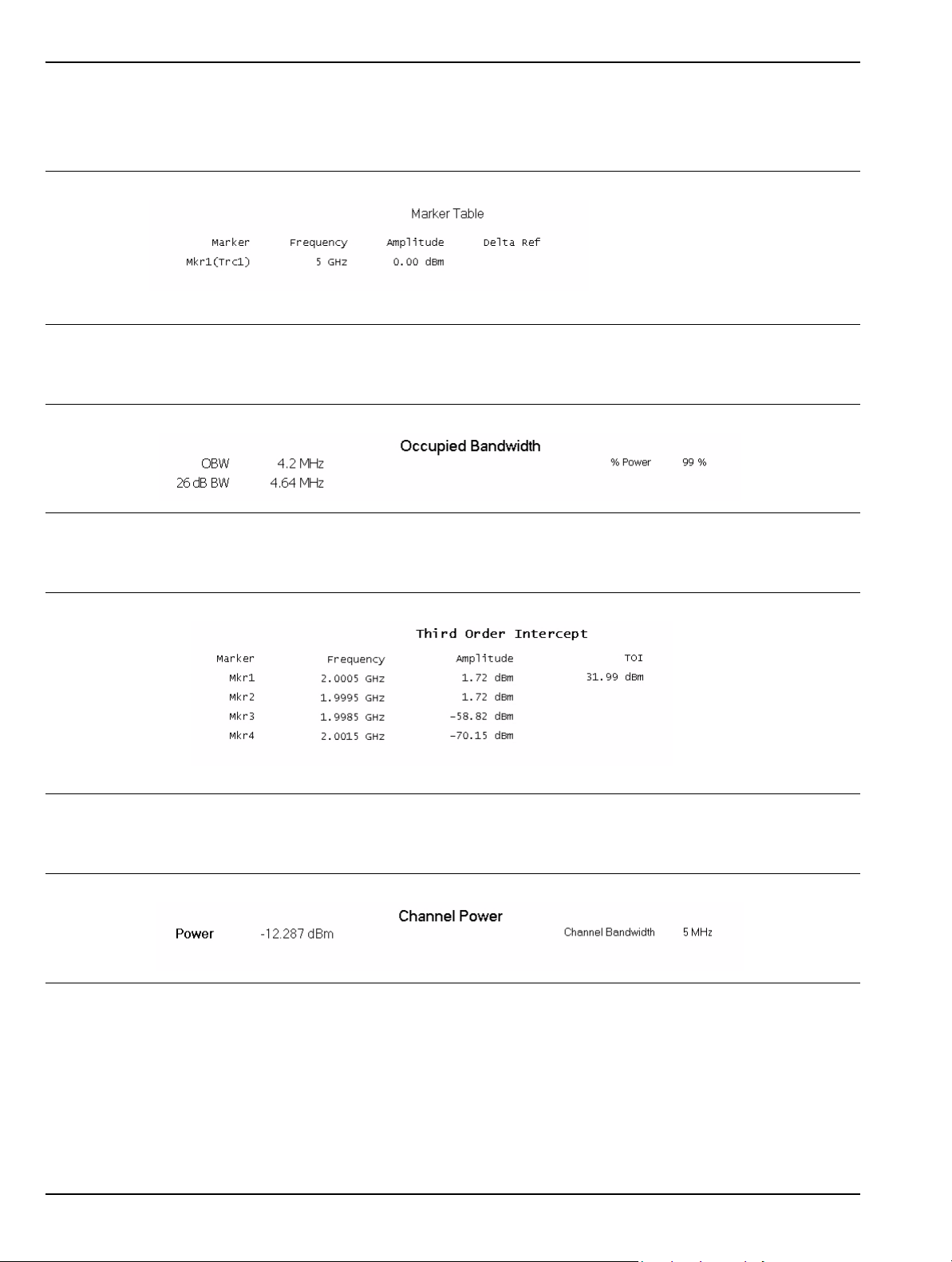

Third Order Intercept Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Occupied Bandwidth Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Channel Power Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

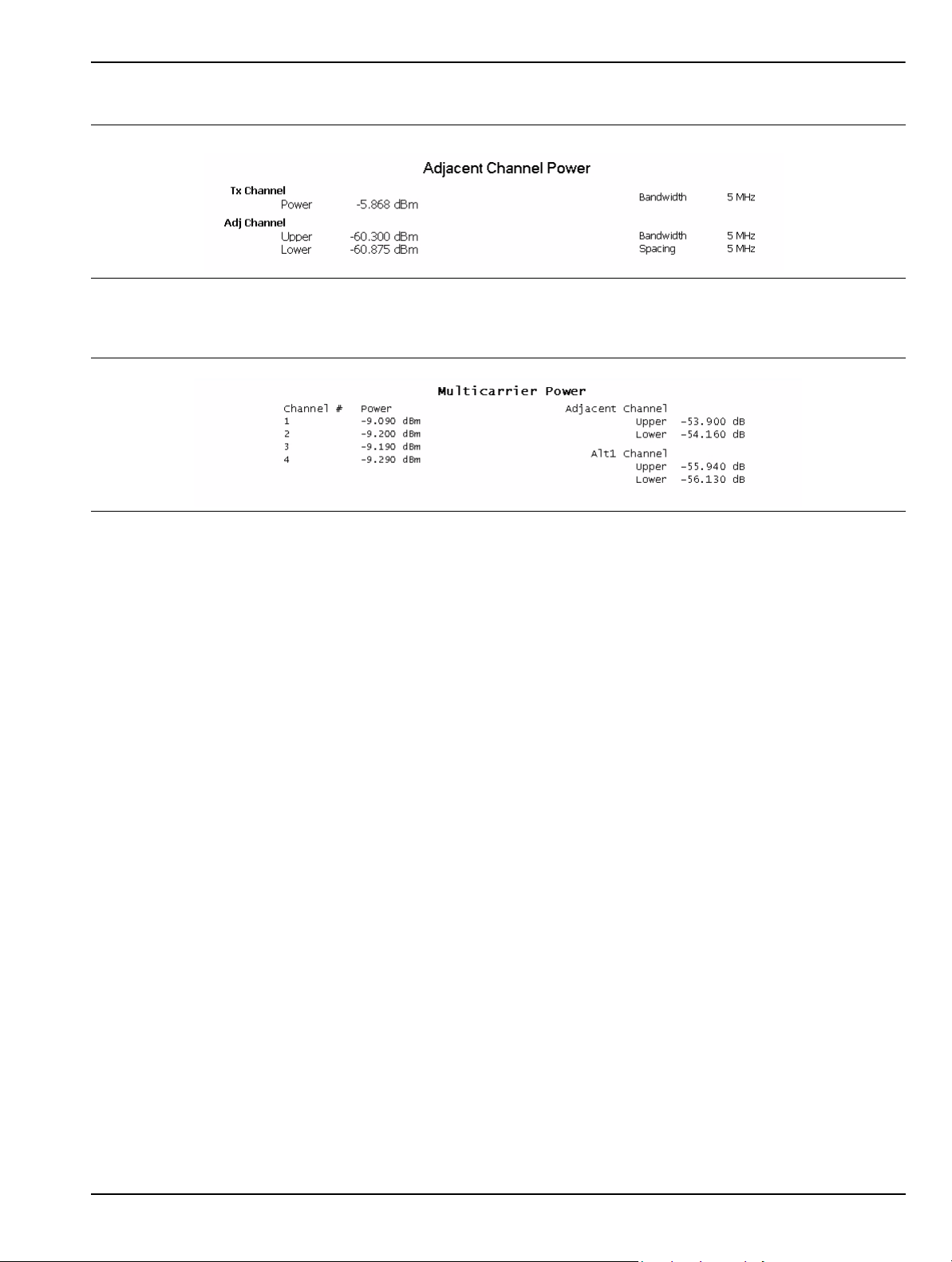

Adjacent Channel Power Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Multicarrier Channel Power Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

MS278XB OM v

Page 14

Table of Contents (Continued)

5-5 Modulation Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

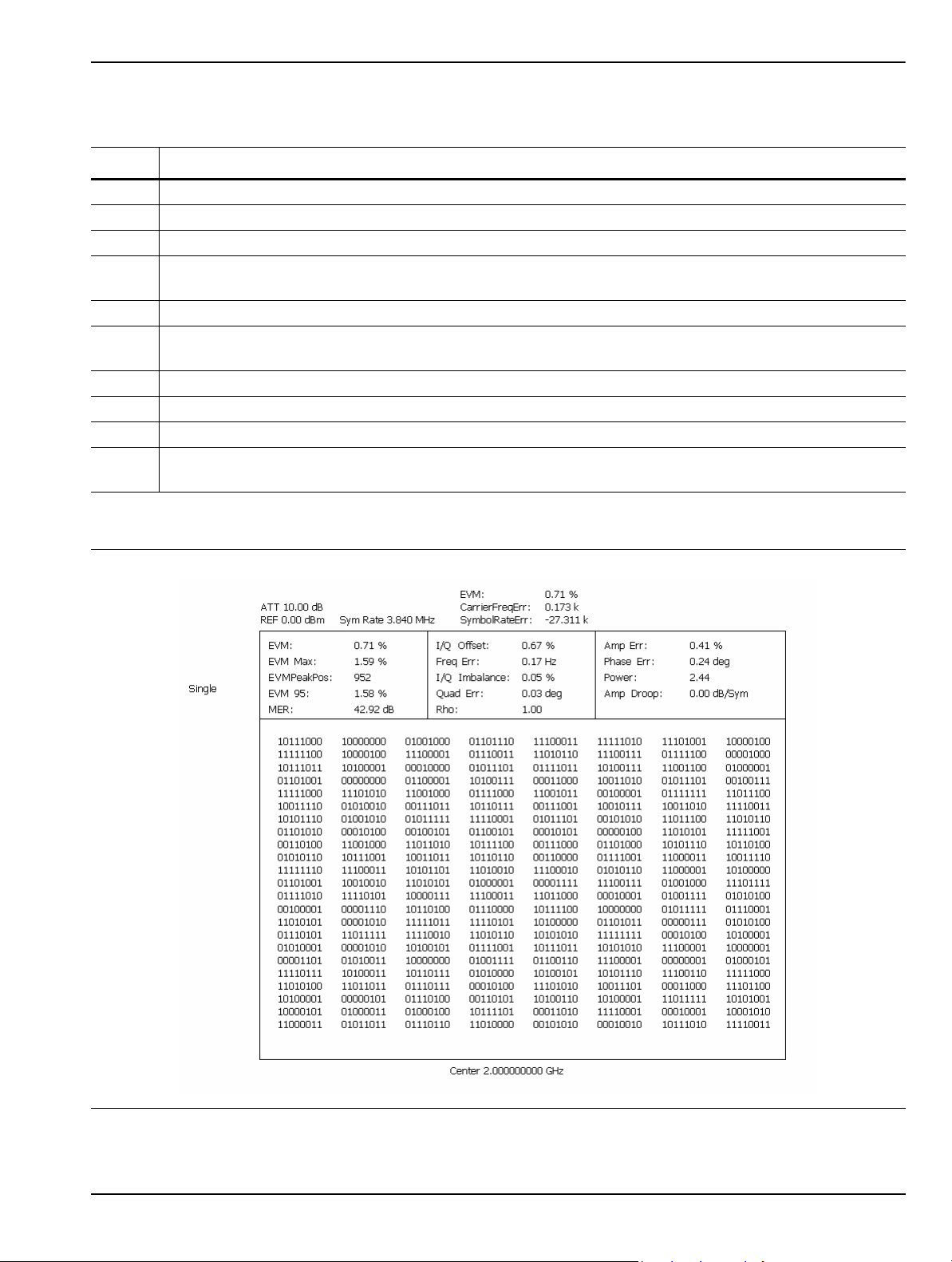

QPSK Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

QAM Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

WCDMA Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Code Domain Power Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Code Domain Error Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

QPSK Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

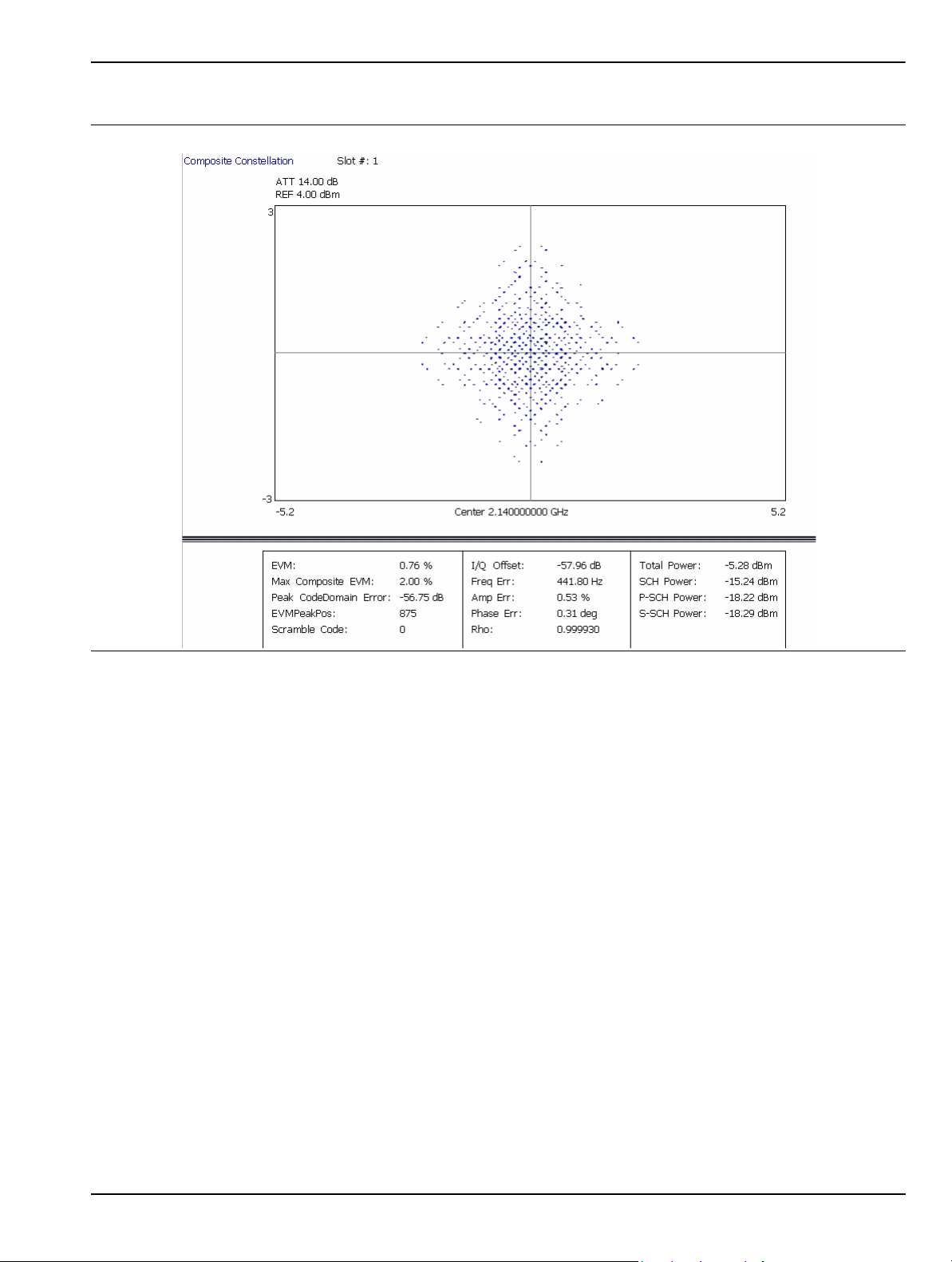

Composite Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

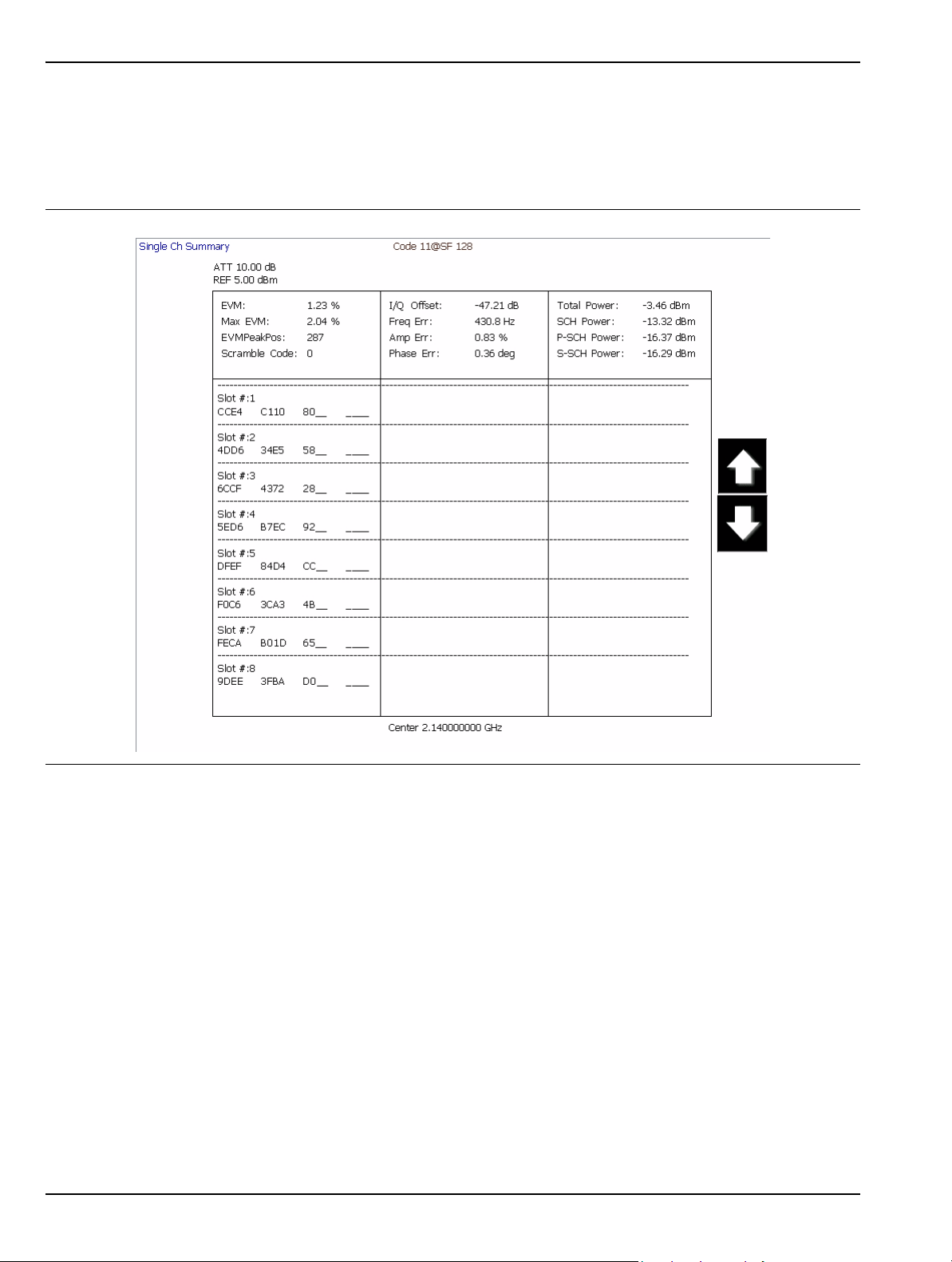

Single Code Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

Single Code with Compressed Mode Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

WCDMA Uplink Code Domain Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

WCDMA Uplink Code Domain Single Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

5-6 Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

Reference Oscillator Aging Rate (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-74

Frequency Readout Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

Frequency Span Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

Swept Resolution Bandwidth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-79

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-79

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-79

Single Sideband Phase Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-81

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-81

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-81

Average Noise Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-84

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-84

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-84

Frequency Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-87

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-87

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-87

Reference Level Switching Uncertainty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-89

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-89

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-89

Resolution Bandwidth (RBW) Switching Uncertainty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-91

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-91

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-91

Residual Spurious Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93

Input-related Spurious Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-95

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-95

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-95

vi MS278XB OM

Page 15

Table of Contents (Continued)

Chapter 6—Software Peripherals

6-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Signature–MathWorks Connectivity (Option 40 only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Signature MathWorks Connectivity Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Integrated MathWorks Computational Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Integrated MathWorks Computational Components–Flow of Events. . . . . . . . . . . . . . . 6-1

PreConditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Connecting to MATLAB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

MATLAB Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Advanced MATLAB Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-3 Microsoft Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Copying Graphical Screen Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Copying Screen Shots to Image Editors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Copying Screen Shots to Office Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Exporting Trace Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Importing the Trace Data to Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Importing the Trace Data to Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Chapter 7—Remote Operation

7-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2 Remote Desktop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Setting Up Your Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Enabling the Analyzer as the Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Installing the Client Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Starting a Remote Desktop Session. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Advanced Connection Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Logging Off and Ending a Remote Desktop Session. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Appendix A—Specifications

Subject Index

MS278XB OM vii

Page 16

Page 17

Chapter 1 — General Information

1-1 About this Manual

This manual provides general information, installation, and operating information for the model MS278XB

High Performance Spectrum/Vector Signal Analyzer (SPA/VSA), Signature™. Manual organization is shown

in the table of contents.

Introduction

This chapter provides general information about the MS278XB. It includes a general description of the

analyzer and information on its identification number, related manuals, options, and performance

specifications. This chapter also provides preventative maintenance and customer service information.

The MS278XB manual set is installed on the analyzer’s hard drive as an Adobe Acrobat™ (*.pdf) file. The file

can be viewed on the analyzer’s front panel display using Acrobat Reader™. The file is “linked” such that you

can choose a topic to view from the displayed “bookmark” list and “jump” to the page on which the topic resides.

The text can also be word-searched.

The MS2781B is also equipped with online Help called Signature Help System. The Help system is integrated

into the product software making it context sensitive to front panel actions as well as providing full context

search, advanced navigation controls, and custom bookmarking capabilities. The Signature Help System can

also run independent of the product and is included on the Signature Manuals CD-ROM.

Performance specifications can be found in Appendix A, Specifications, located at the back of the Signature

operation manual. Updates can be downloaded from the Documents area of the Anritsu Internet site:

http://www.us.anritsu.com

Associated Documentation

This manual is one of a three part series containing the following:

• MS278XB Operation Manual, Part Number: 10410-00273

• MS278XB Programming Manual, Part Number: 10410-00274

• MS278XB Maintenance Manual, Part Number: 10410-00275

Conventions

Throughout this manual, the terms MS278XB and analyzer will be used interchangeably to refer to the

instrument. The term DUT is used in place of device under test.

Path names may be used to represent the keystrokes and button presses for a desired action or procedure. The

path name generally begins with a front panel key, keyboard key, or main menu icon selection followed by

additional sub-menu selections, each separated by a vertical line ( | ). Front panel key names and menu

selections are presented in the manual as they are on the system, that is in initial caps, all uppercase letters,

or with symbols as appropriate.

Note: In cases where a sub-menu is automatically expanded by accessing the main menu, the path still shows

that sub-menu as part of the selection.

MS278XB OM 1-1

Page 18

Product Description General Information

1-2 Product Description

The Signature Signal Analyzer is a single instrument that integrates state-of-the-art spectrum, vector signal

and digital modulation analysis into one easy to use instrument. It incorporates the following capabilities:

• Highly accurate spectrum measurements covering the range of 100 Hz to 8 GHz in a single band

• Vector measurements of modulated signals up to 30 MHz bandwidth

• Modulation and signal quality measurements of cellular and WLAN signals at the press of a button

• Multiple sweep and detector modes available in a single multi-trace setup

• Easy to use, customizable Microsoft Windows based User Interface

• Custom waveform and signal analysis using on board direct data linking to MATLAB® and Simulink®

tools

• Control of external signal sources and other instruments via SCPI, IEEE488.2, and Web Services

• Remote Control via a Local Area Network or the Internet

• Ability to run user applications and device drivers on its embedded PC

The advanced design of the Anritsu Signature Signal Analyzer features the following innovations:

• RF/analog architecture optimized for maximum dynamic range, high accuracy, and operation to 8 GHz

in a single band

• Exclusive low conversion loss mixer technology

• Exclusive 2 dB per step impedance-matched input attenuator

• Advanced design digital phase-lock loop local oscillator technology for maximum stability and sweep

speed with lowest phase noise and spurious signals

• Upgradeable open architecture for lowest total cost of ownership

• Field replaceable, pre-calibrated functional modules

• Digital FPGA technology for maximum performance and ease of upgrade

• Industry standard, obsolescence-proof Compact PCI digital modules

• Improved reliability through an advanced, low ambient noise thermal management system

1-2 MS278XB OM

Page 19

General Information Product Description

RF/Analog Architecture

The RF/analog architecture of the Signature Signal Analyzer is designed to maximize performance over a wide

frequency and dynamic range. Signature’s basic RF/analog block diagram is shown in Figure 1-1, below:

Figure 1-1. Basic Signature RF/Analog Block Diagram

The input signal, from either the internal 50 MHz calibrator or the test port input, is routed through the input

attenuator and then to the first mixer where it is converted to the first IF frequency of 9.5 GHz. This allows the

entire range of 100 Hz to 8 GHz to be covered in a single band without the need for preselecting. The signal is

then down-converted in the second mixer to 1.1 GHz. The frequencies of both the first and second local

oscillators can be adjusted to avoid any possible spurious response. In the third mixer, the signal is converted

to 75 MHz. While the system’s pass bandwidth up to this point has been maintained at greater than 100 MHz,

the signal path is now routed to either a wideband 75 MHz IF section, used exclusively for vector signal

analysis, or a lower bandwidth 10.7 MHz IF section, used for spectrum analysis and low bandwidth signal

analysis. While there are prefilters in the RF/analog section, the task of shaping the IF bandwidth is left

mainly to the digital section, where advanced DSP technology can be used.

Digital Architecture

The digital architecture of the Signature Signal Analyzer is built around an industry-standard Compact PCI

based embedded PC. The PC section handles all control, data management, display, and user interface aspects

of the instrument’s operation. In addition to the embedded PC, two specialized modules play important roles in

the instrument’s operation:

• The Digital IF Module employs a state-of-the-art FPGA (Field Programmable Gate Array) to perform IF

bandwidth filtering, detection, and data formatting, as well as providing the heartbeat for the real-time

data acquisition circuitry.

• The optional 30 MHz Wideband IF Module employs an advanced design analog-to-digital conversion

circuit working in conjunction with an LSI based digital signal processing section to capture large

contiguous samples of wideband I/Q data for analysis.

These two modules pass data to the embedded PC for further processing, display, storage or transmission to

external devices.

MS278XB OM 1-3

Page 20

Product Description General Information

Software Architecture

The operating software of the Signature Signal Analyzer is based on the Microsoft® .Net platform and takes

full advantage of the Windows® XP Professional operating system. All of the user interface constructs are

based on the Windows model so that a new user who is familiar with Windows applications can learn to

operate the instrument very quickly.

The fact that the Signature’s main software is a Windows application also means that users can write their

own programs in languages such as Visual Basic to run on the embedded PC and customize the operation of

the instrument. Commercially available software, such as Microsoft Office and MATLAB from The

MathWorks, can also interact with the instrument’s programming and measurement data.

In order to maximize the responsiveness of the system, additional control programs run on dedicated

microcomputers in most of the system’s modules. These programs receive their instructions from the embedded

PC through an internal network, but can operate autonomously to provide high speed hardware real-time

control. This approach frees the instrument from the inherent response time limitations of the Windows-based

PC while improving flexibility and measurement speed.

When used as a standalone instrument, the 8 GHz analyzer can perform the following measurements:

• All typical spectrum analysis, including channel power, carrier to noise ratio, conformance to spectral

mask, peak signal frequency, and amplitude

• All typical vector signal measurements, such as constellation and vector plots, carrier leakage, I/Q

imbalance, and quadrature error

• Smart one-button measurements such as ACPR, signal bandwidth, EVM (error vector magnitude), and

BER (bit error rate)

When configured with one external source, the 8 GHz analyzer can perform the following network

measurements:

• Frequency Response

• Return Loss

• Group Delay

• 1 dB Compression

When configured with two external sources, the 8 GHz analyzer can perform the same set of measurements, as

well as perform the following network measurements:

• Conversion Loss

• Group Delay (frequency translating devices)

• Intermodulation Distortion

nd

• 2

Order Intercept

rd

• 3

Order Intercept

1-4 MS278XB OM

Page 21

General Information Product Description

External Interfaces

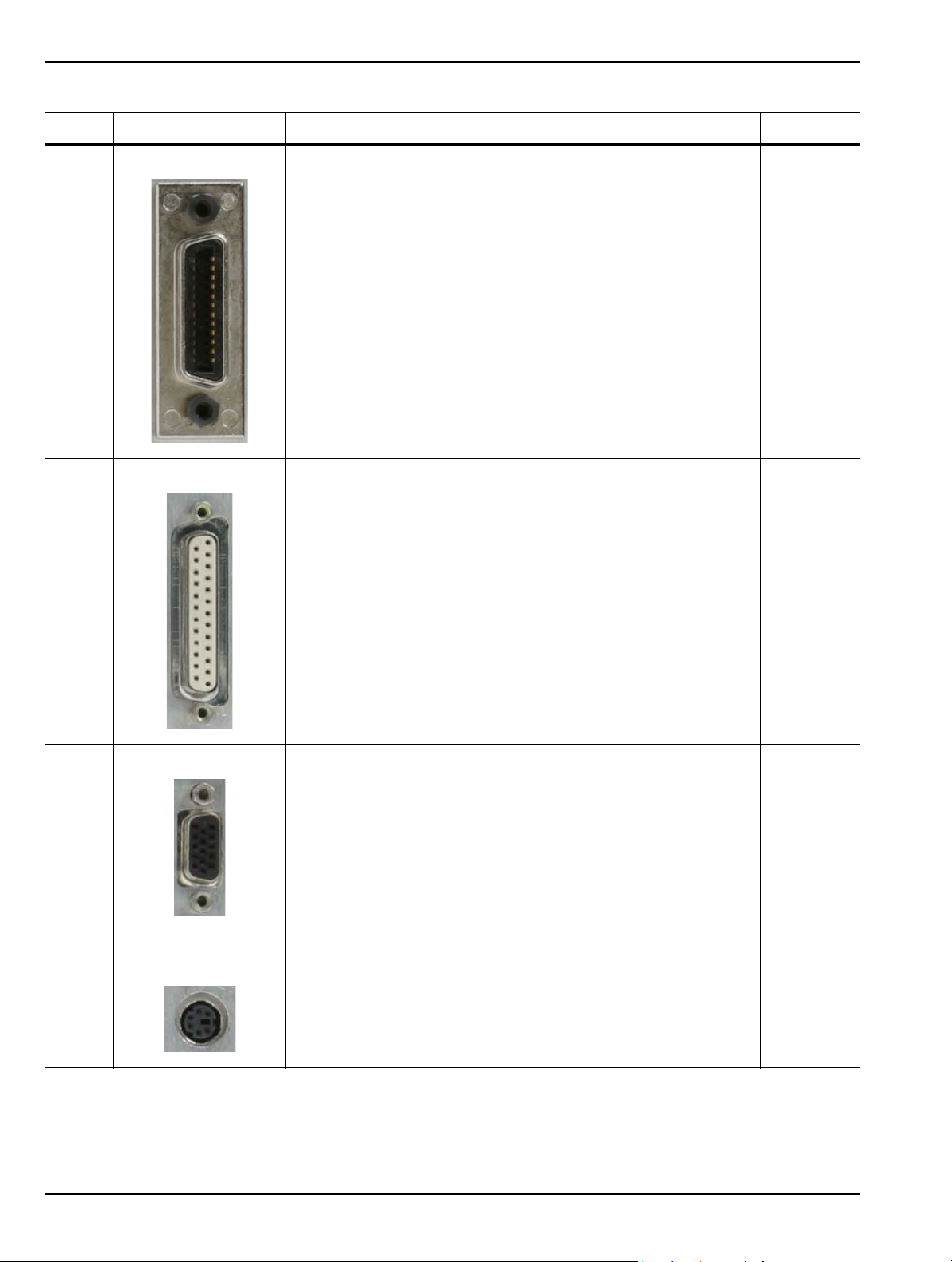

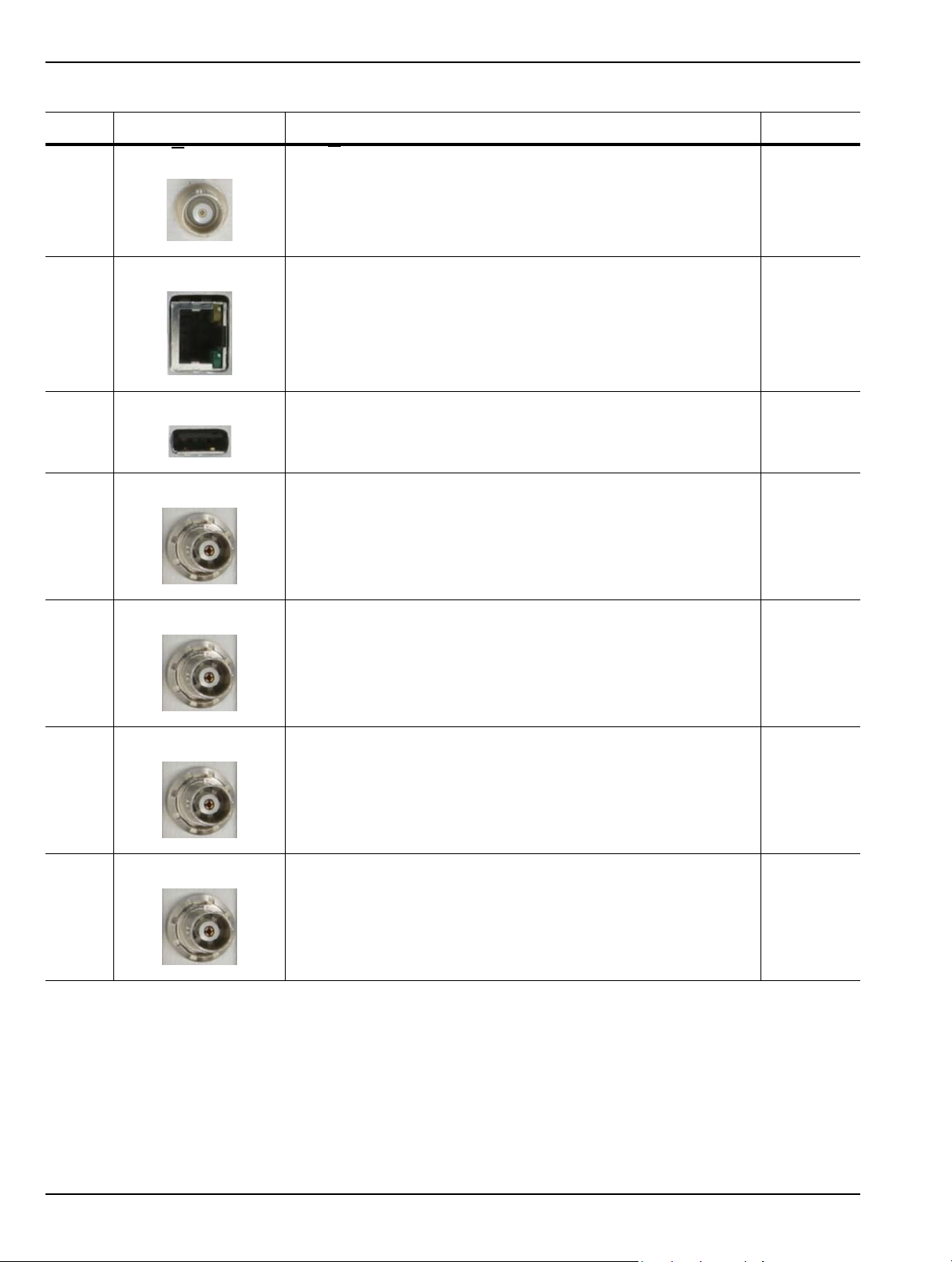

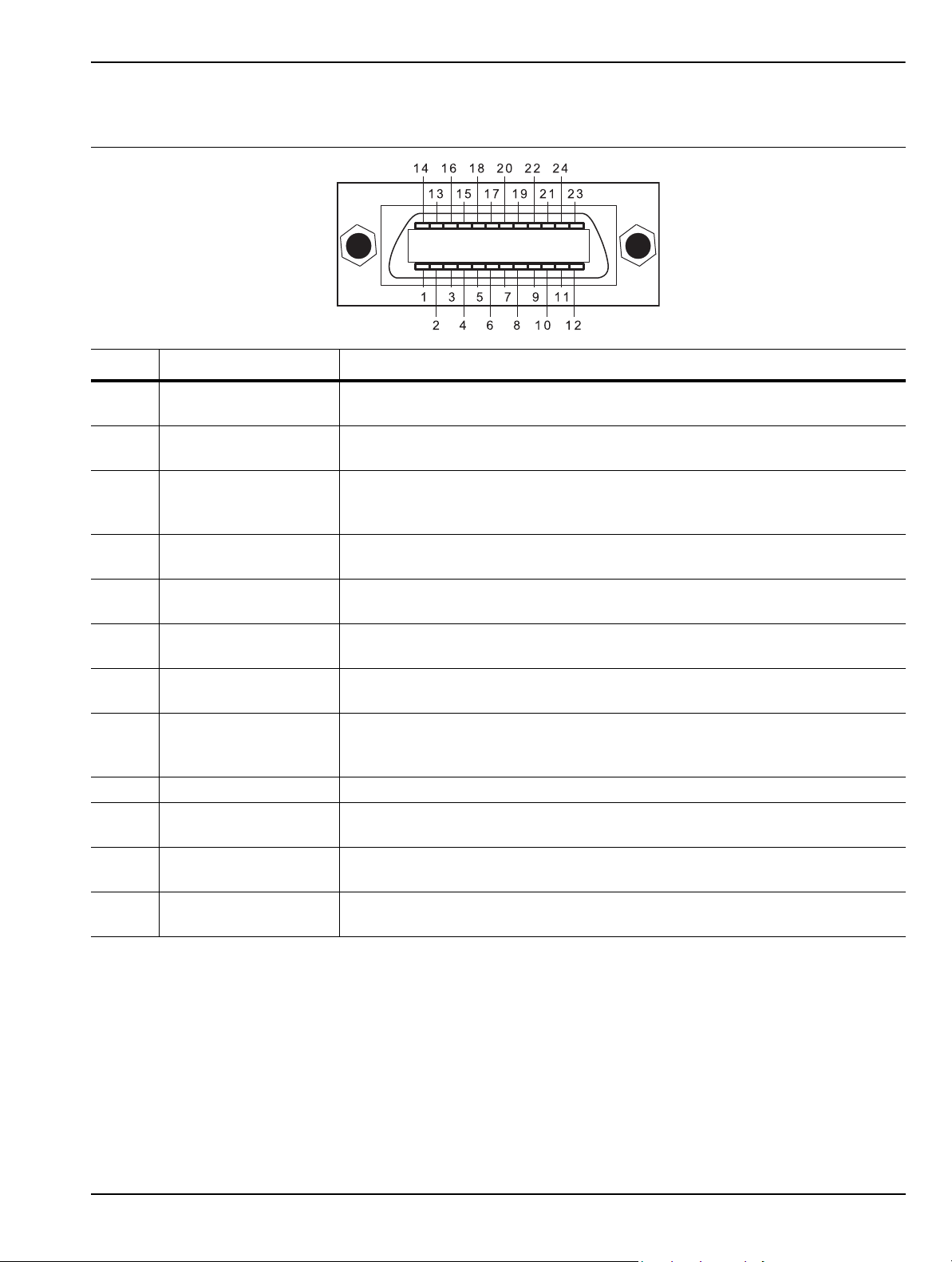

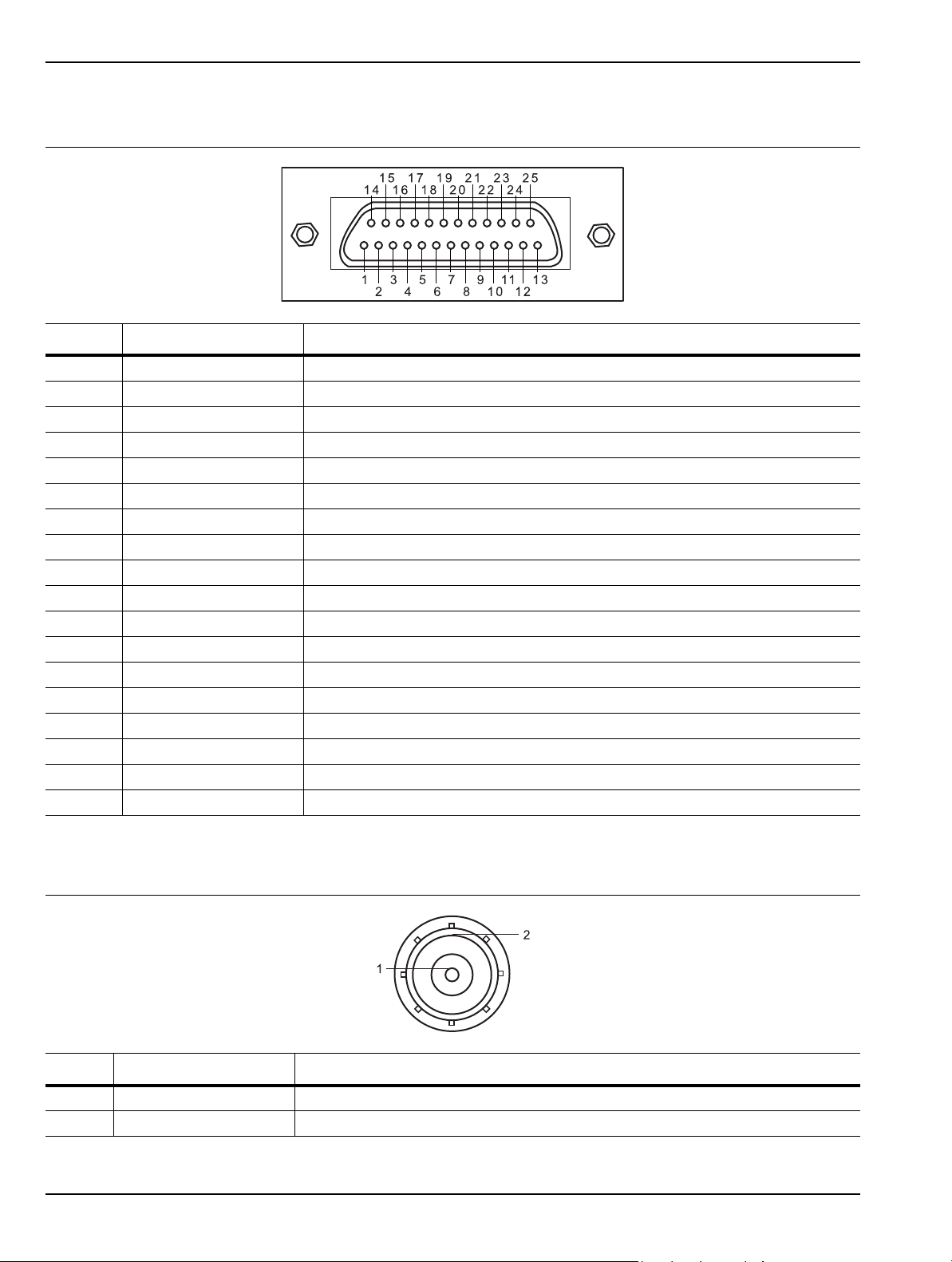

In addition to the visible front panel interfaces, the MS278XB provides the following device interfaces:

• IEEE488.2 GPIB: Connects the MS278XB to an external controller for remote programming. This

interface is detailed in the MS278XB Programming Manual, Part Number: 10410-00274.

•Printer: Provides a connection for printers with Parallel (Centronics) interfaces.

• XGA Output: Provides an Extended Graphics Array connector for an external monitor.

• PS/2 Keyboard and Mouse: Provides for the use of an external PS/2 keyboard and mouse.

• Ethernet: Provides network interface and control of the MS278XB. This interface is detailed in the

MS278XB Programming Manual, Part Number: 10410-00274.

•USB: Provides Type A USB ports on the front and rear panel to connect most USB compatible devices.

Identification Number

All Anritsu instruments are assigned a unique six-digit ID number, such as “040101.” This number is affixed to

a decal on the rear panel of each unit. In any correspondence with Anritsu customer service, please use this

number.

Options and Accessories

Table 1-1 and Table 1-2 lists Signature’s options and accessories with a brief description of each.

Table 1-1. Signature’s Available Options List

Option Number Option Description

Option 1 Rack Mount Adapter

Option 1A Slide Mount Adapter

Option 3 GPIB Interface

Option 22 30 MHz IF Bandwidth (includes baseband differential I & Q inputs)

Option 30 WCDMA Modulation Analysis

Option 38 QAM/PSK modulation analysis (requires Option 22)

Option 40 MATLAB Connectivity

Option 41 WiMAX Modulation Analysis

Option 52 Phase Noise Measurements

Option 98 Z540/ISO Guide 25 Calibration

Option 99 Premium Calibration

ES50MMD Extends Warranty to 5 Years

Table 1-2. Signature’s Optio nal Accessories

Part Number Optional Accessory Description

10410-00275 Signature MS278XB Maintenance Manual (Hard Copy)

1N50B Limiter/DC Block, N(m) to N(f), 50 W, 1 MHz to 3 GHz

1N50C Limiter, N(m) to N(f), 50 W, 10 MHz to 18 GHz

42N50A-30 30 dB Attenuator, 50W N(m) to N(f)

12N50-75B 75 W Matching Pad, DC to 3 GHz, 50 W, N(m) to 75 W N(f)

11N50B Power Divider, 1 MHz to 3 GHz, 50 W, N(f) Input, N(f) Output

2100-1 GPIB Cable, 1M

2100-2 GPIB Cable, 2M

70-28 Headset

MS278XB OM 1-5

Page 22

Preventive Maintenance General Information

1-3 Preventive Maintenance

Routine maintenance that can be performed by the operator consists of cleaning the data display, protecting

the operating system, and replacing a defective line fuse.

Cleaning the Touch Screen

The touch screen is protected by a plastic display filter. To clean the display filter, dampen a soft cloth with a

mild soap and water solution, or a commercial window cleaner. Do not use abrasive cleaners, tissues, or paper

towels that can scratch the plastic surface. Gently wipe the display filter to clean.

Operating System Integrity

The Microsoft Windows XP operating system is configured for optimum signal analysis performance when it

leaves the factory. To maintain the system’s operating integrity, follow proper Windows shutdown procedures

and do NOT modify the operating system settings or registry, hard drive partitions, or Anritsu user accounts.

Antivirus Protection

Signature is compatible with McAfee® VirusScan® Enterprise version 8.0.0. Signature has also been

tested with most common antivirus software, but stability is not guaranteed with all antivirus software.

Anritsu recommends that antivirus software be installed when the instrument is connected to a

network/Internet. The user assumes the responsibility to provide antivirus software as this is not

supplied with the instrument.

Windows Updates

Anritsu tests Signature with the latest Microsoft security updates as they become available; however,

not all Microsoft updates are compatible with Signature and may affect the performance of the analyzer,

if installed. Before connecting Signature to the Internet, consult Anritsu customer service for procedures

on how to safeguard the instrument from undesired conditions that could result from Windows

vulnerabilities.

1-6 MS278XB OM

Page 23

General Information Preventive Maintenance

Operating System Backup and Recovery

Signature is configured with the Norton® Ghost® backup and recovery system. This system can be accessed

from the desktop Start menu or by double clicking the Ghost icon in the system tray.

You can configure Ghost to make system backups or recover previous backups through its backup and recovery

dialogs below:

Figure 1-2. Norton Ghost Backup and Recovery Dialog

Ghost backups are stored to a recovery partition (D:) on the Signature hard drive.

In the event that the Signature operating system becomes corrupted or inoperable, the instrument is shipped

with a System Restore DVD that allows a complete system restoration. To restore the system to the original

factory configuration, you will need to boot the instrument from the Norton Ghost CD and have the Signature

System Restore DVD.

Caution: Restoring the system software will remove all user data and programs from the instrument hard drive.

The instrument will be configured exactly as it was when it was shipped from the factory, including the

original option configuration. Before starting the system recovery procedure, back up all user data and

ensure that installation files for any additional software or instrument options is available for

reinstallation.

The Norton Ghost CD will load a menu and prompt you with installation instructions. Follow the on-screen

instructions to reinstall the Signature operating system.

Note: The recovery DVD is printed with the serial number of the instrument and the date when it was made.

Ensure that the proper recovery DVD is used when restoring the Signature system.

For more information about using Norton Ghost, refer to its online Help, which is accessed from the upper

right corner of the dialogs, or to the Norton Ghost user guide, which is found on the Norton Ghost CD shipped

with the instrument.

MS278XB OM 1-7

Page 24

Preventive Maintenance General Information

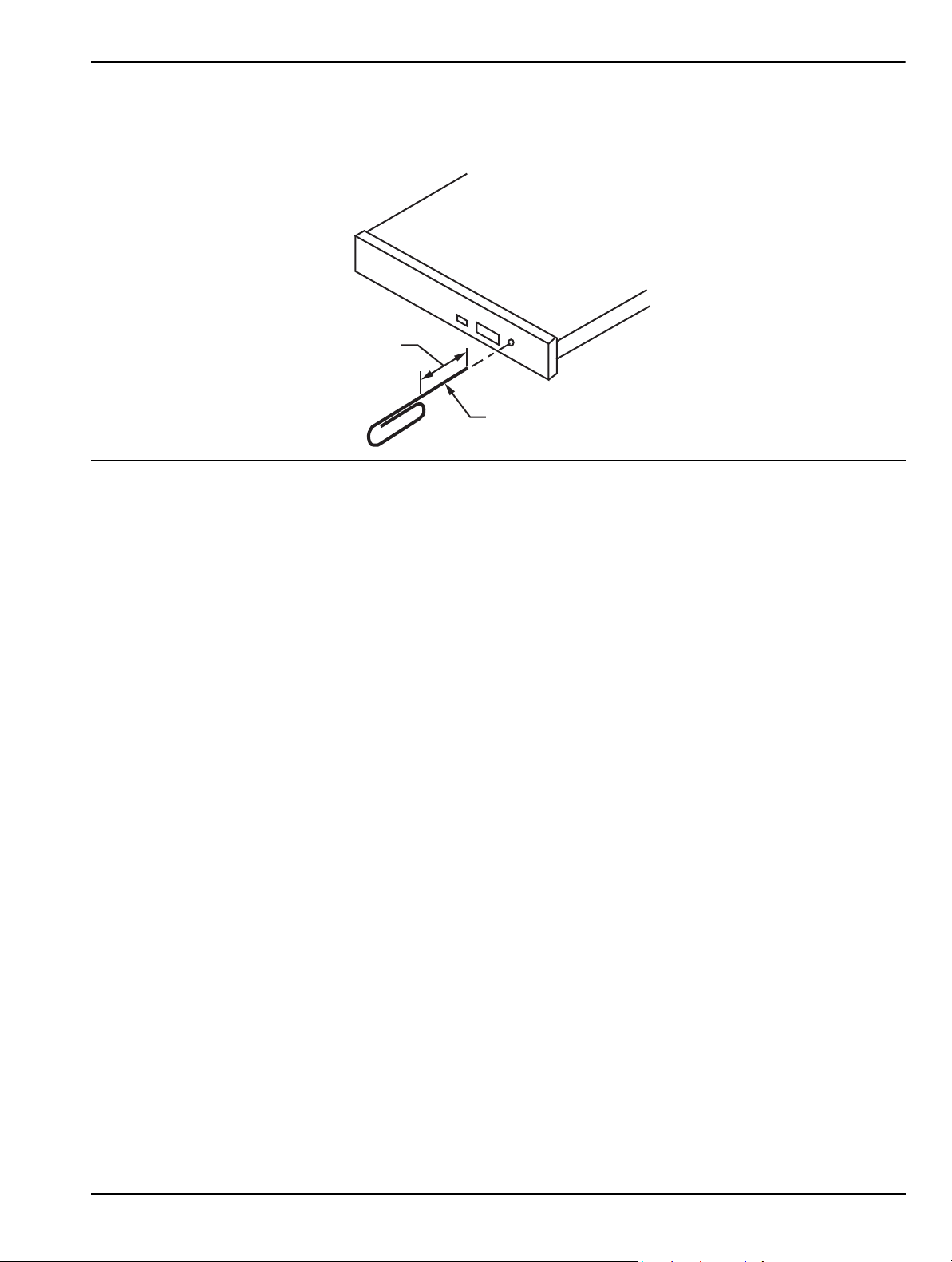

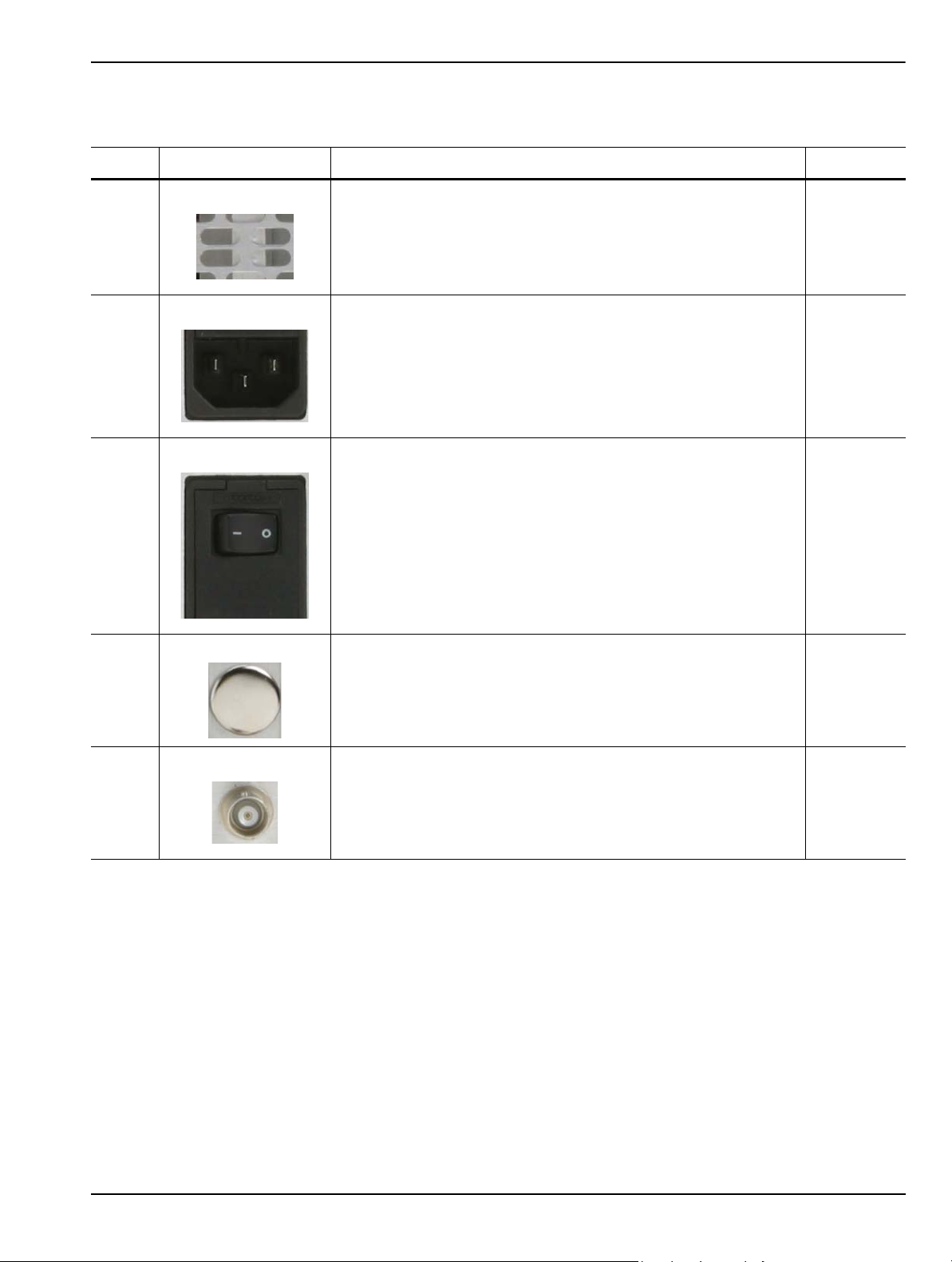

Replacing the Line Fuses

The line fuses used in the MS278XB are 6.3A, type T fuses. The line fuse values are printed on the rear panel

next to the power connector. Always use a new fuse of the type and rating specified by the fuse markings on the

rear panel of the instrument. To replace the line fuses, follow the procedure below.

Danger: Before changi ng the fuse, always remove the power cord from the power outlet. Th ere is the risk of

receiving a fatal electric shock if the fuse is replaced with the power cord connected.

Refer to Figure 1-3, below, during the following steps:

1. Set the MS278XB to standby mode using the power button and disconnect the power cord from the rear

panel power receptacle.

2. Using a small flat-blade screwdriver, carefully pry under the tab next to the rear panel power receptacle

to open the fuse block cover and gain access to the fuse holder.

3. Slide out the fuse holder.

4. Replace the fuse in the fuse holder.

5. Install the fuse holder back into the rear panel fuse block.

6. Close the cover to secure the fuse holder in place. The cover will close with an audible snap.

Figure 1-3. Replacing the Rear Panel Fuse

7. Reconnect the analyzer to the power source and set the MS278XB to Operate using the front panel power

button.

Internal Battery

The MS278XB has a Lithium battery installed on the CPU assembly. Battery replacement should be referred

to an authorized Anritsu service center.

1-8 MS278XB OM

Page 25

Chapter 2 — Preparation for Use

2-1 Introduction

This chapter provides information for the initial inspection, preparation for use, and installation instructions

for the MS278XB signal analyzer. Information is also included for interfacing the MS278XB through:

• IEEE-488.2 General Purpose Interface Bus

• Ethernet Port

• External Devices

Detailed programming information can be found in the MS278XB programming manual (part number: 10410-

00274) that came with the analyzer on CD or in the online Help system.

2-2 Operating Environment

The MS278XB operational environmental specifications are listed below:

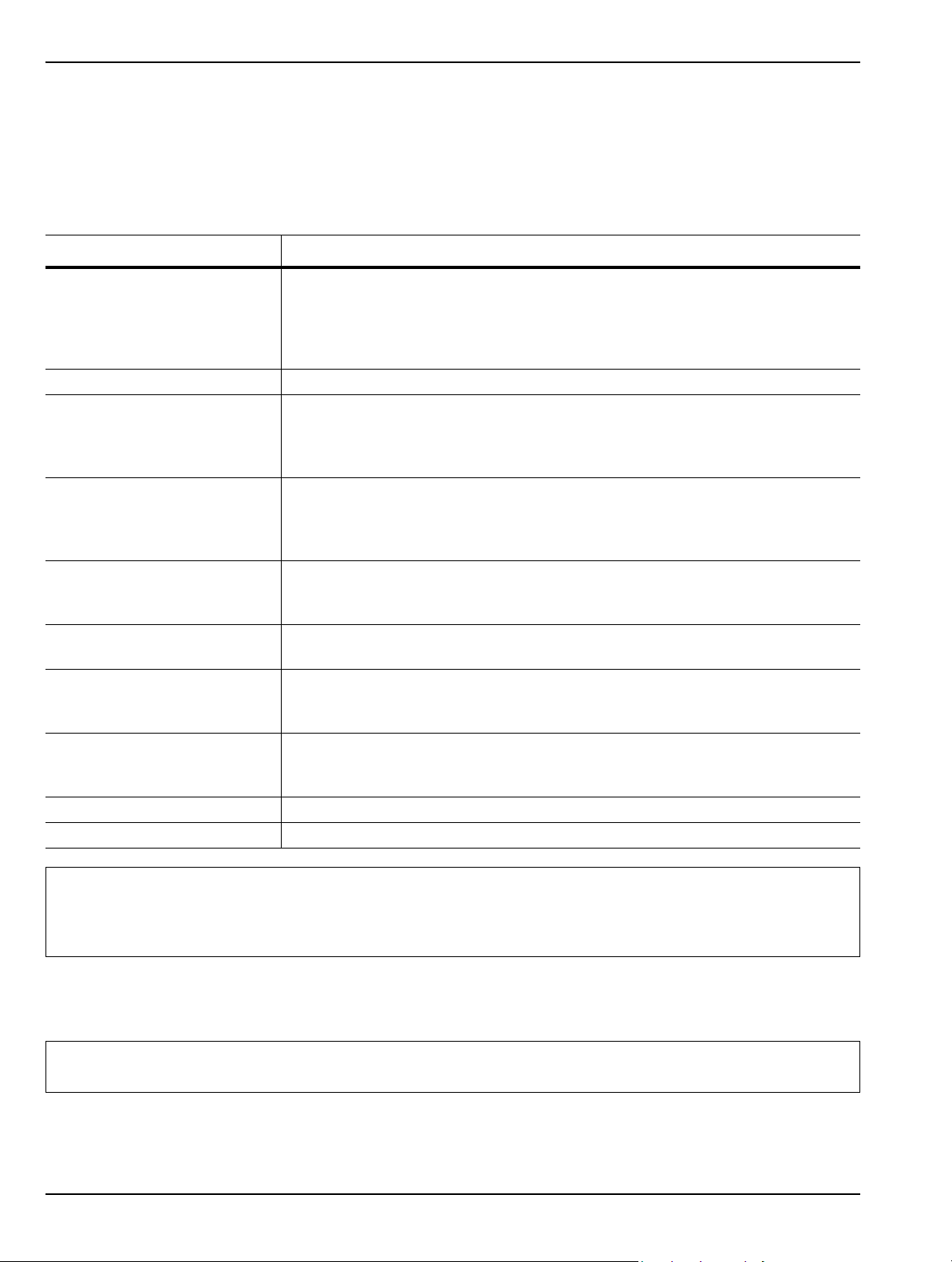

Table 2-1. MS278XB Operational Environmental Specifications

Operating Temperature Range: 0 to +50 degrees Celsius (per MIL-PRF-28800F)

Relative Humidity: 5% to 95% (per MIL-PRF-28800F)

Altitude: 4,600 meters, 43.9 cm Hg

Vibration: Sinusoidal 5 Hz to 55 Hz on 3 axes

2-3 Power Requirements

The MS278XB is equipped with automatic line-power sensing and will operate with any of the following line

voltages: 100V, 120V, 220V, 240V (+5%, –10%), 48–63 Hz, 350 VA. The MS278XB is intended for Installation

Category (Over Voltage Category) II.

Warning: When supplying power to this equipment, connect the accessory 3-

pin power cord to a 3-pin grounded power outlet. If a grounded 3-pin

outlet is not available, use a conversion adapter and ground the

green wire, or connect the frame ground on the rear panel of the

equipment to ground. If power is supplied without grounding the

equipment, there is a risk of receiving a severe or fatal electric shock.

MS278XB OM 2-1

Page 26

Unpacking the Product Preparation for Use

2-4 Unpacking the Product

Initial Inspection

Inspect the shipping container for damage. If the container or cushioning material is damaged, retain until the

contents of the shipment have been checked against the packing list and the instrument has been checked for

mechanical and electrical operation.

If the MS278XB is damaged mechanically, notify your local sales representative or Anritsu Customer Service.

If either the shipping container is damaged or the cushioning material shows signs of stress, notify the carrier

as well as Anritsu. Keep the shipping materials for the carrier’s inspection.

Warning: Use two or more people to lift and move this equipment, or use an

equipment cart. There is a risk of back injury if this equipment is lifted

by one person.

After removing the instrument from the shipping container, inspect the contents against the list found in the

following section.

Package Contents

Signature comes with a standard set of accessories. In addition to the basic instrument, Table 2-1 lists the

standard set of items that are commonly shipped with the base model.

Table 2-2. Standard Shipment Contents

Part Number Description

MS278XB High Performance Signature SPA/VSA

800-XXX Power Cord

60004 Restore Software DVD-ROM

2000-1389 USB Optical Mouse

970-635 Blank CD R/W Disk

631-73 Spare Fuse

Standard Document Set (on CD-ROM and installed in the instrument)

10920-00048 Manuals CD-ROM

10410-00273 MS278XB Operation Manual

10410-00274 MS278XB Programming Manual

10450-00002 Signature Online Help System

2-2 MS278XB OM

Page 27

Preparation for Use Assembly (optional)

2-5 Assembly (optional)

Rack Mount Installation

Instruments that are ordered from the factory with Option 1, Rack Mount, should have the rack mount preinstalled. Option 1 may be ordered at a later time. To install the Option 1 rack mount kit, refer to the

procedure below:

1. Disconnect the line cord and any other attachments from the instrument.

2. Carefully place the instrument on a secure and stable work surface.

3. Using a Phillips screwdriver, remove the two front panel handles and the four feet at the rear (see

Figure 2-1). Save the screws for later use.

Note: The green-headed screws have a metric thread and must be reused in the same locations from which they

were removed. Replacing these screws with different thread, such as SAE threaded screws, will damage

the instrument chassis.

Figure 2-1. Instrument Handles and Feet Removal Diagram

MS278XB OM 2-3

Page 28

Assembly (optional) Preparation for Use

4. Install the rack mount slides over the threaded studs on the rack mount bracket and handle fixtures as

shown in Figure 2-2, below, and secure them in place with the two fastening nuts.

(Push the button at 1 to release and extend the slide.)

Figure 2-2. Rack Mount Slide Assembly Diagram

5. Install the two rack mount bracket and slide assemblies onto the instrument sides using the greenheaded screws removed earlier (Figure 2-3).

Figure 2-3. Rack Mount Assembly Installation Diagram

This completes the installation of the slide assembly.

2-4 MS278XB OM

Page 29

Preparation for Use Power On Procedure

2-6 Power On Procedure

No initial setup is required. After unpacking, the MS278XB is ready for use; however, it is strongly

recommended that you connect an external keyboard and mouse to facilitate ease of use of the Windows

operating system, particularly when installing third-party software (refer to Section 2-4).

The MS278XB is equipped with automatic line-power sensing and will operate with any of the following line

voltages: 100V, 120V, 220V, 240V (+5%, –10%), 48–63 Hz, 350 VA. The MS278XB is intended for Installation

Category (Over Voltage Category) II.

Warning: When supplying power to this equipment, connect the accessory 3-

pin power cord to a 3-pin grounded power outlet. If a grounded 3-pin

outlet is not available, use a conversion adapter and ground the

green wire, or connect the frame ground on the rear panel of the

equipment to ground. If power is supplied without grounding the

equipment, there is a risk of receiving a severe or fatal electric shock.

After the above warning has been addressed, plug the instrument into an adequate mains supply and set the

instrument to Operate by pressing the Standby/Operate front panel key.

Instrument Startup

Signature requires at least two minutes to initially power up, load the system software, and perform a series of

internal calibrations. During this time, informational screens will be displayed.

After the instrument has completed its startup, the Signature application will be running. To access the PC

functions and minimize the Signature application, access the View drop-down menu and select Desktop.

During power-up, the system goes into a “startup” state in which a self-test checks all of the sub-systems for

proper operation; the firmware is also downloaded into the various peripheral devices. During this time, an

informational splash screen is shown as illustrated below:

Figure 2-4. Signature Startup Splash Screen

Warm-up Time

Signature requires 30 minutes warm-up time to meet operating specifications.

MS278XB OM 2-5

Page 30

Configuration Preparation for Use

Instrument Shutdown

To shut down the instrument press and hold the front panel Standby/Operate key for longer than one second.

Windows will begin the shutdown process and automatically close open applications. It is not advised to turn

the power off at the rear panel or pull the power cord until Windows has been properly shut down.

Note: After turning off the instrument, you must wait at least 10 to 15 seconds before turning the instrument back

on again. This delay is required to allow the internal power supplies to discharge and to assure a reliable

cold start.

2-7 Configuration

This section describes the various aspects of the instrument configurations both inside and outside of the main

instrument software. The following system configurations are described below:

• BIOS Configuration

• Windows XP Configuration

• Analyzer Configuration

• Main Menu Tool Bar Configuration

BIOS Configuration

This section describes a few requirements of the BIOS setup.

Caution: It is strongly recommended that you do not enter or change the BIOS settings. The BIOS is configured

at the factory for optimum system performance. Incorrect BIOS settings can render the system

unusable.

Before entering the BIOS, you mu st install a PS2 keyboard. USB de vices are not sup ported outside of

the Windows operating environment.

The BIOS setup utility can be accessed by pressing F2 during the initial power up state when the Anritsu blue

screen appears. If the system proceeds to the Windows XP startup screen, the BIOS will not be entered and the

system will require a restart before BIOS entry can be attempted.

Note: After turning off the instrument, you must wait at least 10 to 15 seconds before turning the instrument back

on again. This delay is required to allow the internal power supplies to discharge and to assure a reliable

cold start.

Once the BIOS setup utility is entered, changes can be made in the usual manner. USB BIOS Legacy

Support must remain disabled and the USB Host Controller must remain enabled. Failure to preserve

these setting may result in display malfunction.

Pressing F3 will load the BIOS Setup Defaults. Pressing F4 will save the current settings (including any

changes that were made) to BIOS and exit the BIOS setup utility.

2-6 MS278XB OM

Page 31

Preparation for Use Configuration

Windows XP Configuration

This section describes the various aspects of the instrument outside of the main instrument software

(Signature application). It specifically addresses the various configurations and properties of the “open”

Windows XP environment that are set at the Factory.

Caution: Changing some of the default Windows XP settings may cause a loss of instr ument control or undesired

instrument behavior. Changing the Windows Regional and Language Options settings may cause

unstable front panel operation. These setting s must be maintained as English (United States) as is set

at the factory by default.

Several of the Windows XP settings (primarily Desktop settings, Folder options, and Task Bar settings) can be

saved and recalled using the File and Settings Transfer Wizard in Windows XP (“migwiz.exe” accessed from

the command line).

Note: The Quick Launch properties and Power Savings settings do not get saved using the “migwiz.exe” tool.

User Installed Applications and Data

If Signature requires service or calibration, the system may be returned to factory specifications and

reimaged with a standard software configuration. User installed applications and data may be lost and

unable to be retrieved. It is advised that user data be backed up or copied and retained by the user.

Applications will need to be reinstalled from their original installation disks. A complete system restore

from a previous user backup is not advised after service or calibration as this will result in the new

calibrations being overwritten, thus voiding the calibration accuracy.

Desktop Properties

Background—Wallpaper set to None.

Screen Saver—Set to None.

Fonts—Size set to Large Fonts and the font properties for the Menu category set to Tahoma 14

with a size of 30.

Power Savings—In the “Home/Office Desk Power Scheme” group, the “Turn Off monitor” setting

should be set to “Never.”

User Accounts

There is one User Account set up by default:

SignatureUser—This account is password protected (the password is “2780”). A password is necessary

for the Remote Desktop feature to work. This account is the default account and is set to Auto Logon.

Directory Structure

The following Directory Structure is used for installation of Signature related programs, files, etc.:

• C:\Signature: Root Directory

• C:\Signature\SignatureHelpSystem: Contains Help Files, Application Notes, Manuals,

Examples, Data Sheets, etc.

• C:\Signature\Bin: Contains Instrument Binary Files

• C:\Signature\Dependencies: Contains Calibration Data, Initialization Files, etc.

• C:\Signature\Setup: Contains Instrument Setup Files

• C:\Signature\External Applications: Contains Executable Files for

Option 41 (WiMAX Modulation Analysis) and Option 52 (Phase Noise Measurements)

MS278XB OM 2-7

Page 32

Configuration Preparation for Use

Security Settings

The following security related settings are configured in the instrument:

• Internet Explorer Security Settings set to High

• Firewall set to On

• Encryption on File System set to Off

• Passwords are Enabled on all User Accounts

Remote Access

GPIB

The default GPIB properties that are set in the factory are:

• GPIB Address 1

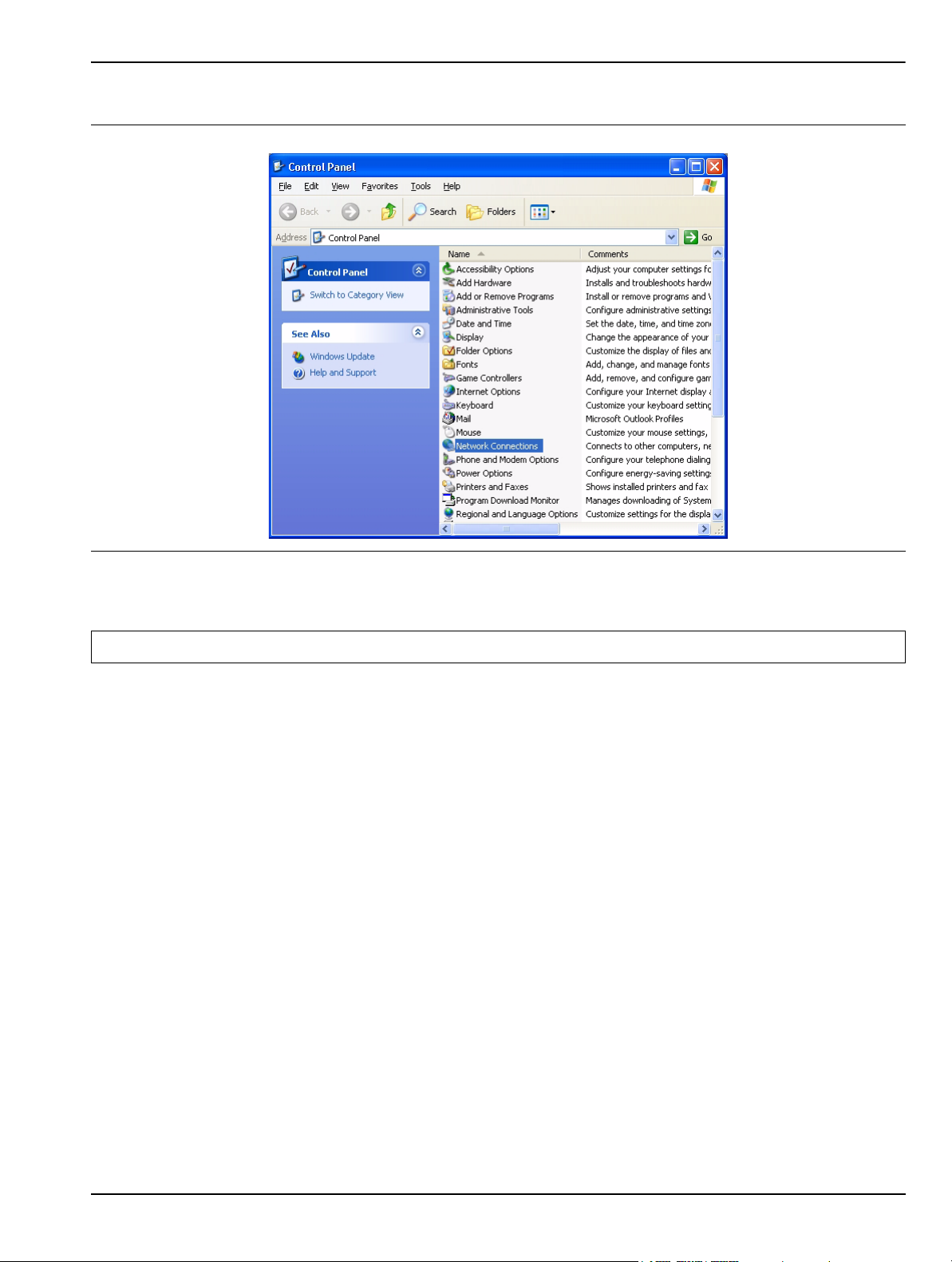

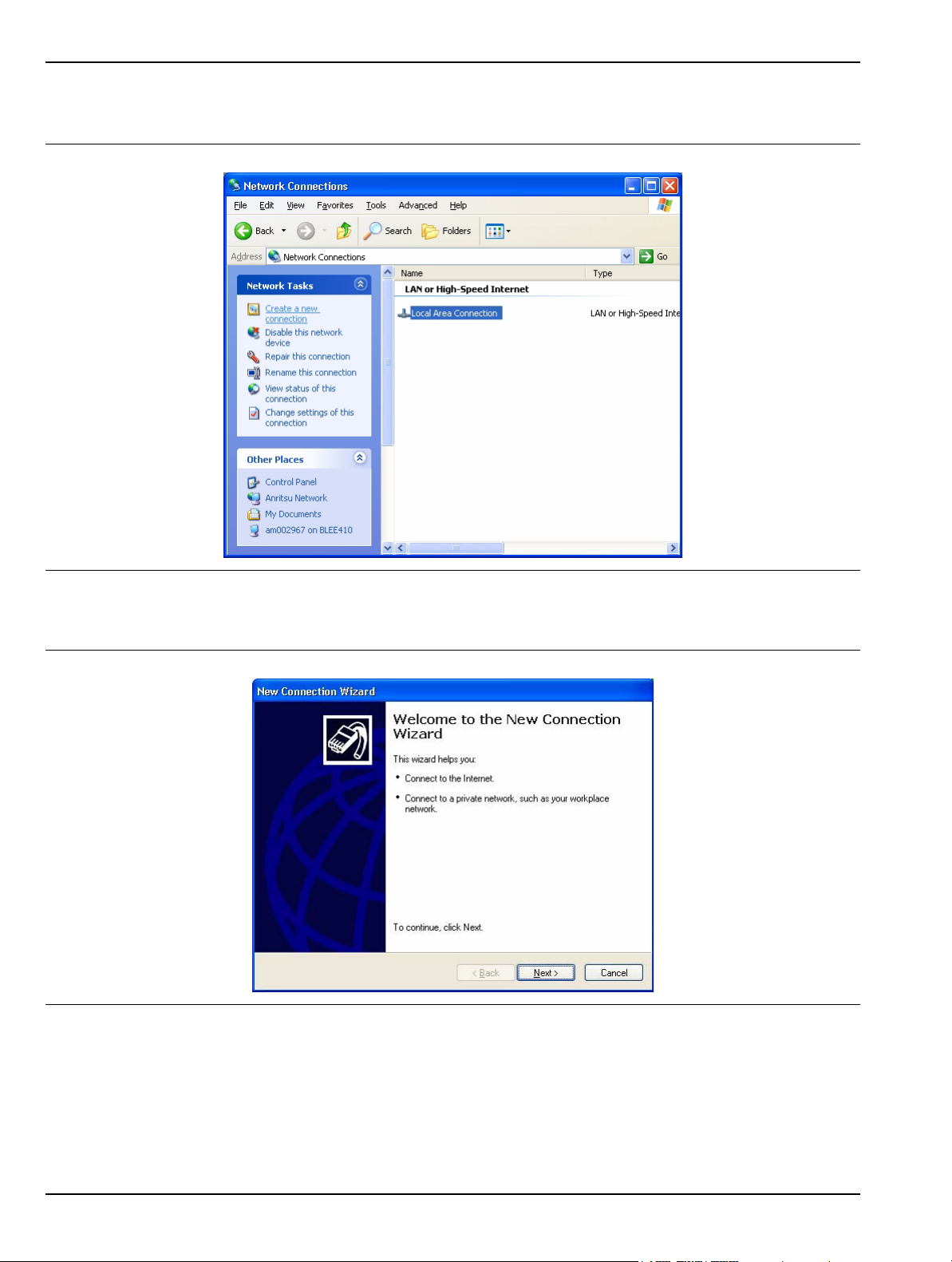

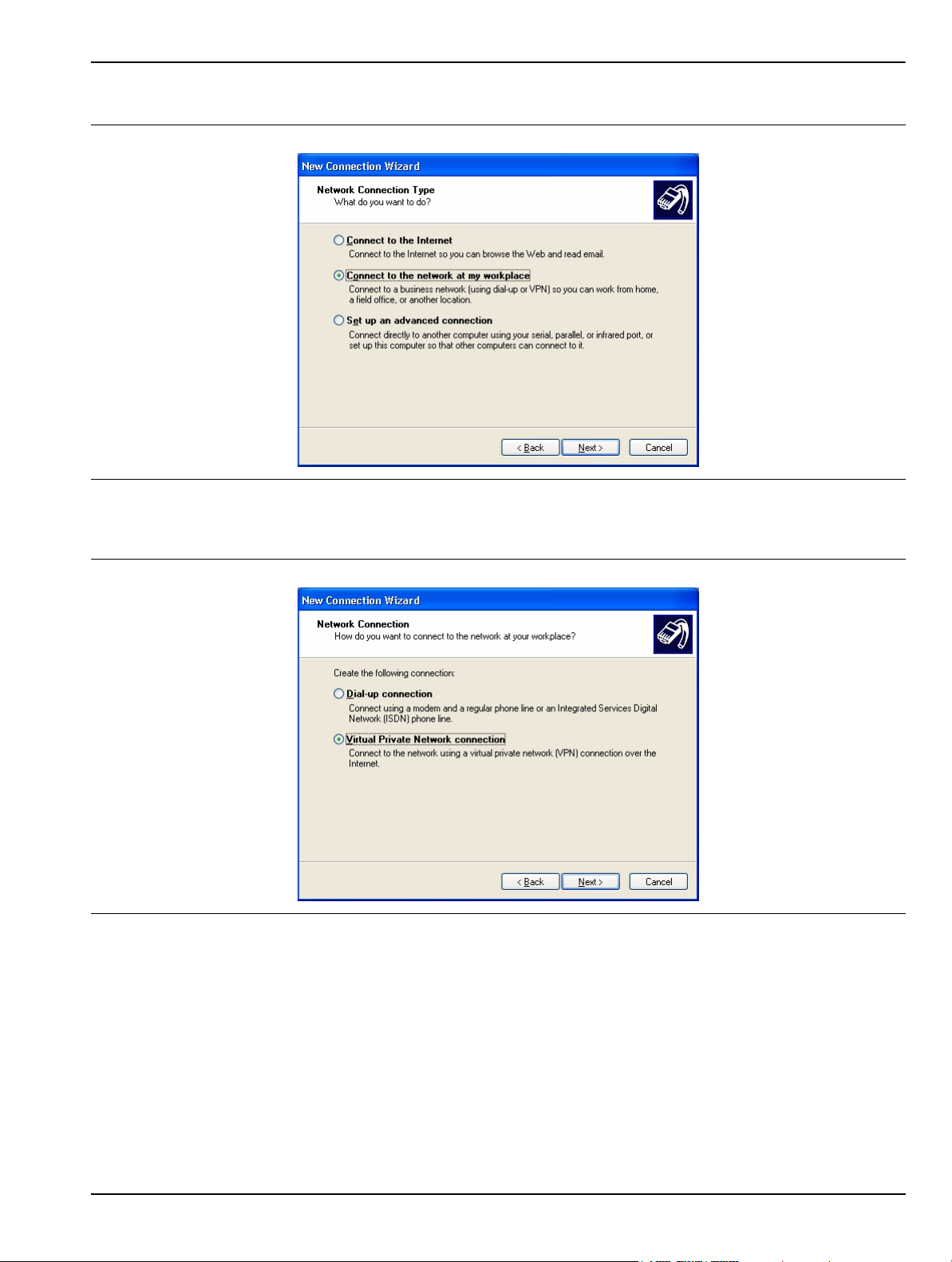

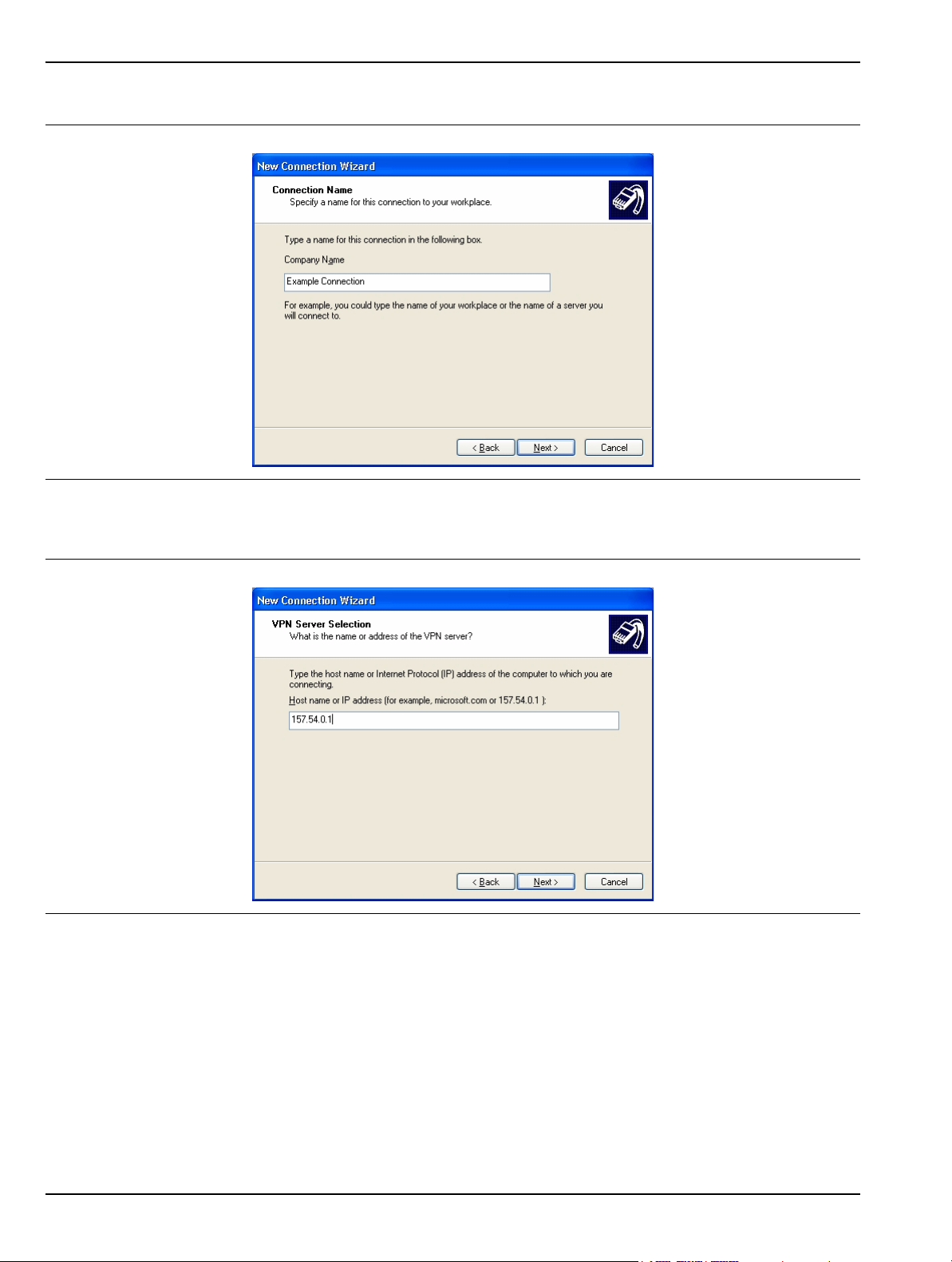

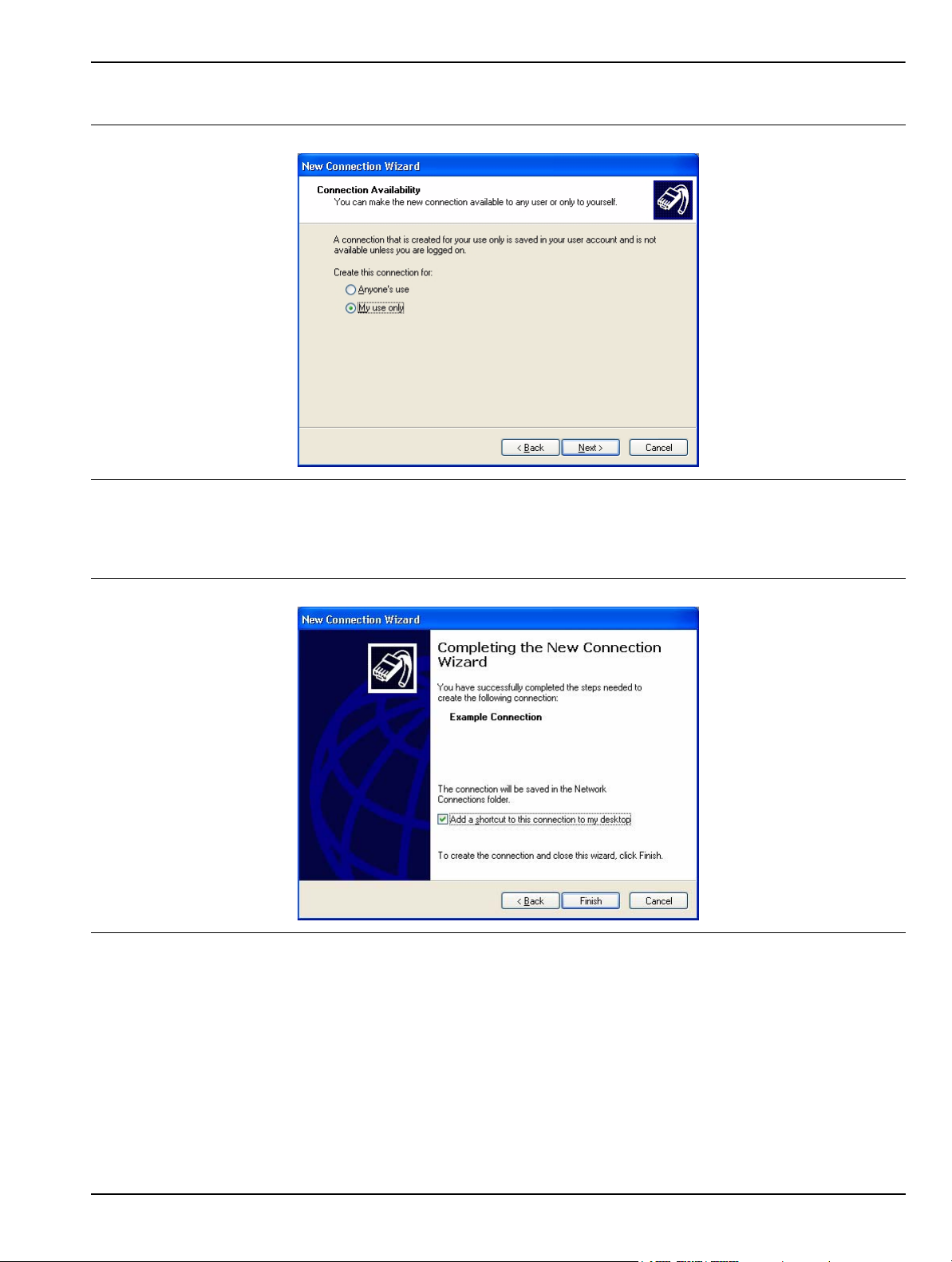

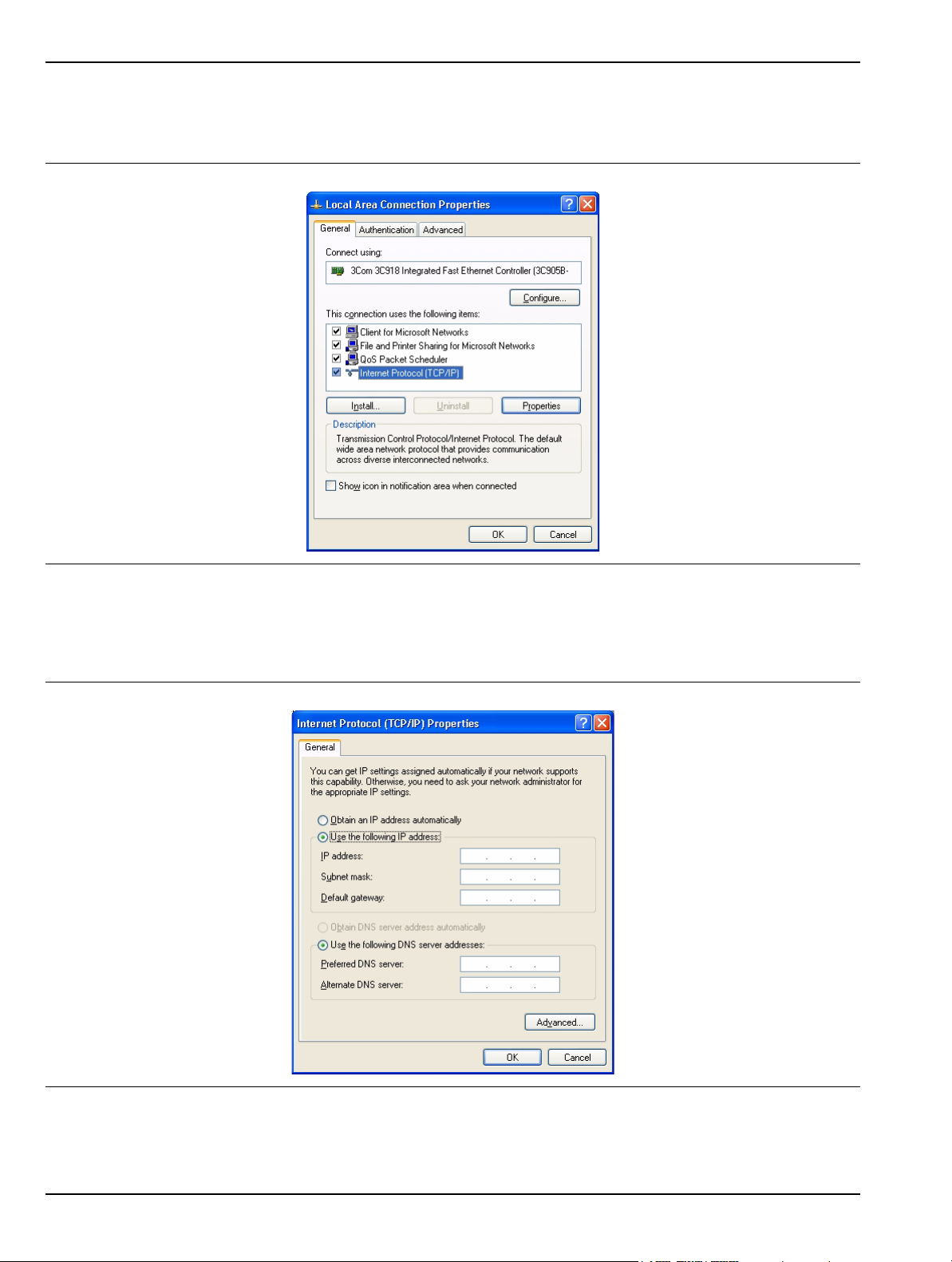

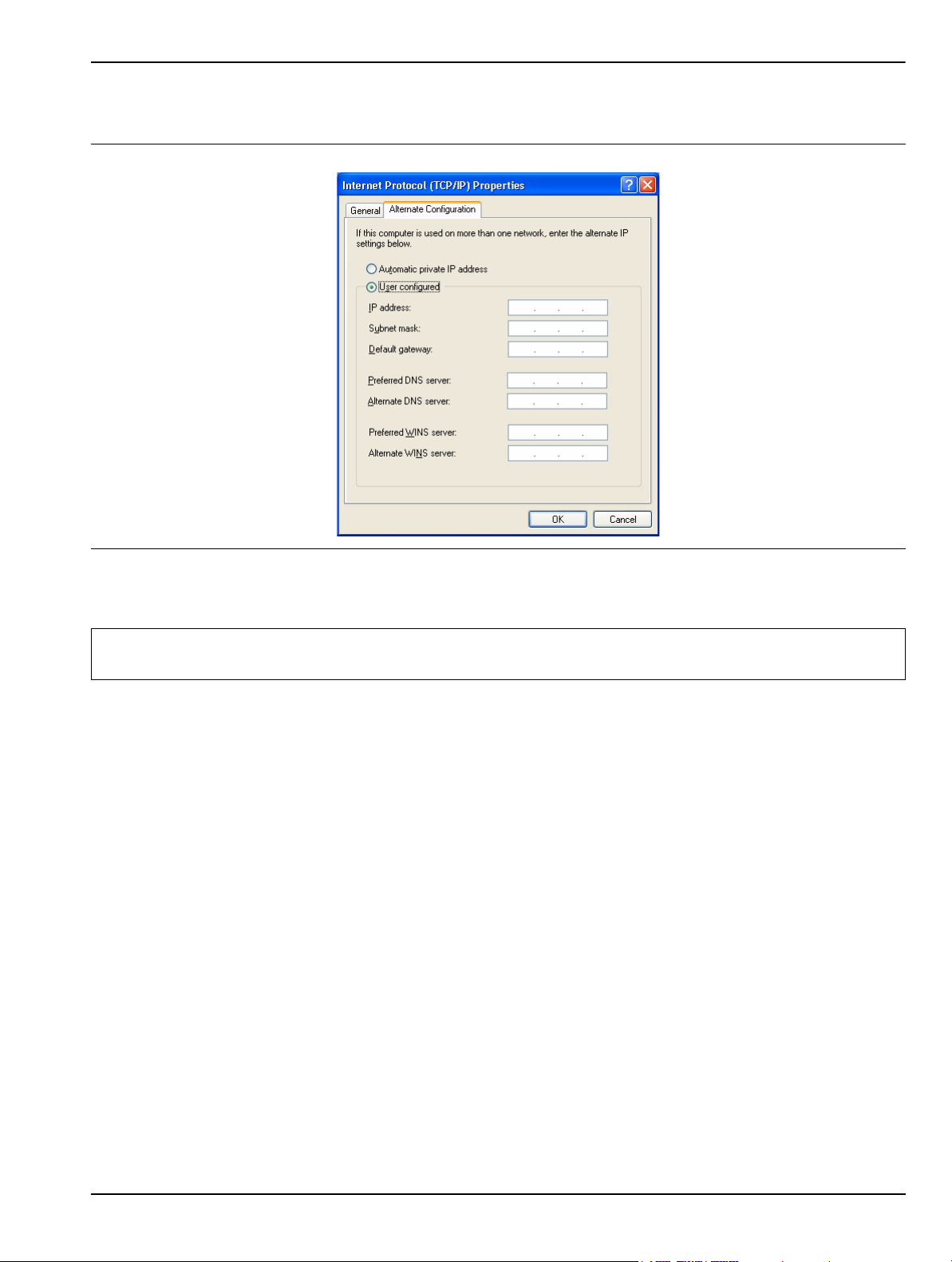

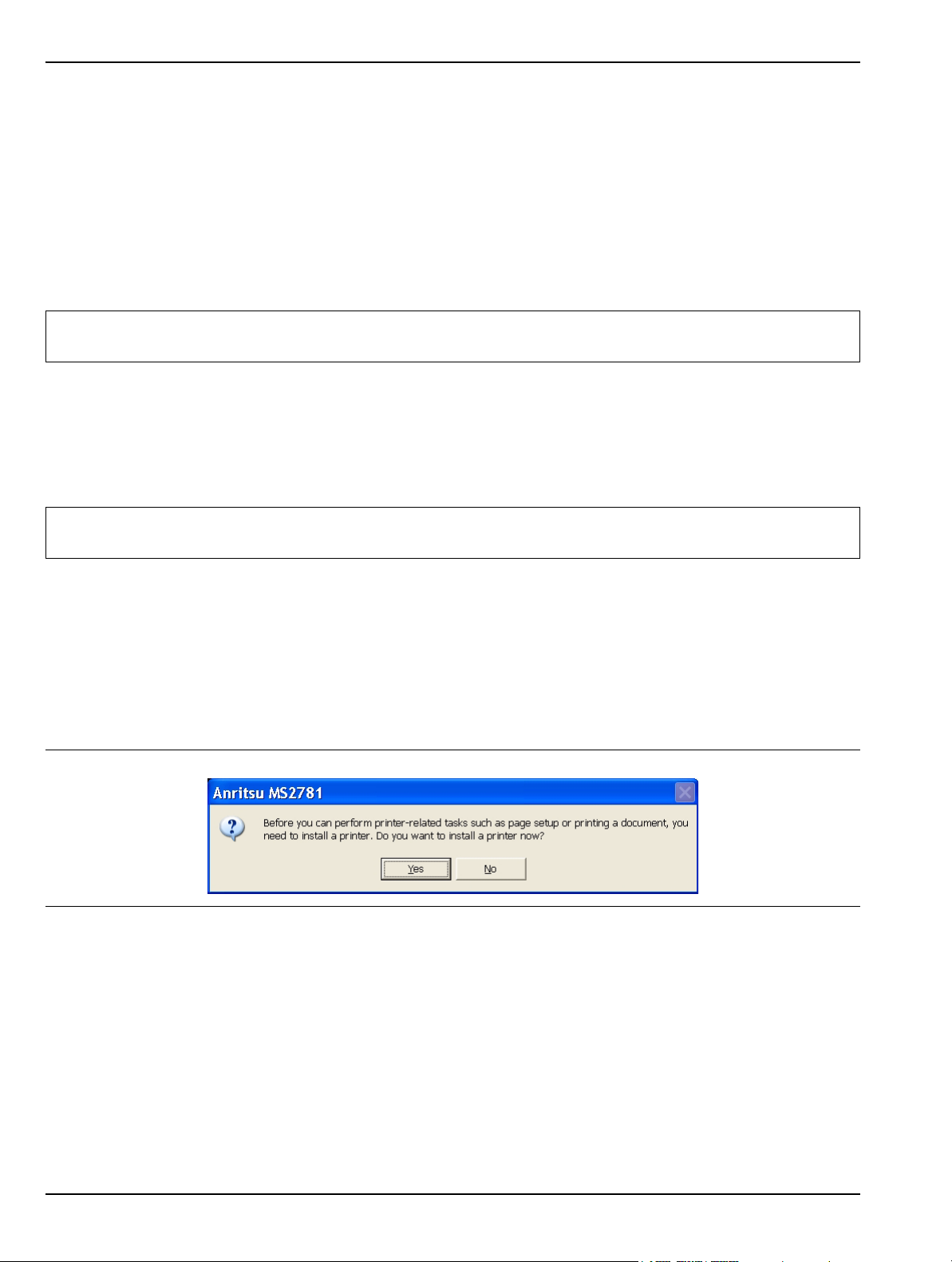

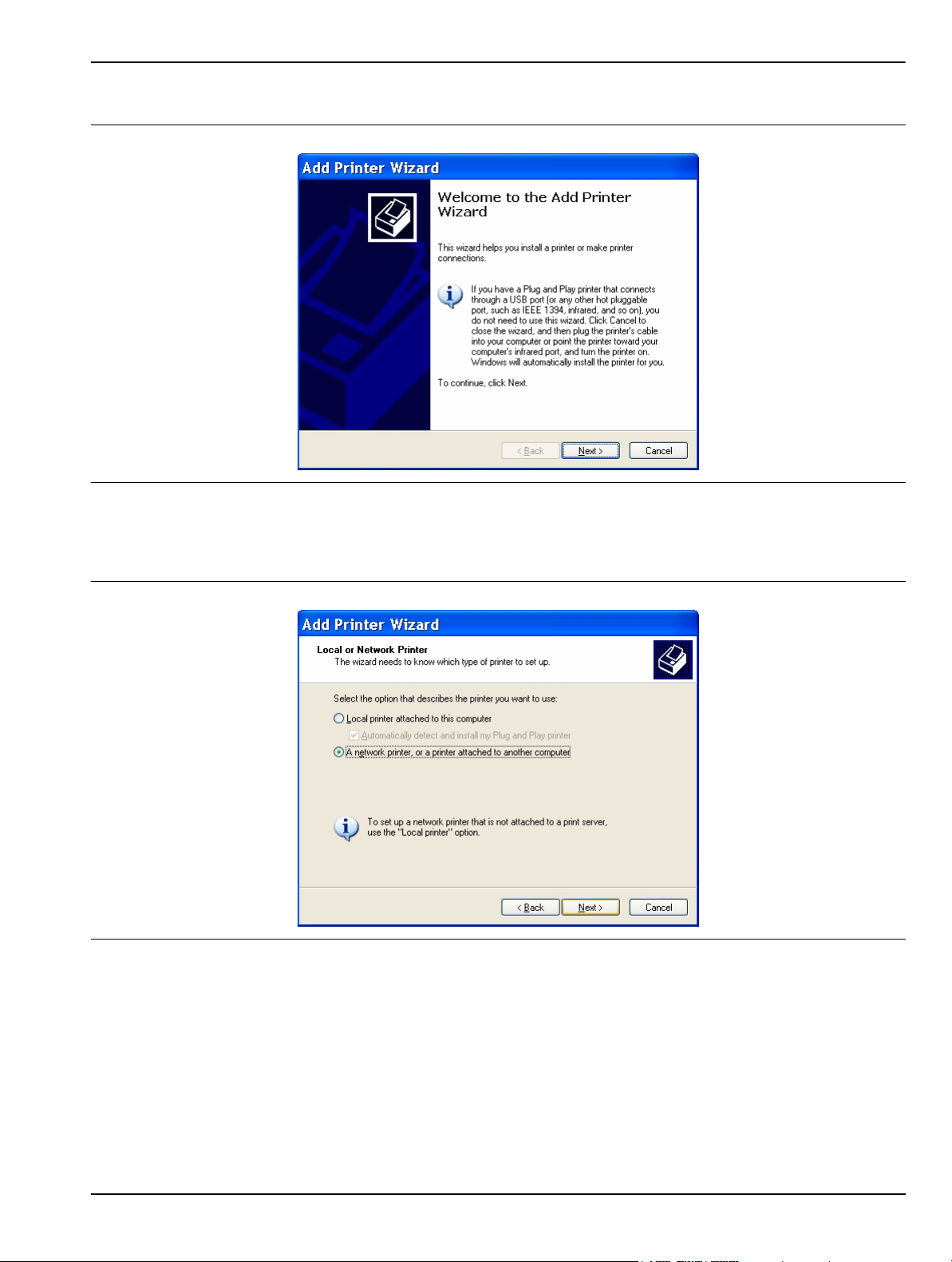

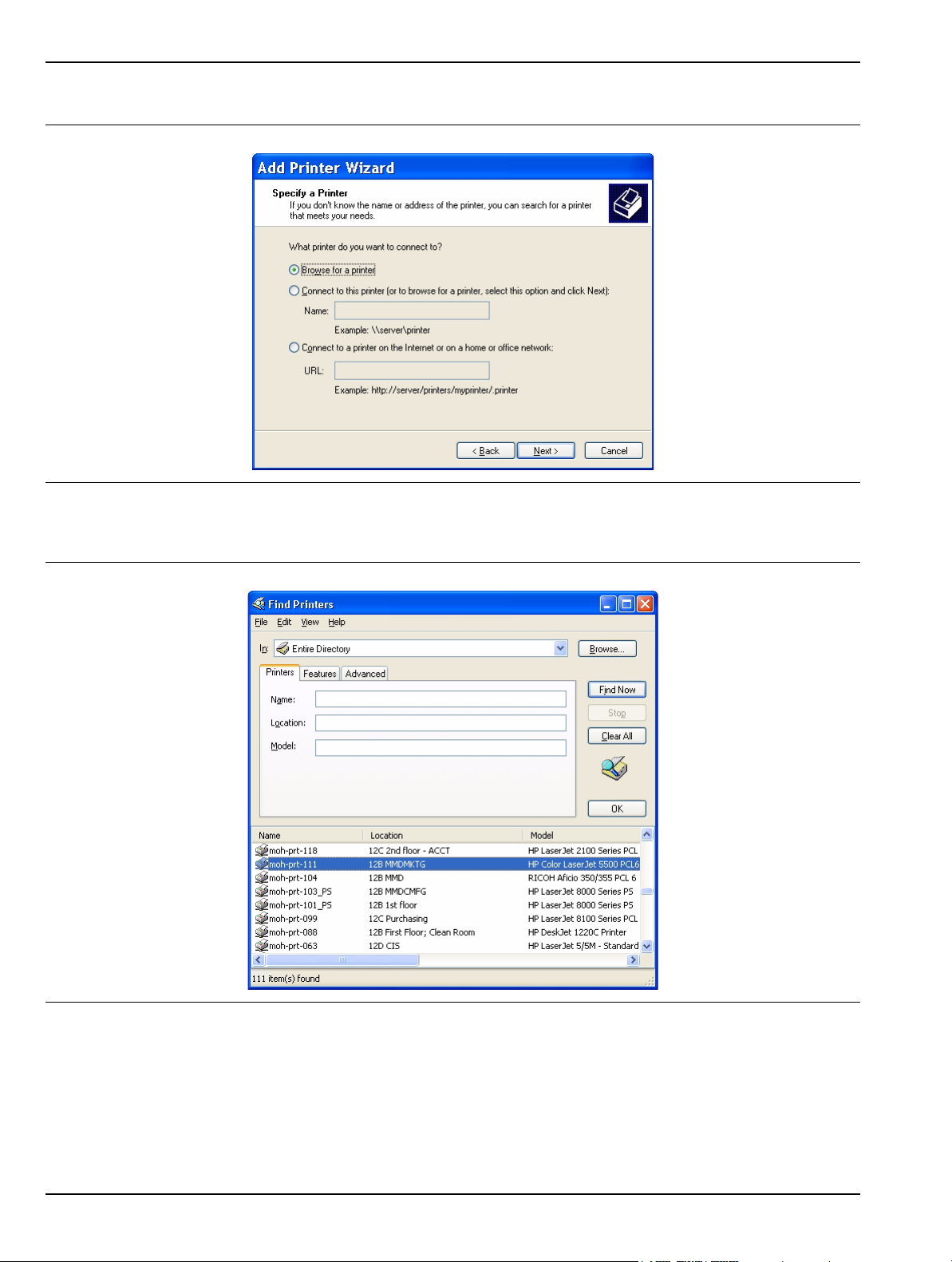

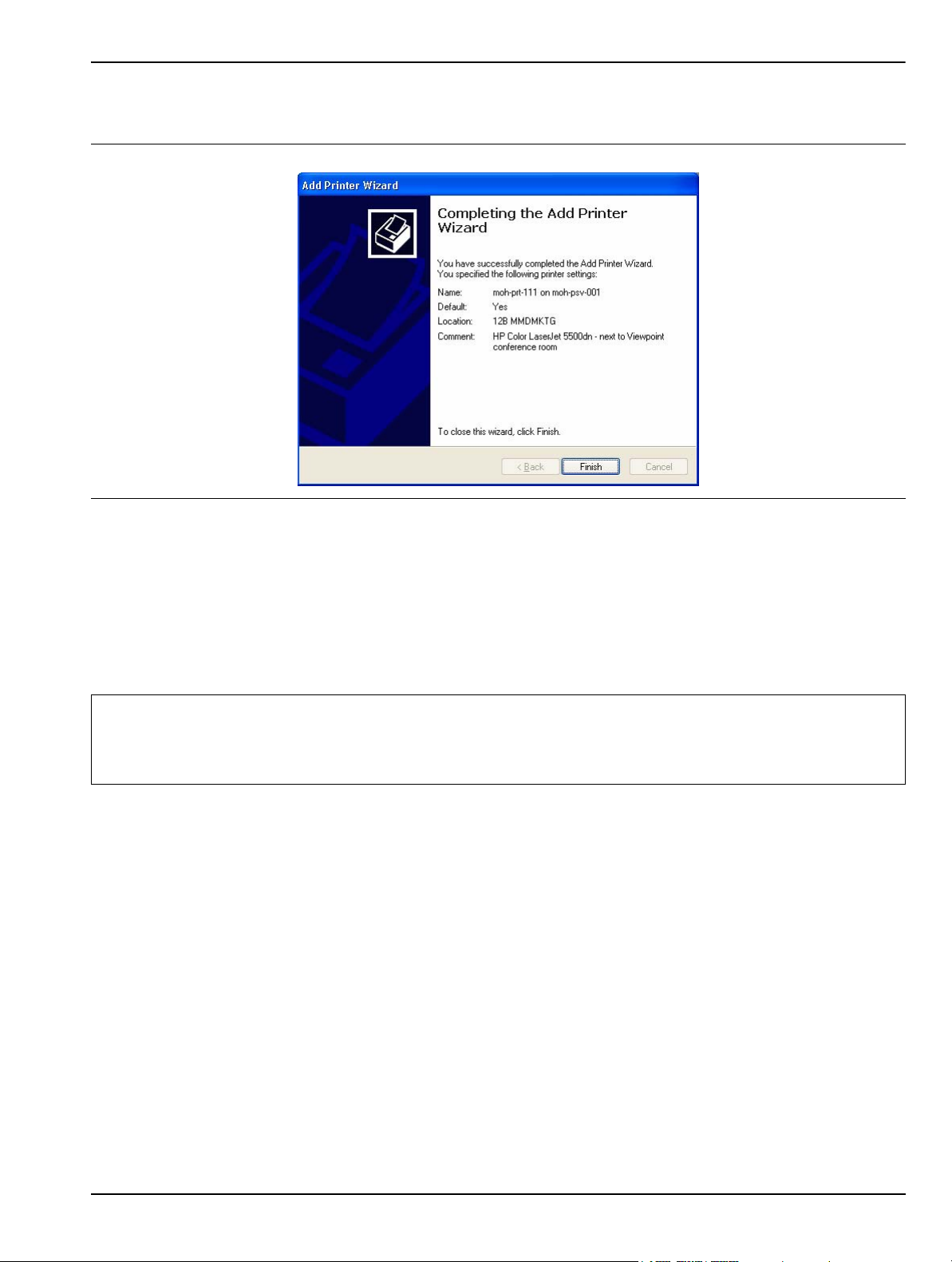

• Mode Talker/Listener