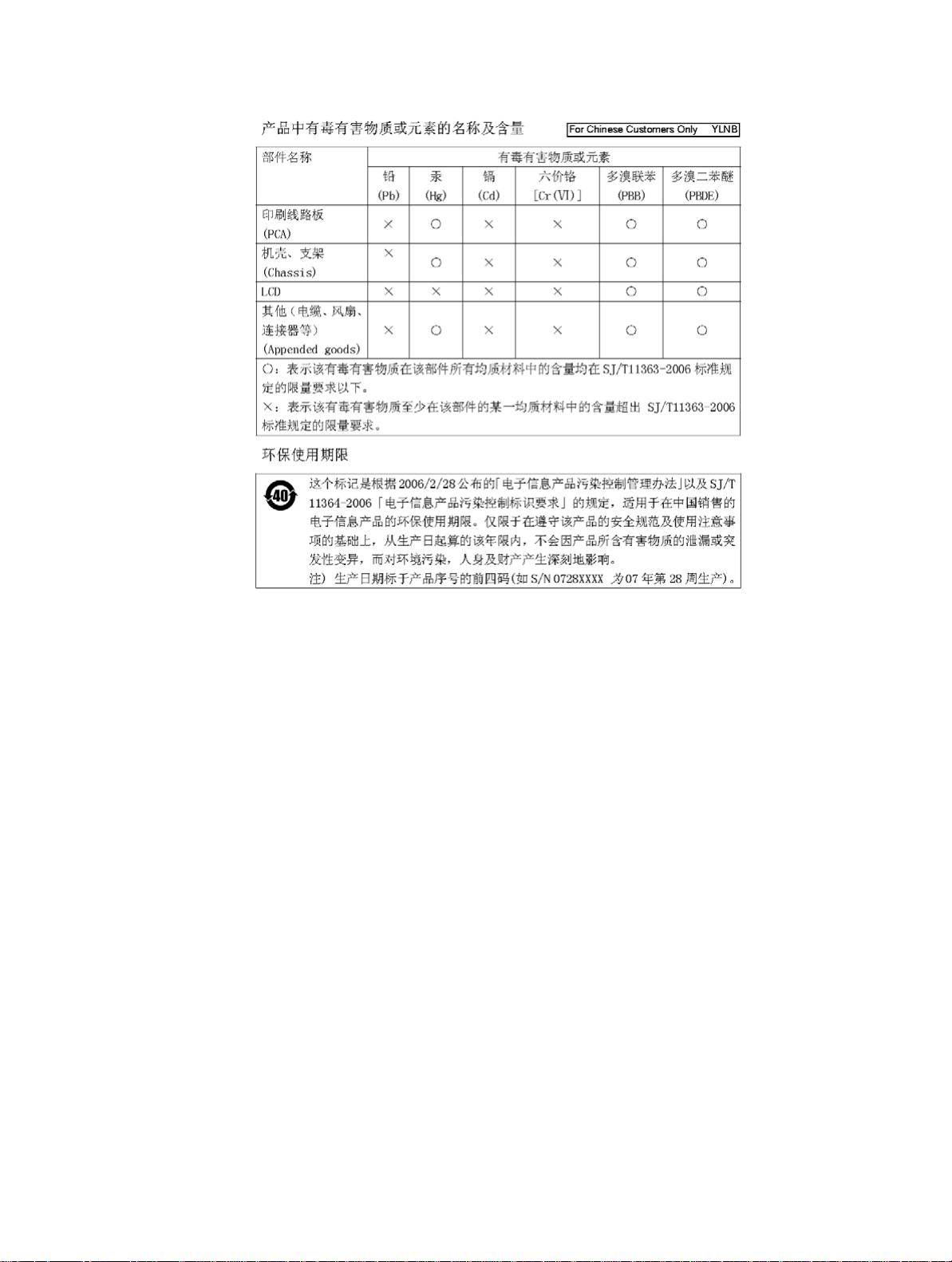

Page 1

Maintenance Manual

Site Master Spectrum Analyzer

MS2711B

Handheld Spectrum Analyzer for Measuring, Monitoring, and

Analyzing Signal Environments

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

P/N: 10580-00072

Revision: C

Copyright 2009 Anritsu Company

Printed: June 2009

Page 2

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and workmanship for

three years from the date of shipment.

Anritsu’s obligation covers repairing or replacing products which prove to be defective during the warranty period.

Buyers shall prepay transportation charges for equipment returned to Anritsu for warranty repairs. Obligation is

limited to the original purchaser. Anritsu is not liable for consequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear. Also, the warranty

does not apply to defects resulting from improper or inadequate maintenance by the Buyer, unauthorized

modification or misuse, or operation outside of the environmental specifications of the product. No other warranty is

expressed or implied, and the remedies provided herein are the Buyer’s sole and exclusive remedies.

DISCLAIMER OF WARRANTY

DISCLAIMER OF WARRANTIES. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, ANRITSU

COMPANY AND ITS SUPPLIERS DISCLAIM ALL WARRANTIES, EITHER EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, WITH REGARD TO THE SOFTWARE PRODUCT. THE USER ASSUMES THE ENTIRE

RISK OF USING THE PROGRAM. ANY LIABILITY OF PROVIDER OR MANUFACTURER WILL BE LIMITED

EXCLUSIVELY TO PRODUCT REPLACEMENT.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES. TO THE MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, IN NO EVENT SHALL ANRITSU COMPANY OR ITS SUPPLIERS BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING,

WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS

OF BUSINESS INFORMATION, OR ANY OTHER PECUNIARY LOSS) ARISING OUT OF THE USE OF OR

INABILITY TO USE THE SOFTWARE PRODUCTS, EVEN IF ANRITSU COMPANY HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES AND JURISDICTIONS DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

TRADEMARK ACKNOWLEDGMENTS

Windows, Windows XP, Microsoft Paint, Microsoft Word, Microsoft Access, Microsoft Excel, Microsoft PowerPoint,

and Visual Studio are all registered trademarks of Microsoft Corporation.

Acrobat Reader is a registered trademark of Adobe Corporation.

MATLAB is a a registered trademark of The MathWorks Corporation.

NI is a trademark of the National Instruments Corporation.

Signature is a trademark of Anritsu Company.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers as a guide for the

proper installation, operation and maintenance of Anritsu Company equipment and computer programs. The

drawings, specifications, and information contained herein are the property of Anritsu Company, and any

unauthorized use or disclosure of these drawings, specifications, and information is prohibited; they shall not be

reproduced, copied, or used in whole or in part as the basis for manufacture or sale of the equipment or software

programs without the prior written consent of Anritsu Company.

UPDATES

Updates, if any, can be downloaded from the Documents area of the Anritsu web site at:

http://www.us.anritsu.com

Page 3

Page 4

CE Conformity Marking

Anritsu affixes the CE Conformity marking onto its conforming products in accordance with Council Directives

of The Council Of The European Communities in order to indicate that these products conform to the EMC and

LVD directive of the European Union (EU).

C-tick Conformity Marking

Anritsu affixes the C-tick marking onto its conforming products in accordance with the electromagnetic

compliance regulations of Australia and New Zealand in order to indicate that these products conform to the

EMC regulations of Australia and New Zealand.

Notes On Export Management

This product and its manuals may require an Export License or approval by the government of the product

country of origin for re-export from your country.

Before you export this product or any of its manuals, please contact Anritsu Company to confirm whether or

not these items are export-controlled.

When disposing of export-controlled items, the products and manuals need to be broken or shredded to such a

degree that they cannot be unlawfully used for military purposes.

Mercury Notification

This product uses an LCD backlight lamp that contains mercury. Disposal may be regulated due to

environmental considerations. Please contact your local authorities or, within the United States, the

Electronics Industries Alliance (www.eiae.org) for disposal or recycling information.

Page 5

Page 6

Page 7

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Company uses the

following symbols to indicate safety-related information. For your own safety, please read the information

carefully before operating the equipment.

Symbols Used in Manuals

Danger

This indicates a very dangerous procedure that could result in serious

injury or death, and possible loss related to equipment malfunction, if not

performed properly.

Warning

This indicates a hazardous procedure that could result in light-to-severe

injury or loss related to equipment malfunction, if proper precautions are

not taken.

Caution

This indicates a hazardous procedure that could result in loss related to

equipment malfunction if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manuals

The following safety symbols are used inside or on the equipment near operation locations to provide

information about safety items and operation precautions. Ensure that you clearly understand the meanings of

the symbols and take the necessary precautions before operating the equipment. Some or all of the following

five symbols may or may not be used on all Anritsu equipment. In addition, there may be other labels attached

to products that are not shown in the diagrams in this manual.

This indicates a prohibited operation. The prohibited operation is indicated symbolically in or near

the barred circle.

This indicates a compulsory safety precaution. The required operation is indicated symbolically in or

near the circle.

This indicates a warning or caution. The contents are indicated symbolically in or near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

MS2711B Maintenance 10580-00072 C Safety-1

Page 8

For Safety

Warning

Warning

Warning

Always refer to the operation manual when working near locations at which

the alert mark, shown on the left, is attached. If the operation, etc., is

performed without heeding the advice in the operation manual, there is a

risk of personal injury. In addition, the equipment performance may be

reduced.

Moreover, this alert mark is sometimes used with other marks and

descriptions indicating other dangers.

When supplying power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet. If a grounded 3-pin outlet is

not available, use a conversion adapter and ground the green wire, or

connect the frame ground on the rear panel of the equipment to ground. If

power is supplied without grounding the equipment, there is a risk of

receiving a severe or fatal electric shock.

This equipment can not be repaired by the operator. Do not attempt to

remove the equipment covers or to disassemble internal components.

Only qualified service technicians with a knowledge of electrical fire and

shock hazards should service this equipment. There are hig h-voltage p arts

in this equipment presenting a risk of severe injury or fatal electric shock to

untrained personnel. In addition, there is a risk of damage to precision

components.

Warning

Use two or more people to lift and move this equipment, or use an

equipment cart. There is a risk of back injury if this equipment is lifted by

one person.

Electrostatic Discharge (ESD) can damage the highly sensitive circuits in

the instrument. ESD is most likely to occur as test devices are being

Caution

Safety-2 10580-00072 C MS2711B Maintenance

connected to, or disconnected from, the instrument’s front and rear panel

ports and connectors. You can protect the instrument and test devices by

wearing a static-discharge wristband. Alternatively, you can ground

yourself to discharge any static charge by touching the outer chassis of the

grounded instrument before touching the instrume nt’s front and rear panel

ports and connectors. Avoid touching the test port center conductors

unless you are properly grounded and have eliminated the possibility of

static discharge.

Repair of damage that is found to be caused by electrostatic discharge is

not covered under warranty.

Page 9

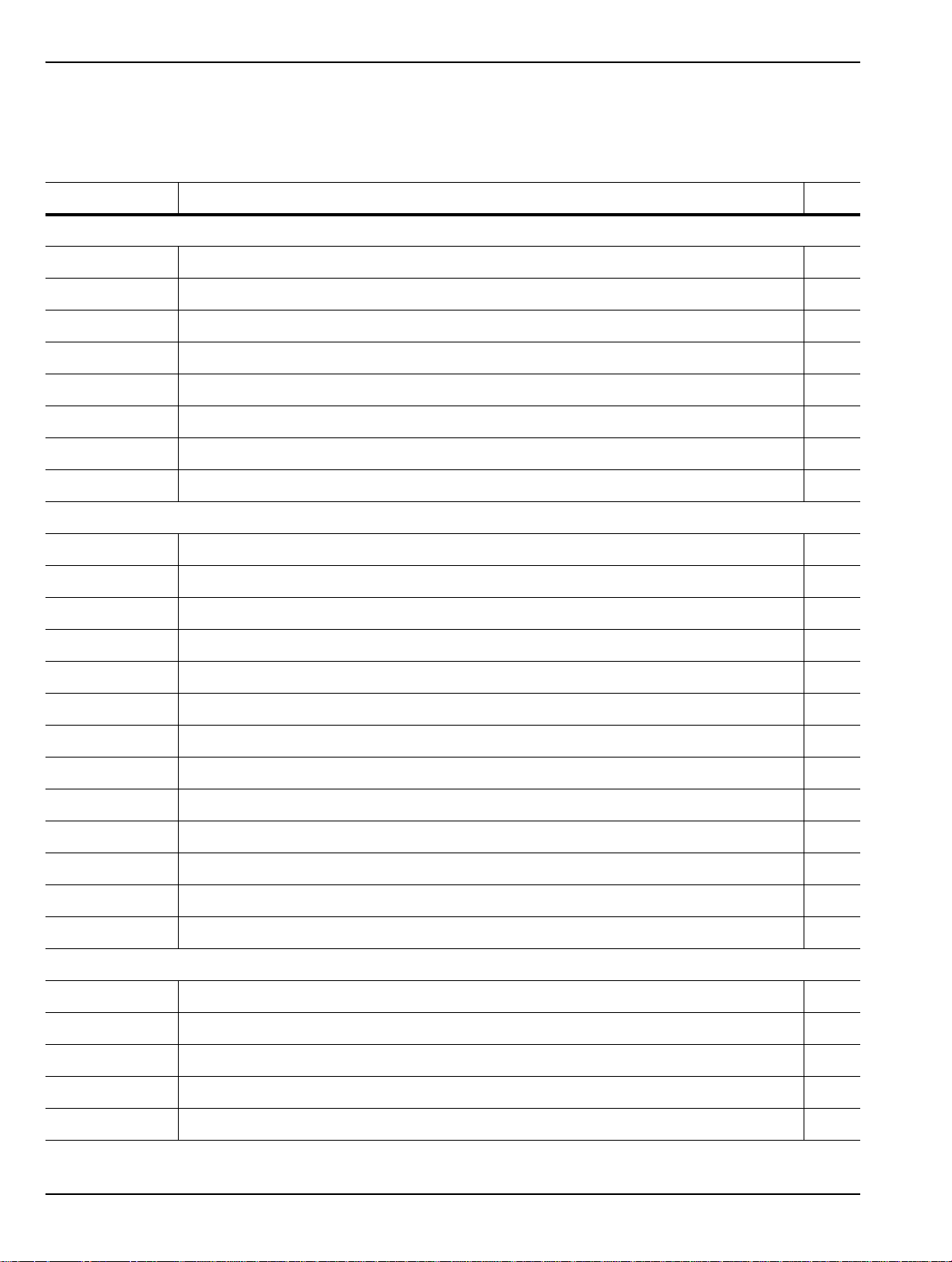

Table of Contents

Chapter 1—General Information

1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Identification Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-4 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-5 Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2—Performance Verification

2-1 Performance Verification Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Frequency Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Phase Noise Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-4 Second Harmonic Distortion Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-5 Residual Spurious Response Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-6 Level Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-7 Dynamic Range Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Equipment required: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-8 Power Monitor (Option 5) Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-9 Preamplifier (Option 8) Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2-10 Level Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

MS2711B Maintenance 10580-00072 C Contents-1

Page 10

2-11 Tracking Generator (Option 20) Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Equipment Required:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Procedure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Chapter 3—Removal and Replacement

3-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Static Sensitive Assembly Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Additional Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3 Battery Pack Removal And Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Battery Testing Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-4 Front Panel Assembly Removal And Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-5 LCD Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-6 Key Pad PCB Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-7 Key Pad Membrane Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-8 PCB Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

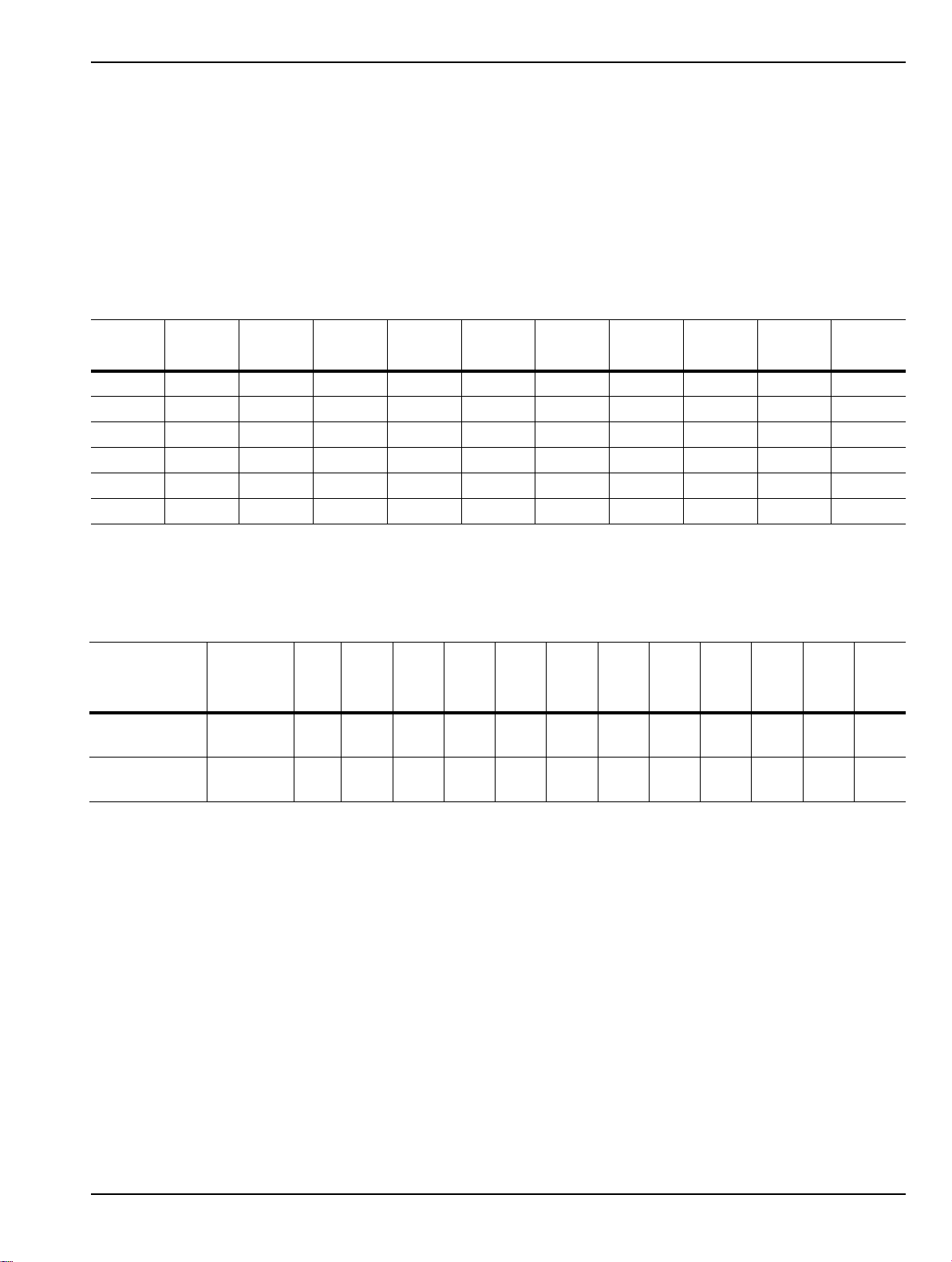

Appendix A—Test Records

A-1 Preamplifier (Option 8) Level Accuracy Test Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A-2 Preamplifier (Option 8) Level Accuracy Test Characterization . . . . . . . . . . . . . . . . . . . . . . . . A-3

A-3 Preamplifier (Option 8) Level Accuracy Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A-4 Tracking Generator Option Level Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A-5 Tracking Generator Harmonics and Spurious Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Contents-2 10580-00072 C MS2711B Maintenance

Page 11

Chapter 1 — General Information

1-1 Introduction

This manual provides maintenance instructions for the MS2711B Spectrum Analyzer. It describes the product

and provides performance verification procedures, parts replacement procedures, and a replaceable parts list.

1-2 Identification Number

All Anritsu instruments are assigned a six-digit serial number, such as “101001”. This number appears on a

decal affixed to the back panel of the instrument. Please use this identification number during any

correspondence with Anritsu Service Centers about this instrument.

1-3 Description

The MS2711B Spectrum Analyzer is a synthesizer-based hand held spectrum analyzer that provides quick and

accurate signal results. Measurements can be easily made using the main instrument functions: frequency,

span, amplitude, and bandwidth. A simplified block diagram is provided in Figure 1-1.

Figure 1-1. MS2711B Spectrum Analyzer Block Diagram

1-4 Options

The following options are available for the MS2711B:

• Option 5: RF Wattmeter Power Monitor (RF detector not included)

• Option 8: 3/4 Built-in 20 dB Preamplifier, 1 MHz to 3 GHz

• Option 20: 3/4 Built-in Tracking Generator, 10 MHz to 3 GHz

Note

MS2711B Maintenance 10580-00072 C 1-1

Option 5 and Option 8 are mutually exclusive; that is, they cannot both be installed in the same

instrument at the same time.

Page 12

Replaceable Parts General Information

1-5 Replaceable Parts

Replaceable parts for the Model MS2711B Spectrum Analyzer are listed below.

Table 1-1. Replaceable Parts List

Part Number Description Qty

Accessories

10580-00074

10580-00071

2300-347

40-115

2000-1029

806-62

800-441

48258

510-87

551-152

15-102

633-27

ND58427

ND58428

User Guide, MS2711B Spectrum Analyzer 1

Programming Manual, MS2711B Spectrum Analyzer (available on disk only) 1

Software Tools, MS2711B Spectrum Analyzer 1

Power Supply 1

Battery Charger 1

Cable Assy, Cig Plug, Female 1

Serial Interface Cable Assy 1

Soft Carrying Case 1

Replaceable Parts

N-Connector 1

Option 05 Input Connector 1

Liquid Crystal Display Assy 1

Rechargeable Battery, NiMH 1

MS2711B PCB Assembly 1

MS2711B PCB Assembly with Option 05 1

ND58429

ND58430

ND58431

ND58432

52737-3

46649-3

ND56502

900-861

900-869

900-720

900-697

900-326

MS2711B PCB Assembly with Option 8 1

MS2711B PCB Assembly with Option 20 1

MS2711B PCB Assembly with Option 05 and Option 20 1

MS2711B PCB Assembly with Option 08 and Option 20 1

Keypad PCB Assy 1

Membrane Keypad, Main 1

Speaker and Cable Assembly 1

Hardware

Pan Head Screw, 4-20, 0.365 18

Screw, 4-40, 0.875 4

Screw, 4-40, 0.187 9

Screw, 4-40, 0.312 3

Kep Nut, 4-40, 0.187 12

1-2 10580-00072 C MS2711B Maintenance

Page 13

General Information Replaceable Parts

Table 1-1. Replaceable Parts List (Continued)

Part Number Description Qty

Hardware (Continued)

790-516

790-42

761-79

46652-4

46653-1

48231-1

790-509

790-510

790-511

46655

46662

48241

48278

46659

46661

Hole Plug, 0.6875L 1

Hole Plug, 0.625 1

Cap Vinyl, Black, round 1

Case Parts

Top Case 1

Bottom Case 1

Battery Door 1

1

Battery Door Latch (3 pieces)

Case Corner Bumpers 4

LCD Retainer Plate 1

Foam, LCD Corners 8

Foam, LCD Window 1

Foam, LCD Backing 1

Foam, Keypad Backing 1

48246

48271

720-19

790-515

55212

Foam, Battery Door 1

Foam, Battery Compartment 1

Cable Clamp 1

Spring, Battery Compartment 3

ID Label, Model MS2711B 1

MS2711B Maintenance 10580-00072 C 1-3

Page 14

Replaceable Parts General Information

1-4 10580-00072 C MS2711B Maintenance

Page 15

Chapter 2 — Performance Verification

2-1 Performance Verification Procedures

The following procedures can be used to verify the performance of the MS2711B Spectrum Analyzer having

firmware version 2.09 or later.

2-2 Frequency Accuracy

The following test can be used to verify the CW frequency accuracy of the Spectrum Analyzer.

Equipment Required:

• Anritsu MG3692A Synthesized Signal Source with Option 15A, or equivalent

• Anritsu 34RSN50 50 ohm adapter or equivalent

• Anritsu 15NNF50-1.5C RF Coaxial Cable or equivalent

• 10 MHz Reference Standard

• BNC male to BNC male coaxial cable

Procedure:

1. Connect the 10 MHz reference source to the Anritsu MG3692A Synthesized Signal Source.

2. Connect the output of the source to the MS2711B RF Input.

3. Connect the external power supply (Anritsu part number 40-115) to the MS2711B.

4. Press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn on the Spectrum Analyzer.

(This sets the instrument to the factory preset state.)

5. Turn on the 10 MHz reference source and the Anritsu MG3692A Synthesized Signal Source.

6. Set the MG3692A output to 2000 MHz CW with an RF output level of 0 dBm.

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

7. On the MS2711B, press the AMPLITUDE key and the REF LEVEL soft key.

8. Enter 20 and press the ENTER key to set the Reference Level to 20 dBm.

9. Press the FREQ/SPAN key and the CENTER soft key.

10. Enter 2000 and press the ENTER key to set the center frequency to 2000 MHz.

11. Press the SPAN soft key and enter 50. Press the kHz soft key to set the span to 50 kHz.

12. Press the BW/SWEEP key.

13. Press the RBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 10 kHz.

Press ENTER to set the resolution bandwidth to 10 kHz, and press BACK.

14. Press the VBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 3 kHz.

Press ENTER to set the video bandwidth to 3 kHz.

15. Press the MARKER (8) key, then the M1 soft key.

16. Press the EDIT soft key and use the Up/Down arrow key to center the marker on the waveform. Verify

that the marker frequency is 2000 MHz ±4 kHz.

MS2711B Maintenance 10580-00072 C 2-1

Page 16

Phase Noise Verification Performance Verification

2-3 Phase Noise Ve rification

Equipment Required:

• Anritsu MG3692A Synthesized Signal Source with Option 2A, Option 4, and Option 15A, or equivalent

• Anritsu 34RSN50 50 ohm adapter or equivalent

• Anritsu 15NNF50-1.5C RF Coaxial Cable or equivalent

Procedure:

1. Connect the output of the source to the MS2711B RF Input.

2. Connect the external power supply (Anritsu part number 40-115) to the MS2711B.

3. Press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn on the Spectrum Analyzer.

(This sets the instrument to the factory preset state.)

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

4. Set the MG3692A output to 1000 MHz CW with an RF output level of – 30 dBm.

5. On the MS2711B, press the BW/SWEEP key.

6. Press the RBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 10 kHz.

Press ENTER to set the resolution bandwidth to 10 kHz, and then press BACK.

7. Press the VBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 3 kHz.

Press ENTER to set the video bandwidth to 3 kHz.

8. On the MS2711B, press the FREQ/SPAN key and the CENTER soft key.

9. Enter 1000 and press the MHz soft key to set the center frequency to 1000 MHz.

10. Press the SPAN soft key and enter 0.1. Press the MHz soft key to set the span to 0.100 MHz.

11. Press the AMPLITUDE key.

12. Press the REF LEVEL soft key and enter –27. Press the ENTER key to set the reference level to – 27 dBm.

13. Press the MARKER (8) key, then the M1 soft key.

14. Press EDIT and enter 1000. Press the MHz soft key to set the M1 marker frequency to 1000 MHz.

15. Press the BACK soft key and the M2 soft key.

16. Press EDIT and enter 1000.03. Press MHz to set the M2 marker frequency to 1000.030 MHz (30 kHz

higher than the center frequency).

17. Press the DELTA (M2-M1)

18. Press the SINGLE/CONT (+/–) key and read and record the D2 reading.

19. Press the SINGLE/CONT (+/–) key to read and record five values, then calculate the average of the five

recorded values.

20. Subtract 40 dB from the average value and verify that the result is ≤ –75 dBc/Hz.

(For example: –35dBc measured –40dB=–75dBc/Hz.)

soft key.

2-2 10580-00072 C MS2711B Maintenance

Page 17

Performance Verification Phase Noise Verification

The measured value is converted to dBc/Hz using the following formula:

dBc

---------- -

Hz

Note

At 10 kHz RBW, , so

dBc

---------- -

Hz

21. Press the BACK soft key and the M3 soft key.

22. Press the EDIT key and enter 999.970. Press MHz to set the M3 marker frequency to 999.970 MHz

(30 kHz lower than the center frequency).

23. Press the DELTA (M3-M1) soft key.

24. Press the SINGLE/CONT (+/–) key. Read and record the Δ3 reading.

25. Press the SINGLE/CONT (+/–) key to read and record five values, then calculate the average of the five

recorded values.

Subtract 40 dB from the average value and verify that the result is ≤ –75 dBc/Hz.

(For example: –35 dBc measured –40 dB = –75 dBc/Hz)

measured dBc⋅ 10

RBW

⎛⎞

10

--------------

⎝⎠

1Hz

measured dBc⋅–40–=

40=log×

RBW

⎛⎞

--------------

log×––=

⎝⎠

1Hz

MS2711B Maintenance 10580-00072 C 2-3

Page 18

Second Harmonic Distortion Test Performance Verification

2-4 Second Harmonic Distortion Test

The following test can be used to verify the input related spurious response of the Spectrum Analyzer.

Equipment Required:

• Anritsu MG3692A Synthesized Signal Source with Option 2A, Option 4, and Option 15A, or equivalent

• Anritsu 34RSN50 50 ohm adapter or equivalent

• Anritsu 15NNF50-1.5C RF Coaxial Cable or equivalent

• 10 MHz Reference Standard

• 50 MHz Low Pass Filter (Anritsu part number 1030-96)

• BNC male to BNC male coaxial cable

Procedure:

1. Connect the 10 MHz reference source to the Anritsu MG3692A Synthesized Signal Source.

2. Connect one end of the 50 MHz Low Pass Filter to the output of the source and the other end to the

Spectrum Analyzer RF Input with the RF coaxial cable.

3. Connect the external power supply (Anritsu part number 40-115) to the Site Master.

4. On the MS2711B, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn on the

Spectrum Analyzer. (This sets the instrument to the factory preset state.)

5. Turn on the 10 MHz reference source and the Anritsu MG3692A Synthesized Signal Source.

6. Set the MG3692A output to 40 MHz CW, with an RF output level of –30 dBm.

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

7. On the Spectrum Analyzer, press the AMPLITUDE key and the REF LEVEL soft key.

8. Enter –27 and press the ENTER key to set the Reference Level to –27 dBm.

9. Press the SCALE soft key and enter 7, then press ENTER.

10. Press the FREQ/SPAN key and then the CENTER soft key.

11. Enter 40 and press the MHz soft key to set the center frequency to 40 MHz.

12. Press the SPAN soft key and enter 0.2. Press the MHz soft key to set the span to 0.200 MHz.

13. Press the BW/SWEEP key.

14. Press the RBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 10 kHz.

Press ENTER to set the resolution bandwidth to 10 kHz and press BACK.

15. Press the VBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 3 kHz.

Press ENTER to set the video bandwidth to 3 kHz.

16. Press the MARKER (8) key, then the M1 soft key.

17. Press the EDIT soft key, then enter 40. Press the MHz soft key to set M1 to 40 MHz.

18. On the MG3692A Synthesized Signal Source, adjust the output level so that the M1 reading of the

Spectrum Analyzer is –30 dBm at 40 MHz.

19. On the Spectrum Analyzer, press the FREQ/SPAN key and then the CENTER soft key.

20. Enter 80 and press the MHz soft key to set the center frequency to 80 MHz.

21. Press the MARKER (8) key and the M1 soft key.

22. Press the EDIT soft key, then enter 80. Press the MHz soft key to set M1 to 80 MHz.

23. Record the amplitude of the signal at M1 80 MHz:

Second Harmonic Level @ 80 MHz =____dBm

2-4 10580-00072 C MS2711B Maintenance

Page 19

Performance Verification Second Harmonic Distortion Test

24. Convert this measured value to dBc using the following formula:

Input Related Spurious Response (dBc) =

[Second Harmonic Level @ 80 MHz] + 30 dBm = ___ dBc

Specifications for this measurement are –45 dBc with –30 dBm into the first

mixer.

MS2711B Maintenance 10580-00072 C 2-5

Page 20

Residual Spurious Response Test Performance Verification

2-5 Residual Spurious Response Test

The following test can be used to verify the residual spurious response of the Spectrum Analyzer.

Equipment Required:

Anritsu 28N50-2 or SM/PL 50 ohm Termination or equivalent

Procedure:

1. Connect the 50 ohm termination to the Spectrum Analyzer RF Input.

2. On the Spectrum Analyzer, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn

on the Spectrum Analyzer. (This sets the instrument to the factory preset state.)

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

3. On the Spectrum Analyzer, press the AMPLITUDE key and the REF LEVEL soft key.

4. Enter –75 and press the ENTER key to set the Reference Level to –75 dBm.

5. Press the SCALE soft key and enter 5, then press ENTER.

6. Press the BW/SWEEP key.

7. Press the RBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 10 kHz.

Press ENTER to set the resolution bandwidth to 10 kHz, and press BACK.

8. Press the VBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 100 Hz, and

press ENTER to set the video bandwidth to 100 Hz.

9. Press the FREQ/SPAN key and the START soft key.

10. Enter 500 and press the kHz soft key to set the start frequency to 500 kHz.

11. Press the STOP soft key and enter 4, then press the MHz soft key to set the stop frequency to 4 MHz.

12. Wait until one full sweep is complete.

13. Press the MARKER (8) key and then the M1 soft key.

14. Press the ON/OFF soft key and then the MARKER TO PEAK soft key.

15. Record the M1 amplitude reading and verify whether it is less than or equal to –90 dBm.

If a spur with an amplitude larger than –90 dBm occurs, then wait another full sweep and observe

Note

16. Press the BW/SWEEP key.

17. Press the VBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 3 kHz, and

press ENTER

18. Press the FREQ/SPAN key and the START soft key.

19. Enter 4 and press the MHz soft key to set the start frequency to 4 MHz.

20. Press the STOP soft key and enter 1000, then press the MHz soft key to set the stop frequency

to 1000 MHz.

21. Wait until one full sweep is complete.

whether the spur occurs at the same point on the second sweep. If the spur does not occur at the

same point on the second sweep, then the spur on the first sweep was not real.

to set the video bandwidth to 3 kHz.

22. Press the MARKER (8) key and then the M1 soft key.

23. Press the ON/OFF soft key and then the MARKER TO PEAK soft key.

24. Record the M1 amplitude reading and verify that it is ≤ –90 dBm.

25. Press the FREQ/SPAN key and the START soft key.

2-6 10580-00072 C MS2711B Maintenance

Page 21

Performance Verification Residual Spurious Response Test

26. Enter 1000 and press the MHz soft key to set the start frequency to 1000 MHz.

27. Press the STOP soft key and enter 2000, then press MHz soft key to set the stop frequency to 2000 MHz.

28. Wait until one full sweep is complete.

29. Press the MARKER (8) key and then the M1 soft key.

30. Press the ON/OFF soft key and then the MARKER TO PEAK soft key.

31. Record the M1 amplitude reading and verify that it is ≤ –90 dBm.

32. Press the FREQ/SPAN key and the START soft key.

33. Enter 2000 and press the MHz soft key to set the start frequency to 2000 MHz.

34. Press the STOP soft key and enter 3000, then press the MHz soft key to set the stop frequency

to 3000 MHz.

35. Wait until one full sweep is complete.

36. Press the MARKER (8) key and then the M1 soft key.

37. Press the ON/OFF soft key and then the MARKER TO PEAK soft key.

38. Record the M1 amplitude reading and verify that it is ≤ –90 dBm.

MS2711B Maintenance 10580-00072 C 2-7

Page 22

Level Accuracy Test Performance Verification

2-6 Level Accuracy Test

This test verifies the level accuracy of the Spectrum Analyzer.

Equipment Required:

Anritsu MG3692A Synthesized Signal Source, with Option 2A, Option 4, and Option 15A

Anritsu ML2430A-Series Power Meter or equivalent

Anritsu MA2442A High Accuracy Power Sensor or equivalent

Anritsu N241A50 Power Splitter or equivalent

Anritsu 34NN50A 50 ohm adapter or equivalent

Anritsu 34RSN50 50 ohm adapter or equivalent

Anritsu 15NNF50-1.5C RF Coaxial Cable or equivalent

Procedure:

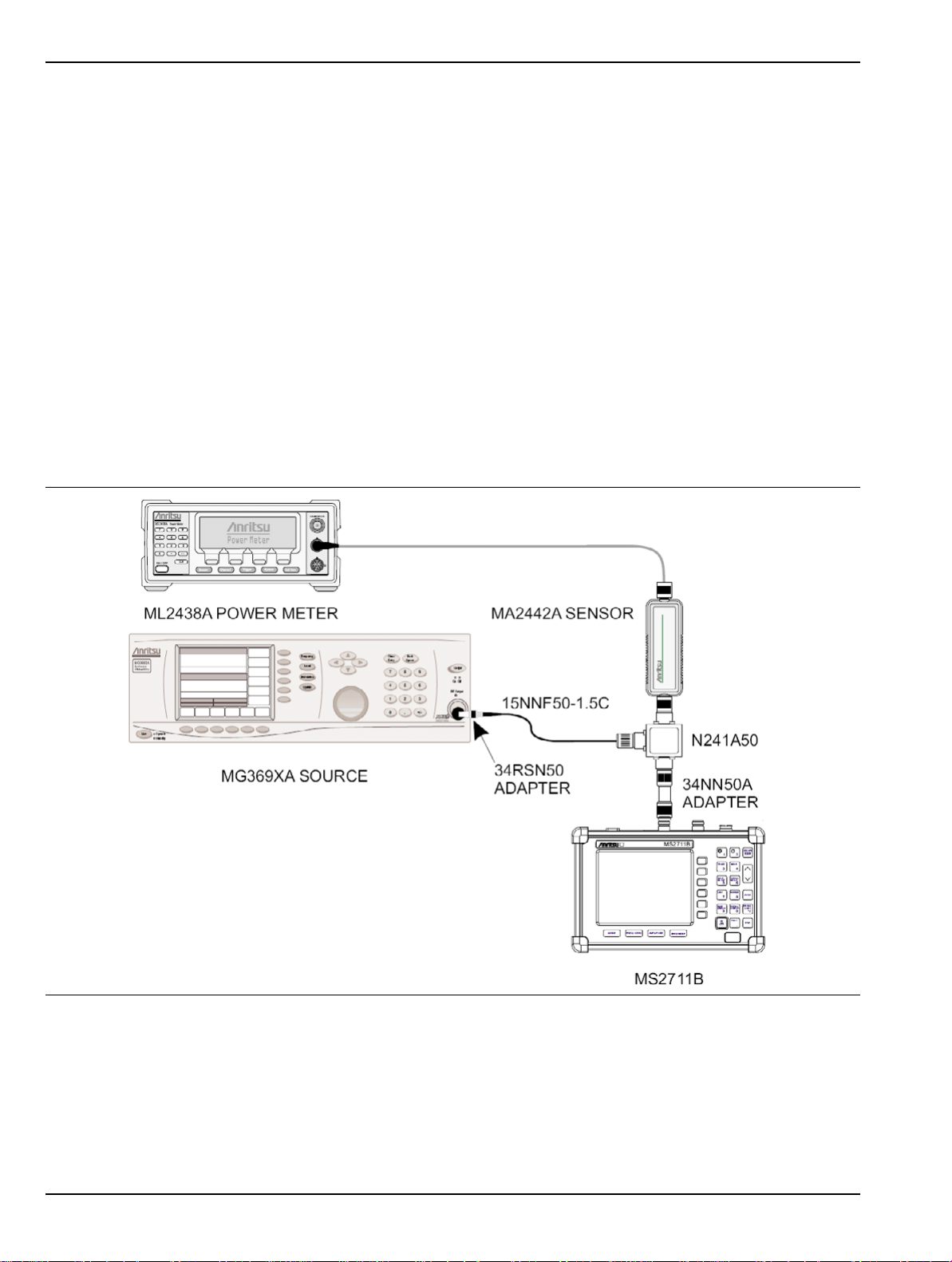

1. Connect the power sensor to the power meter and calibrate the sensor.

2. Using the power splitter, coaxial cable and adapters, connect the Spectrum Analyzer to the signal source

and the power sensor as shown in Figure 2-1

Figure 2-1. Measurement Accuracy Setup

3. Connect the external power supply (Anritsu part number 40-115) to the Spectrum Analyzer.

4. On the Spectrum Analyzer, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn

on the Spectrum Analyzer. (This sets the instrument to the factory preset state.)

2-8 10580-00072 C MS2711B Maintenance

Page 23

Performance Verification Level Accuracy Test

5. Turn on the power meter and signal source.

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

6. On the Spectrum Analyzer, press the BW/SWEEP key.

7. Press the RBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 10 kHz.

Press ENTER to set the resolution bandwidth to 10 kHz.

8. Press BACK, then the VBW soft key, and then the MANUAL soft key. Use the Up/Down arrow key to

select 3 kHz. Press ENTER to set the video bandwidth to 3 kHz.

9. Press BACK, then DETECTION, then AVERAGE.

10. Press the FREQ/SPAN key.

11. Press the SPAN soft key and enter 0.5, then press the MHz key to set the span to 0.5 MHz.

12. Press the AMPLITUDE key.

13. Press the REF LEVEL soft key, enter –20, and press the ENTER key to set the reference level to –20 dBm.

14. Press the FREQ/SPAN key and the CENTER soft key.

15. Enter 50 and press the MHz soft key to set the center frequency to 50 MHz.

16. On the Anritsu ML2430A-Series Power Meter, press the Sensor key and then the CalFactor soft key.

Press the FREQ soft key and enter 50 MHz for the Input Signal Frequency. This sets the power meter to

the proper power sensor cal factor. Press the Sensor key to display the power reading.

17. Set the MG3692A power level to –30 dBm as indicated on the power meter.

18. Verify that the M1 reading is within ± 1 dBm maximum from the input signal.

MS2711B Maintenance 10580-00072 C 2-9

Page 24

Dynamic Range Test Performance Verification

2-7 Dynamic Range Test

This test can be used to verify the dynamic range of the Spectrum Analyzer.

Equipment required:

• Two Anritsu MG3692A Synthesized Signal Sources with Option 2A, Option 4, and Option 15A, or

equivalent

• Anritsu N241A50 Power Splitter or equivalent

• Anritsu 34NN50A 50 ohm adapter or equivalent

• Anritsu 34RSN50 50 ohm adapter or equivalent

• Two Anritsu 15NNF50-1.5C RF Coaxial Cables or equivalent

Procedure:

1. Connect the output of the Power Splitter to the RF In port of the Spectrum Analyzer.

2. Connect the output of both signal sources to the input of the Power Splitter and turn on both sources.

3. On the Spectrum Analyzer, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn

on the Spectrum Analyzer. (This sets the instrument to the factory preset state.)

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

4. Set the center frequency of the first source to 1.0 GHz, and set the center frequency of the second source

to 1.2 GHz.

5. On the Spectrum Analyzer, press the FREQ/SPAN key.

6. Press the CENTER soft key, enter 1100, and press the MHz soft key to set the center frequency

to 1100 MHz.

7. Press the SPAN soft key and enter 500, then press the MHz key to set the span to 500 MHz.

8. Press the AMPLITUDE key and then the REF LEVEL soft key.

9. Enter –20 and then press the ENTER key to set the reference level to –20 dBm.

10. Press the BW/SWEEP key.

11. Press the RBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 30 kHz,

then press ENTER to set the resolution bandwidth to 30 kHz.

12. Press BACK, then the VBW soft key, and then the MANUAL soft key. Use the Up/Down arrow key to

select 30 kHz, then press ENTER to set the video bandwidth to 30 kHz.

13. Adjust the signal levels of both signal sources so that both signal peaks are at – 20 dBm as indicated on

the Spectrum Analyzer display.

14. Refer to Step 10 through Step 12, and set the RBW to 10 kHz and the VBW to 1 kHz.

15. When the sweep is complete, reduce the power level of the second source signal to below –85 dBm and

verify that the signal is visible at below –85 dBm.

2-10 10580-00072 C MS2711B Maintenance

Page 25

Performance Verification Power Monitor (Option 5) Verification

2-8 Power Monitor (Option 5) Verification

If the Power Monitor is installed in the Spectrum Analyzer, then the following test can be used to verify the

accuracy of the power measurements. Measurement calibration of the Spectrum Analyzer is not required for

this test.

Equipment Required:

RF Detector, 10 MHz to 20 GHz, Anritsu 560-7N50B

10 dB Attenuator, Weinschel 1-10

30 dB Attenuator, Weinschel 1-30

RF Reference Source, 0.050 GHz, Anritsu MA2418A

DC Power Supply, Anritsu 2000-933

Procedure

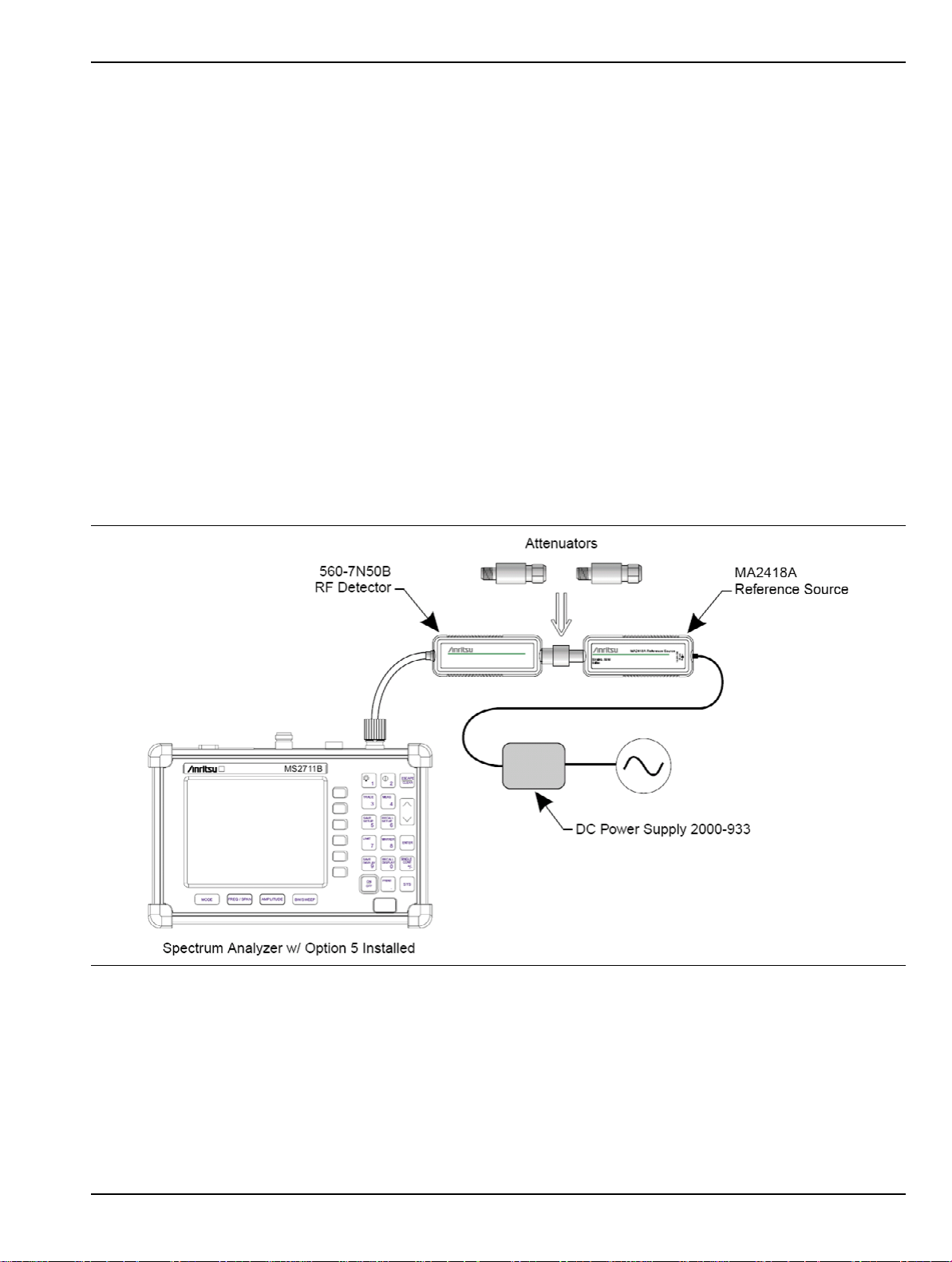

1. Connect the DC power supply to the MA2418A Reference Source. (Refer to Figure 2-2.)

2. Connect the MA2418A Reference Source to the input of the 560-7N50B RF detector.

3. Connect the RF Detector output to the RF Detector input of the MS2711B Spectrum Analyzer.

4. Connect the DC power supply to the appropriate line voltage in order to supply power to the MA2418A

Reference Source.

Figure 2-2. Power Monitor Verification

5. Press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn on the Spectrum Analyzer.

(This sets the instrument to the factory preset state.)

6. Press the MODE soft key.

7. Use the Up/Down arrow key to highlight POWER MONITOR, then press ENTER.

8. Press the ZERO soft key to zero the power monitor. When complete, ZERO ADJ:ON is displayed in the

message area.

MS2711B Maintenance 10580-00072 C 2-11

Page 26

Preamplifier (Option 8) Verification Performance Verification

9. Verify that the power monitor reading is 0.0 dBm ±1 dB.

10. Connect the output of the MA2418A Reference Source to the two attenuators so as to add 40 dB of

attenuation (refer to Figure 2-2).

11. Connect the MA2418A Reference Source and the attenuators to the input of the 560-7N50B RF detector.

12. Verify that the power monitor reading is now –40.0 dBm ±2 dB.

2-9 Preamplifier (Option 8) Verification

If the Preamplifier (Option 8) is installed in the Spectrum Analyzer, then the following tests can be used to

verify the functionality of the Preamplifier.

Displayed Average Noise Level (DANL)

This test verifies the performance of the displayed average noise level with the Preamplifier turned on.

Equipment Required:

Anritsu 28N50-2 or SM/PL 50 ohm Termination or equivalent

Procedure:

1. Connect the 50 ohm termination to the MS2711B RF Input.

2. On the Spectrum Analyzer, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn

on the Spectrum Analyzer. (This sets the instrument to the factory preset state.)

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

3. On the MS2711B, press the AMPLITUDE key and the REF LEVEL soft key.

4. Enter –75 and press the ENTER key to set the Reference Level to –75 dBm.

5. Press the SCALE soft key and enter 5, then press ENTER.

6. Press the BW/SWEEP key.

7. Press the DETECTION soft key, then press the AVERAGE soft key, then press BACK.

8. Press the RBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 10 kHz.

9. Press ENTER to set the resolution bandwidth to 10 kHz, and press the BACK soft key.

10. Press the VBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 100 Hz.

Press ENTER to set the video bandwidth to 100 Hz.

11. Press the MEAS (4) key and then press the PREAMP soft key to turn the Preamplifier on.

12. Press the FREQ/SPAN key and the START soft key.

13. Enter 1 and press the MHz soft key to set the start frequency to 1 MHz.

14. Press the STOP soft key and enter 4, then press the MHz soft key to set the stop frequency to 4 MHz.

15. Wait until a full sweep is complete.

16. Press the MARKER (8) key and then press the M1 soft key.

17. Press the MARKER TO PEAK soft key. Record the M1 amplitude reading and verify that it is ≤ –115 dBm.

18. Press the BW/SWEEP key.

19. Press the VBW soft key, and then the MANUAL soft key. Use the Up/Down arrow key to select 3 kHz.

Press ENTER to set the video bandwidth to 3 kHz.

20. Press the FREQ/SPAN key and the START soft key.

21. Enter 4 and press the MHz soft key to set the start frequency to 4 MHz.

2-12 10580-00072 C MS2711B Maintenance

Page 27

Performance Verification Preamplifier (Option 8) Verification

22. Press the STOP soft key and enter 1000, then press the MHz soft key to set the stop frequency

to 1000 MHz.

23. Wait until a full sweep is complete.

24. Press the MARKER (8) key and then press the M1 soft key.

25. Press the MARKER TO PEAK soft key. Record the M1 amplitude reading and verify that it is ≤ – 115 dBm.

26. Press the FREQ/SPAN key and the START soft key.

27. Enter 1000 and press the MHz soft key to set the start frequency to 1000 MHz.

28. Press the STOP soft key, enter 2000, and press the MHz soft key to set the stop frequency to 2000 MHz.

29. Wait until a full sweep is complete.

30. Press the MARKER (8) key and then press the M1 soft key.

31. Press the MARKER TO PEAK soft key. Record the M1 amplitude reading and verify that it is ≤ – 115 dBm.

32. Press the FREQ/SPAN key and the START soft key.

33. Enter 2000 and press the MHz soft key to set the start frequency to 2000 MHz.

34. Press the STOP soft key and enter 3000, then press MHz soft key to set the stop frequency to 3000 MHz.

35. Wait until a full sweep is complete.

36. Press the MARKER (8) key and then press the M1 soft key.

37. Press the MARKER TO PEAK soft key. Record the M1 amplitude reading and verify whether it

is ≤ –115 dBm.

MS2711B Maintenance 10580-00072 C 2-13

Page 28

Level Accuracy Test Performance Verification

2-10 Level Accuracy Test

This test verifies the level accuracy of the spectrum analyzer with the Preamplifier turned on.

Equipment Required:

• Anritsu MG3692A Synthesized Signal Source, with Option 2A, Option 4, and Option 15A

• Anritsu ML2430A-Series Power Meter or equivalent

• Anritsu MA2442A High Accuracy Power Sensor or equivalent

• Anritsu N241A50 Power Splitter or equivalent

• Anritsu 34NN50A 50 ohm adapter or equivalent

• Anritsu 34RSN50 50 ohm adapter or equivalent

• Anritsu 34RKNF50 50 ohm adapter or equivalent

• Anritsu 15NNF50-1.5C RF Coaxial Cable or equivalent

• Weinschel 1-30 Fixed Attenuator, 30 dB

Procedure:

1. Connect the power sensor to the power meter and calibrate the sensor.

2. Connect the power meter, source, sensor, and attenuator as shown in Figure 2-3.

Figure 2-3. Power Meter Setup

3. On the power meter, press the Sensor key, the Cal Factor soft key, and then the FREQ soft key. Use the

keypad to enter 50 MHz as the input signal frequency, which sets the power meter to the proper power

sensor cal factor.

4. Set the MG3692A output power level to 5 dBm.

5. Set the MG3692A output to 50 MHz CW.

6. Connect the power sensor to the RF output of the MG3692A. Record the output power level in Table A-1,

“Preamplifier Level Accuracy Test Settings” on page A-2 in Appendix A “Test Records”.

7. Connect the 30 dB Fixed Attenuator between the RF output of the MG3692A and the power sensor.

2-14 10580-00072 C MS2711B Maintenance

Page 29

Performance Verification Level Accuracy Test

8. Enter the proper input signal frequency into the power meter and record the measured value in

Table A-1.

9. Calculate the Attenuator Insertion Loss using the following formula:

Attenuator Loss = Output Power @ Source – Output Power @ Attenuator

10. Disconnect the 30 dB Fixed Attenuator.

11. Repeat Step 6 through Step 10 for frequencies of 500 MHz, 1000 MHz, 1500 MHz, 2000 MHz, 2500 MHz

and 2950 MHz.

12. Using the power splitter, coaxial cable, adapters, and fixed attenuator, connect the MS2711B to the

signal source and to the power sensor as shown in Figure 2-4.

Figure 2-4. Level Accuracy Setup

13. Calculate the output power level that is required at the power splitter end that is connected to the power

sensor in order to provide the desired power level at the MS2711B RF Input. Record the calculated value

in Table A-2, “Attenuator Characterization” on page A-3 in Appendix A “Test Records”.

14. Connect the external power supply (Anritsu part number 40-115) to the MS2711B.

15. On the Spectrum Analyzer, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn

on the Spectrum Analyzer. (This sets the instrument to the factory preset state.)

16. Turn on the power meter and signal source.

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

17. Press the BW/SWEEP key.

18. Press the RBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to select 10 kHz.

Press ENTER to set the resolution bandwidth to 10 kHz.

19. Press BACK, then the VBW soft key and then the MANUAL soft key. Use the Up/Down arrow key to

select 3 kHz, then press ENTER to set the video bandwidth to 3 kHz.

20. Press BACK, then DETECTION, then AVERAGE, and then press BACK.

MS2711B Maintenance 10580-00072 C 2-15

Page 30

Level Accuracy Test Performance Verification

21. Press the MEAS (4) key and then press the PREAMP soft key to turn the Preamplifier on.

22. Press the FREQ/SPAN key.

23. Press the SPAN soft key and enter 0.5, then press the MHz key to set the span to 0.5 MHz.

24. Press the AMPLITUDE key.

25. Press the REF LEVEL soft key and enter – 40, and then press the ENTER key to set the reference level

to –40 dBm.

26. Press the FREQ/SPAN key and the CENTER soft key.

27. Enter 50 and press the MHz soft key to set the center frequency to 50 MHz.

28. On the power meter, press the Sensor key and then the CalFactor soft key. Press the FREQ soft key, then

use the keypad to enter 50 MHz for the Input signal Frequency. This sets up the power meter to use the

proper power sensor Cal Factor. Press the Sensor key to display the power reading.

29. Set the MG3692A output to 50 MHz CW and the power level to the value that was recorded in the

Required Power Meter Level column of Table A-2, “Attenuator Characterization” on page A-3 in

Appendix A “Test Records” for –50 dBm, as indicated on the power meter.

Note

30. On the MS2711B, press the MARKER (8) key, then the M1 soft key.

31. Press the MARKER TO PEAK soft key to position the marker at the center of the response for the test

frequency.

32. Verify that the M1 reading is ±2 dB maximum from the input signal, and record the M1 reading in

Table A-3, “Preamplifier Level Accuracy Test Results” on page A-4 in Appendix A.

33. Press the AMPLITUDE key.

34. Press the REF LEVEL soft key and enter – 45, and then press the ENTER key to set the reference level

to –45 dBm.

35. Set the MG3692A power level to the value that was recorded in the Required Power Meter Level column

of Table A-2, “Attenuator Characterization” on page A-3

power meter.

36. Verify that the M1 reading is ±2 dB maximum from the input signal, and record the M1 reading in

Table A-3.

37. Press the AMPLITUDE key.

38. Press the REF LEVEL soft key and enter –50. Press ENTER to set the reference level to –50 dBm.

39. Set the MG3692A power level to the value that was recorded in the Required Power Meter Level column

of Table A-2 for –60 dBm, as indicated on the power meter.

40. Verify that the M1 reading is ±2 dB maximum from the input signal, and record the M1 reading in

Table A-3.

41. Repeat Step 24 24 through Step 40 40 for frequencies of 500 MHz, 1000 MHz, 1500 MHz, 2000 MHz,

2500 MHz and 2950 MHz.

To insure accuracy, set the output of the signal source by using the power meter reading. Do not rely

on the signal source display.

in Appendix A for –55 dBm, as indicated on the

2-16 10580-00072 C MS2711B Maintenance

Page 31

Performance Verification Tracking Generator (Option 20) Verification

2-11 Tracking Generator (Option 20) Verification

If the Tracking Generator (Option 20) is installed in the Spectrum Analyzer, then the following tests can be

used to verify the functionality of the tracking generator.

Output Level Accuracy Test

This test verifies the output level accuracy of the tracking generator.

Equipment Required:

• Anritsu ML2430A Series Power Meter

• Anritsu MA2442A High Accuracy Power Sensor

Procedure:

1. Connect the external power supply (Anritsu part number 40-115) to the MS2711B.

2. On the Spectrum Analyzer, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn

on the Spectrum Analyzer. (This sets the instrument to the factory preset state.

3. Press the ON/OFF key to turn off the instrument.

4. Press and hold the 1 key, 5 key, and 9 key simultaneously, and then press the ON/OFF key to turn on the

Spectrum Analyzer in the service mode.

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

5. Press the MODE key. Use the Up/Down arrow key to select TRACKING GENERATOR and press the

ENTER key.

6. Press the SYS key.

7. Press the SERVICE soft key, then the TG soft key, and then the TG POWER STATE soft key twice in order

to switch the state to ON.

8. Press the FREQ/SPAN key.

9. Press the SPAN and then the ZERO soft keys.

10. Connect the Power Sensor to the Power Meter Calibrator output.

11. On the Power Meter, press the Cal/Zero key and then the Zero/Cal soft key. Wait until the Power Meter

completes the zeroing of the Power Sensor.

12. Disconnect the Power Sensor from the Power Meter Calibrator output and connect it to the RF Out

connector of the MS2711B Spectrum Analyzer.

13. On the Power Meter, press the Sensor key and then the CalFactor soft key.

14. Press the FREQ soft key, then use the keypad to enter 10 MHz for the Input signal Frequency. This sets

up the Power Meter to use the proper Power Sensor Cal Factor.

15. Press the Sensor key to display the measurement reading.

16. On the Spectrum Analyzer, press the FREQ/SPAN key and then the CENTER soft key.

17. Enter 10 and press the MHz soft key.

18. Press the AMPLITUDE key and then the TG OUTPUT LEVEL soft key.

19. Enter –50 and then press the ENTER key to set the tracking Generator output power level to –50 dBm.

20. On the power meter, verify that the reading is ±4 dB maximum from the set power level, and record the

reading in Table A-4, “Tracking Generator Option Level Accuracy” on page A-5 in Appendix A “Test

Records”.

21. On the Spectrum Analyzer, press the TG OUTPUT LEVEL soft key. Enter –40 and press the ENTER key.

This sets the tracking generator power output level to –40 dBm.

MS2711B Maintenance 10580-00072 C 2-17

Page 32

Tracking Generator (Option 20) Verification Performance Verification

22. On the power meter, verify that the reading is ±1.5 dB maximum from the set power level, and record the

reading in Table A-4.

23. On the Spectrum Analyzer, press the TG OUTPUT LEVEL soft key. Enter – 30 and press the ENTER key.

This sets the tracking generator power output level to –30 dBm.

24. On the power meter, verify that the reading is ± 1.5 dB maximum from the set power level, and record

the reading in Table A-4.

25. On the Spectrum Analyzer, press the TG OUTPUT LEVEL soft key. Enter – 20 and press the ENTER key.

This sets the tracking generator power output level to –20 dBm.

26. On the power meter, verify that the reading is ± 1.5 dB maximum from the set power level, and record the

reading in Table A-4.

27. On the Spectrum Analyzer, press the TG OUTPUT LEVEL soft key. Enter – 10 and press the ENTER key.

This sets the tracking generator power output level to –10 dBm.

28. On the power meter, verify that the reading is ± 1.5 dB maximum from the set power level, and record the

reading in Table A-4.

29. On the Spectrum Analyzer, press the TG OUTPUT LEVEL soft key. Enter 0 and press the ENTER key.

This sets the tracking generator power output level to 0 dBm.

30. On the power meter, verify that the reading is ± 1.5 dB maximum from the set power level, and record the

reading in Table A-4.

31. Repeat Step 13 through Step 30 for frequencies of 100 MHz, 500 MHz, 1000 MHz, 1500 MHz, 2060 MHz,

2061 MHz, 2500 MHz and 3000 MHz.

2-18 10580-00072 C MS2711B Maintenance

Page 33

Performance Verification Tracking Generator (Option 20) Verification

Tracking Generator Harmonics And Spurious Test

This test verifies the second harmonics and spurious generated from the tracking generator.

Equipment Required:

• Anritsu MS2665C Spectrum Analyzer or equivalent

• Anritsu 15NN50-1.5C RF Coaxial Cable or equivalent

Procedure:

1. Set up the MS2665C Spectrum Analyzer as follows:

a. Press the Preset key and then press the Preset All (F1) soft key.

b. Press the Frequency key.(

c. Press the Start Freq (F2) soft key and enter 550 MHz to set the start frequency to 550 MHz.

d. Press the Stop Freq (F3) soft key and enter 4 GHz to set the stop frequency to 4 GHz.

2. Connect the external power supply (Anritsu part number 40-115) to the MS2711B.

3. On the Spectrum Analyzer, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn

on the Spectrum Analyzer. (This sets the instrument to the factory preset state.)

4. Press the ON/OFF key to turn off the instrument.

5. Press and hold the 1 key, 5 key, and 9 key simultaneously, and then press the ON/OFF key to turn on the

Spectrum Analyzer in the service mode.

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

6. Press the MODE key. Use the Up/Down arrow key to select TRACKING GENERATOR and press the

ENTER key.

7. Press the SYS key.

8. Press the SERVICE soft key, then the TG soft key, and then the TG POWER STATE soft key twice to

switch the state to ON.

9. Press the AMPLITUDE key and then the TG OUTPUT LEVEL soft key.

10. Enter 0 and the press the ENTER key to set the tracking Generator output power level to 0 dBm.

11. Press the FREQ/SPAN key.

12. Press the SPAN and then the ZERO soft keys.

13. Press the BACK soft key.

14. Press the CENTER soft key.

15. Enter 750 and press the MHz

16. Connect an RF cable between the RF Out connector of the MS2711B and the RF Input connector of the

MS2665C.

17. On the MS2665C, press the AMPLITUDE key.

18. Press the Peak –>RLV (F2) soft key to search the peak reference value.

19. Press the MARKER (8) key.

20. Press the Zone Width (F5) soft key.

21. Press the Spot (F1) soft key and then the Return (F6) soft key.

soft key to set the tracking generator frequency to 750 MHz.

22. Use the rotary knob to move the marker to the response that is the second harmonic frequency of the

tracking generator output frequency.

MS2711B Maintenance 10580-00072 C 2-19

Page 34

Tracking Generator (Option 20) Verification Performance Verification

23. Subtract the marker reading from the Reference value reading. Verify that the calculated value

is ≤ – 20 dBc, and record the reading in Table A-5, “Tracking Generator Harmonics and Spur” on

page A-5 in Appendix A “Test Records”.

24. Use the rotary knob to move the marker to the worst non-harmonic response.

25. Subtract the marker reading from the Reference value reading. Verify that the calculated value

is ≤ – 20 dBc, and record the reading in Table A-5.

26. On the MS2711B, press the CENTER soft key. Enter 790 and press the MHz soft key to set the tracking

generator frequency to 790 MHz.

27. On the MS2665C, press the AMPLITUDE key.

28. Press the Peak –>RLV(F2) soft key to search the peak reference value.

29. Repeat Step 22 through Step 25.

30. Repeat Step 26 through Step 29 for frequencies of 830 MHz, 870 MHz, 910 MHz, 950 MHz, 1600 MHz,

1680 MHz, 1760 MHz, 1840 MHz, 1920 MHz and 2000 MHz.

Note

Change the Stop Freq uency of the MS2665C to 6 GHz when you are testing frequencies that are

higher than 1600 MHz.

2-20 10580-00072 C MS2711B Maintenance

Page 35

Performance Verification Tracking Generator (Option 20) Verification

Frequency Offset Tracking Test

This test verifies the functionality of the frequency offset tracking capability of the Tracking Generator.

Equipment Required:

• Anritsu MS2665C Spectrum Analyzer or equivalent

• Anritsu 15NN50-1.5C RF Coaxial Cable or equivalent

Procedure:

1. Set up the MS2665C Spectrum Analyzer as follows:

a. Press the Preset key and then press the Preset All (F1) soft key.

b. Press the Frequency key.

c. Press the Center Freq (F1) soft key and enter 2 GHz.

d. Press the Span key and then the Span (F1) soft key.

e. Enter 15 MHz to set the frequency span to 15 MHz.

2. Connect the external power supply (Anritsu part number 40-115) to the MS2711B.

3. On the Spectrum Analyzer, press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn

on the Spectrum Analyzer. (This sets the instrument to the factory preset state.)

Note Before continuing, allow a 30-minute warm up for the internal circuitry to stabilize.

4. Press the MODE key. Use the Up/Down arrow key to select TRACKING GENERATOR, and press the

ENTER key.

5. Press the AMPLITUDE key and then the TG OUTPUT LEVEL soft key.

6. Enter 0 and the press the ENTER key to set the tracking Generator output power level to 0 dBm.

7. Press the FREQ/SPAN key.

8. Press the SPAN and then the ZERO soft keys.

9. Press the BACK soft key.

10. Press the CENTER soft key.

11. Enter 2 and press the GHz soft key to set the tracking generator frequency to 2 GHz.

12. Connect an RF cable between the RF Out connector of the MS2711B and the RF Input connector of the

MS2665C.

13. On the MS2665C, press the A.B key and then the Storage (F5) soft key.

14. Press the MaxHold (F2) soft key.

15. When a smooth peak response appears on the display, press the AMPLITUDE key.

16. Press the Peak –>RLV (F2) soft key to search the peak reference value.

17. Press the

log Scale (F5) soft key and then press the 5dB/Div (F2) soft key.

18. Press the MARKER (8) key.

19. Press the Zone Width (F5) soft key.

20. Press the Spot (F1) soft key and then the Return (F6) soft key.

21. Press the Marker Peak Search key and record the marker reading.

22. On the MS2711B, press the TG FREQ OFFSET soft key.

23. Enter 5 and press the ENTER key to set the offset frequency to +5 MHz above the selected center

frequency.

MS2711B Maintenance 10580-00072 C 2-21

Page 36

Tracking Generator (Option 20) Verification Performance Verification

24. On the MS2665C, press the A.B key and then the Restart (F5) soft key.

25. Press the Marker Peak Search key and record the marker reading. Then subtract the marking reading

obtained in Step 21 from this new marker reading.

26. Verify that the calculated difference is 5 MHz ±400 kHz.

27. On the MS2711B, press the TG OFFSET soft key.

28. Enter –5 and press the ENTER key to set the offset frequency to –5 MHz below the selected center

frequency.

29. On the MS2665C, press the A.B key and then the Restart (F5) soft key.

30. Press the Marker Peak Search key and record the marker reading. Then subtract this new marker

reading from the marker reading that was obtained in Step 21.

31. Verify that the calculated difference is 5 MHz ±400 kHz.

2-22 10580-00072 C MS2711B Maintenance

Page 37

Performance Verification Tracking Generator (Option 20) Verification

MS2711B Maintenance 10580-00072 C 2-23

Page 38

Tracking Generator (Option 20) Verification Performance Verification

2-24 10580-00072 C MS2711B Maintenance

Page 39

Chapter 3 — Removal and Replacement

3-1 Introduction

Only qualified personnel should open the case and replace internal assemblies. Assemblies that are shown in

the replaceable parts list are typically the only items that may be replaced. Because they are highly fragile,

items that must be soldered may not be replaced without specialized training. Removing RF shields from PC

boards or adjusting screws on or near the shields may detune sensitive RF circuits and will result in degraded

instrument performance.

An Electrostatic Discharge (ESD) safe work area and proper ESD handlin g procedures (that conform

to ANSI/ESD S20.20-1999 or ANSI/ESD S20.20-2007) are mandatory to avoid ESD damage when

Caution

3-2 Static Sensitive Assembly Handling

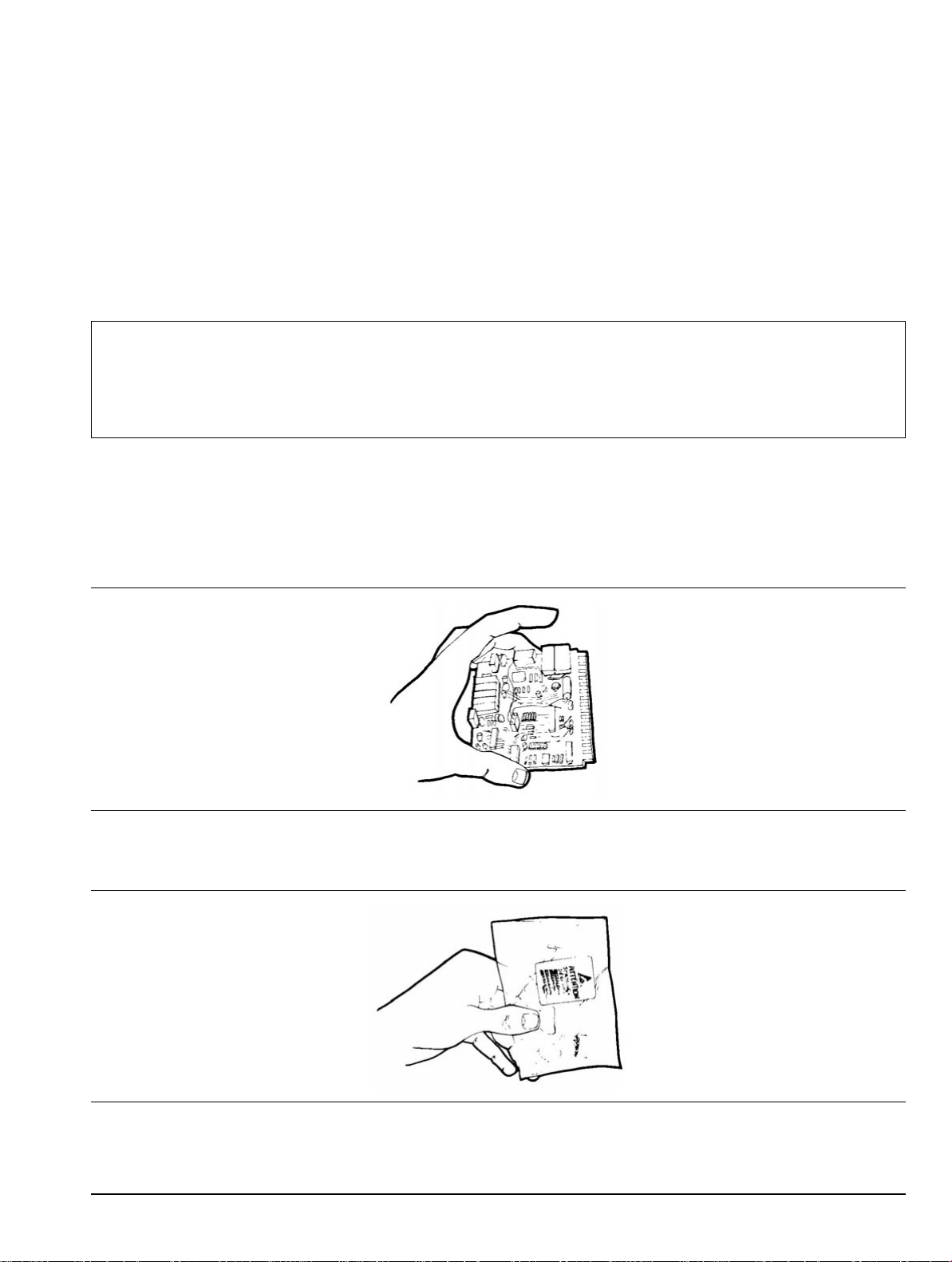

The MS2711B contains components that can be damaged by static electricity. Figure 3-1 through Figure 3-3

illustrate the precautions that should be followed when handling static-sensitive subassemblies and

components. If followed, these precautions will minimize the possibilities of static-shock damage to these

items.

handling subassemblies or components found in the MS2711B. Additional information pertaining to

ESD can be found at the ESD Association Web site:

http://www.esda.org/s2020.html

Figure 3-1. Handling a PCB

Handle PCBs only by the edges. Do not handle by the edge connectors.

Figure 3-2. Static-Shielded Container

MS2711B Maintenance 10580-00072 C 3-1

Page 40

Static Sensitive Assembly Handling Removal and Replacement

Transport and store PCBs in static-shielded containers only.

Figure 3-3. Static-Discharge W ristband

Always wear a static-discharge wristband when working with static sensitive components.

Additional Precautions

• Do not handle static sensitive components in areas where the floor or work surface covering is capable of

generating a static charge.

• Keep work areas clean and free of any objects capable of holding or storing a static charge.

3-2 10580-00072 C MS2711B Maintenance

Page 41

Removal and Replacement Battery Pack Removal And Replacement

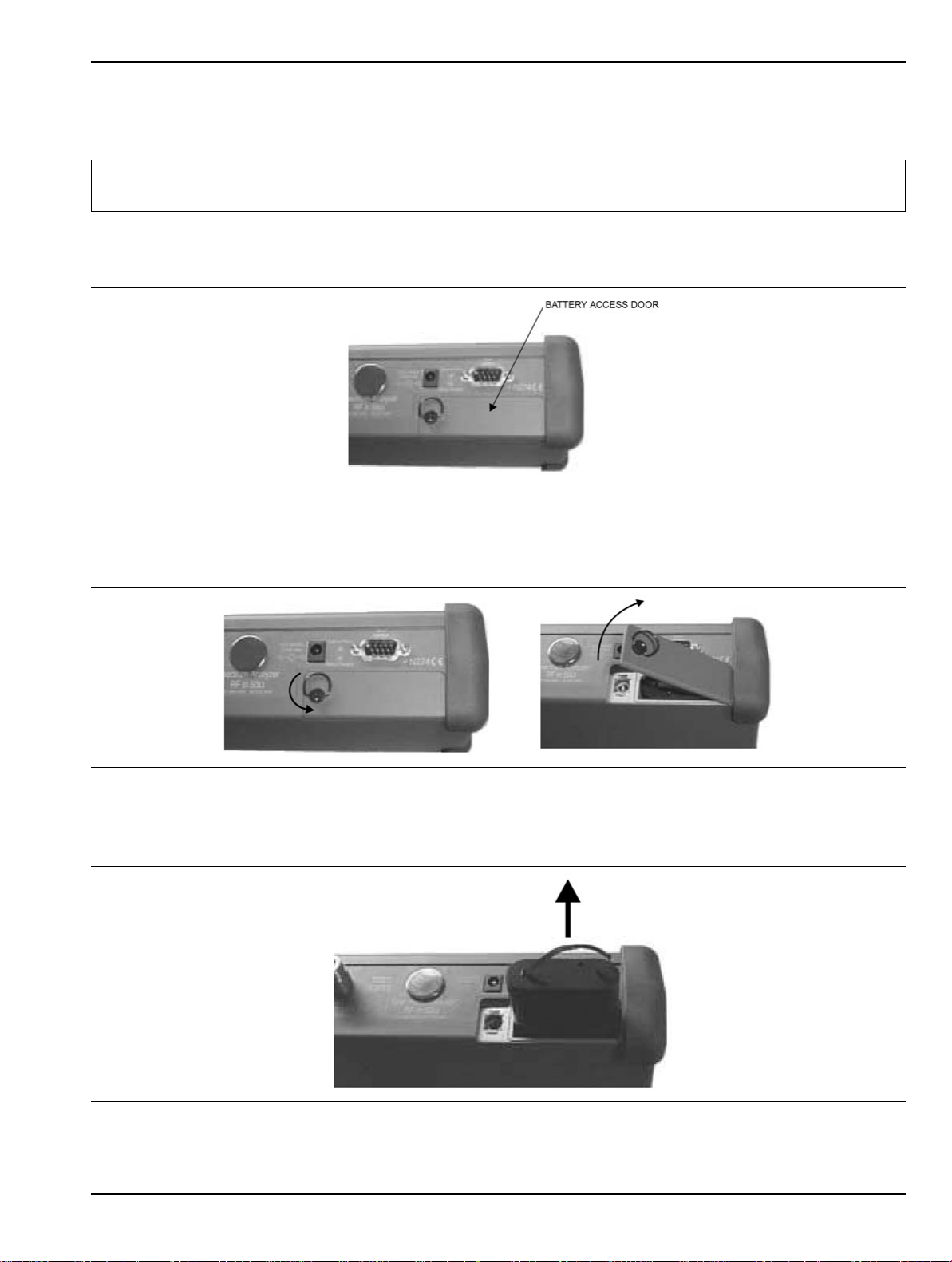

3-3 Battery Pack Removal And Replacement

This procedure provides instructions for removing and replacing the Spectrum Analyzer battery pack.

Note

1. With the Spectrum Analyzer standing upright on a stable surface, locate the battery access door

(Figure 3-4).

Figure 3-4. Opening the Battery Access Door

2. Lift up the access door handle and rotate it 90 degrees counterclockwise, as illustrated in Figure 3-4.

3. Lift the door and remove the door, as illustrated in Figure 3-5.

Procedures in this manual may apply to many similar instruments. Photos and illustrations used are

representative and may show instruments other than the MS2711B Spectrum Analyzer.

Figure 3-5. Battery Access Door, Opening

4. Grasp the battery lanyard and pull the battery straight up and out of the unit, as illustrated in

Figure 3-6.

Figure 3-6. Removing the Battery

MS2711B Maintenance 10580-00072 C 3-3

Page 42

Battery Pack Removal And Replacement Removal and Replacement

5. Replacement is the opposite of removal. Note the orientation of the battery contacts, and be sure to insert

the new battery with the contacts facing the rear of the unit (Figure 3-7).

Figure 3-7. Battery Contacts

Battery Information

The following information relates to the care and handling of the instrument battery, and NiMH batteries in

general.

• The Nickel Metal Hydride (NiMH) battery that is supplied with the MS2711B is shipped in a discharged

state. Before using the MS2711B Spectrum Analyzer, the internal battery must first be charged for

three hours, either in the instrument or in the optional battery charger (Anritsu part

number: 2000-1029).

• Use only Anritsu approved battery packs.

• Recharge the battery only in the instrument or in an Anritsu approved charger.

• With a new NiMH battery, full performance is achieved after three to five complete charge and discharge

cycles.

• When either the MS2711B or the charger is not in use, disconnect it from the power source.

• Do not charge batteries for longer than 24 hours. Overcharging may shorten battery life.

• If left unused, a fully charged battery will discharge itself over time.

• Temperature extremes affect the ability of the battery to charge. Allow the battery to cool down or warm

up as necessary before use or charging.

• Discharge an NiMH battery from time to time to improve battery performance and battery life.

• The battery can be charged and discharged hundreds of times, but it will eventually wear out.

• The battery may need to be replaced when the operating time between charges becomes noticeably

shorter than normal.

• Never use a damaged or worn out charger or battery.

• Storing the battery in extreme hot or cold places reduces the capacity and the lifetime of the battery.

• Never short-circuit the battery terminals.

• Do not drop, mutilate, or attempt to disassemble the battery.

• Do not dispose of batteries in a fire!

• Batteries must be recycled or disposed of properly. Do not place batteries in household garbage.

• Always use the battery for its intended purpose only.

3-4 10580-00072 C MS2711B Maintenance

Page 43

Removal and Replacement Battery Pack Removal And Replacement

Battery Testing Procedure

1. With the instrument off and the battery installed, connect the Universal AC Adapter to the 12.5-15VDC

(1100 mA) connector. The External Power LED and the Battery Charging LED will light.

If the Battery Charging LED does not illuminate, then the battery state of charge may be too

low to immediately start full charging. Leaving the unit connected to AC power for several

Note

2. Disconnect the AC-DC Adapter when the Battery Charging LED turns off, indicating that the battery is

fully charged.

3. Press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn on the instrument. This sets

the instrument to the factory preset state. Press Enter when prompted to continue.

4. Press the SYS key, followed by the STATUS soft key. Verify that the indicated battery charge is ≥ 80%. If

the value is 80% or above, then press the ESCAPE/CLEAR key and continue with this procedure. If the

value is lower than 80%, then a discharge/charge cycle may be needed in order to improve the battery

capacity. Completely discharge the battery, as described in Step 5 and Step 6 below, and then recharge

the battery as described in Step 1 and Step 2. If the battery capacity does not increase after a

discharge/charge cycle, then replace the battery.

5. Press the START CAL key (to keep the instrument from going into HOLD mode) and make note of the test

start time.

hours may bring the battery up to a level where full charging can begin. Turn the unit off and

back on to see if the Battery Charging LED illuminates, thereby indicating that a full charge

cycle has begun.

6. When the instrument display fades and the instrument switches itself off, make note of the test stop

time.

7. The total test time (Step 5 and Step 6) should be ≥ 2.5 hours. If the total test time is < 2.5 hours, then

replace the battery.

MS2711B Maintenance 10580-00072 C 3-5

Page 44

Front Panel Assembly Removal And Replacement Removal and Replacement

3-4 Front Panel Assembly Removal And Replacement

This procedure provides instructions for removing and replacing the Spectrum Analyzer front panel assembly.

With the front panel assembly removed, the LCD display, keypad PCB, keypad membrane, and main PCB

assemblies can be removed and replaced.

1. Place the Spectrum Analyzer face up on a work surface.

2. Remove the four rubber corner bumpers by carefully sliding the bumpers off of the case corners

(Figure 3-8).

Figure 3-8. Removing the Corner bumpers

3. With the bumpers removed, the access holes for the case screws are revealed. Use a Phillips screwdriver

to remove the four screws that secure the two halves of the Spectrum Analyzer case together.

4. Carefully lift up on the right side (as viewed from the front) of the front half of the case and begin to

separate the two halves.

Caution

5. Carefully depress the latch tab and disconnect the LCD display cable from J12 on the main PCB.

6. Carefully disconnect the keypad interface cable from J1 on the main PCB.

7. Carefully disconnect the speaker cable from J23 on the main PCB.

8. Carefully disconnect the LCD display backlight cable from J15 on the main PCB.

Do not force or pull the two halves of the case apart because delicate cables are attached between

the two halves. These cables must be disconne cted first. Refer to Figure 3-9.

3-6 10580-00072 C MS2711B Maintenance

Page 45

Removal and Replacement Front Panel Assembly Removal And Replacement

Figure 3-9. Spectrum Analyzer Front Panel Cable Connections

9. Remove the front panel assembly.

10. Reverse the above steps to replace the front panel assembly.

Note

Figure 3-10. Corner Bumper Detail

The corner bumpers mount only one way. That is, the raised area inside one end of the bumper

(Figure 3-10) is made to conform to the contour of only the front cover.

MS2711B Maintenance 10580-00072 C 3-7

Page 46

LCD Assembly Replacement Removal and Replacement

3-5 LCD Assembly Replacement

This procedure provides instructions for removing and replacing the Liquid Crystal Display (LCD) after the

front panel assembly has been separated from the Spectrum Analyzer.

1. Remove the front panel assembly as directed in section “Front Panel Assembly Removal And

Replacement” on page 3-6.

2. Place the front panel assembly face down on a protected work surface.

3. Remove the 14 Phillips screws that attach the backing plate to the front panel assembly.

4. Release the LCD display cable and speaker cable from the retaining clips on the front panel backing

plate.

Figure 3-11. Front Panel Backing Plate

5. Remove the front panel backing plate, carefully feeding the LCD cable through the access hole in order to

avoid damage to the cable or its connector.

6. Remove the rubber cushion pad from the LCD assembly and remove the assembly.

7. Reverse the above steps to install the replacement assembly.

3-8 10580-00072 C MS2711B Maintenance

Page 47

Removal and Replacement Key Pad PCB Replacement

3-6 Key Pad PCB Replacement

This procedure provides instructions for removing and replacing the key pad PCB.

1. Remove the front panel assembly as directed in section “Front Panel Assembly Removal And

Replacement” on page 3-6.

2. Place the front panel assembly face down on a protected work surface.

3. Remove the 14 Phillips screws that attach the backing plate to the front panel assembly.

4. Release the LCD display cable and speaker cable from the retaining clips on the front panel backing plate

(Figure 3-12).

5. Remove the front panel backing plate, carefully feeding the LCD cable through the access hole to avoid

damage to the cable or its connector.

6. Remove the rubber cushion pad from the key pad PCB and remove the PCB.

Figure 3-12. Front Panel Keypad PCB Location

7. Reverse the above steps to install the replacement assembly. Take care to position the speaker and

speaker cable properly.

MS2711B Maintenance 10580-00072 C 3-9

Page 48

Key Pad Membrane Replacement Removal and Replacement

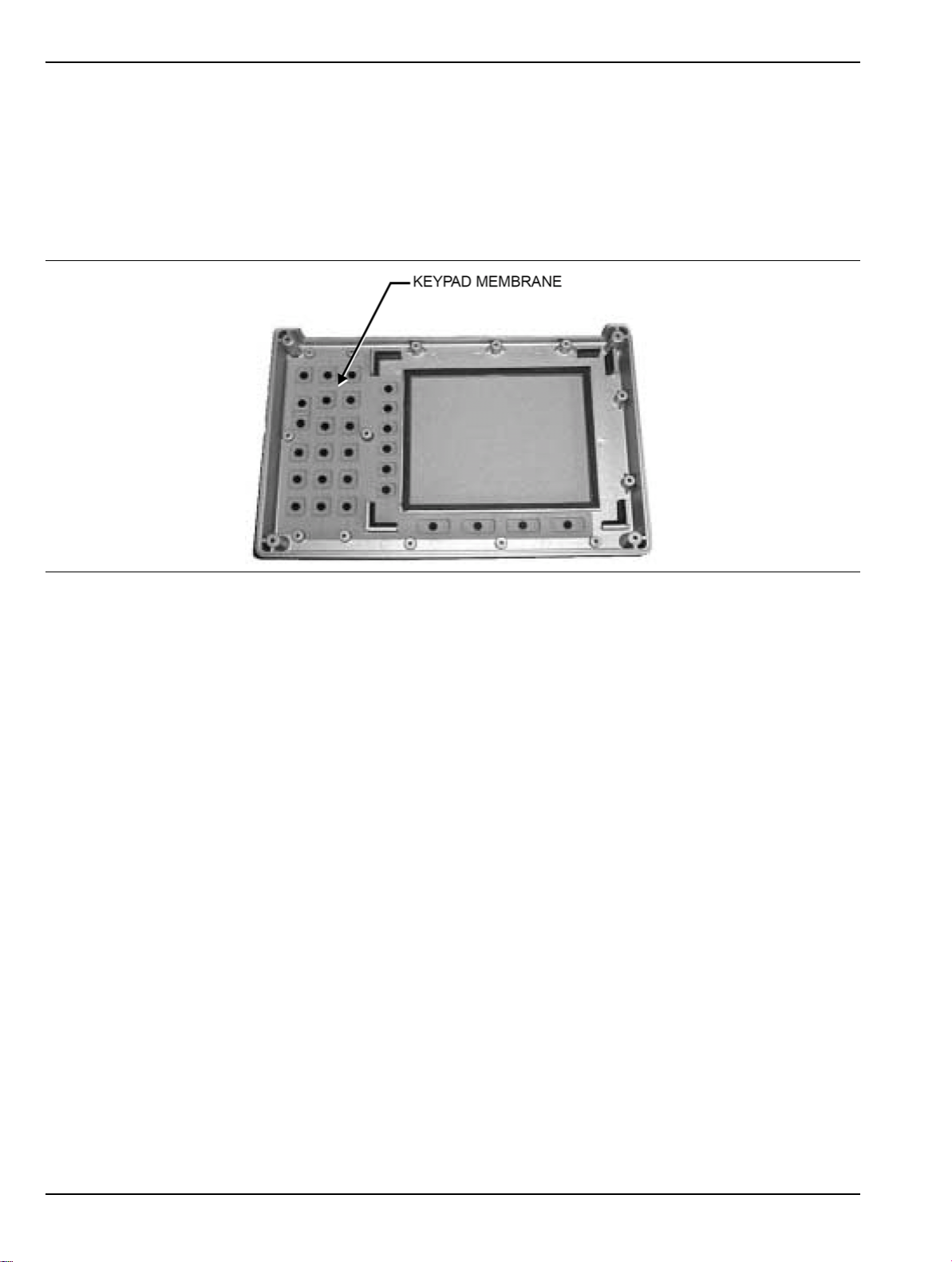

3-7 Key Pad Membrane Replacement

This procedure provides instructions for replacing the key pad membrane.

1. Remove the front panel assembly as directed in section “Front Panel Assembly Removal And

Replacement” on page 3-6.

2. Remove the key pad PCB as directed in section “Key Pad PCB Replacement” on page 3-9.

3. Remove the keypad membrane by gently pulling the membrane up and out of the holes in the front panel.

if

Figure 3-13. Front Panel Keypad Membrane

4. Reverse the above steps to install the replacement membrane.

3-10 10580-00072 C MS2711B Maintenance

Page 49

Removal and Replacement PCB Assembly Replacement

3-8 PCB Assembly Replacement

This procedure provides instructions for replacing the PCB assembly with the connector panel attached. For an

MS2711B with no options, or for an MS2711B with only Option 20, the PCB assembly consists of two PCBs

(Control and Spectrum Analyzer). For an MS2711B with Option 5 or Option 8 installed, the assembly consists

of three PCBs (Control, Spectrum Analyzer, and Preamplifier or Power Monitor). These PCB assemblies must

always be replaced as a matched set.

1. Remove the front panel assembly as directed in Section “Front Panel Assembly Removal And

Replacement” on page 3-6.

2. Disconnect the battery connector from J13 on the main PCB.