APA2120/2121

Stereo 2-W Audio Power Amplifier (with DC_Volume Control)

Features

••

•

Low operating current with 14mA

••

• Improved depop circuitry to eliminate turn-on

and turn off transients in outputs

• High PSRR

• 32 steps volume adjustable by DC voltage with

hysteresis

• 2W per channel output power into 4Ω load at 5V,

BTL mode

• Two output modes allowable with BTL and SE

modes selected by SE/BTL pin

• Low current consumption in shutdown mode

(50µA)

• Short Circuit Protection

• Power off depop circuit integration

• TSSOP-24 with or without thermal pad package

General Description

APA2120/1 is a monolithic integrated circuit, which

provides precise DC volume control, and a stereo

bridged audio power amplifiers capable of producing

2.7W(2.0W) into 3Ω with less than 10% (1.0%)

THD+N. The attenuator range of the volume control

in APA2120/1 is from 20dB (DC_Vol=0V) to -80dB

(DC_Vol=3.54V) with 32 steps. The advantage of

internal gain setting can be less components and PCB

area. Both of the depop circuitry and the thermal

shutdown protection circuitry are integrated in

APA2120/1, that reduce pops and clicks noise during power up or shutdown mode operation. It also

improves the power off pop noise and protects the

chip from being destroyed by over temperature and

short current failure. To simplify the audio system

Applications

design, APA2120/1 combines a stereo bridge-tied

loads (BTL) mode for speaker drive and a stereo

• NoteBook PC

• LCD Monitor or TV

single-end (SE) mode for headphone drive into a

single chip, where both modes are easily switched

by the SE/BTL input control pin signal. Besides, the

multiple input selection is used for portable audio

system.

Ordering and Marking Information

APA 2120/1

Handling Code

Tem p. Range

Package C ode

AP A2120/1 R :

* TSSOP-P is a standard TSSOP package with a thermal pad exposure on the bottom of the package.

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and advise

customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

AP A2120/1

XXXXX

Package C ode

R : TSSOP-P *

Tem p. Range

I : - 4 0 to 8 5 C

Handling Code

T U : T u b e T R : T a pe & R e e l

T Y : T ra y

XXXXX - Date Code

°

www.anpec.com.tw1

APA2120/2121

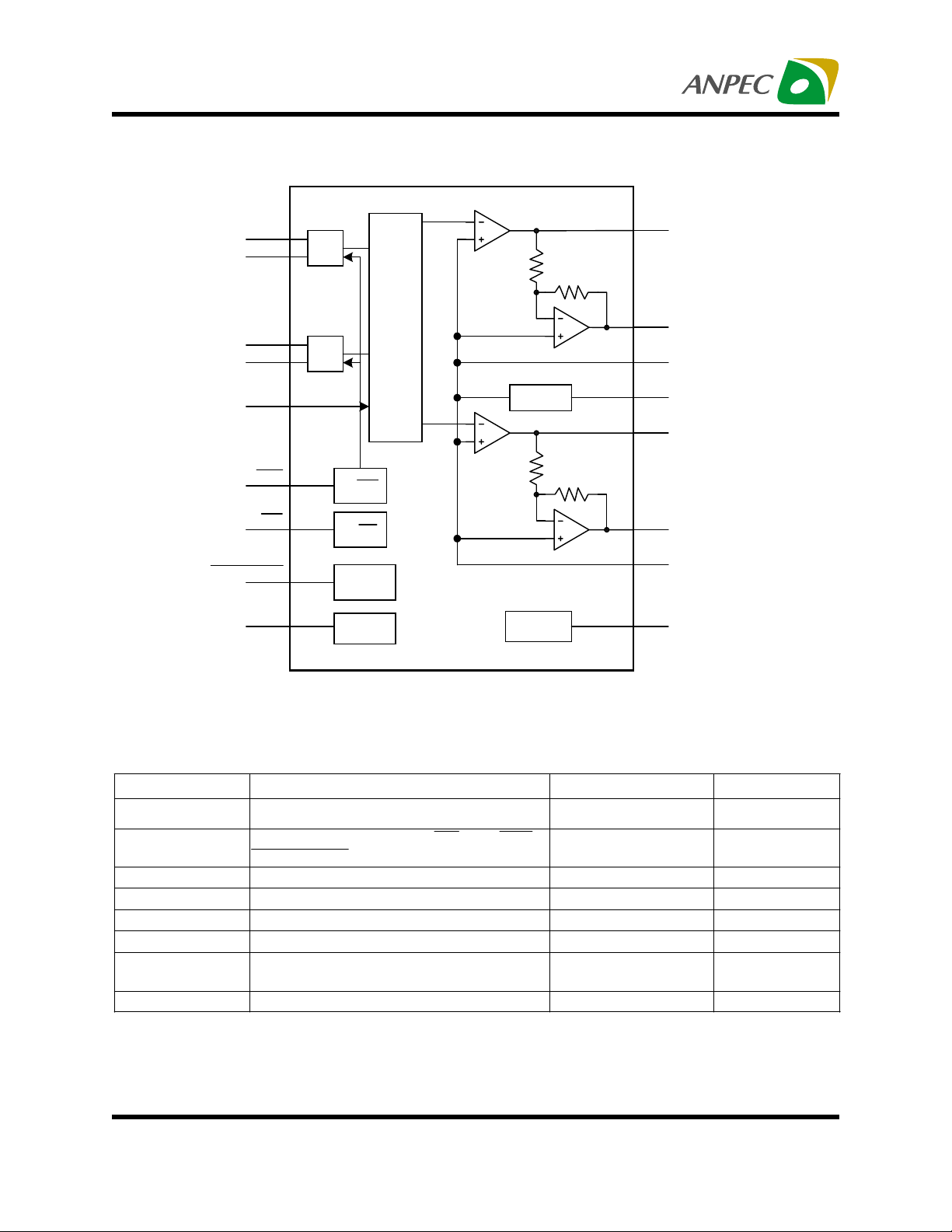

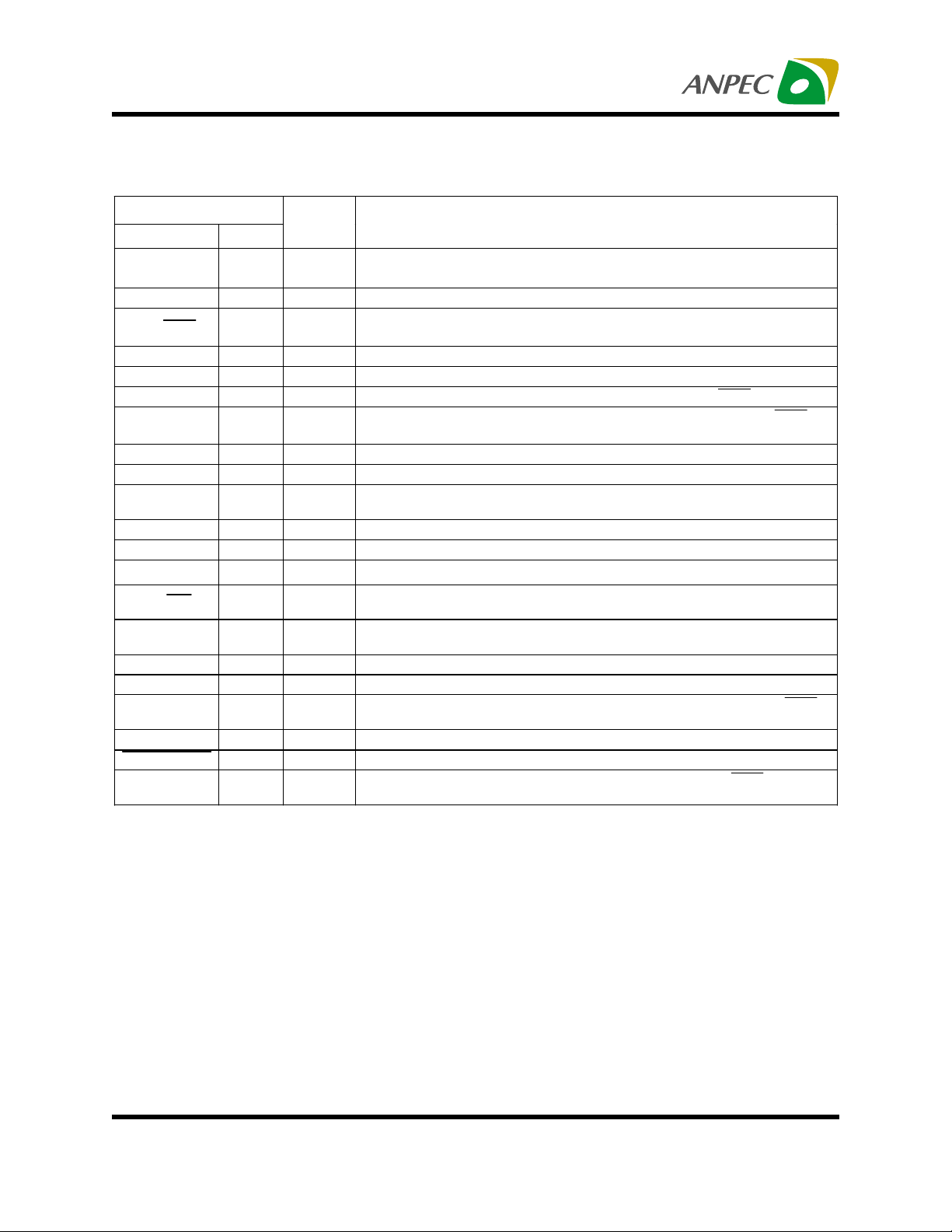

Block Diagram

LLINEIN

LHPIN

RLINEIN

RHPIN

VOLUME

HP/L IN E

SE/BTL

SHUTDOWN

PCBEEP

MUX

MUX

HP /L IN E

SE/BTL

Shutdown

ckt

PC-BEEP

ckt

Volume

Control

BYPASS

Clock Gen

LOUT+

LOUT-

LBYPASS

BYPASS

ROUT+

ROUT-

RBYPASS

CLK

For APA2121

Absolute Maximum Ratings

(Over operating free-air temperature range unless otherwise noted.)

Symbol Parameter Rating Unit

V

DD

V

IN

T

A

T

J

T

STG

T

S

V

ESD

P

D

Note:

1.APA2120/1 integrated internal thermal shutdown protection when junction temperature ramp up to 150°C

2.Human body model: C=100pF, R=1500Ω, 3 positives pulse plus 3 negative pulses

3.Machine model: C=200pF, L=0.5µF, 3 positive pulses plus 3 negative pulses

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

Supply Voltage Range -0.3 to 6 V

Input Voltage Range, SE/BTL, HP/LINE,

SHUTDOWN, PCBEN

-0.3 to V

+0.3 V

DD

Operating Ambient Temperature Range -40 to 85

Maximum Junction Temperature Intermal Limited*

1

Storage Temperature Range -65 to +150

Soldering Temperature,10 seconds 260

2

3

Electrostatic Discharge

-3000 to 3000*

-200 to 200*

Pow e r D issipatio n Inter mal Limited

C

°

C

°

C

°

C

°

V

www.anpec.com.tw2

APA2120/2121

Recommended Operating Conditions

Min. Max. Unit

Supply Voltage, V

DD

High level threshold voltage, V

Low level threshold voltage, V

Common mode input voltage, V

IH

SE/BTL , HP/LINE 4

SHUTDOWN, PCBEN 1.0

SHUTDOWN, PCBEN 2

IL

ICM

SE/BTL , HP/LINE 3

4.5 5.5 V

VDD-1.0 V

Thermal Characteristics

Symbol Parameter Value Unit

R

THJA

Thermal Resistance from Junction to Ambient in Free Air

TSSOP-P* 45 K/W

* 5 in2 printed circuit board with 2oz trace and copper pad through 9 25mil diameter vias.

The thermal pad on the TSSOP_P package with solder on the printed circuit board.

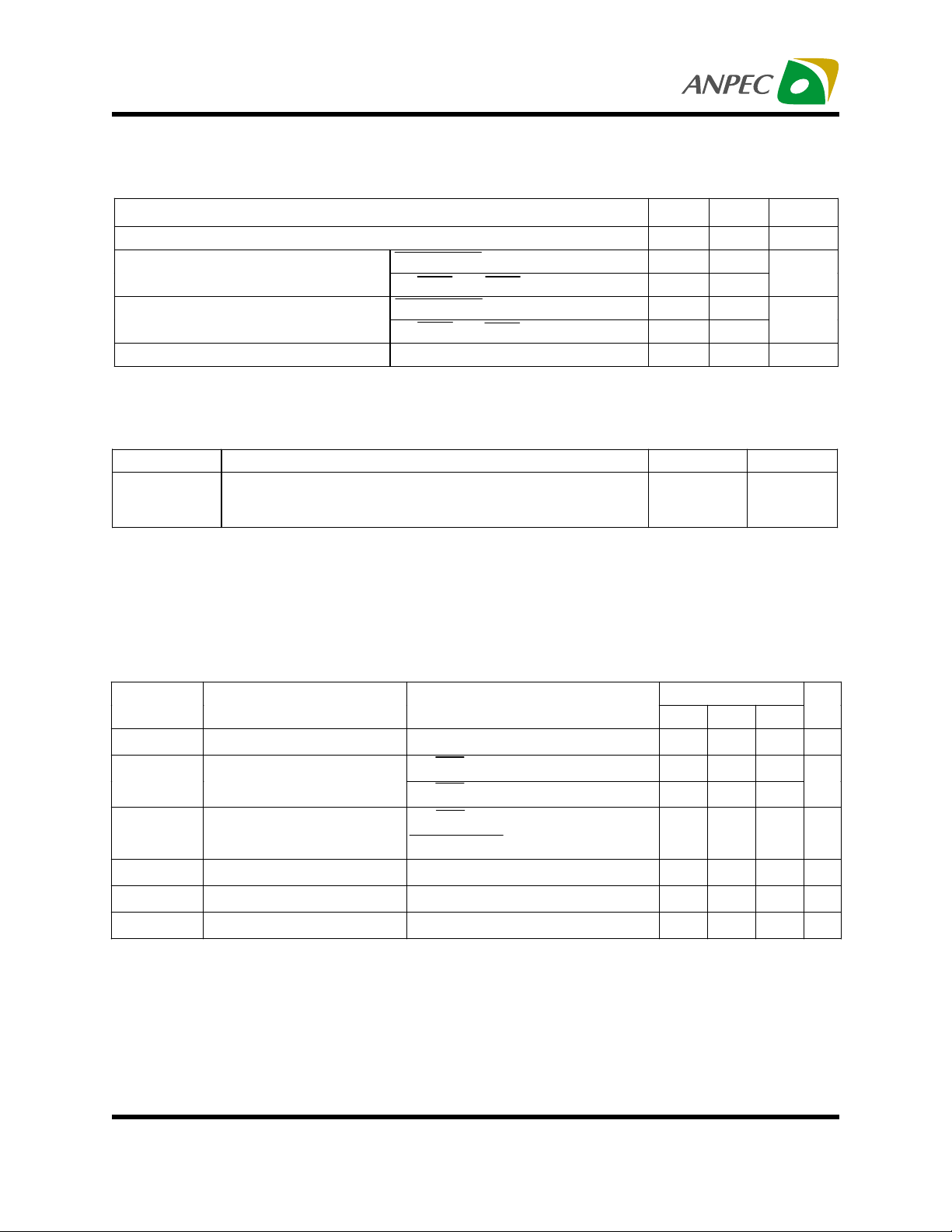

Electrical Characteristics

VDD=5V, -20°C<TA<85°C (unless otherwise noted)

V

V

Symbol Parameter Test Condition

V

DD

Supply Voltage 4.5 5.5 V

SE/BTL=0V

I

DD

I

SD

I

IH

I

IL

V

OS

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

Supply Current

Supply Current in Shutdown

Mode

SE/BTL=5V

SE/BTL=5V

SHUTDOWN=0V

High input Current 900 nA

Low Input Current 900 nA

Output Differential Voltage 5 mV

APA2120/1

Min. Typ. Max.

14 25

8.0 15

50

www.anpec.com.tw3

Unit

mA

A

µ

APA2120/2121

Electrical Characteristics (Cont.)

Operating Characteristics, BTL mode

VDD=5V,TA=25°C,RL=4Ω, Gain=2V/V (unless otherwise noted)

Symbol Parameter Test Condition

THD=10%, RL=3Ω, Fin=1kHz

THD=10%, RL=4Ω, Fin=1kHz

P

O

THD+N

PSRR

Maximum Output Power

Total Harmonic Distortion Plus

Noise

Power Ripple Rejection Ratio

THD=10%, RL=8Ω, Fin=1kHz

THD=1%, RL=3Ω, Fin=1kHz

THD=1%, RL=4Ω, Fin=1kHz

THD=0.5%, R

=8Ω, Fin=1kHz

L

PO=1.5W, RL=4Ω, Fin=1kHz

P

=1W, RL=8Ω, Fin=1kHz

O

V

=0.1Vrms, RL=8Ω, CB=1µF,

IN

Fin=120Hz

APA2120/1

Min. Typ. Max.

2.7

2.3

1.5

2.0

1.9

11.1

0.05

0.07

60 dB

Unit

W

%

Xtalk

S/N

Channel Separation

Signal to Noise Ratio

=1µF, RL=8Ω, Fin=1kHz

C

B

=1.1W, RL=8Ω, A_wieght

P

O

Operating Characteristics, SE mode

VDD=5V,TA=25°C,RL=4Ω, Gain=1V/V (unless otherwise noted)

Symbol Parameter Test Condition

THD=10%, RL=8Ω, Fin=1kHz

THD=10%, RL=32Ω, Fin=1kHz

P

O

THD+N

PSRR

Xtalk

S/N

Maximum Output Power

Total Harmonic Distortion Plus

Noise

Power Ripple Rejection Ratio

Channel Separation

Signal to Noise Ratio

THD=1%, RL=8Ω, Fin=1kHz

THD=1%, R

=32Ω, Fin=1kHz

L

PO=250mW, RL=8Ω, Fin=1kHz

P

=75mW, RL=32Ω, Fin=1kHz

O

=0.1Vrms, RL=8Ω, CB=1µF,

V

IN

Fin=120Hz

C

=1µF, RL=32Ω, Fin=1kHz

B

=75mW, SE, RL=32Ω, A_wieght

P

O

90 dB

95 dB

APA2120/1

Min. Typ. Max.

400

110

320

90

0.08

0.08

48 dB

100

100 dB

Unit

mW

%

dB

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw4

APA2120/2121

Pin Description

GND

PCBEN

VOLUME

LOUT+

LLINEIN

LHPIN

PVDD

RBYPASS

LOUT-

LBYPASS

BYPASS

GND

1

2

3

4

5

6

7

8

9

10

11

12

APA2120

TOP View

Thermal

Pad

24

23

22

21

20

19

18

17

16

15

14

13

GND

RLINEIN

SHUTDOWN

ROUT+

RHPIN

VDD

PVDD

CLK

ROUTSE/BTL

PC-BEEP

GND

GND

HP/LINE

VOLUME

LOUT+

LLINEIN

LHPIN

PVDD

RBYPASS

LOUT-

LBYPASS

BYPASS

GND

1

2

3

4

5

6

7

8

9

10

11

12

APA2121

TOP View

24

23

22

21

20

19

18

17

16

15

14

13

GND

RLINEIN

SHUTDOWN

ROUT+

RHPIN

VDD

PVDD

CLK

ROUTSE/BTL

PC-BEEP

GND

APA2120/1

Bottom View

Multiple Input Selection PCBEEP Control Input

APA2120 SE/BTL PCBEN

APA2121 HP/LINE -

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw5

APA2120/2121

Pin Function Description

Pin

Name No

GND

PCBEN 2 I/P BE EP mo de control input, active H, for APA2120 only

HP/LI N E 2 I/P

VOLUME 3 Input signal for internal volume g ain s etting.

LOUT+ 4 O/P

LLIN E IN 5 I/P

LHPIN 6 O/P

PVDD 7,18 Supply voltage only for pow e r a m plifier.

RBYPASS 8 I/P Right channel bypass voltage.

LOUT- 9 O/P

LBYPASS 10 I/P

BYPASS 11 Bias voltage generator

PC_BEEP

SE/BTL 15 I/P

ROUT- 16 O/P

CLK 17 Clock signal generator

VDD 19

RHP IN 20 I/P

ROUT+ 21 O/P

SHUTDOWN 22 I/P

RLIN E IN 23 I/P

1,12,

13,24

Config.

14 I/P

Description

Ground connection, Connected to thermal pad.

Multi-input selection input, headphone mode when held high, line-in

mode when held low for APA2121 only.

Left channel po sitive output in BTL mode and SE mode.

Left channel line input terminal, selected when HP/LINE is held low.

Left channel headphone input terminal, selected when HP/LINE is

held high.

Left channel negative output in BTL mode and high impedance in

SE mode.

Left channel bias voltage generator.

PCBEP signal input

Output mode control input, high for SE output mode and low for

BTL m ode .

Right channel negative output in BTL mode and high impedance in

SE mode.

Supply voltage for internal circuit excepting pow er am p lifier.

Right channel headphone input terminal, selected when HP/LINE is

held high.

Right channel positive output in BTL mode and SE mode.

It will be into shutdown m ode w hen pu ll low.

Right channel line input terminal, selected when HP/LINE is held

low.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw6

APA2120/2121

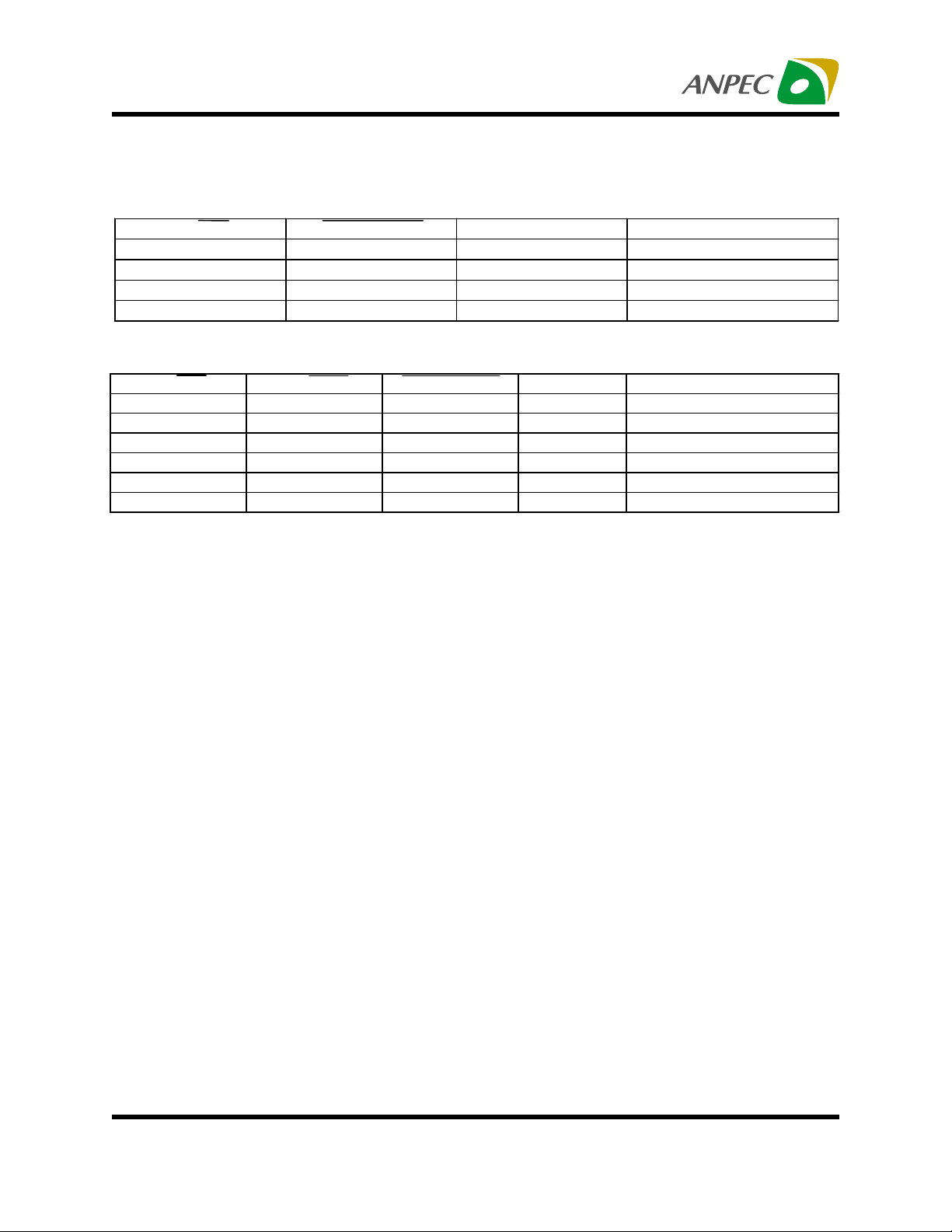

Control Input Table

For APA2120

SE/BTL SHUTDOW N PC-BEEP Operating mode

X L Disable Shutdown mode

L H Disable L ine input, BTL ou t

H H Disable HP input, SE out

X X Enable PCBEEP input, BTL out

For APA2121

SE/BTL HP/LINE SHUTDO WN PC-BEEP Operating mode

X X L Disable Shutdown mode

L L H Disable Line input, BTL out

L H H Disable HP input, BTL out

H L H Disable Line input, SE out

H H H Disable HP input, BTL out

X X X Enable PCBEEP input, BTL out

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw7

APA2120/2121

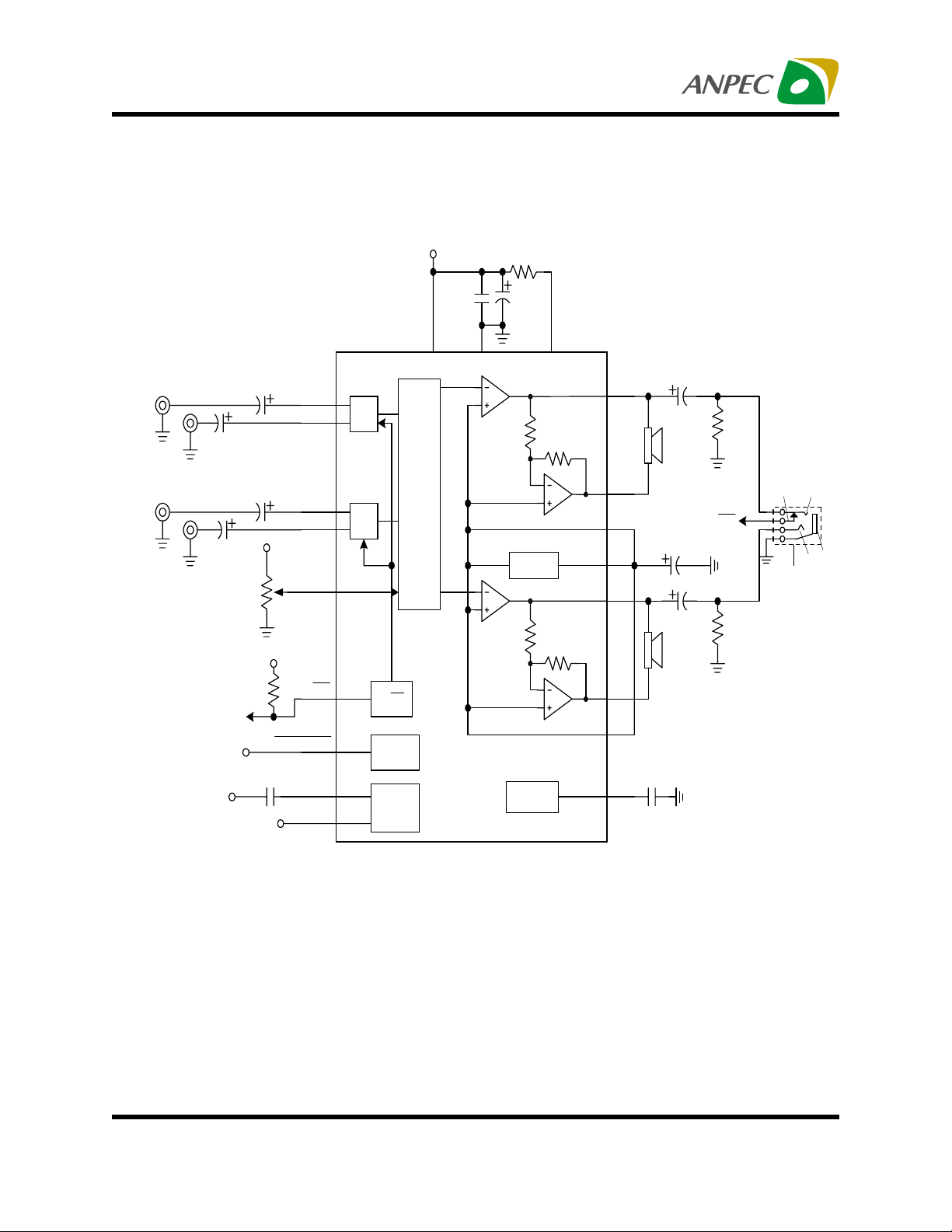

Typical Application Circuit

APA2120

L-LIN E

R-LINE

L-HP

R-HP

VDD

0.1

µ

0

Ω

F

100µF

VDD PVDDGND

F

µ

1

F

µ

1

1

F

1

µ

50k

LLINEIN

LHPIN

F

µ

RLINEIN

RHPIN

MUX

MUX

Volume

Control

VDD

BYPASS

VOLUME

Ω

LOUT+

LOUT-

LBYPASS

BYPASS

ROUT+

4

Ω

2.2µF

220

220

F

µ

µ

SE/BTL

F

1k

Ω

Control

Ring

Pin

Sleeve

Tip

Headphone Jack

1k

Ω

VDD

4

100k

SE/BTL

Ω

SE/BTL

ROUT-

Ω

Shutdown

SHUTDOWN

Signal

0.47µF

BEEP

Signal

PCBEN

PCBEEP

PCBEN

Signal

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

Shutdown

ckt

PC-BEEP

ckt

Clock Gen

RBYPASS

CLK

47nF

www.anpec.com.tw8

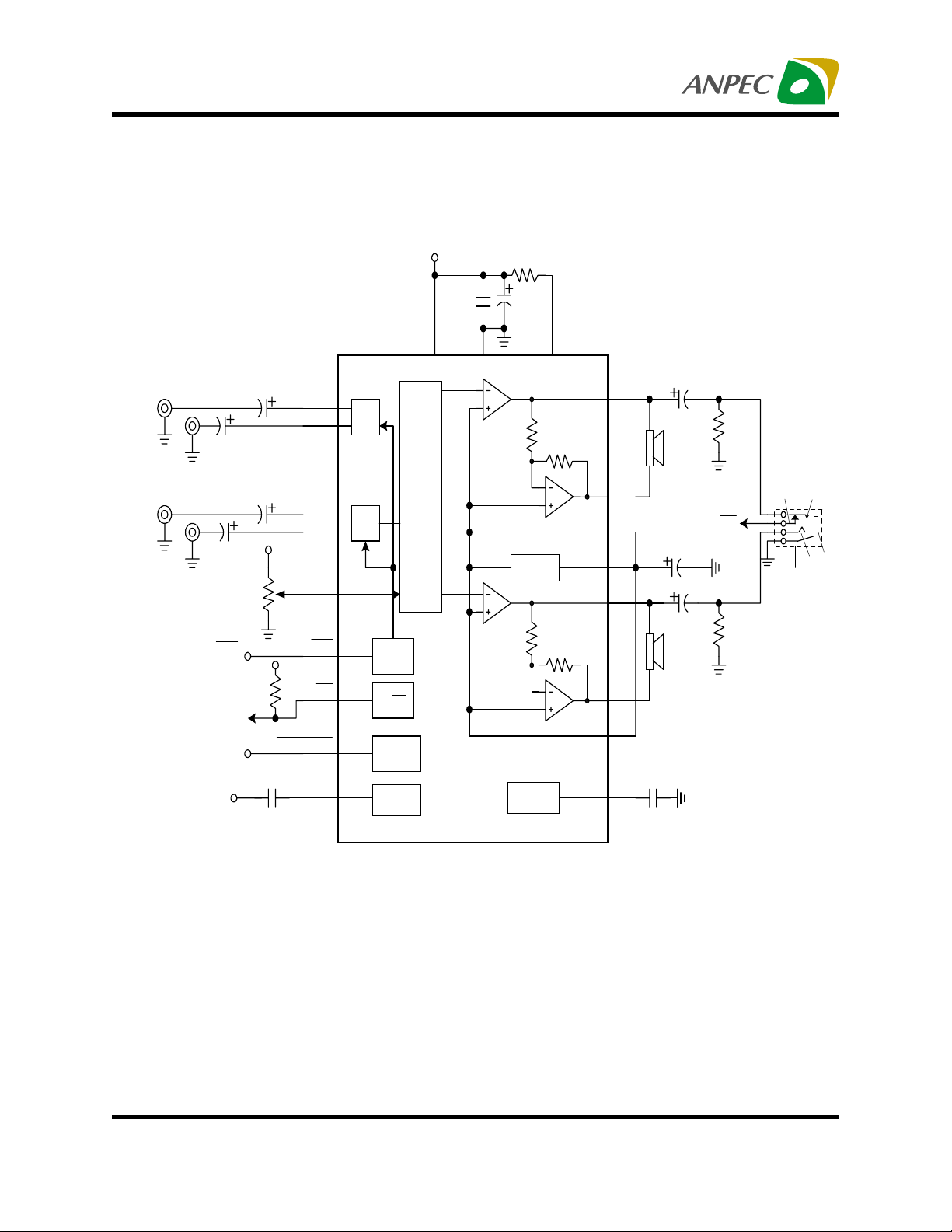

APA2120/2121

Typical Application Circuit

APA2121

VDD PVDDGND

µF

L-LINE

R-LINE

L-HP

R-HP

1

1

µ

F

1µF

1

µ

F

50k

LLINEIN

LHPIN

RLINEIN

RHPIN

MUX

MUX

Volume

Control

VDD

VOLUME

Ω

VDD

0

Ω

100µF0.1µF

BYPASS

LOUT+

LOUT-

LBYPASS

BYPASS

ROUT+

Ω

4

2.2µF

220

µ

F

SE/BTL

Ω

1k

Control

Ring

Pin

Sleeve

Tip

Headphone Jack

HP /LINE

Signal

Shutdown

Signal

BEEP

Signal

100k

VDD

Ω

SHUTDOWN

0.47µF

HP /LINE

SE/BTL

PCBEEP

HP/LINE

SE/BTL

Shutdown

ckt

PC-BEEP

ckt

Clock Gen

ROUT-

RBYPASS

CLK

47nF

4

Ω

220µF

Ω

1k

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw9

APA2120/2121

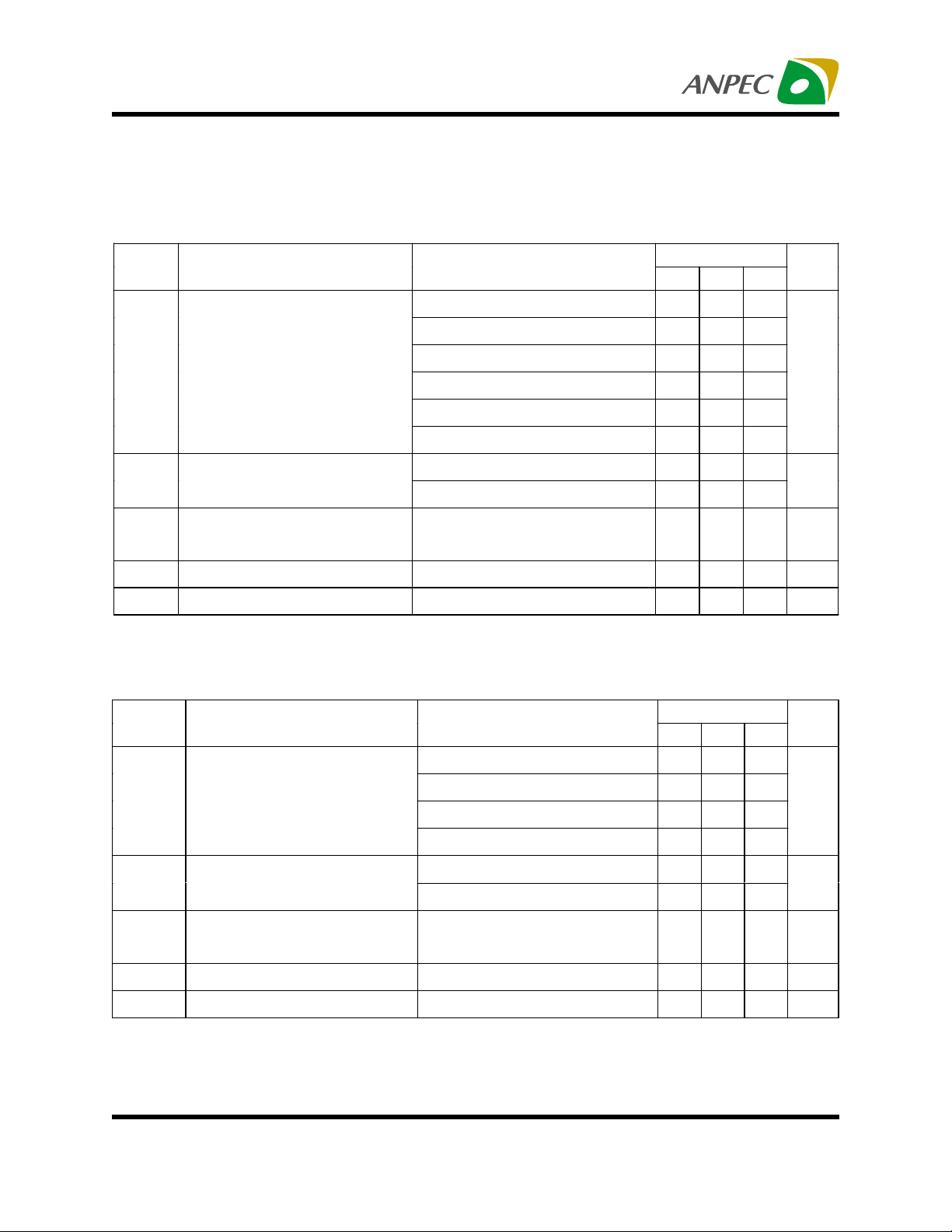

Volume Control Table_BTL Mode

Supply Voltage Vdd=5V

Gain(dB) High(V) Low(V) Hysteresis(mV) Recommended Voltage(V)

20 0.12 0.00 0

18 0.23 0.17 52 0.20

16 0.34 0.28 51 0.31

14 0.46 0.39 50 0.43

12 0.57 0.51 49 0.54

10 0.69 0.62 47 0.65

8 0.80 0.73 46 0.77

6 0.91 0.84 45 0.88

4 1.03 0.96 44 0.99

2 1.14 1.07 43 1.10

0 1.25 1.18 41 1.22

-2 1.37 1.29 40 1.33

-4 1.48 1.41 39 1.44

-6 1.59 1.52 38 1.56

-8 1.71 1.63 37 1.67

-10 1.82 1.74 35 1.78

-12 1.93 1.85 34 1.89

-14 2.05 1.97 33 2.01

-16 2.16 2.08 32 2.12

-18 2.28 2.19 30 2.23

-20 2.39 2.30 29 2.35

-22 2.50 2.42 28 2.46

-24 2.62 2.53 27 2.57

-26 2.73 2.64 26 2.69

-28 2.84 2.75 24 2.80

-30 2.96 2.87 23 2.91

-32 3.07 2.98 22 3.02

-34 3.18 3.09 21 3.14

-36 3.30 3.20 20 3.25

-38 3.41 3.32 18 3.36

-40 3.52 3.43 17 3.48

-80 5.00 3.54 16 5

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw10

APA2120/2121

Typical Characteristics

THD+N vs. Frequency

10

VDD=5V

RL=3Ω

Po=1.75W

BTL

1

THD+N (%)

0.1

0.01

20 20k100 1k

AV=10

Frequency (Hz)

THD+N vs. Frequency

10

VDD=5V

RL=4Ω

Po=1.5W

BTL

AV=2

AV=5

THD+N vs. Output Power

10

VDD=5V

RL=3Ω

V=2

A

BTL

1

THD+N (%)

0.1

0.01

10m 3100m 1 2

f=20kHz

f=1kHz

f=20Hz

Output Power (W)

THD+N vs. Output Power

10

VDD=5V

RL=4Ω

AV=2

BTL

1

0.1

THD+N (%)

0.01

20 20k50 100 200 500 1k 2k 5k

AV=2

AV=5

AV=10

Frequency (W)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

1

f=20kHz

THD+N (%)

0.1

0.01

100m 3200m 500m 800m 2

f=1kHz

f=20Hz

Output Power (W)

www.anpec.com.tw11

APA2120/2121

Typical Characteristics (Cont.)

THD+N vs. Frequency

10

VDD=5V

RL=8Ω

Po=1.0W

BTL

1

THD+N (%)

0.1

0.01

20 20k100 1k

AV=2

AV=5

AV=10

Frequency (Hz)

THD+N vs. Frequency

10

VDD=5V

RL=8Ω

Po=250mW

SE

THD+N vs. Output Power

10

VDD=5V

RL=8Ω

AV=2

BTL

1

f=20kHz

0.1

THD+N (%)

f=1kHz

f=20Hz

0.01

10m 2100m 1

Output Power (W)

THD+N vs. Output Power

10

VDD=5V

RL=8Ω

AV=2

BTL

1

AV=5

THD+N (%)

0.1

0.01

20 20k100 1k

AV=1

AV=2.5

Frequency (Hz)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

1

f=20kHz

0.1

THD+N (%)

f=20Hz

f=1kHz

0.01

10m 500m

100m

Output Power (W)

www.anpec.com.tw12

APA2120/2121

Typical Characteristics (Cont.)

THD+N vs. Frequency

10

VDD=5V

RL=16Ω

Po=100mW

SE

1

THD+N (%)

AV=2

0.1

0.01

20 20k50 100 200 500 1k 2k 5k

AV=1

AV=2.5

Frequency (Hz)

THD+N vs. Frequency

10

VDD=5V

RL=32Ω

Po=75mW

SE

1

THD+N vs. Output Power

10

VDD=5V

RL=16Ω

AV=1

BTL

1

f=20Hz

THD+N (%)

0.1

0.01

10m 300m

f=20kHz

f=1kHz

100m

Output Power (W)

THD+N vs. Output Power

10

VDD=5V

5

RL=32Ω

AV=1

BTL

1

f=20kHz

THD+N (%)

0.1

0.01

20 20k100 1k

AV=2.5

AV=1

AV=5

Frequency (Hz)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

THD+N (%)

0.01

f=20Hz

0.1

f=1kHz

10m 200m50m 100m

Output Power (W)

www.anpec.com.tw13

APA2120/2121

Typical Characteristics (Cont.)

THD+N vs. Frequency

10

VDD=5V

RL=10Ω

Vo=1VRMS

SE

1

THD+N (%)

0.1

0.01

20 20k100 1k

AV=2.5

AV=1

AV=5

Frequency (Hz)

Crosstalk vs. Frequency

+0

VDD=5V

RL=8Ω

Po=1.0W

-20

AV=2

BTL

-40

THD+N vs. Output Swing

10

VDD=5V

RL=10Ω

A

V=1

SE

1

THD+N (%)

0.1

0.01

100m 3500m

Output Swing (VRMS)

Crosstalk vs. Frequency

+0

VDD=5V

RL=32Ω

Po=75mW

-20

AV=1

SE

-40

f=1kHz

f=20kHz

f=20Hz

1

2

-60

-80

Crosstalk (dB)

-100

-120

20 20k100 1k

R-ch to L-ch

Frequency (Hz)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

L-ch to R-ch

-60

-80

Crosstalk (dB)

-100

-120

R-ch to L-ch

20 20k100 1k

Frequency (Hz)

L-ch to R-ch

www.anpec.com.tw14

APA2120/2121

Typical Characteristics (Cont.)

Noise Floor vs. Frequency

100u

50u

20u

10u

5u

Noise Floor (µVRMS)

2u

1u

20 20k100 1k

Frequency (Hz)

Noise Floor vs. Frequency

100u

VDD=5V

RL=10KΩ

50u

AV=1

SE

RMS)

20u

10u

5u

Noise Floor (µV

2u

1u

20 20k100 1k

No Filter

A-Weight

No Filter

A-Weight

VDD=5V

RL=8Ω

AV=2

BTL

Noise Floor vs. Frequency

100u

VDD=5V

RL=32Ω

50u

V=1

A

SE

20u

No Filter

10u

5u

A-Weight

Noise Floor (µVRMS)

2u

1u

20 20k100 1k

Frequency (Hz)

Power Dissipation vs. Output Power

0.2

0.18

0.16

0.14

0.12

0.1

0.08

0.06

Power Dissipation (W)

RL=32Ω

0.04

0.02

0

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

RL=16Ω

RL=8Ω

VDD=5V

AV=1

SE

Frequency (Hz)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

Output Power (W)

www.anpec.com.tw15

APA2120/2121

Typical Characteristics (Cont.)

Power Dissipation vs. Output Power

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

Power Dissipation (W)

0.2

0

0 0 .5 1 1 .5 2 2 .5

RL=8Ω

RL=3Ω

RL=4Ω

Output Power (W)

Output Power vs. Supply Voltage

VDD=5V

AV=2

BTL

Supply Current vs. Supply Voltage

20

17.5

15

12.5

10

7.5

5

Suuply Current (mA)

2.5

1 1.5 2 2.5 3 3 .5 4 4 .5 5 5.5

BTL

SE

Supply Voltage (V)

Output Power vs. Supply Voltage

No Load

2.0

RL=8Ω

1.8

AV=2

BTL

1.6

1.4

1.2

1.0

0.8

0.6

Output Power (W)

0.4

0.2

0

2.5 3 3.5 4 4.5 5 5.5

THD+N=10%

THD+N=1%

Supply Voltage (V)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

160

RL=32Ω

AV=1

140

SE

120

100

80

60

40

Output Power (mW)

20

0

2.5 3 3.5 4 4.5 5 5.5

THD+N=10%

THD+N=1%

Supply Voltage (V)

www.anpec.com.tw16

APA2120/2121

Typical Characteristics (Cont.)

Output Power vs. Load Resistance

3

VDD=5V

A

V=2

BTL

2.5

2

1.5

1

Output Power (W)

0.5

THD+N=1%

0

4 8 121620242832 364044 485256 60 64

THD+N=10%

Load Resistance (Ω)

Close Loop Response

+12

VDD=5V

RL=8Ω

AV=2

+10

BTL

CO=330µF

+8

Output Power vs. Load Resistance

0.7

VDD=5V

AV=1

0.6

SE

0.5

0.4

0.3

0.2

Output Power (W)

0.1

THD+N=1%

0

4 8 1216202428 3236 40444852 566064

THD+N=10%

Load Resistance (Ω)

Close Loop Response

+6

VDD=5V

RL=32Ω

AV=1

+4

SE

CO=330µF

+2

+6

AV=2

+4

Loop Gain (dB)

+2

-0

20 20k100 1k

AV=5

AV=10

Frequency (Hz)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

+0

AV=1

-2

Loop Gain (dB)

-4

-6

20 20k100 1k

AV=2.5

AV=5

Frequency (Hz)

www.anpec.com.tw17

APA2120/2121

Typical Characteristics (Cont.)

PSRR vs. Frequency

+0

-20

-40

-60

-80

66666666

VDD=5V

Vin=100mVRMS

RL=8Ω

Cbypass=2.2µF

BTL

SE

Ripple Rejection Ratio (dB)

20 20k100 1k

Frequency (Hz)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw18

APA2120/2121

Application Descriptions

BTL Operation

The APA2120/1 output stage (power amplifier) has

two pairs of operational amplifiers internally, allowed

for different amplifier configurations.

OUT+

Volume Control

amplifier output

signal

Vbias

Circuit

OP1

RL

OUT-

OP2

Figure 1: APA2120/1 internal configuration

(each channel)

The power amplifier’s OP1 gain is setting by internal

unity-gain and input audio signal is come from internal volume control amplifier, while the second amplifier OP2 is internally fixed in a unity-gain, inverting

configuration. Figure 1 shows that the output of OP1

is connected to the input to OP2, which results in the

output signals of with both amplifiers with identical in

magnitude, but out of phase 180°. Consequently,

the differential gain for each channel is 2 x (Gain of

SE mode).

By driving the load differentially through outputs OUT+

and OUT-, an amplifier configuration commonly re-

BTL Operation (Cont.)

Four times the output power same conditions.

A BTL

configuration, such as the one used in APA2120/1,

also creates a second advantage over SE amplifiers.

Since the differential outputs, ROUT+, ROUT-,

LOUT+, and LOUT-, are biased at half-supply, no

need DC voltage exists across the load. This eliminates the need for an output coupling capacitor which

is required in a single supply, SE configuration.

Single-Ended Operation

Consider the single-supply SE configuration shown

Application Circuit. A coupling capacitor is required

to block the DC offset voltage from reaching the load.

These capacitors can be quite large (approximately

33µF to 1000µF) so they tend to be expensive, occupy valuable PCB area, and have the additional

drawback of limiting low-frequency performance of

the system (refer to the Output Coupling Capacitor).

The rules described still hold with the addition of the

following relationship:

1

Cbypass x 125kΩ

1

≤

RiCi

<<

1

RLCC

(1)

Output SE/BTL Operation

ferred to as bridged mode is established. BTL mode

operation is different from the classical single-ended

SE amplifier configuration where one side of its load

is connected to ground.

A BTL amplifier design has a few distinct advantages

over the SE configuration, as it provides differential

drive to the load, thus doubling the output swing for a

specified supply voltage.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

The ability of the APA2120/1 to easily switch between

BTL and SE modes is one of its most important costs

saving features. This feature eliminates the requirement for an additional headphone amplifier in applications where internal stereo speakers are driven in

BTL mode but external headphone or speakers must

be accommodated.

www.anpec.com.tw19

APA2120/2121

Application Descriptions (Cont.)

Output SE/BTL Operation (Cont.) Output SE/BTL Operation (Cont.)

Internal to the APA2120/1, two separate amplifiers

drive OUT+ and OUT- (see Figure 1). The SE/BTL

input controls the operation of the follower amplifier

that drives LOUT- and ROUT-.

• When SE/BTL is held low, the OP2 is turn on and

the APA2120/1 is in the BTL mode.

•When SE/BTL is held high, the OP2 is in a high

output impedance state, which configures the

APA2120/1 as SE driver from OUT+. I

is reduced

DD

by approximately one-half in SE mode.

Control of the SE/BTL input can be a logic-level TTL

source or a resistor divider network or the stereo

headphone jack with switch pin as shown in Application Circuit.

Ω

1k

100k

SE/BTL

VDD

Ω

Control

Pin

Headphone Jack

Ring

Tip

Sleeve

Figure 2: SE/BTL input selection by phonejack plug

In Figure 2, input SE/BTL operates as follows :

When the phonejack plug is inserted, the 1kΩ resistor is disconnected and the SE/BTL input is pulled

high and enables the SE mode. When the input goes

high, the OUT- amplifier is shutdown causing the

speaker to mute. The OUT+ amplifier then drives

through the output capacitor (CC) into the headphone

jack. When there is no headphone plugged into the

system, the contact pin of the headphone jack is connected from the signal pin, the voltage divider set up

by resistors 100kΩ and 1kΩ.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

Resistor 1kΩ then pulls low the SE/BTL pin, enabling

the BTL function.

Volume Control Function

APA2120/1 has an internal stereo volume control

whose setting is a function of the DC voltage applied

to the VOLUME input pin. The APA2120/1 volume

control consists of 32 steps that are individually selected by a variable DC voltage level on the VOLUME control pin. The range of the steps, controlled

by the DC voltage, are from 20dB to -80dB. Each

gain step corresponds to a specific input voltage

range, as shown in table. To minimize the effect of

noise on the volume control pin, which can affect the

selected gain level, hysteresis and clock delay are

implemented. The amount of hysteresis corresponds

to half of the step width, as shown in volume control

graph.

Gain_BTL mode

20

16

12

8

4

0

-4

-8

-12

-16

-20

-24

-28

-32

-36

-40

-44

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3 3.2 3.4 3.6 3.8

APA2021 volume control curve

Forward

Backward

(V)

Figure 3: Gain setting vs VOLUME pin voltage

www.anpec.com.tw20

APA2120/2121

Application Descriptions (Cont.)

Volume Control Function (Cont.)

For highest accuracy, the voltage shown in the ‘recommended voltage’ column of the table is used to

select a desired gain. This recommended voltage is

exactly halfway between the two nearest transitions.

The gain levels are 2dB/step from 20dB to -40dB in

BTL mode, and the last step at -80dB as mute mode.

Input Resistance, Ri

The gain for each audio input of the APA2120/1 is

set by the internal resistors (Ri and Rf) of volume

control amplifier in inverting configuration.

SE Gain =

BTL Gain

=

AV

-2 x

RF

-

=

Ri

RF

Ri

(2)

(3)

BTL mode operation brings the factor of 2 in the gain

equation due to the inverting amplifier mirroring the

voltage swing across the load. For the varying gain

setting, APA2120/1 generates each input resistance

on figure 4. The input resistance will affect the low

Ri(kΩ)

120

100

80

60

40

20

0

-40 -30 -20 -10 0 10 20

Ri vs Gain(BTL)

Gain(dB)

Figure 4: Input resistance vs Gain setting

Input Capacitor, Ci

In the typical application an input capacitor, Ci, is required to allow the amplifier to bias the input signal to

the proper DC level for optimum operation. In this

case, Ci and the minimum input impedance Ri (10kΩ)

form a high-pass filter with the corner frequency determined in the follow equation :

FC(highpass)=

1

2πx10kΩxCi

(4)

frequency performance of audio signal. The minmum

input resistance is 10kΩ when gain setting is 20dB

and the resistance will ramp up when close loop gain

below 20dB. The input resistance has wide variation

(+/-10%) caused by process variation.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

The value of Ci is important to consider as it directly

affects the low frequency performance of the circuit.

Consider the example where Ri is 10kΩ and the specification calls for a flat bass response down to 100Hz.

Equation is reconfigured as follow :

Ci=

2πx10kΩxfC

1

(5)

Consider to input resistance variation, the Ci is 0.16µF

so one would likely choose a value in the range

of 0.22µF to 1.0µF.

www.anpec.com.tw21

APA2120/2121

Application Descriptions (Cont.)

Input Capacitor, Ci (Cont.)

A further consideration for this capacitor is the leakage path from the input source through the input network (Ri+Rf, Ci) to the load. This leakage current

creates a DC offset voltage at the input to the amplifier that reduces useful headroom, especially in high

gain applications. For this reason a low-leakage tantalum or ceramic capacitor is the best choice. When

polarized capacitors are used, the positive side of

the capacitor should face the amplifier input in most

applications as the DC level there is held at VDD/2,

which is likely higher that the source DC level.

sPlease note that it is important to confirm the capacitor polarity in the application.

Effective Bypass Capacitor, Cbypass

As other power amplifiers, proper supply bypassing

Effective Bypass Capacitor, Cbypass (Cont.)

The effective capacitance is the Cbypass=(Cb//

CLbyasss//CRbypass). When absolute minimum

cost and/or component space is required, one bypass capacitor can be used.

To avoid start-up pop noise occurred, the bypass

voltage should rise slower than the input bias voltage

and the relationship shown in equation (6) should be

maintained.

1

Cbypass x 125kΩ

The bypass capacitor is fed thru from a 125kΩ resistor inside the amplifier and the 100kΩ is maximum

input resistance of (Ri+ Rf). Bypass capacitor, Cb,

values of 3.3µF to 10µF ceramic or tantalum low-ESR

capacitors are recommended for the best THD and

noise performance.

<<

1

100kΩ x Ci

(6)

is critical for low noise performance and high power

supply rejection.

The capacitors located on both the bypass and power

supply pins should be as close to the device as

possible. The effect of a larger bypass capacitor will

improve PSRR due to increased supply stability. Typical applications employ a 5V regulator with 1.0µF and

a 0.1µF bypass capacitor as supply filtering. This

does not eliminate the need for bypassing the supply

nodes of the APA2120/1. The selection of bypass

capacitors, especially Cbypass, is thus dependent

upon desired PSRR requirements, click and pop

performance.

On the chip, there are three bypass pins for used,

and they are tied together in the internal circuit.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

The bypass capacitance also effects to the start up

time. It is determined in the following equation :

Tstart up = 5 x (Cbypass x 125KΩ)

Output Coupling Capacitor, Cc

In the typical single-supply SE configuration, an output coupling capacitor (Cc) is required to block the

DC bias at the output of the amplifier thus preventing

DC currents in the load. As with the input coupling

capacitor, the output coupling capacitor and impedance of the load form a high-pass filter governed by

equation.

FC(highpass)=

1

2πRLCC

www.anpec.com.tw22

(7)

(8)

APA2120/2121

Application Descriptions (Cont.)

Output Coupling Capacitor, Cc (Cont.)

For example, a 330µF capacitor with an 8Ω speaker

would attenuate low frequencies below 60.6Hz. The

main disadvantage, from a performance standpoint,

is the load impedance is typically small, which drives

the low-frequency corner higher degrading the bass

response. Large values of CC are required to pass

low frequencies into the load.

Power Supply Decoupling, Cs

The APA2120/1 provides PVDD and VDD two independent power inputs for used. PVDD is used for power

amplifier only and VDD is used for volume control

amplifier and internal circuit excepting power amplifier.

The APA2120/1 is a high-performance CMOS audio

amplifier that requires adequate power supply

decoupling to ensure the output total harmonic distortion (THD) is as low as possible. Power supply

decoupling also prevents the oscillations causing by

long lead length between the amplifier and the

speaker. The optimum decoupling is achieved by

using two different type capacitors that target on different type of noise on the power supply leads.

For higher frequency transients, spikes, or digital hash

on the line, a good low equivalent-series-resistance

(ESR) ceramic capacitor, typically 0.1µF placed as

close as possible to the device VDD and PVDD lead

Optimizing Depop Circuitry

Circuitry has been included in the APA2120/1 to minimize the amount of popping noise at power-up and

when coming out of shutdown mode. Popping occurs whenever a voltage step is applied to the

speaker. In order to eliminate clicks and pops, all

capacitors must be fully discharged before turn-on.

Rapid on/off switching of the device or the shutdown

function will cause the click and pop circuitry.

The value of Ci will also affect turn-on pops. (Refer

to Effective Bypass Capacitance) The bypass voltage ramp up should be slower than input bias voltage.

Although the bypass pin current source cannot be

modified, the size of Cbypass can be changed to alter the device turn-on time and the amount of clicks

and pops. By increasing the value of Cbypass, turnon pop can be reduced. However, the tradeoff for

using a larger bypass capacitor is to increase the turnon time for this device. There is a linear relationship

between the size of Cbypass and the turn-on time.

In a SE configuration, the output coupling capacitor,

CC, is of particular concern.

This capacitor discharges through the internal 10kΩ

resistors. Depending on the size of CC, the time constant can be relatively large. To reduce transients in

SE mode, an external 1kΩ resistor can be placed in

parallel with the internal 10kΩ resistor. The tradeoff

for using this resistor is an increase in quiescent

works best. For filtering lower-frequency noise

signals, a large aluminum electrolytic capacitor of

10µF or greater placed near the audio power amplifier is recommended.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

current. In the most cases, choosing a small value

of Ci in the range of 0.33µF to 1µF, Cb being equal to

4.7µF and an external 1kΩ resistor should be placed

in parallel with the internal 10kΩ resistor should pro-

duce a virtually clickless and popless turn-on.

www.anpec.com.tw23

APA2120/2121

Application Descriptions (Cont.)

Optimizing Depop Circuitry (Cont.)

A high gain amplifier intensifies the problem as the

small delta in voltage is multiplied by the gain. So it

is advantageous to use low-gain configurations.

Shutdown Function

In order to reduce power consumption while not in

use, the APA2120/1 contains a shutdown pin to externally turn off the amplifier bias circuitry. This shutdown feature turns the amplifier off when a logic low

is placed on the SHUTDOWN pin. The trigger point

between a logic high and logic low level is typically

2.0V. It is best to switch between ground and the supply VDD to provide maximum device performance.

By switching the SHUTDOWN pin to low, the amplifier enters a low-current state, IDD<50µA. APA2120/1

is in shutdown mode, except PC-BEEP detect circuit.

Input HP/LINE Operation (Cont.)

This logic-low voltage at the SE/BTL pin makes

APA2120 into LINE input mode operation. It becomes

HP input mode when phonejack plugged.

An internal multiplexor selects the input to connect to

the amplifier based on the state of the HP/LINE pin

of the APA2121.

• To select the LINE inputs, set HP/LINE pin to low

level.

• To enable the HP(headphone) inputs, set HP/LINE

pin to high level.

As APA2121, HP/LINE input multiplexor, and SE/BTL

output operating mode have independent control

paths, which can be used for multiple audio input

system. This function will be the same as APA2120

when HP/LINE and SE/BTL are tied together.

PC-BEEP Detection

On normal operating, SHUTDOWN pin pull to high

level to keeping the IC out of the shutdown mode.

The SHUTDOWN pin should be tied to a definite voltage to avoid unwanted state changes.

Input HP/LINE Operation

APA2120/1 amplifier has two separate inputs for each

of the left and right stereo channels. The APA2120

and APA2121 have different control input by SE/BTL

and HP/LINE, respectively.

APA2120 internal multiplexor is selected by SE/BTL

control input. Refer to the ‘Output SE/BTL Operation’,

the voltage divider of 100kΩ and 1kΩ sets the voltage at the SE/BTL pin to be approximately 50mV

when no phonejack plugged into the system.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

APA2120/1 integrates a BEEP detect circuit for

NOTEBOOK PC. When BEEP signal is provided on

PCBEEP input pin, the BEEP mode is active.

APA2120/1 will force to BTL mode and the internal

gain is fixed at -10dB. The PCBEEP signal becomes

the amplifier input signal and plays on the speaker

without coupling capacitor. It will be out of shutdown

mode whenever BEEP mode is enabled. APA2120/

1 will return to previous setting when it is out of BEEP

mode. The input impedance is 100kΩ on PCBEEP

input pin.

APA2120 provides extra PCBEN control input signal

to force IC into BEEP mode. The BEEP mode will be

enabled when PCBEN goes to high level. When

BEEP mode is overridden, the signal from PCBEEP

will pass to speaker directly.

www.anpec.com.tw24

APA2120/2121

Application Descriptions (Cont.)

Clock Generator BTL Amplifier Efficiency (Cont.)

APA2120/1 integrates a clock block to avoid volume

control function abnormal when VOLUME control signal with spike or noise. APA2120/1 changes each

step of volume gain after four clock cycles to make

sure control signal ready. It provides 130kHz frequency if no capacitor place on CLK pin to ground.

The larger capacitance will slow down the and clock

frequency. A capacitor 33nF between CLK to ground

and will generates 147Hz frequency on CLK pin.

BTL Amplifier Efficiency

An easy-to-use equation to calculate efficiency starts

out as being equal to the ratio of power from the power

supply to the power delivered to the load.

The following equations are the basis for calculating

amplifier efficiency.

VP

√2

VPxVP

2RL

PO

PSUP

RL

VPxVP

2RL

2VP

πRL

2VP

πRL

Efficiency =

Where :

PO = =

VORMS =

PSUP = VDD x IDDRMS = VDD x

Efficiency of a BTL configuration :

VORMS x VORMS

PO

( ) / (VDD x ) =

=

PSUP

πVP

2VDD

(9)

(10)

(11)

(12)

Note that the efficiency of the amplifier is quite low

for lower power levels and rises sharply as power to

the load is increased resulting in a nearly flat internal

power dissipation over the normal operating range.

Note that the internal dissipation at full output power

is less than in the half power range. Calculating the

efficiency for a specific system is the key to proper

power supply design. For a stereo 1W audio system

with 8Ω loads and a 5V supply, the maximum draw

on the power supply is almost 3W.

A final point to remember about linear amplifiers

(either SE or BTL) is how to manipulate the terms in

the efficiency equation to utmost advantage when

possible. Note that in equation, VDD is in the

denominator. This indicates that as VDD goes down,

efficiency goes up. In other words, use the efficiency

analysis to choose the correct supply voltage and

speaker impedance for the application.

Po (W) Efficiency (%) IDD(A) VPP(V) PD (W)

0.25 31.25 0.16 2.00 0.55

0.50 47.62 0.21 2.83 0.55

1.00 66.67 0.30 4.00 0.5

1.25 78.13 0.32 4.47 0.35

**High peak voltages cause the THD to increase.

Table 1 calculates efficiencies for four different output power levels.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

Table 1. Efficiency Vs Output Power in 5-V/8Ω BTL

Systems

www.anpec.com.tw25

APA2120/2121

Application Descriptions (Cont.)

Power Dissipation

Whether the power amplifier is operated in BTL or

SE modes, power dissipation is a major concern. In

equation13 states the maximum power dissipation

point for a SE mode operating at a given supply voltage and driving a specified load.

2

V

SE mode : P

D,MAX= (13)

DD

2

2π RL

In BTL mode operation, the output voltage swing is

doubled as in SE mode. Thus the maximum power

dissipation point for a BTL mode operating at the

same given conditions is 4 times as in SE mode.

2

BTL mode : PD,MAX=

4VDD

2

2π RL

(14)

Since the APA2120/1 is a dual channel power

amplifier, the maximum internal power dissipation is

2 times that both of equations depending on the mode

of operation. Even with this substantial increase in

power dissipation, the APA2120/1 does not require

extra heatsink. The power dissipation from

equation14, assuming a 5V-power supply and an 8Ω

load, must not be greater than the power dissipation

that results from the equation15 :

PD,MAX=

TJ,MAX - TA

θJA

(15)

For TSSOP-24 package with thermal pad, the thermal resistance (θJA) is equal to 45οC/W.

Since the maximum junction temperature (T

J,MAX

) of

APA2120/1 is 150οC and the ambient temperature

(TA) is defined by the power system design, the maximum power dissipation which the IC package is able

to handle can be obtained from equation16.

Power Dissipation (Cont.)

Once the power dissipation is greater than the maximum limit (P

), either the supply voltage (VDD) must

D,MAX

be decreased, the load impedance (RL) must be increased or the ambient temperature should be

reduced.

Thermal Pad Considerations

The thermal pad must be connected to ground. The

package with thermal pad of the APA2120/1 requires

special attention on thermal design. If the thermal

design issues are not properly addressed, the

APA2120/1 4Ω will go into thermal shutdown when

driving a 4Ω load.

The thermal pad on the bottom of the APA2120/1

should be soldered down to a copper pad on the circuit board. Heat can be conducted away from the

thermal pad through the copper plane to ambient. If

the copper plane is not on the top surface of the circuit board, 8 to 10 vias of 13 mil or smaller in diameter should be used to thermally couple the thermal

pad to the bottom plane.

For good thermal conduction, the vias must be plated

through and solder filled. The copper plane used to

conduct heat away from the thermal pad should be

as large as practical.

If the ambient temperature is higher than 25°C, a

larger copper plane or forced-air cooling will be required to keep the APA2120/1 junction temperature

below the thermal shutdown temperature (150°C). In

higher ambient temperature, higher airflow rate and/

or larger copper area will be required to keep the IC

out of thermal shutdown.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw26

APA2120/2121

0

8

0

8

φ

3

Packaging Information

TSSOP/ TSSOP-P ( Reference JEDEC Registration MO-153)

2 x E / 2

EXPOSED THERMAL

PAD ZONE

(THERMALLY ENHANCED VARIATIONDS ONLY)

Dim

Min. Max. Min. Max.

A 1.2 0.047

A1 0.00 0.15 0.000 0.006

A2 0.80 1.05 0.031 0.041

D

6.4 (N=20PIN)

7.7 (N=24PIN)

9.6 (N=28PIN)

D1

e 0.65 BSC 0.026 BSC

E 6.40 BSC 0.252 BSC

E1 4.30 4.50 0.169 0.177

E2

L 0.45 0.75 0.018 0.030

L1 1.0 REF 0.039REF

R 0.09 0.004

R1 0.09 0.004

S 0.2 0.008

1

2 12° REF 12° REF

12° REF 12°REF

e

N

E1 E

12

3

e/2

D

b

D1

BOTTOM VIEW

Millimeters Inches

6.6 (N=20PIN)

7.9 (N=24PIN)

9.8 (N=28PIN)

4.2 BSC (N=20PIN)

4.7 BSC (N=24PIN)

3.8 BSC (N=28PIN)

3.0 BSC (N=20PIN)

3.2 BSC (N=24PIN)

2.8 BSC (N=28PIN)

°

A2

A

A1

E2

0.25

(3)

0.252 (N=20PIN)

0.303 (N=24PIN)

0.378 (N=28PIN)

S

(2)

(L1)

GAUGE

PLANE

L

1

0.260 (N=20PIN)

0.311 (N=24PIN)

0.386 (N=28PIN)

0.165 BSC (N=20PIN)

0.188 BSC (N=24PIN)

0.150 BSC (N=28PIN)

0.118 BSC (N=20PIN)

0.127 BSC (N=24PIN)

0.110 BSC (N=28PIN)

°

°

°

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw27

APA2120/2121

Physical Specifications

Terminal Material Solder-Plated Copper (Solder Material : 90/10 or 63/37 SnPb)

Lead Solderability M e ets E IA Specification RSI8 6-91, A NSI/J-STD-002 Category 3.

Reflow Condition (IR/Convection or VPR Reflow)

Reference JEDEC Standard J-STD-020A APRIL 1999

Peak temperature

temperature

Pre-heat temperature

°

183 C

Time

Classification Reflow Profiles

Convection or IR/

Convection

Average ramp-up rate(183°C to Peak) 3°C/second max. 10 °C /second max .

Preheat temperature 125 ± 25°C)

Temperature maintained above 183°C

Time within 5°C of actual peak temperature

Peak temperature range

Ramp-down rate

Time 25°C to peak temperature

120 seconds max

60 – 150 seconds

10 –20 seconds 60 seconds

220 +5/-0°C or 235 +5/-0°C 215-219°C or 235 +5/-0°C

6 °C /second max . 10 °C /second max .

6 minutes max.

VPR

Package Reflow Conditions

pkg. thickness

and all bgas

Convection 220 +5/-0 °C Convection 235 +5/-0 °C

VPR 215-219 °C VPR 235 +5/-0 °C

IR/Convection 220 +5/-0 °C IR/Convection 235 +5/-0 °C

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

2.5mm

≥≥≥≥

pkg. thickness < 2.5mm and

pkg. volume

350 mm³

≥≥≥≥

pkg. thickness < 2.5mm and pkg.

volume < 350mm³

www.anpec.com.tw28

APA2120/2121

Re liability test p r o g r a m

Test item Metho d Descript ion

SOLDERABILITY MIL-STD-883D-2003

HOLT MIL-STD-883D-1005.7

PCT JESD-22-B, A102

TST MIL-STD-883D-1011.9

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JESD 78 10ms , Itr > 100mA

245°C , 5 SEC

1000 Hrs Bias @ 125 °C

168 Hrs, 100 % RH , 121°C

-65°C ~ 150°C, 200 C ycles

Carrier Tape & Reel Dimensions

E

F

W

A

Po

J

P

P1

Ao

C

t

D

Bo

Ko

D1

T2

B

Application

A B C J T1 T2 W P E

330 ±1 100 ref 13 ±0.5 2 ±0.5 16.4 ±0.2 2 ±0.2 16 ±0.3 12 ±0.1 1.75±0.1

TSSOP- 24

F D D1 Po P1 Ao Bo Ko t

7.5 ±0.1 1.5 +0.1 1.5 min 4.0 ±0.1 2.0 ±0.1 6.9 ±0.1 8.3 ±0.1 1.5 ±0.1 0.3±0.05

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

T1

www.anpec.com.tw29

APA2120/2121

Cover Tape Dimensions

Application Carrier Width Cover Tape Width Devices Per Reel

TSSOP- 24

Customer Service

Anpec Electronics Corp.

Head Office :

5F, No. 2 Li-Hsin Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

7F, No. 137, Lane 235, Pac Chiao Rd.,

Hsin Tien City, Taipei Hsien, Taiwan, R. O. C.

Tel : 886-2-89191368

Fax : 886-2-89191369

16 21.3 2000

Copyright ANPEC Electronics Corp.

Rev. A.1 - Mar., 2003

www.anpec.com.tw30

Loading...

Loading...