APA0710/0711

1.1W Mono Low-Voltage Audio Power Amplifier

Features General Description

• Operating Voltage : 2.6V-5.5V

• APA0710 Compatible with TPA711

APA071 1 Compatible with TPA751

• Bridge -Tied Load (BTL) or Single-Ended (SE)

Mode s Operation (for APA0710 only)

• Supply Curren t

– IDD=1.3mA at VDD=5V ,BTL mode

– IDD=0.9mA at VDD=3.3V ,BTL mode

• Low Shutdown Current

– IDD=0.1µA

• Low Distortion

– 630mW, at VDD=5V, BTL, RL=8Ω

THD +N=0.15%

– 280mW, at VDD=3.3V, BTL, RL=8Ω

THD +N=0.15%

• Output Pow er

at 1% TH D+N

– 900mW, at VDD=5V, BTL, RL=8Ω

– 400mW, at VDD=3.3V, BTL, RL=8Ω

at 10% THD+N

–1.1W at VDD=5V, BTL, RL=8Ω

–480mW at VDD=3.3V, BTL, RL=8Ω

The APA0710 is a bridged-tied load (BTL) or singledended (SE) aud io power amplifier developed especially

for low-voltage applications where internal speakers

and external earphone operation are required. The

APA0 711 is a only BTL audio power amplifier developed

especially for low-voltage applications where internal

spea kers are required. Operating with a 5V supply,

the APA0710/1 can deliver 1.1W of continuous power

into a BTL 8Ω load at 10% THD+N througho ut voice

band frequencies. Altho ugh this device is characterized

out to 20kHz,its operatio n is optimized for narrow band

a pplications such as wireless communications. The

BTL conf iguration eliminates the need for external

coup ling capacitors on the output in most applications,

which is particularly important for small battery-powered

equip ment. A unique feature of the APA0710 is that it

allows the a mplifier to switch from BTL to SE on the

fly when an earphone drive is required. This eliminates

complica ted mechanical switching or auxiliary devices

just to drive the external load. This de vice features a

shutd own mode for power-sensitive applications with

sp ecial depop circuitry to eliminate speaker noise when

exiting shutdow n mode. The APA0710/1 are available

in an 8-pin SOP and 8-pin MSOP-P with enhanced

thermal pad.

• Depop Circuitry Integrated

• Thermal Shutdown Protection and

Over Current Protection Circuitry

• High supply voltage ripple rejection

• Surface-Moun t Packaging

– 8 pin MSOP-P (with e nhanced thermal pad)

pow er package available

– SOP-8 package

Applications

• Mobil Phones

• PDAs

• Digital Camera

• Porta ble Electronic Devices

• Lead Free Available (RoHS Compliant)

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and advise

customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw1

APA0710/0711

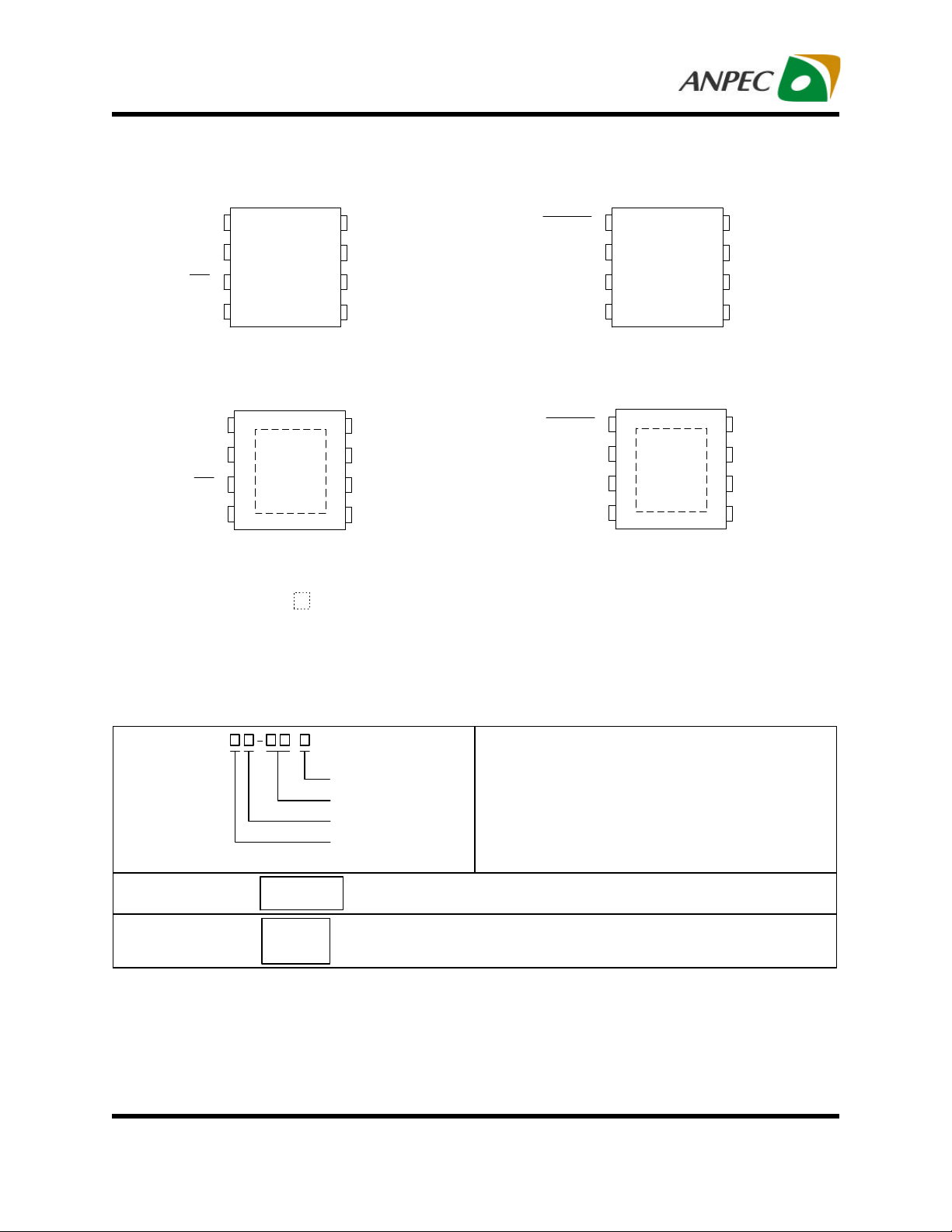

Pin Description

Shutdown

Bypass

SE/BTL

Shutdown

Bypass

SE/BTL

APA0710

1

2

3

4

IN

8

7

6

5

VO-

GND

VDD

VO+

Shutdown

Bypass

IN+

IN-

SOP-8

APA0710

1

2

3

4

IN

8

7

6

5

VO-

GND

VDD

VO+

Shutdown

Bypass

IN+

IN-

MSOP-8-P

1

2

3

4

1

2

3

4

APA0711

SOP-8

APA0711

MSOP-8-P

8

7

6

5

8

7

6

5

VO-

GND

VDD

VO+

VO-

GND

VDD

VO+

NC = N o internal connection

= Th ermal Pad

(con nected to GND plane for better heat dissipation)

Ordering and Marking Information

APA0710/1

Lead Free Code

Handling Code

Temp. Range

Package Code

APA0710/1 K :

APA0710/1 XA :

APA0710/1

XXXXX

A0710/1

XXX

XX

Note: AN PEC lead-free products contain molding compo unds/die attach ma terials and 100% matte tin plate

termination finish; which are fully compliant with RoHS and compatible with both SnPb and lead-free soldiering

op erations. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J STD-020C

fo r MSL classification at lead-free peak reflow temperature.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

Package Code

K : SOP-8 XA : MSOP-8-P

Temp. Range

I : -40 to 85 C

°

Handling Code

TR : Tape & Reel

Lead Free Code

L : Lead Free Device Blank : Original Device

XXXXX - Date Code

XXXXX - Date Code

www.anpec.com.tw2

APA0710/0711

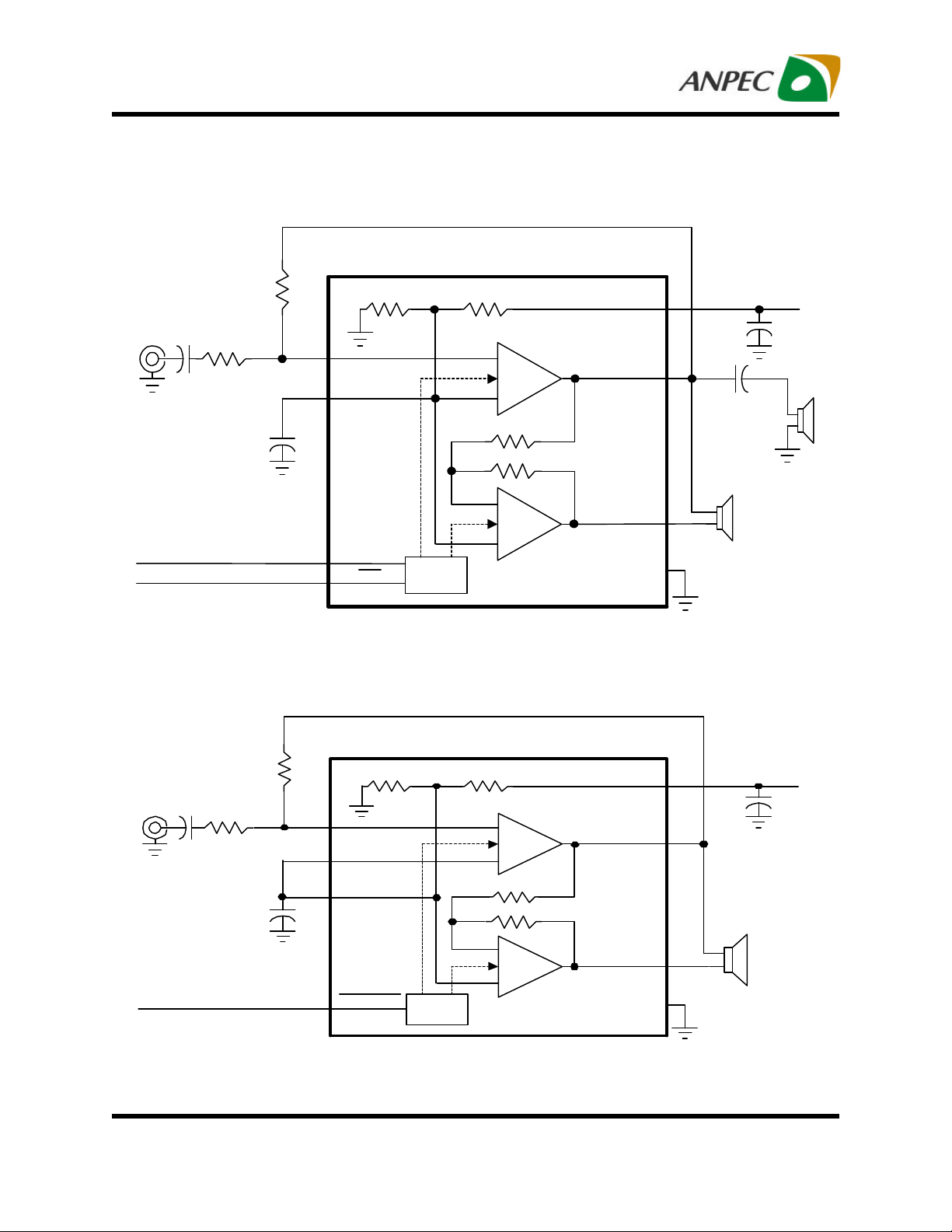

Block Diag ram

Audio

Input

From System Control

From HP Jack

RI

CI

CB

RF

4

IN

Bypass

2

1

Shutdown

3

SE/BTL

VDD/2

Bias

Control

APA0710

VDD

6

VDD

Cs

_

5

Vo+

+

CC

_

Vo-

8

+

7

GND

RF

Audio

Input

From System Control

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

CI

RI

4

3

2

CB

1

IN-

IN+

Bypass

Shutdown

Bias

Control

VDD/2

_

+

_

+

APA0711

VDD

Vo+

Vo-

GND

6

5

8

7

www.anpec.com.tw3

VDD

Cs

APA0710/0711

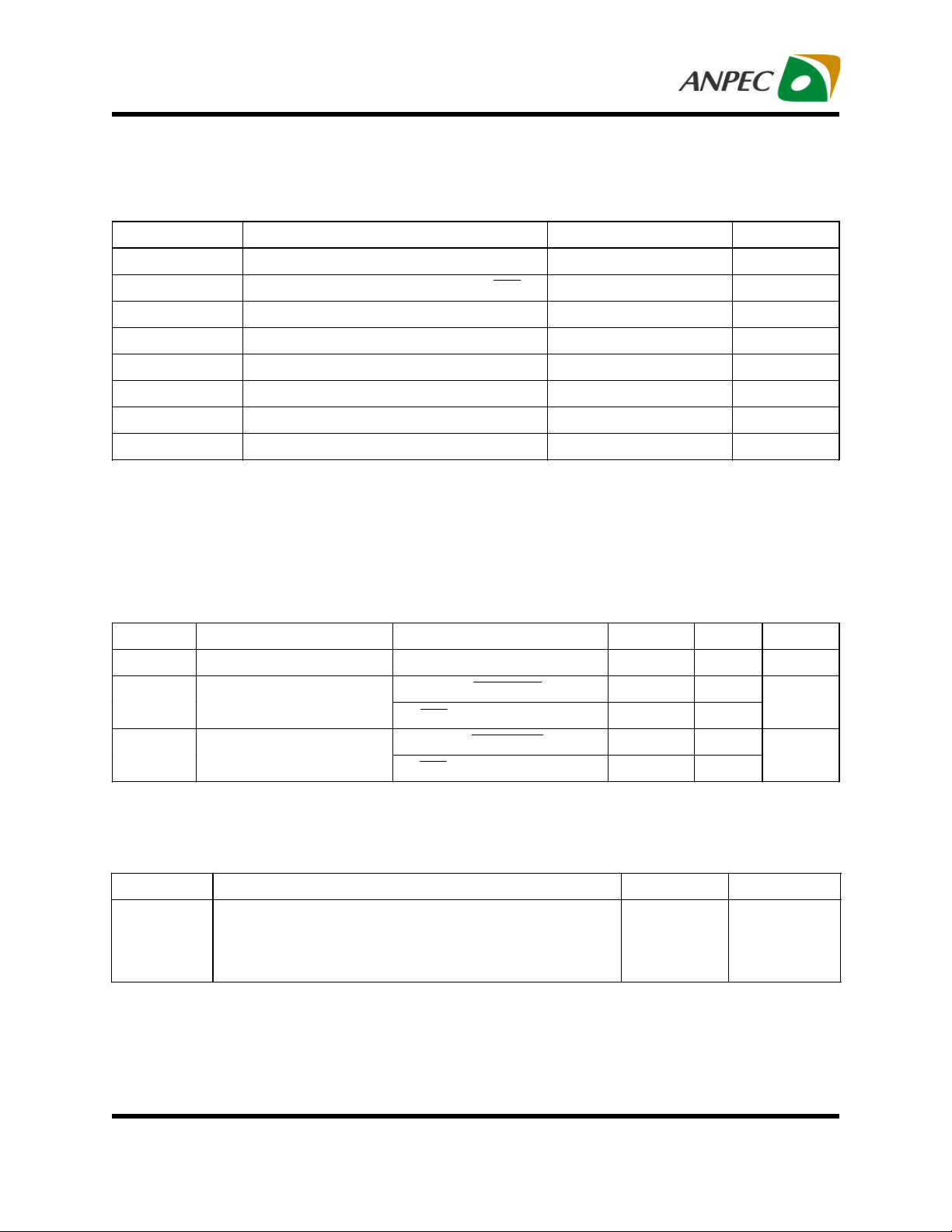

Absolute Maximum Ratings

(Over operating free-air temperature range un less otherwise noted.)

Symbol Parameter Rating Unit

VDD Supply Voltage -0.3 to 6 V

VIN

TA Operating Ambient Temperature Range -40 to 85

TJ Maximum Junction Temperature Internally Limited*1

T

Storage Temperature Range -65 to +150

STG

TS Soldering Temperature, 10 seconds 260

V

Electrostatic Discharge -2000 to 2000*2 V

ESD

PD Power Dissipation Internally Limited W

Note:

1.APA0710/1 integrated internal thermal shutdown protection when junction temperature ramp up to 170°C

2.Human body model: C=100pF, R=1500Ω, 3 positives pulses plus 3 negative pulses

3.Machine model: C=200pF, L=0.5µF, 3 positive pulses plus 3 negative pulses

Input Voltage Range, Shutdown, SE/BTL

-0.3 to VDD+0.3 V

Recommende d Operating Conditions

Symbol

VDD Supply Voltage

VIH High-Level Voltage

VIL Low-Level Voltage

Parameter Test Conditions Min. Max. Unit

Shutdown, Shutdown

SE/BTL

Shutdown, Shutdown

SE/BTL

2.6 5.5

2.2

0.9VDD

0.4

0.9VDD-1

°C

°

C

°C

°C

V

V

V

Thermal Characteristics

Symbol Parameter Value Unit

R

Thermal Resistance from Junction to Ambient in Free Air

THJA

MSOP-8-P*

SOP-8

* 3.42 in2 printed c ircuit board with 20z trace and copper through 6 vias of 12mil diameter vias.

Th e thermal pad on the MSOP-8-P package with solder on the printed circuit board.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

50

160

°

C/W

www.anpec.com.tw4

APA0710/0711

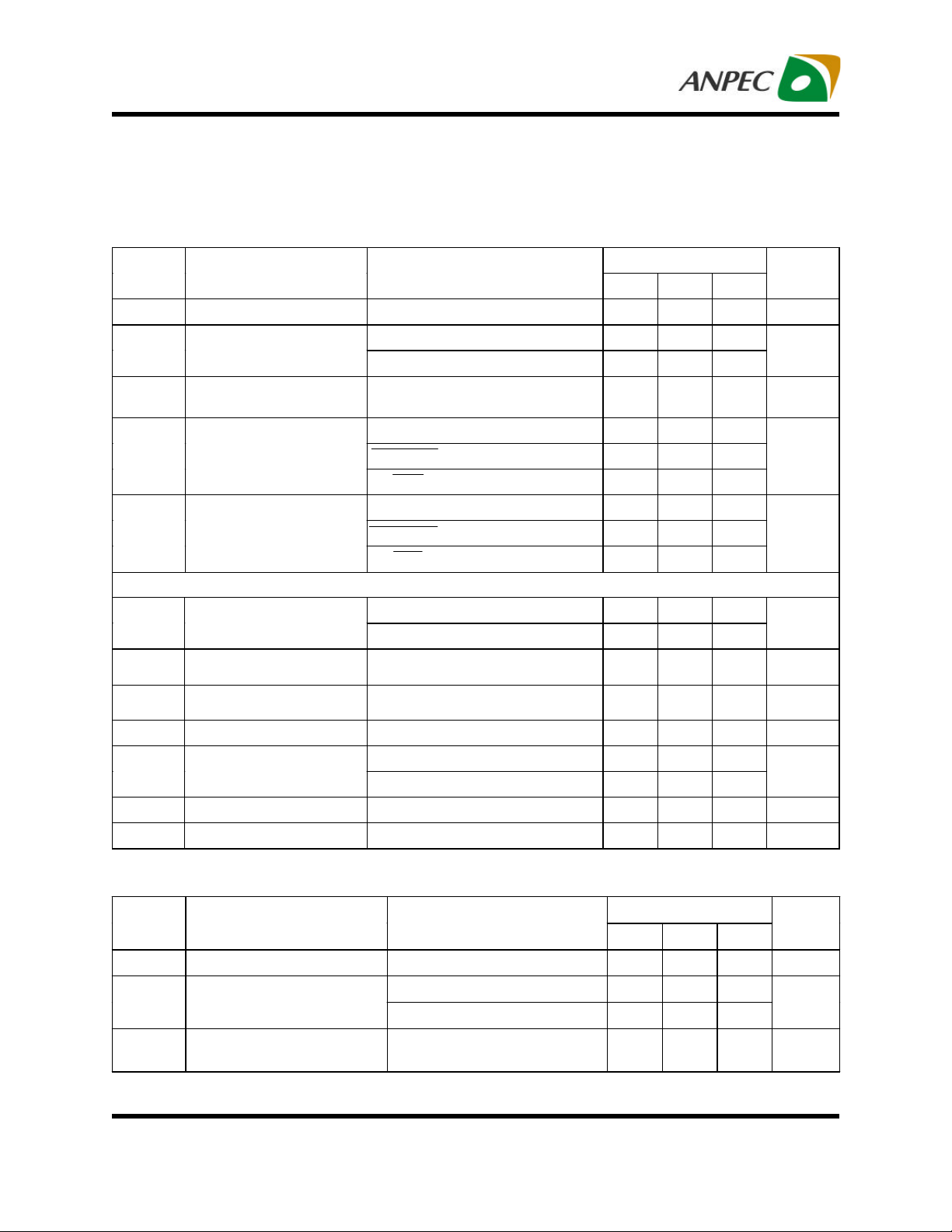

Electrical Characteristics

Electrical Characteristics at Spe cified Free - Air Temperature

V

= 3.3V, TA = 25 °C (unless otherwise noted)

DD

Symbol

Parameter Test Conditions

APA0710/1

Min. Typ. Max.

VOO Output Offset Voltage

IDD Supply Current

I

DD(SD)

Supply Current,

Shutdown Mode

RL = 8Ω, RF = 10kΩ

BTL mode, RF = 10kΩ

SE mode, RF = 10kΩ

RF = 10kΩ

20 mV

0.9 1.8

0.55 1.1

0.1 2

Shutdown, VI = VDD 1

Shutdown, VI = VDD 1 |IH|

SE/BTL, VI = VDD

1

Shutdown, VI = 0V 1

Shutdown, VI = 0V 1 |IL|

SE/BTL, VI = 0V 1

Operating characteristic, V

PO Output Power

THD+N

Bom

Total Harmonic Distortion

Plus Noise

Maximum Output Power

Bandwidth

(Note 1)

(Note 1)

= 3.3V, TA = 25°C, RL = 8Ω

DD

THD = 1%, BTL mode, RL = 8Ω

THD = 1%, SE mode, RL = 32Ω

PO = 280mW, BTL mode, RL = 8Ω

Gain = 2, THD+N = 2% 20 kHz

400

40

0.15

B1 Unity-Gain Bandwidth Open Loop 2 MHz

PSRR

Power Supply Rejection

(Note1)

Ratio

Vn Noise Output Voltage

TWU Wake-up time

CB = 1µF, BTL mode, RL = 8Ω

CB = 1µF, SE mode, RL = 8Ω

Gain = 1, CB = 0.1µF

CB = 1µF

74

61

28

380 ms

VDD= 5V, TA= 25 °C (unless otherwise noted)

Unit

mA

µA

µA

µA

mW

%

dB

µV(rms)

Symbol

Parameter Test Conditions

Unit

Min. Typ. Max.

APA0710/1

VOO Output Offset Voltage

IDD Supply Current

I

DD(SD)

Supply Current ,

Shutdown Mode

RL = 8Ω, RF = 10kΩ

BTL mode, RF = 10kΩ

SE mode, RF = 10kΩ

RF = 10kΩ

20 mV

1.3 2.6

mA

0.75 1.5

0.1 2 µ

A

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw5

APA0710/0711

Shutdown mode control signal input, place entire IC in shutdown mode

When SE/BTL is held low, the APA0710 is in BTL mode. When SE/BTL is

ut in SE

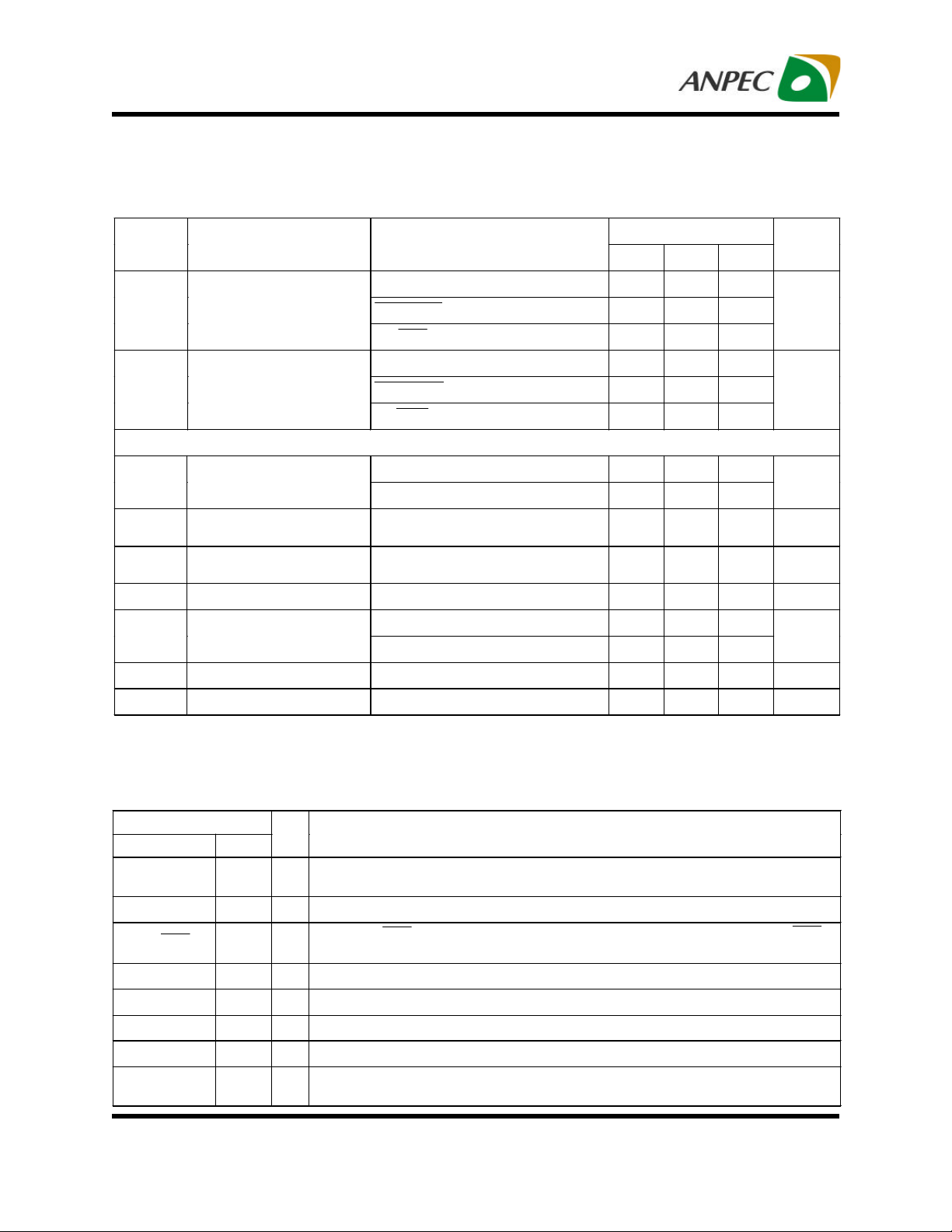

Ele ctrical Characteristics(Cont.)

Electrical Chara cteristics at Specified Free - Air Temperature (Cont.)

VDD= 5V, TA= 25°C (unless otherwise noted)

Symbol

Parameter Test Conditions

Min. Typ. Max.

Shutdown, VI = VDD 1

Shutdown, VI = VDD 1 |IH|

SE/BTL, VI = VDD 1

Shutdown, VI = 0V 1

APA0710/1

|IL|

Shutdown, VI = 0V 1

SE/BTL, VI = 0V 1

Operating characteristic, V

PO

THD+N

Bom

Output Power

Total Harmonic Distortion

Plus Noise

(Note 1)

Maximum Output Power

Bandwidth

= 5V, TA = 25°C, RL = 8Ω

DD

(Note 1)

THD = 1%, BTL mode, RL = 8Ω

THD = 1%, SE mode, RL = 32Ω

PO = 630mW, BTL mode,

RL = 8Ω

Gain = 2, THD+N = 2% 20 kHz

900

94

0.15

B1 Unity-Gain Bandwidth Open Loop 2 MHz

PSRR

Power Supply Rejection

(Note1)

Ratio

Vn Noise Output Voltage

Twu Wake-up time

CB = 1µF, BTL mode, RL = 8Ω

CB = 1µF, SE mode, RL = 8Ω

Gain = 1, CB = 0.1µF

CB = 1µF

74

61

28

400 ms

Unit

µ

µ

mW

%

dB

µ

V(rms)

A

A

Note1 : Output po wer is measured at the output terminals of device at f=1KHz.

Pin Description

APA0710

Pin

Name No

Shutdown 1 I

Bypass 2 I Bypass pin

SE/BTL 3 I

IN 4 I In is the audio input terminal

VO+ 5 O VO+ is the positive output for BTL and SE modes

VDD 6 Supply voltage input pin

GND 7 Ground connection for circuitry

VO- 8

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

I/O

Description

when held high.

held high, the APA0710 is in SE mode

VO- is the negative output in BTL mode and a high-impedance outp

O

mode

www.anpec.com.tw6

APA0710/0711

Shutdown mode control signal input, place entire IC in shutdown mode

Pin Description

APA0711

Pin

Name No

Shutdown 1

I/O

I

when held low.

Description

Bypass 2 I Bypass pin

IN+ 3 I IN+ is the non-inverting input. IN+ is typically tied to the Bypass terminal.

IN- 4 I IN- is the inverting input. IN- is typically used as the audio input terminal.

VO+ 5 O VO+ is the positive BTL output.

VDD 6 Supply voltage input pin.

GND 7 Ground connection for circuitry.

VO- 8 O VO- is the negative BTL output.

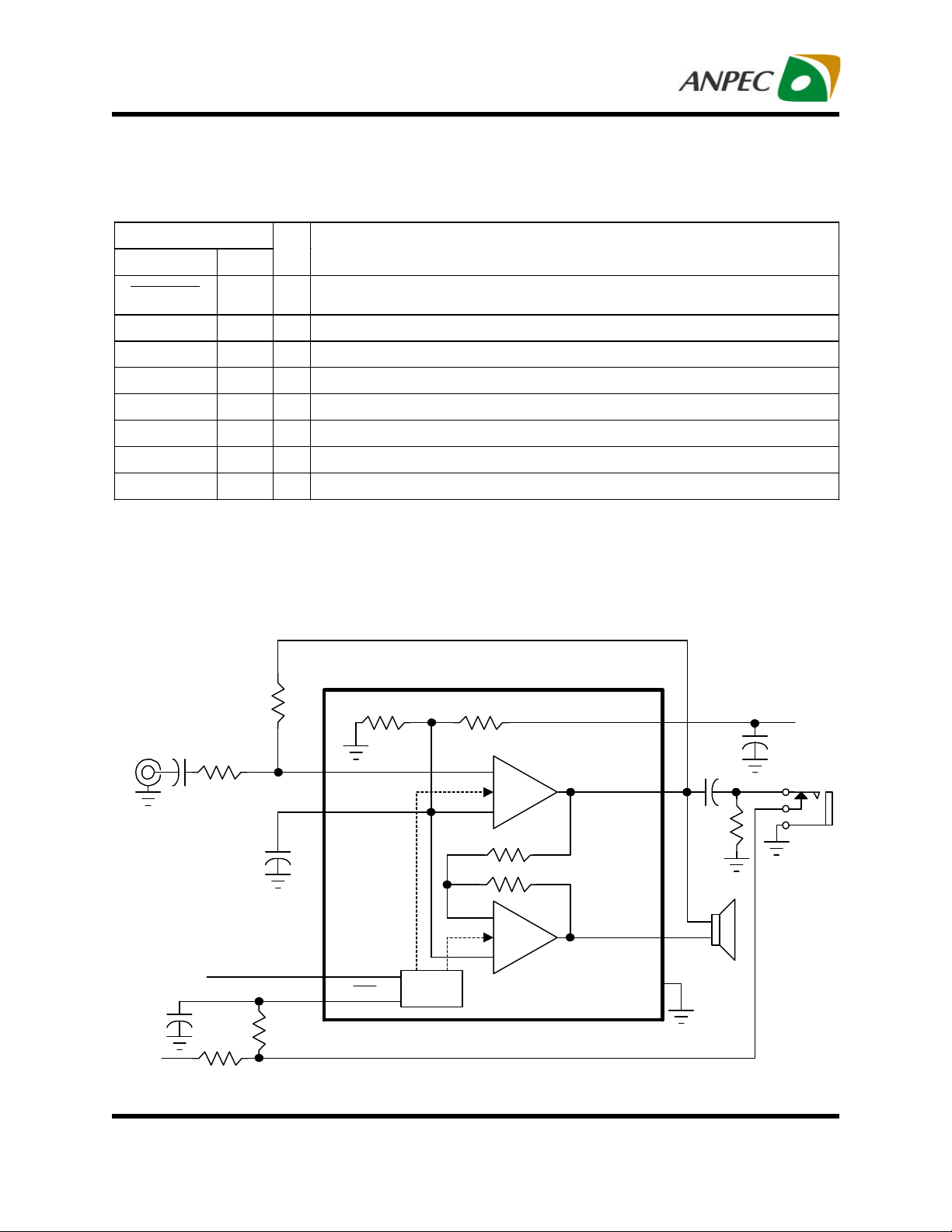

Typ ical Application Circuit

for APA0710 Application

RF

Audio

Input

CI

0.47µ F

RI

10kΩ

10kΩ

CB

1 µF

4

2

IN

Bypass

VDD/2

_

+

VDD

Vo+

6

CC

330µ F

5

1k Ω

VDD

Cs

1µF

_

1

From System Control

0.1µF

VDD

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

100kΩ

100kΩ

Shutdown

SE/BTL

3

Bias

Control

+

Vo-

GND

8

7

www.anpec.com.tw7

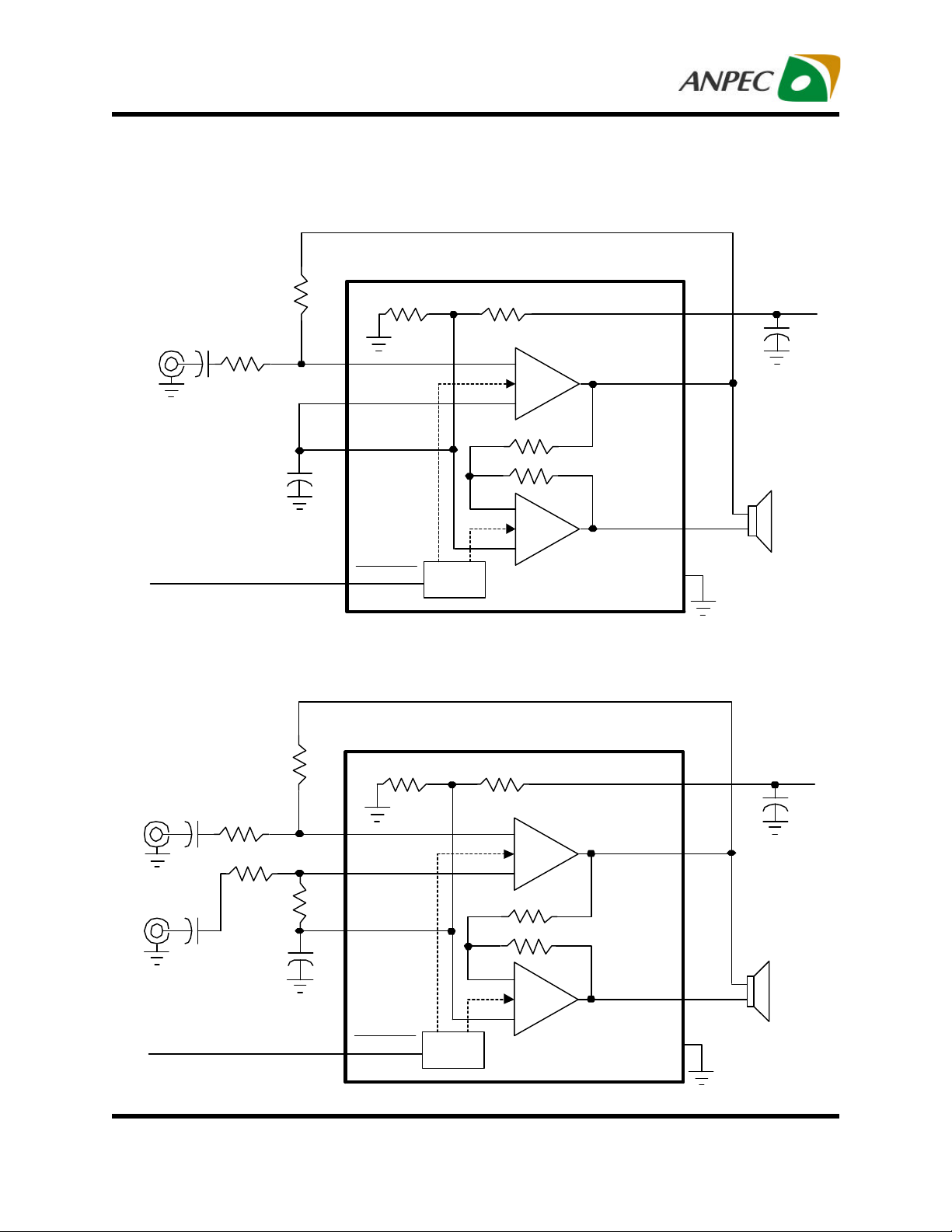

APA0710/0711

Typ ical Application Circuit (Cont.)

for APA0711 Application

RF

10 kΩ

Audio

Input

0.47µF

CI

RI

10kΩ

CB

1 µ F

4

3

2

IN-

IN+

Bypass

_

+

_

VDD

Vo+

Vo-

6

5

8

VDD

CsVDD/2

1 µ F

From System Control

1

Shutdown

for APA0711 Differential Input Application

RF

10 kΩ

Audio

Input-

Audio

Input+

CI

0.47µF

CI

0.47µF

RI

10kΩ

RI

10kΩ

RF

10 kΩ

CB

1 µ F

4

3

2

IN-

IN+

Bypass

Bias

Control

+

7

GND

VDD

6

_

Vo+

5

VDD

CsVDD/2

1 µ F

+

_

Vo-

8

From System Control

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

1

Shutdown

Bias

Control

+

7

GND

www.anpec.com.tw8

APA0710/0711

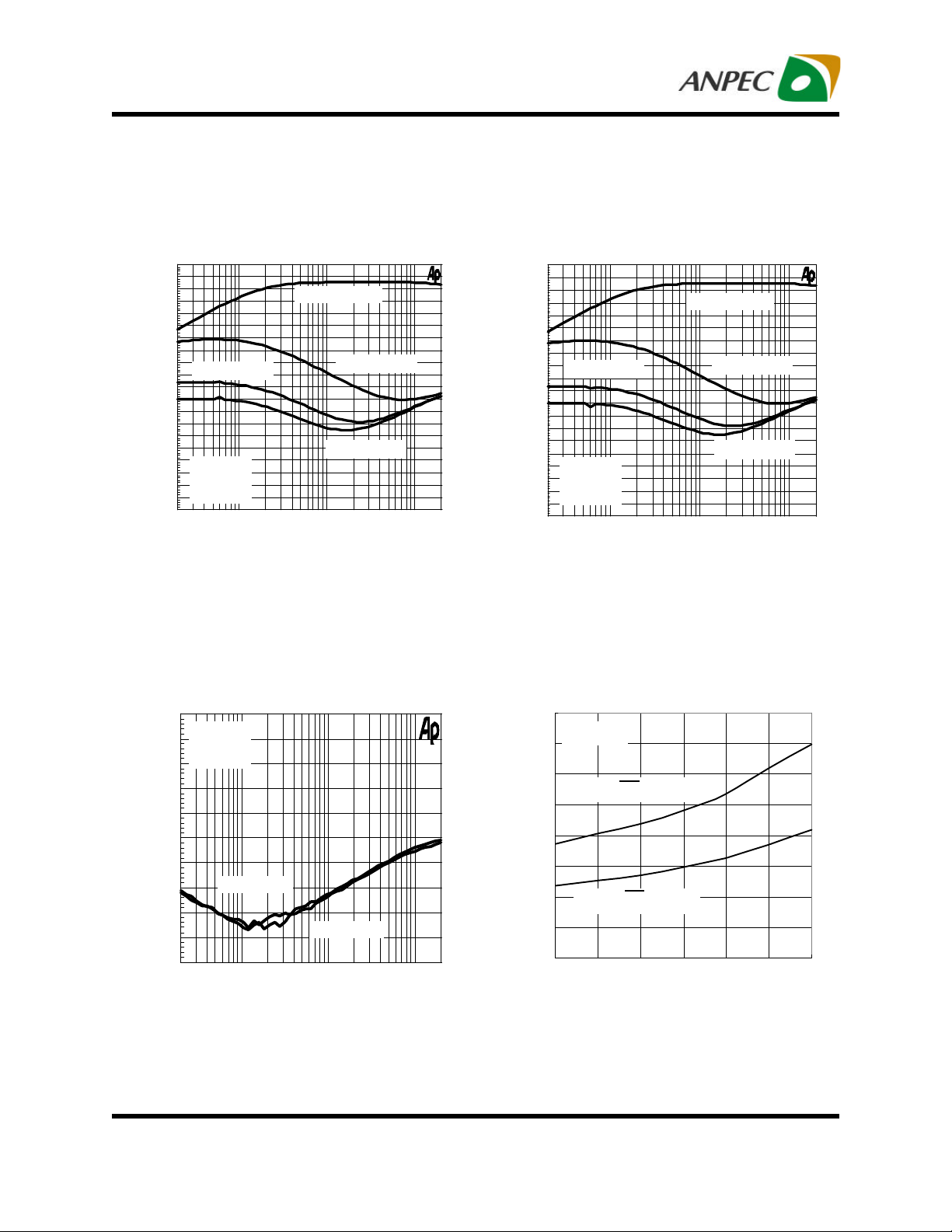

Typ ical Characteristics

PSRR vs. Freque ncy PSRR vs. Freque ncy

+0

No-Capa citor

-20

+0

No-Capa citor

-20

-40

-60

-80

Ripple Rejection Ration (dB)

-100

CB=1 µF

VDD=3.3V

RL=8Ω

SE

Frequency (H z) Frequency (H z)

PSRR vs. Freque ncy

+0

T

RL=8Ω

CB=1 µF

BTL

-20

-40

-60

VDD=3.3V

-80

Ripple Rejection Ration (dB)

-100

20 20k100 1k 10k

VDD=5V

Frequency (H z)

CB=0.1µF

CB=2.2µF

-40

-60

-80

Ripple Rejection Ration (dB)

20k10k1k10020

-100

CB=1 µF

VDD=5V

RL=8Ω

SE

CB=0.1µF

CB=2.2µF

20k10k1k10020

Supply Current vs. Supply Voltage

1600

RF=10kΩ

1400

1200

BTL(SE/BTL=0.1VDD)

1000

800

600

400

Supply Current (µA)

SE(SE/BTL=0.9VDD)

200

0

2.5 3 3.5 4 4.5 5 5.5

Supply Voltage(V)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw9

APA0710/0711

Typ ical Characteristics (Cont.)

Supply Current vs. Supply Voltage

0.12

RF=10kΩ

0.11

0.1

0.09

Supply Current (uA)

0.08

2.5 3 3.5 4 4.5 5 5.5

Supply Voltage(V)

Output Pow er vs. Supply Voltage

400

THD+N=1%

350

f=1kHz

SE

300

250

200

150

100

Output Power (mW)

50

0

2.5 3 3.5 4 4.5 5 5.5

RL=8Ω

RL=32Ω

Supply Voltage(V)

Output Pow er vs. Supply Voltage

1200

THD+N=1%

f=1kHz

1000

BTL

800

600

400

RL=8Ω

Output Power (mW)

200

0

2.5 3 3.5 4 4.5 5 5.5

RL=32Ω

Supply Voltage(V)

Output Power vs. Load Resistance

1000

900

800

700

600

500

400

300

200

Output Power (mW)

VDD=3.3V

100

0

8 16 24 32 40 48 56 64

VDD=5V

THD+N=1%

f=1kHz

BTL

Load Resistance(Ω)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw10

APA0710/0711

Typ ical Characteristics (Cont.)

Output Power vs. Load Resistance

350

THD+N=1%

f=1kHz

300

SE

250

200

150

100

Output Power (mW)

50

VDD=3.3V

0

8 16 24 32 40 48 56 64

VDD=5V

Load Resistance(Ω)

THD+N vs. Frequen cy

10

VDD=3.3V

RL=8Ω

AV=-2V/V

BTL

THD+N vs. Frequen cy

10

VDD=3.3V

Po=2 50mW

RL=8 Ω

BTL

1

0.1

THD+N (%)

0.01

20 20k

AV=-10V/V

100 1k

AV=-20V/V

Frequency (H z)

THD+N vs. Output Pow er

10

VDD=3.3V

f=1kHz

AV=-2V/V

BTL

AV=-2V/V

10k

1

Po=125mW

0.1

THD+N (%)

0.01

20

100

1k 10k

Frequency (H z)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

Po=50mW

Po=250mW

20k

1

0.1

THD+N (%)

0.01

0

RL=8Ω

0.1 0.2 0.3

Output Pow er (W)

0.4 0.5

www.anpec.com.tw11

0.6

APA0710/0711

Typ ical Characteristics (Cont.)

10

f=10kHz

1

0.1

THD+N (%)

0.01

0.01

10

RR

VDD=5V

RL=8Ω

AV=-2V/V

BTL

THD+N vs. Output Pow er

f=20kHz

f=1kHz

f=20Hz

VDD=3.3V

RL=8Ω

CB=1µF

AV=-2V/V

BTL

Output Pow er (W)

THD+N vs. Frequen cy

THD+N vs. Frequen cy

10

VDD=5V

Po=700mW

RL=8Ω

BTL

1

AV=-10V/V

0.1

THD+N (%)

0.01

10.1

20 20k100 1k 10k

AV=-20V/V

AV=-2V/V

Frequency (H z)

THD+N vs. Output Pow er

10

VDD=5V

f=1kHz

AV=-2V/V

BTL

1

Po=700mW

0.1

THD+N (%)

0.01

20 20k100

1k

Frequency (H z)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

Po=50mW

Po=350mW

10k

1

0.1

THD+N (%)

0.01

0.1 0.3

RL=8Ω

0.5

0.7 0.9 1.1 1.2

Output Pow er (W)

www.anpec.com.tw12

APA0710/0711

Typ ical Characteristics (Cont.)

THD+N vs. Output Pow er

10

VDD=5V

RL=8 Ω

CB=1 µF

AV=2V/V

BTL

f=10kHz

f=20kHz

f=1kHz

f=20Hz

0.1

1

0.1

THD+N (%)

0.01

0.01 1

Output Pow er (W)

THD+N vs. Frequen cy

10

R

VDD=3.3V

RL=32Ω

AV=-1V/V

SE

1

THD+N vs. Frequen cy

10

VDD=3.3V

Po=30mW

RL=32Ω

SE

0.1

1

AV=-5V/V

AV=-10V/V

THD+N (%)

AV=-1V/V

0.001

20 100 1k 10k 20k

Frequency (H z)

THD+N vs. Output Pow er

10

VDD=3.3V

f=1kHz

RL=32Ω

AV=-1V/V

SE

1

0.1

Po=15mW

THD+N (%)

0.01

0.001

20 20k100 1k 10k

Frequency (H z)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

Po=10mW

Po=30mW

0.1

THD+N (%)

0.01

0.001

0.02 0.050.025 0.03 0.035 0.04 0.045

Output Pow er (W)

www.anpec.com.tw13

APA0710/0711

Typ ical Characteristics (Cont.)

10

VDD=3.3V

RL=32Ω

AV=-1V/V

SE

1

0.1

THD+N (%)

0.01

0.001

0.002

10

RRRRR

VDD=5V

RL=32Ω

AV=-1V/V

SE

1

THD+N vs. Output Pow er

f=20Hz

f=20kHz

f=1kHz

0.01

Output Pow er (W)

THD+N vs. Frequen cy

f=10kHz

0.1

10

T T TT T TT TT TTT TT T T TTTTTTTTTTTTTTTTTTTTTTTTTTTTT T

VDD=5V

Po= 60mW

RL=32Ω

SE

1

0.1

THD+N (%)

0.01

0.001

20 20k100

10

VDD=5V

f=1kHz

RL=32Ω

AV=-1V/V

SE

1

THD+N vs. Frequen cy

AV=-10V/V

AV=-5V/V

AV=-1V/V

1k

Frequency (H z)

THD+N vs. Output Pow er

10k

0.1

Po=15mW

Po=30mW

THD+N (%)

0.01

0.001

20 20k

100

Po=60mW

1k

Frequency (H z)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

10k

0.1

THD+N (%)

0.01

0.02

0.04 0.06 0.08 0.1 0.12

Output Pow er (W)

www.anpec.com.tw14

0.14

APA0710/0711

Typ ical Characteristics (Cont.)

10

VDD=5V

RL=32Ω

AV=-1V/V

SE

1

0.1

THD+N (%)

0.01

0.002 0.20.01

10

VDD=3.3V

RL=10kΩ

AV=-1V/V

SE

1

THD+N vs. Output Pow er

f=20kHz

f=20Hz

f=10kHz

f=1kHz

Output Pow er (W)

THD+N vs. Frequen cy

THD+N vs. Frequen cy

10

1

0.1

VDD=3.3V

Po=0.1mW

RL=10kΩ

SE

AV=-2V/V

AV=-1V/V

T

THD+N (%)

0.01

AV=-5V/V

0.1

20

100

1k

10k

20k

Frequency (H z)

THD+N vs. Output Pow er

10

VDD=3.3V

f=1kHz

RL=10kΩ

AV=-1V/V

SE

1

0.1

THD+N (%)

0.01

20 20k100 1k 10k

Po=0.1mW

Po=0.05mW

Po=0.13mW

Frequency (H z)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

THD+N (%)

0.1

0.01

50 20075 100 125 150 175

Output Power (µW)

www.anpec.com.tw15

APA0710/0711

Typ ical Characteristics (Cont.)

THD+N vs. Output Pow er

10

VDD=3.3V

RL=10kΩ

AV=-1V/V

SE

1

f=20Hz

0.1

f=20kHz

THD+N (%)

0.01

f=1kHz

50 500

100

f=10kHz

200

Output Power (µW)

THD+N vs. Frequen cy

10

VDD=5V

RL=10kΩ

AV=-1V/V

SE

1

300

400

THD+N vs. Frequen cy

10

1

0.1

TTTTT

VDD=5V

Po=0.3mW

RL=10kΩ

SE

AV=-5V/V

THD+N (%)

0.01

AV=-2V/V

0.001

20 20k

100

1k 10k

Frequency (H z)

THD+N vs. Output Pow er

10

VDD=5V

f=1kHz

RL=10kΩ

AV=-1V/V

1

SE

AV=-1V/V

0.1

THD+N (%)

Po=0.1mW

0.01

Po=0.3mW

0.001

20 20k100 1k 10k

Frequency (H z)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

Po=0.2mW

0.1

THD+N (%)

0.01

0.001

50

100 150 200 250 300 350 400 450

500

Outpu t Power (µW)

www.anpec.com.tw16

APA0710/0711

Typ ical Characteristics (Cont.)

THD+N vs. Output Pow er

10

VDD=5V

RL=10kΩ

AV=-1V/V

SE

1

f=20Hz

0.1

f=20kHz

THD+N (%)

0.01

f=10kHz

f=1kHz

0.001

10

Output Power (µW)

Close Lo op Gain and Phase vs. Frequency

Close Lo op Gain and Phase vs. Frequency

+28

+24

+20

+16

+12

Phase

Gain

+8

Close Loop Gain (dB)

+4

-0

500100

10 100k100 1k 10k

VDD=3.3V

RL=8Ω

AV=-4V/V

Po=250mW

BTL

+220

+180

+140

+100

Phase(°)

+60

+20

Frequency (H z)

Close Lo op Gain and Phase vs. Frequency

+28

+24

+20

+16

+12

Phase

Gain

+8

Close Loop Gain (dB)

+4

-0

10 100k100

1k

10k

Frequency (H z)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

VDD=5V

RL=8Ω

AV=-4V/V

Po=700mW

BTL

+220

+180

+140

+100

+60

+20

+10

+8

+6

+4

+2

+0

Phase(°)

-2

-4

-6

Close Loop Gain (dB)

-8

-10

10 100k

100

1k 10k

Frequency (H z)

Gain

Phase

VDD=3.3V

RL=32Ω

AV=-2V/V

Po=30mW

SE

www.anpec.com.tw17

+300

+260

+220

+180

+140

+100

+60

+20

Phase(°)

APA0710/0711

Typ ical Characteristics (Cont.)

Close Lo op Gain and Phase vs. Frequency

+10

+8

+6

+4

+2

+0

-2

-4

Close Loop Gain (dB)

-6

-8

-10

10

100 1k

Gain

Phase

VDD=5V

RL=32Ω

AV=-2V/V

Po=60mW

SE

10k

Frequency (H z)

Noise Floor vs. Frequency

100

100k

+300

+260

+220

+180

+140

+100

+60

+20

Noise Floor vs. Frequency

100

RL= 8Ω, BTL

10

RL= 3 2Ω, SE

Phase(°)

Noise Floor (µVrms)

VDD=3.3V

BW=22Hz to 22kHz

AV=-1V/V

1

20 20k

100 1k

10k

Frequency (H z)

Power D issipation vs. Output Power

350

RL= 8Ω, BTL

10

RL= 3 2Ω, SE

Noise Floor (µVrms)

VDD=5V

BW=22Hz to 22kHz

AV=-1V/V

1

20 20k100 1k 10k

Frequency (H z)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

300

250

200

150

100

Power Dissipation (mW)

50

0

0 200 400 600

RL=8 Ω

RL=32Ω

Outp ut Power (mW)

www.anpec.com.tw18

VDD=3.3V

BTL

APA0710/0711

Typ ical Characteristics (Cont.)

Power D issipation vs. Output Power

100

90

80

70

60

50

40

30

20

Power Dissipation (mW)

10

0

0 50 100 150

RL=8 Ω

RL=32Ω

Outp ut Power (mW)

Power D issipation vs. Output Power

200

180

160

140

120

100

80

60

40

Power Dissipation (mW)

20

0

0 50 100 150 200 250 300

RL=8 Ω

RL=32Ω

VDD=3.3V

SE

VDD=5V

SE

Power D issipation vs. Output Power

800

700

600

500

400

300

200

Power Dissipation (mW)

100

0

0 200 400 600 800 1000

RL=8 Ω

RL=32Ω

Outp ut Power (mW)

VDD=5V

BTL

Outp ut Power (mW)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw19

APA0710/0711

Application Descriptions

BTL Operation

Vo+

OP1

RL

Vo-

Vbias

OP2

Fig ure1:

APA07 10/1 power amplifier internal configuration

The power amplifier OP1 gain is setting by external

gain sett ing, while the second amplifier OP2 is

internally fixed in a unity-gain , inverting configuration.

Figure 1 show s that the output of OP1 is connected

to the input to OP2, which results in the output

signals of with both amplifiers with identical in

magnitude, but out o f phase 180°. Consequently, the

differential gain for each channel is 2X (Gain of SE

mode ).

By driving the loa d differentially through outputs Vo+

a nd Vo-, an amplifier configuration commonly referred

to as bridged mod e is established. BTL mode operation

is diffe rent from the classical single-ended SE amplifier

configuration where one side of its load is connected

to ground.

A BTL amplifier design has a few d istinct advantages

over the SE configuration, as it provides differential

drive to the load, thus doubling the output swing for a

spe cified supply voltage.

Four times the output pow er is possible as compared

to a SE a mplifier under the same conditions. A BTL

configuration, such a s the one used in APA0710, also

cre ates a second advantage over SE amplifiers. Since

the diff erential outputs, Vo+, Vo- are biased at half-

supply, no need DC voltage exists across the load.

This eliminates t he need for an output coupling

capacitor which is required in a single supply, SE

con figuration.

Single-Ended Operation

Consider the single-supply SE configuration shown

Application Circuit. A coupling ca pacitor is required to

block the DC offset voltage from reaching the load.

These capacitors can be quite large (approximately

33µF to 1000 µF) so they tend to be expensive, occupy

valuable PCB are a, and have the additional drawback

of limiting low-frequency perfo rmance of the system

(refer to the Output Coupling Capacitor).

The rules described still hold w ith the addition of the

following relationship :

1

80kCbypass

× O

≤

1

C)R(R

×+

<<

1

(1)

CLIFI CR

Output SE/BTL Opera tion (for APA0710 only)

The ability of the APA0710 to ea sily switch between

BTL and SE modes is one of its most important costs

saving features. This feature eliminates the requirement

for an additional headphon e amplifier in applications

where internal speakers are d riven in BTL mode but

exte rnal headphone or speakers must be accommodated.

Internal to the APA0710, two separate amplifiers drive

Vo+ and Vo- (see Figure 2). The SE/BTL input controls

the operation of the follower amplifier that drives Vo-.

• When SE/BTL is he ld low, the OP2 is turn on and

the APA071 0 is in the BTL mode.

• When SE/BTL is held high, the OP2 is in a high

output impedance state, which configures the

APA0710 as SE driver from Vo +. IDD is reduce d by

a pproximately one-half in SE mode.

Control of the SE/BTL input can be a logic-level TTL

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw20

APA0710/0711

Application Descriptions (Cont.)

Output SE/BTL Opera tion (for APA0710 only)

sou rce or a resistor divider network or the mono head-

phone jack with switch pin as shown in Application

Circuit.

+

vo

1kΩ

VDD

100kΩ

SE/BTL

100kΩ

Control

Pin

Headphone

Jack

Figure 2: SE/BTL input selection by phonejack p lug

In Figure 2, input SE/BTL operates as follows :

When the phon ejack plug is inserted, the 1kΩ resistor

is disconnected and the SE/BTL input is pulled high

an d enables the SE mode.

When this inp ut goes high level, the Vo- amplifier is

shutdown causing the speaker to mute. The Vo+

a mplifier then drives through the output capacitor (CC)

into the headph one jack.

When there is no headphone plugged into the system,

the contact pin of the headphone jack is connected

from the signal pin, t he voltage divider set up by

resist ors 100kΩ and 1kΩ. Resistor 1kΩ then pulls

low the SE/BTL pin, enabling the BTL function.

Input Capacitor, Ci

In t he typical application an input capacitor, Ci, is

required to allow the amplifier to bias the input sign al

to the proper DC level for optimum operation. In this

case, Ci and the minimum input impedance Ri form a

high-pass filter with the corner f requency determined

in the follow equation :

FC(highpass)=

1

2πRiCi

(2)

The value of Ci is importa nt to consider as it directly

affects the low frequency performance of the circuit.

Consider the example where Ri is 100kΩ and t he

specif ication calls for a flat bass response down to

40Hz. Equa tion is reconfigured as follow :

Ci=

1

2πRifC

(3)

Con sider to input resistance variation, the Ci is 0.04µF

so one would likely choose a value in the range of

0.1µF to 1.0µF.

A furthe r consideration for this capacitor is the leakage

path from the input source through the input network

(Ri+Rf, Ci) to the load.

This leakage current crea tes a DC offset voltage at the

input to the amplifier that reduces useful headroom,

especially in high gain applications. For this re ason a

low-leakage tantalum or ceramic capacitor is the best

choice. When polarized capacitors are used, the

positive side of the ca pacitor should face the amplifier

inpu t in most applications as the DC level there is held

at VDD/2, which is likely higher that the source DC

level. Please note that it is important to confirm the

capacitor polarity in the application.

Effe ctive Bypass Capacitor, Cbypass

As other p ower amplifiers, proper supply bypassing is

critical for low noise performance and high power

supply rejection.

The capacitors located on the bypass and power

supply pins should be as close to the device as

possible. The effect of a larger half supply bypass

capacit or will improve PSRR due to increased halfsupply st ability. Typical application employ a 5V

regulat or with 1.0µF and a 0.1µF bypass as supply

filtering. This does n ot eliminate the need for bypassing

the supply nodes of the APA0710/1. The sele ction of

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw21

APA0710/0711

Application Descriptions (Cont.)

Effe ctive Bypass Capacitor, Cbypass (Cont.)

bypass capacitors, especially Cbypass, is thus

dependent upon desired PSRR requirements, click

a nd pop performance.

To avoid start-up pop noise occurred, the bypass

voltage should rise slower tha n the input bias voltage

and the relationship shown in equation (4) should be

mainta ined.

<<

O80kCbypass1×

1

(4)

IFI C)R(R

×+

The bypass capacitor is fed f rom a 80kΩ resistor

inside th e amplifier. Bypass capacitor, Cbypass, values

of 0.1µF to 2.2µF ceramic or tantalum low-ESR

capacitors are recommended for the best THD and

noise performan ce.

The bypass capacitance also effects to t he start up

time. It is determined in the following equation :

Tstart up = 5 x (Cbypass x 80kΩ)

(5)

Output Coupling Ca pacitor, Cc (for APA0710 only)

In the typical single-supply (SE) configuration on a

APA0710 , an output coupling capacitor (Cc) is required

to block the DC bias at the output of the amplifier thus

preventing DC currents in the load. As with the input

coupling capacitor, the ou tput coupling capacitor and

imped ance of the load form a high-pass filter governed

by equation.

FC(highpass)=

1

2πR LCC

(6)

For example, a 330µF ca pacitor with an 8Ω speaker

would atten uate low frequencies below 60.6Hz. The

main disad vantage, from a performance standpoint, is

the load impedance is typically small, which drives

the low-frequency corner higher degrading the bass

response. Large value s of CC are required to pass low

frequencies into the load.

Power Supply Decoupling, Cs

The APA0710/1 is a high-perfo rmance CMOS audio

amplif ier that requires adequate power supply

decoupling t o ensure the output total harmonic

distortion (THD) is as low as possible. Power supply

decoupling also prevents the oscillations ca using by

long lead length between the amplifier and the speaker.

The optimum decoupling is achieved by using two

different type capacitors that target on different type

of noise on the power supply leads. For higher freq uency

tran sients, spikes, or digital hash on the line, a good

low equivalent-series-resistance (ESR) ceramic

capacitor, typically 0.1µF pla ced as close as possible

to the device VDD lea d works best. For filtering lowerfreque ncy noise signals, a large aluminum electrolytic

capacitor of 10µF or greater placed near the audio

pow er amplifier is recommended.

Optimizing Depop Circuitry

Circuitry has been included in the APA0710/1 to

minimize the a mount of popping noise at power-up

and when coming out of shutdown mode. Popping

occurs whenever a voltage step is applied to the

speaker. In order t o eliminate clicks and pops, all

ca pacitors must be fully discharged before turn-on.

Rapid on/o ff switching of the device or the shutdown

function will cause the click and pop circuitry. The

valu e of Ci will also affect turn-on pops (refer to Effective

Bypass Capacitance). The bypass volt age rise up

shou ld be slower than input bias voltage.

Alt hough the bypass pin current source cannot be

modified, the size of Cbyp ass can be changed to alter

the de vice turn-on time and the amount of clicks and

pops. By incre asing the value of Cbypass, turn-on pop

can be red uced. However, the tradeoff for using a larger

bypass capacitor is to increase the turn-on time for

this d evice. There is a linear relationship between the

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw22

APA0710/0711

Application Descriptions (Cont.)

Optimizing Depop Circuitry (Cont.)

size o f Cbypass and the turn-on time.

In a SE configuration, the output coupling capacitor,

CC, is of particu lar concern. This capacitor discharges

throu gh the internal 10kΩ resistors. Depending on the

size of CC, the time constant can be relatively large.

In the most ca ses, choosing a small value of Ci in the

rang e of 0.33µF to 1µF, Cbypass being equal to 1µF

should produce a virtually clickless and popless turn-on.

A high gain amplif ier intensifies the problem as the

small delta in voltage is multip lied by the gain. So it is

adva ntageous to use low-gain configurations.

Shutdown Function

In orde r to reduce power consumption while not in use,

the APA0710/1 contains a shutdown function to

externally turn off t he amplifier bias circuitry. This

shutdown feature turns the amplifier off when a logic

high is pla ced on the Shutdown pin for APA0710 and a

logic low on the Shutdown pin for APA0711.

The trigger point between a logic high and logic low

level is typically 0.4VDD. It is best to sw itch between

groun d and the supply voltage VDD to provide maximum

device performance.

By sw itching the Shutdown/Shutdown pin to high level/

low level, the a mplifier enters a low-current state, I

for APA0710/1. APA0710/1 are in shutdown mode. On

norma l operating, APA0710’s Shutdown pin pull to low

level and APA0711’s Shutdow n pin should pull to high

level to keeping the IC out of the shutdown mode. The

Shutdown/Shutdow n pin should be tied to a definite

voltage to avoid unwa nted state changes.

BTL Amplifier Efficiency

An easy-to-use equation to calculate efficiency starts

out a s being equal to the ratio of power from the power

su pply to the power delivered to the load. The following

equations are t he basis for calculating amplifier

efficiency.

Efficiency =

PO

PSUP

Where :

PO = =

VO,RMS =

VO,RMS x VO,RMS

R L

VP

√2

PSUP = VDD x IDD,AVG = VDDx

VPxVP

2RL

2VP

πRL

Efficiency of a BTL configuration :

PO

VPxVP

( ) / (VDD x ) =

=

PSUP

Po (W) Efficiency (%) VP(V) PD (W)

0.125 33.6 1.41 0.26

0.25 47.6 2.00 0.29

0.375 58.3 2.45* 0.28

*High peak voltages c ause the THD to increase.

Table 1. E fficiency Vs Output Power in 3.3V/8Ω BTL

Systems.

Table 1 employs equation10 to calculate e fficiencies

DD

2RL

2VP

πRL

πVP

4VDD

for thre e different output power levels when load is 8Ω.

The efficiency of the amplifier is quite low for lower

powe r levels and rises sharply as power to the load is

increased result ing in a nearly flat internal power

dissipation over the norma l operating range. Note that

the interna l dissipation at full output power is less than

in the half power range. Calculating the efficiency for a

specific syst em is the key to proper power supply

design. For a mono 900mW audio system with 8Ω

loads and a 5V supply, the maximum draw on the

(7)

(8)

(9)

(10)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw23

APA0710/0711

Application Descriptions (Cont.)

BTL Amplifier Efficiency (Cont.)

power supply is almost 1.5W.

A final point to re member about linear amplifiers (either

SE or BTL) is how to manipulate the terms in the

eff iciency equation to utmost advantage when

possible. Note that in equation10, VDD is in the

denominator.

This indicates that a s VDD goe s down, efficiency goes

up. In other words, use the efficiency analysis to choose

the corre ct supply voltage and speaker impedance for

the application.

Power Dissipation

Whether the pow er amplifier is operated in BTL or SE

modes, power dissipation is a major concern. In

equat ion11 states the maximum power dissipation

point for a SE mode operating at a given supply

voltage an d driving a specified load.

2

SE mode : PD,MAX= (11)

VDD

2

2π RL

In BTL mode operation, the output voltage swing is

doubled as in SE mode. Thus the maximum power

dissipation point for a BTL mode operating at the same

given conditions is 4 times as in SE mode.

2

BTL mode : PD,MAX=

4VDD

2

2π RL

(12)

Since the APA0710/1 is a mono channel power

a mplifier, the maximum internal power dissipation is

equa l to the both of equations depending on the mode

of operation. Even with this substantial increase in

power dissipation, the APA0710/1 does not require

extra hea tsink. The power dissipation from equation12,

a ssuming a 5V-power supply and an 8Ω load, must

not be greater than the power dissipation that results

from the equation13 :

PD,MAX=

TJ,MAX - TA

θJA

(13)

For MSO P-8-P package with and SOP-8 without

thermal pad, the thermal resistance (θJA) is equal to

50οC/W an d 160οC/W, respe ctively.

Since the maximum junction temperature (T

J,MAX

) of

APA0710/1 are 170οC a nd the ambient temperature

(TA) is defined by the power system design, the

maximum power dissipation wh ich the IC package is

ab le to handle can be obtained from equation13. Once

the power dissipation is greater than the maximum

limit (P

), e ither the supply voltage (VDD) must be

D,MAX

de creased, the load impedance (RL) must be increased

or the a mbient temperature should be reduced.

Thermal Pad Considerations

The thermal pad must be connected to ground. The

pa ckage with thermal pad of the APA0710/1 requires

special attention on thermal design. I f the thermal

design issues are not properly addressed, the

APA0710/1 8Ω will go into thermal shutdown when

driving a 8Ω load.

The thermal pad on the bottom of the APA0710/1

should be soldered down to a copper pad on the

circuit board. He at can be conducted away from the

thermal pad through the copper pla ne to ambient. If

the copper pla ne is not on the top surface of the circuit

board, 6 to 10 vias of 12 mil or smaller in diameter

sho uld be used to thermally couple the thermal pad to

the bottom plane. For good thermal conduction, the

vias must be plated through and solder filled. The

copper plane used t o conduct heat away from the

thermal pad should be as large as practical.

If the a mbient temperature is higher than 25°C, a larger

copper p lane or forced-air cooling will be required to

keep the APA0710/1 junction te mperature below the

therma l shutdown temperature (170°C).

In higher a mbient temperature, higher airflow rate

and/or larger cop per area will be required to keep the

IC out of thermal shu tdown.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw24

APA0710/0711

Packa ging Information

SOP-8 pin ( Reference JEDEC Registration MS-012)

HE

0.015X45

e1 e2

D

A1

A

0.004max.

Dim

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

H 5.80 6.20 0.228 0.244

L 0.40 1.27 0.016 0.050

e1 0.33 0.51 0.013 0.020

e2 1.27BSC 0.50BSC

φ

1

Min. Max. Min. Max.

Millimeters Inches

0° 8° 0° 8°

1

L

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw25

APA0710/0711

Packa ging Information

MSOP-8-P

e1

A1

E

Dim

H1

D1

e

A3

Min. Max. Min. Max.

E1

C

0.25

A2

Millimeters Inches

A1 0.06 0.15 0.002 0.006

A2 0.86 TYP 0.34 TYP

A3 0.25 0.4 0.01 0.0126

C 0.13 0.23 0.005 0.009

e 0.65 TYP 0.0256 TYP

e1 2.90 3.1 0.114 0.122

E 4.8 5.0 0.189 0.197

E1 2.90 3.1 0.114 0.122

D1 2.146 REF 0.0845 REF

H1 1.740 REF 0.0685 REF

L 0.9 1.0 0.036 0.039

L1 0.45 0.65 0.018 0.026

φ

6° 6°

GAUGE

PLANE

L

L1

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw26

APA0710/0711

Physical Specifications

Terminal Material Solder-Plated Copper (Solder Material : 90/10 or 63/37 SnPb), 100%Sn

Lead Solderability Meets EIA Specification RSI86-91, ANSI/J-STD-002 Category 3.

Reflow Condition (IR/Convection or VPR Reflow)

T

P

Ramp-up

T

L

Tsmax

Tsmin

Temperature

ts

Preheat

25

°

t 25 C to Peak

Classificatin Reflow Profiles

tp

Ramp-down

Time

Critical Zone

TL to T

P

t

L

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Average ramp-up rate

(TL to TP)

Preheat

-

Temperature Min (Tsmin)

-

Temperature Max (Tsmax)

-

Time (min to max) (ts)

Time maintained above:

-

Temperature (TL)

-

Time (tL)

Peak/Classificatioon Temperature (Tp)

Time within 5°C of actual

Peak Temperature (tp)

Ramp-down Rate

Time 25°C to Peak Temperature

3°C/second max. 3°C/second max.

100°C

150°C

60-120 seconds

183°C

60-150 seconds

150°C

200°C

60-180 seconds

217°C

60-150 seconds

See table 1 See table 2

10-30 seconds 20-40 seconds

6°C/second max. 6°C/second max.

6 minutes max. 8 minutes max.

Notes: All temperatures refer to topside of the package .Measured on the body surface.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw27

APA0710/0711

Classifica tin Reflow Profiles(Cont.)

Table 1. SnPb Entectic Process – Package Peak Reflow Temperature s

Package Thickness Volume mm

<350

<2.5 mm

≥

2.5 mm 225 +0/-5°C 225 +0/-5°C

240 +0/-5°C 225 +0/-5°C

3

Volume mm

3

≥ 350

Table 2. Pb-free Process – Package Classification Reflow Temperatures

Package Thickness Volume mm3

<350

<1.6 mm

1.6 mm – 2.5 mm

≥

2.5 mm 250 +0°C* 245 +0°C* 245 +0°C*

260 +0°C* 260 +0°C* 260 +0°C*

260 +0°C* 250 +0°C* 245 +0°C*

*Tolerance: The device manufacturer/supplier

shall

Volume mm3

350-2000

Volume mm3

>2000

assure process compatibility up to and

including the stated classification temperature (this means Peak reflow temperature +0°C.

For example 260°C+0°C) at the rated MSL level.

Reliab ility Test Program

Test item Method Description

SOLDERABILITY MIL-STD-883D-2003

HOLT MIL-STD-883D-1005.7

PCT JESD-22-B,A102

TST MIL-STD-883D-1011.9

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JESD 78 10ms, 1tr > 100mA

245°C, 5 SEC

1000 Hrs Bias @125°C

168 Hrs, 100%RH, 121°C

-65°C~150°C, 200 Cycles

Carrier Tape & Reel Dimensions

E

Po

F

W

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

P

P1

Ao

t

D

Bo

Ko

D1

www.anpec.com.tw28

APA0710/0711

12.4 +0.2

Carrie r Tape & Reel Dimensions(Cont.)

J

C

A

T2

B

T1

Application

M/SOP-8

A B C J T1 T2 W P E

330±1 62 ± 1.5

F D D1 Po P1 Ao Bo Ko t

5.5 ± 0.1 1.55±0.1

12.75 +

0.1 5

1.55+ 0.25

2 + 0.5

4.0 ± 0.1 2.0 ± 0.1 6.4 ± 0.1 5.2± 0.1 2.1± 0.1 0.3±0.013

2± 0.2

12 + 0.3

- 0.1

8± 0.1 1.75± 0.1

(mm)

Cover Tape Dimensions

Application Carrier Width Cover Tape Width Devices Per Reel

SOP- 8

MSOP- 8

12 9.3 2500

12 9.3 3000

Customer Service

Anpe c Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

7F, No. 13 7, Lane 235, Pac Chiao Rd.,

Hsin Tien City, Taipei Hsien, Taiwan, R. O. C.

Tel : 886-2 -89191368

Fax : 8 86-2-89191369

Copyright ANPEC Electronics Corp.

Rev. A.5 - Oct., 2005

www.anpec.com.tw29

Loading...

Loading...