Evaluation Board User Guide

One Technology Way • P. O . Box 9106 • Norwood, MA 02062-9106, U.S.A . • Te l: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

UG-339

ADL5304 Evaluation Board User Guide

FEATURES

4-layer printed circuit board (PCB), 53 mm × 72 mm form factor

Resistor programmable log slope and intercept

Single-or dual-supply operation

Full two argument logarithmic computation

On-board precision 100 nA reference

Optimized for very fast response at all input currents

Overall bandwidth of >4 MHz for inputs >1 μA

Bandwidth: 25 kHz at input of 1 nA and 350 kHz at 10 nA

10 decades of input range: 1 pA to 10 mA

Law conformance: ±0.25 dB from 100 pA to 100 μA

Log ratio or fixed-intercept operation

On-board precision 1.5 V and 2.0 V voltage references

Adaptive photodiode (PD) bias for low dark current

Default log slope of 10 mV/dB at VLOG pin

GENERAL DESCRIPTION

This user guide refers to the ADL5304 evaluation board, which

allows users to connect the ADL5304 precision log amplifier to

current sources with simple SMA connections or, with modification of the default configuration, to mount a photodiode to the

INUM input for optical power level applications.

The ADL5304 evaluation board is laid out to minimize errors

due to leakage into the sensitive INUM and IDEN nodes

through driven guards.

Slope and logarithmic intercept are programmable through

on-chip resistors and can be further optimized for specific

applications using external resistors. Additional components

can be added to optimize filtering for specific applications.

Adaptive photodiode bias is available using the IMON output to

optimize photodiode response and dark current.

Full details about the part are available in the ADL5304 data sheet,

which should be consulted when using the ADL5304-EVALZ.

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

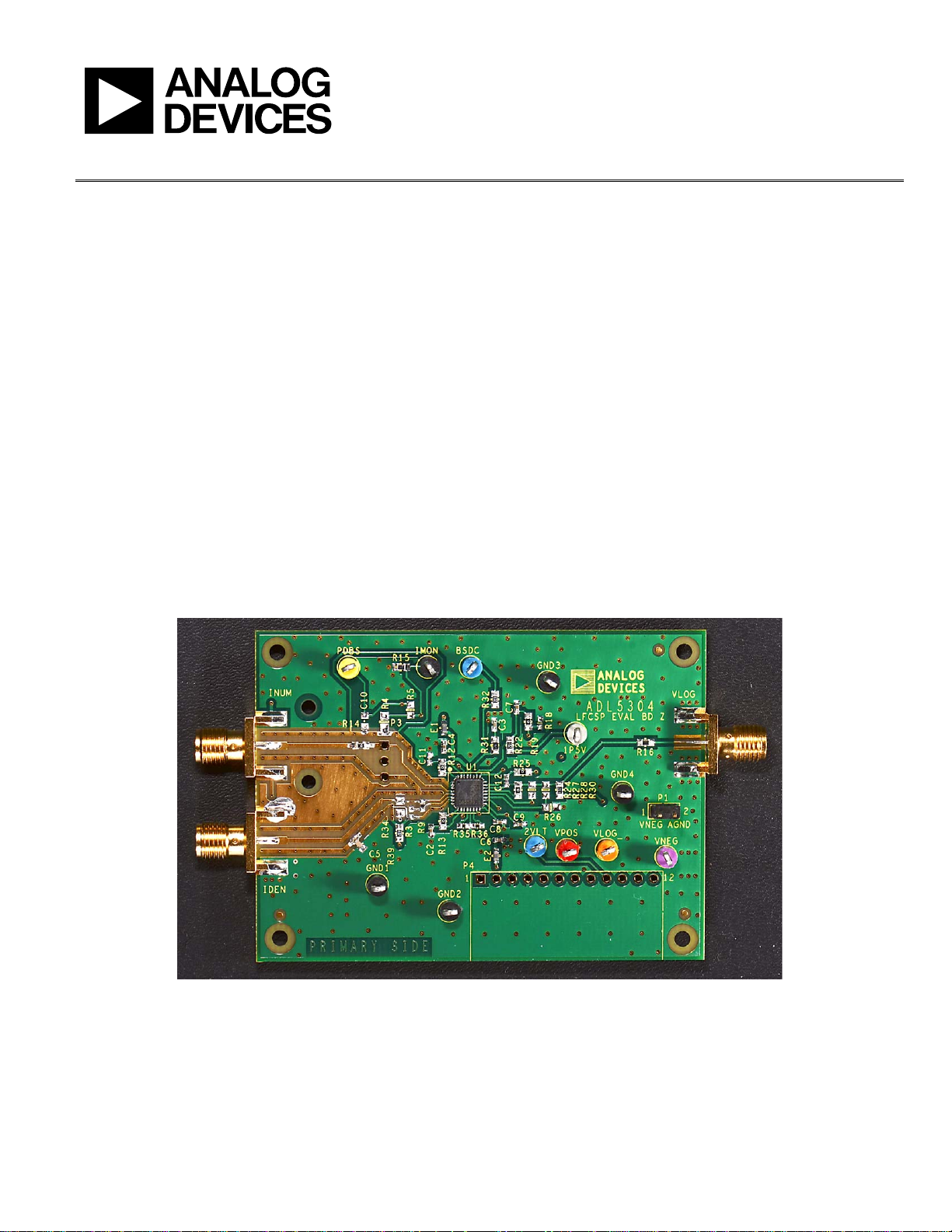

Figure 1. Top View of ADL5304 Evaluation Board

Rev. 0 | Page 1 of 16

10321-001

UG-339 Evaluation Board User Guide

TABLE OF CONTENTS

Features .............................................................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Evaluation Board Features ............................................................... 3

Power Supply ................................................................................. 3

Programming Slope and Intercept ............................................. 3

Photodiode Connections ............................................................. 3

1.5 V and 2.0 V References .......................................................... 3

IREF Fixed Current Reference .................................................... 3

Shields and Guards ....................................................................... 4

Stray Magnetic Fields ................................................................... 4

Logarithmic Ratio Operation ..................................................... 4

Voltage Source Operation ........................................................... 5

REVISION HISTORY

11/11—Revision 0: Initial Version

Speed and Filtering .......................................................................5

Guard Configurations .......................................................................6

Slope/Intercept Options ....................................................................7

External Connectors .........................................................................8

Analog I/O Connector, P4 ...........................................................8

INUM, IDEN, and VLOG SMA Connectors ............................8

Output Loading .............................................................................8

Single-/Dual-Supply Jumper, P1 .................................................8

Evaluation Board Schematics and Artwork ...................................9

Evaluation Board Optional Components .................................... 11

Ordering Information .................................................................... 12

Bill of Materials ........................................................................... 12

Related Links ............................................................................... 12

Rev. 0 | Page 2 of 16

Evaluation Board User Guide UG-339

EVALUATION BOARD FEATURES

POWER SUPPLY

The ADL5304 evaluation board can be powered from a single 5 V

supply for specified inputs from 1 pA to 3 mA. In single-supply

configuration, the VNEG bus is connected to ground using

Jumper P1. This is the default configuration of the board. In

single-supply operation, the V

the range of the VLOG output swing is 0.5 V to 2.5 V. Ground

referenced V

operation is not allowed in single-supply

SUM

configuration. With Jumper P1 removed, the ADL5304

evaluation board can be used in dual-supply mode. In dualsupply mode operation, the VNEG supply is connected to a

−2 V to −5 V source. This increases the specified input range

from 1 pA to 10 mA. The ADL5304 evaluation board can be

configured to operate with V

swing from −1 V to +1 V when VNEG is less than −2 V.

PROGRAMMING SLOPE AND INTERCEPT

The ADL5304 provides precision trimmed internal resistors to

allow programming options for slope and intercept without the

need for external components. The internal resistors connected

to Pin SCL1 to Pin SCL3 are accessed by Resistors R24 to R28.

Table 1 shows the values for slope, intercept, and offset available

through programming using 0 Ω resistors in the R24 to R28

positions. Additional slope, intercept, and offset values can be

configured by using nonzero resistors; however, performance

may be affected by drift and tolerance of the external components.

The intercept can also be adjusted by using both the INUM and

IDEN inputs.

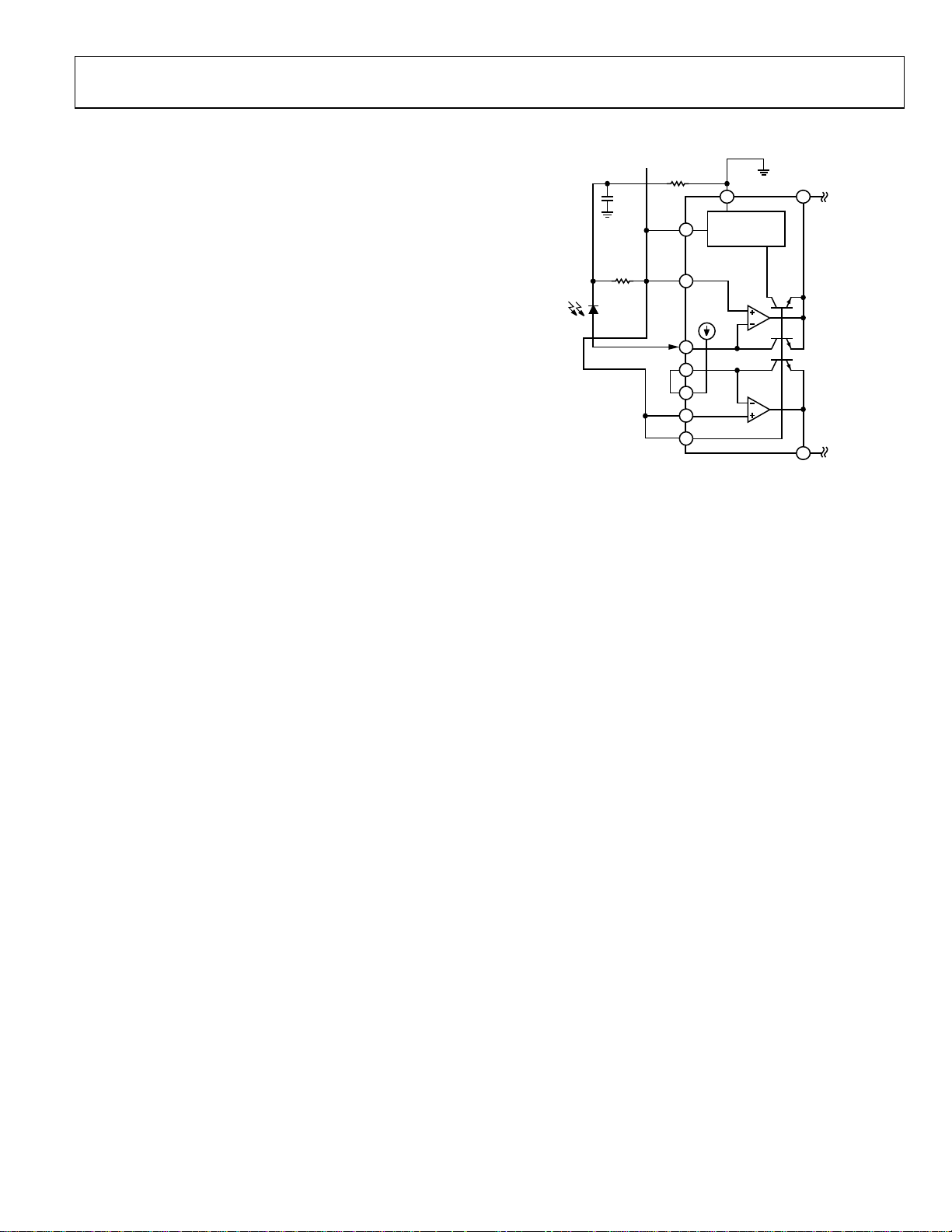

PHOTODIODE CONNECTIONS

The ADL5304 evaluation board has a provision to connect a

p-intrinsic-n (PIN) photodiode to the INUM input at Connector

P3 (see Table 4). The monitor current output (I

easy configuration of an adaptive photodiode bias scheme. Input

current, I

the IMON pin of 1.1 × I

I

, the additional current must flow in an external resistor,

NUM

R4, equal to 10 × R

series resistance of the photodiode. This ensures that the actual

junction of the photodiode is biased as close as possible to 0 V

to minimize dark current. Capacitor C10 provides potential

filtering and dynamic currents during fast transients. The value

for best bias response depends on the photodiode used and

should be determined experimentally.

If the adaptive bias is not used, the IMON pin must be

connected to ground by populating R5 with a 0 Ω resistor.

, is multiplied to give an effective output current at

NUM

NUM

, where RS is the value of the internal parasitic

S

reference voltage is 1.5 V and

SUM

at ground and a V

SUM

LOG

) provides

MON

output

. Because the photodiode produces

FROM 1. 5V VREF

C10

R4

10*R

DIO

PD

SHIELD

SHIELD

Figure 2. Adaptive Photodiode Bias

VSM1

VSM2

INUM

IDEN

IREF

VSM3

VSM4

R5

0

2

3

4

5

6

7

8

30

MONITOR AND

PD BIAS

(1.1× I

1.5V

100nA

1.5V

NUM

Q1

Q2

VNUMIMON

)

Q3

VDEN

32

9

10321-002

1.5 V AND 2.0 V REFERENCES

Accurate 1.5 V (Pin 1P5V) and 2.0 V (Pin 2VLT) reference

outputs allow precise repositioning of the intercept using external resistors. These voltages are available on test points and on

the P4 connector (see Table 2). The 2.0 V reference can be used

in adaptive photodiode mode to set up a precise 0.5 V bias across

the photodiode. See the ADL5304 data sheet for more information. The 2.0 V reference can also be used to set a different

current reference for the IDEN input by removing R9 and

populating R3 and R34. The value of R34 is calculated based on

the V

V

voltage, R34 = (2.0 −V

SUM

= 1.5 V to generate an I

SUM

)/I

SUM

current of 1 A, R34 = 500 kΩ.

DEN

. For example, with

DEN

IREF FIXED CURRENT REFERENCE

The ADL5304 provides a fixed 100 nA reference (I

in the default configuration, is connected to the IDEN input for

single input log calculation. For applications requiring both

inputs to the logarithmic argument, IREF can be disconnected

from IDEN by removing Resistor R9 and applying current

directly to the IDEN input. When IREF is not used, it must be

connected to V

through Resistor R3 to dump the generated

SUM

100 nA current.

), which,

REF

Rev. 0 | Page 3 of 16

UG-339 Evaluation Board User Guide

SHIELDS AND GUARDS

Reducing errors from external sources in a current sensing

circuit requires a different approach from the voltage sensing

input of the typical high impedance op amp circuit. Leakage

can be a significant source of error for highly sensitive log amps,

especially at the low end of their range. For example, a 1 GΩ

leakage path to ground from the INUM input with V

the default 1.5 V generates a 1.5 nA offset. The ADL5304 evaluation board makes extensive use of guards to reduce the effects

of leakage at low input levels; however, it is still important to

carefully handle and clean the ADL5304 evaluation board to

prevent contaminants from handling or leakage currents from

improper washing of the PCB. A common mistake for those

unfamiliar with low level current sensing is to attach a high

impedance scope probe or meter to measure the input for debugging. This can cause significant error, because the typical 1 M ~

100 MΩ impedance of these probes sources/sinks current from

the input depending on their bias.

In instrumentation applications where measurements <1 nA are

required, the use of triaxial cables and connectors is common to

reduce leakage through the insulating dielectric by carrying a

continuous guard from current source to sensing circuit on the

intermediate conductor. This type of guarding circuit is different from a conventional electrostatic shield used in voltage sensing

applications. An electrostatic shield relies on low impedance

and the ability to flow current freely to minimize voltage induced

on the shield that can capacitively couple into a high impedance

input. A guard is actively driven to the same voltage as the

current-carrying center conductor, eliminating leakage through

the dielectric between the center conductor and the guard. The

guard does not flow current other than the leakage from the guard

to the outer shield and is usually only connected to a single end

of the cable, because any significant current flow through the

guard can couple inductively to the center conductor. Using the

ADL5304 evaluation board, the guard can be driven either from

the current source (see Figure 5) or from the ADL5304 (see

Figure 6).

The ADL5304 evaluation board can bias the shield of a coaxial

cable that is connected to the INUM input to the nominal V

voltage by removing Resistor R41 and populating Resistor R40,

but this requires careful consideration of the environment on

the other side of the cable. For example, if the ADL5304 evaluation board is configured for V

= 1.5 V, connecting the other

SUM

end of the INUM coaxial cable to an instrument with a ground

referenced shield pulls V

to ground and collapses the input

SUM

stage of the ADL5304. Floating the current source end of the

shield provides a low leakage guard, but a separate return path

for the signal current must then be provided (see Figure 7). If

cable dielectric leakage is not a concern, the INUM input can be

connected directly to a coaxial cable with the shield, providing

signal ground (see Figure 8).

SUM

set to

SUM

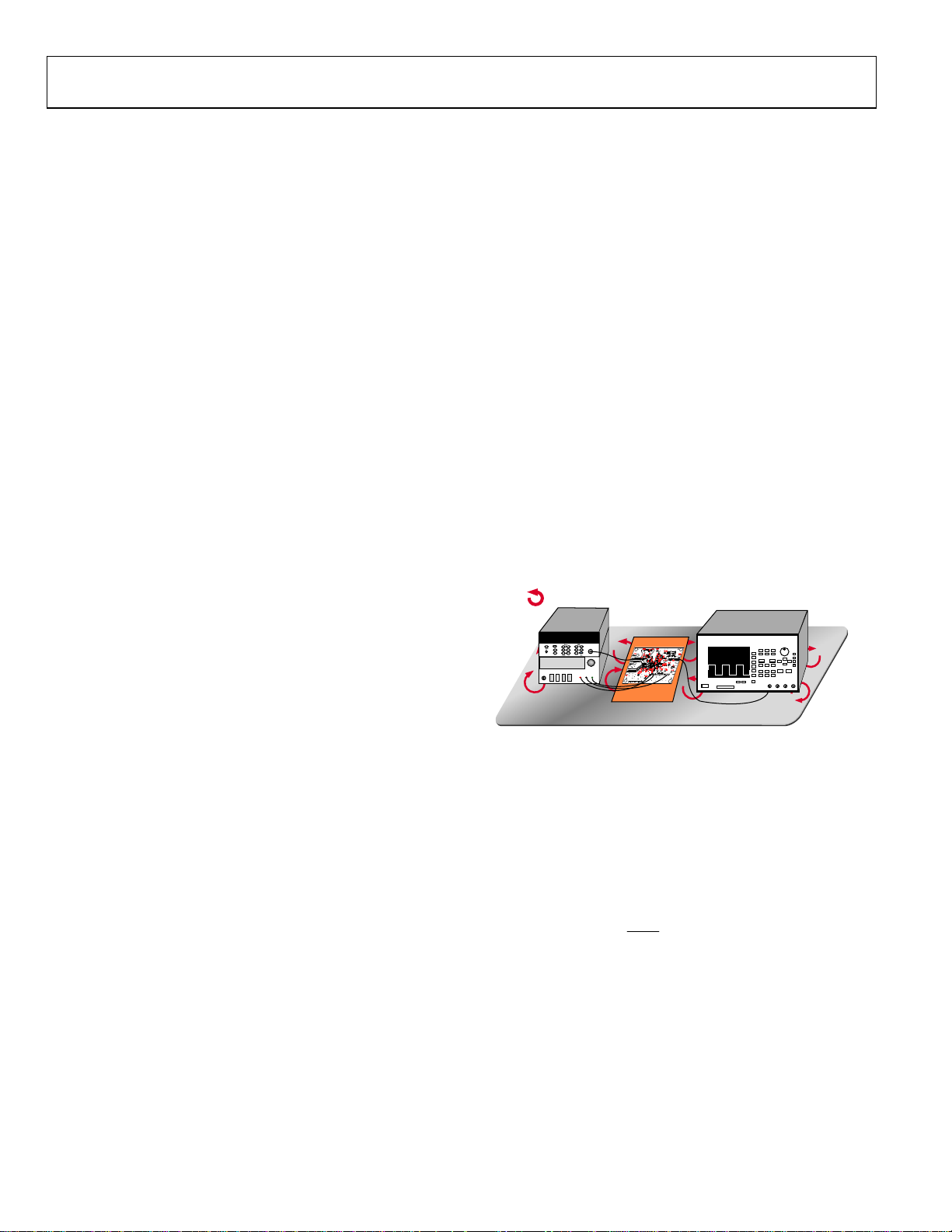

STRAY MAGNETIC FIELDS

Current input devices such as the ADL5304 are sensitive to their

environments in ways that are not typically a problem with high

impedance input devices like voltage input op amps, particularly

in high bandwidth applications where filtering is not an option.

Because of its excellent sensitivity and low noise, the ADL5304

is capable of operation at currents easily influenced by stray

magnetic fields. This can lead to unwanted signals coupling into

the ADL5304 in unexpected ways. An example of this is shown

in Figure 3. In a typical circuit testing environment, eddy currents from instrument power supplies are contained in the steel

of the test cart. The low impedance of the cart prevents the eddy

currents from generating a sufficient voltage for electrostatic

coupling into the typical voltage sensing circuit. In a current

sensing application using the ADL5304, the loop currents in the

metal cart can inductively couple into the traces and cable used

to build the test circuit and into the INUM and IDEN inputs. In

this instance, shielding and guarding are ineffective at decoupling

the interferer and receiver circuits. The best ways to prevent this

type of coupling are careful design to minimize stray magnetic

fields, increasing the distance between the interferer and receiver

circuits, removing the coupling mechanism, in this example the

steel work surface, or using Mu-Metal or similar high magnetic

permeability material to provide a magnetic shield.

EDDY CURRENT S INDUCED BY STRAY MAGNETIC FIELDS

FUNCTION GENERATOR

SQUARE

SINE

1.000 kHZ

TRIANGLE

Sto/Rcl

POWER SUPPLY

INSULATING SILICONE PAD

STEEL WORK SURFACE

Figure 3. Inductive Coupling of Poorly Shielded Instrument Power Supplies

OSCILLOSCOPE

Output

1 2 3 4

LOGARITHMIC RATIO OPERATION

Log ratio operation of the ADL5304 is possible using both the

INUM and IDEN inputs. For log ratio operation, IREF must be

disconnected from IDEN by removing R9.

The value of V

I

and the programmed slope (R24/R28), offset by the INPS

DEN

depends on the log of the ratio of I

LOG

voltage (R18, R19) according to the following formula:

I

NUM

VV

log

Y

LOG

10

V

I

DEN

OFS

where:

denotes slope.

V

Y

V

denotes the voltage offset applied at the INPS pin (1.5 V in

OFS

the default configuration).

Because the ratio of I

unity, V

can be of either polarity, requiring a negative supply

LOG

NUM/IDEN

can be either greater or less than

in some cases. For example, if the ratio varies from 1:1000 to

1000:1 and a slope of 20 mV/dB is required, the peak swing is

±1.2 V around V

OFS

.

NUM

and

10321-003

Rev. 0 | Page 4 of 16

Evaluation Board User Guide UG-339

Option 5 in Table 1 provides this with an intercept, IZ, of 17.8 pA

(V

= 1.5 V) with V

OFS

results in 0.3 V ≤ V

The electrical characteristics of I

the exception of the I

I

signal and allows adaptive photodiode bias at the INUM

NUM

= ±1.2 V around V

LOG

≤ 2.7 V.

LOG

and I

NUM

current, which is derived from the

MON

= 1.5 V, which

OFS

are identical, with

DEN

input only.

VOLTAGE SOURCE OPERATION

In test situations where a precision current source is not available

or a dynamic signal is required, a voltage source or function

generator can be used to supply I

current through a resistor

NUM

in series with the INUM input. In the default configuration,

R14 is a 0 Ω, 0603 resistor. Due to the large input range of the

ADL5304, it is very difficult to find a voltage source with

sufficient range to fully exercise the ADL5304. This limitation

can be mitigated by using different resistor values to access

different segments of the ADL5304’s ra nge .

The INUM and IDEN inputs cannot source current. When

using a voltage source and series resistor to provide INUM or

IDEN current, the source voltage must always be positive

relative to the V

, the translinear device that performs the logarithmic

V

SUM

voltage. If the voltage source drops below

SUM

function saturates and the feedback amplifier rails as it attempts

to balance the loop around the translinear device. This will not

damage the ADL5304, but the recovery time of the input is

directly related to the input current and the capacitance seen by

the input. At low input currents, the input can take significantly

longer to recover from momentary transients that attempt to

source current.

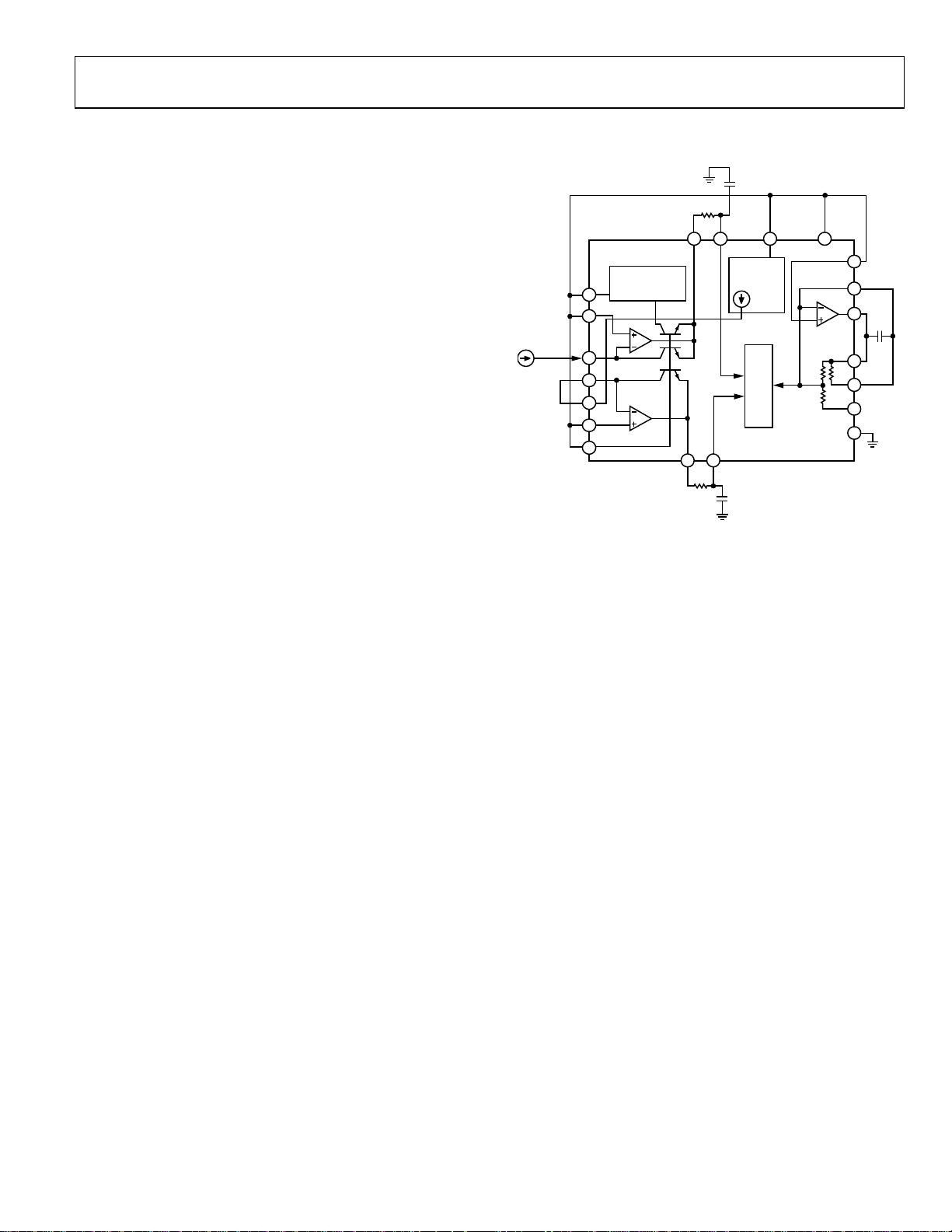

SPEED AND FILTERING

Filtering to Improve Noise and Dynamic Behavior

The noise at the output of a log amp, particularly at low current

levels, leads to uncertainty in the measurement. Noise amplitude

is limited by the finite bandwidth. If measurement speed is not of

primary concern, additional filtering can reduce noise. Figure 4

shows the locations provided on the ADL5304 evaluation board

for additional external filtering.

Typically, capacitors are not used on the numerator side (I

to keep the speed of the device as high as possible. On the

denominator side (I

noise. In applications where I

logarithmic equation and I

), additional filtering is useful to reduce

DEN

is used as the reference to the

NUM

is a variable, for example, where a

DEN

NUM

)

reverse logarithmic slope is desired, filtering can be performed

on the numerator side (I

MONITO R AND

PD BIAS

(1.1× I

2

VSM1

VSM2

INUM

IDEN

IREF

VSM3

VSM4

1.5V

3

4

5

6

1.5V

7

8

Figure 4. Evaluation Board Filtering Locations

).

NUM

R12

VNUM INNM

32 31 26

)

NUM

V

NUM

V

9

VDEN INDN

10

R13

DEN

C2

C11

100nA

BIAS

TEMPERATURE

1P5V DCBI

1.5V

5kΩ 5kΩ

I

LOG

7.5kΩ

COMPENSATION

27

24

INPS

INMS

23

VLOG

22

CFB

21

SCL1

20

SCL2

19

SCL3

ACOM

18

A capacitor placed on the INUM and IDEN inputs effectively

reduces the bandwidth of the input stages. A few picofarads

of capacitance (<5 pF) reduce the bandwidth significantly for

currents below approximately 1 µA, and 1 nF to 10 nF are

normally enough to reduce the bandwidth up to the maximum

10 mA of input current. When measurement speed is of primary

importance, it is better to add filtering after the FET amp outputs,

in which case, C2 and R13 for the INDN inputs and C11 and R12

for the INNM inputs are the best locations. A bias current of

approximately 35 µA flows from the INNM and INDN pins

through Resistors R12 and R13, raising the voltage at the INNM

and INDN pins. To prevent this voltage rise from limiting headroom in the temperature compensation block, the value of R12

and R13 should not be much larger than 1 kΩ.

Adding a capacitor, C12, adds additional filtering at the buffer

output. This capacitor also helps to optimize the pulse response

by placing a zero across the feedback resistor (2.5 kΩ in the

default configuration). A good value to start with is 22 pF; this

introduces a zero at 2.9 MHz that can improve the pulse response

for input currents greater than 100 µA.

10321-004

Rev. 0 | Page 5 of 16

Loading...

Loading...