Evaluation Board User Guide

UG-334

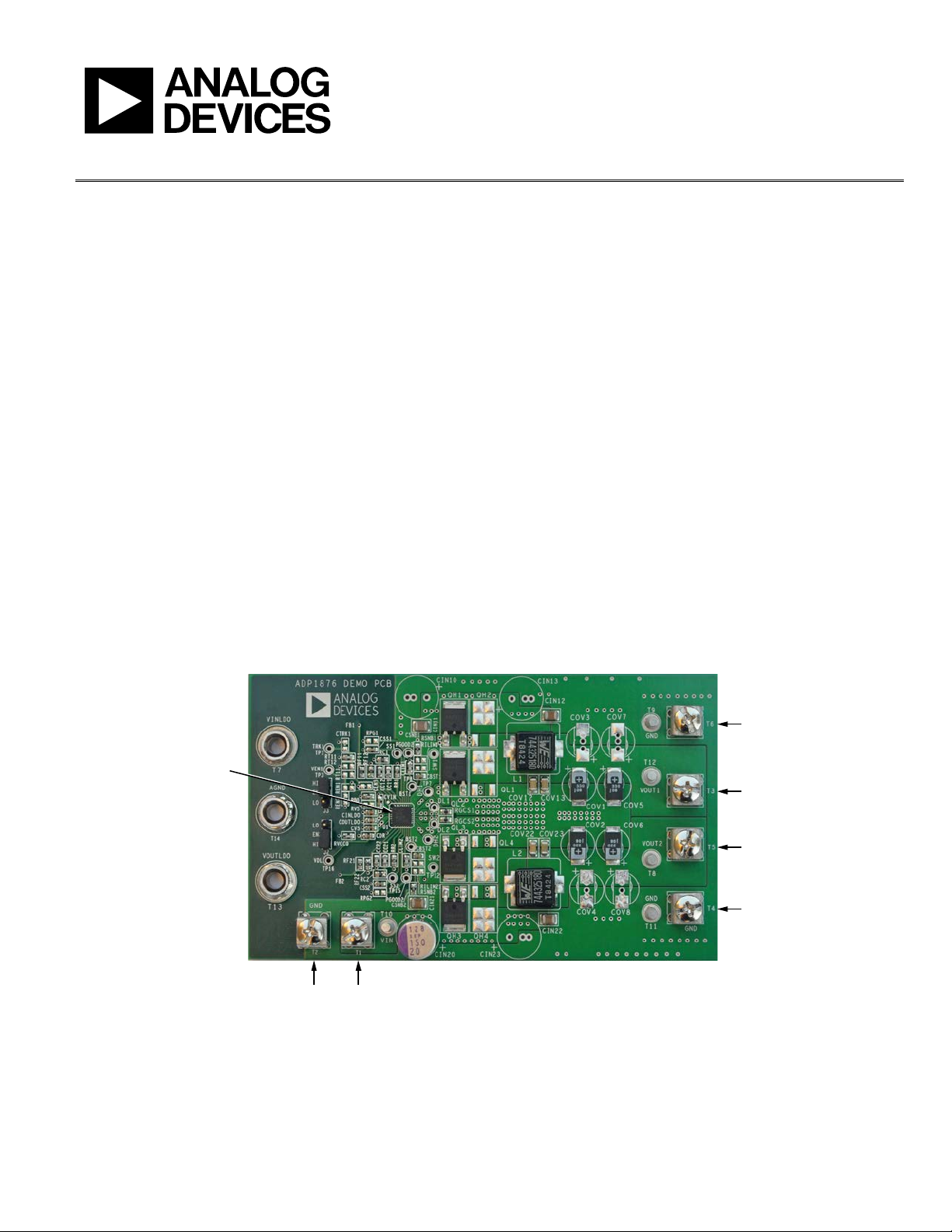

10272-001

ADP1876

GND

TERMINAL

VIN

TERMINAL

GND

TERMINAL

V

OUT1

TERMINAL

V

OUT2

TERMINAL

GND

TERMINAL

One Technology Way • P. O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

Evaluation Board for the ADP1876 Step-Down DC-to-DC Controller

FEATURES

Input range: 10 V to 20 V

Two output voltages: 5 V and 1.8 V

Output current: 13 A per channel

Switching frequency: 600 kHz

Operates in PWM

Compact, low cost, and efficient design

EVALUATION BOARD DESCRIPTION

This user guide describes the design, operation, and test results

of the ADP1876-E VA L Z . The input range for this evaluation

board is 10 V to 20 V, and the two regulated output voltages are

set to 5 V (V

current. The power components, such as the MOFSETS, inductors,

and bulk input and output capacitors, were chosen to yield a low

system cost and good efficiency.

) and 1.8 V (V

OUT1

) with a maximum 13 A output

OUT2

ADP1876-EVALZ EVALUATION BOARD

ADP1876 DEVICE DESCRIPTION

The ADP1876 is a dual-channel, step-down switching controller

with integrated drivers for external N-channel synchronous power

MOSFETs. The two PWM outputs are phase shifted 180°, which

reduces the input rms ripple current, thus minimizing the required

input capacitance.

In addition, boost diodes are integrated into the ADP1876,

which lowers the overall system cost and component count. The

ADP1876 is configured to operate in forced PWM continuous

conduction mode.

The ADP1876 includes externally adjustable soft start, output

overvoltage protection, externally adjustable current limit,

power good and tracking function for Channel 1. The ADP1876

provides an output voltage accuracy of ±0.85% for a −40°C to

+85°C junction temperature and ±1.5% for a −40°C to +125°C

junction temperature. This controller can be powered from a

2.75 V to 20 V supply and is available in a 32-lead, 5 mm × 5 mm

lead frame chip scale package (LFCSP).

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

Figure 1.

Rev. 0 | Page 1 of 16

UG-334 Evaluation Board User Guide

TABLE OF CONTENTS

Features .............................................................................................. 1

Evaluation Board Description......................................................... 1

ADP1876 Device Description ......................................................... 1

ADP1876-EVALZ Evaluation Board .............................................. 1

Revision History ............................................................................... 2

Component Design .......................................................................... 3

Inductor Selection ........................................................................ 3

Input Capacitors ........................................................................... 3

REVISION HISTORY

11/11—Revision 0: Initial Version

Output Capacitors .........................................................................3

MOSFET Selection ........................................................................3

Test Results .........................................................................................4

Evaluation Board Operating Instructions ......................................6

Evaluation Board PCB Layout .........................................................7

Evaluation Board Schematics and Artwork ...................................8

Ordering Information .................................................................... 12

Bill of Materials ........................................................................... 12

Rev. 0 | Page 2 of 16

Evaluation Board User Guide UG-334

COMPONENT DESIGN

For information about selecting power components and

calculating component values, see the ADP1876 data sheet.

INDUCTOR SELECTION

A 1.8 µH inductor with an 18 A saturation current rating

(744325180 from Würth Elektronik) is selected. This is a

compact inductor with a ferrite core, which offers high

performance in terms of low R

and low core loss.

DC

INPUT CAPACITORS

Because of the very low ESR and high input current rating of

multilayer ceramic capacitors (MLCCs), two 10 µF MLCCs in

Size 1210 are selected as the input capacitors at the input of each

channel. In addition, a 150 µF bulk OS-CON™ (aluminum solid

capacitor with conductive polymer) capacitor from SANYO is

chosen for filtering out unwanted low frequency noise from the

input power supply.

OUTPUT CAPACITORS

A combination of POSCAP™ polymer capacitors and MLCCs

are selected for the output rails. Polymer capacitors have low

ESR and high current ripple rating. Connecting polymer

capacitors and MLCCs in parallel is very effective in reducing

voltage ripple. Two 330 µF POSCAP capacitors and two 22 µF

MLCCs are selected for each output.

MOSFET SELECTION

For low output or low duty cycle, select a high-side MOSFET

with fast rise and fall times and with low input capacitance to

minimize charging and switching power loss. For the synchronous

rectifier (low-side MOSFET), select a MOSFET with low R

because the switching speed is not critical and there is no switching

power loss in the low-side MOSFET.

The MOSFET IPD050N03L in PG-TO252-3-11 (DPA K ) from

Infineon is chosen for both the high-side and low-side MOSFETs

for a balance between low cost and good efficiency. The R

the IPD050N03L is about 6 mΩ at a V

of 5 V.

GS

DSON

DSON

of

Rev. 0 | Page 3 of 16

UG-334 Evaluation Board User Guide

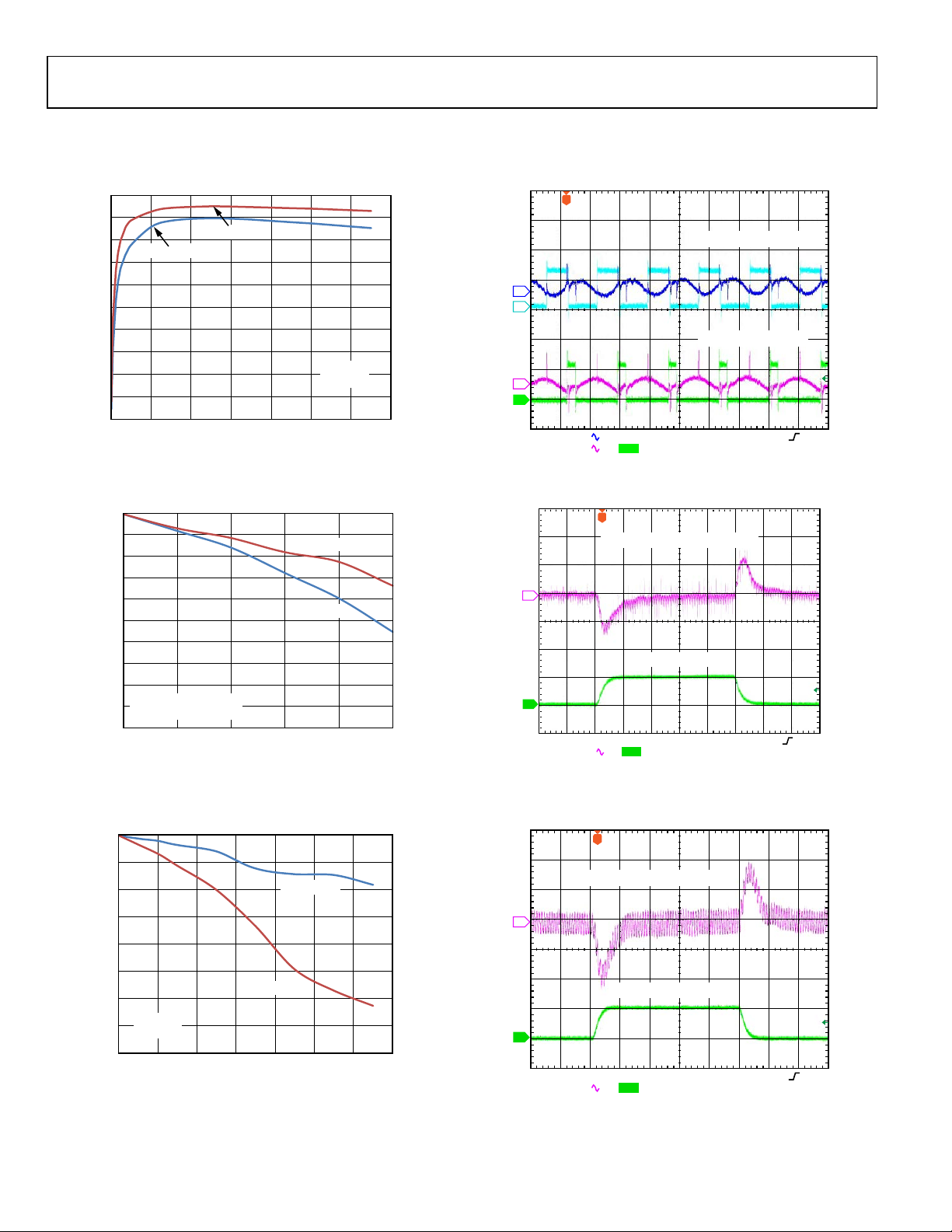

100

90

80

70

60

50

40

30

20

10

0

0 2 4 6 8 10 12 14

LOAD (A)

EFFICIENCY (%)

10272-002

V

OUT2

= 1.8V

T

A

= 25°C

V

IN

= 12V

V

OUT1

= 5V

0

–0.005

–0.010

–0.015

–0.020

–0.025

–0.030

–0.035

–0.040

–0.045

–0.050

10 12 14 16 18 20

V

IN

(V)

LINE REGULATION (%)

10272-003

V

OUT2

= 1.8V

TA = 25°C

V

IN

= 12V WITH 5A LOAD

V

OUT1

= 5V

0

–0.05

–0.10

–0.15

–0.20

–0.25

–0.30

–0.35

–0.40

0 2 4 6

8 10 12 14

LOAD (A)

LOAD REGUL ATION (%)

10272-004

V

OUT2

= 1.8V

V

OUT1

= 5V

TA = 25°C

V

IN

= 12V

10272-005

CH1 20.0mV CH2 10. 0V M1.00µs A CH4 10.2V

1

4

2

3

B

W

CH3 20.0mV CH4 10.0V

B

W

SW1

SW2

T

V

OUT1

RIPPLE AT 10A

V

OUT2

RIPPLE AT 10A

10272-006

M20.0µs A CH4 7.60V

4

3

CH3 20.0mV CH4 5.00A Ω

B

W

T

V

OUT2

= 1.8V OUT P UT RESPONSE

V

OUT2

5A STEP LOAD

10272-007

M20.0µs A CH4 7.60V

4

3

CH3 20.0mV CH4 5. 00A Ω

B

W

T

V

OUT1

= OUTPUT RESPONSE

V

OUT1

5A STEP LOAD

TEST RESULTS

TA = 25°C.

Figure 2. Efficiency (Measurement Is Ma de with the Adjacent Channel Disabled)

Figure 5. Output Ripple, 10 A Load

Figure 3. Line Regulation

Figure 4. Load Regulation

Figure 6. Step Load Transient, V

OUT2

Figure 7. Step Load Transient, V

OUT1

Rev. 0 | Page 4 of 16

Evaluation Board User Guide UG-334

0.035

0.030

0.025

0.020

0.015

0.010

0.005

0

3.0 3.5

4.0 4.5 5.0 5.5 6.0

VINLDO (V)

LINE REGULATION (%)

10272-008

T

A

= 25°C

V

IN

= 12V

–0.02

–0.04

–0.06

–0.08

–0.10

–0.12

–0.14

–0.16

–0.18

–0.20

0

0 0.025 0.050 0.075 0.100 0.125 0.150 0.175 0.200

VOUTLDO LOAD (A)

LOAD REGUL ATION (%)

10272-009

VINLDO = 5V

VINLDO = 3V

T

A

= 25°C

V

IN

= 12V

10272-010

CH1 100mA Ω CH2 50.0mV

M10.0µs A CH1 118mA

1

2

B

W

T

STEP LOAD

1mA TO 200mA

C

INLDO

= 1µF, C

OUTLDO

= 4.7µF

OUTPUT TRANSIENT

Figure 8. VOUTLDO Line Regulation

Figure 10. VOUTLDO Step Load Response

Figure 9. VOUTLDO Load Regulation

Rev. 0 | Page 5 of 16

Loading...

Loading...