2 W Filterless Class-D

FEATURES

Filterless Class-D amplifier with built-in output stage

2 W into 4 Ω and 1.4 W into 8 Ω at 5.0 V supply with <10% THD

85% efficiency at 5.0 V, 1.4 W into 8 Ω speaker

Better than 98 dB SNR (signal-to-noise ratio)

Available in 16-lead, 3 mm × 3 mm LFCSP

Single-supply operation from 2.5 V to 5.0 V

20 nA ultralow shutdown current

Short-circuit and thermal protection

Pop-and-click suppression

Built-in resistors reduce board component count

Default fixed 18 dB gain and user-adjustable

APPLICATIONS

Notebooks and PCs

Mobile phones

MP3 players

Portable gaming

Portable electronics

Educational toys

GENERAL DESCRIPTION

The SSM2304 is a fully integrated, high efficiency, Class-D stereo

audio amplifier. It is designed to maximize performance for

portable applications. The application circuit requires a minimum of external components and operates from a single 2.5 V

to 5.0 V supply. It is capable of delivering 2 W of continuous

output power with less than 10% THD + N driving a 4 Ω load

from a 5.0 V supply.

Stereo Audio Amplifier

SSM2304

The SSM2304 features a high efficiency, low noise modulation

scheme. It operates with 85% efficiency at 1.4 W into 8 Ω from a

5.0 V supply and has a signal-to-noise ratio (SNR) that is better

than 98 dB. PDM modulation is used to provide lower EMIradiated emissions compared with other Class-D architectures.

The SSM2304 has a micropower shutdown mode with a typical

shutdown current of 20 nA. Shutdown is enabled by applying a

logic low to the

The architecture of the device allows it to achieve a very low level

of pop and click. This minimizes voltage glitches at the output

during turn-on and turn-off, thus reducing audible noise on

activation and deactivation.

The fully differential input of the SSM2304 provides excellent

rejection of common-mode noise on the input. Input coupling

capacitors can be omitted if the dc input common-mode voltage

is approximately V

The SSM2304 also has excellent rejection of power supply noise,

including noise caused by GSM transmission bursts and RF

rectification.

The SSM2304 has a preset gain of 18 dB, which can be reduced

by using external resistors.

The SSM2304 is specified over the commercial temperature range

(−40°C to +85°C). It has built-in thermal shutdown and output

short-circuit protection. It is available in a 16-lead, 3 mm × 3 mm

lead-frame chip scale package (LFCSP).

SD

pin.

/2.

DD

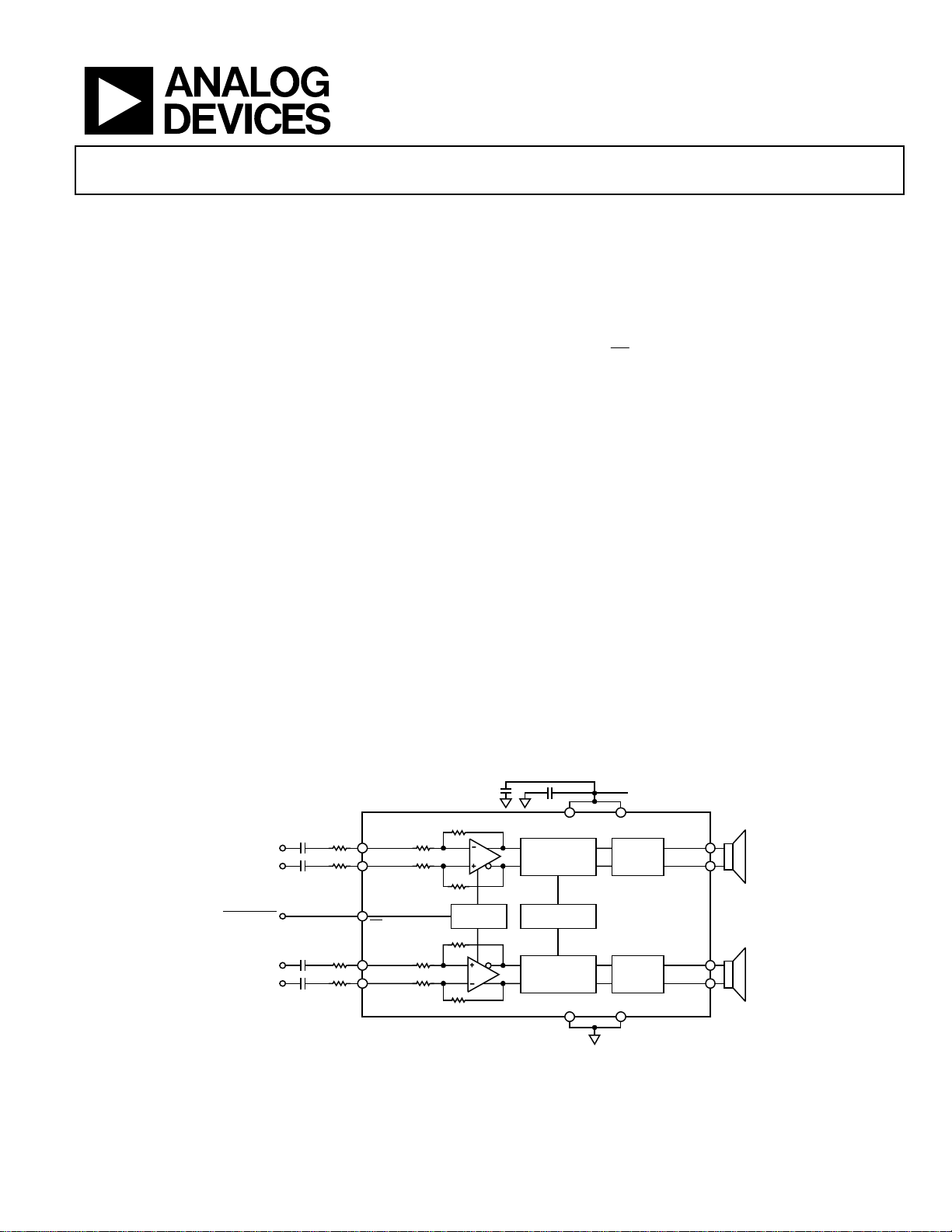

FUNCTIONAL BLOCK DIAGRAM

Rext

Rext

Rext

Rext

SSM2304

INR+

INR–

SD

INL+

INL–

1

RIGHT IN+

RIGHT IN–

SHUTDOWN

LEFT IN+

LEFT IN–

GAIN = 300kΩ/ (47kΩ + Rext)

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

22nF

1

22nF

1

22nF

1

22nF

1

INPUT CAPS ARE OPTIONAL I F INPUT DC COM MON-MODE

VOLTAGE IS APPRO XIMATELY V

47kΩ

47kΩ

47kΩ

47kΩ

DD

300kΩ

300kΩ

300kΩ

300kΩ

/2.

10µF

BIAS

Figure 1.

VBATT

0.1µF

MODULATOR

INTERNAL

OSCILLAT OR

MODULATOR

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved.

2.5V TO 5. 0V

VDDVDD

FET

DRIVER

FET

DRIVER

GNDGND

OUTR+

OUTR–

OUTL+

OUTL–

06162-001

SSM2304

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications....................................................................................... 1

General Description......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 4

Thermal Resistance ...................................................................... 4

ESD Caution.................................................................................. 4

Pin Configuration and Function Descriptions............................. 5

Typical Performance Characteristics ............................................. 6

Typical Applicat i o n C i rc uits.......................................................... 12

Application Notes ........................................................................... 13

Overview...................................................................................... 13

Gain Selection............................................................................. 13

Pop-and-Click Suppression ...................................................... 13

EMI Noise.................................................................................... 13

Layout .......................................................................................... 14

Input Capacitor Selection.......................................................... 14

Proper Power Supply Decoupling ............................................ 14

Evaluation Board Information...................................................... 15

Introduction................................................................................ 15

Board Description...................................................................... 15

Getting Started............................................................................ 18

What to Test ................................................................................ 18

PCB Layout Guidelines.............................................................. 19

Outline Dimensions ....................................................................... 20

Ordering Guide .......................................................................... 20

REVISION HISTORY

12/06—Revision 0: Initial Version

Rev. 0 | Page 2 of 20

SSM2304

SPECIFICATIONS

VDD = 5.0 V; TA = 25oC; RL = 4 Ω, 8 Ω; gain = 18 dB; unless otherwise noted.

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

DEVICE CHARACTERISTICS

Output Power P

O

R

R

R

R

R

R

R

R

R

R

R

Efficiency η P

P

Total Harmonic Distortion + Noise THD + N PO = 2 W into 4 Ω each channel, f = 1 kHz, VDD = 5.0 V 0.2 %

P

Input Common-Mode Voltage Range V

CM

Common-Mode Rejection Ratio CMRR

Channel Separation

Average Switching Frequency f

Differential Output Offset Voltage V

X

TAL K

SW

OOS

POWER SUPPLY

Supply Voltage Range V

DD

Power Supply Rejection Ratio PSRR VDD = 2.5 V to 5.0 V, 70 85 dB

PSRR

Supply Current I

SY

V

V

Shutdown Current I

SD

GAIN

Closed-Loop Gain Av Rext = 0 18 dB

Differential Input Impedance Z

IN

SHUTDOWN CONTROL

Input Voltage High V

Input Voltage Low V

Turn-On Time t

Turn-Off Time t

Output Impedance Z

IH

IL

WU

SD

OUT

NOISE PERFORMANCE

Output Voltage Noise e

n

Signal-to-Noise Ratio SNR P

RL = 4 Ω, THD = 1%, f = 1 kHz, 20 kHz BW, VDD = 5.0 V 1.8 W

= 8 Ω, THD = 1%, f = 1 kHz, 20 kHz BW, VDD = 5.0 V 1.4 W

L

= 4 Ω, THD = 1%, f = 1 kHz, 20 kHz BW, VDD = 3.6 V 0.9 W

L

= 8 Ω, THD = 1%, f = 1 kHz, 20 kHz BW, VDD = 3.6 V 0.615 W

L

= 4 Ω, THD = 1%, f = 1 kHz, 20 kHz BW, VDD = 2.5 V 0.35 W

L

= 8 Ω, THD = 1%, f = 1 kHz, 20 kHz BW, VDD = 2.5 V 0.275 W

L

= 4 Ω, THD = 10%, f = 1 kHz, 20 kHz BW, VDD = 5.0 V 2.4 W

L

= 8 Ω, THD = 10%, f = 1 kHz, 20 kHz BW, VDD = 5.0 V 1.53 W

L

= 4 Ω, THD = 10%, f = 1 kHz, 20 kHz BW, VDD = 3.6 V 1.1 W

L

= 8 Ω, THD = 10%, f = 1 kHz, 20 kHz BW, VDD = 3.6 V 0.77 W

L

= 4 Ω, THD = 10%, f = 1 kHz, 20 kHz BW, VDD = 2.5 V 0.45 W

L

= 8 Ω, THD = 10%, f = 1 kHz, 20 kHz BW, VDD = 2.5 V 0.35 W

L

= 2 W, 4 Ω, VDD = 5.0 V 75 %

OUT

= 1.4 W, 8 Ω, VDD = 5.0 V 85 %

OUT

= 1 W into 8 Ω each channel, f = 1 kHz, VDD = 3.6 V 0.25 %

O

1.0 VDD − 1 V

GSMVCM

= 2.5 V ± 100 mV at 217 Hz 60 dB

PO = 100 mW , f = 1 kHz 78 dB

1.8 MHz

2.0 mV

Guaranteed from PSRR test 2.5 5.0 V

GSM

V

= 100 mV rms at 217 Hz, inputs ac GND,

RIPPLE

= 0.01 μF, input referred

C

IN

68 dB

VIN = 0 V, no load, VDD = 5.0 V 7.0 mA

= 0 V, no load, VDD = 3.6 V 6.5 mA

IN

= 0 V, no load, VDD = 2.5 V 5.2 mA

IN

SD

= GND

SD

= VDD

20 nA

47 kΩ

ISY ≥ 1 mA 1.2 V

ISY ≤ 300 nA 0.5 V

SD

rising edge from GND to V

SD

falling edge from VDD to GND

SD

= GND

DD

VDD = 3.6 V, f = 20 Hz to 20 kHz, inputs are ac

grounded, A

= 2.0 W, RL = 4 Ω 102 dB

OUT

= 6 dB, RL = 4 Ω, A weighting

V

30 ms

5 μs

>100 kΩ

22 μV

Rev. 0 | Page 3 of 20

SSM2304

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings apply at 25°C, unless otherwise noted.

Table 2.

Parameter Rating

Supply Voltage 6 V

Input Voltage V

Common-Mode Input Voltage V

ESD Susceptibility 4 kV

Storage Temperature Range −65°C to +150°C

Operating Temperature Range −40°C to +85°C

Junction Temperature Range −65°C to +165°C

Lead Temperature Range

(Soldering, 60 sec)

DD

DD

300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 3. Thermal Resistance

Package Type θ

16-lead, 3 mm × 3 mm LFCSP 44 31.5 °C/W

θ

JA

Unit

JC

ESD CAUTION

Rev. 0 | Page 4 of 20

SSM2304

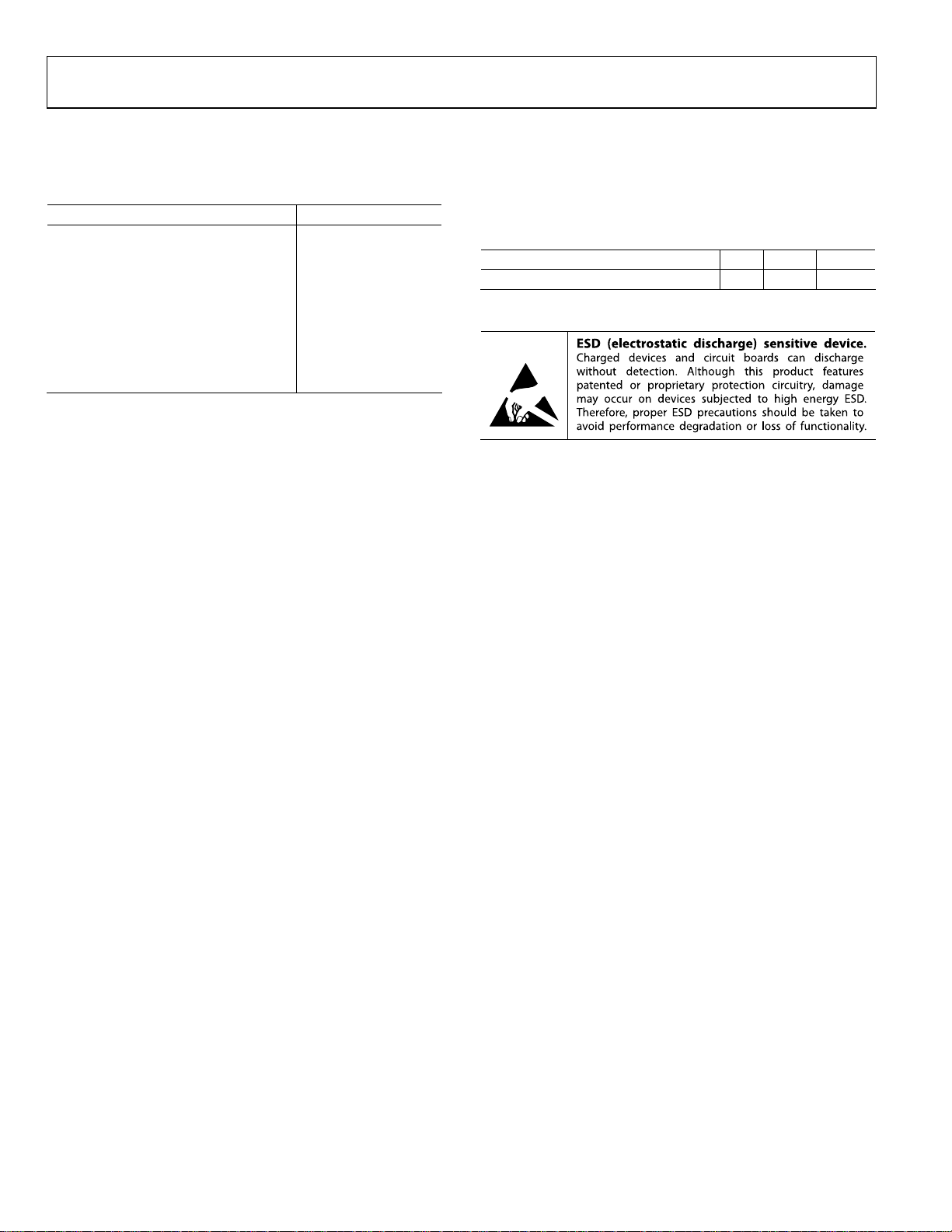

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

ND

VDD

GND

G

VDD

14

13

16

15

PIN 1

INDICATOR

1OUTL+

2OUTL–

SSM2304

3SD

TOP VIEW

(Not to Scale)

4INL+

5

6

NC

INL–

NC = NO CONNECT

Figure 2. SSM2304 LFCSP Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 OUTL+ Inverting Output for Left Channel.

2 OUTL− Noninverting Output for Left Channel.

3

SD

Shutdown Input. Active low digital input.

4 INL+ Noninverting Input for Left Channel.

5 INL− Inverting Input for Left Channel.

6 NC No Connect.

7 NC No Connect.

8 INR− Inverting Input for Right Channel.

9 INR+ Noninverting Input for Right Channel.

10 NC No Connect

11 OUTR− Noninverting Output for Right Channel.

12 OUTR+

Inverting Output for Right Channel.

13 GND Ground for Output Amplifiers.

14 VDD Power Supply for Output Amplifiers.

15 VDD Power Supply for Output Amplifiers.

16 GND Ground for Output Amplifiers.

12 OUTR+

11 OU TR–

10 NC

9INR+

8

7

NC

INR–

6162-002

Rev. 0 | Page 5 of 20

SSM2304

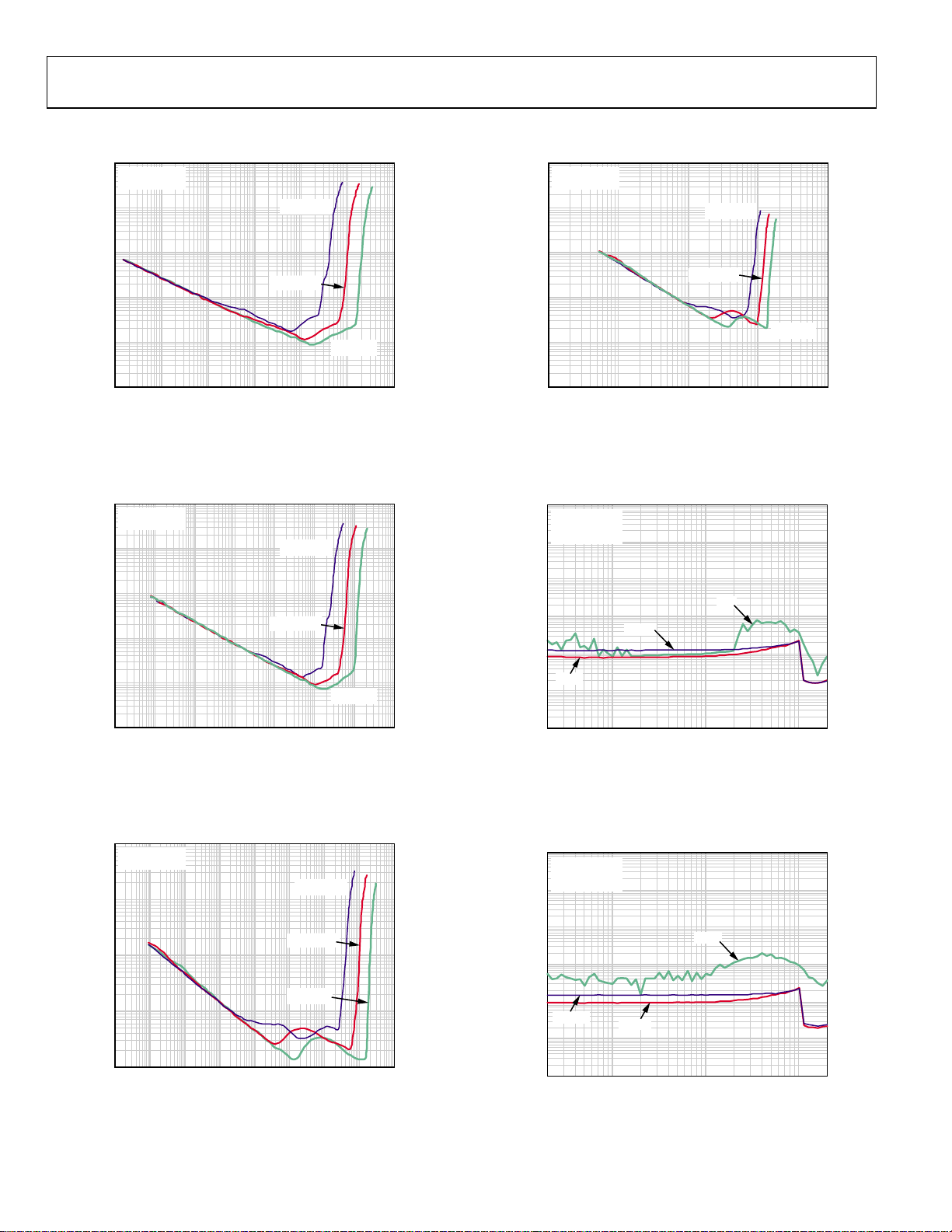

TYPICAL PERFORMANCE CHARACTERISTICS

100

10

RL = 4Ω, 33µH

GAIN = 18dB

VDD = 2.5V

100

10

RL = 8Ω, 33µH

GAIN = 6dB

VDD = 2.5V

1

VDD = 3.6V

THD + N (%)

0.01

0.001

0.1

0.00010.00001 10

0.001 0. 01 0.1 1

OUTPUT PO WER (W)

Figure 3. THD + N vs. Output Power into 4 Ω, A

100

RL = 8Ω, 33µH

GAIN = 18dB

10

1

0.1

THD + N (%)

0.01

VDD = 3.6V

VDD = 2.5V

VDD = 5V

= 18 dB

V

VDD = 5V

1

VDD = 3.6V

0.1

THD + N (%)

0.01

0.001

06162-020

0.000010.0000001 10

0.001 0.1

OUTPUT PO WER (W)

Figure 6. THD + N vs. Output Power into 8 Ω, A

100

VDD = 5V

R

= 8Ω, 33µH

L

GAIN = 6dB

10

1

1W

THD + N (%)

0.01

0.001

0.1

0.25W

0.5W

VDD = 5V

= 6 dB

V

06162-004

0.001

0.000001 0.00010.00001 10

Figure 4. THD + N vs. Output Power into 8 Ω, A

100

RL = 4Ω, 33µH

GAIN = 6dB

10

1

THD + N (%)

0.1

0.01

0.000001 0.0001

0.0000001

0.00001 10

Figure 5. THD + N vs. Output Power into 4 Ω, A

0.001 0.01 0.1 1

OUTPUT PO WER (W)

VDD = 2.5V

VDD = 3.6V

VDD = 5V

0.01

0.001

OUTPUT PO WER (W)

0.1

= 18 dB

V

1

= 6 dB

V

06162-003

06162-021

Rev. 0 | Page 6 of 20

0.0001

20 20k

Figure 7. THD + N vs. Frequency, V

100

VDD = 3.6V

R

GAIN = 6dB

10

1

0.1

THD + N (%)

0.01

0.125W

0.001

0.0001

20 20k

Figure 8. THD + N vs. Frequency, V

100 1k 10k

FREQUENCY (Hz)

DD

= 8Ω, 33µH

L

0.5W

0.25W

100 1k 10k

FREQUENCY (Hz)

= 3.6 V, RL = 8 Ω, AV = 6 dB

DD

= 5 V, RL = 8 Ω, AV = 6 dB

06162-005

06162-006

SSM2304

100

THD + N (%)

0.01

0.001

10

1

0.1

VDD = 2.5V

R

= 8Ω, 33µH

L

GAIN = 6dB

0.25W

0.125W

0.075W

100

THD + N (%)

0.01

0.001

10

1

0.1

VDD = 2.5V

= 4Ω, 33µH

R

L

GAIN = 6dB

0.25W

0.5W

0.125W

0.0001

20 20k

Figure 9. THD + N vs. Frequency, V

100

VDD = 5V

R

GAIN = 6dB

10

1

0.1

THD + N (%)

0.01

0.001

0.0001

20 20k

Figure 10. THD + N vs. Frequency, V

100 1k 10k

FREQUENCY (Hz)

= 2.5 V, RL = 8 Ω, AV = 6 dB

DD

= 4Ω, 33µH

L

100 1k 10k

FREQUENCY (Hz)

DD

2W

1W

= 5 V, RL = 4 Ω, AV = 6 dB

0.5W

0.0001

20 20k

06162-007

Figure 12. THD + N vs. Frequency, V

100

VDD = 5V

R

GAIN = 18dB

10

1

0.1

THD + N (%)

0.01

0.001

0.0001

20 20k

06162-022

Figure 13. THD + N vs. Frequency, V

100 1k 10k

FREQUENCY (Hz)

= 2.5 V, RL = 4 Ω, AV = 6 dB

DD

= 8Ω, 33µH

L

0.5W

0.25W

100 1k 10k

FREQUENCY (Hz)

DD

1W

= 5 V, RL = 8 Ω, AV = 18 dB

06162-024

06162-025

100

VDD = 3.6V

= 4Ω, 33µH

R

L

GAIN = 6dB

10

1

0.1

THD + N (%)

0.01

0.001

0.0001

0.25W

0.5W

20 20k

100 1k 10k

FREQUENCY (Hz)

Figure 11. THD + N vs. Frequency, V

1W

= 3.6 V, RL = 4 Ω, AV = 6 dB

DD

06162-023

Rev. 0 | Page 7 of 20

100

VDD = 3.6V

= 8Ω, 33µH

R

L

GAIN = 18dB

10

1

0.1

THD + N (%)

0.01

0.001

0.0001

20 20k

100 1k 10k

FREQUENCY (Hz)

Figure 14. THD + N vs. Frequency, V

0.5W

0.25W

0.125W

= 3.6 V, RL = 8 Ω, AV = 18 dB

DD

06162-026

SSM2304

THD + N (%)

0.01

0.001

100

10

1

0.1

VDD = 2.5V

= 8Ω, 33µH

R

L

GAIN = 18dB

0.25W

0.125W

0.075W

THD + N (%)

0.01

0.001

100

10

1

0.1

VDD = 2.5V

= 4Ω, 33µH

R

L

GAIN = 18dB

0.5W

0.25W

0.125W

0.0001

20 20k

Figure 15. THD + N vs. Frequency, V

100

VDD = 5V

R

GAIN = 18dB

10

1

0.1

THD + N (%)

0.01

0.001

0.0001

20 20k

Figure 16. THD + N vs. Frequency, V

100 1k 10k

FREQUENCY (Hz)

= 2.5 V, RL = 8 Ω, AV = 18 dB

DD

= 4Ω, 33µH

L

1W

0.5W

100 1k 10k

FREQUENCY (Hz)

DD

2W

= 5 V, RL = 4 Ω, AV = 18 dB

0.0001

20 20k

06162-027

Figure 18. THD + N vs. Frequency, V

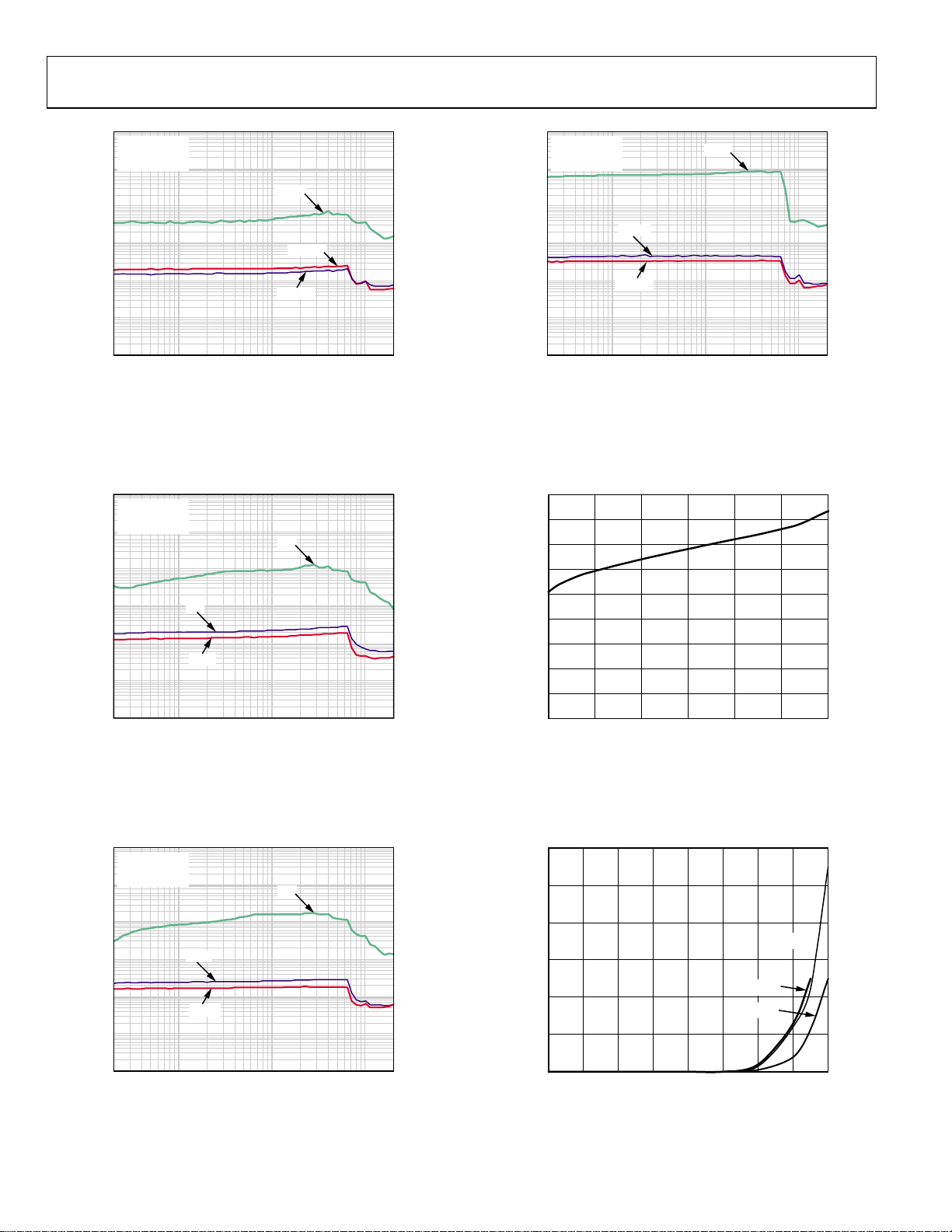

9

8

7

6

5

4

3

SUPPLY CURRENT (mA)

2

1

0

2.5 5.5

06162-028

100 1k 10k

FREQUENCY (Hz)

= 2.5 V, RL = 4 Ω, AV = 18 dB

DD

3.0 3.5 4.0 4.5 5.0

SUPPLY VOLTAGE (V)

06162-041

06162-008

Figure 19. Supply Current vs. Supply Voltage, No Load

100

VDD = 3.6V

= 4Ω, 33µH

R

L

GAIN = 18dB

10

1

0.1

THD + N (%)

0.01

0.001

0.0001

20 20k

0.5W

0.25W

100 1k 10k

FREQUENCY (Hz)

Figure 17. THD + N vs. Frequency, V

1W

= 3.6 V, RL = 4 Ω, AV = 18 dB

DD

06162-029

Rev. 0 | Page 8 of 20

12

10

8

VDD = 5V

6

4

SHUTDOWN CURRENT (µ A)

2

0

0.1 0.2 0.3 0.4 0. 5 0.6 0.7

00

SHUTDOWN VOL TAGE (V)

VDD = 2.5V

VDD = 3.6V

.8

06162-009

Figure 20. Supply Current vs. Shutdown Voltage

SSM2304

3.0

f

1.8

f

= 1kHz

GAIN = 6dB

1.6

R

= 8Ω, 15µH

L

1.4

1.2

1.0

0.8

0.6

OUTPUT POW ER (W)

0.4

0.2

0

3.6 5.0

10%

1%

SUPPLY VOLTAGE (V)

Figure 21. Maximum Output Power vs. Supply Voltage, R

4.84.64.44.24.03.8

= 8 Ω, AV = 6 dB

L

06162-010

Figure 24. Maximum Output Power vs. Supply Voltage, R

= 1kHz

GAIN = 18dB

= 4Ω, 15µH

R

L

2.5

2.0

1.5

1.0

OUTPUT POWER (W)

0.5

0

3.6 5.0

10%

1%

SUPPLY VOLTAGE (V)

L

4.84.64.44.24.03.8

06162-062

= 4 Ω, AV = 18 dB

3.0

f

= 1kHz

GAIN = 6dB

R

= 4Ω, 15µH

L

2.5

2.0

1.5

1.0

OUTPUT POW ER (W)

0.5

0

3.6 5.0

10%

1%

SUPPLY VOLTAGE (V)

4.84.64.44.24.03.8

06162-060

Figure 22. Maximum Output Power vs. Supply Voltage, RL = 4 Ω, AV = 6 dB

1.8

f

= 1kHz

GAIN = 18dB

1.6

= 8Ω, 15µH

R

L

1.4

1.2

1.0

0.8

0.6

OUTPUT POWER (W)

0.4

0.2

0

3.6 5.0

10%

SUPPLY VOLTAGE (V)

1%

4.84.64.44.24.03.8

06162-061

Figure 23. Maximum Output Power vs. Supply Voltage, RL = 8 Ω, AV = 18 dB

Rev. 0 | Page 9 of 20

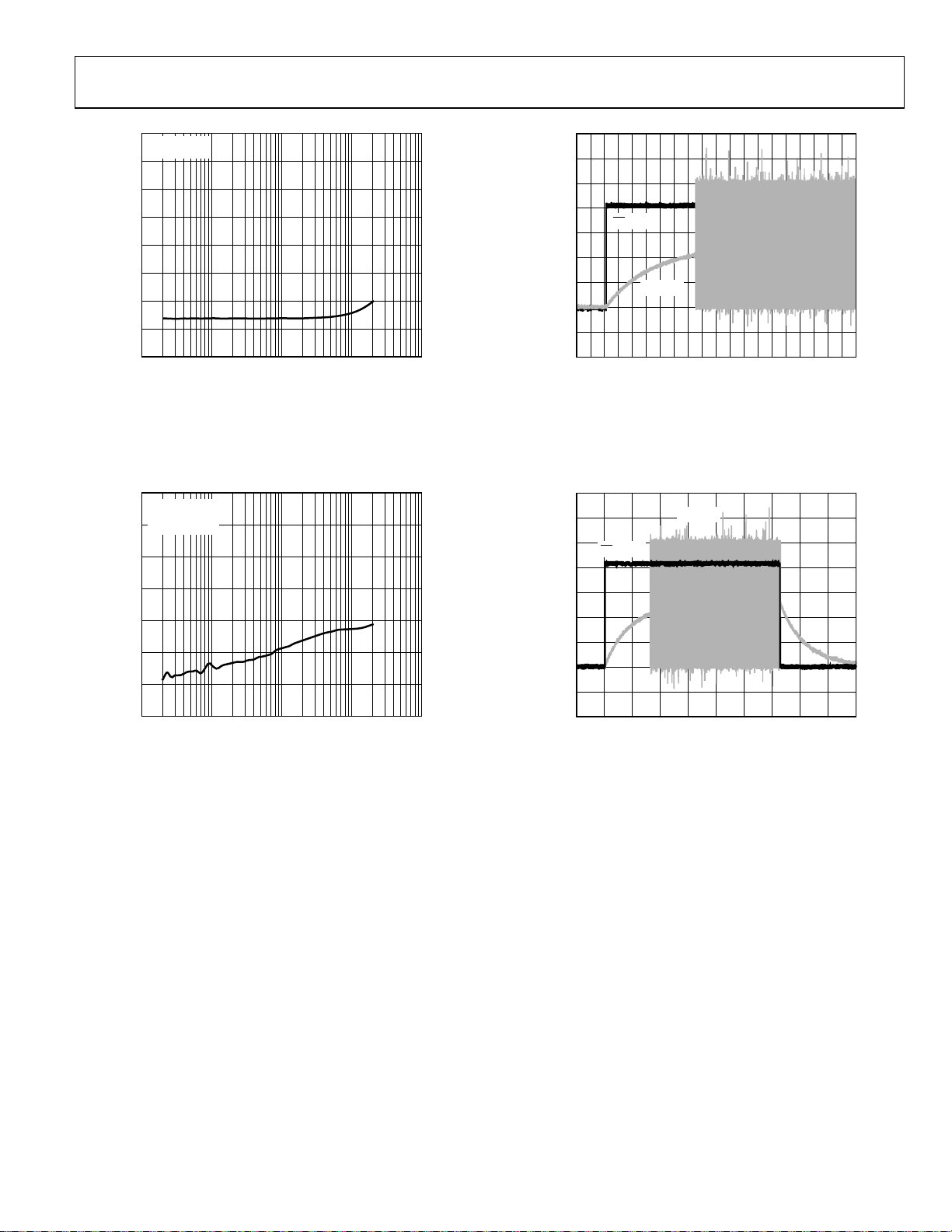

100

RL = 4Ω, 15µH

90

80

70

60

VDD = 2.5V

50

40

EFFICIENCY (%)

30

20

10

0

0

0.2 0.60.4 0.8 1.0 1.2 1.4 1.6 2.01.8

0.1 0.3 0.5 0.7 0.9 1.1 1.3 1.5 1. 7 1.9

VDD = 3.6V

OUTPUT PO WER (W)

VDD = 5V

2.1

06162-042

Figure 25. Efficiency vs. Output Power into 4 Ω

100

RL = 8Ω, 15µH

90

80

70

VDD = 2.5V

60

50

40

EFFICIENCY (%)

30

20

10

0

02

0.2 0.4 0.6 0.8 1. 0 1.2 1. 4 1.6 1.8

VDD = 3.6V

OUTPUT PO WER (W)

VDD = 5V

.0

06162-011

Figure 26. Efficiency vs. Output Power into 8 Ω

SSM2304

1.0

VDD = 3.6V

R

= 8Ω, 33µH

0.9

L

0.8

0.7

0.6

0.5

0.4

0.3

POWER DISSI PATION (W )

0.2

0.1

0

00

0.1 0.2 0.3 0.4 0.5 0. 6 0.7

OUTPUT PO WER (W)

Figure 27. Power Dissipation vs. Output Power at V

= 3.6 V, RL = 8 Ω

DD

.8

06162-012

3.0

VDD = 5V

R

= 4Ω, 15µH

L

2.5

2.0

1.5

1.0

POWER DISSIPATION (W)

0.5

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

OUTPUT PO WER (W)

Figure 30. Power Dissipation vs. Output Power at V

= 5.0 V, RL = 8 Ω

DD

06162-063

1.8

VDD = 5V

R

= 8Ω, 33µH

L

1.6

1.4

1.2

1.0

0.8

0.6

POWER DISSI PATION (W )

0.4

0.2

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

01

OUTPUT PO WER (W)

Figure 28. Power Dissipation vs. Output Power at V

1.8

VDD = 3.6V

R

= 4Ω, 15µH

L

1.6

1.4

1.2

1.0

0.8

0.6

POWER DISSI PATIO N (W)

0.4

0.2

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

OUTPUT PO WER (W)

Figure 29. Power Dissipation vs. Output Power at V

= 5.0 V, RL = 8 Ω

DD

= 3.6 V, RL = 4 Ω

DD

.3

06162-013

06162-064

400

RL = 8Ω, 33µH

350

300

250

200

VDD = 2.5V

150

SUPPLY CURRENT (mA)

100

50

0

01.6

Figure 31. Output Power vs. Supply Current, One Channel

0

–10

–20

–30

–40

–50

PSRR (dB)

–60

–70

–80

–90

–100

10 100k

Figure 32. Power Supply Rejection Ratio vs. Frequency

Rev. 0 | Page 10 of 20

VDD = 5V

VDD = 3.6V

0.2 0.4 0.6 0.8 1. 0 1.2 1.4

OUTPUT PO WER (W)

100 1k 10k

FREQUENCY (Hz)

06162-014

06162-015

SSM2304

0

RL = 8Ω, 33µH

GAIN = 6dB

–10

–20

–30

–40

CMRR (dB)

–50

–60

–70

–80

10 100k

100 1k 10k

FREQUENCY (Hz)

Figure 33. Common-Mode Rejection Ratio vs. Frequency

06162-016

7

6

5

4

SD INPUT

3

2

VOLTAGE

1

0

–1

–2

–5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85

–10 90

OUTPUT

TIME (ms)

Figure 35. Turn-On Response

06162-018

0

VDD = 3.6V

= 1V rms

V

RIPPLE

–20

= 8Ω, 33µH

R

L

–40

–60

–80

CROSSTALK (dB)

–100

–120

–140

10 100k

100 1k 10k

FREQUENCY (Hz)

Figure 34. Crosstalk vs. Frequency

06162-017

7

6

5

SD INPUT

4

3

2

VOLTAGE

1

0

–1

–2

0 20 40 60 80 100 120 140 160

–20 180

OUTPUT

TIME (ms)

Figure 36. Turn-Off Response

06162-019

Rev. 0 | Page 11 of 20

SSM2304

TYPICAL APPLICATION CIRCUITS

10µF

0.1µF

VBATT

2.5V TO 5. 0V

VDDVDD

DRIVER

DRIVER

GNDGND

FET

FET

OUTR+

OUTR–

OUTL+

OUTL–

06162-030

RIGHT IN+

RIGHT IN–

SHUTDOWN

LEFT IN+

LEFT IN–

SSM2304

1

22nF

Rext

INR+

INR–

Rext

1

22nF

SD

1

22nF

Rext

INL+

INL–

Rext

1

22nF

1

INPUT CAPS ARE O PTIONAL IF INPUT DC COMMON-M ODE

VOLTAGE IS APPROXIMATELY V

BIAS

/2.

DD

MODULATOR

INTERNAL

OSCILLATOR

MODULATOR

Figure 37. Stereo Differential Input Configuration

0.1µF

MODULATOR

VBATT

2.5V TO 5. 0V

VDDVDD

FET

DRIVER

OUTR+

OUTR–

RIGHT IN

22nF

22nF

Rext

Rext

10µF

SSM2304

INR+

INR–

SHUTDOWN

LEFT IN

22nF

22nF

Rext

Rext

SD

INL+

INL–

BIAS

INTERNAL

OSCILLATOR

MODULATOR

DRIVER

GNDGND

FET

OUTL+

OUTL–

06162-031

Figure 38. Stereo Single-Ended Input Configuration

Rev. 0 | Page 12 of 20

SSM2304

APPLICATION NOTES

OVERVIEW

The SSM2304 stereo Class-D audio amplifier features a filterless

modulation scheme that greatly reduces the external components

count, conserving board space and thus reducing systems cost.

The SSM2304 does not require an output filter, but instead relies

on the inherent inductance of the speaker coil and the natural

filtering of the speaker and human ear to fully recover the audio

component of the square-wave output. While most Class-D amplifiers use some variation of pulse-width modulation (PWM), the

SSM2304 uses a Σ-Δ modulation to determine the switching

pattern of the output devices. This provides a number of important

benefits. Σ-Δ modulators do not produce a sharp peak with

many harmonics in the AM frequency band, as pulse-width

modulators often do. Σ-Δ modulation provides the benefits of

reducing the amplitude of spectral components at high frequencies;

that is, reducing EMI emission that might otherwise be radiated

by speakers and long cable traces. The SSM2304 also offers

protection circuits for overcurrent and temperature protection.

GAIN SELECTION

The SSM2304 has a pair of internal resistors that set an 18 dB

default gain for the amplifier.

It is possible to adjust the SSM2304 gain by using external resistors

at the input. To set a gain lower than 18 dB refer to

differential input configuration and

Figure 38 for single-ended

Figure 37 for

configuration. The external gain configuration is calculated as

External Gain Settings = 376 kΩ/(47 kΩ + Rext)

POP-AND-CLICK SUPPRESSION

Voltage transients at the output of audio amplifiers can occur when

shutdown is activated or deactivated. Voltage transients as low

as 10 mV can be heard as an audio pop in the speaker. Clicks

and pops can also be classified as undesirable audible transients

generated by the amplifier system, therefore as not coming from

the system input signal. Such transients can be generated when

the amplifier system changes its operating mode. For example, the

following can be sources of audible transients: system power-up/

power-down, mute/unmute, input source change, and sample rate

change. The SSM2304 has a pop-and-click suppression architecture

that reduces these output transients, resulting in noiseless activation

and deactivation.

EMI NOISE

The SSM2304 uses a proprietary modulation and spreadspectrum technology to minimize EMI emissions from the

device.

Figure 39 shows SSM2304 EMI emission starting from

100 kHz to 30 MHz.

from 30 kHz to 2 GHz. These figures clearly describe the SSM2304

EMI behavior as being well below the FCC regulation values,

starting from 100 kHz and passing beyond 1 GHz of frequency.

Although the overall EMI noise floor is slightly higher, frequency

spurs from the SSM2304 are greatly reduced.

70

60

50

40

30

LEVEL (dB(µV/m))

20

10

0

0.1 100

70

60

50

40

30

LEVEL (dB(µV/m))

20

10

0

10 10k

The measurements for Figure 39 and Figure 40 were taken with

a 1 kHz input signal, producing 0.5 W output power into an 8 Ω

load from a 3.6 V supply. Cable length was approximately 5 cm.

The EMI was detected using a magnetic probe touching the 2”

output trace to the load.

Figure 40 shows SSM2304 EMI emission

= HORIZONT AL

= VERTICAL

= REGULATION VALUE

110

FREQUENCY (MHz)

Figure 39. EMI Emissions from SSM2304

= HORIZONT AL

= VERTICAL

= REGULATION VALUE

100 1k

FREQUENCY (MHz)

Figure 40. EMI Emissions from SSM2304

06162-032

06162-033

Rev. 0 | Page 13 of 20

SSM2304

LAYOUT

As output power continues to increase, care needs to be taken to

lay out PCB traces and wires properly between the amplifier,

load, and power supply. A good practice is to use short, wide

PCB tracks to decrease voltage drops and minimize inductance.

Make track widths at least 200 mil for every inch of track length

for lowest DCR, and use 1 oz or 2 oz of copper PCB traces to

further reduce IR drops and inductance. A poor layout

increases voltage drops, consequently affecting efficiency. Use

large traces for the power supply inputs and amplifier outputs to

minimize losses due to parasitic trace resistance. Proper

grounding guidelines helps to improve audio performance,

minimize crosstalk between channels, and prevent switching

noise from coupling into the audio signal. To maintain high

output swing and high peak output power, the PCB traces that

connect the output pins to the load and supply pins should be as

wide as possible to maintain the minimum trace resistances. It

is also recommended to use a large-area ground plane for

minimum impedances. Good PCB layouts also isolate critical

analog paths from sources of high interference. High frequency

circuits (analog and digital) should be separated from low

frequency ones. Properly designed multilayer printed circuit

boards can reduce EMI emission and increase immunity to RF

field by a factor of 10 or more compared with double-sided

boards. A multilayer board allows a complete layer to be used

for ground plane, whereas the ground plane side of a doubleside board is often disrupted with signal crossover. If the system

has separate analog and digital ground and power planes, the

analog ground plane should be underneath the analog power

plane, and, similarly, the digital ground plane should be

underneath the digital power plane. There should be no overlap

between analog and digital ground planes nor analog and

digital power planes.

INPUT CAPACITOR SELECTION

The SSM2304 will not require input coupling capacitors if the

input signal is biased from 1.0 V to V

capacitors are required if the input signal is not biased within

this recommended input dc common-mode voltage range, if

high-pass filtering is needed (

ended source (

input, the input capacitor along with the input resistor of the

SSM2304 will form a high-pass filter whose corner frequency is

determined by the following equation:

= 1/(2π × RIN × CIN)

f

C

Input capacitor can have very important effects on the circuit

performance. Not using input capacitors degrades the output

offset of the amplifier as well as the PSRR performance.

Figure 38). If high-pass filtering is needed at the

Figure 37), or if using a single-

− 1.0 V. Input

DD

PROPER POWER SUPPLY DECOUPLING

To ensure high efficiency, low total harmonic distortion (THD),

and high PSRR, proper power supply decoupling is necessary.

Noise transients on the power supply lines are short-duration

voltage spikes. Although the actual switching frequency can

range from 10 kHz to 100 kHz, these spikes can contain

frequency components that extend into the hundreds of

megahertz. The power supply input needs to be decoupled with

a good quality low ESL and low ESR capacitor—usually around

4.7 μF. This capacitor bypasses low frequency noises to the

ground plane. For high frequency transients noises, use a 0.1 μF

capacitor as close as possible to the VDD pin of the device.

Placing the decoupling capacitor as close as possible to the

SSM2304 helps maintain efficiency performance.

Rev. 0 | Page 14 of 20

SSM2304

EVALUATION BOARD INFORMATION

INTRODUCTION

This section describes how to configure and use the SSM2304

Evaluation Board Revision 3.0.

There are several ways to connect the audio signal to the

amplifier on the evaluation board. For example, the signal can

be connected in single-ended or differential mode, and the

output signals can be taken either after the ferrite beads or the

inductors.

BOARD DESCRIPTION

The SSM2304 evaluation board has a complete application

circuit for driving two stereo loudspeakers.

The silkscreen layer of the evaluation board is shown in Figure 41

with other top layers, including top copper, top solder mask,

and multilayer (vias).

Figure 42 shows the top silkscreen layer only. There is no

component in the bottom side; therefore, there is no bottom

silkscreen layer.

Figure 43 shows the top layers without the silkscreen layer.

Figure 44 shows the bottom layers, including bottom copper,

bottom solder mask, and multilayer (vias).

Figure 45 shows the mirrored bottom layers.

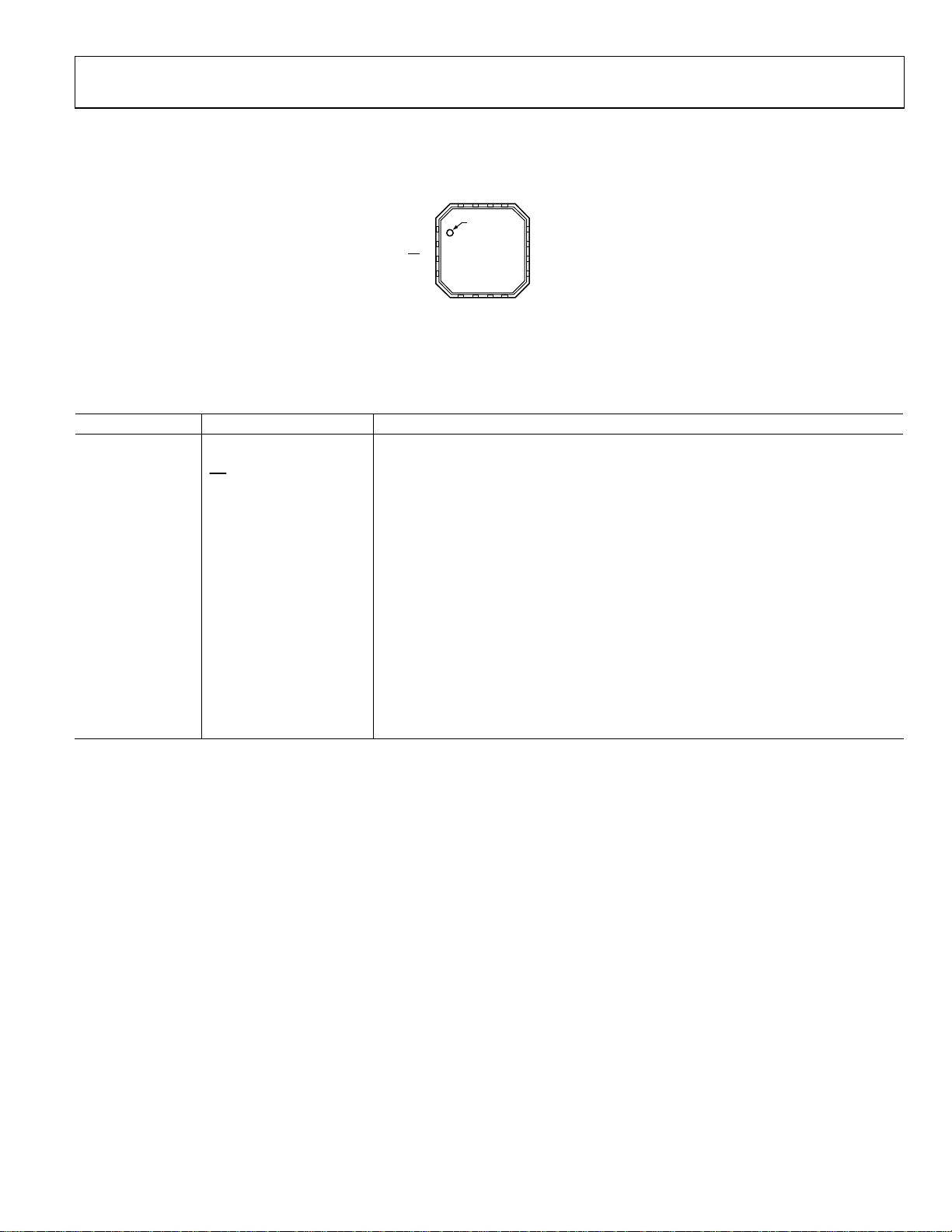

The schematic is shown in

Figure 46.

Figure 42. Top Silkscreen

06162-071

Figure 41. Top Silkscreen Layer with Other Top Layers

06162-070

Rev. 0 | Page 15 of 20

Figure 43. Top Layers Without Top Screen Layer

06162-072

SSM2304

When differential mode audio signals are used as the input

signal source, either use Headers 3HD1 and 3HD2 or the

soldering pads located on the left side of the board and turn

Switches S1E and S1F to the off position (lower position). The

top header is for the left channel signals and the lower is for the

right channel signals. There are two ground soldering pads on

the lower left corner.

The lower side of the board has a switch bank and its corres-

Tabl e 5

Figure 44. Bottom Layers

Figure 45. Mirrored Bottom Layers

On the upper left corner of the schematic shown in Figure 46,

there is an audio stereo jack connector (3.5 mm), J1. This jack is

compatible with standard stereo audio signals. It uses a

conventional audio stereo signal connector/cable to obtain

audio signals from common appliances, such as DVD players,

personal computers, TVs, and so on. Because this connector

only provides single-ended audio signals, turn Switches S1E and

S1F to the upper positions when this input connector is utilized

to ac short circuit the negative input ports to ground (see the

schematic in

Figure 46).

ponding channels are listed in

Table 5. Switch Channels

Switch Name Corresponding Channel

S1A Left positive

S1B Left negative

S1C Right negative

S1D Right positive

06162-073

When the switches listed in Tab le 5 are placed in the upper

positions, their corresponding coupling capacitors are shorted;

when the switches are placed in the lower positions, the coupling

capacitors are inserted in the signal paths.

As previously described, Switches S1E and S1F are used to ac

short circuit the left and right channel negative input ports to

ground, respectively. This function is only needed when driving

the input ports in single-ended mode. After shortening the

negative input ports to ground, the noise picked up by the input

port connections will be conducted to the ground.

S1G is not connected for the SSM2304.

S1H controls the shutdown function. The upper position shuts

down the amplifier, and the lower position turns on the amplifier.

The upper right corner has a dc power jack connector. The

center pin is for the positive terminal. It is compatible with 3 V

06162-074

to 5 V voltage, and the maximum peak current is approximately

1.2 A when driving a 4 Ω load (for SSM2304 only) and 0.6 A

when driving an 8 Ω load with an input voltage of 5 V.

There are two solder pads in the upper center edge area for

connecting the power supply voltages by clipping or soldering.

All the output ports are located on the right side of the board

and marked with the corresponding names. Please see the legend

on the board in

Figure 42 and the schematic in Figure 46.

There are three ways to connect the output signals to the loads

(the loudspeakers): using the four 2-pin headers, the terminal

block, or the soldering pads.

Rev. 0 | Page 16 of 20

SSM2304

-

OUTBL

OUTBL+

1

1

B1

12

C21

C7

100pF

12

OUTLL+

1

2HD1

2

BEAD

1 2

1nF

1

S1H

-

OUTLL

1

2PINA

1 2

1 2

C24

100pF

12

VDD

12

B2

R7

100K

8 9

TB1

2HD2

L2

L1

10PST

R1

7109

2PINA

1

2

10uH

10uH

C23

100pF

12

C12

12

C11

12

17

BEAD

PAD

1 2

100

1 2

GND16VDD

OUTL+

1

OUTL-

2

SD

3

INL+

4

INL-

5

R2

2143658

C16

1uF

C18

12

1 2

C15

1uF

C17

12

1 2

1nF

1nF

15

VDD14GND

U1

SSM2302

NC

6

7

100

1 2

C13

1 2

C14

1 2

13

R3

1uF

1uF

INR-8NC

2

C25

100pF

1 2

1nF

1nF

100

1 2

10P_T_BLOCK

2HD3

2PINA

1

1 2

1 2

C26

1 2

OUTR+

OUTR-

GAIN

INR+

-

OUTLR+

OUTLR

1

1

2HD4

2PINA

1

2

L4

10uH

L3

10uH

100pF

B4

B3

BEAD

1 2

12

11

10

R4

9

R6

12

100

12

C10

10uF

20

12

VDD

1 2

OUTBR+

B5

BEAD

-

GND

OUTBR

1

2HD5

1

2

C20

BEAD

1 2

VDD

12

R8

S1G

1 2

S1F

1

2PINA

10uF

C19

100K

C8

12

12

C22

12

100pF

1

J2

PS_JACK

1

123

10uF

1nF

10PST

710

10PST

611

06162-075

GND

1

VDD

PGND

1

C9

10uF

20

C6

100pF

12

C5

100pF

12

C1

1

-

INL

INL+

S1A

100nF

1 2

1

1

GND

C2

10PST

1 16

123

3HD1

S1B

100nF

1 2

J1

3P_HEADER

C3

10PST

2 15

123

3HD2

SJ-3523A

R5

12

S1C

100nF

1 2

3

2

3 14

1

1

3P_HEADER

12

10PST

INR+

S1E

C4

S1D

100nF

1 2

1

-

INR

10PST

512

10PST

4 13

1

GND

Figure 46. Schematic of SSM2304 Evaluation Board Rev. 3.0

Rev. 0 | Page 17 of 20

SSM2304

GETTING STARTED

To ensure proper operation, follow these steps:

1. Verify that the control switches are at the proper positions.

2. Put S1H, the shutdown control, in the lower position to

turn on the amplifier.

3. Put S1G, the gain selection, in the upper position for

higher gain and in the lower position for lower gain.

4. Connect the power supply with the right polarity and

proper voltage.

5. Connect the loads to the proper output ports. Depending

on the application, use nodes OUTBL+, OUTBL−, OUTBR+,

and OUTBR− to connect the loads after the beads or use

nodes OUTLL+, OUTLL−, OUTLR+, and OUTLR− to

connect the loads after the inductors.

WHAT TO TEST

1. EMI (electromagnetic interference). Connect wires for the

speakers that are the length required for the application

and perform the EMI test.

2. Signal-to-noise ratio.

3. Output noise. Use an A-weighting filter to filter the output

before the measurement meter.

4. Maximum output power.

5. Efficiency.

6. Component selections.

Selecting the correct components is the key for achieving the

performance required at the cost budgeted.

1. Input coupling capacitor selection. Capacitors C1, C2, C3,

and C4 should be large enough to couple the low frequency

signal components in the incoming signal, but small enough

to filter out unnecessary low frequency signals. For music

signals, the cutoff frequency is often chosen between 20 Hz

and 30 Hz. The cutoff frequency is calculated by

C = 1/(2 Rfc)

where R is 150k, and fc is the cutoff frequency.

Table 6.

Part No. Manufacturer Z (Ω) I

MPZ1608S601A TDK 600 1000 0.15 1.6 × 0.8 × 0.8

2. Input serial resistors (R1, R2, R3, and R4). These resistors

are not necessary for the amplifier to operate and are only

needed when special gain values are required. Using

resistors of too high a value increases the input noise.

3. Output beads (B1, B2, B3, and B4). The output beads are

necessary components for filtering out the EMIs caused at

the switching output nodes. Ensure that these beads have

enough current conducting capability while providing

sufficient EMI attenuation. The current rating needed for

an 8 Ω load is about 600 mA, and the impedance for

100 MHz must be greater than 600 Ω. In addition, the

lower the DCR (dc resistance) of these beads, the better for

minimizing their power consumptions. The recommended

bead is described in

Tabl e 6.

4. Output shunting capacitors for the beads. There are two

groups of these capacitors: C11, C12, C13, and C14 and

C23, C24, C25, and C26. The former is for filtering out the

lower frequency EMIs (those up to 250 MHz), and the latter

is for filtering out the higher frequency EMIs (those greater

than 250 MHz). Use small size (0603 or 0402) multilayer

ceramic capacitors of a X7R or COG (NPO) material. The

higher the value of these capacitors, the lower the residual

EMI level at the output and the higher the quiescent current

at the power supply. It is recommend to use 500 pF to 1 nF

values for the first group of capacitors and 100 pF to 200 pF

for the second group of capacitors.

5. Output inductors. Some users do not allow high frequency

EMIs in the system and prefer using inductors to filter the

output of the high frequency components at the output nodes.

Choose an inductance greater than 2.2 μH for these inductors.

The higher the inductance, the lower the EMI at the output

and the lower the quiescent current at the power supply.

However, higher inductance also corresponds with higher

power consumption by the inductors when the output power

level is high. It is recommended to use 2.2 μH to 10 μH

inductors; the current rating must be greater than 600 mA

(saturation current) for an 8 Ω load.

Tabl e 7 describes the

recommended inductors.

(mA) DCR (Ω) Size (mm)

MAX

Table 7.

Part No. Manufacturer L (μH) I

LQH32CN4R7M53 Murata Manufacturing Co., Ltd. 4.7 650 0.15 3.2 × 2.5 × 1.55

LQH32CN3R3M53 Murata Manufacturing Co., Ltd. 3.3 710 0.12 3.2 × 2.5 × 1.55

LQH32CN2R2M53 Murata Manufacturing Co., Ltd. 2.2 790 0.1 3.2 × 2.5 × 1.55

SD3118-100-R Cooper Bussmann, Inc. 10 900 0.3 3.1 × 3.1 × 1.8

ELL4LM100M Panasonic Corporation 10 690 0.18 3.8 × 3.8 × 1.8

LBC2518T2R2M Taiyo Yuden Co., Ltd. 2.2 630 0.13 2.5 × 1.8 × 2

1033AS-4R7M Toko Inc. 4.7 680 0.31 3.8 × 3.8 × 1

Rev. 0 | Page 18 of 20

(mA) DCR (Ω) Size (mm)

MAX

SSM2304

PCB LAYOUT GUIDELINES

To keep the EMI within the allowable limits and ensure that the

amplifier chip operates within the temperature limits, adhere to

the following guidelines.

1. Place nine vias onto the thermal pad of the amplifier. The

outer diameter of the vias should be 0.5 mm and the inner

diameter should be 0.33 mm. Use a PCB area of at least

2 cm × 2 cm or an equivalent area on the back side of the

PCB layer as the heat sink (see

Figure 43). If there are internal layers available within the

PCB, allocate an area as large as possible for the ground

plane(s) and connect these vias to the plane(s).

2. Place the EMI filtering beads, B1, B2, B3, and B4, as close

to the amplifier chip as possible. The same principle applies

to the output inductors, L1, L2, L3, and L4, if they are

included in the application design.

3. Place C11, C12, C13, and C14, the decoupling capacitors

for the beads, as close to the amplifier chip as possible and

connect their ground terminals together as close as

possible. The same principle applies to the decoupling

capacitors for the inductors, C15, C16, C17, and C18, if

they are included in the application design.

4. Place C19, the decoupling capacitor for the power supply,

as close to the amplifier chip as possible and connect its

ground terminal directly to the IC’s ground pins, Pins 13

and 16.

5. Place C20, the decoupling capacitor for the power supply,

as close to the amplifier chip as possible and connect its

ground terminal to the PCB ground area containing the

power supply traces.

Figure 41, Figure 42, and

6. Place B5, the bead for the power supply, as close to the

amplifier chip as possible, keeping it on the same side of

the PCB as the chip.

7. The ferrite beads can block an EMI of up to 160 MHz in

frequency. To eliminate EMIs greater than the 160 MHz,

place a small capacitor, such as 100 pF, in parallel with the

decoupling capacitors, C11, C12, C15, and C16, at least

20 mm from the 1 nF decoupling capacitor. Ideally, the

ground terminals of these capacitors are connected to the

ground terminals or the PCB traces, which are placed as

close to the output loads (loudspeakers) as possible. In this

way, the PCB connecting trace between these two capacitors

serves as an inductor for filtering out the high frequency

component.

8. Decouple the input port nodes and the digital pins, Pins 3,

4, 5, 8, 9, and 10, with small capacitors, such as 100 pF.

These capacitors are not necessary, but can lower the EMI

from these pins. The ground terminals of these capacitors

should be connected to the chip ground as close as possible

(see

Figure 41, Figure 42, and Figure 43).

9. Ground the unconnected pins, Pins 6 and 7.

10. Connect the ground pins, Pins 6, 7, 13, and 16, to the

thermal pad and place grounding vias as shown in

Figure 42, and Figure 43.

11. Use a solid polygon plane on the other side of the PCB for

the area of the vias that are placed on the thermal pad of

the chip (see

12. Keep the PCB traces for high EMI nodes on the same side

of the PCB and as short as possible. The high EMI nodes

are Pins 1, 2, 11, and 12 of the SSM2304.

Figure 44 or Figure 45).

Figure 41,

Rev. 0 | Page 19 of 20

SSM2304

R

R

OUTLINE DIMENSIONS

0.50

0.40

PIN 1

INDICATO

0.90

0.85

0.80

SEATING

PLANE

12° MAX

3.00

BSC SQ

TOP

VIEW

0.30

0.23

0.18

*

COMPLIANT

EXCEPT FOR EXPOSED PAD DIMENSION.

2.75

BSC SQ

0.80 MAX

0.65 TYP

0.05 MAX

0.02 NOM

0.20 REF

TO

JEDEC STANDARDS MO-220-VEED-2

0.45

0.50

BSC

1.50 REF

0.60 MAX

13

12

(BOTTOM VIEW)

9

8

Figure 47. 16-Lead Lead Frame Chip Scale Package [LFCSP_VQ]

3 mm × 3 mm Body, Very Thin Quad

(CP-16-3)

Dimensions shown in millimeters

EXPOSED

PAD

0.30

16

1

4

5

N

I

P

D

N

I

*

1.65

1.50 SQ

1.35

0.25 MIN

1

O

T

C

I

A

ORDERING GUIDE

Model Temperature Range Package Description Package Option Branding

SSM2304CPZ-REEL −40°C to +85°C 16-Lead Lead Frame Chip Scale Package [LFCSP_VQ] CP-16-3 A1F

SSM2304CPZ-REEL7 −40°C to +85°C 16-Lead Lead Frame Chip Scale Package [LFCSP_VQ] CP-16-3 A1F

SSM2304Z-EVAL Evaluation Board

1

Z = Pb-free part.

1

1

1

©2006 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D06162-0-12/06(0)

Rev. 0 | Page 20 of 20

Loading...

Loading...