PIN CONFIGURATIONS

a

Rail-to-Rail High Output

Current Operational Amplifiers

OP179/OP279

GENERAL DESCRIPTION

The OP179 and OP279 are rail-to-rail, high output current,

single-supply amplifiers. They are designed for low voltage

applications that require either current or capacitive load drive

capability. The OP179/OP279 can sink and source currents of

±60 mA (typical) and are stable with capacitive loads to 10 nF.

Applications that benefit from the high output current of the

OP179/OP279 include driving headphones, displays, transformers and power transistors. The powerful output is combined with a

unique input stage that maintains very low distortion with wide

common-mode range, even in single supply designs.

The OP179/OP279 can be used as a buffer to provide much

greater drive capability than can usually be provided by CMOS

outputs. CMOS ASICs and DAC often have outputs that can

swing to both the positive supply and ground, but cannot drive

more than a few milliamps.

Bandwidth is typically 5 MHz and the slew rate is 3 V/µs, making

these amplifiers well suited for single supply applications that

require audio bandwidths when used in high gain configurations.

Operation is guaranteed from voltages as low as 4.5 V, up to 12 V.

Very good audio performance can be attained when using the

OP179/OP279 in 5 volt systems. THD is below 0.01% with a

600 Ω load, and noise is a respectable 21 nV/√Hz. Supply current

is less than 3.5 mA per amplifier.

The single OP179 is available in the 5-lead SOT-23-5 package.

It is specified over the industrial (–40°C to +85°C) temperature range.

The OP279 is available in 8-lead TSSOP and SO-8 surface

mount packages. They are specified over the industrial (–40°C

to +85°C) temperature range.

8-Lead SOIC and TSSOP

SO-8 (S) and RU-8

1

2

3

4

8

7

6

5

OP279

ⴚIN A

Vⴚ

+IN A

OUT B

ⴚIN B

V+

+IN B

OUT A

FEATURES

Rail-to-Rail Inputs and Outputs

High Output Current: ⴞ60 mA

Single Supply: 5 V to 12 V

Wide Bandwidth: 5 MHz

High Slew Rate: 3 V/s

Low Distortion: 0.01%

Unity-Gain Stable

No Phase Reversal

Short-Circuit Protected

Drives Capacitive Loads: 10 nF

APPLICATIONS

Multimedia

Telecom

DAA Transformer Driver

LCD Driver

Low Voltage Servo Control

Modems

FET Drivers

5-Lead SOT-23-5

(RT-5)

1

2

3

5

4

ⴚIN A

+IN A

V–

OUT A

OP179

V+

8-Lead SOIC

(S Suffix)

1

2

3

4

8

7

6

5

OP179

ⴚIN A

Vⴚ

+IN A

V+

OUT A

NC

NC

NC

NC = NO CONNECT

REV. G

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

ELECTRICAL SPECIFICATIONS

(@ VS = 5.0 V, VCM = 2.5 V, –40ⴗC ≤ TA ≤ +85ⴗC unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage

OP179 V

OS

V

OUT

= 2.5 V ±5mV

OP279 V

OS

V

OUT

= 2.5 V ±4mV

Input Bias Current I

B

V

OUT

= 2.5 V, TA = 25°C ±300 nA

V

OUT

= 2.5 V ±700 nA

Input Offset Current I

OS

V

OUT

= 2.5 V, TA = 25°C ±50 nA

V

OUT

= 2.5 V ±100 nA

Input Voltage Range V

CM

05V

Common-Mode Rejection Ratio CMRR V

CM

= 0 V to 5 V 56 66 dB

Large Signal Voltage Gain A

VO

RL = 1 kΩ, 0.3 V ≤ V

OUT

≤ 4.7 V 20 V/mV

Offset Voltage Drift ∆VOS/∆T4µV/°C

OUTPUT CHARACTERISTICS

Output Voltage High V

OH

IL = 10 mA Source +4.8 V

Output Voltage Low V

OL

IL = 10 mA Sink, TA = 25°C75mV

I

L

= 10 mA Sink 100 mV

Short-Circuit Limit I

SC

TA = 25°C ±40 mA

Output Impedance Z

OUT

f = 1 MHz, AV = 1 22 Ω

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

S

= 4.5 V to 12 V 70 88 dB

Supply Current/Amplifier I

SY

V

OUT

= 2.5 V 3.5 mA

Supply Voltage Range V

S

+4.5 +12 V

DYNAMIC PERFORMANCE

Slew Rate SR R

L

= 1 kΩ, 1 nF 3 V/µs

Gain Bandwidth Product GBP 5 MHz

Phase Margin φm 60 Degrees

Capacitive Load Drive No Oscillation 10 nF

AUDIO PERFORMANCE

Total Harmonic Distortion THD 0.01 %

Voltage Noise Density e

n

f = 1 kHz 22 nV/√Hz

ELECTRICAL SPECIFICATIONS

(@ VS = ⴞ5.0 V, –40ⴗC ≤ TA ≤ +85ⴗC unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage

OP179 V

OS

V

OUT

= 0 ±5mV

OP279 V

OS

V

OUT

= 0 ±4mV

Input Bias Current I

B

TA = 25°C ±300 nA

±700 nA

Input Offset Current I

OS

TA = 25°C ±50 nA

±100 nA

Input Voltage Range V

CM

–5 +5 V

Common-Mode Rejection Ratio CMRR V

CM

= –5 V to +5 V 56 66 dB

Large Signal Voltage Gain A

VO

RL = 1 kΩ, –4.7 V ≤ V

OUT

≤ 4.7 V 20 V/mV

Offset Voltage Drift ∆VOS/∆T3µV/°C

OUTPUT CHARACTERISTICS

Output Voltage High V

OH

IL = 10 mA Source +4.8 V

Output Voltage Low V

OL

IL = 10 mA Sink –4.85 V

Short Circuit Limit I

SC

TA = 25°C ±50 mA

Open-Loop Output Impedance Z

OUT

f = 1 MHz, AV = +1 22 Ω

POWER SUPPLY

Supply Current/Amplifier I

SY

VS = ±6 V, V

OUT

= 0 V 3.75 mA

DYNAMIC PERFORMANCE

Slew Rate SR R

L

= 1 kΩ, 1 nF 3 V/µs

Full-Power Bandwidth BW

p

1% Distortion kHz

Gain Bandwidth Product GBP 5 MHz

Phase Margin φm 69 Degrees

NOISE PERFORMANCE

Voltage Noise e

n

p-p 0.1 Hz to 10 Hz 2 µV p-p

Voltage Noise Density e

n

f = 1 kHz 22 nV/√Hz

Current Noise Density i

n

1

pA/√Hz

Specifications subject to change without notice.

OP179/OP279–SPECIFICATIONS

–2–

REV. G

OP179/OP279

–3–

REV. G

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 V

Differential Input Voltage

1

. . . . . . . . . . . . . . . . . . . . . . . . .±1 V

Output Short-Circuit Duration to GND . . . . . . . . . . Indefinite

Storage Temperature Range

S, RT, RU Package . . . . . . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range

OP179G/OP279G . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature Range

S, RT, RU Package . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . . 300°C

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the OP179/OP279 features proprietary ESD protection circuitry, permanent damage

may occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

ORDERING GUIDE

Package Temperature Range Package Description Package Option Brand Code

OP179GRT –40°C to +85°C 5-Lead SOT-23 RT-5 A2G

OP279GS –40°C to +85°C 8-Lead SOIC SO-8

OP279GRU –40°C to +85°C 8-Lead TSSOP RU-8

WARNING!

ESD SENSITIVE DEVICE

Package Types

JA

2

JC

Unit

5-Lead SOT-23 (RT) 256 81 °C/W

8-Lead SOIC (S) 158 43 °C/W

8-Lead TSSOP (RU) 240 43 °C/W

NOTES

1

The inputs are clamped with back-to-back diodes. If the differential input voltage

exceeds 1 volt, the input current should be limited to 5 mA.

2

θJA is specified for the worst-case conditions, i.e., θJA is specified for device soldered

in circuit board for SOIC packages.

OP179/OP279

–4–

REV. G

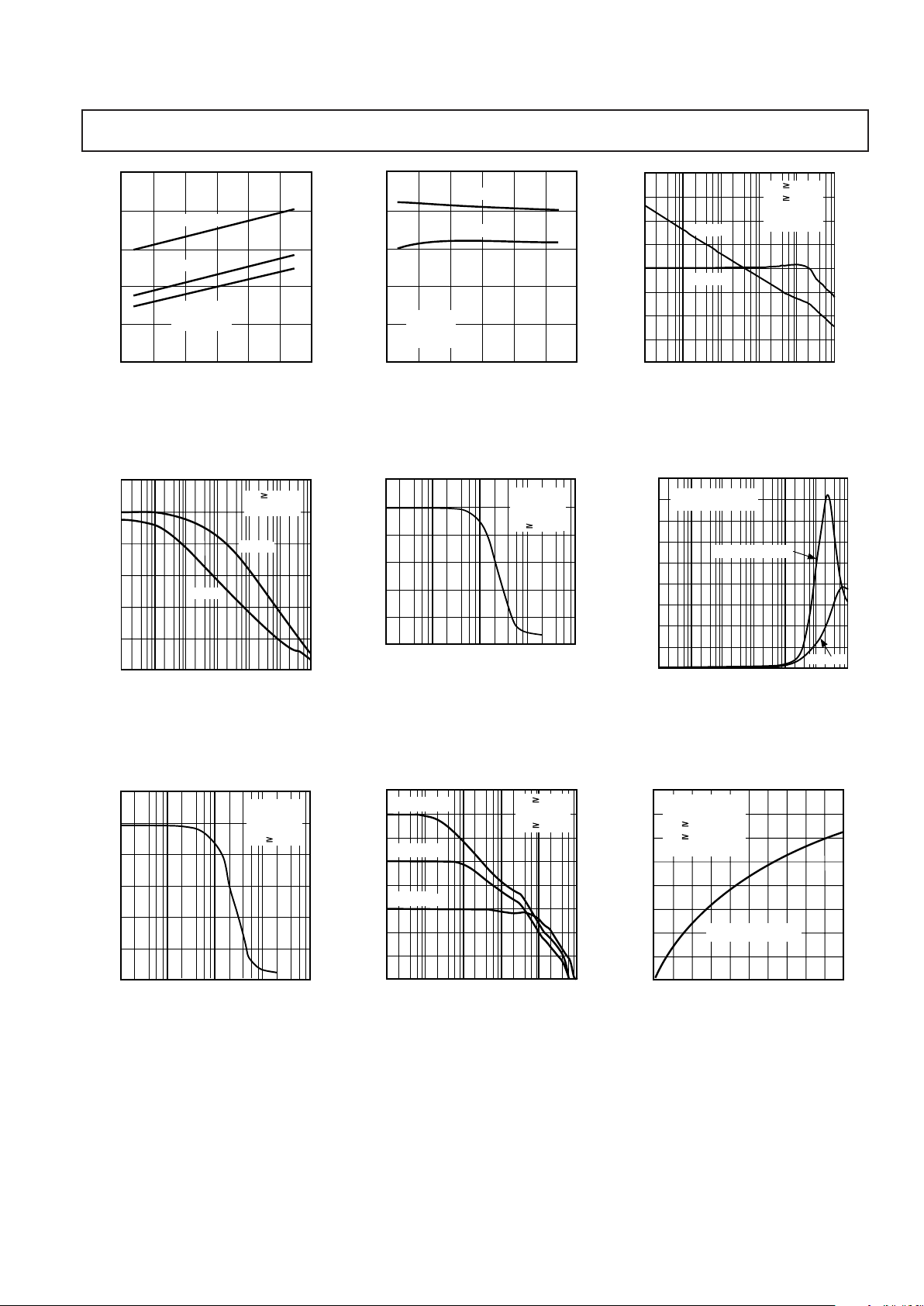

160

0

2.5

40

20

–2.5

80

60

100

120

140

1.50.5–0.5–1.5

INPUT OFFSET – mV

UNITS

VS ⴝ 5V

T

A

ⴝ 25ⴗC

620 ⴛ OP AMPS

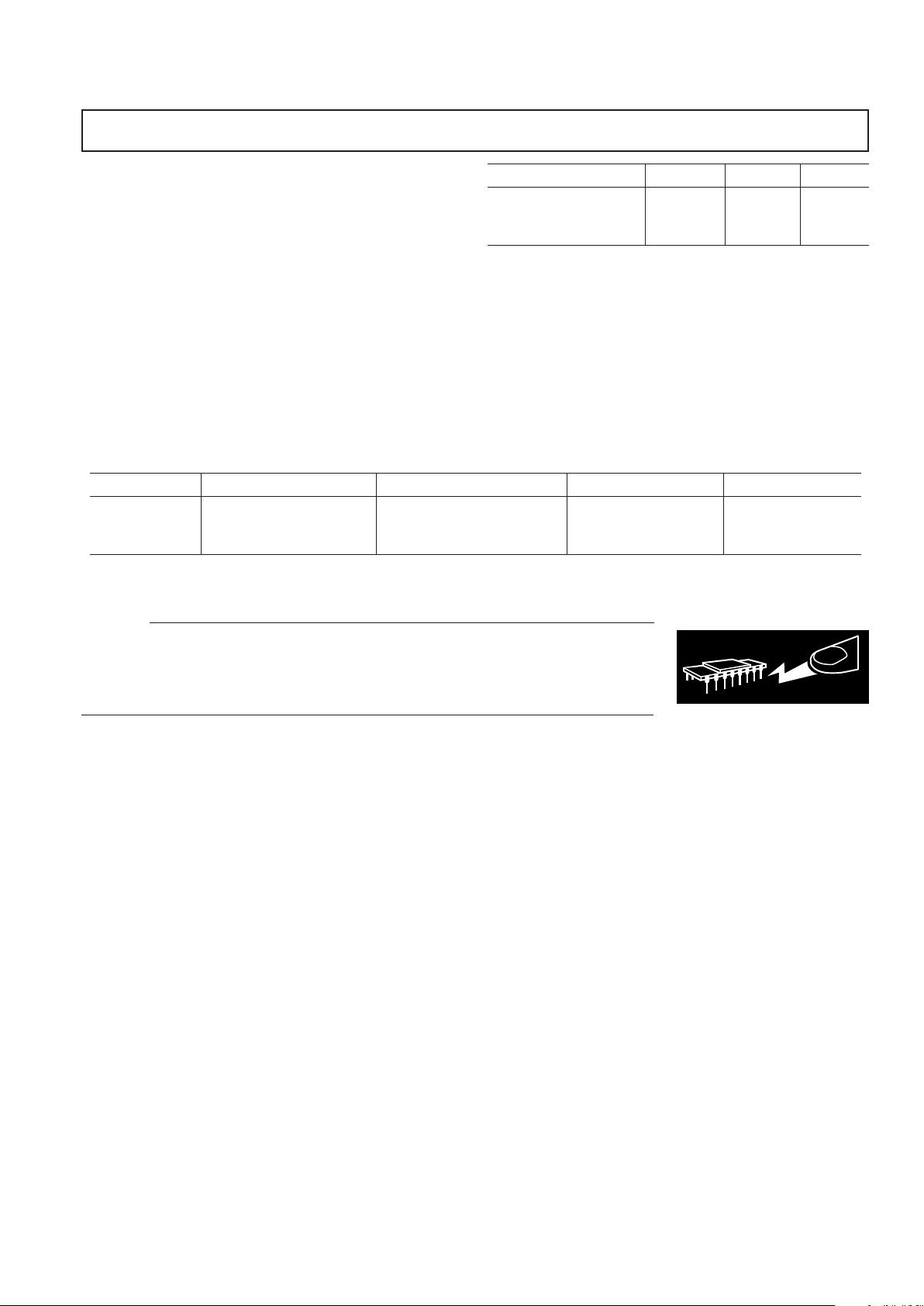

TPC 1. Input Offset Distribution

COMMON-MODE VOLTAGE – Volts

OFFSET VOLTAGE – mV

3.0

0

5

1.5

0.5

1

1.0

0

2.5

2.0

432

VS ⴝ 5V

T

A

ⴝ 25ⴗC

TPC 4. Offset Voltage vs.

Common-Mode Voltage

1000

0

100

600

200

–25

400

–50

800

7550250

TEMPERATURE – ⴗC

RL ⴝ 2k⍀

RL ⴝ 1k⍀

OPEN-LOOP GAIN – V/mV

VS ⴝ 15V

0.3

V

OUT

4.7V

TPC 7. Open-Loop Gain vs.

Temperature

VS ⴝ 5V

V

CM

ⴝ 2.5V

90

40

100

70

50

–25

60

–50

80

7550250

TEMPERATURE – ⴗC

–I

SC

SHORT-CIRCUIT CURRENT – mA

+I

SC

TPC 2. Short-Circuit Current vs.

Temperature

VS ⴝ ⴞ5V

100

50

100

80

60

–25

70

–50

90

7550250

TEMPERATURE – ⴗC

SHORT-CIRCUIT CURRENT – mA

–I

SC

+I

SC

TPC 5. Short-Circuit Current vs.

Temperature

5

0

100

3

1

–25

2

–50

4

7550250

TEMPERATURE – ⴗC

SLEW RATE – VⲐs

VS ⴝ 5V

R

L

ⴝ 1k⍀

C

L

ⴝ +1nF

+EDGE

–EDGE

TPC 8. Slew Rate vs.

Temperature

400

–400

5

–200

–300

10

0

–100

100

200

300

432

+85ⴗC

+25ⴗC

COMMON-MODE VOLTAGE – Volts

INPUT BIAS CURRENT – nA

VS ⴝ 5V

–40ⴗC

TPC 3. Input Bias Current

vs. Common-Mode Voltage

COMMON-MODE VOLTAGE – Volts

7

0

5

3

1

1

2

0

6

4

5

432

BANDWIDTH – MHz

VS ⴝ 5V

TA ⴝ 25ⴗC

TPC 6. Bandwidth vs.

Common-Mode Voltage

PHASE

GAIN

40

–40

100 1k 10M1M100k10k

60

80

100

–20

0

20

90

–90

135

180

225

–45

0

45

FREQUENCY – Hz

OPEN-LOOP GAIN – dB

PHASE – Degrees

120 270

VS ⴞ2.5V

T

A

–40ⴗC

R

L

ⴝ 2k⍀

TPC 9. Open-Loop Gain and

Phase vs. Frequency

–

Typical Performance Characteristics

OP179/OP279

–5–

REV. G

VS ⴝ 5V

V

CM

ⴝ 2.5V

6.5

4.0

100

5.5

4.5

–25

5.0

–50

6.0

7550250

TEMPERATURE – ⴗC

SUPPLY CURRENT – mA

VS ⴝ ⴞ6V

VS ⴝ ⴞ5V

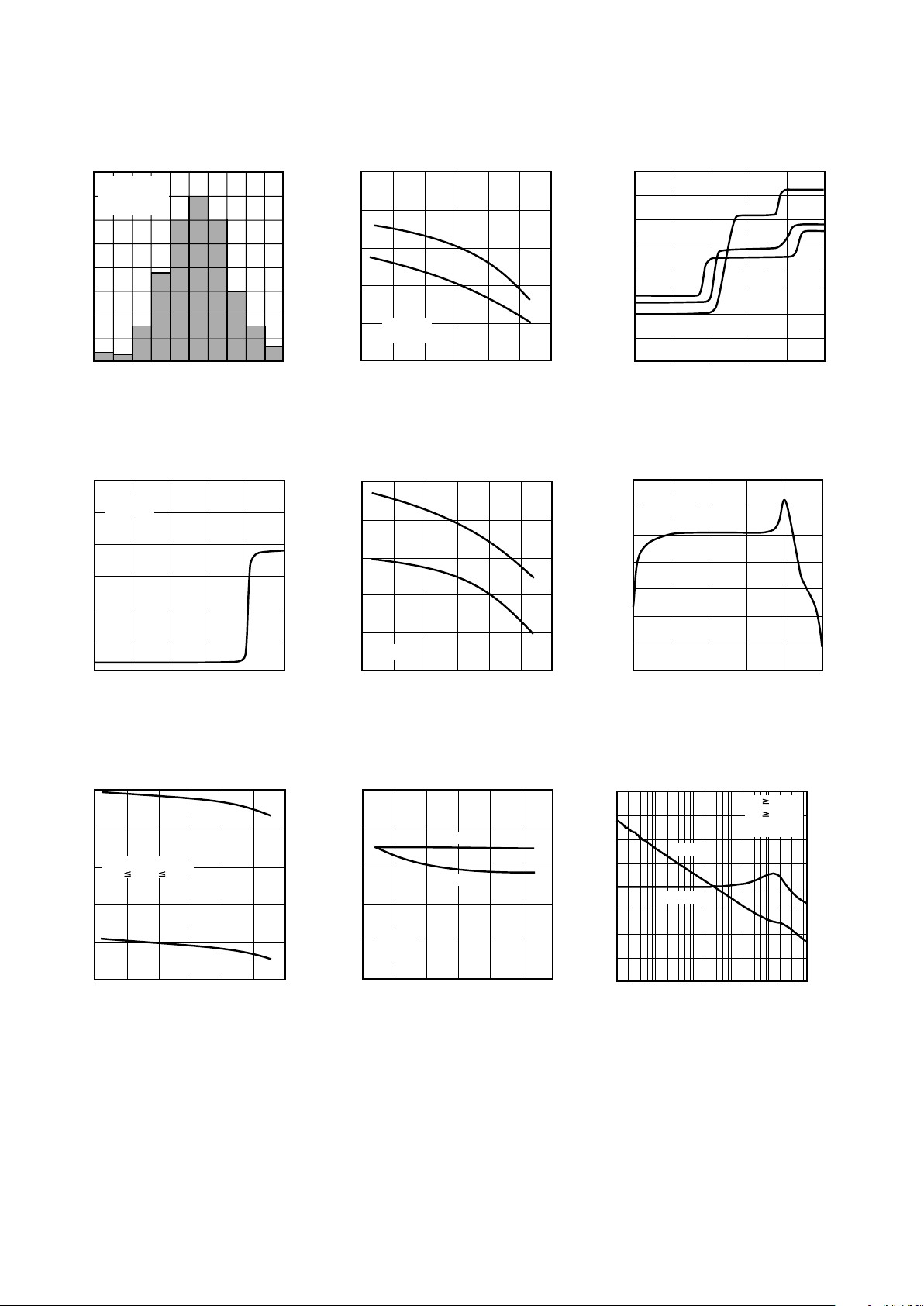

TPC 10. Supply Current vs.

Temperature

FREQUENCY – Hz

POWER SUPPLY REJECTION – dB

120

60

0

10 100 10M1M100k10k1k

80

100

20

40

VS ⴞ2.5V

T

A

ⴝ 25ⴗC

–PSRR

+PSRR

TPC 13. Power Supply Rejection vs.

Frequency

12

6

0

10k 10M1M100k1k

4

2

8

10

FREQUENCY – Hz

MAXIMUM OUTPUT SWING – Volts

TA ⴝ 25ⴗC

V

S

ⴝ ⴞ5V

A

VCL

ⴝ +1

R

L

1k⍀

TPC 16. Maximum Output Swing vs.

Frequency

5

0

100

3

1

–25

2

–50

4

7550250

TEMPERATURE – ⴗC

SLEW RATE – V/s

VS ⴝ ⴞ5V

R

L

ⴝ 1k⍀

C

L

ⴝ +1nF

+EDGE

–EDGE

TPC 11. Slew Rate vs. Temperature

6

3

0

10k

10M

1M100k1k

2

1

4

5

FREQUENCY – Hz

MAXIMUM OUTPUT SWING – Volts

TA ⴝ 25ⴗC

V

S

ⴝ ⴞ2.5V

A

VCL

ⴝ +1

R

L

1k⍀

TPC 14. Maximum Output

Swing vs. Frequency

50

10

–30

1k 10k 100M10M1M100k

20

30

40

–20

–10

0

FREQUENCY – Hz

CLOSED-LOOP GAIN – dB

A

VCL

ⴝ +100

A

VCL

ⴝ +10

A

VCL

ⴝ +1

VS ⴞ2.5V

T

A

ⴝ 25ⴗC

R

L

1k

⍀

TPC 17. Closed-Loop Gain vs.

Frequency

PHASE

GAIN

120

40

–40

100 1k 10M1M100k10k

60

80

100

–20

0

20

270

90

–90

135

180

225

–45

0

45

FREQUENCY – Hz

OPEN-LOOP GAIN – dB

PHASE – Degrees

VS ⴞ2.5V

T

A

– 40ⴗC

R

L

ⴝ 2k⍀

C

L

ⴝ 500pF

TPC 12. Open-Loop Gain and

Phase vs. Frequency

180

160

140

120

100

80

60

40

20

0

10 100 10M1M100k10k1k

TA ⴝ 25ⴗC

V

S

ⴝ ⴞ2.5V OR ⴞ5V

FREQUENCY – Hz

IMPEDANCE – ⍀

A

VCL

ⴝ 1

A

VCL

ⴝ 10 OR 100

TPC 15. Closed-Loop Output

Impedance vs. Frequency

80

0

10k

20

10

0

40

30

50

60

70

8k6k4k2k

LOAD CAPACITANCE – pF

OVERSHOOT – %

TA ⴝ 25ⴗC

A

VCL

ⴝ +1

R

L

1k⍀

V

S

ⴞ2.5V

V

IN

ⴝ 100mV p-p

POSITIVE EDGE AND

NEGATIVE EDGE

TPC 18. Small Signal Overshoot vs.

Load Capacitance

OP179/OP279

–6–

REV. G

THEORY OF OPERATION

The OP179/OP279 is the latest entry in Analog Devices’ expanding family of single-supply devices, designed for the multimedia

and telecom marketplaces. It is a high output current drive,

rail-to-rail input /output operational amplifier, powered from a

single 5 V supply. It is also intended for other low supply voltage

applications where low distortion and high output current drive

are needed. To combine the attributes of high output current

and low distortion in rail-to-rail input/output operation, novel

circuit design techniques are used.

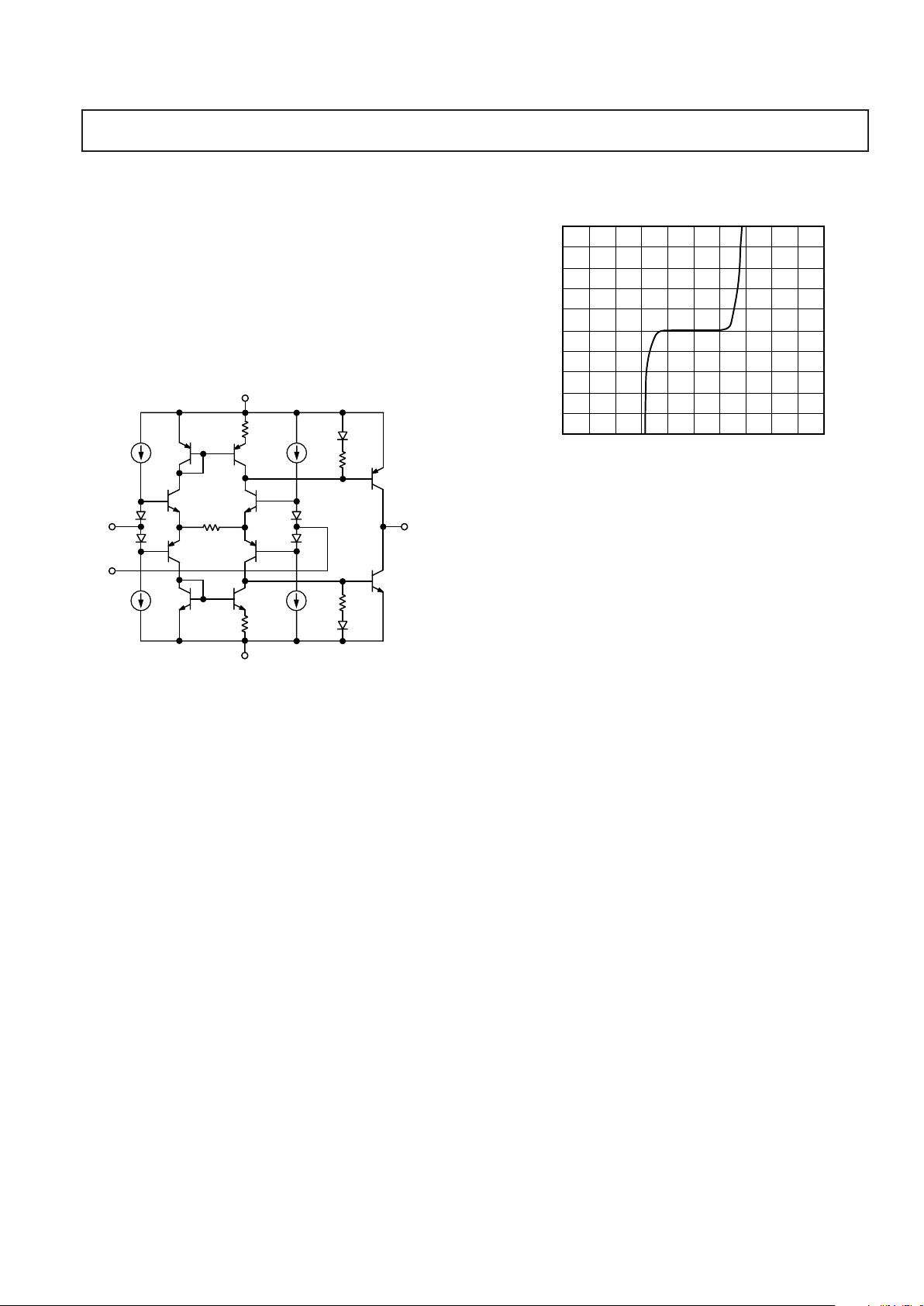

For example, TPC 1 illustrates a simplified equivalent circuit for

the OP179/OP279’s input stage. It is comprised of two PNP

differential pairs, Q5-Q6 and Q7-Q8, operating in parallel, with

diode protection networks. Diode networks D5-D6 and D7-D8

serve to clamp the applied differential input voltage to the

OP179/OP279, thereby protecting the input transistors against

avalanche damage. The fundamental differences between these

two PNP gain stages are that the Q7-Q8 pair are normally OFF

and that their inputs are buffered from the operational amplifier

inputs by Q1-D1-D2 and Q9-D3-D4. Operation is best understood as a function of the applied common-mode voltage: When

the inputs of the OP179/OP279 are biased midway between the

supplies, the differential signal path gain is controlled by the

resistively loaded (via R7, R8) Q5-Q6. As the input common-mode

level is reduced toward the negative supply (V

NEG

or GND), the

input transistor current sources, I1 and I3, are forced into saturation, thereby forcing the Q1-D1-D2 and Q9-D3-D4 networks

into cutoff; however, Q5-Q6 remain active, providing input stage

gain. On the other hand, when the common-mode input voltage

is increased toward the positive supply, Q5-Q6 are driven into

cutoff, Q3 is driven into saturation, and Q4 becomes active,

providing bias to the Q7-Q8 differential pair. The point at which

the Q7-Q8 differential pair becomes active is approximately equal

to (V

POS

– 1 V).

I2

R5

4k⍀

D7

I1

R6

4k⍀

D8

D5 D6

R3

2.5k⍀

R4

2.5k⍀

Q4

Q3

Q2

Q5

Q6

Q9

Q1

R1

6k⍀

R2

3k⍀

V

POS

V

NEG

R7

2.2k⍀

R8

2.2k⍀

I3

D1

D2

D3

D4

V

O

– +

IN–

IN+

Q8

Q7

Figure 1. OP179/OP279 Equivalent Input Circuit

The key issue here is the behavior of the input bias currents

in this stage. The input bias currents of the OP179/OP279 over

the range of common-mode voltages from (V

NEG

+ 1 V) to

(V

POS

– 1 V) are the arithmetic sum of the base currents in Q1-Q5

and Q9-Q6. Outside of this range, the input bias currents are

dominated by the base current sum of Q5-Q6 for input signals

close to V

NEG

, and of Q1-Q5 (Q9-Q6) for input signals close to

V

POS

. As a result of this design approach, the input bias currents

in the OP179/OP279 not only exhibit different amplitudes, but

also exhibit different polarities. This input bias current behavior

is best illustrated in TPC 3. It is, therefore, of paramount

importance that the effective source impedances connected to

the OP179/OP279’s inputs are balanced for optimum dc and

ac performance.

100

60

0

10 10k1k1001

40

20

80

FREQUENCY – Hz

VOLTAGE NOISE DENSITY – nV/冪Hz

VS ⴝ 5V

T

A

ⴝ 25ⴗC

TPC 19. Voltage Noise Density vs.

Frequency

120

60

0

1k 1M100k10k100

40

20

80

100

FREQUENCY – Hz

COMMON-MODE REJECTION – dB

TA ⴝ 25ⴗC

V

S

ⴞ2.5V

TPC 21. Common-Mode

Rejection vs. Frequency

COMMON-MODE VOLTAGE – Volts

60

0

5

30

10

1

20

0

50

40

432

VOLTAGE NOISE DENSITY – nV/

冪

Hz

VS ⴝ 5V

T

A

ⴝ 25ⴗC

FREQUENCY ⴝ 1kHz

TPC 20. Voltage Noise Density vs.

Common-Mode Voltage

OP179/OP279

–7–

REV. G

In order to achieve rail-to-rail output behavior, the OP179/OP279

design employs a complementary common-emitter (or g

mRL

)

output stage (Q15-Q16), as illustrated in Figure 2. These

amplifiers provide output current until they are forced into

saturation, which occurs at approximately 50 mV from either

supply rail. Thus, their saturation voltage is the limit on the

maximum output voltage swing in the OP179/OP279. The

output stage also exhibits voltage gain, by virtue of the use of

common-emitter amplifiers; and, as a result, the voltage gain of

the output stage (thus, the open-loop gain of the device) exhibits a strong dependence to the total load resistance at the output

of the OP179/OP279 as illustrated in TPC 7.

Q7

Q3

Q15

Q9

105⍀

V

POS

V

NEG

Q13

V

OUT

Q4

Q16

I3

I4

Q11

Q12

Q5

Q10

I2

Q1

Q2

I1

Q8

Q6

105⍀

Q14

150⍀

Figure 2. OP179/OP279 Equivalent Output Circuit

Input Overvoltage Protection

As with any semiconductor device, whenever the condition

exists for the input to exceed either supply voltage, the device’s

input overvoltage characteristic must be considered. When an

overvoltage occurs, the amplifier could be damaged, depending

on the magnitude of the applied voltage and the magnitude of

the fault current. Figure 3 illustrates the input overvoltage characteristic of the OP179/OP279. This graph was generated with

the power supplies at ground and a curve tracer connected to

the input. As can be seen, when the input voltage exceeds either

supply by more than 0.6 V, internal pn-junctions energize,

which allows current to flow from the input to the supplies. As

illustrated in the simplified equivalent input circuit (Figure 1),

the OP179/OP279 does not have any internal current limiting

resistors, so fault currents can quickly rise to damaging levels.

This input current is not inherently damaging to the device as

long as it is limited to 5 mA or less. For the OP179/OP279, once

the input voltage exceeds the supply by more than 0.6 V, the

input current quickly exceeds 5 mA. If this condition continues to

exist, an external series resistor should be added. The size of the

resistor is calculated by dividing the maximum overvoltage by

5 mA. For example, if the input voltage could reach 100 V, the

external resistor should be (100 V/5 mA) = 20 kΩ. This resistance should be placed in series with either or both inputs if they

are exposed to an overvoltage. Again, in order to ensure optimum

dc and ac performance, it is important to balance source imped-

ance levels. For more information on general overvoltage characteristics of amplifiers refer to the 1993 Seminar Applications Guide,

available from the Analog Devices Literature Center.

5

–3

–5

–2.0

–4

1

–2

–1

2

3

4

2.01.00–1.0

0

INPUT CURRENT – mA

INPUT VOLTAGE – V

Figure 3. OP179/OP279 Input Overvoltage Characteristic

Output Phase Reversal

Some operational amplifiers designed for single-supply operation

exhibit an output voltage phase reversal when their inputs are

driven beyond their useful common-mode range. Typically for

single-supply bipolar op amps, the negative supply determines

the lower limit of their common-mode range. With these devices,

external clamping diodes, with the anode connected to ground

and the cathode to the inputs, input signal excursions are prevented from exceeding the device’s negative supply (i.e., GND),

preventing a condition that could cause the output voltage to

change phase. JFET input amplifiers may also exhibit phase

reversal and, if so, a series input resistor is usually required to

prevent it.

The OP179/OP279 is free from reasonable input voltage range

restrictions provided that input voltages no greater than the

supply voltages are applied. Although the device’s output will

not change phase, large currents can flow through the input

protection diodes, shown in Figure 1. Therefore, the technique

recommended in the Input Overvoltage Protection section should

be applied in those applications where the likelihood of input

voltages exceeding the supply voltages is possible.

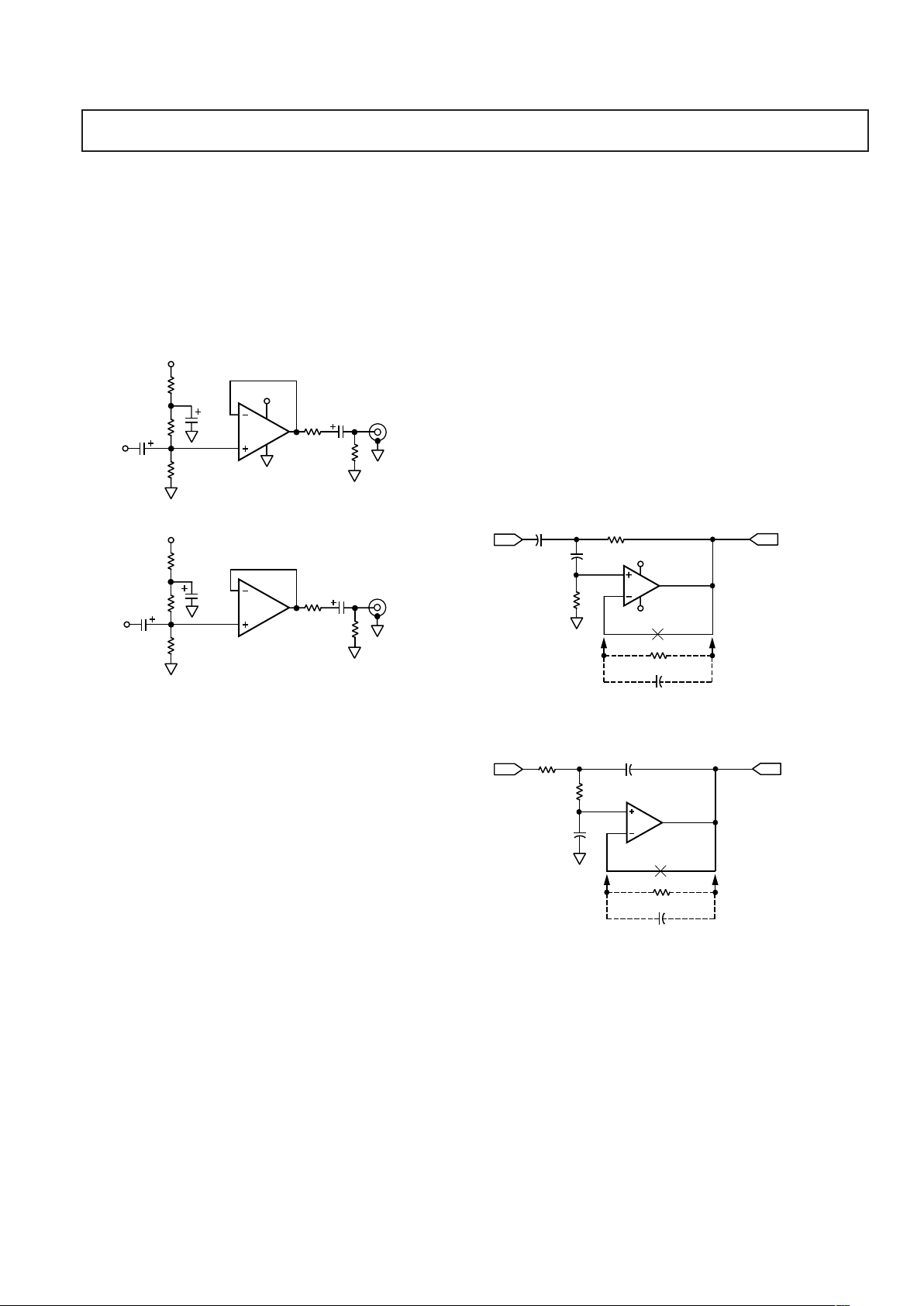

Capacitive Load Drive

The OP179/OP279 has excellent capacitive load driving capabilities. It can drive up to 10 nF directly as the performance

graph titled Small Signal Overshoot vs. Load Capacitance

(TPC 18) shows. However, even though the device is stable, a

capacitive load does not come without a penalty in bandwidth.

As shown in Figure 4, the bandwidth is reduced to under 1 MHz

for loads greater than 3 nF. A “snubber” network on the output

will not increase the bandwidth, but it does significantly reduce

the amount of overshoot for a given capacitive load. A snubber

consists of a series R-C network (R

S

, CS), as shown in Figure 5,

connected from the output of the device to ground. This network operates in parallel with the load capacitor, C

L

, to provide

phase lag compensation. The actual value of the resistor and

capacitor is best determined empirically.

OP179/OP279

–8–

REV. G

7

2

0

0.01 0.100 101

5

1

3

4

6

CAPACITIVE LOAD – nF

BANDWIDTH – MHz

VS ⴝ ⴞ5V

R

L

ⴝ 1k⍀

T

A

ⴝ 25ⴗC

Figure 4. OP179/OP279 Bandwidth vs. Capacitive Load

1/2

OP279

R

S

20V

C

S

1F

C

L

10nF

5V

V

IN

100mV p-p

V

OUT

Figure 5. Snubber Network Compensates for Capacitive

Load

The first step is to determine the value of the resistor, RS. A

good starting value is 100 Ω (typically, the optimum value will

be less than 100 Ω). This value is reduced until the small-signal

transient response is optimized. Next, C

S

is determined—10 µF

is a good starting point. This value is reduced to the smallest

value for acceptable performance (typically, 1 µF). For the case

of a 10 nF load capacitor on the OP179/OP279, the optimal

snubber network is a 20 Ω in series with 1 µF. The benefit is

immediately apparent as seen in the scope photo in Figure 6.

The top trace was taken with a 10 nF load and the bottom trace

with the 20 Ω, 1 µF snubber network in place. The amount of

overshot and ringing is dramatically reduced. Table I illustrates a

few sample snubber networks for large load capacitors.

90

100

10nF LOAD

ONLY

SNUBBER

IN CIRCUIT

10

0%

50mV

2s

Figure 6. Overshoot and Ringing Are Reduced by Adding

a “Snubber” Network in Parallel with the 10 nF Load

Table I. Snubber Networks for Large Capacitive Loads

Load Capacitance (CL) Snubber Network (RS, CS)

10 nF 20 Ω, 1 µF

100 nF 5 Ω, 10 µF

1 µF0 Ω, 10 µF

Overload Recovery Time

Overload, or overdrive, recovery time of an operational amplifier

is the time required for the output voltage to recover to its linear

region from a saturated condition. This recovery time is important in applications where the amplifier must recover after a

large transient event. The circuit in Figure 7 was used to

evaluate the OP179/OP279’s overload recovery time. The

OP179/OP279 takes approximately 1 µs to recover from positive

saturation and approximately 1.2 µs to recover from negative

saturation.

1/2

OP279

R

L

499⍀

+5V

V

OUT

–5V

R3

10k⍀

R2

1k⍀

R1

909⍀

2V p-p

@ 100Hz

Figure 7. Overload Recovery Time Test Circuit

Output Transient Current Recovery

In many applications, operational amplifiers are used to provide

moderate levels of output current to drive the inputs of ADCs,

small motors, transmission lines and current sources. It is in these

applications that operational amplifiers must recover quickly to

step changes in the load current while maintaining steady-state

load current levels. Because of its high output current capability

and low closed-loop output impedance, the OP179/OP279 is an

excellent choice for these types of applications. For example,

when sourcing or sinking a 25 mA steady-state load current, the

OP179/OP279 exhibits a recovery time of less than 500 ns to

0.1% for a 10 mA (i.e., 25 mA to 35 mA and 35 mA to 25 mA)

step change in load current.

A Precision Negative Voltage Reference

In many data acquisition applications, the need for a precision

negative reference is required. In general, any positive voltage

reference can be converted into a negative voltage reference

through the use of an operational amplifier and a pair of matched

resistors in an inverting configuration. The disadvantage to that

approach is that the largest single source of error in the circuit is

the relative matching of the resistors used.

The circuit illustrated in Figure 8 avoids the need for tightly

matched resistors with the use of an active integrator circuit. In

this circuit, the output of the voltage reference provides the

input drive for the integrator. The integrator, to maintain circuit

equilibrium, adjusts its output to establish the proper relationship between the reference’s V

OUT

and GND. Thus, various

negative output voltages can be chosen simply by substituting

for the appropriate reference IC (see table). To speed up the

OP179/OP279

–9–

REV. G

ON-OFF settling time of the circuit, R2 can be reduced to

50 kΩ or less. Although the integrator’s time constant chosen

here is 1 ms, room exists to trade off circuit bandwidth and

noise by increasing R3 and decreasing C2. The SHUTDOWN

feature is maintained in the circuit with the simple addition of a

PNP transistor and a 10 kΩ resistor. One caveat with this

approach should be mentioned: although rail-to-rail output

amplifiers work best in the application, these operational amplifiers require a finite amount (mV) of headroom when required

to provide any load current. The choice for the circuit’s negative

supply should take this issue into account.

R4

10⍀

1/2

OP279

+5V

–10V

R3

1k⍀

C2

1F

C1

1F

R2

100k⍀

U1

REF195

GND

R5

10k⍀

R1

10k⍀

2N3904

4

6

2

3

SHUTDOWN

TTL/CMOS

+5V

–V

REF

U1

REF192

REF193

REF196

REF194

V

OUT

(V)

2.5

3.0

3.3

4.5

Figure 8. A Negative Precision Voltage Reference That

Uses No Precision Resistors Exhibits High Output Current

Drive

A High Output Current, Buffered Reference/Regulator

Many applications require stable voltage outputs relatively close

in potential to an unregulated input source. This “low dropout”

type of reference/regulator is readily implemented with a rail-torail output op amp, and is particularly useful when using a

higher current device such as the OP179/OP279. A typical

example is the 3.3 V or 4.5 V reference voltage developed from

a 5 V system source. Generating these voltages requires a threeterminal reference, such as the REF196 (3.3 V) or the REF194

(4.5 V), both of which feature low power, with sourcing outputs

of 30 mA or less. Figure 9 shows how such a reference can be

outfitted with an OP179/OP279 buffer for higher currents and/

or voltage levels, plus sink and source load capability.

C2

0.1F

R2

10k⍀

1%

U2

1/2 OP279

V

OUT1

=

3.3V @ 30mA

R5

1⍀

C5

10F/25V

TANTALUM

R1

10k⍀

1%

C1

0.1F

V

S

5V

V

OUT2

=

3.3V

C4

1F

6

2

3

4

V

OUT

COMMON

C3

0.1F

V

C

ON/OFF

CONTROL

INPUT CMOS HI

(OR OPEN) = ON

LO = OFF

V

S

COMMON

R3

(SEE TEXT)

R4

3.3k⍀

U1

REF196

Figure 9. A High Output Current Reference/Regulator

The low dropout performance of this circuit is provided by stage

U2, one-half of an OP179/OP279 connected as a follower/buffer

for the basic reference voltage produced by U1. The low voltage

saturation characteristic of the OP179/OP279 allows up to 30 mA

of load current in the illustrated use, as a 5 V to 3.3 V converter

with high dc accuracy. In fact, the dc output voltage change for

a 30 mA load current delta measures less than 1 mV. This

corresponds to an equivalent output impedance of < 0.03 Ω. In

this application, the stable 3.3 V from U1 is applied to U2

through a noise filter, R1-C1. U2 replicates the U1 voltage

within a few mV, but at a higher current output at V

OUT1

, with

the ability to both sink and source output current(s)—unlike

most IC references. R2 and C2 in the feedback path of U2

provide bias compensation for lowest dc error and additional

noise filtering.

Transient performance of the reference/regulator for a 10 mA

step change in load current is also quite good and is determined

largely by the R5-C5 output network. With values as shown, the

transient is about 10 mV peak and settles to within 2 mV in 8 µs,

for either polarity. Although room exists for optimizing the

transient response, any changes to the R5-C5 network should

be verified by experiment to preclude the possibility of excessive

ringing with some capacitor types.

To scale V

OUT2

to another (higher) output level, the optional

resistor R3 (shown dotted) is added, causing the new V

OUT1

to

become:

VV

R

R

OUT1 OUT2

=×+

1

2

3

As an example, for a V

OUT1

= 4.5 V, and V

OUT2

= 2.5 V from a

REF192, the gain required of U2 is 1.8 times, so R2 and R3

would be chosen for a ratio of 0.8:1, or 18 kΩ:22.5 kΩ. Note that

for the lowest V

OUT1

dc error, the parallel combination of R2 and

R3 should be maintained equal to R1 (as here), and the R2-R3

resistors should be stable, close tolerance metal film types.

The circuit can be used as shown as either a 5 V to 3.3 V reference/

regulator, or it can be used with ON/OFF control. By driving

Pin 3 of U1 with a logic control signal as noted, the output is

switched ON/OFF. Note that when ON/OFF control is used,

resistor R4 should be used with U1 to speed ON-OFF switching.

Direct Access Arrangement for Telephone Line Interface

Figure 10 illustrates a 5 V only transmit/receive telephone line

interface for 110 Ω transmission systems. It allows full duplex

transmission of signals on a transformer coupled 110 Ω line in

a differential manner. Amplifier A1 provides gain that can be

adjusted to meet the modem output drive requirements. Both

A1 and A2 are configured to apply the largest possible signal on a

single supply to the transformer. Because of the OP179/OP279’s

high output current drive and low dropout voltage, the largest

signal available on a single 5 V supply is approximately 4.5 V p-p

into a 110 Ω transmission system. Amplifier A3 is configured as

a difference amplifier to extract the receive signal from the

transmission line for amplification by A4. A4’s gain can be adjusted

in the same manner as A1’s to meet the modem’s input signal

requirements. Standard resistor values permit the use of SIP

(Single In-line Package) format resistor arrays. Couple this with

the OP179/OP279’s 8-lead SOIC footprint and this circuit

offers a compact, cost-sensitive solution.

OP179/OP279

–10–

REV. G

6.2V

6.2V

TRANSMIT

TXA

RECEIVE

RXA

C1

0.1F

R1

10k⍀

R2

9.09k⍀

2k⍀

P1

TX GAIN

ADJUST

A1

A2

A3

A4

A1, A2 = 1/2 OP279

A3, A4 = 1/2 OP279

R3

55⍀

R4

55⍀

1:1

T1

TO TELEPHONE

LINE

1

2

3

7

6

5

2

3

1

6

5

7

10F

R7

10k⍀

R8

10k⍀

R5

10k⍀

R6

10k⍀

R9

10k⍀

R14

9.09k⍀

R10

10k⍀

R11

10k⍀

R12

10k⍀

R13

10k⍀

C2

0.1F

P2

RX GAIN

ADJUST

2k⍀

Z

O

110⍀

5V DC

Figure 10. A Single-Supply Direct Access Arrangement for

Modems

A Single-Supply, Remote Strain Gage Signal Conditioner

The circuit in Figure 11 illustrates a way by which the OP179/

OP279 can be used in a 12 V single supply, 350 Ω strain gage

signal conditioning circuit. In this circuit, the OP179/OP279

serves two functions: (1) By servoing the output of the REF43’s

2.5 V output across R1, it provides a 20 mA drive to the 350 Ω

strain gage. In this way, small changes in the strain gage produce large differential output voltages across the AMP04’s

inputs. (2) To maximize the circuit’s dynamic range, the other

half of the OP179/OP279 is configured as a supply-splitter

connected to the AMP04’s REF terminal. Thus, tension or

compression in the application can be measured by the circuit.

REF43

AMP04

0.1F

2

6

4

2.5V

3

1

8

4

2

A1

7

1

8

6

3

2

4

C

X

C2

0.1F

R4

1k⍀

12V

5

V

O

80mV/⍀

V

O

COMMON

R1

124⍀

0.1%, LOW TCR

100-ft TWISTED PAIR

BELDEN TYPE 9502

S+

S–

350⍀

STRAIN GAGE

F–

F+

A2

12V

R2

10k⍀

R3

10k⍀

C1

10F

7

6

5

+6V

A1, A2 = 1/2 OP279

12V

20mA DRIVE

Figure 11. A Single-Supply, Remote Strain Gage Signal

Conditioner

The AMP04 is configured for a gain of 100, producing a circuit

sensitivity of 80 mV/Ω. Capacitor C2 is used across the AMP04’s

Pins 8 and 6 to provide a 16-Hz noise filter. If additional noise

filtering is required, an optional capacitor, C

X

, can be used across

the AMP04’s input to provide differential-mode noise rejection.

A Single-Supply, Balanced Line Driver

The circuit in Figure 12 is a unique line driver circuit topology

used in professional audio applications and has been modified

for automotive audio applications. On a single 12 V supply, the

line driver exhibits less than 0.02% distortion into a 600 Ω load

across the entire audio band (not shown). For loads greater than

600 Ω, distortion performance improves to where the circuit

exhibits less than 0.002%. The design is a transformerless, balanced

transmission system where output common-mode rejection of

noise is of paramount importance. Like the transformer-based

system, either output can be shorted to ground for unbalanced

line driver applications without changing the circuit gain of 1.

Other circuit gains can be set according to the equation in the

diagram. This allows the design to be easily configured for

noninverting, inverting, or differential operation.

R

L

600⍀

C1

22F

A2

7

6

5

3

1

2

A1

12V

R1

10k⍀

R2

10k⍀

R11

10k⍀

R7

10k⍀

6

7

5

A1

12V

12V

R8

100k⍀

R9

100k⍀

C2

1F

R12

10k⍀

R14

50⍀

A2

1

2

3

R3

10k⍀

R6

10k⍀

R13

10k⍀

C3

47F

V

O1

V

O2

C4

47F

A1, A2 = 1/2 OP279

GAIN =

R3

R2

SET: R7, R10, R11 = R2

SET: R6, R12, R13 = R3

V

IN

R5

50⍀

Figure 12. A Single-Supply, Balanced Line Driver for

Automotive Applications

OP179/OP279

–11–

REV. G

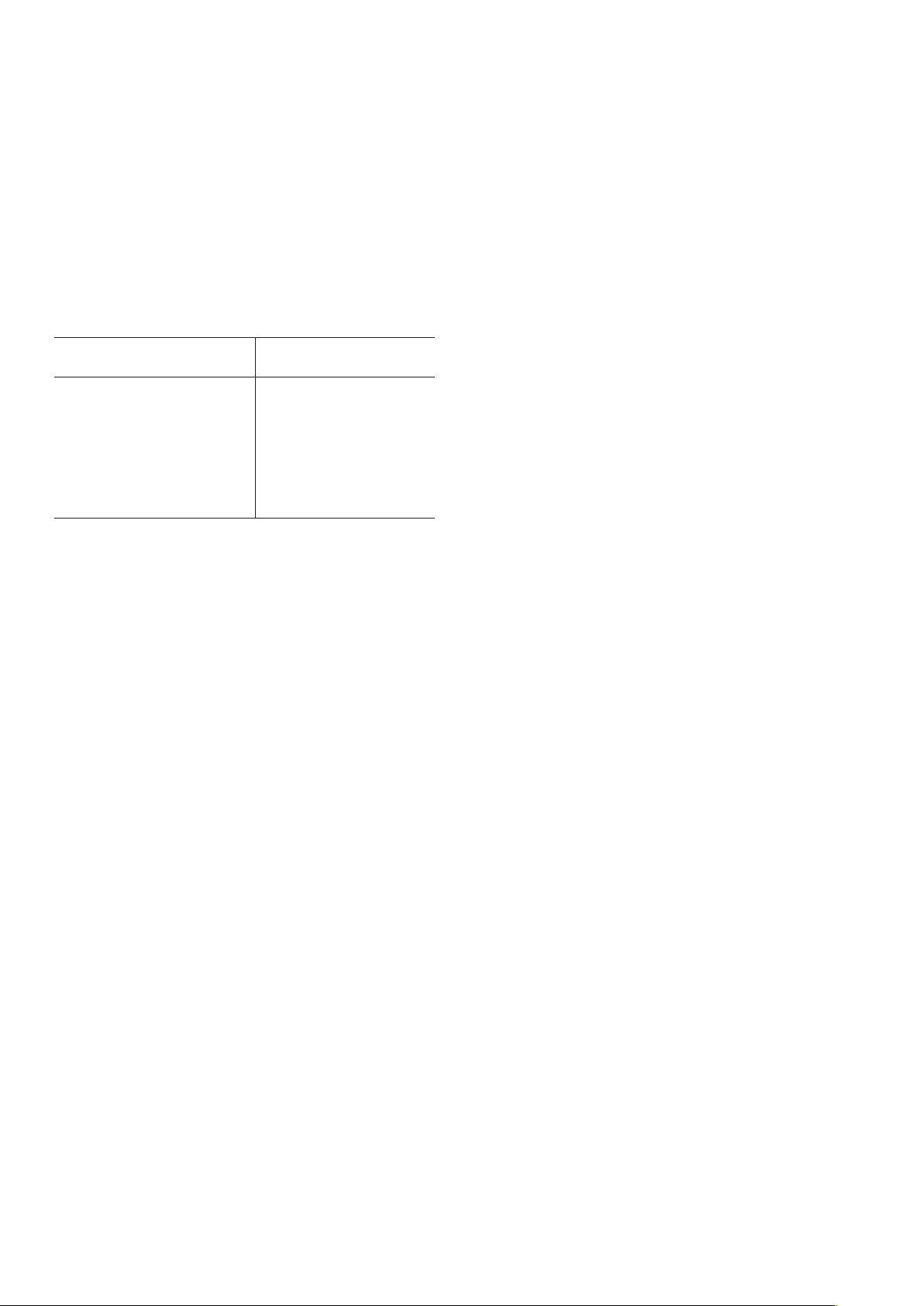

UNITY-GAIN, SALLEN-KEY (VCVS) FILTERS

High Pass Configurations

Figure 14a is the HP form of a unity-gain 2-pole SK filter

using an OP179/OP279 section. For this filter and its LP counterpart, the gain in the passband is inherently unity, and the

signal phase is noninverting due to the follower hookup. For

simplicity and practicality, capacitors C1-C2

are set equal, and

resistors R2-R1

are adjusted to a ratio “N,” which provides the

filter damping “α” as per the design expressions. An HP design

starts with the selection of standard capacitor values for C1 and

C2, and a calculation of N. R1 and R2 are then calculated as

per the figure expressions.

In these examples, α (or 1/Q) is set equal to √2, providing a

Butterworth (maximally flat) response characteristic. The filter

corner frequency is normalized to 1 kHz, with resistor values

shown in both rounded and (exact) form. Various other two-pole

response shapes are also possible with appropriate selection of

α. For a given response type (α), frequency can be easily scaled,

using proportional R or C values.

+V

S

–V

S

U1A

OP279

1

3

2

4

8

IN

R2

22k⍀

(22.508k⍀)

R1

11k⍀

(11.254k⍀)

C2

0.01F

R = R2

0.1F

Z

f

(HIGH PASS)

C1

0.01F

GIVEN: ALPHA, F

SET C1 = C2 = C

ALPHA = 2/(N^0.5) = 1/Q

N = 4/(ALPHA)^2 = R2/R1

R1 = 1/(2*PI*F*C* (N^0.5))

R2 = N*R1

1kHz BW SHOWN

OUT

7

5

6

R = R1+R2

Z

f

(LOW PASS)

GIVEN: ALPHA, F

SET R1 = R2 = R

ALPHA = 2/(M^0.5) = 1/Q

N = 4/(ALPHA)^2 = C2/C1

PICK C1

C1 = M*C1

R = 1/(2*P1*F*C1* (M^0.5))

1kHz BW SHOWN

IN

R2

11k⍀

(11.254k⍀)

C2

0.01F

0.1F

C1

0.02F

OUT

U1B

OP279

R1

11k⍀

(11.254k⍀)

a. High Pass

b. Low Pass

Figure 14. Two-Pole Unity-Gain Sallen Key HP/LP Filters

Low Pass Configurations

In the LP SK arrangement of Figure 14b, R and C elements are

interchanged, and the resistors are made equal. Here the C2/C1

ratio “M” is used to set the filter α, as noted. This design is begun

with the choice of a standard capacitor value for C1 and a calculation of M, which forces a value of “M × C1” for C2. Then, the

value “R” for R1 and R2 is calculated as per the expression.

For highest performance, the passive components used for tuning active filters deserve attention. Resistors should be 1%, low

TC, metal film types of the RN55 or RN60 style, or similar.

A Single-Supply Headphone Amplifier

Because of its high speed and large output drive, the OP179/P279

makes for an excellent headphone driver, as illustrated in Figure

13. Its low supply operation and rail-to-rail inputs and outputs

give a maximum signal swing on a single 5 V supply. To ensure

maximum signal swing available to drive the headphone, the

amplifier inputs are biased to V+/2, which is in this case 2.5 V.

The 100 kΩ resistor to the positive supply is equally split into

two 50 kΩ with their common point bypassed by 10 µF to pre-

vent power supply noise from contaminating the audio signal.

16⍀

50k⍀

220F

LEFT

HEADPHONE

10F

50k⍀

50k⍀

100k⍀

10F

LEFT

INPUT

+V + 5V

1/2

OP279

16⍀

50k⍀

220F

RIGHT

HEADPHONE

10F

50k⍀

50k⍀

100k⍀

10F

RIGHT

INPUT

+V

+V + 5V

1/2

OP279

Figure 13. A Single-Supply, Stereo Headphone Driver

The audio signal is then ac-coupled to each input through a

10 µF capacitor. A large value is needed to ensure that the

20 Hz audio information is not blocked. If the input already has

the proper dc bias, the ac coupling and biasing resistors are not

required. A 220 µF capacitor is used at the output to couple the

amplifier to the headphone. This value is much larger than that

used for the input because of the low impedance of the headphones, which can range from 32 Ω to 600 Ω. An additional

16 Ω resistor is used in series with the output capacitor to protect the op amp’s output stage by limiting capacitor discharge

current. When driving a 48 Ω load, the circuit exhibits less than

0.02% THD+N at low output drive levels (not shown). The

OP179/OP279’s high current output stage can drive this heavy

load to 4 V p-p and maintain less than 1% THD+N.

Active Filters

Several active filter topologies are useful with the OP179/OP279.

Among these are two popular architectures, the familiar SallenKey (SK) voltage controlled voltage source (VCVS) and the

multiple feedback (MFB) topologies. These filter types can be

arranged for high pass (HP), low pass (LP), and band-pass (BP)

filters. The SK filter type uses the op amp as a fixed gain voltage

follower at unity or a higher gain, while the MFB structure uses

it as an inverting stage. Discussed here are simplified, 2-pole

forms of these filters, highly useful as system building blocks.

OP179/OP279

–12–

REV. G

loading can be tempered somewhat by using a small series input

resistance of about 100 Ω, but can still be an issue.

7

6

5

0.1F

GIVEN:

ALPHA, F AND H (PASSBAND GAIN)

ALPHA = 1/Q

PICK A STD C1 VALUE, THEN:

C3 = C1, C2 = C1/H

R1 = ALPHA/((2*PI*F*C1)*(2+(1/H)))

R2 = (H*(2+(1/H)))/(ALPHA*(2*PI*F*C1))

1kHz BW EXAMPLE SHOWN

(NOTE: SEE TEXT ON C1 LOADING

CONSIDERATIONS)

IN

R1

7.5k⍀

OUT

U1B

OP279

R2

33.6k⍀

C3

0.01F

C2

0.01F

C1

0.01F

Z

b

R = R2

Figure 15. Two-Pole, High Pass Multiple Feedback Filters

In this example, the filter gain is set to unity, the corner frequency is 1 kHz, and the response is a Butterworth type. For

applications where dc output offset is critical, bias current compensation can be used for the amplifier. This is provided by

network Z

b

, where R is equal to R2, and the capacitor provides

a noise bypass.

Low Pass Configurations

Figure 16 is a LP MFB 2-pole filter using an OP179/OP279

section. For this filter, the gain in the pass band is user configurable over a wide range, and the pass band signal phase is

inverting. Given the design parameters for α, F, and H, a simplified

design process is begun by picking a standard value for C2. Then

C1

and resistors R1-R3 are selected as per the relationships

noted. Optional dc bias current compensation is provided by Z

b

,

where R is equal to the value of R3 plus the parallel equivalent

value of R1

and R2.

7

5

6

(R1 R2)+R3

GIVEN:

ALPHA, F AND H (PASSBAND GAIN)

ALPHA = 1/Q

PICK A STD C2 VALUE, THEN:

C1 = C2 • (4 • (H +1))/ALPHA^2

R1 = ALPHA/(4 • H • PI • F • C2)

R2 = H • R1

R3 = ALPHA/(4 • (H + 1) • PI • F • C2)

1kHz BW EXAMPLE SHOWN

(NOTE: SEE TEXT ON C1 LOADING

CONSIDERATIONS)

IN

OUT

U1B

OP279

R1

11.3k⍀

R2

11.3k⍀

R3

5.62k⍀

C2

0.01F

0.1F

Z

b

C1

0.04F

Figure 16. Two-Pole, Low-Pass Multiple Feedback Filters

Gain of this filter, H, is set here by resistors R2 and R1 (as in a

standard op amp inverter), and can be just as precise as these

resistors allow at low frequencies. Because of this flexible and

accurate gain characteristic, plus a low range of component

value spread, this filter is perhaps the most practical of all the

MFB types. Capacitor ratios are best satisfied by paralleling two

or more common types, as in the example, which is a 1 kHz

unity-gain Butterworth filter.

Capacitors should be 1% or 2% film types preferably, such as

polypropylene or polystyrene, or NPO (COG) ceramic for

smaller values. Somewhat lesser performance is available with

the use of polyester capacitors.

Parasitic Effects in Sallen-Key Implementations

In designing these circuits, moderately low (10 kΩ or less) values for R1-R2 can be used to minimize the effects of Johnson

noise when critical, with, of course, practical tradeoffs of capacitor size and expense. DC errors will result for larger values of

resistance, unless bias current compensation is used. To add

bias compensation in the HP filter of Figure 14a, a feedback

compensation resistor with a value equal to R2 is used, shown

optionally as Z

f

. This will minimize bias induced offset, reduc-

ing it to the product of the OP179/OP279’s I

OS

and R2. Similar

compensation is applied to the LP filter, using a Z

f

resistance of

R1 + R2. Using dc compensation and relatively low filter values,

filter output dc errors using the OP179/OP279 will be dominated by V

OS

, which is limited to 4 mV or less. A caveat here is

that the additional resistors increase noise substantially—for

example, an unbypassed 10 kΩ resistor generates ≈ 12 nV/√Hz

of noise. However, the resistance can be ac-bypassed to eliminate noise with a simple shunt capacitor, such as 0.1 µF.

Sallen-Key Implementations in Single-Supply Applications

The hookups shown illustrate a classical dual supply op amp

application, which for the OP179/OP279 would use supplies up

to ±5 V. However, these filters can also use the op amp in a

single-supply mode, with little if any alteration to the filter itself.

To operate single supply, the OP179/OP279 is powered from

5 V at Pin 8 with Pin 4 grounded. The input dc bias for the op

amp must be supplied from a dc source equal to one-half supply,

or 2.5 V in this case.

For the HP section, dc bias is applied to the common end of R2.

R2 is simply returned to an ac ground that is a well-bypassed

2:1 divider across the 5 V source. This can be as simple as a pair

of 100 kΩ resistors with a 10 µF bypass cap. The output from

the stage is then ac coupled, using an appropriate coupling cap

from U1A to the next stage. For the LP section dc bias is applied

to the input end of R1, in common with the input signal. This

dc can be taken from an unbypassed dual 100 kΩ divider across

the supply, with the input signal ac coupled to the divider and R1.

Multiple Feedback Filters

MFB filters, like their SK relatives, can be used as building

blocks as well. They feature LP and HP operation as well, but

can also be used in a band-pass BP mode. They have the property

of inverting operation in the pass band, since they are based on

an inverting amplifier structure. Another useful asset is their

ability to be easily configured for gain.

High Pass Configurations

Figure 15 shows an HP MFB 2-pole filter using an OP179/

OP279 section. For this filter, the gain in the pass band is user

configurable, and the signal phase is inverting. The circuit uses

one more tuning component than the SK types. For simplicity,

capacitors C1 and C3

are set to equal standard values, and resis-

tors R1-R2

are selected as per the relationships noted. Gain of

this filter, H, is set by capacitors C1 and C2, and this factor

limits both gain selectability and precision. Also, input capacitance C1 makes the load seen by the driving stage highly reactive,

and limits overall practicality of this filter. The dire effect of C1

OP179/OP279

–13–

REV. G

V

IN

3

2

1

U1A

OP279

+V

S

4

–V

S

R1

31.6k⍀

C1

0.01F

C2

0.01F

R2

31.6k⍀

R5

31.6k⍀

R6

31.6k⍀

R4

49.9⍀

HI

LO

500Hz AND UP

DC – 500Hz

6

5

7

C3

0.01F

U1B

OP279

C4

0.02F

R7

15.8k⍀

R3

49.9⍀

0.1F

0.1F

100F/25V

100F/25V

+V

S

–V

S

TO U1

+5V

–5V

COM

Figure 18. Two-Way Active Crossover Networks

In the filter sections, component values have been selected for

good balance between reasonable physical/electrical size, and

lowest noise and distortion. DC offset errors can be minimized

by using dc compensation in the feedback and bias paths, ac

bypassed with capacitors for low noise. Also, since the network

input is reactive, it should driven from a directly coupled low

impedance source at V

IN

.

Figure 19 shows this filter architecture adapted for single-supply

operation from a 5 V dc source, along the lines discussed

previously.

V

IN

3

2

1

U1A

OP279

+V

S

4

R1

31.6k⍀

C1

0.01F

C2

0.01F

R2

31.6k⍀

R5

31.6k⍀

R6

31.6k⍀

R4

49.9⍀

HI

LO

500Hz

AND UP

DC –

500Hz

6

5

7

C3

0.01F

U1B

OP279

C4

0.02F

R7

15.8k⍀

R3

49.9⍀

10F

10F

100k⍀

+V

S

10F

100k⍀

100k⍀

C

IN

10F

R

IN

100k⍀

0.1F 100F/25V

+V

S

TO U1

+5V

COM

+

100k⍀

+

Figure 19. A Single-Supply, Two-Way Active Crossover

Band-pass Configurations

The MFB band-pass filter using an OP179/OP279 section is

shown in Figure 17. This filter provides reasonably stable medium

Q designs for frequencies of up to a few kHz. For best predictability and stability, operation should be restricted to

applications where the OP179/OP279 has an open-loop gain

in excess of 2Q

2

at the filter center frequency.

7

6

5

R = R3

0.1F

GIVEN:

Q, F, AND A

O

(PASSBAND GAIN)

ALPHA = 1/Q, H = A

O

/Q

PICK A STD C1 VALUE, THEN:

C2 = C1

R1 = 1/(H*(2*PI*F*C1))

R2 = 1/(((2*Q) –H)*(2*PI*F*C1))

R3 = Q/(PI*F*C1)

EXAMPLE: 60Hz, Q = 10,

AO = 10 (OR 1)

A

O

= 1 FOR '( )' VALUES

IN

R2

1.4k⍀

(1.33k⍀)

OUT

U1B

OP279

R3

530k⍀

C2

0.1F

C1

0.1F

Z

b

R1

26.4k⍀

(264k⍀)

Figure 17. Two-Pole, Band-pass Multiple Feedback Filters

Given the band-pass design parameters for Q, F, and pass band

gain A

O

, the design process is begun by picking a standard value

for C1. Then C2

and resistors R1-R3 are selected as per the

relationships noted. This filter is subject to a wide range of

component values by nature. Practical designs should attempt

to restrict resistances to a 1 kΩ to 1 MΩ range, with capacitor

values of 1 µF or less. When needed, dc bias current compensa-

tion is provided by Z

b

, where R is equal to R3.

Two-Way Loudspeaker Crossover Networks

Active filters are useful in loudspeaker crossover networks for

reasons of small size, relative freedom from parasitic effects,

and the ease of controlling low/high channel drive, plus the controlled driver damping provided by a dedicated amplifier. Both

Sallen-Key (SK) VCVS and multiple-feedback (MFB) filter

architectures are useful in implementing active crossover

networks (see Reference 4, page 14), and the circuit shown in

Figure 18 is a two-way active crossover that combines the advantages of both filter topologies. This active crossover exhibits less

than 0.01% THD+N at output levels of 1 V rms using general

purpose unity gain HP/LP stages. In this two-way example, the

LO signal is a dc-500 Hz LP woofer output, and the HI signal is

the HP (> 500 Hz) tweeter output. U1B forms an MFB LP

section at 500 Hz, while U1A provides an SK HP section, covering frequencies ≥ 500 Hz.

This crossover network is a Linkwitz-Riley type

(see Reference 5,

page 14), with a damping factor or α of 2 (also referred to as

“Butterworth squared”). A hallmark of the Linkwitz-Riley type

of filter is the fact that the summed magnitude response is flat

across the pass band. A necessary condition for this to happen

is the relative signal polarity of the HI output must be inverted

with respect to the LOW outputs. If only SK filter sections were

used, this requires that the connections to one speaker be reversed

on installation. Alternately, with one inverting stage used in the

LO channel, this accomplishes the same effect. In the circuit as

shown, stage U1B is the MFB LP filter, which provides the

necessary polarity inversion. Like the SK sections, it is configured for unity gain and an α of 2. The cutoff frequency is 500 Hz,

which complements the SK HP section of U4.

OP179/OP279

–14–

REV. G

References on Active Filters and Active Crossover Networks

1. Sallen, R.P.; Key, E.L., “A Practical Method of Designing

RC Active Filters,” IRE Transactions on Circuit Theory, Vol.

CT-2, March 1955.

2. Huelsman, L.P.; Allen, P.E., Introduction to the Theory and

Design of Active Filters, McGraw-Hill, 1980.

3. Zumbahlen, H., “Chapter 6: Passive and Active Analog

Filtering,” within 1992 Analog Devices Amplifier Applications

Guide.

4. Zumbahlen, H., “Speaker Crossovers,” within Chapter 8 of

1993 Analog Devices System Applications Guide.

5. Linkwitz, S., “Active Crossover Networks for Noncoincident

Drivers,” JAES, Vol. 24, #1, Jan/Feb 1976.

The crossover example frequency of 500 Hz can be shifted lower

or higher by frequency scaling of either resistors or capacitors. In

configuring the circuit for other frequencies, complementary LP/

HP action must be maintained between sections, and component

values within the sections must be in the same ratio. Table II

provides a design aid to adaptation, with suggested standard

component values for other frequencies.

Table II. RC Component Selection for Various Crossover

Frequencies

R1/C1 (U1A)*

Crossover Frequency (Hz) R5/C3 (U1B)**

100 160 kΩ/0.01 µF

200 80.6 kΩ/0.01 µF

319 49.9 kΩ/0.01 µF

500 31.6 kΩ/0.01 µF

1 k 16 kΩ/0.01 µF

2 k 8.06 kΩ/0.01 µF

5 k 3.16 kΩ/0.01 µF

10 k 1.6 kΩ/0.01 µF

Table notes (applicable for α = 2).

** For SK stage U1A: R1 = R2, and C1 = C2, etc.

** For MFB stage U1B: R6 = R5, R7 = R5/2, and C4 = 2C3.

OP179/OP279

–15–

REV. G

R10 16 98 10

C3 15 16 15.915E-12

*

* ZERO AT 1.5 MHz

*

E1 14 98 (9,39) 1E6

R5 14 18 1E6

R6 18 98 1

C4 14 18 106.103E-15

*

* BIAS CURRENT-VS-COMMON-MODE VOLTAGE

*

EP 97 0 (99,0) 1

EN 51 0 (50,0) 1

V3 20 21 1.6

V4 22 23 2.8

R12 97 20 530

R13 23 51 1E3

D13 15 21 DX

D14 22 15 DX

FIB 98 24 POLY(2) V3 V4 0 –1 1

RIB 24 98 10E3

E3 97 25 POLY(1) (99,39) –1.63 1

E4 26 51 POLY(1) (39,50) –2.73 1

D15 24 25 DX

D16 26 24 DX

*

* POLE AT 6 MHz

*

G6 98 40 (18,39) 1E 6

R20 40 98 1E6

C10 40 98 26.526E-15

*

* OUTPUT STAGE

*

RS1 99 39 6.0345E3

RS2 39 50 6.0345E3

RO1 99 45 40

RO2 45 50 40

G7 45 99 (99,40) 25E-3

G8 50 45 (40,50) 25E-3

G9 98 60 (45,40) 25E-3

D9 60 61 DX

D10 62 60 DX

V7 61 98 DC 0

V8 98 62 DC 0

FSY 99 50 POLY(2) V7 V8 1.711E-3 1 1

D11 41 45 DZ

D12 45 42 DZ

V5 40 41 1.54

V6 42 40 1.54

.MODEL DX D()

.MODEL DZ D(IS=1E-6)

.MODEL QN NPN(BF=300)

.ENDS

OP179/OP279 Spice Macro Model

* OP179/OP279 SPICE Macro Model Rev. A, 5/94

* ARG / ADI

*

* Copyright 1994 by Analog Devices

*

* Refer to “README.DOC” file for License Statement. Use of

* this model indicates your acceptance of the terms and pro-

* visions in the License Statement.

*

* Node assignments

* noninverting input

* | inverting input

* | | positive supply

* | | | negative supply

* ||||output

* |||||

.SUBCKT OP179/OP279 3 2 99 50 45

*

* INPUT STAGE AND POLE AT 6 MHz

*

I1 1 50 60.2E-6

Q1 5 2 7 QN

Q2 6 4 8 QN

D1 4 2 DX

D2 2 4 DX

R1 1 7 1.628E3

R2 1 8 1.628E3

R3 5 99 2.487E3

R4 6 99 2.487E3

C1 5 6 5.333E-12

EOS 4 3 POLY(1) (16,39) 0.25E-3 50.118

IOS 2 3 5E-9

GB1 2 98 (24,98) 100E-9

GB2 4 98 (24,98) 100E-9

CIN 2 3 1E-12

*

* GAIN STAGE AND DOMINANT POLE AT 16 Hz

*

EREF 98 0 (39,0) 1

G1 98 9 (5,6) 402.124E-6

R7 9 98 497.359E6

C2 9 98 20E-12

V1 99 10 0.58

V2 11 50 0.47

D5 9 10 DX

D6 11 9 DX

*

* COMMON-MODE STAGE WITH ZERO AT 10 kHz

*

ECM 15 98 POLY(2) (3,39) (2,39) 0 0.5 0.5

R9 15 16 1E6

OP179/OP279

–16–

REV. G

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

C00290–0–1/02(G)

PRINTED IN U.S.A.

8-Lead TSSOP

(RU-8)

8

5

4

1

0.122 (3.10)

0.114 (2.90)

0.256 (6.50)

0.246 (6.25)

0.177 (4.50)

0.169 (4.30)

PIN 1

0.0256 (0.65)

BSC

SEATING

PLANE

0.006 (0.15)

0.002 (0.05)

0.0118 (0.30)

0.0075 (0.19)

0.0433

(1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

0.028 (0.70)

0.020 (0.50)

8ⴗ

0ⴗ

8-Lead Narrow-Body SO

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

85

41

0.2440 (6.20)

0.2284 (5.80)

PIN 1

0.1574 (4.00)

0.1497 (3.80)

0.0688 (1.75)

0.0532 (1.35)

SEATING

PLANE

0.0098 (0.25)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

0.0500

(1.27)

BSC

0.0098 (0.25)

0.0075 (0.19)

0.0500 (1.27)

0.0160 (0.41)

8°

0°

0.0196 (0.50)

0.0099 (0.25)

x 45°

5-Lead SOT-23

(RT-5)

0.0079 (0.200)

0.0035 (0.090)

0.0236 (0.600)

0.0039 (0.100)

10ⴗ

0ⴗ

0.0197 (0.500)

0.0118 (0.300)

0.0590 (0.150)

0.0000 (0.000)

0.0512 (1.300)

0.0354 (0.900)

SEATING

PLANE

0.0571 (1.450)

0.0354 (0.900)

0.1220 (3.100)

0.1063 (2.700)

PIN 1

0.0709 (1.800)

0.0590 (1.500)

0.1181 (3.000)

0.0984 (2.500)

1 3

4 5

0.0748 (1.900)

REF

0.0374 (0.950) REF

2

NOTE:

PACKAGE OUTLINE INCLUSIVE AS SOLDER PLATING.

Revision History

Location Page

Data Sheet changed from REV. F to REV. G.

Edits to GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to PIN CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to PACKAGE TYPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loading...

Loading...