Quad 12-Bit Serial

a

FEATURES

Guaranteed Monotonic Over Temperature

Excellent Matching Between DACs

Unipolar or Bipolar Operation

Buffered Voltage Outputs

High Speed Serial Digital Interface

Reset to Zero- or Center-Scale

Wide Supply Range, +5 V-Only to 615 V

Low Power Consumption (35 mW max)

Available in 16-Pin DIP and SOL Packages

APPLICATIONS

Software Controlled Calibration

Servo Controls

Process Control and Automation

ATE

GENERAL DESCRIPTION

The DAC8420 is a quad, 12-bit voltage-output DAC with serial

digital interface, in a 16-pin package. Utilizing BiCMOS technology, this monolithic device features unusually high circuit

density and low power consumption. The simple, easy-to-use

serial digital input and fully buffered analog voltage outputs

require no external components to achieve specified performance.

The three-wire serial digital input is easily interfaced to microprocessors running at 10 MHz rates, with minimal additional

circuitry. Each DAC is addressed individually by a 16-bit serial

word consisting of a 12-bit data word and an address header.

The user-programmable reset control

outputs to either zero or midscale, asynchronously overriding

the current DAC register values. The output voltage range, determined by the inputs VREFHI and VREFLO, is set by the

user for positive or negative unipolar or bipolar signal swings

within the supplies allowing considerable design flexibility.

CLR forces all four DAC

Voltage Output DAC

DAC8420

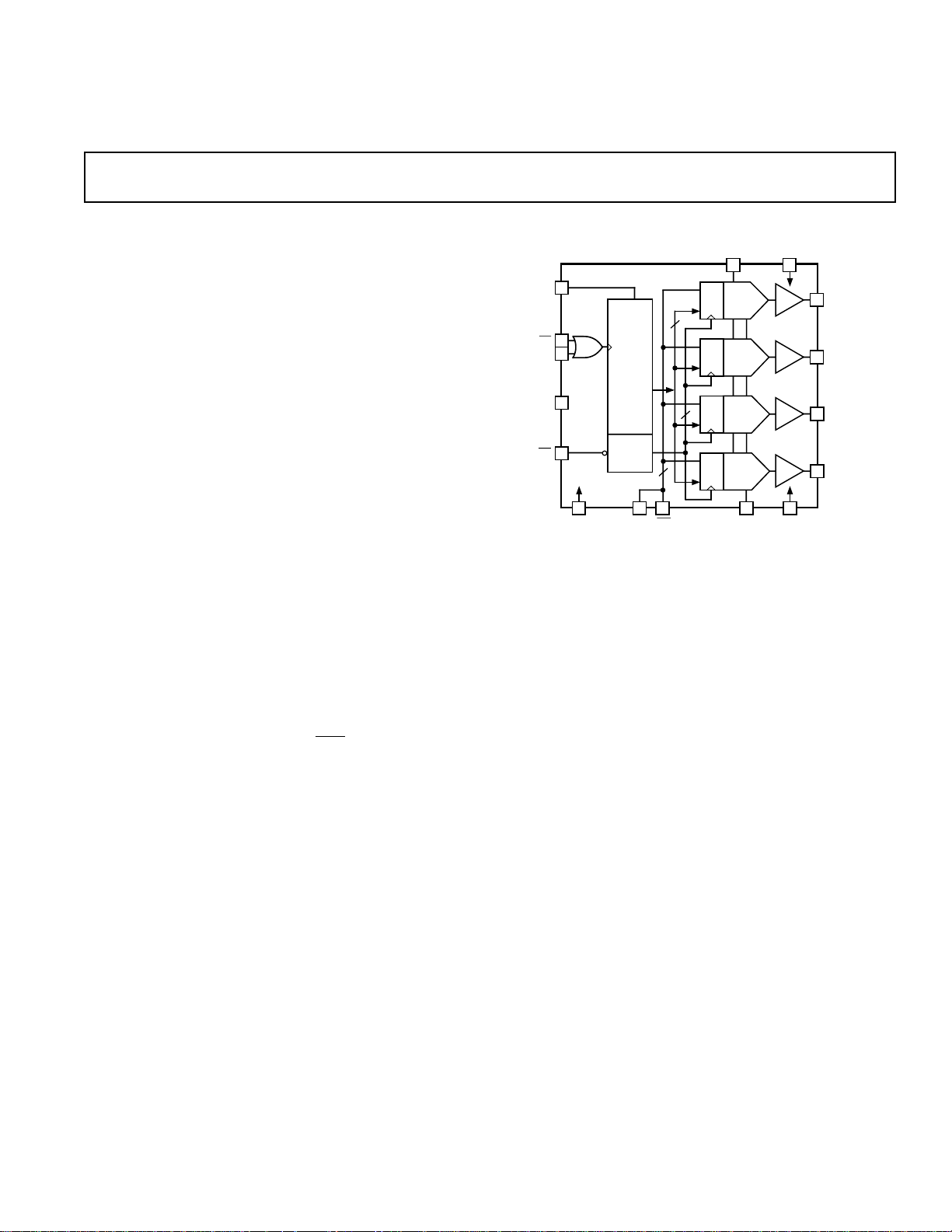

FUNCTIONAL BLOCK DIAGRAM

VREFHI

5

10

SDI

CLK

12

CS

11

NC

13

14

LD

GND

SHIFT

REGISTER

DECODE

CLSEL

CLR

REG

REG

DAC A

A

A

12

REG

DAC B

B

REG

DAC C

4

C

REG

DAC D

D

2

VREFLO VSS

The DAC8420 is available in 16-pin epoxy DIP, cerdip, and

wide-body SOL (small-outline surface mount) packages. Operation is specified with supplies ranging from +5 V-only to ± 15 V,

with references of +2.5 V to ±10 V respectively. Power dissipation when operating from ±15 V supplies is less than 255 mW

(max), and only 35 mW (max) with a +5 V supply.

For applications requiring product meeting MIL-STD-883,

contact your local sales office for the DAC8420/883 data sheet,

which specifies operation over the –55°C to +125°C temperature range.

VDD

1

VOUTA

7

VOUTB

6

3

VOUTC

2

VOUTD

815169

4

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

DAC8420–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

VSS = –5.0 V 6 5%, V

= –2.5 V, –408C ≤ TA ≤ +858C unless otherwise noted. See Note 1 for supply variations.)

VREFLO

(at VDD = +5.0 V 6 5%, VSS = 0.0 V, V

VREFHI

= +2.5 V, V

= 0.0 V, and

VREFLD

Parameter Symbol Condition Min Typ Max Units

STATIC ACCURACY

Integral Linearity “E” INL ±1/4 ±1 LSB

Integral Linearity “E” INL Note 2, V

= 0 V ±1/2 ±3 LSB

SS

Integral Linearity “F” INL ±3/4 ±2 LSB

Integral Linearity “F” INL Note 2, V

= 0 V ±1 ±4 LSB

SS

Differential Linearity DNL Monotonic Over Temperature ±1/4 ±1 LSB

Min-Scale Error ZSE R

Full-Scale Error FSE R

Min-Scale Error ZSE Note 2, R

Full-Scale Error FSE Note 2, R

Min-Scale Tempco TC

Full-Scale Tempco TC

ZSE

FSE

= 2 kΩ, VSS = –5 V ±4 LSB

L

= 2 kΩ, VSS = –5 V ±4 LSB

L

= 2 kΩ, VSS = 0 V ±8 LSB

L

= 2 kΩ, VSS = 0 V ±8 LSB

L

Note 3, RL = 2 kΩ, VSS = –5 V ±10 ppm/°C

Note 3, RL = 2 kΩ, VSS = –5 V ±10 ppm/°C

MATCHING PERFORMANCE

Linearity Matching ±1 LSB

REFERENCE

Positive Reference Input Range V

Negative Reference Input Range V

Negative Reference Input Range V

Reference High Input Current I

Reference Low Input Current I

VREFHI

VREFLO

VREFLO

VREFHI

VREFLO

Note 4 V

Note 4 V

Note 4, VSS = 0 V 0 V

Codes 000H, 555

H

–0.75 ±0.25 +0.75 mA

Codes 000H, 555H, VSS = –5 V –1.0 –0.6 mA

+2.5 VDD –2.5 V

VREFLO

SS

V

VREFHI

VREFHI

–2.5 V

–2.5 V

AMPLIFIER CHARACTERISTICS

Output Current I

Settling Time t

OUT

S

VSS = –5 V –1.25 +1.25 mA

to 0.01%, Note 5 8 µs

Slew Rate SR 10% to 90%, Note 5 1.5 V/µs

LOGIC CHARACTERISTICS

Logic Input High Voltage V

Logic Input Low Voltage V

Logic Input Current I

Input Capacitance C

LOGIC TIMING CHARACTERISTICS

Data Setup Time t

Data Hold t

Clock Pulse Width HIGH t

Clock Pulse Width LOW t

Select Time t

Deselect Delay t

Load Disable Time t

Load Delay t

Load Pulse Width t

Clear Pulse Width t

3, 6

INH

INL

IN

IN

DS

DH

CH

CL

CSS

CSH

LD1

LD2

LDW

CLRW

Note 3 13 pF

2.4 V

0.8 V

10 µA

25 ns

55 ns

90 ns

120 ns

90 ns

5ns

130 ns

35 ns

80 ns

150 ns

SUPPLY CHARACTERISTICS

Power Supply Sensitivity PSRR 0.002 0.01 %/%

Positive Supply Current I

Negative Supply Current I

Power Dissipation P

NOTES

1

All supplies can be varied ±5% and operation is guaranteed. Device is tested with VDD = +4.75 V.

2

For single-supply operation (V

3

Guaranteed but not tested.

4

Operation is guaranteed over this reference range, but linearity is neither tested nor guaranteed.

5

V

swing between +2.5 V and –2.5 V with VDD = 5.0 V.

OUT

6

All input control signals are specified with tr = tf =5 ns (10% to 90% of +5 V) and timed from a voltage level of 1.6 V.

7

Typical values indicate performance measured at +25°C.

Specifications subject to change without notice.

= 0 V, VSS = 0 V), due to internal offset errors INL and DNL are measured beginning at code 003H.

VREFLO

DD

SS

DISS

–6 –3 mA

VSS = 0 V 20 35 mW

47 mA

–2–

REV. 0

DAC8420

ELECTRICAL CHARACTERISTICS

V

= –10.0 V, –408C ≤ TA ≤ +858C unless otherwise noted. See Note 1 for supply variations.)

VREFLO

(at VDD = +15.0 V 6 5%, VSS = –15.0 V 6 5%, V

VREFHI

= +10.0 V,

Parameter Symbol Condition Min Typ Max Units

STATIC ACCURACY

Integral Linearity “E” INL ±1/4 ±1/2 LSB

Integral Linearity “F” INL ±1/2 ±1 LSB

Differential Linearity DNL Monotonic Over Temperature ± 1/4 ±1 LSB

Min-Scale Error ZSE R

Full-Scale Error FSE R

Min-Scale Tempco TC

Full-Scale Tempco TC

ZSE

FSE

= 2 kΩ±2 LSB

L

= 2 kΩ±2 LSB

L

Note 2, RL = 2 kΩ±4 ppm/°C

Note 2, RL = 2 kΩ±4 ppm/°C

MATCHING PERFORMANCE

Linearity Matching ±1 LSB

REFERENCE

Positive Reference Input Range V

Negative Reference Input Range V

Reference High Input Current I

Reference Low Input Current I

VREFHI

VREFLO

VREFHI

VREFLO

Note 3 V

Note 3 –10 V

Codes 000H, 555

Codes 000H, 555

H

H

+2.5 VDD –2.5 V

VREFLO

VREFHI

–2.5 V

–2.0 ±1.0 +2.0 mA

–3.5 –2.0 mA

AMPLIFIER CHARACTERISTICS

Output Current I

Settling Time t

OUT

S

to 0.01%, Note 4 13 µs

–5 +5 mA

Slew Rate SR 10% to 90%, Note 4 2 V/µs

DYNAMIC PERFORMANCE

Analog Crosstalk Note 2 >64 dB

Digital Feedthrough Note 2 >72 dB

Large Signal Bandwidth 3 dB, V

V

VREFLO

= 5 V + 10 V p-p, 90 kHz

VREFHI

= –10 V, Note 2

Glitch Impulse Code Transition = 7FFH to 800H, Note 2 64 nV-s

LOGIC CHARACTERISTICS

Logic Input High Voltage V

Logic Input Low Voltage V

Logic Input Current I

Input Capacitance C

LOGIC TIMING CHARACTERISTICS

2, 5

Data Setup Time t

Data Hold t

Clock Pulse Width HIGH t

Clock Pulse Width LOW t

Select Time t

Deselect Delay t

Load Disable Time t

Load Delay t

Load Pulse Width t

Clear Pulse Width t

INH

INL

IN

IN

DS

DH

CH

CL

CSS

CSH

LD1

LD2

LDW

CLRW

Note 2 13 pF

2.4 V

0.8 V

10 µA

25 ns

20 ns

30 ns

50 ns

55 ns

15 ns

40 ns

15 ns

45 ns

70 ns

SUPPLY CHARACTERISTICS

Power Supply Sensitivity PSRR 0.002 0.01 %/%

Positive Supply Current I

Negative Supply Current I

Power Dissipation P

NOTES

1

All supplies can be varied ±5% and operation is guaranteed.

2

Guaranteed but not tested.

3

Operation is guaranteed over this reference range, but linearity is neither tested nor guaranteed.

4

V

swing between +10 V and –10 V.

OUT

5

All input control signals are specified with tr = tf =5 ns (10% to 90% of +5 V) and timed from a voltage level of 1.6 V.

6

Typical values indicate performance measured at +25°C.

Specifications subject to change without notice.

DD

SS

DISS

–8 –5 mA

69 mA

255 mW

REV. 0

–3–

DAC8420

10

SDI

9

GND

8

VSS

7

VOUTA

CLR

15

CLSEL

16

(SUBSTRATE)

VDD

1

VOUTD

2

VOUTC 3

VREFLO 4

VREFHI 5

VOUTB 6

11 CLK

12 CS

14 LD

13 NC

NC = NO CONNECT

WAFER TEST LIMITS

(at VDD = +15.0 V, VSS = –15.0 V, V

unless otherwise noted)

= +10.0 V, V

REFHI

= –10.0 V, TA = +258C

REFLO

DAC8420G

Parameter Symbol Conditions Limit Units

Integral Linearity INL ±1 LSB max

Differential Linearity DNL ±1 LSB max

Min-Scale Offset ±1 LSB max

Max-Scale Offset ±1 LSB max

Logic Input High Voltage V

Logic Input Low Voltage V

Logic Input Current I

Positive Supply Current I

Negative Supply Current I

NOTE

Electrical tests are performed at wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed

for standard product dice. Consult factory to negotiate specifications based on dice lot qualification through sample lot assembly and testing.

ABSOLUTE MAXIMUM RATINGS

(TA = +25°C unless otherwise noted)

VDD to GND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +18.0 V

V

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V, –18.0 V

SS

V

to VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +36.0 V

SS

V

to V

SS

V

VREFHI

V

VREFHI

I

VREFHI

to V

to VDD . . . . . . . . . . . . . . . . . . . . . . . +2.0 V, +33.0 V

, I

. . . . . . . . . . . . . . . . . . . . . . –0.3 V, VSS – 2.0 V

VREFLO

VREFLO

. . . . . . . . . . . . . . . . . . . +2.0 V, VDD – V

VREFLO

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 mA

Digital Input Voltage to GND . . . . . . . . . –0.3 V, V

IN

DD

SS

INH

INL

+ 0.3 V

DD

3. Remove power before inserting or removing units from their

sockets.

4. Analog Outputs are protected from short circuits to ground

or either supply.

SS

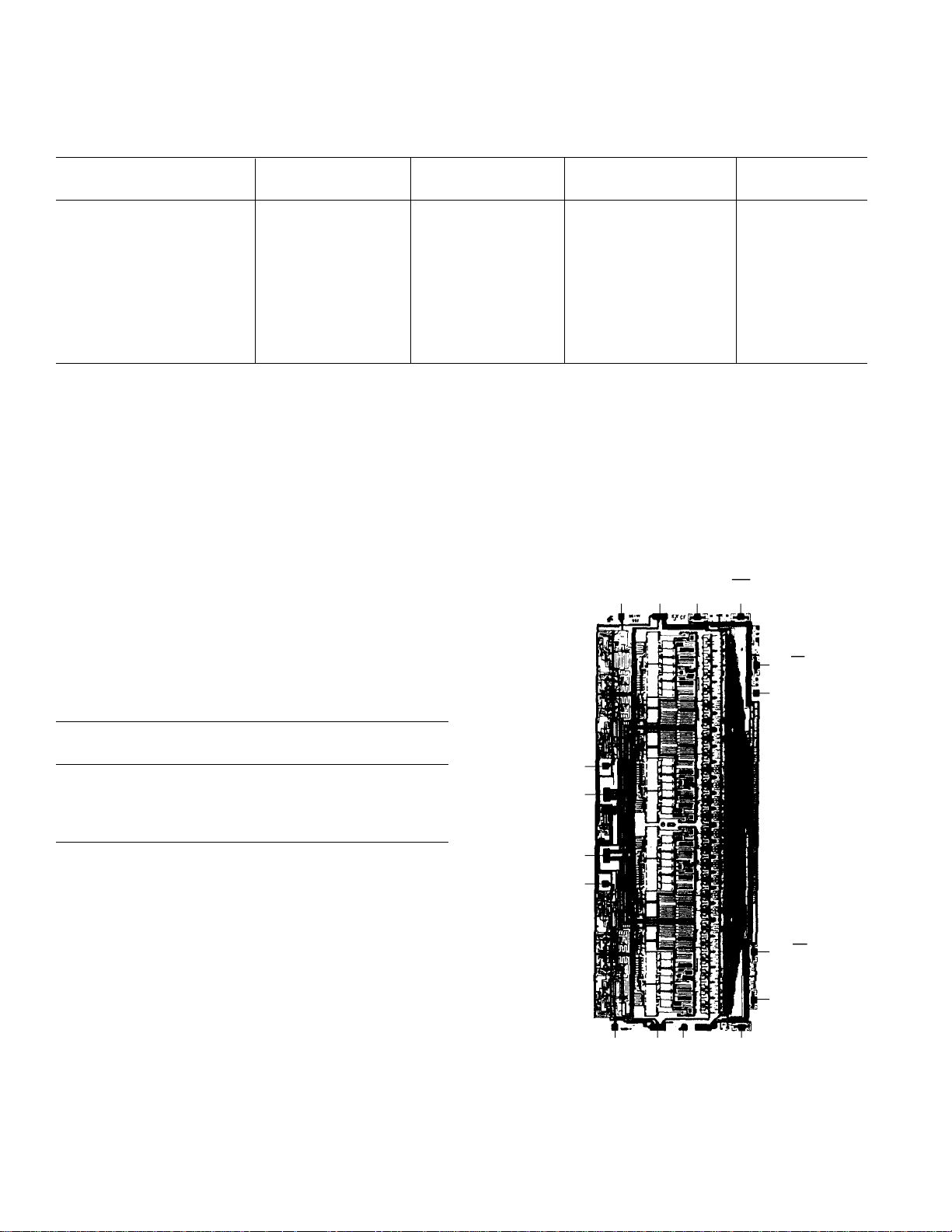

DICE CHARACTERISTICS

2.4 V min

0.8 V max

1 µA max

8 mA max

7 mA max

Output Short Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Operating Temperature Range

EP, FP, ES, FS, EQ, FQ . . . . . . . . . . . . . . –40°C to +85°C

Dice Junction Temperature . . . . . . . . . . . . . . . . . . . . . +150°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . 1000 mW

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . . +300°C

Package Type θ

16-Pin Plastic DIP (P) 70

16-Pin Hermetic DIP (Q) 82

16-Lead Small Outline

Surface Mount (S) 86

NOTES

1

θJA is specified for worst case mounting conditions, i.e., θJA is specified for

device in socket.

2

θJA is specified for device on board.

Thermal Resistance

JA

1

1

2

θ

JC

Units

27 °C/W

9 °C/W

22 °C/W

CAUTION

1. Stresses above those listed under “Absolute Maximum Rat-

ings” may cause permanent damage to the device. This is a

stress rating only and functional operation at or above this

specification is not implied. Exposure to the above maximum

rating conditions for extended periods may affect device

reliability.

2. Digital inputs and outputs are protected, however, permanent

damage may occur on unprotected units from high-energy

electrostatic fields. Keep units in conductive foam or packaging

at all times until ready to use. Use proper antistatic handling

procedures.

Die Size 0.119 × 0.283 inch, 33,677 sq. mils

×

(3.023

7.188 mm, 21.73 sq. mm)

Transistor Count 2,207

For additional DICE ordering information, refer to databook.

–4–

REV. 0

DAC8420

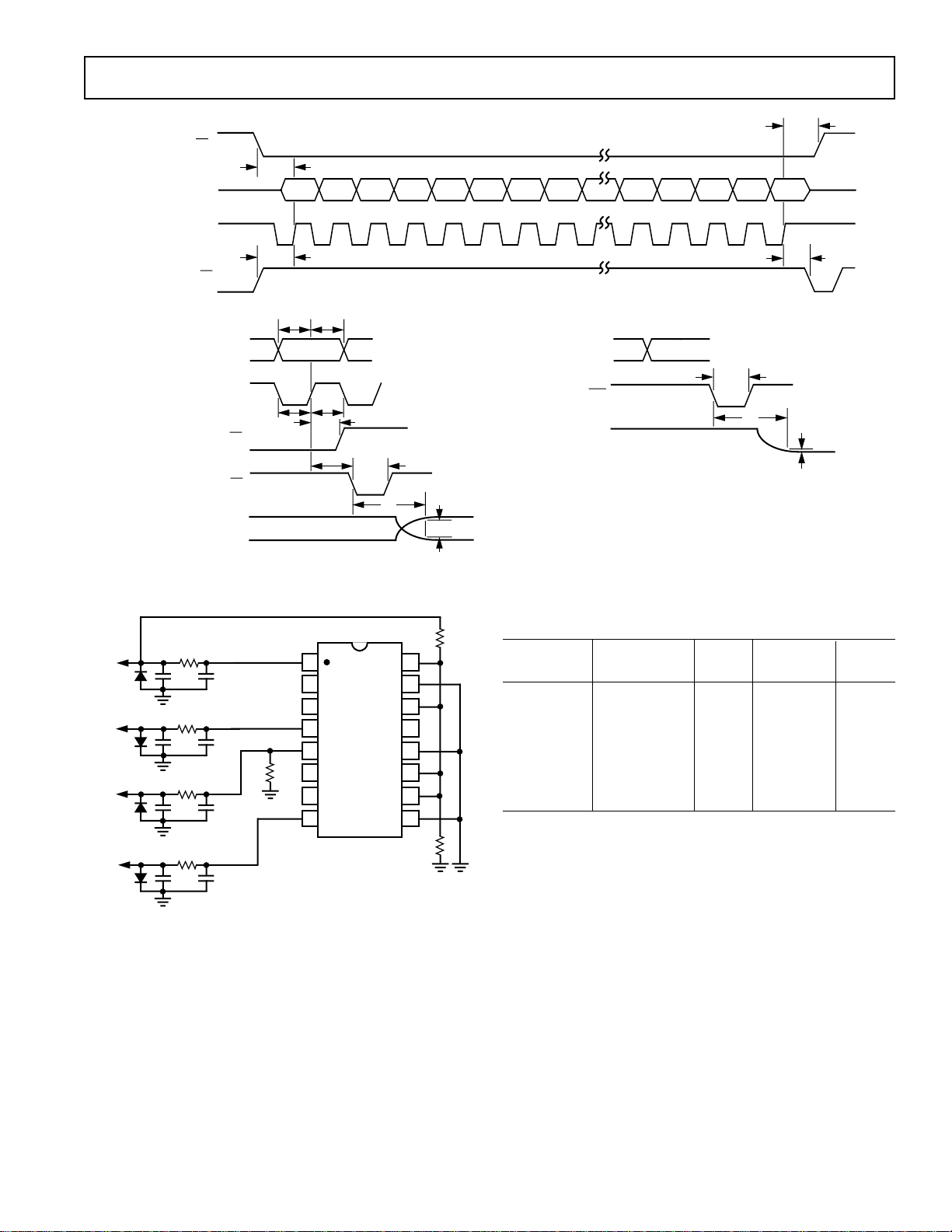

DATA LOAD SEQUENCE

CS

SDI

CLK

LD

DATA LOAD TIMING

SDI

CLK

CS

LD

V

OUT

t

CSS

A1 A0 X X D11 D10 D9 D8 D4 D3 D2 D1 D0

t

LD1

t

t

DH

DS

CLEAR TIMING

CLSEL

t

t

t

CL

CH

t

CSH

t

LD2

t

LDW

t

S

±1LSB

CLR

V

OUT

Timing Diagram

CLRW

t

CSH

t

LD2

t

S

±1LSB

+15V

1N4001

–10V

1N4001

+10V

1N4001

–15V

1N4001

10Ω

+

10µF 0.1µF

10Ω

10µF 0.1µF

+

10Ω

+

10µF 0.1µF

10Ω

10µF 0.1µF

+

1

2

NC

NC

3

4

5

5kΩ

6

NC

NC

7

8

NC = NO CONNECT

Burn-In Diagram

DUT

16

15

14

13

12

11

10

9

5kΩ

10kΩ

NC

ORDERING GUIDE

1

Model

DAC8420EP –40°C to +85°C 0.5 Plastic DIP P

DAC8420EQ –40°C to +85°C 0.5 Cerdip Q

DAC8420ES –40°C to +85°C 0.5 SOIC SOL

DAC8420FP –40°C to +85°C 1.0 Plastic DIP P

DAC8420FQ –40°C to +85°C 1.0 Cerdip Q

DAC8420FS –40°C to +85°C 1.0 SOIC SOL

DAC8420QBC –40°C to +85°C 1.0 Dice

NOTES

1

A complete /883 data sheet is available. For availability and burn-in information, contact your local sales office.

2

PMI division letter designator.

3

Dice tested at +25°C only.

Temperature INL Package Package

Range (6LSB) Description Option

3

2

REV. 0

–5–

DAC8420

1

2

3

4

8

7

6

5

TOP VIEW

(Not to Scale)

DAC-8420

TOP VIEW

(Not to Scale)

DAC-8420

9

16

15

14

13

12

11

10

NC = NO CONNECT

VDD

VOUTD

VOUTC

VREFLO

VREFHI

VOUTB

VOUTA

VSS

CLSEL

NC

CLK

SDI

GND

CLR

LD

CS

TOP VIEW

(Not to Scale)

DAC8420

PIN CONFIGURATIONS

SOL

VDD

VOUTD

VOUTC

VREFLO

VREFHI

VOUTB

VOUTA

VSS

DIP

1

2

3

4

DAC8420

TOP VIEW

5

(Not to Scale)

6

7

8

NC = NO CONNECT

CLSEL

16

15

CLR

LD

14

13

NC

CS

12

CLK

11

SDI

10

9

GND

PIN FUNCTION DESCRIPTION

Power Supplies VDD: Positive Supply, +5 V to +15 V.

VSS: Negative Supply, 0 V to –15 V.

GND: Digital Ground.

Clock CLK: System Serial Data Clock Input, TTL/CMOS levels. Data presented to the input SDI is shifted into

the internal serial-parallel input register on the rising edge of clock. This input is logically ORed with

CS.

Control Inputs (All are CMOS/TTL compatible.)

CLR: Asynchronous Clear, active low. Sets internal data registers A-D to zero or midscale, depending on current state of CLSEL. The data in the serial input shift register is unaffected by this control.

CLSEL: Determines action of

midscale (800

). If LOW, the registers are set to zero (000H).

H

CLR. If HIGH, a Clear command will set the internal DAC registers A-D to

CS: Device Chip Select, active low. This input is logically ORed with the clock and disables the serial data

register input when HIGH. When LOW, data input clocking is enabled, see the Control Function Table.

LD: Asynchronous DAC Register Load Control, active low. The data currently contained in the serial input

shift register is shifted out to the DAC data registers on the falling edge of

must remain stable while

LD is LOW.

LD, independent of CS. Input data

Data Input (All are CMOS/TTL compatible.)

SDI: Serial Data Input. Data presented to this pin is loaded into the internal serial-parallel shift register, which

shifts data in beginning with DAC address Bit A1. This input is ignored when CS is HIGH.

The format of the 16-bit serial word is:

(FIRST) (LAST)

B0 B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14 B15

A1 A0 NC NC D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

—Address Word— (MSB) —DAC Data Word— (LSB)

NC = Don’t Care.

Reference Inputs VREFHI: Upper DAC ladder reference voltage input. Allowable range is (VDD – 2.5 V) to (V

Analog Outputs VOUTA through VOUTD: Four buffered DAC voltage outputs.

VREFLO: Lower DAC ladder reference voltage input, equal to zero scale output. Allowable range is V

(V

VREFHI

– 2.5 V).

–6–

VREFLO

+2.5 V).

SS

to

REV. 0

CLK

DAC8420

Table I. Control Function Logic Table

1

CS

1

LD CLR CLSEL Serial Input Shift Register DAC Registers A-D

NC H H L H No Change Loads Midscale Value (800

NC H H L L No Change Loads Zero-Scale Value (000

)

H

H

NC H H ↑ H/L No Change Latches Value

↑ L H H NC Shifts Register One Bit No Change

L ↑ H H NC Shifts Register One Bit No Change

H NC (

) ↓ H NC No Change Loads the Serial Data Word

↑

H NC L H NC No Change Transparent

3

2

NC H H H NC No Change No Change

NC = Don’t Care.

NOTES

1

CS and CLK are interchangeable.

2

Returning CS HIGH while CLK is HIGH avoids an additional “false clock” of serial input data. See Note 1.

3

Do not clock in serial data while LD is LOW.

(000

OPERATION

Introduction

The DAC8420 is a quad, voltage-output 12-bit DAC with serial

digital input, capable of operating from a single +5 V supply.

The straightforward serial interface can be connected directly to

most popular microprocessors and microcontrollers, and can accept data at a 10 MHz clock rate when operating from ±15 V

) or midscale (800H), depending on the state of CLSEL as

H

shown in the Digital Function Table. The CLEAR function is

asynchronous and is totally independent of

CS. When CLR

returns HIGH, the DAC outputs remain latched at the reset

value until

LD is strobed, reloading the individual DAC data word

registers with either the data held in the serial input register prior

to the reset, or new data loaded through the serial interface.

supplies. A unique voltage reference structure assures maximum

utilization of DAC output resolution by allowing the user to set

the zero- and full-scale output levels within the supply rails. The

analog voltage outputs are fully buffered, and are capable of

driving a 2 kΩ load. Output glitch impulse during major code

transitions is a very low 64 nV-s (typ).

Digital Interface Operation

The serial input of the DAC-8420, consisting of CS, SDI, and

Table II. DAC Address Word Decode Table

A1 A0 DAC Addressed

0 0 DAC A

0 1 DAC B

1 0 DAC C

1 1 DAC D

LD, is easily interfaced to a wide variety of microprocessor serial

ports. As shown in Table I and the Timing Diagram, while

CS

is LOW the data presented to the input SDI is shifted into the

internal serial/parallel shift register on the rising edge of the

clock, with the address MSB first, data LSB last. The data format, shown above, is two bits of DAC address and two “don’t

care” fill bits, followed by the 12-bit DAC data word. Once all

16 bits of the serial data word have been input, the load control

LD is strobed and the word is parallel-shifted out onto the internal data bus. The two address bits are decoded and used to

route the 12-bit data word to the appropriate DAC data register, see the Applications Information.

Correct Operation of CS and CLK

As mentioned in Table I, the control pins CLK and CS require

some attention during a data load cycle. Since these two inputs

are fed to the same logical “OR” gate, their operation is in fact

identical. The user must take care to operate them accordingly

Programming the Analog Outputs

The unique differential reference structure of the DAC8420

allows the user to tailor the output voltage range precisely to the

needs of the application. Instead of spending DAC resolution

on an unused region near the positive or negative rail, the

DAC8420 allows the user to determine both the upper and

lower limits of the analog output voltage range. Thus, as shown

in Table III and Figure 1, the outputs of DACs A through D

range between VREFHI and VREFLO, within the limits specified in the Electrical Characteristics tables. Note also that

VREFHI must be greater than VREFLO.

V

DD

V

VREFHI

2.5V MIN

FFF

H

in order to avoid clocking in false data bits. As shown in the

Timing Diagram, CLK must be either halted HIGH, or

brought HIGH during the last HIGH portion of the CLK fol-

CS

2.5V MIN

1 LSB

lowing the rising edge which latched in the last data bit. Otherwise, an additional rising edge is generated by

CLK is LOW, causing

CS to act as the clock and allowing a

false data bit into the serial input register. The same issue must

be considered in the beginning of the data load sequence also.

Using CLR and CLSEL

The CLEAR (CLR) control allows the user to perform an asynchronous reset function. Asserting

CLR loads all four DAC data

CS rising while

000

V

VREFLO

V

H

0V MIN

SS

–10V MIN

Figure 1. Output Voltage Range Programming

word registers, forcing the DAC outputs to either zero-scale

)

REV. 0

–7–

DAC8420

1.2

0

1000

0.6

0.2

200

0.4

0

1.0

0.8

800600400

T = HOURS OF OPERATION AT +125°C

ZERO-SCALE ERROR WITH R

L

= 2k – LSB

x + 3σ

x

x – 3σ

CURVES NOT NORMALIZED

V

DD

= +15V, V

SS

= –15V

V

VREFHI

= +10V

V

VREFLO

= –10V

Ω

Table III. Analog Output Code

DAC Data Word (HEX) V

FFF

OUT

VREFLO +

(VREFHI –VREFLO )

801

VREFLO +

(VREFHI –VREFLO )

800

7FF

000

VREFLO +

VREFLO +

VREFLO +

(VREFHI –VREFLO )

(VREFHI –VREFLO )

(VREFHI –VREFLO )

Typical Performance Characteristics

0.3

0.2

0.1

0

DNL – LSB

–0.1

–0.2

–0.3

–6

–4

TA = +25°C

V

= +15V, V

DD

V

VREFLO

V

VREFHI

– V

= –10V

SS

= –15V

121086420–2

Figure 2. Differential Linearity vs.

±

VREFHI (

15 V)

14

0.10

0.05

0

–0.05

–0.10

DNL – LSB

–0.15

–0.20

–0.25

–0.30

Figure 3. Differential Linearity vs.

VREFHI (+5 V)

1.5

4096

4096

4096

4096

4096

V

VREFHI

TA = +25°C

V

= +5V, VSS = 0V

DD

= 0V

V

VREFLO

– V

× 4095

×2049

×2048

×2047

×0

3.53.02.52.0

Note

Full-Scale Output

Midscale + 1

Midscale

Midscale – 1

Zero Scale

0.3

0.2

0.1

0

INL – LSB

–0.1

–0.2

–0.3

–4

–6

TA = +25°C

V

DD

V

VREFLO

V

VREFHI

= +15V, V

= –10V

– V

SS

= –15V

121086420–2

Figure 4. INL vs. VREFHI (±15 V)

14

0.4

0.3

0.2

0.1

0

INL – LSB

–0.1

–0.2

–0.3

–0.4

Figure 5. INL vs. VREFHI (+5 V)

1.5

V

VREFHI

TA = +25°C

= +5V, V

V

DD

V

VREFLO

– V

= 0V

SS

= 0V

3.53.02.52.0

0.7

0.5

Ω

= 2k – LSB

L

0.3

0.1

–0.1

–0.3

FULL-SCALE ERROR WITH R

–0.5

200

0

T = HOURS OF OPERATION AT +125°C

CURVES NOT NORMALIZED

V

DD

V

VREFHI

V

VREFLO

= +15V, V

= +10V

= –10V

SS

800600400

Figure 6. Full-Scale Error vs.

Time Accelerated by Burn-In

–8–

x + 3σ

= –15V

x

x – 3σ

1000

Figure 7. Zero-Scale Error vs.

Time Accelerated by Burn-In

REV. 0

DAC8420

0.9

–0.9

4500

–0.5

–0.7

5000

–0.1

–0.3

0.1

0.3

0.5

0.7

4000350030002500200015001000

TA = +25°C

V

DD

= +15V, V

SS

= –15V

V

VREFHI

= +10V

V

VREFLO

= –10V

DIGITAL INPUT CODE

ERROR – ±LSB

+0.8

–0.2

–0.4

5000

+0.1

–0.1

0

+0.2

+0.3

+0.4

+0.6

+0.5

+0.7

3500 400030002500200015001000

TA = +25, –55, 125°C

V

DD

= +15V, V

SS

= –15V

V

VREFHI

= +10V

V

VREFLO

= –10V

DIGITAL INPUT CODE

INL – LSB

–0.3

4500

0.2

V

= +15V, V

DD

0.1

V

VREFHI

V

0

VREFLO

–0.1

–0.2

–0.3

–0.4

FULL-SCALE ERROR – LSB

–0.5

–0.6

–50–75

= –15V

SS

= +10V

= –10V

DAC C

TEMPERATURE – °C

DAC D

DAC A

DAC B

Figure 8. Full-Scale Error vs.

Temperature

+1.5

+1.0

+0.5

0

ERROR – LSB

–0.5

–1.0

–1.5

500

0

TA = +25°C

V

= +5V, V

DD

V

= +2.5V

VREFHI

V

= 0V

VREFLO

DIGITAL INPUT CODE

SS

Figure 11. Channel-to-Channel

Matching +5/+2.5

1007550250–25

= 0V

4000350030002500200015001000

125

4500

1.2

V

= +15V, V

DD

1.0

V

VREFHI

0.8

V

VREFLO

0.6

0.4

0.2

DAC A

0

ZERO-SCALE ERROR – LSB

–0.2

–0.4

–50–75

= –15V

SS

= +10V

= –10V

DAC B

TEMPERATURE – °C

Figure 9. Zero-Scale Error vs.

Temperature

13

12

11

10

9

– mA

8

DD

I

7

6

5

4

–5–7

Figure 12. IDD vs. V

TA = +25°C

V

V

0

V

VREFHI

= +15V, V

DD

VREFLO

= –10V

– V

VREFHI

DACs HIGH

DAC C

DAC D

= –15V

SS

, All

1007550250–25

125

Figure 10. Channel-to-Channel

±

Matching

13

1197531–1–3

15/±10

Figure 13. INL vs. Code ±15/±10

+1.5

+1.0

+0.5

– mA

0

VREFHI

I

TA = +25°C

V

DD

–0.5

V

VREFHI

V

VREFLO

–1.0

500

0

Figure 14. I

REV. 0

= +15V, V

= –15V

SS

= +10V

= –10V

DIGITAL INPUT CODE

VREFHI

vs. Code

–250µV

LD

1.22mV

1 LSB

0mV

TA = +25°C

= +5V, V

V

DD

V

VREFHI

V

4000350030002500200015001000

–10.25mV

t

SETT

≈ 8µs

VREFLO

SS

= +2.5V

= –2.5V

= –5V

45.1µs–4.9µs 5µs/DIV

Figure 15. Settling Time (+)(±5 V)

6.5mV

CLR

TA = +25°C

= +5V, V

V

0mV

1 LSB

–1.22mV

–3.5mV

t

SETT

≈ 8µs

DD

V

VREFHI

V

VREFLO

SS

= +2.5V

= –2.5V

Figure 16. Settling Time (–)(±5 V)

= –5V

+45.1µs–4.9µs +5µs/DIV

–9–

DAC8420

+31.25mV

LD

TA = +25°C

V

= +15V, V

4.88mV

1 LSB

0mV

–18.75mV

–9.8µs

t

SETT

≈ 13µs

DD

V

VREFHI

V

VREFLO

+10µs/DIV

= +10V

= –10V

SS

Figure 17. Settling Time (+)(±15 V)

+25V

LD

CLR

+5V

/DIV

0

TA = +25°C

–25V

V

DD

V

VREFHI

SR

= +15V, V

RISE

SS

= +10V, V

= 1.9

µs

= –15V

VREFLO

20µs/DIV

V

SR

= –10V

FALL

= 2.02

V

µs

Figure 20. Slew Rate (±15 V)

= –15V

166.4µs–33.6µs

+90.2µs

+43.75mV

0mV

1 LSB

–4.88mV

–6.25mV

CLR

t

SETT

≈ 13µs

TA = +25°C

V

= +15V, V

DD

V

VREFHI

V

VREFLO

= +10V

= –10V

SS

= –15V

Figure 18. Settling Time (–)(±15 V)

+10

0

–10

–20

GAIN – dB

–30

TA = +25°C

V

= +15V, V

DD

V

VREFHI

V

VREFLO

ALL BITS HIGH 200mV p-p

10 100 10M1M100k10k1k

= –15V

SS

= 0 ± 100mV

= –10V

FREQUENCY – Hz

Figure 21. Small-Signal Response

+5V

+1V

/DIV

0

TA = +25°C

V

= +5V, V

DD

V

VREFHI

V

+90.2µs–9.8µs +10µs/DIV

–5V

SR

VREFLO

= 1.65 SR

RISE

V

µs

= +2.5V

= –2.5V

20µs/DIV

SS

= –5V

FALL

= 1.17

152.4µs–47.6µs

V

µs

Figure 19. Slew Rate (±5 V)

100

90

80

70

60

50

40

PSRR – dB

TA = +25°C

30

20

10

0

10

DATA = 000

V

DD

V

VREFHI

V

VREFLO

H

= +15V ±1V, V

= +10V

= –10V

100 1k 10k 100k 1M

FREQUENCY – Hz

SS

= –15V

Figure 22. PSRR vs. Frequency

6

4

2

V

= +15V

DD

V

= –15V

SS

0

V

= +10V

VREFHI

V

= –10V

VREFLO

ALL DACS HIGH (FULL SCALE)

–2

–4

POWER SUPPLY CURRENT – mA

–6

–75

TEMPERATURE – °C

I

DD

I

SS

750

Figure 23. Power Supply Current

vs. Temperature

150

VOUTA THROUGH VOUTD

T

= +25°C

A

V

= +15V

DD

V

= –15V

SS

V

= +10V

VREFHI

V

= –10V

VREFLO

DATA = 800

H

10mA/DIV

5V/DIV

Figure 24. DAC Output Current vs.

VOUTX

10

8

6

PEAK – V

4

OUT

V

2

0

10 100 10k1k

LOAD RESISTANCE – Ω

TA = +25°C

V

= +15V

DD

V

= –15V

SS

V

= +10V

VREFHI

V

VREFLO

DATA = FFFH OR 000

Figure 25. Output Swing vs.

Load Resistance

= –10V

H

–10–

REV. 0

DAC8420

100µF

ELECT.

10–22µF

TANT.

0.1µF

CER.

TTL/CMOS

LOGIC

CIRCUITS

+5V

POWER SUPPLY

+5V

+5V

RETURN

FERRITE BEADS:

2 TURNS, FAIR-RITE

#2677006301

VREFHI Input Requirements

The DAC8420 utilizes a unique, patented DAC switch driver

circuit which compensates for different supply, reference voltage, and digital code inputs. This ensures that all DAC ladder

switches are always biased equally, ensuring excellent linearity

under all conditions. Thus, as indicated in the specifications,

the VREFHI input of the DAC8420 will require both sourcing

and sinking current capability from the reference voltage source.

Many positive voltage references are intended as current sources

only, and offer little sinking capability. The user should consider

references such as the AD584, AD586, AD587, AD588, AD780,

and REF43 in this application.

APPLICATIONS

Power Supply Bypassing and Grounding

In any circuit where accuracy is important, careful consideration

of the power supply and ground return layout helps to ensure

the rated performance. The DAC8420 has a single ground pin

that is internally connected to the digital section as the logic

reference level. The first thought may be to connect this pin to

the digital ground; however, in large systems the digital ground

is often noisy because of the switching currents of other digital

circuitry. Any noise that is introduced at the ground pin could

couple into the analog output. Thus, to avoid error causing

digital noise in the sensitive analog circuitry, the ground pin

should be connected to the system analog ground. The ground

path (circuit board trace) should be as wide as possible to reduce any effects of parasitic inductance and ohmic drops. A

ground plane is recommended if possible. The noise immunity

of the onboard digital circuitry, typically in the hundreds of millivolts, is well able to reject the common-mode noise typically

seen between system analog and digital grounds. Finally, the

analog and digital ground should be connected together at a

single point in the system to provide a common reference.

This is preferably done at the power supply.

Good grounding practice is essential to maintaining analog

performance in the surrounding analog support circuitry as well.

With two reference inputs, and four analog outputs capable of

moderate bandwidth and output current, there is a significant

potential for ground loops. Again, a ground plane is recommended as the most effective solution to minimizing errors due

to noise and ground offsets.

+V

S

0.1µF10µF

–V

S

Figure 26. Recommended Supply Bypassing Scheme

0.1µF10µF

REV. 0

1

VDD

89

10µF = TANTALUM

0.1µF = CERAMIC

VSS

GND

–11–

The DAC8420 should have ample supply bypassing, located as

close to the package as possible. Figure 26 shows the recommended capacitor values of 10 µF in parallel with 0.1 µF. The

0.1 µF cap should have low “Effective Series Resistance” (ESR)

and “Effective Series Inductance” (ESI), such as the common

ceramic types, which provide a low impedance path to ground

at high frequencies to handle transient currents due to internal

logic switching. In order to preserve the specified analog performance of the device, the supply should be as noise free as possible. In the case of 5 V only systems it is desirable to use the

same 5 V supply for both the analog circuitry and the digital

portion of the circuit. Unfortunately, the typical 5 V supply is

extremely noisy due to the fast edge rates of the popular CMOS

logic families which induce large inductive voltage spikes, and

busy microcontroller or microprocessor busses which commonly

have large current spikes during bus activity. However, by properly filtering the supply as shown in Figure 27, the digital 5 V

supply can be used. The inductors and capacitors generate a filter that not only rejects noise due to the digital circuitry, but

also filters out the lower frequency noise of switch mode power

supplies. The analog supply should be connected as close as

possible to the origin of the digital supply to minimize noise

pickup from the digital section.

Figure 27. Single-Supply Analog Supply Filter

Analog Outputs

The DAC8420 features buffered analog voltage outputs capable

of sourcing and sinking up to 5 mA when operating from ±15 V

supplies, eliminating the need for external buffer amplifiers in

most applications while maintaining specified accuracy over the

rated operating conditions. The buffered outputs are simply an

op amp connected as a voltage follower, and thus have output

characteristics very similar to the typical operational amplifier.

These amplifiers are short-circuit protected. The designer

should verify that the output load meets the capabilities of the

device, in terms of both output current and load capacitance.

The DAC8420 is stable with capacitive loads up to 2 nF typical.

However, any capacitive load will increase the settling time, and

should be minimized if speed is a concern.

The output stage includes a p-channel MOSFET to pull the

output voltage down to the negative supply. This is very important in single supply systems, where VREFLO usually has the

same potential as the negative supply. With no load, the

zero-scale output voltage in these applications will be less than

500 µV typically, or less than 1 LSB when V

VREFHI

= 2.5 V.

However, when sinking current this voltage does increase

because of the finite impedance of the output stage. The effective value of the pull-down resistor in the output stage is

typically 320 Ω. With a 100 kΩ resistor connected to +5 V, the

resulting zero-scale output voltage is 16 mV. Thus, the best

DAC8420

single supply operation is obtained with the output load

connected to ground, so the output stage does not have to sink

current.

Like all amplifiers, the DAC8420 output buffers do generate

voltage noise, 52 nV/√

Hz typically. This is easily reduced by

adding a simple RC low-pass filter on each output.

Reference Configuration

The two reference inputs of the DAC8420 allow a great deal of

flexibility in circuit design. The user must take care, however, to

observe the minimum voltage input levels on VREFHI and

VREFLO to maintain the accuracy shown in the data sheet.

These input voltages can be set anywhere across a wide range

within the supplies, but must be a minimum of 2.5 V apart in

any case. See Figure 1. A wide output voltage range can be

obtained with ±5 V references, which can be provided by the

AD588 as shown in Figure 28. Many applications utilize the

1µF

7

7

R

B

A1

R2

R3

A2

6

5

9

6

4 3

A3

1

AD588

R1

10

R4

R5

R6

12

8

13

11

14

15

A4

2

+V

S

0.1µF

–V

16

S

0.1µF

+5V

–5V

+15V

SUPPLY

SYSTEM

GROUND

–15V

SUPPLY

DACs to synthesize symmetric bipolar wave forms, which

requires an accurate, low drift bipolar reference. The AD588

provides both voltages and needs no external components. Additionally, the part is trimmed in production for 12-bit accuracy

over the full temperature range without user calibration. Performing a Clear with the reset select CLSEL HIGH allows the

user to easily reset the DAC outputs to midscale, or zero volts in

these applications.

When driving the reference inputs VREFHI and VREFLO, it is

important to note that VREFHI both sinks and sources current,

and that the input currents of both are code dependent. Many

voltage reference products have limited current sinking capability and must be buffered with an amplifier to drive VREFHI, in

order to maintain overall system accuracy. The input VREFLO,

however, has no such requirement.

+15V SUPPLY

DAC-8420

DIGITAL

CONTROL

DIGITAL INPUTS

5

DAC A

DAC B

DAC C

DAC D

GND

+5V

VREFHI

4915 1614121110 8

VREFLO

–5V

1

0.1µF

VOUTA

7

VOUTB

6

VOUTC

3

VOUTD

2

0.1µF

Figure 28.±10 V Bipolar Reference Configuration Using the AD588

–12–

–15V SUPPLY

REV. 0

DAC8420

10kΩ

10kΩ

+5V

10kΩ

LD

SCLK

SDI

+5V

REG

+5V

POWER

HIGH VOLTAGE

ISOLATION

+5V

+5V

0.1µF

+5V

CLR

CLSEL

CLK

SDI

LD

CS

4

5

VREFHI

VREFLO VSS

GND

1µF

10kΩ

DAC-8420

VOUTA

VOUTB

VOUTC

VOUTD

REF-43

VOUT

GND

VIN

+5V

6

2

4

2.5V

9

8

1

6

7

3

2

11

10

14

16

15

12

VDD

For a single 5 V supply, V

is limited to at most 2.5 V, and

VREFHI

must always be at least 2.5 V less than the positive supply to

ensure linearity of the device. For these applications, the REF43

is an excellent low drift 2.5 V reference that consumes only

450 µA (max). It works well with the DAC8420 in a single 5 V

system as shown in Figure 29.

+5V SUPPLY

0.1µF

VIN

2

4

DAC-8420

DIGITAL

CONTROL

REF-43

VOUTGND

+5V SUPPLY

2.5V

6

VREFHI

5

DAC A

DAC B

DAC C

DAC D

1

0.1µF

VOUTA

7

6

VOUTB

VOUTC

3

2

VOUTD

One opto-isolated line (

LD) can be eliminated from this circuit

by adding an inexpensive 4-bit TTL Counter to generate the

Load pulse for the DAC8420 after 16 clock cycles. The counter

is used to count of the number of clock cycles loading serial data

to the DAC8420. After all 16 bits have been clocked into the

converter, the counter resets, and a load pulse is generated on

clock 17. In either circuit, the DAC8420’s serial interface provides a simple, low cost method of isolating the digital control.

915 1614121110 8

4

GND VREFLO

DIGITAL INPUTS

Figure 29. +5 V Single Supply Operation Using REF43

Isolated Digital Interface

Because the DAC8420 is ideal for generating accurate voltages

in process control and industrial applications, due to noise,

safety requirements, or distance, it may be necessary to isolate it

from the central controller. This can be easily achieved by using

opto-isolators, which are commonly used to provide electrical

isolation in excess of 3 kV. Figure 30 shows a simple 3-wire

interface scheme to control the clock, data, and load pulse. For

normal operation,

CS is tied permanently LOW so that the

DAC8420 is always selected. The resistor and capacitor on the

CLR pin provide a power-on reset with 10 ms time constant. The

three opto-isolators are used for the SDI, CLK, and

REV. 0

LD lines.

–13–

Figure 30. Opto-lsolated 3-Wire Interface

Dual Window Comparator

Often a comparator is needed to signal an out-of-range warning.

Combining the DAC8420 with a quad comparator such as the

CMP04 provides a simple dual window comparator with adjustable trip points as shown in Figure 31. This circuit can be

operated with either a dual or a single supply. For the A input

channel, DAC B sets the low trip point and DAC A sets the upper trip point. The CMP04 has open-collector outputs that are

connected together in “Wired-OR” configuration to generate an

out-of-range signal. For example, when VINA goes below the

trip point set by DAC B, comparator C2 pulls the output down,

turning the red LED on. The output can also be used as a logic

signal for further processing.

DAC8420

+5V SUPPLY

0.1µF

REF-43

VIN

2

4

GND

DAC-8420

DIGITAL

CONTROL

DIGITAL INPUTS

+5V SUPPLY

2.5V

6

V

OUT

VREFHI

DAC A

DAC B

DAC C

DAC D

15 1614121110

49

GND VREFLO

15

8

VSS

0.1µF

VOUTA

7

VOUTB

6

VOUTC

3

VOUTD

2

VINA

VINB

+5V

0.1µF

3

CMP-04

5

C1

4

7

C2

6

9

C3

8

11

C4

10

2

1

14

13

12

+5V

604Ω

RED LED

OUT A

+5V

604Ω

RED LED

OUT B

Figure 31. Dual Programmable Window Comparator

MC68HC11 Microcontroller Interfacing

Figure 32 shows a serial interface between the DAC8420 and

the MC68HC11 8-bit microcontroller. The SCK output of the

68HC11 drives the CLK input of the DAC, and the MOSI port

outputs the serial data to load into the SDI input of the DAC.

The port lines PD5, PC0, PC1, and PC2 provide the controls to

the DAC as shown.

PC2

PC1

PC0

MC68HC11*

(PD5) SS

SCK

MOSI

*ADDITIONAL PINS OMITTED FOR CLARITY

CLSEL

CLR

CS

DAC-8420*

LD

CLK

SDI

Figure 32. MC68HC11 Microcontroller Interface

For correct operation, the 68HC11 should be configured such

that its CPOL bit and CPHA bit are both set to 1. In this configuration, serial data on MOSI of the 68HC11 is valid on the

rising edge of the clock, which is the required timing for the

DAC8420 Data is transmitted in 8-bit bytes (MSB first), with

only eight rising clock edges occurring in the transmit cycle. To

load data to the DAC8420’s input register, PC0 is taken low

and held low during the entire loading cycle. The first 8 bits are

shifted in address first, immediately followed by another 8 bits

in the second least-significant byte to load the complete 16-bit

word. At the end of the second byte load, PC0 is then taken

high. To prevent an additional advancing of the internal shift

register, SCK must already be asserted before PC0 is taken

high. To transfer the contents of the input shift register to the

DAC register, PD5 is then taken low, asserting the

LD input of

the DAC and completing the loading process. PD5 should return high before the next load cycle begins. The DAC8420’s

CLR input, controlled by the output PC1, provides an asynchronous clear function.

–14–

REV. 0

DAC8420 to M68HC11 Interface Assembly Program

*

M68HC11 Register Definitions

PORTC EQU $1003 Port C control register

* “0,0,0,0;0,CLSEL,

DDRC EQU $1007 Port C data direction

PORTD EQU $1008 Port D data register

* “0,0,

DDRD EQU $1009 Port D data direction

SPCR EQU $1028 SPI control register

* “SPIE,SPE,DWOM,MSTR;CPOL,CPHA,SPR1,SPR0”

SPSR EQU $1029 SPI status register

* “SPIF,WCOL,0,MODF;0,0,0,0”

SPDR EQU $102A SPI data register; Read-Buffer; Write-Shifter

*

* SDI RAM variables: SDI1 is encoded from 0 (Hex) to CF (Hex)

* To select: DAC A – Set SDI1 to $0X

* DAC requires two 8-bit loads – Address + 12 bits

SDI1 EQU $00 SDI packed byte 1 “A1,A0,0,0;MSB,DB10,DB9,DB8”

SDI2 EQU $01 SDI packed byte 2

“DB7,DB6,DB5,DB4;DB3,DB2,DB1,DB0”

* Main Program

ORG $C000 Start of user’s RAM in EVB

INIT LDS #$CFFF Top of C page RAM

* Initialize Port C Outputs

LDAA #$07 0,0,0,0;0,1,1,1

* CLSEL-Hi,

* To reset DAC to ZERO-SCALE, set CLSEL-Lo ($03)

* To reset DAC to MID-SCALE, set CLSEL-Hi ($07)

STAA PORTC Initialize Port C Outputs

LDAA #$07 0,0,0,0;0,1,1,1

STAA DDRC CLSEL,

* Initialize Port D Outputs

LDAA #$30 0,0,1,1;0,0,0,0

*

STAA PORTD Initialize Port D Outputs

LDAA #$38 0,0,1,1;1,0,0,0

STAA DDRD

LD,SCLK;SDI,0,0,0”

DAC B – Set SDI1 to $4X

DAC C – Set SDI1 to $8X

DAC D – Set SDI1 to $CX

SDI2 is encoded from 00 (Hex) to FF (Hex)

LD-Hi,SCLK-Hi,SDI-Lo

LD,SCLK, and SDI are now enabled as outputs

CLR,CS”

CLR-Hi, CS-Hi

CLR, and CS are now enabled as outputs

DAC8420

* Initialize SPI Interface

LDAA #$5F

STAA SPCR SPI is Master,CPHA=1,CPOL=1,Clk rate=E/32

* Call update subroutine

BSR UPDATE Xfer 2 8-bit words to DAC-8420

JMP $E000 Restart BUFFALO

* Subroutine UPDATE

UPDATE PSHX Save registers X, Y, and A

PSHY

PSHA

* Enter Contents of SDI1 Data Register (DAC# and 4 MSBs)

LDAA #$80 1,0,0,0;0,0,0,0

STAA SDI1 SDI1 is set to 80 (Hex)

* Enter Contents of SDI2 Data Register

LDAA #$00 0,0,0,0;0,0,0,0

STAA SDI2 SDI2 is set to 00 (Hex)

LDX #SDI1 Stack pointer at 1st byte to send via SDI

LDY #$1000 Stack pointer at on-chip registers

* Clear DAC output to zero

BCLR PORTC,Y $02 Assert

BSET PORTC,Y $02 Deassert

* Get DAC ready for data input

BCLR PORTC,Y $01 Assert

TFRLP LDAA 0,X Get a byte to transfer via SPI

STAA SPDR Write SDI data reg to start xfer

WAIT LDAA SPSR Loop to wait for SPIF

BPL WAIT SPIF is the MSB of SPSR

* (when SPIF is set, SPSR is negated)

INX Increment counter to next byte for xfer

CPX #SDI2+ 1 Are we done yet ?

BNE TFRLP If not, xfer the second byte

* Update DAC output with contents of DAC register

BCLR PORTD,Y 520 Assert

BSET PORTD,Y $20 Latch DAC register

BSET PORTC,Y $01 De-assert

PULA When done, restore registers X, Y & A

PULY

PULX

RTS ** Return to Main Program **

CLR

CLR

CS

LD

CS

REV. 0

–15–

DAC8420

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

16-Pin Epoxy DIP

(P Suffix)

PIN 1

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

PIN 1

16

1

0.022 (0.558)

0.014 (0.356)

16

1

0.840 (21.33)

0.745 (18.93)

0.100

(2.54)

BSC

0.070 (1.77)

0.045 (1.15)

16-Pin Wide-Body SOL

9

8

0.4133 (10.50)

0.3977 (10.00)

9

8

(SOL)

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

0.1043 (2.65)

0.0926 (2.35)

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.0291 (0.74)

0.0098 (0.25)

x 45

0.195 (4.95)

0.115 (2.93)

°

C1836–18–9/93

0.0118 (0.30)

0.0040 (0.10)

0.005 (0.13) MIN

PIN 1

0.200

(5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.0500

(1.27)

BSC

16

1

0.023 (0.58)

0.014 (0.36)

0.0192 (0.49)

0.0138 (0.35)

16-Pin Cerdip

(Q Suffix)

0.840 (21.34) MAX

0.100

(2.54)

BSC

0.0125 (0.32)

0.0091 (0.23)

0.080 (2.03) MAX

0.070 (1.78)

0.030 (0.76)

–16–

9

0.310 (7.87)

0.220 (5.59)

8

0.060 (1.52)

0.015 (0.38)

8

°

0

°

0.150

(3.81)

MIN

SEATING

PLANE

0.0500 (1.27)

0.0157 (0.40)

0.320 (8.13)

0.290 (7.37)

0.015 (0.38)

0.008 (0.20)

15

°

0

°

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...