Octal 14-Bit, Parallel Input,

a

FEATURES

Eight 14-Bit DACs in One Package

Voltage Outputs

Offset Adjust for Each DAC Pair

Reference Range of ⴞ5 V

Maximum Output Voltage Range of ⴞ10 V

ⴞ15 V ⴞ 10% Operation

Clear Function to User-Defined Voltage

44-Lead MQFP Package

APPLICATIONS

Automatic Test Equipment

Process Control

General Purpose Instrumentation

V

CCVSSVDD

GENERAL DESCRIPTION

The AD7841 contains eight 14-bit DACs on one monolithic

chip. It has output voltages with a full-scale range of ±10 V

from reference voltages of ±5 V.

The AD7841 accepts 14-bit parallel loaded data from the external bus into one of the input registers under the control of the

WR, CS and DAC channel address pins, A0–A2.

The DAC outputs are updated on reception of new data into

the DAC registers. All the outputs may be updated simultaneously by taking the LDAC input low.

Each DAC output is buffered with a gain-of-two amplifier into

which an external DAC offset voltage can be inserted via the

DUTGNDx pins.

The AD7841 is available in a 44-lead MQFP package.

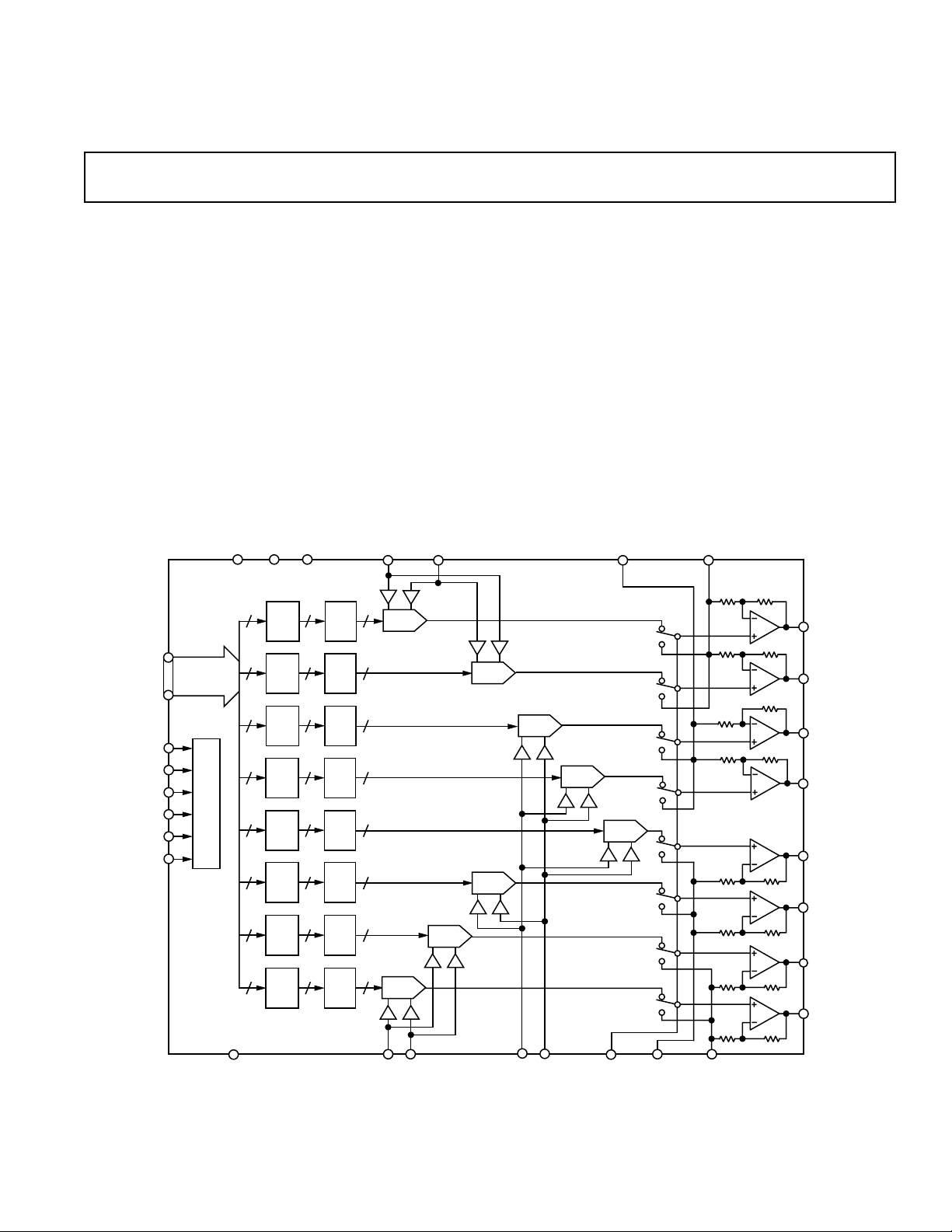

FUNCTIONAL BLOCK DIAGRAM

V

REF

(+)ABV

REF

(–)

AB

DUTGND

CD

Voltage-Output DAC

AD7841

DUTGND

AB

DB13

DB0

WR

CS

A0

LDAC

AD7841

14 14 14

INPUT

REG

A

14 14 14

INPUT

REG

B

14 14 14

INPUT

REG

C

14 14 14

INPUT

REG

D

A1

A2

14 14 14

DECODE

ADDRESS

INPUT

REG

E

14 14 14

INPUT

REG

F

14 14 14

INPUT

REG

G

14

INPUT

REG

H

DAC

REG

A

DAC

REG

B

DAC

REG

C

DAC

REG

D

DAC

REG

E

DAC

REG

F

DAC

REG

G

14 14

DAC

REG

H

DAC A

DAC B

DAC C

DAC D

DAC E

DAC F

DAC G

DAC H

RR

RR

R

R

R

R

R

R

R

R

R

R

R

R

A

V

OUT

B

V

OUT

C

V

OUT

D

V

OUT

E

V

OUT

F

V

OUT

G

V

OUT

H

V

OUT

V

GND

V

REF

GH

(–)

(+)

REF

GH

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

V

REF

CDEF

(–)

(+)

V

REF

CDEF

CLR

DUTGND

EF

DUTGND

GH

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

(VCC = +5 V ⴞ 5%; VDD = +15 V ⴞ 10%; VSS = –15 V ⴞ 10%; GND = DUTGND =

AD7841–SPECIFICATIONS

0 V; RL = 5 k⍀ and CL = 50 pF to GND, T

Parameter A B Units Test Conditions/Comments

ACCURACY

Resolution 14 14 Bits

Relative Accuracy ±4 ±2 LSB max

Differential Nonlinearity –0.9/2 ±1 LSB max Guaranteed Monotonic Over Temperature for All

Zero-Scale Error ±8 ±8 LSB max V

Full-Scale Error ±8 ±8 LSB max V

Gain Error ±2 ±2 LSB typ V

Gain Temperature Coefficient

DC Crosstalk

REFERENCE INPUTS

2

2

2

0.5 0.5 ppm FSR/°C typ

10 10 ppm FSR/°C max

120 120 µV max See Terminology. Typically 75 µV

DC Input Impedance 100 100 MΩ typ

Input Current ±1 ±1 µA max Per Input. Typically ±0.03 µA

(+) Range 0/+5 0/+5 V min/max

V

REF

V

(–) Range –5/0 –5/0 V min/max

REF

(+) – V

[V

REF

DUTGND INPUTS

(–)] +2/+10 +2/+10 V min/max For Specified Performance. Can Go as Low as 0 V,

REF

2

DC Input Impedance 60 60 kΩ typ

Max Input Current ±0.3 ±0.3 mA typ Per Input

Input Range

OUTPUT CHARACTERISTICS

3

–2/+2 –2/+2 V min/max

2

Output Voltage Swing VSS + 2.5 V to VSS + 2.5 V to V typ V

V

– 2.5 V VDD – 2.5 V – V

DD

Short Circuit Current 15 15 mA max

Resistive Load 5 5 kΩ min To 0 V

Capacitive Load 50 50 pF max To 0 V

DC Output Impedance 0.5 0.5 Ω max

DIGITAL INPUTS

V

, Input High Voltage 2.4 2.4 V min

INH

, Input Low Voltage 0.8 0.8 V max

V

INL

I

, Input Current Total for All Pins

INH

2

@ +25°C ±1 ±1 µA max

to T

T

MIN

MAX

±10 ±10 µA max

CIN, Input Capacitance 10 10 pF max

POWER REQUIREMENTS

V

CC

V

DD

V

SS

Power Supply Sensitivity

␣␣ ∆Full Scale/∆V

␣␣ ∆Full Scale/∆V

I

CC

I

DD

I

SS

NOTES

1

Temperature range for A and B Versions: –40°C to +85°C.

2

Guaranteed by characterization. Not production tested.

3

See DUTGND Voltage Range section.

4

The AD7841 is functional with power supplies of ±12 V ±10% with reduced output range. Output amplifier requires 2.5 V of head room at the bottom and top ends

of the transfer for function. At 12 V supplies it is recommended to restrict the reference range to ±4 V.

Specifications subject to change without notice.

DD

SS

4

+4.75/+5.25 +4.75/+5.25 V min/max For Specified Performance

+15 V ± 10% +15 V ± 10% V min/max For Specified Performance

2

–15 V ± 10% –15 V ± 10% V min/max For Specified Performance

90 90 dB typ

90 90 dB typ

0.5 0.5 mA max V

10 10 mA max Outputs Unloaded. Typically 8 mA

10 10 mA max Outputs Unloaded. Typically 8 mA

1

= T

to T

A

MIN

, unless otherwise noted)

MAX

Grades

(+) = +5 V, V

REF

(–) = –5 V. Typically within

REF

±2 LSB

(+) = +5 V, V

REF

(–) = –5 V. Typically within

REF

±2 LSB

(+) = +5 V, V

REF

(–) = –5 V

REF

but Performance Not Guaranteed

= 2 × (V

OUT

DUTGND

= VCC, V

INH

(–) + [V

REF

= GND. Dynamic Current

INL

REF

(+) – V

(–)] × D)

REF

–2–

REV. 0

AD7841

(These characteristics are included for Design Guidance and are not subject

AC PERFORMANCE CHARACTERISTICS

A & B

Parameter Versions Units Test Conditions/Comments

DYNAMIC PERFORMANCE

Output Voltage Settling Time 31 µs typ Full-Scale Change to ±1/2 LSB. DAC Latch Contents Alternately

Slew Rate 0.7 V/µs typ

Digital-to-Analog Glitch Impulse 230 nV-s typ Measured with V

Channel-to-Channel Isolation 99 dB typ See Terminology

DAC-to-DAC Crosstalk 40 nV-s typ See Terminology

Digital Crosstalk 0.2 nV-s typ Feedthrough to DAC Output Under Test Due to Change in Digital

Digital Feedthrough 0.1 nV-s typ Effect of Input Bus Activity on DAC Output Under Test

Output Noise Spectral Density

␣ ␣ @ 1 kHz 200 nV/√Hz

1, 2

TIMING SPECIFICATIONS

(VCC = +5 V ⴞ 5%; VDD = +15 V ⴞ 10%; VSS = –15 V ⴞ 10%; GND = DUTGND = 0 V)

to production testing.)

Loaded with All 0s and All 1s

(+) = +5 V, V

REF

(–) = –5 V. DAC Latch

REF

Alternately Loaded with 1FFF Hex and 2000 Hex. Not Dependent

on Load Conditions

Input Code to Another Converter

typ All 1s Loaded to DAC. V

(+) = V

REF

(–) = 0 V

REF

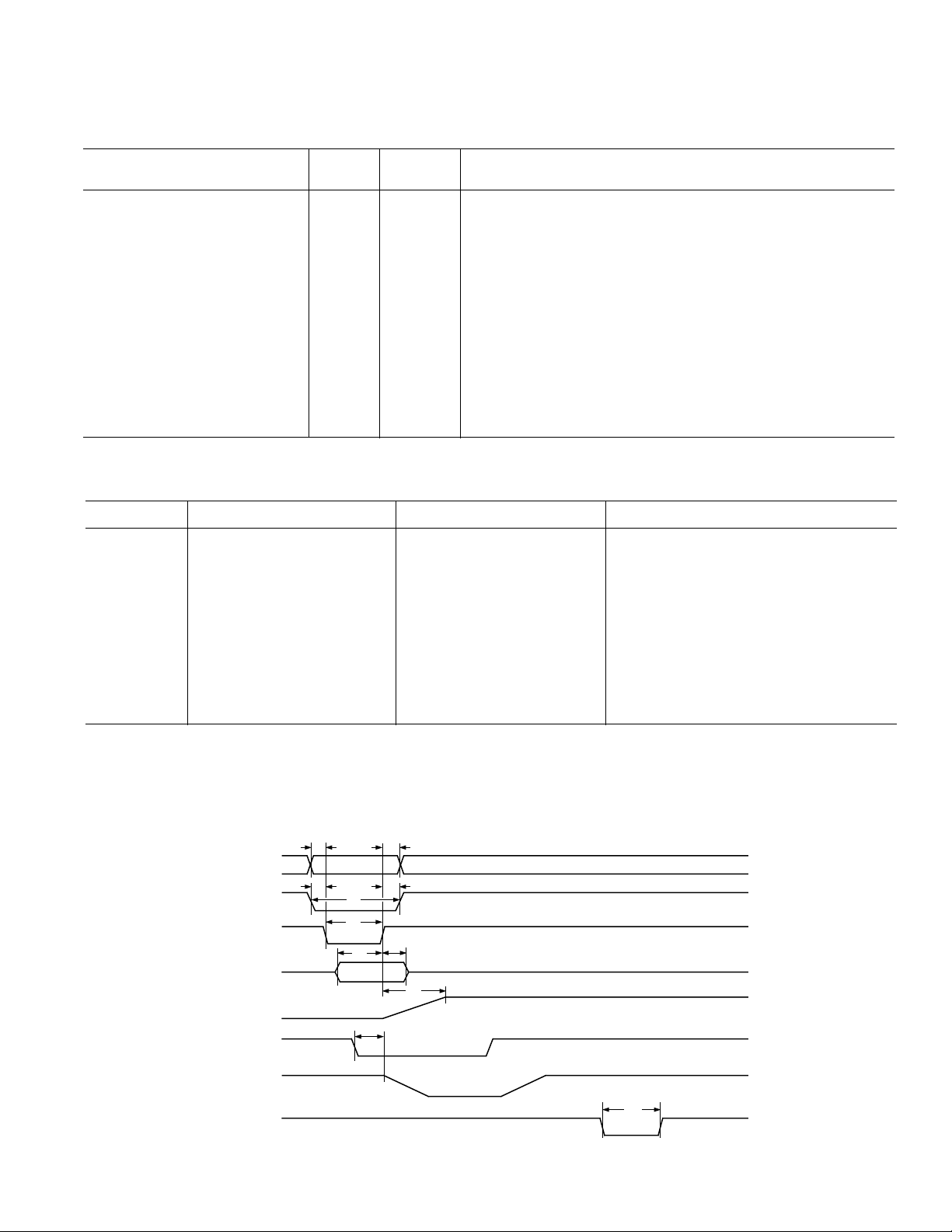

Parameter Limit at T

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

NOTES

1

All input signals are specified with tr = tf = 5 ns (10% to 90% of 5 V) and timed from a voltage level of 1.6 V.

2

Rise and fall times should be no longer than 50 ns.

Specifications subject to change without notice.

15 ns min Address to WR Setup Time

0 ns min Address to WR Hold Time

50 ns min CS Pulsewidth Low

50 ns min WR Pulsewidth Low

0 ns min CS to WR Setup Time

0 ns min WR to CS Hold Time

20 ns min Data Setup Time

0 ns min Data Hold Time

31 µs typ Settling Time

300 ns max CLR Pulse Activation Time

50 ns min LDAC Pulsewidth Low

A0, A1, A2

DATA

V

CS

WR

OUT

CLR

MIN, TMAX

t

1

t

5

t

2

t

6

t

3

t

4

t

8

t

7

t

9

t

10

Units Description

V

OUT

LDAC

Figure 1. Timing Diagram

–3–REV. 0

t

11

AD7841

V

DD

V

CC

AD7841

HP5082-2811

V

DD

V

CC

IN4148

ABSOLUTE MAXIMUM RATINGS

(T

= +25°C unless otherwise noted)

A

VCC to GND3 . . . . . . . . . . . . . . . –0.3 V, +7 V or V

1, 2

+ 0.3 V

DD

(Whichever Is Lower)

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +17 V

V

DD

V

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V, –17 V

SS

Digital Inputs to GND . . . . . . . . . . . . . . –0.3 V, V

(+) to V

V

REF

V

(+) to GND . . . . . . . . . . . . . . . VSS – 0.3 V, VDD + 0.3 V

REF

V

(–) to GND . . . . . . . . . . . . . . . VSS – 0.3 V, VDD + 0.3 V

REF

DUTGND to GND . . . . . . . . . . . . . V

V

(A–H) to GND . . . . . . . . . . . . VSS – 0.3 V, VDD + 0.3 V

OUT

(–) . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +18 V

REF

– 0.3 V, VDD + 0.3 V

SS

+ 0.3 V

CC

Operating Temperature Range

Industrial (A Version) . . . . . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

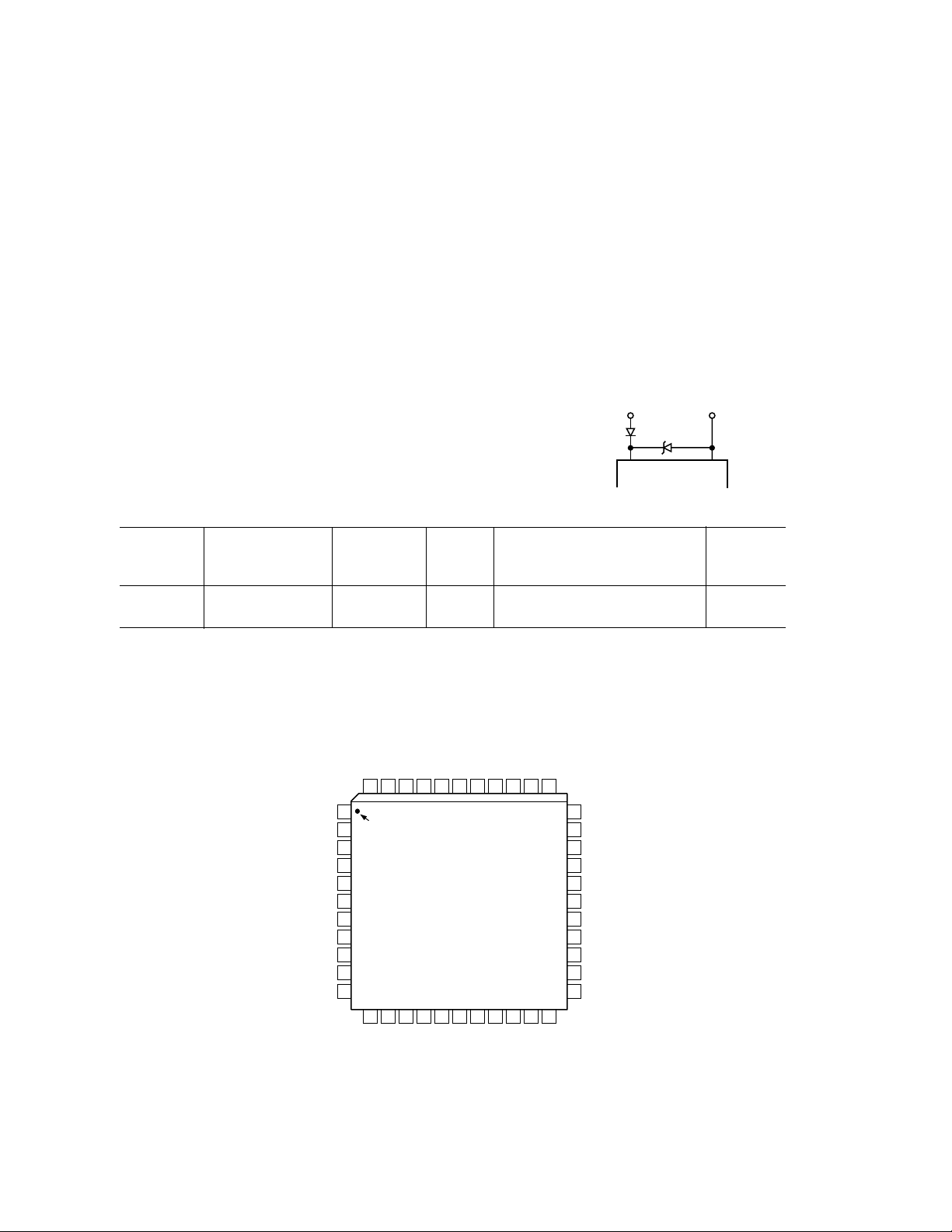

ORDERING GUIDE

Linearity

Temperature Error DNL Package Package

Model Range (LSBs) (LSBs) Description Option

AD7841AS –40°C to +85°C ±4 –0.9/+2 Plastic Quad Flatpack (MQFP) S-44

AD7841BS –40°C to +85°C ±2 ±1 Plastic Quad Flatpack (MQFP) S-44

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . .+150°C

MQFP Package

Power Dissipation . . . . . . . . . . . . . . . . . . (T

Max – T

J

)/θ

A

JA

θJA Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 95°C/W

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . .+215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . .+220°C

ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . >4000 V

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Transient currents of up to 100 mA will not cause SCR latch-up.

3

VCC must not exceed VDD by more than 0.3 V. If it is possible for this to happen

during power supply sequencing, the following diode protection scheme will ensure

protection.

DUTGND_AB

V

OUT

V

(–)AB

REF

V

(+)AB

REF

V

DD

V

LDAC

A2

A1

A0

CS

PIN CONFIGURATION

C

OUT

V

DUTGND_CD

CC

V

GND

D

(–)CDEF

OUT

REF

V

V

40 39 3841424344 36 35 3437

AD7841

TOP VIEW

(Not to Scale)

DB1

DB0

B

OUT

V

1

PIN 1

IDENTIFIER

2

A

3

4

5

6

SS

7

8

9

10

11

12 13 14 15 16 17 18 19 20 21 22

WR

(+)CDEF

DD

REF

V

V

DB3

DB2

E

OUT

V

DUTGND_EF

DB5

DB4

F

OUT

V

DB6

G

OUT

V

DB7

33

32

31

30

29

28

27

26

25

24

23

DUTGND_GH

H

V

OUT

V

(–)GH

REF

(+)GH

V

REF

CLR

DB13

DB12

DB11

DB10

DB9

DB8

–4–

REV. 0

PIN FUNCTION DESCRIPTIONS

Pin

No. Mnemonic Description

AD7841

1 DUTGND_AB Device Sense Ground for DACs A and B. V

OUT

A and V

B are referenced to the voltage

OUT

applied to this pin.

2, 32, 34, V

OUT

A..V

H DAC Outputs.

OUT

35, 37, 41,

43, 44

3, 4 V

5, 38 V

6, 29 V

(–)AB, V

REF

DD

SS

(+)AB Reference Inputs for DACs A and B. These reference voltages are referred to GND.

REF

Positive Analog Power Supply; +15 V ± 10% for Special Performance.

Negative Analog Power Supply; –15 V ± 10% for Special Performance.

7 LDAC Load DAC Logic Input (active low). When this logic input is taken low the contents of the

registers are transferred to their respective DAC registers. LDAC can be tied permanently

low enabling the outputs to be updated on the rising edge of WR.

8, 9, 10 A2, A1, A0 Address inputs. A0, A1 and A2 are decoded to select one of the eight input registers for a

data transfer.

11 CS Level-Triggered Chip Select Input (active low). The device is selected when this input is low.

12 WR Level-Triggered Write Input (active low), used in conjunction with CS to write data to the

AD7841 data registers. Data is latched into the selected input register on the rising edge

of WR.

13 V

CC

Logic Power Supply; +5 V ± 5%.

14 GND Ground.

15–28 DB0␣ .␣ .␣ DB12 Parallel Data Inputs. The AD7841 can accept a straight 14-bit parallel word on DB0 to

DB13 where DB13 is the MSB and DB0 is the LSB.

29 CLR Asynchronous Clear Input (level sensitive, active low). When this input is low, all analog

outputs are switched to the externally set potential on the relevant DUTGND pin. The contents of input registers and DAC registers A to H are not affected when the CLR pin is taken

low. When CLR is brought back high, the DAC outputs revert to their original outputs as

determined by the data in their DAC registers.

30, 31 V

33 DUTGND_GH Device Sense Ground for DACs G and H. V

(+)GH, V

REF

(–)GH Reference Inputs for DACs G and H. These reference voltages are referred to GND.

REF

OUT

G and V

H are referenced to the voltage

OUT

applied to this pin.

36 DUTGND_EF Device Sense Ground for DACs E and F. V

OUT

E and V

F are referenced to the voltage

OUT

applied to this pin.

39 V

40 V

42 DUTGND_CD Device Sense Ground for DACs C and D. V

(+)CDEF Reference Inputs for DACs C, D, E and F. These reference voltages are referred to GND.

REF

(–)CDEF Reference Inputs for DACs C, D, E and F. These reference voltages are referred to GND.

REF

OUT

C and V

D are referenced to the voltage

OUT

applied to this pin.

–5–REV. 0

AD7841

TERMINOLOGY

Relative Accuracy

Relative accuracy or endpoint linearity is a measure of the maximum deviation from a straight line passing through the endpoints

of the DAC transfer function. It is measured after adjusting for

zero-scale error and full-scale error and is expressed in Least

Significant Bits.

Differential Nonlinearity

Differential nonlinearity is the difference between the measured

change and the ideal 1 LSB change between any two adjacent

codes. A specified differential nonlinearity of 1 LSB maximum

ensures monotonicity.

DC Crosstalk

Although the common input reference voltage signals are internally buffered, small IR drops in the individual DAC reference

inputs across the die can mean that an update to one channel

can produce a dc output change in one or another of the channel outputs.

The eight DAC outputs are buffered by op amps that share

common V

and VSS power supplies. If the dc load current

DD

changes in one channel (due to an update), this can result in a

further dc change in one or another of the channel outputs. This

effect is most obvious at high load currents and reduces as the

load currents are reduced. With high impedance loads the effect

is virtually impossible to measure.

Output Voltage Settling Time

This is the amount of time it takes for the output to settle to a

specified level for a full-scale input change.

Digital-to-Analog Glitch Impulse

This is the amount of charge injected into the analog output

when the inputs change state. It is specified as the area of the

glitch in nV-secs. It is measured with V

V

(–) = –5 V and the digital inputs toggled between 1FFFH and

REF

(+) = +5 V and

REF

2000H.

Channel-to-Channel Isolation

Channel-to-channel isolation refers to the proportion of input

signal from one DAC’s reference input that appears at the output of another DAC. It is expressed in dBs.

DAC-to-DAC Crosstalk

DAC-to-DAC crosstalk is defined as the glitch impulse that

appears at the output of one converter due to both the digital

change and subsequent analog O/P change at another converter.

It is specified in nV-secs.

Digital Crosstalk

The glitch impulse transferred to the output of one converter

due to a change in digital input code to the other converter is

defined as the digital crosstalk and is specified in nV-secs.

Digital Feedthrough

When the device is not selected, high frequency logic activity on

the device’s digital inputs can be capacitively coupled both

across and through the device to show up as noise on the V

OUT

pins. This noise is digital feedthrough.

DC Output Impedance

This is the effective output source resistance. It is dominated by

package lead resistance.

Full-Scale Error

This is the error in DAC output voltage when all 1s are loaded

into the DAC latch. Ideally the output voltage, with all 1s loaded

into the DAC latch, should be 2 V

Zero-Scale Error

(+) – 1 LSB.

REF

Zero-scale error is the error in the DAC output voltage when all

0s are loaded into the DAC latch. Ideally the output voltage,

with all 0s in the DAC latch should be equal to 2 V

(–). Zero-

REF

scale error is mainly due to offsets in the output amplifier.

Gain Error

Gain Error is defined as (Full-Scale Error) – (Zero-Scale Error).

GENERAL DESCRIPTION

DAC Architecture—General

Each channel consists of a straight 14-bit R-2R voltage-mode

DAC. The full-scale output voltage range is equal to twice the

reference span of V

REF

(+) – V

binary; all 0s produces an output of 2 V

an output of 2 V

(+) – 1 LSB.

REF

(–). The DAC coding is straight

REF

(–); all 1s produces

REF

The analog output voltage of each DAC channel reflects the

contents of its own DAC register. Data is transferred from the

external bus to the input register of each DAC on a per channel

basis.

Bringing the CLR line low switches all the signal outputs, V

to V

H, to the voltage level on the relevant DUTGND pin.

OUT

OUT

A

When the CLR signal is brought back high, the output voltages

from the DACs will reflect the data stored in the relevant DAC

registers.

Data Loading to the AD7841

Data is loaded into the AD7841 in straight parallel 14-bit wide

words.

The DAC output voltages, V

OUT

A – V

H are updated to

OUT

reflect new data in the DAC registers.

The actual input register being written to is determined by the

logic levels present on the device’s address lines, as shown in

Table I.

Table I. Address Line Truth Table

A2 A1 A0 DAC Selected

0 0 0 INPUT REG A (DAC A)

0 0 1 INPUT REG B (DAC B)

0 1 0 INPUT REG C (DAC C)

0 1 1 INPUT REG D (DAC D)

1 0 0 INPUT REG E (DAC E)

1 0 1 INPUT REG F (DAC F)

1 1 0 INPUT REG G (DAC G)

1 1 1 INPUT REG H (DAC H)

–6–

REV. 0

Typical Performance Characteristics–

0 5001000150020002500 3000 350040004500 5000

m

AD7841

2

VDD = +15V

= –15V

V

SS

(+) = +5V

V

REF

1

(–) = –5V

V

REF

= 258C

T

A

0

INL ERROR – LSBs

–1

–2

0 2048

4096 12288 16384

6144 8192 10240 14336

CODE

Figure 2. Typical INL Plot

1

0.5

VDD = +15V

= –15V

V

SS

(+) = +5V

V

REF

(+) = –5V

V

0

REF

DNL ERROR – LSBs

–0.5

–1

–40 100–20020406080

TEMPERATURE – 8C

Figure 5. Typical DNL Error vs.

Temperature

1

0.75

0.5

0.25

0

–0.25

VDD = +15V

DNL ERROR – LSBs

–0.75

–0.5

–1

V

SS

V

REF

V

REF

= 258C

T

A

0 2048

= –15V

(+) = +5V

(–) = –5V

4096 6144 8192

10240 12288 14336 16384

CODE

Figure 3. Typical DNL Plot

4

VDD = +15V

= –15V

V

SS

= +5V

V

REF(+)

2

0

ERROR – LSBs

–2

–4

–40 –20 100

= –5V

V

REF(–)

ZERO-SCALE ERROR

FULL-SCALE ERROR

0 20406080

TEMPERATURE – 8C

Figure 6. Zero-Scale and Full-Scale

Error vs. Temperature

4

VDD = +15V

= –15V

V

SS

(+) = +5V

V

REF

(–) = –5V

V

2

0

INL ERROR – LSBs

–2

–1

REF

–40 –20 1000 20406080

TEMPERATURE – 8C

Figure 4. Typical INL Error vs.

Temperature

6

5

4

DIGITAL INPUTS @

THRESHOLDS

3

– mA

2

CC

I

1

DIGITAL INPUTS @ SUPPLIES

0

–1

–40 100–200 20406080

TEMPERATURE – 8C

VCC = +5V

= +15V

V

DD

V

= –15V

SS

Figure 7. ICC vs. Temperature

0.6

0.5

0.4

0.3

0.2

Volts

0.1

0

–0.1

–0.2

Figure 8. Typical Digital-to-Analog

Glitch Impulse

10.19

10.18

– Volts

OUT

10.17

V

10.16

27 3328 29 30 31 32

SETTLING TIME –

Figure 9. Settling Time (+)

–7–REV. 0

10

VDD = +15V

= –15V

V

SS

= +5V

V

CC

I

8

– mA

SS

/I

DD

I

6

4

s

–40 –20 0 20 40 60

DD

I

SS

TEMPERATURE – °C

80

100

Figure 10. IDD, ISS vs. Temperature

AD7841

Unipolar Configuration

Figure 11 shows the AD7841 in the unipolar binary circuit

configuration. The V

AD586, a +5 V reference. V

(+) input of the DAC is driven by the

REF

(–) is tied to ground. Table II

REF

gives the code table for unipolar operation of the AD7841.

Other suitable references include the REF02, a precision +5 V

reference, and the REF195, a low dropout, micropower precision +5 V reference.

+5V+15V

1mF

2

8

C1

6

AD586

5

R1

4

SIGNAL

GND

*ADDITIONAL PINS OMITTED FOR CLARITY

10kV

V

V

REF

V

REF

DDVCC

(+)

AD7841*

DUTGND

(–)

V

SS

–15V

V

GND

OUT

V

OUT

(0 TO +10V)

SIGNAL

GND

Figure 11. Unipolar +10 V Operation

Offset and gain may be adjusted in Figure 11 as follows: To

adjust offset, disconnect the V

DAC with all 0s and adjust the V

(–) input from 0 V, load the

REF

(–) voltage until V

REF

OUT

= 0 V.

For gain adjustment, the AD7841 should be loaded with all 1s

and R1 adjusted until V

OUT

= 2 V

(+) – 1 LSB = 10 V(16383/

REF

16384) = 9.99939 V.

Many circuits will not require these offset and gain adjustments.

In these circuits R1 can be omitted. Pin 5 of the AD586 may be

left open circuit and Pin 2 (V

(–)) of the AD7841 tied to 0 V.

REF

Table II. Code Table for Unipolar Operation

Binary Number in DAC Register Analog Output

MSB␣␣␣␣␣␣␣␣ LSB (V

11 1111 1111 1111 2 V

10 0000 0000 0000 2 V

01 1111 1111 1111 2 V

00 0000 0000 0001 2 V

)

OUT

(16383/16384) V

REF

(8192/16384) V

REF

(8191/16384) V

REF

(1/16384) V

REF

00 0000 0000 0000 0 V

NOTES

V

= V

(+); V

REF

REF

For V

(+) = +5 V, 1 LSB = +10 V/2

REF

(–) = 0 V for unipolar operation.

REF

14

= +10 V/16384 = 610 µV.

Bipolar Configuration

Figure 12 shows the AD7841 set up for ±10 V operation. The

AD588 provides precision ±5 V tracking outputs that are fed to

the V

(+) and V

REF

(–) inputs of the AD7841. The code table

REF

for bipolar operation of the AD7841 is shown in Table III.

In Figure 12, full-scale and bipolar zero adjustments are provided by varying the gain and balance on the AD588. R2 varies

the gain on the AD588 while R3 adjusts the offset of both the

+5 V and –5 V outputs together with respect to ground.

For bipolar-zero adjustment, the DAC is loaded with

1000␣ .␣ .␣ .␣ 0000 and R3 is adjusted until V

= 0 V. Full scale

OUT

is adjusted by loading the DAC with all 1s and adjusting R2

until V

= 10(8191/8192) V = 9.99878 V.

OUT

When bipolar-zero and full-scale adjustment are not needed, R2

and R3 can be omitted. Pin 12 on the AD588 should be connected to Pin 11 and Pin 5 should be left floating.

V

DDVCC

(+)

AD7841*

DUTGND

(–)

V

SS

–15V

+5V+15V

V

OUT

GND

V

OUT

(–10V TO +10V)

SIGNAL

GND

100kV

R1

39kV

46

7

C1

9

1mF

R2

100kV

5

10

11

12 8 13

R3

2

3

V

REF

1

AD588

14

15

V

REF

16

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 12. Bipolar ±10 V Operation

Table III. Code Table for Bipolar Operation

Binary Number in DAC

Register Analog Output

MSB LSB (V

11 1111 1111 1111 2[V

10 0000 0000 0001 2[V

10 0000 0000 0000 2[V

01 1111 1111 1111 2[V

00 0000 0000 0001 2[V

00 0000 0000 0000 2[V

NOTES

V

= (V

REF

For V

20 V/16384 = 1.22 mV.

(+) – V

REF

(+) = +5 V, and V

REF

REF

(–)).

(–) = –5 V, V

REF

)

OUT

(–) + V

REF

(–) + V

REF

(–) + V

REF

(–) + V

REF

(–) + V

REF

(–)] V

REF

= 10 V, 1 LSB = 2 V

REF

(16383/16384)] V

REF

(8193/16384)] V

REF

(8192/16384)] V

REF

(8191/16384)] V

REF

(1/16384)] V

REF

REF

V/214 =

CONTROLLED POWER-ON OF THE OUTPUT STAGE

A block diagram of the output stage of the AD7841 is shown in

Figure 13. It is capable of driving a load of 5 kΩ in parallel with

50 pF. G

power on voltage present at V

also used in conjunction with the CLR input to set V

to G6 are transmission gates used to control the

1

. On power up G1 and G2 are

OUT

OUT

to the

user defined voltage present at the DUTGND pin. When CLR

is taken back high, the DAC outputs reflect the data in the DAC

registers.

G

DAC

1

G

G

2

R

DUTGND

G

4

R = 60kV

G

G

6

3

5

14kV

V

OUT

Figure 13. Block Diagram of AD7841 Output Stage

–8–

REV. 0

Power-On with CLR Low

The output stage of the AD7841 has been designed to allow

output stability during power-on. If CLR is kept low during

power-on, then just after power is applied to the AD7841, the

situation is as depicted in Figure 14. G

while G

, G3 and G5 are closed.

2

G

DAC

1

G

2

R

DUTGND

G

4

G

G

Figure 14. Output Stage with VDD < 7 V or VSS > –3 V;

, G4 and G6 are open

1

G

6

3

R

5

14kV

V

OUT

CLR

Low

V

is kept within a few hundred millivolts of DUTGND via

OUT

G

and a 14 kΩ resistor. This thin-film resistor is connected in

5

parallel with the gain resistors of the output amplifier. The

output amplifier is connected as a unity gain buffer via G

the DUTGND voltage is applied to the buffer input via G

, and

3

. The

2

amplifier’s output is thus at the same voltage as the DUTGND

pin. The output stage remains configured as in Figure 14 until

the voltage at V

exceeds 7 V and VSS is more negative than

DD

–3 V. By now the output amplifier has enough headroom to

handle signals at its input and has also had time to settle. The

internal power-on circuitry opens G

G

. This situation is shown in Figure 15. Now the output ampli-

6

fier is configured in its noise gain configuration via G

and G5 and closes G4 and

3

and G6.

4

The DUTGND voltage is still connected to the noninverting

input via G

and this voltage appears at V

2

G

1

DAC

G

3

G

OUT

6

.

V

OUT

AD7841

G

DAC

1

G

G

2

R

DUTGND

G

4

G

Figure 16. Output Stage After

Power-On with CLR High

If CLR is high on the application of power to the device, the

output stages of the AD7841 are configured as in Figure 17

while V

closed and G

is less than 7 V and VSS is more positive than –3 V. G1 is

DD

is open, thereby connecting the output of the

2

DAC to the input of its output amplifier. G

while G

a unity gain buffer. V

through a 14 kΩ resistor until V

and G6 are open, thus connecting the output amplifier as

4

is connected to DUTGND via G

OUT

DD

negative than –3 V.

G

G

1

2

R

DUTGND

G

G

4

G

DAC

Figure 17. Output Stage Powering Up with

While V

< 7 V or VSS > –3 V

DD

When the difference between the supply voltages reaches +10 V,

the internal power-on circuitry opens G

and G6 configuring the output stage as shown in Figure 18.

G

6

3

R

5

14kV

CLR

Is Taken High

and G5 are closed

3

V

OUT

5

exceeds 7 V and VSS is more

G

6

3

R

5

14kV

and G5 and closes G

3

CLR

V

OUT

High

4

G

2

Figure 15.␣ Output Stage with VDD > 7 V and VSS < –3 V;

R

DUTGND

G

4

R

G

5

14kV

CLR

Low

V

has been disconnected from the DUTGND pin by the

OUT

opening of G

, but will track the voltage present at DUTGND

5

via the configuration shown in Figure 15.

When CLR is taken back high, the output stage is configured as

shown in Figure 16. The internal control logic closes G

opens G

. The output amplifier is connected in a noninverting

2

gain-of-two configuration. The voltage that appears on the V

and

1

OUT

pins is determined by the data present in the DAC registers.

–9–REV. 0

G

DAC

1

G

G

2

R

DUTGND

G

4

G

G

6

3

R

5

14kV

Figure 18.␣ Output Stage Powering Up with

When V

> V and VSS < –3 V

DD

CLR

V

OUT

High

AD7841

DUTGND Voltage Range

During power-on, the V

to the relevant DUTGND pins via G

pins of the AD7841 are connected

OUT

and the 14 kΩ thin-film

5

resistor. The DUTGND potential must obey the max ratings at

all times. Thus, the voltage at DUTGND must always be within

the range V

– 0.3 V, V

SS

voltages at the V

OUT

+ 0.3 V. However, in order that the

DD

pins of the AD7841 stay within ±2 V of the

relevant DUTGND potential during power-on, the voltage

applied to DUTGND should also be kept within the range

GND – 2␣ V, GND + 2 V.

Once the AD7841 has powered on and the on-chip amplifiers

have settled, any voltage that is now applied to the DUTGND

pin is subtracted from the DAC output, which has been gained

up by a factor of two. Thus, for specified operation, the maximum voltage that can be applied to the DUTGND pin increases to the maximum allowable 2 V

(+) voltage, and the

REF

minimum voltage that can be applied to DUTGND is the

minimum 2 V

(–) voltage. After the AD7841 has fully

REF

powered on, the outputs can track any DUTGND voltage within

this minimum/maximum range.

Power Supply Sequencing

When operating the AD7841, it is important that ground be

connected at all times to avoid high current states. The recommended power-up sequence is V

followed by VCC. If V

DD/VSS

CC

can exceed VDD on power-up, the diode scheme shown in the

absolute maximum ratings section will ensure protection. The

reference inputs and digital inputs should be powered up last.

Should the references exceed V

on power-up, current

DD/VSS

limiting resistors should be inserted in series with the reference

inputs to limit the current to 20 mA. Logic inputs should not be

applied before V

. Current limiting resistors (470 Ω) in series

CC

with the logic inputs should be inserted if these inputs come up

before V

CC

.

MICROPROCESSOR INTERFACING

Interfacing the AD7841—16-Bit Interface

The AD7841 can be interfaced to a variety of 16-bit microcontrollers or DSP processors. Figure 19 shows the AD7841

interfaced to a generic 16-bit microcontroller/DSP processor.

The lower address lines from the processor are connected to A0,

A1 and A2 on the AD7841 as shown. The upper address lines

are decoded to provide a chip select signal or an LDAC signal

for the AD7841. The fast interface timing of the AD7841 allows

direct interface to a wide variety of microcontrollers and DSPs

as shown in Figure 19.

mCONTROLLER/

DSP PROCESSOR*

D13

DATA

BUS

UPPER BITS OF

ADDRESS BUS

R/W

*ADDITIONAL PINS OMITTED FOR CLARITY

D0

ADDRESS

DECODE

A2

A1

A0

AD7841

D13

D0

CS

LDAC

A2

A1

A0

WR

Figure 19. AD7841 Parallel Interface

APPLICATIONS

Power Supply Bypassing and Grounding

In any circuit where accuracy is important, careful consideration

of the power supply and ground return layout helps to ensure

the rated performance. The printed circuit board on which the

AD7841 is mounted should be designed such that the analog

and digital sections are separated and confined to certain areas

of the board. This facilitates the use of ground planes that can

be easily separated. A minimum etch technique is generally best

for ground planes as it gives the best shielding. Digital and analog ground planes should be joined at only one place. The GND

pin of the AD7841 should be connected to the AGND of the

system. If the AD7841 is in a system where multiple devices

require an AGND-to-DGND connection, the connection should

be made at one point only, a star ground point that should be

established as close as possible to the AD7841.

Digital lines running under the device should be avoided as

these will couple noise onto the die. The analog ground plane

should be allowed to run under the AD7841 to avoid noise

coupling. The power supply lines of the AD7841 should use as

large a trace as possible to provide low impedance paths and

reduce the effects of glitches on the power supply line. Fast

switching signals like clocks should be shielded with digital

ground to avoid radiating noise to other parts of the board and

should never be run near the analog inputs.

Avoid crossover of digital and analog signals. Traces on opposite

sides of the board should run at right angles to each other. This

reduces the effects of feedthrough through the board. A microstrip technique is by far the best but not always possible with a

double sided board. In this technique, the component side of

the board is dedicated to ground plane while signal traces are

placed on the solder side.

The AD7841 should have ample supply bypassing located as

close to the package as possible, ideally right up against the

–10–

REV. 0

AD7841

device. Figure 20 shows the recommended capacitor values of

10 µF in parallel with 0.1 µF on each of the supplies. The 10 µF

capacitors are the tantalum bead type. The 0.1 µF capacitor

should have low Effective Series Resistance (ESR) and Effective

Series Inductance (ESI), such as the common ceramic types,

which provide a low impedance path to ground at high frequencies to handle transient currents due to internal logic switching.

CC

AD7841

V

DD

V

SS

10mF

0.1mF

10mF0.1mF10mF 0.1mF

V

Figure 20. Recommended Decoupling Scheme for AD7841

Automated Test Equipment

The AD7841 is particularly suited for use in an automated test

environment. Figure 21 shows the AD7841 providing the necessary voltages for the pin driver and the window comparator in a

typical ATE pin electronics configuration. AD588s are used to

provide reference voltages for the AD7841. In the configuration

shown, the AD588s are configured so that the voltage at Pin 1 is

5 V greater than the voltage at Pin 9 and the voltage at Pin 15 is

5 V less than the voltage at Pin 9.

+15V –15V

4

6

8

13

10

11

12

1mF

+15V –15V

4

6

8

13

10

11

12

1mF

2

AD588

2

AD588

V

OFFSET

16

3

1

15

14

9

7

16

3

1

15

14

9

7

*ADDITIONAL PINS OMITTED FOR CLARITY

0.1mF

DEVICE

GND

V

(+)AB

REF

(–)AB

V

REF

DUTGND_AB

AD7841*

DUTGND_GH

V

(+)GH

REF

V

(–)GH

REF

GND

V

OUT

V

OUT

V

OUT

V

OUT

COMPARATOR

A

B

G

H

WINDOW

+15V

PIN

DRIVER

–15V

DEVICE

GND

TO TESTER

V

DEVICE

GND

OUT

Figure 21. ATE Application

One of the AD588s is used as a reference for DACs A and B.

These DACs are used to provide high and low levels for the pin

driver. The pin driver may have an associated offset. This can

be nulled by applying an offset voltage to Pin 9 of the AD588.

First, the code 1000␣ .␣ .␣ .␣ 0000 is loaded into the DACA latch

and the pin driver output is set to the DACA output. The

V

driver output and DUTGND. This causes both V

V

TrimDAC is a registered trademark of Analog Devices, Inc.

voltage is adjusted until 0 V appears between the pin

OFFSET

(–) to be offset with respect to GND by an amount equal to

REF

(+) and

REF

–11–REV. 0

V

. However, the output of the pin driver will vary from

OFFSET

–10 V to +10 V with respect to DUTGND as the DAC input

code varies from 000␣ .␣ .␣ .␣ 000 to 111␣ .␣ .␣ .␣ 111. The V

OFFSET

voltage is also applied to the DUTGND pins. When a clear is

performed on the AD7841, the output of the pin driver will be

0 V with respect to DUTGND.

The other AD588 is used to provide a reference voltage for

DACs G and H. These provide the reference voltages for the

window comparator shown in the diagram. Note that Pin 9 of

this AD588 is connected to Device GND. This causes V

and V

(–)GH to be referenced to Device GND. As DAC G

REF

REF

(+)GH

and DAC H input codes vary from 000␣ .␣ .␣ .␣ 000 to 111␣ .␣ .␣ .␣ 111,

V

G and V

OUT

H vary from –10 V to +10 V with respect to

OUT

Device GND. Device GND is also connected to DUTGND.

When the AD7841 is cleared, V

OUT

G and V

H are cleared to

OUT

0 V with respect to Device GND.

Programmable Reference Generation for the AD7841 in an

ATE Application

The AD7841 is particularly suited for use in an automated test

environment. The reference input for the AD7841 octal 14-bit

DAC requires three differential references for the eight DACs.

Programmable references may be a requirement in some ATE

applications as the offset and gain errors at the output of a DAC

can be adjusted by varying the voltages on the reference pins of

the DAC. To trim offset errors, the DAC is loaded with the

digital code 000␣ .␣ .␣ .␣ 000 and the voltage on the V

(–) pin is

REF

adjusted until the desired negative output voltage is obtained.

To trim out gain errors, first the offset error is trimmed. Then

the DAC is loaded with the code 111␣ .␣ .␣ .␣ 111 and the voltage

on the V

(+) pin is adjusted until the desired full-scale voltage

REF

minus one LSB is obtained.

It is not uncommon in ATE design, to have other circuitry at

the output of the AD7841 that can have offset and gain errors of

up to say ±300 mV. These offset and gain errors can be easily

removed by adjusting the reference voltages of the AD7841.

The AD7841 uses nominal reference values of ±5 V to achieve

an output span of ±10 V. Since the AD7841 has a gain of two

from the reference inputs to the DAC output, adjusting the

reference voltages by ±150 mV will adjust the DAC offset and

gain by ±300 mV.

There are a number of suitable 8- and 10-bit DACs available

that would be suitable to drive the reference inputs of the

AD7841, such as the AD7804, a quad 10-bit digital-to-analog

converter with serial load capabilities. The voltage output from

this DAC is in the form of V

BIAS

±

V

and rail-to-rail opera-

SWING

tion is achievable. The voltage reference for this DAC can be

internally generated or provided externally. This DAC also

contains an 8-bit SUB DAC which can be used to shift the

complete transfer function of each DAC around the V

BIAS

point.

This can be used as a fine trim on the output voltage. In this

application two AD7804s are required to provide programmable

reference capability for all eight DACs. One AD7804 is used to

drive the V

V

(–) pins.

REF

Another suitable DAC for providing programmable reference

capability is the AD8803. This is an octal 8-bit trimDAC

(+) pins and the second package used to drive the

REF

®

and

provides independent control of both the top and bottom ends

of the trimDAC. This is helpful in maximizing the resolution of

devices with a limited allowable voltage control range.

AD7841

The AD8803 has an output voltage range of GND to VDD (0 V

to +5 V). To trim the V

on the AD8803 DAC can be set using the V

(+) input, the appropriate trim range

REF

REFL

and V

REFH

pins

allowing 8 bits of resolution between the two points. This will

allow the V

To trim the V

(+) pin to be adjusted to remove gain errors.

REF

(–) voltage, some method of providing a trim

REF

voltage in the required negative voltage range is required. Neither the AD7804 or the AD8803 can provide this range in normal operation as their output range is 0 V to +5 V. There are

two methods of producing this negative voltage. One method is

ADDR BUS

+5V

ADDR

SDATA

SCLK

CONTROLLER

DECODER

LOGIC LEVEL

SHIFT

FSIN/CS

D IN

SCLK

FSIN/CS

D IN

SCLK

8/10-BIT

DAC

8/10-BIT

DAC

V

GND

V

GND

to provide a positive output voltage and then to level shift that

analog voltage to the required negative range. Alternatively

these DACs can be operated with supplies of 0 V and –5 V, with

the V

pin connected to 0 V and the GND pin connected to

DD

–5 V. Now these can be used to provide the negative reference

voltages for the V

(–) inputs on the AD7841. However, the

REF

digital signals driving the DACs need to be level-shifted from

the 0 V to +5 V range to the –5 V to 0 V range. Figure 22 shows

a typical application circuit to provide programmable reference

capabilities for the AD7841.

DD

0V TO +5V

DD

0V TO 25V

V

REF

V

REF

A0, A1, A2

(+)AB

AD7841*

(2)AB

V

A

V

OUT

V

B

OUT

A

OUT

V

B

OUT

C3402–2–4/99

DATA BUS

25V

DATA BUS

*ADDITIONAL PINS OMITTED FOR CLARITY

GND

Figure 22. Programmable Reference Generation for the AD7841

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

44-Lead MQFP (S-44)

0.548 (13.925)

34

33

0.546 (13.875)

0.398 (10.11)

0.390 (9.91)

TOP VIEW

(PINS DOWN)

23

22

0.037 (0.94)

0.025 (0.64)

SEATING

PLANE

0.096 (2.44)

MAX

8°

0.8°

PRINTED IN U.S.A.

0.040 (1.02)

0.032 (0.81)

0.083 (2.11)

0.077 (1.96)

0.040 (1.02)

0.032 (0.81)

44

–12–

1

0.033 (0.84)

0.029 (0.74)

12

11

0.016 (0.41)

0.012 (0.30)

REV. 0

Loading...

Loading...