Dual-Precision, Low-Cost,

a

FEATURES

Enhanced Replacement for LF412 and TL082

AC PERFORMANCE

Settles to 0.01% in 1.0 s

16 V/s Min Slew Rate (AD712J)

3 MHz Min Unity Gain Bandwidth (AD712J)

DC PERFORMANCE

0.30 mV Max Offset Voltage: (AD712C)

5 V/C Max Drift: (AD712C)

200 V/mV Min Open-Loop Gain (AD712K)

4 V p-p Max Noise, 0.1 Hz to 10 Hz (AD712C)

Surface Mount Available in Tape and Reel in

Accordance with EIA-481A Standard

MIL-STD-883B Parts Available

Single Version Available: AD711

Quad Version: AD713

Available in Plastic Mini-DIP, Plastic SOIC, and

Hermetic CERDIP

PRODUCT DESCRIPTION

The AD712 is a high-speed, precision monolithic operational

amplifier offering high performance at very modest prices. Its

very low offset voltage and offset voltage drift are the results of

advanced laser wafer trimming technology. These performance

benefits allow the user to easily upgrade existing designs that use

older precision BiFETs and, in many cases, bipolar op amps.

The superior ac and dc performance of this op amp makes it

suitable for active filter applications. With a slew rate of 16 V/ms

and a settling time of 1 ms to ± 0.01%, the AD712 is ideal as a

buffer for 12-bit D/A and A/D converters and as a high-speed

integrator. The settling time is unmatched by any similar IC

amplifier.

The combination of excellent noise performance and low input

current also make the AD712 useful for photo diode preamps.

Common-mode rejection of 88 dB and open loop gain of

400 V/mV ensure 12-bit performance even in high-speed unity

gain buffer circuits.

The AD712 is pinned out in a standard op amp configuration

and is available in seven performance grades. The AD712J and

AD712K are rated over the commercial temperature range of

0∞C to 70∞C. The AD712A, AD712B, and AD712C are rated

over the industrial temperature range of –40∞C to +85∞C. The

AD712S and AD712T are rated over the military temperature

range of –55∞C to +125∞C and are available processed to MILSTD-883-B, Rev. C.

Extended reliability PLUS screening is available, specified over

the commercial and industrial temperature ranges. PLUS

High-Speed, BiFET Op Amp

AD712

CONNECTION DIAGRAMS

Plastic Mini-DIP (N) Package

SOIC (R) Package and CERDIP (Q) Package

AMPLIFIER NO. 2AMPLIFIER NO. 1

OUTPUT

INVERTING

OUTPUT

NONINVERTING

OUTPUT

1

2

3

V–

4

AD712

screening includes 168-hour burn-in, as well as other environmental and physical tests.

The AD712 is available in an 8-lead plastic mini-DIP, SOIC,

and CERDIP.

PRODUCT HIGHLIGHTS

1. The AD712 offers excellent overall performance at very

competitive prices.

2. Analog Devices’ advanced processing technology and 100%

testing guarantee a low input offset voltage (0.3 mV max,

C grade, 3 mV max, J grade). Input offset voltage is specified

in the warmed-up condition. Analog Devices’ laser wafer drift

trimming process reduces input offset voltage drifts to 5 mV/∞C

max on the AD712C.

3. Along with precision dc performance, the AD712 offers

excellent dynamic response. It settles to ±0.01% in 1 ms and

has a minimum slew rate of 16 V/ms. Thus this device is ideal

for applications such as DAC and ADC buffers which require a

combination of superior ac and dc performance.

4. The AD712 has a guaranteed and tested maximum voltage

noise of 4 mV p-p, 0.1 Hz to 10 Hz (AD712C).

5. Analog Devices’ well-matched, ion-implanted JFETs ensure

a guaranteed input bias current (at either input) of 50 pA

max (AD712C) and an input offset current of 10 pA max

(AD712C). Both input bias current and input offset current

are guaranteed in the warmed-up condition.

8

V+

OUTPUT

7

INVERTING

6

INPUT

NONINVERTING

5

INPUT

REV. E

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

AD712–SPECIFICATIONS

(VS = 15 V @ TA = 25C unless otherwise noted.)

Parameter Min Typ Max Min Typ Max Min Typ Max Unit

AD712J/A/S AD712K/B/T AD712C

INPUT OFFSET VOLTAGE

1

Initial Offset 0.3 3/1/1 0.2 1.0/0.7/0.7 0.1 0.3 mV

to T

T

MIN

MAX

4/2/2 2.0/1.5/1.5 0.6 mV

vs. Temp 7 20/20/20 7 10 3 5 mV/∞C

vs. Supply 76 95 80 100 86 110 dB

to T

T

MIN

MAX

76/76/76 80 86 dB

Long-Term Offset Stability 15 15 15 mV/Month

INPUT BIAS CURRENT

2

VCM = 0 V 25 75 20 75 20 50 pA

= 0 V @ T

V

CM

MAX

0.6/1.6/26 1.7/4.8/77 0.5/1.3/20 1.7/4.8/77 1.3 3.2 nA

VCM = ±10 V 100 100 75 pA

INPUT OFFSET CURRENT

V

= 0 V 10 25 5 25 5 10 pA

CM

VCM = 0 V @ T

MAX

0.3/0.7/11 0.6/1.6/26 0.1/0.3/5 0.6/1.6/26 0.3 0.7 nA

MATCHING CHARACTERISTICS

Input Offset Voltage 3/1/1 1.0/0.7/0.7 0.3 mV

to T

T

MIN

MAX

4/2/2 2.0/1.5/1.5 0.6 mV

Input Offset Voltage Drift 20/20/20 10 5 mV/∞C

Input Bias Current 25 25 10 pA

Crosstalk @ f = 1 kHz 120 120 120 dB

@ f = 100 kHz 90 90 90 dB

FREQUENCY RESPONSE

Small Signal Bandwidth 3.0 4.0 3.4 4.0 3.4 4.0 MHz

Full Power Response 200 200 200 kHz

Slew Rate 16 20 18 20 18 20 V/ms

Settling Time to 0.01% 1.0 1.2 1.0 1.2 1.0 1.2 ms

Total Harmonic Distortion 0.0003 0.0003 0.0003 %

INPUT IMPEDANCE

Differential 3 ¥ 10

12

5.5 3 ¥ 10125.5 3 ¥ 10125.5 WpF

Common Mode 3 ¥ 10125.5 3 ¥ 10125.5 3 ¥ 10125.5 WpF

INPUT VOLTAGE RANGE

Differential

Common-Mode Voltage

3

to T

T

MIN

MAX

4

–VS + 4 +VS – 2 –VS + 4 +VS – 2 –VS + 4 +VS – 2 V

±20 ± 20 ± 20 V

+14.5, –11.5 +14.5, –11.5 +14.5, –11.5

Common-Mode

Rejection Ratio

= ±10 V 76 88 80 88 86 94 dB

V

CM

to T

T

MIN

MAX

= ±11 V 70 84 76 84 76 90 dB

V

CM

T

to T

MIN

MAX

76/76/76 84 80 84 86 90 dB

70/70/70 80 74 80 74 84 dB

INPUT VOLTAGE NOISE 2 2 2 mV p-p

45 45 45 nV/÷

22 22 22 nV/÷

18 18 18 nV/÷

Hz

Hz

Hz

16 16 16 nV/÷Hz

INPUT CURRENT NOISE 0.01 0.01 0.01 pA/÷Hz

OPEN-LOOP GAIN 150 400 200 400 200 400 V/mV

100/100/100 100 100 V/mV

OUTPUT CHARACTERISTICS

Voltage +13, –12.5 +13.9, –13.3 +13, –12.5 +13.9, –13.3 +13, –12.5 +13.9, –13.3 V

±12/± 12/12 +13.8, –13.1 12 +13.8, –13.1 12 +13.8, –13.1 V

Current 25 25 25 mA

POWER SUPPLY

Rated Performance ±15 ± 15 ± 15 V

Operating Range 4.5 18 4.5 18 4.5 18 V

Quiescent Current 5.0 6.8 5.0 6.0 5.0 5.6 mA

NOTES

1

Input Offset Voltage specifications are guaranteed after 5 minutes of operation at TA = 25∞C.

2

Bias Current specifications are guaranteed maximum at either input after 5 minutes of operation at TA = 25∞C. For higher temperatures, the current doubles every 10∞C.

3

Defined as voltage between inputs, such that neither exceeds ± 10 V from ground.

4

Typically exceeding –14.1 V negative common-mode voltage on either input results in an output phase reversal.

Specifications in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min and max

specifications are guaranteed, although only those shown in boldface are tested on all production units.

Specifications subject to change without notice.

–2–

REV. E

AD712

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 18 V

Internal Power Dissipation

2

Input Voltage3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Output Short Circuit Duration . . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage . . . . . . . . . . . . . . . . . . +V

Storage Temperature Range (Q) . . . . . . . . . . –65∞C to +150∞C

Storage Temperature Range (N, R) . . . . . . . .–65∞C to +125∞C

Operating Temperature Range

AD712J/K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0∞C to 70∞C

AD712A/B/C . . . . . . . . . . . . . . . . . . . . . . . . –40∞C to +85∞C

AD712S/T . . . . . . . . . . . . . . . . . . . . . . . . . –55∞C to +125∞C

Lead Temperature Range (Soldering 60 sec) . . . . . . . . . 300∞C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Thermal Characteristics:

8-Lead Plastic Package: qJA = 165∞C/W

8-Lead Cerdip Package: qJC = 22∞C/W; qJA = 110∞C/W

8-Lead SOIC Package: qJA = 100∞C

3

For supply voltages less than ± 18 V, the absolute maximum input voltage is equal

to the supply voltage.

1

Model Range Description Option

AD712AQ –40∞ C to +85∞C 8-Lead Ceramic DIP Q-8

and –V

S

AD712BQ* –40∞C to +85∞C 8-Lead Ceramic DIP Q-8

S

AD712CN* –40∞C to +85∞C 8-Lead Plastic DIP N-8

AD712JN 0∞C to 70∞C 8-Lead Plastic DIP N-8

AD712JR 0∞C to 70∞C 8-Lead Plastic SOIC R-8

AD712JR-REEL 0∞C to 70∞ C 8-Lead Plastic SOIC R-8

AD712JR-REEL7 0∞C to 70∞C 8-Lead Plastic SOIC R-8

AD712KN 0∞C to 70∞C 8-Lead Plastic DIP N-8

AD712KR 0∞C to 70∞C 8-Lead Plastic SOIC R-8

AD712KR-REEL 0∞C to 70∞C 8-Lead Plastic SOIC R-8

AD712KR-REEL7 0∞C to 70∞C 8-Lead Plastic SOIC R-8

AD712SQ* –55∞C to +125∞C 8-Lead Ceramic DIP Q-8

AD712SQ/883B –55∞C to +125∞C 8-Lead Ceramic DIP Q-8

AD712TQ* –55∞C to +125∞C 8-Lead Ceramic DIP Q-8

AD712TQ/883B* –55∞C to +125∞C 8-Lead Ceramic DIP Q-8

*

Not for new design, obsolete April 2002.

ORDERING GUIDE

Temperature Package Package

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD712 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. E

–3–

AD712

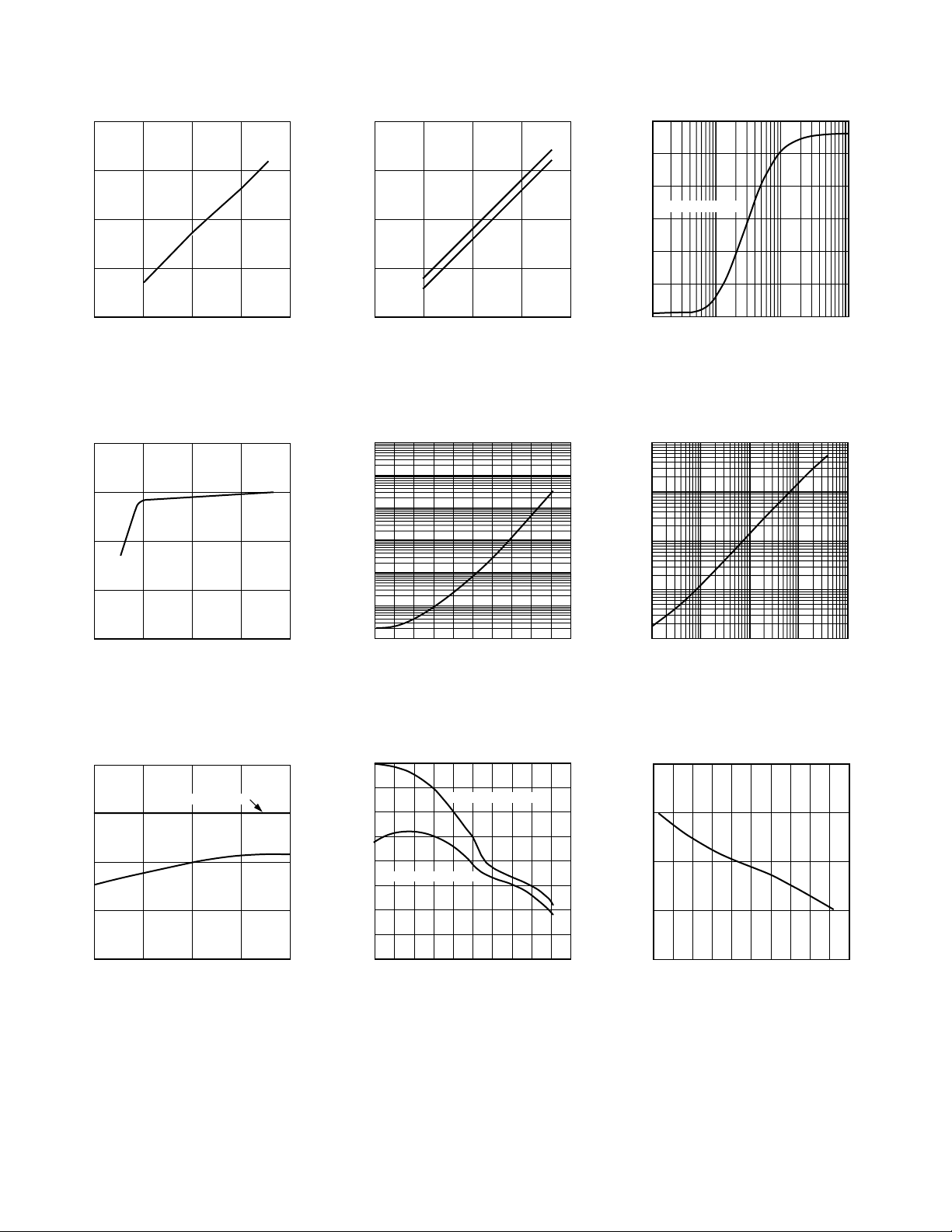

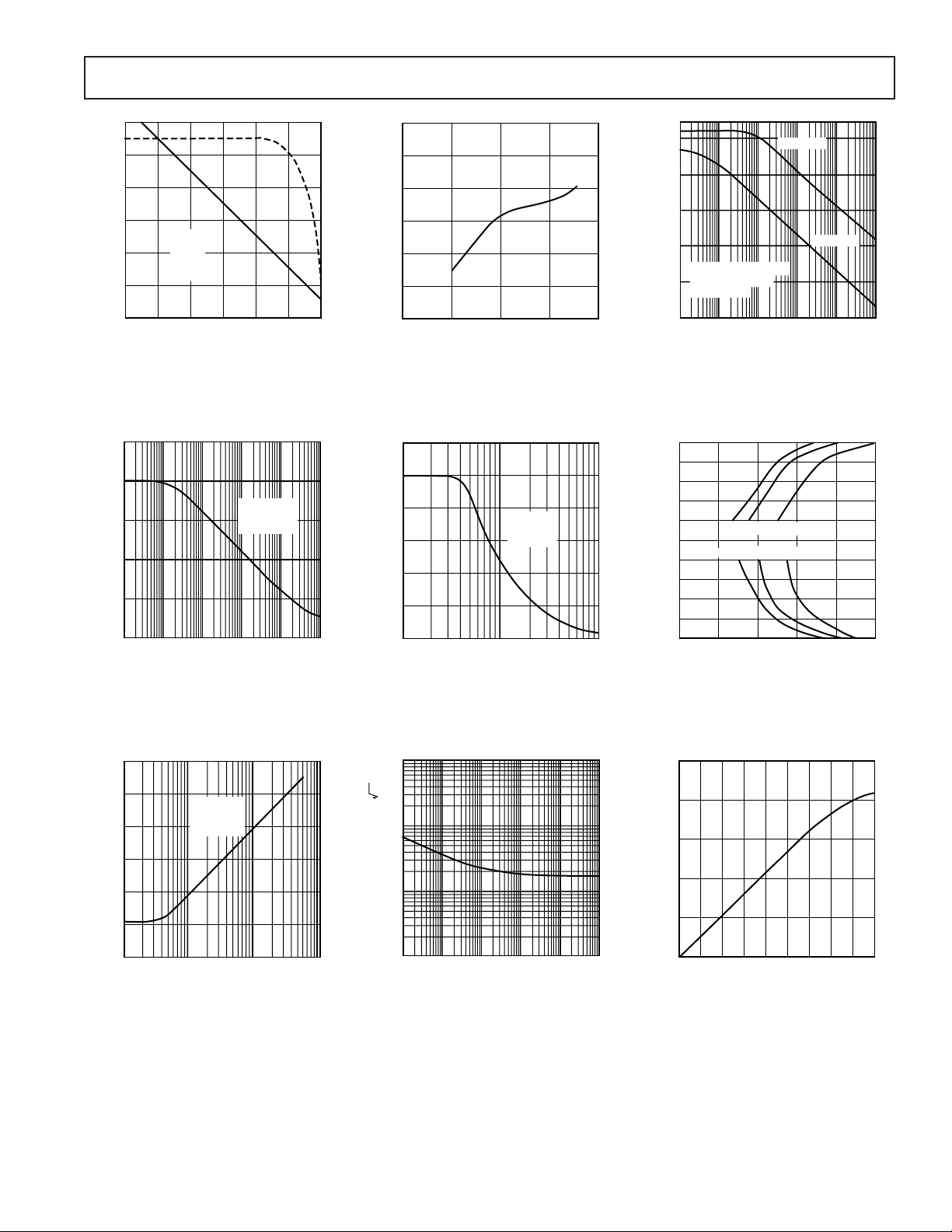

–Typical Performance Characteristics

20

15

10

R

= 2k

L

25C

5

INPUT VOLTAGE SWING – V

0

0

520

SUPPLY VOLTAGE V

10 15

TPC 1. Input Voltage Swing vs.

Supply Voltage

6

5

4

3

QUIESCENT CURRENT – mA

2

0

520

SUPPLY VOLTAGE V

10 15

TPC 4. Quiescent Current vs.

Supply Voltage

20

15

10

5

OUTPUT VOLTAGE SWING – V

0

0

520

SUPPLY VOLTAGE V

+V

OUT

–V

OUT

R

= 2k

L

25C

10 15

TPC 2. Output Voltage Swing vs.

Supply Voltage

6

10

7

10

= 0) – Amps

8

10

CM

9

10

10

10

11

10

INPUT BIAS CURRENT (V

12

10

–60

0

TEMPERATURE – C

TPC 5. Input Bias Current vs.

Temperature

30

25

20

15V SUPPLIES

15

10

5

OUTPUT VOLTAGE SWING – V p–p

0

10 100 10k1k

LOAD RESISTANCE –

TPC 3. Output Voltage Swing vs.

Load Resistance

100

10

1.0

0.1

OUTPUT IMPEDANCE –

140–40 –40 20 12040 60 80 100

0.01

1k

10k 100k 1M 10M

FREQUENCY – Hz

TPC 6. Output Impedance vs.

Frequency

100

75

50

25

INPUT BIAS CURRENT – pA

0

–10

MAX J GRADE LIMIT

V

= 15V

S

25C

–5 1005

COMMON MODE VOLTAGE – V

TPC 7. Input Bias Current vs.

Common Mode Voltage

26

24

22

20

18

– OUTPUT CURRENT

16

14

12

SHORT CIRCUIT CURRENT LIMIT – mA

10

–40 –20 0 20 40 60 80 100 120 140

–60

AMBIENT TEMPERATURE – C

+ OUTPUT CURRENT

TPC 8. Short Circuit Current Limit

vs. Temperature

–4–

5.0

4.5

4.0

3.5

UNITY GAIN BANDWIDTH – MHz

3.0

–60 –40 –20 0 20 40 60 80 100 120 140

TEMPERATURE – C

TPC 9. Unity Gain Bandwidth vs.

Temperature

REV. E

AD712

(

)

100

80

60

40

20

OPEN LOOP GAIN – dB

0

–20

GAIN

PHASE

2k

100pF

LOAD

100 1k 1M10 10k 100k 10M

FREQUENCY – Hz

TPC 10. Open-Loop Gain and

Phase Margin vs. Frequency

100

80

VS = 15V

= 1Vp-p

V

60

CMR – dB

40

20

0

10

100 1k 10k 100k 1M

FREQUENCY – Hz

CM

25C

TPC 13. Common Mode

Rejection vs. Frequency

100

80

60

40

20

0

–20

125

120

115

110

105

PHASE MARGIN – C

OPEN LOOP GAIN – dB

100

95

0

R

= 2k

L

25C

520

SUPPLY VOLTAGE V

10 15

TPC 11. Open-Loop Gain vs. Supply Voltage

30

25

20

15

10

5

OUTPUT VOLTAGE – Volts p–p

0

100k 10M1M

INPUT FREQUENCY – Hz

RL = 2k

25C

V

= 15V

S

TPC 14. Large Signal Frequency

Response

110

100

80

60

40

VS = 15V SUPPLIES

WITH 1V p-p SINE

20

WAVE 25C

POWER SUPPLY REJECTION – dB

0

10

100 1k 10k 100k 1M

SUPPLY MODULATION FREQUENCY – Hz

+ SUPPLY

– SUPPLY

TPC 12. Power Supply Rejection

vs. Frequency

10

8

6

4

2

0

–2

–4

–6

–8

OUTPUT SWING FROM 0V TO VOLTS

–10

0.5

0.1%1%

0.1%1%ERROR

0.7

0.6

SETTLING TIME – s

0.01%

0.01%

0.8 0.9 1.0

TPC 15. Output Swing and Error

vs. Settling Time

–70

–80

–90

–100

THD – dB

–110

–120

–130

100 10k1k

3V RMS

R

L

C

L

FREQUENCY – Hz

TPC 16. Total Harmonic

Distortion vs. Frequency

REV. E

= 2k

= 100pF

100k

1k

Hz

100

10

INPUT NOISE VOLTAGE – nV/

1

FREQUENCY – Hz

1k

TPC 17. Input Noise Voltage

Spectral Density

–5–

25

20

15

10

SLEW RATE – V/s

5

10k 100k100101

0

100

200 300 400 500 600 700 800 9000

INPUT ERROR SIGNAL – mV

AT SUMMING JUNCTION

TPC 18. Slew Rate vs. Input

Error Signal

AD712

25

+V

S

0.1F

20

SLEW RATE – V/s

15

–60 –40 –20 0 20 40 60 80 100 120 140

TEMPERATURE – C

TPC 19. Slew Rate vs. Temperature

+V

S

0.1F

V

V

IN

SQUARE

WAVE

INPUT

1/2

AD712

–V

0.1F

S

R

2k

OUT

C

L

L

100pF

INPUT

1/2

AD712

–V

2k

0.1F

S

OUTPUT

100pF

TPC 20. THD Test Circuit

V

OUT

20k 2.2k

1/2

7

AD712

4

–V

S

6

5

2

20V p-p

AD712

3

V

IN

CROSSTALK = 20 LOG

+V

S

8

1/2

1

5k 5k

V

OUT

10V

IN

TPC 21. Crosstalk Test Circuit

100

90

10

0%

5V

1s

100

90

10

0%

50mV

100ns

TPC 22a. Unity Gain Follower

5k

+V

S

0.1F

5k

V

IN

1/2

AD712

SQUARE

WAVE

INPUT

0.1F

–V

S

TPC 23a. Unity Gain Inverter

R

2k

TPC 22b. Unity Gain Follower

Pulse Response (Large Signal)

100

90

V

OUT

C

L

L

100pF

10

0%

5V

1s

TPC 23b. Unity Gain Inverter

Pulse Response (Large Signal)

TPC 22c. Unity Gain Follower

Pulse Response (Small Signal)

100

90

10

0%

50mV

200ns

TPC 23c. Unity Gain Inverter Pulse

Response (Small Signal)

–6–

REV. E

AD712

OPTIMIZING SETTLING TIME

Most bipolar high-speed D/A converters have current outputs;

therefore, for most applications, an external op amp is required

for current-to-voltage conversion. The settling time of the converter/op amp combination depends on the settling time of the

DAC and output amplifier. A good approximation is:

tSTotal = (tSDAC )2+(tSAMP )

2

The settling time of an op amp DAC buffer will vary with the

noise gain of the circuit, the DAC output capacitance, and with

the amount of external compensation capacitance across the

DAC output scaling resistor.

Settling time for a bipolar DAC is typically 100 ns to 500 ns.

Previously, conventional op amps have required much longer

settling times than have typical state-of-the-art DACs; therefore,

the amplifier settling time has been the major limitation to a

high-speed voltage-output D-to-A function. The introduction of

the AD711/AD712 family of op amps with their 1 ms (to ±0.01%

of final value) settling time now permits the full high-speed

capabilities of most modern DACs to be realized.

0.1F

BIPOLAR

OFFSET ADJUST

V

CC

R1

100

AD565A

I

OUT

I

REF

DAC

= 4

CODE

BIPOLAR

OFF

9.95k

I

O

GAIN

ADJUST

R2

100

REF

IN

REF

GND

+

–

REF

OUT

10V

19.95k

20k

0.5mA

I

REF

In addition to a significant improvement in settling time, the

low offset voltage, low offset voltage drift, and high open-loop

gain of the AD711/AD712 family assure 12-bit accuracy over

the full operating temperature range.

The excellent high-speed performance of the AD712 is shown in

the oscilloscope photos of Figure 2. Measurements were taken

using a low input capacitance amplifier connected directly to the

summing junction of the AD712 – both photos show the worst

case situation: a full-scale input transition. The DAC’s 4 kW

[10 kW||8 kW = 4.4 kW] output impedance together with a

10 kW feedback resistor produce an op amp noise gain of 3.25.

The current output from the DAC produces a 10 V step at the

op amp output (0 to –10 V Figure 2a, –10 V to 0 V Figure 2b.)

Therefore, with an ideal op amp, settling to ±1/2 LSB (±0.01%)

requires that 375 mV or less appears at the summing junction.

This means that the error between the input and output (that

voltage which appears at the AD712 summing junction) must be

less than 375 mV. As shown in Figure 2, the total settling time

for the AD712/AD565 combination is 1.2 microseconds.

20V

SPAN

5k

5k

8k

10V

SPAN

DAC

OUT

10pF

+15V

1/2

AD712

0.1F

0.1F

OUTPUT

–10V TO +10V

REV. E

POWER

–V

0.1F

EE

GND

Figure 1.±10 V Voltage Output Bipolar DAC

5V1mV

100

–10V

90

0V

10

0%

SUMMING

JUNCTION

OUTPUT

500ns

a. (Full-Scale Negative Transition)

Figure 2. Settling Characteristics for AD712 with AD565A

MSB LSB

–7–

–15V

5V1mV

100

90

SUMMING

JUNCTION

–10V

0V

0%

OUTPUT

10

500ns

b. (Full-Scale Positive Transition)

AD712

OP AMP SETTLING TIME A MATHEMATICAL MODEL

The design of the AD712 gives careful attention to optimizing

individual circuit components; in addition, a careful trade-off

was made: the gain bandwidth product (4 MHz) and slew rate

(20 V/ms) were chosen to be high enough to provide very fast

settling time but not too high to cause a significant reduction in

phase margin (and therefore, stability). Thus designed, the

AD712 settles to ±0.01%, with a 10 V output step, in under

1 ms, while retaining the ability to drive a 250 pF load capacitance

when operating as a unity gain follower.

If an op amp is modeled as an ideal integrator with a unity gain

crossover frequency of w

/2p, Equation 1 will accurately describe

o

the small signal behavior of the circuit of Figure 3a, consisting

of an op amp connected as an I-to-V converter at the output of

a bipolar or CMOS DAC. This equation would completely

describe the output of the system if not for the op amp’s finite

slew rate and other nonlinear effects.

V

O

=

R(C

I

IN

w

where

2

G

= “noise” gain of circuit

N

= CX)

f

w

o

o

= op amp’s unity gain frequency

p

s2+

–R

(1)

+ RC

Ê

1+

Á

Ë

ˆ

s +1

˜

f

¯

ˆ

R

˜

R

¯

O

Ê

G

N

Á

w

Ë

o

This equation may then be solved for Cf:

Cf=

2 - G

Rw

2 RC

N

+

o

In these equations, capacitor C

+(1 - GN)

Xwo

Rw

o

is the total capacitor appearing

X

(2)

the inverting terminal of the op amp. When modeling a DAC

buffer application, the Norton equivalent circuit of Figure 3a

can be used directly; capacitance C

is the total capacitance of

X

the output of the DAC plus the input capacitance of the op amp

(since the two are in parallel).

When RO and IO are replaced with their Thevenin VIN and R

IN

equivalents, the general purpose inverting amplifier of Figure 3b

is created. Note that when using this general model, capacitance

C

is either the input capacitance of the op amp if a simple in-

X

verting op amp is being simulated or the combined capacitance of

the DAC output and the op amp input if the DAC buffer is being

modeled.

1/2

AD712

C

R

IN

V

IN

C

X

R

RLC

F

V

OUT

L

Figure 3b. Simplified Model of the AD712

Used as an Inverter

In either case, the capacitance CX causes the system to go from

a one-pole to a two-pole response; this additional pole increases

settling time by introducing peaking or ringing in the op amp

output. Since the value of C

can be estimated with reasonable

X

accuracy, Equation 2 can be used to choose a small capacitor,

C

, to cancel the input pole and optimize amplifier response.

F

Figure 4 is a graphical solution of Equation 2 for the AD712

with R = 4 kW.

60

50

GN = 4.0

40

X

30

C

20

10

GN = 3.0

GN = 2.0

GN = 1.5

GN = 1.0

I

ORO

1/2

AD712

C

R

C

X

RLC

F

V

OUT

L

Figure 3a. Simplified Model of the AD712 Used as a

Current-Out DAC Buffer

–8–

0

20 30 40 50 60

100

C

F

Figure 4. Value of Capacitor CF vs. Value of C

X

REV. E

AD712

8

7

6

5

4

3

2

1

PLASTIC MINI-DIP (N) PACKAGE

CERDIP (Q) PACKAGE

AND SOIC (R) PACKAGE

The photos of Figures 5a and 5b show the dynamic response of

the AD712 in the settling test circuit of Figure 6.

5V

100

90

10

0%

5mV

500ns

Figure 5a. Settling Characteristics 0 V to +10 V Step

Upper Trace: Output of AD712 Under Test (5 V/Div)

Lower Trace: Amplified Error Voltage (0.01%/Div)

5V

100

90

10

0%

5mV

500ns

The input of the settling time fixture is driven by a flat-top pulse

generator. The error signal output from the false summing node

of A1 is clamped, amplified by A2 and then clamped again. The

error signal is thus clamped twice: once to prevent overloading

amplifier A2 and then a second time to avoid overloading the

oscilloscope preamp. The Tektronix oscilloscope preamp type

7A26 was carefully chosen because it does not overload with

these input levels. Amplifier A2 needs to be a very high speed

FET-input op amp; it provides a gain of 10, amplifying the error

signal output of A1.

GUARDING

The low input bias current (15 pA) and low noise characteristics

of the AD712 BiFET op amp make it suitable for electrometer

applications such as photo diode preamplifiers and picoampere

current-to-voltage converters. The use of a guarding technique,

such as that shown in Figure 7, in printed circuit board layout

and construction is critical to minimize leakage currents. The

guard ring is connected to a low impedance potential at the same

level as the inputs. High impedance signal lines should not be

extended for any unnecessary length on the printed circuit board.

Figure 5b. Settling Characteristics 0 V to –10 V Step

Upper Trace: Output of AD712 Under Test (5 V/Div)

Lower Trace: Amplified Error Voltage (0.01%/Div)

REV. E

DATA

DYNAMICS

5109

(OR EQUIVALENT

FLAT TOP

PULSE

GENERATION)

Figure 7. Board Layout for Guarding Inputs

5pF

V

1/2

0.47F

1.1k

10pF

AD712

–15V +15V

0.2-0.6pF

V

OUT

0.47F

10k

HP2835

200

10k

4.99k

5-18pF

1/2

4.99k

V

IN

10k

AD712

5k

0.1F

–15V

0.1F

+15V

205

ERROR

5

HP2835

TEKTRONIX 7A26

OSCILLOSCOPE

PREAMP

INPUT SECTION

1M

20pF

Figure 6. Settling Time Test Circuit

–9–

AD712

D/A CONVERTER APPLICATIONS

The AD712 is an excellent output amplifier for CMOS DACs.

It can be used to perform both 2-quadrant and 4-quadrant operation. The output impedance of a DAC using an inverted R-2R

ladder approaches R for codes containing many 1s, 3R for codes

containing a single 1, and for codes containing all zero, the output

impedance is infinite.

For example, the output resistance of the AD7545 will modulate

between 11 kW and 33 kW. Therefore, with the DAC’s internal

feedback resistance of 11 kW, the noise gain will vary from 2 to

4/3. This changing noise gain modulates the effect of the input

offset voltage of the amplifier, resulting in nonlinear DAC amplifier

performance.

The AD712K with guaranteed 700 mV offset voltage minimizes

this effect to achieve 12-bit performance.

Figures 8 and 9 show the AD712 and AD7545 (12-bit CMOS

DAC) configured for unipolar binary (2-quadrant multiplication)

or bipolar (4-quadrant multiplication) operation. Capacitor C1

provides phase compensation to reduce overshoot and ringing.

GAIN

ADJUST

V

IN

*REFER TO

TABLE I

GAIN

ADJUST

V

IN

*REFER TO

TABLE I

R1A*

R1B*

V

DD

V

DD

V

REF

DB11–DB0

V

DD

V

DD

V

REF

DB11–DB0

AD7545

AD7545

R

FB

AGND

DGND

R

FB

AGND

DGND

OUT1

OUT1

R2A*

R2B*

ANALOG

COMMON

ANALOG

COMMON

C1A

33pF

C1B

33pF

+15V

1/2

AD712

1/2

AD712

–15V

0.1F

0.1F

V

V

OUTA

OUTB

Figure 8. Unipolar Binary Operation

R1 and R2 calibrate the zero offset and gain error of the DAC.

Specific values for these resistors depend upon the grade of

AD7545 and are shown below.

Table I. Recommended Trim Resistor Values vs. Grades

of the AD7545 for V

DD

= 5 V

Trim

Resistor JN/AQ/SD KN/BQ/TD LN/UD GLN/GUD

R1 500 W 200 W 100 W 20 W

R2 150 W 68 W 33 W 6.8 W

GAIN

ADJUST

V

IN

*FOR VALUES OF

R1 AND R2 SEE TABLE I

R1*

V

DD

V

DD

AD7545

V

REF

DB11–DB0

12

DATA INPUT

R2*

+15V

R

FB

AGND

DGND

OUT1

C1

33pF

ANALOG

COMMON

1/2

AD712

0.1F

Figure 9. Bipolar Operation

R3

10k 1%

R4

20k 1%

20k 1%

AD712

R5

1/2

–15V

0.1F

V

OUT

–10–

REV. E

AD712

Figures 10a and 10b show the settling time characteristics of the

AD712 when used as a DAC output buffer for the AD7545.

100

90

10

0%

500ns

a. Full-Scale Positive Transition

100

90

10

0%

500ns

b. Full-Scale Negative Transition

Figure 10. Settling Characteristics for AD712 with AD7545

NOISE CHARACTERISTICS

The random nature of noise, particularly in the 1/f region, makes it

difficult to specify in practical terms. At the same time, designers of

precision instrumentation require certain guaranteed maximum

noise levels to realize the full accuracy of their equipment.

The AD712C grade is specified at a maximum level of 4.0 mV p-p,

in a 0.1 Hz to 10 Hz bandwidth. Each AD712C receives a 100%

noise test for two 10-second intervals; devices with any excursion

in excess of 4.0 mV are rejected. The screened lot is then submitted

to Quality Control for verification on an AQL basis.

All other grades of the AD712 are sample-tested on an AQL basis

to a limit of 6 mV p-p, 0.1 Hz to 10 Hz.

DRIVING THE ANALOG INPUT OF AN A/D CONVERTER

An op amp driving the analog input of an A/D converter, such as

that shown in Figure 11, must be capable of maintaining a constant output voltage under dynamically changing load conditions.

In successive approximation converters, the input current is

compared to a series of switched trial currents. The comparison

point is diode clamped but may deviate several hundred millivolts resulting in high frequency modulation of A/D input current.

The output impedance of a feedback amplifier is made artificially low by the loop gain. At high frequencies, where the loop

gain is low, the amplifier output impedance can approach its

open loop value. Most IC amplifiers exhibit a minimum open

loop output impedance of 25 W due to current limiting resistors.

AD574

MIDDLE

STS

HIGH

BITS

BITS

LOW

BITS

+5V

+15V

–15V

DIG

COM

10V

ANALOG

INPUT

+15V

1/2

AD712

–15V

0.1F

0.1F

GAIN

ADJUST

R2

100

R1

100

OFFSET

ADJUST

ANALOG COM

12/8

CS

A

O

R/C

CE

REF IN

REF OUT

BIP OFF

10V

IN

20V

IN

ANA

COM

Figure 11. AD712 as ADC Unity Gain Buffer

A few hundred microamps reflected from the change in converter

loading can introduce errors in instantaneous input voltage. If

the A/D conversion speed is not excessive and the bandwidth of

the amplifier is sufficient, the amplifier’s output will return to

the nominal value before the converter makes its comparison.

However, many amplifiers have relatively narrow bandwidth

yielding slow recovery from output transients. The AD712 is

ideally suited to drive high speed A/D converters since it offers

both wide bandwidth and high open-loop gain.

REV. E

–11–

AD712

PD711 BUFF

100

90

10

0%

–10V ADC IN

200ns500mV

a. Source Current = 2 mA

PD711 BUFF

100

90

10

0%

500mV

–5V ADC IN

200ns

b. Sink Current = 1 mA

Figure 12. ADC Input Unity Gain Buffer Recovery Times

DRIVING A LARGE CAPACITIVE LOAD

The circuit in Figure 13 employs a 100 W isolation resistor which

enables the amplifier to drive capacitive loads exceeding 1500 pF;

the resistor effectively isolates the high frequency feedback from

the load and stabilizes the circuit. Low frequency feedback is

returned to the amplifier summing junction via the low pass

filter formed by the 100 W series resistor and the load capacitance, C

. Figure 14 shows a typical transient response for this

L

connection.

5V

100

90

10

0%

1s

Figure 14. Transient Response RL = 2 kW, CL = 500 pF

ACTIVE FILTER APPLICATIONS

In active filter applications using op amps, the dc accuracy of

the amplifier is critical to optimal filter performance. The

amplifier’s offset voltage and bias current contribute to output

error. Offset voltage will be passed by the filter and may be

amplified to produce excessive output offset. For low frequency

applications requiring large value input resistors, bias currents

flowing through these resistors will also generate an offset voltage.

In addition, at higher frequencies, an op amp’s dynamics must

be carefully considered. Here, slew rate, bandwidth, and openloop gain play a major role in op amp selection. The slew rate

must be fast as well as symmetrical to minimize distortion. The

amplifier’s bandwidth in conjunction with the filter’s gain will

dictate the frequency response of the filter.

The use of a high performance amplifier such as the AD712 will

minimize both dc and ac errors in all active filter applications.

4.99k

30pF

+V

IN

0.1F

+

–

4.99k

INPUT

TYPICAL CAPACITANCE

LIMIT FOR VARIOUS

LOAD RESISTORS

R

C1 UP TO

1

2k 1500pF

10k 1500pF

20 1000pF

1/2

AD712

–V

IN

0.1F

–

100

C

1

+

R

OUTPUT

1

Figure 13. Circuit for Driving a Large Capacitive Load

–12–

REV. E

AD712

SECOND ORDER LOW PASS FILTER

Figure 15 depicts the AD712 configured as a second order

Butterworth low pass filter. With the values as shown, the corner

frequency will be 20 kHz; however, the wide bandwidth of the

AD712 permits a corner frequency as high as several hundred

kilohertz. Equations for component selection are shown below.

R1 = R2 = user selected (typical values: 10 kW – 100 kW)

C1(in farads) =

R1

20k

V

IN

(2p)( f

R2

20k

280pF

1. 414

cutoff

C1

560pF

C2

)( R1)

+15V

1/2

AD712

–15V

C2 =

0.1F

0.1F

(2p)( f

0.707

cutoff

V

OUT

)( R1)

Figure 15. Second Order Low-Pass Filter

An important property of filters is their out-of-band rejection.

The simple 20 kHz low pass filter shown in Figure 15, might be

used to condition a signal contaminated with clock pulses or

sampling glitches which have considerable energy content at

high frequencies.

The low output impedance and high bandwidth of the AD712

minimize high frequency feedthrough as shown in Figure 16.

The upper trace is that of another low-cost BiFET op amp showing 17 dB more feedthrough at 5 MHz.

REF 20.0 dBm

10 dB/DIV

TYPICAL BIFET

CENTER 5 000 000.0 Hz

RBW 30 kHz

RANGE 15.0 dBm

VBW 30 kHz

OFFSET .0 Hz

AD712

SPAN 10 000 000.0 Hz

0 dB

ST .8 SEC

Figure 16. TBD

REV. E

–13–

AD712

+15V

0.1F

V

IN

A1

AD711

–15V

0.1F

0.001F

100k

2800 6190 6490 6190 2800

4.9395E

–15

A

*

5.9276E

SEE TEXT

*

–15

–15

5.9276E

B

*

C

*

4.9395E

–15

D

*

0.001F

124k

+15V

A2

AD711

–15V

0.1F

0.1F

V

4.99k

4.99k

OUT

Figure 17. 9-Pole Chebychev Filter

9-POLE CHEBYCHEV FILTER

Figure 17 shows the AD712 and its dual counterpart, the AD711,

as a 9-pole Chebychev filter using active frequency dependent

negative resistors (FDNR). With a cutoff frequency of 50 kHz

and better than 90 dB rejection, it may be used as an antialiasing

filter for a 12-bit data acquisition system with 100 kHz throughput.

As shown in Figure 17, the filter is comprised of four FDNRs (A,

B, C, D) having values of 4.9395 ⫻ 10

–15

and 5.9276 ⫻ 10

–15

farad-seconds. Each FDNR active network provides a two-pole

response for a total of 8 poles. The 9th pole consists of a 0.001 mF

capacitor and a 124 kW resistor at Pin 3 of amplifier A2. Figure 18

depicts the circuits for each FDNR with the proper selection of

R. To achieve optimal performance, the 0.001 mF capacitors

must be selected for 1% or better matching and all resistors

should have 1% or better tolerance.

+15V

0.1F

0.001F

1/2

AD712

0.1F

–15V

1/2

AD712

R

0.001F

1.0k

REF 5.0 dBm

10 dB/DIV

START.0 Hz

RBW 300 Hz

RANGE –5.0 dBm

VBW 30 Hz

MARKER 96 800.0 Hz

–90 dBm

STOP 200 000.0 Hz

ST 69.6 SEC

Figure 19. High Frequency Response for 9-Pole

Chebychev Filter

R: 24.9k FOR 4.9395E

29.4k FOR 5.9276E

–15

–15

4.99k

Figure 18. FDNR for 9-Pole Chebychev Filter

–14–

REV. E

OUTLINE DIMENSIONS

0.25 (0.0098)

0.19 (0.0075)

1.27 (0.0500)

0.41 (0.0160)

0.50 (0.0196)

0.25 (0.0099)

45

8

0

1.75 (0.0688)

1.35 (0.0532)

SEATING

PLANE

0.25 (0.0098)

0.10 (0.0040)

85

41

5.00 (0.1968)

4.80 (0.1890)

PIN 1

0.1574 (4.00)

0.1497 (3.80)

1.27 (0.0500)

BSC

6.20 (0.2440)

5.80 (0.2284)

0.51 (0.0201)

0.33 (0.0130)

COPLANARITY

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

COMPLIANT TO JEDEC STANDARDS MS-012 AA

Dimensions shown in inches and (mm).

AD712

0.165 0.01

4.19 0.25

0.125 (3.18)

MIN

0.018 0.003

(0.460 0.081)

0.200 (5.08)

0.125 (3.18)

0.200 (5.08)

0.390 (9.91)

8

14

PIN 1

0.100

(2.54)

TYP

0.005 (0.13)

MIN

8

0.25R

(0.64)

1

PIN 1

0.405 (10.29)

MAX

MAX

0.014 (0.36)

0.023 (0.58)

0.100

(2.54)

5

0.033 (0.84)

0.055 (1.35)

BSC

Mini-DIP

(N-8)

0.250

(6.35)

0.035 0.01

(0.890 0.25)

NOM

CERDIP

(Q-8)

MAX

5

0.310 (7.87)

0.220 (5.59)

4

0.015 (0.38)

0.060 (1.52)

0.030 (0.76)

0.070 (1.78)

0.310

(7.87)

0.18 0.01

(4.57 0.76)

SEATING

PLANE

0.150

(3.81)

MIN

SEATING

PLANE

0.300 (7.62)

15

0

15

0

REF

0.011 0.003

(0.204 0.081)

0.220 (5.59)

0.310 (7.87)

SOIC

(R-8)

0.195 (4.95)

0.115 (2.93)

0.008 (0.20)

0.015 (0.38)

Revision History

Location Page

7/02—Data Sheet changed from REV. D to REV. E.

Edits to FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

9/01—Data Sheet changed from REV. C to REV. D.

Edits to FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Deleted METALIZATION PHOTOGRAPH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to Figure 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Edits to OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

REV. E

–15–

C00823–0–7/02(E)

–16–

PRINTED IN U.S.A.

Loading...

Loading...