Low Cost, 14-Bit, Dual Channel

www.BDTIC.com/ADI

Synchro/Resolver-to-Digital Converter

FEATURES

Low per-channel cost

32-lead DIL hybrid package

2.6 arc minute accuracy

14-bit resolution

Built-in test

Independent reference inputs

High tracking rate

APPLICATIONS

Gimbal/gyro control systems

Robotics

Engine controllers

Coordinate conversion

Military servo control systems

Fire control systems

Avionic systems

Antenna monitoring

CNC machine tooling

GENERAL DESCRIPTION

The AD2S44 is a 14-bit dual channel, continuous tracking synchro/

resolver-to-digital converter. It has been designed specifically

for applications where space, weight, and cost are at a premium.

Each 32-lead hybrid device contains two independent Type II servo

loop tracking converters. The ratiometric conversion technique

employed provides excellent noise immunity and tolerance of

long lead lengths.

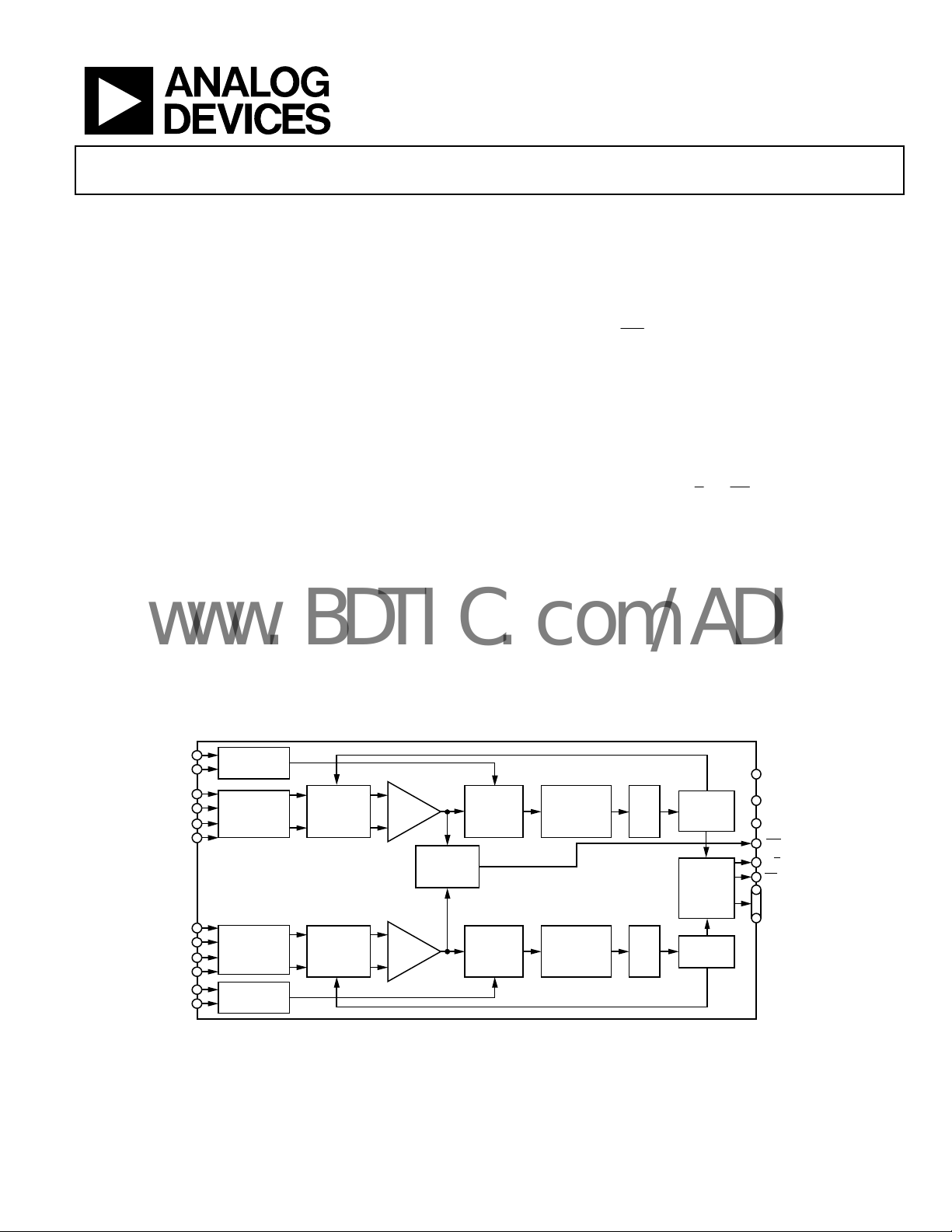

FUNCTIONAL BLOCK DIAGRAM

R

(A)

HI

R

(A)

LO

S1 (A)

S2 (A)

S3 (A)

S4 (A)

S1 (B)

S2 (B)

S3 (B)

S4 (B)

(B)

R

HI

R

(B)

LO

REFERENCE

CONDIT IONE R

SYNCHRO/

RESOLVER

CONDIT IONE R

SYNCHRO/

RESOLVER

CONDIT IONE R

REFERENCE

CONDIT IONE R

AD2S44

HIGH

SPEED

SIN/COS

MULTIPLIER

HIGH

SPEED

SIN/COS

MULTIPLIER

ERROR

AMP

ERROR

AMP

BUILT-IN

TEST

DETECT ION

PHASE-

SENSITIVE

DETECTOR

PHASE-

SENSITIVE

DETECTOR

Figure 1.

AD2S44

The core of each conversion is performed by state-of-the-art monolithic, integrated circuits manufactured by the Analog Devices, Inc.,

proprietary BiMOS II process, which combines the advantages of

low power CMOS digital logic with bipolar linear circuits. The

use of these ICs keeps the internal component count low and

ensures high reliability.

The built-in test (

provide an indication of whether the converter is tracking

accurately.

Each channel incorporates a high accuracy differential conditioning circuit for signal inputs providing more than 74 dB of

common-mode rejection. Options are available for both synchro

and resolver format inputs. The converter output is via a three-state

transparent latch allowing data to be read without interruption of

the converter operation. The A/

channel and present the digital position to the common data

outputs.

The AD2S44 also features independent reference inputs where

different reference frequencies can be used for each channel.

All components are 100% tested at −55°C, +25°C, and +125°C.

Devices are processed to high reliability screening standards

and receive further levels of testing and screening to ensure

high levels of reliability.

INTEGRATOR VCO

INTEGRATOR

BIT

) facility can be used in failsafe systems to

B

and OE control lines select the

+V

S

GND

–V

S

BIT

A/B

OE

DB1 (LSB)

TO

DB14 (MSB)

02947-001

VCO

UP-DOWN

COUNTER

THREE-

STATE

OUTPUT

LATCHES

UP-DOWN

COUNTER

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©1989–2008 Analog Devices, Inc. All rights reserved.

AD2S44

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Table of Contents .............................................................................. 2

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 5

ESD Caution .................................................................................. 5

Pin Configuration and Function Descriptions ............................. 6

Theory of Operation ........................................................................ 7

Connecting the Converter ........................................................... 7

Channel Select (A/B) ................................................................... 7

REVISION HISTORY

08/08—Rev. 0 to Rev. A

Updated Format .................................................................. Universal

Changes to Specifications Section .................................................. 3

Changes to Absolute Maximum Ratings Section ......................... 5

Deleted Standard Processing Section ............................................. 7

Output Enable (OE) ......................................................................8

Built-In Test (

Scaling for Nonstandard Signals .................................................9

Dynamic Performance ..................................................................9

Acceleration Error .........................................................................9

Reliability ..................................................................................... 10

Processing for High Reliability (B Suffix) ............................... 10

Other Products ........................................................................... 10

Outline Dimensions ....................................................................... 11

Ordering Guide .......................................................................... 11

Ordering Information ................................................................ 11

Changes to Processing for High Reliability Section and

Other Products Section ................................................................. 10

Updated Outline Dimensions ....................................................... 11

Changes to Ordering Guide .......................................................... 11

Changes to Ordering Information ............................................... 11

10/89—Revision 0: Initial Version

BIT

) .........................................................................8

Rev. A | Page 2 of 12

AD2S44

www.BDTIC.com/ADI

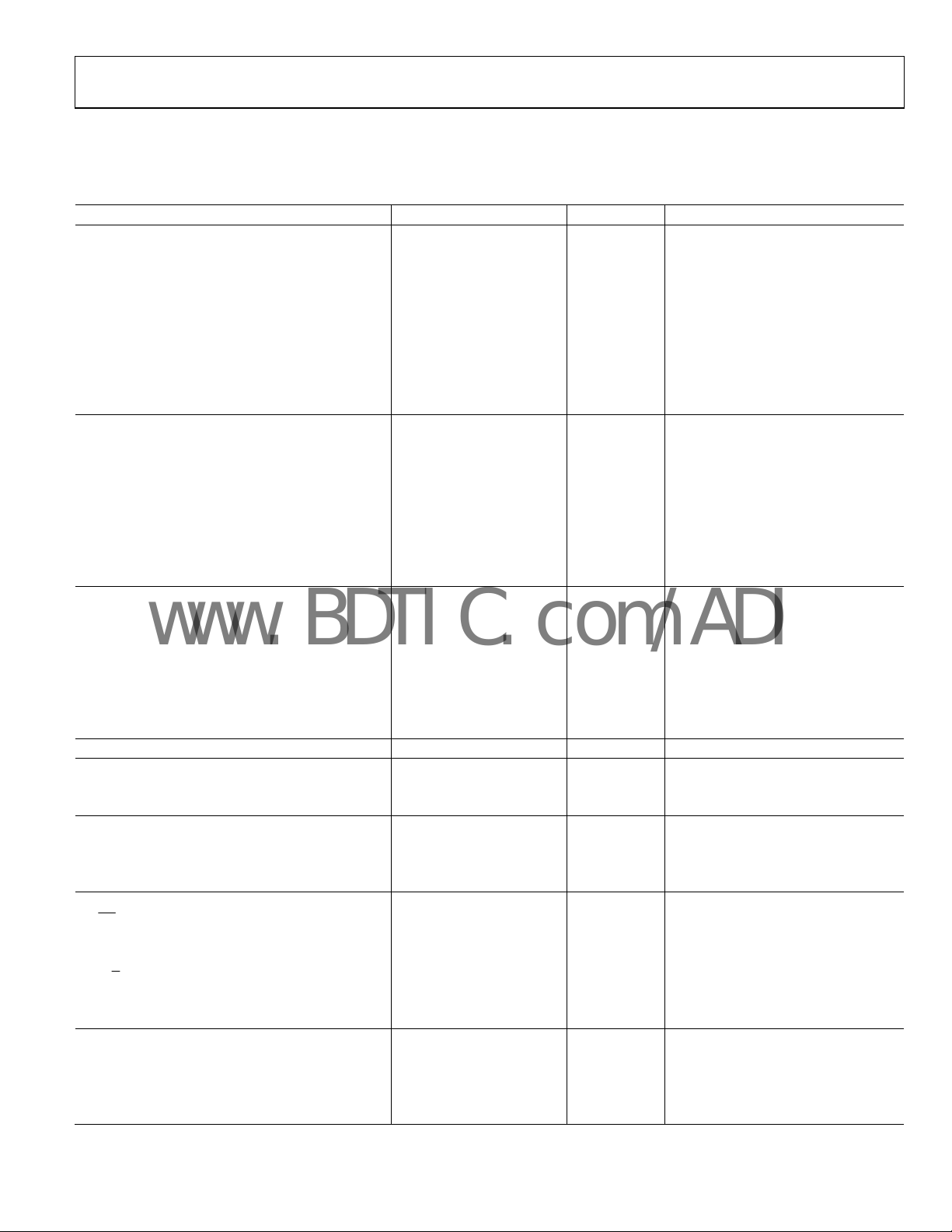

SPECIFICATIONS

VS = ±15 V at TA = 25°C, unless otherwise noted.

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

PERFORMANCE

Accuracy

Tracking Rate 20 Rev/sec

Resolution (1 LSB = 1.3 Arc Minutes) 14 Bits Output coding parallel natural binary

Repeatability 1 LSB

Signal/Reference Frequency 400 2600 Hz

Bandwidth 100 Hz

SIGNAL INPUTS

Signal Voltage 11.8 or 90 V rms See the Ordering Information section

Input Impedance

Common-Mode Rejection 74 dB

Common-Mode Range

REFERENCE INPUTS

Reference Voltage 26 or 115 V rms See the Ordering Information section

Input Impedance

Common-Mode Range

ACCELERATION CONSTANT 62,000 sec

STEP RESPONSE

Large Step

Small Step

POWER LINES

+VS = +15 V

–VS = −15 V

Power Dissipation 1.7 1.9 W Quiescent condition

DIGITAL INPUTS

OE

A/B

DIGITAL OUTPUTS (DB1 to DB14)

V

V

Three-State Leakage Current ±40 μA

Drive Capability 3 LSTTL loads

1

AD2S44-UMB

2

−4.0 +4.0 Arc minutes −55°C to +125°C

−2.6 +2.6 Arc minutes −25°C to +85°C

AD2S44-TMB

2

−4.0 +4.0 Arc minutes −55°C to +125°C

90 V Signal 200 kΩ Resistive tolerance ±2%

11.8 V Signal 26 kΩ

90 V Signal ±250 V dc

11.8 V Signal ±60 V dc

115 V 270 kΩ Resistive tolerance ±5%

26 V 270 kΩ

115 V ±210 V dc

26 V ±210 V dc

–2

1, 2

1, 2

25 30 ms 2° to 1 LSB of error

1, 2

1, 2

63 75 ms 179° to 1 LSB of error

75 80 mA Quiescent condition

40 45 mA Quiescent condition

VIL 0.7 V dc IIL = 5 μA

VIH 2.0 V dc IIH = 5 μA

VIL 0.7 V dc IIL = 1.2 mA

VIH 2.0 V dc IIH = –60 μA

1, 2

OL

1, 2

OH

0.4 V dc IIL = 1.2 mA

2.4 V dc IOH = 60 μA

Rev. A | Page 3 of 12

AD2S44

www.BDTIC.com/ADI

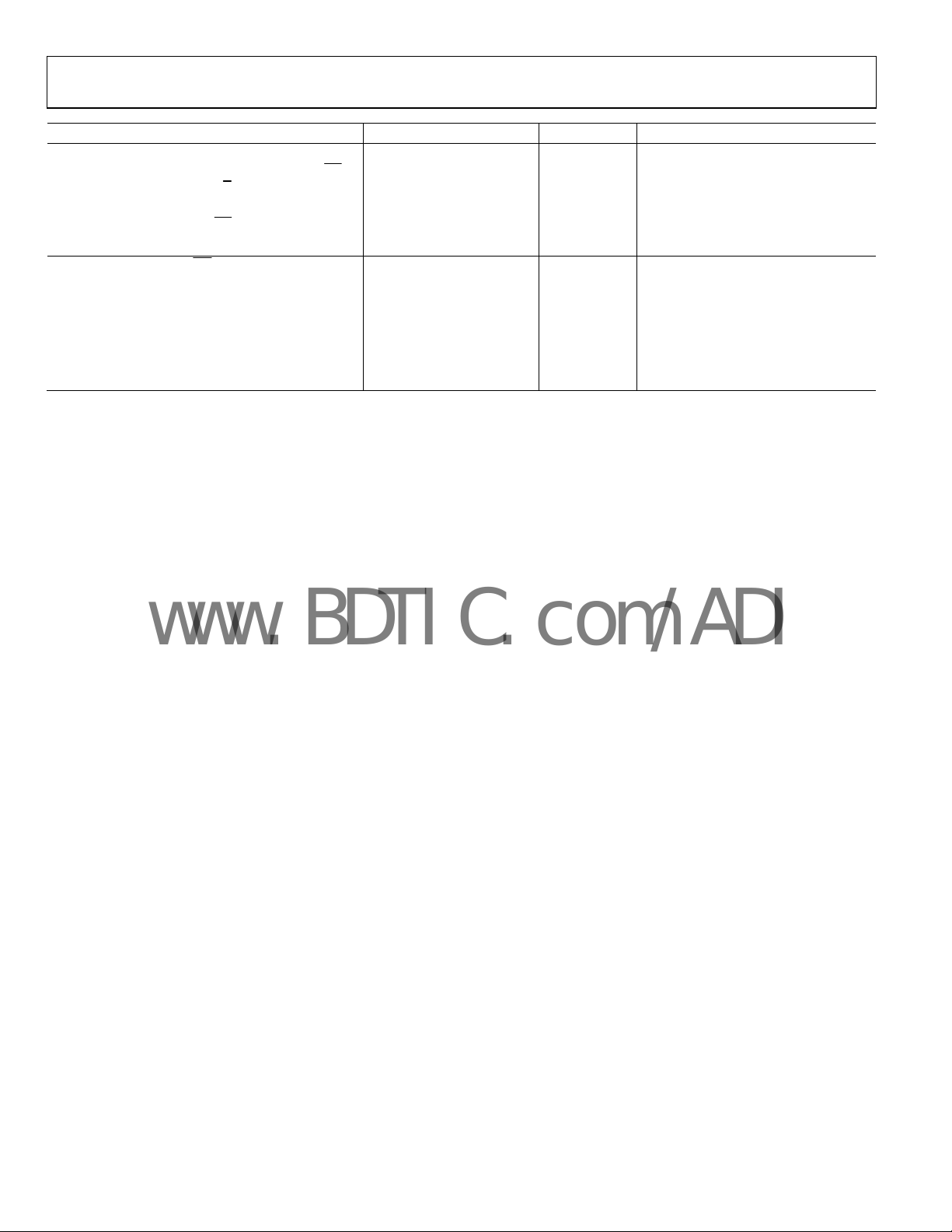

Parameter Min Typ Max Unit Test Conditions/Comments

DATA TRANSFER See Figure 6

Time to Data Stable (After Negative Edge of OE

or Change of Level of A/B)

Time to Data in High Impedance State

(After Positive Edge of OE

Time for Repetitive Strobing of Selected Channel 200 ns tP

BUILT-IN TEST OUTPUT (BIT)

Sense Active low Low = error condition

VOL 0.4 V dc IOL = 3.2 mA

VOH 2.4 V dc IOH = −160 μA

Drive Capability 8 LSTTL loads

Error Condition Set 55 LSB

Error Condition Cleared 45 LSB

1

Specified overtemperature range, −55°C to +125°C, and for: (a) ±10% signal and reference amplitude variation; (b) ±10% signal and reference harmonic distortion; (c)

±5% power supply variation; and (d) ±10% variation in reference frequency.

2

These parameters are 100% tested at nominal values of power supplies, input signal voltages, and operating frequency. All other parameters are guaranteed by

design, not tested.

)

640 ns t

200 ns t

S

R

Rev. A | Page 4 of 12

AD2S44

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

+VS to GND +17.25 V dc

–VS to GND −17.25 V dc

Any Logic Input to GND +6.0 V dc (maximum)

Any Logic Input to GND −0.4 V dc (minimum)

Maximum Junction Temperature 150°C

S1, S2, S3, S4 Pins (Line-to-Line)

90 V Option ±600 V dc

11.8 V Option ±80 V dc

S1, S2, S3, S4 Pins to GND

90 V Option ±600 V dc

11.8 V Option ±80 V dc

RHI Pins to RLO Pins

26 V, 115 V Options ±600 V dc

RHI Pins to RLO Pins to GND

26 V, 115 V Options ±600 V dc

Storage Temperature Range −65°C to +150°C

Operating Temperature Range −55°C to +125°C

1

On synchro input options, line-to-line voltage refers to the differential voltages

of S2 (A)/S2 (B) to S1 (A)/S1 (B), S1 (A)/S1 (B) to S3 (A)/S3 (B), and S3 (A)/S3 (B)

to S2 (A)/S2 (B). On resolver input options, line-to-line levels refer to the S1 (A)/

S1 (B) to S3 (A)/S3 (B) and S2 (A)/S2 (B) to S4 (A)/S4 (B) voltages.

1

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. A | Page 5 of 12

AD2S44

www.BDTIC.com/ADI

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

1

DB8

2

DB9

3

DB10

4

DB11

5

DB12

6

DB13

DB14 (LSB)

7

AD2S44

8

OE

A/B

BIT

(A)

R

LO

R

(A)

HI

S4 (A) S4 (B)

S3 (A)

S2 (A) S2 (B)

S1 (A) S1 (B)

9

(Not to Scale)

10

11

12

13

14

15

16

TOP VIEW

Figure 2. Pin Configuration

Table 3. Pin Function Descriptions

Pin No. Mnemonic Description

1 to 7 DB8 to DB14 (LSB) Parallel Output Data Bits.

8

9

10

OE

A/B

BIT

Output Enable Input.

Channel A or Channel B Select Input.

Built-In Test Error Output.

11 RLO (A) Input Pin for Channel A Reference Low.

12 RHI (A) Input Pin for Channel A Reference High.

13 to 16 S4 (A) to S1 (A) Channel A Input Signal.

17 to 20 S1 (B) to S4 (B) Channel B Input Signal.

21 RHI (B) Input Pin for Channel B Reference High.

22 RLO (B) Input Pin for Channel B Reference Low.

23 GND Power Supply Ground. This pin is electrically connected to the case.

24 –VS Negative Power Supply.

25 +VS Positive Power Supply.

26 to 32 DB1 (MSB) to DB7 Parallel Output Data Bits.

32

DB7

31

DB6

30

DB5

29

DB4

28

DB3

27

DB2

26

DB1 (MSB)

25

+V

24

–V

23

GND

22

R

21

R

20

19

S3 (B)

18

17

S

S

(B)

LO

(B)

HI

02947-003

Rev. A | Page 6 of 12

AD2S44

www.BDTIC.com/ADI

THEORY OF OPERATION

The AD2S44 operates on a tracking principle. The output digital

word continually tracks the position of the synchro/resolver shaft

without the need for external convert commands and status wait

loops. As the transducer moves through a position equivalent

to the least significant bit weighting, the output digital word is

updated.

Each channel is identical in operation, sharing power supply and

output pins. Both channels operate continuously and independently of each other. The digital output from either channel is

available after switching the channel select and output enable

inputs.

If the device is a synchro-to-digital converter, the 3-wire synchro

output is connected to the S1, S2, and S3 pins on the unit, and

a solid-state Scott T input conditioner converts these signals into

resolver format given by

V

= K E0 sin ωt sin θ

1

V

= K E0 sin ωt cos θ

2

where:

θ is the angle of the synchro shaft.

E

sin ωt is the reference signal.

0

K is the transformation ratio of the input signal conditioner.

If the unit is a resolver-to-digital converter, the 4-wire resolver

output is connected directly to the S1, S2, S3, and S4 pins on

the unit.

To understand the conversion process, assume that the current

word state of the up-down counter is ϕ. V

and V

is multiplied by sin ϕ to give the following:

2

sin ωt sin θ cos ϕ

K E

0

K E

sin ωt cos θ sin ϕ

0

is multiplied by cos ϕ,

1

These signals are subtracted by the error amplifier to give

K E

sin ωt (sin θ cos ϕ − cos θ sin ϕ)

0

or

K E

sin ωt sin (θ − ϕ)

0

R

(A)

HI

R

LO

S1 (A)

S2 (A)

S3 (A)

S4 (A)

S1 (B)

S2 (B)

S3 (B)

S4 (B)

R

HI

R

LO

(A)

(B)

(B)

REFERENCE

CONDITI ONER

SYNCHRO/

RESOLVER

CONDITI ONER

SYNCHRO/

RESOLVER

CONDITI ONER

REFERENCE

CONDITI ONER

V

1

MULTIPLIER

V

2

AD2S44

MULTIPLIER

HIGH

SPEED

SIN/CO S

HIGH

SPEED

SIN/CO S

ERROR

AMP

BUILT-IN

TEST

DETECTION

ERROR

AMP

Figure 3. Functional Block Diagram

SENSITIVE

DETECTO R

SENSITIVE

DETECTO R

A phase sensitive detector, integrator, and voltage-controlled

oscillator (VCO) form a closed-loop system that seeks to null sin

(θ − ϕ). When this is accomplished, the word state of the up-down

counter (ϕ) equals the synchro/resolver shaft angle (θ), to within

the rated accuracy of the converter.

CONNECTING THE CONVERTER

The power supply voltages connected to −VS and +VS are to be

±15 V and cannot be reversed.

It is suggested that a parallel combination of a ceramic 100 nF

capacitor and a tantalum 6.8 μF capacitor be placed from each

of the supply pins to GND.

The pin marked GND is connected electrically to the case and

is to be taken to 0 V potential in the system.

The digital output is taken from Pin 26 to Pin 32 and from Pin 1

to Pin 7. Pin 26 is the MSB, and Pin 7 is the LSB.

The reference connections are made to the R

pins and the RLO

HI

pins. In the case of a synchro, the signals are connected to the

S1, S2, and S3 pins, according to the following convention:

E

E

E

S1−S3

S3−S2

S2−S1

= E

= E

= E

sin ωt sin θ

RLO−RHI

sin ωt sin (θ − 120°)

RLO−RHI

sin ωt sin (θ – 240°)

RLO−RHI

For a resolver, the signals are connected to the S1, S2, S3, and S4

pins, according to the following convention:

E

E

S1−S3

S2−S4

= E

= E

RLO−RHI

RLO−RHI

sin ωt sin θ

sin ωt cos θ

CHANNEL SELECT (A/B)

A/B is the channel select input. A Logic 1 selects Channel A, and

a Logic 0 selects Channel B. Data becomes valid 640 ns after A/

is toggled. Timing information is shown in and . Figure 4 Figure 5

+V

S

PHASE-

PHASE-

INTEGRATOR VCO

INTEGRATOR

VCO

UP-DOWN

COUNTER

THREE-

STATE

OUTPUT

LATCHES

UP-DOWN

COUNTER

GND

–V

S

BIT

A/B

OE

DB1 (LSB)

TO

DB14 (MSB)

02947-010

B

Rev. A | Page 7 of 12

AD2S44

www.BDTIC.com/ADI

OUTPUT ENABLE (OE)

OE

is the output enable input; the signal is active low. When set

to Logic 1, DB1 to DB14 are in high impedance state. When

is set to Logic 0, DB1 to DB14 represent the angle of the transducer

shaft to within the stated accuracy of the converter (see bit weights

in ). Data becomes valid 640 ns after the Tabl e 4

Timing information is shown in and and

detailed in .

Tabl e 1

Figure 4 Figure 5

OE

is switched.

Table 4. Bit Weight

Bit No. Weight (Degrees)

1 (MSB) 180.0000

2 90.0000

3 45.0000

4 22.5000

5 11.2500

6 5.6250

7 2.8125

8 1.4063

9 0.7031

10 0.3516

11 0.1758

12 0.0879

13 0.0439

14 ( LSB) 0.0220

OE

A/B

t

S

DATA

BITS

(1 TO 14)

*CONVERT ER DATA OUTPUT I S INHIBITED F ROM UPDATES

DURING CHANNE L VALID.

Figure 4. Repetitive Reading of One Channel

CHANNEL B

VAL ID*

t

S

CHANNEL A

VAL ID*

OE

t

R

02947-005

BUILT-IN TEST (BIT)

BIT

The

velocity or fault indication signal for the channel selected via A/

The error voltage of each channel is continuously monitored. When

the error exceeds ±50 bits for the currently selected channel, the

BIT

imately one angular degree exists, and the data is, therefore, invalid.

The

set the

The

the error goes below 45 LSBs. This mode of operation guarantees

that the

The

the change in the state of A/

tion that sets the

reference signal prior to the

Table 5.

Condition Description

Power-Up Transient

Response

Step Input > 1°

Excessive Velocity

Signal Failure

Converter/System

Fai lure

is the built-in test error output, which provides an over-

B

.

output goes low, indicating that an error greater than approx-

BIT

signal has a built-in hysteresis; that is, the error required to

BIT

is greater than the error required for it to be cleared.

BIT

is set when the error exceeds 55 LSBs and is cleared when

BIT

does not flicker when the error threshold is crossed.

BIT

is valid for the selected channel approximately 50 ns after

B

. In most instances, the error condi-

BIT

must persist for at least one period of the

BIT

responding to the condition.

BIT

Output Faults

The BIT returns to a logic high state after

the AD2S44 position output synchronizes

with the angle input to within 1°.

Normally, the BIT is low at power-up for

a period less than or equal to the large

signal step response settling time of the

AD2S44 after the ±VS supplies have

stabilized to within 5% of their final values.

returns to a logic high state after

The BIT

the selected channel of the AD2S44 has

settled to within 1° of the input angle

resulting from an instantaneous step.

is driven to a logic low if the

The BIT

maximum tracking rate of the AD2S44 is

exceeded (20 rps typical).

may be driven to a logic low state if

The BIT

all signal voltages to the selected channel

are lost.

Any failure that causes the AD2S44 to fail

to track the input synchro/resolver angles

drives the BIT

to a logic low. This may

include, but is not limited to, acceleration

conditions, poor supply voltage regulation,

or excessive noise on the signal connections.

OE

t

P

A/B

DATA

VAL ID *

t

R

DATA

VAL ID*

02947-004

Rev. A | Page 8 of 12

t

S

DATA

BITS

(1 TO 14)

*CONVERTER DATA OUT PUT IS I NHIBITED FRO M UPDATES

DURING CHANNE L VALID.

Figure 5. Alternative Reading of Each Channel

AD2S44

www.BDTIC.com/ADI

SCALING FOR NONSTANDARD SIGNALS

A feature of these converters is that the signal and reference inputs

can be resistively scaled to accommodate nonstandard input signal

and reference voltages that are outside the nominal ±10% limits of

the converter. Using this technique, it is possible to use a standard

converter with a personality card in systems where a wide range

of input and reference voltages are encountered.

The accuracy of the converter is affected by the matching accuracies of resistors used for external scaling. For resolver format

options, it is critical that the value of the resistors on the S1 (A)/

S1 (B) to S3 (A)/S3 (B) signal input pair be precisely matched to

the S4 (A)/S4 (B) to S2 (A)/S2 (B) input pair. For synchro options,

the three resistors on the S1, S2, and S3 pins must be matched. In

general, a 0.1% mismatch between resistor values contributes an

additional 1.7 arc minutes of error to the conversion. In addition,

imbalances in resistor values can greatly reduce the commonmode rejection ratio of the signal inputs.

To calculate the values of the external scaling resistors, add

2.222 kΩ for each volt of signal in series with the S1, S2, S3, and

S4 pins (no resistor is required on the S4 pins for synchro options)

and add 3 kΩ extra per volt of reference in series with the R

LO

pins and the RHI pins.

DYNAMIC PERFORMANCE

θ

IN

Figure 6. Transfer Function of AD2S44

K

S

The transfer function of the converter is as follows:

Open-loop transfer function

1 + sT

a

2

1 + sT

1

2

θ

OUT

02947-006

The gain and phase diagrams are shown in Figure 7 and Figure 8.

6

3

0

–3

–6

GAIN (dB)

–9

–12

–15

10 100

180

135

90

45

0

–45

PHASE (Degrees)

–90

–135

–180

10 100

FREQUENCY ( Hz)

Figure 7. Gain Plot

FREQUENCY ( Hz)

Figure 8. Phase Plot

02947-007

02947-008

sT

+

θ

OUT

θ

IN

1

K

a

2

s

1

×=

sT

+

1

2

Closed-loop transfer function

sT

1

θ

OUT

=

1

θ

IN

+

where:

= 62000 sec–2.

K

a

= 0.0061 sec.

T

1

= 0.001 sec.

T

2

ACCELERATION ERROR

A tracking converter employing a Type II servo loop does not

suffer any velocity lag. However, there is an additional error

due to acceleration. This error is defined using the acceleration

1

32

+++

KTsKssT

a2a1

constant (K

The numerator and denominator must have consistent angular

units. For example, if K

tion is to be specified in degrees/sec

to be specified in degrees. Alternatively, the angular unit of measure

can also be in units such as radians, arc minutes, or LSBs.

Rev. A | Page 9 of 12

) of the converter

a

K

= Input Acceleration/Error in Output Angle

a

is expressed in sec–2, the input accelera-

a

2

and the output angle error is

AD2S44

www.BDTIC.com/ADI

Ka does not define maximum acceleration; it defines only the

error due to acceleration. The maximum acceleration of which

the AD2S44 keeps track is approximate to 5 × K

2

or about 800 revolutions/sec

can be used to predict the output position error due to input

K

a

.

= 310,000°/sec2

a

acceleration. For example, an acceleration of 50 revolutions/sec

= 62,000 is calculated using the following equation:

with K

a

LSB

⎤

⎡

onAcceleratiInput

2

⎥

⎢

sec

⎦

50

LSBsinErrors

=

LSBrev

⎡

⎤

⎡

⎢

sec

⎣

14

×

2

2

⎢

⎥

⎦

rev

⎣

2

−

[]

sec000,62

K

a

⎤

⎥

⎦

=

2.13

⎣

−2

[]

sec

LSBs

=

2

PROCESSING FOR HIGH RELIABILITY (B SUFFIX)

As a part of the high reliability manufacturing procedure, all

converters receive the processing shown in Tab l e 6 .

Table 6.

Process1 Conditions

Precap Visual Inspection MIL-STD-883, Method 2017

Temperature Cycling 10 cycles, –65°C to +150°C

Constant Acceleration 5000 Gs, Y1 plane

Interim Electrical Tests @ 25°C

Operating Burn In 160 hours @ 125°C

Seal Test, Fine and Gross MIL-STD-883, Method 1014

Final Electrical Test Performed at T

External Visual Inspection MIL-STD-883, Method 2009

1

Test and screening data supplied by request.

MIN

, T

, T

AMB

MAX

RELIABILITY

The reliability of these products is very high due to the extensive

use of custom chip circuits that decrease the active component

count. Calculations of the MTBF figure under various environmental conditions are available upon request from Analog

Devices.

Figure 9 shows the MTBF in years vs. case temperature for

Naval Sheltered conditions calculated in accordance with the

Mil-Hdbk-217E.

100

10

MTBF (Years)

1

25 6545 85 105 125

Figure 9. MTBF vs. Temperature

TEMPERATURE (°C)

02947-009

OTHER PRODUCTS

Analog Devices manufactures many other products concerned

with the conversion of synchro/resolver data, such as the

SDC/RDC1740 series and the AD2S80A series.

Hybrid

The SDC/RDC1740 is a hybrid synchro/resolver-to-digital

converter with internal isolating micro transformers.

Monolithic

The AD2S80A series are ICs performing resolver-to-digital

conversion with accuracies up to ±2 arc minutes and 16-bit

resolution.

Rev. A | Page 10 of 12

AD2S44

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

1.728 (43.89) MAX

1732

1.102 (27.99)

1.079 (27.41)

0.225 (5.72)

MAX

0.192 (4.88)

0.152 (3.86)

0.025 (0.64)

1

PIN 1

INDICATOR

(NOTE 1)

MIN

0.023 (0.58)

0.014 (0.36)

0.100 (2.54)

BSC

0.070 (1.78)

0.030 (0.76)

NOTES:

1. INDEX AREA IS INDICATED BY A NOTCH OR LEAD ONE

IDENTIFICATION MARK LOCATED ADJACENT TO LEAD ONE.

2. CONTROLLING DIMENSION S ARE IN INCHES. MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

0.025 (0.64)

0.015 (0.38)

16

0.206 (5.23)

0.186 (4.72)

0.120 (3.05)

MAX

0.910 (23.11)

0.890 (22.61)

0.015 (0.38)

0.008 (0.20)

Figure 10. 32-Lead Bottom-Brazed Ceramic DIP for Hybrid [BBDIP_H]

(DH-32E)

Dimensions shown in inches and (millimeters)

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD2S44–TM11B −55°C to +125°C 32-Lead Bottom-Brazed Ceramic DIP for Hybrid [BBDIP_H] DH-32E

AD2S44–TM12B −55°C to +125°C 32-Lead Bottom-Brazed Ceramic DIP for Hybrid [BBDIP_H] DH-32E

AD2S44–TM18B −55°C to +125°C 32-Lead Bottom-Brazed Ceramic DIP for Hybrid [BBDIP_H] DH-32E

AD2S44–UM18B −55°C to +125°C 32-Lead Bottom-Brazed Ceramic DIP for Hybrid [BBDIP_H] DH-32E

ORDERING INFORMATION

When ordering, the converter part numbers are to be suffixed by

a two-letter code defining the accuracy grade, and a two digit

numeric code defining the signal/reference voltage and frequency.

All the standard options, and their option codes, are shown in

Figure 11. For nonstandard configurations, contact Analog

Devices.

For example, the AD2S44–TM12B is the correct part number

for a component that operates with 90 V signal, 115 V reference

synchro format inputs and yields a ±4.0 arc minutes accuracy

over the −55°C to +125°C temperature range processed to high

reliability standards.

Rev. A | Page 11 of 12

AD2S44-

BASE PART

*MODEL I S OBSOLETE AND NO LONG ER AVAILABLE.

NUMBER

XM Y BZ

HIGH-REL PRO CESSING

Z = 0* SIGNAL, 2V REFERENCE, 2V RESOLVE R

Z = 1 SIGNAL, 1 1.8V REFE RENCE, 26V S YNCHRO

Z = 2 SIGNAL, 9 0V REFERENCE, 115V SYNCHRO

Z = 3* SIGNAL, 11. 8V REFERENCE, 11. 8V RESOLVER

Z = 4* SIGNAL, 26V REFERENCE, 26V RESOLVER

BASE PART

Z = 8 SIGNAL, 1 1.8V REFE RENCE, 26V RE SOLVER

Y = 1 400Hz TO 2 .6kHz REFERENCE FREQUENCY

X = U –55°C TO +1 25°C OPERAT ING TEM PERATURE

RANGE

±4.0 ARC M IN ACCURACY

±2.6 ARC M IN ACCURACY ( –25°C TO +85°C)

X = T –55°C TO +125°C OPERATI NG TEMPE RATURE

RANGE±4 .0 ARC MI N ACCURACY

X = S* –55°C TO +1 25°C OPERATING TEMPERATURE

RANGE±5 .2 ARC MI N ACCURACY

Figure 11.

02947-002

AD2S44

www.BDTIC.com/ADI

NOTES

©1989–2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D02947-0-8/08(A)

Rev. A | Page 12 of 12

Loading...

Loading...