Variable Resolution, 10-Bit to 16-Bit R/D

www.BDTIC.com/ADI

FEATURES

Complete monolithic resolver-to-digital converter

3125 rps maximum tracking rate (10-bit resolution)

±2.5 arc minutes of accuracy

10-/12-/14-/16-bit resolution, set by user

Parallel and serial 10-bit to 16-bit data ports

Absolute position and velocity outputs

System fault detection

Programmable fault detection thresholds

Differential inputs

Incremental encoder emulation

Programmable sinusoidal oscillator on-board

Compatible with DSP and SPI interface standards

5 V supply with 2.3 V to 5 V logic interface

−40°C to +125°C temperature rating

APPLICATIONS

DC and ac servo motor control

Encoder emulation

Electric power steering

Electric vehicles

Integrated starter generators/alternators

Automotive motion sensing and control

Converter with Reference Oscillator

AD2S1210

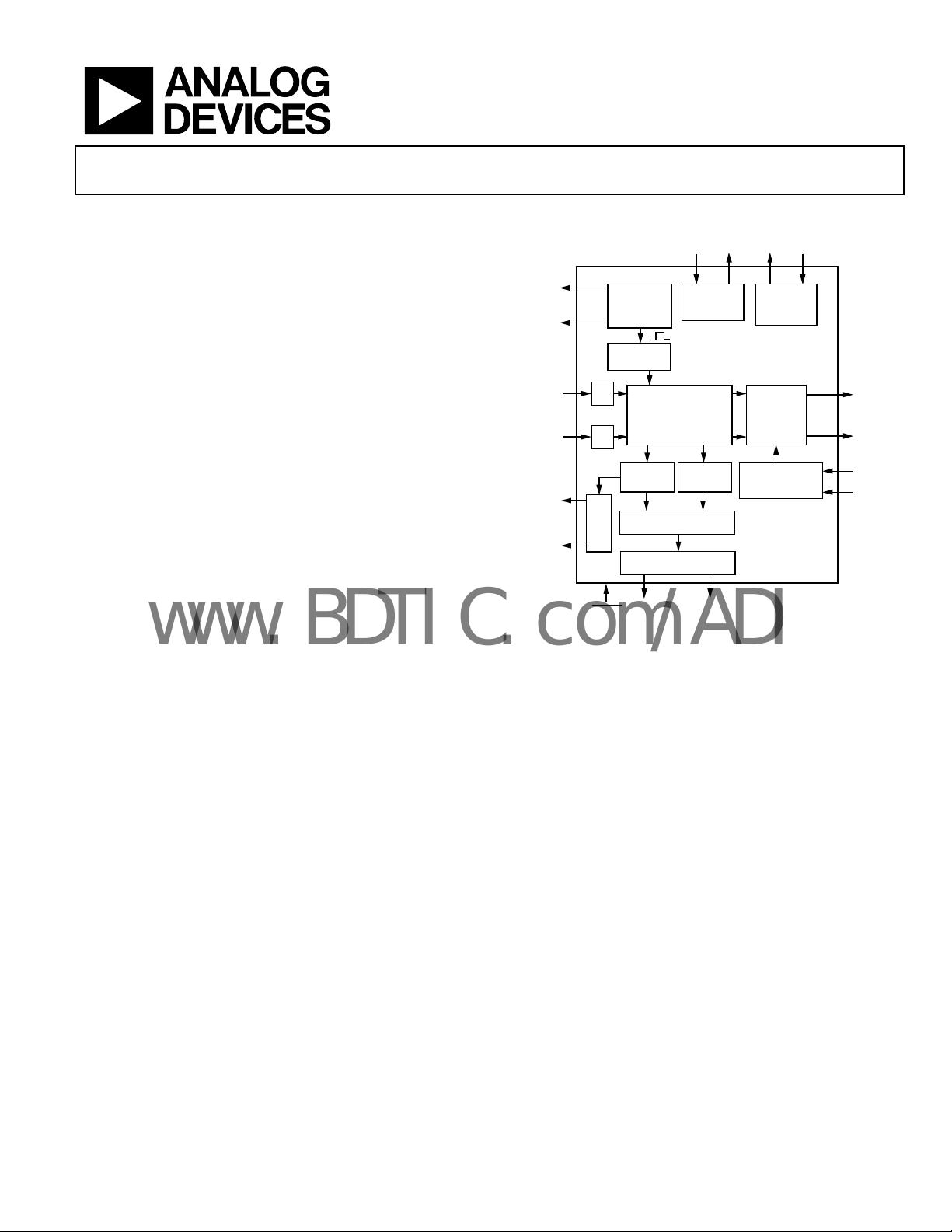

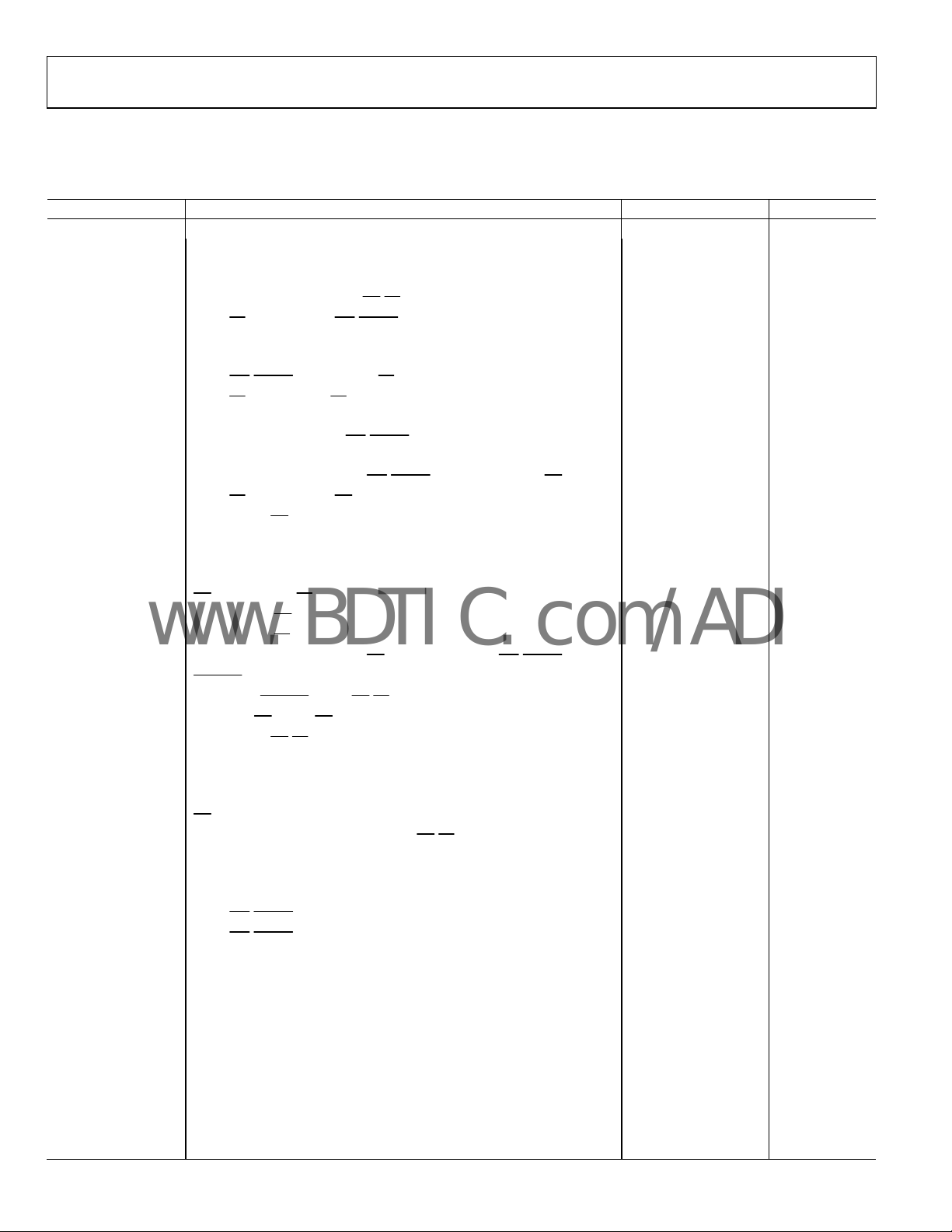

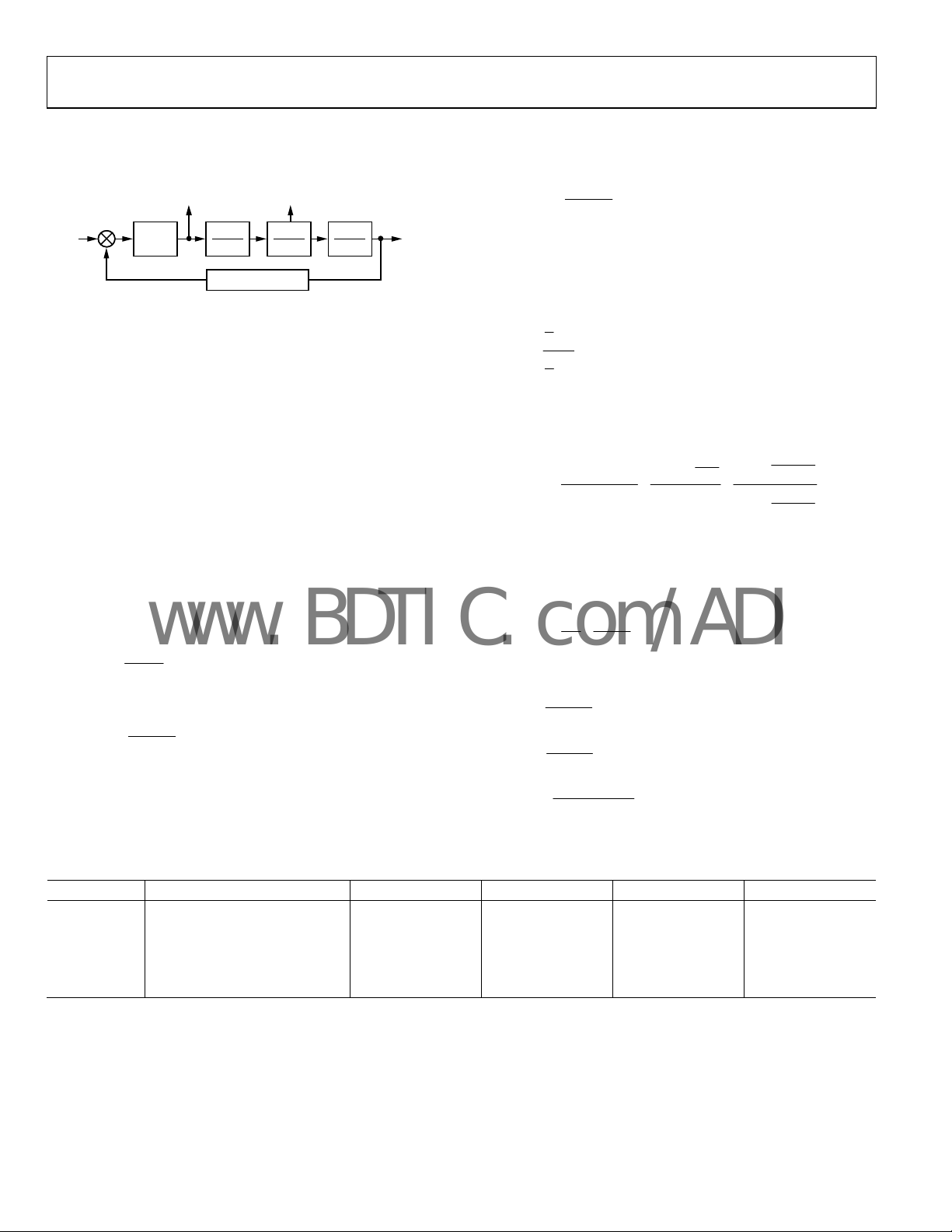

FUNCTIONAL BLOCK DIAGRAM

EXCITATION

OUTPUTS

INPUTS

FROM

RESOLVER

ENCODER

EMULATION

OUTPUTS

REFERENCE

OSCILLATOR

SYNTHETIC

REFERENCE

ADC

ADC

ENCODER

EMULATION

RESET

(DAC)

TYPE II

TRACKING LO OP

POSITION

REGISTER

MULTIPLEXER

DATA BUS OUTPUT

DATA I/O

REFERENCE

PINS

VOLTAGE

REFERENCE

VELOCITY

REGISTER

Figure 1.

CRYSTAL

INTERNAL

GENERATOR

AD2S1210

FAULT

DETECT ION

CONFIGURATION

REGISTER

CLOCK

FAULT

DETECTION

OUTPUTS

DATA I/O

07467-001

GENERAL DESCRIPTION

The AD2S1210 is a complete 10-bit to 16-bit resolution tracking

resolver-to-digital converter, integrating an on-board programmable sinusoidal oscillator that provides sine wave excitation

for resolvers.

The converter accepts 3.15 V p-p ± 27% input signals, in the range

of 2 kHz to 20 kHz on the sine and cosine inputs. A Type II

servo loop is employed to track the inputs and convert the input

sine and cosine information into a digital representation of the

input angle and velocity. The maximum tracking rate is 3125 rps.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

PRODUCT HIGHLIGHTS

1. Ratiometric tracking conversion. The Type II tracking loop

provides continuous output position data without

conversion delay. It also provides noise immunity and

tolerance of harmonic distortion on the reference and

input signals.

2. System fault detection. A fault detection circuit can sense

loss of resolver signals, out-of-range input signals, input

signal mismatch, or loss of position tracking. The fault

detection threshold levels can be individually programmed

by the user for optimization within a particular application.

3. Input signal range. The sine and cosine inputs can accept

differential input voltages of 3.15 V p-p ± 27%.

4. Programmable excitation frequency. Excitation frequency

is easily programmable to a number of standard frequencies

between 2 kHz and 20 kHz.

5. Triple format position data. Absolute 10-bit to 16-bit angular

position data is accessed via either a 16-bit parallel port or a

4-wire serial interface. Incremental encoder emulation is in

standard A-quad-B format with direction output available.

6. Digital velocity output. 10-bit to 16-bit signed digital velocity

accessed via either a 16-bit parallel port or a 4-wire serial

interface.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

AD2S1210

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Specifications .................................................................. 6

Absolute Maximum Ratings ............................................................ 8

ESD Caution .................................................................................. 8

Pin Configuration and Function Descriptions ............................. 9

Typical Performance Characteristics ........................................... 11

Resolver Format Signals ................................................................. 15

Theory of Operation ...................................................................... 16

Resolver to Digital Conversion ................................................. 16

Fault Detection Circuit .............................................................. 16

On-Board Programmable Sinusoidal Oscillator .................... 18

Synthetic Reference Generation ............................................... 18

Configuration of AD2S1210 ......................................................... 20

Modes of Operation ................................................................... 20

Register Map .................................................................................... 21

Position Register ......................................................................... 21

Velocity Register ......................................................................... 21

REVISION HISTORY

8/08—Revision 0: Initial Version

LOS Threshold Register ............................................................ 21

DOS Overrange Threshold Register ........................................ 21

DOS Mismatch Threshold Register ......................................... 21

DOS Reset Maximum and Minimum Threshold Registers . 22

LOT High Threshold Register .................................................. 22

LOT Low Threshold Register ................................................... 22

Excitation Frequency Register .................................................. 22

Control Register ......................................................................... 22

Software Reset Register ............................................................. 23

Fault Register .............................................................................. 23

Digital interface .............................................................................. 24

SOE

Input .................................................................................... 24

SAMPLE

Data Format ................................................................................ 24

Parallel Interface ......................................................................... 24

Serial Interface ............................................................................ 28

Incremental Encoder Outputs .................................................. 31

Supply Sequencing and Reset ................................................... 31

Circuit Dynamics ........................................................................... 32

Loop Response Model ............................................................... 32

Sources of Error .......................................................................... 33

Outline Dimensions ....................................................................... 34

Ordering Guide .......................................................................... 34

Input............................................................................ 24

Rev. 0 | Page 2 of 36

AD2S1210

www.BDTIC.com/ADI

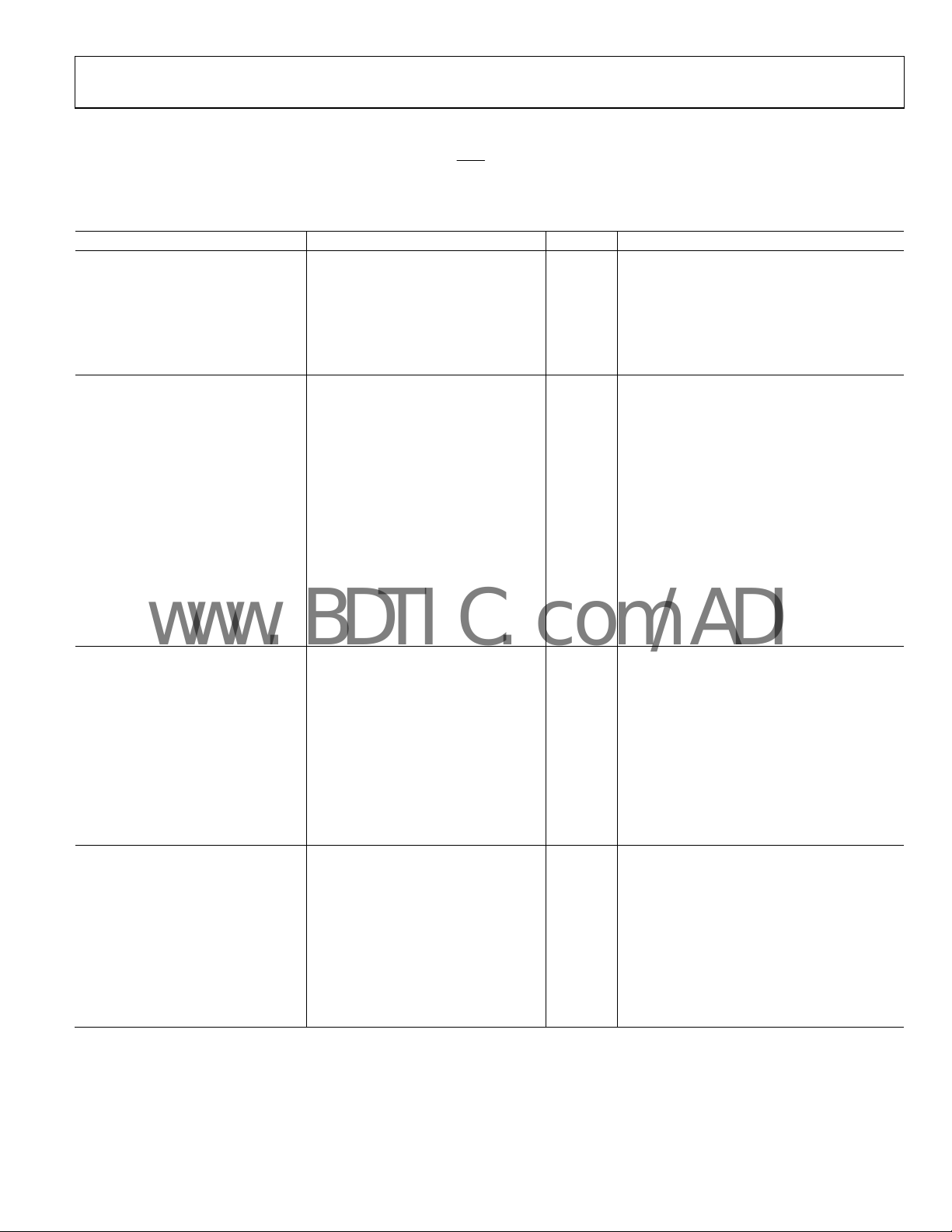

SPECIFICATIONS

MIN

EXC

frequency = 10 kHz to 20 kHz (10-bit); 6 kHz to 20 kHz (12-bit);

to T

; unless otherwise noted.1

MAX

COS to COSLO

AVDD = DVDD = 5.0 V ± 5%, CLKIN = 8.192 MHz ± 25%, EXC,

3 kHz to 12 kHz (14-bit); 2 kHz to 10 kHz (16-bit); T

= T

A

Table 1.

Parameter Min Typ Max Unit Conditions/Comments

SINE, COSINE INPUTS2

Voltage Amplitude 2.3 3.15 4.0 V p-p Sinusoidal waveforms, differential SIN to SINLO,

Input Bias Current 8.25 μA VIN = 4.0 V p-p, CLKIN = 8.192 MHz

Input Impedance 485 kΩ VIN = 4.0 V p-p, CLKIN = 8.192 MHz

Phase Lock Range −44 +44 Degrees Sine/cosine vs. EXC output, Control Register D3 = 0

Common-Mode Rejection ±20 arc sec/V 10 Hz to 1 MHz, Control Register D4 = 0

ANGULAR ACCURACY3

Angular Accuracy ±2.5 + 1 LSB ±5 + 1 LSB arc min B, D grades

±5 + 1 LSB ±10 + 1 LSB arc min A, C grades

Resolution 10, 12, 14, 16 Bits No missing codes

Linearity INL

10-bit ±1 LSB B, D grades

±2 LSB A, C grades

12-bit ±2 LSB B, D grades

±4 LSB A, C grades

14-bit ±4 LSB B, D grades

±8 LSB A, C grades

16-bit ±16 LSB B, D grades

±32 LSB A, C grades

Linearity DNL ±0.9 LSB

Repeatability ±1 LSB

VELOCITY OUTPUT

Velocity Accuracy4

10-bit ±2 LSB B, D grades, zero acceleration

±4 LSB A, C grades, zero acceleration

12-bit ±2 LSB B, D grades, zero acceleration

±4 LSB A, C grades, zero acceleration

14-bit ±4 LSB B, D grades, zero acceleration

±8 LSB A, C grades, zero acceleration

16-bit ±16 LSB B, D grades, zero acceleration

±32 LSB A, C grades, zero acceleration

Resolution5 9, 11, 13, 15 Bits

DYNAMNIC PERFORMANCE

Bandwidth

10-bit 2000 6500 Hz

2900 5300 Hz CLKIN = 8.192 MHz

12-bit 900 2800 Hz

1200 2200 Hz CLKIN = 8.192 MHz

14-bit 400 1500 Hz

600 1200 Hz CLKIN = 8.192 MHz

16-bit 100 350 Hz

125 275 Hz CLKIN = 8.192 MHz

Rev. 0 | Page 3 of 36

AD2S1210

www.BDTIC.com/ADI

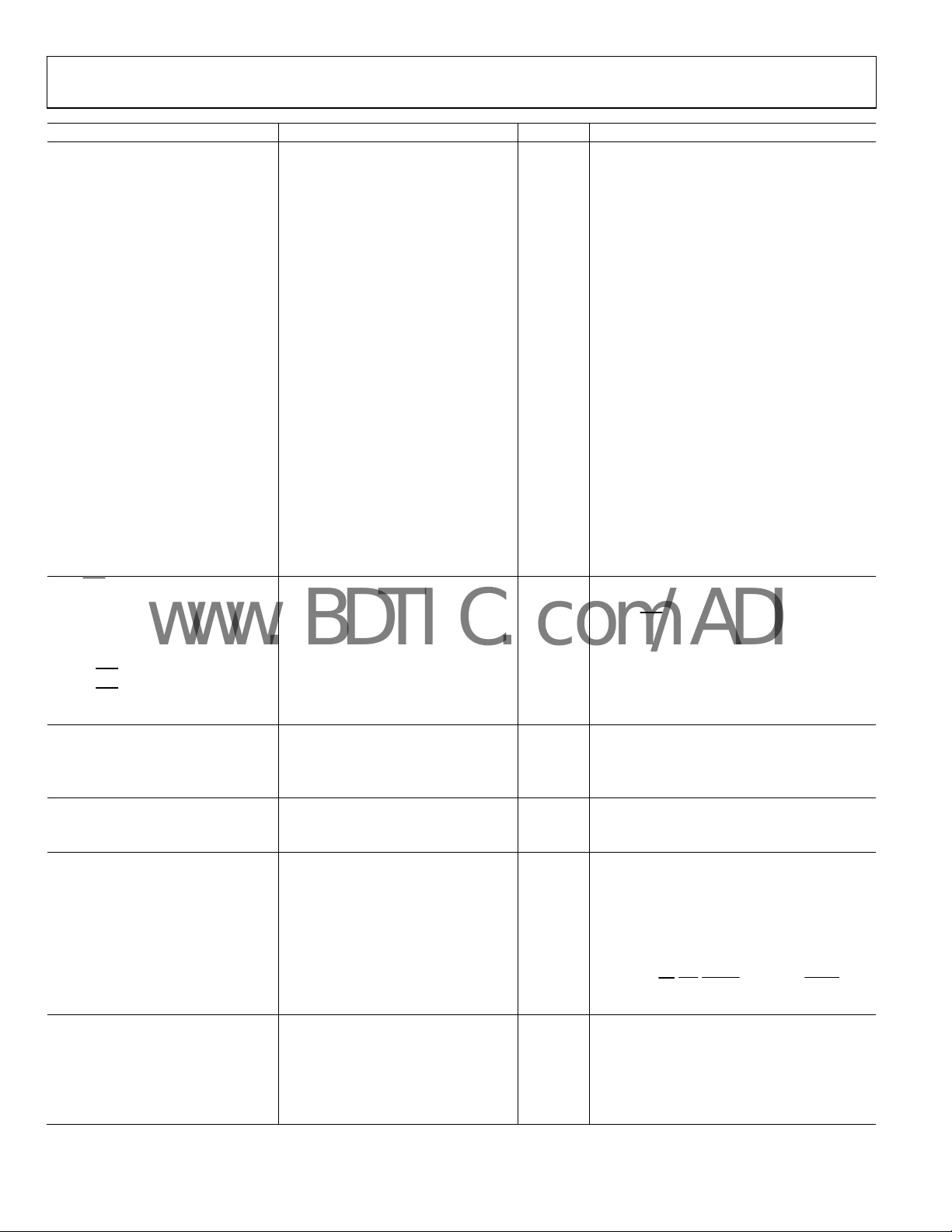

Parameter Min Typ Max Unit Conditions/Comments

Tracking Rate

10-bit 3125 rps CLKIN = 10.24 MHz

2500 CLKIN = 8.192 MHz

12-bit 1250 rps CLKIN = 10.24 MHz

1000 CLKIN = 8.192 MHz

14-bit 625 rps CLKIN = 10.24 MHz

500 CLKIN = 8.192 MHz

16-bit 156.25 rps CLKIN = 10.24 MHz

125 CLKIN = 8.192 MHz

Acceleration Error

10-bit 30 arc min At 50,000 rps2, CLKIN = 8.192 MHz

12-bit 30 arc min At 10,000 rps2, CLKIN = 8.192 MHz

14-bit 30 arc min At 2500 rps2, CLKIN = 8.192 MHz

16-bit 30 arc min At 125 rps2, CLKIN = 8.192 MHz

Settling Time 10° Step Input

10-bit 0.6 0.9 ms To settle to within ±2 LSB , CLKIN = 8.192 MHz

12-bit 2.2 3.1 ms To settle to within ±2 LSB, CLKIN = 8.192 MHz

14-bit 6.5 9.0 ms To settle to within ±2 LSB , CLKIN = 8.192 MHz

16-bit 27.5 40 ms To settle to within ±2 LSB, CLKIN = 8.192 MHz

Settling Time 179° Step Input

10-bit 1.5 2.2 ms To settle to within ±2 LSB , CLKIN = 8.192 MHz

12-bit 4.75 6.0 ms To settle to within ±2 LSB, CLKIN = 8.192 MHz

14-bit 10.5 14.7 ms To settle to within ±2 LSB , CLKIN = 8.192 MHz

16-bit 45 66 ms To settle to within ±2 LSB, CLKIN = 8.192 MHz

EXC

EXC,

VOLTAGE REFERENCE

CLKIN, XTALOUT6

LOGIC INPUTS

LOGIC OUTPUTS

OUTPUTS

Voltage 3.2 3.6 4.0 V p-p Load ±100 μA, typical differential output

Center Voltage 2.40 2.47 2.53 V

Frequency 2 20 kHz

EXC

EXC/

EXC/

THD −58 dB First five harmonics

REFOUT 2.40 2.47 2.53 V ±I

Drift 100 ppm/°C

PSRR −60 dB

VIL Voltage Input Low 0.8 V

VIH Voltage Input High 2.0 V

VIL Voltage Input Low 0.8 V V

0.7 V V

VIH Voltage Input High 2.0 V V

1.7 V V

IIL Low Level Input Current (Non

IIL Low Level Input Current (Pull-Up) 80 μA

IIH High Level Input Current −10 μA

VOL Voltage Output Low 0.4 V V

VOH Voltage Output High 2.4 V V

2.0 V V

I

I

DC Mismatch

EXC

AC Mismatch

Pull-Up)

High Level Three-State Leakage −10 μA

OZH

Low Level Three-State Leakage 10 μA

OZL

EXC

(EXC to

30 mV

100 mV

= 100 μA

OUT

= 2.7 V to 5.25 V

DRIVE

= 2.3 V to 2.7 V

DRIVE

= 2.7 V to 5.25 V

DRIVE

= 2.3 V to 2.7 V

DRIVE

10 μA

RES0, RES1,

= 2.3 V to 5.25 V

DRIVE

= 2.7 V to 5.25 V

DRIVE

= 2.3 V to 2.7 V

DRIVE

) = 7.2 V p-p

RD

, WR/FSYNC, A0, A1, and RESET pins

Rev. 0 | Page 4 of 36

AD2S1210

www.BDTIC.com/ADI

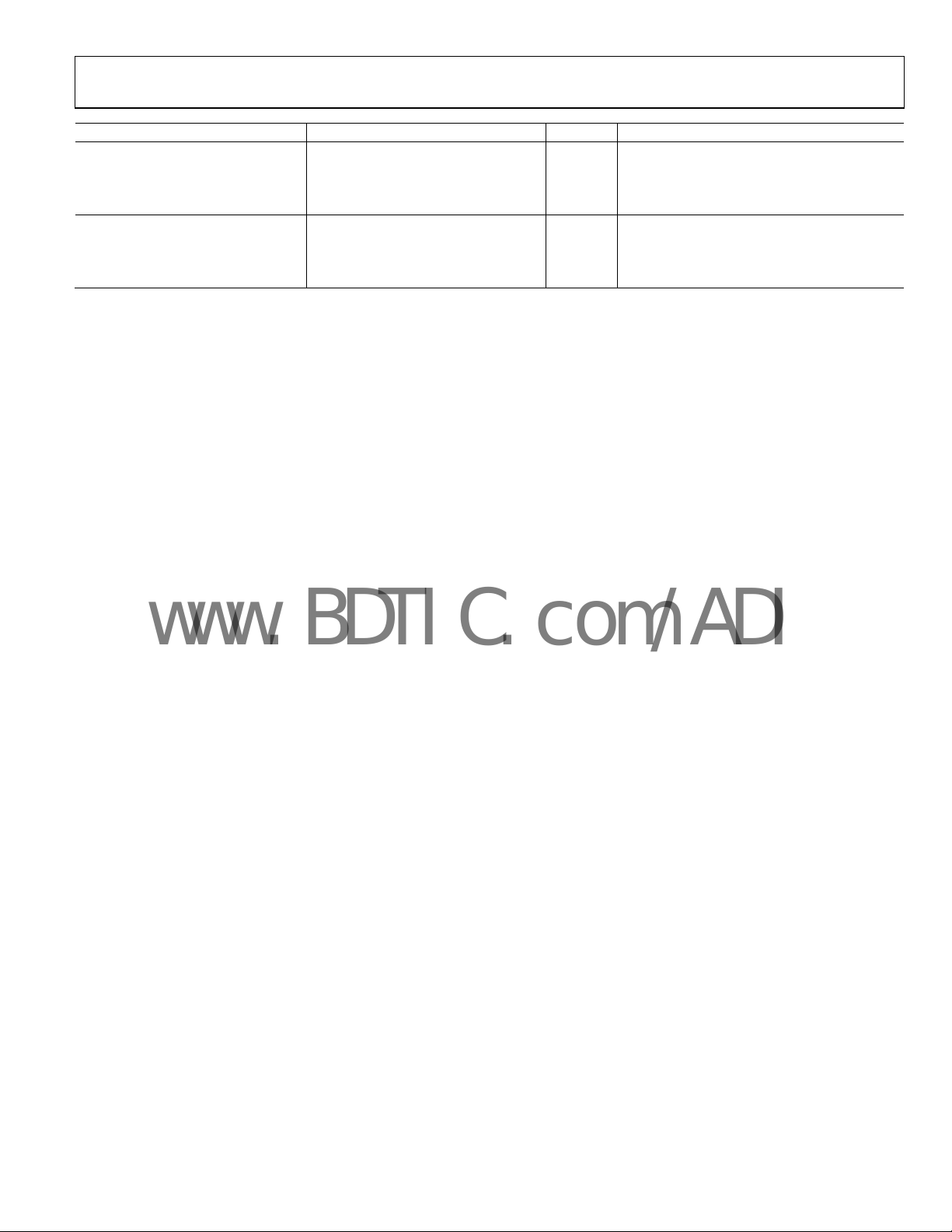

Parameter Min Typ Max Unit Conditions/Comments

POWER REQUIREMENTS

AVDD 4.75 5.25 V

DVDD 4.75 5.25 V

V

2.3 5.25 V

DRIVE

POWER SUPPLY

I

12 mA

AVDD

I

35 mA

DVDD

I

2 mA

OVDD

1

Temperature ranges are as follows: A, B grades: –40°C to +85°C; C, D grades: –40°C to +125°C.

2

The voltages, SIN, SINLO, COS, and COSLO, relative to AGND, must always be between 0.15 V and AVDD − 0.2 V.

3

All specifications within the angular accuracy parameter are tested at constant velocity, that is, zero acceleration.

4

The velocity accuracy specification includes velocity offset and dynamic ripple.

5

For example when RES0 = 0 and RES1 = 1, the position output has a resolution of 12 bits. The velocity output has a resolution of 11 bits with the MSB indicating the

direction of rotation. In this example, with a CLKIN frequency of 8.192 MHz the velocity LSB is 0.488 rps, that is, 1000 rps/(211).

6

The clock frequency of the AD2S1210 can be supplied with a crystal, an oscillator, or directly from a DSP/microprocessor digital output. When using a single-ended

clock signal directly from the DSP/microprocessor, the XTALOUT pin should remain open circuit and the logic levels outlined under the logic inputs parameter in Table 1 apply.

Rev. 0 | Page 5 of 36

AD2S1210

www.BDTIC.com/ADI

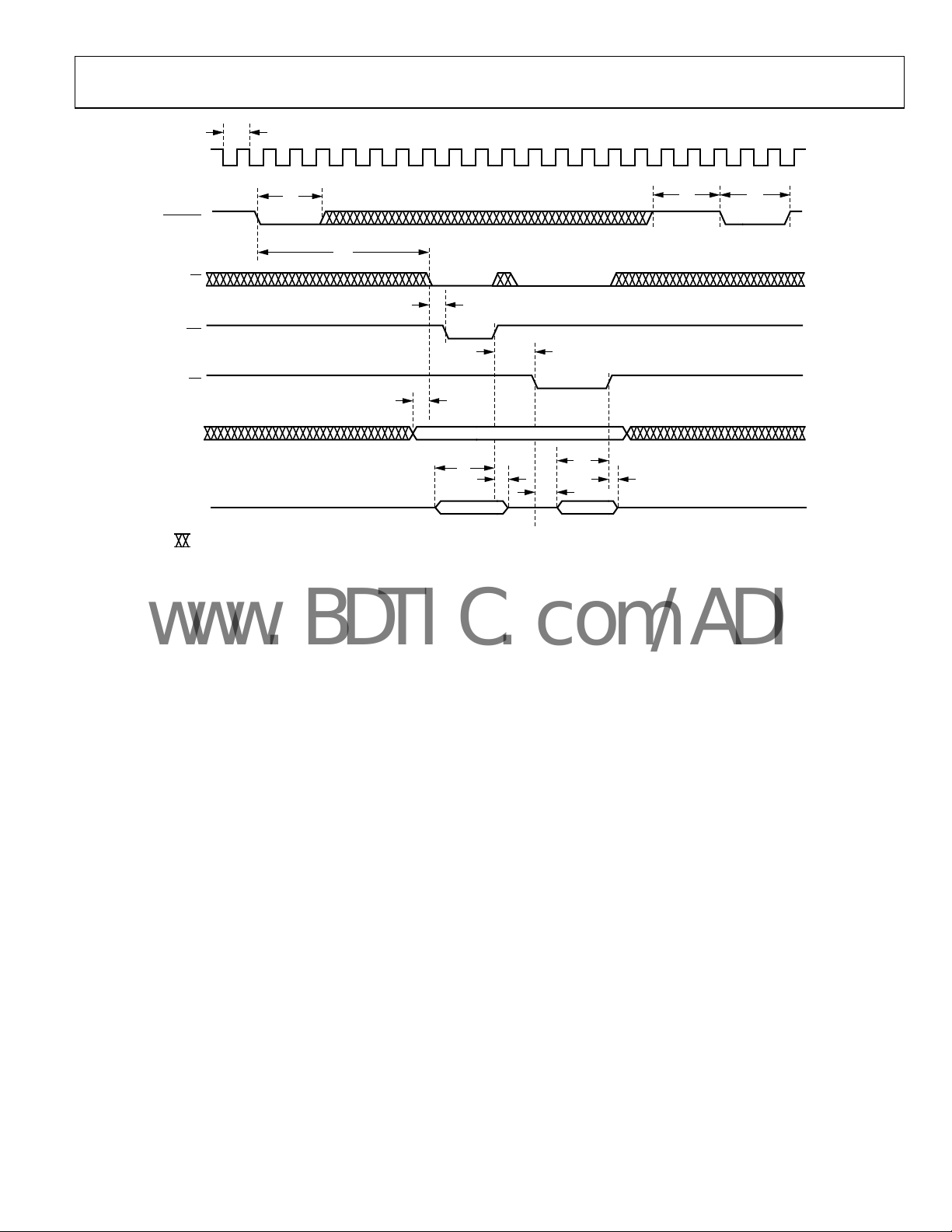

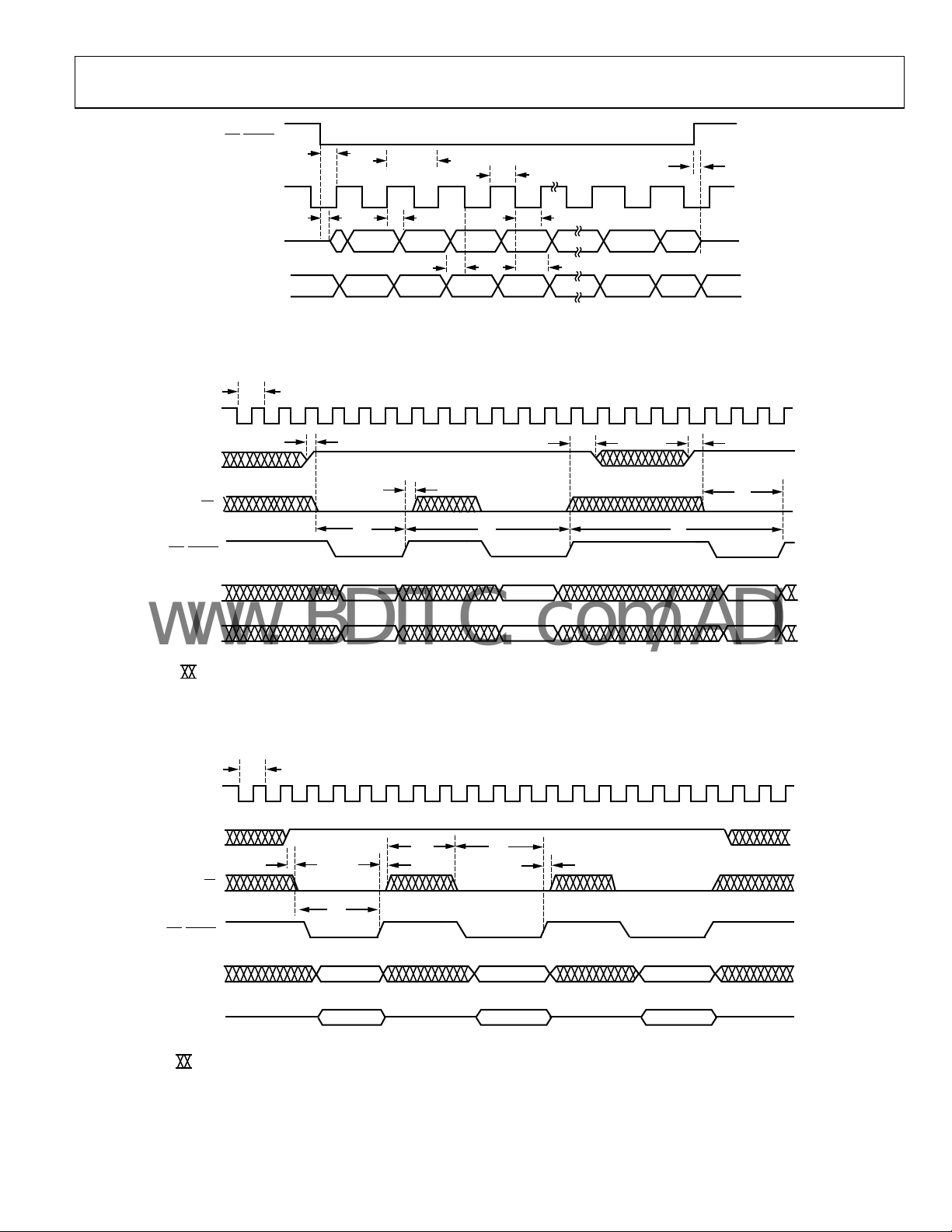

TIMING SPECIFICATIONS

AVDD = DVDD = 5.0 V ± 5%, TA = T

Table 2.

Parameter Description Limit at T

f

Frequency of clock input 6.144 MHz min

CLKIN

10.24 MHz max

tCK Clock period ( = 1/f

163 ns max

t1

t2

A0 and A1 setup time before RD

Delay CS

t3 Address/data setup time during a write cycle 3 ns min

t4 Address/data hold time during a write cycle 2 ns min

t5

t6

Delay WR

Delay CS

t7 Delay between writing address and writing data 2 × tCK + 20 ns min

t8

A0 and A1 hold time after WR

t9 Delay between successive write cycles 6 × tCK + 20 ns min

t10

t11

t12

V

V

V

t13

t

14A

t

14B

t15

t16

t17

t18

t19

V

V

V

t20

t21

V

V

V

t22

t23

V

V

V

Delay between rising edge of WR

Delay CS

Enable delay RD

DRIVE

DRIVE

DRIVE

rising edge to CS rising edge

RD

Disable delay RD

Disable delay CS

Delay between rising edge of RD

SAMPLE

Delay from SAMPLE

Hold time RD

Enable delay RD

DRIVE

DRIVE

DRIVE

pulse width

RD

A0 and A1 set time to data valid when RD

DRIVE

DRIVE

DRIVE

Delay WR

Delay WR

DRIVE

DRIVE

DRIVE

t24 Delay SCLK rising edge to DBx valid

V

V

V

DRIVE

DRIVE

DRIVE

t25 SCLK high time 0.4 × tCK ns min

t26 SCLK low time 0.4 × tCK ns min

t27 SDI setup time prior to SCLK falling edge 3 ns min

t28 SDI hold time after SCLK falling edge 2 ns min

to T

MIN

falling edge to WR/FSYNC rising edge

/FSYNC rising edge to CS rising edge

rising edge to CS falling edge

falling edge to RD falling edge

unless otherwise noted.1

MAX,

, T

MIN

) 98 ns min

CLKIN

/CS low

2 ns min

Unit

MAX

22 ns min

2 ns min

10 ns min

/FSYNC rising edge

/FSYNC and falling edge of RD

2 ns min

2 ns min

2 ns min

low to data valid in configuration mode

= 4.5 V to 5.25 V 37 ns min

= 2.7 V to 3.6 V 25 ns min

= 2.3 V to 2.7 V 30 ns min

2 ns min

high to data high-Z

high to data high-Z

and falling edge of WR/FSYNC

pulse width

before RD/CS low

before RD low

/CS low to data valid

16 ns min

16 ns min

2 ns min

2 × t

+ 20 ns min

CK

6 × t

+ 20 ns min

CK

2 ns min

= 4.5 V to 5.25 V 17 ns min

= 2.7 V to 3.6 V 21 ns min

= 2.3 V to 2.7 V 33 ns min

6 ns min

/CS low

= 4.5 V to 5.25 V 36 ns min

= 2.7 V to 3.6 V 37 ns min

= 2.3 V to 2.7 V 29 ns min

/FSYNC falling edge to SCLK rising edge

/FSYNC falling edge to SDO release from high-Z

3 ns min

= 4.5 V to 5.25 V 16 ns min

= 2.7 V to 3.6 V 26 ns min

= 2.3 V to 2.7 V 29 ns min

= 4.5 V to 5.25 V 24 ns min

= 2.7 V to 3.6 V 18 ns min

= 2.3 V to 2.7 V 32 ns min

Rev. 0 | Page 6 of 36

AD2S1210

www.BDTIC.com/ADI

Parameter Description Limit at T

t29

t30

t31

t32

t33

In normal mode, A0 = 0, A1 = 0/1 24 × tCK + 5 ns ns min

In configuration mode, A0 = 1, A1 = 1 8 × tCK + 5 ns ns min

t34

f

Frequency of SCLK input

SCLK

V

V

V

1

Temperature ranges are as follows: A, B grades: –40°C to +85°C; C, D grades: –40°C to +125°C.

2

A0 and A1 should remain constant for the duration of the serial readback. This may require 24 clock periods to read back the 8-bit fault information in addition to the

16 bits of position/velocity data. If the fault information is not required, A0/A1 may be released following 16 clock cycles.

Delay WR

Delay from SAMPLE

Delay CS

A0 and A1 setup time before WR

A0 and A1 hold time after WR

Delay WR

/FSYNC rising edge to SDO high-Z

before WR/FSYNC falling edge

falling edge to WR/FSYNC falling edge in normal mode

/FSYNC falling edge

/FSYNC falling edge2

/FSYNC rising edge to WR/FSYNC falling edge

= 4.5 V to 5.25 V 20 MHz

DRIVE

= 2.7 V to 3.6 V 25 MHz

DRIVE

= 2.3 V to 2.7 V 15 MHz

DRIVE

15 ns min

6 × t

2 ns min

2 ns min

10 ns min

, T

MIN

+ 20 ns ns min

CK

Unit

MAX

Rev. 0 | Page 7 of 36

AD2S1210

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

AVDD to AGND, DGND −0.3 V to +7.0 V

DVDD to AGND, DGND −0.3 V to +7.0 V

V

to AGND, DGND −0.3 V to AVDD

DRIVE

AVDD to DVDD −0.3 V to +0.3 V

AGND to DGND −0.3 V to +0.3 V

Analog Input Voltage to AGND −0.3 V to AVDD + 0.3 V

Digital Input Voltage to DGND −0.3 V to V

Digital Output Voltage to DGND −0.3 V to V

Analog Output Voltage Swing −0.3 V to AVDD + 0.3 V

Input Current to Any Pin Except Supplies1 ±10 mA

Operating Temperature Range (Ambient)

A, B Grades −40°C to +85°C

C, D Grades −40°C to +125°C

Storage Temperature Range −65°C to +150°C

θJA Thermal Impedance2 54°C/W

θJA Thermal Impedance2 15°C/W

RoHS-Compliant Temperature, Soldering

Reflow

ESD 2 kV HBM

1

Transient currents of up to 100 mA do not cause latch-up.

2

JEDEC 2S2P standard board.

260(−5/+0)oC

DRIVE

DRIVE

+ 0.3 V

+ 0.3 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. 0 | Page 8 of 36

AD2S1210

T

W

www.BDTIC.com/ADI

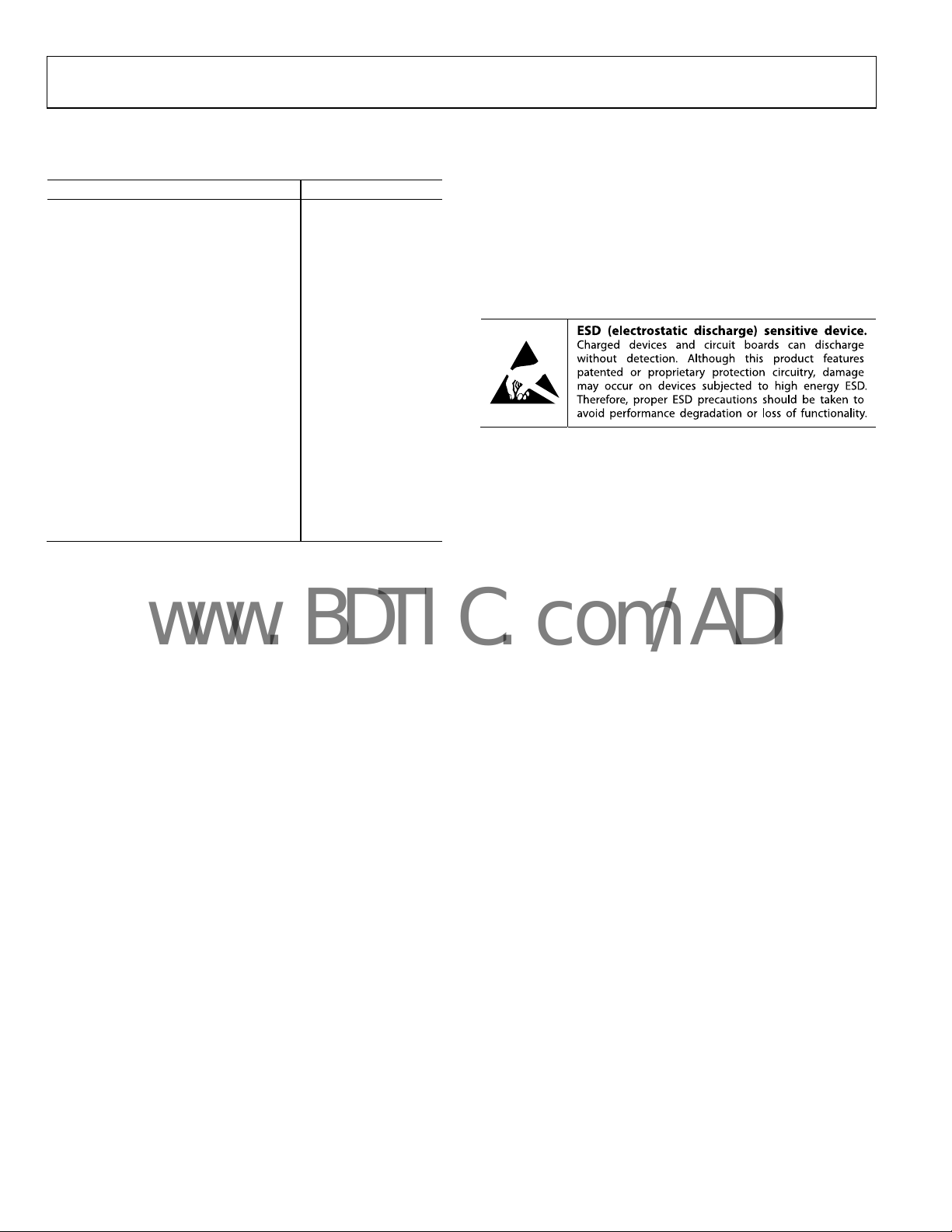

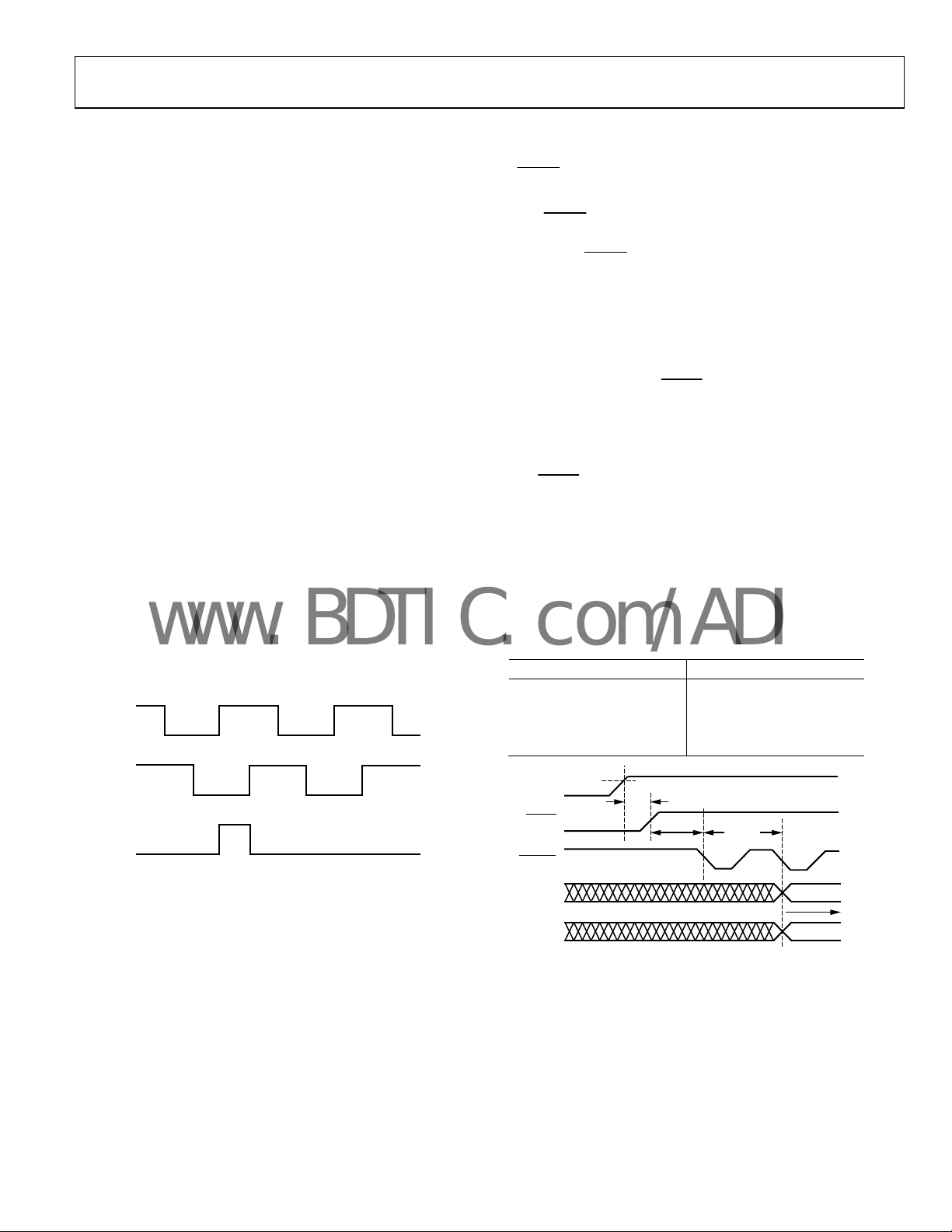

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Table 4. Pin Function Descriptions

Pin

No. Mnemonic Description

1 RES1

Resolution Select 1. Logic input. RES1 in conjunction with RES0 allows the resolution of the AD2S1210 to be

programmed. Refer to the Configuration of AD2S1210 section.

2

3

Chip Select. Active low logic input. The device is enabled when CS is held low.

CS

Edge-Triggered Logic Input. When the SOE pin is high, this pin acts as a frame synchronization signal and output

RD

enable for the parallel data outputs, DB15 to DB0. The output buffer is enabled when CS

the SOE pin is low, the RD pin should be held high.

4

/FSYNC Edge-Triggered Logic Input. When the SOE pin is high, this pin acts as a frame synchronization signal and input

WR

enable for the parallel data inputs, DB7 to DB0. The input buffer is enabled when CS

When the SOE

5, 19 DGND

Digital Ground. These pins are ground reference points for digital circuitry on the AD2S1210. Refer all digital input

signals to this DGND voltage. Both of these pins can be connected to the AGND plane of a system. The DGND and

AGND voltages should ideally be at the same potential and must not be more than 0.3 V apart, even on a transient basis.

6 DVDD

Digital Supply Voltage, 4.75 V to 5.25 V. This is the supply voltage for all digital circuitry on the AD2S1210. The AV

voltages ideally should be at the same potential and must not be more than 0.3 V apart, even on a transient basis.

7 CLKIN

Clock Input. A crystal or oscillator can be used at the CLKIN and XTALOUT pins to supply the required clock frequency of

the AD2S1210. Alternatively, a single-ended clock can be applied to the CLKIN pin. The input frequency of the AD2S1210 is

specified from 6.144 MHz to 10.24 MHz.

8 XTALOUT

Crystal Output. When using a crystal or oscillator to supply the clock frequency to the AD2S1210, apply the crystal

across the CLKIN and XTALOUT pins. When using a single-ended clock source, the XTALOUT pin should be

considered a no connect pin.

9

Serial Output Enable. Logic input. This pin enables either the parallel or serial interface. The serial interface is selected

SOE

by holding the SOE

10

SAMPLE

Sample Result. Logic input. Data is transferred from the position and velocity integrators to the position and velocity

registers, after a high-to-low transition on the SAMPLE

transition on the SAMPLE

11 DB15/SDO

Data Bit 15/Serial Data Output Bus. When the SOE

controlled by CS

WR/FSYNC. The bits are clocked out on the rising edge of SCLK.

12 DB14/SDI

Data Bit 14/Serial Data Input Bus. When the SOE

and RD. When the SOE pin is low, this pin acts as SDI, the serial data input bus controlled by CS and WR/FSYNC. The

by CS

bits are clocked in on the falling edge of SCLK.

AD2S1210

TOP VIEW

(Not to Scale)

16

18

17

DB9

DB10

DD

SINLO41SIN40AGND39EXC38EXC37A0

42

20

19

DB821DB722DB623DB524DB4

DRIVE

DGND

V

36

35

34

33

32

31

30

29

28

27

26

25

A1

DOS

LOT

RESET

DIR

NM

B

A

DB0

DB1

DB2

DB3

07467-002

RES1

CS

RD

R/FSYNC

DGND

DV

CLKIN

XTALOUT

SOE

SAMPLE

DB15/SDO

DB14/SDI

RES047REFOU

REFBYP45COS44COSLO43AV

48

46

1

PIN 1

2

3

4

5

6

DD

7

8

9

10

11

12

13

14

15

DB11

DB12

DB13/SCLK

Figure 2. Pin Configuration

and RD are held low. When

and WR/FSYNC are held low.

pin is low, the WR/FSYNC pin acts as a frame synchronization signal and enable for the serial data bus.

and DVDD

DD

pin low, and the parallel interface is selected by holding the SOE pin high.

signal. The fault register is also updated after a high-to-low

signal.

pin is high, this pin acts as DB15, a three-state data output pin

and RD. When the SOE pin is low, this pin acts as SDO, the serial data output bus controlled by CS and

pin is high, this pin acts as DB14, a three-state data output pin controlled

Rev. 0 | Page 9 of 36

AD2S1210

www.BDTIC.com/ADI

Pin

No. Mnemonic Description

13 DB13/SCLK

14 to

17

18 V

20 DB8

21 to

28

29 A

30 B

31 NM

32 DIR

33

34 LOT

35 DOS

36 A1

37 A0

38 EXC

39

40 AGND

41 SIN Positive Analog Input of Differential SIN/SINLO Pair. The input range is 2.3 V p-p to 4.0 V p-p.

42 SINLO Negative Analog Input of Differential SIN/SINLO Pair. The input range is 2.3 V p-p to 4.0 V p-p.

43 AVDD

44 COSLO Negative Analog Input of Differential COS/COSLO Pair. The input range is 2.3 V p-p to 4.0 V p-p.

45 COS Positive Analog Input of Differential COS/COSLO Pair. The input range is 2.3 V p-p to 4.0 V p-p.

46 REFBYP Reference Bypass. Connect reference decoupling capacitors at this pin. Typical recommended values are 10 μF and 0.01 μF.

47 REFOUT Voltage Reference Output.

48 RES0

DB12 to

DB9

DRIVE

DB7 to DB0

Reset. Logic input. The AD2S1210 requires an external reset signal to hold the RESET input low until VDD is within the

RESET

Excitation Frequency Complement. Analog output. An on-board oscillator provides the sinusoidal excitation signal

EXC

Data Bit 13/Serial Clock. In parallel mode, this pin acts as DB13, a three-state data output pin controlled by CS

serial mode, this pin acts as the serial clock input.

Data Bit 12 to Data Bit 9. Three-state data output pins controlled by CS and RD.

Logic Power Supply Input. The voltage supplied at this pin determines at what voltage the interface operates.

Decouple this pin to DGND. The voltage range on this pin is 2.3 V to 5.25 V and may be different to the voltage range

and DVDD but should never exceed either by more than 0.3 V.

at AV

DD

Data Bit 8. Three-state data output pin controlled by CS

Data Bit 7 to Data Bit 0. Three-state data input/output pins controlled by CS

Incremental Encoder Emulation Output A. Logic output. This output is free running and is valid if the resolver format

input signals applied to the converter are valid.

Incremental Encoder Emulation Output B. Logic output. This output is free running and is valid if the resolver format

input signals applied to the converter are valid.

North Marker Incremental Encoder Emulation Output. Logic output. This output is free running and is valid if the

resolver format input signals applied to the converter are valid.

Direction. Logic output. This output is used in conjunction with the incremental encoder emulation outputs. The DIR

output indicates the direction of the input rotation and is high for increasing angular rotation.

specified operating range of 4.75 V to 5.25 V.

Loss of Tracking. Logic output. LOT is indicated by a logic low on the LOT pin and is not latched. Refer to the Loss of

Position Tracking Detection section.

Degradation of Signal. Logic output. Degradation of signal (DOS) is detected when either resolver input (sine or cosine)

exceeds the specified DOS sine/cosine threshold or when an amplitude mismatch occurs between the sine and

cosine input voltages. DOS is indicated by a logic low on the DOS pin. Refer to the Signal Degradation Detection

section.

Mode Select 1. Logic input. A1 in conjunction with A0 allows the mode of the AD2S1210 to be selected. Refer to the

Configuration of AD2S1210 section.

Mode Select 0. Logic input. A0 in conjunction with A1 allows the mode of the AD2S1210 to be selected. Refer to the

Configuration of AD2S1210 section.

Excitation Frequency. Analog output. An on-board oscillator provides the sinusoidal excitation signal (EXC) and its

complement signal (EXC

frequency register.

(EXC) and its complement signal (EXC

excitation frequency register.

Analog Ground. This pin is the ground reference points for analog circuitry on the AD2S1210. Refer all analog input

signals and any external reference signal to this AGND voltage. Connect the AGND pin to the AGND plane of a

system. The AGND and DGND voltages should ideally be at the same potential and must not be more than 0.3 V

apart, even on a transient basis.

Analog Supply Voltage, 4.75 V to 5.25 V. This pin is the supply voltage for all analog circuitry on the AD2S1210. The

and DVDD voltages ideally should be at the same potential and must not be more than 0.3 V apart, even on a

AV

DD

transient basis.

Resolution Select 0. Logic input. RES0 in conjunction with RES1 allows the resolution of the AD2S1210 to be

programmed. Refer to the Configuration of AD2S1210 section.

) to the resolver. The frequency of this reference signal is programmable via the excitation

) to the resolver. The frequency of this reference signal is programmable via the

and RD.

, RD, and WR/FSYNC.

and RD. In

Rev. 0 | Page 10 of 36

AD2S1210

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, AVDD = DVDD = V

400

350

300

250

200

150

HITS P ER CODE

100

50

0

8178

8179

8180

8181

8182

8183

8184

8185

8186

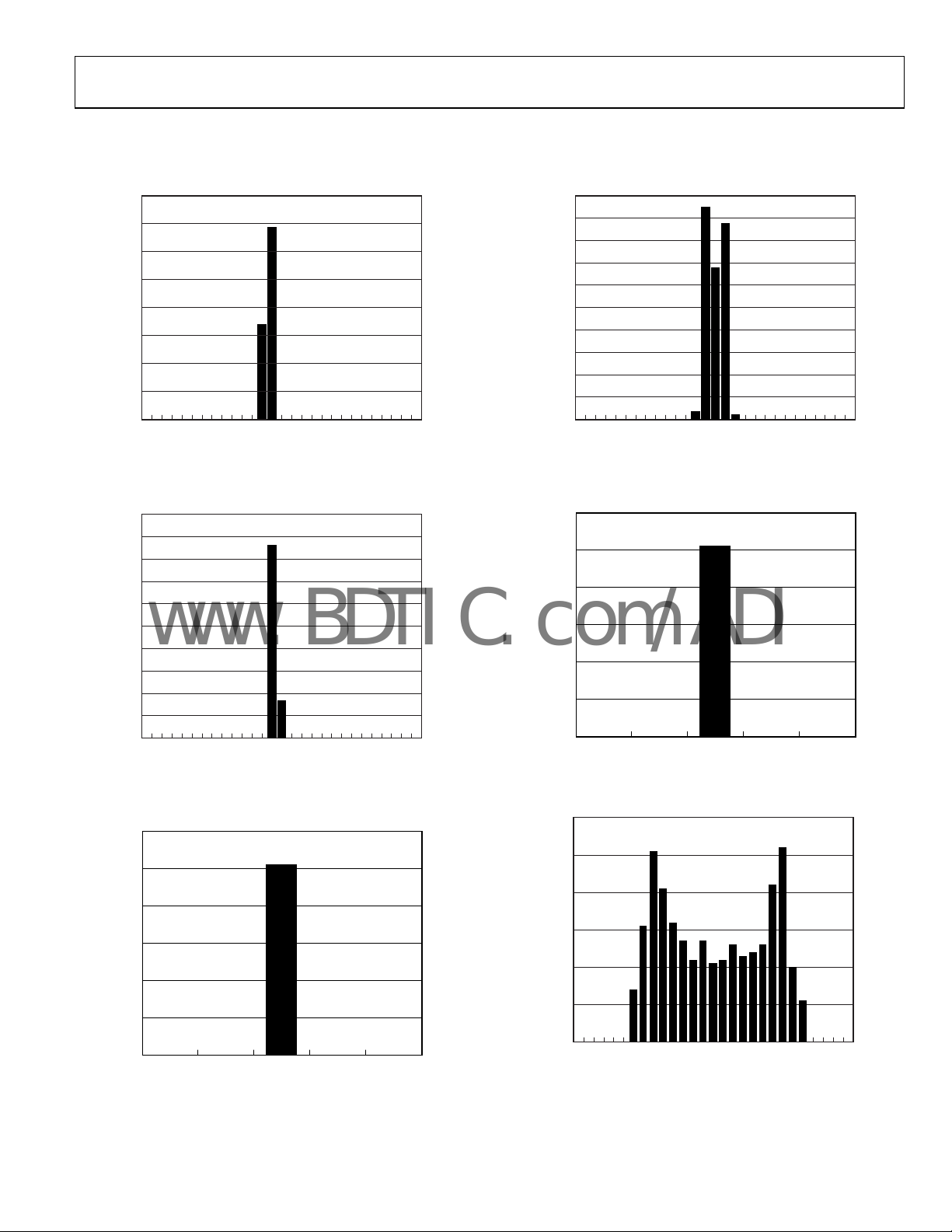

Figure 3. Typical 16-Bit Angular Accuracy Histogram Of Codes, 512 Samples

500

450

400

350

300

250

200

HITS PER CODE

150

100

50

0

8178

8179

8180

8181

8182

8183

8184

8185

8186

Figure 4. Typical 14-Bit Angular Accuracy Histogram of Codes, 512 Samples,

600

500

400

300

HITS PER CODE

200

100

0

2045 2046 2047 2048 2049

Figure 5. Typical 14-Bit Angular Accuracy Histogram of Codes, 512 Samples,

= 5 V, SIN/SINLO = 3.15 V p-p, COS/COSLO = 3.15 V p-p, CLKIN = 8.192 MHz , unless otherwise noted.

DRIVE

200

180

160

140

120

100

80

HITS PER CODE

60

40

20

0

8188

8189

8190

8191

8192

8193

8194

8195

8196

8197

8198

8199

8200

8201

8202

8203

8204

8205

8187

CODE

8206

07467-003

8178

8179

8180

8181

8182

8183

8184

8185

8186

8188

8189

8190

8191

8192

8193

8194

8195

8187

CODE

8196

Figure 6. Typical 12-Bit Angular Accuracy Histogram of Codes, 512 Samples,

Hysteresis Disabled

600

500

400

300

HITS PER CODE

200

100

0

8187

8188

8189

8190

8191

8192

8193

8194

8195

8196

8197

8198

8199

8200

8201

8202

8203

8204

8205

8206

CODE

07467-004

Figure 7. Typical 12-Bit Angular Accuracy Histogram of Codes, 512 Samples,

510 511 512 513 514

CODES

Hysteresis Enabled

Hysteresis Disabled

CODES

07467-005

HITS PER CODE

60

50

40

30

20

10

0

8178

8179

8180

8181

8182

8183

8184

8185

8186

8188

8189

8190

8191

8192

8193

8194

8195

8196

8187

CODE

8197

Figure 8. Typical 10-Bit Angular Accuracy Histogram of Codes, 512 Samples,

Hysteresis Enabled

Hysteresis Disabled

8197

8198

8199

8200

8201

8202

8203

8204

8205

8206

07467-006

07467-017

8198

8199

8200

8201

8202

8203

8204

8205

8206

07467-018

Rev. 0 | Page 11 of 36

AD2S1210

www.BDTIC.com/ADI

600

500

400

300

HITS PER CODE

200

100

0

126 127 128 129 130

CODES

07467-038

Figure 9. Typical 10-Bit Angular Accuracy Histogram of Codes, 512 Samples,

Hysteresis Enabled

20

18

16

14

12

10

8

ANGLE (Deg rees)

6

4

2

0

0 4 8 1216 202428323640

TIME (ms)

07467-010

Figure 10. Typical 16-Bit 10° Step Response

20

18

16

14

12

10

8

ANGLE (Degrees)

6

4

2

0

0 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00

TIME (ms)

Figure 12. Typical 12-Bit 10° Step Response

20

18

16

14

12

10

8

ANGLE (Deg rees)

6

4

2

0

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50

TIME (ms)

Figure 13. Typical 10-Bit 10° Step Response

07467-008

07467-007

20

18

16

14

12

10

8

ANGLE (Degrees)

6

4

2

0

01 2345678910

TIME (ms)

Figure 11. Typical 14-Bit 10° Step Response

07467-009

Rev. 0 | Page 12 of 36

250

225

200

175

150

125

100

ANGLE (Deg rees)

75

50

25

0

0 8 16 24 32 40 48 56 64 72 80

TIME (ms)

Figure 14. Typical 16-Bit 179° Step Response

07467-014

AD2S1210

www.BDTIC.com/ADI

250

225

200

175

150

125

100

ANGLE (Degrees)

75

50

25

0

0 2 4 6 8 10 12 14 16 18 20

TIME (ms)

Figure 15. Typical 14-Bit 179° Step Response

07467-013

5

0

–5

–10

–15

–20

–25

MAGNITUDE (dB)

–30

–35

–40

–45

1 10 100 1k 10k 100k

14-BIT

16-BIT

FREQUENCY (Hz)

10-BIT

12-BIT

Figure 18. Typical System Magnitude Response

07467-015

250

225

200

175

150

125

100

ANGLE (Degrees)

75

50

25

0

012345678910

TIME (ms)

Figure 16. Typical 12-Bit 179° Step Response

250

225

200

175

150

125

100

ANGLE (Deg rees)

75

50

25

0

012345

TIME (ms)

Figure 17. Typical 10-Bit 179° Step Response

0

–20

–40

–60

–80

–100

–120

PHASE (dB)

–140

–160

–180

–200

1 10 100 1k 10k 100k

07467-012

14-BIT 12-BIT

16-BIT

FREQUENCY (Hz)

10-BIT

07467-016

Figure 19. Typical System Phase Response

10

9

8

7

6

5

4

3

TRACKING ERROR ( Degrees)

2

1

0

07467-011

0 500 1000 1500 2000 2500

ACCELERATIO N (rps

2

)

07467-022

Figure 20. Typical 16-Bit Tracking Error vs. Acceleration

Rev. 0 | Page 13 of 36

AD2S1210

www.BDTIC.com/ADI

10

9

8

7

6

5

4

3

TRACKING ERROR ( Degrees)

2

1

0

0 5000 10000 15000 20000 25000 30000 35000 40000 45000

ACCELERATIO N (rps

2

)

Figure 21. Typical 14-Bit Tracking Error vs. Acceleration

10

9

8

7

6

5

4

3

TRACKING ERROR ( Degrees)

2

1

0

0 20000 60000 100000 140000 180000

ACCELERATIO N (rps

2

)

Figure 22. Typical 12-Bit Tracking Error vs. Acceleration

07467-021

07467-020

10

9

8

7

6

5

4

3

TRACKING ERROR ( Degrees)

2

1

0

0 200000 400000 600000 800000 1000000

ACCELERATIO N (rps

2

)

Figure 23. Typical 10-Bit Tracking Error vs. Acceleration

07467-019

Rev. 0 | Page 14 of 36

AD2S1210

V

V

V

V

)

θ

ω

www.BDTIC.com/ADI

RESOLVER FORMAT SIGNALS

=

× sin(ωt)

r

p

R1

θ

R2

S1 S3

= Vs × sin(ωt) × sin(θ)

V

b

(A) CLASSICAL RESOLVER

S2

Va = Vs × sin(ωt) × cos(θ)

S4

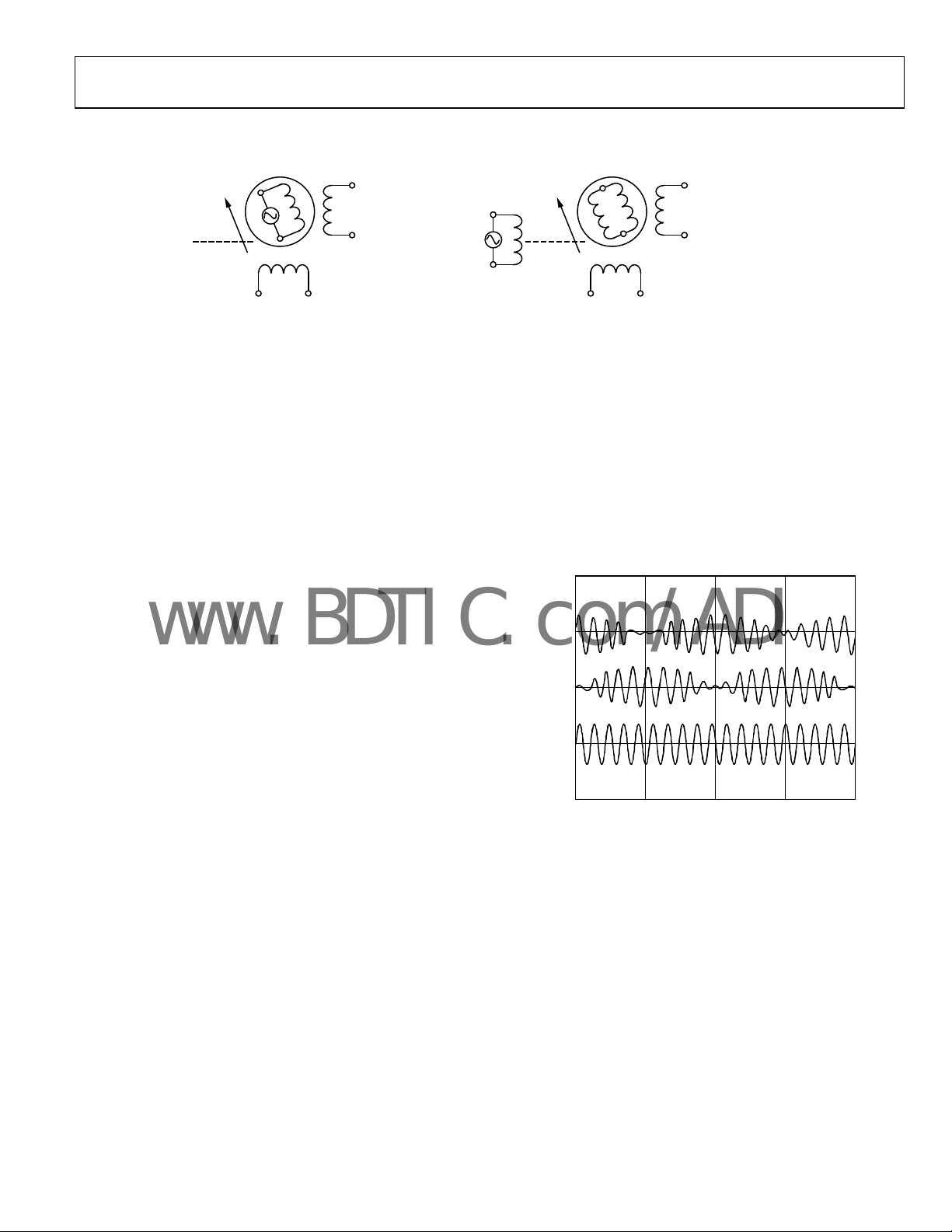

Figure 24. Classical Resolver vs. Variable Reluctance Resolver

A resolver is a rotating transformer, typically with a primary

winding on the rotor and two secondary windings on the stator.

In the case of a variable reluctance resolver, there are no windings on the rotor, as shown in Figure 24. The primary winding

is on the stator as well as the secondary windings, but the saliency

in the rotor design provides the sinusoidal variation in the

secondary coupling with the angular position. Either way, the

resolver output voltages (S3 − S1, S2 − S4) have the same

equations, as shown in Equation 1.

0

tESS

0

(1)

θω

cossin42

×=−

sinsin13

×=−

tESS

where:

θ is the shaft angle.

Sinωt is the rotor excitation frequency.

E

is the rotor excitation amplitude.

0

R1

R2

=

× sin(ωt)

r

p

S2

Va = Vs × sin(ωt) × cos(θ

θ

S1 S3

= Vs × sin(ωt) × sin(θ)

V

b

(B) VARIABLE RELUCTANCE RESOLVER

S4

07467-023

The stator windings are displaced mechanically by 90° (see

Figure 24). The primary winding is excited with an ac reference.

The amplitude of subsequent coupling onto the stator secondary

windings is a function of the position of the rotor (shaft) relative to

the stator. The resolver, therefore, produces two output voltages

(S3 − S1, S2 − S4) modulated by the sine and cosine of shaft

angle. Resolver format signals refer to the signals derived from

the output of a resolver, as shown in Equation 1. Figure 25

illustrates the output format.

S2 – S4

(cos)

S3 – S1

(sin)

R2 – R4

(REF)

0°

90° 180°

θ

Figure 25. Electrical Resolver Representation

270° 360°

07467-024

Rev. 0 | Page 15 of 36

AD2S1210

φθω

φθω

φθφθω

φθφ

θ

φθφ

θ

××=

www.BDTIC.com/ADI

THEORY OF OPERATION

RESOLVER TO DIGITAL CONVERSION

The AD2S1210 operates on a Type II tracking closed-loop

principle. The output continually tracks the position of the

resolver without the need for external conversion and wait

states. As the resolver moves through a position equivalent

to the least significant bit weighting, the output is updated by

one LSB.

The converter tracks the shaft angle θ by producing an output

angle ϕ that is fed back and compared to the input angle θ, and

the resulting error between the two is driven towards 0 when

the converter is correctly tracking the input angle. To measure

the error, S3 − S1 is multiplied by cosϕ and S2 − S4 is multiplied by

sinϕ to give

cossinsin0×tE (for S3 − S1)

sincossin0×tE (for S2 − S4)

The difference is taken, giving

0

This signal is demodulated using the internally generated

synthetic reference, yielding

0

Equation 3 is equivalent to E

equal to E

angular error.

The value E

of the rotor and the digital angle output of the converter.

A phase-sensitive demodulator, some integrators, and a compensation filter form a closed-loop system that seeks to null the error

signal. When this is accomplished, ϕ equals the Resolver Angle θ

within the rated accuracy of the converter. A Type II tracking

loop is used so that constant velocity inputs can be tracked

without inherent error.

(θ − ϕ) for small values of θ − ϕ, where θ − ϕ =

0

−E (3)

(θ − ϕ) is the difference between the angular error

0

−×tE (2)

)sincoscos(sin

sin(θ − ϕ), which is approximately

0

)sincoscos(sinsin

FAULT DETECTION CIRCUIT

The AD2S1210 fault detection circuit can sense loss of resolver

signals, out-of-range input signals, input signal mismatch, or

loss of position tracking; however, in the event of a fault, the

position indicated by the AD2S1210 may differ significantly

from the actual shaft position of the resolver.

Monitor Signal

The AD2S1210 generates a monitor signal by comparing the

angle in the position register to the incoming sine and cosine

signals from the resolver. The monitor signal is created in a

similar fashion to the error signal described in the Resolver to

Digital Conversion section. The incoming signals, sinθ and

cosθ, are multiplied by the sin and cos of the output angle,

respectively, and then added together.

AAMonitor (4)

where:

A1 is the amplitude of the incoming sine signal (A1 × sinθ).

A2 is the amplitude of the incoming cosine signal (A2 × cosθ).

θ is the resolver angle.

ϕ is the angle stored in the position register.

Note that Equation 4 is shown after demodulation, with the

Carrier Signal sinωt removed. Also, note that for matched input

signal (that is, a no fault condition), A1 = A2.

When A1 = A2 and the converter is tracking (θ = ϕ), the

monitor signal output has a constant magnitude of A1 (Monitor

= A1 × (sin

angle. When A1 ≠ A2, the monitor signal magnitude varies

between A1 and A2 at twice the rate of shaft rotation. The

monitor signal is used as described in the following sections to

detect degradation or loss of input signals.

2

θ + cos2 θ) = A1), which is independent of shaft

Loss of Signal Detection

The AD2S1210 indicates that a loss of signal (LOS) has

occurred for four separate conditions.

• When either resolver input (sine or cosine) falls below the

specified LOS sine/cosine threshold. This threshold is

defined by the user and is set by writing to the internal

register, Address 0x88 (see the Register Map section).

• When any of the resolver input pins (SIN, SINLO, COS, or

COSLO) are disconnected from the sensor.

• When any of the resolver input pins (SIN, SINLO, COS, or

COSLO) are clipping the power rail or ground rail of the

AD2S1210. Refer to the Sine/Cosine Input Clipping section.

• When a configuration parity error has occurred. Refer to

the Configuration Parity Error section.

A loss of signal is caused if either of the stator windings of the

resolver (sine or cosine) are open circuit or have a number of

shorted turns. LOS is indicated by both the DOS and LOT pins

latching as logic low outputs. The DOS and LOT pins are reset

to a no fault state when the user enters configuration mode and

reads the fault register. The LOS condition has priority over

both the DOS and LOT conditions, as shown in Table 6. To

determine the cause of the LOS fault detection, the user must

read the fault register, Address 0xFF (see the Register Map

section).

When a loss of signal is detected due to the resolver inputs (sine

or cosine) falling below the specified LOS sine/cosine threshold,

the electrical angle through which the resolver may rotate before

the LOS can be detected by the AD2S1210 is referred to as the

LOS angular latency. This is defined by the specified LOS sine/

cosine threshold set by the user and the maximum amplitude of

the input signals being applied to the AD2S1210. The worst-case

angular latency can be calculated as follows:

coscos2sinsin1 ××+

Rev. 0 | Page 16 of 36

AD2S1210

www.BDTIC.com/ADI

Angular Latency =

×

The preceding equation is based on the worst-case angular

error, which can be seen by the AD2S1210 before an LOS fault

is indicated. This occurs if one of the resolver input signals,

either sine or cosine, is lost while the remaining signal is at its

peak amplitude, for example, if the sine input is lost while the

input angle is 90°. The worst-case angular latency is twice the

worst-case angular error.

⎢

⎢

⎣

⎡

Arc

cos2 (5)

thresholdLOS

/max

amplitudecosinesine

⎤

⎥

⎥

⎦

Signal Degradation Detection

The AD2S1210 indicates that a degradation of signal (DOS) has

occurred for two separate conditions.

• When either resolver input (sine or cosine) exceeds the

specified DOS sine/cosine threshold. This threshold is

defined by the user and is set by writing to the internal

register, Address 0x89 (see the Register Map section).

• When the amplitudes of the input signals, sine and cosine,

mismatch by more than the specified DOS sine/cosine

mismatch threshold. This threshold is defined by the user

and is set by writing to the internal register, Address 0x8A

(see the Register Map section). The AD2S1210 continuously

stores the minimum and maximum magnitude of the monitor signal in internal registers. The difference between the

minimum and maximum is calculated to determine if a

DOS mismatch has occurred. The initial values for the

minimum and maximum internal registers must be defined

by the user, at Address 0x8C and Address 0x8B, respectively

(see the Register Map section).

DOS is indicated by a logic low on the DOS pin. When DOS is

indicated, the output is latched low until the user enters configuration mode and reads the fault register. The DOS condition has

priority over the LOT condition, as shown in Table 6. To determine the cause of the DOS fault detection, the user must read

the fault register, Address 0xFF (see the Register Map section).

Time Latency for LOS and DOS Detection

Note that the monitor signal is generated on the active edge of

the internal AD2S1210 clock. The internal clock is generated

by dividing the externally applied CLKIN frequency by 2; for

example, when using a CLKIN frequency of 8.192 MHz the

internal AD2S1210 clock is 4.096 MHz. The AD2S1210 continuously stores the minimum and maximum magnitude of the

monitor signal in internal registers. The values stored in these

internal registers are compared to the LOS and DOS thresholds

configured by the user at set intervals. This interval, known as

the window counter period, is dependent on the excitation

frequency configured by the user. It is set to ensure that two

window counter periods include at least one full period of the

excitation frequency applied to the resolver. The window

counter period is defined in terms of internal clock cycles. The

window counter periods for the range of excitation frequencies

on the AD2S1210 are outlined in Table 5.

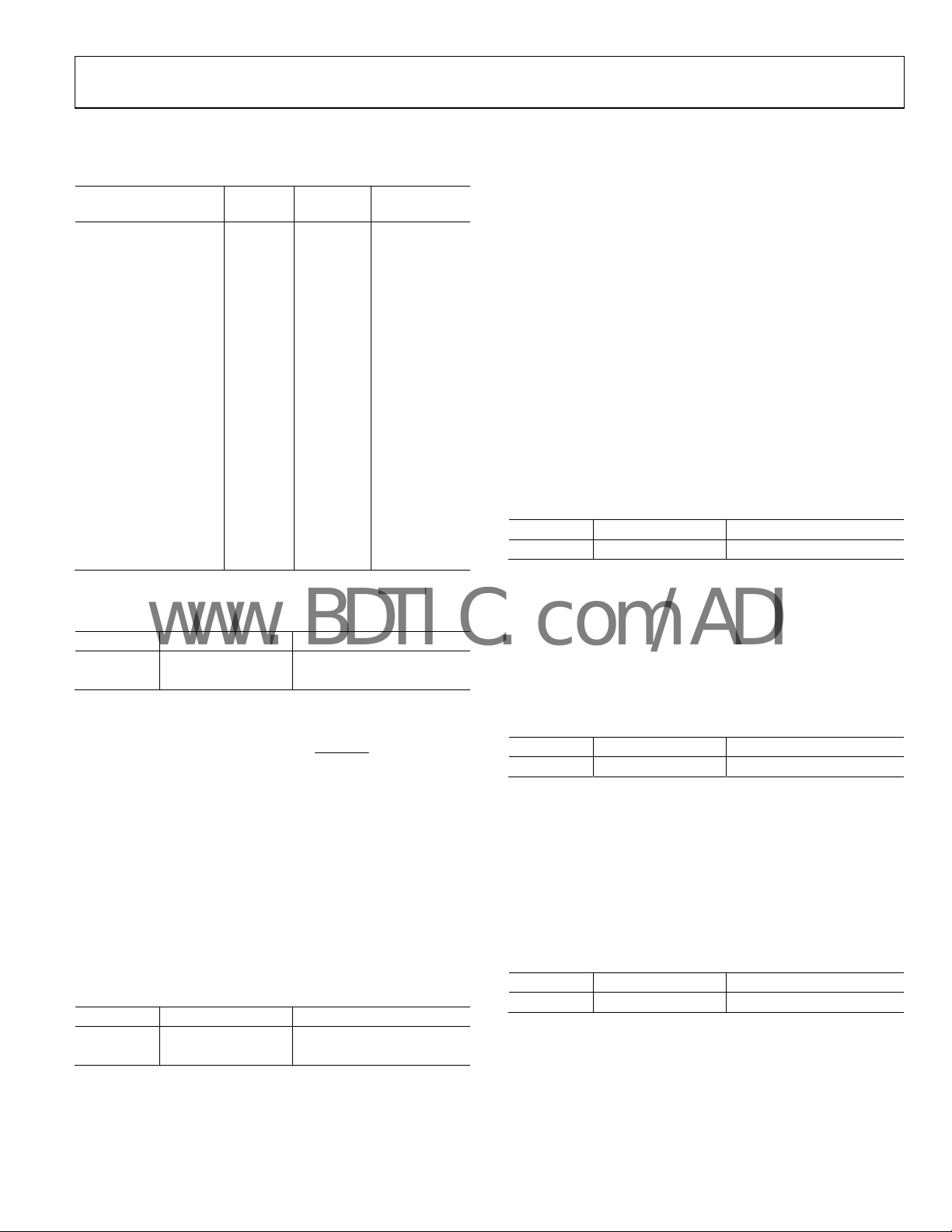

Table 5. Window Counter Period vs. Excitation Frequency

Range, CLKIN = 8.192 MHz

Number of

Excitation Frequency

Range

2 kHz ≤ Exc Freq < 4 kHz 1065 260

4 kHz ≤ Exc Freq < 8 kHz 554 135.25

8 kHz ≤ Exc Freq ≤ 20 kHz 256 62.5

1

CLKIN = 8.192 MHz. The window counter period scales with clock frequency

and can be calculated by multiplying the number of internal clock cycles by

the period of the internal clock frequency, that is, CLKIN/2.

The AD2S1210 detects an LOS or DOS due to the resolver inputs

(sine or cosine) falling below or exceeding the LOS and DOS

thresholds within two window counter periods. For example,

with an excitation frequency of 10 kHz, a fault is detected within

125 μs. A persistent fault is detected within one window counter

period of the reading and clearing the fault register.

Note that the time latency to detect the occurrence of a DOS

mismatch fault is dependent on the speed of rotation of the

resolver. The worst-case time latency to detect a DOS mismatch

fault is the time required for one full rotation of the resolver.

Internal Clock

Cycles

Window

Counter Period

1

(μs)

Loss of Position Tracking Detection

The AD2S1210 indicates that a loss of tracking (LOT) has

occurred when

• The internal error signal of the AD2S1210 has exceeded

the specified angular threshold. This threshold is defined

by the user and is set by writing to the internal register,

Address 0x8D (see the Register Map section).

• The input signal exceeds the maximum tracking rate. The

maximum tracking rate depends on the resolution defined

by the user and the CLKIN frequency.

LOT is indicated by a logic low on the LOT pin and is not latched.

LOT has hysteresis and is not cleared until the internal error

signal is less than the value defined in the LOT low threshold

register, Address 0x8E (see the Register Map section).

When the maximum tracking rate is exceeded, LOT is cleared

only if the velocity is less than the maximum tracking rate and

the internal error signal is less than the value defined in the LOT

low threshold register. LOT can be indicated for step changes in

RESET

position (such as after a

It is also useful as a built-in test to indicate that the tracking

converter is functioning properly. The LOT condition has lower

priority than both the DOS and LOS conditions, as shown in

Table 6. The LOT and DOS conditions cannot be indicated using

the LOT and DOS pins at the same time. However, both conditions are indicated separately in the fault register. To determine

the cause of the LOT fault detection, the user must read the fault

register, Address 0xFF (see the Register Map section).

signal is applied to the AD2S1210).

Rev. 0 | Page 17 of 36

AD2S1210

www.BDTIC.com/ADI

Table 6. Fault Detection Decoding

Order of

Condition DOS Pin LOT Pin

Loss of Signal (LOS) 0 0 1

Degradation of Signal (DOS) 0 1 2

Loss of Tracking (LOT) 1 0 3

No Fault 1 1 N/A

Priority

Sine/Cosine Input Clipping

The AD2S1210 indicates that a clipping error has occurred if

any of the resolver input pins (SIN, SINLO, COS, or COSLO)

are clipping the power rail or ground rail of the AD2S1210. The

clipping fault is indicated if the input amplitudes are less than

0.15 V or greater then AV

Sine/cosine input clipping error is indicated by both the DOS and

LOT pins latching as logic low outputs. Sine/cosine input clipping

error is also indicated by Bit D7 of the fault register being set high.

The DOS and LOT pins are reset to a no fault state when the

user enters configuration mode and reads the fault register.

− 0.2 V for more than 4 μs.

DD

Configuration Parity Error

The AD2S1210 includes a number of user programmable registers

that allow the user to configure the part. Each read/write register

on the AD2S1210 is programmed with seven bits of information by the user. The 8

the event that the data within these registers becomes corrupted,

the AD2S1210 indicates that a configuration parity error has

occurred. Configuration parity error is indicated by both the DOS

and LOT pins latching as logic low outputs. Configuration parity

error is also indicated by Bit D0 of the fault register being set

high. In the event that a parity error occurs, it is recommended

that the user reset the part using the

th

bit is reserved as a parity error bit. In

RESET

pin.

Phase Lock Error

The AD2S1210 indicates that a phase lock error has occurred if

the difference between the phase of the excitation frequency

and the phase of the sine and cosine signals exceeds the specified

phase lock range. Phase lock error is indicated by a logic low on

the LOT pin and is not latched. Phase lock error is also indicated

by Bit D1 of the fault register being set high.

ON-BOARD PROGRAMMABLE SINUSOIDAL OSCILLATOR

An on-board oscillator provides the sinusoidal excitation signal

EXC

(EXC) to the resolver as well as its complemented signal (

The frequency of this reference signal is programmable to a

number of standard frequencies between 2 kHz and 20 kHz.

The amplitude of this signal is 3.6 V p-p and is centered on 2.5 V.

The reference excitation output of the AD2S1210 needs an

external buffer amplifier to provide gain and the additional

current to drive a resolver.

).

The AD2S1210 also provides an internal synthetic reference

signal that is phase locked to its sine and cosine inputs. Phase

errors between the resolver primary and secondary windings

can degrade the accuracy of the RDC and are compensated by

this synchronous reference signal. This also compensates the

phase shifts due to temperature and cabling and eliminates the

need of an external preset phase compensation circuit.

SYNTHETIC REFERENCE GENERATION

When a resolver undergoes a high rotation rate, the RDC tends

to act as an electric motor and produces speed voltages, along

with the ideal sine and cosine outputs. These speed voltages are

in quadrature to the main signal waveform. Moreover, nonzero

resistance in the resolver windings causes a nonzero phase shift

between the reference input and the sine and cosine outputs.

The combination of speed voltages and phase shift causes a tracking error in the RDC that is approximated by

ShiftPhaseError ×=

To compensate for the described phase error between the resolver

reference excitation and the sine/cosine signals, an internal

synthetic reference signal is generated in phase with the reference frequency carrier. The synthetic reference is derived using

the internally filtered sine and cosine signals. It is generated

by determining the zero crossing of either the sine or cosine

(whichever signal is larger, to improve phase accuracy) and

evaluating the phase of the resolver reference excitation. The

synthetic reference reduces the phase shift between the reference and sine/cosine inputs to less than 10°, and operates for

phase shifts of ±44°. If additional phase lock range is required,

Bit D5 in the control register can be set to zero to expand the

phase lock range to 360° (see the Control Register section).

RateRotation

FrequencyReference

(6)

CONNECTING THE CONVERTER

Ground is connected to the AGND and DGND pins (see

Figure 26). A positive power supply (V

connected to the AV

decoupling capacitors being 10 nF and 4.7 μF. These capacitors

are then placed as close to the device pins as possible and are

connected to both AV

to the supply voltage of the microprocessor. The voltage applied

to the V

interfaces. V

for the V

Typical values for the oscillator decoupling capacitors are 20 pF,

whereas typical values for the reference decoupling capacitors are

10 nF and 10 μF.

input controls the voltage of the parallel and serial

DRIVE

DRIVE

decoupling capacitors are 10 nF and 4.7 μF.

DRIVE

and DVDD pins, with typical values for the

DD

and DVDD. The V

DD

can be set to 5 V, 3 V, or 2.5 V. Typical values

) of 5 V dc ± 5% is

DD

pin is connected

DRIVE

Rev. 0 | Page 18 of 36

AD2S1210

×

×+×−

=

www.BDTIC.com/ADI

4.7µF 10n F

10nF 10µF

5V

20pF 20pF

4.7µF10nF

8.192

MHZ

5V

48 47

1

2

3

4

5

DGND

6

DV

DD

7

CLKIN

8

XTALOUT

9

10

11

12

13

S2 R2

S4 S3 S1 R1

46

45

44

43

COS

COSLO

REFBYP

REFOUT

AD2S1210

14 15

161718

V

DRIVE

10nF

42

41

DD

AV

SINLO

DRIVE

V

DGND

19

202122 23 24

BUFFER

CIRCUIT

40

SIN

AGND

4.7µF

39

EXC38EXC

BUFFER

CIRCUIT

37

36

35

34

33

32

31

30

29

28

27

26

25

07467-025

Figure 26. Connecting the AD2S1210 to a Resolver

In this recommended configuration, the converter introduces a

/2 offset in the SIN, SINLO, COS, and COSLO signal outputs

V

REF

from the resolver. The sine and cosine signals can each be

connected to a different potential relative to ground if the sine

and cosine signals adhere to the recommended specifications.

EXC

Note that because the EXC and

outputs are differential,

there is an inherent gain of 2×.

Figure 27 shows a suggested buffer circuit. Capacitor C1 may be

used in parallel with Resistor R2 to filter out any noise that may

EXC

exist on the EXC and

outputs. Care should be taken when

selecting the cutoff frequency of this filter to ensure that phase

shifts of the carrier caused by the filter do not exceed the phase

lock range of the AD2S1210.

The gain of the circuit is

))1/(1()/( ωC1R2R1R2GainCarrier

(7)

and

OUT

⎛

VV

⎜

⎝

R2

⎛

1 (8)

+×=

⎜

R1

⎝

R2

⎞

⎞

⎛

⎞

⎟

⎟

⎠

⎠

×

−

⎟

⎜

⎠

⎝

1

⎛

⎜

1

⎝

⎞

V

⎟

C1R2R1

INREF

××+

ω

⎠

where:

ω is the radian frequency of the applied signal.

, a dc voltage, is set so that V

V

REF

is always a positive value,

OUT

eliminating the need for a negative supply.

C1

EXC/EXC

(V

R2

12V

R1

)

IN

(V

)

AD8662

REF

5V

12V

V

OUT

04767-026

Figure 27. Buffer Circuit

A separate screened twisted pair cable is recommended for the

analog input pins, SIN, SINLO, COS, and COSLO. The screens

should terminate to either REFOUT or AGND.

Rev. 0 | Page 19 of 36

AD2S1210

(

)

www.BDTIC.com/ADI

CONFIGURATION OF AD2S1210

MODES OF OPERATION

The AD2S1210 has two modes of operation: configuration mode

and normal mode. The configuration mode is used to program

the registers that set the excitation frequency, the resolution,

and the fault detection thresholds of the AD2S1210. Configuration

mode is also used to read back the information in the fault register.

The data in the position and velocity registers can also be read

back while in configuration mode. The AD2S1210 can be operated

entirely in configuration mode or, when the initial configuration is

completed, the part can be taken out of configuration mode and

operated in normal mode. When operating in normal mode, the

data outputs can provide angular position or angular velocity

data. The A0 and A1 inputs are used to determine whether the

AD2S1210 is in configuration mode and to determine whether

the position or velocity data is supplied to the output pins, see

Tabl e 8.

Setting the Excitation Frequency

The excitation frequency of the AD2S1210 is set by writing a

frequency control word to the excitation frequency register,

Address 0x91 (see the Register Map section).

FrequencyExcitation

where FCW is the frequency control word and f

frequency of the AD2S1210.

The specified range of the excitation frequency is from 2 kHz to

20 kHz and can be set in increments of 250 Hz. To achieve the

angular accuracy specifications in Table 1, the excitation frequency

should be selected as outlined in Table 7.

Table 7. Recommended Excitation Frequency vs. Resolution

= 8.192 MHz)

(f

CLKIN

Typ ic al

Resolution

10 Bits 4100 Hz 10 kHz 20 kHz

12 Bits 1700 Hz 6 kHz 20 kHz

14 Bits 900 Hz 3 kHz 12 kHz

16 Bits 250 Hz 2 kHz 10 kHz

Bandwidth

=

×

15

2

Min Excitation

Frequency

fFCW

CLKIN

is the clock

CLKIN

Max Excitation

Frequency

Note that the recommended frequency range for each resolution

and bandwidth, as outlined in Table 7, are defined for a clock

frequency of 8.192 MHz. The recommended excitation frequency

range scales with the clock frequency of the AD2S1210. The

default excitation frequency of the AD2S1210 is 10 kHz when

operated with a clock frequency of 8.192 MHz.

A0, A1 Inputs

The AD2S1210 allows the user to read the angular position or

the angular velocity data directly from the parallel outputs or

through the serial interface. The required information can be

selected using the A0 and A1 inputs. These inputs should also

be used to put the part into configuration mode. The data from

the fault register and the remaining on-chip registers can be

accessed in configuration mode.

Table 8. Configuration Mode Settings

A0 A1 Result

0 0 Normal mode—position output

0 1 Normal mode—velocity output

1 0 Reserved

1 1 Configuration mode

RES0, RES1 Inputs

In normal mode, the resolution of the digital output is selected

using the RES0 and RES1 input pins. In configuration mode,

the resolution is selected by setting the RES0 and RES1 bits in

the control register. When switching between normal mode and

configuration mode, it is the responsibility of the user to ensure

that the resolution set in the control register matches the resolution

set by the RES0 and RES1 input pins. Failure to do so may result

in incorrect data on the outputs, caused by the differences

between the resolution settings.

Table 9. Resolution Settings

Resolution

RES0 RES1

0 0 10 21.1 4.88

0 1 12 5.3 0.488

1 0 14 1.3 0.03

1 1 16 0.3 0.004

1

CLKIN = 8.192 MHz. The velocity LSB size and maximum tracking rate scale

linearly with the CLKIN frequency.

(Bits)

Position LSB

(Arc min)

Velocity LSB

(rps)1

Rev. 0 | Page 20 of 36

AD2S1210

www.BDTIC.com/ADI

REGISTER MAP

Table 10. Register Map

Register

Register Name

Position 0x80 D15 to D8 Read only

0x81 D7 to D0 Read only

Velocity 0x82 D15 to D8 Read only

0x83 D7 to D0 Read only

LOS Threshold 0x88 D7 to D0 Read/write

DOS Overrange

Threshold

DOS Mismatch

Threshold

DOS Reset Max

Threshold

DOS Reset Min

Threshold

LOT High Threshold 0x8D D7 to D0 Read/write

LOT Low Threshold 0x8E D7 to D0 Read/write

Excitation Frequency 0x91 D7 to D0 Read/write

Control 0x92 D7 to D0 Read/write

Soft Reset 0xF0 D7 to D0 Write only

Fault 0xFF D7 to D0 Read only

Address

0x89 D7 to D0 Read/write

0x8A D7 to D0 Read/write

0x8B D7 to D0 Read/write

0x8C D7 to D0 Read/write

Register

Data

Read/Write

Register

POSITION REGISTER

Table 11. 16-Bit Register

Address Bit Read/Write

0x80 D15 to D8 Read only

0x81 D7 to D0 Read only

The position register contains a digital representation of the

angular position of the resolver input signals. The values are

stored in 16-bit binary format. The value in the position register

is updated following a falling edge on the

Note that with hysteresis enabled (see the Control Register

section), at lower resolutions, the LSBs of the 16-bit digital output

are set to zero. For example, at 10-bit resolution, Data Bit D15 to

Data Bit D6 provide valid data; D5 to D0 are set to zero. With

hysteresis disabled, the value stored in the position register is 16

bits regardless of resolution. At lower resolutions, the LSBs of

the 16-bit digital output can be ignored. For example, at 10-bit

resolution, Data Bit D15 to Data Bit D6 provide valid data; D5

to D0 can be ignored.

SAMPLE

input.

VELOCITY REGISTER

Table 12. 16-Bit Register

Address Bit Read/Write

0x82 D15 to D8 Read only

0x83 D7 to D0 Read only

The velocity register contains a digital representation of the angular

velocity of the resolver input signals. The value in the velocity

register is updated following a falling edge on the sample input.

The values are stored in 16-bit, twos complement format. The

maximum velocity that the AD2S1210 can track for each

resolution is specified in Table 1. For example, the maximum

tracking rate of the AD2S1210 at 16 bits resolution, with an

8.192 MHz input clock, is

results in 0x7FFF being stored in the velocity register; a velocity

of −125 rps results in 0x8000 being stored in the velocity register.

The value stored in the velocity register is 16 bits regardless of

resolution. At lower resolutions, the LSBs of the 16-bit digital

output should be ignored. For example, at 10-bit resolution,

Data Bit D15 to Data Bit D6 provide valid data; D5 to D0 should

be ignored. The maximum tracking rate of the AD2S1210 at

10-bit resolution with an 8.192 MHz input clock is

A velocity of +2500 rps results in 0x1FF being stored in Bit D15 to

Bit D6 of the velocity register; a velocity of −2500 rps results in

0x3FF being stored in Bit D15 to Bit D6 of the velocity register. In

this 10-bit example, the LSB size of the velocity output is 4.88 rps.

±125 rps. A velocity of +125 rps

±2500 rps.

LOS THRESHOLD REGISTER

Table 13. 8-Bit Register

Address Bit Read/Write

0x88 D7 to D0 Read/write

The LOS threshold register determines the loss of signal threshold

of the AD2S1210. The AD2S1210 allows the user to set the LOS

threshold to a value between 0 V and 4.82 V. The resolution of

the LOS threshold is seven bits, that is, 38 mV. Note that the MSB,

D7, should be set to 0. The default value of the LOS threshold

on power-up is 2.2 V.

DOS OVERRANGE THRESHOLD REGISTER

Table 14. 8-Bit Register

Address Bit Read/Write

0x89 D7 to D0 Read/write

The DOS overrange threshold register determines the degradation

of signal threshold of the AD2S1210. The AD2S1210 allows the

user to set the DOS overrange threshold to a value between 0 V

and 4.82 V. The resolution of the DOS overrange threshold is

seven bits, that is, 38 mV. Note that the MSB, D7, should be set to

0. The default value of the DOS overrange threshold on power-up

is 4.1 V.

DOS MISMATCH THRESHOLD REGISTER

Table 15. 8-Bit Register

Address Bit Read/Write

0x8A D7 to D0 Read/write

The DOS mismatch threshold register determines the signal

mismatch threshold of the AD2S1210. The AD2S1210 allows

the user to set the DOS mismatch threshold to a value between

0 V and 4.82 V. The resolution of the DOS mismatch threshold

is seven bits, that is, 38 mV. Note that the MSB, D7, should be

set to 0.The default value of the DOS mismatch threshold on

power-up is 380 mV.

Rev. 0 | Page 21 of 36

AD2S1210

(

)

(

)

www.BDTIC.com/ADI

DOS RESET MAXIMUM AND MINIMUM THRESHOLD REGISTERS

Table 16. 8-Bit Registers

Address Bit Read/Write

0x8B D7 to D0 Read/write

0x8C D7 to D0 Read/write

The AD2S1210 continuously stores the minimum and maximum

magnitude of the monitor signal in internal registers. The difference between the minimum and maximum is calculated to

determine if a DOS mismatch has occurred. The initial values

for the minimum and maximum internal registers must be

defined by the user. When the fault register is cleared, the

registers that store the maximum and minimum amplitudes of

the monitor signal are reset to the values stored in the DOS reset

maximum and minimum threshold registers. The resolution of

the DOS reset maximum and minimum thresholds is seven bits

each, that is, 38 mV. Note that the MSB, D7, should be set to

0.To ensure correct operation, it is recommended that the DOS

reset minimum threshold register be set to at least 1 LSB less

than the DOS overrange threshold, and the DOS reset maximum

threshold register be set to at least 1 LSB greater than the LOS

threshold register. The default value of the DOS reset minimum

threshold register and the DOS reset maximum threshold

register are 3.99 V and 2.28 V, respectively.

LOT HIGH THRESHOLD REGISTER

Table 17. 8-Bit Register

Address Bit Read/Write

0x8D D7 to D0 Read/write

The LOT high threshold register determines the loss of position

tracking threshold for the AD2S1210. The LOT high threshold

is a 7-bit word. Note that the MSB, D7, should be set to 0. The

range of the LOT high threshold, the LSB size, and the default

value of the LOT high threshold on power-up are dependent on

the resolution setting of the AD2S1210, and are outlined in

Table 19.

LOT LOW THRESHOLD REGISTER

Table 18. 8-Bit Register

Address Bit Read/Write

0x8E D7 to D0 Read/write

The LOT low threshold register determines the level of hysteresis

on the loss of position tracking fault detection. Loss of tracking

(LOT) occurs when the internal error signal of the AD2S1210

exceeds the LOT high threshold. LOT has hysteresis and is not

cleared until the internal error signal is less than the value defined

in the LOT low threshold register. The LOT low threshold is a

7-bit word. Note that the MSB, D7, should be set to 0. The range

of the LOT high threshold, the LSB size, and the default value of

the LOT high threshold on power-up are dependent on the resolution setting of the AD2S1210, and are outlined in Table 19.

Rev. 0 | Page 22 of 36

Table 19. LOT High/Low Threshold

LOT Low

Resolution

(Bits)

10 0 to 45 0.35 2.5 12.5

12 0 to 18 0.14 1.0 5.0

14 0 to 9 0.09 0.5 2.5

16 0 to 9 0.09 0.5 2.5

Range

(Degrees)

LSB Size

(Degrees)

Default

(Degrees)

LOT High

Default

(Degrees)

EXCITATION FREQUENCY REGISTER

Table 20. 8-Bit Register

Address Bit Read/Write

0x91 D7 to D0 Read/write

The excitation frequency register determines the frequency of

the excitation outputs of the AD2S1210. A 7-bit frequency control

word is written to the register to set the excitation frequency.

Note that the MSB, D7, should be set to 0.

FCW

= (9)

where FCW is the frequency control word and f

frequency of the AD2S1210. The specified range of the excitation

frequency is from 2 kHz to 20 kHz and can be set in increments

of 250 Hz. To ensure that the AD2S1210 is operated within the

specified frequency range, the frequency control word should

be a value between 0x4 and 0x50.

For example, if the user requires an excitation frequency of 5 kHz

and has an 8.192 MHz clock frequency, the code that needs to

be programmed is given by

=FCW (hexadecimal)

The default excitation frequency of the AD2S1210 on power-up

is 10 kHz.

FrequencyExcitation

f

CLKIN

15

2kHz5

×

MHz192.8

14

=

15

2×

is the clock

CLKIN

CONTROL REGISTER

Table 21. 8-Bit Register

Address Bit Read/Write

0x92 D7 to D0 Read/write

The control register is an 8-bit register that sets the AD2S1210

control modes. The default value of the control register on

power-up is 0x7E.

Table 22. Control Register Bit Descriptions

Bit Description

D7 Address/data bit

D6 Reserved; set to 1

D5 Phase lock range

0 = 360°, 1 = ±44°

D4 0 = disable hysteresis, 1 = enable hysteresis

D3 Set Encoder Resolution EnRES1

D2 Set Encoder Resolution EnRES0

D1 Set Resolution RES1

D0 Set Resolution RES0

AD2S1210

www.BDTIC.com/ADI

Address/Data Bit

The MSB of each 8-bit word written to the AD2S1210 indicates

whether the 8-bit word is a register address or data. The MSB

(D7) of each register address defined on the AD2S1210 is high.

The MSB of each data word written to the AD2S1210 is low.

Note that when a data word is written to the AD2S1210, the

MSB is internally reconfigured as a parity bit. When reading

data from any of the read/write registers (see Table 10), the

parity of Bit D6 to Bit D0 is recalculated and compared to the

previously stored parity bit. The MSB of the 8-bit output is used

to indicate whether a configuration error has occurred. If the

MSB is returned high, this indicates that the data read back from

the device does not match the configuration data written to the

device in the previous write cycle.

Phase Lock Range

The phase lock range allows the AD2S1210 to compensate for

phase errors between the excitation frequency and the sine/cosine

inputs. The recommended mode of operation is to use the default

phase lock range of ±44°. If additional phase lock range is

required, a range of 360° can be set. However, in this mode of

operation, the AD2S1210 should be reset following a loss of

signal error. Failure to do so may result in a 180° error in the

angular output data.

Hysteresis

The AD2S1210 includes a hysteresis function, ±1 LSB, between

the output of the position integrator and the input to the position

register. When operating in a noisy environment, this can be used

to prevent flicker on the LSB. On the AD2S1210, the maximum

tracking rate is defined by the bandwidth. Each resolution setting

is internally configured with a different bandwidth, as outlined

in Table 1. The maximum tracking rate and the bandwidth are

inversely proportional to the resolution, that is, the maximum

tracking rate increases as the resolution is decreased. The option

of disabling the hysteresis allows the user to oversample the

position output and to achieve a higher resolution output within

the specified bandwidths through external averaging.

The hysteresis function can be enabled or disabled through

setting Bit D4 in the control register. Hysteresis is enabled by

default on power-up.

Set Encoder Resolution

The resolution of the encoder outputs of the AD2S1210 can be

set to the same resolution as the digital output or it can also be

set to a lower resolution. For example, when the resolution of

the AD2S1210 position outputs is set to 16 bits, the resolution

of the encoder outputs may be set to 14, 12, or 10 bits. This

allows the user to take advantage of the lower bandwidth and

improved performance of the 16-bit resolution setting without

requiring external divide down of the A-quad-B encoder outputs.