Page 1

t e m p e r a t u r e

Specification Sheet

SS-CP-2284-US

Model ATC-140/250

Advanced Temperature

Calibrator

Wide temperature range

ATC-140 -20 to 140°C (-4 to 284°F)

ATC-250 28 to 250°C (82 to 482°F)

Liquid bath or dry-block

Use ATC-140 and ATC-250 as liquid bath

or large diameter dry-block calibrator

Improved temperature homogeneity

Unique dual-zone block ensures good

temperature homogeneity in the critical

calibration zone

High accuracy

Using the internal reference or the external reference probe. 4-wire True-OhmMeasurement technology is used

Enhanced stability

MVI circuitry ensures temperature stability

despite mains supply variations

Cost effective calibration system

Stand-alone operation eliminates the

need for secondary equipment and PC.

Universal inputs handle multiple type temperature sensors

Timesaving features

Up- and download complete calibration

tasks. Auto-stepping, switch testing and

many more features make the daily use

smooth and fast

Documentation made easy

RS232 communication and JOFRACAL

calibration software are included in the

standard delivery

Complete marine program

Part of a complete program of marine

approved temperature, pressure and signal

calibrators; including temperature sensors

PRODUCT DESCRIPTION

The JOFRA ATC series

(Advanced Temperature

Calibrators) combines the

accuracy of laboratory

temperature sources with

the speed and portability

of field dry-block calibrators.

With the JOFRA ATC-140

and ATC-250 (Advanced

Temperature Calibrators)

it is possible to calibrate

even more sensors at the same time and to calibrate large and odd

size sensors in either a large diameter dry-block or in a liquid bath.

Features

JOFRA ATC-140 and ATC-250 both features the unique dual-zone heating block - designed for optimum performance and superior temperature

homogeneity throughout the block. This new design has a performance

equivalent to a liquid temperature bath.

Each ATC dry-block calibrator may be used to perform fully automatic

calibration routines without using an external computer. Use the computer for full upload and download capabilities. Units may also be supplied

with inputs for external reference sensors and for sensors-under-test. All

ATC calibrators feature RS232 serial communication and standard delivery also includes the JOFRACAL calibration PC software.

The ATC-140 and ATC-250 calibrators are part of a serie of calibrators, that also includes the ATC-156, ATC-157, ATC-320 and ATC-650

dry-block calibarators covering temperature ranges between -45°C and

650°C.

See more about the ATC-156, ATC-157, ATC-320 and ATC-650 calibrators at page 5 or in specification sheet SS-CP-2285 at www.jofra.com

ISO 9001 Manufacturer

Page 2

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

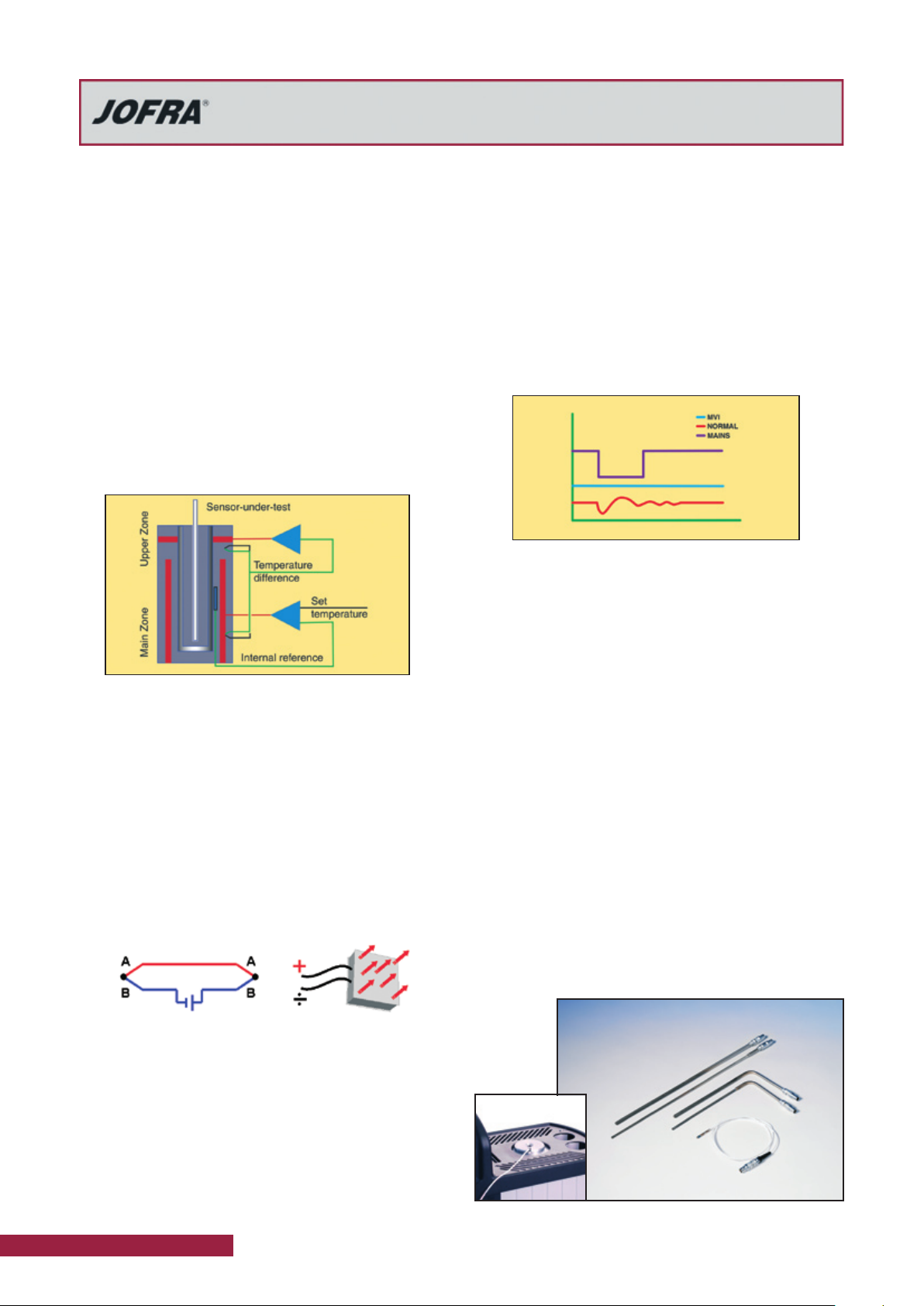

Unique temperature performance

The ATC series of calibrators provide precision temperature calibration of sensors; whatever the type or format.

This is accomplished through an innovative dual-zone

heating technology.

Both the ATC-140 and ATC-250 feature a dual-zone heating technology. Each heating zone is independently controlled for precision temperature calibration. The homogeneity in the lower part is close to that of a laboratory liquid

bath. The lower zone ensures optimum heat dissipation

throughout the entire calibration zone. The upper zone

compensates for heat loss from the sensor-under-test

and from the open top. This design also eliminates the

need for insulation of the sensors-under-test and makes

it possible to calibrate liquid-filled and other mechanical

sensors.

MVI - Improved temperature stability

MVI stands for ’’Mains power Variance Immunity’’.

Unstable mains power supplies are a major contributor to

on-site calibration inaccuracies. Traditional temperature

calibrators often become unstable in production environments where large electrical motors, heating elements,

and other devices are periodically cycled on or off. The

cycling of supply power can cause the temperature regulator to perform inconsistently leading to both inaccurate

readings and unstable temperatures.

The JOFRA ATC-250 calibrator employ the MVI, thus

avoiding such stability problems. The MVI circuitry continuously monitors the supply voltage and ensures a constant energy flow to the heating elements.

The ATC-140 models run on stabilized DC voltage and

thus do not need the MVI circuitry.

ATC heating and cooling models

The ATC-140 model with both heating and cooling capabilities

feature the Peltier element multi-stage-technology. This

both improves efficiency and extends the life of the »electronic heat pump«.

Peltier effect (ATC-140)

In 1834, Jean Peltier, a French physicist found that an

’’opposite thermocouple effect’’ could be observed when

an electric current was connected to a thermocouple. Heat

would be absorbed at one of the junctions and discharged

at the other junction. This effect is called the ’’PELTIER

EFFECT’’.

The practical Peltier element (electronic heating pump)

consists of many elements of semiconductor material connected electrically in series and thermally in parallel. These

thermoelectric elements and their electrical interconnections are mounted between two ceramic plates. The plates

serve to mechanically hold the overall structure together

and to electrically insulate the individual elements from

one another.

Highest accuracy (model B only)

ATC series calibrators may be supplied with a built-in reference thermometer for use with an external probe. This

feature allows one instrument to provide the freedom and

flexibility to perform calibrations at the process site while

maintaining a high accuracy.

A special 90° angled external reference sensor has been

designed to accommodate sensors with a transmitter

head, top connector or similar arrangement.

The user can decide whether to read the built-in reference sensor or the more accurate angled reference sensor

from the calibrator’s large, easy-to-read LCD display. The

external sensor and the internal sensor are independent of

one another. Downloading of reference sensor linearization

is done via a personal computer.

Please find more information about JOFRA STS reference

sensors in specification sheet: SS-CP-2290 at www.jofra.

com.

2 www.jofra.com

Page 3

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

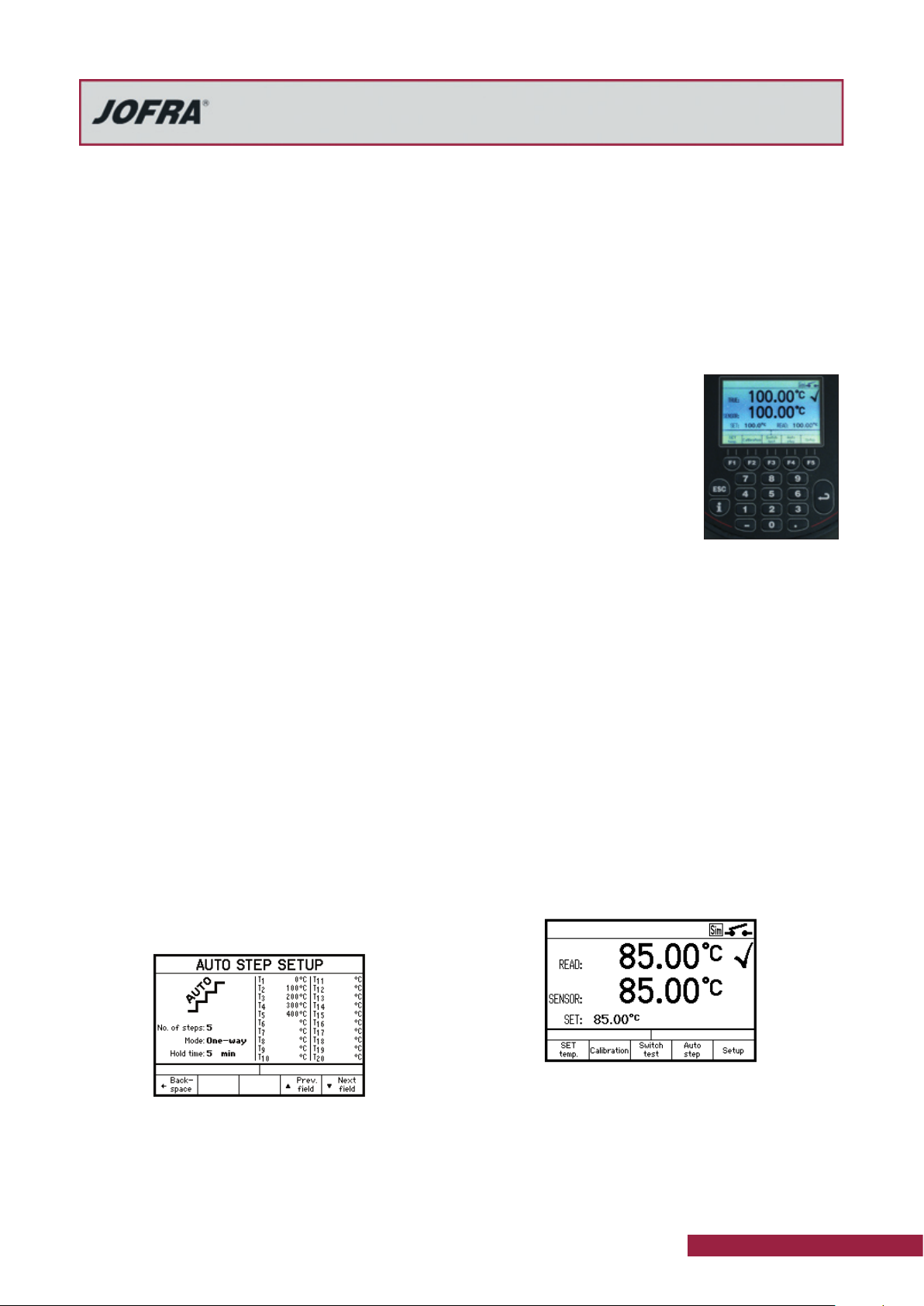

SET-Follows-TRUE (model B only)

Available on B models only, the “SET-Follows TRUE”

makes the instrument tune in until the temperature of

the external reference “TRUE” meets the desired “SET”

temperature. This is used when it is critical that the temperature of the calibration zone matches the desired temperature when measured with accurate external reference

sensors.

This feature is ideal when calibrating gas correctors or

other custody transfer applications. It is also extremely

useful to calculation procedures.

Reading of sensor-under-test (model B only)

The ATC series model B is equipped with built-in converters (inputs) that enables measurement of virtually any type

of temperature sensor including:

thermostats

•

resistance thermometers (RTD)

•

thermocouples (TC)

•

transmitters

•

milliamps (mA)

•

voltage (V)

•

The ATC calibrators can be user-programmed for completely automated temperature calibrations. Once the unit

is programmed, the instrument operates itself by performing the configured calibration routine. All calibration data

is stored and available for uploading and generating exact

calibration certificates or reports.

Switch test (model B only)

Users may perform a thermoswitch test and find “Open”,

“Closed” and the hysteresis (deadband) automatically. The

instrument retains the last five tests.

Auto-stepping

Up to 20 different temperature steps may be programmed

including the hold time for each step. Upon completion of

an auto step routine, the user can easily read the results

for the sensor-under-test. Up to five (5) auto step results

are stored.

Easy-to-use, intuitive operation

All instrument settings can be performed from the front

panel. The heat source is positioned away from the panel

which helps protect the operator.

The ATC keyboard is equipped with five, positive feedback

function keys. They correspond to the text in the display

and change functionality based on instrument operations.

There are also dedicated function keys with permanent

functions.

The easy-to-read, backlit display

is large with a high contrast that

is readible even in high ambient

light conditions. The display is

easily read from all angles and

from a distance without parallax

problems. The display also features icons which help identifying

instrument conditions and operational steps, making it more intuitive to work with.

Set temperature

The “Set temperature” feature allows the user to set the

exact desired temperature with a resolution of 0.01°.

Enhanced stability

A stability indicator shows when the ATC calibrator has

reached the desired temperature and is stable. The user

may change the stability criteria, external reference and

the sensor-under-test quickly and simply. The stability

criteria is the user’s security for a correct calibration. A

count-down timer is displayed next to the temperature

read-out.

Instrument setups

The ATC series allows the user to store up to nine (9)

complete instrument setups. You may store all sorts of

information including temperature units, stability criteria,

use of external reference sensor, resolution, sensor-undertest (SUT), conversion to temperature, display contrast,

etc. The setup may be recalled at any time.

Maximum temperature

From the setup menu, the user can select the maximum

temperature limit for the calibrator. This function prevents

damage to the sensor-under-test caused by the application of excessive temperatures. The feature also aids in reducing drift resulting from extended periods of exposures

to high temperatures. This feature can be locked with an

access code.

www.jofra.com 3

Page 4

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

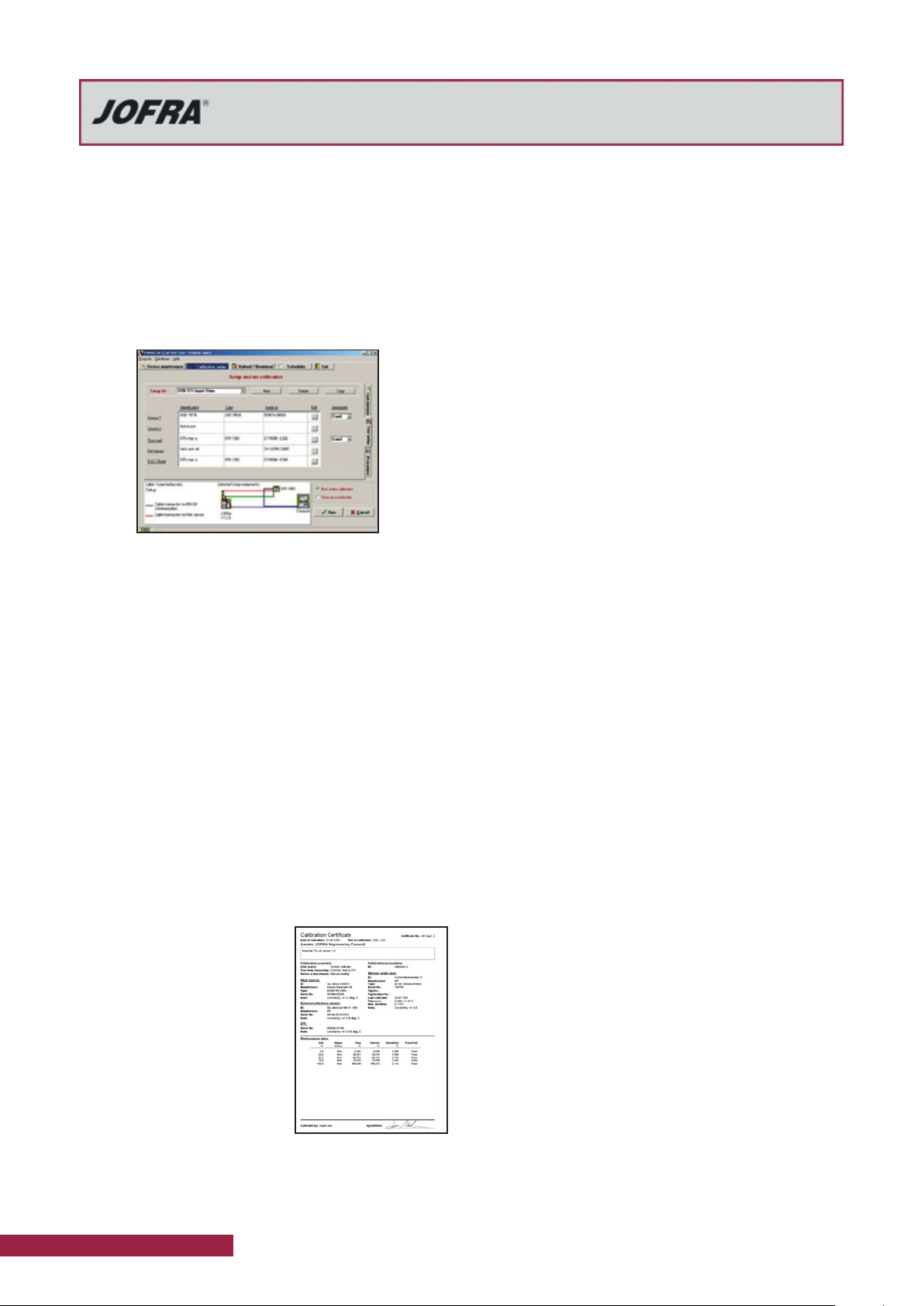

JOFRACAL CALIBRATION SOFTWARE

JOFRACAL calibration software ensures easy calibration

of RTD´s, thermocouples, transmitters, thermoswithes,

pressure gauges and pressure switches. JOFRACAL can

be used with JOFRA DPC-500, APC, CPC and IPI pressure calibrators, all JOFRA temperature calibrators, as well

as JOFRA AMC900, ASC300 multi signal calibrator and

ASM-800 signal multi scanner.

JOFRACAL calibration software may also be used for

manual calibrations, as it can be set up to accept manual

entry of calibration data together with other liquid baths,

ice points or dry-block heat sources.

The calibration data collected may be stored on a PC for

later recall or analysis. The ATC calibrator stores the calibration procedure and may be taken out to the process

site without using a personal computer.

This allows the ATC calibrator to:

•

Operate as a stand-alone instrument, using advanced

calibration routines without the assistance of a

personal computer on site;

•

Prevent unauthorized changes to a calibration routine.

Personnel who are not authorized to alter a calibration

routine cannot do so.

As found/as left (model B only)

The JOFRA ATC series calibrator automatically handles

“As Found/As Left” calibrations. The calibrator stores both

results. The first performed calibration is “As found” and

the last performed calibration is the “As left”, regardless

of the number of calibrations/adjustments that may have

been made in between.

SYNC output

An output is located directly on the front of the ATC calibrator. This output signals when the instrument is stable

and may be used with ancillary devices such as video

recorders, digital cameras or as an input to a data logging

device. The SYNC output may be useful for automating

and documenting your calibrations when calibrating external reading devices.

Calibration (model B only)

Users may perform or read the results of the calibration

tasks directly on the instrument. When calibrating an indicating device, users may key in the results during or after the

test. Using the “Calibration info” function, the user may view

the complete calibration task, including the “Scenario” before the calibration takes place.

Calibration of up to 24 sensors with JOFRA ASM

Using the JOFRA ATC series together with the ASM

Advanced Signal Multi-scanner offers a great time-saving

automatic solution to calibrate multiple temperature sensors at the same time. The ASM series is an eight channel

scanner controlled by the JOFRACAL software on a PC.

Up to 3 ASM units can be stacked to calibrate up to 24

sensors at the same time. It can handle signals from 2-,

3- and 4 wire RTD’s, TC’s, transmitters, thermisters, temperature switches and voltage.

Please also see more in specification sheet SS-CP-2360,

which can be found at www.jofra.com

Once all calibrations are completed, the data may be

uploaded to the JOFRACAL calibration software for postprocessing and printing of certificates. The calibration data

collected may be stored on the personal computer for

later recall or analysis.

The JOFRACAL temperature

calibration software may be

donwloaded free of charge from

our web-page www.jofra.com.

Please also see more about

JOFRACAL calibration software

in specification sheet SS-CP2510, which can be found at

www.jofra.com

4 www.jofra.com

JOFRACAL software

Minimum hardware requirements for JOFRACAL calibration software.

INTELTM 486 processor

•

(PENTIUMTM 800 MHz recommended)

•

32 MB RAM (64 MB recommended)

•

80 MB free disk space on hard disk prior to installation

•

Standard VGA (800 x 600, 16 colors) compatible screen

•

(1024 x 786, 256 colors recommended)

•

CD-ROM drive for installation of the program

•

1 free RS232 serial port

•

Page 5

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

FUNCTIONAL COMPARISON

ATC series

ATC-125 A

Temperature range @ ambient 23°C / 73°F

-90 to 125°C -130 to 257°F X X

-20 to 140°C -4 to 284°F X X

-24 to 155°C -11 to 311°F X X

-45 to 155°C -49 to 311°F X X

28 to 250°C 82 to 482°F X X

33 to 320°C 91 to 608°F X X

33 to 650°C 91 to 1202°F X X

Temperature stability

±0.01°C ±0.018°F S S S S S S

±0.02°C ±0.036°F X X X X S S

±0.03°C ±0.054°F X X

Accuracy incl. external STS reference sensor

±0.04°C ±0.07°F X

±0.06°C ±0.11°F X X

±0.07°C ±0.13°F X 1X

±0.11°C ±0.2°F X

Accuracy with internal reference sensor

±0.10°C ±0.18°F S S

±0.13°C ±0.23°F S S

±0.18°C ±0.32°F S S

±0.20°C ±0.36°F S S

±0.28°C ±0.50°F S S

±0.30°C ±0.54°F X X

±0.35°C ±0.63°F S S

Immersion depth

185 mm 7.3 in X X

180 mm 7.1 in X 2X

160 mm 6.3 in X X X X

150 mm 5.9 in X 3X

Insertion tube diameter

63.5 mm 2.5 in X X X X

30 mm 1.2 in X X X X X X X X

20 mm 0.8 in X X

Dual-zone heating/cooling block • •

MVI - Mains Variance Immunity (or similar) • •

Stability indicator • •

Automatic step function • •

JOFRACAL Calibration software included as standard • •

SYNC output (for external recording device) • •

Display resolution 0.01° • •

Programmable max. temperature • •

Input for RTD, TC, V, mA •

4-20 mA transmitter input incl. 24 VDC supply •

All inputs scalable to temperature •

Automatic switch test (open, close and hysteresis) •

External precision reference probe input •

Download of calibration work orders from PC •

Upload of calibration results (as found & as left) •

“SET” follows “TRUE” •

ATC-140 A

ATC-125 B

ATC-156 A

ATC-140 B

1

X

2

3

ATC-157 A

ATC-156 B

1

ATC-250 A

ATC-157 B

1

X

Model A Model B

ATC-250 B

X 4X X X X X

ATC-320 A

ATC-320 B

1

ATC-650 A

ATC-650 B

1

JOFRA ATC-156/157/320/650

For a wider product description of

the ATC-156/157/320/650 please

see spec. sheet SS-CP-2285, at

www.jofra.com

JOFRA ATC-125

For a wider product description

of the ATC-125 please see spec.

sheet SS-CP-2282, at www.jofra.

com

X = Delivered as standard

S = Improved specifications

(from October 01, 2006)

1

Using an external STS reference sensor

connected to the reference probe input

2

Immersion depth for ATC-140 as dry-block

3

Immersion depth for ATC-140 as liquid bath

4

Immersion depth for ATC-250 as dry-block and

as liquid bath

www.jofra.com 5

Page 6

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

Liquid bath / large diameter insert

The ATC-140 and ATC-250 are fitted with a 150 mm (5.9

in) deep well with a diameter of 63.5 mm (2.5 in) can be

used both as dry-block calibrators and as liquid calibration

baths with a magnetic stirrer.

A liquid bath and a dry-block diameter of 63.5 mm (2.5 in),

which is twice the size of any other JOFRA dry-block, are

both new in the JOFRA product range. With these options

it is now possible to calibrate even more temperature sensors at the same time and to calibrate large as well as odd

sizes and shapes of sensors, which is not possible to calibrate in the remaining product range.

ATC-140 & ATC-250 can be used without an external

reference sensor, but if a STS-100 reference sensor is

connected directly to a B version or the JOFRA reference

thermometer DTI-1000, you obtain better accuracies and

thereby use the full potential of the calibrators.

Liquid bath versus dry-block kit

The basic advantages of the liquid bath configuration versus the dry-block configuration are as follows:

You do not need insertion tubes for all your different

•

types of sensors

You can calibrate sensors, which do not fit into

•

insertion tubes

You can calibrate glass thermometers and gas or liquid

•

filled sensors

The basic advantages of the dry-block configuration

•

versus the liquid bath configuration are the following:

No hazardous hot liquids

•

Easier to handle insertion tubes than liquids

•

More convenient to carry than when filled with liquid

•

No need for external exhaustion

•

All specifications given in the liquid bath configuration are

based on the silicone oil supplied and recommended by

JOFRA.

Why ATC-140 and ATC-250?

Calibration of many sensors at the same time due to more space for

example in connection with validation of many thermocouples, which

saves time

Calibration of as many as 24 sensors at the same time by using 3

•

JOFRA ASM Signal Multi-Scanners

For customers, who only want to use liquid baths

•

For calibration of odd sizes and shapes of sensors

•

WET = no need for inserts, which fit the sensors

DRY = more space for calibration of special sensors

The Pharmaceutical industry often wants to calibrate more sensors

•

at the same time and often has many short sensors

The Food industry often has odd sizes and shapes of sensors

•

including sanitary ones

The JOFRACAL software and the ATC B-models on-line can handle

•

the calibration and documentation of multiple sensors calibrated at

the same time. However, you need to change the input connection

manually one-by-one

6 www.jofra.com

Page 7

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

CONFIGURATIONS

Liquid bath kit for ATC-140 A/B and ATC-250 A/B

1 x Sensor basket

2 x Covering lids

1 x Magnet – for the

magnetic stirrer

1 x Magnet remover

1 x Liquid drainage tube

1 x Silicone oil 0,75 l

(25.4 oz)

It is also possible to order

extra silicone oil and a

support rod for sensors,

which can be mounted on

the side of all JOFRA dryblock calibrators and hold

the sensors under test in

the correct position during calibraton.

The support rod is especially important, when

working with liquid baths

and do not have the

inserts to hold the sensors under test.

Dry-block kit for the ATC-140 A/B and ATC-250

A/B

1 x Multi-hole insert - it is possible to choose between a

metric and an imperial version:

The metric version has holes for the following sizes of sensors: 1 x 12, 1 x 11, 1 x 9, 1 x 8, 2 x 6, 1 x 5, 2 x 4, 1 x 3

mm and

1 x 1/4 in.

The imperial version has holes for the following sizes of

sensors: 1 x 1/8 in, 1 x

3/16 in, 1 x 1/4 in, 1 x

5/16 in, 1 x 3/8 in, 1 x

7/16 in, 1 x 1/2 in, 1 x

9/16 in, 1 x 5/8 in and 1

x 4 mm.

1 x Insulation plug for

the ATC-140.

It is also possible to

order undrilled and special drilled inserts.

PHYSICAL SPECIFICATIONS

Instrument dimensions (L x W x H)

All models ........ 352 x 156 x 360 mm / 13.9 x 6.1 x 14.2 in

Instrument weight

ATC-140 ..................................................... 12.8 kg / 28.2 lb

ATC-250 ..................................................... 10.8 kg / 23.8 lb

Insert dimensions

ATC-140/250 outer diameter ............................63.5 / 2.5 in

ATC-140/250 inner diameter ....................57,5 mm / 2.26 in

ATC-140/250 length ..................................160 mm / 6.30 in

Weight of non-drilled insert (approximate)

ATC-140 ..................................................... 1200 g / 42.3 oz

ATC-250 ..................................................... 1200 g / 42.3 oz

Shipping (including optional carrying case)

ATC-140 * ...................................................23.4 kg / 51.6 lb

ATC-250 * ...................................................21.3 kg / 47.0 lb

Size: L x W x H .. 670 x 309 x 514 mm / 26 x 12.2 x 20.2 in

Shipping (without carrying case)

ATC-140 * ...................................................16.7 kg / 36.8 lb

ATC-250 * ...................................................14.6 kg / 32.2 lb

Size: L x W x H . 570 x 235 x 440 mm / 22.4 x 9.3 x 17.3 in

Shipping (carrying case only)

Weight: ........................................................6.0 kg / 13.2 lb

Size: L x W x H .. 670 x 309 x 514 mm / 26 x 12.2 x 20.2 in

Miscellaneous

Serial data interface ............................. RS232 (9-pin male)

Operating temperature ....................0 to 40°C / 32 to 104°F

Storage temperature .................. -20 to 50oC / -4 to 122oF

Humidity ......................................................... 0 to 90% RH

Protection class ..........................................................IP-10

DNV Marine Approval, Certificate no ......................A-10384

*If a dry-block or liquid bath kit is ordered, there will be an extra

collie of approximately 2 kg (4.4 lb).

www.jofra.com 7

Page 8

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

FUNCTIONAL SPECIFICATIONS

Mains specifications

ATC-140/250 ........................ 115V(90-127) / 230V(180-254)

Frequency, non US deliveries ............... 50 Hz ±5, 60 Hz ±5

Frequency, US deliveries .......................................60 Hz ±5

Power consumption (max.) ATC-140 ........................300 VA

Power consumption (max.) ATC-250 ......................1150 VA

Temperature range

ATC-140 Maximum (Dry block) ..................... 140°C / 284°F

Minimum @ ambient temp. 0°C / 32°F .........-35°C / -31°F

Minimum @ ambient temp. 23°C / 73°F ...........-20°C / -4°F

Minimum @ ambient temp. 40°C / 104°F .......... -5°C / 23°F

ATC-140 Maximum (Liquid bath) .................. 140°C / 284°F

Minimum @ ambient temp. 0°C / 32°F .........-33°C / -27°F

Minimum @ ambient temp. 23°C / 73°F ............ -18°C / 0°F

Minimum @ ambient temp. 40°C / 104°F .......... -3°C / 27°F

ATC-250 (Dry block) ....................28 to 250°C / 82 to 482°F

ATC-250 (Liquid bath) .................28 to 250°C / 82 to 482°F

Stability

ATC-140/250 ........................................... +0.02°C / +0.04°F

Measured after the stability indicator has been on for 15 minutes.

Measuring time is 30 minutes.

Time to stability (approximate)

ATC-140/250 ...................................................... 15 minutes

Accuracy (model B) with external STS reference sensor

ATC-140 .................................................. +0.04°C / +0.07°F

ATC-250 .................................................. +0.07°C / +0.13°F

12 month period. Relative to reference standard. Specifications

by use of the external JOFRA STS-100 reference sensor (see

specification sheet SS-CP-2290, which can be found at www.

jofra.com)

Accuracy (model A+B) with internal reference sensor

ATC-140 A+B .................................. +0.18°C / +0.32°F 1) 2)

ATC-250 A+B .................................. +0.28°C / +0.50°F 1) 3)

12 month period. Specifications by use of the internal reference sensor.

1) Improved specifications (from October 1, 2006)

2) When used with the dry-block kit. When used with the liquid

bath kit the standard accuracy is ±0.30°C (0.54°F).

3) When used with the dry-block kit. When used with the liquid

bath kit the standard accuracy is ±0.50°C (0.90°F).

Better accuracy with the liquid kits is obtainable, if a special calibration and adjustment are done with liquid.

Resolution (user-selectable)

All temperatures ..................................... 1° or 0.1° or 0.01°

Radial homogeneity (difference between holes)

ATC-140/250 (dry-block) .............................. 0.05°C /0.09°F

ATC-140/250 (liquid bath) ....................... 0.025°C / 0.045°F

Immersion depth

ATC-140 (dry-block) ....................................180 mm / 7.1 in

ATC-140/250 (liquid bath) ........................... 150 mm / 5.9 in

ATC-250 (dry-block) ....................................150 mm / 5.9 in

Well diameter

ATC-140 .......................................................... 63.8 / 2.51 in

ATC-250 .......................................................... 63.8 / 2.51 in

Heating time

ATC-140 -20 to 23°C / -4 to 73°F ............... 10 minutes

23 to 100°C / 73 to 212°F ...........

100 to 140°C / 212 to 284°F .......

ATC-250 50 to 250°C / 122 to 482°F .........

31 minutes

23 minutes

11 minutes

Cooling time

ATC-140 140 to 100°C / 284 to 212°F ......... 7 minutes

100 to 23°C / 212 to 73°F ...........

23 to 0°C / 73 to 32°F .................

0 to -15°C / 32 to 5°F ..................

ATC-250 250 to 100°C / 482 to 212°F .......

100 to 50°C / 212 to 122°F .........

27 minutes

17 minutes

35 minutes

27 minutes

27 minutes

SYNC output (dry contact)

Switching voltage ................................... Maximum 30 VDC

Switching current ...................................Maximum 100 mA

INPUT SPEC’S (B MODELS ONLY)

All input specifications apply to the calibrator’s dry-block running at the respective temperature (stable plus an additional 20

minutes period). Where the input measuring range is out of the

calibrator’s range, the SET temperature is either MIN. or MAX.

Transmitter supply

Output voltage ................................................ 24VDC +10%

Output current .......................................... Maximum 25 mA

Transmitter input mA

Range ................................................................. 0 to 24 mA

Accuracy (12 months) ............. +0.01% Rdg. +0.015% F.S.

Voltage input VDC

Range: .............................................................. 0 to 12 VDC

Accuracy (12 months) ........... +0.005% Rdg. +0.015% F.S.

Switch input

Switch dry contacts

Test voltage ............................................... Maximum 5 VDC

Test current .............................................. Maximum 2.5 mA

RTD reference input (B models only)

Type .................4-wire RTD with true ohm measurements1)

F.S. (Full Scale) ...................................................... 350 ohm

Accuracy (12 months) ............±0.001% rdg. + 0.002% F.S.

RTD Type Temperature 12 months

°C °F °C °F

Pt100

reference

Note 1: True ohm measurements are an effective method to eliminate errors from induced thermoelectrical voltages

-50 -58 ±0.020 ±0.036

0 32 ±0.021 ±0.038

155 311 ±0.023 ±0.041

320 608 ±0.026 ±0.047

650 1202 ±0.032 ±0.058

700 1292 ±0.034 ±0.061

8 www.jofra.com

Page 9

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

RTD input

Type of RTD ............................................................... 2-wire

F.S. (range) ....................................... 350 ohm or 2900 ohm

Accuracy (12 months) ..........................................................

.............................. ±(0.005% rdg. + 0.005% F.S. + 50 mΩ)

Type of RTD ...................................................... 3- or 4-wire

F.S. (range) ....................................... 350 ohm or 2900 ohm

Accuracy (12 months) ..........±(0.005% rdg. + 0.005% F.S.)

RTD Type Temperature 12 months

°C °F °C °F

Pt1000

Pt500

Pt100

Pt50

(only in

Russian

versions)

Pt10

Cu100

Cu50

-50 -58 ±0.046 ±0.083

0 32 ±0.050 ±0.090

155 311 ±0.061 ±0.110

320 608 ±0.071 ±0.127

500 932 ±0.087 ±0.156

-50 -58 ±0.083 ±0.149

0 32 ±0.087 ±0.157

155 311 ±0.100 ±0.180

320 608 ±0.111 ±0.200

500

-50 -58 ±0.054 ±0.097

0 32 ±0.058 ±0.104

155 311 ±0.069 ±0.124

320 608 ±0.079 ±0.142

650 1202 ±0.106 ±0.191

700 1292 ±0.112 ±0.202

-50 -58 ±0.098 ±0.176

0 32 ±0.103 ±0.185

155 311 ±0.116 ±0.209

320 608 ±0.128 ±0.230

650 1202 ±0.161 ±0.290

700 1292 ±0.169 ±0.303

-50 -58 ±0.453 ±0.815

0 32 ±0.462 ±0.831

155 311 ±0.495 ±0.891

320 608 ±0.524 ±0.943

650 1202 ±0.610 ±1.098

700 1292 ±0.620 ±1.116

-50 -58 ±0.050 ±0.090

0 32 ±0.052 ±0.094

150 302 ±0.060 ±0.108

-50 -58 ±0.090 ±0.162

0 32 ±0.093 ±0.167

150 302 ±0.100 ±0.180

932

±0.130 ±0.235

If automatic cold junction compensation is used, the specification

for CJ is ±0.40°C (±0.72°F).

Thermocouple input

Range ....................................................................... 78 mV

F.S. (Full Scale) ......................................................... 78 mV

Accuracy (12 months) ........... ±(0.01% rdg. + 0.005% F.S.)

TC Type Temperature 12 months

°C °F °C °F

E

J

K

T

R

S

B

N

XK

(only in

Russian

versions)

U

-50 -58 ±0.08 ±0.14

0 32 ±0.07 ±0.12

155 311 ±0.07 ±0.12

320 608 ±0.08 ±0.14

650 1202 ±0.11 ±0.20

1000 1832 ±0.15 ±0.28

-50 -58 ±0.10 ±0.17

0 32 ±0.08 ±0.14

155 311 ±0.08 ±0.15

320 608 ±0.10 ±0.18

650 1202 ±0.12 ±0.22

1200 2192 ±0.19 ±0.34

-50 -58 ±0.11 ±0.20

0 32 ±0.10 ±0.18

155 311 ±0.11 ±0.20

320 608 ±0.12 ±0.22

650 1202 ±0.16 ±0.28

1372 2502 ±0.28 ±0.50

-50 -58 ±0.12 ±0.22

0 32 ±0.10 ±0.18

155 311 ±0.09 ±0.16

320 608 ±0.09 ±0.17

400 752 ±0.10 ±0.17

-50 -58 ±1.31 ±2.35

0 32 ±0.78 ±1.40

155 311 ±0.50 ±0.90

320 608 ±0.42 ±0.75

650 1202 ±0.41 ±0.74

1760 3200 ±0.50 ±0.90

-50 -58 ±0.98 ±1.77

0 32 ±0.78 ±1.40

155 311 ±0.50 ±0.90

320 608 ±0.46 ±0.83

650 1202 ±0.45 ±0.81

1768 3214 ±0.52 ±0.94

250 482 ±1.57 ±2.83

320 608 ±0.99 ±1.78

650 1202 ±0.69 ±1.23

1820 3308 ±0.48 ±0.86

-50 -58 ±0.16 ±0.29

0 32 ±0.15 ±0.27

155 311 ±0.14 ±0.24

320 608 ±0.14 ±0.25

650 1202 ±0.16 ±0.28

800 1472 ±0.17 ±0.31

-50 -58 ±0.07 ±0.13

0 32 ±0.06 ±0.11

155 311 ±0.06 ±0.12

320 608 ±0.07 ±0.13

650 1202 ±0.11 ±0.19

800 1472 ±0.12 ±0.22

-50 -58 ±0.12 ±0.21

0 32 ±0.10 ±0.18

155 311 ±0.09 ±0.17

320 608 ±0.09 ±0.17

600 1112 ±0.10 ±0.19

www.jofra.com 9

Page 10

Model ATC-140/250

Advanced Temperature Calibrator

Specification Sheet

SS-CP-2284-US

STANDARD DELIVERY

ATC dry-block calibrator (user specified)

•

Mains power cable (user specified)

•

Traceable certificate - temperature performance

•

Insert (user specified)

•

Tool for insertion tubes

•

RS232 cable

•

JOFRACAL calibration software

•

AMETRIM-ATC software to adjust the ATC series

•

User manual

•

Reference manual (English)

•

Model B instruments contain the following extra items:

Test cables (2 x red, 2 x black)

•

Traceable certificate - input performance

•

Model ATC-140/250 instruments contain either a kit for

•

liquid bath use OR a kit for dry-block use as standard

Liquid bath kit

The liquid bath kit for

ATC-140 and ATC-250

contains a sensor basket,

2 covering lids, a magnet

and a magnetic remover,

a liquid drainage tube and

0.75 l silicone oil.

Kit - liquid bath - ATC-140 A/B: 125022

Kit - liquid bath - ATC-250 A/B: 125035

ACCESSORIES

125066 Extra fixture for sensor grib

125067 Extra sensor grib

122771 Mini-Jack Connector for stable relay Output

120516 Thermocouple Male Plug - Type J - Black

120517 Thermocouple Male Plug - Type K - Yellow

120514 Thermocouple Male Plug - Type N - Orange

120515 Thermocouple Male Plug - Type T - Blue

120518 Thermocouple Male Plug - Type R / S - Green

120519 Thermocouple Male Plug - Type Cu-Cu - White

122801 Cable 0.5 m with LEMO / LEMO connectors

122823 2 m Cable Female Banana to LEMO connection

125002 Edge port Converter with 4 pcs of RS232 ports

124878 Sensor basket

124880 Covering lid for transportation/calibration

124883 Stirring magnet

124886 Stirring magnet remover

125126 Liquid drainage tube

125033 Silicone Oil, Type 200/10cSt, 0.75L for ATC-140

Heat shield (Optional) 105496

An external heat shield may be

placed on top of the calibrator to

reduce the hot air stream around

the sensor-under-test. This is especially important for testing thermocouples having head-mounted

transmitters with cold-junction

compensation.

Carrying case (Optional) 105805

The optional protective carrying

case ensures safe transportation

and storage of the instrument and

all associated equipment.

Dry-block kit

The dry-block kit for ATC140 and ATC-250 contains

a multihole insert .

The dry-block kit for the

ATC-140 also contains a

matching insulation plug.

Kit - dry-block - ATC-140 A/B - metric: 125023

Kit - dry-block - ATC-140 A/B - inch: 125024

Kit - dry-block - ATC-250 A/B - metric: 125025

Kit - dry-block - ATC-250 A/B - inch: 125026

10 www.jofra.com

Trolley (Optional) - 124315

A removable trolley for ATC carrying case 105805 ensures easy

and safe transportation of the

instrument.

Support rod set (Optional)

- 125068

Support rod for sensors to be

mounted on all JOFRA dry-block

calibrators. Holds the sensor

under test in their position, while

calibrating. Includes 2 sensors

grips and 2 fixtures for sensor

gribs.

Page 11

Model ATC-140/250

Advanced Temperature Calibrator

UNDRILLED INSERTS FOR ATC-140 AND ATC-250

Specification Sheet

SS-CP-2284-US

Inserts, undrilled

Instruments

Inserts ATC-140 A/B ATC-250 A/B

One undrilled insert

Insulation plug

124899 124891

124895 N/A

MULTI-HOLE INSERTS FOR ATC-140 AND ATC-250 - METRIC (MM)

Spare part no. for multi-hole inserts - metric (mm)

Instruments

Insert code

M01

1

ATC-140 A/B ATC-250 A/B

124897 124889

Note: All inserts (metric and inches) for ATC-140 are

supplied with a matching insulation plug.

Note 1: Use the insert code, when ordered as the

standard insert together with a new calibrator.

1/4 in

Reference

sensor

4 mm

8 mm

12 mm

1:1

1:1

3 mm

6 mm

4 mm

Reference

sensor

5 mm

6 mm

11 mm

MULTI-HOLE INSERTS FOR ATC-140 AND ATC-250 - IMPERIAL (INCH)

Spare part no. for multi-hole inserts - imperial (inch)

Instruments

Insert code

M02

1

ATC-140 A/B ATC-250 A/B

124898 124890

Note: All inserts (metric and inches) for ATC-140 are

supplied with a matching insulation plug.

Note 1: Use the insert code, when ordered as the

standard insert together with a new calibrator.

5/16 in

1/4 in

Reference

sensor

3/16 in

3/16 in

1/4 in

7/16 in

1/2 in

9 mm

1:1

1/8 in

1/4 in

4 mm

Reference

sensor

3/8 in

www.jofra.com 11

Page 12

ORDERING INFORMATION

Order number Description

Base model number

ATC140 ATC-140 series, -20 to 140°C (-4 to 284°F)

ATC250 ATC-250 series, 28 to 250°C (82 to 482°F)

Model version

A Basic model no sensor-under-test or reference

probe input

B Including sensor-under-test and reference probe

input

Power supply (US deliveries 60 Hz only)

115 115VAC

230 230VAC

Mains power cable type

A European, 230V,

B USA/CANADA, 115V

C UK, 240V

D South Africa, 220V

E Italy, 220V

F Australia, 240V

G Denmark, 230V

H Switzerland, 220V

I Israel, 230V

Insert type and size

XXX 1 x Insert for dry-block configuration

(please see the previous insert pages for

the right insert codes)

BAT Liquid bath

Calibration certificate

F NPL Traceable temperature certificate

(standard for Europe, Asia, Australia and Africa)

G NIST traceable temperature certificate

(standard for Americas)

H Accredited certificate

Options

C Carrying case

M Additional liquid kit, if dry-block configuration

is ordered above

R 90° angled reference probe with accredited

certificate (STS100A901AH)

X No option used

ATC140B230AM01FX Sample order number

JOFRA ATC-140 B with standard accessories,

230VAC, European power cord, dry-block

configuration with multihole insert type M01,

and NPL traceable temperature certificate.

is one of the world’s leading manufacturers and

AMETEK Calibration Instruments

developers of calibration instruments for

temperature, pressure and process signals

as well as for temperature sensors both from

a commercial and a technological point of view.

JOFRA Temperature Instruments

Portable precision thermometers. Dry-block and

liquid bath calibrators : 4 series, with more than

25 models and temperature ranges from

-90° to 1205°C / -130° to 2200°F. All featuring speed,

portabilit y, accuracy and advanced documenting

functions with JOFRACAL calibration software.

JOFRA Pressure Instruments

Convenient electronic systems ranging from

-1 to 1000 bar (25 inHg to 14,500 psi) -

multiple choices of pressure ranges, pumps and

accuracies, fully temperature- compensated

for problem-free and accurate field use.

JOFRA Signal Instruments

Process signal measurement and simulation for

easy control loop calibration and measurement

tasks - from handheld field instruments to

laboratory reference level bench top instruments.

JOFRA / JF Marine Instruments

A complete range of calibration equipment

for temperature, pressure and signal,

approved for marine use.

FP Temperature Sensors

A complete range of temperature sensors

for industrial and marine use.

M&G Pressure Testers

Pneumatic floating-ball or hydraulic piston dead

weight testers with accuracies to 0.015% of reading.

M&G Pumps

Pressure generators from small pneumatic

“bicycle” style pumps to hydraulic pumps

generating up to 1,000 bar (15,000 psi).

.. .beca use calib ratio n is

a ma tter of c onfid ence

Headquarters:

AMETEK Denmark A/S

Gydevang 32-34 • 3450 Allerød • Denmark

Tel: +45 4816 8000 • ametek@ametek.dk

Sales & Service:

Europe, Asia, Africa, Middle East and South America

Information in this document is subject to change without notice.

©2007, by AMETEK, Inc., www.ametek.com. All rights reserved.

Pub code SS-C P-228 4-US Is sue 0712

12 www.jofra.com

www.ametekcalibration.com

www.jofra.com

Sales & Service Offices:

AMETEK Mansfield & Green (North America)

Tel: +1 800 527 9999 • cal.info@ametek.com

AMETEK Singapore Pte. Ltd. (Singapore)

Tel: +65 6 484 2388 • aspl@ametek.com.sg

AMETEK Inc. Beijing Rep. Office (China)

Tel: +86 10 8526 2111 • jofra@ametek.com.cn

AMETEK GmbH (Germany)

Tel: +49 2159 91360 • info@ametek.de

AMETEK Lloyd Instruments (UK)

Tel: +44 (0) 1489 486 404 • jofra@ametek.co.uk

Loading...

Loading...