Page 1

HandPunch 1000

Installation and Operation Manual

Recognition Systems Inc.

1520 Dell Ave.

Campbell, CA 95008

Customer Care: 408-341-4110

RSI Main Tel: 408-341-4100

RSI Main Fax: 408-341-4101

Web: www.handreader.com

P/N: 70100-6009

Page 2

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy, and, if not installed and used

in accordance with the Installation Manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at the user’s own

expense.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numerique de la classe A respecte toutes les exigences du Reglemente sure le

materiel brouilleur du Canada.

© 2001 Ingersoll-Rand Company – ALL RIGHTS RESERVED

Document Part Number: 70100-6009 – Revision 1.2 – March, 2002

HandPunch is a trademark of Recognition Systems, Inc.

Windows is a trademark of Microsoft Corporation.

The trademarks used in this Manual are the property of the trademark holders. The use of these

trademarks in this Manual should not be regarded as infringing upon or affecting the validity of

any of these trademarks.

Recognition Systems, Inc. reserves the right to change, without notice, product offerings or

specifications.

No part of this publication may be reproduced in any form without the express written permission

of Recognition Systems, Inc.

Page 3

HandPunch 1000 Installation and Operation Manual

Table of Contents

HandPunch 1000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Biometrics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Principle of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The HandPunch Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Planning an Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Site Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

HandPunch Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wall Plate Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

End of Line Termination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Communication Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Erasing HandPunch Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Closing the HandPunch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Powering the HandPunch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programming the HandPunch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Authority Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Programming Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

System Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Design an ID Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Enter a Command Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Management Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Enrollment Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Special Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Revision 1.2 Page 3

Page 4

HandPunch 1000 Installation and Operation Manual

This page is intentionally left blank.

Page 4 Revision 1.2

Page 5

1.0 HandPunch 1000

The HandPunch 1000 is a member of the Recognition Systems’ line of biometric hand

geometry Time and Attendance Terminals1. The HandPunch records and stores the

three-dimensional shape of the human hand for comparison and identity verification.

Upon verification, the HandPunch records the time, date, user ID number, and

collected time and attendance data for collection by a host computer. The HandPunch

can communicate with a host computer.

The HandPunch provides proof-positive employee identification combined with the

sophisticated operating features one expects in a modern Time and Attendance

Terminal. Because of this unique combination of capabilities, the HandPunch provides

the most accurate Time and Attendance data collection terminal available. The key

features of the HandPunch include:

• Transaction Buffer

- 5,120 event capacity

• Programmable Clock and Date Formats and Daylight Savings Switch-over

HandPunch 1000 Installation and Operation Manual

1.1 Biometrics

Biometrics is a term describing the automatic measurement and comparison of human

characteristics. While its origins are ancient, the evolution of advanced scanning and

microprocessor technology brought biometrics into everyday life. Electronic hand

geometry technology first appeared in the 1970s. Recognition Systems Inc., founded

in 1986, built the first mass-produced hand geometry readers and made biometric

technology affordable for the commercial market. Today, Recognition Systems’

products are in use in every imaginable application from protecting cash vaults to

verifying employee attendance in hospitals.

1. For the sake of using a consistent name throughout the manual, the HandPunch 1000 terminal is

referred to as the HandPunch for the remainder of this manual.

Revision 1.2 Page 5

Page 6

HandPunch 1000 Installation and Operation Manual

1.2 Principle of Operation

The HandPunch uses low-level infrared light, optics, and a CCD (IC chip) camera to

capture a three-dimensional image of the hand. Using advanced microprocessor

technology, the HandPunch converts the image to an electronic template. It stores the

template in a database with the user’s ID number.

To gain punch, the user enters his or her ID number at the HandPunch’s keypad or uses

an external card reader. The HandPunch prompts the user to place his or her hand on

the HandPunch’s platen1. The HandPunch compares the hand on the platen with the

user’s unique template. If the images match, the HandPunch records the transaction for

processing.

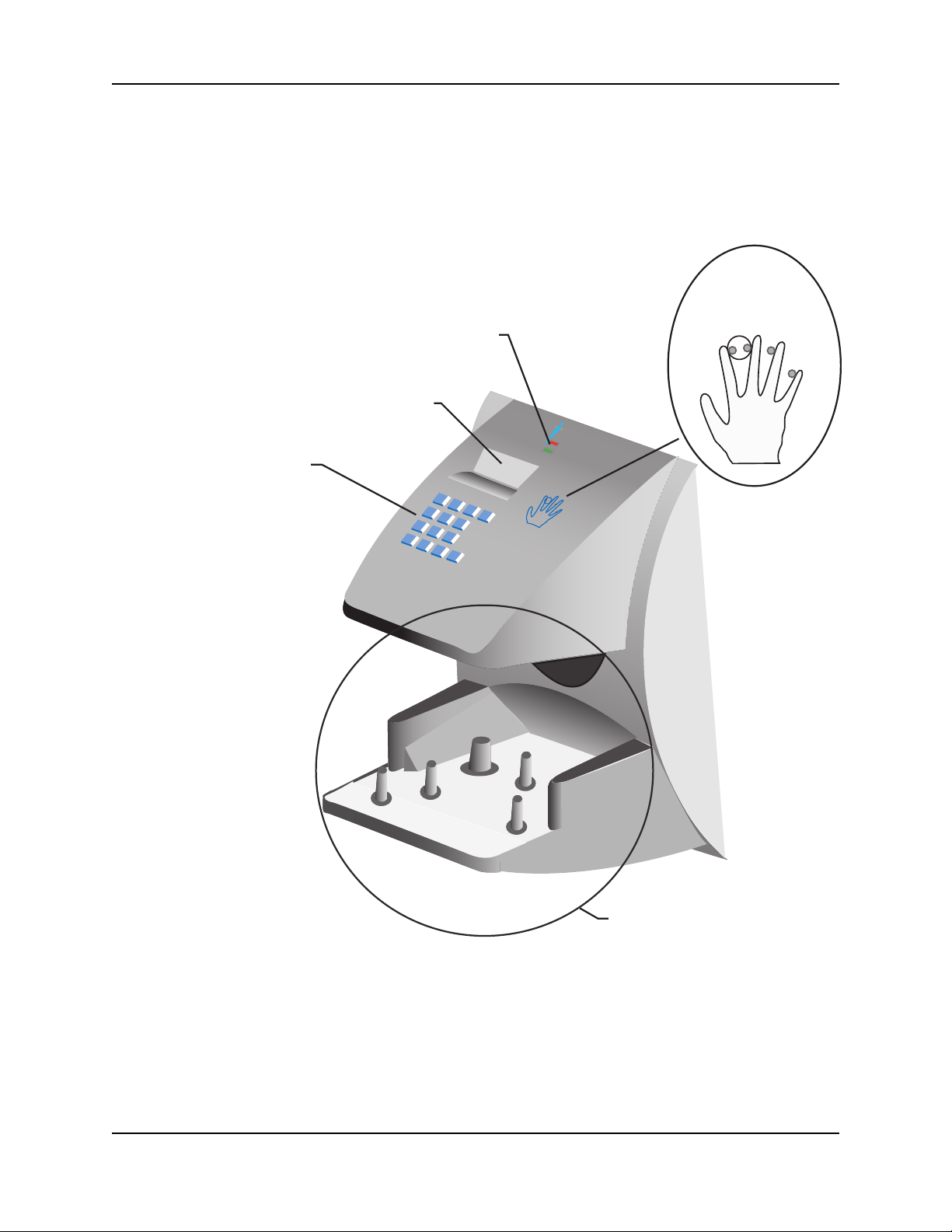

1.3 The HandPunch Terminal

The HandPunch is a time and attendance terminal designed for use with time and

attendance software. Refer to Figure 1-1 on page 7 when reviewing the information in

this section.

The HandPunch has an integrated keypad for ID entry (see Figure 1-1). The

CLEAR ENTER

Four different features assist the user with hand placement and read verification.

1. A light emitting diode (LED) hand placement display on the HandPunch’s top

panel assists users with hand placement on the platen.

2. A liquid crystal display (LCD) shows operational data and programming menus.

3. “Red light/Green light” verification LEDs quickly inform users if their verification

attempts were rejected or accepted.

4. An internal beeper provides audible feedback during keypad data entry and user

verification.

and keys are used for data entry and programming.

1. The Platen is the flat surface at the base of the HandPunch (see Figure 1-1). This is where users

place their hands for enrollment and verification. It has guide pins to assist positioning the

fingers during use.

Page 6 Revision 1.2

Page 7

HandPunch 1000 Installation and Operation Manual

N

VERIFICATION

LIGHTS

HAND

PLACEMENT

DISPLAY

UMERICAL

KEYPAD

LCD DISPLAY

Recogniti

on Systems Inc.

1

2

3

4

7

8

*

No

0

Cl

e

a

r

5

6

9

#

No

Y

e

s

Enter

PLATEN AND GUIDE PINS

Figure 1-1: The HandPunch 1000

Revision 1.2 Page 7

Page 8

HandPunch 1000 Installation and Operation Manual

1.4 Specifications

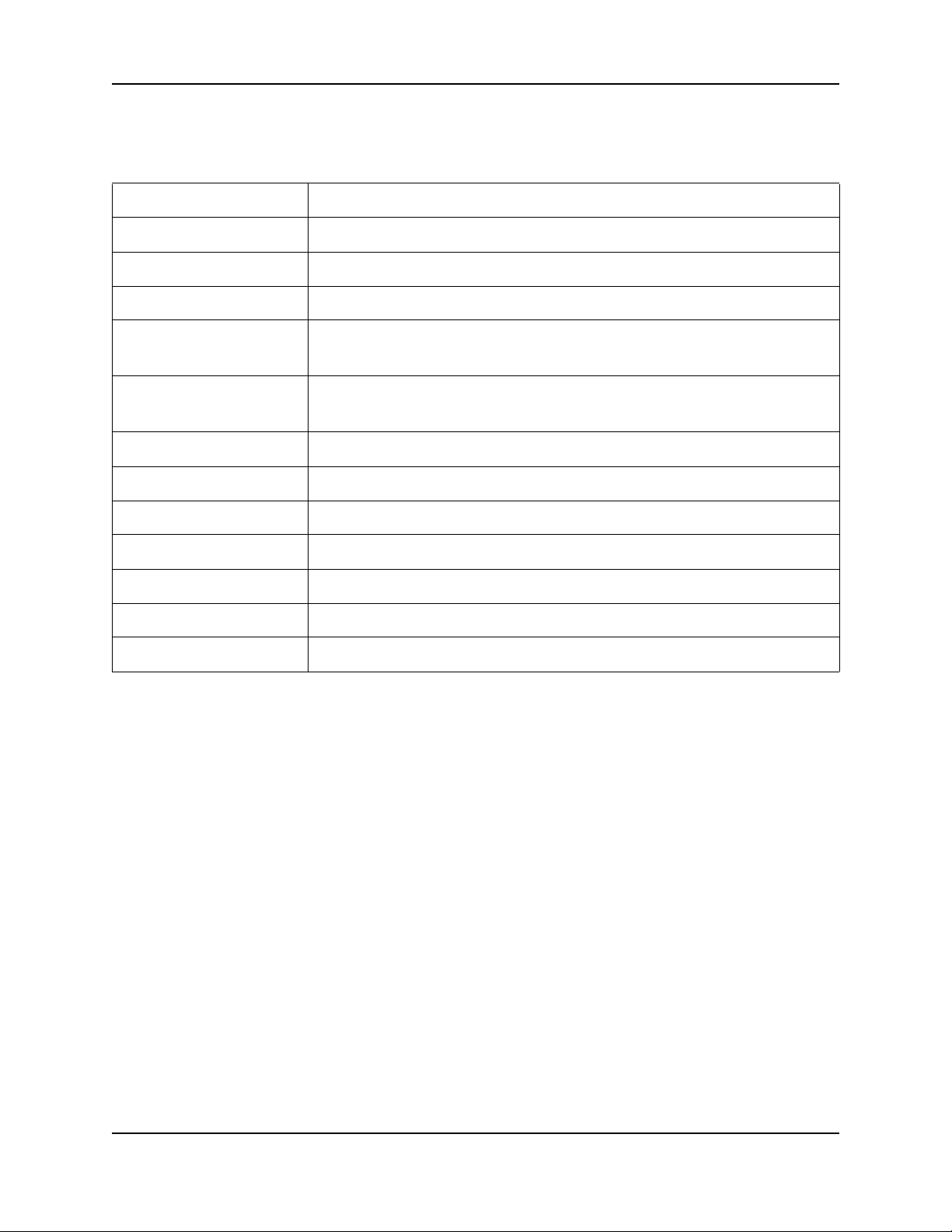

Table 1: Specifications

Size: 8.85 inches wide by 11.65 inches high by 8.55 inches deep

22.3 cm wide by 29.6 cm high by 21.7 cm deep

Power: 12 to 24 VDC or 12 to 24 VAC 50-60 Hz, 7 watts

Weight: 6 lbs (2.7 kg) – 7 lbs (3.2 kg) with optional backup battery

Temperature: -10°C to +60°C – non-operating/storage (14°F to 140°F)

5°C to 40°C – operating (40°F to 110°F)

Relative Humidity

Non-Condensing:

Verification Time: 1 second or less

Memory Retention: 5 years using a standard internal lithium battery

Transaction Buffer: 5,120 transactions

ID Number Length: 1 to 10 digits

Baud Rate: 300 to 28.8 K bps

Communications: RS-232, optional Modem

User Capacity: 50, 100, 512 users

5% to 95% – non-operating/storage (non-condensing)

20% to 80% – operating

Page 8 Revision 1.2

Page 9

1.5 Options

The HandPunch has the following options available.

• Backup Battery Support See Technical Note 70200-0012 – Rev. C

• Modem Communication See Technical Note 70200-0013 – Rev. C

• Memory Upgrade See Technical Note 70200-0039 – Rev. A

Recommended European Power Supply:

Ault, Inc.

7300 Boone Ave. North

Minneapolis, MN 55428 USA

PH: 612-493-1900

E-mail: info@ault.com

Part number: D48-121000-A040G

230 VAC Input, 12 VDC @ 1Amp output (unregulated)

Ault style #41 connector (barrel plug)

HandPunch 1000 Installation and Operation Manual

approved

recyclable

Revision 1.2 Page 9

Page 10

HandPunch 1000 Installation and Operation Manual

This page is intentionally left blank.

Page 10 Revision 1.2

Page 11

HandPunch 1000 Installation and Operation Manual

2.0 Planning an Installation

2.1 Site Preparation

Before you begin installation, check the site blueprints, riser diagrams, and

specifications for important information about HandPunch location and for other

systems that connect to the HandPunch. Look for any existing wall preparations and

wiring that other contractors may have installed for the HandPunch. A wire routing

layout diagram (see Figure 3-2 on page 17) is provided to assist in planning wire

routing.

2.2 HandPunch Placement

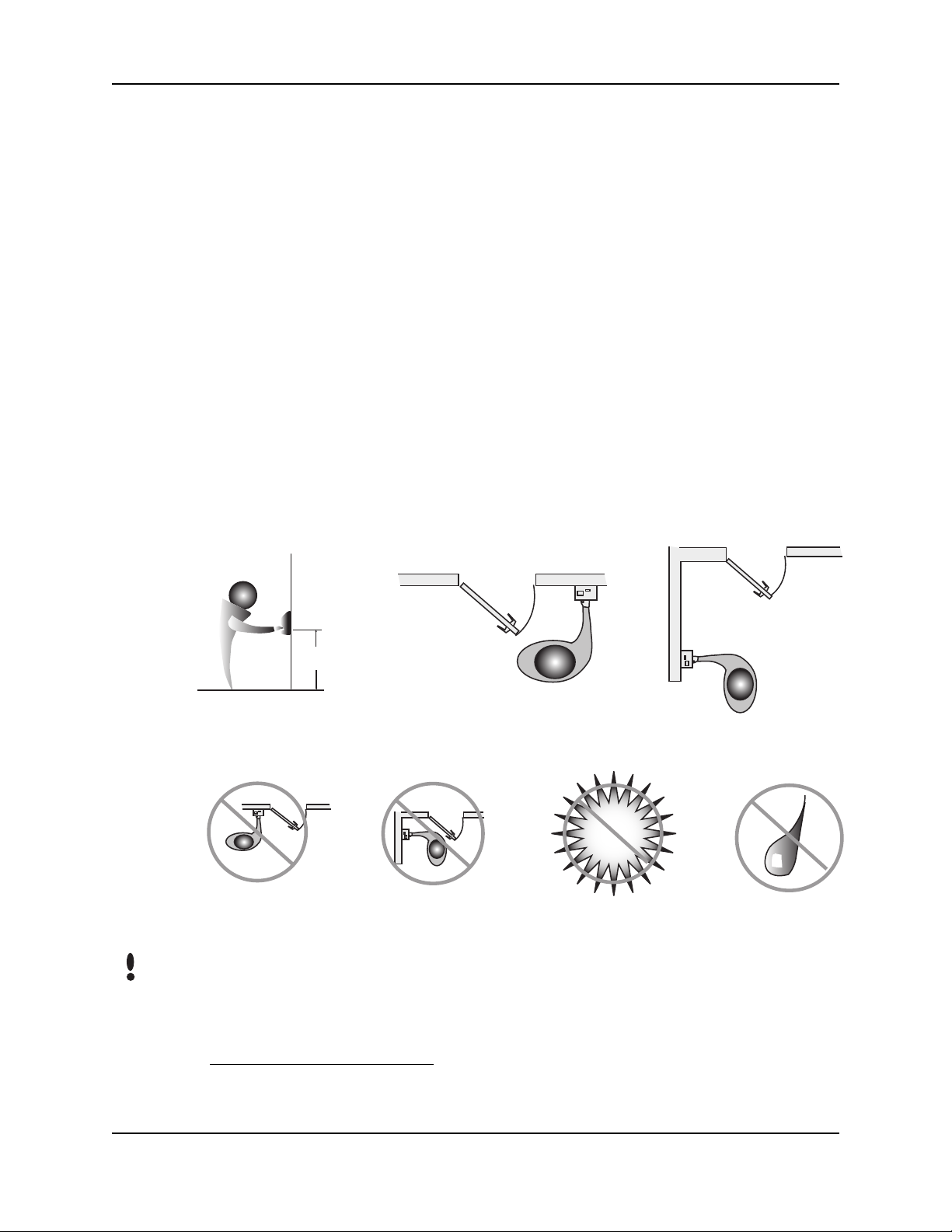

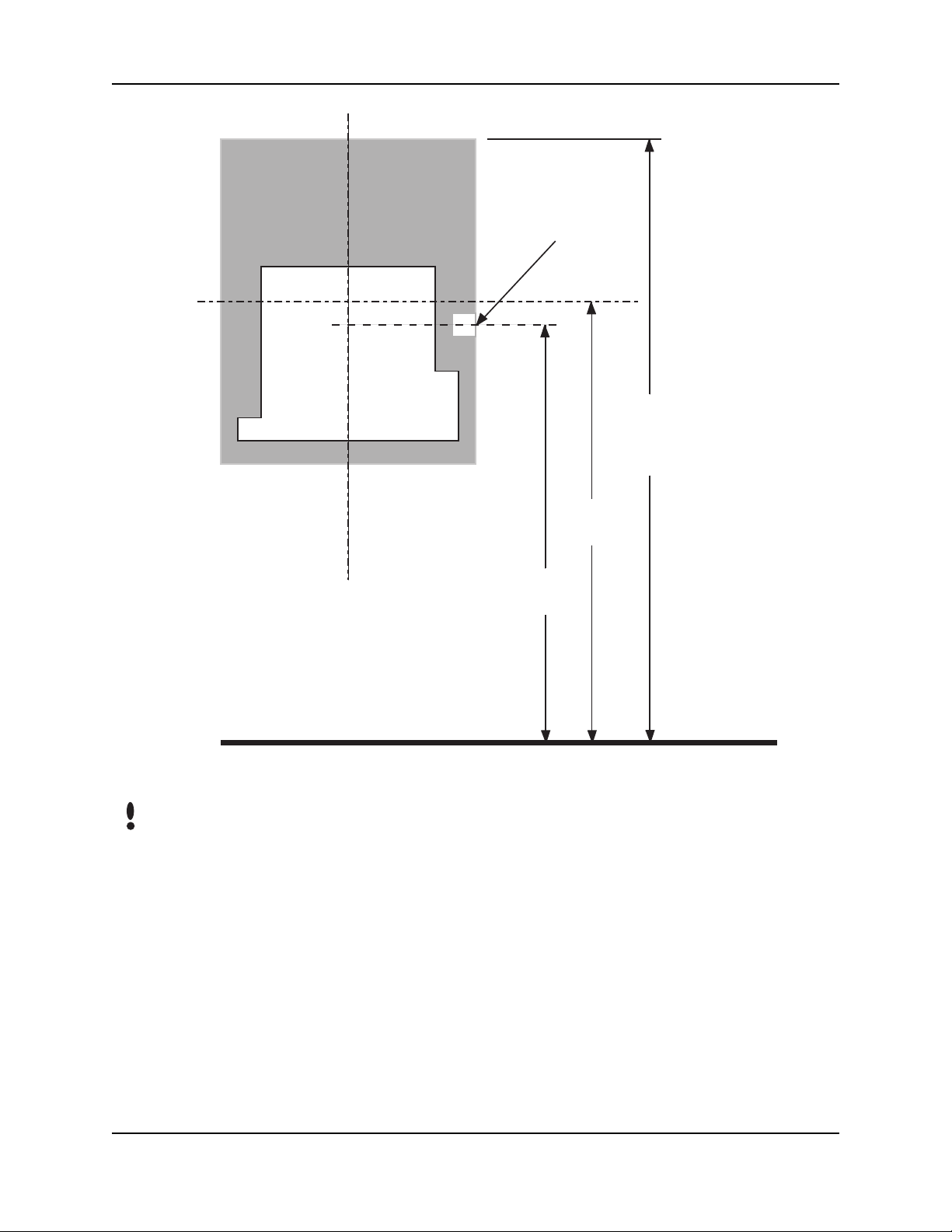

The recommended height for the HandPunch platen is 40 inches1 (102 cm) from the

finished floor. The HandPunch should be out of the path of pedestrian and vehicular

traffic, and convenient to the door it is controlling. Avoid placing the HandPunch

where users must cross the swing path of the door. The HandPunch should be in an

area where it is not exposed to excessive airborne dust, direct sunlight, water, or

chemicals.

NOTE

40 in. (102 cm.)

Figure 2-1: HandPunch Placement Rules

For the following sections, Recognition Systems does not supply hardware items such

as power or communications wiring.

1. This height conforms to ADA standards.

Revision 1.2 Page 11

Page 12

HandPunch 1000 Installation and Operation Manual

2.3 Wiring

Two basic circuits typically connect to the HandPunch:

• Power Input

• HandPunch to Host Computer

- RS-232

- modem

The minimum wire size for these circuits is AWG 22; the maximum is AWG 18.

2.3.1 Power Input

The HandPunch uses an internal switching regulator to obtain internal operational

power. It accepts input voltages from 12 to 24 VDC or 12 to 24 VAC at 50 to 60 Hz.

The HandPunch comes with a 120 VAC to 13.5 VDC power supply (Class 2, Model

No. P48131000A010G – 120 VAC, 60 Hz, 21 W, 13.5 VDC output @ 1000mA). An

optional 220 VAC to 13.5 VDC power supply is also available.

To power the HandPunch with this power supply, a 120 VAC (or 220 VAC as

applicable) duplex outlet must be within 5 feet of the HandPunch. The power supply

has a 6-foot cable to provide a comfortable reach between power outlet and

HandPunch. The barrel jack at the end of the power supply’s cable is connected to J12

on the HandPunch PCB.

NOTE

2.3.1.1 Battery Backup Operation

Do not connect a HandPunch’s power supply to a switched duplex outlet. The

HandPunch must have a constant source of power for proper operation.

An optional power-fail protection circuit board can be attached to the main circuit

board to provide and control battery backup. The battery backup option uses a 12 volt

800 ma/hour sealed lead acid battery to provide backup battery power. This battery is

located immediately inside the rear panel of the HandPunch and plugs into jack J4 on

the keypad control circuit board located in the top of the chassis.

The design of the HandPunch’s internal power supply is such that any range of the

above input voltages may be used and still provide proper battery charge voltage and

battery backup operation. Switch-over to battery power is automatic and occurs when

the input voltage falls to approximately 10.5 volts. At that time the backup battery

charger is disabled to save power, and uninterrupted operation continues on battery

power.

When input power is restored, the HandPunch switches off of battery operation and

the battery charger is re-enabled to recharge the battery. Battery charge voltage is set at

approximately 13.65 volts, and battery charge current is limited to approximately 50

mA. A fully discharged battery requires approximately 12 hours of charge to fully

recover.

Page 12 Revision 1.2

Page 13

HandPunch 1000 Installation and Operation Manual

Additional options installed and specific configurations within the HandPunch make it

difficult to predict precisely how long battery support will last, but in general two

hours of battery operation can be expected. While operating on battery backup due to

loss of main input power, the battery output voltage is constantly monitored by

internal circuitry. If the battery voltage reaches approximately 9.5 volts the

HandPunch automatically shuts down. This is done to prevent full exhaustion of the

battery. A yellow indicator on the top panel illuminates to indicate that the HandPunch

is running on battery power. This indicator turns off when main input power is

restored.

Shunt J7, which is located immediately in front of the DIP switches on the main logic

board (see Figure 4-1 on page 19), enables or disables battery operation on those

HandPunches equipped with optional battery backup. If a HandPunch does not have

the optional battery backup package installed, J7 is not used. On HandPunches

equipped with the battery backup option, J7 allows service personnel a mechanism for

disabling battery backup operation before removal of main input power.

To fully power down a HandPunch equipped with battery backup, remove or

reposition shunt J7 so that the two pins protruding up from the main logic board are

not connected to each other. This effectively opens the circuit, removing the battery

from any internal circuitry. Main input power can then be removed and the HandPunch

will fully shut down. Once the HandPunch has fully shut down, shunt J7 may be

reinstalled.

The design of the power supply is such that main input power must be reapplied to reenable the battery protection mechanism. If shunt J7 is not properly installed, the

internal backup battery will not be charged, and in the event of a main input power

loss, the HandPunch will shut down.

2.3.2 HandPunch to Host Computer Connection

HandPunch/host computer communications can be configured in one of two ways:

• via a direct RS-232 connection

• via an optional Modem connection

2.3.2.1 RS-232 Host Computer Connection

A direct HandPunch connection to a host computer can be made through an 8conductor cable in an RS-232 serial configuration. An RJ-45 jack must be installed

within 6 feet of the host computer. The HandPunch RS-232 cable is connected to this

jack. The cable connects to the host computer’s serial port through an RJ-45/DB-9F

connector. Figure 4-3 on page 21 provides a wiring diagram for the RS-232 to host

computer connection.

Revision 1.2 Page 13

Page 14

HandPunch 1000 Installation and Operation Manual

2.3.2.2 Modem Host Computer Connection

The HandPunch is also available with an optional modem module for telephone line

communications between the HandPunch network and the host computer. When

connecting via modem, one HandPunch terminal must be configured with the modem

option. This terminal will communicate with the host computer.

To make the modem connection, a telephone jack must be installed on or in the wall

behind the modem HandPunch terminal. Position the RJ-11 jack location using the

template provided in this manual (see Figure 3-2 on page 17). The short black cable

provided with the modem HandPunch connects the terminal to the telephone jack.

Figure 4-5 on page 21 a wiring diagram for a modem to host computer connection.

Page 14 Revision 1.2

Page 15

HandPunch 1000 Installation and Operation Manual

3.0 Mechanical Installation

Select an installation location based on the guidelines provided in the Planning an

Installation section beginning on page 11.

3.1 Wall Plate Installation

3.1.1 Wall Preparation

NOTE

For the following procedure protect the HandPunch from the dust and debris

generated during the wall plate installation process.

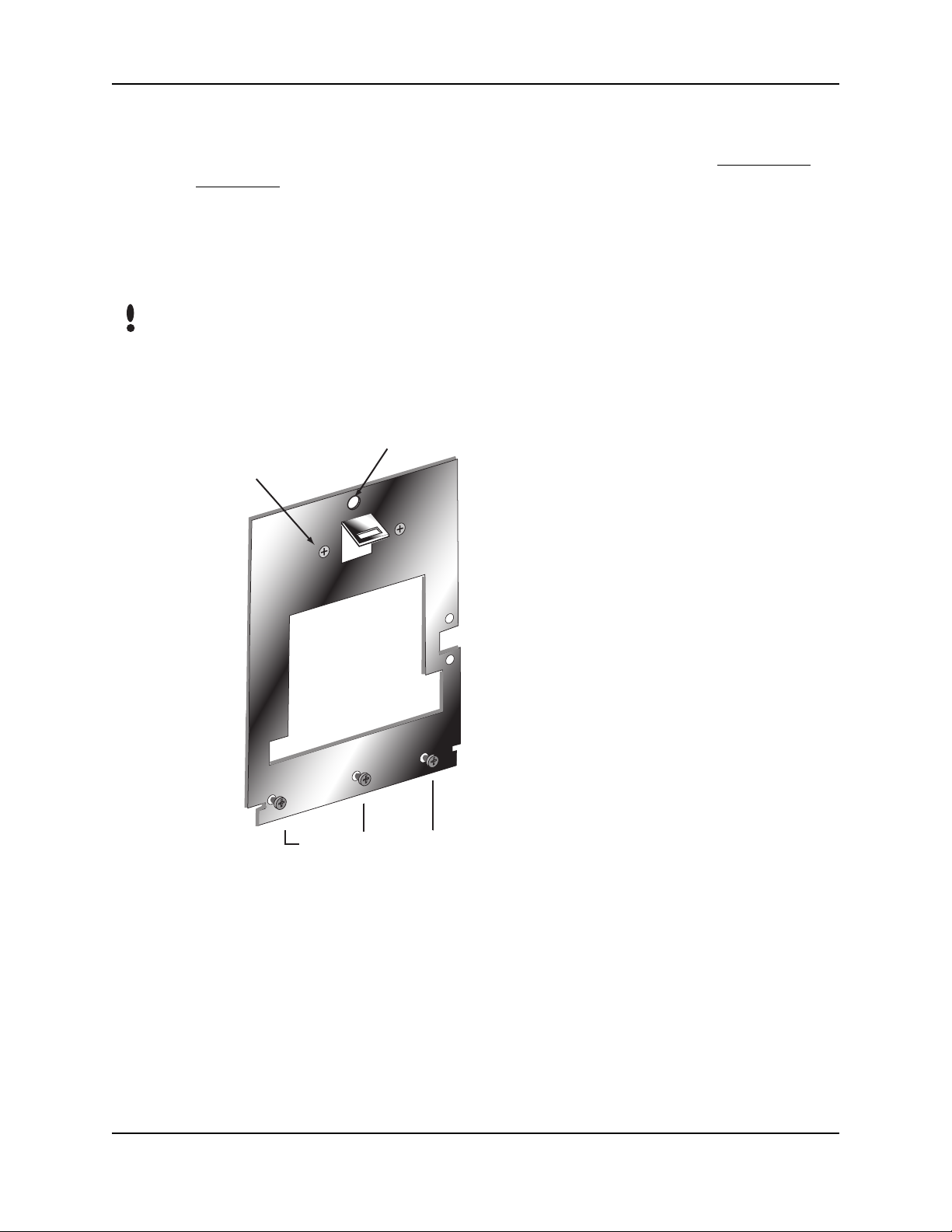

1. Remove the wall plate from the packing carton. Refer to Figure 3-1 for all wall

plate references in the following section.

LEVELING HOLE

2 UPPER SCREWS

SURFACE

CONDUIT

ENTRY

3 LOWER SCREWS

Figure 3-1: Wall Plate

2. Measure and mark a point 48 1/2 inches (123 cm) from the surface of the finished

floor. This point will correspond to the Leveling Hole where the top-center point of

the HandPunch should be mounted.

3. For a hollow wall, drive a small nail into the wall at the mark and hang the wall

plate from the Leveling Hole located near the top of the wall plate.

4. For a solid wall, hold the wall plate against the wall, centering the Leveling Hole

over the mark in the wall.

Revision 1.2 Page 15

Page 16

HandPunch 1000 Installation and Operation Manual

5. Align a bubble level with the top edge of the wall plate and gently rotate the wall

plate until the bubble level shows that the top edge of the wall plate is level.

6. Secure the plate to the wall using heavy masking tape.

7. Using the wall plate as a template, mark the locations of the two upper screw holes

and the three lower screw holes.

8. For a concealed wiring connection, trace the outline of the open area in the center

of the wall plate. Identify and mark a 1/2 inch hole through which the HandPunch’s wiring will be mounted.

9. For a surface conduit wiring connection, mark the two conduit clamp holes at the

right side of the wall plate.

10. Remove the wall plate, masking tape, and the nail (if used).

3.1.2 Mounting the Wall Plate

1. For a hollow wall, use the provided hardware to mount the wall plate. Use the two

auger style fasteners for the upper two mounting holes. Use the toggle bolts for the

three lower mounting holes.

2. For a solid wall, use expansion bolts to mount the wall plate. For all five mounting

holes, drill a 1/4 inch diameter hole, 1/4 of an inch deeper than the length of the

expansion anchor.

3.1.3 Routing the Wiring

1. Refer to Figure 3-2 on page 17 for a template diagram to assist in routing wiring.

2. For a concealed wiring connection, drill a 1/2 inch hole in a convenient location

within the open area of the wall plate. Pull the wiring to enter the HandPunch

through this hole in the open area.

3. For a surface conduit wiring connection, drill a 1/4 inch diameter hole, 1/4 of an

inch deeper than the length of the expansion anchor for each of the two conduit

clamp holes. Route 1/2 inch, flexible conduit to the HandPunch, ending the conduit between the two conduit clamp holes. Pull the wiring to enter the HandPunch

through the conduit. Pull 18 inches of wire past the end of the conduit to allow

enough space for final connection to the HandPunch.

4. Clear all dust and debris away from the HandPunch mounting location.

Page 16 Revision 1.2

Page 17

HandPunch 1000 Installation and Operation Manual

Wall Plate

C

HandPunch

L

SURFACE

CONDUIT

ENTRY POINT

C

50" Reference

42.75"

(108.6 cm)

42.5"

(108 cm)

L

(127 cm)

to Top of

Wall Plate

Finished Floor

Figure 3-2: HandPunch Wire Routing Layout

NOTE

Dust and debris surrounding the HandPunch can drastically affect the terminal’s

operation. It is important to ensure the HandPunch mounting location is free from dust

and debris.

3.1.4 Attaching the HandPunch

1. Loosen the three bottom mounting screws until there is approximately 1/8 inch (3

mm) clearance between the screw head and the wall plate.

2. Remove the HandPunch from its carton.

3. At the base of the HandPunch is a piano hinge with three keyhole shaped slots that

correspond with the three lower mounting screws. Align and hang the HandPunch

from the three lower mounting screws (see Figure 3-3 on page 18).

4. Tighten all three lower mounting screws.

5. The HandPunch is now ready for its wiring connections.

Revision 1.2 Page 17

Page 18

HandPunch 1000 Installation and Operation Manual

LEVELING HOLE

2 UPPER SCREWS

SURFACE

CONDUIT

ENTRY

KEYHOLE

HOLES

3 LOWER

MOUNTING

SCREWS

REAR OF TERMINAL

Figure 3-3: Attaching the HandPunch to the Wall Plate

Page 18 Revision 1.2

Page 19

4.0 Wiring Connections

Once the HandPunch is attached to the wall plate the wiring connections to the

HandPunch can be made (see Figure 4-1).

HandPunch 1000 Installation and Operation Manual

Serial RS-232

RJ-45 Jack

Power

Connectors

Figure 4-1: Wiring Connections and Dip Switches

4.1 Wiring Examples

Table 2 on page 20 provides the pinouts for the RJ-45/RS-232 Serial Host Computer

Connection.

WALL

Top of HandPunch

J7 Battery

Jumper

Optional Modem

Wall Plate

5 4 3 2 1

Dip Switches

Top of

Terminal

OFF

ON

Figure 4-2 on page 20 provides a diagram of the RJ-45/RS-232 Connector.

Figure 4-5 on page 21 provides a Host PC to HandPunch Modem Network wiring

diagram (Modem wiring is a HandPunch option).

Revision 1.2 Page 19

Page 20

HandPunch 1000 Installation and Operation Manual

Table 2: RJ-45/RS-232 Serial Connection

J8 Pin Signal Connection

1 RI - not used -

2 CD - not used -

3 DTR - not used -

4 GND Ground

5 Rx Data Receive Data Input (from external device)

6 Tx Data Transmit Data Output (to external device)

7 CTS - not used -

8 RTS - not used -

J4 Pins

1234567

Figure 4-2: J4 - RJ-45/RS-232 Jack Pinout

Page 20 Revision 1.2

Page 21

HandPunch 1000 Installation and Operation Manual

HandPunch

Recognition Systems Inc.

1

2

3

4

Clear

5

6

7

F1

8

9

*

No

F2

0

#

No

Yes

Enter

RJ-45

Serial Port

Serial Cable

RS-232 Serial Unit

Figure 4-3: Host PC to RS-232 Connection

Recognition Systems Inc.

1

2

3

4

Clear

5

6

7

F1

8

9

*

No

F2

0

#

No

Yes

Enter

HandPunch

RJ-11

Modem Port

RSI Supplied Cable (Black)

Connection

to Serial

Converter

Connection

to Host

Computer

Host Computer

RJ-11

Jack

Modem Unit

Figure 4-4: Host PC to HandPunch Modem Connection

RJ-11 Telephone Outlet

Revision 1.2 Page 21

Page 22

HandPunch 1000 Installation and Operation Manual

5.0 Setting the DIP Switches

The DIP Switch settings perform three tasks for the HandPunch (see Figure 5-1).

• Set End of Line (EOL) Termination to match the type of termination needed by the

network.

• Set the Communication Method to match the type of network used.

• Erase Memory to clear HandPunch memory to all factory default values and also

clear all user memory.

WALL

12345

OFF

ON

TOP OF HAND READER

Figure 5-1: HandPunch Dip Switches

EOL Termination

EOL Termination

Communication Method

Erase Hand Reader Setup

Erase Hand Reader Setup and Database

Page 22 Revision 1.2

Page 23

5.1 End of Line Termination

Termination helps to ensure clean data signals are transmitted through the network

wiring. Termination is applied to the end-of-line (EOL) HandPunch in the network

daisy-chain. The factory default setting is for EOL termination to be disabled –

switches 1 and 2 OFF. Refer to Figure 5-1 on page 22 for switch ON/OFF positioning.

• To enable EOL termination at a HandPunch, both switches 1 and 2 must be ON.

• To disable EOL termination at a HandPunch, both switches 1 and 2 must be OFF.

EOL Termination must be enabled for:

• A single HandPunch terminal installation.

• In a Modem to PC network the HandPunch terminal with the Modem option (for

communication with the host computer).

5.2 Communication Method

The factory default setting and for standard operation, switch 3 must be OFF.

• Switch 3 must always be OFF.

HandPunch 1000 Installation and Operation Manual

5.3 Erasing HandPunch Memory

The erase memory function can perform either or both of the following:

• Erase a HandPunch’s configuration data.

• Erase a HandPunch’s user database and transaction buffer.

The factory default setting (and normal operation setting) is for switches 4 and 5 to be

OFF, retaining memory.

NOTE

5.3.1 Erasing the HandPunch Setup

If the HandPunch is equipped with the battery backup option, remove shunt J7 in front

of the DIP switch array (see Figure 4-1 on page 19) before proceeding. Replace shunt

J7 after completion of the following steps.

Perform the following steps to erase the configuration data but retain the user

database.

1. With system power OFF, set switch 4 ON.

2. Turn system power ON and wait for HandPunch boot information to appear on the

display.

3. Turn switch 4 OFF.

Revision 1.2 Page 23

Page 24

HandPunch 1000 Installation and Operation Manual

5.3.2 Erasing the HandPunch Setup and User Database

Perform the following steps to erase both the configuration data and the user database.

1. With system power OFF, set both switches 4 and 5 ON.

2. Turn system power ON and wait 5 seconds.

3. Turn both switches 4 and 5 OFF.

NOTE

Before putting the HandPunch into service ensure DIP switches 4 and 5 are both

OFF. If switches 4 and 5 are not off, the next time the HandPunch’s power is cycled

the HandPunch’s memory will be erased.

Page 24 Revision 1.2

Page 25

HandPunch 1000 Installation and Operation Manual

6.0 Closing the HandPunch

Before closing the HandPunch, ensure dip switches 4 and 5 are OFF (refer to Figure 51 on page 22). Clear all dust and debris away from the HandPunch. With the wall

mount latch in the unlocked position, swing the body of the HandPunch up and lock

the latch into place with the key provided with the HandPunch (see Figure 6-1).

NOTE

NOTE

Dust and debris surrounding the HandPunch can drastically affect the terminal’s

operation. It is important to ensure the HandPunch is free from dust and debris before

closing the terminal.

Do not force the HandPunch onto the wall mount latch when the latch is in the

locked position.

Wall Plate

Recognition Systems Inc.

Latch

Key

No

LOCK

Unlocked Position

Wall Plate

Latch

Key

Locked Position

Figure 6-1: Closing the HandPunch

Revision 1.2 Page 25

Page 26

HandPunch 1000 Installation and Operation Manual

7.0 Powering the HandPunch

Apply power to the HandPunch. The HandPunch’s display lights up, the HandPunch

beeps almost immediately, and the display flashes the following information.

FRONT PANEL

VERSION X.X

A series of setup screens appear and after a several second delay the HandPunch’s

display shows the following information.

- ENTER ID TIME DATE

Depending upon how the HandPunch is configured, the “- ENTER ID -” string may be

replaced by a user-programmed string.

If the display remains blank, verify the power connections made to the HandPunch.

Page 26 Revision 1.2

Page 27

HandPunch 1000 Installation and Operation Manual

8.0 Programming the HandPunch

As the HandPunch was designed to be connected to a host computer, generally only

those commands not addressed by the Time and Attendance software need to be set at

the HandPunch (i.e. Set Address, Set Language). All other commands should be set

via the Time and Attendance software. A summary of all the commands and command

menus is given in Table 3.

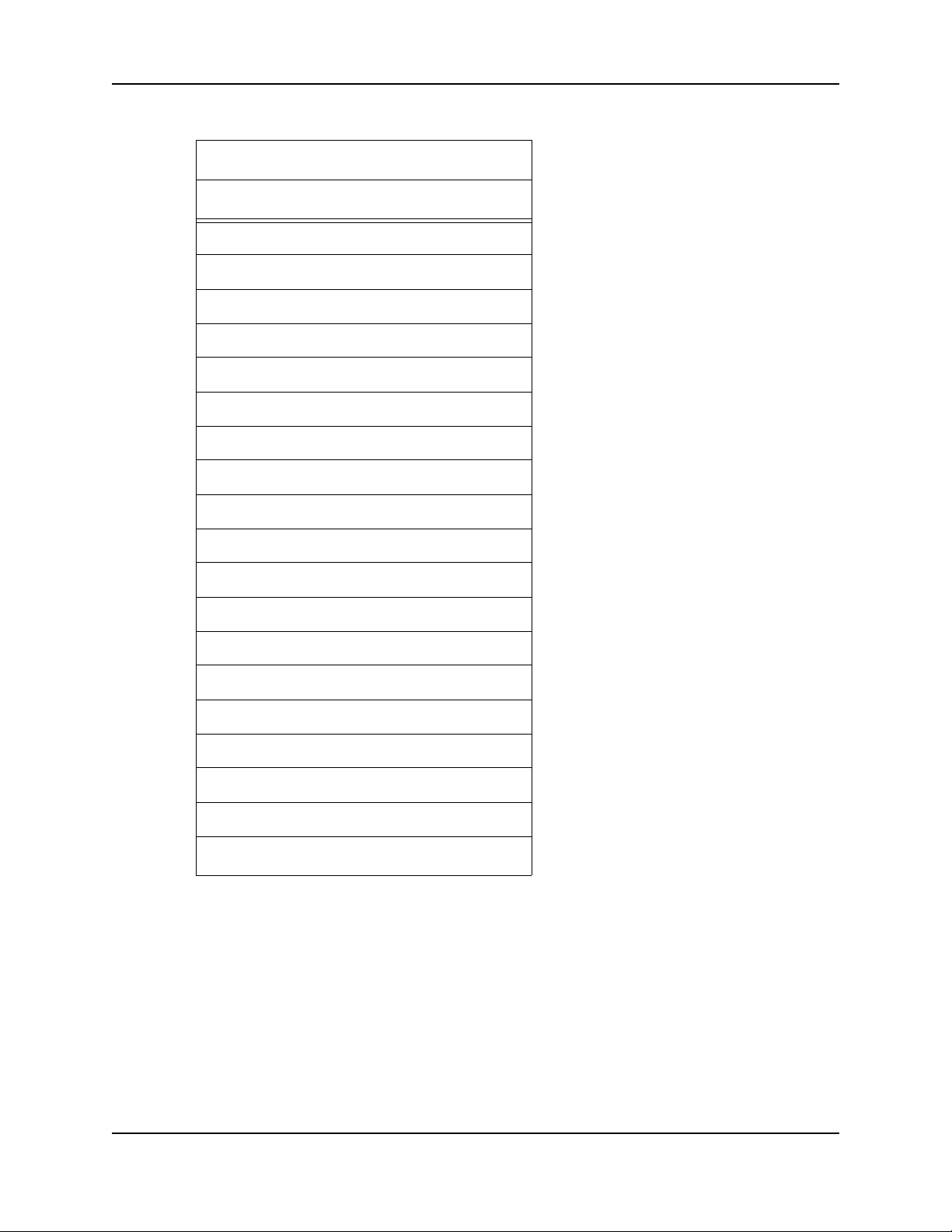

Table 3: Basic Command Mode Structure

Service Menu Setup Menu

Password 1 Password 2 Password 3 Password 4 Password 5

Calibrate Set Language List Users Add Employee Special Enroll

Status Display Set Date Format Set User Data Add Supervisor

Set Time & Date Remove User

Set Address

Set ID Length

Set Serial

Upgrade

To control access to the command menus, each menu has a unique password. This

password is requested as a part of the process for accessing each menu. A supervisor

must enter the correct password for that menu to access that menu. The default menu

passwords are given in Table 3.

Management

Menu

Enrollment

Menu

Special Menu

To increase the security of the HandPunch, Recognition Systems recommends

changing the passwords for the command menus to new numbers. These password

numbers can be up to 10 digits long. This is done at the host computer via the Time

and Attendance software package. Please refer to the Time and Attendance software

Users Guide or Manual for information on how to change the passwords.

8.1 Authority Level

A second method for controlling access to the command menus is through the use of

Authority Levels. Authority Levels control whether or not a user may access

command menus.

• Level 0 is assigned to users who do not need access to any of the command menus.

• Level 5 is assigned to supervisors who need access to all command menus.

Revision 1.2 Page 27

Page 28

HandPunch 1000 Installation and Operation Manual

The HandPunch automatically assigns Authority Level 0 to users enrolled by the Add

Employee command. Authority Level 5 is automatically assigned to users enrolled by

the Add Supervisor command.

NOTE

Until a user has been assigned to Authority Level 5, every user can access every menu.

Once a user has been enrolled using the Add Supervisor (designated as a supervisor),

all further user authority levels are assigned. The first person enrolled should be

enrolled using the Add Supervisor command. This protects the integrity of the system.

Recognition Systems strongly recommends enrolling at least two users as supervisors

to ensure that more than one person has the authority to access all menus and all

commands.

8.2 Programming Order

When setting up HandPunch operations there is a general programming/operations

order that should be followed.

Design an ID Numbering System – Define the format for user ID assignments. A

properly designed ID numbering system makes the HandPunch easier and faster to

use. Information for designing an ID numbering system begins on page 29.

Enroll Supervisory Staff – Enroll yourself and the supervisors who will have

responsibility for HandPunch management. This is done through the Enrollment

Menu (see Supervisor Enrollment on page 48).

Set HandPunch Site Parameters – Set the HandPunch site parameters to meet site-

specific needs and usage: change the language used by the display and set the

HandPunch’s address.

NOTE

The time, date, and ID number length are normally set by the host computer. However,

a supervisor can change these parameters at a HandPunch after setup information

has been downloaded from the host computer.

These tasks are done through the Setup Menu. The instructions for reader setup

parameters begin on page 37.

Train and Enroll Users – Train each user regarding Hand Reader usage and then Enroll

each user. This is done through the Enrollment Menu. The instructions for

employee training begin on page 43. The instructions for employee enrollment

begin on page 48. Special enrollment allows you to enroll people with disabilities

that prevent them from using the HandPunch properly. Employees with special

enrollment ID numbers can punch in without biometric verification.

This means that anyone who knows a special enrollment ID number can punch in. This

WARNING

function should only be used if absolutely necessary. The instructions for special

enrollment begin on page 50.

Page 28 Revision 1.2

Page 29

HandPunch 1000 Installation and Operation Manual

8.3 System Management

Once a HandPunch system is in operation the following commands are used for

system management.

List Users – List the users authorized to use a HandPunch. This is done through the

Management Menu. The instructions for listing employees begin on page 41.

Set User Data – Set a user’s reject threshold (adjusting the sensitivity applied when a

HandPunch reads a hand) and assign time zones to users (defining when users are

allowed to punch in and out). These tasks should be done through your user

software, however they can be done through the Management Menu. The

instructions for setting user data through the Management Menu begin on page 42.

Remove User – Remove employees (and supervisors) from a HandPunch. This task

should be done through your user software, however it can be done through the

Enrollment Menu. The instructions for removing employees through the

Enrollment Menu begin on page 48.

8.4 Design an ID Numbering System

The ID numbering system helps identify the user about to use the HandPunch. ID

numbers are used during user enrollment and verification. A properly designed ID

numbering system allows for quicker user recognition (through the use of the Set ID

Length command). Use the following guidelines when designing an ID numbering

system.

• Each user must have a unique ID number.

• ID numbers can be up to 10 digits long.

• For ease of memorization, make each number as short as possible. Generally

speaking, it is easier to remember ID numbers that are 4 digits or less (if your

installation has less than 10,000 users).

• Make all ID numbers the same length. This allows the Set ID Length command to

be used, automatically reading an ID number when the proper number of digits

have been entered. If different ID number lengths are used, a user must press either

# ENTER

the key or the key to identify when the complete ID number has

been entered.

• If an ID number has a leading 0 (zero), that leading 0 will be ignored.

8.5 Enter a Command Menu

While the HandPunch waits for a command, the display appears as follows.

- ENTER ID -

CURRENT TIME TODAY’S DATE

Revision 1.2 Page 29

Page 30

HandPunch 1000 Installation and Operation Manual

8.5.1 If No One is Enrolled in the Hand Reader

1. To enter the command menu, press the and keys

simultaneously (within approximately 0.5 seconds). The display appears as

follows.

ENTER PASSWORD

2. Press the default password for the menu you wish to enter.

• Press for the Service Menu.

• Press for the Setup Menu.

• Press for the Management Menu.

• Press for the Enrollment Menu.

• Press for the Special Menu.

3. Press and the first command option in the selected menu appears.

1

2

3

4

5

ENTER

CLEAR ENTER

8.5.2 If Employees and Supervisors are Enrolled in the Hand Reader

1. To enter the command menu, press the and keys

simultaneously (within approximately 0.5 seconds). The display appears as

follows.

- ENTER ID -

*:

2. Enter your ID number on the keypad and press .

3. Place your hand on the platen for verification. If verification is not successful or if

your Authority Level (see page 27) does not authorize you to enter supervisor

mode, the HandPunch sounds a double-beep and the display returns to its initial

state.

- ENTER ID -

CURRENT TIME TODAY’S DATE

CLEAR ENTER

ENTER

Page 30 Revision 1.2

Page 31

HandPunch 1000 Installation and Operation Manual

4. If verification is successful, the display appears as follows.

ENTER PASSWORD

5. Enter the password for the menu you wish to enter. The default passwords are as

follows.

NOTE

NOTE

• Press for the Service Menu.

• Press for the Setup Menu.

• Press for the Management Menu.

• Press for the Enrollment Menu.

• Press for the Special Menu.

6. Press . The initial screen for the entered menu appears.

1

2

3

4

5

ENTER

To access these menus you must be the first person enrolled in a new system

installation or you must have been enrolled as a supervisor. If you are blocked from the

supervisory menus, verify your access rights with management personnel. If

enrollment information has been incorrectly changed and you must have supervisory

access to all menus, make these changes through software.

It is possible to physically reset the HandPunch’s memory, however resetting memory

sets all unit parameters back to the factory default values. Resetting memory allows

access to all menus by the first person enrolled (as if it is a new system installation),

but this means that all employee information programmed into the HandPunch is

lost and must be re-entered manually. Be sure you need to reset memory before

performing this function. To reset memory, refer to the Erasing HandPunch Memory

section on page 23.

Revision 1.2 Page 31

Page 32

HandPunch 1000 Installation and Operation Manual

8.5.3 Navigating Command Menus

Once you have entered a command menu, there are three options available for

navigating the command menu system.

• Press to enter the command shown on the display.

• Press to step to the next command in the menu.

• Press to exit the command menu (pressing any numeric key also exits

the command menu). If you are in a command’s sub-menu, you may have to press

#

*

CLEAR

CLEAR

multiple times to completely exit the command menu.

8.6 System Maintenance

Once a HandPunch system is in operation the following commands are used for

system maintenance. These commands are performed through the Service Menu. The

instructions for system maintenance begin on page 35.

Calibrate – View HandPunch calibration values.

Status Display – Display HandPunch Input/Output status.

NOTE

8.6.1 Cleaning the HandPunch

There are NO user servicable parts inside the HandPunch.

NOTE

Inspect and clean the HandPunch regularly to maintain optimum performance. Clean

the platen, side mirror, reflector, and the window above the platen using a clean cloth

dampened with ordinary, non-abrasive window cleaner (see Figure 8-1). Start at the

rear corners of the platen and work your way forward.

DO NOT SPRAY CLEANING FLUID DIRECTLY INTO OR ON THE HANDPUNCH.

Figure 8-1: HandPunch Cleaning

Page 32 Revision 1.2

Page 33

8.6.2 User Score

Periodically check users’ scores (refer to the Read Score section on page 45). Scores

should average under 30. Occasionally a user will score above 30. This is not

necessarily an indication of poor performance. If a number of scores average over 30,

clean the HandPunch and check scores again. If scores remain high, or if users are

experiencing frequent rejections, run the Calibration command (see page 36).

HandPunch 1000 Installation and Operation Manual

Revision 1.2 Page 33

Page 34

HandPunch 1000 Installation and Operation Manual

This page is intentionally left blank.

Page 34 Revision 1.2

Page 35

8.7 Service Menu

The Service menu commands provide information that help you determine if the

HandPunch is performing within normal operating parameters. The following section

provides a brief summary of the Service Menu commands.

HandPunch 1000 Installation and Operation Manual

NOTE

There are no user serviceable parts inside the HandPunch.

8.7.1 Navigating the Service Command Menu

Enter the appropriate password to enter the Service command menu. Once you have

entered the command menu, there are three options available for navigating the

command menu system.

• Press to enter the command shown on the display.

• Press to step to the next command in the menu.

• Press to exit the command menu (pressing any numeric key also exits

the command menu). If you are in a command’s sub-menu, press

multiple times to completely exit the command menu.

#

*

CLEAR

8.7.2 Service Commands

There are two commands available from the Service command menu.

•Calibrate

• Status Display

CLEAR

Refer to Table 4 and identify the command you need to perform. Step through all

previous commands until you reach the desired command.

Table 4: Service Command Menu

Service Menu

Password = 1

Calibrate

Recal (Y/N)

Status Display

On/Off (Y/N)

Revision 1.2 Page 35

Page 36

HandPunch 1000 Installation and Operation Manual

8.7.2.1 Calibrate

The Calibrate command displays the HandPunch’s exposure values, allowing you to

verify these values are within normal operating parameters. The standard operating

parameters are shown in Table 5.

Table 5: Normal Operating Parameters

Parameter Normal Range

Row “r” 0 +/- 2

Column “c” 0 +/- 2

Exposure “e” 100 +/- 10

8.7.2.2 Status Display

The status display command allow you to enable or disable the displaying of the

following information.

• the hand read score of the last user to verify on the system

When the status display is enabled, Figure 8-2 identifies each status display field

value.

- ENTER ID -

O C O C O H L H L NN

O C O C O H L H L NN

Last Hand Read Score

Aux Out 2

Aux Out 1

* Aux Out 0

* Lock

Aux In 2

Request to Exit

Aux In 1

Door Monitor Switch

Tamper

* These status values are inactive if the

reader is in Card Reader Output Mode.

These Input/Output

values do not apply to

the HandPunch 2000

O = Circuit Open H = Output is OFF (High)

C = Circuit Closed L = Output is ON (Low)

Figure 8-2 Status Display Chart

Page 36 Revision 1.2

Page 37

8.8 Setup Menu

The Setup menu commands allow you to set the basic operating parameters for the

HandPunch unit. The following section provides a brief summary of all the parameters

that may be set on a HandPunch unit.

HandPunch 1000 Installation and Operation Manual

NOTE

Once in the Command Menu, you can step through and set the parameters for each

command sequentially. You do not have to exit command mode after setting any

individual command.

8.8.1 Navigating the Setup Command Menu

Enter the appropriate password to enter the Setup command menu. Once you have

entered the command menu, there are three options available for navigating the

command menu system.

• Press to enter the command shown on the display.

• Press to step to the next command in the menu.

• Press to exit the command menu (pressing any numeric key also exits

the command menu). If you are in a command’s sub-menu, press

multiple times to completely exit the command menu.

#

*

CLEAR

8.8.2 Setup Commands

There are six commands available from the Setup command menu.

CLEAR

• Set Language

• Set Date Format

• Set Date and Time

• Set Address

• Set ID Length

• Set Serial

• Upgrade

Refer to Table 6 on page 38 and identify the command you need to perform. Step

through all previous commands until you reach the desired command.

Revision 1.2 Page 37

Page 38

HandPunch 1000 Installation and Operation Manual

Table 6: Setup Command Menu

Setup Menu

Password = 2

Set Language

Select Language

Set Date Format

Select Date Format

Set Time and Date

Month (MM)

Day (DD)

Year (YY)

Hour (HH)

Minute (MM)

Set Address

New Address

Set ID Length

New ID Length

Set T & A Mode

Set Serial

RS-232

Select Baud Rate

Upgrade

a

a. See Technical Note 70200-0039

Page 38 Revision 1.2

Page 39

8.8.2.1 Set Language

The Set Language command allows the language shown on the HandPunch’s display

to be “localized” for a variety of countries.

- English - German

- Japanese - Russian

- French - Indonesian

- Italian - Portuguese

- Spanish - Polish

8.8.2.2 Set Date Format

The Set Date Format command allows the date format shown on the HandPunch’s

display to be “localized” for a variety of countries.

- mm/dd/yy - mm-dd-yy

- dd-MMM-yy - MMM dd,yy

- dd-mm-yy - ddMMMyyyy

- dd/mm/yy

HandPunch 1000 Installation and Operation Manual

8.8.2.3 Set Time and Date

The Set Time and Date command allows the HandPunch’s time and date to be set. This

is normally not necessary as the HandPunch’s time and date are set by the host

computer.

8.8.2.4 Set Address

The Set Address command allows a unique address to be set for each HandPunch. For

proper operation, each HandPunch in the network must have a unique address. All

units may use any address from 0 to 254. The factory default is for all units to be sent

with the address set to 1.

8.8.2.5 Set ID Length

The Set ID Length command allows you to reduce the number of keystrokes required

to enter the ID number by eliminating the use of the key to complete an ID

number entry. Once the ID Length is set, the HandPunch will automatically accept an

ID number entry once the correct number of characters have been entered.

Set ID Length does not apply when ID entry is made from a card reader. Once the ID

Length is set, the T & A Mode Set command appears, allowing you to configure the

HandPunch to prepare punch data for time and attendance software.

ENTER

Revision 1.2 Page 39

Page 40

HandPunch 1000 Installation and Operation Manual

This page is intentionally left blank.

Page 40 Revision 1.2

Page 41

HandPunch 1000 Installation and Operation Manual

8.9 Management Menu

The Management menu commands allow you to manage employee data stored in a

HandPunch unit. The following section provides a brief summary of the employee

data that may be manipulated on a HandPunch unit.

8.9.1 Navigating the Setup Command Menu

Enter the appropriate password to enter the Setup command menu. Once you have

entered the command menu, there are three options available for navigating the

command menu system.

• Press to enter the command shown on the display.

• Press to step to the next command in the menu.

• Press to exit the command menu (pressing any numeric key also exits

the command menu). If you are in a command’s sub-menu, press

multiple times to completely exit the command menu.

#

*

CLEAR

8.9.2 Management Commands

There are four commands available from the Management command menu.

• List Users

• Set User Data

Refer to Table 7 on page 41 and identify the command you need to perform. Step

through all previous commands until you reach the desired command.

Table 7: Setup Command Menu

Setup Menu

CLEAR

Password = 3

List Users

Set User Data

User Reject

8.9.2.1 List Users

The List Users command allows you to display a list of all the employees enrolled in a

Hand Reader.

Revision 1.2 Page 41

Page 42

HandPunch 1000 Installation and Operation Manual

8.9.2.2 Set User Data

The Set User Data command allows you to set an employee’s Reject Threshold,

adjusting the hand read threshold for one employee without affecting the threshold of

other employees. This task should be done through your user software, however it can

be done through the Management Menu.

Page 42 Revision 1.2

Page 43

8.10 Enrollment Menu

Enrollment is the process of recording a hand image and associating it with an ID

number. The first person to enroll in the HandPunch has access to all command menus.

This person should enroll using the Add Supervisor command (see page 48). Once a

supervisor has been enrolled, all further enrollments use the following rules:

• A user enrolled through the Add Employee command (page 48) is assigned

Authority Level 0. This allows the user to punch in and/or gain access through a

door secured by the HandPunch.

• A user enrolled through the Add Supervisor command (see page 48) is assigned

Authority Level 5. This allows the supervisor to punch in and gain access through

a door secured by the HandPunch, and it allows the supervisor to access all

command menus.

HandPunch 1000 Installation and Operation Manual

NOTE

Until a user has been assigned to Authority Level 5 using the Add Supervisor

command, every user with Authority Level 0 can access every menu. This is done to

ensure that the first person enrolled is able to access all the menus to perform all the

programming required to support the HandPunch. Once a user has been enrolled

using the Add Supervisor command, all further user authority levels are assigned as

per the list above. This protects the integrity of the system by enacting the Authority

Level rules described above. Recognition Systems strongly recommends enrolling at

least two users as supervisors to ensure that more than one person has the authority to

access all menus and all commands.

Advance planning and training make enrollment fast and easy. Users should be

informed on what to expect and how to place their hands on the HandPunch before

you enroll them.

8.10.1 Navigating the Setup Command Menu

Enter the appropriate password to enter the Setup command menu. Once you have

entered the command menu, there are three options available for navigating the

command menu system.

• Press to enter the command shown on the display.

#

• Press to step to the next command in the menu.

• Press to exit the command menu (pressing any numeric key also exits

the command menu). If you are in a command’s sub-menu, press

multiple times to completely exit the command menu.

Revision 1.2 Page 43

*

CLEAR

CLEAR

Page 44

HandPunch 1000 Installation and Operation Manual

8.10.2 Preparation

Here are a few guidelines to help you prepare for an enrollment session.

• You can enroll one person or a group of people during an enrollment session.

• Each user must have a unique personal identification (ID) number. It will save you

considerable time if you assign the ID numbers in advance (Refer to the Design an

ID Numbering System section on page 29).

• The HandPunch will not accept two people with the same ID number.

• If you enroll people using the last four digits of their phone numbers or social

security numbers, you may get duplicate numbers.

• If you are enrolling large groups of people you may consider using an enrollment

trainer. It is a replica of a platen that is available through your Recognition

Systems reseller.

8.10.3 User Education

The HandPunch is easy to use and non-threatening. However, most people have never

used a biometric HandPunch. Training users on how the HandPunch works and how to

use it will eliminate most fears and concerns before they occur. Inform the users of

these facts.

• The HandPunch reads the shape of the hand, not the fingerprints or palmprints.

• It does not identify people. It confirms people’s identity.

• It scans with an invisible light of the type used in TV remote controls.

• It does not transfer germs any more than a doorknob or money.

• It does not invade privacy; it guarantees it.

• The enrollment process requires three or more reads to collect enough information

to create a template.

8.10.4 Proper Hand Placement

For correct, consistent hand reads it is very important that your hand is placed on the

platen in the same manner every time. The following rules apply for proper hand

placement on the platen (for the following rules, refer to Figure 8-3 on page 45).

• If you are wearing a ring, rotate the ring so the stone faces up in its normal

position.

• Slide your right hand onto the platen rather like an airplane landing at the airport.

• Slide your hand forward until the web between your index and middle finger stops

against the Web Pin.

• Keep your hand flat. You should feel the surface of the platen on your palm and the

underside of your fingers.

• Close your fingers together until they touch the Finger Pins and watch the hand

diagram light display on the top panel.

• The lights go out when you have properly placed your fingers. If a light remains

on, a finger is not in proper contact with its Finger Pin.

Page 44 Revision 1.2

Page 45

Figure 8-3: Placing Your Hand on the Platen

8.10.5 Left Hand Enrollment

Some right hands cannot be used in the HandPunch due to disabilities such as missing

fingers. You can enroll a user with the left hand facing palm side up. The techniques

for left hand enrollment are the same as for standard enrollment. The user should keep

the back of the hand flat against the platen and move the fingers against the web pin

and the finger pins in the same manner as in standard enrollment. Users enrolled with

the left hand must always verify with the left hand. Extra practice on placing the hand

on the platen may be required to ensure correct, consistent hand reads.

8.10.6 Read Score

HandPunch 1000 Installation and Operation Manual

WEB PIN

When a user uses the HandPunch the display appears as follows.

OKAY (USER ID)

SCORE IS: (SCORE NUMBER)

The score number on the display reflects how accurately the user’s hand is placed on

the platen (see page 44). Scores that vary greatly between low and high numbers are

indicative of inconsistent hand placement. Scores above 50 are indicative of improper

hand placement or of a drastic change in the physical appearance of the hand.

When this occurs, emphasize the importance of sliding the hand onto the platen and

keeping the hand flat. Re-training and practice should lower a user’s score. It might be

necessary to change a user’s reject threshold if the user has a mild disability. Reenrollment might be necessary to create a new user template.

Revision 1.2 Page 45

Page 46

HandPunch 1000 Installation and Operation Manual

8.10.7 Display Messages During Verification

Various messages can appear on the HandPunch’s display during hand verification.

These messages are defined in Table 8.

Table 8: Display Messages During Verification

Message Definition

PLACE HAND The platen is ready to receive your hand for verification.

ID VERIFIED You are verified, proceed.

REMOVE HAND Remove your hand and place it on the platen again. Follow

proper hand placement rules.

TRY AGAIN Your attempt was rejected. Repeat verification following

proper hand placement rules.

ID REFUSED Your rejections exceeded the maximum number of tries

allowed. Wait until another employee has verified and try

again or call your supervisor.

ENTER ID You entered your ID number incorrectly or your access time

is restricted.

• If the display shows TRY AGAIN, you are not verified. You may have made an

error in entering your ID number or in placing your hand on the platen. Re-enter

your ID number and try again, taking care to follow proper hand placement rules

(see page 44).

• If the display shows TIME RESTRICTION, you are not authorized to punch in

at this time. If this seems to be in error, contact your supervisor about time

restrictions.

• After a pre-programmed number of denied attempts, an ID number will no longer

be accepted and the display will appear as follows.

ID INVALID

TEMPORARILY

This is called a “lockout.” Before the rejected ID number can be used again,

another employee or a supervisor must successfully verify at the HandPunch.

Page 46 Revision 1.2

Page 47

HandPunch 1000 Installation and Operation Manual

• If you enter your ID number, but do not place your hand on the platen, the

HandPunch will time-out in about 25 seconds. You can immediately end this time-

out by pressing the key.

CLEAR

8.10.8 Beeper and LED Status During Verification

The HandPunch’s beeper and LED status display also display hand verification

information. This information is defined in Table 9.

Table 9: Beeper and LED Status During Verification

Operation Beeps LED Meaning

During Keypad

Entry

After ID Entry – – OK - Proceed

After ID Entry 2 – ID Number Not in

After Hand

Placement

After Hand

Placement

1 per Keystroke – Keystroke

1 Green ID Verified

2 Red ID Not Verified -

Accepted

Database

Try Again

After Hand

Placement

1 Long Red ID Refused

8.10.9 Enrollment Commands

There are three commands available from the Enrollment command menu.

• Add Employee

• Add Supervisor

• Remove User

Refer to Table 10 on page 48 and identify the command you need to perform. Step

through all previous commands until you reach the desired command.

Revision 1.2 Page 47

Page 48

HandPunch 1000 Installation and Operation Manual

Table 10: Enrollment Command Menu

Service Menu

Password = 4

Add Employee

ID #

Add Supervisor

ID #

Remove User

ID #

8.10.9.1 Add Employee

The Add Employee command allows you to enroll a new employee into the

HandPunch.

8.10.9.2 Add Supervisor

The Add Supervisor command allows you to enroll a new supervisor into the

HandPunch.

8.10.9.3 Remove User

The Remove User command allows you to remove an employee or supervisor from

the HandPunch.

Page 48 Revision 1.2

Page 49

HandPunch 1000 Installation and Operation Manual

8.11 Special Menu

The Special menu has one command – Special Enroll. This command accommodates

users with disabilities that make it difficult or impossible to use a HandPunch in its

standard way. The following section provides a brief description of the Special Menu

command.

8.11.1 Navigating the Special Command Menu

Enter the appropriate password to enter the Special command menu. Once you have

entered the command menu, there are three options available for navigating the

command menu system.

• Press to enter the command shown on the display.

• Press to step to the next command in the menu.

• Press to exit the command menu (pressing any numeric key also exits

the command menu). If you are in a command’s sub-menu, press

multiple times to completely exit the command menu.

#

*

CLEAR

8.11.2 Special Command

There is one command available from the Special command menu.

• Special Enroll

Refer to Table 11 and identify the command you need to perform. Step through all

previous commands until you reach the desired command.

Table 11: Special Command Menu

Special Menu

CLEAR

Password = 5

Special Enroll

ID #

On/Off (Y/N)

Revision 1.2 Page 49

Page 50

HandPunch 1000 Installation and Operation Manual

8.11.2.1 Special Enroll

The Special Enroll command allows a user to be enrolled such that the ID number is

the primary criteria for determining access. A hand read is required, but is not verified

against any stored identification data. A time zone value can be applied to the Special

Enrollment ID number to limit access times (see page 42). The HandPunch default is

for no time zone to be applied.

NOTE

Special Enrollment affects the integrity of the HandPunch terminal and should only be

used as a last resort. Anyone who knows a Special Enroll ID number is granted access

when the ID number is used. Before specially enrolling a user, try to alleviate

verification problems by adjusting the individual user’s reject threshold (see page 42)

or by using left hand enrollment (see page 45).

Page 50 Revision 1.2

Page 51

9.0 Limited Warranty

Recognition Systems, Inc. (the “Company”) warrants to the original user the products

manufactured by the Company (the “Product”) to be free of defects in material and

workmanship for a period of three months from the date of purchase by such user or

six months from the date of shipment from the factory, whichever is sooner, provided:

1. The Company has been notified within such period by return of any alleged defective product, free and clear of all liens and encumbrances, to the Company or its

authorized dealer, transportation prepaid; and

2. The Product has not been abused, misused, or improperly maintained and/or

repaired during such period; and

3. Such defect has not been caused by ordinary wear and tear; and

4. Such defect is not the result of voltage surges/brownouts, lightning, water damage/

flooding, fire, explosion, earthquakes, tornadoes, acts of aggression/war, or similar

phenomenon; and

HandPunch 1000 Installation and Operation Manual

5. Accessories used as integral to the Product have been approved by the Company.

The Company shall, at its option, either repair or replace, free of charge, the Product

found, upon the Company’s inspection, to be so defective, or if agreed upon, refund

the purchase price, less a reasonable allowance for depreciation, in exchange for the

Product.

THE COMPANY MAKES NO OTHER WARRANTY AND ALL IMPLIED

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO THE DURATION

OF THE EXPRESSED WARRANTY PERIOD AS SET FORTH ABOVE.

THE COMPANY’S MAXIMUM LIABILITY THEREUNDER IS LIMITED TO

THE PURCHASE PRICE OF THE PRODUCT. IN NO EVENT SHALL THE

COMPANY BE LIABLE FOR ANY CONSEQUENTIAL, INDIRECT,

INCIDENTAL, OR SPECIAL DAMAGES OF ANY NATURE ARISING FROM

THE SAME OR THE USE OF THE PRODUCT.

Recognition Systems Inc. reserves the right to make changes in the design of any of its

products without incurring any obligation to make the same change on units

previously purchased.

Revision 1.2 Page 51

Page 52

HandPunch 1000 Installation and Operation Manual

This page is intentionally left blank.

Page 52 Revision 1.2

Page 53

10.0 Glossary

Address, HandPunch – A HandPunch Address is a unique identification number

assigned to a HandPunch. Each HandPunch on a network must be assigned a

unique address.

AWG – American Wire Gauge is a U.S. standard set of wire conductor sizes. The

“gauge” refers to the diameter of the wire. The higher the gauge number, the

smaller the diameter, the thinner the wire, and the greater the electrical

resistance. Thicker, smaller gauge wire carries more current because it has less

electrical resistance over a given length. Thicker wire is better for long wire

distances.

HandPunch Address – see Address, HandPunch

Platen – The Platen is the flat surface at the base of the HandPunch, on which a user

places his/her hand for enrollment and verification. The platen has guide pins

to ensure the user’s fingers are consistently positioned correctly.

Template – A Template is a set of data generated for a user. It is made up of the user’s

enrollment information and any system configuration parameters that are

assigned to the user. The template is stored at each HandPunch and can be

stored at the host computer with the Time and Attendance software.

HandPunch 1000 Installation and Operation Manual

Transaction – A Transaction is any kind of event recorded at a HandPunch.

Transactions may include In or Out punches, department transfers, and

supervisor edits.

Revision 1.2 Page 53

Page 54

HandPunch 1000 Installation and Operation Manual

Page 54 Revision 1.2

Page 55

B

C

D

E

H

I

M

HandPunch 1000 Installation and Operation Manual

Index

Biometrics, 5

Closing the HandPunch, 25

Command Menu

Entering, 29

Dip Switches

End of Line Termination, 23

Erasing HandPunch Memory, 23

Setting, 22

Enrollment

Command Menu, 43, 47

Education, 44

Hand Placement, 44

Left Hand, 45

Preparation, 44

Read Score, 45

Hand Verification

Beeper Status, 47

Display Messages, 46

LED Status, 47

HandPunch

Features, 5

Options, 9

Principle of Operation, 6

Specifications, 8

ID Numbering

System Design, 29

Management

Command Menu, 41

Mechanical Installation, 15

HandPunch, 17

Wall Plate Mounting, 16

Wall Plate, 15

Wall Preparation, 15

Wire Routing, 16

Revision 1.2 Page 55

Page 56

HandPunch 1000 Installation and Operation Manual

O

Options, 9

P

Powering On, 26

Programming, 27

Authority Level, 27

Menu Passwords, 27

Order of, 28

Special Menu, 49

R

Read Score, 45

S

Security

Command Menu

Special Enroll, 49

Service

Cleaning the HandPunch, 32

Command Menu, 35

Calibrate, 36

Status Display, 36

User Score, 33

Setup Menu, 37

Site Preparation, 11

Communications

Connection to Host Computer, 13

Modem, 14

RS-232, 13

HandPunch Placement, 11

Power, 12

Battery Backup, 12

Wiring Size, 12

Wiring, 12

Special Menu, 49

Specifications, 8

System Maintenance, 32

System Management, 29

W

Warranty, 51

Wiring Connections, 19

Page 56 Revision 1.2

Loading...

Loading...