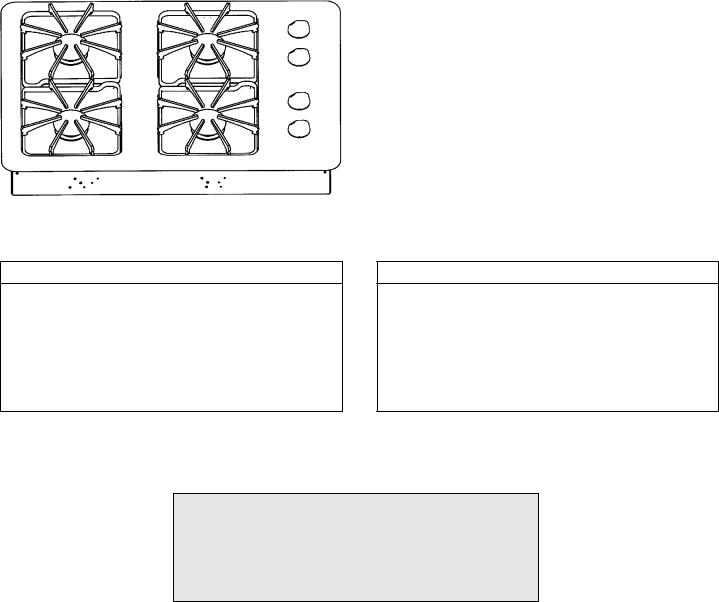

Amana AGC6356KFW, MGC4436BDW, MGC4436BDB, MGC4430BDW, MGC4430BDC Installation Instructions

...

INSTALLATION |

SEALED GAS COOKTOPS |

MANUAL |

30” and 36” |

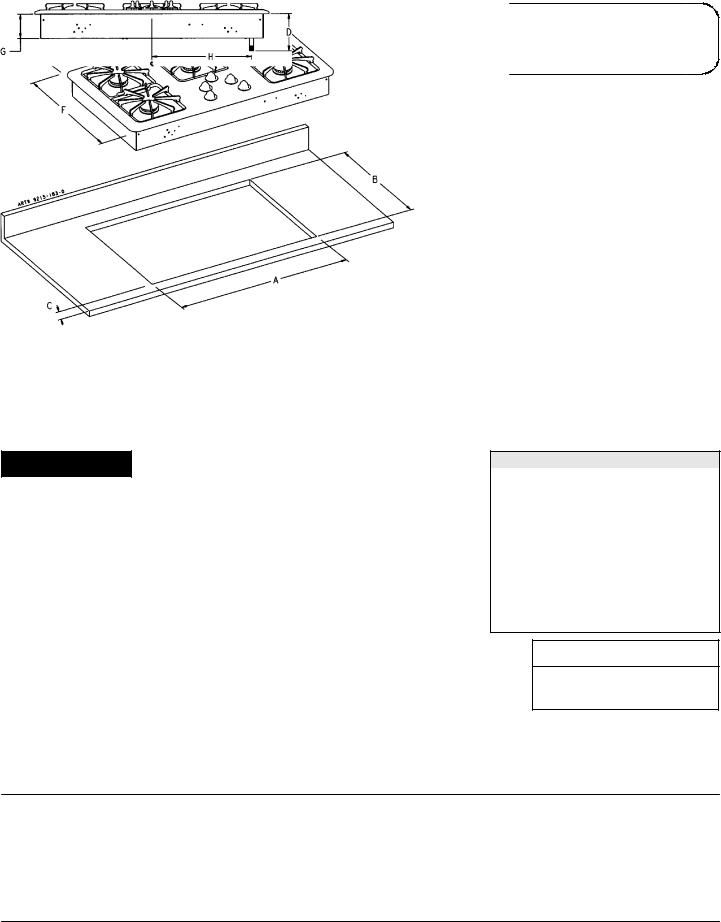

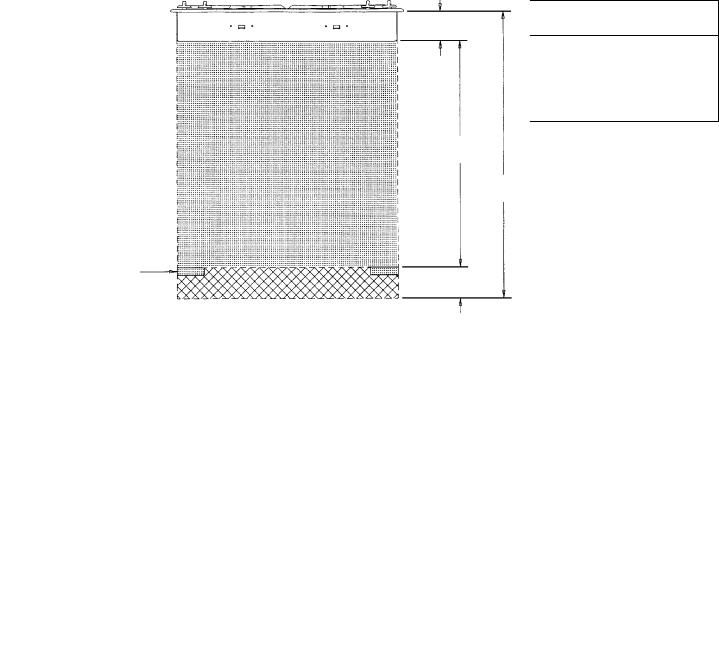

IMPORTANT: Dimensions Shown in Both Inches and Centimeters.

IMPORTANT: Be sure the appliance being installed is equipped for the gas to be supplied. Refer to serial plate on underside of burner box for this information. Do not attempt to convert this appliance for use with a gas other than the type specified.

30″ |

|

|

|

|

DIMENSIONS |

|

|

||

|

|

|

|

inches |

|

cm |

|

||

|

|

|

|

|

|

|

|||

|

|

A |

28 |

1/2 |

+ 1/16 |

72.4 |

+ |

0.2 |

|

|

|

B |

19 |

15/16 + 1/16 |

50.6 |

+ |

0.2 |

||

|

|

C |

2 |

1/8 |

+ 1/16 |

5.4 |

+ |

0.2 |

|

|

|

D |

5 |

1/4 |

+ 1/16 |

13.3 |

+ |

0.2 |

|

|

|

E |

29 |

1/2 |

+ 1/16 |

74.9 |

+ |

0.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

21 |

|

+ 1/16 |

53.3 |

+ |

0.2 |

|

|

|

G |

3 |

13/16 |

+ 1/16 |

9.7 |

+ |

0.2 |

|

|

|

H |

12 |

1/4 |

+ 1/16 |

31.1 |

+ |

0.2 |

|

|

|

|

|

|

|

|

|

|

|

DIMENSIONS

|

|

|

inches |

|

cm |

|

|||

A |

34 |

1/2 |

+ 1/16 |

87.6 |

+ |

0.2 |

|||

|

|

|

|

|

|

||||

B |

19 |

15/16 + 1/16 |

50.6 |

+ |

0.2 |

||||

C |

2 |

1/8 |

+ 1/16 |

5.4 |

+ |

0.2 |

|||

D |

5 |

1/4 |

+ 1/16 |

13.3 |

+ |

0.2 |

|||

E |

36 |

|

+ 1/16 |

91.4 |

+ |

0.2 |

|||

|

|

|

|

|

|

|

|||

F |

21 |

|

+ 1/16 |

53.3 |

+ |

0.2 |

|||

|

|

|

|

|

|

|

|||

G |

3 |

13/16 |

+ 1/16 |

9.7 |

+ |

0.2 |

|||

H |

15 |

1/4 |

+ 1/16 |

38.7 |

+ |

0.2 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CUTOUT DIMENSIONS

ARE CRITICAL

SPECIAL WARNING:

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, MAINTENANCE OR USE OF RANGE CAN RESULT IN SERIOUS INJURY OR PROPERTY DAMAGE.

NOTICE TO INSTALLER: Leave these instructions with the appliance.

NOTICE TO CONSUMER: Retain these instructions for future reference.

W10187822

(01-08-00)

Location Of Your Appliance

Locate this appliance away from combustible materials such as window curtains and combustible wall decorations.

Minimum horizontal clearance between the edge of the appliance and combustible construction extending from the cooking surface to 18″ (45.72 cm) above the cooking surface is:

1.0″ (2.54 cm) at rear

6″ (15.24 cm) at sides

(Dimensions apply to both 30″ and 36″ wide models).

cm

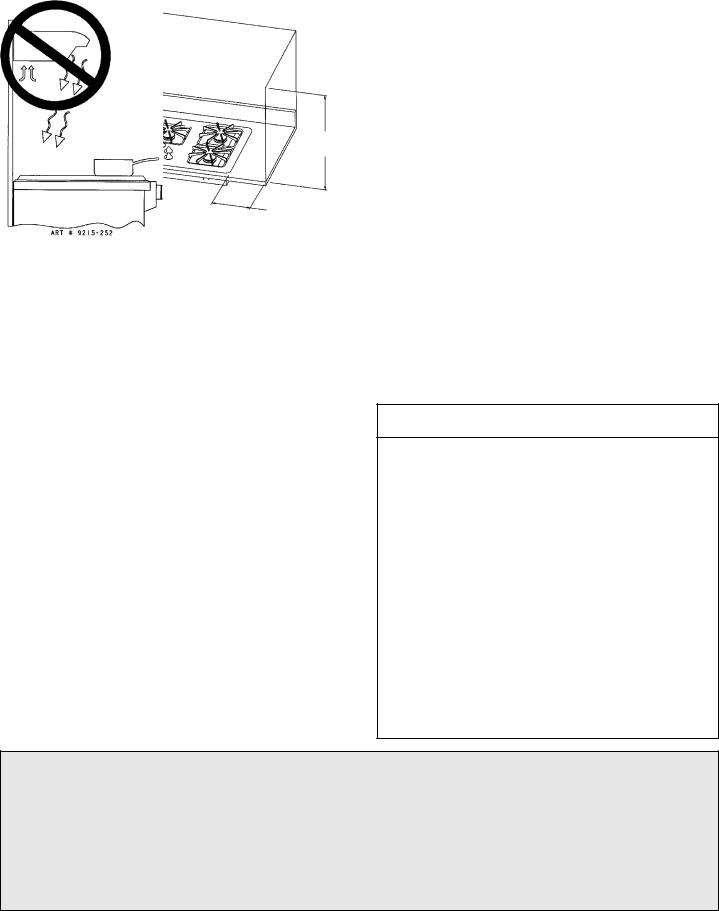

Installing Cabinetry Over Your Cooktop

A = 30″ (76.2 cm) minimum vertical clearance between cooking surface and construction above the appliance. This clearance may be reduced to not less than 24 inches (60.96 cm) by protecting the underside of the combustible material or metal cabinet above the cooking surface with not less than 1/4 inch (.635 cm) insulating millboard covered with sheet metal

not less than 0.0122 inch FIGURE 2 thick.

B = 13″ (33.02 cm) maximum depth of cabinets installed above cooktop.

Avoid use of cabinets above cooktop for storage space to eliminate associated potential hazards such as reaching over open flames.

Preparation Of Countertop

The countertop cutout must be prepared according to the illustration on page 1 of these instructions.

CAUTION: Cutout dimensions are critical. Dimensions must be measured and cut accurately to within + 1/16″ (.159 cm) to ensure proper fit.

Important Preparation Suggestions

1.Chamfer all exposed edges of decorative laminate to prevent damage from chipping.

2.Radius corners of cutout and file to insure smooth edges and prevent corner cracking. Recommend 1/4″ or 3/8″ diameter drill in each corner.

3.Rough edges, inside corners which have not been rounded and forced fits can contribute to cracking of the countertop laminate.

4.Countertop must be supported within 3″ (7.62 cm) of cutout.

WARNING

WARNING

THIS PRODUCT SHOULD NOT

BE INSTALLED BELOW A

VENTILATION TYPE HOOD

SYSTEM THAT DIRECTS AIR

IN A DOWNWARD DIRECTION.

(SEE FIGURE)

THESE SYSTEMS MAY CAUSE

IGNITION AND COMBUSTION

PROBLEMS WITH THE GAS

BURNERS RESULTING IN

PERSONAL INJURY AND MAY

AFFECT THE COOKING

PERFORMANCE OF THE UNIT.

NOTE: THE FIGURE MAY NOT ACCURATELY REPRESENT YOUR RANGE OR COOKTOP; HOWEVER, THIS WARNING APPLIES TO ALL GAS COOKING PRODUCTS.

Required Adjustments At Time Of Installation

The installation of this appliance must conform with local codes, or in the absence of local codes, with the latest edition of the National Fuel Gas Code ANSI Z223.1 USA or current CAN/CGA-B149 INSTALLATION CODE.

V

V V

This appliance was manufactured for use with Natural Gas. If LP gas is the fuel of choice, follow the conversion to LP procedure found in the installation instructions.

Test all external connections for gas leaks. Never test for gas leaks with an open flame.

Test all electrical connections.

Check the cooktop serial plate to see if the cooktop is approved for installation in mobile homes and/or recreational park trailers. Serial plate is located on the bottom of the unit.

If approved, the following items are applicable:

Mobile Homes

The installation of a range designed for mobile home installation must conform with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 [formerly the Federal Standard for Mobile Home Construction and Safety, Title 24 HUD, (Part 280)] or, when such standard is not applicable, the Standard for Manufactured Home Installations, ANSI A225.1/NFPA 501A, or with local codes.

In Canada the range must be installed in accordance with the current CSA Standard C22.1 -- Canadian Electrical Code Part 1 and Section Z240.4.1 -- Installation Requirements for Gas Burning Appliances in Mobile Homes (CSA Standard CAN/CSA -- Z240MH).

Recreational Park Trailers

The installation of a range designed for recreational park trailers must conform with state or other codes or, in the absence of such codes, with the Standard for Recreational Park Trailers, ANSI A119.5-latest edition.

In Canada the range must be installed in accordance with CAN/CSA -- Z240.6.2 -- Electrical Requirements for R.V.’s (CSA Standard CAN/CSA -- Z240 RV Series) and Section Z240.4.2 -- Installation Requirements for Propane Appliances and Equipment in R.V.’s (CSA Standard CAN/CSA -- Z240 RV Series).

Installation Of Appliance

The installation of this appliance must conform with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1--Latest Edition, or, in Canada, CAN/CGA-B149 Installation Code, Latest Edition.

This appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local codes, with the National Electrical Code ANSI/NFPA No. 70--Latest Edition, or, in Canada, current CSA Standard C22.1 Canadian Electrical Code, Part 1.

In The Commonwealth Of Massachusetts

This product must be installed by a licensed plumber or gas fitter when installed within the Commonwealth of Massachusetts.

A “T” handle type manual gas valve must be installed in the gas supply line to this appliance.

A flexible gas connector, when used, must not exceed a length of three (3) feet / 36 inches.

All supply piping, except as noted, should use common National Pipe Thread (N.P.T.). For all pipe connections use an approved pipe joint compound resistant to the action of LP gas.

CAUTION: Warranty is void on Maytag equipment installed other than as recommended by manufacturer.

This appliance is designed for use with the appliance gas pressure regulator supplied with this appliance. It must be installed in the gas line ahead of the gas manifold entrance. It is preset for use with natural gas and must be converted, as described on pages 7 and 8, for use with LP gas. (See figures 6 -- 11).

This appliance is designed to operate at a pressure of 5 inches of water column (36″ models), 4 inches of water column (30″ models) on natural gas or, if converted for use with LP gas (propane or butane), 10 inches water column. Make sure this appliance is supplied with and adjusted for the type of gas for which it is designed.

This appliance was adjusted at the factory for use with natural gas. If, at any time, this appliance is to be used with a different type of gas, all of the conversion adjustments described on pages 7 and 8 must be made by a qualified service technician before attempting to operate the cooktop on that gas. Natural gas should be supplied to the appliance pressure regulator at a line pressure between 6 and 14 inches of water column or, if converted for LP gas, between 11 and 14 inches.

WARNING

WARNING

If the line pressure supplying the appliance pressure regulator exceeds 14″ water column (any gas), an external regulator must be installed in the gas line ahead of the appliance regulator to reduce the pressure to no more than 14″ water column. Failure to do this can result in malfunction and damage to the appliance.

Insure this appliance is adjusted for the type of gas supplied to it and that the gas supply pressure to the appliance regulator is within the proper pressure range.

NOTE: In Canada, gas utilization codes prohibit use of street elbows. Use standard pipe elbows and make modifications to these instructions as necessary.

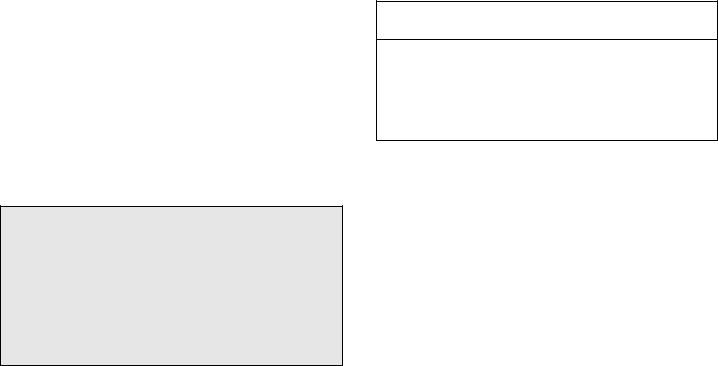

Connecting Appliance To Gas Supply

A QUALIFIED SERVICE TECHNICIAN OR GAS APPLIANCE INSTALLER MUST MAKE THE GAS SUPPLY CONNECTION. Leak testing of the appliance shall be conducted by the installer according to the instructions given.

Gas supply piping MUST conform to all local, municipal and state building codes and local utility regulations.

IF NO OTHER APPLIANCE IS TO BE INSTALLED BELOW THIS COOKTOP

Join the appliance pressure regulator supplied with this appliance to the entrance threads of the Gas Manifold. The appliance regulator is marked with a directional arrow indicating correct direction of gas flow. Ensure the appliance regulator is installed with the arrow pointing toward the gas manifold entrance. Tighten the appliance regulator to 20 to 30 ft-lbs of torque.

I M P O R T A N T

Never tighten to more than 35 ft-lbs of torque. Always use an approved pipe joint compound resistant to the action of LP gas.

Install the appliance in its counter cutout.

Make the gas connection to the inlet of the appliance pressure regulator with 1/2″ NPT male pipe threads.

Install a manual shut-off valve in an accessible location in the gas line ahead of the appliance pressure regulator and external to this appliance for the purpose of turning on or shutting off gas to the appliance.

Make additional pipe connections as necessary ahead of the shut-off valve to the gas supply source. Assure all pipe joint connections are gas tight.

I M P O R T A N T

Apply a non-corrosive leak detection fluid to all joints and fittings in the gas connection between the supply line shut-off valve and the cooktop. Include gas fittings and joints in the cooktop if connections were disturbed during installation. Check for leaks! Bubbles appearing around fittings and connections will indicate a leak. If a leak appears, turn off supply line gas shut-off valve, tighten connections, turn on the supply line gas shut off valve, and retest for leaks. Never test for gas leaks with an open flame.

ILLUSTRATIVE GAS SUPPLY PIPING

(3/8″ N.P.T.)

ALL SUPPLY SIDE

PIPE JOINTS

1/2″ N.P.T.

FIGURE 3

WARNING

WARNING

Gas leaks may occur in your system and result in a dangerous situation. Gas leaks may not be detected by smell alone. Gas suppliers recommend you purchase and install an UL approved gas detector. Install and use in accordance with the manufacturer’s instructions.

Alternative Piping Methods To Connect Appliance To Gas Supply

A TRAINED SERVICE TECHNICIAN OR GAS APPLIANCE INSTALLER MUST MAKE THE GAS SUPPLY CONNECTION. Leak testing of the appliance shall be conducted by the installer according to the instructions given.

Unless prohibited by local codes or ordinances, a new A.G.A. -- Certified, flexible metal appliance connector may be used to connect this appliance to its gas supply. The connector must be no more than 5 feet in length. Per figure 5, use appropriate flare union adapter at each end of the flexible connector. If a flexible connector is used assure that both the appliance pressure regulator and manual shut-off valve are joined solidly to other permanent hard piping (either gas supply or the appliance manifold) so as to be physically stationary. See illustrations below.

CAUTION: Do not attempt to attach the flexible connector directly to an external pipe thread. Connection requires flare union adapters.

I M P O R T A N T

Apply a non-corrosive leak detection fluid to all joints and fittings in the gas connection between the supply line shut-off valve and the range. Include gas fittings and joints in the range if connections were disturbed during installation. Check for leaks! Bubbles appearing around fittings and connections will indicate a leak. If a leak appears, turn off supply line gas shut-off valve, tighten connections, turn on the supply line gas shut off valve, and retest for leaks. Never test for gas leaks with an open flame.

Pressure Testing

The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 pounds per square inch (3.5 kPa).

This appliance, as well as its individual shut-off valve, must be disconnected from the gas supply piping system during any pressure testing of the system at test pressures in excess of 1/2 pounds per square inch (3.5 kPa).

When checking appliance regulator function, make certain pressure of natural gas supply is between 6 and 14 inches of water column or, if converted for LP gas, between 11 and 14 inches of water column.

ILLUSTRATIVE ALTERNATIVE PIPING

Manifold

Entrance

Appliance Pressure Regulator, Supplied (Observe directionality of Gas Flow)

Flare Union Adaptor

1/2″ N.P.T. Flexible Appliance Connector (5 ft. max.)

3/8″ N.P.T.

Flare Union Elbow

Adaptor

3/8″ N.P.T. Flexible Appliance Connector (5 ft. max.)

Flare Union Adaptor |

Flare Union Adaptor |

|

|

||

Gas Shut-Off Valve |

Appliance Pressure |

|

Regulator, Supplied |

||

|

||

|

(Observe |

|

|

directionality of Gas |

|

1/2″ N.P.T. Pipe |

Flow) |

|

|

||

(Stationary Supply Pipe) |

|

|

|

1/2″ N.P.T. Pipe |

|

|

Nipple |

|

|

Gas Shut-Off Valve |

|

|

1/2″ N.P.T. Pipe |

|

|

(Stationary Supply |

|

FIGURE 4 |

Pipe) |

|

|

Electrical Wiring Information

This appliance is equipped with a grounded type power cord. A grounded outlet must be provided. It is recommended, for convenience, the outlet be located within either the shaded area or the cross hatched area shown in figure 5.

User may experience occasional circuit tripping if Ground Fault Circuit Interrupter (GFCI) outlet or breaker is in use.

WARNING

WARNING

Electrical Grounding Instructions

This appliance is equipped with a (three-prong) grounding plug for your protection against shock hazard and should be plugged directly into a properly grounded receptacle. Do not cut or remove the grounding prong from this plug.

In planning any installation, note that the free length of this appliance’s power cord, extending beyond a point 3-3/4″ (9.53 cm) left of the nominal center of the rear wall of the burner box, when viewed from the front of the unit, is approximately 46″ (117 cm).

WARNING

WARNING

THIS APPLIANCE MUST BE DISCONNECTED FROM ITS ELECTRICAL SUPPLY AT THE WALL RECEPTACLE BEFORE SERVICING THE APPLIANCE.

3 13/16″

9.7 cm

29 3/8″

74.61 cm

37 3/16″

94.46 cm

3 1/2″ (8.89 cm) WIDE |

4″ MAX. |

|

SLATS WHEN A WALL |

||

10.16 cm |

||

OVEN IS INSTALLED |

||

CABINET BOTTOM |

||

BELOW 30″ MODEL |

FIGURE 5

Converting Appliance For Use

With LP Gas

WARNING

WARNING

Propane conversion is to be performed by a AUTHORIZED SERVICER (or other qualified agency) in accordance with the manufacturer’s instructions and all codes and requirements of the authority having jurisdiction. Failure to follow instructions could result in serious injury or property damage. The qualified agency performing this work assumes responsibility for this conversion.

WARNING

WARNING

Electrical power and gas must be turned off prior to conversion.

This appliance was adjusted at the factory for use with natural gas. To convert it for use with LP gas (propane or butane), each of the following modifications must be performed: (A, B, and C)

A.REPLACE ALL ORIFICE SPUDS

Step 1: Remove the grates and burner caps.

Step 2: Remove burner base by removing 2 screws. (See figure 6).

Step 3: Firmly press 9/32″ (or 7mm) nut driver over the orifice spud (figures 6 and 7) and loosen spud by turning counterclockwise. Carefully lift nut driver out of burner throat. Orifice spud should be captured in the nut driver. Repeat steps 2 & 3 for each burner.

REMOVAL OF ORIFICE SPUD

Orifice

Spud

FIGURE 7

FIGURE 6

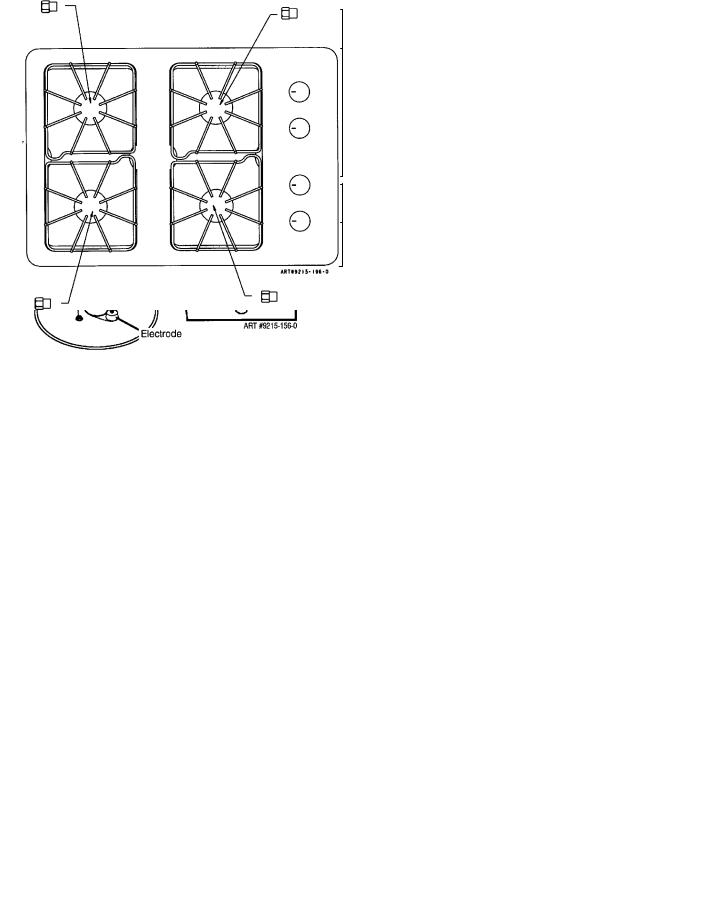

Installation Of LP Orifice Spud

0.91 |

0.91 |

0.91 |

0.91 |

0.97 |

|

FIGURE 8

Step 4: Locate the LP orifice spud packet included in the literature packet. The spuds have small numbers stamped on the side. This number codes the orifice diameter and its correct burner location. Figures 8 and 9 show the correct LP orifice spud location.

Step 5: Carefully install the orifice spud in the appropriate burner throat by turning clockwise to tighten. Tighten to a torque of 15 to 20 inch-lbs.

Step 6: Replace burner base, caps, and grates. Tighten screws (do not cross thread) to 25-30 in lbs.

Step 7: Save the orifices removed from the appliance for future use.

0.91 |

0.91 |

|

0.91 |

0.91 |

|

FIGURE 9

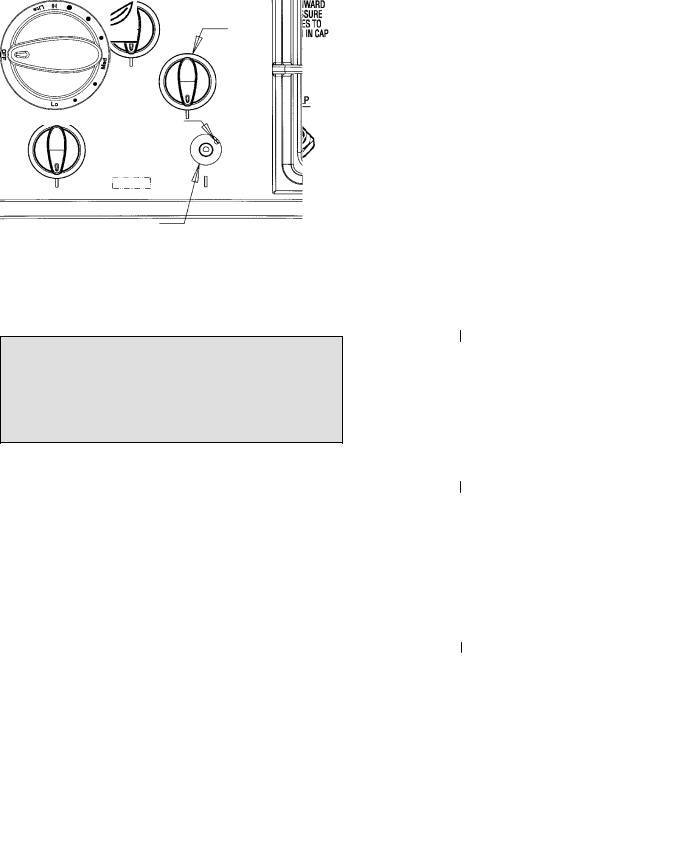

B.INVERT CAP IN APPLIANCE PRESSURE

REGULATOR (See figure 10)

With the appliance installed, the appliance regulator should be located as shown in figures 3 or 4.

CONVERSION OF APPLIANCE

C.LOW FLAME ADJUSTMENT (See figure 11)

This appliance is shipped from the factory with low and high flame settings adjusted for use with natural gas. To set for use with LP proceed as follows:

1. Remove control knob from valve stem.

CAUTION: NEVER USE A METAL BLADE TO PRY KNOB OFF. IF KNOB CANNOT BE EASILY REMOVED, TUCK THE FOLDS OF A CLOTH DISHTOWEL UNDER THE KNOB AND PULL THE TOWEL UPWARD WITH STEADY, EVEN PRESSURE.

2.Carefully remove rubber grommet.

3.Locate the valve adjustment screw. See figure 11.

4.Insert a slender, thin-blade screwdriver into knob hole and engage blade with slot in adjusting screw.

5.Turn the adjusting screw clockwise until tight (5-7 in-lbs max.). Do not over tighten.

6.Replace rubber grommet and control knob.

7.Repeat for remaining burners.

KNOB

ADJUSTMENT

SCREW

KNOB HOLE

(KNOB AND GROMMET REMOVED)

After adjusting the screw the burner should produce a stable, steady blue flame of minimum size. The setting should be checked by turning knob from high to low several times without extinguishing the flame.

This operation will automatically provide the proper flame size at medium setting.

After Conversion Steps A, B and C have been completed, check the appearance of each burner flame at the Hi and Lo settings against figure 12. If the flames appear too large or too small, review each step to make sure it was completed correctly.

FLAME APPEARANCE AT HI AND LO

FIGURE 12

FIGURE 11

To Convert Appliance For Use With

Natural Gas

WARNING

WARNING

Electrical power and gas must be turned off prior to conversion.

If this appliance has been converted for use with LP gas, each of the following modifications must be performed to convert the unit back to natural gas.

A.REPLACE ALL ORIFICE SPUDS.

1.Perform Steps 1 and 2 on page 7.

2.Perform Step 3 on page 7.

3.For Step 4: Locate the brass natural gas orifice spuds that were originally installed in this appliance before its conversion for use with LP gas. Observe the number on each of the spuds and note the correct burner location for each spud as shown in figures 13 and 14.

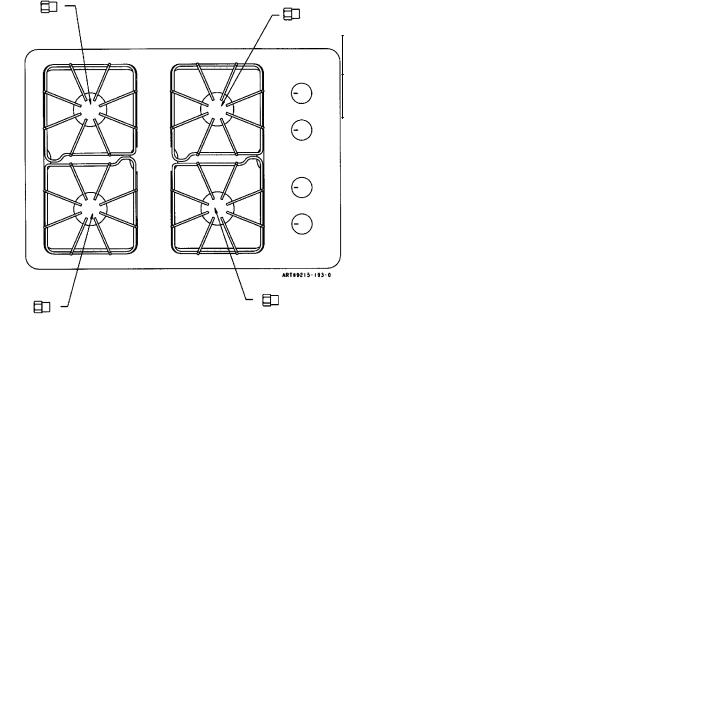

Installation Of Natural Gas Orifice Spuds

5 BURNER MODEL (36″ WIDE)

4 BURNER MODEL (30″ WIDE)

1.55 |

1.55 |

|

1.55 |

1.85 |

|

FIGURE 14 |

||

|

4.Complete Steps 5, 6 and 7 on page 7 to complete the installation of natural gas main spuds in their correct locations.

5.Save the orifices removed from the appliance for future use. They will be needed if this appliance is again converted for use with LP gas.

1.55 |

1.42 |

1.42

FIGURE 13

1.42B. INVERT CAP IN APPLIANCE PRESSURE REGULATOR. (See figure 10).

With the appliance installed the appliance regulator should be located as shown in either figure 3 or 4 (pages 4 & 5). Identify the type of appliance regulator and follow the instructions in the appropriate illustration.

C.RESET THE VALVES FOR NATURAL GAS

1.Light one burner, and set on low.

2.Remove the knob.

3.Remove the rubber grommets.

4.Locate the valve adjustment screw. See figure 11.

1.615. Insert a slender, thin-blade screwdriver into knob hole and engage blade with slot in adjusting screw.

6.Starting from the LP position (see #5 on page 8, under C. LOW FLAME ADJUSTMENT), turn the screw counter clockwise until the flame stabilizes and matches the pictured “low” setting on figure 12. Proper adjustment will produce a stable, steady blue flame of minimum size. The final adjustment should be checked by turning the knob from high to low several times without extinguishing the flame.

After Steps A, B and C have been completed, check the appearance of each burner’s flame at the Hi and Lo settings against figure 12. If the flames appear too large or too small, make sure all steps were completed correctly.

Burner Performance

CAUTION: Never cover control knobs or surrounding control surface with utensils, towels, or other objects. Never obstruct free air passage past the control knobs. The knob openings have been sized to properly control air entry to the interior of the appliance during operation.

This appliance has no air shutters. Primary air adjustments are unnecessary. The burners are designed to provide optimum aeration for all gases without air

shutters. When operating properly, burners should produce clearly defined, even blue flames. If the flames have yellow tips or are hazy and otherwise appear to have insufficient air, obtain the services of a qualified service technician. Some yellow tipping on LP gas is normal.

Specified input rates are as shown in figures 15 and 16 below.

5 BURNER MODEL (36″ Wide) |

4 BURNER MODEL (30″ Wide) |

FIGURE 15

36″ Cooktop

INPUT RATES - NATURAL GAS / LP GAS (BTU/HR)

BURNER LOCATION |

Hi |

|

Lo |

|

Right Front |

12,500 |

/ 10,500 |

1300 / 1300 |

|

Right Rear |

9,200 |

/ |

9,100 |

1300 / 1300 |

Left Front |

9,200 |

/ |

9,100 |

1300 / 1300 |

Left Rear |

10,500 |

/ |

9,100 |

1300 / 1300 |

Center |

9,200 |

/ |

9,100 |

1300 / 1300 |

|

|

|

|

|

FIGURE 16

30″ Cooktop

INPUT RATES - NATURAL GAS / LP GAS (BTU/HR)

BURNER LOCATION |

Hi |

|

Lo |

|

Right Front |

12,500 |

/ 10,500 |

1300 / 1300 |

|

Right Rear |

9,200 |

/ |

9,100 |

1300 / 1300 |

Left Front |

9,200 |

/ |

9,100 |

1300 / 1300 |

Left Rear |

9,200 |

/ |

9,100 |

1300 / 1300 |

Center |

---------------------- |

---------------------- |

||

|

|

|

|

|

High Altitude Notice

The specified gas burner ratings typically apply to elevations up to 2000 feet. For higher altitudes, the rates may need to be reduced to achieve satisfactory operation. A local certified gas servicer will be able to advise if a reduction is necessary.

Loading...

Loading...