Page 1

OPERATOR’S MANUAL

WARNING

WARNING

CT PROFORMANCE™

CTP6-10E

CTP10-10E

CTP7-20E

CTP10-20E

CTP20-10E

CTP20-20E

CTP6-10G

CTP10-10G

CTP7-20G

CTP10-20G

CTP20-10G

CTP20-20G

To prevent personal injury, death or

property damage:

Do not store or use gasoline or other

flammable vapors or liquids in the vicinity

of this or any other appliance.

Improper installation, alteration,

adjustment, service, cleaning, or

maintenance could result in property

damage, severe injury, or death.

Read and understand the installation,

operating and maintenance instructions

thoroughly before installing, servicing, or

operating this equipment.

MN-35948 Rev 14

EN

07/17

Page 2

DANGER

This manual covers the following CTP series models:

Boiler-Free Models Steam Generator Models

6-10E, 6-10G

10-10E, 10-10G

7-20E, 7-20G

10-20E, 10-20G

20-10E, 20-10G

20-20E, 20-20G

Please post the following instructions in a prominent location

in the event the user smells gas.

6-10EB

10-10EB

7-20EB

10-20EB

20-10EB

20-20EB

Before starting the appliance, make certain

you do not detect the odor ofgas.

If you smell gas:

• Shut off the gas supply immediately.

• Do not attempt to light any appliance.

• Do not touch any electrical elements.

• Extinguish any open flame.

• Evacuate the area.

• Use a telephone outside the property and

immediately contact your gas supplier.

• If unable to contact your as supplier,

contact the fire department.

Page 3

Enjoy your Alto-Shaam Combi Oven!

The combi oven combines a steam and convection oven into

one versatile unit and can serve a variety of cooking functions.

Alto-Shaam’s combi ovens allow chefs to control humidity and

temperature separately, with powerful results. The same oven

can be used to dehydrate vegetables, roast pork, steam rice,

smoke brisket and bake loaves of bread.

The PROtouch™ recipe management system with one-touch

cooking provides complete control over the oven, allowing chefs

and foodservice employees to select pre-programmed recipes

Before Use

If this is the rst time this oven is being used, or if the oven has

just been removed from storage, follow these steps for cleaning:

1. Remove all packing material from the oven,

2. Remove and wash any detachable items such as wire shelves,

side racks, pans, and drip trays with hot, soapy water. Dry

with a clean, damp lint-free cloth.

3. Remove all visible grease or oil from the oven.

4. Clean the interior and exterior of the oven with a mild soap

and water solution. Apply the solution with a clean, damp

cloth. Do not use commercial or household cleaners that

contain ammonia. Wipe with a clean, damp cloth to remove

all detergent residue. Dry with a clean, lint-free cloth.

Introduction

Introduction

for maximum consistency. To store and secure important

information, a HACCP data system pairs up with an onboard USB

port, so settings can be downloaded and saved for the future.

When it’s time to clean up, Alto-Shaam’s CombiClean Plus™

automated cleaning system saves labor previously spent

scrubbing the oven cavity. On the oven’s exterior, a PROrinse™

retractable hose gives you spray-washing power without opening

the oven door.

5. Clean the oven glass with glass cleaner or distilled vinegar.

Re-install the side racks and wire shelves – position shelves

with the curved end up and toward the rear of the oven.

When cleaning is complete, the oven must acclimate to room

temperature in the environment where it is placed.

Twenty four (24) hours is recommended.

The oven is now ready for operation.

EXTEND YOUR ORIGINAL MANUFACTURER’S WARRANTY

Register online today at www.alto-shaam.com/warranty

Register your Alto-Shaam appliance online, and you will automatically be

entered into a monthly drawing to win an additional year extended warranty!

Registering your equipment ensures prompt service in the event of a warranty

claim. You will also receive direct notifications of soware updates and additional

product information.

Your personal information will not be shared with any other company.

ALTO-SHAAM 24/7 EMERGENCY REPAIR SERVICE

Call 800-558-8744 to reach our twenty-four hour emergency service call center

for immediate access to local authorized service agencies outside standard business hours. The

emergency service access is provided exclusively for Alto-Shaam equipment and is available

throughout the United States through Alto-Shaam’s toll free number.

Emergency service access is available seven days a week, including holidays.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 3

Page 4

4 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 5

Table of Contents

Introduction .....................................3

Safety Procedures ................................6

Operation .......................................9

How to Turn On the Oven ....................................9

How to Start a Manual Calibration ............................9

How to Calibrate theTouch Screen ............................9

How to Turn O the Oven ....................................9

Control Panel Identification .................................10

Home Screen ............................................10

Utility Screen ............................................10

Upload/Download Screen ................................10

Setting Screen 1 .........................................11

Setting Screen 2 .........................................11

Preventative Maintenance Screen .........................12

Preventative Maintenance - Editing .......................12

Soware Updates ..........................................13

Cooking Screen Identification ............................14

Auxiliary Functions and Features ............................15

Power Settings ..........................................15

Multiple Fan Speeds .....................................15

Multi-Shelf Timer ........................................15

Preheat Features ........................................16

Cool-Down Feature ......................................16

Humidity Control Feature ................................17

Rapid Cool ..............................................17

Rest .....................................................17

Door ....................................................17

Factory Default Settings .....................................18

Cooking Modes - Steam .....................................19

Steam Mode Operating Tips .................................20

Cooking Modes - Combination ..............................21

Combination Mode Operating Tips ..........................22

Cooking Modes - Convection ................................23

Convection Mode Operating Tips ............................24

Cooking Modes - Retherm ...................................25

Retherm Mode Operating Tips ...............................26

Cooking Modes - Dehydration ...............................27

Dehydration Mode Operating Tips ...........................28

Cooking Modes - Delta-T Core Temperature ..................29

CombiSmoker® Procedures .................................30

Recipe Programming .......................................32

Using Programmed Recipes ..............................33

To Cook with Preprogrammed Recipes ....................33

Editing Programmed Recipes .............................34

Organizing Programmed Recipes .........................35

HACCP Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

HACCP Access and Download ...............................38

Options ........................................39

CombiHood PLUS™ Ventless Hood ..........................39

Connecting the Optional Grease Collection System ...........40

Connecting the Optional Liquid Cleaner. . . . . . . . . . . . . . . . . . . . . .41

How To Use the Combilatch™ Door Interlock .................42

Recipe Guidelines ...............................43

Bakery Items ...............................................43

Convenience Product Items .................................45

Fish & Seafood Items .......................................46

Meat Recipes ...............................................47

Miscellaneous Recipes ......................................49

Poultry Recipes .............................................50

Vegetable Recipes ..........................................52

Cleaning and Preventative Maintenance ............54

CombiClean® Cleaning Agents ...............................54

Preventive Maintenance ....................................55

Weekly Maintenance ........................................56

Daily Inspection ............................................57

Weekly Inspection ..........................................58

Monthly Inspection .........................................59

Yearly Inspection ...........................................60

Protecting Stainless Steel Sufaces ...........................63

Cleaning Agents ............................................63

Cleaning Materials ..........................................63

Daily Cleaning of the Oven ..................................64

Probe and Probe Prong Cleaning ............................64

Roll-In Cart/Food Trolley Cleaning ...........................64

CT PROtouch™ with CombiClean® ...........................65

CT PROtouch™ with Automatic Liquid Cleaning ...............66

Troubleshooting .................................67

Error Codes ................................................67

Touch Motor Control Error Codes ............................73

Notes ..........................................74

Limited Warranty ................................75

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 5

Page 6

Safety Procedures

• The appliance is intended to cook, hold or process foods

Knowledge of proper procedures is essential to the

for the purpose of human consumption. No other use for

this appliance is authorized and is therefore considered

dangerous. The appliance must not be used to cook

food containing ammable materials (such as food with

alcohol). Substances with a low ash point can ignite

spontaneously and cause a re.

• The appliance is intended for use in commercial

establishments where all operators are familiar with

the purpose, limitations, and associated hazards of this

appliance. Operating instructions and warnings must

be read and understood by all operators and users.

Alto-Shaam recommends regular staff training to avoid

the risk of accident or damage to the appliance. Operators

must also receive regular safety instructions.

• Any troubleshooting guides, component views, and

partslists included in this manual are for general

reference only and are intended for use by quali ed and

trained technicians.

• This manual should be considered a permanent part of

this appliance. This manual and all supplied instructions,

diagrams, schematics, parts lists, notices, and labels must

remain with the appliance if the item is sold or moved to

another location.

safe operation of electrically and/or gas energized

equipment. The following signal words and symbols

may be used throughout this manual.

DANGER

Indicates a hazardous situation that, if not avoided, will

result in death or serious injury.

WARNING

Indicates a hazardous situation that, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a hazardous situation that, if not avoided, could

result in minor or moderate injury.

notICE: Indicates information considered important,

but not hazard-related (e.g., messages relating

to property damage).

notICE: For equipment delivered for use in any

location regulated by the following

directive: 2012/95/EC WEEE

Do not dispose of electrical or electronic

equipment with other municipal waste.

6 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 7

Safety Procedures

• To prevent serious injury, death or property damage,

• If the gas appliance is installed under an exhaust

appliance is in use to avoid the build up of combustion

vents. Thisarea is hot and could be a potential ignition

suddentemperature change can damage the appliance

the appliance should be inspected and serviced at

least every twelve (12) months by an authorized

service partner or trained technician.

• Only allow an authorized service partner or trained

technician to service or to repair the appliance.

Installation or repairs that are not performed by an

authorized service partner or trained technician, or

the use of non-factory authorized parts will void the

warranty and relieve Alto-Shaam of all liability.

• When working on this appliance, observe precautions

in the literature, on tags, on labels attached to

or shipped with the appliance and other safety

precautions that may apply.

• If the appliance is installed on casters freedom of

movement of the appliance must be restricted so

that utility connections (including gas, water, and

electricity) cannot be damaged when the appliance

is moved. If the appliance is moved, ensure that all

utility connections are properly disconnected. If the

appliance is returned to its original position, ensure

that retention devices and utility connections are

properly connected.

• Only use the appliance when it is stationary. Mobile

appliance racks, mobile plate racks, transport trolleys,

andappliances on casters can tip over when being

moved over an uneven oor or threshold and cause

serious injury.

• Always apply caster brakes on mobile appliances or

accessories when these are not being moved. These

items could move or roll on uneven oors and cause

property damage or serious injury.

• Be extremely careful when moving appliances

because the food trays may contain hot uids that may

spill, causing serious injury.

• Always open the appliance door very slowly. Escaping

hot vapors or steam can cause serious injury or death.

hood, the hood must be switched On when the

gases. Failure to do so may result in serious injury,

death or property damage.

• Accumulations on the main burners of gas appliances

can result in ring out of normal sequence. This

delayed ignition creates an alarmingly loud sound.

If your appliance makes an especially loud noise

when starting up, shut down the appliance and call a

quali ed and trained service technician.

• NEVER place objects near the appliance exhaust

source for a re.

• Do not allow objects to block or obstruct the area

below the appliance base. This may result in re,

damage to the equipment or serious injury.

• Do not use the attached hand-held hose to

sprayanything other than the interior of the

appliancecompartment.

• Do not use the attached hand-held hose on the

surface of a hot cooking compartment. The

interior. Allow the appliance to cool to a minimum of

150°F(66°C). Failure to observe this precaution can

void the warranty.

WARNING

This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision

concerning use of the appliance by person

responsible for their safety.

Children should be supervised to ensure

that they do not play with the appliance.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 7

Page 8

Safety Procedures

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

To prevent serious personal injury, death, or

property damage:

Do not steam clean, hose down or flood the

interior or exterior with water or liquid solution

of any kind. Do not use water jet toclean. Failure

to observe this precaution will void the warranty.

To prevent SERIOUS PERSONAL INJURY or

PROPERTY DAMAGE:

DO NOT handle pans containing liquid or

semiliquid products positioned above the

eye level of the operator. Such products

may scald and cause serious injury.

DO NOT obstruct or block exhaust flues

or attach any flue extension that may

impede proper burner operation, restrict

the exhaust fumes and cause negative

backdra or the appliance to shut down.

Failure to do so may result in serious injury

or death.

To prevent serious personal injury, death,

or property damage:

The appliance must be cleaned thoroughly

to avoid deposits of grease and or food

residues inside the appliance that may

catch fire. If fat deposits and/or food waste

inside the appliance ignite, shut down

the appliance immediately and keep the

appliance door closed to extinguish the

fire. If further extinguishing is required,

disconnect the appliance from the main

power and use a fire extinguisher (do not

use water to extinguish a grease fire!).

Failure to clean the appliance properly

invalidates the warranty and relieves

Alto-Shaam of all liability.

To prevent personal injury or

propertydamage:

Always use hand protection when

operating this appliance to avoid burns.

Metal parts of this equipment become

extremely hot when in operation.

notICE: Automatic steam venting is a standard safety

feature built into all Combitherm oven models.

This feature vents all steam from the oven

compartment immediately before cooking time

expires or set probe temperature is reached.

Automatic steam venting does not function if the

oven door is opened before time expires or when

the oven has been set to continuous operation.

8 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

To prevent INJURY or PROPERTY DAMAGE,

make certain the area around the appliance

is kept clear of combustible items.

notICE: Use authorized Combitherm oven cleaner only.

Unauthorized cleaning agents may discolor or

harm interior surfaces of the oven. Read and

understand label and material safety data sheet

before using the oven cleaner.

Page 9

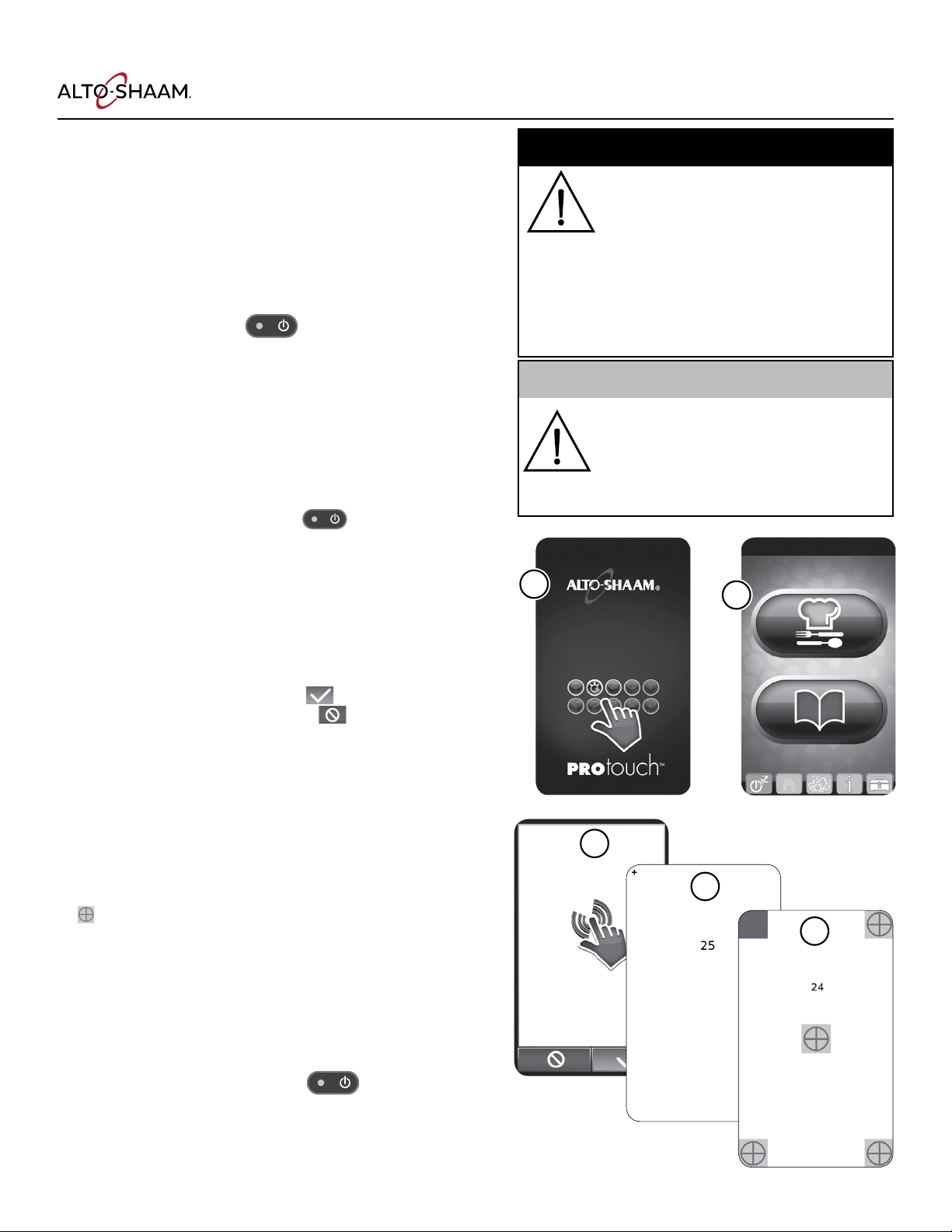

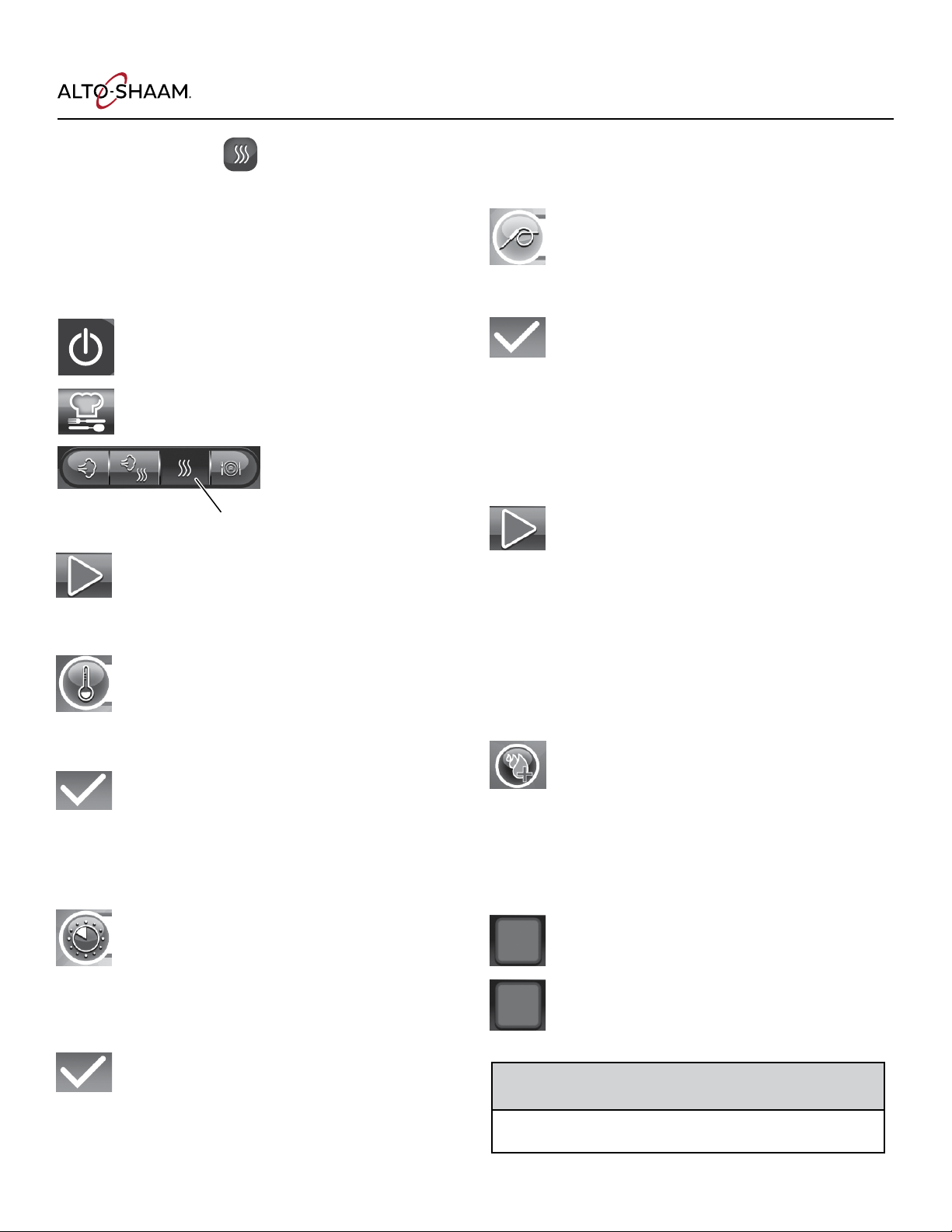

How to Turn On the Oven

Prerequisites

1. Turn on the exhaust hood.

2. Make sure that the water supply to the oven is turned on.

3. Make sure that the electrical power supply to the oven is

turned on.

4. For gas ovens, make sure the gas supply valve is in the open

position.

Steps

1. Press the ON/OFF button

The ON/OFF indicator glows green and the loading screen

displays while the controller soware loads. When the

soware is 100% loaded, the home screen b displays.

notE: If the oven has a steam generator, the steam generator

lls with water and the oven heats the water to an initial

temperature of 188°F (77°C).

.

a

How to Start a Manual Calibration

1. Make sure the oven is off.

2. Press and hold the ON/OFF button for eight (8) seconds.

The ON/OFF indicator glows red and the calibration prompt c

displays.

The prompt moves from the center to all four corners of

the screen. This sequence repeats three (3) times. Then the

calibration screen

notE: The rst time the oven is turned on, or if the oven loses

power during startup, the touchscreen calibration prompt

displays at the end of the next startup.

notE: Touch the check mark icon to start the calibration

immediately. Touch the cancel icon to cancel the

calibration.

d

displays.

c

Operation

DANGER

Before starting the appliance, make certain you do

not detect the odor ofgas.

If you smell gas:

• Shut o the gas supply immediately.

• Do not attempt to light any appliance.

• Do not touch any electrical elements.

• Extinguish any open flame.

• Evacuate the area.

• Use a telephone outside the property and

immediately contact your gas supplier.

• If unable to contact your as supplier, contact the

fire department.

CAUTION

Accumulations on the main burners of gas

appliances can result in firing out of normal

sequence. This delayed ignition creates an

alarmingly loud sound. If your appliance makes

an especially loud noise when starting up, shut

down the appliance and call a qualified and

trained service technician.

1

2

How to Calibrate the Touchscreen

1. Touch the target icon (+) each time it appears on screen. The

icon appears in all four corners, then the center of the screen.

notE: If the controller soware has not been updated to

the current version (11/16 update), the calibration stops

when this step is complete. Download the current controller

soware from the Alto-Shaam website and install it.

2. The verication screen e displays. Touch all ve target icons

. The icons change to green boxes when they are touched.

notE: The calibration screen and verication screen both

display a 30-second countdown. If you do not touch all ve

icons before the countdown is complete, the controller stops

the calibration. If you do not see the countdown, download

the current controller soware from the Alto-Shaam website

and install it.

How to Turn Off the Oven

1. Press and hold the ON/OFF button for ve to

ten (5-10) seconds.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 9

3

4

5

Page 10

Operation

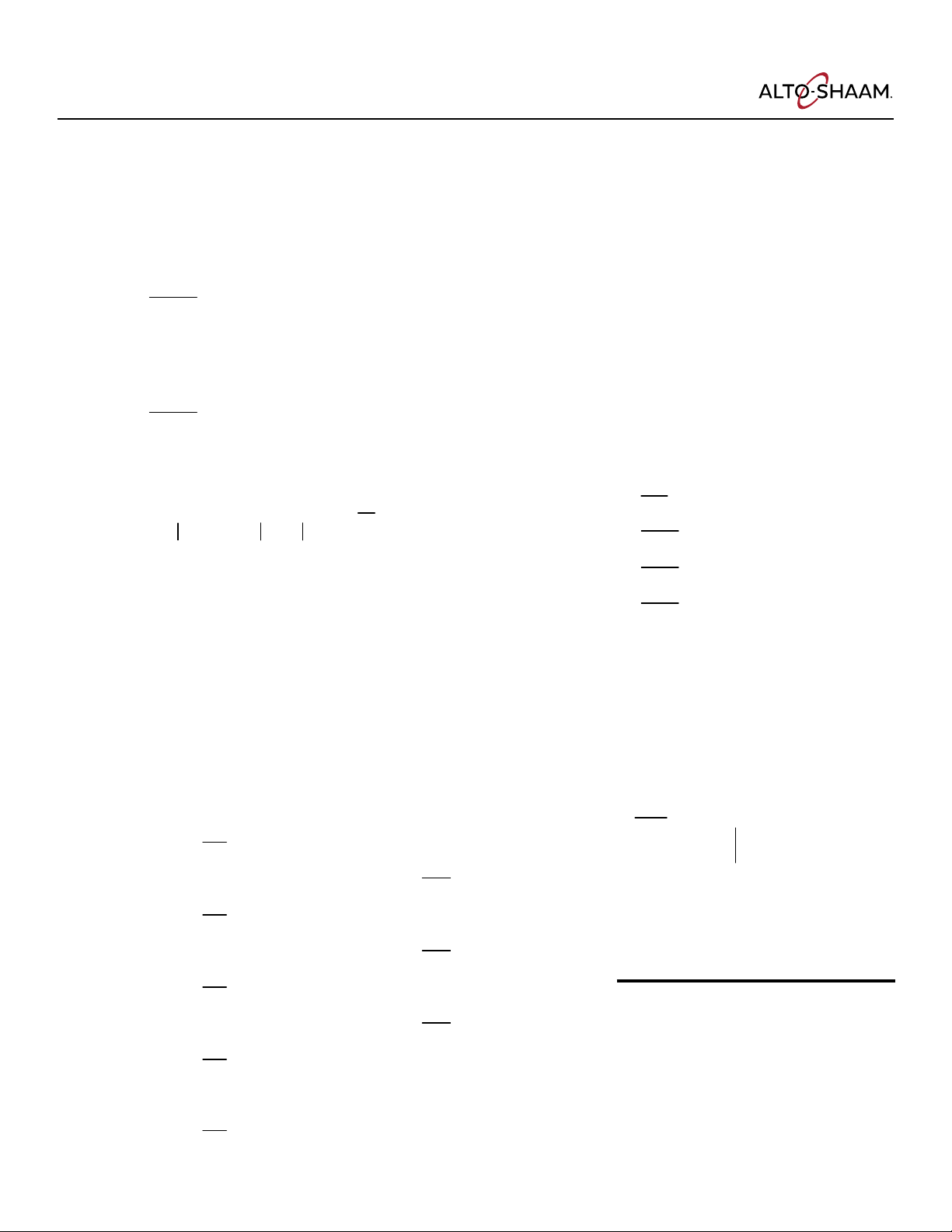

Control Panel Identi cation

Control Panel Identication

Professional

Cooking Mode

Cookbook with

Saved Recipes

CleaningSleep Mode

Information

Call outs

Utility Screen

So ware Version

Utilities

Upload/Download

Settings

Download Recipes from

USB stick — overwrites

any existing recipes

Add all recipes on a

USB stick to the list of

recipes on the oven

leaving all other recipes

on the oven untouched

*Download new

so ware from a

USBstick

Upload odometer

info to USB stick

Return to

previous screen

Upload/Download Screen

(password protected)

Upload all recipes

from control to a

USB stick

Upload HACCP

info to USB stick

Upload audit trail

info to USB stick

Service Mode

Return to

previous screen

Return to

home screen

* The PROtouch control plays an

important part in our continuous

improvement process. New features

and abilities can be loaded to your

oven as they become available.

So ware for your oven can be

accessed from the Alto-Shaam

website, under the Downloads tab.

10 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 11

Control Panel Identi cation

recipe display with text, and recipes are not

Operation

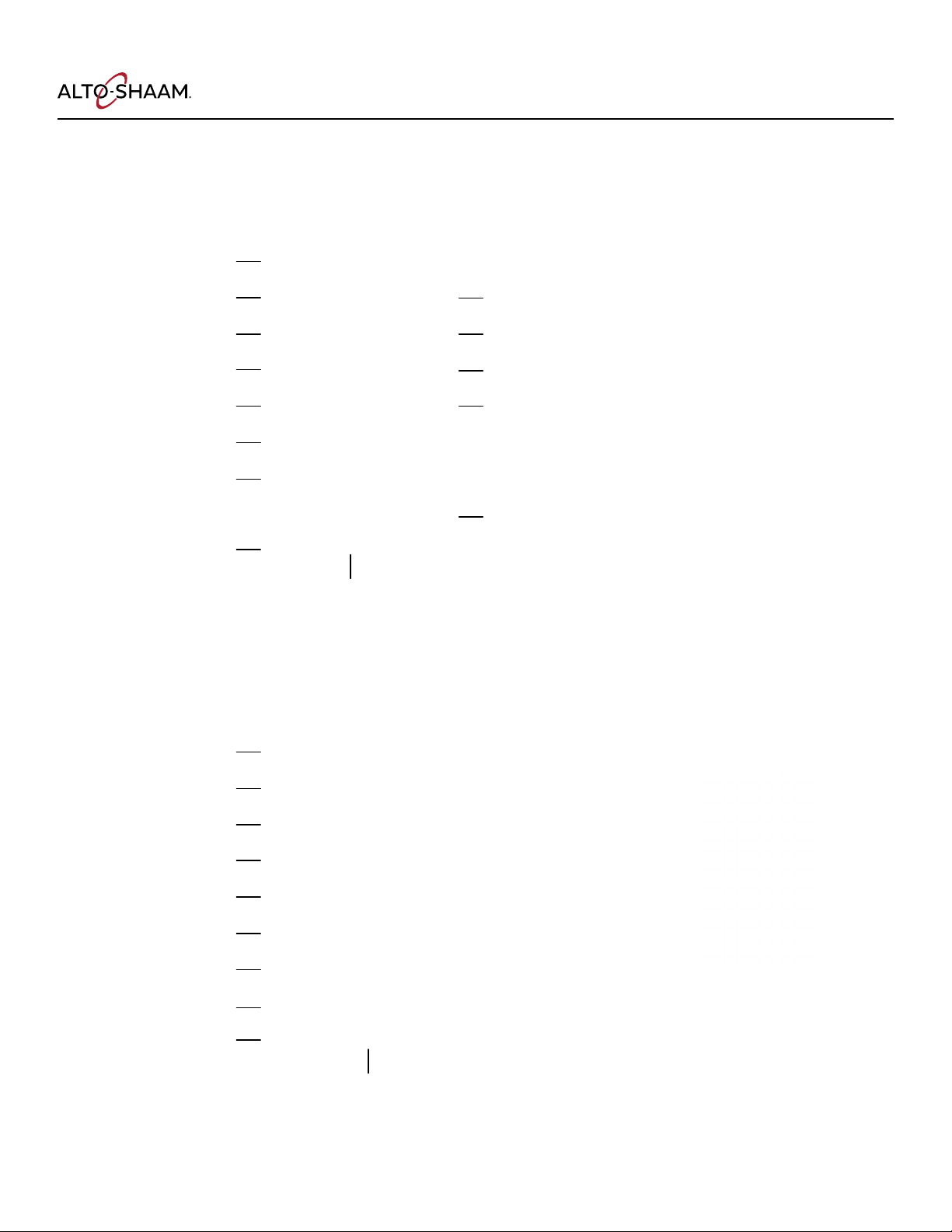

Settings Screen 1

Fahrenheit /Celsius

Keep last user setting

Handle LED on

Recipe display

names on

Unlock recipes

Beeper volume

& alarm clips

Screen brightness

Return to

previous screen

Screen 1 of 2

Settings Screen 2

Use factory

default settings

Handle LED off

Recipe display

names off

Lock recipes

Advance to next

setting screen

When a setting has been selected, the

graphic will be vibrant in color while the

alternate choice will appear faded and

gray. In the illustration above, Fahrenheit,

factory default setting, handle LED on,

locked have been chosen.

notE: A password is required to lock

and unlock the recipes. Simply

call an Alto-Shaam Culinary

Chef for assistance.

Language Choices

Date/Time

Future Feature

(not yet available)

Calibrate product probe

Preventative

Maintenance Actions

Run diagnostics

Force Boiler Flush

Return to previous

setting screen

Return to

utility screen

Language choices available:

English, French, German, Korean,

Mandarin, Russian, or Spanish.

Time format available:

12-hour clock

24-hour clock

Different date

formats available:

YYYY/MM/DD

MM/DD/YYYY

DD/MM/YYYY

Screen 2 of 2

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 11

Page 12

Operation

Control Panel Identi cation

Preventative Maintenance Screen

Cleaning Timer

Gasket Inspection

Ventless Hood

Filter Replacement

Return to

previous screen

Water Filter

Replacement

Boiler De-Liming

Utilities

Return to

home screen

Preventative Maintenance - Editing

Alarm in home screen indicates that a

maintenance interval has elapsed.

Return to

previous

screen

Increase or decrease

alarm setting to

match your preferred

timelines.

A er the task has

been completed, set

elapsed time to 0 to

begin countdown

process again.

Utilities

Return to

home screen

12 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 13

Operation

So ware Updates

Soware Updates

The PROtouch controller plays an important part in our continuous improvement process. New features and abilities

can be loaded to your oven as they become available. So ware for your oven can be accessed from the Alto-Shaam

website, under the Resource Library Tab, then So ware Center. http://www.alto-shaam.com/en/so ware-download-center

Use a USB stick to copy the PROtouch so ware from the website to the USB stick.

Press the ON button to power the oven on.

Touch the utilities icon.

Touch the download icon.

Touch the download new so ware icon.

Most so ware updates will require the full oven update

as shown below. Additional options are available in the

event a special need arises. Call our Service Department

for assistance with these special circumstances.

Remove the cover of the USB port on the oven.

Insert the USB stick. If the USB stick is not recognized

by the Combitherm, a question mark will appear on

screen. Try again with another ash drive device or call

Alto-Shaam Service.

So ware Upload Screen

Full oven update:

IB, CB, and OB

Update the CB

(control board) only

Update the OB

(option board) only

Update the IB

(interface board) only

Return to

previous screen

When the data has made a

successful transfer to the USB

drive, the screen will change.

Touch the green check mark

icon to complete the process.

Remove the USB stick and

replace the cover on the USB

port on the oven.

NOTICE: A er the so ware update has

been completed, the oven may

automatically initiate a shut down

and reboot sequence if required.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 13

Page 14

Operation

Cooking Screen Identi cation

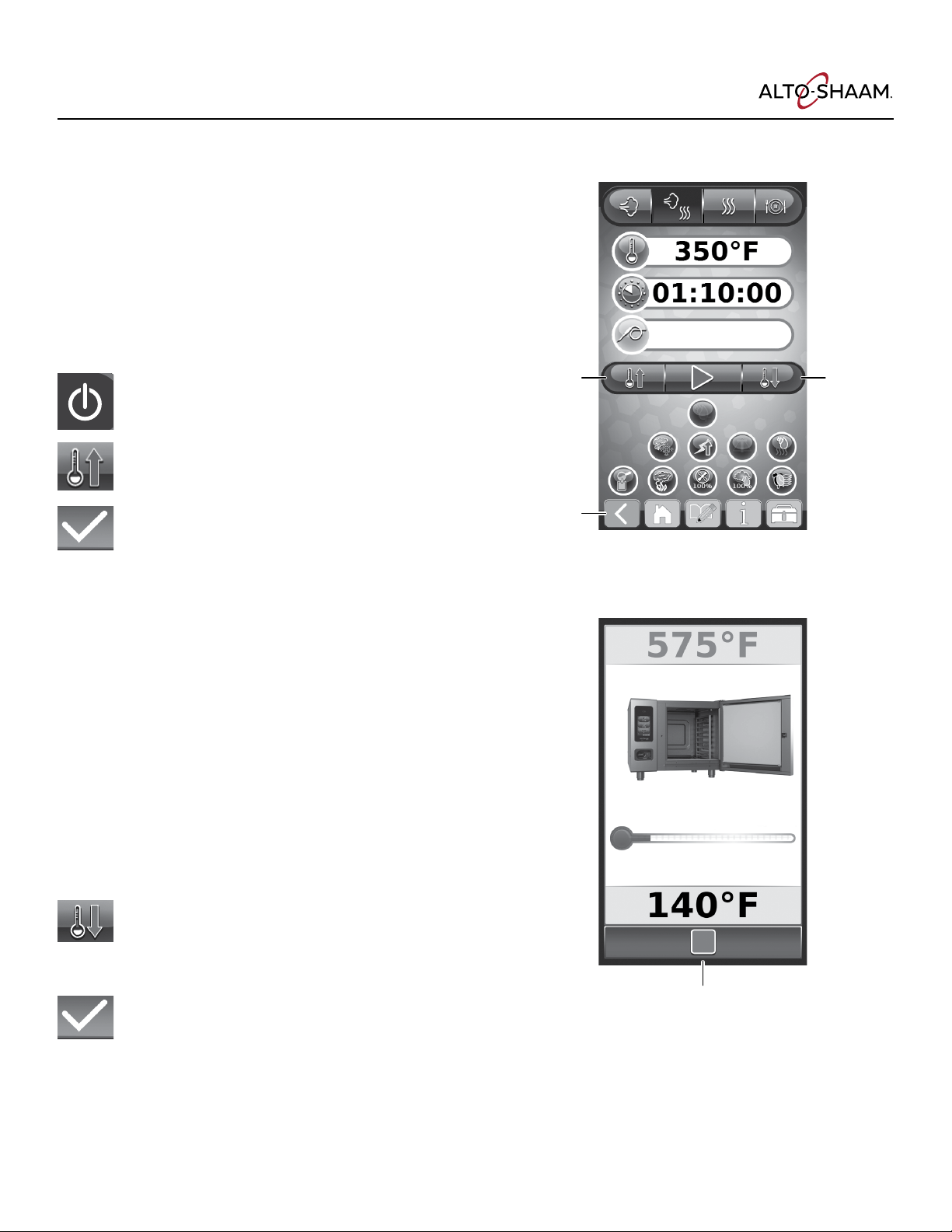

Cooking Screen Identication

Steam

Mode

Oven Temperature

Cook Time

Probe Temperature

Preheat

Start

Return to

previous screen

Combi

Mode

Return to

Home Page

Convection

Recipe

Mode

Retherm

Mode

Cook Time is displayed as

hours : minutes : seconds

Cool Down

UtilitiesWrite

Chosen

Cooking

Mode

Return to

previous screen

Chosen

Entry

Field

Allowable

Temperature

Range

Entry Keypad

Enter

notE: When a cooking mode has been selected, it will appear darker

blue. When the cooking mode is calling for heat, it will appear red.

When the cooking mode is calling for moisture, it will appear light

blue. In the illustration above, Combi Mode has been chosen and is

calling for heat. Also, the PROpower™ level has been chosen, and

the fan speed has been set at 100%.

14 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 15

Auxiliary Functions and Features

Power Settings

Auxiliary Functions and Features

Operation

Two power levels: reduced power to manage kitchen

power peaks, and eco power for optimal oven ef ciency.

A third choice is optional on electric models, but

standard on gas models. PROpower™ is an accelerated

turbo power for an instant boost of heat or quick heat

recovery [patent pending].

notE: Reduced power will result in longer cooking

times and PROpower will decrease your cooking

time by several minutes.

Multiple Fan Speeds

The PROtouch™ control includes ve different fan

speeds. The reduced fan speed function is useful for

ow-sensitive products such as souf és and meringues,

or any products affected by a high velocity of air

movement.

notE: Fan speed choices are based upon the power

level you have chosen.

PROpower

Eco Power

Reduced Power

Return to previous screen to

set the remaining auxiliary

functions for full functionality

Power level icon appears

during operation

Fan speed choices

Reduced Power Level

Eco Power Level

PROpower™ Power Level

Multi-Shelf Timer

The multi-shelf timer allows the operator to program

alarm times for the oven shelves. This can be one

common time for corresponding oven shelves or by

food item that is cooking. The multi-shelf timer can

be edited when in a recipe mode.

Touch shelf number to

enter a recipe identifier

(text or number)

previous screen

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 15

Return to

Chosen

Cooking

Mode

Chosen

Temperature

Timer ready, touch

green arrow to begin

Time value, touch this area

to change the time value

Timer countdown in process,

Touch red square to stop

Page 16

Operation

Auxiliary Functions and Features

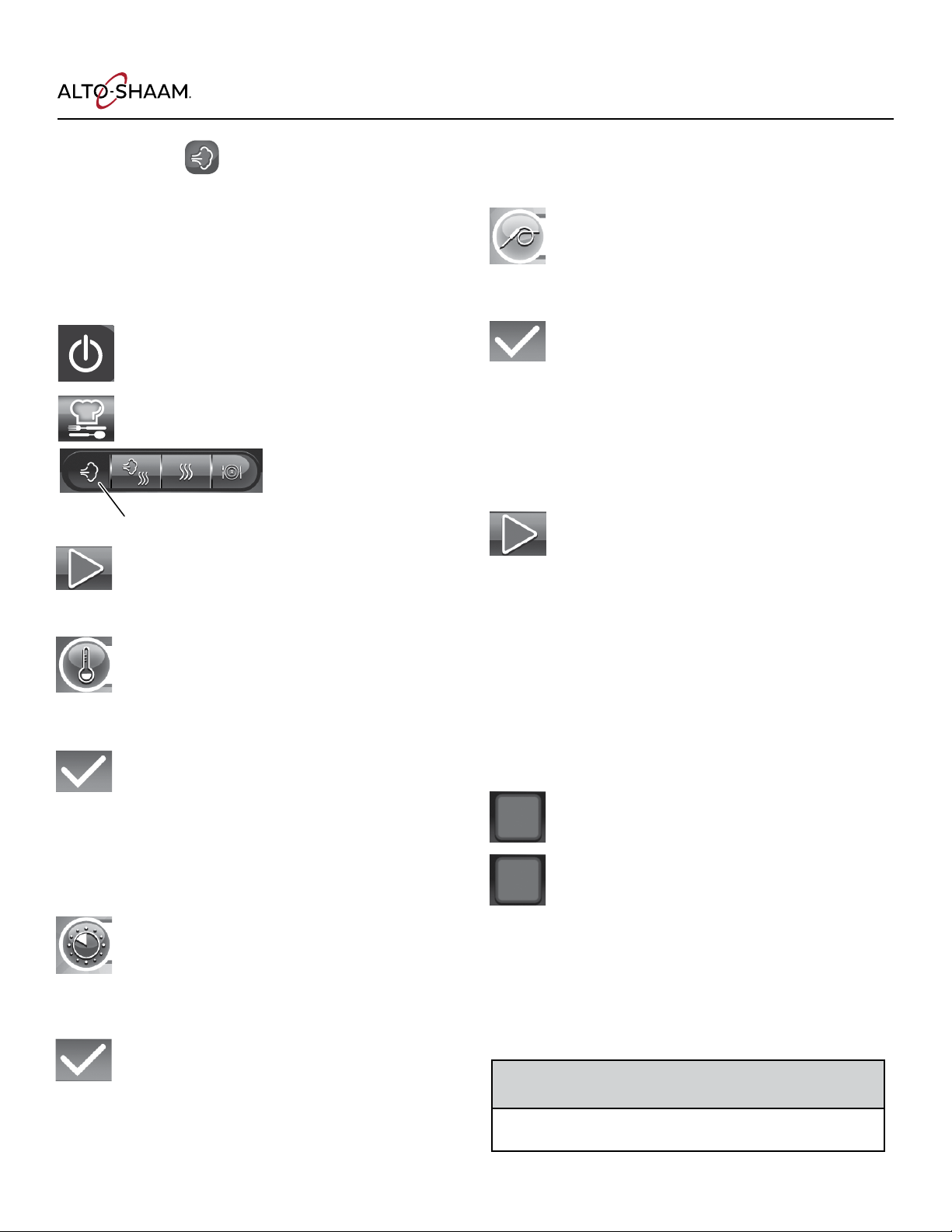

Preheat Feature

The oven should be preheated before most cooking

functions. When cooking full loads, use a temperature

50°F (10°C) greater than the cook temperature in order

to recover from heat loss when the door is opened

to add food to the oven. For items that use the Steam

mode, it is necessary to use a preheat temperature

lower than the cook temperature in order to create the

proper amount ofsteam.

Press the On button to power oven on.

Touch the Preheat icon.

Type in desired temperature.

Touch the green Check Mark icon to

startpreheating.

Cool Down Feature

The cool-down feature provides the operator with

the ability to lower the temperature of the oven

compartment at an accelerated pace. This function

is useful when it is necessary to immediately change

from a high temperature cooking function to a lower

temperature function or to the steam program.

This function is also useful to help cool the oven

compartment in preparation for cleaning.

TIP: Always allow the oven walls to cool to a minimum

of 140°F (60°C) before spraying the compartment

with oven cleaner.

Preheat

Return to previous

screen

Cool Down

Open the oven door.

Touch the Cool Down icon.

Type in desired temperature.

Touch the green Check Mark icon to beginthe

Cool Down process.

The target oven temperature chosen will appear

just above the red Stop button.

The current oven temperature will appear at the

top of the screen.

16 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Touch to

Stop

Page 17

Auxiliary Functions and Features

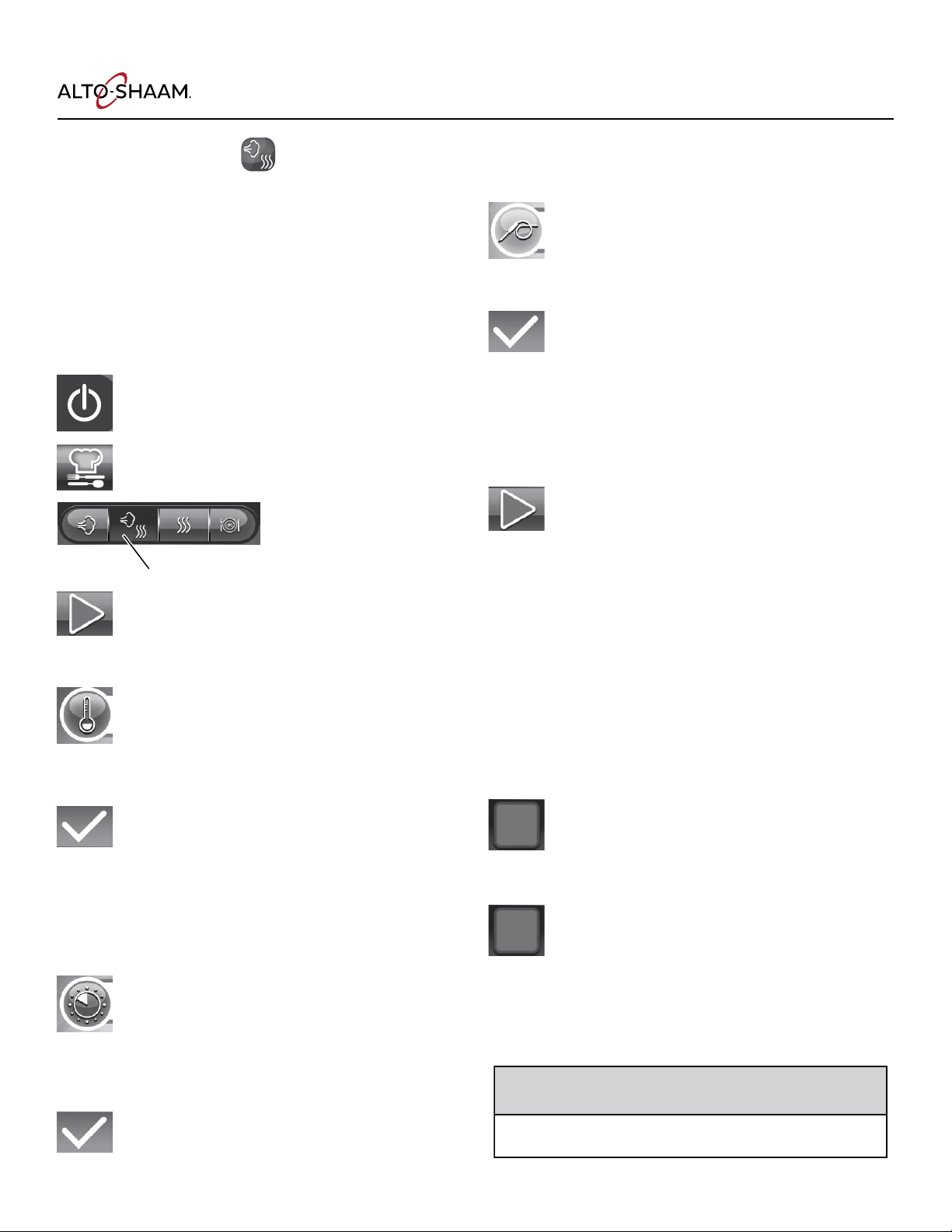

Humidity Control Feature

The humidity control feature is an automatic

function designed to regulate humidity to provide

additional color to food as needed. This feature

is particularly useful for adding color to high

moisture products such as chicken and other

poultry, or for additional browning of full loads

and other moist products. In addition, this feature

may be used to add texture to fried items such

as french fries or breaded chicken. Humidity

control can be used in any cooking mode and can

be programmed into a cooking procedure.

Touch the nearest 10% increment on the le side

of the screen, and then adjust up or down using

the + or – icons.

0% humidity is the driest cooking environment

available. The percentage level chosen will

appear on the icon. In the illustration at right,

72% is shown.

Humidity level choices

in increments of 10%

Return to

previous screen

Operation

Adjust humidity level up or

down in increments of 1%

Touch the check mark to

approve the value entered.

Rapid Cool (available on boiler-free models only)

This function, when used with a program, rapidly

removes heat from the oven cavity. Swi ly move

from a high cooking temperature to a lower

temperature without overcooking your food.

Rest

This step allows you to pause the oven during a

program. The rest step is ideal for cold smoking

or automatic cleaning. Infuse your food with

smoke avor a er the actual smoking step has

stopped.

Door

The door function allows the user to program

a reminder—in the form of an animated door

opening and closing—that it is time to open the

door. This reminder may be programmed at the

end of a programmed segment or at the end of

the program.

Return to

previous screen

Rapid Cool

(boiler-free models)

Chosen Humidity

Level % shown

Door

Rest

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 17

Page 18

Operation

CT PROformance™ Factory Default Settings

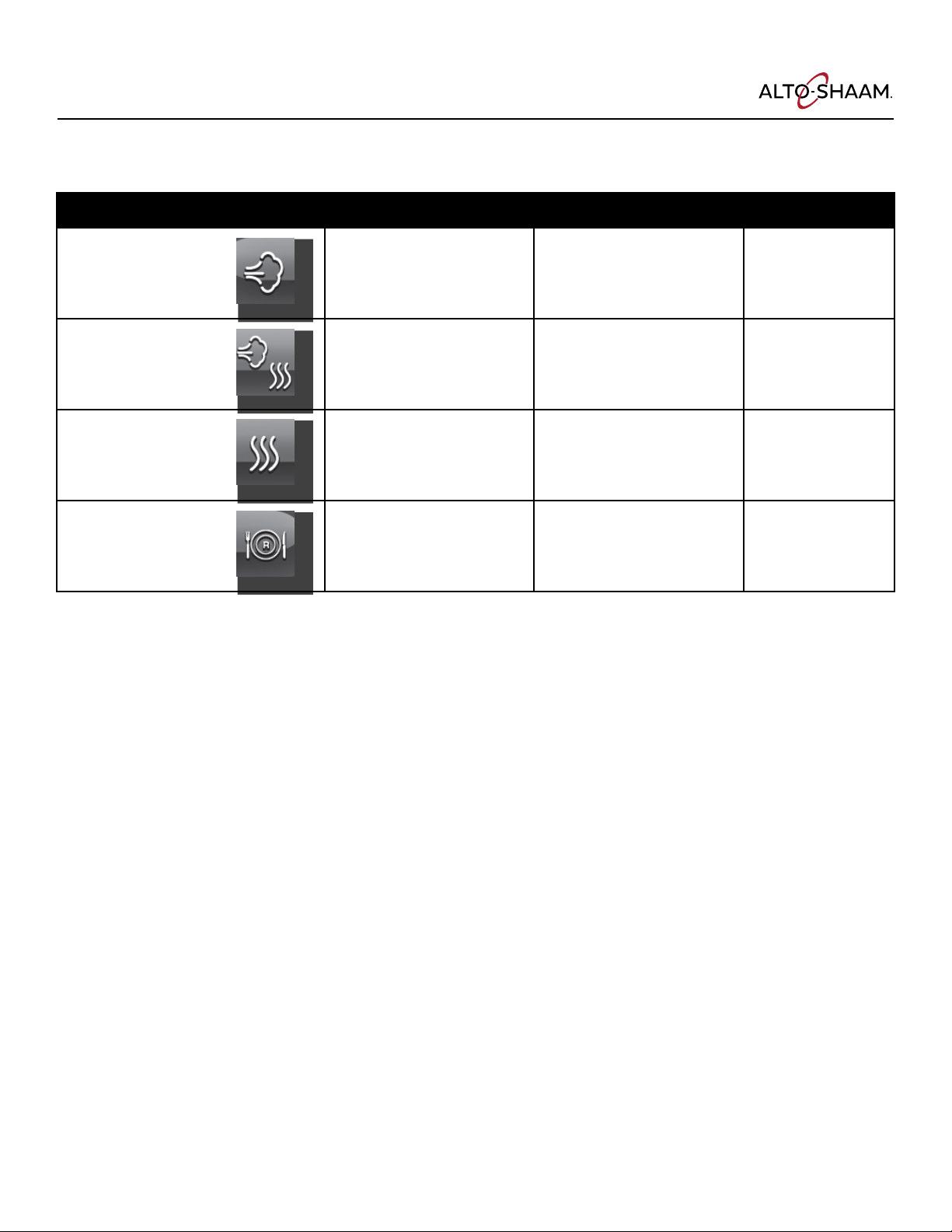

Cooking Mode Oven Temperature Core Temperature Cooking Time

Steam

Combination Steam

Convection

Retherm

212°F

(100°C)

350°F

(175C)

350°F

(175C)

275°F

(135°C)

160°F

(70°C)

160°F

(70°C)

160°F

(70°C)

160°F

(70°C)

25 minutes

70 minutes

30 minutes

5 minutes

18 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 19

CAUTION HOT

Steam Mode

Operation

The Steam mode provides the operator with the

ability to steam, poach, or blanch. This mode will

automaticallysteam at the boiling point of water; quicksteam above the boiling point for faster cooking results;

or low temperature steam, below the boiling point, for

more delicate products such as pâté, mousse, seafood,

orcustard.

Press the On button to power oven on.

Touch the Professional Cooking mode icon.

Touch the Steam mode icon.

Touch the Start icon to steam at the

displayedsettings.

To Change the Displayed Settings:

Touch the area to the right of the

temperatureicon.

Type in desired temperature.

Touch the green Check Mark icon to

conrmchange.

• Automatic Steaming 212°F (100°C)

• Quick Steaming 213°F to 250°F (101°C to 120°C)

• Low Temperature Steaming 85°F to 211°F (30°C to 99°C)

To Cook by Time:

To Cook by Product Core Temperature:

Touch the area to the right of the probeicon.

Type in desired temperature.

Touch the green Check Mark icon to

conrmchange.

Insert probe into product.

Set available auxiliary functions as desired,

such as energy level, fan speed, multi-shelf

timer, etc.

Touch the Start icon to begin cooking in the

Steam mode.

• The cavity set-temperature will appear in the display.

• If cooking by probe, the actual internal product

temperature will appear next to the probe icon during

operation. To change the set value for core temperature,

touch the temperature next to the probe icon and make

changes as required.

When the cooking time has expired or the desired core

temperature has been reached, an alarm will sound and

handle light will ash several times indicating the end of

the operating mode.

Touch the red Stop icon to stop the buzzer or

open the oven door.

To stop cooking program at any time, touch the

red Stop icon.

Touch the area to the right of the timeicon.

Type in desired time or set continuous time by

touching --:--.

Touch the green Check Mark icon to

conrmchange.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 19

Use caution when opening the oven door when the

cooking chamber is hot to avoid possible burns.

Page 20

Operation

Steam Mode Chef Operating Tips

This mode will steam a full or partial load of a single

product, or multiple products without transfer of avors.

When steaming multiple products, however, individual

product cooking times must be taken into consideration.

Steam

Perforated, 2-1/2" (65mm) deep pans

are particularly suitable for use in

this program mode. These pans will

provide a shorter cooking time and

will prevent product over-cooking at

the bottom of the pan.

Separate ice-encrusted vegetables

before steaming to ensure

evencooking.

A variety of products can be steamed

at the same time but attention must

be paid to the different cooking times

required for each food product.

When cooking by probe, the probe

must be inserted so that the tip is

positioned in the center of the food

mass. For liquid or semi-liquid foods,

suspend the probe in the center of

the product and secure the probe

wire to the edge of the container.

High Temp Steam

High temperature steaming is

suitable for hearty, root-type

vegetables such as potatoes, turnips,

carrots, and cabbage.

High temperature steaming

provides a cooking time which is

approximately 10% shorter than the

regular steam mode temperature of

212°F (100°C).

The non-pressurized atmosphere of the Combitherm

also provides the ability to open the door during the

steam mode in order to monitor products more closely

throughout the steaming process.

Low Temp Steam

The low temperature steam mode

will function whenever the oven

compartment temperature is below

212°F (100°C).

It will take longer to steam

products using the low temperature

steammode.

Steaming sausages in low

temperature steam prevents cracked

or peeling skins.

Use low temperature steam for

delicate foods such as shrimp,

sh,seafood, crème caramel, and

sous vide.

For best results, low temperature

steam all delicate food items at a

temperature of 210°F (99°C) or below.

20 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 21

Combination Mode

CAUTION HOT

Operation

The Combination mode will prove to be the most versatile

and widely used mode the Combitherm oven has to offer.

It will produce the best possible results on the widest

variety of products — all within the shortest period of

time. The unique control function of this mode enables

the operator to roast or bake with a combination of steam

and convection heat. In addition to shorter cooking times,

this combination of steam and heat offers less product

shrinkage and more moisture retention than obtained in a

convection oven.

Press On button to power oven on.

Touch the Professional Cooking mode icon.

Touch the Combination mode icon.

Touch the Start icon to cook at the displayed

settings.

To Change the Displayed Settings:

Touch the area to the right of the

Temperatureicon.

Type in desired temperature.

To Cook by Product Core Temperature:

Touch the area to the right of the Probe icon.

Type in desired temperature.

Touch the green Check Mark icon to

conrmchange.

Insert probe into product.

Set available auxiliary functions as desired,

such as energy level, fan speed, multi-shelf

timer, steam injection, etc.

Touch the Start icon to begin cooking in the

Steam mode.

• The cavity set-temperature will appear in the display.

• If cooking by probe, the actual internal product

temperature will appear next to the PROBE icon during

operation. To change the set value for core temperature,

touch the temperature next to the PROBE icon and make

changes as required.

When the cooking time has expired or the desired core

temperature has been reached, an alarm will sound and

handle light will ash several times indicating the end of

the operating mode.

Touch the green Check Mark icon to

conrmchange.

• Cooking temperature range:

85°F to 575°F (30°C to 301°C)

To Cook by Time:

Touch the area to the right of the timeicon.

Type in desired time or set continuous time by

touching --:--.

Touch the green Check Mark icon to

conrmchange.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 21

Touch the red Stop icon to stop the buzzer or

open the oven door.

To stop cooking program at any time, touch the

red Stop icon.

Use caution when opening the oven door when the

cooking chamber is hot to avoid possible burns.

Page 22

Operation

Combination Mode Chef Operating Tips

The Combination mode injects the optimum amount of

steam automatically. There is no need to select humidity

levels. Foods do not dry out. Flavors are retained with no

transfer of avors when mixing product loads.

Due to automatic steam adjustment, the door can be

opened at any time during a cooking operation. Be

certainto observe the safety warning when opening the

oven door.

The Combination mode is particularly efcient when

used for baking, broiling, grilling, stewing, braising,

androasting.

When using the Combination mode, cooking

temperatures can be reduced 10%–20% below the

temperatures used for conventional cooking methods.

Cooking time will be reduced approximately 40% when

cooking at the same temperature used for convection

oven cooking and up to 50%60% less time when cooking

at the same temperature used for a conventional oven.

Food browning in the Combitherm begins at a cooking

temperature of approximately 250°F (120°C).

A higher cooking temperature results in heavier browning

but also results in greater product weight loss. To achieve

additional browning set humidity control into the product

procedure. Humidity control is particularly useful for

adding color to high moisture products such as chicken

and other poultry items or for additional browning of full

loads and other moist products.

The Combination mode provides even browning without

the necessity to turn the pans.

For more even cooking, do not cook in pans deeper than

4"(100mm).

When cooking by probe, the probe must be inserted so

that the tip is positioned in the center of the food mass.

For liquid or semi-liquid foods, suspend the probe in the

center of the product and secure the probe wire to the

edge of the container.

22 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 23

Convection Mode

CAUTION HOT

Operation

The Convection mode operates with hot circulated air

within a temperature range of 85°F to 575°F (30°C to

300°C). For many applications, better results may be

achieved with the Combination mode; therefore, the

operator may want to consider using the Convection mode

on a more limited basis. The use of high temperatures

(500°F to 575°F) are not intended for continuoususe.

Press On button to power oven on.

Touch the Professional Cooking mode icon.

Touch the Convection mode icon.

Touch the Start icon to cook at the

displayedsettings.

To Change the Displayed Settings:

Touch the area to the right of the

temperatureicon.

To Cook by Product Core Temperature:

Touch the area to the right of the Probeicon.

Type in desired temperature.

Touch the green check mark key to conrm

change.

Insert probe into product.

Set available auxiliary functions as desired, such

as energy level, fan speed, multi-shelf timer,

steam injection, etc.

Touch the Start icon to begin cooking in the

Steam mode.

• The cavity set-temperature will appear in the display.

• If cooking by probe, the actual internal product

temperature will appear next to the probe icon during

operation. To change the set value for core temperature,

touch the temperature next to the probe icon and make

changes as required.

Type in desired temperature.

Touch the green Check Mark icon to

conrmchange.

• Cooking temperature range: 85°F to 575°F (30°C to 300°C)

To Cook by Time:

Touch the area to the right of the Timeicon.

Type in desired time or use up and down arrows

to adjust temperature or set continuous time by

Touching --:--.

Touch the green check mark key to

conrmchange.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 23

Touch steam Injection at any time during

cooking. Steam will inject into the cavity as long

as the icon is touched.

When the cooking time has expired or the desired core

temperature has been reached, an alarm will sound and

handle light will ash several times indicating the end of

the operating mode.

Touch the red Stop icon to stop the buzzer or

open the oven door.

To stop cooking program at any time, touch the

red Stop icon.

Use caution when opening the oven door when the

cooking chamber is hot to avoid possible burns.

Page 24

Operation

Convection Mode Chef Operating Tips

The Convection Mode can be used to roast or bake

products needing very short cooking times or for high

moisture products such as mufns, cakes, and cookies, or

for browning the surface of the food.

The Convection mode works best with low moisture

foodsor for very moist food which require a dryer

nished product.

For baking, preheat the Combitherm at a temperature of

325°F to 375°F (163°C to 191°C). Once preheated, reset the

temperature as required.

A higher cooking temperature results in heavier

browning but also results in greater product weight loss.

To achieve additional browning set the Humidity control

into the product procedure.

When cooking by probe, the probe must be inserted so

that the tip is positioned in the center of the food mass.

For liquid or semi-liquid foods, suspend the probe in the

center of the product and secure the probe wire to the

edge of the container.

24 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 25

Retherm Mode

CAUTION HOT

Operation

The Retherm mode operates with hot circulated air within

a temperature range of 245°F to 320°F (120°C to 160°C).

Press On button to power oven on.

Touch the Professional Cooking mode icon.

Touch the Retherm mode icon.

Touch the Start icon to retherm at the

displayedsettings.

To Change the Displayed Settings:

Touch the area to the right of the

Temperatureicon.

Type in desired temperature.

To Cook by Product Core Temperature:

Touch the area to the right of the Probeicon.

Type in desired temperature.

Touch the green Check Mark icon to

conrmchange.

Insert probe into product.

Set available auxiliary functions as desired,

such as energy level, fan speed, multi-shelf

timer, steam injection, etc.

Touch the Start icon to begin cooking in

Steammode.

• The cavity set-temperature will appear in the display.

• If cooking or retherming by probe, the actual internal

product temperature will appear next to the PROBE

icon during operation. To change the set value for core

temperature, touch the temperature next to the PROBE

icon and make changes as required.

Touch the green Check Mark icon to

conrmchange.

• Cooking or retherming temperature range:

245°F to 320°F (120°C to 160°C)

To Cook by Time:

Touch the area to the right of the

Time icon.

Type in desired time or set continuous time by

touching --:--.

Touch the green Check Mark icon to

conrmchange.

Touch Steam Injection at any time during

cooking. Steam will inject into the cavity as

long as the icon is touched.

When the cooking time has expired or the desired core

temperature has been reached, an alarm will sound and

handle light will ash several times indicating the end of

the operating mode.

Touch the red Stop icon to stop the buzzer or

open the oven door.

To stop cooking program at any time, touch the

red Stop icon.

Use caution when opening the oven door when the

cooking chamber is hot to avoid possible burns.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 25

Page 26

Operation

Retherm Mode Chef Operating Tips

Since plated meals consist of dissimilar products, there

are several important factors to consider in order to

produce the nest results. Product density (compactness),

thickness, quantity of product on each plate, and quantity

of plates all relate to the length of time necessary to

reheat. Again, experience is the best method to determine

reheating time. Once the time has been determined and

recorded for a specic meal, the results will be consistent

for future reheating times.

Helpful Hints For Reheating On The Plate

• All food components on the plate should be of similar

densities and thickness.

• Arrange all food components evenly on the plate.

• Avoid excessive overlapping of product.

• Sauces must be heated and added to product aer

reheating.

• A mixed variety of meals can be reheated at the same

time.

À La Carte Rethermalization

À la carte rethermalization is designed to take a single

plate from a refrigerated temperature to serving

temperature for immediate service. Plates are prepared

in advance, covered, and refrigerated. Preheat the

Combitherm oven. Remove plate from refrigeration and

place in the oven at 275°F (135°C) for an uncovered plate

or 300°F (150°C) for a covered plate. Plates with meat

components will take more time than plates containing

all vegetable components. Follow internal temperature

requirements for reheating and allow for override time.

Aer reheating, remove the plate from the oven, add any

sauces, garnish, and serve. This process can be repeated

as required.

For the most efcient continuous service, it is suggested

that the Combitherm oven be dedicated to the

rethermalization process during serving hours.

Banquet Rethermalization

Banquet rethermalization is designed for high volume,

full or partial load (multiple plate) reheating.

Plates are assembled in advance, covered, and

refrigerated or loaded on the roll-in cart and refrigerated.

Preheat the Combitherm oven at 275°F (135°C) for

uncovered plates or 300°F (150°C) for covered plates.

Remove plates or the roll-in cart from refrigeration, load

in the oven and set timer as required. Follow internal

temperature requirements for reheating and allow for

override time. Remove the plates or roll-in cart from the

Combitherm.

Placing our thermal blanket cover over the roll-in cart

keeps food hot for 20 to 40 minutes, depending on the

type of food, retherm temperature, and environmental

factors. For longer holding times, roll the cart into the

CombiMate® companion holding cabinet.

Rethermalizing Prefabricated and

Vacuum-Packed Frozen Foods

For bulk product rethermalization, completely defrost

product bags in walk-in cooler. DO NOT REMOVE

PRODUCT FROM THE BAG. Load thawed bags in

preheated oven and rethermalize in the Low Temperature

Steam mode until the required internal temperature is

reached. Place rethermalized bags in a preheated holding

cabinet set at 140° to 165°F (60° to 74°C) until ready

forservice.

For large volume on-the-plate regeneration, defrost

bags in walk-in cooler. Open bags and plate per menu

requirements in a (maximum) 55°F (13°C) refrigerated

room. Place on Alto-Shaam roll-in cart (trolley), and roll

into Combitherm oven preheated at 275°F (135°C).

Regenerate in the Convection mode for 3 to 5 minutes.

Switch to the Retherm mode for an additional 3 minutes

or more if required. Placing our thermal blanket cover

over the roll-in cart keeps food hot for 20 to 40 minutes,

depending on the type of food, retherm temperature, and

environmental factors. For longer holding times, roll the

cart into the CombiMate® companion holding cabinet.

Plate covers must be used for on-the-plate regeneration.

26 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 27

Dehydration Mode

Dehydration is a long, slow process that takes place at low

heat and zero humidity. It changes the physical properties

of food items and intensies avors. Dehydrated items

can be combined and presented in new and unexpected

ways, from pliable leathers to crispy chips to powders.

Dehydration is also an effective way to preserve food

items for long-term storage with minimal impact on

avor.

How To Cook Using Dehydration Mode

1. Touch the dehydrate icon e. The controller does the

following:

Operation

1

2

3

• Sets the cooking mode a to convection.

• Sets the power mode f to ECO.

• Sets the cooking temperature b to 140°F (60°C).

• Sets the cooking time c to continuous (--:--).

• Sets the fan speed h to 60%.

• Sets the humidity level i to 0%.

• Turns off the smoker

they have been selected.

notE: These functions should remain off during

dehydration

2. To change the cooking temperature, touch the displayed

temperature b. The touchpad screen displays.

3. Use the number keys k to enter the cooking

temperature, then touch the check mark icon l.

4. To set a cooking time, instead of having the dehydration

run continuously, touch the displayed time 3. The

touchpad screen displays.

5. Use the number keys k to enter the cooking time

(hh:mm:ss), then touch the check mark icon l.

g

and Delta-T j functions, if

4

5

6

7

8 9

10

11

notICE: Changing any of the default settings other than

temperature and time is not recommended.

6. Load food into the oven.

7. Touch the start icon d. The start icon changes to a red

square (stop icon) and the oven begins cooking.

notE: If the cooking time is continuous, cooking continues

until the stop icon is touched. If the cooking time is set, the

controller sounds an alarm and cooking stops when the

cooking time has elapsed.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 27

12

Page 28

Operation

Dehydration Mode Chef Operating Tips

• Place a silpat or other silicon liner on each cooking tray.

Do not use liners made of parchment or paper.

• All food items should be well spaced and placed at on

the cooking tray.

• Allow dehydrated food items to cool fully before

removing them from the cooking tray.

• Many food items benet from processing before

dehydration. Examples include:

Puree vegetables, then dehydrate in an even, thin

layer to create papers and powders.

Cut fruit into thin slices and dip in a simple syrup

prior to dehydration.

Mix pureed items prior to dehydration to create new

avor proles.

Pre-cook vegetables such as carrots before pureeing

and dehydrating.

28 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 29

Delta-T Core Temperature Cooking Mode

CAUTION HOT

Operation

This special program function cooks by internal product

temperature with the use of the probe. The Delta-T

cooking program increases the oven temperature in

direct proportion to the internal temperature of the

product, in contrast to the traditionally constant oven

temperature. For example, the oven temperature will

always be 100°F higher than the product itself. This slow

cooking allows more time for enzymes to tenderize the

meat. The Delta-T mode can be used with both convection

and combination modes, providing a more gentle method

of cooking. Browning occurs toward the end of the

cooking cycle.

Press On button to power oven on.

Touch the professional cooking mode.

Available in convection mode or combination

mode, touch the desired Cooking Mode icon.

Touch the area to the right of the probe icon.

• The actual internal product temperature will appear

next to the probe icon during operation. To change the

set value for core temperature, touch the temperature

next to the probe icon and make changes as required.

Touch steam Injection at Any Time During

Cooking. Steam will inject into the cavity as long

as the icon is touched.

When the operator-set internal temperature has been

reached, an alarm will sound and handle light will ash

several times indicating the end of the operating mode.

Touch the red Stop icon to stop the buzzer or

open the oven door.

To stop cooking program at any time, touch the

red stop icon

Use caution when opening the oven door when the

cooking chamber is hot to avoid possible burns.

Type in desired nal internal

producttemperature.

Touch the green check mark key to conrm

change.

Insert probe into product.

Touch auxiliary function Delta-T icon.

Type in desired Delta-T temperature.

Touch the Start icon to begin cooking.

Calibrate the Touch Oven Probe

Fill a pitcher with blended ice and water and place

inside the combi oven.

Snap probe in place at top of oven and insert probe

into the pitcher of blended ice water.

With the CT PROformance oven “ON”, touch the

“Utilities” icon on the home page.

Touch the “Settings” icon.

Touch the “>” icon to advance to page 2 of the

Settings screen.

Touch the “probe” icon on the Settings screen.

Once the temperature reading has stabilized, adjust

setting to 32°F (0°C) using the + or - icons. Touch the

“Home” icon to return to the home screen.

The control has now been calibrated to use the

probe at appropriate temperatures.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 29

Page 30

Operation

CombiSmoker® Procedures

Loading Wood Chips

• Measure one container full of dry wood chips.

• Soak dry chips in water for 5 minutes.

• Shake excess water off wood chips.

• Place moistened chips back into the container and

position the container securely on the two prongs

located on the interior side panel of the oven.

A full container of wood chips will produce smoke for an

approximate period of one to two hours depending on the

cooking temperature being used for the selected product.

The recommended Touch recipes have been tested to

ensure complete product smoke penetration and full

smoke avor.

Chef Operating Tip

Products such as ribs that require heavier smoke

penetration to reach full smoke avor should remain in

the oven aer cooking has been completed. Do not open

the oven door.

Set the oven in the Low Temperature Steam Mode at 140°

to 160°F (60° to 71°C) and allow the product to remain in

the oven for a period of one hour.

If you would like assistance, you are invited to contact an

Alto-Shaam corporate chef for recommendations.

notICE: Always keep the oven door closed whenever

operating the smoking function.

The CT PROformance CombiSmoker can be operated

without using the smoking function. Aer using the

oven as a smoker, however, it is necessary to clean the

oven in order to prevent a transfer of smoke avor to

non-smokedproducts. Cleaning instructions are provided

in this manual.

WARNING

When smoking is completed, remove smoker box

from oven. Dispose of wood chips in a re proof

waste receptacle to prevent the risk of re.

Available From Alto-Shaam

Wood Chips 20 pound bulk packs

The total weight of wood

chip bulk packs may vary

due to high moisture

content when packaged.

Apple WC-22543

Hickory WC-2829

Cherry WC-22541

Sugar Maple WC-22545

CAUTION

DO NOT open the oven door during the smoking function. The

introduction of outside air into the oven compartment may

cause the wood chips to flame. Use the hand held sprayer hose

to extinguish the flames.

30 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

To prevent personal injury or property damage:

DO NOT use improper materials, sawdust, or woodchips

smaller than thumbnail size for the smoking function.

Page 31

CombiSmoker® Procedures

CAUTION

CAUTION HOT

The ability to smoke product, hot or cold, is offered on

all CTP models. The smoking function can be engaged in

either the Combination mode or the Convection mode of

operation. The smoking function cannot be operated when

the oven is operating in the steam mode or the retherm

mode.

Press on button to power oven on.

Touch the professional cooking mode.

Touch the desired cooking MODE icon,

convection or combination.

Operation

To prevent personal injury or

propertydamage:

Always use hand protection when

operating this appliance to avoid burns.

Metal parts of this equipment become

extremely hot when in operation.

Cold Smoking Procedures

Touch convection cooking MODE icon.

To Change the Displayed Settings:

Touch the area to the right of the

temperature icon.

Type in desired temperature.

Touch the green check mark key to

conrm change.

To Cook by Time:

Touch the area to the right of the

time icon.

Type in desired time.

Touch the green check mark key to

conrm change.

To Activate CombiSmoke:

To Change The Displayed Settings:

Touch the cold smoking icon.

The temperature will display ------°.

To Cook by Time:

Touch the area to the right of the timeicon.

Type in desired time.

Touch the green check mark key to

conrmchange.

Place a pan of ice on a shelf immediately

below the product.

Touch THE START icon TO begin smoking.

Touch auxiliary function smoking icon.

Touch the Start icon to begin smoking.

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 31

Use caution when opening the oven door when the

cooking chamber is hot to avoid possible burns.

Page 32

Operation

Recipe Programming

Oven Temperature

Cook Time

Probe Temperature

Preheat

Step

Append

Save

Return to

previous screen

Steam

Mode

Combi

Mode

Return to

Home Page

Convection

Mode

Retherm

Mode

Utilities

1. While on the cooking mode screen, touch the Write a

Recipe icon.

2. Enter the desired cooking mode, cooking temperature,

and cooking time.

3. Add any desired special functions. For example:

• If the recipe requires a reminder to open the door at the

end of the segment, touch the Door icon.

• If the recipe requires a rest period, touch the Rest icon.

• If the recipe requires rapid remomal of heat, touch the

Rapid Cool icon.

4. If the recipe is complete, go to step 6. If the recipe calls

for additional segments, touch the Append icon.

5. Enter the desired cooking mode, cooking temperature,

and cooking time. If required, add a special function—see

step 3. Then, touch the Append icon. Repeat for each

additional cooking segment.

6. Touch the Save icon when all segments have been

written. A touch pad will appear.

7. Choose a photo or input the name of the recipe, then

touch the Check Mark icon.

notE: Each recipe can have up to 10 segments.

32 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 33

Using Programmed Recipes

Cookbook with

Saved Recipes

Operation

Sort Recipes Favorites

Recipe Favorite

Saved Recipe

Le Arrow Right Arrow

Cleaning

To Cook with Preprogrammed Recipes

• Touch the cookbook with saved recipes icon in the

home screen. The recipe screen displays.

• Locate the recipe by doing one of the following:

Touch the favorites icon to display favorite recipes.

Touch the sort recipes icon to sort recipes, then

select frequency, alphabetic order, or last modied

date as the sort criteria.

Touch the recipe search icon to open the search

screen, then use the touch pad keys to enter the

recipe name.

Touch the le arrow icon or the right arrow icon to

navigate between recipe pages.

• Load food into the oven.

notE: Some recipes include the preheat function.

Make sure the desired preheat temperature

has been reached before loading food into the

oven.

• Touch the icon for the selected recipe. The oven

begins cooking.

notE: To stop cooking program at any time, touch

the red stop icon .

SORT CHOICES

Frequency

Alphabetically

Last Modified

Recipe

Search

Recipe

Utility

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 33

Page 34

Operation

Editing Programmed Recipes

The CT PROformance™ recipes that have been programmed

can be edited, saved as a favorite recipe, and organized

in folders or by time day they are used to help speed the

search for specic recipes.

To Change Saved Recipes:

Touch Recipe Utility icon located at the bottom of

the recipe page.

The recipe utility screen is bright red to indicate

that the user is now in edit mode.

Touch the edit recipe icon.

Touch the icon of the recipe to be edited.

The rst cooking step of the recipe will be displayed.

Change cooking mode, temperature, time, probe

temperature, and /or any of the auxiliary functions.

If an additional step needs to be added, touch

Quick

return to

professional

cooking mode

Recipe

favorite

Saved

recipe

Return to

previous

recipe menu

Recipe search

by name

View

recipes

saved in

folders

View

recipes

marked as

favorites

Advance

to next

menu

screen

Recipe

utility

Append to add next step

Change the previous step

Insert a step

Edit as necessary. When there are no further

changes to be made, touch the Save icon.

Enter the name of the recipe if it is to be changed.

Touch the green check mark key to conrm

change.

To Delete Saved Recipes:

Touch Recipe Utility icon located at the bottom of

the recipe page.

The recipe utility screen is bright red to indicate that the

user is now in Edit Mode.

Touch the Delete Recipe icon.

Touch the icon of the recipe to be deleted.

Edit recipe

Delete recipe

Saved

recipes

Recipe

favorite

Return to

previous

recipe screen

notICE: Each recipe can have up to 10

Recipe search

by name

sequential steps.

Organize

recipes in

folders

Lock

selected

recipes

Mark

recipes as

favorites

Advance

to next

menu

screen

Recipe

utility

The recipe will be removed from the screen.

34 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

(continued on next page)

Page 35

Organizing Programmed Recipes

The CT PROformance™ recipes that have been programmed

can be organized in folders to help your kitchen staff be

more productive.

To Create A Recipe Folder:

Operation

Recipe

favorite

Touch the folder icon located at the top of the

recipe page.

The recipe utility screen is bright red to indicate that the

user is now in edit mode.

Touch the add folder icon.

The keyboard will appear - allowing you to enter in a name

for the recipe folder.

Touch the green check mark to conrm the folder

name.

Continue to add recipe folders as necessary.

Touch the recipe utility icon to add programmed

recipes to the folder.

Touch the folder icon on the red background.

Touch the named folder icon to reveal the

programmed recipe choices available.

Saved

recipes

Add folder

Named

folder

Recipe

folder

Recipe

folder

Touch each of the programmed recipes to be

added to the folder.

A small blue folder will appear on the lower le of the

recipe icon, indicating that it has been selected to be added

to the recipe folder.

Touch the return to previous screen icon when

your choices have been completed.

Return to

previous screen

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 35

Folder search

by name

Recipe

utility

Page 36

Operation

Organizing Programmed Recipes (Continued From Previous Page)

To Mark Saved Recipes as a Favorite:

Touch the Favorites recipe icon.

Touch the icon of the recipe to be marked.

A gold star will appear at the top le of the recipe icon. All

favorites can be viewed when you touch the gold star while

viewing the list of saved recipes.

To Lock Saved Recipes:

Touch the lock recipe icon.

Touch a single icon of the recipe or a group of

icons to be locked.

A red lock will appear at the top right of the recipe icon.

Sort Recipes

Recipe

Favorite

Saved

Recipe

Recipe

Search

Recipe

Utility

36 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 37

HACCP Access

HACCP Access

The Combitherm CT PROformance™ oven meets

the requirements of established HACCP criteria by

providing automated sampling, record keeping, setpoint validation, recipe used, dates and time. Data is

captured when Core Temperature Probe cooking method

is chosen. The information can be viewed on screen for

veri cation or troubleshooting. The HACCP preview

page will be displayed in LIFO (last in, rst out) order.

This data is retained inde nitely - until the information

is downloaded. Once downloaded, the information is

removed from the ovens memory. Best practice would be

to download the information every 30 days to a USB stick.

This information can then be copied to your computer.

The le format is text (.txt).

CAUtIon: The CombiOven USB port is not recommended

Operation

for use with personal hand held devices.

To Access the Data Collected:

Touch the utilities icon located on the

homepage.

Touch the upload/download icon.

Touch the HaCCP USB icon.

The HACCP screen can help diagnose a problem or error

code if limited information is available.

(next steps continued on next page)

Start time

Stop time

Utilities

Highest

probe

temperature

Lowest

probe

temperature

Download

MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual • 37

Page 38

Operation

To Download the Data Collected:

Pull back the cap of the USB port on the oven.

Insert the USB stick. The USB stick, if recognized, will

automatically take the user to the download page. If the

USB stick is not recognized by the Combitherm oven,

a question mark will appear on screen. Try again with

another ash drive device or call Alto-ShaamService.

When the data has made a successful transfer to the USB

drive, the screen will change. See below.

Touch the green Check Mark icon to complete the process.

Remove the USB stick and close the cap on the USB port

on the oven.

(steps continued from previous page)

HACCP Access And Download

The download process will automatically create a folder

on the USB stick titled “haccp”. Each text le contains

cooking program speci cs and each function the oven

performed.

Confirm

38 • MN-35948 • Rev 14 • 07/17 • Combitherm® CT PROformance™ Series Operator’s Manual

Page 39

Remove the grease lter by pulling it straight out of

The air ow arrow on the lter casing should point toward

CombiHood Plus Charcoal Filter with paper housing, Class II

FRONT OF HOOD

ALIGNS WITH FRONT

OF COMBI DOOR

Test the drain for proper drainage

CombiHood PLUS™ Ventless Hood

The CombiHood PLUS option is factory installed directly

on the top of the Alto-Shaam Combitherm CTP or CTC

series oven.

• Using EPA method 202 testing, grease laden vapors

emitted by the Combi Ventless hood are 0.58 mg/m

far less than U.L.’s established standard of 5 mg/m

• A high-powered fan captures all steam and fumes from

the oven cavity into the hood intake and out the back

surface exhaust vent, trapping grease as the air moves

through the lter system.

• As fumes and vapors are circulated through the hood,

condensed steam drains from a drain at the rear of the

hood.

• An activated charcoal lter cleans the air before