Alto Shaam CTP20-10G User Manual

U.S.A./C ANADA

U.S.A.

CAPACITY

CT PROFORMANCE – STANDARD FEATURES

•

•

•

•

•

• Access an unlimited number of programmed titled recipes

PATENT PENDING

PATENT PENDING

• Auto-detect USB for HACCP data access, Recipe

programmed in hours, minutes and seconds giving greater

FACTORY INSTALLED OPTIONS

Electrical Choices

Gas Type

Door Swing

U.S. PATENT

CHOOSE ONLY ONE

AVAILABLE IN THE U.S. AND CANADA ONLY

AVAILABLE THROUGH AN

ALTO-SHAAM AUTHORIZED SERVICE AGENCY

NOT AVAILABLE ON UNITS WITH SECURITY DEVICES

• Twenty (20) full-size or GN 1/1 pans, twenty (20)

half-size sheet pans; one row deep

• Roll-in pan cart with twenty (20) non-tilt support

rails; 13" (330mm) horizontal width between rails,

2-9/16" (65mm) vertical spacing between rails

CONSTRUCTION

• Stainless steel exterior, bright annealed interior

• Seamless welded interior stainless steel cavity

• CoolTouch3™ triple pane window door with hinged

inner glass prevents additional heat loss and

increases cooking efficiency

• Door is hinged right with a 130° swing

• High efficiency LED lighting integrated in the door

• Door mounted drip tray

Item no. _______________________

CTP20-10G

Gas boiler-free

• Hands free positive catch door handle with lighted

visual alerts [patent pending]

• PROrinse™ ergonomic retractable hand shower

includes a safety shutoff interlock that shuts off water

to the hose when fully retracted [patent pending] and

a built-in backflow preventer

• SafeVent™ provides automatic steam venting at the

end of the cooking cycle [patent #7,282,674]

• Zero Clearance system maximizes floor space

utilization with features that carefully protect

temperature sensitive components and control

[patent pending]

• Adjustable stainless steel flange legs provide stability

• Roll-in pan cart includes mounted drip tray and four

(4) swivel casters, including two (2) with brakes.

• High efficiency modulating gas burner maximizes the

residence time of flue gases [patent pending]

Oven with state-of-the-art innovative solutions that meld

together perfectly to deliver the highest performance

standards, consistent food quality, and production

efficiency.

PROtouch™ control provides a simple and intuitive touch

screen interface, large screen display and icons that are

easy to use and identify.

Software operation in English, French, German, Korean,

Mandarin, Russian, or Spanish.

Four cooking modes:

Steam - 85°F to 250°F (30°C to 120°C)

Convection - 85°F to 575°F (30°C to 301°C)

Combination - 85°F to 575°F (30°C to 301°C)

Retherm - 245°F to 320°F (120°C to 160°C)

Cook time is displayed in hours : minutes : seconds for

greater precision.

SHORT FORM SPEC

Provide Alto-Shaam Combitherm® CT PROformance™ floor-standing model CTP20-10g

boiler-free gas CombiOven designed with EcoSmart® technology for reduced energy and

water consumption. Includes operational modes for steam, convection, a combination

of steam and convection heat, and retherm. Oven is to be constructed of 18 gauge

stainless steel interior cavity. Oven includes an attached retractable hand shower spray

hose with safety shutoff interlock system and a backflow preventer. PROtouch™ control

features include a cool-down function, automatic cleaning function, recipe programming,

120V 1ph 208-240V 1ph

208-240V 3ph 380-415V 3ph

Natural Propane

Right-hand Door Hinging, standard

Recessed Door, optional; increases oven width

by 5" (127mm)

Extended One-year Warranty

Printed in the U.S.A.

that you’ve customized, marked as favorites, or placed into

category folders.

Management, and software updates.

• Multi-shelf timers can be labeled by product name and

• Removable, single-point, quick-connect, core temperature

product probe.

• Three power levels: reduced power to manage kitchen

power peaks, eco power for optimal oven efficiency, and

PROpower™ - an accelerated turbo power for an instant

boost of heat or quick heat recovery [

].

• Absolute Humidity Control™ (AHC) provides 0-100%

humidity levels allowing more control over the ideal

cooking environment and product finish [

• Auto-reversing fan with five different fan speeds expands

cooking capabilities - from braising, roasting, to flow

sensitive products such as soufflés and meringues, or any

product affected by a high velocity of air movement.

• Moisture injection feature provides perfect sheen and crust

on breads and pastry items.

control for delicate items.

• Sleep mode can be used to save valuable time by

eliminating the need to power down and restart.

• Low temperature Delta-T feature for lower temperature

cooking or longer term roasting.

• Programmable cool down feature provides the operator

with the ability to lower the temperature of the oven

].

compartment at an accelerated pace.

• Dehydration auxiliary function.

• CombiClean PLUS™ fully automated cleaning with 5

cleaning levels.

• Odometer tracking and audit trail provides extensive

diagnostic and troubleshooting features.

three power levels, 0-100% humidity levels, auto-reversing fan with five (5) fan speeds,

multi-shelf timers, and sleep mode. Oven includes right-hand door hinging with integrated

preheat strip, USB port, HACCP data access, and six (6) adjustable stainless steel

seismic legs. Roll-in pan cart accommodates up to twenty (20) half-size sheet pans or

twenty (20) full-size hotel pans (GN 1/1), twenty (20) non-tilt support rails, and includes

ten (10) stainless steel shelves.

Automatic Grease Collection System [

8,997,730 B2], includes four (4) 6-piece, self-trussing

poultry racks with deflectors #5020829, interior drip

collection pan, and grease collection container with shut

off valve

Cleaning system choices

Automatic tablet-based cleaning system, standard

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 • U.S.A.

Phone: 262.251.3800 800.558.8744

Automatic liquid cleaning system pumps through the

system for a deep cleaning, hands free process,

includes one (1) removable support tray for liquid

cleaner container, optional

Installation Options (

Alto-Shaam Combitherm Factory Authorized Installation

Program -

Installation Start-Up Check -

Due to ongoing product improvement, specifications are subject to change without notice.

)

Fax: 262.251.7067 800.329.8744

www.alto-shaam.com

Probe Choices

Removable, single-point, quick-connect core

temperature probe, standard

Removable, single-point, quick-connect sous vide

temperature probe, optional

Hard-wired, multi-point core temperature probe, optional

Security Devices for correctional facility use

Optional base package (not available with recessed

door): Includes tamper-proof screw package, secured

door glass, and correctional institution roll-in pan cart,

excludes temperature probe

Anti-entrapment device, optional

Control panel security cover, optional

Hasp door lock (padlock not included), optional

Removable, single-point, quick-connect core

temperature probe, optional

Smoking Feature - including one-step cold smoking

(

)

only

# 43 5 - 10 /1 6

GAS REQUIREMENTS (GAS TYPE MUST BE SPECIFIED ON ORDER)

HOOK-UP: 3/4" NPT

RATED THERMAL LOAD CONNECTED PRESSURE

NORTH AMERICA INTERNATIONAL NORTH AMERICA INTERNATIONAL

Natural Gas/Propane G20, G25, G31 Natural Gas Propane

G20 20mbar (2kPa)

Gross Heating Value (HHV) Net Heating Value (LHV) Minimum: 5.5" W.C. dynamic Minimum: 9" W.C. dynamic

G25 20mbar (2kPa)

160,000 Btu / hr 42.5 kW Maximum: 14" W.C. static Maximum: 14" W.C. static G31 30mbar (3kPa)

WEIGHT SHIP DIMENSIONS PAN CAPACITY

NET 905 lbs est 411 kg

(L x W x H)

56" x 45" x 87"*

FULL–SIZE: 20" x 12" x 2-1/2" Twenty (20)

PRODUCT MAXIMUM: 240 lb (109 kg)

SHIP 1175 lbs* 533 kg* (1422 x 1143 x 2210mm)*

GN 1/1: 530 x 325 x 65mm Twenty (20)

VOLUME MAXIMUM: 150 quarts (190 liters)

*

DOMESTIC GROUND SHIPPING INFORMATION. CONTACT FACTORY FOR

EXPORT WEIGHT AND DIMENSIONS.

**HALF–SIZE SHEET: 18" x 13" x 1" Twenty (20)

**ON WIRE SHELVES ONLY. ADDITIONAL WIRE SHELVES

REQUIRED FOR MAXIMUM CAPACITY

ELECTRICAL - CTP20-10G

(DEDICATED CIRCUIT REQUIRED)

WITH COMBISMOKER® OPTION

VOLTAGE PH HZ AWG (mm

2

)

CONNECTION

no cord, no plug

AMPS BREAKER kW

CONNECTION

no cord, no plug

AMPS BREAKER kW

✑

✎

▲

120 1 60 12 (3.31) L1, L2/N, G 13.6 20 1.7 L1, L2/N, G 18.4 25 2.3

✑

✒

▲

208 – 240

1

✝

50/60 14 (2.08) L1, L2/N, G 9.6 – 8.4 15 2.0 L1, L2/N, G 12.1 – 11.3 15 2.5 – 2.7

✑

✒

▲

208 – 240 3 50/60 14 (2.08) L1, L2, L3, G 9.6 – 8.4 15 2.0 L1, L2, L3, G 12.1 – 11.3 15 2.5 – 2.7

✒

380 – 415 3 50/60 14 (2.08) L1, L2, L3, N, G 9.2 – 8.4 15 2.0 L1, L2, L3, N, G 11.8 – 11.3 15 2.6 – 2.7

✑

NORTH AMERICA VOLTAGE CHOICE

✎

GROUND FAULT OR RESIDUAL CURRENT PROTECTION DEVICE MUST ACCOMMODATE A LEAKAGE CURRENT OF

20mA

✒

INTERNATIONAL VOLTAGE CHOICE

✝

ELECTRICAL SERVICE CHARGE APPLIES

▲

PER UL REQUIREMENTS, MUST BE PERMANENTLY CONNECTED TO ELECTRICAL SUPPLY SOURCE

WATER REQUIREMENTS WATER QUALITY STANDARDS

TWO (2) COLD WATER INLETS - DRINKING QUALITY

ONE (1) TREATED WATER INLET: 3/4" NPT*

ONE (1) UNTREATED WATER INLET: 3/4" NPT*

LINE PRESSURE: 30 psi minimum dynamic and 90 psi maximum static (200 to 600 kPa)

WATER DRAIN:

1-1/ 2" (40mm)

CONNE CTION WITH A

VERTI CAL

VENT TO EXTEN D ABOVE THE EXHAU ST

VENT.

MATERIA LS MUST WITHS TAND TEMPE RATURES UP TO

200°F (93°C).

CLEARANCE REQUIREMENTS

LEFT: 0" (0mm) 18" (457mm)

RECOMMENDED SERVICE ACCESS

RIGHT:

0" (0mm) NON-COMBUSTIBLE SURFACES

2" (51mm) DOOR SWING OR

COMBUSTIBLE SURFACES

TOP: 20" (508mm) FOR AIR MOVEMENT

BACK:

4" (102mm)

4-5/16" (109mm)

OPTIONAL PLUMBING KIT

BOTTOM: 5-1/8" (130mm)

FOR LEGS, AIR INTAKE

INSTALLATION REQUIREMENTS

• Oven must be installed level. • Hood installation is required.

• Water supply shut-off valve and back-flow preventer when required by local code.

It is the sole responsibility of the owner/operator/purchaser of this equipment

to verify that the incoming water supply is comprehensively tested and if

required, a means of “water treatment” provided that would meet compliance

requirements with the published water quality standards shown below.

Non-compliance with these minimum standards will potentially damage this

equipment and/or components and void the original equipment manufacturer’s

warranty. Alto-Shaam recommends using OptiPure

®

[www.optipurewater.com]

products to properly treat your water.

Contaminant

Free Chlorine

Hardness

Chloride

pH

Silica

Total Dissolved Solids (tds)

Inlet Water Requirements

Less than 0.1 ppm (mg/L)

30-70 ppm

Less than 30 ppm (mg/L)

7.0 to 8.5

Less than 12 ppm (mg/L)

50-125 ppm

* Both inlets can be from same 3/4" source.

Divide using a manifold. Run one side through

treatment device before running to oven.

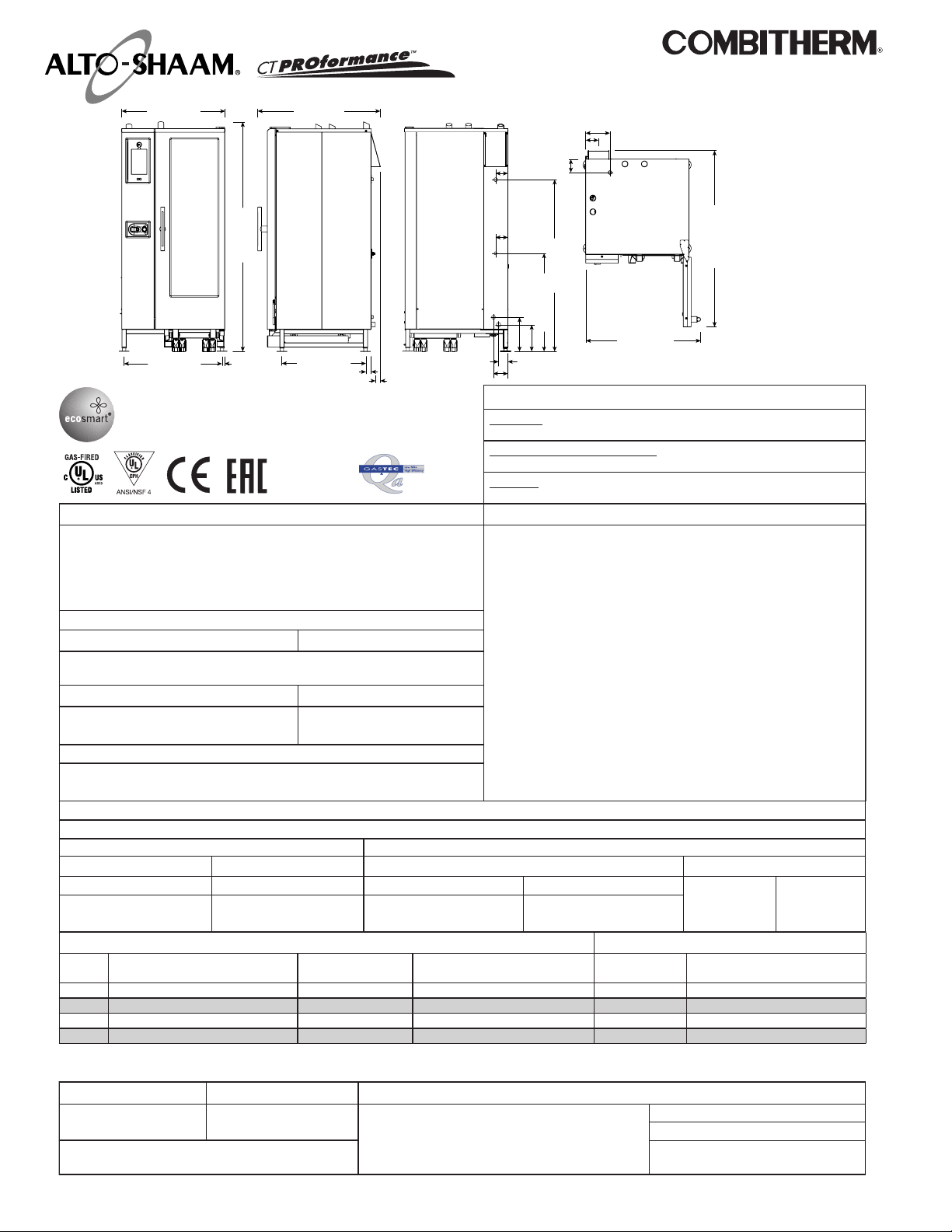

DIMENSIONS: H x W x D

EXTERIOR:

79-1/4" x 35-11/16" x 42-1/4" (2012mm x 906mm x 1072mm)

EXTERIOR WITH RECESSED DOOR:

79-1/4" x 40-11/16" x 42-1/4" (2012mm x 1033mm x 1072mm)

INTERIOR:

60-7/16" x 16-1/4" x 28-1/16" (1535mm x 411mm x 712mm)

IP X5

35-11/16" (906mm)

1-11/16" (42mm)

33-13/16" (858mm)

79-1/4" (2012mm)

1" (24mm)

42-1/4" (1072mm)

28-13/16" (732mm)

1-15/16" (49mm)

CTP20-10G

Gas boiler-free

60-13/16" (1545mm)

4-1/2" (114mm)

A= UNTREATED WATER

B= TREATED WATER

C= ELECTRICAL

D= GAS

E= WATER DRAIN

7-15/16" (202mm)

C (at bottom of oven)

39-11/16" (1008mm)

4-1/4" (108mm)

4-1/8" (105mm)

B

D

A

E

B

4-3/16"

(106mm)

D

59-1/4" (1504mm)

11-13/16" (299mm)

A

E

9-3/16" (233mm)

33-13/16" (858mm)

3-1/4" (81mm)

5" (126mm)

# 43 5 - 10 /1 6 d ue to on go i n g pr o d uc t i mp r ov e me n t , sp e c if i ca t io n s a r e s ub j e ct to ch an g e w i th o u t no t i ce . w ww . al to - sh a am . co m

Loading...

Loading...