Page 1

PH ONE

U.S.A./C ANAD A

FA X

U.S.A. O NLY

D UE TO ON G O IN G P R OD U C T IM P RO V EM E NT , S P EC I FI C AT I ON S A RE SU BJ E CT TO CH AN G E W IT H OU T N O T IC E .P RI N TE D IN U. S. A.

step-by-step procedures

DANGER

DANGER

CTC6-10E, CTC6-10G

CTC10-10E, CTC10-10G

CTC7-20E, CTC7-20G

CTC10-20E, CTC10-20G

CTC20-10E, CTC20-10G

CTC20-20E, CTC20-20G

Consult

instructions

for installation

and use.

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 • U.S.A.

www.alto-shaam.com

DO NOT store or use gasoline or other

fl ammable vapors or liquids in the

vicinity of this or any other appliance.

: 262.251.3800 800.558.8744

IMPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH,

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

: 262.251.7067 800.329.8744

MN-36455 • REV. 2 • 02/14

Page 2

INTRODUCTION .......................1

DANGER

• If unable to contact your gas supplier,

SAFETY PRECAUTIONS ................2

CT CLASSIC CONTROL INSTRUCTIONS

Control Panel Identification .................4

Oven Cool Down Process ................... 4

Fahrenheit or Celsius Format ................ 4

Operating Instructions .....................6

RECIPES

Bakery Recipes ............................ 9

Convenience Product Recipes .............. 10

Fish & Seafood Recipes ....................11

Meat Recipes ............................12

Miscellaneous Recipes ....................13

Poultry Recipes ..........................14

Vegetable Recipes ........................ 15

CLEANING & MAINTENANCE

Cleaning Agents .........................16

Precautions ..............................16

First Aid ................................ 16

Preventive Maintenance ...................17

Protecting Stainless Steel Surfaces. . . . . . . . . . . 18

Daily Gasket Cleaning ....................19

Probe Usage and Cleaning .................19

Daily Oven Cleaning ...................... 19

Monthly Cleaning ........................19

Combihood PLUS™ Filters ................ 20

CombiClean® ...........................21

TROUBLE SHOOTING

Error Codes .............................22

WARRANTY & TRANSPORTATION

Original Equipment Limited Warranty .......29

Transportation Damage & Claims ........... 30

Please post the following instructions in a prominent

location in the event the user smells gas.

BEFORE STARTING THE

APPLIANCE, MAKE CERTAIN

YOU DO NOT DETECT THE

ODOR OF GAS.

IF THE ODOR OF GAS IS DETECTED:

• DO NOT attempt to light any appliance.

• DO NOT touch any electrical switches.

• Extinguish any open fl ame.

• Use a telephone OUTSIDE THE

PROPERTY & IMMEDIATELY

contact your gas supplier.

contact the fi re department.

i

Page 3

ECOSMART® TECHNOLOGY

IntroductIon

The Alto-Shaam Combitherm combination

oven/steamer employs Ecosmart operating

efficiencies in the design and application

of all operating and programming

functions. Ecosmart operational

characteristics include the use of a water barrier

to close the oven compartment to the outside air.

While maintaining a non-pressurized atmosphere,

the primary purpose of the Ecosmart system is to

prevent the steam and heat generated within the oven

compartment from freely escaping to the outside.

The Ecosmart design displaces the air within the

cooking compartment and achieves a higher level

of steam saturation that offers quick-steaming at

temperatures above 212°F (100°C).

This guide is provided as an operational aid with

step-by-step instructions of the basic functions of

the Combitherm oven, along with the many other

additional features of the control.

CLASSIC CONTROL

The CT Classic features a simple, push button control that commands

all the oven functions. Whether you cook by time, or cook using the

optional product probe, rest assured you will be able to bake, roast,

steam, poach, grill, broil, proof, braise and oven fry with confidence.

STEAM MODE

LED display - Easy to read display indicates temperature settings, time

remaining, and various instructions.

COMBINATION MODE

CONVECTION MODE

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 1.

Page 4

2. This appliance is intended for use in commercial

SAFETY PROCEDURES

AND PRECAUTIONS

NOTE

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

DANGER

Used to indicate the presence of

a hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

WARNING

Used to indicate the presence of

a hazard that CAN cause personal

injury, possible death, or major

property damage if the warning

included with this symbol is ignored.

1. This appliance is intended to cook, hold

or process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

establishments where all operators are

familiar with the purpose, limitations, and

associated hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

CAUTION

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

CAUTION

Used to indicate the presence of a hazard that

can or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

NOTE: Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

CAUTION

WHEN WELDING ANY STAINLESS

STEEL COMPONENTS ON THIS

APPLIANCE, THE ELECTRONIC

CONTROL BOARDS MUST BE

ISOLATED FROM THE APPLIANCE.

CAUTION

CHILDREN MUST BE SUPERVISED

AT ALL TIMES WHILE IN THE

PRESENCE OF THIS APPLIANCE

AND NOT ALLOWED TO PLAY WITH

OR OPERATE THE OVEN.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 2.

Page 5

ANY KIND. DO NOT USE WATER JET

IntroductIon

CAUTION

IMPORTANT SAFETY PRECAUTIONS

NOTE: Automatic steam venting is a standard

safety feature built into all Combitherm

oven models. This feature vents all steam

from the oven compartment immediately

before cooking time expires or set probe

temperature is reached.

Automatic steam venting does not function

if the oven door is opened before time

expires or when the oven has been set to

continuous operation.

HOT STEAM CAUSES BURNS

ROTATE THE DOOR HANDLE TO RELEASE THE

DOOR LATCH. WAIT UNTIL THE STEAM IS VENTED

BEFORE FULLY OPENING THE DOOR.

CAUTION

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN

IN OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

NOTE: Use authorized Combitherm oven cleaner

only. Unauthorized cleaning agents may

discolor or harm interior surfaces of the

oven. Read and understand label and

material safety data sheet before using the

oven cleaner.

FOR OPERATOR SAFETY

NOTE AND OBSERVE ALL SAFETY PRECAUTIONS

LOCATED THROUGHOUT THIS GUIDE

DO NOT HANDLE PANS CONTAINING LIQUID

OR SEMILIQUID PRODUCTS POSITIONED

ABOVE THE EYE LEVEL OF THE OPERATOR.

SUCH PRODUCTS CAN SCALD AND CAUSE

SERIOUS INJURY.

DANGER

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

TO CLEAN.

SEVERE DAMAGE OR

ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

CAUTION

MAKE CERTAIN THE AREA AROUND

THE APPLIANCE IS KEPT CLEAR OF

COMBUSTIBLE ITEMS.

To prevent malfunction or cause

negative back draft, DO NOT obstruct

exhaust fl ues or attach any fl ue

extension that will impede proper

burner operation.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 3.

DO NOT USE THE ATTACHED HAND-HELD

HOSE TO SPRAY ANYTHING OTHER THAN

THE INTERIOR OF THE COMBITHERM OVEN

COMPARTMENT.

DO NOT USE THE SPRAY HOSE ON

THE SURFACE OF A HOT COOKING

COMPARTMENT. ALLOW THE OVEN TO COOL

TO A MINIMUM OF 150°F (66°C).

Page 6

CT CLassiC operaTing insTruCTions

160°F

00:00

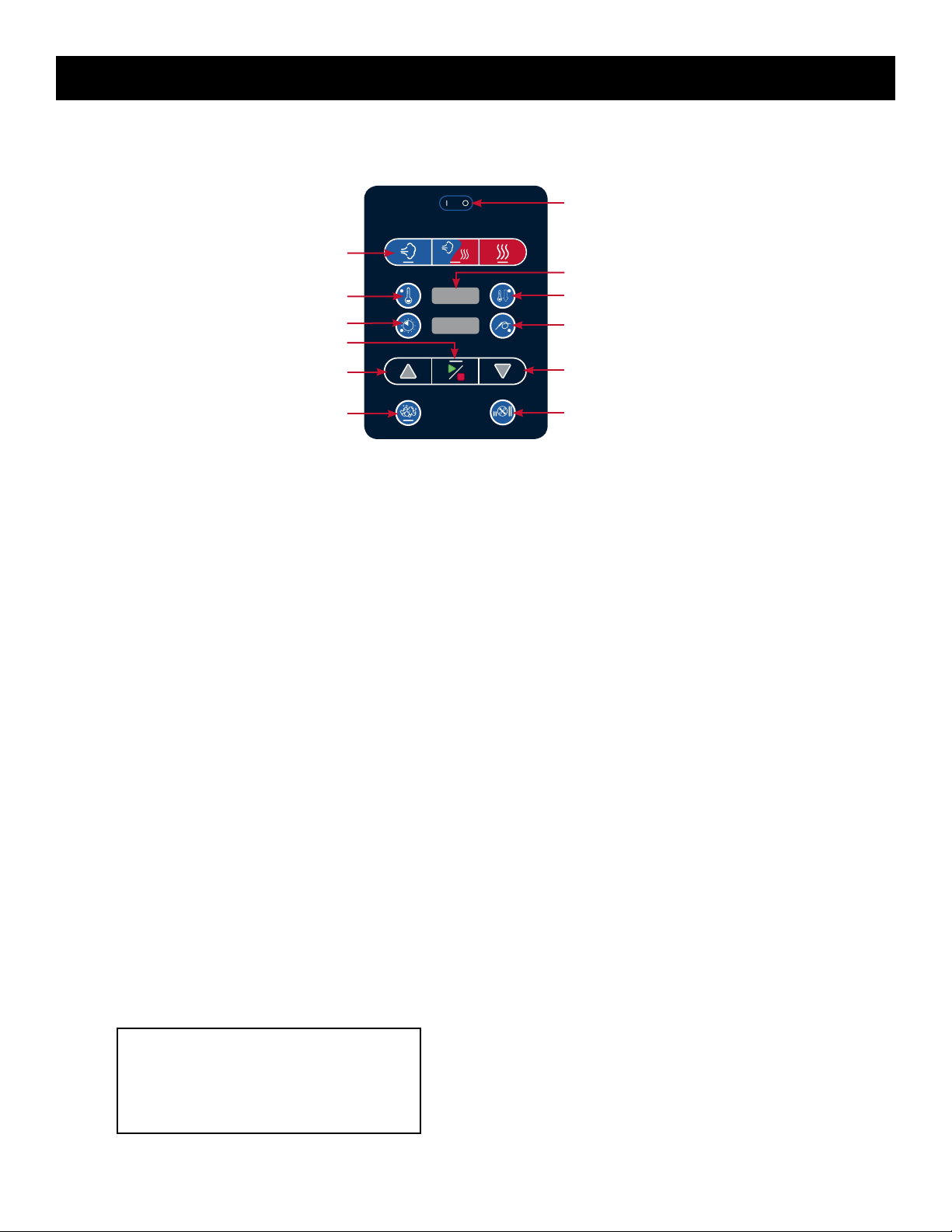

CONTROL PANEL IDENTIFICATION

Power Key

Cooking Mode Keys

LED display

Temperature key

Time key

Start/Stop key

Cool down key

Probe key

Up Arrow key

Cleaning key

The Steam mode provides the operator with the ability

to steam, poach, blanch, or sous vide. This mode will

automatically steam at the boiling point of water; quicksteam above the boiling point for faster cooking results; or

low temperature steam, below the boiling point, for more

delicate products such as pâté, mousse, seafood, or custard.

The Combination mode will prove to be the most

versatile and widely used mode the Combitherm oven has

to offer. It will produce the best possible results on the

widest variety of products — all within the shortest period

of time. The unique control function of this mode enables

the operator to roast or bake with a combination of steam

and convection heat. In addition to shorter cooking times,

this combination of steam and heat offers less product

shrinkage and more moisture retention than obtained in a

standard convection oven.

The Convection mode operates with hot circulated air

within a temperature range of 85°F to 575°F

(29°C to 300°C). For many applications, better results may

be achieved with the Combination mode; therefore, the

operator may want to consider using the Convection mode

on a more limited basis.

NOTE: In the event of a power failure,

the oven will not operate.

Down Arrow key

Fan Speed key

Oven Cool Down Process:

• Cooking process must be inactive

• Press "Cool Down" button until LED lights (LED

remains ON while in Cool Down mode)

• Press "Decrease Value" or "Increase Value" to adjust

cool down temperature

• Cook temperature display area is used to display cool

down temperature

• Display will show last valid cool down temperature

• Cool down temperature range is 85°F - 575°F

(30°C - 300°C)

• Press "Start/Stop" until LED lights to accept cool

down temperature and initiate cool down process

• Door must be open to start cool down process;

Cook time display area will display "door" if door

is not open

• Cook temperature display area will display set cool

down temperature

• Cook time display area will display current cool down

temperature

Fahrenheit or Celsius Function -

choose temperature format:

• Unit is not in a cooking or cleaning process

• Press "Set Cooking Temperature", "Decrease Value"

and "Increase Value" buttons simultaneously for

1 second

• Cooking temperature display area will display last

value "C" or "F"; Display will alternate between "C"

and "F" every 2 seconds

• Press "Start/Stop" key when the display is showing

the desired value ("C" or "F")

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 4.

Page 7

CT ClassiC operaTing insTruCTions

160°F

160°F

00:00

160°F

00:00

160°F

00:00

160°F

00:00

160°F

160°F

00:00

160°F

160°F

00:00

160°F

00:00

160°F

00:00

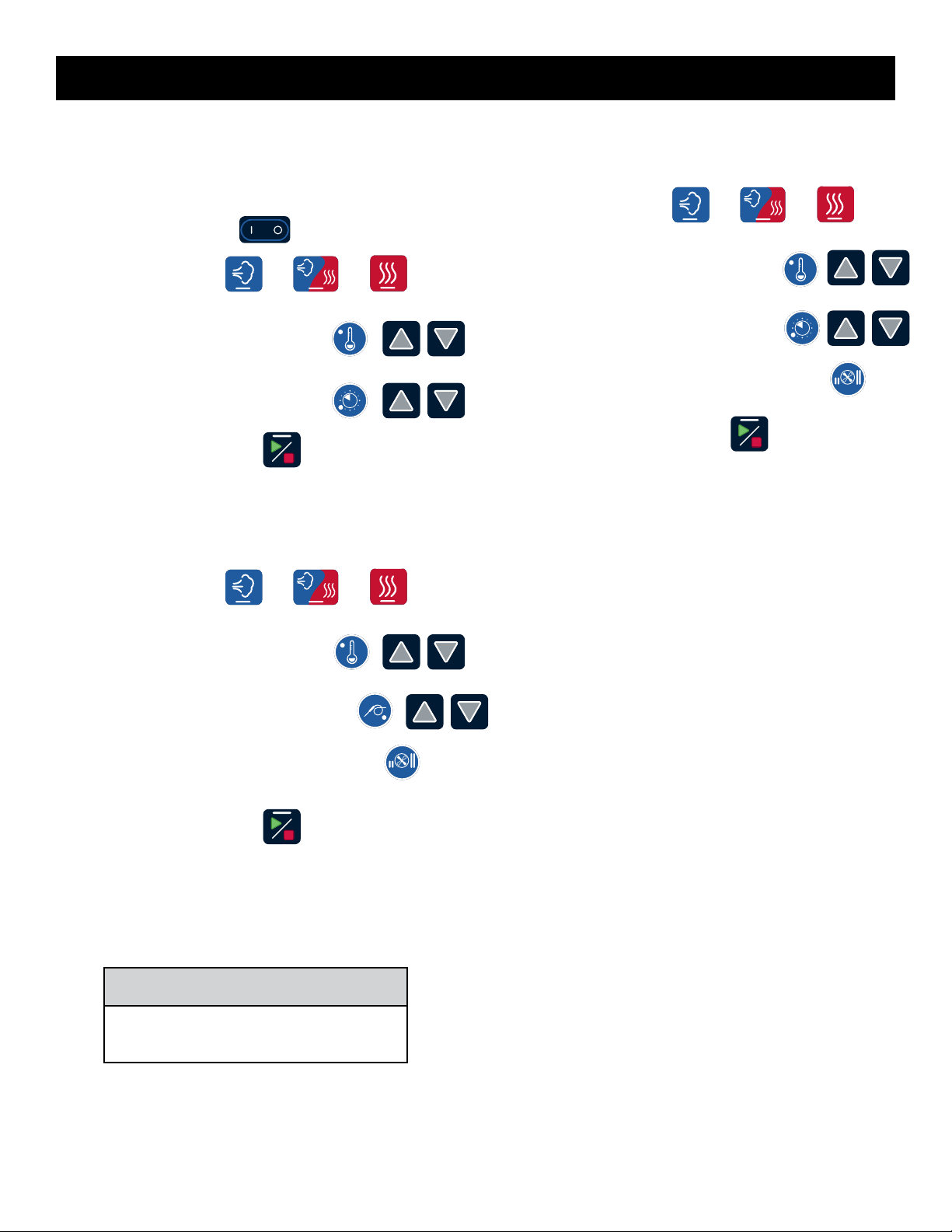

Turn on and preheat the oven

Alto-Shaam recommends preheating the Combitherm® before cooking.

• Press the Power key.

• Choose a Mode.

Steam

• Press Oven Temperature key;

adjust temperature with arrow keys.

• Press Cook Time Key;

adjust time with arrow keys.

• Press the Start/Stop key.

• Preheat oven before loading food.

Combi

Convection

To cook by probe

• Choose a Mode.

Steam

• Press the Oven Temperature key;

adjust temperature with arrow keys.

Combi

Convection

To cook by time

• Choose a Mode.

Steam

• Press the Oven Temperature key;

adjust temperature with arrow keys.

• Press the Cook Time key;

adjust time with arrow keys.

• Press Fan Speed key to set to High or Low.

• Load food into oven.

• Press the Start/Stop key.

Combi

Convection

• Press the Probe Temperature key;

adjust probe temperature with arrow keys.

• Press Fan Speed key to set to High or Low.

• Load food into oven and insert probe into food.

• Press the Start/Stop key.

CAUTION HOT

USE CAUTION WHEN OPENING THE OVEN DOOR

WHEN THE COOKING CHAMBER IS HOT TO

AVOID POSSIBLE BURNS.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 5.

In the event of a prolonged power

failure during the cooking process,

it is strongly recommended that

you ensure the food is safe for

consumption according to local

health regulations.

Page 8

OPERATING INSTRUCTIONS

STEAM MODE CHEF OPERATING TIPS

This mode will steam a full or partial load of a single product,

or multiple products without transfer of flavors. When

steaming multiple products, however, individual product

cooking times must be taken into consideration.

STEAM

Perforated, 2-1/2" deep pans (65mm)

are particularly suitable for use in

this program mode. These pans will

provide a shorter cooking time and will

prevent product over-cooking at the

bottom of the pan.

Separate ice-encrusted vegetables

before steaming to ensure

even cooking.

A variety of products can be steamed

at the same time but attention must

be paid to the different cooking times

required for each food product.

When cooking by probe, the probe

must be inserted so that the tip is

positioned in the center of the food

mass. For liquid or semi-liquid foods,

suspend the probe in the center of the

product and secure the probe wire to

the edge of the container.

HIGH TEMP STEAM

High temperature steaming is suitable

for hearty, root-type vegetables such as

potatoes, turnips, carrots, and cabbage.

High temperature steaming provides

a cooking time which is approximately

10-percent shorter than the regular

steam mode temperature of 212°F

(100°C).

The non-pressurized atmosphere of the Combitherm also

provides the ability to open the door during the steam mode

in order to monitor products more closely throughout the

steaming process.

LOW TEMP STEAM

The low temperature steam mode

will function whenever the oven

compartment temperature is below

212°F (100°C).

It will take longer to steam products

using the low temperature

steam mode.

Steaming sausages in low temperature

steam prevents cracked or peeling

skins.

Use low temperature steam for delicate

foods such as shrimp, fish, seafood,

crème caramel, and sous vide.

For best results, low temperature steam

all delicate food items at a temperature

of 210°F (99°C) or below.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 6.

Page 9

OPERATING INSTRUCTIONS

COMBINATION MODE CHEF OPERATING TIPS

The Combination mode injects the optimum amount of

steam automatically. There is no need to select humidity

levels. Foods do not dry out. Flavors are retained with no

transfer of flavors when mixing product loads.

Due to automatic steam adjustment, the door can be opened

at any time during a cooking operation. Be certain to observe

the safety warning when opening the oven door.

The Combination mode is particularly efficient when used

for baking, broiling, grilling, stewing, braising, and roasting.

When using the Combination mode, cooking temperatures

can be reduced 10- to 20-percent below the temperatures

used for conventional cooking methods.

Cooking time will be reduced approximately 40-percent

when cooking at the same temperature used for convection

oven cooking and up to 50- to 60-percent less time when

cooking at the same temperature used for a conventional

oven.

Food browning in the Combitherm begins at a cooking

temperature of approximately 250°F (120°C).

A higher cooking temperature results in heavier browning

but also results in greater product weight loss.

The Combination mode provides even browning without the

necessity to turn the pans.

For more even cooking, do not cook in pans deeper than

4" (100mm).

When cooking by probe, the probe must be inserted so

that the tip is positioned in the center of the food mass. For

liquid or semi-liquid foods, suspend the probe in the center

of the product and secure the probe wire to the edge of the

container.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 7.

Page 10

OPERATING INSTRUCTIONS

CONVECTION MODE CHEF OPERATING TIPS

The Convection Mode can be used to roast or bake products

needing very short cooking times or for high moisture

products such as muffins, cakes, and cookies, or for

browning the surface of the food.

The Convection mode works best with low moisture foods or

for very moist food which require a dryer finished product.

For baking, preheat the Combitherm at a temperature of

325°F to 375°F (163°C to 191°C). Once preheated, reset the

temperature as required.

A higher cooking temperature results in heavier browning

but also results in greater product weight loss.

When cooking by probe, the probe must be inserted so

that the tip is positioned in the center of the food mass. For

liquid or semi-liquid foods, suspend the probe in the center

of the product and secure the probe wire to the edge of the

container.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 8.

Page 11

recipe guidelines

BAKERY ITEMS

PREHEAT

RECIPE

Bakery (retherm)

Brownies

Cinnamon Rolls

Cookies

Croissants

Danish Pastry

Dinner Rolls

French Bread

Fruit Pie

Muffins

Par-baked Bread Frozen

Par-baked Rolls

Proofing — Steam

Puff Pastry

Sheet Cake

TEMP

275°F

(135°C)

325°F

(163°C)

350°F

(177°C)

325°F

(163°C)

340°F

(171°C)

340°F

(171°C)

350°F

(177°C)

385°F

(196°C)

340°F

(171°C)

340°F

(171°C)

350°F

(177°C)

350°F

(177°C)

375°F

(191°C)

340°F

(171°C)

COOKING

MODE

Combi

Convection

Combi

Convection

Combi

Combi

Combi

Combi

Convection

Convection

Convection

Combi

Convection

Combi

Combi

Convection

Convection

COOK

TEMP

275°F

(135°C)

325°F

(163°C)

350°F

(177°C)

325°F

(163°C)

340°F

(171°C)

340°F

(171°C)

350°F

(177°C)

385°F

(196°C)

385°F

(196°C)

340°F

(171°C)

340°F

(171°C)

350°F

(196°C)

350°F

(177°C)

350°F

(177°C)

90°F

(32°C)

375°F

(191°C)

375°F

(191°C)

325°F

(163°C)

TIME /

PROBE

4

minutes

25

minutes

8

minutes

12

minutes

9

minutes

11

minutes

10

minutes

1

minute

15

minutes

60

minutes

20

minutes

1

minute

9

minutes

13

minutes

30

minutes

1

minute

16

minutes

20

minutes

FAN

SPEED

100%

100%

100%

100%

100%

100%

100%

100%

100%

50%

50%

100%

100%

100%

100%

Note: Times & temperatures shown are for 50% - 80% of oven capacity.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 9.

Page 12

recipe guidelines

CONVENIENCE PRODUCT ITEMS

RECIPE

Chicken Wings

Corn Dogs - Thawed

Egg Rolls

Entrée

(4 lb frozen)

French Fries - Full

Load

Hamburger Patties Frozen

Hamburger Patties Thawed

Mini Pizza

5"

Pizza - Fresh

Spring Rolls - Fresh or

Frozen

Tater Tots

PREHEAT

TEMP

425°F

(218°C)

300°F

(149°C)

400°F

(204°C)

350°F

(177°C)

475°F

(246°C)

375°F

(191°C)

375°F

(191°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

425°F

(218°C)

COOKING

MODE

Combi

Combi

Combi

Combi

Combi

Convection

Combi

Combi

Combi

Combi

Combi

Convection

Combi

COOK

TEMP

400°F

(204°C)

300°F

(149°C)

375°F

(191°C)

350°F

(177°C)

375°F

(191°C)

375°F

(191°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

375°F

(191°C)

TIME /

PROBE

10

minutes

10

minutes

15

minutes

140-160

minutes

1

minute

10

minutes

12

minutes

5

minutes

10

minutes

11

minutes

1

minute

14

minutes

10

minutes

FAN

SPEED

100%

100%

100%

50%

100%

100%

100%

100%

50%

100%

100%

Note: Times & temperatures shown are for 50% - 80% of oven capacity.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 10.

Page 13

recipe guidelines

FISH & SEAFOOD ITEMS

PREHEAT

RECIPE

Baked Fish - Fresh

Lobster - Whole

Salmon Filets — Steam

Salmon Steaks — Steam

Shrimp - Frozen — Steam

TEMP

450°F

(232°C)

160°F

(71°C)

COOKING

MODE

Combi

Steam

COOK

TEMP

400°F

(204°C)

195°F

(91°C)

145°F

(63°C)

145°F

(63°C)

158°F

(70°C)

TIME /

PROBE

10

minutes

13

minutes

7

minutes

8

minutes

12

minutes

FAN

SPEED

100%

50%

50%

100%

50%

Note: Times & temperatures shown are for 50% - 80% of oven capacity.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 11.

Page 14

recipe guidelines

MEAT RECIPES

PREHEAT

RECIPE

Bacon

Beef - Tenderloin

Beef - Tri Tips

Beef Rounds - Using

Probe

Breakfast Sausage

Links

Burgers (School) Precooked and Grilled

Hamburger Patties Frozen

Meat Loaf by Core

Temp

Pork - Back Ribs Raw

Pork - Loin - by Core

Temp

Pork Ribs Reheat

Sausage - Fresh Low Temp Steam

TEMP

318°F

(159°C)

250°F

(121°C)

250°F

(121°C)

250°F

(121°C)

350°F

(177°C)

350°F

(177°C)

375°F

(191°C)

325°F

(163°C)

250°F

(121°C)

325°F

(163°C)

400°F

(204°C)

COOKING

MODE

Combi

Convection

Combi

Combi

Combi

Combi

Combi

Combi

Combi

Combi

Combi

Combi

COOK

TEMP

318°F

(159°C)

318°F

(159°C)

250°F

(121°C)

250°F

(121°C)

250°F

(121°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

275°F

(135°C)

250°F

(121°C)

300°F

(149°C)

400°F

(204°C)

160°F

(71°C)

TIME /

PROBE

1

minute

15

minutes

Probe option

125°F (52°C)

Probe option

125°F (52°C)

Probe option

125°F (52°C)

8

minutes

Frozen - 8

minutes

Thawed - 4

minutes

1

minute

Probe option

155°F (68°C)

1 hour 15

minutes

Probe option

150°F (66°C)

7

minutes

15

minutes

FAN

SPEED

100%

50%

50%

50%

100%

100%

100%

100%

100%

100%

100%

50%

Note: Times & temperatures shown are for 50% - 80% of oven capacity.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 12.

Page 15

recipe guidelines

MISCELLANEOUS RECIPES

PREHEAT

RECIPE

Custard Creme Brûlée Steam

Eggs - Hardboiled

Eggs - Poaching Pan

Eggs - Poaching Pan

(Low Steam)

Eggs - Scrambled

in bag: shake at 18

minutes

Eggs - Scrambled in

pan

Eggs - Sous Vide — Steam

Pasta - Linguine or

Spaghetti

Rice

Tamales

TEMP

212°F

(100°C)

212°F

(100°C)

— Steam

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

COOKING

MODE

Steam

Steam

Steam

Steam

Steam

Steam

Steam

COOK

TEMP

190°F

(88°C)

212°F

(100°C)

212°F

(100°C)

170°F

(77°C)

212°F

(100°C)

212°F

(100°C)

148°F

(64°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

TIME /

PROBE

55

minutes

12

minutes

3

minutes

12

minutes

25

minutes

15

minutes

60

minutes

20

minutes

30

minutes

30

minutes

FAN

SPEED

50%

100%

50%

—

100%

100%

50%

100%

100%

100%

Note: Times & temperatures shown are for 50% - 80% of oven capacity.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 13.

Page 16

recipe guidelines

POULTRY RECIPES

RECIPE

Chicken - Oven Fried

Pieces

Chicken - Pre-Cooked

Pieces - Frozen

Chicken - Pre-Cooked

Pieces - Refrigerated

Chicken - Thawed

Whole

Chicken - 8 Piece Cut

Up

Grilled Chicken

Breasts

PREHEAT

TEMP

450°F

(232°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

375°F

(191°C)

550°F

(288°C)

COOKING

MODE

Combi

Convection

Combi

Combi

Combi

Combi

Combi

COOK

TEMP

450°F

(232°C)

450°F

(232°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

375°F

(191°C)

460°F

(238°C)

TIME /

PROBE

2

minutes

16

minutes

35

minutes

15

minutes

35

minutes

30

minutes

6

minutes

FAN

SPEED

100%

100%

100%

100%

100%

100%

Note: Times & temperatures shown are for 50% - 80% of oven capacity.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 14.

Page 17

recipe guidelines

VEGETABLE RECIPES

PREHEAT

RECIPE

Asparagus - Fresh — Steam

Broccoli, Cauliflower,

Squash, Zucchini Fresh

Cabbage, Green Beans

- Fresh

Carrots - Fresh

Corn-on-the-Cob Fresh

Frozen Vegetables

Potatoes, for mashed,

Full Loaded

Potatoes, for mashed,

Small Loaded

Potatoes, Red or Salad

Potatoes, Roasted

TEMP

212°F

(100°C)

212°F

(100°C)

225°F

(107°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

400°F

(204°C)

COOKING

MODE

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Combi

COOK

TEMP

190°F

(88°C)

212°F

(100°C)

212°F

(100°C)

225°F

(107°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

400°F

(204°C)

TIME /

PROBE

3

minutes

3 - 6

minutes

8 -10

minutes

10

minutes

14

minutes

8

minutes

30

minutes

30

minutes

30

minutes

18

minutes

FAN

SPEED

50%

100%

100%

100%

100%

100%

100%

100%

100%

100%

Note: Times & temperatures shown are for 50% - 80% of oven capacity.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 15.

Page 18

cleaning & Maintenance

WARNING

MOBILE EQUIPMENT RESTRAINT FOR GAS MODELS

The gas Combitherm must use a connector that

complies with The Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69 CSA 6.16 and

addenda Z21.69a-1989. A quick disconnect device

must be installed to comply with The Standard for

Quick Disconnect Devices for Use with Gas Fuel,

ANSI Z21 CSA 6.9. and European Standard EN203.

Adequate means must be provided to limit the

movement of this appliance. Limitation of movement

must be made without depending on the connector,

the quick disconnect device, nor the associated

piping designed to limit appliance movement. If it

becomes necessary to disconnect the restraint, it must

be reconnected immediately following the return of

the appliance to its original position.

1. Install a manual gas shut-off valve along with an

approved disconnect device.

2. Install an A.G.A. certified, heavy-duty connector

that complies with ANSI Z 21.69 or

CAN 1-6.10m88 along with a quick-disconnect

device in compliance with ANSI Z21.41 or

CAN 1-6.9m70. Connectors must be installed

with a cable restraint to prevent excessive tension

from being placed on the connector.

RISK OF ELECTRIC SHOCK.

Appliance must be secured

to building structure.

MOBILE EQUIPMENT RESTRAINT FOR ELECTRIC MODELS

Any appliance that is not furnished with a

power supply cord but includes a set of casters

must be installed with a tether. Adequate means

must be provided to limit the movement of this

appliance without depending on or transmitting

stress to the electrical conduit. The following

requirements apply:

1. Casters must be a maximum height of 6" (152mm).

2. Two of the casters must be the locking type.

3. Such mobile appliances or appliances on

mobile stands must be installed with the use

of a flexible connector secured to the

building structure.

CAUTION

THIS SECTION IS PROVIDED FOR THE ASSISTANCE

OF QUALIFIED SERVICE TECHNICIANS ONLY AND

IS NOT INTENDED FOR USE BY UNTRAINED OR

UNAUTHORIZED SERVICE PERSONNEL.

A mounting connector for a restraining device is

located on the lower back flange of the appliance

chassis or on an oven stand, approximately

18" (457mm) from the floor. A flexible connector is

not supplied by nor is it available from the factory.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 16.

Page 19

cleaning & Maintenance

Com b i Clea n CLEANING AGENTS

DANGER

RUBBER GLOVES MUST BE WORN WHEN USING

COMBICLEAN TABLETS OR SPRAY OVEN CLEANER.

NOTE: Use authorized Combitherm cleaner only.

Unauthorized cleaning agents may discolor or harm interior

surfaces of the oven. Read and understand

label and material safety data sheet before using the

oven cleaner.

CAUTION: Causes eye, skin, and respiratory tract

irritation. keep out of reach of children.

PRECAUTIONS:

- Do not take internally.

- Avoid contact with eyes and skin.

- Use rubber gloves when using this product.

- Wash hands thoroughly after handling.

- Avoid mixing with strong, concentrated acids.

DANGER

PROTECTIVE EYE WEAR MUST BE WORN

WHEN USING SPRAY OVEN CLEANER.

FIRST AID:

Skin: Flush with water. Remove contaminated clothing

and do not re-wear until washed. If irritation persists see a

physician.

Eyes: Flush with water for 15 minutes. See a

physician immediately.

Inhalation: If difficulty in breathing occurs, leave area

immediately and do not return until dust is settled. If

irritation persists, see a physician.

Ingestion: Drink large quantities of milk or water. DO

NOT INDUCE VOMITING. See a physician immediately.

PROTECTIVE PACKAGING OF TABLETS WILL

BEGIN TO DISSOLVE ONTO SKIN IF HANDLED

WITH DAMP OR WET HANDS.

Part Number CE-36354 Water Soluble Packets, 1 ounce each

Precautions:

Do not take internally. Avoid contact with eyes and skin. Use rubber gloves when using this product.

Wash skin thoroughly after handling. Avoid mixing with strong, concentrated acids.

First Aid:

Skin: Flush skin with water. Remove contaminated clothing and do not wear again until washed.

If irritation persists, see a physician.

Eyes: Flush eyes with water for 15 minutes. See a physician immediately.

Inhalation: If difficulty in breathing occurs, leave area immediately and do not return until dust is settled.

If irritation persists, see a physician.

Ingestion: Drink large quantities of milk or water. DO NOT INDUCE VOMITING. See a physician immediately.

Keep out of reach of children.

Danger: CORROSIVE. May cause severe burns to eyes and skin.

Warnings:

• Unauthorized cleaning agents may discolor or

harm interior surfaces of the oven.

• Read and understand label and material safety

data sheet before using the oven cleaner.

• Always wear rubber gloves when handling.

• Protective packaging will begin to dissolve onto

skin if handled with damp or wet hands.

• Cleaning agent causes burns to eyes, skin and

mucous membranes.

• Do not get in eyes, on skin, or on clothing.

• Harmful if swallowed.

• Keep out of reach of children.

• Do not mix with anything but water.

Instructions:

• Remove all food scraps and residue from the oven drain.

• Remove the smoker tray, if applicable.

• Ensure that the water is turned on for the oven.

• Allow oven to cool below 150°F (66°C).

• Wearing rubber gloves, remove oven interior drain screen at bottom of oven.

• Using the oven control, choose the cleaning level you would like to run.

• Insert the appropriate number of cleaning tablets into the oven cavity drain

as directed by the cleaning program you have chosen.

• Replace drain screen and close oven door.

• Press the Start key or the Yes key, depending upon the oven model you have.

• Oven will begin the cleaning cycle and will beep when the cleaning cycle

is completed.

• Leave door slightly ajar when cleaning is finished.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 17.

Page 20

cleaning & Maintenance

DANGER

PREVENTATIVE MAINTENANCE

In addition to the routine cleaning and maintenance

procedures, there are several additional steps to be taken

for both sanitation and to keep the oven running efficiently.

These additional safeguards will help prevent down time and

costly repairs.

DO NOT DISPOSE OF GREASE, FAT, WOOD

CHIPS OR SOLID WASTE DOWN THE OVEN

DRAIN.

Fats and solids will eventually coagulate in the drain system,

causing blockage. Consequently, water will back-up into the

condenser and interior oven compartment, resulting in an

oven that is inoperable.

MAKE CERTAIN THE DRAIN SCREEN IS

ALWAYS IN PLACE. REMOVE ANY SOLID WASTE

MATERIAL FROM THE DRAIN SCREEN BEFORE

IT ENTERS THE DRAIN SYSTEM.

The routine removal of solids from the drain screen will help

prevent blockage.

USE THE AUTHORIZED COMBITHERM OVEN

CLEANER ONLY.

The use of unauthorized cleaning agents may discolor or

harm the interior surfaces of the oven.

TO PROLONG THE LIFE OF THE DOOR GASKET,

CLEAN THIS ITEM DAILY.

The acids and related compounds found in fat, particularly

chicken fat, will weaken the composition of the gasket unless

cleaned on a daily basis. Wipe with a hot, soapy cloth.

TO ADDITIONALLY PROTECT GASKET LIFE,

ALLOW OVEN DOOR TO REMAIN SLIGHTLY

OPEN AT THE END OF THE PRODUCTION DAY.

An open door will relieve the pressure on the door gasket.

ROUTINELY CLEAN DOOR HINGES.

Open oven door to relieve tension. Clean all parts of

the hinge.

When smoking is completed, remove smoker box

from oven. Dispose of wood chips in a fire proof

waste receptacle.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 18.

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

ANY KIND. DO NOT USE WATER JET

TO CLEAN.

SEVERE DAMAGE OR

ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

Page 21

cleaning & Maintenance

The cleaning function can usually be accomplished

CAUTION

CLEANING AND PREVENTATIVE MAINTENANCE

PROTECTING STAINLESS STEEL SURFACES

It is important to guard against corrosion

in the care of stainless steel

surfaces. Harsh, corrosive,

or inappropriate chemicals

can completely destroy the

protective surface layer

of stainless steel. Abrasive

pads, steel wool, or metal implements will abrade

surfaces causing damage to this protective coating

and will eventually result in areas of corrosion.

Even water, particularly hard water that contains

high to moderate concentrations of chloride, will

cause oxidation and pitting that result in rust

and corrosion. In addition, many acidic foods

spilled and left to remain on metal surfaces are

contributing factors that will corrode surfaces.

Proper cleaning agents, materials, and

methods are vital to maintaining the appearance

and life of this appliance. Spilled foods should be

removed and the area wiped as soon as possible

but at the very least, a minimum of once a day.

Always thoroughly rinse surfaces after using a

cleaning agent and wipe standing water as quickly

CLEANING AGENTS

Use non-abrasive cleaning products designed for

use on stainless steel surfaces. Cleaning agents

must be chloride-free compounds and must not

contain quaternary salts. Never use hydrochloric

acid (muriatic acid) on stainless steel surfaces.

Always use the proper cleaning agent at the

manufacturer's recommended strength.

Contact your local cleaning supplier for

product recommendations.

CLEANING MATERIALS

with the proper cleaning agent and a soft, clean

cloth. When more aggressive methods must be

employed, use a non-abrasive scouring pad on

difficult areas and make certain to scrub with the

visible grain of surface metal to avoid surface

scratches. Never use wire brushes, metal scouring

pads, or scrapers to remove food residue.

S

O

N

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 19.

I

W

O

N

S

O

N

A

R

P

C

E

R

TO PROTECT STAINLESS STEEL

S

SURFACES, COMPLETELY AVOID

THE USE OF ABRASIVE CLEANING

B

E

R

COMPOUNDS, CHLORIDE BASED

R

U

S

H

CLEANERS, OR CLEANERS

E

S

CONTAINING QUATERNARY SALTS.

NEVER USE HYDROCHLORIC ACID

E

L

E

T

(MURIATIC ACID) ON STAINLESS

P

A

D

S

STEEL. NEVER USE WIRE

BRUSHES, METAL SCOURING

PADS OR SCRAPERS.

Page 22

cleaning & Maintenance

DANGER

ANY KIND. DO NOT USE WATER JET

CLEANING SCHEDULE

DAILY GASKET CLEANING

It is important to prolong the life of the oven gasket by

cleaning on a daily basis. Routine cleaning will help protect

the gasket from deterioration caused by acidic foods.

1. Allow the oven to cool, then wipe the gasket and crevices

with clean cloth soaked in warm detergent solution.

2. Wipe the gasket and crevices with a cloth and clean rinse

water.

Do not attempt to remove gasket or place in the dishwasher.

PROBE USAGE AND CLEANING

After each use of the CORE TEMP mode, wipe the probe tip

with a clean paper towel to remove food debris. Follow by

wiping the probe with a disposable alcohol pad. Return the

probe to the proper door bracket position.

Probe and Probe Prong Cleaning Procedures

1. Remove all food debris from probe between loads and at

the end of each production shift. Wipe the entire probe,

probe cable assembly, probe prongs, and probe holding

bracket with a clean cloth and warm detergent solution.

5. Allow trolley to air dry.

As an alternative, trolleys can be cleaned while inside the

oven. Allow the trolley to remain in the oven through the

normal cleaning cycle, followed by steps 2 through 5.

MONTHLY CLEANING

1. Spray Head

2. Water Intake Filters

3. Drain Pipe

2. Remove detergent by wiping the probe, cable, probe

prongs, and bracket with a cloth and clean rinse water.

3. Wipe probe and probe bracket with disposable alcohol

pad or sanitizing solution recommended for food contact

surfaces.

4. Allow probe, probe prongs, and cable to air dry in the

probe holding bracket.

5. Wipe the probe with a disposable alcohol pad prior to

inserting into a new food product.

DAILY OVEN CLEANING

To be performed at the end of the production day or

between production shifts.

ROLL-IN CART/FOOD TROLLEY CLEANING

(ON EQUIPPED MODELS)

1. Remove food trolley to a cart wash area. Trolleys may

be cleaned using any mild cleaning detergent and warm

water.

2. Hand wipe all framing, slides, drip pan, and base.

Thoroughly clean debris from the casters. A spray hose

can be used for easier cart cleaning.

3. Remove detergent solution with warm water.

4. Wipe or spray with a sanitizing solution designed for use

on metal and vinyl food contact surfaces.

TREATED WATER

UNTREATED WATER

WATER DRAIN

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

TO CLEAN.

SEVERE DAMAGE OR

ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 20.

Page 23

cleaning & Maintenance

COMBIHOOD PLUS™ VENTLESS HOOD OPTION

Grease Filter

(FI-25867):

Cleaning frequency should be based on oven

usage with a maximum of two weeks between

cleaning if the oven is used for non-grease laden

products or steam applications only. Grease

laden products require cleaning frequency of at

least once a week.

Remove the grease filter by pulling it straight

out of the housing. Place the filter in the

dishwasher or wash separately by placing in

hot, soapy water until all grease and particles

have been removed. Rinse thoroughly. Allow

the filter to air dry before reinstalling.

To replace the grease filter, the air flow arrow on

the filter casing should be pointing toward the

hood fan.

NOTE:

A pressure switch is used to detect when the airflow

through the charcoal filter is reduced by 25% indicating a possible blockage. This will generate an

E101 error message on the oven control display. The

filters will need to cleaned or replaced.

Charcoal Filter

(Class I - FI-36620; Class II - FI-25866):

The charcoal filter should be inspected for

contaminant's on a regular basis. Replacement

must be made at a minimum of three month

intervals — more often if heavy contaminant's

are visible or if the filter no longer controls

odors.

To remove the filter, pull and slide out while

holding the bottom housing. When replacing

the filter, make certain the air flow arrow(s)

point toward the hood fan, and that the filter

is replaced in the three-sided metal frame

provided with the hood.

If the filters are not seated properly, an error code E102

will appear on the oven control display.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 21.

Page 24

cleaning & Maintenance

160°F

00:00

160°F

00:00

One (1) heavy-duty cleaning cycle (2 hours 5 minutes) is

offered. CombiClean® CombiTabs™ CE-36354, 1 ounce

packets or Combitherm Spray Cleaning Liquid CE-24750

may be used. Side racks and shelves may remain inside oven

during cleaning. Remove solid wastes from the bottom of the

oven and the drain screen to prevent blockage.

Note: If a power outage were to occur during

any portion of the cleaning cycle, the oven will

begin a six (6) minute forced-rinse cycle.

Cook temperature display area will display “RIN”.

Cook time display area will display “-.--”

Power Key

LED display

Start/Stop key

Cleaning key

TO CLEAN THE OVEN

• Press the Cleaning key.

• Insert appropriate number of CombiClean® tabs

as directed by the LED Screen (CLn4 appears). The

“4” refers to the number of cleaning tablets that are

to be inserted in the cavity drain. User may add one

additional tablet for particularly dirty ovens.

• Close the oven door and

press the Start/Stop key.

• If oven is too hot to proceed, dOOr will display on the

LED screen. Open the oven door to allow the oven to

cool to below 150°F (66°C). When the oven is finished

cooling, begin the cleaning procedure again.

• Oven beeps when it is done cleaning. Leave door

slightly ajar when cleaning is finished.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 22.

Page 25

INSTALLATION

ERROR CODES

This section is provided for the assistance of qualified technicians only and is not intended for use by

untrained or unauthorized service personnel. If your Alto-Shaam

following before calling your Authorized Alto-Shaam Service Agent:

☛ Check that unit is receiving power. Circuit breaker turned on?

Do not attempt to repair or service the oven beyond this point. Contact Alto-Shaam for the nearest

authorized service agent. Repairs made by any other service agents without prior authorization by

Alto-Shaam will void the warranty on the unit.

When the oven malfunctions, an error code will appear in the display.

PRESS THE START ICON TO ACKNOWLEDGE THE ERROR.

When the oven error notification has been acknowledged, the Combitherm will attempt to return

to normal operation.

®

unit is not operating properly, check the

Error

Code

E01

E02

E03

E04

E05

E06

Error Call Out in Display Description of Error Possible Cause

Low Water Boiler Upper water level probe B1 is

not satisfi ed within 5 minutes,

after water solenoid valve Y1

is activated.

Control Temperature High Low voltage relay board

temperature higher than

176°F (80°C).

Fan Motor Error Fan motor does not spin after

60 seconds, detected by the

Hall Sensor.

Error 03 does not appear if

error E53 is detected fi rst.

Lower Fan Motor Error Lower Fan motor does

not spin after 60 seconds,

detected by the Hall Sensor.

Error 04 does not appear if

error E54 is detected fi rst.

VFD Comm Failure When VFD does not respond

to a query on the CAN

interface.

Lower VFD Comm Failure When VFD does not respond

to a query on the CAN

interface.

— Water supply is shut off.

— Low water pressure.

— Boiler drain cap is missing.

— Boiler drain pump is defective.

— Drain pump elbow leaking.

— Water level probe has calcium build up.

— Double water solenoid valve is defective (Y1).

— Relay board, high voltage is defective.

— Check wiring to all components listed below.

— Cooling fan on relay board assembly is

defective.

— Cooling fan on display board assembly is

defective.

— Main cooling fan is defective.

— Cooling fan on motor drive is defective.

— Check wiring to all components listed below.

— If LED on motor control fl ashes, see error codes

for motor control.

— Motor or fan wheel locked.

— Hall sensor does not detect motor rotation.

— Motor Thermo Temperature protection.

— Fan wheel damaged.

— Check wiring to all components mentioned

below.

— If LED on motor control fl ashes, see error codes

for motor control.

— Motor or fan wheel locked.

— Hall sensor does not detect motor rotation.

— Motor Thermo Temperature protection.

— Fan wheel damaged.

— Loss of power to VFD.

— VFD malfunction.

— CAN cable disconnected.

— CAN address not correct on VFD.

— Loss of power to VFD.

— VFD malfunction.

— CAN cable disconnected.

— CAN address not correct on VFD.

con ti nue d o n n ext p age

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 23.

Page 26

ERROR CODES

INSTALLATION

Error

Code

E07

E08

E11

E13

E15

E20

E21

E22

Error Call Out in Display Description of Error Possible Cause

Error Received from VFD When VFD is fl ashing the

green light

Error Received from Lower

VFD

Convection Temperature

High

Boiler Temperature High Boiler temperature is more

Condensor Temperature

High

B11 Core Temperature

Probe

Single Point Fault

N6 Cavity Probe Fault Cavity temperature probe

B10 Core Temperature

Probe

Multi-point Fault

When VFD is fl ashing the

green light

In Combination program,

cavity temperature N6 is

measuring in excess of 572ºF

(300ºC) for a minimum of 25

seconds

In Convection program,

cavity temperature N6 is

measuring in excess of 572ºF

(300ºC) for a minimum of 25

seconds

than 248ºF (120ºC) for more

than 25 seconds, detected by

B4 Probe

Condensor water

temperature is more than

212ºF (100ºC) for more than

180 seconds, detected by B3

probe

Single point core temperature

probe defective or

disconnected

defective or disconnected

Multipoint core temperature

probe defective or

disconnected

— Refer to VFD error code list and match to

number of blinks on the green LED of VFD.

— Refer to VFD error code list and match to

number of blinks on the green LED of VFD.

— Check wiring to all components mentioned

below.

— Steam element contactor locked/on.

— N6 oven cavity temperature probe is defective.

— N6 oven cavity temperature probe wires

connected backwards

— Relay board, high voltage, defective.

— Calcium build up in boiler

— Check wiring to all components mentioned

below.

— Steam element contactor locked/on.

— B4 boiler temperature probe is defective.

— B4 probe wires connected backwards

— Water level probe has calcium build up.

— Water supply is shut off.

— Check wiring to all components mentioned

below.

— B3 condensor temperature probe is defective.

— B3 condensor probe wires connected backwards

— Single water solenoid valve defective (Y2).

— Relay board, high voltage, defective.

— Clean probe receptacle pins with sand paper.

— B11 Single Point Core Temperature probe with

quick connect defective.

— B11 Single Point Core Temperature probe wires

with quick connect disconnected.

— B11 Single Point Core Temperature probe

receptacle defective.

— B11 Single Point Core Temperature probe

receptacle wires disconnected.

— N6 oven cavity temperature probe defective.

— N6 oven cavity temperature probe wires.

— B10 multipoint core temperature probe defective.

— B10 multipoint core temperature probe wires

disconnected.

con ti nue d o n n ext p age

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 24.

Page 27

ERROR CODES

INSTALLATION

Error

Code

E23

E24

E25

E26

E27

E34

E36

E40

E41

E42

E43

E44

E45

Error Call Out in Display Description of Error Possible Cause

B4 Boiler Probe Fault Boiler temperature probe

defective or disconnected

B5 Bypass Probe Fault Bypass steam temperature

probe defective or

disconnected

B3 Condensor Probe Fault Condensor water

temperature probe defective

or disconnected.

N8 Boiler Safety

Temperature Probe Fault

Boiler Element Temperature

High

Steam Generator Drain

Pump Fault

Steam Temperature High In Steam program, cavity

B3 Fault B3 probe shorted to ground — Defective or miswired probe.

B4 Fault B4 probe shorted to ground — Defective or miswired probe.

B5 Fault B5 probe shorted to ground — Defective or miswired probe.

N6 Fault N6 probe shorted to ground — Defective or miswired probe.

N8 Fault N8 probe shorted to ground — Defective or miswired probe.

B10 Fault B10 probe shorted to ground — Defective or miswired probe.

Boiler heating element

protection probe defective or

disconnected.

Boiler protection heat

element temperature is more

than 266°F (130°C) for more

than 25 seconds, detected by

N8 probe.

If water level does not drop

below lower water level

probe after three minutes

when steam generator drain

pump is activated in cleaning

program.

temperature N6 is measuring

in excess of 395ºF (200ºC) for

more than 60 Seconds.

In Combination program,

cavity temperature N6 is

measuring in excess of 520ºF

(270ºC), for more than 60

Seconds.

In Retherm program, cavity

temperature N6 is measuring

in excess of 395ºF (200ºC),

for more than 60 Seconds.

In Cleaning program, cavity

temperature N6 is measuring

in excess of 395ºF (200ºC),

for more than 60 Seconds.

— B4 boiler temperature probe defective.

— B4 probe wires connected backwards.

— B5 bypass steam temperature probe defective.

— B5 bypass steam temperature probe wires

connected backwards.

— B3 condensor temperature probe defective.

— B3 condensor probe wires connected

backwards.

— N8 boiler temperature probe defective.

— N8 probe wires connected backwards.

— Calcium build up in boiler.

— Check wiring to all components mentioned

below.

— Steam element contactor locked/on.

— N8 boiler temperature probe defective.

— N8 probe wires connected backwards.

— Water level probe has calcium buildup.

— Calcium build up in steam generator drain pump.

— Boiler drain pump defective.

— Relay board, high voltage, defective.

— Water level probe defective.

— Water supply is shut off.

— Low water pressure.

— Water injection pipe, calcium build up.

— Water fl ow valve defect or calcium build up.

— Double water solenoid valve defective (Y1).

— Relay board, high voltage, defective.

con ti nue d o n n ext p age

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 25.

Page 28

ERROR CODES

INSTALLATION

Error

Code

E51

E53

E54

E55

E56

E57

E88

E89

E90

Error Call Out in Display Description of Error Possible Cause

No Water In Boiler Lower water level probe B2 is

not satisfi ed within 5 minutes,

after water solenoid valve Y1

is activated

Fan Motor High

Temperatures

Lower Fan Motor High

Temperature

Vent Not Open 60 seconds after the venting

Vent 2 not open 60 seconds after the venting

No Rinse Water Flow switch for solenoid

Lower Gas Ignition Failure Reset output from Ignition

Upper Gas Ignition Failure Reset output from Ignition

Lower Gas Combustion

Blower Not at Speed

Fan motor does not spin,

result in over-heating,

detected by motor coil safety

thermo element. Temperature

more than 320°F (160°C).

Lower fan motor does not

spin, result in over-heating,

detected by motor coil safety

thermo element. Temperature

more than 320°F (160°C).

motor is activated the vent

motor safety switch did not

open.

motor is activated the vent

motor safety switch did not

open.

valve Y4 does not detect any

water fl ow for a minimum of

60 seconds.

Module is ON

Module is ON

Speed is too slow. — Power supply cable is not connected to blower

— Water supply is shut off.

— Low water pressure.

— Boiler drain cap missing.

— Boiler drain pump defective.

— Drain pump elbow leaking.

— Water level probe has calcium build up.

— Double water solenoid valve defective (Y1).

— Relay board, high voltage, defective.

— Motor high limit open or wired incorrectly.

— If LED on motor control fl ashes, see error codes

for motor control.

— Motor or fan wheel locked.

— Fan wheel damaged.

— Motor high limit open or wired incorrectly.

— If LED on motor control fl ashes, see error codes

for motor control.

— Motor or fan wheel locked.

— Fan wheel damaged.

— Alignment issue between motor cam and vent

motor safety switch (micro switch).

— Faulty vent valve (motor).

— Faulty vent valve safety switch (micro switch).

— Alignment issue between motor cam and vent

motor safety switch (micro switch).

— Faulty vent valve (motor).

— Faulty vent valve safety switch (micro switch).

— Water supply is shut off.

— Low water pressure.

— Flow switch is dirty or defective.

— Double water solenoid valve defective (Y3).

— Relay board, high voltage, defective.

— Hot surface ignitor not functioning.

— No gas supply.

— Flame sensor not functioning.

— Faulty ignition control.

— Hot surface ignitor not functioning.

— No gas supply.

— Flame sensor not functioning.

— Faulty ignition control.

motor.

— Speed control cable is not connected to blower

motor.

— Blower motor is blocked, rotation is impeded, or

motor is faulty.

— Faulty control board.

con ti nue d o n n ext p age

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 26.

Page 29

ERROR CODES

INSTALLATION

Error

Code

E91

E92

E94

E100

E101

E102

E103

E104

E105

E106

Error Call Out in Display Description of Error Possible Cause

Upper Gas Blower Not at

Speed

Communication Error

CB does not properly

respond

Communication Error,

TO Interface Board

One or more maintenance

reminder has timed out.

Ventless Hood Fault - No

Pressure

Ventless Hood Fault —

Filters Not Present

Option Board Doesn’t Send

Switch Setting

Option Board Not

Communicating

No or Low Water Pressure Water pressure switch not

Boiler Drain Pump Fault Hall effect or rotational

Speed is to slow. — Power supply cable is not connected to blower

motor

— Speed control cable is not connected to blower

motor

— Blower motor is blocked, rotation is impeded, or

motor is faulty

— Faulty control board

Twelve (12) instances of

no-response from the relay

board (CB) to the display

board (IB).

No signal transfer for more

than 5 seconds between the

Interface Board (IB) and the

Control Board (CB).

When any maintenance

reminder has expired without

action having been taken by

the operator.

If the power switch or

pressure switch is not closed.

If the air fi lter switches are

not closed.

OB not communicating its

switch settings to the CB.

Option board is not

communicating with CB.

activated.

sensor is not sending a signal

to the relay board

— Check CAN cable connections mentioned

below.

— CAN cable defective.

— Relay board, low voltage, connector defective.

— Display board connector defective.

— Check CAN cable connections mentioned

below.

— CAN cable defective.

— Relay board, low voltage, connector defective.

— Display board connector defective.

— Enter maintenance reminder screen and

address the item that has timed out and reset

— Check power switch is on.

— Check vent motor is turning in the proper

direction.

— Pressure switch is mis-wired or defective.

— Filter(s) require cleaning or replacement

— Check fi lters are installed and properly seated.

— Check fi lter switches are not damaged,

defective or dislodged.

— Check CAN cable connection between OB and

CB.

— Ensure CB dip switch is set to see an OB.

— Incompatible OB and CB software (update

software).

— OB defective.

— CB defective.

— Check option board CAN connection at CB and

OB.

— Defective OB.

— Defective CB.

— Water supply not connected.

— Water supply is shut off.

— Water supply to unit blocked or obstructed

— Faulty or miswired pressure switch

— Drain pump motor not running or defective.

— Hall effect sensor broken or incorrectly wired.

— Motor improperly wired.

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 27.

con ti nue d o n n ext p age

Page 30

ERROR CODES

INSTALLATION

Error

Code

E108

E109

Error Call Out in Display Description of Error Possible Cause

Cooling Fan Failure If the temperature on the

control board (relay board) is

greater than 140ºF (60ºC) and

less than 176ºF (80ºC). (See

error code E02)

High Limit Switch The High Limit Switch input

to the CB (N7) is “open”

— Cooling fan damaged.

— Cooling fan blocked or blades have been kept

from rotating.

— Incoming air temperature exceeds 100°F (38°C).

— Air inlet has become blocked.

— Unit has experienced an over heat condition.

— Convection element contactors stuck closed.

— Failed Y1 solenoid.

— Obstruction between Y1 solenoid and injection

pipe.

— Improperly connected drain.

— Condensate pan clean out not closed.

— Improperly wired high limit switch at the switch

or at the CB.

— Defective high limit switch.

see m oto r c ont rol e rro r c har t on nex t p ag e

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 28.

Page 31

INSTALLATION

TOUCH MOTOR CONTROL ERROR CODES

Type of Error Indication Release of Error

Undervoltage LED fl ashing sequence, with 1 fl ash per period. Voltage of intermediate circuit is less than 250V

Overvoltage LED fl ashing sequence, with 2 fl ashes per period. Voltage of intermediate circuit exceeds 445V

Excess

Temperature

Current Peak LED fl ashing sequence, with 4 fl ashes per period.

Overcurrent LED fl ashing sequence, with 5 fl ashes per period. Intermediate circuit current exceeds 4.0 A

Short-circuit LED fl ashing sequence, with 6 fl ashes per period.

Power on LED fl ashing sequence, with 7 fl ashes per period.

Watchdog LED fl ashing sequence, with 8 fl ashes per period.

LED fl ashing sequence, with 3 fl ashes per period.

Temperature sensor in the power unit is more than

199°F (93°C)

Blocked motor, detected by current peak monitoring

from 900 rpm rotating fi eld

Release of interrupt at intermediate circuit current

larger than 53 A

Effective mains voltage does not correspond to

jumper setting 115V/230V

Watchdog of the microcontroller released, program

crash

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 29.

Page 32

ORIGINAL EQUIPMENT LIMITED WARRANTY

Alto-Shaam, Inc. warrants to the original purchaser that any original part that is found to be defective in

Alto-Shaam, Inc. warrants to the original purchaser that any original part that is found to be defective in

material or workmanship will, at Alto-Shaam’s option, subject to provisions hereinafter stated, be replaced

with a new or rebuilt part.

The labor warranty remains in effect one (1) year from installation or fifteen (15) months from the shipping

date, whichever occurs first. Alto-Shaam will bear normal labor charges performed by an authorized

Alto-Shaam service agent during standard business hours, excluding overtime, holiday rates or any additional

fees.

The parts warranty remains in effect for one (1) year from installation or fifteen (15) months from the shipping

date, whichever occurs first. An optional extended warranty is available but must be purchased with the

original equipment order. Please consult the factory for net pricing options and details.

THIS WARRANTY DOES NOT APPLY TO

1. Replacement of wear parts, including light bulbs, door gaskets, and/or the replacement of glass due to

2. Equipment damage caused by accident, shipping and handling, improper installation or alteration of any

3. Equipment chassis or component/system damage as a result of inadequate routine maintenance and

4. Equipment used under conditions of abuse, neglect, misuse, carelessness or abnormal conditions

5. It is the sole responsibility of the owner/operator/purchaser of this equipment to verify that the incoming

6. Any losses or damage resulting from malfunction, including loss of product or consequential or incidental

7. Equipment damage resulting from modification in any manner from original model, substitution of parts

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE. IN NO EVENT SHALL ALTO-SHAAM BE LIABLE FOR LOSS OF USE,

LOSS OF REVENUE OR PROFIT, OR LOSS OF PRODUCT, OR FOR ANY INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

Alto-Shaam any other obligation or liability in connection with Alto-Shaam equipment.

W A RR AN T Y E FF E C T I VE January 1, 2014

damage of any kind.

:

kind.

cleaning. Required maintenance and cleaning of steam generating equipment is the responsibility of the

owner/operator.

including, but not limited to, equipment subjected to non-approved or inappropriate chemicals including,

but not limited to, compounds containing chlorine, chlorides or quaternary salts, or equipment with

missing or altered serial numbers. Damage caused by use of any cleaning agent other than Alto-Shaam’s

Combitherm® Oven Cleaner including, but not limited to, damage due to chlorine, bleach, quaternary

salts, souring powders or other harmful chemicals. Use of Alto-Shaam’s Combitherm® Cleaner on

Combitherm ovens is highly recommended.

water supply is comprehensively tested and if required, a means of “water treatment” provided that would

meet compliance requirements

with the published water quality

standards published at right.

Non-compliance with these

minimum standards will potentially

damage this equipment and/or

components and VOID the original

equipment manufacturer’s warranty.

Alto-Shaam recommends using

OptiPure® products to properly

COMBITHERM WATER QUALITY MINIMUM STANDARDS

CONTAMINANT INLET WATER REQUIREMENTS

Free Chlorine Less than 0.1 ppm (mg\L)

Hardness 30-70 ppm

Chloride Less than 30 ppm (mg\L)

pH 7.0 to 8.5

Silica Less than 12 ppm (mg\L)

Total Dissolved Solids (tds) 50-125 ppm

treat your water.

damages of any kind.

other than factory authorized parts, removal of any parts including legs, or addition of any parts.

No person except an officer of Alto-Shaam, Inc. is authorized to modify this warranty or to incur on behalf of

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 30.

Page 33

access to a local authorized service agency

TRANSPORTATION DAMAGE AND CLAIMS

All Alto-Shaam equipment is sold F.O.B. shipping point, and when accepted by the

carrier, such shipments become the property of the consignee.

Should damage occur in shipment, it is a matter between the carrier and the consignee.

In such cases, the carrier is assumed to be responsible for the safe delivery of the

merchandise, unless negligence can be established on the part of the shipper.

1. Make an immediate inspection while the equipment is still in the truck or immediately after it is moved to the

receiving area. Do not wait until after the material is moved to a storage area.

2. Do not sign a delivery receipt or a freight bill until you have made a proper count and inspection of all

merchandise received.

3. Note all damage to packages directly on the carrier’s delivery receipt.

4. Make certain the driver signs this receipt. If he refuses to sign, make a notation of this refusal on the receipt.

5. If the driver refuses to allow inspection, write the following on the delivery receipt:

Driver refuses to allow inspection of containers for visible damage.

6. Telephone the carrier’s office immediately upon finding damage, and request an inspection. Mail a written

confirmation of the time, date, and the person called.

7. Save any packages and packing material for further inspection by the carrier.

8. Promptly file a written claim with the carrier and attach copies of all supporting paperwork.

We will continue our policy of assisting our customers in collecting claims which have been properly filed and

actively pursued. We cannot, however, file any damage claims for you, assume the responsibility of any claims, or

accept deductions in payment for such claims.

RECORD THE MODEL AND SERIAL NUMBER OF THE APPLIANCE

FOR EASY REFERENCE. ALWAYS REFER TO BOTH MODEL AND SERIAL NUMBER

IN ANY CONTACT WITH ALTO-SHAAM REGARDING THIS APPLIANCE.

Model: ___________________________________________________

Serial Number: _____________________________________________

Date Installed: _____________________________________________

Voltage: __________________________________________________

Purchased From: ___________________________________________

___________________________________________________

___________________________________________________

Alto-Shaam has established

a twenty-four hour emergency service

call center to offer immediate customer

outside of standard business hours. The

emergency service access is provided

exclusively for Alto-Shaam equipment

and is available throughout the United

States through the use of Alto-Shaam’s

toll-free number. Emergency service

access is available seven days a week

including holidays.

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls , Wisconsin 53052-0450 • U.S.A.

PHONE:262.251.3800•800.558-8744USA/CANADA FAX:262.251.7067•800.329.8744U.S.A.ONLY

COMBITHERM CT CLASSIC SERIES • STEP-BY-STEP PROCEDURES • MN-36455 • 31.

www.alto-shaam.com

Loading...

Loading...