Alto Shaam CC-48 Installation Manual

#884 • 1/2002

PRINTED IN U.S .A .

OPERATION and CARE MANUAL

®

COOK/HOLD/SERVE SYSTEMS

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558.8744

U.S.A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

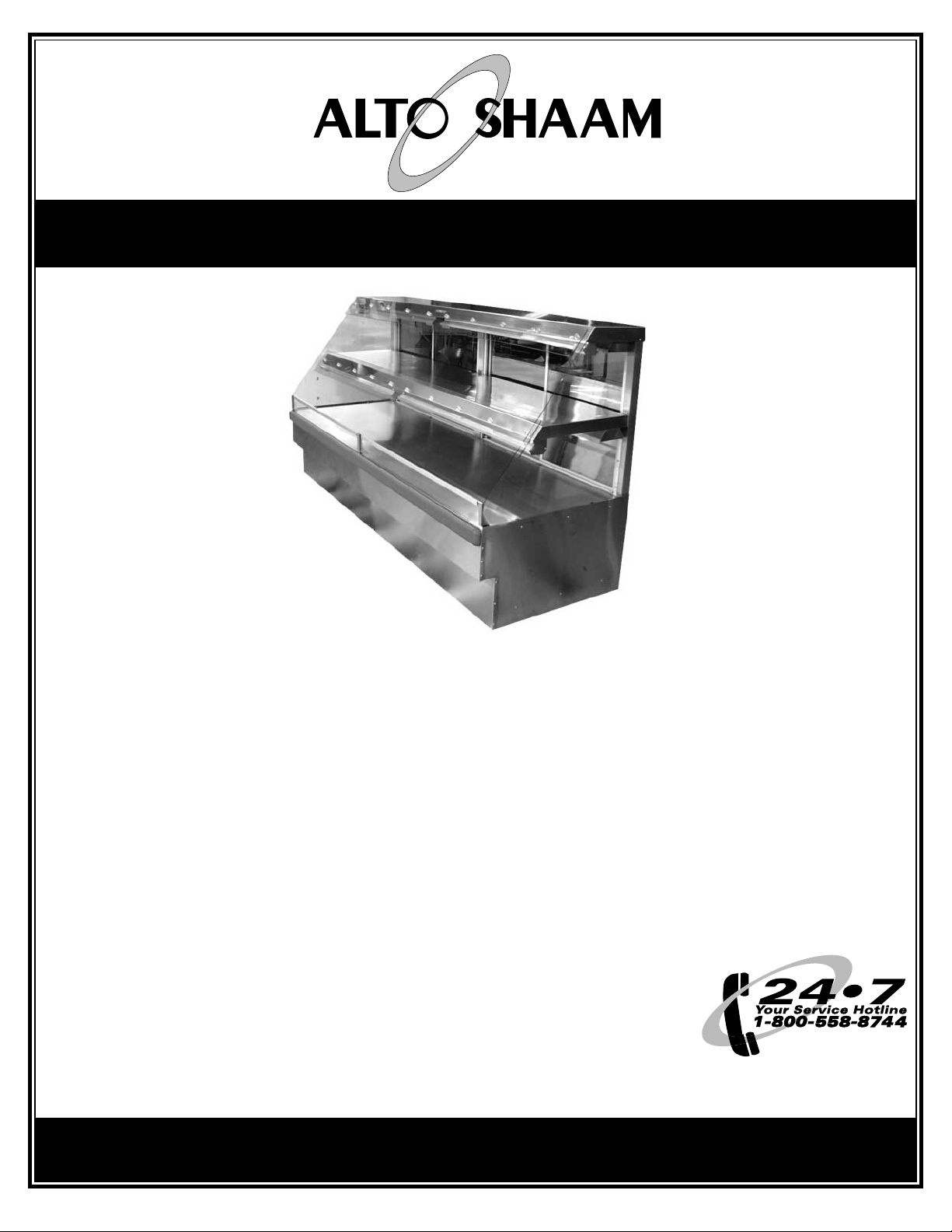

Two Tier, Self Serve

Heated Display Case

Models:

CC-48

CC-72

CC-96

CC-96

The Alto-Shaam Display Case has been

thoroughly tested, checked for calibration,

and inspected to insure only the highest

quality cabinet is provided. When you

receive your cabinet, check for any possible shipping damage and

report it at once to the delivering carrier.

See Transportation Damage and

Claims section located in this manual.

In order to maintain established National Sanitation

Foundation standards, all stationary floor models must be sealed

to the floor with a R.T.V. or silastic meeting N.S.F. requirements or

have 6" (153mm) unobstructed clearance beneath the unit.

Warranty will become null and void if these directions are not

followed.

Save all the information and instructions packed inside the

cabinet. Complete and return the warranty card to the factory as

soon as possible to assure prompt service in the event of a

warranty parts and labor claim. Any and all claims for warranty

must include the full model number and serial number of the

cabinet.

NOTE: The unit can be leveled by adjusting the legs with a wrench.

Use a professional electrician or serviceman for installation

and service in accordance with national codes. A proper

receptacle or outlet configuration or permanent wiring for this

unit must be installed by a licensed electrician in accordance with

applicable, local electrical codes. An identification tag is

permanently mounted on cabinet.

Plug the unit into a properly grounded receptacle remembering to position the unit so that the power cord is easily acccessible

in case of an emergency.

Regarding International Standard Units Only:

If the unit is not equipped with flexible cord with plug, an all-

pole country approved disconnection device which has a contact separation of at least 3mm in all poles must be incorporated in the fixed wiring for disconnection. When using a

cord without a plug, the green/yellow conductor shall be

connected to the terminal which is marked with the ground

symbol. If a plug is used, the socket outlet must be easily

accessible. If power cord needs replacement, use a similar one

obtained from the distributor.

1. INSERT WIRE SHELVES OR TILE INTO THE DISPLAY

CASE (OPTIONAL).

2. CHECK THAT ALL BREAKER SWITCHES ARE IN THE

"ON" POSITION.

Some models have these switches located at the bottom of the

unit behind an access door located on the control side of the

unit. Other models have these breaker switches located to the

right of the thermostat knobs.

3. TURN UPPER AND LOWER DISPLAY LIGHTS “ON”

AND SET THE THERMOSTAT(s) AT NUMBER “7” TO

PREHEAT.

Upper and lower lights will illuminate when light switches are

turned on. An indicator light will illuminate when the

thermostat(s) is turned "ON". The indicator(s) will remain lit

as long as the unit is preheating or calling for heat. Larger

units should be preheated, at the number "7" setting, for a

minimum of sixty

minutes (smaller units for a minimum of

thirty

minutes) before loading the case with food. When

preheating is completed, the indicator light(s) will turn off.

4. LOAD PREPACKAGED HOT FOODS INTO THE CASE.

Be certain only hot food is transferred into the display case.

Case can be loaded from the front or back (control) side.

Before loading food into the case, use a pocket-type meat

thermometer to make certain all products have reached an

internal temperature of 160° F (71°C) or higher. If any food

product is not at proper serving temperature, use a Halo Heat

cooking and holding oven or Combitherm Oven to bring the

product within the correct temperature range. Food product

must be stored in appropriate serving containers.

✔ Do not stack food containers.

✔ Be certain only hot PREPACKAGED foods in heat tested

containers are used in this hot display case.

5. RESET THERMOSTAT AS NEEDED.

Since proper temperature range depends on the type of

products and the quantities being held, it is necessary to

periodically use a pocket thermometer to check each item to

make certain the correct temperatures are being maintained.

Local health regulations may vary regarding minimum serving

temperatures. Proper temperature range is usually 160°F

(71°C) or higher. Normally, this will require a thermostat

setting of number “8” although a higher or lower setting may

sometimes be required.

This unit has had its thermostat set at the

factory so that it will not advance past the number 9

.

#884 Operation & Care Manual • 1.

HOT DISPLAY CASES

UNPACKING and SET-UP

ELECTRICAL INSTALLATION

OPERATIONAL PROCEDURES

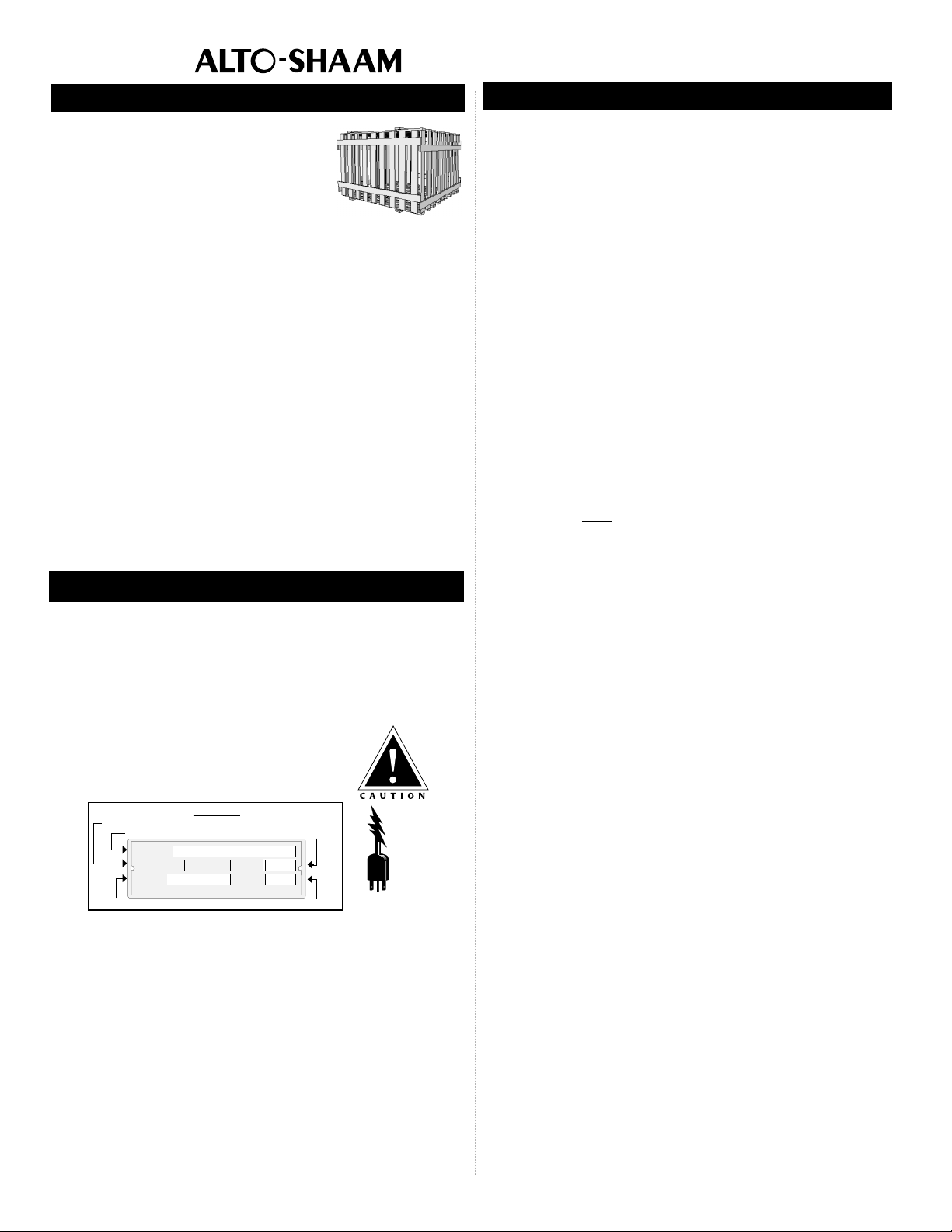

ENSURE POWER SOURCE MATCHES

VOLTAGE ON NAMEPLATE OF UNIT

®

SERIAL NUMBER AND WARRANTY CODE

IDENTIFICATION MODEL NUMBER

MODEL

SERIAL NO. WATTS

VOLTS

MAXIMUM RATED VOLTAGE MAXIMUM RATED FREQUENCY

EXAMPLE

xxx-xx

xxxx-xx xxxx

ALTO-SHAAM INC. MILW. WI. PAT. NO. 3521030

AC

1 PH

MAXIMUM RATED

WATTAGE

xx

HZxxx

The cleanliness and appearance of

this unit will contribute considerably

to operating efficiency and savory,

appetizing food. Good equipment

that is kept clean works better and

lasts longer.

THOROUGHLY CLEAN THE DISPLAY CASE

DAILY

1. Turn lights and adjustable thermostat(s) to the

“OFF” position.

2. Disconnect unit from power source by

turning breaker switch(s) to the "OFF" position.

3. Remove and store unused products under

refrigeration.

4. Clean the interior metal surfaces of the cabinet with a

damp cloth and any good alkaline or

alkaline chlorinated based commercial

detergent or grease solvent at the

recommended strength. Use a plastic

scouring pad or oven cleaner for

difficult areas. Avoid the use of

abrasive cleaning compounds, chloride

based cleaners, or cleaners containing

quaternary salts. Rinse well to remove

all residue and wipe dry.

NOTE: Never use hydrochloric acid (muriatic acid)

on stainless steel.

5. Clean glass with window cleaner.

6. To help maintain the protective film coating on

polished stainless steel, clean the exterior of the unit

with a cleaner recommended for stainless steel

surfaces. Spray the cleaning agent on the cloth and

wipe with the grain of the stainless steel.

Always follow appropriate state or local health

(hygiene) regulations regarding all applicable

cleaning and sanitation requirements for equipment.

Remember to turn the breaker switch(s) ON again

before operating the unit.

➥ White cotton gloves should be worn when handling quartz

elements. Never touch them with bare hands, as oil and dirt

from the skin can contaminate the quartz sheath and cause hot

spots and premature heater failure. If this element is touched,

thoroughly wipe, using a dry, clean cloth and alcohol or other

suitable solvent.

➥ Do not expose these heater elements to water.

➥ Solvent vapors can be flammable. Be sure to provide adequate

ventilation.

➥ Quartz heater elements are designed to be used in a horizontal

position only.

Installation

Care should be taken to insure that all installations meet

local code requirements and safety regulations. The quartz heater

will expand about 1% of its length. Be sure it is mounted to allow

this growth. Check the area around the quartz heat element for

flammable material.

Electrical

Never operate the quartz heater element at a voltage higher than

the design voltage. Disconnect and/or lock out power before

installing heater and making electrical connections. Make

electrical connections according to local, national or country codes.

Be sure all electrical connections are made safely and that the

terminals do not contact the housing. On units supplied with

leads, make certain the lead connections are tight before applying

power. When attaching leads to the heater element, be sure to

hold the inner terminal nut with pliers to prevent twisting or

breaking.

Operation

These heaters are designed to provide trouble-free operation;

however, some minimal precautions are required. Be sure the area

is free of flammable hazards. If the heaters are facing up, be sure

to remove objects that fall into the heaters or the reflectors behind

them. Periodically check to see that the wiring is not frayed, burnt,

or cut. If there is vibration, check to see that mounting screws

remain secure. The heaters will operate best with clean reflectors.

The loss of efficiency can be as high as 30% with dirty reflectors.

Always disconnect and lock out power before parts are replaced.

Replacement

Replacement is accomplished by removal of the screws holding the

end caps, removing the end caps, and disconnecting the power

leads from the terminals on the heater element. Installation is

accomplished by reversing the procedure.

Quartz elements should not be touched

with bare fingers as oil from hands can

destroy or cause premature failure.

If accidentally touched, clean with

a dry, soft cloth and rubbing alcohol.

#884 Operation & Care Manual • 2.

CARE and CLEANING

QUARTZ ELEMENTS

At no time should the case be steam cleaned,

flooded with water or liquid solution. Do

not use water jet to clean. NEVER STEAM

CLEAN. Severe damage or electrical hazard

could result, voiding the warranty.

Always disconnect the unit from

the power source before cleaning

or servicing.

#884 Operation & Care Manual • 3.

Food flavor and aroma are usually so closely related that it is

difficult, if not impossible, to separate them. There is also an

important, inseparable relationship between cleanliness and food

flavor. Cleanliness, top operating efficiency, and appearance of

equipment contribute considerably to savory, appetizing foods.

Good equipment that is kept clean, works better and lasts longer.

Most food imparts its own particular aroma and many foods

also absorb existing odors. Unfortunately, during this absorption,

there is no distinction between

GOOD and BAD odors. The

majority of objectionable flavors and odors troubling food service

operations are caused by bacteria growth. Sourness, rancidity,

mustiness, stale or other

OFF flavors are usually the result of germ

activity.

The easiest way to insure full, natural food flavor is through

comprehensive cleanliness. This means good control of both

visible soil (dirt) and invisible soil (germs). A thorough approach

to sanitation will provide essential cleanliness. It will assure an

attractive appearance of equipment, along with maximum

efficiency and utility. More importantly, a good sanitation

program provides one of the key elements in the prevention of

food-borne illnesses.

A controlled holding environment for prepared foods is just

one of the important factors involved in the prevention of foodborne illnesses. Temperature monitoring and control during

receiving, storage, preparation, and the service of foods are of

equal importance.

The most

accurate method

of measuring safe

temperatures of

both hot and cold

foods is by

internal product

temperature.

A quality

thermometer is

an effective tool

for this purpose, and should be routinely used on all products that

require holding at a specific temperature.

A comprehensive sanitation program should focus on the

training of staff in basic sanitation procedures. This includes

personal hygiene, proper handling of raw foods, cooking to a safe

internal product temperature, and the routine monitoring of

internal temperatures from receiving through service.

Most food-borne illnesses can be prevented through proper

temperature control and a comprehensive program of sanitation.

Both these factors are important to build quality service as the

foundation of customer satisfaction. Safe food handling practices

to prevent food-borne illness is of critical importance to the health

and safety of your customers. HACCP, an acronym for Hazard

Analysis (at) Critical Control Points, is a quality control program of

operating procedures to assure food integrity, quality, and safety.

Taking steps necessary to augment food safety practices are both

cost effective and relatively simple. While HACCP guidelines go

far beyond the scope of this manual, additional information is

available by contacting the USDA/FDA Food-borne Illness

Education Information Center at (301)504-6803.

S

Chefs, cooks and other specialized food service personnel

employ varied methods of cooking. Proper holding temperatures

for a specific food product must be based on the moisture content

of the product, product density, volume, and proper serving

temperatures. Safe holding temperatures must also be correlated

with palatability in determining the length of holding time for a

specific product.

In an enclosed holding environment, too much moisture

content is a condition which can be relieved. A product achieving

extremely high temperatures in preparation must be allowed to

decrease in temperature before being placed in a controlled

holding atmosphere. If the product is not allowed to decrease in

temperature, excessive condensation will form increasing the

moisture content on the outside of the product.

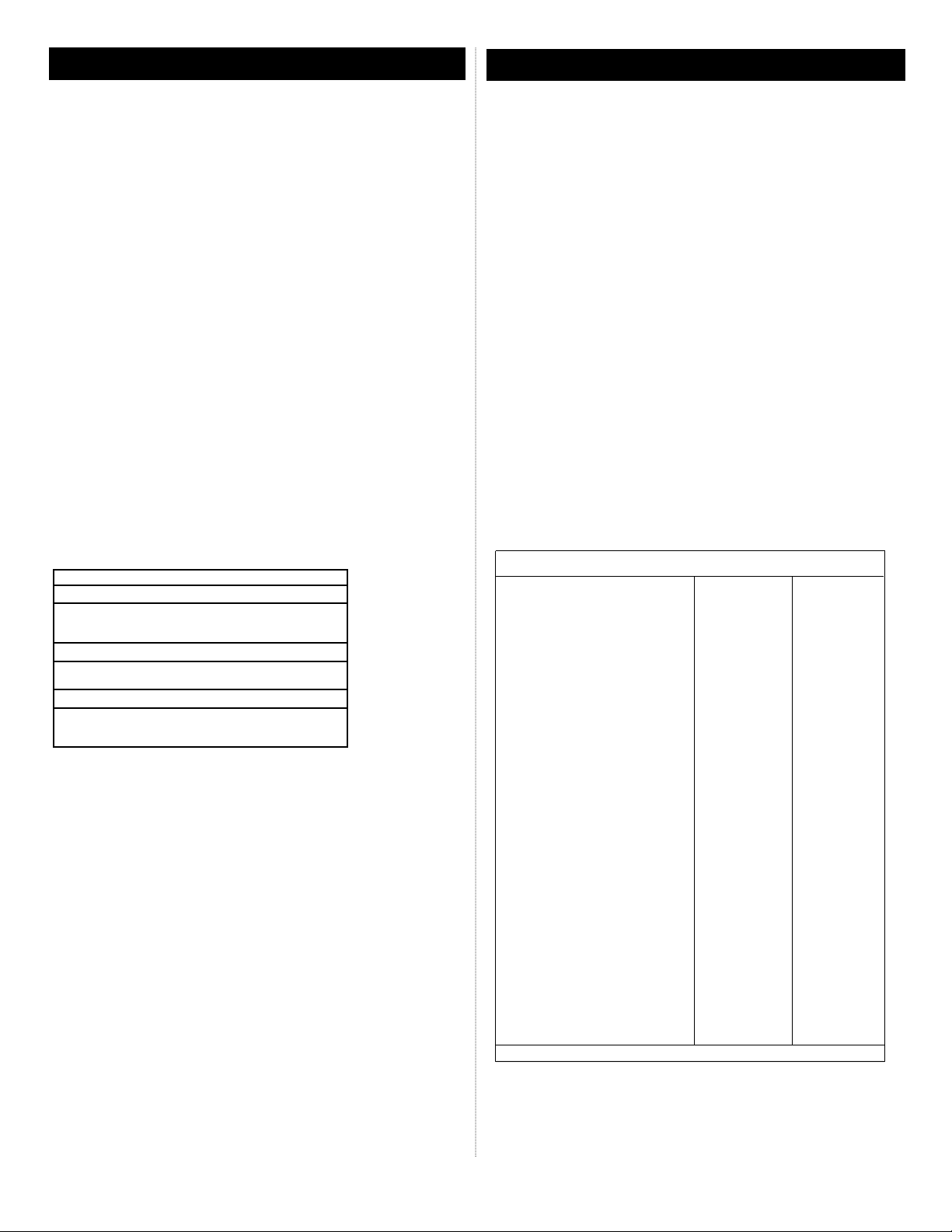

This particular Alto-Shaam holding unit is is equipped with a

thermostat indicating a range of between 1 and 10, but it is factory

set so it will not advance past the number 9. Use a metal-stemmed

indicating thermometer to measure the internal temperature of the

product(s) being held. Adjust the thermostat setting to achieve the

best overall setting based on internal product temperature.

HOLDING TEMPERATURE RANGE

MEAT FAHRENHEIT CELSIUS

BEEF ROAST — Rare 140°F60°C

BEEF ROAST — Med/Well Done 160°F71°C

BEEF BRISKET 160°— 175° F71°— 79°C

CORN BEEF 160°— 175° F71°— 79°C

PASTRAMI 160°— 175° F71°— 79°C

PRIME RIB — Rare 140°F60°C

STEAKS — Broiled/Fried 140°— 160° F60°— 71°C

RIBS — Beef or Pork 160°F71°C

VEAL 160°— 175° F71°— 79°C

HAM 160°— 175° F71°— 79°C

PORK 160°— 175°F71°— 79°C

LAMB 160°— 175° F71°— 79°C

POULTRY

CHICKEN — Fried/Baked 160°— 175° F71°— 79°C

DUCK 160°— 175°F71°— 79°C

TURKEY 160°— 175° F71°— 79°C

GENERAL 160°— 175° F71°— 79°C

FISH/SEAFOOD

FISH — Baked/Fried 160°— 175° F71°— 79°C

LOBSTER 160°— 175° F71°— 79°C

SHRIMP — Fried 160°— 175°F71°— 79°C

BAKED GOODS

BREADS/ROLLS 120°— 140° F49°— 60°C

MISCELLANEOUS

CASSEROLES 160°— 175° F71°— 79°C

DOUGH — Proofing 80°— 100° F27°— 38°C

EGGS —Fried 150°— 160°F66°— 71° C

FROZEN ENTREES 160°— 175° F71°— 79°C

HORS D'OEUVRES 160°— 180°F71°— 82°C

PASTA 160°— 180° F71°— 82°C

PIZZA 160°— 180° F71°— 82°C

POTATOES 180°F82°C

PLATED MEALS 180°F82°C

SAUCES 140°— 200° F60°— 93°C

SOUP 140°— 200°F60°— 93°C

VEGETABLES 160°— 175°F71°— 79°C

THE HOLDING TEMPERATURES LISTED ARE SUGGESTED GUIDELINES ONLY.

INTERNAL FOOD PRODUCT TEMPERATURES

HOT FOODS

DANGER ZONE 40° TO 140°F(4° TO 60°C)

CRITICAL ZONE 70° TO 120°F (21° TO 49° C)

SAFE ZONE 140° TO 165° F (60° TO 74° C)

COLD FOODS

DANGER ZONE ABOVE 40°F (ABOVE 4° C)

SAFE ZONE 36°F TO 40° F(2° C TO 4°C)

FROZEN FOODS

DANGER ZONE ABOVE 32°F (ABOVE 0° C)

CRITICAL ZONE 0° TO 32° F (-18° TO 0°C)

SAFE ZONE 0° F OR BELOW (-18°C OR BELOW)

SANITATION GUIDELINES

GENERAL HOLDING GUIDELINES

#884 Operation & Care Manual • 4.

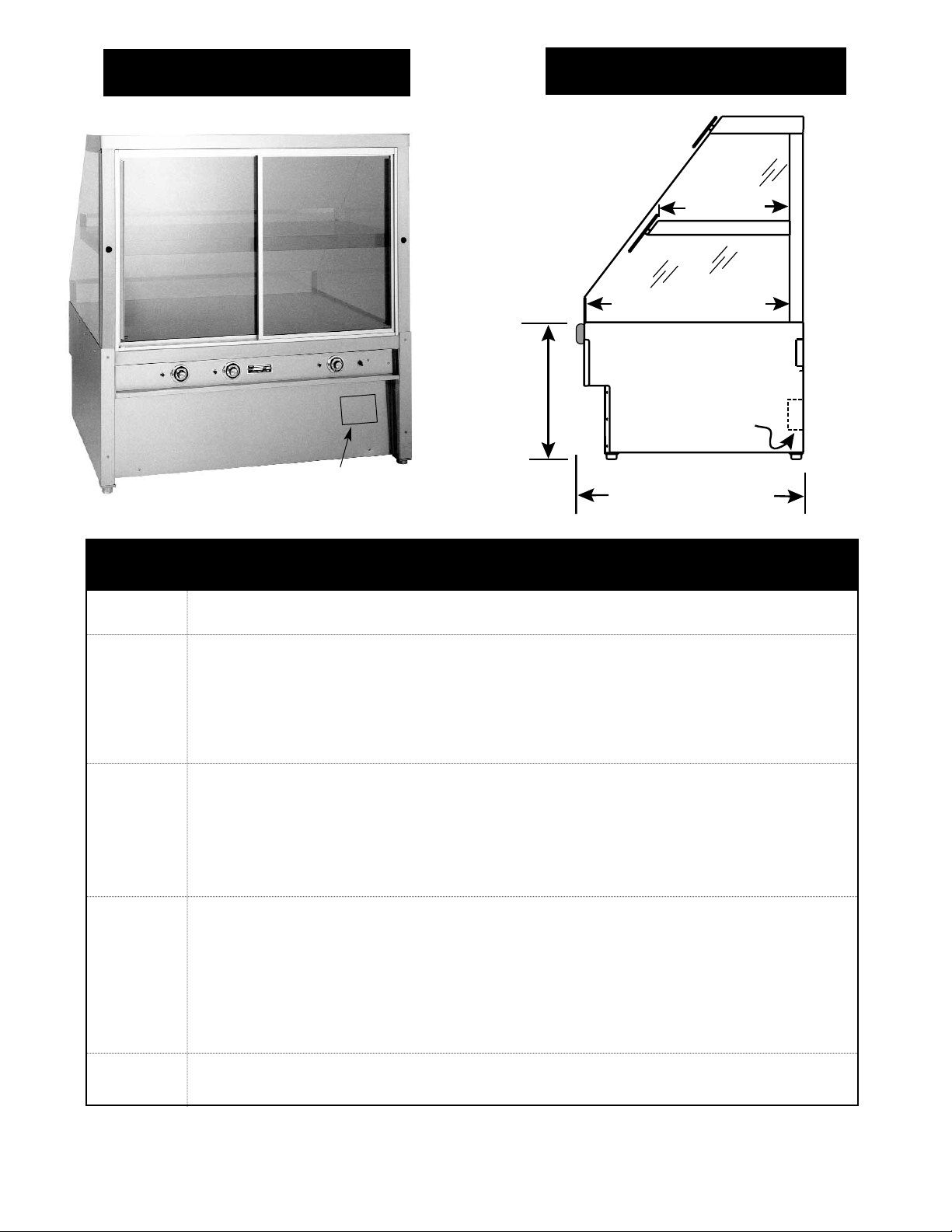

Access door

for breaker switch

CC-48 Control Side

(rear view))

Model CC-48 CC-72 CC-96

Interior

Six 150w halogen lamps Eight 150w halogen lamps Twelve 150w halogen lamps

2 upper tier wire grids 3 upper tier wire grids 4 upper tier wire grids

2 lower tier wire grids 3 lower tier wire grids 4 lower tier wire grids

Top Shelf

Dimensions 47" x 19-5/8" 71" x 19-5/8" 95" x 19-5/8"

(Width x Depth) (1194mm x 499mm) (1803mm x 499mm) (2413mm x 499mm)

Lower Shelf

Dimensions 48" x 30-5/16" 72" x 30-5/16" 96" x 30-5/16"

(Width x Depth) (1219mm x 770mm) (1829mm x 770mm) (2438mm x 770mm)

Electrical 208-240V, 60 Hz, 1 ph 208-240V, 60 Hz, 1 ph 208-240V, 60 Hz, 1 ph

5080 Watts maximum 7500 Watts maximum 10160 Watts maximum

at 208V: 20.04 Amps at 280V: 29.62 Amps at 208V: 45.9 Amps

at 240V: 21.16 Amps at 240V: 31.25 Amps at 240V: 42.3 Amps

no cord & plug no cord & plug no cord & plug

230V, 50/60 Hz, 1 ph 230V, 50/60 Hz, 1 ph 230V, 50/60 Hz, 1 ph

5080 Watts 7500 Watts 10160 Watts

21.1 Amps 32.6 Amps 44.17 Amps

no cord & plug no cord & plug no cord & plug

Ship

Weight

440 lb (200 kg) 660 lb (299 kg) 886 lb (402 kg)

Specifications

18 gauge non-magnetic stainless steel

Side Dimensions for

CC-48 • CC-72 • CC-96

30-5/16" (770mm)

19-5/8"

(499mm)

33-11/16" (855mm)

Electrical

Inlet

20-3/8"

(518mm)

(Wire Grids are

Optional)

Loading...

Loading...