Page 1

HardCopy Series Handbook, Volume 1

101 Innovation Drive

San Jose, CA 95134

www.alter a.com

Preliminary Information

H5V1-4.5

Page 2

Copyright © 2008 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the stylized Altera logo, specific device designations, and all other words and logos that are identified as trademarks and/or service marks are, unless noted otherwise, the trademarks and

service marks of Altera Corporation in the U.S. and other countries. Mentor Graphics and ModelSim are registered trademarks of Mentor Graphics

Corporation. All other product or service names are the property of their respective holders. Altera products are protected under numerous U.S. and

foreign patents and pending applications, maskwork rights, and copyrights. Altera warrants performance of its semiconductor products to current

specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any products and services at any time without

notice. Altera assumes no responsibility or liability arising out of the application or use of any information, product, or service described herein except as expressly agreed to in writing by Altera Corporation. Altera customers are advised to obtain the latest

version of device specifications before relying on any published information and before placing orders for products or services

.

ii Altera Corporation

Preliminary

Page 3

Contents

Chapter Revision Dates ........................................................................... ix

About this Handbook ............................................................................... xi

How to Contact Altera ........ ..................................................................................................................... xi

Typographic Conventions ....................................................................................................................... xi

Section I. HardCopy Stratix Device Family Data Sheet

Revision History .................................................................................................................................... 1–1

Chapter 1. Introduction to HardCopy Stratix Devices

Introduction ............................................................................................................................................ 1–1

Features ................................................................................................................................................... 1–2

Document Revision History ............................................ ..................................................................... 1–4

Chapter 2. Description, Architecture, and Features

Introduction ............................................................................................................................................ 2–1

HardCopy Stratix and Stratix FPGA Differences ............................................................................. 2–2

Logic Elements ....................................................................................................................................... 2–4

Embedded Memory ......................... ...................................................................................................... 2–4

DSP Blocks .............................................................................................................................................. 2–6

PLLs and Clock Networks ............................................................................... ..................................... 2–6

I/O Structure and Features .................................................................................................................. 2–6

Power-Up Modes in HardCopy Stratix Devices ... ............................................................................ 2–7

Hot Socketing ......................................................................................................................................... 2–8

HARDCOPY_ FPGA_ PROTOTYPE Devices ..................................................................................... 2–9

Document Revision History ............................................ ................................................................... 2–10

Chapter 3. Boundary-Scan Support

IEEE Std. 1149.1 (JTAG) Boundary-Scan Support ............................................................................ 3–1

Document Revision History ............................................ ..................................................................... 3–4

Chapter 4. Operating Conditions

Recommended Operating Conditions ................................................................................................ 4–1

Power Consumption ............................................................ ............................................................... 4–15

Timing Closure .................................................................................................................................... 4–15

External Timing Parameters ......................................................................................................... 4–16

HardCopy Stratix External I/O Timing ...................................................................................... 4–17

Altera Corporation iii

Preliminary

Page 4

HardCopy Series Handbook, Volume 1

Maximum Input and Output Clock Rates .................................................................................. 4–23

High-Speed I/O Specification ........................................................................................................... 4–28

PLL Specifications ................................................................................................................................ 4–30

Electrostatic Discharge ........................................................................................................................ 4–33

Positive Voltage Zap ................................................................... ................................................... 4–34

Negative Voltage Zap ............................................... ..................................................................... 4–35

Document Revision History ............................................ ................................................................... 4–36

Chapter 5. Quartus II Support for HardCopy Stratix Devices

Introduction ............................................................................................................................................ 5–1

Features ................................................................................................................................................... 5–2

HARDCOPY_FPGA_PROTOTYPE, HardCopy Stratix and Stratix Devices ................................ 5–3

HardCopy Design Flow ............................................................................................... ......................... 5–5

The Design Flow Steps of the One Step Process ....................................................... ................... 5–6

How to Design HardCopy Stratix Devices ........................................................................................ 5–7

Tcl Support for HardCopy Migration ......................................................................................... 5–11

Design Optimization and Performance Estimation ........................................................................ 5–12

Design Optimization ............................................................... ....................................................... 5–12

Performance Estimation ................................................................................................................ 5–12

Buffer Insertion ............................................................................................................................... 5–16

Placement Constraints ................................................................................................................... 5–16

Location Constraints ........................................................................................................................... 5–17

LAB Assignments .......................................................................... ................................................. 5–17

LogicLock Assignments ................................................................................................................ 5–18

Checking Designs for HardCopy Design Guidelines .................................................................... 5–19

Altera Recommended HDL Coding Guidelines ........................................................................ 5–19

Design Assistant .............................................................................. ............................................... 5–19

Reports and Summary ................................................................................................................... 5–20

Generating the HardCopy Design Database ................................................................................... 5–21

Static Timing Analysis ........................................................................................................................ 5–23

Early Power Estimation ................ ...................................................................................................... 5–23

HardCopy Stratix Early Power Estimation ................................................................................ 5–23

HardCopy APEX Early Power Estimation ................................................................................. 5–24

Tcl Support for HardCopy Stratix ..................................................................................................... 5–24

Targeting Designs to HardCopy APEX Devices ............................................................................. 5–25

Conclusion ............................................................................................................................................ 5–25

Related Documents ............................... .............................................................................................. 5–26

Document Revision History ............................................ ................................................................... 5–26

Chapter 6. Design Guidelines for HardCopy Stratix Performance Improvement

Introduction ............................................................................................................................................ 6–1

Background Information ...................................................................................................................... 6–1

Planning Stratix FPGA Design for HardCopy Stratix Design Conversion ................................... 6–2

Partitioning Your Design ................................................................................................................ 6–2

Physical Synth esis Optimization .................................................................................................... 6–3

Using LogicLock Regions in HardCopy Stratix Designs ................................................................. 6–4

Recommended LogicLock Settings for HardCopy Stratix Designs .......................................... 6–5

iv Altera Corporation

Preliminary

Page 5

Contents

Using Design Space Explorer for HardCopy Stratix Designs ......................................................... 6–6

Recommended DSE Settings for HardCopy Stratix Designs ..................................................... 6–7

Performance Improvement Example .................................................................................................. 6–8

Initial Design Example Settings . .................................................................................................... 6–8

Using Analysis and Synthesis Settings for Performance Improvement ................................ 6–11

Using Fitter Assignments and Physical Synthesis Optimizations for Performance

Improvement .................................................................................................................................. 6–13

Design Space Ex plorer ................................................................................................................... 6–15

Back-Annotation and Location Assignment Adjustments ....................................................... 6–17

Conclusion ............................................................................................................................................ 6–21

Document Revision History ............................................ ................................................................... 6–22

Section II. HardCopy APEX Device Family Data Sheet

Revision History .................................................................................................................................... 6–1

Chapter 7. Introduction to HardCopy APEX Devices

Introduction ............................................................................................................................................ 7–1

Features... ................................................................................................................................................ 7–1

...and More Features .............................................................................................................................. 7–2

Document Revision History ............................................ ..................................................................... 7–5

Chapter 8. Description, Architecture, and Features

Introduction ............................................................................................................................................ 8–1

Differences Between HardCopy APEX and APEX 20K FPGAs ..................................................... 8–5

Power-up Mode and Configuration Emulation ................................................................................ 8–5

Speed Grades ................................................................................................... ....................................... 8–6

Quartus II-Generated Output Files ..................................................................................................... 8–6

Document Revision History ............................................ ..................................................................... 8–7

Chapter 9. Boundary-Scan Support

IEEE Std. 1149.1 (JTAG) Boundary-Scan Support ............................................................................ 9–1

Document Revision History ............................................ ..................................................................... 9–3

Chapter 10. Operating Conditions

Recommended Operating Conditions .............................................................................................. 10–1

Document Revision History ............................................ ................................................................. 10–15

Section III. General HardCopy Series Design Considerations

Revision History .................................................................................................................................. 10–1

Chapter 11. Design Guidelines for HardCopy Series Devices

Introduction .......................................................................................................................................... 11–1

Altera Corporation v

Preliminary

Page 6

HardCopy Series Handbook, Volume 1

Design Assistant Tool ......................................................................................................................... 11–1

Asynchronous Clock Domains ................................ .......................................................................... 11–2

Transferring Data between Two Asynchronous Clock Domains ........................................... 11–4

Gated Clocks ......................................................................................................................................... 11–7

Preferred Clock Gating Circuit ..................................................................................................... 11–7

Alternative Clock Gating Circuits ................................................................................................ 11–9

Inverted Clocks ............................................................................................................................. 11–11

Clocks Driving Non-Clock Pins .................................................................. ............................... 11–11

Clock Signals Should Use Dedicated Clock Resources .......................................................... 11–13

Mixing Clock Edges ..................................................................................................................... 11–14

Combinational Loops ...... .................................................................................................................. 11–16

Intentional Delays .............................................................................................................................. 11–18

Ripple Counters ................................................................................................................................. 11–20

Pulse Generators ................................................................................................................................ 11–21

Combinational Oscillator Circuits ................................................................................................... 11–24

Reset Circuitry .................................................................................................................................... 11–25

Gated Reset .................................................................................................................................... 11–25

Asynchronous Reset Synchronization ...................................................................................... 11–26

Synchronizing Reset Signals Across Clock Domains .............................................................. 11–27

Asynchronous RAM .......................................................................................................................... 11–30

Conclusion .......................................................................................................................................... 11–31

Document Revision History ............................................ ................................................................. 11–31

Chapter 12. Power-Up Modes and Configuration Emulation in HardCopy Series Devices

Introduction .......................................................................................................................................... 12–1

HardCopy Power-Up Options ........................................................................................................... 12–1

Instant On Options ......................................................................................................................... 12–2

Configuration Emulation of FPGA Configuration Sequence .................................................. 12–9

Power-Up Options Summary When Designing With HardCopy Series Devices .................... 12–15

Power-Up Option Selection and Examples ................................................................................... 12–17

Replacing One FPGA With One HardCopy Series Device .................................................... 12–18

Replacing One or More FPGAs With One or More HardCopy Series Devices in a Multiple-

Device Configuration Chain ....................... ................................................................................ 12–19

Replacing all FPGAs with HardCopy Series Devices in a Multiple-Device Configuration Chain

......... .................................................................................................................................................12–21

FPGA to HardCopy Configuration Migration Examples ............................................................ 12–21

HardCopy Series Device Replacing a Stand-Alone FPGA ..................................................... 12–21

HardCopy Series Device Replacing an FPGA in a Cascaded Configuration Chain .......... 12–23

HardCopy Series Device Replacing an FPGA Configured Using a Microprocessor ......... 12–25

HardCopy Stratix Device Replacing FPGA Configured in a JTAG Chain .......................... 12–28

HardCopy II Device Replacing Stratix II Device Configured With a Microprocessor ...... 12–30

Conclusion .......................................................................................................................................... 12–32

Document Revision History ............................................ ................................................................. 12–33

vi Altera Corporation

Preliminary

Page 7

Contents

Section IV. HardCopy Design Center Migration Process

Revision History .................................................................................................................................. 12–1

Chapter 13. Back-End Design Flow for HardCopy Series Devices

Introduction .......................................................................................................................................... 13–1

HardCopy II Back-End Design Flow ................................................................... ............................. 13–1

Device Netlist Generation ........... .................................................................................................. 13–2

Design for Testability Insertion .................................................................................................... 13–3

Clock Tree and Global Signal Insertion ...................................................................................... 13–3

Formal Verification of the Processed Netlist .............................................................................. 13–3

Timing and Signal Integrity Driven Place and Route ............................................................... 13–3

Parasitic Extraction and Timing Analysis ................................................................................... 13–4

Layout Verification ...................................... .................................................................................. 13–4

Design Signoff ................................................................................................................................. 13–4

HardCopy Stratix and HardCopy APEX Migration Flow ............................................................. 13–5

Netli st Generation .......................................................................................................................... 13–6

Testability Audit ............................................................................................................................. 13–6

Placement ........................................................................................................................................ 13–6

Test Vector Generation ................ .................................................................................................. 13–7

Routing ............................................................................................................................................ 13–7

Extracted Delay Calculation ......................................................................................................... 13–7

Static Timing Analysis and Timing Closure .............................................................................. 13–7

Formal Verification ........................................................................................................................ 13–8

Physical Verification ...................................................................................................................... 13–8

Manufacturing .............................................................................................. .................... ................... 13–8

Testing ................................................................................................................................................... 13–9

Unused Resources ........................................................................................................ ..................... 13–11

Conclusion .......................................................................................................................................... 13–12

Document Revision History ............................................ ................................................................. 13–12

Chapter 14. Back-End Timing Closure for HardCopy Series Devices

Introduction .......................................................................................................................................... 14–1

Timing Analysis of HardCopy Prototype Device ..................................................................... 14–1

Cell Structure ........................................................................................................................................ 14–2

HardCopy II .................................................................................................................................... 14–2

HardCopy Stratix, HardCopy APEX ........................................................................................... 14–2

Clock Tree Structure ............................................................................................................................ 14–3

HardCopy II .................................................................................................................................... 14–3

HardCopy Stratix ........................................................................................................................... 14–3

HardCopy APEX ............................................................................................................................ 14–3

Importance of Timing Constraints ........................................................................................... ......... 14–4

Correcting Timing Violations ....................................................................................................... 14–4

Hold-Time Violations .................................................................................................................... 14–5

Setup-Ti me Violations ... .............................................................................................................. 14–10

Timing ECOs ...................................................................................................................................... 14–15

Conclusion .......................................................................................................................................... 14–17

Altera Corporation vii

Preliminary

Page 8

HardCopy Series Handbook, Volume 1

Document Revision History ............................................ ................................................................. 14–17

viii Altera Corporation

Preliminary

Page 9

Chapter Revision Dates

The chapters in this book, HardCopy Series Handbook, were revised on the following dates. Where

chapters or groups of chapters are available separately, part numbers are listed.

Chapter 1. Introduction to HardCopy Stratix Devices

Revised: September 2008

Part number: H51001-2.3

Chapter 2. Description, Architecture, and Features

Revised: September 2008

Part number: H51002-3.3

Chapter 3. Boundary-Scan Support

Revised: September 2008

Part number: H51004-3.3

Chapter 4. Operating Conditions

Revised: September 2008

Part number: H51005-3.3

Chapter 5. Quartus II Support for HardCopy Stratix Devices

Revised: September 2008

Part number: H51014-3.3

Chapter 6. Design Guidelines for HardCopy Stratix Performance Improvement

Revised: September 2008

Part number: H51027-1.3

Chapter 7. Introduction to HardCopy APEX Devices

Revised: September 2008

Part number: H51006-2.2

Chapter 8. Description, Architecture, and Features

Revised: September 2008

Part number: H51007-2.2

Chapter 9. Boundary-Scan Support

Revised: September 2008

Part number: H51009-2.2

Altera Corporation ix

Preliminary

Page 10

HardCopy Series Handbook

Chapter 10. Operating Conditions

Revised: September 2008

Part number: H51010-2.2

Chapter 11. Design Guidelines for HardCopy Series Devices

Revised: September 2008

Part number: H51011-3.3

Chapter 12. Power-Up Modes and Configuration Emulation in HardCopy Series Devices

Revised: September 2008

Part number: H51012-2.4

Chapter 13. Back-End Design Flow for HardCopy Series Devices

Revised: September 2008

Part number: H51019-1.3

Chapter 14. Back-End Timing Closure for HardCopy Series Devices

Revised: September 2008

Part number: H51013-2.3

x Altera Corporation

Preliminary

Page 11

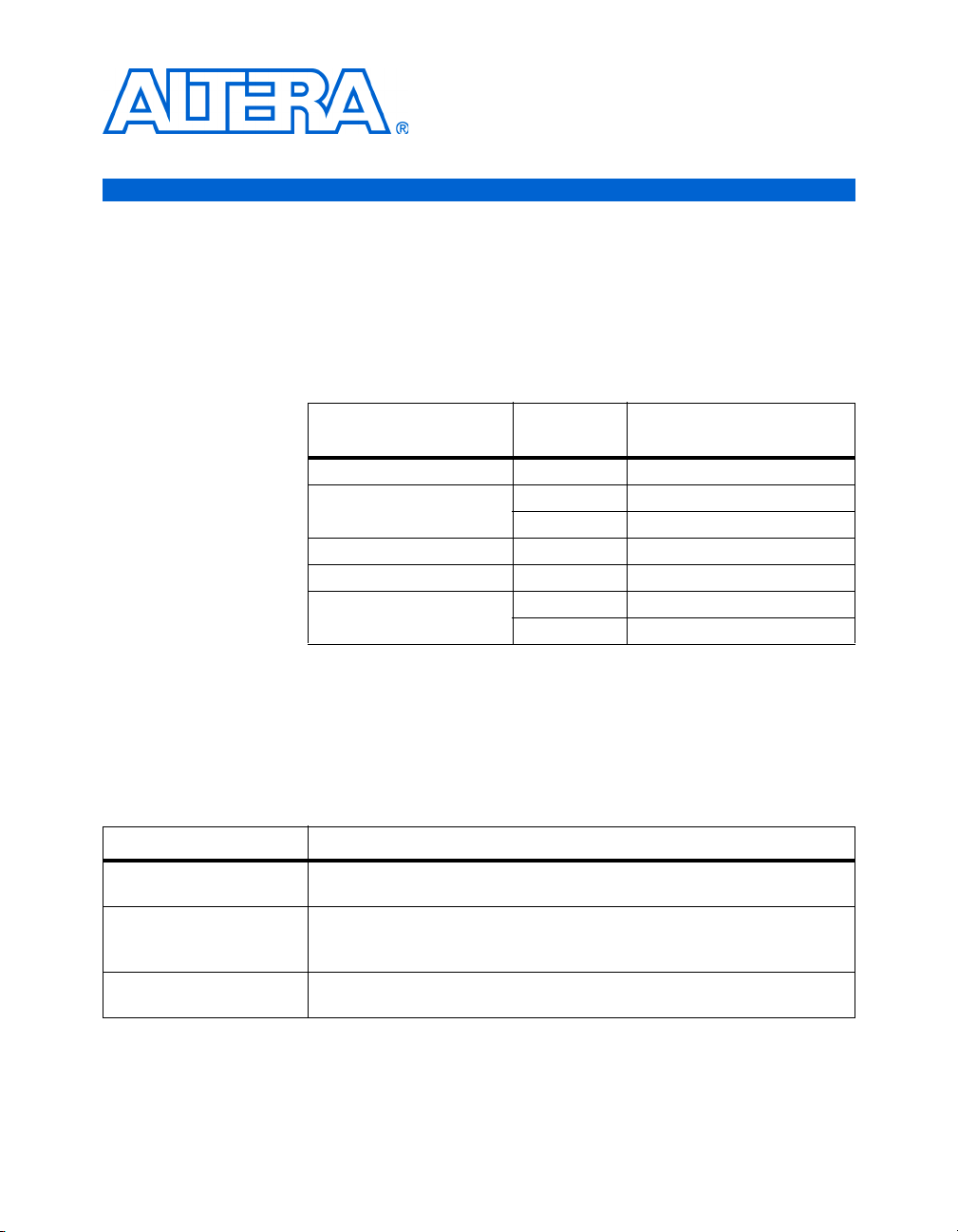

About this Handbook

How to Contact Altera

Typographic Conventions

This handbook provides comprehensive information about the Altera®

HardCopy

®

devices.

For the most up-to-date information about Altera products, refer to the

following table.

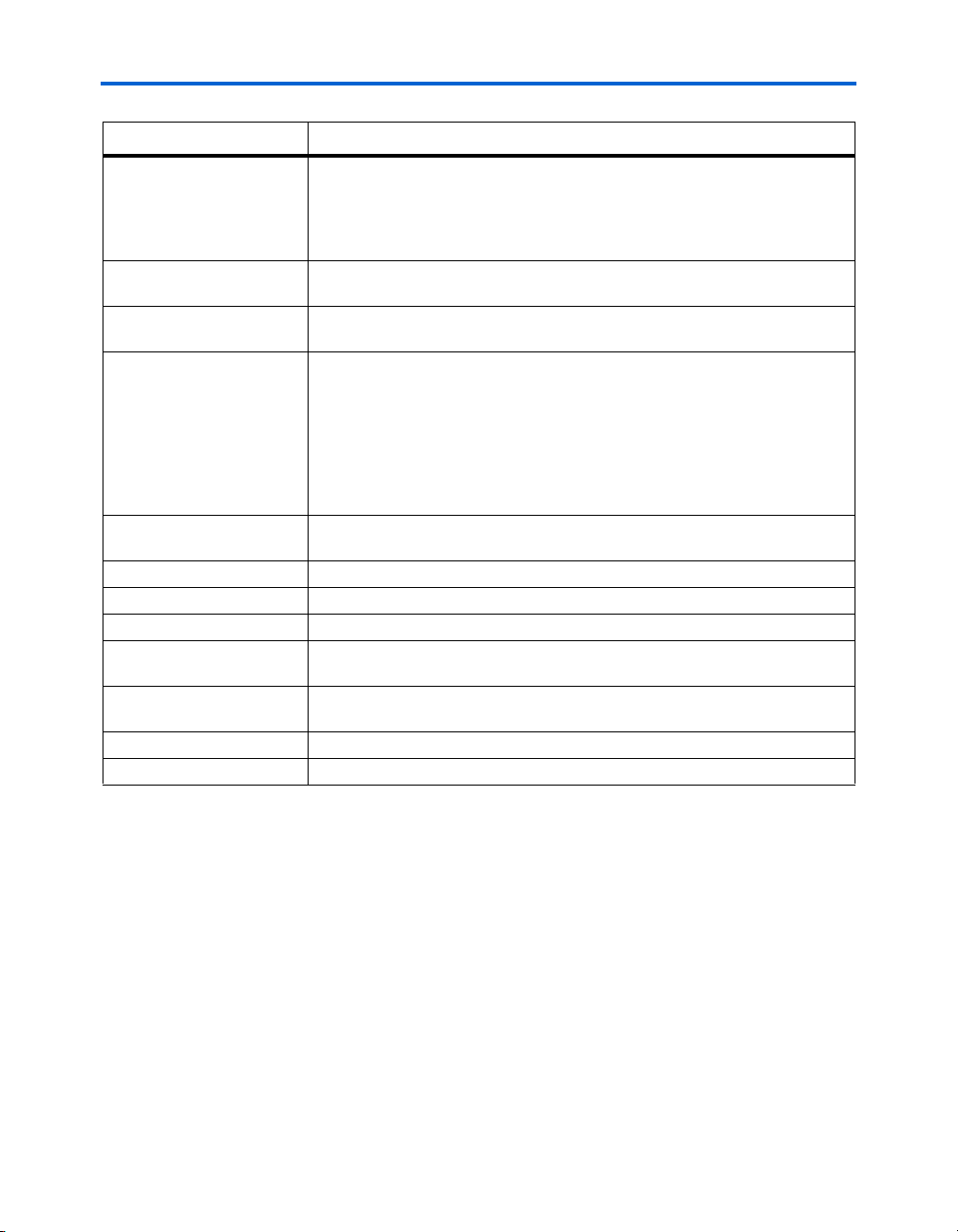

Contact

Technical support Website www.altera.com/support/

Technical training

Product literature Website www.altera.com/literature

Altera literature services Email literat ure@altera.com

Non-technical (General)

(SoftwareLicensing)

Note to table:

(1) You can also contact your local Altera sales office or sales representative.

Contact

Method

Website www.altera.com/training

Email custrain@altera.com

Email nacomp@altera.com

Email authorization@altera.com

Address

This document uses the typographic conventions shown below.

Visual Cue Meaning

Bold Type with Initial

Capital Lett ers

bold type External timing parameters, directory names, project names, disk drive names,

Italic Type with Initial Capital

Letters

Altera Corporation xi

Command names, dialog box titles, checkbox options, and dialog box options are

shown in bold, initial capital letters. Example: Save As dialog box.

filenames, filename extensions, and software utility names are shown in bold

type. Examples: f

Document titles are shown in italic type with initial capital letters. Example: AN 75:

High-Speed Board Design.

, \qdesigns directory, d: dri ve, chiptrip.gdf file.

MAX

Preliminary

Page 12

HardCopy Series Handbook, Volume 1

Visual Cue Meaning

Italic t ype Internal timing parameters and variables are shown in italic type.

Examples: t

Variable names are enclosed in angle brackets (< >) and shown in italic type.

Example: <file name>, <project name>.pof file.

Initial Capital Letters Keyboard keys and menu names are shown with initial capital letters. Examples:

Delete key, the Options menu.

“Subheading” Title” References to sections within a document and titles of on-line help topics are

shown in quotation marks. Example: “Typographic Conventions.”

PIA

, n + 1.

Courier type Signal and port names are shown in lowercase Courier type. Examples: data1,

tdi, input. Active-low signals are denoted by suffix n, e.g., rese tn.

Anything that must be typed exactly as it appears is shown in Courier type. For

example: c:\qdesign s\tutorial\chiptrip.gdf. Also, sections of an

actual file, such as a Report File, references to parts of files (e.g., the AHDL

key wo r d SUBDES IGN), as well as logic function names (e.g., TRI) are shown in

Courier.

1., 2., 3., and

a., b., c., etc.

■ ● • Bullets are used in a list of items when the sequence of the items is not important.

v The checkmark indicates a procedure that consists of one step only.

1 The hand points to information that requires special attention.

c

w

r The angled arrow indicates you should press the Enter key.

f The feet direct you to more information on a particular topic.

Numbered steps are used in a list of items when the sequence of the items is

important, such as the steps listed in a procedure.

A caution calls attention to a condition or possible situation that can damage or

destroy the product or the user’s work.

A warning calls attention to a condition or possible situation that can cause injury

to the user.

xii Altera Corporation

Preliminary

Page 13

Section I. HardCopy Stratix

Device Family Data Sheet

Revision History

This section provides designers with the data sheet specifications for

HardCopy

definitions of the internal architecture, JTAG boundary-scan testing

information, DC operating conditions, AC timing parameters, and a

reference to power consumption for HardCopy Stratix structured ASICs.

This section contains the following:

■ Chapter 1, Introduction to HardCopy Stratix Devices

■ Chapter 2, Description, Architecture, and Features

■ Chapter 3, Boundary-Scan Support

■ Chapter 4, Operating Conditions

■ Chapter 5, Quartus II Support for HardCopy Stratix Devices

■ Chapter 6, Design Guidelines for HardCopy Stratix Performance

Refer to each chapter for its own specific revision history. For information

on when each chapter was updated, refer to the Chapter Revision Dates

section, which appears in the complete handbook.

®

Stratix structured ASICs. The chapters contain feature

Improvement

Altera Corporation Section I–1

Preliminary

Page 14

Revision History HardCopy Series Handbook, Volume 1

Section I–2 Altera Corporation

Preliminary

Page 15

H51001-2.4

1. Introduction to HardCopy Stratix Devices

Introduction

HardCopy® Stratix® structured ASICs, Altera’s second-generation

HardCopy structured ASICs, are low-cost, high-performance devices

with the same architecture as the high-density Stratix FPGAs. The

combination of Stratix FPGAs for prototyping and design verification,

HardCopy Stratix devices for high-volume production, and the

Quartus

complete and powerful alternative to ASIC design and development.

HardCopy Stratix devices are architecturally equivalent and have the

same features as the corresponding Stratix FPGA. They offer pin-to-pin

compatibility using the same package as the corresponding Stratix FPGA

prototype. Designers can prototype their design to verify functionality

with Stratix FPGAs before seamlessly migrating the proven design to a

HardCopy Stratix structured ASIC.

The Quartus II software provides a complete set of inexpensive and

easy-to-use tools for designing HardCopy Stratix devices. Using the

successful and proven methodology from HardCopy APEX™ devices,

Stratix FPGA designs can be seamlessly and quickly migrated to a

low-cost ASIC alternative. Desi gners can use the Quartus II software to

design HardCopy Stratix devices to obtain an average of 50% higher

performance and up to 40% lower power consumption than can be

achieved in the corresponding Stratix FPGAs. The migration process is

fully automated, requires minimal customer involvement, and takes

approximately eight weeks to deliver fully tested HardCopy Stratix

prototypes.

®

II design software beginning with version 3.0, provide a

The HardCopy Stratix devices use the same base arrays across multiple

designs for a given device density and are customized using the top two

metal layers. The HardCopy Stratix family consists of the HC1S25,

HC1S30, HC1S40, HC1S60, and HC1S80 devices. Table 1–1 provides the

details of the HardCopy Stratix devices.

Altera Corporation 1–1

September 2008 Preliminary

Page 16

HardCopy Series Handbook, Volume 1

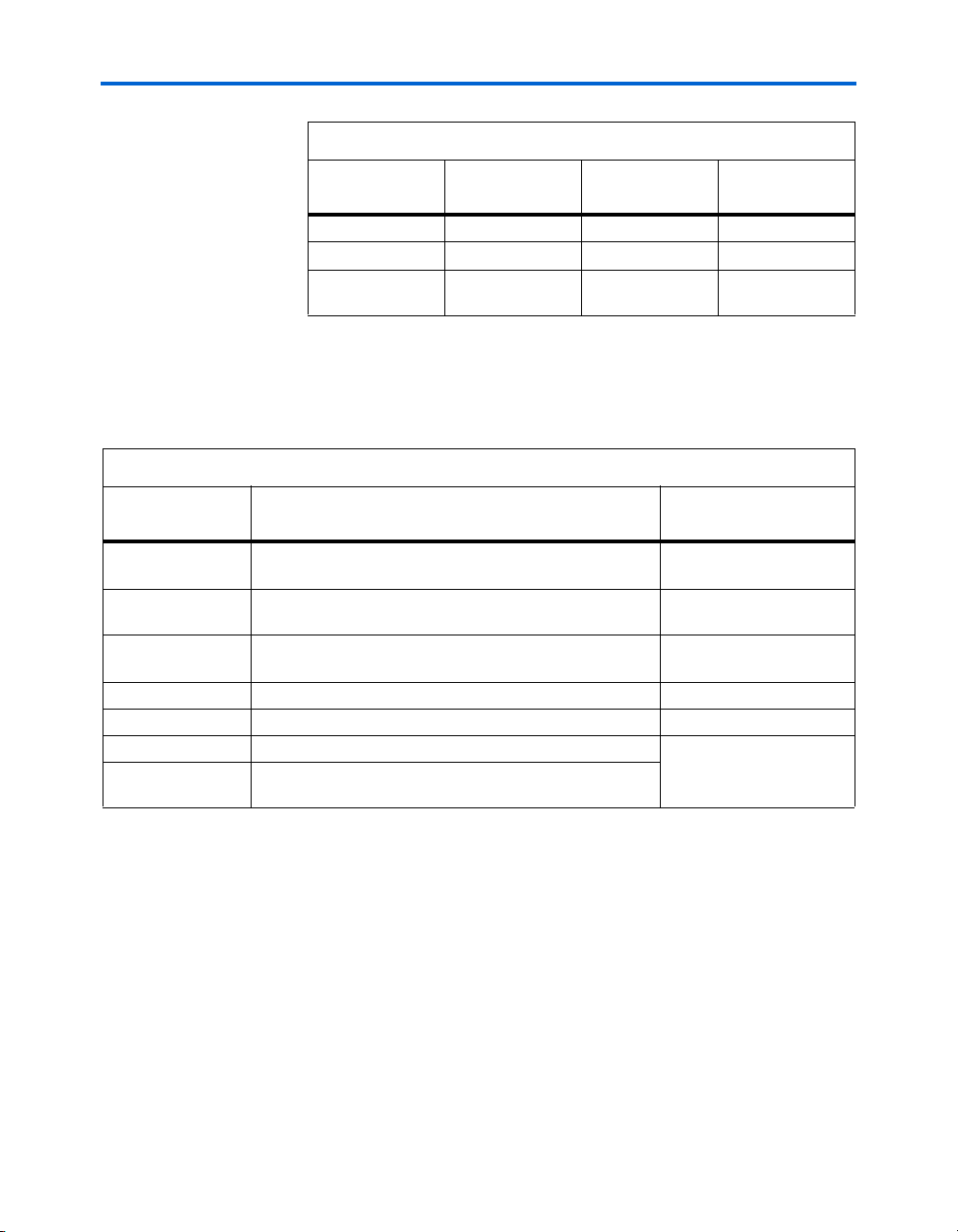

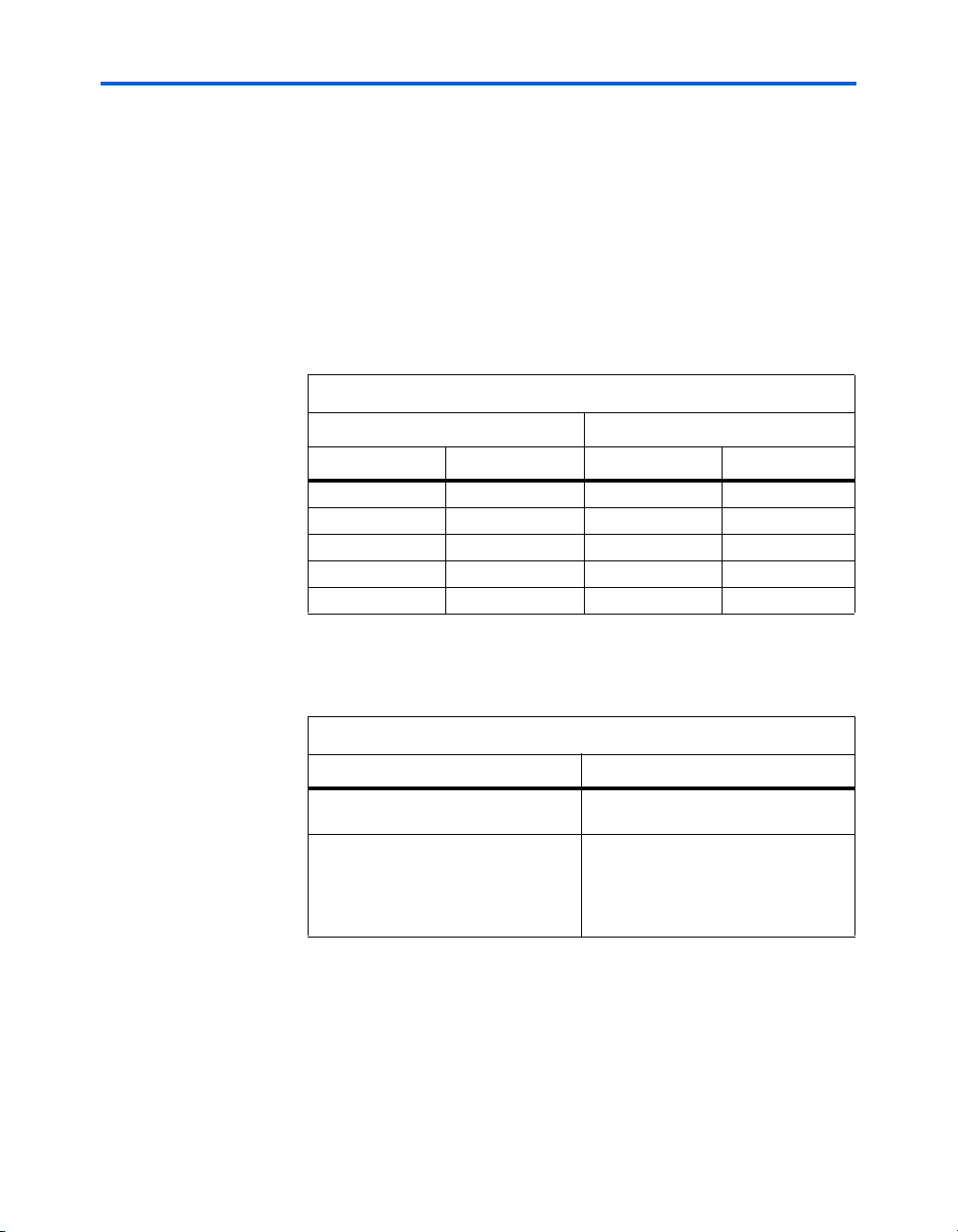

Table 1–1. HardCopy Stratix Devices and Features

Device LEs (1) M512 Blocks M4K Blocks

HC1S25 25,660 224 138 2 10 6

HC1S30 32,470 295 171 2 (4) 12 6

HC1S40 41,250 384 183 2 (4) 14 6

HC1S60 57,120 574 292 6 18 12

HC1S80 79,040 767 364 6 (4) 22 12

Notes to Tab l e 1 –1 :

(1) LE: logic elements.

(2) DSP: digital signal processing.

(3) PLLs: phase-locked loops.

(4) In HC1S30, HC1S40, and HC1S80 devices, there are fewer M-RAM blocks than in the equivalent Stratix FPGA. All

other resources are identical to the Stra tix counterpart.

Features

HardCopy Stratix devices are manufactured on the same 1.5-V, 0.13 μm

all-layer-copper metal fabrication process (up to eight layers of metal) as

M-RAM

Blocks

DSP Blocks (2) PLLs (3)

the Stratix FPGAs.

■ Preserves the functionality of a configured Stratix device

■ Pin-compatible with the Stratix counterparts

■ On average, 50% faster than their Stratix equivalents

■ On average, 40% less power consumption than their Stratix

equivalents

■ 25,660 to 79,040 LEs

■ Up to 5,658,408 RAM bits available

■ TriMatrix memory architecture consisting of three RAM block sizes

to implement true dual-port memory and first-in-first-out (FIFO)

buffers

■ Embedded high-speed DSP blocks provide dedicated

implementation of multipliers, multiply-accumulate functions, and

finite impulse response (FIR) filters

■ Up to 12 PLLs (four enhanced PLLs and eight fast PLLs) per device

which provide identical features as the FPGA counterparts,

including spread spectrum, programmable bandwidth, clock

switchover, real-time PLL reconfiguration, advanced multiplication,

and phase shifting

■ Supports numerous single-ended and differential I/O standards

■ Supports high-speed networking and communications bus

standards including RapidIO™, UTOPIA IV, CSIX, HyperTransport

technology, 10G Ethernet XSBI, SPI-4 Phase 2 (POS-PHY Level 4),

and SFI-4

■ Differential on-chip termination support for LVDS

1–2 Altera Corporation

Preliminary September 2008

Page 17

Features

■ Supports high-speed external memory, including zero bus

turnaround (ZBT) SRAM, quad data rate (QDR and QDRII) SRAM,

double data rate (DDR) SDRAM, DDR fast-cycle RAM (FCRAM),

and single data rate (SDR) SDRAM

■ Support for multiple intellectual property (IP) megafunctions from

■ Available in space-saving flip-chip FineLine BGA

®

Altera

MegaCore® functions, and Altera Megafunction Partners

Program (AMPP

SM

) megafunctions

®

and wire-bond

packages (Tables 1–2 and 1–3)

■ Optional emulation of original FPGA configuration sequence

■ Optional instant-on power-up

1 The actual performance and power consumption improvements

over the Stratix equivalents mentioned in this data sheet are

design-dependent.

Table 1–2. HardCopy Stratix Device Package Options and I/O Pin Counts

Note (1)

Device

HC1S25 473

HC1S30 597

HC1S40 613 (4)

HC1S60 782

HC1S80 782

Notes to Tab l e 1 –2 :

(1) Quartus II I/O pi n counts include one additional pin, PLLENA, which is not a

general-purpose I/O pin. PLLENA can only be used to enable the PLLs.

(2) This device uses a wire-bond package.

(3) This device uses a flip-chip package.

(4) In the Stratix EP 1S40F7 80 FPGA, the I/O pins U12 and U18 are general-purpose

I/O pins. In the F PGA prototype,

EP1S40F780_HARDCOPY_FPGA_PROTOTYPE, and in the HardCopy Stratix

HC1S40F 780 device, U12 and U18 must be connected to ground. The

EP1S40F780_HARDCOPY_FPGA_PROTOTYPE and HC1S40F780 pin-outs are

identical.

672-Pin

FineLine BGA (2)

780-Pin

FineLine BGA (3)

1,020-Pin

FineLine BGA (3)

Altera Corporation 1–3

September 2008 Preliminary

Page 18

HardCopy Series Handbook, Volume 1

Table 1–3. HardCopy Stratix Device Package Sizes

Document

Device

Pitch (mm) 1.00 1.00 1.00

Area (mm2)

Length × width

(mm × mm)

672-Pin

FineLine BGA

729 841 1,089

27 × 27 29 × 29 33 × 33

Table 1–4 shows the revision history for this chapter.

780-Pin

FineLine BGA

Revision History

Table 1–4. Document Revision History

Date and Document

Version

September 2008

v2.4

June 2007 v2.3 Updated Introduction section.

December 2006

v2.2

March 2006 Formerly chapter 5; no content change. —

October 2005 v2.1 Minor edits —

January 2005 v2.0 Minor edits —

June 2003 v1.0 Initial release of Chapter 5, Introduction to HardCopy Stratix

Revised chapter number and metadata. —

Updated Table 1–2.

Updated revision history. —

Devices, in the HardCopy Device Handbook.

Changes Made Summary of Changes

1,020-Pin

FineLine BGA

—

1–4 Altera Corporation

Preliminary September 2008

Page 19

H51002-3.4

2. Description, Architecture, and Features

Introduction

HardCopy® Stratix® structured ASICs provide a comprehensive

alternative to ASICs. The HardCopy Stratix device family is fully

supported by the Quartus

intellectual property (IP) portfolio, provides a complete path from

prototype to volume production. Designers can now procure devices,

tools, and Altera

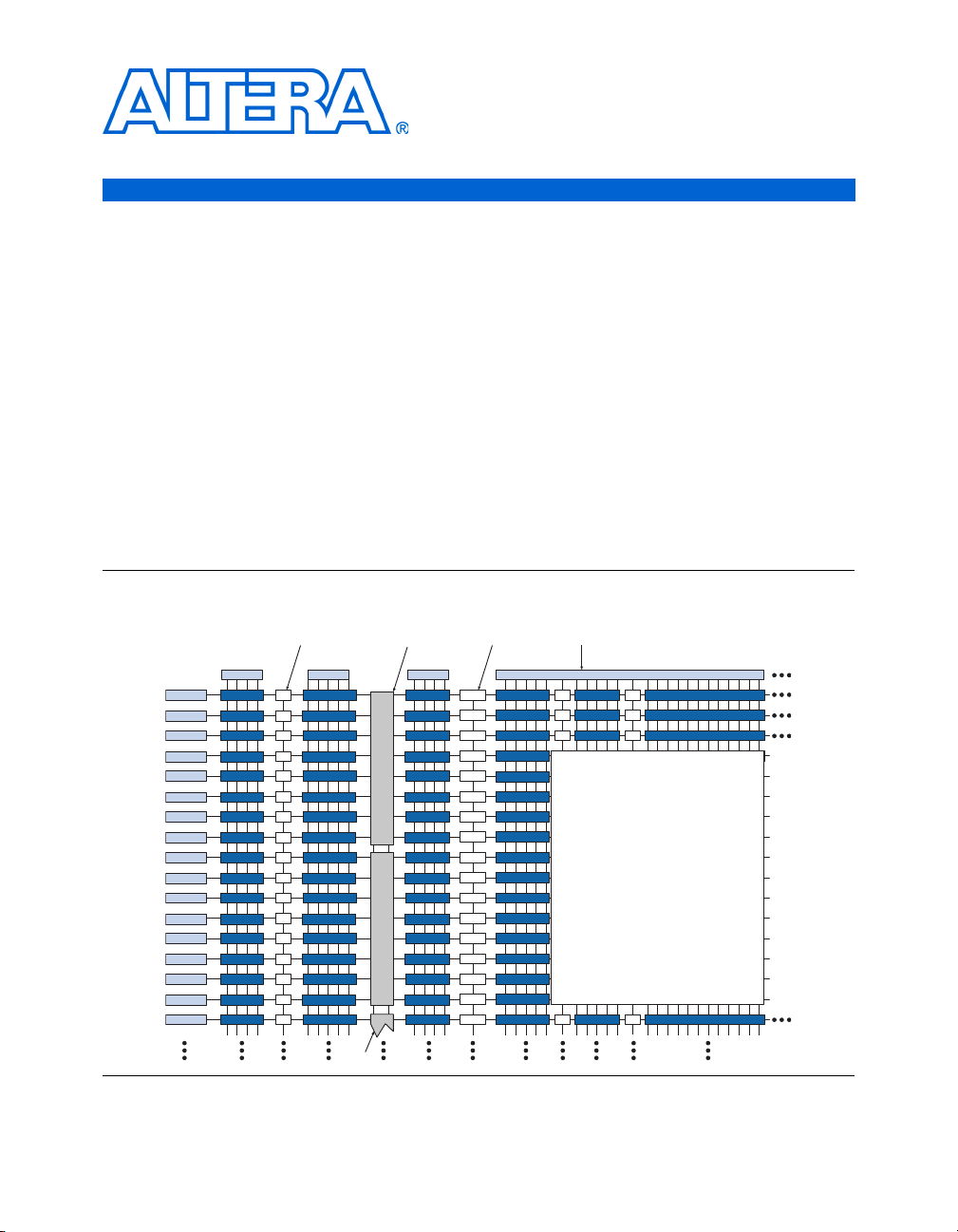

As shown in Figure 2–1, HardCopy Stratix devices preserve their Stratix

FPGA counterpart’s architecture, but the programmability for logic,

memory, and interconnect is removed. HardCopy Stratix devices are also

manufactured in the same process technology and process voltage as

Stratix FPGAs. Removing all configuration and programmable routing

resources and replacing it with direct metal interconnect results in

considerable die size reduction and the ensuing cost savings.

Figure 2–1. HardCopy Stratix Device Architecture

M512 RAM Blocks for

Dual-Port Memory, Shift

Registers, & FIFO Buffers

IOEs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

DSP Blocks for

Multiplication and Full

Implementation of FIR Filters

DSP

Block

IOEs IOEs

LABs LABs

LABs

LABs LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs LABs

®

II des ign software, and, combined with a vast

®

IP for their high-volume applications.

M4K RAM Blocks

for True Dual-Port

Memory & Other Embedded

Memory Functions

IOEs Support DDR, PCI, GTL+, SSTL-3,

SSTL-2, HSTL, LVDS, LVPECL, PCML,

HyperTransport & other I/O Standards

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

M-RAM Block

Altera Corporation 2–1

September 2008

Page 20

HardCopy Stratix and Stratix FPGA Differences

The HardCopy Stratix family consists of base arrays that are common to

all designs for a particular device density. Design-specific customization

is done within the top two metal layers. The base arrays use an

area-efficient sea-of-logic-elements (SOLE) core an d extend the flexibility

of high-density Stratix FPGAs to a cost-effective, high-volume production

solution. With a seamless migration process employed in numerous

successful designs, functionality-verified Stratix FPGA designs can be

migrated to fixed-function HardCopy Stratix devices with minimal risk

and guaranteed first-time success.

The SRAM configuration cells of the original Stratix devices are replaced

in HardCopy Stratix devices by metal connects, which define the function

of each logic element (LE), digital signal processing (DSP) block,

phase-locked loop (PLL), embedded memory, and I/O cell in the device.

These resources are interconnected using metallization layers. Once a

HardCopy Stratix device has been manufactured, the functionality of the

dev ic e i s fixe d an d n o re -p ro gr am mi ng is po ss ib le . H ow ev er, as is th e c as e

with Stratix FPGAs, the PLLs can be dynamically configured in

HardCopy Stratix devices.

HardCopy Stratix

and Stratix FPGA

Differences

To ensure HardCopy Stratix device functionality and performance,

designers should thoroughly test the original Stratix FPGA-based design

for satisfactory results before committing the design for migration to a

HardCopy Stratix device. Unlike Stratix FPGAs, HardCopy Stratix

devices are customized at the time of manufacturing and therefore do not

have programmability support.

Since HardCopy Stratix devices are customized within the top two metal

layers, no configuration circuitry is required. Refer to “Power-Up Modes

in HardCopy Stratix Devices” on page 2–7 for more information.

Depending on the design, HardCopy Stratix devices can provide, on

average, a 50% performance improvement over equivalent Stratix

FPGAs. The performance improvement is achieved by die size reduction,

metal interconnect optimization, and customized signal buffering.

HardCopy Stratix devices consume, on average, 40% less power than

their equivalent Stratix FPGAs.

1 Designers can use the Quartus II software to design HardCopy

Stratix devices, estimate performance and power consumption,

and maximize system throughput.

2–2 Altera Corporation

September 2008

Page 21

Description, Architecture, and Features

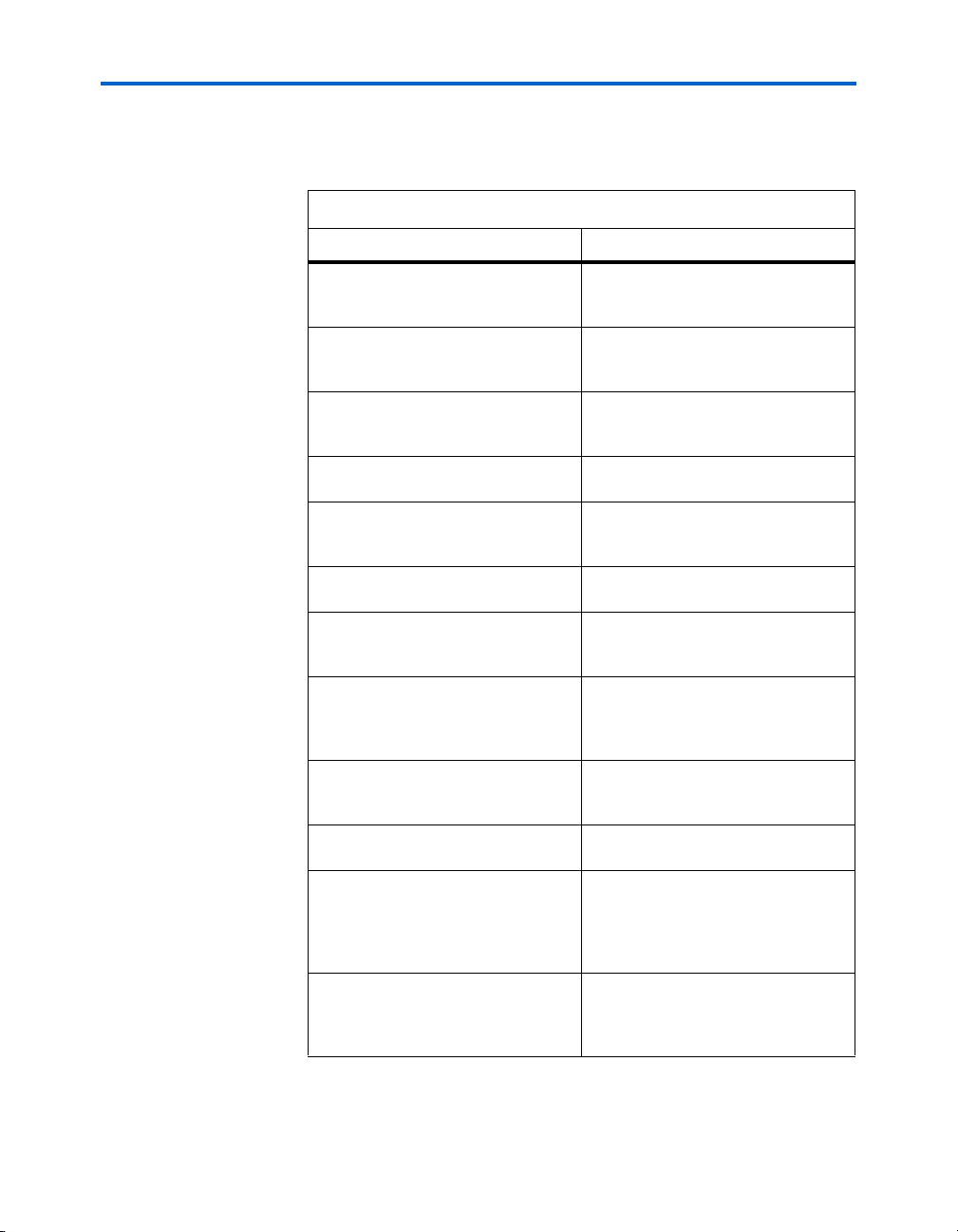

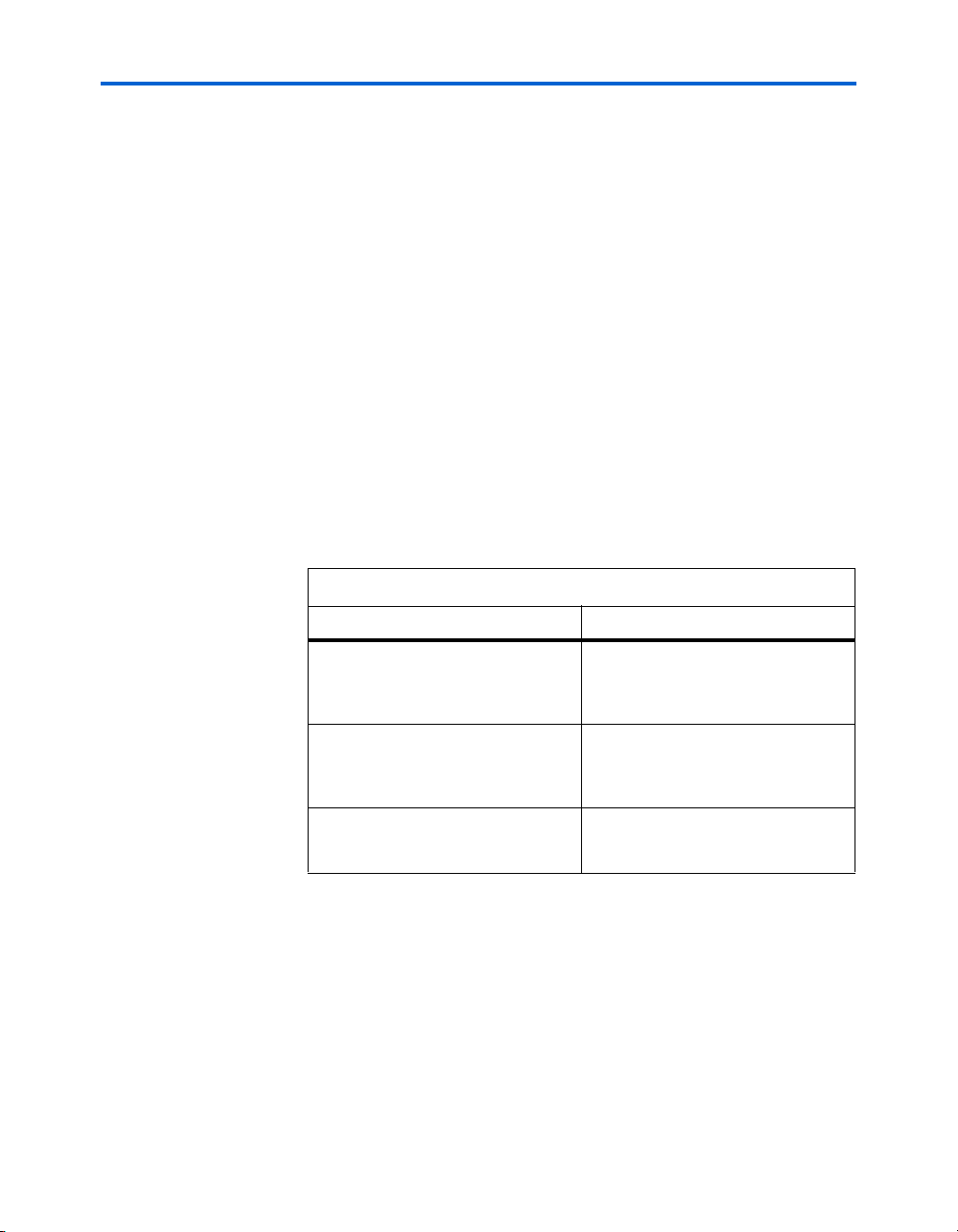

Table 2–1 illustrates the differences between HardCopy Stratix and

Stratix devices.

Table 2–1. HardCopy Stratix and Stratix Device Comparison (Part 1 of 2)

HardCopy Stratix Stratix

Customized device. All

reprogrammability support is removed

and no configuration is required.

Average of 50% performance

improvement over corresponding

FPGA (1).

Average of 40% less power

consumption compared to

corresponding FPGA (1).

Contact Altera for information regarding

specific IP support.

Double data rate (DDR) SDRAM

maximum operating frequency is

pending characterization.

All routing connections are direct and

all unused routing is removed.

HC1S30 and HC1S40 devices have

two M-RAM blocks. HC1S80 devices

have six M-RAM blocks.

It is not possible to initialize M512 and

M4K RAM contents during power-up.

The contents of memory output

registers are unknown after power-on

reset (POR).

HC1S30 and HC1S40 devices have six

PLLs.

PLL dynamic reconfiguration uses

ROM for information. This

reconfiguration is performed in the

back-end and does not affect the

migration fl ow.

The I/O elements (IOEs) are equivalent

but not identical to FPGA IOEs due to

slight design optimizations for

HardCopy devices.

Re-programmable with configuration is

required upon power-up.

High-performance FPGA.

Standard FPGA power consumption.

IP support for all devices is available.

DDR SDRAM can operate at 200 MHz

for -5 speed grade devices.

MultiTrack™ routing stitches together

routing resources to provide a path.

EP1S30 and EP1S40 devices have four

M-RAM blocks. EP1S80 devices have

nine M-RAM blocks.

The contents of M512 and M4K RAM

blocks can be preloaded during

configuration with data specified in a

mem ory initia lization file (.m if).

The contents of memory output

registers are initialized to '0' after POR.

HC1S30 devices have 10 PLLs.

HC1S40 devices have 12 PLLs.

PLL dynamic reconfiguration uses a

MIF to initialize a RAM resource with

information.

The IOEs are optimized for the FPGA

architecture.

Altera Corporation 2–3

September 2008

Page 22

Logic Elements

Table 2–1. HardCopy Stratix and Stratix Device Comparison (Part 2 of 2)

HardCopy Stratix Stratix

The I/O drive strength for single-ended

I/O pins are slightly different and is

modeled in the HardCopy Stratix IBIS

models.

In the HC1S40 780-pin FineLine BGA®

device, the I/O pins U12 and U18 must

be connected to ground.

The BSDL file describes re-ordered

Joint Test Action Group (JTAG)

boundary-scan chains.

Note t o Table 2–1:

(1) Performance and power consumption are design dependant.

The I/O drive strength for single-ended

I/O pins are found in Stratix IBIS

models.

In the HC1S40 780-pin FineLine BGA

device, the I/O pins U12 and U18 are

available as general-purpose I/O pins.

The JTAG boundary-scan chain is

defined in the BSDL file.

Logic Elements

Embedded Memory

Logic is implemented in HardCopy Stratix devices using the same

architectural units as the Stratix device family. The basic unit is the logic

element (LE) with logic array blocks (LAB) consisting of 10 LEs. The

implementation of LEs and LABs is identical to the Stratix device family.

In the HardCopy Stratix device family, all extraneous routing resources

not essential to the specific design are removed for performance and die

size efficiency. Therefore, the MultiTrack interconnect for routing

implementation between LABs and other device resources in the Stratix

device family is no longer necessary in the HardCopy Stratix device

family.

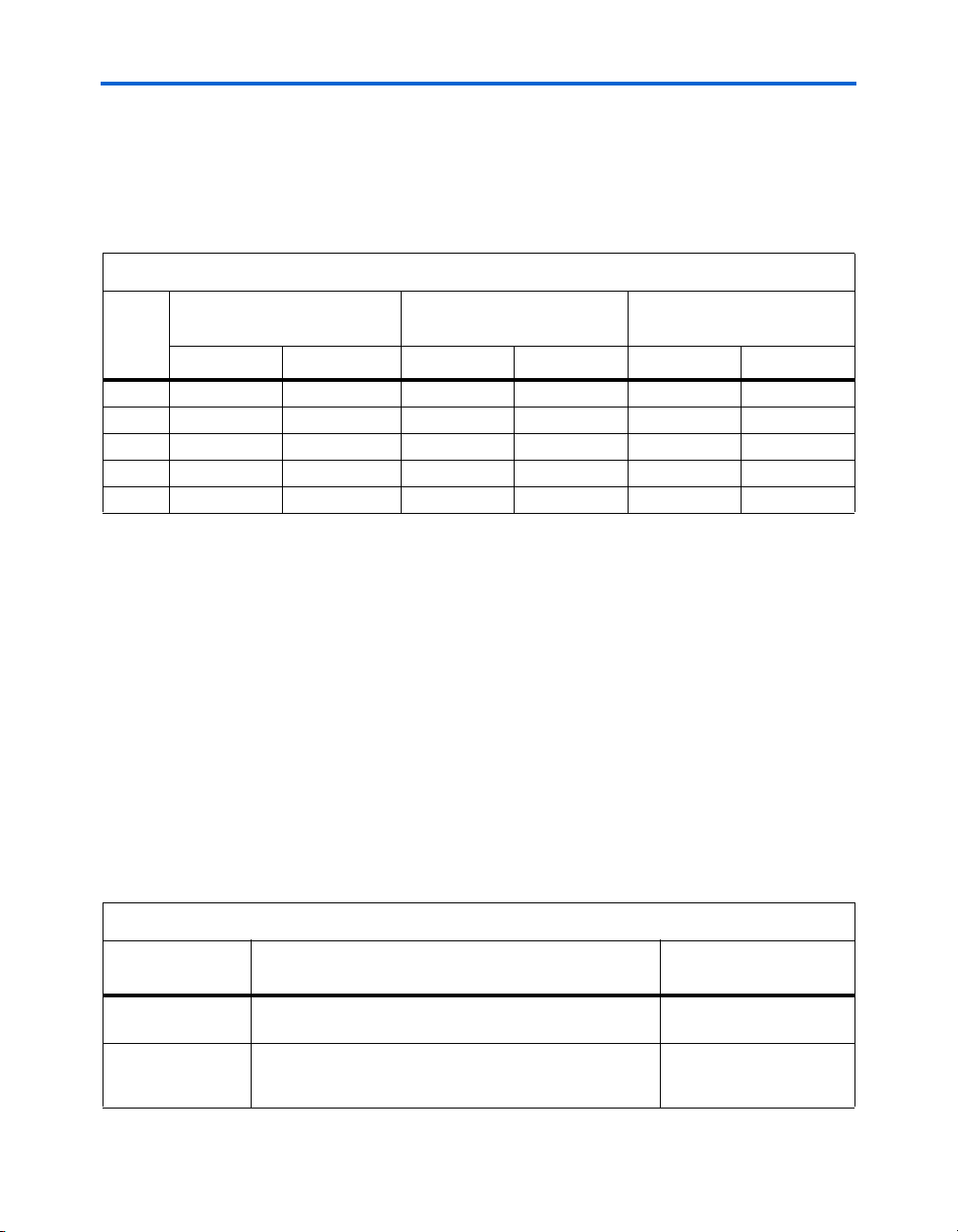

Table 2–2 illustrates the differences between HardCopy Stratix and

Stratix logic.

Table 2–2. HardCopy Stratix and Stratix Logic Comparison

HardCopy Stratix Stratix

All routing connections are direct and

all unused routing is removed.

MultiTrack routing stitches routing

resources together to provide a path.

TriMatrix™ memory blocks from Stratix devices, including M512, M4K,

and M-RAM memory blocks, are available in HardCopy Stratix devices.

Embedded memory is seamlessly implemented in the equivalent

resource.

2–4 Altera Corporation

September 2008

Page 23

Description, Architecture, and Features

Although memory resource implementation is equivalent, the number of

specific M-RAM blocks are not necessarily the same between

corresponding Stratix and HardCopy Stratix devices. Table 2–3 shows the

number of M-RAM blocks available in each device.

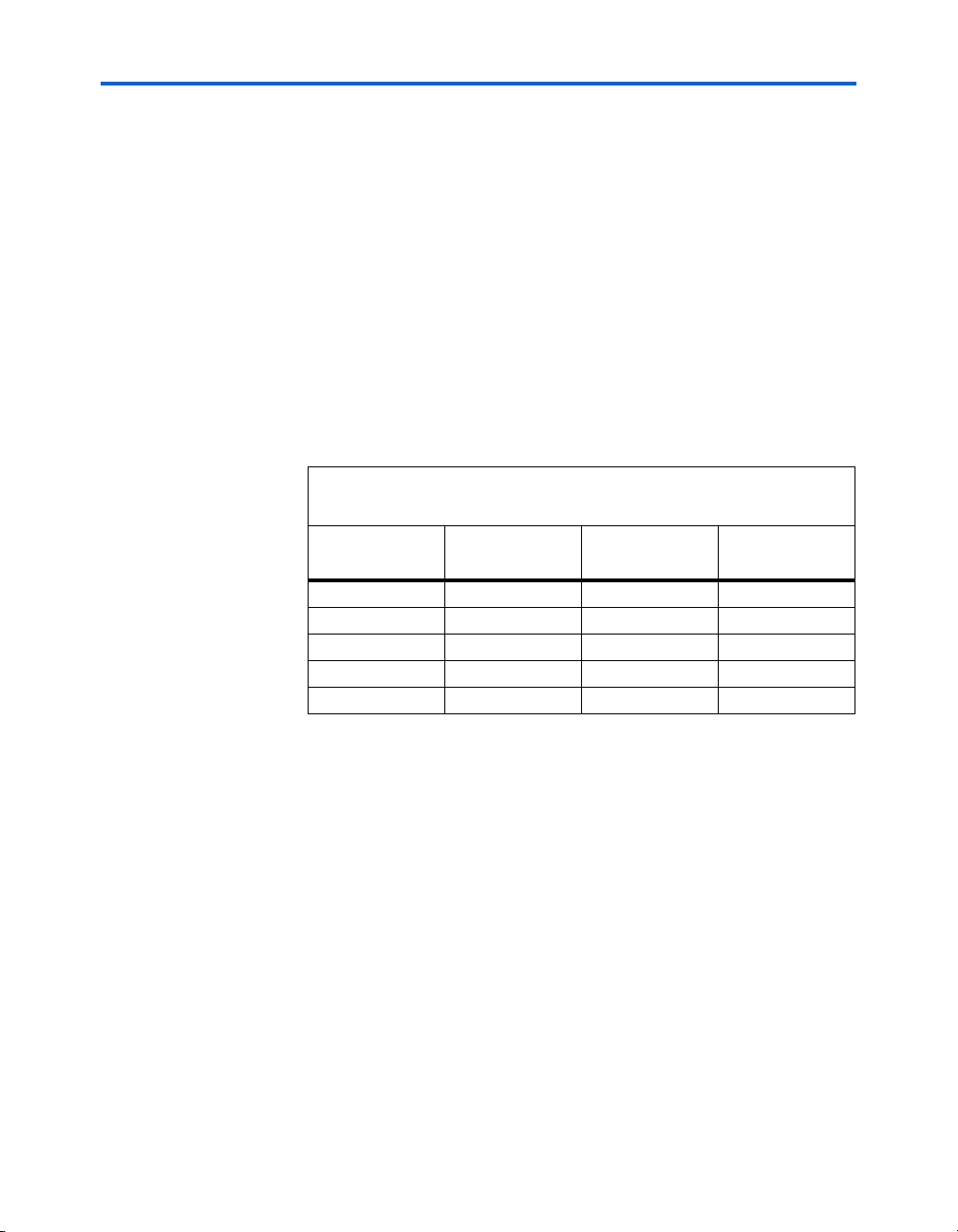

Table 2–3. HardCopy Stratix and Stratix M-RAM Block Comparison

HardCopy Stratix Stratix

Device M-RAM Blocks Device M-RAM Blocks

HC1S25 2 EP1S25 2

HC1S30 2 EP1S30 4

HC1S40 2 EP1S40 4

HC1S60 6 EP1S60 6

HC1S830 6 EP1S830 9

In HardCopy Stratix devices, it is not possible to preload RAM contents

using a MIF after powering up; the output registers of memory blocks

will have unknown values. This occurs because there is no configuration

process that is executed.

1 Violating the setup or hold time requirements on address

registers could corrupt the memory contents. This requirement

applies to both read and write operations.

Table 2–4 illustrates the differences between HardCopy Stratix and

Stratix memory.

Table 2–4. HardCopy Stratix and Stratix Memory Comparison

HardCopy Stratix Stratix

HC1S30 and HC1S40 devices have

two M-RAM blocks. HC1S80 devices

have six M-RAM blocks.

It is not possible to initialize M512 and

M4k RAM contents during power-up.

The contents of memory output

registers are unknown after POR.

Altera Corporation 2–5

September 2008

EP1S30 and EP1S40 devices have four

M-RAM blocks. EP1S80 devices have

nine M-RAM blocks.

The contents of M512 and M4K RAM

blocks can be preloaded during

configuration with data specified in a

MIF.

The contents of memory output

registers are initialized to ‘0’ after POR.

Page 24

DSP Blocks

DSP Blocks

PLLs and Clock Networks

DSP blocks in HardCopy Stratix devices are architecturally identical to

those in Stratix devices. The number of DSP blocks available in

HardCopy Stratix devices matches the number of DSP blocks available in

the corresponding Stratix device.

The PLLs in HardCopy Stratix devices are identical to those in Stratix

devices. The clock networks are also implemented exactly as they are in

Stratix devices. The number of PLLs can vary between corresponding

Stratix and HardCopy Stratix devices. Ta b l e 2 –5 shows the number of

PLLs available in each device.

Table 2–5. HardCopy Stratix and Stratix PLL Comparison

HardCopy Stratix Stratix

Device PLLs Device PLLs

HC1S25 6 EP1S25 6

HC1S30 6 EP1S30 10

HC1S40 6 EP1S40 12

HC1S60 12 EP1S60 12

EP1S830 12 EP1S830 12

Table 2–6 illustrates the differences between HardCopy Stratix and

Stratix PLLs.

Table 2–6. HardCopy Stratix and Stratix PLL Differences

HardCopy Stratix Stratix

HC1S30 and HC1S40 devices have six

PLLs.

PLL dynamic reconfiguration uses

ROM for information. This

reconfiguration is performed in the

back-end and does not affect the

migration fl ow.

I/O Structure and Features

2–6 Altera Corporation

The HardCopy Stratix IOEs are equivalent, but not identical to, the Stratix

FPGA IOEs. This is due to the reduced die size, layout difference, and

metal customization of the HardCopy Stratix device. The differences are

minor but may be relevant to customers designing with tight DC and

switching characteristics. However, no signal integrity concerns are

introduced with HardCopy Stratix IOEs.

HC1S30 devices have 10 PLLs.

HC1S40 devices have12 PLLs.

PLL dynamic reconfiguration uses a

MIF to initialize a RAM resource with

information.

September 2008

Page 25

Description, Architecture, and Features

When designing with very tight timing constraints (for example, DDR or

quad data rate [QDR]), or if using the programmable drive strength

option, Altera recommends verifying final drive strength using updated

IBIS models located on the Altera website at www.alter a.com.

Differential I/O standards are unaffected.

I/O pin placement and VREF pin placement rules are identical between

HardCopy Strati x and Stratix devices. Unused pin settings will carry o ver

from Stratix device settings and are implemented as tri-stated outputs

driving ground or outputs driving V

CC

.

In Stratix EP1S40 780-pin FineLine BGA FPGAs, the I/O pins U12 and

U18 are available as general-purpose I/O pins. In the FPGA prototype,

EP1S40F780_HARDCOPY_FPGA_PROTOTYPE, and in the Hardcopy

Stratix HC1S40 780-pin FineLine BGA device, the I/O pins U12 and U18

must be connected to ground. HC1S40 780-pin FineLine BGA and

EP1S40F780_HARDCOPY_FPGA_PROTOTYPE pin-outs are identical.

Table 2–7 illustrates the differences between HardCopy Stratix and

Stratix I/O pins.

Table 2–7. HardCopy Stratix and Stratix I/O Pin Comparison

HardCopy Stratix Stratix

Power-Up Modes in HardCopy Stratix Devices

The IOEs are equivalent, but not

identical to, the FPGA IOEs due to

slight design optimizations for

HardCopy devices.

The I/O drive strength for single-ended

I/O pins are slightly different and are

found in the HardCopy Stratix IBIS

models.

In the HC1S40 780-pin FineLine BGA

device, the I/O pins U12 and U18 must

be connected to ground.

Designers do not need to configure HardCopy Stratix devices, unlike

their FPGA counterparts. However, to facilitate seamless migration,

configuration can be emulated in HardCopy Stratix devices.

The modes in which a HardCopy Stratix device can be made ready for

operation after power-up are: instant on, instant on after 50 ms, and

IOEs are optimized for the FPGA

architecture.

The I/O drive strength for single-ended

I/O pins are found in Stratix IBIS

models.

In the EP1S40 780-pin FineLine BGA

device, the I/O pins U12 and U18 are

available as general-purpose I/O pins.

configuration emulation. These modes are briefly described below.

Altera Corporation 2–7

September 2008

Page 26

Hot Socketing

■ In instant on mode, the HardCopy Stratix device is available for use

shortly after the device receives power. The on-chip POR circuit

resets all registers. The CONF_DONE output is tri-stated once the POR

has elapsed. No configuration device or configuration data is

necessary.

■ In instant on after 50 ms mode, the HardCopy Stratix device

performs in a fashion similar to the instant on mode, except that there

is an additional delay of 50 ms, during which time the device is held

in reset stage. The CONF_DONE output is pulled low during this time,

and then tri-stated after the 50 ms have elapsed. No configuration

device or configuration data is necessary for this option.

■ In configuration emulation mode, the HardCopy series device

emulates the behavi or of an APEX or Stratix FPGA during its

configuration phase. When this mode is used, the HardCopy device

uses a configuration emulation circuit to receive configuration bit

streams. When all the configuration data is received, the HardCopy

series device transitions into an initialization phase and releases the

CONF_DONE pin to be pulled high. Pulling the CONF_DONE pin high

signals that the HardCopy series device is ready for normal

operation. If the optional open-drain INIT_DONE output is used, the

normal operation is delayed until this signal is released by the

HardCopy series device.

1 HardCopy II and some HardCopy Stratix devices do not

support configuration emulation mode.

Instant on and instant on after 50 ms modes are the recommended

power-up modes because these modes are similar to an ASIC’s

functionality upon power-up. No changes to th e existing board design or

the configuration software are required.

All three modes provide significant benefits to system designers. They

enable seamless migration of the design from the FPGA device to the

HardCopy device with no changes to the existing board design or the

configuration software. The pull-up resistors on nCONFIG, nSTATUS, and

CONF_DONE should be left on the printed circuit board.

f For more information, refer to the HardCopy Series Configuration

Emulation chapter in the HardCopy Series Handbook.

Hot Socketing

2–8 Altera Corporation

HardCopy Stratix devices support hot socketing without any external

components. In a hot socketing situation, a device’s output buffers are

turned off during system power up or power down. To simplify board

design, HardCopy Stratix devices support any power-up or power-down

sequence (V

CCIO

and V

). For mixed-voltage environments, you can

CCINT

September 2008

Page 27

Description, Architecture, and Features

drive signals into the device before or during power up or power down

without damaging the device. HardCopy Stratix devices do not drive out

until they have attained proper operating conditions.

HARDCOPY_ FPGA_ PROTOTYPE Devices

You can power up or power down the V

CCIO

and V

CCINT

pi ns in any

sequence. The power supply ramp rates can range from 100 ns to 100 ms.

During hot socketing, the I/O pin capacitance is less than 15 pF and the

clock pin capacitance is less than 20 pF.

■ The hot socketing DC specification is | I

■ The hot socketing AC specification is | I

| < 300 µA.

IOPIN

| < 8 mA for 10 ns or

IOPIN

less. This specification takes into account the pin capacitance only.

Additional capacitance for trace, connector, and loading needs to be

taken into consideration separately. I

is the current at any user

IOPIN

I/O pin on the device.

1 The DC specifi cation applies when all V

supplies to the device

CC

are stable in the powered-up or powered-down conditions. For

the AC specification, the peak current duration due to power-up

transients is 10 ns or less.

HARDCOPY_FPGA_PROTOTYPE devices are Stratix FPGAs available

for designers to prototype their HardCopy Stratix designs and perform

in-system verification before migration to a HardCopy Stratix device. The

HARDCOPY_FPGA_PROTOTYPE devices have the same available

resources as in the final HardCopy Stratix devices.

The Quartus II software version 4.1 and later contains the latest timing

models. For designs with tight timing constraints, Altera strongly

recommends compiling the design with the Quartus II software

version 4.1 or later. To properly verify I/O features, it is important to

design with the HARDCOPY_FPGA_PROTOTYPE device option prior to

migrating to a HardCopy Stratix device.

Altera Corporation 2–9

September 2008

Page 28

Document Revision History

1 Some HARDCOPY_FPGA_PROTOTYPE devices, as indicated

in Table 2–8, have fewer M-RAM blocks compared to the

equivalent Stratix FPGAs. The selective removal of these

resources provides a significant price benefit to designers using

HardCopy Stratix devices.

Table 2–8. M-RAM Block Comparison Between Various Devices

Number

HARDCOPY_FPGA_PROTOTYPE

Devices

HardCopy Stratix Devices Stratix Devices

of LEs

Device M-RAM Blocks Device M-RAM Blocks Device M-RAM Blocks

25,660 EP1S25 2 HC1S25 2 EP1S25 2

32,470 EP1S30 2 HC1S30 2 EP1S30 4

41,250 EP1S40 2 HC1S40 2 EP1S40 4

57,120 EP1S60 6 HC1S60 6 EP1S60 6

79,040 EP1S830 6 HC1S830 6 EP1S830 9

f For more information about how the various features in the Quartus II

software can be used for designing HardCopy Stratix devices, refer to

the Quartus II Support for HardCopy Stratix Devices chapter of the

HardCopy Series Handbook.

HARDCOPY_FPGA_PROTOTYPE FPGA devices have the identical

speed grade as the equivalent Stratix FPGAs. However, HardCopy Stratix

devices are customized and do not have any speed grading. HardCopy

Stratix devices, on an average, can be 50% faster than their equivalent

HARDCOPY_FPGA_PROTOTYPE devices. The actual improvement is

design-dependent.

Document

Table 2–9 shows the revision history for this chapter.

Revision History

Table 2–9. Document Revision History (Part 1 of 2)

Date and Document

Version

September 2008

v3.4

June 2007 v3.3 ● Updated Table 2–1.

2–10 Altera Corporation

Revised chapter number and metadata. —

● Added note to the “Embedded Memory” section.

● Updated the “Hot Socketing” section.

Changes Made Summary of Changes

—

September 2008

Page 29

Table 2–9. Document Revision History (Part 2 of 2)

Description, Architecture, and Features

Date and Document

Version

December 2006

Updated revision history. —

Changes Made Summary of Changes

v3.2

March 2006 Formerly chapter 6; no content change. —

October 2005 v3.1 ● Minor edits

● Updated graphics

May 2005

v3.0

January 2005

v2.0

● Added Table 6-1

● Added the Logic Elements section

● Added the Embedded Memory section

● Added the DSP Blocks section

● Added the PLLs and Clock Networks section

● Added the I/O Structure and Features section

● Added summary of I/O and timing differences between

Stratix FPGAs and HardCopy Stratix devices

● Removed section on Quartus II support of HardCopy

Minor edits.

Minor update.

Minor update.

Stratix devices

● Added “Hot Socketing” section

August 2003

Edited section headings’ hierarchy. Minor edits.

v1.1

June 2003

v1.0

Initial release of Chapter 6, Description, Architecture and

Features, in the HardCopy Device Handbook

—

Altera Corporation 2–11

September 2008

Page 30

Document Revision History

2–12 Altera Corporation

September 2008

Page 31

H51004-3.4

3. Boundary-Scan Support

IEEE Std. 1149.1 (JTAG) Boundary-Scan Support

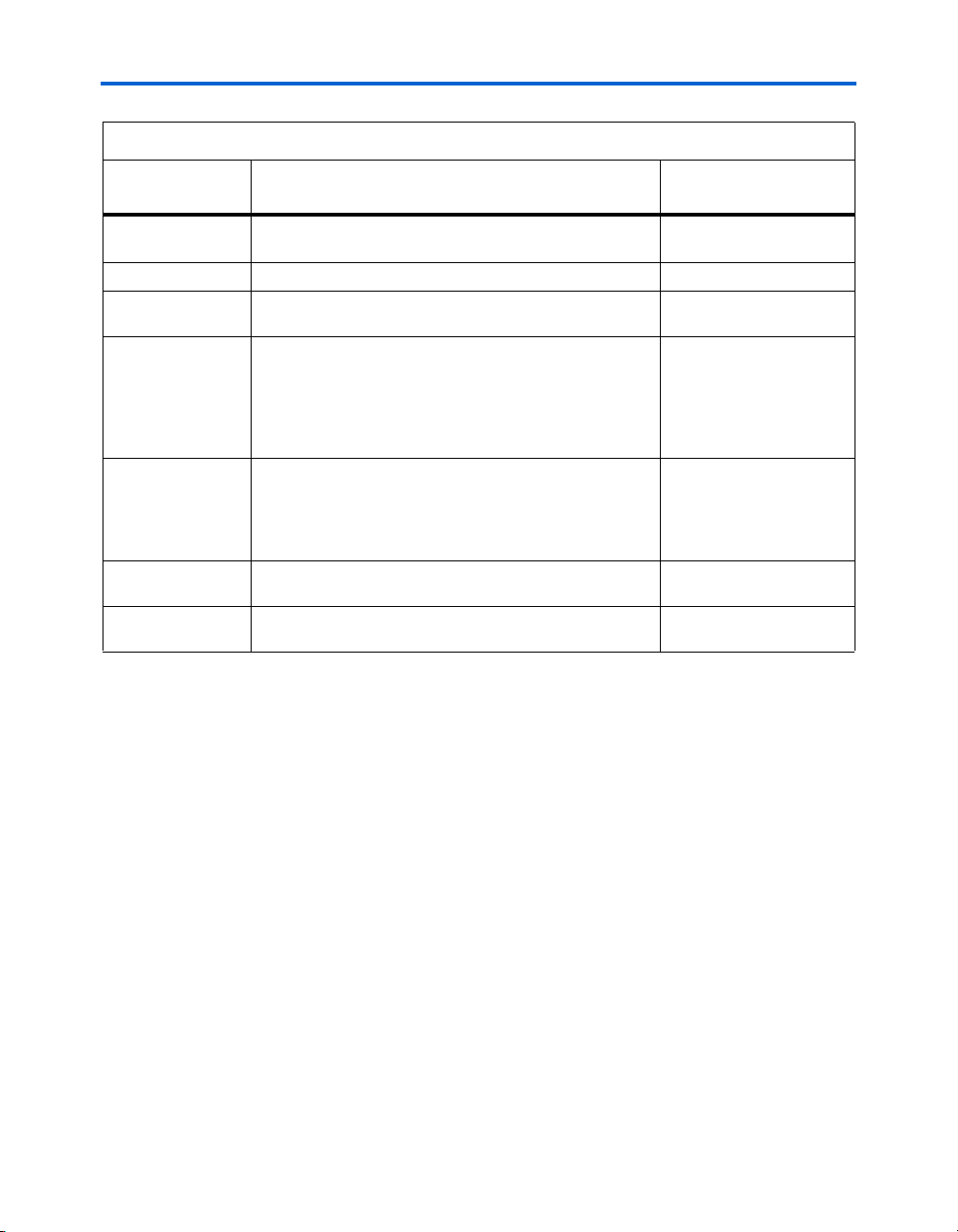

Table 3–1. HardCopy Stratix JTAG Instructions (Part 1 of 2)

JTAG Instruction Instruction Code Description

SAMPLE/PRELOAD 00 0000 0101

EXTEST (1) 00 0000 0000

BYPASS 11 1111 1111 Places the 1-bit bypass register between the TDI and TDO pins,

USERCODE 00 0000 0111 Selects the 32-bit USERCODE register and places it between the

IDCODE 00 0000 0110 Selects the IDCODE register and places it between TDI and TDO,

HIGHZ (1) 00 0000 1011 Places the 1-bit bypass register between the TDI and TDO pins,

All HardCopy® Stratix® structured ASICs provide JTAG boundry-scan

test (BST) circuitry that complies with the IEEE Std. 1149.1-1990

specification. The BST architecture offers the capability to efficiently test

components on printed circuit boards (PCBs) with tight lead spacing by

testing pin connections, without using physical test probes, and

capturing functional data while a device is in normal operation.

Boundary-scan cells in a device can force signals onto pins, or capture

data from pin or core logic signals. Forced test data is serially shifted into

the boundary-scan cells. Captured data is serially shifted out and

externally compared to expected results.

A device using the JTAG interface uses four required pins, TDI, TDO, TMS,

and TCK, and one optional pin, TRST. HardCopy Stratix devices support

the JTAG instructions as shown in Table 3–1.

Allows a snapshot of signals at the device pins to be captured and

examined during normal device operation, and permits an initial

data pattern to be output at the device pins.

Allows the external circuitry and board-level interconnects to be

tested by forcing a test pattern at the output pins and capturing test

results at the input pins.

which allows the BST data to pass synchronously through selected

devices to adjacent devices during normal device operation.

TDI and TDO pins, allowing the USERCODE to be serially shifted

out of TDO.

allowing the IDCODE to be serially shifted out of TDO.

which allows the BST data to pass synchronously through selected

devices to adjacent devices during normal device operation, while

tri-stating all of the I/O pins.

Altera Corporation 3–1

September 2008 Preliminary

Page 32

HardCopy Series Handbook, Volume 1

Table 3–1. HardCopy Stratix JTAG Instructions (Part 2 of 2)

JTAG Instruction Instruction Code Description

CLAMP (1) 00 0000 1010 Places the 1-bit bypass register between the TDI and TDO pins,

which allows the BST data to pass synchronously through selected

devices to adjacent devices during normal device operation while

holding I/O pins to a state defined by the data in the boundary-scan

register.

Note t o Table 3–1:

(1) Bus hold and weak pull-up resistor features override the high-impedance state of HIGHZ, CLAMP, and EXTEST.

f The boundary-scan description language (BSDL) files for HardCopy

Stratix devices are different from the corresponding Stratix FPGAs. The

BSDL files for HardCopy Stratix devices are available for download

from the Altera website at www.altera.com.

The HardCopy Stratix device instruction register length is 10 bits; the

USERCODE register length is 32 bits. The USERCODE registers are

mask-programmed, so they are not re-programmable. The designer can

choose an appropriate 32-bit sequence to program into the USERCODE

registers.

Tables 3–2 and 3–3 show the boundary-scan register length and device

IDCODE information for HardCopy Stratix devices.

Table 3–2. HardCopy Stratix Boundary-Scan Register Length

Device Maximum Boundary-Scan Register Length

HC1S25 672-pin FineLine BGA 1,458

HC1S30 780-pin FineLine BGA 1,878

HC1S40 780-pin FineLine BGA 1,878

HC1S60 1,020-pin FineLine BGA 2,382

HC1S80 1,020-pin FineLine BGA 2,382

3–2 Altera Corporation

Preliminary September 2008

Page 33

IEEE Std. 1149.1 (JTAG) Boundary-Scan Support

Table 3–3. 32-Bit HardCopy Stratix Device IDCODE

IDCODE (32 Bits) (1)

Device

HC1S25 0000 0010 0000 0000 0011 000 0110 1110 1

HC1S30 0000 0010 0000 0000 0100 000 0110 1110 1

HC1S40 0000 0010 0000 0000 0101 000 0110 1110 1

HC1S60 0000 0010 0000 0000 0110 000 0110 1110 1

HC1S80 0000 0010 0000 0000 0111 000 0110 1110 1

Notes to Tab l e 3 –3 :

(1) The most significant bit (MSB) is on the left.

(2) The IDCODE’s least significant bit (LSB) is always 1.

Version

(4 Bits)

Part Number

(16 Bits)

Manufacturer Identity

(11 Bits)

(1 Bit) (2)

Figure 3–1 shows the timing requirements for the JTAG signals.

Figure 3–1. HardCopy Stratix JTAG Waveforms

TMS

LSB

TDI

t

JCP

t

JCH

t

JCL

t

JPSU

t

JPH

TCK

t

JPZX

t

JPCO

t

JPXZ

TDO

t

JSH

t

JSCO

t

JSXZ

Signal

to Be

Captured

Signal

to Be

Driven

t

JSZX

t

JSSU

Altera Corporation 3–3

September 2008 Preliminary

Page 34

HardCopy Series Handbook, Volume 1

Table 3–4 shows the JTAG timing parameters and values for HardCopy

Stratix devices.

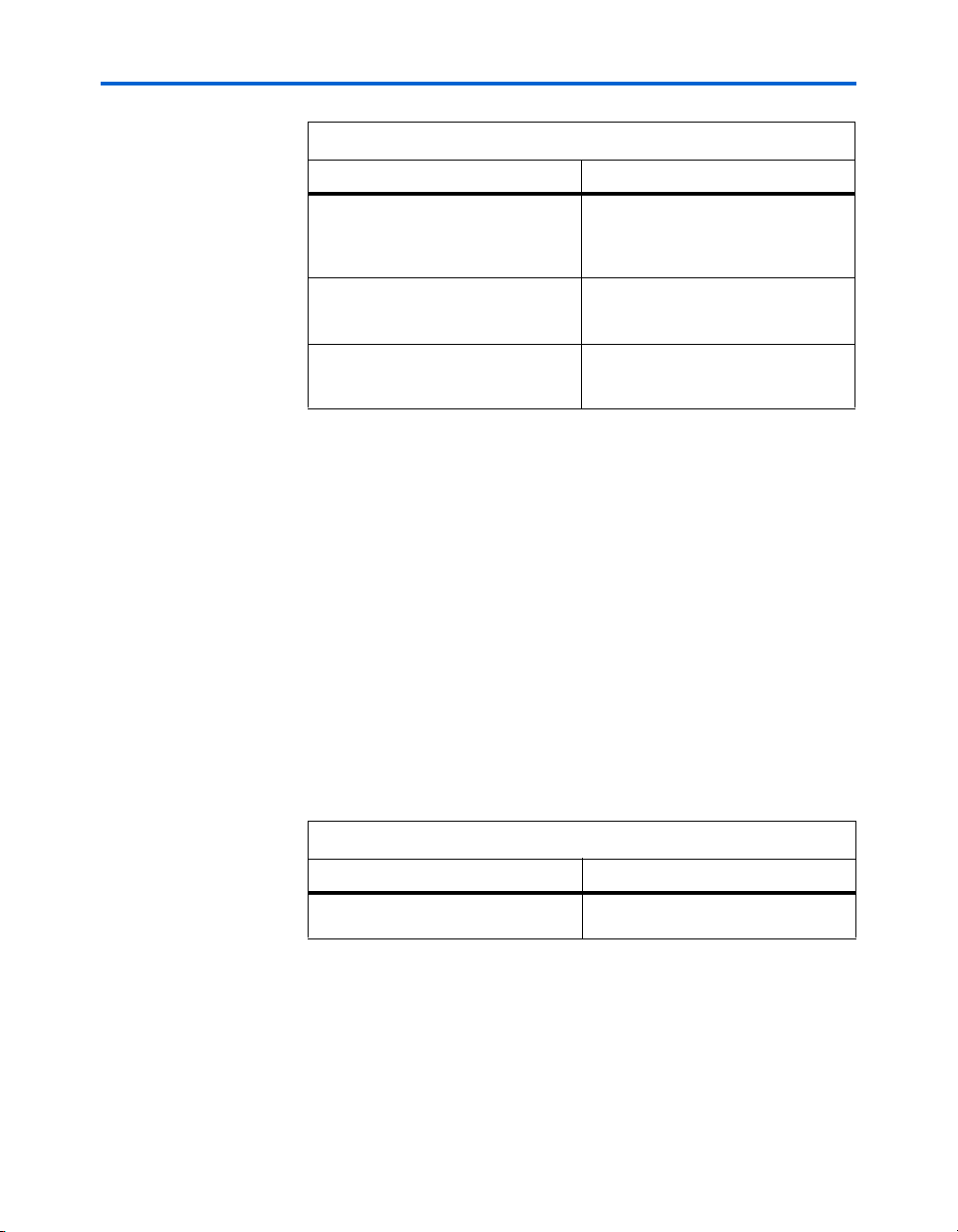

Table 3–4. HardCopy Stratix JTAG Timing Parameters and Values

Symbol Parameter Min Max Unit

t

JCP

t

JCH

t

JCL

t

JPSU

t

JPH

t

JPCO

t

JPZX

t

JPXZ

t

JSSU

t

JSH

t

JSCO

t

JSZX

t

JSXZ

TCK clock period 100 ns

TCK clock high time

TCK clock low time

50 ns

50 ns

JTAG port setup time 20 ns

JTAG port hold time 45 ns

JTAG port clock to output 25 ns

JTAG port high impedance to valid output 25 ns

JTAG port valid output to high impedance 25 ns

Capture register setup time 20 ns

Capture register hold time 45 ns

Update register clock to output 35 ns

Update register high impedance to valid output 35 ns

Update register valid output to high impedance 35 ns

f For more information on JTAG, refer to AN 39: IEEE Std. 1149.1 (JTAG)

Boundary-Scan Testing in Altera Devices.

Document

Table 3–5 shows the revision history for this chapter.

Revision History

Table 3–5. Document Revision History (Part 1 of 2)

Date and Document

Version

September 2008

v3.4

June 2007 v3.3 Updated Figure 3–1.—

December 2006

v3.2

March 2006 Formerly chapter 7; no content change. —

3–4 Altera Corporation

Preliminary September 2008

Updated chapter number and metadata. —

Updated revision history. —

Changes Made Summary of Changes

Page 35

Table 3–5. Document Revision History (Part 2 of 2)

Document Revision History

Date and Document

Version

October 2005 v3.1 ● Minor edits

● Graphic updates

May 2005

v3.0

January 2005

v2.0

June 2003

v1.0

Updated “IEEE Std. 1149.1 (JTAG) Boundary-Scan

Support” section

Added information about USERCODE registers

Initial release of Chapter 7, Boundary-Scan Support, in the

HardCopy Device Handbook

Changes Made Summary of Changes

—

Altera Corporation 3–5

September 2008 Preliminary

Page 36

HardCopy Series Handbook, Volume 1

3–6 Altera Corporation

Preliminary September 2008

Page 37

H51005-3.4

4. Operating Conditions

Recommended

Operating

Tables 4–1 through 4–3 provide information on absolute maximum

ratings, recommended operating conditions, DC operating conditions,

and capacitance for 1.5-V HardCopy

®

Stratix® devices.

Conditions

Table 4–1. HardCopy Stratix Device Absolute Maximum Ratings Notes (1), (2)

Symbol Parameter Conditions Minimum Maximum Unit

V

CCINT

V

CCIO

V

I

I

OUT

T

STG

T

J

Table 4–2. HardCopy Stratix Device Recommended Operating Conditions

Symbol Parameter Conditions Minimum Maximum Unit

V

CCINT

V

CCIO

V

I

V

O

T

J

Supply voltage With respect to ground –0.5 2.4 V

–0.5 4.6 V

DC input voltage (3) –0.5 4.6 V

DC output current, per pin –25 40 mA

Storage temperature No bias –65 150 °C

Junction temperature BGA packages under bias 135 °C

Supply voltage for internal logic

and input buffers

Supply voltage for output

buffers, 3.3-V operation

Supply voltage for output

buffers, 2.5-V operation

Supply voltage for output

buffers, 1.8-V operation

Supply voltage for output

buffers, 1.5-V operation

Input voltage (3), (6) –0.5 4.1 V

Output voltage 0 V

Operating junction temperature For commercial use 0 85 °C

(4) 1.425 1.575 V

(4), (5) 3.00 (3.135) 3.60 (3.465) V

(4) 2.375 2.625 V

(4) 1.71 1.89 V

(4) 1.4 1.6 V

CCIO

For industrial use –40 100 °C

V

Altera Corporation 4–1

September 2008

Page 38

Recommended Operating Conditions

Table 4–3. HardCopy Stratix Device DC Operating Conditions Note (7)

Symbol Parameter Conditions Minimum Typical Maximum Unit

I

I

I

OZ

I

CC0

R

CONF

Notes to Tables 4–1 through 4–3:

(1) Refer to the Operating Requirements for Altera Devices Data Sheet.

(2) Conditions beyond those listed in Ta b l e 4 – 1 may cause permanent damage to a device. Additionally, device

(3) M inim um DC inp ut is –0. 5 V. Duri ng tran siti ons, the i nputs may und ersh oot t o –2 V or ov ersh oot to 4 .6 V f or input

(4) Maximum V

(5) V

(6) All pins, including dedicated inputs , clock, I/O, and JTAG pins, may be driven before V

(7) Typical values are for TA = 25 °C, V

(8) This value is specified for normal device operation. The value may vary during power up. This applies for all V

(9) Pin pull-up resistance values will be lower if an external source drives the pin hig her than V

Input pin leakage current VI = V

Tri-stated I/O pin leakage

current

VCC supply current

(standby) (All memory

VO = V

(8)

VI = ground, no load,

no toggling inputs

to 0 V (8) –10 10 μA

CCIOmax

CCIOmax

to 0 V

–10 10 μA

mA

blocks in power-down

mode)

Value of I/O pin pull-up

resistor before and