Page 1

2014.08.18

www.altera.com

101 Innovation Drive, San Jose, CA 95134

Altera GPIO IP Core User Guide

ug-altera_gpio

Subscribe

Send Feedback

The Altera GPIO megafunction IP core supports General Purpose I/O (GPIO) components and features.

GPIOs are I/Os used in general applications not specific to transceivers, memory-like interfaces or LVDS.

The Altera GPIO IP core features the following components:

• Double data rate input/output (DDIO)—A digital component that doubles, or halves the data-rate of a

communication channel.

• Delay chains— configure the delay chains to perform specific delay and assist in I/O timing closure.

• I/O buffers—connect the pads to the FPGA.

Note: The actual implementations and features of DDIO, delay chains, and I/O buffers vary from family

to family.

The Altera GPIO IP core is only available for Arria 10 devices. For Arria V, Cyclone V, and Stratix V

devices, follow the steps in IP Migration for Arria V, Cyclone V, and Stratix V on page 1 to migrate

your IP.

Related Information

• Double Data Rate I/O (ALTDDIO_IN, ALTDDIO_OUT, and ALTDDIO_BIDIR) Megafunctions

User Guide

• I/O Buffer (ALTIOBUF) Megafunction User Guide

IP Migration for Arria V, Cyclone V, and Stratix V

The Altera GPIO IP core supports the IP migration flow which allows you to migrate your Arria V,

Cyclone V, and Stratix V devices IP into the Altera GPIO IP core in Arria 10 devices.

This IP migration flow configures the new IP to match the settings of the old one and allow you to

regenerate. Some IP cores only support this migration in specific modes.

If your IP core is in a mode that is not supported, you may need to run the Altera GPIO IP Parameter

Editor and configure it manually.

©

2015 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, ENPIRION, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos are

trademarks of Altera Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. Altera warrants performance

of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any

products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information,

product, or service described herein except as expressly agreed to in writing by Altera. Altera customers are advised to obtain the latest version of device

specifications before relying on any published information and before placing orders for products or services.

ISO

9001:2008

Registered

Page 2

2

Migrating Your IP

Migrating Your IP

To use the IP migration flow:

1. Open your ALTDDIO_IN, ALTDDIO_OUT, ALTDDIO_BIDIR, or ALTIOBUF IP in the IP

Parameter Editor.

2. In the Currently selected device family, select Arria 10.

3. Click Finish to open the Altera GPIO IP Parameter Editor.

4. The Altera GPIO IP Parameter Editor will be configured similarly to the old settings.

5. If there are any incompatible settings between the two, select new supported settings.

6. Click Finish in the Altera GPIO IP Parameter Editor to regenerate the IP.

7. Replace your old IP core instantiation in RTL with the newly generated IP.

ug-altera_gpio

2014.08.18

Note:

The port names of the new IP core may not match the old ones, so simply changing the IP name in

the instantiation is not sufficient.

Resource Utilization and Performance

For details about the resource usage and performance of your design, refer to the compilation reports in

the Quartus II software.

To view the compilation reports in the Quartus II software, follow these steps:

1. On the Processing menu, click Start Compilation to run a full compilation.

2. After compiling the design, on the Processing menu, click Compilation Report.

3. In the Table of Contents browser, expand the Fitter folder by clicking the “+” icon.

4. To view the resource usage information, under Fitter, expand Resource section, and select Resource

Usage Summary.

5. To view the resource utilization information, under Fitter, expand Resource section, and select

Resource Utilization by Entity.

Note:

Related Information

The performance of the Altera GPIO IP core depends on the I/O constraints and clock phases.

To validate timing for Altera GPIO configuration, Altera recommends using the TimeQuest

Timing Analyzer.

• The Quartus II TimeQuest Timing Analyzer

Parameter Settings

The following table lists the parameter settings for the Altera GPIO IP core.

Table 1: Altera GPIO Parameter Settings

Name Values Description

General

Data Direction Input, Output,

Altera Corporation

Bidir

This setting specifies the data direction for the

Altera GPIO IP core.

Altera GPIO IP Core User Guide

Send Feedback

Page 3

ug-altera_gpio

2014.08.18

Parameter Settings

Name Values Description

Data width 1 to 128 Specifies the data width.

Use legacy top-level port names Turn on, Turn off Reverts to ports used in Arria V, Cyclone V, and

Stratix V devices. For example, dout becomes

dataout_h and dataout_l and din becomes

datain_h and datain_l.

Buffer

Use differential buffer Turn on, Turn off Allows the use of differential buffer.

Use pseudo-differential buffer Turn on, Turn off Allows the use of pseudo-differential buffer. This

option is only available when you enable the Use

differential buffer option.

Use bus-hold circuitry Turn on, Turn off Allows the use of bus-hold circuitry.

Use open-drain output Turn on, Turn off Allows the use of open-drain output.

Enable output enable port Turn on, Turn off Allows the use of OE input. This option is

available only when you set the Data Direction

option to output.

When you set the Data Direction option to

input and bidir, this option is disabled.

3

Enable seriestermination/

paralleltermination ports

Turn on, Turn off Allows the use of the seriestermination/

paralleltermination ports of the output

buffer.

Registers

Register mode none, Simple

register, DDIO

This setting specifies the register mode for the

Altera GPIO IP core. The values for this

parameter are:

• none—specifies a simple wire connection

from/to the buffer.

• Simple register—specifies that the DDIO is

used as a simple register in single data-rate

mode (SDR). The Fitter may pack this register

in the I/O.

• DDIO— specifies that the IP core uses the

DDIO.

Enable synchronous clear / preset

port

Enable asynchronous clear /

preset port

None, Clear, Preset Specifies how to implement synchronous reset

port.

None, Clear, Preset Specifies how to implement asynchronous reset

port.

Enable clock enable port Specifies whether the DDIO will have the clock

enable port exposed.

Half Rate Logic Turn on, Turn off Allows the Altera GPIO IP core to use half rate

Altera GPIO IP Core User Guide

Send Feedback

logic (half-rate DDIO).

Altera Corporation

Page 4

Buffer

OEIN[1:0]

DATAIN[3:0]

Output

Path

GPIO

OE

Path

Input Path

DATAOUT[3:0]

Core

PAD

ACLR_N

APRE_N

DATAOUT[0]

DATAOUT[2]

DATAOUT[1]

DATAOUT[3]

CLK_HR

CLK_FR

DDIO

IN

DDIO

IN

DDIO

IN

Delay

Element

HR FR

B

A

1

3

2

4

Overview

Name Values Description

Separate input/output Clocks Turn on, Turn off Allows the Altera GPIO to use separate clocks for

input and output data paths.

Overview

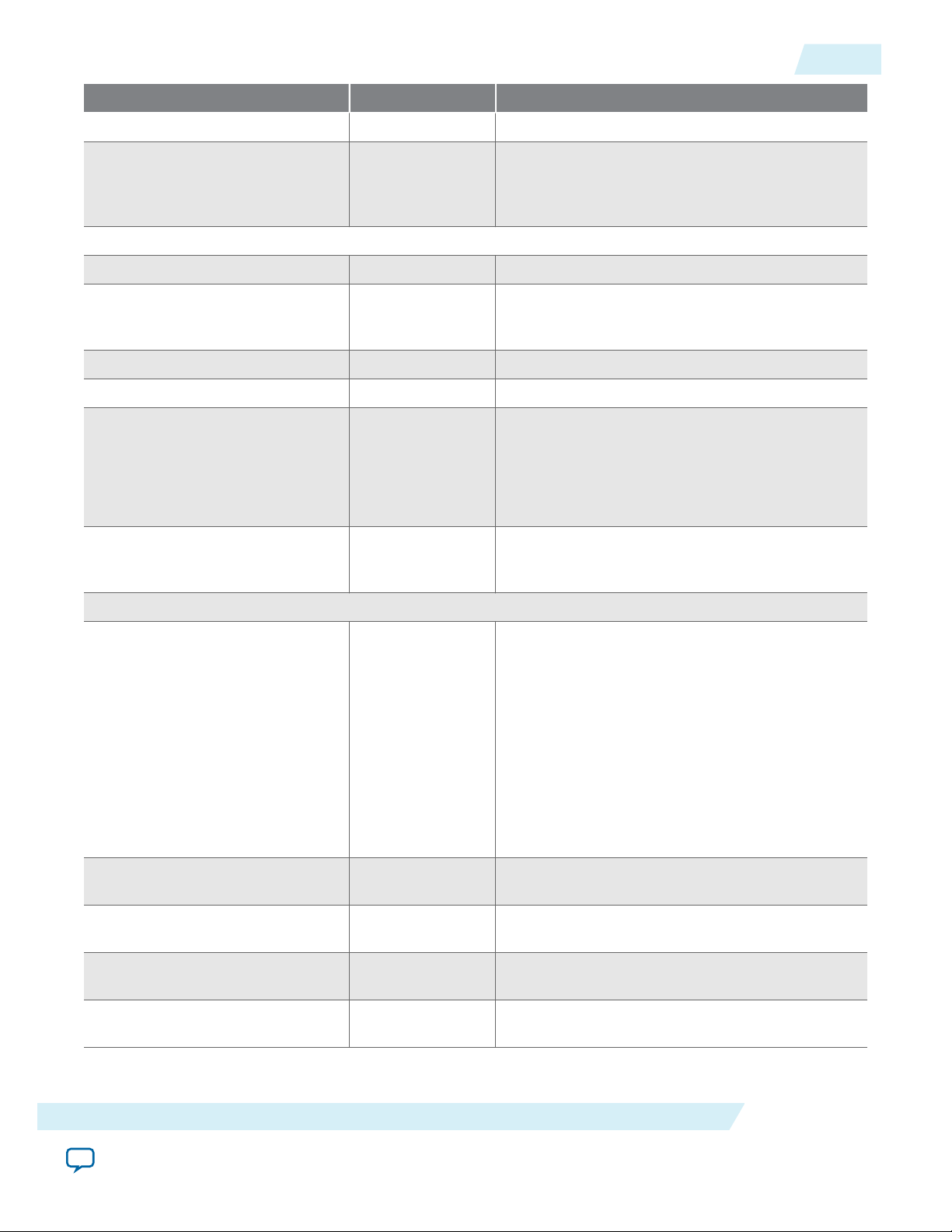

The following figure shows the high-level view of a single-ended GPIO.

Figure 1: Single-Ended GPIO

ug-altera_gpio

2014.08.18

Altera Corporation

Input Path

The following figure shows the simplified view of a single-ended GPIO input path.

Figure 2: Input Path (Simplified View)

The pad sends data to the input buffer, and the input buffer feeds the delay element.

Altera GPIO IP Core User Guide

Send Feedback

Page 5

ug-altera_gpio

2014.08.18

Input Path Waveform

5

Note: The Altera GPIO megafunction does not support dynamic calibration of the input path. For

applications requiring dynamic calibration of the input path, refer to the Altera PHYLite

Megafunction User Guide.

After data goes to the output of the delay element, programmable bypass multiplexers select the features

and paths to use. Each input path contains two stages of DDIOs, which are full-rate and half-rate.

Note: When you set the Register mode option to Simple register, the full-rate DDIO works as a simple

register.

Note: When you set the Register mode option to Simple register, the Fitter chooses whether to pack the

register in the I/O or implement the register in the core, depending on the area and timing tradeoffs.

Use the input path in four modes:

• Bypass—data goes from the delay element to the core, bypassing all DDIOs.

• Packed Register—the full-rate DDIO operates as a register, bypassing half-rate DDIOs.

• Double data rate Input/Output (DDIO) mode with full-rate conversion—The full-rate DDIO operates

as a regular DDIO, bypassing half-rate DDIOs.

• DDIO mode with half-rate conversion—The full-rate DDIO operates as a regular DDIO. Half-rate

DDIOs converts data for full-rate to half-rate.

All DDIOs share the same asynchronous clear and preset signals when used. Half-rate and full-rate

DDIOs connect to separate clocks. When you use half-rate and full-rate DDIOs, the full-rate clock must

run at twice the half-rate frequency. Use different phase relationships to meet timing requirements.

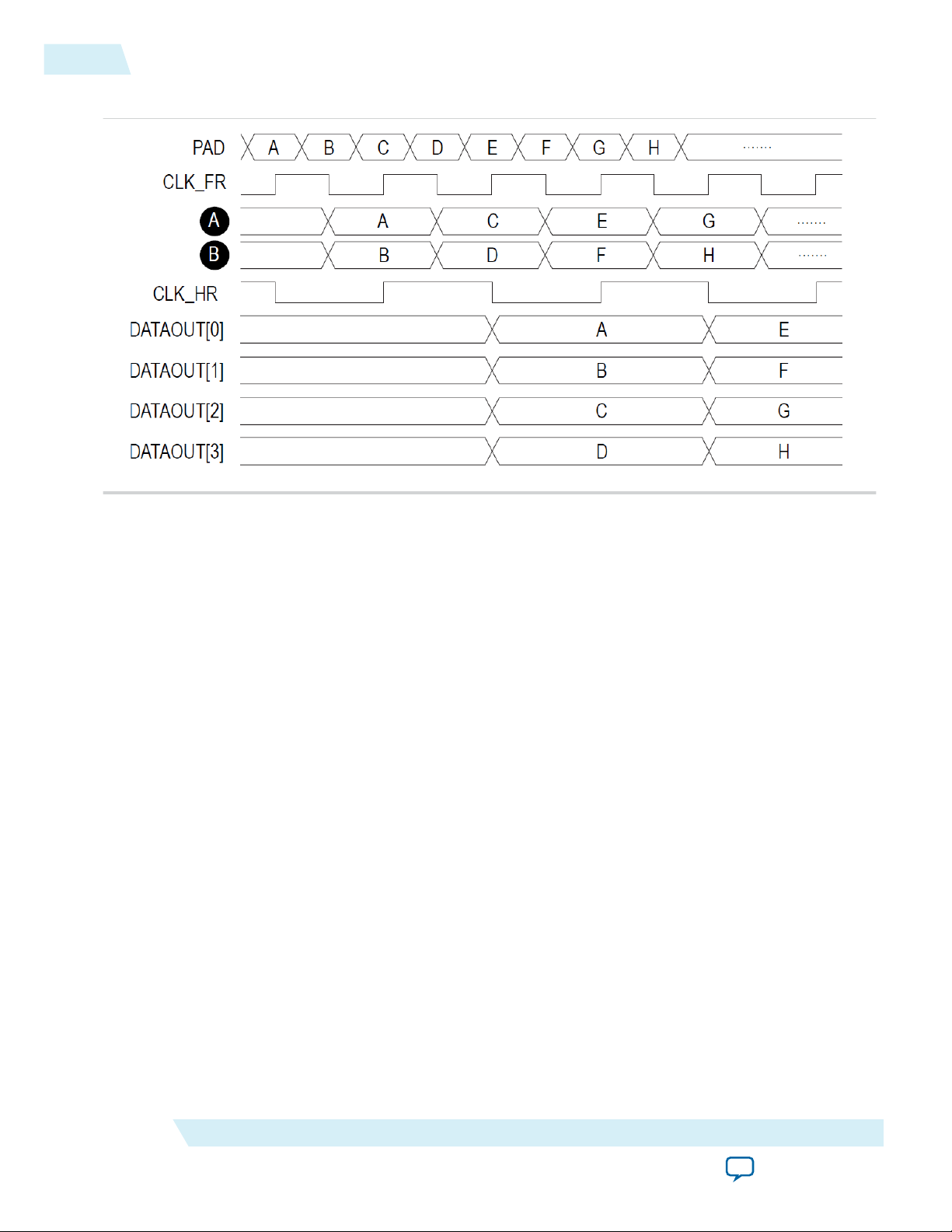

Input Path Waveform

The following figure shows the waveforms for an input path in DDIO mode with half-rate conversion.

This configuration uses all the blocks and refers to the same labels shown in Figure 2.

Note:

The actual timing relationship between different signals may vary depending on the specific design,

delays, and phases that you choose for the full-rate and half-rate clocks.

Altera GPIO IP Core User Guide

Send Feedback

Altera Corporation

Page 6

6

Output Path

Figure 3: Input Path Waveform

ug-altera_gpio

2014.08.18

The pad receives data. DDIO IN (1) (refer to Figure 2) captures data on the rising and falling edges of

CLK_FR, and sends data at SDR (refer to signals (A) and (B) in the waveform). DDIO IN (2) and DDIO

IN (3) (refer to Figure 2) halves the data rate and DATAOUT[3:0] presents data as a half-rate bus.

Notice how going from full-rate clock at double data rate to half-rate clock at single data rate, data rate has

been divided by four and the bus size has increased by the same ratio. The overall throughput through the

Altera GPIO IP core remained unchanged.

Output Path

The following figure shows the simplified view of a single-ended GPIO output path.

Altera Corporation

Altera GPIO IP Core User Guide

Send Feedback

Page 7

PAD

ACLR_N

APRE_N

DATAOUT[0]

DATAOUT[2]

DATAOUT[1]

DATAOUT[3]

CLK_HR

CLK_FR

DDIO

OUT

DDIO

OUT

DDIO

OUT

Delay

Element

HR FR

OE

from Output

Enable Path

ug-altera_gpio

2014.08.18

Figure 4: Output Path (Simplified View)

Output Path

7

The simplified view of a GPIO output path is similar to the input path (refer to Figure 2). The output

delay element sends data to the pad through the output buffer.

Note:

The Altera GPIO IP core does not support dynamic calibration of the input path. For applications

requiring dynamic calibration of the output path, refer to the Altera PHYLite Megafunction User

Guide.

Note: When you set the Register mode option to Simple register, the full-rate DDIO works as a simple

register.

Note: When you set the Register Mode option to Simple register, the Fitter chooses whether to pack the

register in the I/O or implement the register in the core, depending on the area and timing tradeoffs.

You can select a combination of half-rate, full-rate DDIOs, and simple register using programmable

bypass multiplexers to implement the following four output modes:

• Bypass—data goes from the core straight to the delay element, bypassing all DDIOs.

• Packed Register—full-rate DDIO operates as a register, bypassing half-rate DDIOs.

• DDIO output mode, Full-Rate—full-rate DDIO operates as a regular DDIO, bypassing half-rate

DDIOs.

• DDIO output, Half-Rate—full-rate DDIO operates as a regular DDIO. Half-rate DDIOs convert data

from full-rate to half-rate.

All DDIOs share the same asynchronous clear and preset signals when used. Half-rate and full-rate

DDIOs connect to separate clocks. When you use half-rate and full-rate DDIOs, the full-rate clock must

run at twice the half-rate frequency. You can use different phase relationships to meet timing require‐

ments.

Altera GPIO IP Core User Guide

Send Feedback

Altera Corporation

Page 8

ACLR_N

APRE_N

OEIN[0]

OEIN[1]

CLK_HR

CLK_FR

DDIO

OUT

FF Delay

Element

HR FR

From Output

Data Path

Pad

Data

Clock

Altera GPIO

Termination

Reset

8

Output Path Waveform

Output Path Waveform

The waveform for the output path is similar to Figure 3.

OE Path

The following figure shows the simplified view of a GPIO OE path.

Figure 5: OE Path (Simplified View)

ug-altera_gpio

2014.08.18

The simplified view of a GPIO OE path is similar to the Figure 4. The difference between output path and

OE path is that the OE path does not support full-rate DDIO mode. Therefore, there is no full-rate DDIO

in OE path. To support packed-register implementations in the OE path, a simple register operates as fullrate DDIO. For the same reason, there is no need for two half-rate DDIOs. Only one is present.

The OE path operates in the following three fundamental modes:

• Bypass—the core sends data directly to the delay element, bypassing all DDIOs.

• Packed Register—bypasses half-rate DDIO.

• SDR output, half-rate—half-rate DDIOs convert data from full-rate to half-rate.

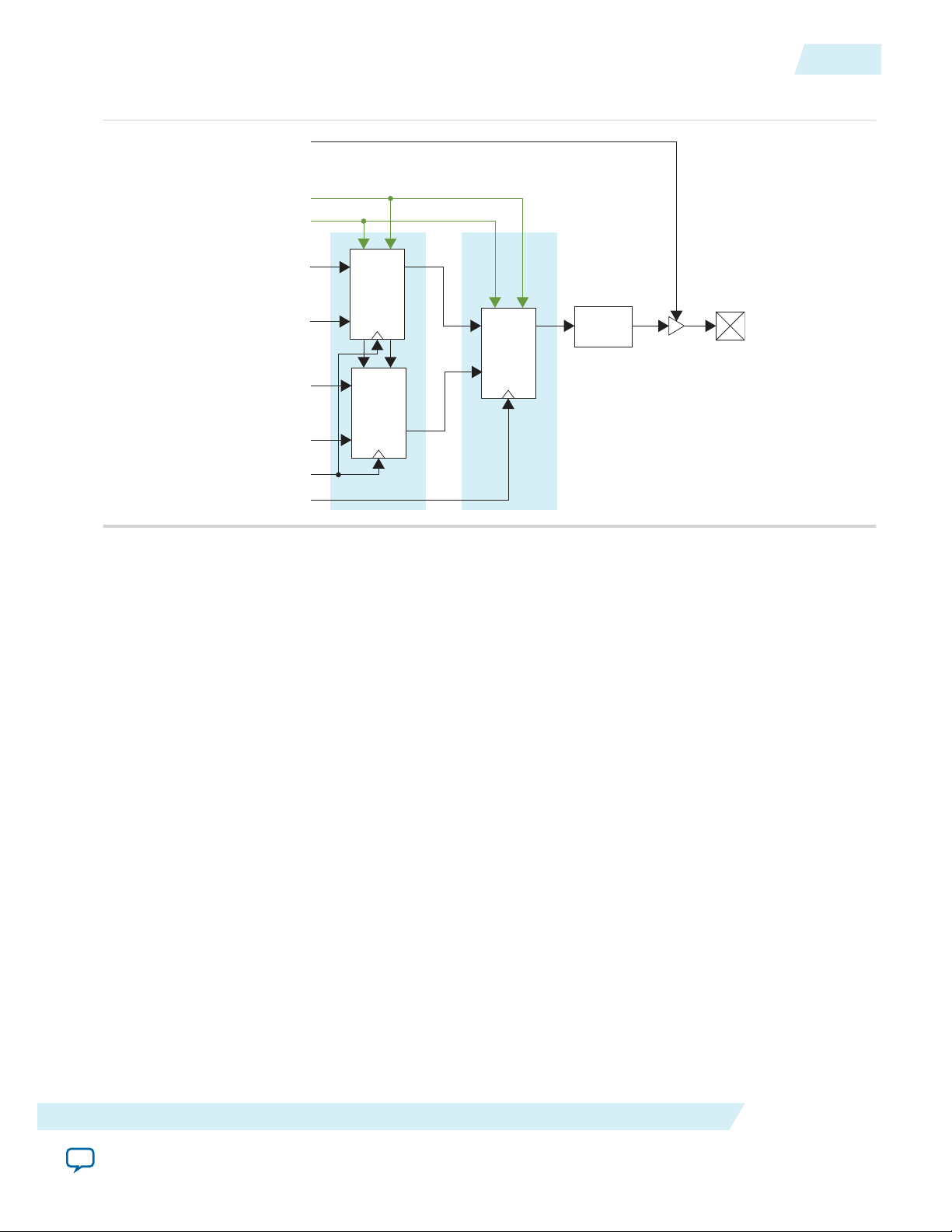

Interfaces

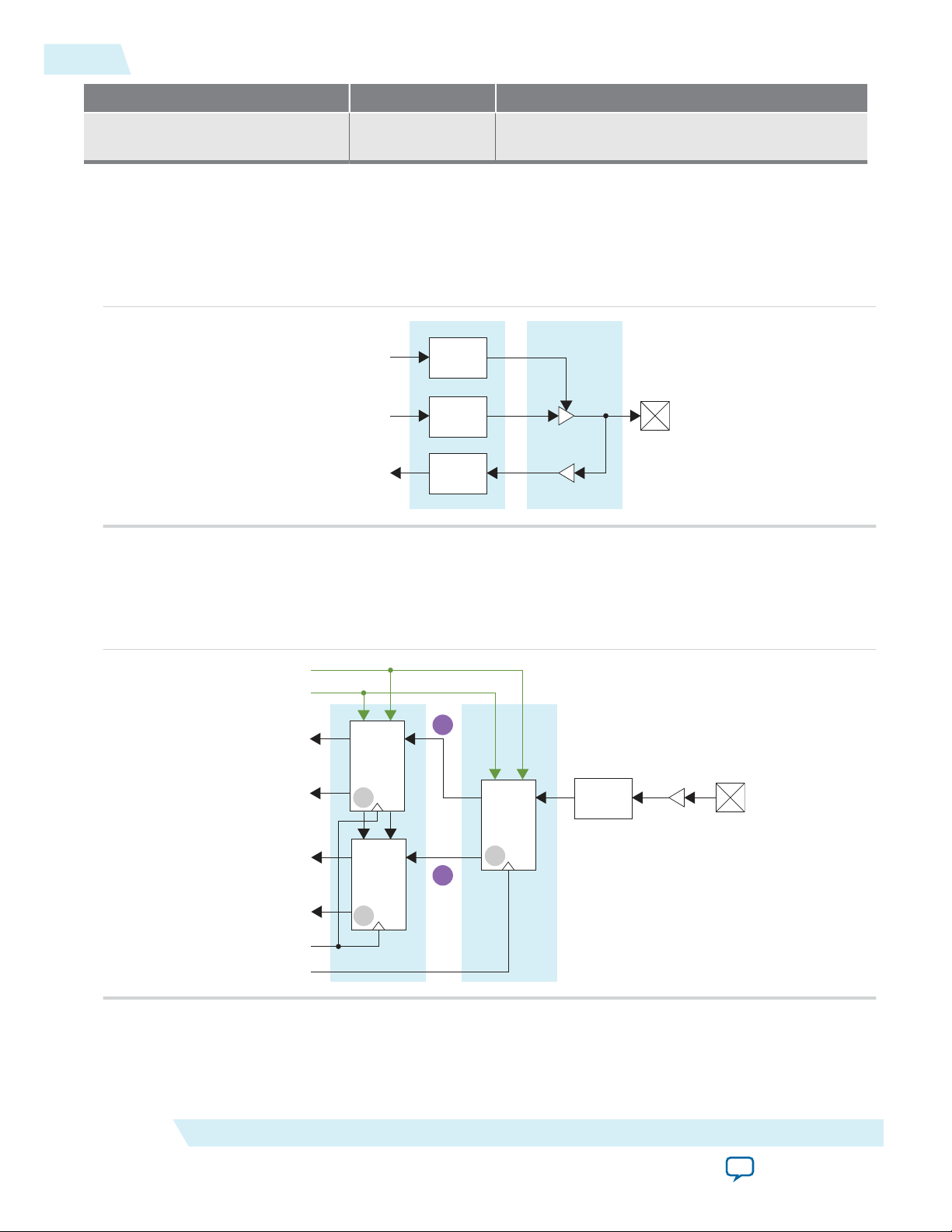

The following figure shows the main interfaces for the Altera GPIO IP core.

Figure 6: Altera GPIO IP Core Interfaces Diagram

Altera Corporation

Altera GPIO IP Core User Guide

Send Feedback

Page 9

din

pad_out

pad_in

oe

pad_io

pad_io_b

pad_out_b

ck

sclr

aclr

aset

sset

ck_fr

ck_hr

ck_fr_in

ck_fr_out

ck_hr_in

ck_hr_out

Altera GPIO

ck_out

ck_in

seriesterminationcontrol

parallelterminationcontrol

dout

Pad Interface Signals

cke

pad_in_b

Reset Interface Signals

Termination Interface Signals

Data Interface Signals

Clock Interface Signals

ug-altera_gpio

2014.08.18

The following table lists the Altera GPIO IP core main interfaces:

Table 2: Altera GPIO IP Core Interfaces

Interface Description

Pad Interface Connects the Altera GPIO IP core to the pads. This interface can be an input,

Data Interface An input and/or output interface to the core. Consists of different signals,

Clock Interface An input clock interface. Consists of different signals, depending on the

Termination Interface Connects the Altera GPIO IP core to the buffers.

Reset Interface Connects the Altera GPIO IP core to the DDIOs.

Interface Signals

output or bidirectional interface, depending on the configuration of the

Altera GPIO IP core.

depending on the configuration of the Altera GPIO IP core.

configuration of the Altera GPIO IP core. The Altera GPIO IP core can have

0, 1, 2 or 4 clock inputs depending on the configuration. Clock ports appear

differently in different configurations, to reflect the actual function

performed by the clock signal.

9

Interface Signals

The following figure list the signals for the data, clock, termination, reset, and pad interfaces.

Pad Interface Signals

Pad interface is the physical connection from the Altera GPIO IP core to the pad. When you configure the

Altera GPIO IP core as an output, the pad signal in an output signal. When you configure the Altera

GPIO IP core as an input, the pad signal is an input signal. When you configure the Altera GPIO IP core

as bidirectional, the pad signal is a bidirectional signal.

Altera GPIO IP Core User Guide

SIZE is the data width selected from the GUI.

Send Feedback

Altera Corporation

Page 10

10

Data Interface Signals

Signal Name Direction Description

pad_in[SIZE -1:0] Input Input pad port only when the input path is used.

pad_in_b[SIZE -1:0] Input Input negative pad port only when input path is

used, and differential buffers are enabled.

pad_out[SIZE -1:0] Output Output pad port only when output path is used.

pad_out_b[SIZE -1:0] Output Output negative pad port only when output path is

used, and differential buffers are enabled.

pad_io[SIZE -1:0] Bidirectional Bidirectional pad port only when bidirectional paths

are used.

pad_io_b[SIZE -1:0] Bidirectional Bidirectional negative pad port only when bidirec‐

tional paths are used, and differential buffers are

enabled.

Data Interface Signals

Signal Name Direction Description

ug-altera_gpio

2014.08.18

din[DATA_SIZE - 1 : 0] Input

Data connection from the core to the Altera GPIO

IP core when in output or bidirectional mode. This

interface is not present in input mode.

DATA_SIZE has different values, depending on the

Altera GPIO configuration:

• Combinational or packed register— DATA_SIZE

= SIZE

• DDIO, no half-rate logic— DATA_SIZE = 2 x

SIZE

• DDIO with half-rate logic—DATA_SIZE = 4 x

SIZE

dout[DATA_SIZE - 1 : 0] Output Data connection from the Altera GPIO IP core to

the core when in input or bidirectional mode. This

interface is not present in output mode. DATA_

SIZE has different values depending on the Altera

GPIO configuration:

• Combinational or packed register—DATA_SIZE

= SIZE

• DDIO, no half-rate logic—DATA_SIZE = 2 x

SIZE

• DDIO with half-rate logic— DATA_SIZE = 4 x

SIZE

Altera Corporation

Altera GPIO IP Core User Guide

Send Feedback

Page 11

SIZE - 1 ... 0

t

3

SIZE - 1 ... 0

t

2

SIZE - 1 ... 0

t

1

SIZE - 1 ... 0

t

0

4 x SIZE

SIZE - 1 ... 0

t

1

SIZE - 1 ... 0

t

0

2 x SIZE

SIZE - 1 ... 0 SIZE

ug-altera_gpio

2014.08.18

Data Bit-Order for Data Interface

Signal Name Direction Description

oe[OE_SIZE - 1 : 0] Input OE connection from the core to the Altera GPIO

IP core when in bidirectional mode or in output

mode if you enable the use output enable port

parameter. OE is active high.

Set this signal to '1' when transmitting data and set

this signal to '0' when receiving data. This interface

is not present in input mode.

OE_SIZE has different values depending on

whether the Altera GPIO configuration:

• Combinational or packed register— DATA_SIZE

= SIZE

• DDIO, no half-rate logic— DATA_SIZE = SIZE

• DDIO with half-rate logic— DATA_SIZE = 2 x

SIZE

Data Bit-Order for Data Interface

The din, dout and oe data signals follow the following bit-order convention.

11

Figure 7: Data Bit-Order

Where:

• If the data bus has the size value of SIZE, the LSB is at the right-most position.

• If the data bus has the size value of 2 x SIZE, it will be made of 2 words of SIZE .

• If the data bus has the size value of 4 x SIZE, it will be made of 4 words of SIZE.

• The LSB is in the right-most position for each word.

• The right-most word specifies the first word going out for output buses and the first word coming in

for input buses.

Note:

Refer to Figure 3.

Altera GPIO IP Core User Guide

Send Feedback

Altera Corporation

Page 12

12

Clock Interface Signals

Clock Interface Signals

Signal Name Direction Description

ck Input This clock feeds a packed register or DDIO in input and output

paths when half-rate DDIOs are not used. If the Altera GPIO IP

core is in bidirectional mode and if you turn off the Separate

Input/Output Clocks parameter, this is the unique clock for

input and output paths.

ug-altera_gpio

2014.08.18

ck_fr

ck_hr

Input

These clocks feed full-rate and half-rate DDIO in both input and

output paths when half-rate DDIOs are used. If the Altera GPIO

IP core is in bidirectional mode and if you turn off the Separate

Input/Output Clocks parameter, the input and output paths use

these clocks.

ck_in

ck_out

Input

These clocks feed a packed register or DDIO in the input and

output path of a bidirectional Altera GPIO when half-rate

DDIOs are not used, and separate clocks are requested by

turning on the Separate Input/Output Clocks parameter.

ck_fr_in

ck_fr_out

Input

ck_hr_in

ck_hr_out

cke Input Clock enable.

These clocks feed full-rate and half-rate DDIOs in the input and

output paths of a bidirectional Altera GPIO when half-rate

DDIOs are used, and separate clocks are requested by turning on

the Separate Input/Output Clocks parameter. For example, ck_

fr_out feeds the full-rate DDIO in the output path.

Termination Interface Signals

Signal Name Direction Description

seriesterminationcontrol Input Input from the termination control block

(OCT) to the buffers. It sets the buffer series

impedance value.

parallelterminationcontrol Input Input from the termination control block

Reset Interface Signals

sclr Input Synchronous clear.

aclr Input Asynchronous clear.

aset Input Asynchronous set.

sset Input Synchronous set.

Shared Signals

The input, output, and OE paths share the same clear and preset signals.

The output and OE path shares the same clock signals.

Altera Corporation

(OCT) to the buffers. It sets the buffer

parallel impedance value.

Signal Name Direction Description

Altera GPIO IP Core User Guide

Send Feedback

Page 13

ug-altera_gpio

2014.08.18

Data Interface Signals and Corresponding Clocks

The following table shows the data interface signals and the corresponding clocks.

Table 3: Data Interface Signals and Corresponding Clocks

Signal Name Configuration Clock

Register Mode: Simple

Register/DDIO

Half-rate: not used

Separate Clocks: Off

Register Mode: DDIO

Data Interface Signals and Corresponding Clocks

ck

ck_hrHalf rate: used

13

din

dout/oe

Separate Clocks: off

Register Mode: Simple

Register/DDIO

Half rate: not used

Separate Clocks: on

Register Mode: DDIO

Separate Clocks: on

Register Mode: Simple

Register/DDIO

Half rate: not used

Separate Clocks: off

Register Mode: DDIO

Separate Clocks: off

Register Mode: Simple

Register/DDIO

Half rate: not used

ck_in

ck_hr_inHalf rate: used

ck

ck_hrHalf rate: used

ck_out

Altera GPIO IP Core User Guide

Send Feedback

Separate Clocks: on

Register Mode: DDIO

ck_hr_outHalf rate: used

Separate Clocks: on

Altera Corporation

Page 14

14

Register Packing

Signal Name Configuration Clock

Register Mode: Simple

Register/DDIO

Half rate: not used

ck

Separate Clocks: off

Register Mode: DDIO

ck_frHalf rate: used

Separate Clocks: off

ug-altera_gpio

2014.08.18

sclr/sset/ all pad signals

Register Mode: Simple

Register/DDIO

Half rate: not used

Separate Clocks: on

Register Mode: DDIO

Half rate: used

Separate Clocks: on

Register Packing

The Altera GPIO IP core allows you to pack register into the periphery to save area and resource utiliza‐

tion.

You can configure the full-rate DDIO on the input and output path as a flip flop. To do so, add the .qsf

assignments listed in this table.

Table 4: Register Packing QSF Assignments

Path QSF Assignment

• Input path: ck_in

• Output path: ck_out

• Input path: ck_fr_in

• Output path: ck_fr_out

Input register packing set_instance_assignment -name FAST_INPUT_REGISTER ON -to <path to

Output register

packing

Output enable

register packing

Note: These assignments do not guarantee register packing but rather enable the Fitter to find a legal

placement. Otherwise, the Fitter will keep the flip flop in the core.

Altera GPIO Timing

The Quartus II software version 14.0a10 does not automatically generate the timing constraints.

Altera Corporation

register>

set_instance_assignment -name FAST_OUTPUT_REGISTER ON -to <path to

register>

set_instance_assignment -name FAST_OUTPUT_ENABLE_REGISTER ON -to

<path to register>

Altera GPIO IP Core User Guide

Send Feedback

Page 15

PAD

ACLR_N

APRE_N

DATAOUT[0]

DATAOUT[2]

DATAOUT[1]

DATAOUT[3]

CLK_HR

CLK_FR

DDIO

IN

DDIO

IN

DDIO

IN

Delay

Element

HR FR

B

A

1

3

2

I/O Path

Core Interface Data Path

Core Interface Clock Path

Full-rate/Half-rate Transfer Path

ug-altera_gpio

2014.08.18

Altera GPIO Timing Components

The following paths are the timing components for Altera GPIO IP core:

• I/O interface paths (from FPGA to external receiving devices and from external transmitting devices to

FPGA)

• Core interface paths of the data and the clock (from I/O to core and from core to I/O)

• Half-rate to full-rate and full-rate to half-rate transfer paths.

Note: The TimeQuest timing analyzer treats the path inside the DDIO_IN and DDIO_OUT blocks as

black boxes.

These figures show the timing components in the Altera GPIO input, output, and output enable paths.

Figure 8: Timing Components in the Altera GPIO Input Path

Altera GPIO Timing Components

15

Altera GPIO IP Core User Guide

Send Feedback

Altera Corporation

Page 16

PAD

ACLR_N

APRE_N

DATAOUT[0]

DATAOUT[2]

DATAOUT[1]

DATAOUT[3]

CLK_HR

CLK_FR

DDIO

OUT

DDIO

OUT

DDIO

OUT

Delay

Element

HR FR

OE

from Output

Enable Path

Half-rate/Full-rate Transfer Path

I/O Path

Core Interface Clock Path

Core Interface Data Path

ACLR_N

APRE_N

OEIN[0]

OEIN[1]

CLK_HR

CLK_FR

DDIO

OUT

FF

Delay

Element

HR FR

From Output

Data Path

Half-rate/Full-rate Transfer Path

Core Interface Data Path

Core Interface Clock Path

I/O Path

16

Timing Analysis

Figure 9: Timing Components in the Altera GPIO Output Path

ug-altera_gpio

2014.08.18

Figure 10: Timing Components in the Altera GPIO Output Enable Path

Timing Analysis

Altera Corporation

The Quartus II software does not automatically generate the SDC timing constraints for Altera GPIO IP

core. You must manually enter the timing constraints. This section provides simple instructions and

examples on how to timing constrain the Altera GPIO IP core to ensure that the TimeQuest Timing

Analyzer analyzes the I/O timing correctly.

Altera GPIO IP Core User Guide

Send Feedback

Page 17

ug-altera_gpio

2014.08.18

Related Information

• AN 433: Constraining and Analyzing Source-Synchronous Interfaces

Describes techniques for constraining and analyzing source-synchronous interfaces.

Core Interface Path Timing Analysis

To properly perform timing analysis for the core interface paths, you must define the clock settings in

the .sdc for the following:

• clock to the core registers and

• clock to the I/O registers (Simple register and DDIO mode)

To properly perform timing analysis for the I/O interface, specify the system level constraints of the data

pins against the system clock pin in the .sdc.

Single Data Rate Input Register

Figure 11: Single Data Rate Input Register

Core Interface Path Timing Analysis

17

This SDC command creates the clock setting for the input clock:

create_clock -name sdr_in_clk -period "100 MHz" sdr_in_clk

This command instructs the TimeQuest timing analyzer to timing analyze the input I/O with 0.15 ns

input delay.

set_input_delay -clock sdr_in_clk 0.15 sdr_in_data

Altera GPIO IP Core User Guide

Altera Corporation

Send Feedback

Page 18

Outside FPGA

FPGA

18

DDIO Input Register (Full-Rate or Half-Rate)

DDIO Input Register (Full-Rate or Half-Rate)

Figure 12: DDIO Input Register (Full-Rate or Half-Rate)

The input side of full-rate and half-rate DDIO is the same. You can properly constrain the system by

using a virtual clock to model the off-chip transmitter to the FPGA.

ug-altera_gpio

2014.08.18

create_clock

These SDC commands create the clock settings for the virtual and the DDIO clock.

create_clock -name virtual_clock -period "200 MHz"

create_clock -name ddio_in_clk -period "200 MHz" ddio_in_clk

set_input_delay

These set_input_delay commands instruct the TimeQuest timing analyzer to analyze the positive clock

edge and the negative clock edge of the transfer. Note the "-add_delay" in the second set_input_delay

command:

set_input_delay -clock virtual_clock 0.25 ddio_in_data

set_input_delay -add_delay -clock_fall -clock virtual_clock 0.25 ddio_in_data

set_false_path

These set_false_path commands instruct the TimeQuest timing analyzer to ignore the positive clock

edge to the negative edge triggered register and the negative clock edge to the positive edge triggered

register:

Altera Corporation

set_false_path -fall_from virtual_clock -rise_to ddio_in_clk

set_false_path -rise_from virtual_clock -fall_to ddio_in_clk

Altera GPIO IP Core User Guide

Send Feedback

Page 19

ug-altera_gpio

2014.08.18

Single Data Rate Output Register

Note: The CLK_HR frequency must be half the frequency of CLK_FR. If the clocks are driven by IOPLL,

you may consider using the derive_pll_clocks SDC command.

Single Data Rate Output Register

Figure 13: Single Data Rate Output Register

19

These SDC commands generate the source clock and the output clock to be transmitted:

create_clock -name sdr_out_clk -period "100 MHz" sdr_out_clk

create_generated_clock -source sdr_out_clk -name sdr_out_outclk sdr_out_outclk

This SDC command instructs the TimeQuest timing analyzer to analyze the output data to be transmitted

against the output clock to be transmitted.

set_output_delay -clock sdr_out_clk 0.45 sdr_out_data

DDIO Output Register

The output side of the full-rate and half-rate DDIO output register is the same.

create_clock and create_generated_clock

These SDC commands generate the clocks to the DDIO and the clock to be transmitted:

create_clock -name ddio_out_fr_clk -period "200 MHz" ddio_out_fr_clk

create_generated_clock -source ddio_out_fr_clk -name ddio_out_fr_outclk

ddio_out_fr_outclk

Altera GPIO IP Core User Guide

Send Feedback

Altera Corporation

Page 20

20

Altera GPIO Delay Elements

set_output_delay

These commands instruct the TimeQuest Timing Analyzer to timing analyze the positive data and the

negative data against the output clock

set_output_delay -clock ddio_out_fr_outclk 0.55 ddio_out_fr_data

set_output_delay -add_delay -clock_fall -clock ddio_out_fr_outclk 0.55

ddio_out_fr_data

set_false_path

You need these set_false_path commands to stop the TimeQuest timing anaylzer from timing analyzing

the rising edge of the source clock against the falling edge of the output clock and the falling edge of

source clock against rising edge of output clock:

set_false_path -rise_from ddio_out_fr_clk -fall_to ddio_out_fr_outclk

set_false_path -fall_from ddio_out_fr_clk -rise_to ddio_out_fr_outclk

Altera GPIO Delay Elements

ug-altera_gpio

2014.08.18

The Quartus II software version 14.0a10 does not support automatic setting of delay elements to

maximize slack of I/O timing analysis. You must manually set the delay elements through QSF settings to

close timing or maximize slack on the I/O timing analysis.

You can access the delay elements using these QSF assignments:

Table 5: QSF Assignments for Altera GPIO Delay Elements

Delay Element QSF Assignments

Input Delay Element

Output Delay Element

Output Enable Delay

Element

set_intance_assignment –to <PIN> -name INPUT_DELAY_CHAIN

<0..63>

set_intance_assignment –to <PIN> -name OUTPUT_DELAY_CHAIN

<0..15>

set_intance_assignment –to <PIN> -name OE_DELAY_CHAIN

<0..15>

Timing Closure Guideline

For the input registers of the Altera GPIO IP core, if you do not set the input delay chain, it is likely the

input I/O transfer will fail hold time, because the clock delay is larger than the data delay. In such cases,

use the input delay chain to add delay to the input data path to meet hold time. As a general guide, the

input delay chain is about 60 ps per step at -1 speed grade. Dividing the negative hold slack by 60 ps

provides an approximate input delay chain setting to set to pass timing.

However, if the clocks of the GPIO input registers (simple register mode or DDIO mode) are driven by an

I/O phase locked loop (IOPLL), you can choose to set the compensation mode to source synchronous

Altera Corporation

Altera GPIO IP Core User Guide

Send Feedback

Page 21

ug-altera_gpio

2014.08.18

mode. The Fitter will attempt to configure the IOPLL for a better setup and hold slack of the input I/O

timing analysis.

For the output and output enable registers of the Altera GPIO IP core, you can use the output delay chain

and output enable delay chain to add delay to the output data and the output clock. If setup time violation

is observed, you can increase the delay chain setting of the output clock. If hold time violation is observed,

you can increase the delay chain setting of output data.

Design Example

The Altera GPIO IP core is able to generate a design example that matches the same configuration chosen

for the IP. The design example is a simple design that does not target any specific application; however

you can use the design example as a reference on how to instantiate the IP core and what behavior to

expect in a simulation.

Note: The .qsys files are for internal use during example design generation only. You cannot edit the files.

Generating Design Example

During generation, the Generation dialog box displays the option to generate a design example. Turn on

the Generate Example Design option.

Design Example

21

The software generates the <instance>_example_design directory along with the IP, where <instance> is

the name of your IP.

The <instance>_example_design directory contains two TCL scripts:

• - make_qii_design.tcl

• - make_sim_design.tcl

Generating Quartus Design Example

The make_qii_design.tcl generates a synthesizable design example along with a Quartus project, ready

for compilation.

To generate synthesizable design example, run the following script at the end of IP generation:

quartus_sh -t make_qii_design.tcl

To specify an exact device to use, run the following script:

quartus_sh -t make_qii_design.tcl [device_name]

This script generates a qii directory containing a project called ed_synth.qpf. You can open and compile

this project with the Quartus II software.

Generating Simulation Design Example

The make_sim_design.tcl generates a simulation design example along with tool-specific scripts to

compile and elaborate the necessary files.

To generate a simulation design example, run the following script at the end of IP generation:

quartus_sh -t make_sim_design.tcl

Altera GPIO IP Core User Guide

Send Feedback

Altera Corporation

Page 22

22

Document Revision History

To generate simulation design example for a VHDL-only simulator, run the following script:

quartus_sh -t make_sim_design.tcl VHDL

This script generates a sim directory containing one subdirectory for each supported simulation tools.

Each subdirectory contains the specific scripts to run simulation with the corresponding tool.

The simulation design example is made of a driver connected to the generated IP. The driver generates

random traffic and internally checks the legality of the out going data.

Document Revision History

Date Version Changes

ug-altera_gpio

2014.08.18

August, 2014 2014.08.18

November,

2013.11.29 Initial release.

2013

• Added timing information.

• Added register packing information.

• Added Use legacy top-level port names parameter. This is a new

parameter.

• Added register packing information.

• Replaced the term megafunction with IP core.

Altera Corporation

Altera GPIO IP Core User Guide

Send Feedback

Loading...

Loading...