Page 1

查询EPF81188A供应商查询EPF81188A供应商

FLEX 8000

®

Programmable Logic

Device Family

September 1998, ver. 9.11 Data Sheet

Low-cost, high-density, register-rich CMOS programmable logic

Features...

■

device (PLD) family (see Table 1)

– 2,500 to 16,000 usable gates

– 282 to 1,500 registers

System-level features

■

– In-circuit reconfigurability (ICR) via external Configuration

EPROM or intelligent controller

– Fully compliant with the peripheral component interconnect

(PCI) standard

– Built-in Joint-Test Action Group (JTAG) boundary-scan test (BST)

circuitry compliant with IEEE Std. 1149.1-1990 on selected devices

– MultiVolt

while I/O pins are compatible with 5.0-V and 3.3-V logic levels

– Low power consumption (typical specification less than 0.5 mA

in standby mode)

Flexible interconnect

■

– FastTrack

predictable interconnect delays

– Dedicated carry chain that implements arithmetic functions such

as fast adders, counters, and comparators (automatically used by

software tools and megafunctions)

– Dedicated cascade chain that implements high-speed, high-fan-in

logic functions (automatically used by software tools and

megafunctions)

– Tri-state emulation that implements internal tri-state nets

Powerful I/O pins

■

– Programmable output slew-rate control reduces switching noise

Peripheral register for fast setup and clock-to-output delay

■

™

I/O interface enabling device core to run at 5.0 V,

™

Interconnect continuous routing structure for fast,

3

FLEX 8000

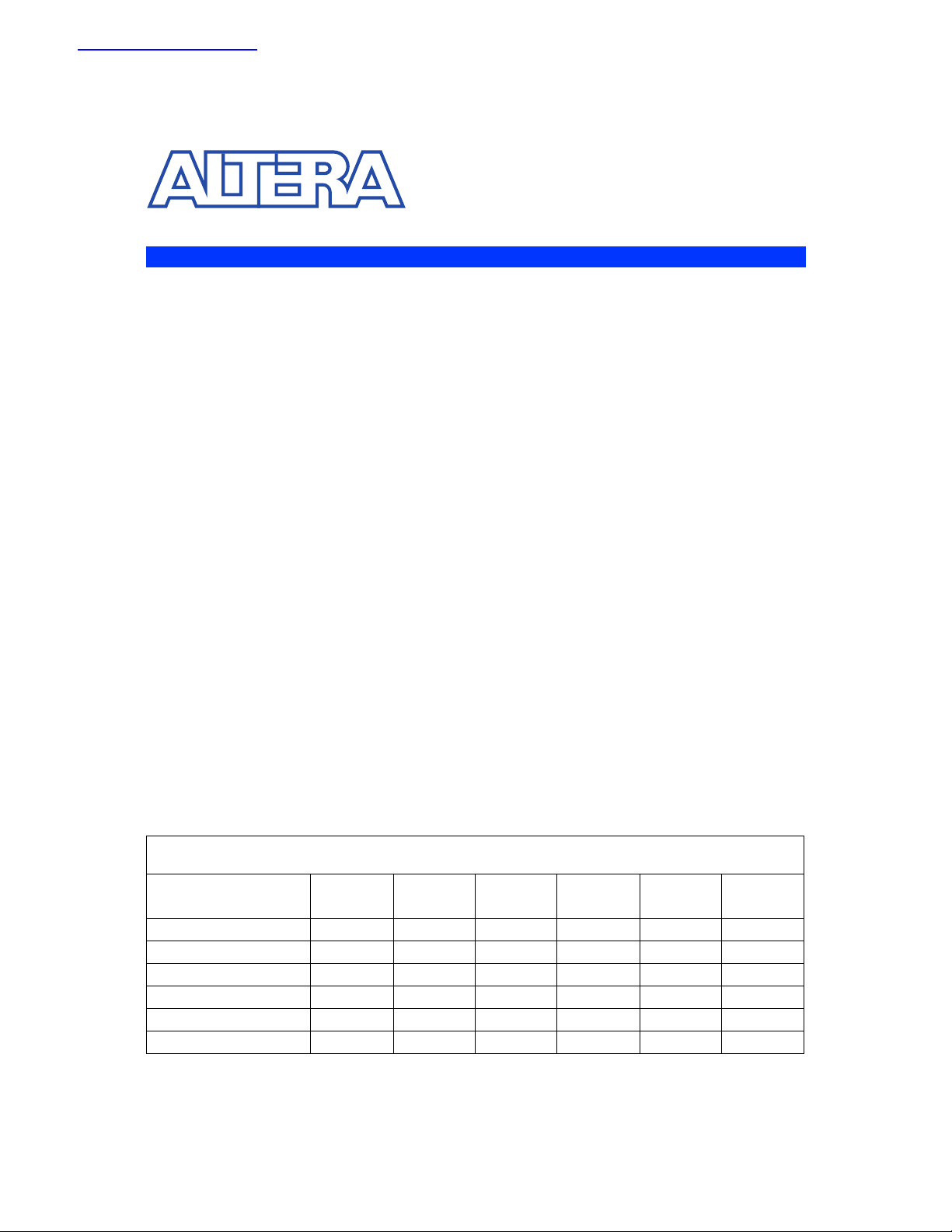

Table 1. FLEX 8000 Device Features

Feature EPF8282A

EPF8282AV

Usable gates 2,500 4,000 6,000 8,000 12,000 16,000

Flipflops 282 452 636 820 1,188 1,500

Logic array blocks (LABs) 26 42 63 84 126 162

Logic elements (LEs) 208 336 504 672 1,008 1,296

Maximum user I/O pins 78 120 136 152 184 208

JTAG BST circuitry Yes No Yes Yes No Yes

Altera Corporation 1

A-DS-F8000-09.11

EPF8452A EPF8636A EPF8820A EPF81188A EPF81500A

Page 2

FLEX 8000 Programmable Logic Device Family Data Sheet

■

...and More

Features

Fabricated on an advanced SRAM process

■

Available in a variety of packages with 84 to 304 pins (see Table 2)

■

Software design support and automatic place-and-route provided by

the Altera

®

MAX+PLUS

Pentium-based PCs, and Sun SPARCstation, HP 9000 Series 700/800,

and IBM RISC System/6000 workstations

■

Additional design entry and simulation support provided by EDIF

2 0 0 and 3 0 0 netlist files, library of parameterized modules (LPM),

Verilog HDL, VHDL, and other interfaces to popular EDA tools from

manufacturers such as Cadence, Exemplar Logic, Mentor Graphics,

OrCAD, Synopsys, Synplicity, and Veribest

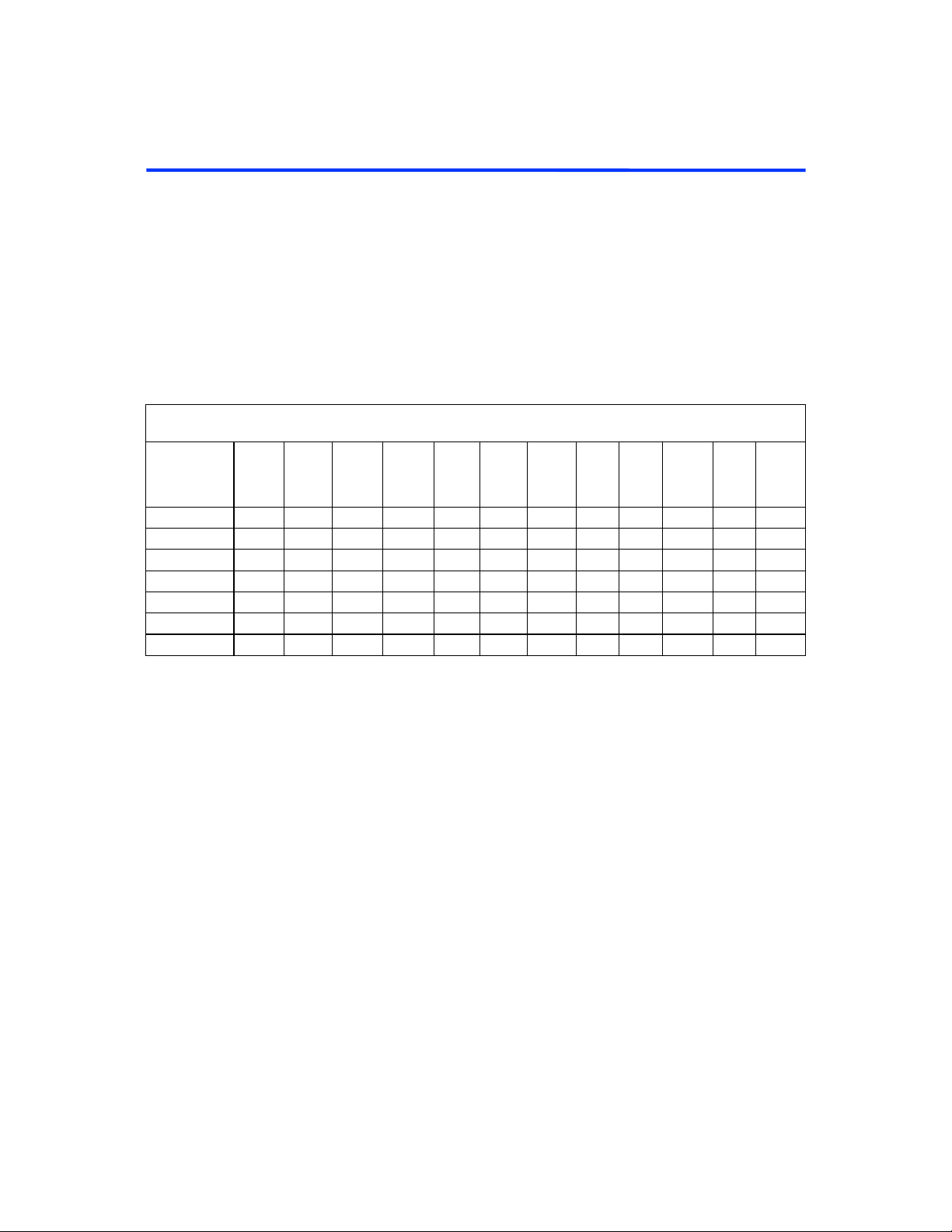

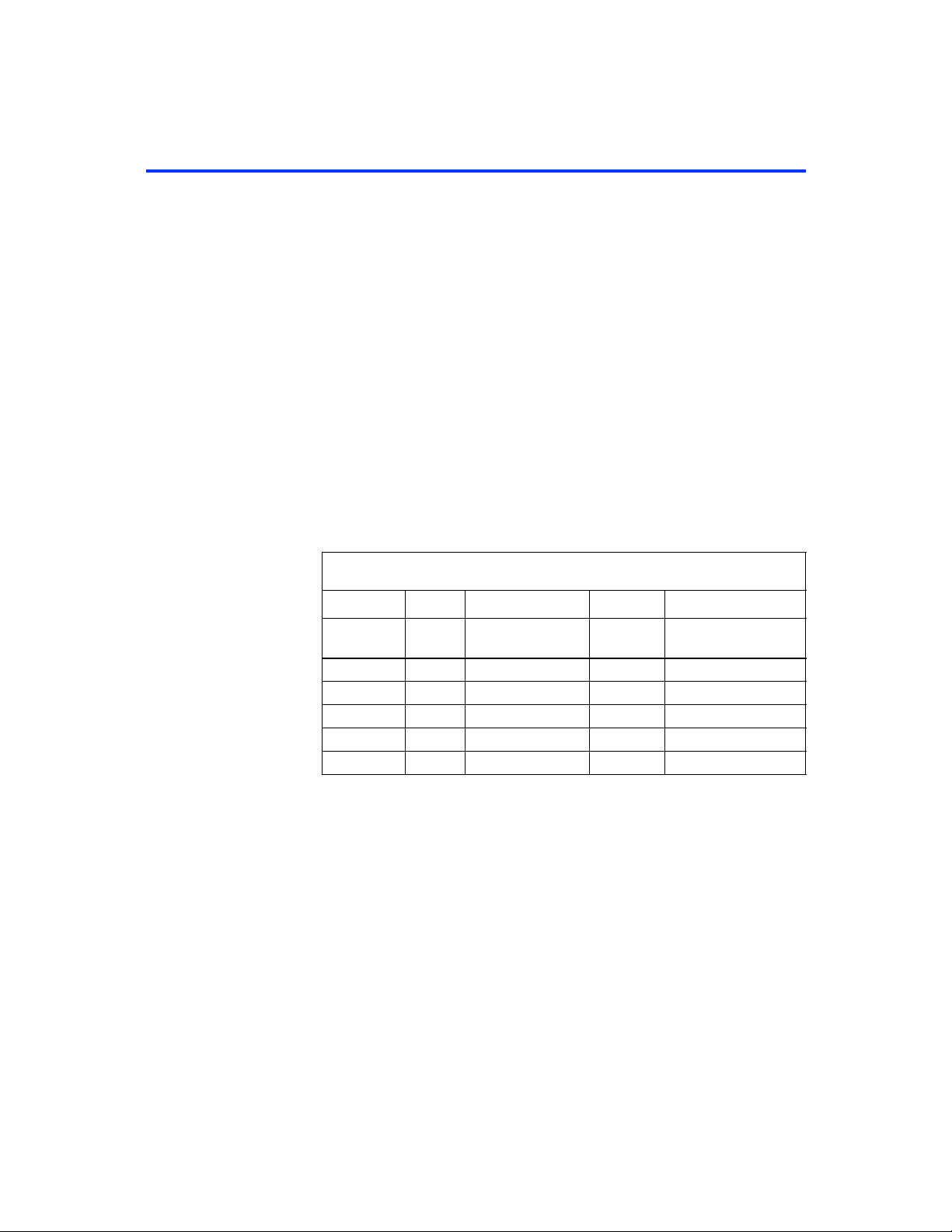

Table 2. FLEX 8000 Package Options & I/O Pin Count Note (1)

®

II development system for 486- and

Device 84-Pin

PLCC

EPF8282A 68 78

EPF8282AV 78

EPF8452A 68 68 120 120

EPF8636A 68 118 136 136

EPF8820A 112 120 152 152 152

EPF81188A 148 184 184

EPF81500A 181 208 208

Note:

(1) FLEX 8000 device package types include plastic J-lead chip carrier (PLCC), thin quad flat pack (TQFP), plastic quad

flat pack (PQFP), power quad flat pack (RQFP), ball-grid array (BGA), and pin-grid array (PGA) packages.

General

Description

100-

TQFP

Pin

144-

Pin

TQFP

160-

Pin

PQFP

160-

Pin

PGA

192-

Pin

PGA

208-

Pin

PQFP

Altera’s Flexible Logic Element MatriX (FLEX

225-

Pin

BGA

232-

PGA

®

240-

280-

Pin

Pin

PQFP

Pin

PGA

) family combines the

benefits of both erasable programmable logic devices (EPLDs) and fieldprogrammable gate arrays (FPGAs). The FLEX 8000 device family is ideal

304-

Pin

RQFP

for a variety of applications because it combines the fine-grained

architecture and high register count characteristics of FPGAs with the

high speed and predictable interconnect delays of EPLDs. Logic is

implemented in LEs that include compact 4-input look-up tables (LUTs)

and programmable registers. High performance is provided by a fast,

continuous network of routing resources.

2 Altera Corporation

Page 3

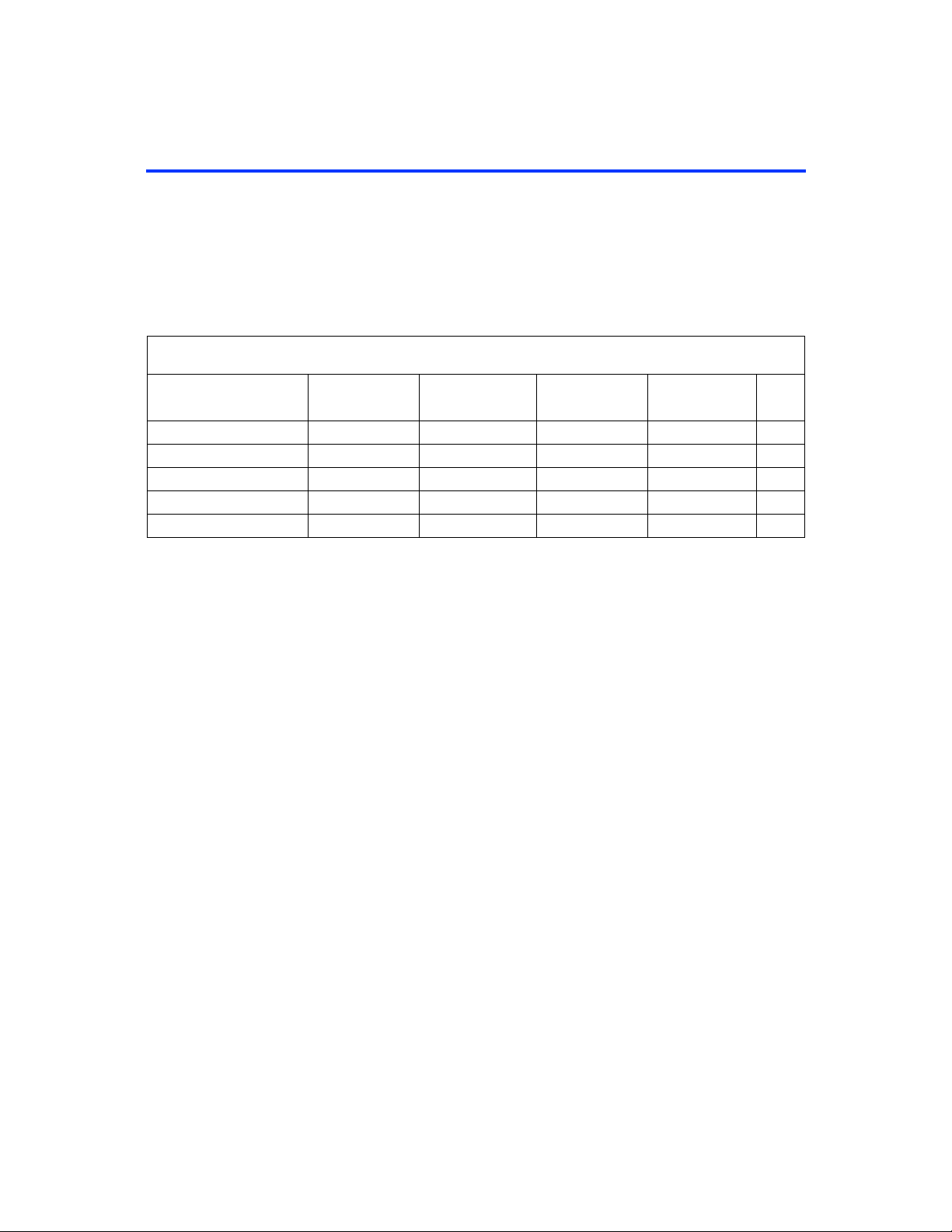

FLEX 8000 devices provide a large number of storage elements for

applications such as digital signal processing (DSP), wide-data-path

manipulation, and data transformation. These devices are an excellent

choice for bus interfaces, TTL integration, coprocessor functions, and

high-speed controllers. The high-pin-count packages can integrate

multiple 32-bit buses into a single device. Table 3 shows FLEX 8000

performance and LE requirements for typical applications.

Table 3. FLEX 8000 Performance

FLEX 8000 Programmable Logic Device Family Data Sheet

Application LEs Used A-2 Speed Grade A-3 Speed Grade A-4 Speed

16-bit loadable counter

16-bit up/down counter

24-bit accumulator

16-bit address decode

16-to-1 multiplexer

16

16

24

10

125 95 83 MHz

125 95 83 MHz

87 67 58 MHz

4

4.2 4.9 6.3 ns

6.6 7.9 9.5 ns

All FLEX 8000 device packages provide four dedicated inputs for

synchronous control signals with large fan-outs. Each I/O pin has an

associated register on the periphery of the device. As outputs, these

registers provide fast clock-to-output times; as inputs, they offer quick

setup times.

The logic and interconnections in the FLEX 8000 architecture are

configured with CMOS SRAM elements. FLEX 8000 devices are

configured at system power-up with data stored in an industry-standard

parallel EPROM or an Altera serial Configuration EPROM device, or with

data provided by a system controller. Altera offers the EPC1, EPC1213,

EPC1064, and EPC1441 Configuration EPROMs, which configure

FLEX 8000 devices via a serial data stream. Configuration data can also be

stored in an industry-standard 32 K × 8 bit or larger EPROM, or

downloaded from system RAM. After a FLEX 8000 device has been

configured, it can be reconfigured in-circuit by resetting the device and

loading new data. Because reconfiguration requires less than 100 ms, realtime changes can be made during system operation.

Units

Grade

3

FLEX 8000

f

Altera Corporation 3

For information on how to configure FLEX 8000 devices, go to the

following documents:

Configuration EPROMs for FLEX Devices Data Sheet

■

BitBlaster Serial Download Cable Data Sheet

■

ByteBlaster Parallel Port Download Cable Data Sheet

■

Application Note 33 (Configuring FLEX 8000 Devices)

■

Application Note 38 (Configuring Multiple FLEX 8000 Devices)

■

Page 4

FLEX 8000 Programmable Logic Device Family Data Sheet

FLEX 8000 devices contain an optimized microprocessor interface that

permits the microprocessor to configure FLEX 8000 devices serially, in

parallel, synchronously, or asynchronously. The interface also enables the

microprocessor to treat a FLEX 8000 device as memory and configure the

device by writing to a virtual memory location, making it very easy for the

designer to create configuration software.

The FLEX 8000 family is supported by Altera’s MAX+PLUS II

development system, a single, integrated package that offers schematic,

text—including the Altera Hardware Description Language (AHDL),

VHDL, and Verilog HDL—and waveform design entry; compilation and

logic synthesis; simulation and timing analysis; and device programming.

The MAX+PLUS II software provides EDIF 2 0 0 and 3 0 0, library of

parameterized modules (LPM), VHDL, Verilog HDL, and other interfaces

for additional design entry and simulation support from other industrystandard PC- and UNIX workstation-based EDA tools. The

MAX+PLUS II software runs on 486- and Pentium-based PCs, and Sun

SPARCstation, HP 9000 Series 700/800, and IBM RISC System/6000

workstations.

f

Functional

Description

The MAX+PLUS II software interfaces easily with common gate array

EDA tools for synthesis and simulation. For example, the MAX+PLUS II

software can generate Verilog HDL files for simulation with tools such as

Cadence Verilog-XL. Additionally, the MAX+PLUS II software contains

EDA libraries that use device-specific features such as carry chains, which

are used for fast counter and arithmetic functions. For instance, the

Synopsys Design Compiler library supplied with the MAX+PLUS II

development system includes DesignWare functions that are optimized

for the FLEX 8000 architecture.

For more information on the MAX+PLUS II software, go to the

MAX+PLUS II Programmable Logic Development System & Software Data

Sheet in this data book.

The FLEX 8000 architecture incorporates a large matrix of compact

building blocks called logic elements (LEs). Each LE contains a 4-input

LUT that provides combinatorial logic capability and a programmable

register that offers sequential logic capability. The fine-grained structure

of the LE provides highly efficient logic implementation.

Eight LEs are grouped together to form a logic array block (LAB). Each

FLEX 8000 LAB is an independent structure with common inputs,

interconnections, and control signals. The LAB architecture provides a

coarse-grained structure for high device performance and easy routing.

4 Altera Corporation

Page 5

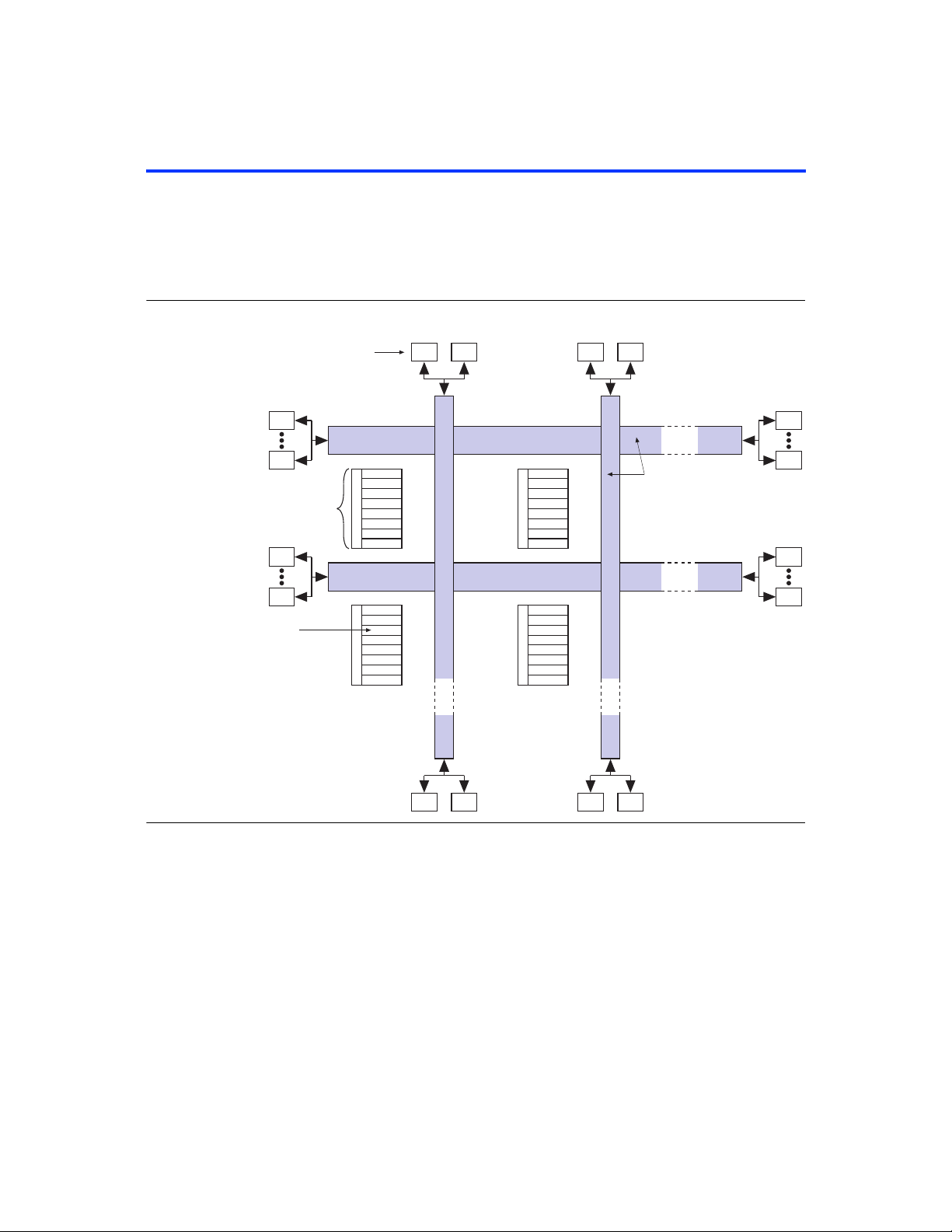

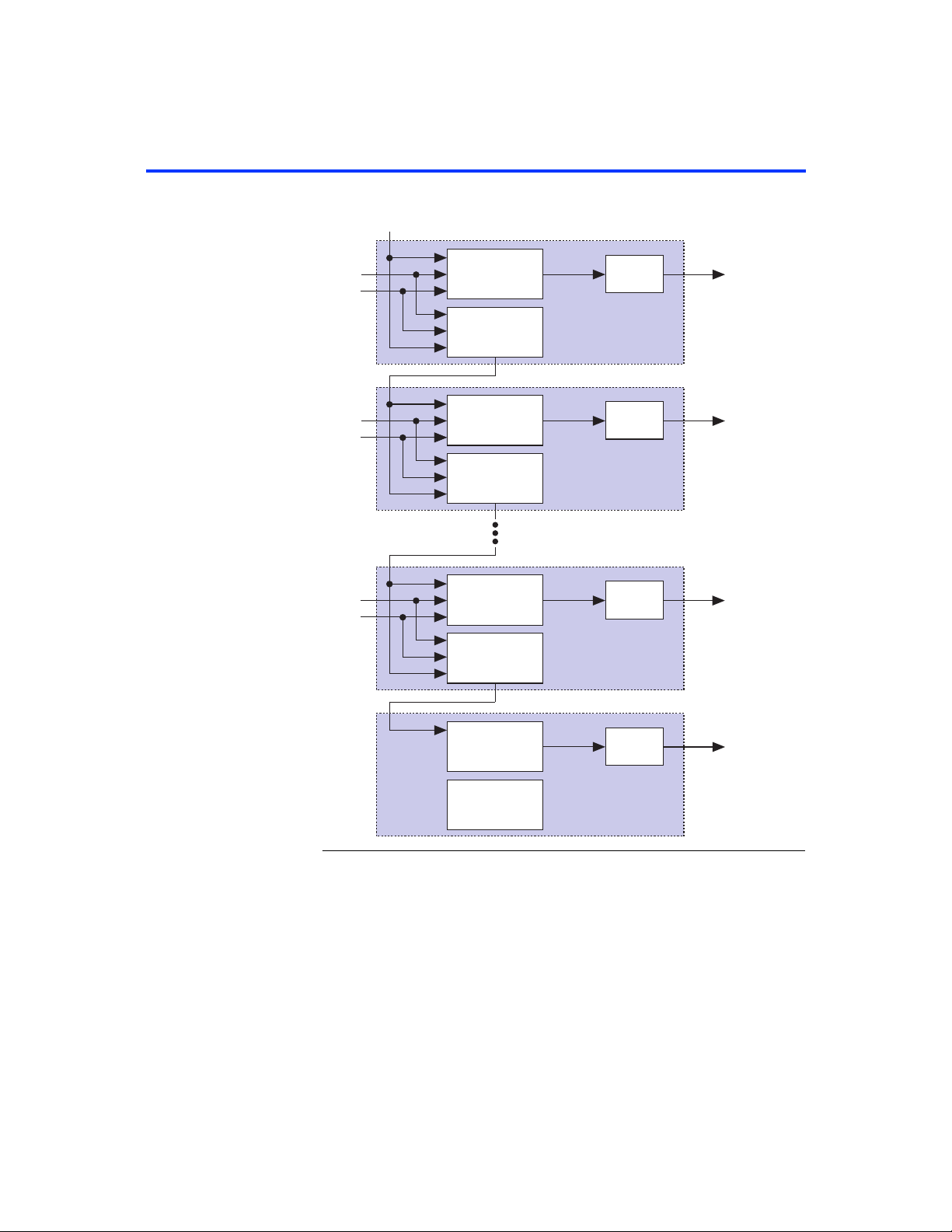

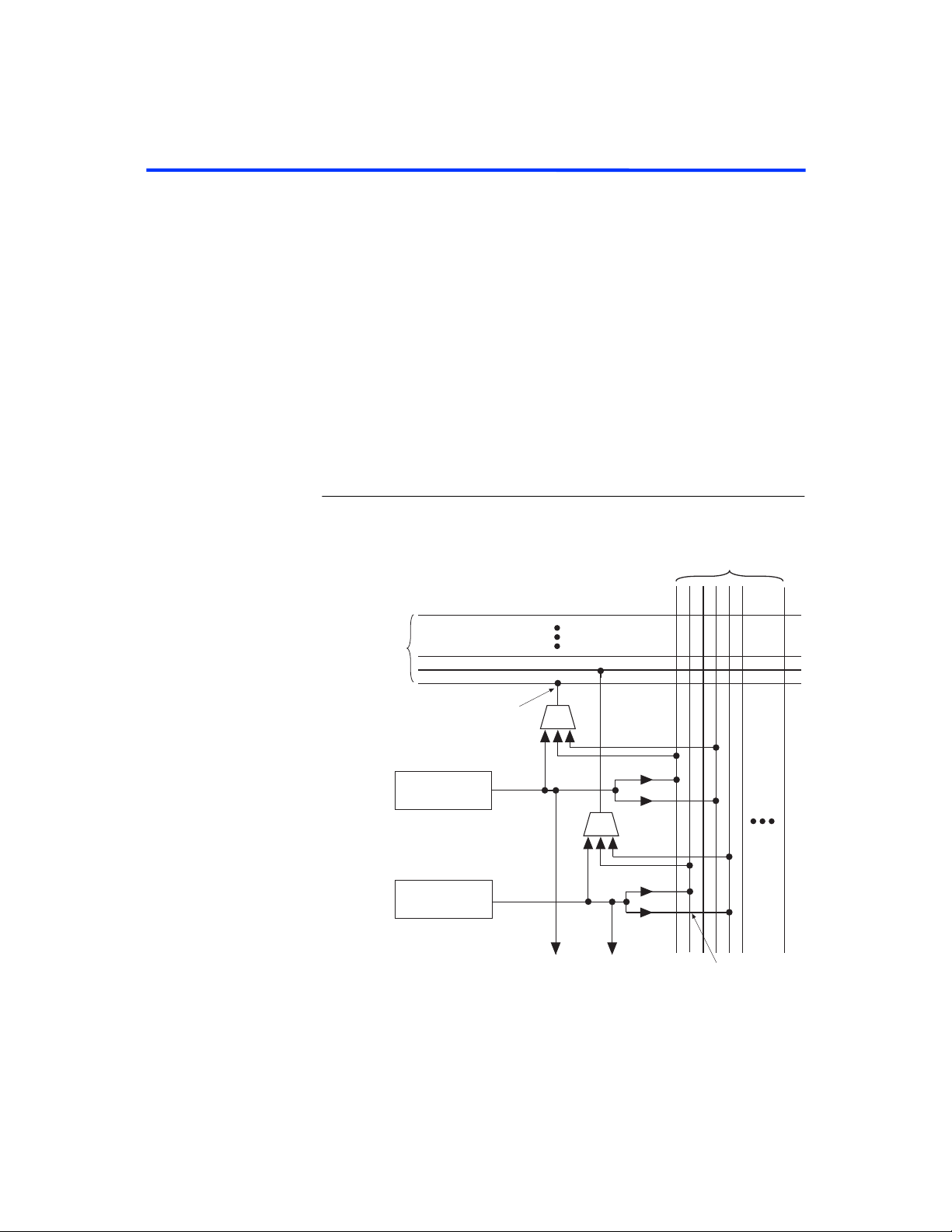

Figure 1 shows a block diagram of the FLEX 8000 architecture. Each

group of eight LEs is combined into an LAB; LABs are arranged into rows

and columns. The I/O pins are supported by I/O elements (IOEs) located

at the ends of rows and columns. Each IOE contains a bidirectional I/O

buffer and a flipflop that can be used as either an input or output register.

Figure 1. FLEX 8000 Device Block Diagram

FLEX 8000 Programmable Logic Device Family Data Sheet

I/O Element

(IOE)

IOE

IOE

Logic Array

Block (LAB)

IOE

IOE

Logic

Element (LE)

IOEIOE IOEIOE

IOEIOE IOEIOE

FastTrack

Interconnect

IOE

IOE

IOE

IOE

3

FLEX 8000

Signal interconnections within FLEX 8000 devices and between device

pins are provided by the FastTrack Interconnect, a series of fast,

continuous channels that run the entire length and width of the device.

IOEs are located at the end of each row (horizontal) and column (vertical)

FastTrack Interconnect path.

Altera Corporation 5

Page 6

FLEX 8000 Programmable Logic Device Family Data Sheet

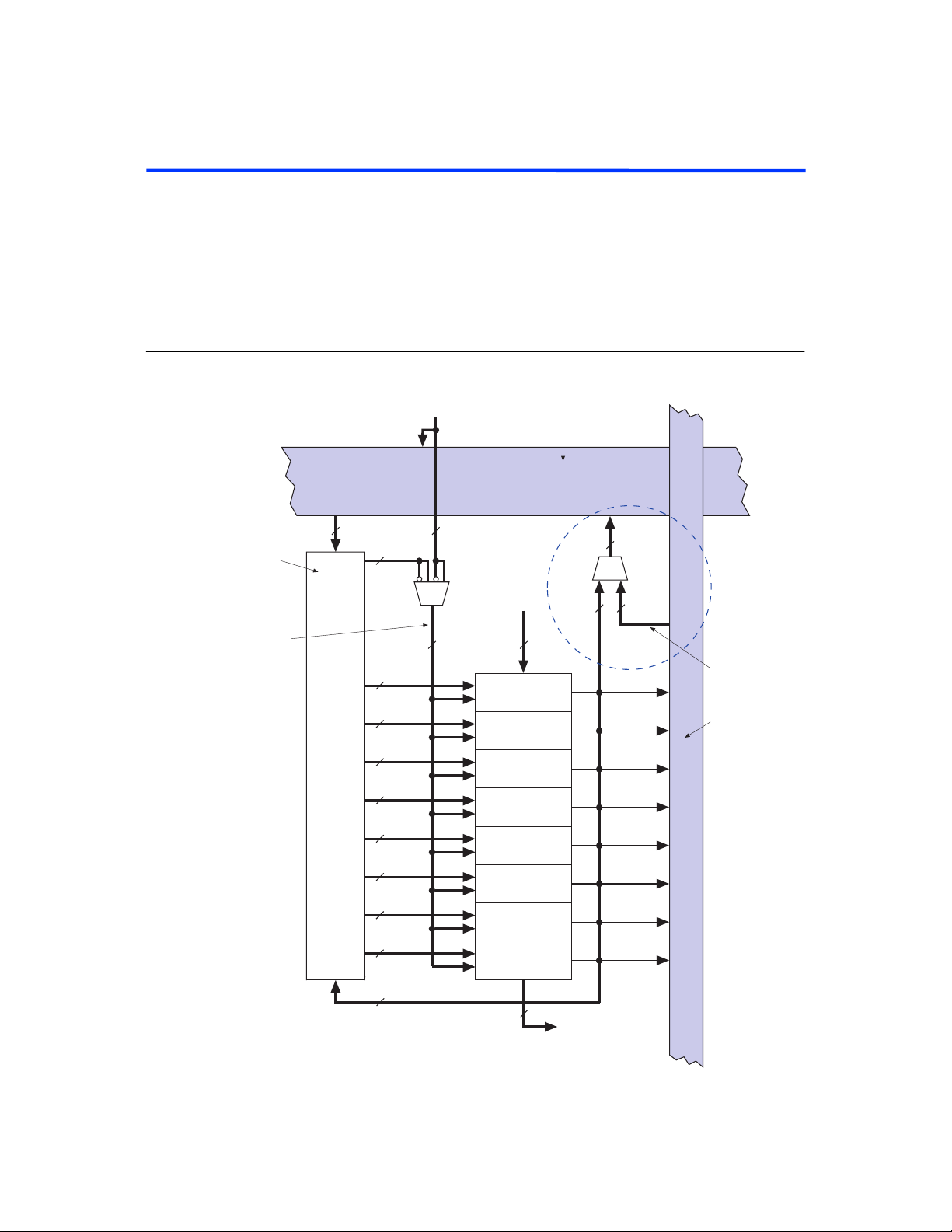

Logic Array Block

A logic array block (LAB) consists of eight LEs, their associated carry and

cascade chains, LAB control signals, and the LAB local interconnect. The

LAB provides the coarse-grained structure of the FLEX 8000 architecture.

This structure enables FLEX 8000 devices to provide efficient routing,

high device utilization, and high performance. Figure 2 shows a block

diagram of the FLEX 8000 LAB.

Figure 2. FLEX 8000 Logic Array Block

Dedicated

Inputs

Row Interconnect

LAB Local

Interconnect

(32 channels)

LAB Control

Signals

24

4

4

4

Carry-In and

Cascade-In

from LAB

on Left

2

8

See Figure 8

for details.

8

16

Column-to-Row

4

4

4

4

4

4

4

4

LE1

LE2

LE3

LE4

LE5

LE6

LE7

LE8

Interconnect

Column

Interconnect

8

2

Carry-Out and

Cascade-Out

to LAB on Right

6 Altera Corporation

Page 7

FLEX 8000 Programmable Logic Device Family Data Sheet

Each LAB provides four control signals that can be used in all eight LEs.

Two of these signals can be used as clocks, and the other two for

clear/preset control. The LAB control signals can be driven directly from

a dedicated input pin, an I/O pin, or any internal signal via the LAB local

interconnect. The dedicated inputs are typically used for global clock,

clear, or preset signals because they provide synchronous control with

very low skew across the device. FLEX 8000 devices support up to four

individual global clock, clear, or preset control signals. If logic is required

on a control signal, it can be generated in one or more LEs in any LAB and

driven into the local interconnect of the target LAB. This process is called

programmable inversion, and is available for all four LAB control signals.

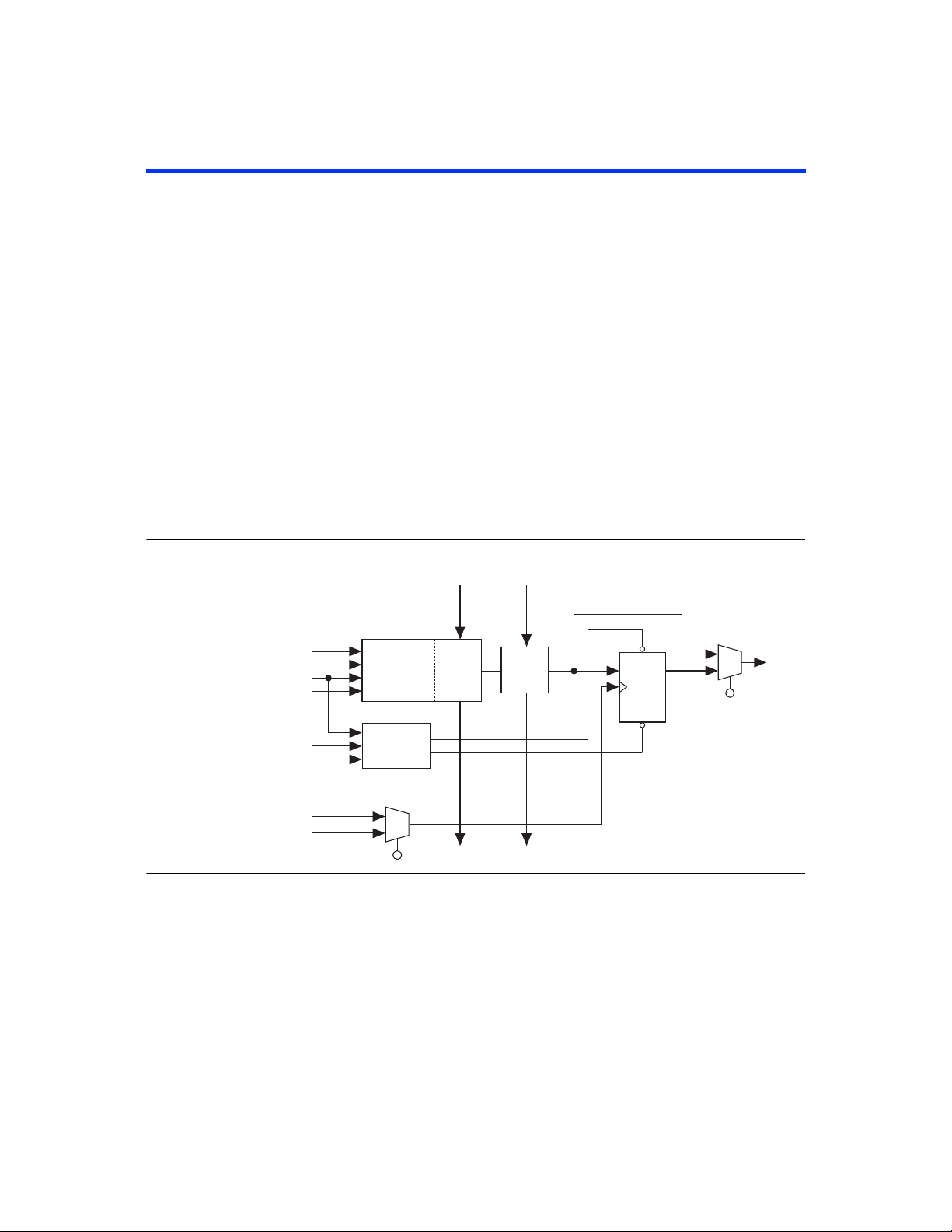

Logic Element

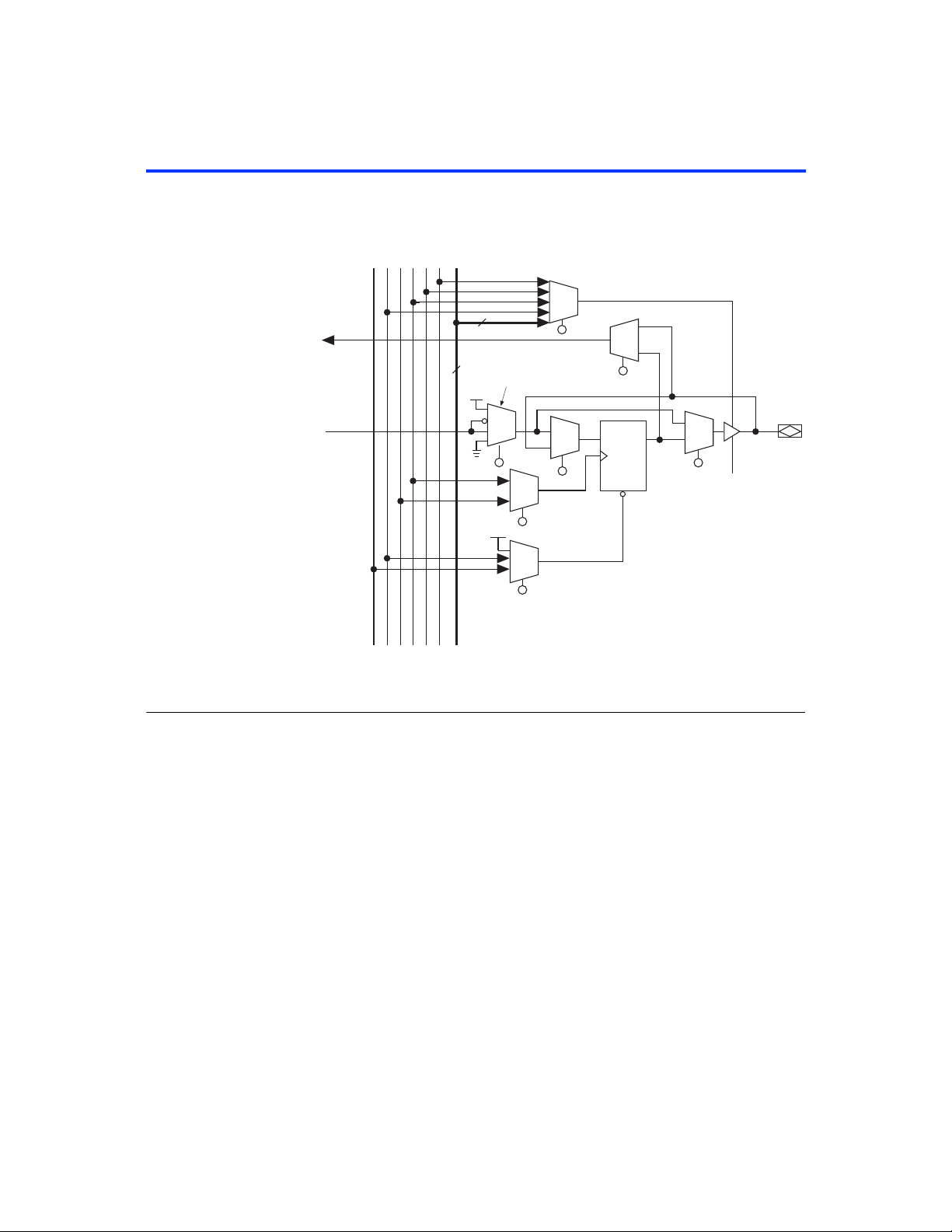

Figure 3. FLEX 8000 LE

DATA1

DATA2

DATA3

DATA4

LABCTRL1

LABCTRL2

LABCTRL3

LABCTRL4

The logic element (LE) is the smallest unit of logic in the FLEX 8000

architecture, with a compact size that provides efficient logic utilization.

Each LE contains a 4-input LUT, a programmable flipflop, a carry chain,

and cascade chain. Figure 3 shows a block diagram of an LE.

Look-Up

T able

(LUT)

Clear/

Preset

Logic

Clock

Select

Carry-In

Carry

Chain

Carry-Out

Cascade-In

Cascade

Chain

Cascade-Out

DFF

PRN

DQ

CLRN

LE-Out

The LUT is a function generator that can quickly compute any function of

four variables. The programmable flipflop in the LE can be configured for

D, T, JK, or SR operation. The clock, clear, and preset control signals on the

flipflop can be driven by dedicated input pins, general-purpose I/O pins,

or any internal logic. For purely combinatorial functions, the flipflop is

bypassed and the output of the LUT goes directly to the output of the LE.

3

FLEX 8000

Altera Corporation 7

Page 8

FLEX 8000 Programmable Logic Device Family Data Sheet

The FLEX 8000 architecture provides two dedicated high-speed data

paths—carry chains and cascade chains—that connect adjacent LEs

without using local interconnect paths. The carry chain supports highspeed counters and adders; the cascade chain implements wide-input

functions with minimum delay. Carry and cascade chains connect all LEs

in an LAB and all LABs in the same row. Heavy use of carry and cascade

chains can reduce routing flexibility. Therefore, the use of carry and

cascade chains should be limited to speed-critical portions of a design.

Carry Chain

The carry chain provides a very fast (less than 1 ns) carry-forward

function between LEs. The carry-in signal from a lower-order bit moves

forward into the higher-order bit via the carry chain, and feeds into both

the LUT and the next portion of the carry chain. This feature allows the

FLEX 8000 architecture to implement high-speed counters and adders of

arbitrary width. The MAX+PLUS II Compiler can create carry chains

automatically during design processing; designers can also insert carry

chain logic manually during design entry.

Figure 4 shows how an n -bit full adder can be implemented in n + 1 LEs

with the carry chain. One portion of the LUT generates the sum of two bits

using the input signals and the carry-in signal; the sum is routed to the

output of the LE. The register is typically bypassed for simple adders, but

can be used for an accumulator function. Another portion of the LUT and

the carry chain logic generate the carry-out signal, which is routed directly

to the carry-in signal of the next-higher-order bit. The final carry-out

signal is routed to another LE, where it can be used as a general-purpose

signal. In addition to mathematical functions, carry chain logic supports

very fast counters and comparators.

8 Altera Corporation

Page 9

FLEX 8000 Programmable Logic Device Family Data Sheet

Figure 4. FLEX 8000 Carry Chain Operation

Carry-In

a1

b1

a2

b2

a

b

LU

Carry

LUT

Carry Chain

Register

LE

Register

LE

s1

s2

3

n

n

LUT

Carry Chain

Register

LE

s

n

FLEX 8000

LUT

Carry Chain

Register

LE

n

+ 1

Carry-Out

Cascade Chain

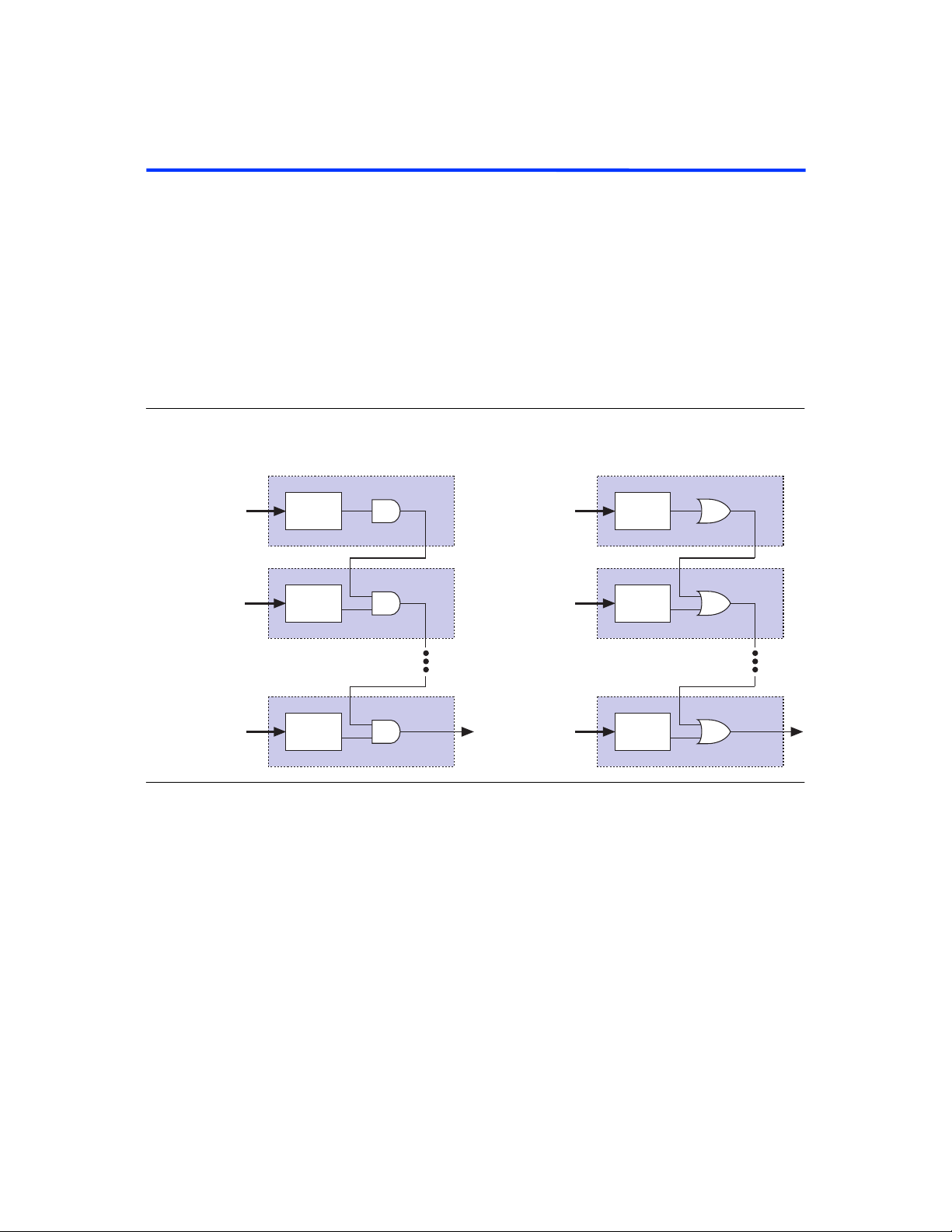

With the cascade chain, the FLEX 8000 architecture can implement

functions that have a very wide fan-in. Adjacent LUTs can be used to

compute portions of the function in parallel; the cascade chain serially

connects the intermediate values. The cascade chain can use a logical AND

or logical OR (via De Morgan’s inversion) to connect the outputs of

adjacent LEs. Each additional LE provides four more inputs to the

effective width of a function, with a delay as low as 0.6 ns per LE.

Altera Corporation 9

Page 10

FLEX 8000 Programmable Logic Device Family Data Sheet

The MAX+PLUS II Compiler can create cascade chains automatically

during design processing; designers can also insert cascade chain logic

manually during design entry. Cascade chains longer than eight LEs are

automatically implemented by linking LABs together. The last LE of an

LAB cascades to the first LE in the next LAB in the row.

Figure 5 shows how the cascade function can connect adjacent LEs to

form functions with a wide fan-in. These examples show functions of 4 n

variables implemented with n LEs. For a device with an A-2 speed grade,

the LUT delay is approximately 1.6 ns; the cascade chain delay is 0.6 ns.

With the cascade chain, 4.2 ns is needed to decode a 16-bit address.

Figure 5. FLEX 8000 Cascade Chain Operation

AND Cascade Chain OR Cascade Chain

LE1

d[3..0]

d[7..4]

d[(4n-1)..4(n-1)]

LUT

LUT

LUT

LE2

LE

n

d[3..0]

d[7..4]

d[(4n-1)..4(n-1)]

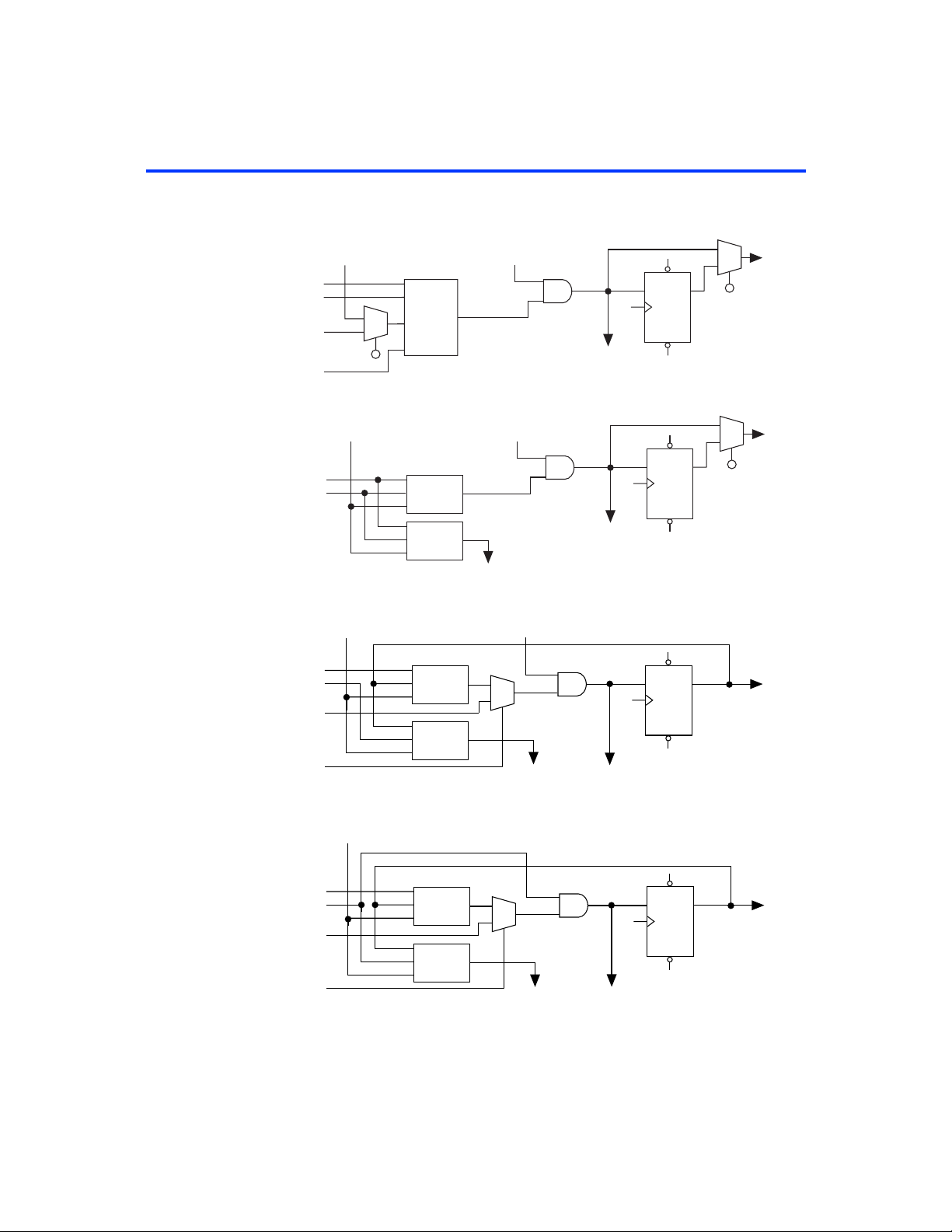

LE Operating Modes

The FLEX 8000 LE can operate in one of four modes, each of which uses

LE resources differently. See Figure 6. In each mode, seven of the ten

available inputs to the LE—the four data inputs from the LAB local

interconnect, the feedback from the programmable register, and the

carry-in and cascade-in from the previous LE—are directed to different

destinations to implement the desired logic function. The three remaining

inputs to the LE provide clock, clear, and preset control for the register.

The MAX+PLUS II software automatically chooses the appropriate mode

for each application. Design performance can also be enhanced by

designing for the operating mode that supports the desired application.

LUT

LUT

LUT

LE1

LE2

LE

n

10 Altera Corporation

Page 11

Figure 6. FLEX 8000 LE Operating Modes

Normal Mode

FLEX 8000 Programmable Logic Device Family Data Sheet

Arithmetic Mode

Up/Down

DATA1

DATA2

DATA3

DATA4

DATA1

DATA2

DATA1 (ena)

DATA2 (nclr)

DATA3 (data)

DATA4 (nload)

Carry-In

Carry-In

Carry-In

4-Input

LUT

3-Input

LUT

3-Input

LUT

3-Input

LUT

3-Input

LUT

Cascade-In

Cascade-In

Carry-Out

1

0

Cascade-In

Carry-Out

Cascade-Out

Cascade-Out

Cascade-Out

PRN

DQ

CLRN

PRN

DQ

CLRN

PRN

DQ

CLRN

LE-Out

LE-Out

3

FLEX 8000

LE-Out

Clearable Counter Mode

Carry-In

DATA1 (ena)

DATA2 (nclr)

DATA3 (data)

DATA4 (nload)

3-Input

LUT

3-Input

LUT

1

0

Carry-Out

Cascade-Out

PRN

DQ

CLRN

LE-Out

Altera Corporation 11

Page 12

FLEX 8000 Programmable Logic Device Family Data Sheet

Normal Mode

The normal mode is suitable for general logic applications and wide

decoding functions that can take advantage of a cascade chain. In normal

mode, four data inputs from the LAB local interconnect and the carry-in

signal are the inputs to a 4-input LUT. Using a configurable SRAM bit, the

MAX+PLUS II Compiler automatically selects the carry-in or the DATA3

signal as an input. The LUT output can be combined with the cascade-in

signal to form a cascade chain through the cascade-out signal. The LE-Out

signal—the data output of the LE—is either the combinatorial output of

the LUT and cascade chain, or the data output ( Q) of the programmable

register.

Arithmetic Mode

The arithmetic mode offers two 3-input LUTs that are ideal for

implementing adders, accumulators, and comparators. One LUT

provides a 3-bit function; the other generates a carry bit. As shown in

Figure 6, the first LUT uses the carry-in signal and two data inputs from

the LAB local interconnect to generate a combinatorial or registered

output. For example, in an adder, this output is the sum of three bits: a , b ,

and the carry-in. The second LUT uses the same three signals to generate

a carry-out signal, thereby creating a carry chain. The arithmetic mode

also supports a cascade chain.

Up/Down Counter Mode

The up/down counter mode offers counter enable, synchronous

up/down control, and data loading options. These control signals are

generated by the data inputs from the LAB local interconnect, the carry-in

signal, and output feedback from the programmable register. Two 3-input

LUTs are used: one generates the counter data, and the other generates the

fast carry bit. A 2-to-1 multiplexer provides synchronous loading. Data

can also be loaded asynchronously with the clear and preset register

control signals, without using the LUT resources.

Clearable Counter Mode

The clearable counter mode is similar to the up/down counter mode, but

supports a synchronous clear instead of the up/down control; the clear

function is substituted for the cascade-in signal in the up/down counter

mode. Two 3-input LUTs are used: one generates the counter data, and

the other generates the fast carry bit. Synchronous loading is provided by

a 2-to-1 multiplexer, and the output of this multiplexer is AND ed with a

synchronous clear.

12 Altera Corporation

Page 13

FLEX 8000 Programmable Logic Device Family Data Sheet

Internal Tri-State Emulation

Internal tri-state emulation provides internal tri-stating without the

limitations of a physical tri-state bus. In a physical tri-state bus, the

tri-state buffers’ output enable signals select the signal that drives the bus.

However, if multiple output enable signals are active, contending signals

can be driven onto the bus. Conversely, if no output enable signals are

active, the bus will float. Internal tri-state emulation resolves contending

tri-state buffers to a low value and floating buses to a high value, thereby

eliminating these problems. The MAX+PLUS II software automatically

implements tri-state bus functionality with a multiplexer.

Clear & Preset Logic Control

Logic for the programmable register’s clear and preset functions is

controlled by the DATA3 , LABCTRL1 , and LABCTRL2 inputs to the LE. The

clear and preset control structure of the LE is used to asynchronously load

signals into a register. The register can be set up so that LABCTRL1

implements an asynchronous load. The data to be loaded is driven to

DATA3 ; when LABCTRL1 is asserted, DATA3 is loaded into the register.

During compilation, the MAX+PLUS II Compiler automatically selects

the best control signal implementation. Because the clear and preset

functions are active-low, the Compiler automatically assigns a logic high

to an unused clear or preset.

The clear and preset logic is implemented in one of the following six

asynchronous modes, which are chosen during design entry. LPM

functions that use registers will automatically use the correct

asynchronous mode. See Figure 7.

Clear only

■

Preset only

■

Clear and preset

■

Load with clear

■

Load with preset

■

Load without clear or preset

■

3

FLEX 8000

Altera Corporation 13

Page 14

FLEX 8000 Programmable Logic Device Family Data Sheet

Figure 7. FLEX 8000 LE Asynchronous Clear & Preset Modes

Asynchronous Clear

VCC

PRN

Q

D

CLRN

LABCTRL1 or

LABCTRL2

Asynchronous Load with Clear

LABCTRL1

(Asynchronous

Load)

DATA3

(Data)

LABCTRL2

(Clear)

NOT

NOT

Asynchronous Load with Preset

LABCTRL1

(Asynchronous

Load)

NOT

Asynchronous Preset

LABCTRL1 or

LABCTRL2

D

D

PRN

CLRN

PRN

CLRN

Q

Asynchronous Clear & Preset

LABCTRL1

PRN

Q

Q

LABCTRL2

D

CLRN

LABCTRL2

(Preset)

DATA3

(Data)

NOT

D

PRN

CLRN

Q

Asynchronous Load without Clear or Preset

LABCTRL1

(Asynchronous

Load)

DATA3

(Data)

NOT

NOT

PRN

D

CLRN

Q

14 Altera Corporation

Page 15

FLEX 8000 Programmable Logic Device Family Data Sheet

Asynchronous Clear

A register is cleared by one of the two LABCTRL signals. When the CLRn

port receives a low signal, the register is set to zero.

Asynchronous Preset

An asynchronous preset is implemented as either an asynchronous load

or an asynchronous clear. If DATA3 is tied to VCC, asserting LABCTRLl

asynchronously loads a 1 into the register. Alternatively, the

MAX+PLUS II software can provide preset control by using the clear and

inverting the input and output of the register. Inversion control is

available for the inputs to both LEs and IOEs. Therefore, if a register is

preset by only one of the two LABCTRL signals, the DATA3 input is not

needed and can be used for one of the LE operating modes.

Asynchronous Clear & Preset

When implementing asynchronous clear and preset, LABCTRL1 controls

the preset and LABCTRL2 controls the clear. The DATA3 input is tied to VCC;

therefore, asserting LABCTRL1 asynchronously loads a 1 into the register,

effectively presetting the register. Asserting LABCTRL2 clears the register.

Asynchronous Load with Clear

3

FLEX 8000

When implementing an asynchronous load with the clear, LABCTRL1

implements the asynchronous load of DATA3 by controlling the register

preset and clear. LABCTRL2 implements the clear by controlling the

register clear.

Asynchronous Load with Preset

When implementing an asynchronous load in conjunction with a preset,

the MAX+PLUS II software provides preset control by using the clear and

inverting the input and output of the register. Asserting LABCTRL2 clears

the register, while asserting LABCTRL1 loads the register. The

MAX+PLUS II software inverts the signal that drives the DATA3 signal to

account for the inversion of the register’s output.

Asynchronous Load without Clear or Preset

When implementing an asynchronous load without the clear or preset,

LABCTRL1 implements the asynchronous load of DATA3 by controlling the

register preset and clear.

Altera Corporation 15

Page 16

FLEX 8000 Programmable Logic Device Family Data Sheet

FastTrack Interconnect

In the FLEX 8000 architecture, connections between LEs and device I/O

pins are provided by the FastTrack Interconnect, a series of continuous

horizontal (row) and vertical (column) routing channels that traverse the

entire FLEX 8000 device. This device-wide routing structure provides

predictable performance even in complex designs. In contrast, the

segmented routing structure in FPGAs requires switch matrices to

connect a variable number of routing paths, which increases the delays

between logic resources and reduces performance.

The LABs within FLEX 8000 devices are arranged into a matrix of

columns and rows. Each row of LABs has a dedicated row interconnect

that routes signals both into and out of the LABs in the row. The row

interconnect can then drive I/O pins or feed other LABs in the device.

Figure 8 shows how an LE drives the row and column interconnect.

Figure 8. FLEX 8000 LAB Connections to Row & Column Interconnect

16 Column

Channels

Row Channels

Note (1)

Each LE drives one

row channel.

LE1

LE2

to Local

Feedback

Note:

(1) See Table 4 for the number of row channels.

16 Altera Corporation

to Local

Feedback

Each LE drives up to

two column channels.

Page 17

FLEX 8000 Programmable Logic Device Family Data Sheet

Each LE in an LAB can drive up to two separate column interconnect

channels. Therefore, all 16 available column channels can be driven by the

LAB. The column channels run vertically across the entire device, and

share access to LABs in the same column but in different rows. The

MAX+PLUS II Compiler chooses which LEs must be connected to a

column channel. A row interconnect channel can be fed by the output of

the LE or by two column channels. These three signals feed a multiplexer

that connects to a specific row channel. Each LE is connected to one 3-to-1

multiplexer. In an LAB, the multiplexers provide all 16 column channels

with access to 8 row channels.

Each column of LABs has a dedicated column interconnect that routes

signals out of the LABs into the column. The column interconnect can then

drive I/O pins or feed into the row interconnect to route the signals to

other LABs in the device. A signal from the column interconnect, which

can be either the output of an LE or an input from an I/O pin, must

transfer to the row interconnect before it can enter an LAB. Table 4

summarizes the FastTrack Interconnect resources available in each

FLEX 8000 device.

Table 4. FLEX 8000 FastTrack Interconnect Resources

Device Rows Channels per Row Columns Channels per Column

EPF8282A

EPF8282AV

EPF8452A 2 168 21 16

EPF8636A 3 168 21 16

EPF8820A 4 168 21 16

EPF81188A 6 168 21 16

EPF81500A 6 216 27 16

2 168 13 16

3

FLEX 8000

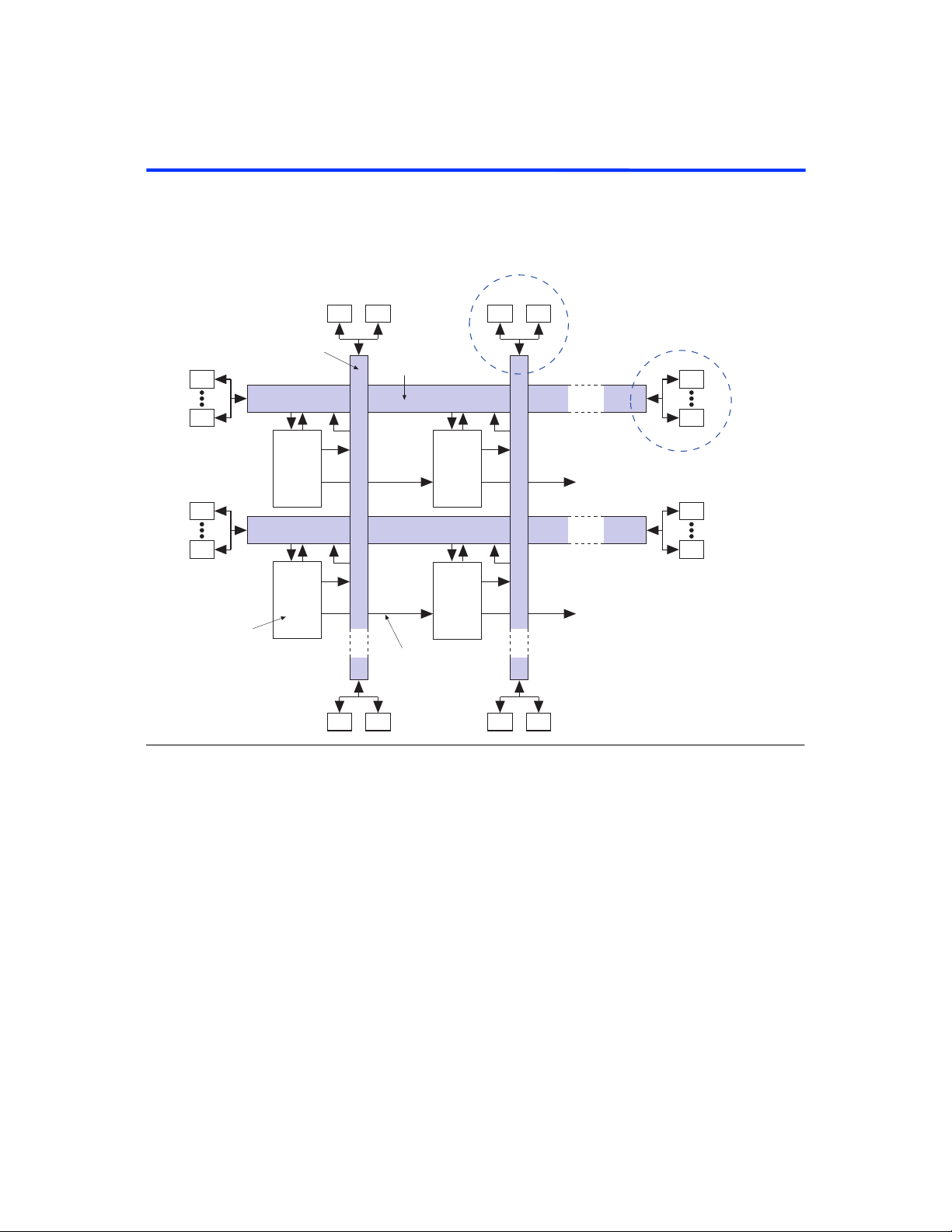

Figure 9 shows the interconnection of four adjacent LABs, with row,

column, and local interconnects, as well as the associated cascade and

carry chains.

Altera Corporation 17

Page 18

FLEX 8000 Programmable Logic Device Family Data Sheet

Figure 9. FLEX 8000 Device Interconnect Resources

Each LAB is named according to its physical row (A, B, C, etc.) and column (1, 2, 3, etc.) position within the device.

See Figure 11

for details.

IOE

1

IOE

8

IOE

1

IOE

8

LAB Local

Interconnect

Column

Interconnect

LAB

A1

LAB

B1

IOEIOE

Row

Interconnect

LAB

A2

LAB

B2

Cascade &

Carry Chain

IOEIOE IOEIOE

IOEIOE

See Figure 10

for details.

IOE

1

IOE

8

IOE

1

IOE

8

I/O Element

An IOE contains a bidirectional I/O buffer and a register that can be used

either as an input register for external data that requires a fast setup time,

or as an output register for data that requires fast clock-to-output

performance. IOEs can be used as input, output, or bidirectional pins. The

MAX+PLUS II Compiler uses the programmable inversion option to

automatically invert signals from the row and column interconnect where

appropriate. Figure 10 shows the IOE block diagram.

18 Altera Corporation

Page 19

Figure 10. FLEX 8000 IOE

Numbers in parentheses are for EPF81500A devices only.

I/O Controls

FLEX 8000 Programmable Logic Device Family Data Sheet

to Row or Column

Interconnect

from Row or Column

Interconnect

6

Programmable

(6)

Inversion

VCC

DQ

Slew-Rate

Control

CLR0

CLR1/OE0

CLK0

CLK1/OE1

OE2

CLRN

VCC

OE3

(OE [4..9])

Row-to-IOE Connections

Figure 11 illustrates the connection between row interconnect channels

and IOEs. An input signal from an IOE can drive two separate row

channels. When an IOE is used as an output, the signal is driven by an

n-to-1 multiplexer that selects the row channels. The size of the

multiplexer varies with the number of columns in a device. EPF81500A

devices use a 27-to-1 multiplexer; EPF81188A, EPF8820A, EPF8636A, and

EPF8452A devices use a 21-to-1 multiplexer; and EPF8282A and

EPF8282AV devices use a 13-to-1 multiplexer. Eight IOEs are connected to

each side of the row channels.

3

FLEX 8000

Altera Corporation 19

Page 20

FLEX 8000 Programmable Logic Device Family Data Sheet

Figure 11. FLEX 8000 Row-to-IOE Connections

Numbers in parentheses are for EPF81500A devices. See Note (1).

2

2

2

2

Each IOE can drive

up to two row

channels.

Row Interconnect

Each IOE is

driven by an

n-to-1

multiplexer.

168

(216)

22

2

2

2

2

2

2

168

(216)

n

n

n

n

n

n

n

n

2

2

2

2

IOE 1

IOE 2

IOE 3

IOE 4

IOE 5

IOE 6

IOE 7

IOE 8

Note:

(1) n = 13 for EPF8282A and EPF8282AV devices.

n = 21 for EPF8452A, EPF8636A, EPF8820A, and EPF81188A devices.

n = 27 for EPF81500A devices.

Column-to-IOE Connections

Two IOEs are located at the top and bottom of the column channels (see

Figure 12). When an IOE is used as an input, it can drive up to two

separate column channels. The output signal to an IOE can choose from 8

of the 16 column channels through an 8-to-1 multiplexer.

20 Altera Corporation

Page 21

FLEX 8000 Programmable Logic Device Family Data Sheet

Figure 12. FLEX 8000 Column-to-IOE Connections

Each IOE is

driven by an

8-to-1

multiplexer.

IOE

8

Column Interconnect

IOE

8

16

Each IOE can drive

up to two column

signals.

In addition to general-purpose I/O pins, FLEX 8000 devices have four

dedicated input pins. These dedicated inputs provide low-skew, devicewide signal distribution, and are typically used for global clock, clear, and

preset control signals. The signals from the dedicated inputs are available

as control signals for all LABs and I/O elements in the device. The

dedicated inputs can also be used as general-purpose data inputs because

they can feed the local interconnect of each LAB in the device.

3

FLEX 8000

Signals enter the FLEX 8000 device either from the I/O pins that provide

general-purpose input capability or from the four dedicated inputs. The

IOEs are located at the ends of the row and column interconnect channels.

I/O pins can be used as input, output, or bidirectional pins. Each I/O pin

has a register that can be used either as an input register for external data

that requires fast setup times, or as an output register for data that

requires fast clock-to-output performance. The MAX+PLUS II Compiler

uses the programmable inversion option to automatically invert signals

from the row and column interconnect when appropriate.

The clock, clear, and output enable controls for the IOEs are provided by

a network of I/O control signals. These signals can be supplied by either

the dedicated input pins or by internal logic. The IOE control-signal paths

are designed to minimize the skew across the device. All control-signal

sources are buffered onto high-speed drivers that drive the signals around

the periphery of the device. This “peripheral bus” can be configured to

provide up to four output enable signals (10 in EPF81500A devices), and

up to two clock or clear signals. Figure 13 shows how two output enable

signals are shared with one clock and one clear signal.

Altera Corporation 21

Page 22

FLEX 8000 Programmable Logic Device Family Data Sheet

The signals for the peripheral bus can be generated by any of the four

dedicated inputs or signals on the row interconnect channels, as shown in

Figure 13. The number of row channels in a row that can drive the

peripheral bus correlates to the number of columns in the FLEX 8000

device. EPF8282A and EPF8282AV devices use 13 channels; EPF8452A,

EPF8636A, EPF8820A, and EPF81188A devices use 21 channels; and

EPF81500A devices use 27 channels. The first LE in each LAB is the source

of the row channel signal. The six peripheral control signals (12 in

EPF81500A devices) can be accessed by each IOE.

Figure 13. FLEX 8000 Peripheral Bus

Numbers in parentheses are for EPF81500A devices.

Programmable

Inversion

Peripheral Control

Signals

Dedicated

Inputs

Row Channels

1

n

Note (1)

4

2

Note:

(1) n = 13 for EPF8282A and EPF8282AV devices.

n = 21 for EPF8452A, EPF8636A, EPF8820A, and EPF81188A devices.

n = 27 for EPF81500A devices.

CLR0

CLR1/OE0

CLK0

CLK1/OE1

OE2

OE3

(OE[4..9])

22 Altera Corporation

Page 23

FLEX 8000 Programmable Logic Device Family Data Sheet

Table 5 lists the source of the peripheral control signal for each FLEX 8000

device by row.

Table 5. Row Sources of FLEX 8000 Peripheral Control Signals

Peripheral

Control Signal

CLK0 Row A Row A Row A Row A Row E Row E

CLK1/OE1 Row B Row B Row C Row C Row B Row B

CLR0 Row A Row A Row B Row B Row F Row F

CLR1/OE0 Row B Row B Row C Row D Row C Row C

OE2 Row A Row A Row A Row A Row D Row A

OE3 Row B Row B Row B Row B Row A Row A

OE4 –––––Row B

OE5 –––––Row C

OE6 –––––Row D

OE7 –––––Row D

OE8 –––––Row E

OE9 –––––Row F

Output

EPF8282A

EPF8282AV

EPF8452A EPF8636A EPF8820A EPF81188A EPF81500A

This section discusses slew-rate control and MultiVolt I/O interface

operation for FLEX 8000 devices.

Configuration

Slew-Rate Control

The output buffer in each IOE has an adjustable output slew rate that can

be configured for low-noise or high-speed performance. A slow slew rate

reduces system noise by slowing signal transitions, adding a maximum

delay of 3.5 ns. The slow slew-rate setting affects only the falling edge of

a signal. The fast slew rate should be used for speed-critical outputs in

systems that are adequately protected against noise. Designers can specify

the slew rate on a pin-by-pin basis during design entry or assign a default

slew rate to all pins on a global basis.

3

FLEX 8000

f

Altera Corporation 23

For more information on high-speed system design, go to Application

Note 75 (High-Speed Board Designs) in this data book.

Page 24

FLEX 8000 Programmable Logic Device Family Data Sheet

MultiVolt I/O Interface

The FLEX 8000 device architecture supports the MultiVolt I/O interface

feature, which allows EPF81500A, EPF81188A, EPF8820A, and EPF8636A

devices to interface with systems with differing supply voltages. These

devices in all packages—except for EPF8636A devices in 84-pin PLCC

packages—can be set for 3.3-V or 5.0-V I/O pin operation. These devices

have one set of VCC pins for internal operation and input buffers

(VCCINT), and another set for I/O output drivers (VCCIO).

The VCCINT pins must always be connected to a 5.0-V power supply. With

a 5.0-V V

compatible with 3.3-V and 5.0-V inputs.

The VCCIO pins can be connected to either a 3.3-V or 5.0-V power supply,

depending on the output requirements. When the VCCIO pins are

connected to a 5.0-V power supply, the output levels are compatible with

5.0-V systems. When the VCCIO pins are connected to a 3.3-V power

supply, the output high is at 3.3 V and is therefore compatible with 3.3-V

or 5.0-V systems. Devices operating with V

incur a nominally greater timing delay of t

on page 26.

level, input voltages are at TTL levels and are therefore

CCINT

levels lower than 4.75 V

CCIO

instead of t

OD2

OD1

. See Table 7

IEEE 1149.1

(JTAG)

Boundary-Scan

The EPF8282A, EPF8282AV, EPF8636A, EPF8820A, and EPF81500A

devices provide JTAG BST circuitry. FLEX 8000 devices with JTAG

circuitry support the JTAG instructions shown in Table 6. Figure 14

shows the timing requirements for the JTAG signals.

Support

Table 6. EPF8282A, EPF8282AV, EPF8636A, EPF8820A & EPF81500A JTAG Instructions

JTAG Instruction Description

SAMPLE/PRELOAD Allows a snapshot of the signals at the device pins to be captured and examined during

normal device operation, and permits an initial data pattern to be output at the device pins.

EXTEST Allows the external circuitry and board-level interconnections to be tested by forcing a test

pattern at the output pins and capturing test results at the input pins.

BYPASS Places the 1-bit bypass register between the TDI and TDO pins, which allows the BST

data to pass synchronously through the selected device to adjacent devices during

normal device operation.

24 Altera Corporation

Page 25

FLEX 8000 Programmable Logic Device Family Data Sheet

Figure 14. EPF8282A, EPF8282AV, EPF8636A, EPF8820A & EPF81500A JTAG

Waveforms

TMS

TDI

t

JCP

JCH

t

JCL

t

JPSU

t

JPH

t

TCK

t

JPZX

t

JPCO

t

JPXZ

TDO

t

JSH

t

JSCO

t

JSXZ

Signal

to Be

Captured

Signal

to Be

Driven

t

JSZX

t

JSSU

Table 7 shows the timing parameters and values for EPF8282A,

EPF8282AV, EPF8636A, EPF8820A, and EPF81500A devices.

3

FLEX 8000

Altera Corporation 25

Page 26

FLEX 8000 Programmable Logic Device Family Data Sheet

Table 7. JTAG Timing Parameters & Values

f

Symbol Parameter EPF8282A

Unit

EPF8282AV

EPF8636A

EPF8820A

EPF81500A

Min Max

t

JCP

t

JCH

t

JCL

t

JPSU

t

JPH

t

JPCO

t

JPZX

t

JPXZ

t

JSSU

t

JSH

t

JSCO

t

JSZX

t

JSXZ

TCK clock period 100 ns

TCK clock high time 50 ns

TCK clock low time 50 ns

JTAG port setup time 20 ns

JTAG port hold time 45 ns

JTAG port clock to output 25 ns

JTAG port high-impedance to valid output 25 ns

JTAG port valid output to high-impedance 25 ns

Capture register setup time 20 ns

Capture register hold time 45 ns

Update register clock to output 35 ns

Update register high-impedance to valid output 35 ns

Update register valid output to high-impedance 35 ns

For detailed information on JTAG operation in FLEX 8000 devices, refer to

Application Note 39 (JTAG Boundary-Scan Testing in Altera Devices).

Generic Testing

Each FLEX 8000 device is functionally tested and specified by Altera.

Complete testing of each configurable SRAM bit and all logic

functionality ensures 100% configuration yield. AC test measurements for

FLEX 8000 devices are made under conditions equivalent to those shown

in Figure 15. Designers can use multiple test patterns to configure devices

during all stages of the production flow.

26 Altera Corporation

Page 27

FLEX 8000 Programmable Logic Device Family Data Sheet

Figure 15. FLEX 8000 AC Test Conditions

Power supply transients can affect AC

measurements. Simultaneous transitions of

multiple outputs should be avoided for

accurate measurement. Threshold tests

must not be performed under AC

conditions.

Large-amplitude, fast-ground-current

transients normally occur as the device

outputs discharge the load capacitances.

When these transients flow through the

parasitic inductance between the device

ground pin and the test system ground,

significant reductions in observable noise

immunity can result. Numbers in

464 Ω

(703 Ω)

Device

Output

250 Ω

(8.06 KΩ)

Device input

rise and fall

times < 3 ns

VCC

to T est

System

C1 (includes

JIG capacitance)

Operating

Conditions

The following tables provide information on absolute maximum ratings,

recommended operating conditions, operating conditions, and

capacitance for 5.0-V and 3.3-V FLEX 8000 devices.

FLEX 8000 5.0-V Device Absolute Maximum Ratings Note (1)

Symbol Parameter Conditions Min Max Unit

V

V

I

T

T

T

OUT

Supply voltage With respect to ground,

CC

DC input voltage –2.0 7.0 V

I

DC output current, per pin –25 25 mA

Storage temperature No bias –65 150 ° C

STG

Ambient temperature Under bias –65 135 ° C

AMB

Junction temperature Ceramic packages, under bias 150 ° C

J

PQFP and RQFP, under bias 135 ° C

Note (2)

–2.0 7.0 V

FLEX 8000 5.0-V Device Recommended Operating Conditions

Symbol Parameter Conditions Min Max Unit

V

V

V

V

T

t

R

t

F

Supply voltage for internal logic and

CCINT

input buffers

Supply voltage for output buffers,

CCIO

5.0-V operation

Supply voltage for output buffers,

3.3-V operation

Input voltage 0 V

I

Output voltage 0 V

O

Operating temperature For commercial use 0 70 ° C

A

Input rise time 40 ns

Input fall time 40 ns

Notes (3), (4)

Notes (3), (4)

Notes (3), (4)

For industrial use –40 85 ° C

4.75 (4.50) 5.25 (5.50) V

4.75 (4.50) 5.25 (5.50) V

3.00 (3.00) 3.60 (3.60) V

CCINT

CCIO

3

FLEX 8000

V

V

Altera Corporation 27

Page 28

FLEX 8000 Programmable Logic Device Family Data Sheet

FLEX 8000 5.0-V Device DC Operating Conditions Notes (5), (6)

Symbol Parameter Conditions Min Typ Max Unit

V

V

V

V

I

I

I

I

OZ

CC0

High-level input voltage 2.0 V

IH

Low-level input voltage –0.3 0.8 V

IL

5.0-V high-level TTL output

OH

voltage

3.3-V high-level TTL output

voltage

3.3-V high-level CMOS output

voltage

5.0-V low-level TTL output voltage IOL = 12 mA DC,

OL

3.3-V low-level TTL output voltage I

3.3-V low-level CMOS output

voltage

IOH = –4 mA DC,

V

= 4.75 V

CCIO

I

= –4 mA DC,

OH

V

= 3.00 V

CCIO

I

= –0.1 mA DC,

OH

V

= 3.00 V

CCIO

V

= 4.75 V

CCIO

= 12 mA DC,

OL

V

= 3.00 V

CCIO

I

= 0.1 mA DC,

OL

V

= 3.00 V

CCIO

Note (7)

Note (7)

Note (7)

Note (7)

Note (7)

Note (7)

2.4 V

2.4 V

V

– 0.2 V

CCIO

Input leakage current VI = VCC or ground –10 10 µA

Tri-state output off-state current VO = VCC or ground –40 40 µA

VCC supply current (standby) VI = ground, no load 0.5 10 mA

+

CCINT

0.3

0.45 V

0.45 V

0.2 V

FLEX 8000 5.0-V Device Capacitance Note (8)

V

Symbol Parameter Conditions Min Max Unit

C

C

28 Altera Corporation

Input capacitance VIN = 0 V, f = 1.0 MHz 10 pF

IN

Output capacitance V

OUT

= 0 V, f = 1.0 MHz 10 pF

OUT

Page 29

FLEX 8000 Programmable Logic Device Family Data Sheet

Notes to tables:

(1) See the Operating Requirements for Altera Devices Data Sheet in this data book.

(2) Minimum DC input is –0.3 V. During transitions, the inputs may undershoot to –2.0 V or overshoot to 7.0 V for

periods shorter than 20 ns under no-load conditions.

(3) The maximum V

(4) Numbers in parentheses are for industrial-temperature-range devices.

(5) Typical values are for T

(6) These values are specified under “FLEX 8000 5.0-V Device Recommended Operating Conditions” on page 27.

(7) The I

parameter refers to high-level TTL or CMOS output current; the IOL parameter refers to low-level TTL or

OH

CMOS output current.

rise time is 100 ms.

CC

= 25° C and VCC = 5.0 V.

A

(8) Capacitance is sample-tested only.

FLEX 8000 3.3-V Device Absolute Maximum Ratings

Note (1)

Symbol Parameter Conditions Min Max Unit

V

V

I

T

T

T

OUT

Supply voltage With respect to ground,

CC

DC input voltage –2.0 5.3 V

I

DC output current, per pin –25 25 mA

Storage temperature No bias –65 150 ° C

STG

Ambient temperature Under bias –65 135 ° C

AMB

Junction temperature Plastic packages, under bias 135 ° C

J

Note (2)

–2.0 5.3 V

FLEX 8000 3.3-V Device Recommended Operating Conditions

Symbol Parameter Conditions Min Max Unit

V

V

V

T

t

R

t

F

Supply voltage

CC

Input voltage 0VCCV

I

Output voltage 0VCCV

O

Operating temperature For commercial use 0 70 ° C

A

Input rise time 40 ns

Input fall time 40 ns

Note (3)

3.0 3.6 V

FLEX 8000 3.3-V Device DC Operating Conditions Note (4)

Symbol Parameter Conditions Min Typ Max Unit

V

V

V

V

I

I

I

I

OZ

CC0

High-level input voltage 2.0 VCC + 0.3 V

IH

Low-level input voltage –0.3 0.8 V

IL

High-level output voltage IOH = –0.1 mA DC,

OH

Low-level output voltage IOL = 4 mA DC,

OL

Input leakage current VI = VCC or ground –10 10 µA

Tri-state output off-state current VO = VCC or ground –40 40 µA

VCC supply current (standby) VI = ground, no load,

Note (5)

Note (5)

Note (6)

VCC – 0.2 V

0.3 10 mA

0.45 V

3

FLEX 8000

Altera Corporation 29

Page 30

FLEX 8000 Programmable Logic Device Family Data Sheet

e

FLEX 8000 3.3-V Device Capacitance Note (7)

Symbol Parameter Conditions Min Max Unit

C

C

Notes to tables:

(1) See the Operating Requirements for Altera Devices Data Sheet in this data book.

(2) Minimum DC input is –0.3 V. During transitions, the inputs may undershoot to –2.0 V or overshoot to 5.3 V for

(3) The maximum V

(4) These values are specified under “FLEX 8000 3.3-V Device Recommended Operating Conditions” on page 29.

(5) The I

(6) Typical values are for T

(7) Capacitance is sample-tested only.

Input capacitance VIN = 0 V, f = 1.0 MHz 10 pF

IN

Output capacitance V

OUT

= 0 V, f = 1.0 MHz 10 pF

OUT

periods shorter than 20 ns under no-load conditions.

rise time is 100 ms. VCC must rise monotonically.

CC

parameter refers to high-level TTL output current; the IOL parameter refers to low-level TTL output current.

OH

= 25° C and VCC = 3.3 V.

A

Figures 16 and 17 show the typical output drive characteristics of 5.0-V

FLEX 8000 devices. The output driver is compliant with the PCI Local Bus

Specification, Revision 2.1.

Figure 16. Output Drive Characteristics of 5.0-V FLEX 8000 Devices (except EPF8282A)

200

200

Output Current (mA) Typ.

O

I

150

100

I

OL

V

= 5.0 V

CCINT

V

= 5.0 V

CCIO

150

100

Room T emperature

I

50

12345

OH

50

Output Current (mA) Typ.

O

I

VO Output Voltage (V)

I

OL

V

= 5.0 V

CCINT

V

= 3.3 V

CCIO

Room Temperatur

I

OH

1234

VO Output Voltage (V)

30 Altera Corporation

Page 31

FLEX 8000 Programmable Logic Device Family Data Sheet

Figure 17. Output Drive Characteristics of EPF8282A Devices with 5.0-V V

150

120

I

OL

CCIO

VCC = 5.0 V

Room Temperature

90

I

OH

Output Current (mA) Typ.

O

I

60

30

12345

VO Output Voltage (V)

Figure 18 shows the typical output drive characteristics of EPF8282AV

devices.

Figure 18. Output Drive Characteristics of EPF8282AV Devices

100

3

FLEX 8000

I

75

50

OL

VCC = 3.3 V

Room Temperature

I

OH

Output Current (mA) Typ.

O

I

25

1234

VO Output Voltage (V)

Altera Corporation 31

Page 32

FLEX 8000 Programmable Logic Device Family Data Sheet

Timing Model

The continuous, high-performance FastTrack Interconnect routing

structure ensures predictable performance and accurate simulation and

timing analysis. This predictable performance contrasts with that of

FPGAs, which use a segmented connection scheme and hence have

unpredictable performance. Timing simulation and delay prediction are

available with the MAX+PLUS II Simulator and Timing Analyzer, or with

industry-standard EDA tools. The Simulator offers both pre-synthesis

functional simulation to evaluate logic design accuracy and postsynthesis timing simulation with 0.1-ns resolution. The Timing Analyzer

provides point-to-point timing delay information, setup and hold time

prediction, and device-wide performance analysis.

Tables 8 through 11 describe the FLEX 8000 timing parameters and their

symbols.

Table 8. FLEX 8000 Internal Timing Parameters Note (1)

Symbol Parameter

t

IOD

t

IOC

t

IOE

t

IOCO

t

IOCOMB

t

IOSU

t

IOH

t

IOCLR

t

IN

t

OD1

t

OD2

t

OD3

t

XZ

t

ZX1

t

ZX2

t

ZX3

IOE register data delay

IOE register control signal delay

Output enable delay

IOE register clock-to-output delay

IOE combinatorial delay

IOE register setup time before clock; IOE register recovery time after asynchronous clear

IOE register hold time after clock

IOE register clear delay

Input pad and buffer delay

Output buffer and pad delay, slow slew rate = off, V

Output buffer and pad delay, slow slew rate = off, V

Output buffer and pad delay, slow slew rate = on, C1 = 35 pF,

Output buffer disable delay, C1 = 5 pF

Output buffer enable delay, slow slew rate = off, V

Output buffer enable delay, slow slew rate = off, V

CCIO

CCIO

Output buffer enable delay, slow slew rate = on, C1 = 35 pF,

= 5.0 V, C1 = 35 pF,

CCIO

= 3.3 V, C1 = 35 pF,

CCIO

Note (3)

= 5.0 V, C1 = 35 pF,

= 3.3 V, C1 = 35 pF,

Note (3)

Note (2)

Note (2)

Note (2)

Note (2)

32 Altera Corporation

Page 33

FLEX 8000 Programmable Logic Device Family Data Sheet

Table 9. FLEX 8000 LE Timing Parameters Note (1)

Symbol Parameter

t

LUT

t

CLUT

t

RLUT

t

GATE

t

CASC

t

CICO

t

CGEN

t

CGENR

t

C

t

CH

t

CL

t

CO

t

COMB

t

SU

t

H

t

PRE

t

CLR

LUT delay for data-in

LUT delay for carry-in

LUT delay for LE register feedback

Cascade gate delay

Cascade chain routing delay

Carry-in to carry-out delay

Data-in to carry-out delay

LE register feedback to carry-out delay

LE register control signal delay

LE register clock high time

LE register clock low time

LE register clock-to-output delay

Combinatorial delay

LE register setup time before clock; LE register recovery time after asynchronous preset, clear, or load

LE register hold time after clock

LE register preset delay

LE register clear delay

3

FLEX 8000

Table 10. FLEX 8000 Interconnect Timing Parameters Note (1)

Symbol Parameter

t

LABCASC

t

LABCARRY

t

LOCAL

t

ROW

t

COL

t

DIN_C

t

DIN_D

t

DIN_IO

Cascade delay between LEs in different LABs

Carry delay between LEs in different LABs

LAB local interconnect delay

Row interconnect routing delay,

Note (4)

Column interconnect routing delay

Dedicated input to LE control delay

Dedicated input to LE data delay,

Note (4)

Dedicated input to IOE control delay

Table 11. FLEX 8000 External Reference Timing Characteristics Note (5)

Symbol Parameter

t

DRR

t

ODH

Altera Corporation 33

Register-to-register delay via 4 LEs, 3 row interconnects, and 4 local interconnects,

Output data hold time after clock,

Note (7)

Note (6)

Page 34

FLEX 8000 Programmable Logic Device Family Data Sheet

Notes to tables:

(1) Internal timing parameters cannot be measured explicitly. They are worst-case delays based on testable and

external parameters specified by Altera. Internal timing parameters should be used for estimating device

performance. Post-compilation timing simulation or timing analysis is required to determine actual worst-case

performance.

(2) These values are specified under “FLEX 8000 3.3-V Device Recommended Operating Conditions” on page 29.

(3) For the t

(4) The t

timing analysis is required to determine actual worst-case performance.

(5) External reference timing characteristics are factory-tested, worst-case values specified by Altera. A representative

subset of signal paths is tested to approximate typical device applications.

(6) For more information on test conditions, see Application Note 76 (Understanding FLEX 8000 Timing) in this data book.

(7) This parameter is a guideline that is sample-tested only and is based on extensive device characterization. This

parameter applies to global and non-global clocking, and for LE and I/O element registers.

ROW

OD3

and t

and t

DIN_D

parameters, V

ZX3

delays are worst-case values for typical applications. Post-compilation timing simulation or

= 3.3 V or 5.0 V.

CCIO

The FLEX 8000 timing model shows the delays for various paths and

functions in the circuit. See Figure 19. This model contains three distinct

parts: the LE; the IOE; and the interconnect, including the row and column

FastTrack Interconnect, LAB local interconnect, and carry and cascade

interconnect paths. Each parameter shown in Figure 19 is expressed as a

worst-case value in the “Timing Parameters” tables in this data sheet.

Hand-calculations that use the FLEX 8000 timing model and these timing

parameters can be used to estimate FLEX 8000 device performance.

Timing simulation or timing analysis after compilation is required to

determine the final worst-case performance. Table 12 summarizes the

interconnect paths shown in Figure 19.

f

For more information on timing parameters, go to Application Note 76

(Understanding FLEX 8000 Timing) in this data book.

Table 12. FLEX 8000 Timing Model Interconnect Paths

Source Destination Total Delay

LE-Out LE in same LAB

LE-Out LE in same row, different LAB

LE-Out LE in different row

LE-Out IOE on column

LE-Out IOE on row

IOE on row LE in same row

IOE on column Any LE

34 Altera Corporation

t

LOCAL

t

ROW

t

COL

t

COL

t

ROW

t

ROW

t

COL

+ t

+ t

+ t

+ t

LOCAL

ROW

LOCAL

ROW

+ t

+ t

LOCAL

LOCAL

Page 35

Figure 19. FLEX 8000 Timing Model

I/O Pin

IOE

FLEX 8000 Programmable Logic Device Family Data Sheet

ROW

t

Output

I/O Register

Output Data

LE

Register

Cascade

OD1tOD2tOD3tXZtZX1tZX2tZX3

t

Delays

IOCOtIOCOMBtIOSUtIOHtIOCLR

Delays

t

IOD

t

Delay

LE-Out

tCOt

Delays

GATE

t

Gate Delay

Control

I/O Register

COMBtSUtHtPREtCLR

IOCtIOE

t

COL

t

Input

Delay

IN

t

Data-In

Cascade

Routing Delay

CASC

t

LABCASC

t

Cascade-Out

to Next LE in

Same LAB

Cascade-Out

to Next LE in

Next LAB

3

FLEX 8000

Carry-Out

to Next LE

in Next

Carry-Out

to Next LE

in Same

LAB

LAB

Cascade-In from

Previous LE

Carry-In from

Previous LE

LUT Delay

LABCARRY

t

C

Delay

CGEN

RLUT

LUT

CLUT

t

t

t

t

Carry Chain

LOCAL

t

CGENRtCICO

t

Control

Register

t

DIN_D

DIN_CtDIN_IO

t

t

Dedicated

Input Delays

Altera Corporation 35

Page 36

FLEX 8000 Programmable Logic Device Family Data Sheet

EPF8282A Internal Timing Parameters

EPF8282A I/O Element Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

IOD

t

IOC

t

IOE

t

IOCO

t

IOCOMB

t

IOSU

t

IOH

t

IOCLR

t

IN

t

OD1

t

OD2

t

OD3

t

XZ

t

ZX1

t

ZX2

t

ZX3

1.4 1.6 1.8 ns

0.0 0.0 0.0 ns

0.7 0.8 0.9 ns

1.7 1.8 1.9 ns

1.7 1.8 1.9 ns

1.0 1.0 1.0 ns

0.3 0.2 0.1 ns

1.2 1.2 1.2 ns

1.5 1.6 1.7 ns

1.1 1.4 1.7 ns

–––ns

4.6 4.9 5.2 ns

1.4 1.6 1.8 ns

1.4 1.6 1.8 ns

–––ns

4.9 5.1 5.3 ns

Unit

EPF8282A Interconnect Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max Min Max

t

LABCASC

t

LABCARRY

t

LOCAL

t

ROW

t

COL

t

DIN_C

t

DIN_D

t

DIN_IO

36 Altera Corporation

0.3 0.3 0.4 ns

0.3 0.3 0.4 ns

0.5 0.6 0.8 ns

4.2 4.2 4.2 ns

2.5 2.5 2.5 ns

5.0 5.0 5.5 ns

7.2 7.2 7.2 ns

5.0 5.0 5.5 ns

Page 37

EPF8282A LE Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

LUT

t

CLUT

t

RLUT

t

GATE

t

CASC

t

CICO

t

CGEN

t

CGENR

t

C

t

CH

t

CL

t

CO

t

COMB

t

SU

t

H

t

PRE

t

CLR

4.0 4.0 4.0 ns

4.0 4.0 4.0 ns

0.8 1.1 1.2 ns

0.9 1.1 1.5 ns

FLEX 8000 Programmable Logic Device Family Data Sheet

Unit

2.0 2.5 3.2 ns

0.0 0.0 0.0 ns

0.9 1.1 1.5 ns

0.0 0.0 0.0 ns

0.6 0.7 0.9 ns

0.4 0.5 0.6 ns

0.4 0.5 0.7 ns

0.9 1.1 1.5 ns

1.6 2.0 2.5 ns

0.4 0.5 0.6 ns

0.4 0.5 0.6 ns

3

FLEX 8000

0.6 0.7 0.8 ns

0.6 0.7 0.8 ns

EPF8282A External Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max Min Max

t

DRR

t

ODH

1.0 1.0 1.0 ns

Altera Corporation 37

15.8 19.8 24.8 ns

Page 38

FLEX 8000 Programmable Logic Device Family Data Sheet

EPF8282AV Internal Timing Parameters

EPF8282AV I/O Element Timing Parameters

Symbol

A-3 Speed Grade A-4 Speed Grade

Min Max Min Max

t

IOD

t

IOC

t

IOE

t

IOCO

t

IOCOMB

t

IOSU

t

IOH

t

IOCLR

t

IN

t

OD1

t

OD2

t

OD3

t

XZ

t

ZX1

t

ZX2

t

ZX3

1.8 2.8 ns

0.0 0.2 ns

0.9 2.2 ns

1.9 2.0 ns

1.9 2.0 ns

1.0 2.0 ns

0.1 0.0 ns

1.2 2.3 ns

1.7 3.4 ns

1.7 4.1 ns

––ns

5.2 7.1 ns

1.8 4.3 ns

1.8 4.3 ns

––ns

5.3 8.3 ns

EPF8282AV Interconnect Timing Parameters

Unit

Symbol

A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max

t

LABCASC

t

LABCARRY

t

LOCAL

t

ROW

t

COL

t

DIN_C

t

DIN_D

t

DIN_IO

38 Altera Corporation

0.4 1.3 ns

0.4 0.8 ns

0.8 1.5 ns

4.2 6.3 ns

2.5 3.8 ns

5.5 8.0 ns

7.2 10.8 ns

5.5 9.0 ns

Page 39

FLEX 8000 Programmable Logic Device Family Data Sheet

EPF8282AV Logic Element Timing Parameters

Symbol

A-3 Speed Grade A-4 Speed Grade

Min Max Min Max

t

LUT

t

CLUT

t

RLUT

t

GATE

t

CASC

t

CICO

t

CGEN

t

CGENR

t

C

t

CH

t

CL

t

CO

t

COMB

t

SU

t

H

t

PRE

t

CLR

4.0 6.0 ns

4.0 6.0 ns

1.2 2.4 ns

1.5 4.6 ns

3.2 7.3 ns

0.0 1.4 ns

1.5 5.1 ns

0.0 0.0 ns

0.9 2.8 ns

0.6 1.5 ns

0.7 2.2 ns

1.5 3.7 ns

2.5 4.7 ns

0.6 0.9 ns

0.6 0.9 ns

0.8 1.3 ns

0.8 1.3 ns

EPF8282AV External Timing Parameters

Unit

3

FLEX 8000

Symbol

A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max

t

DRR

t

ODH

1.0 1.0 ns

Altera Corporation 39

24.8 50.1 ns

Page 40

FLEX 8000 Programmable Logic Device Family Data Sheet

EPF8452A Internal Timing Parameters

EPF8452A I/O Element Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

IOD

t

IOC

t

IOE

t

IOCO

t

IOCOMB

t

IOSU

t

IOH

t

IOCLR

t

IN

t

OD1

t

OD2

t

OD3

t

XZ

t

ZX1

t

ZX2

t

ZX3

1.4 1.6 1.8 ns

0.0 0.0 0.0 ns

0.7 0.8 0.9 ns

1.7 1.8 1.9 ns

1.7 1.8 1.9 ns

1.0 1.0 1.0 ns

0.3 0.2 0.1 ns

1.2 1.2 1.2 ns

1.5 1.6 1.7 ns

1.1 1.4 1.7 ns

–––ns

4.6 4.9 5.2 ns

1.4 1.6 1.8 ns

1.4 1.6 1.8 ns

–––ns

4.9 5.1 5.3 ns

Unit

EPF8452A Interconnect Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max Min Max

t

LABCASC

t

LABCARRY

t

LOCAL

t

ROW

t

COL

t

DIN_C

t

DIN_D

t

DIN_IO

40 Altera Corporation

0.3 0.4 0.4 ns

0.3 0.4 0.4 ns

0.5 0.5 0.7 ns

5.0 5.0 5.0 ns

3.0 3.0 3.0 ns

5.0 5.0 5.5 ns

7.0 7.0 7.5 ns

5.0 5.0 5.5 ns

Page 41

EPF8452A LE Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

LUT

t

CLUT

t

RLUT

t

GATE

t

CASC

t

CICO

t

CGEN

t

CGENR

t

C

t

CH

t

CL

t

CO

t

COMB

t

SU

t

H

t

PRE

t

CLR

4.0 4.0 4.0 ns

4.0 4.0 4.0 ns

0.8 1.0 1.1 ns

0.9 1.1 1.4 ns

FLEX 8000 Programmable Logic Device Family Data Sheet

Unit

2.0 2.3 3.0 ns

0.0 0.2 0.1 ns

0.9 1.6 1.6 ns

0.0 0.0 0.0 ns

0.6 0.7 0.9 ns

0.4 0.5 0.6 ns

0.4 0.9 0.8 ns

0.9 1.4 1.5 ns

1.6 1.8 2.4 ns

0.4 0.5 0.6 ns

0.4 0.5 0.6 ns

3

FLEX 8000

0.6 0.7 0.8 ns

0.6 0.7 0.8 ns

EPF8452A External Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max Min Max

t

DRR

t

ODH

1.0 1.0 1.0 ns

Altera Corporation 41

16.0 20.0 25.0 ns

Page 42

FLEX 8000 Programmable Logic Device Family Data Sheet

EPF8636A Internal Timing Parameters

EPF8636A I/O Element Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

IOD

t

IOC

t

IOE

t

IOCO

t

IOCOMB

t

IOSU

t

IOH

t

IOCLR

t

IN

t

OD1

t

OD2

t

OD3

t

XZ

t

ZX1

t

ZX2

t

ZX3

1.4 1.6 1.8 ns

0.0 0.0 0.0 ns

0.7 0.8 0.9 ns

1.7 1.8 1.9 ns

1.7 1.8 1.9 ns

1.0 1.0 1.0 ns

0.3 0.2 0.1 ns

1.2 1.2 1.2 ns

1.5 1.6 1.7 ns

1.1 1.4 1.7 ns

1.6 1.9 2.2 ns

4.6 4.9 5.2 ns

1.4 1.6 1.8 ns

1.4 1.6 1.8 ns

1.9 2.1 2.3 ns

4.9 5.1 5.3 ns

Unit

EPF8636A Interconnect Timing Parameters

Symbol

A-2 Speed Grade

A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max Min Max

t

LABCASC

t

LABCARRY

t

LOCAL

t

ROW

t

COL

t

DIN_C

t

DIN_D

t

DIN_IO

42 Altera Corporation

0.3 0.4 0.4 ns

0.3 0.4 0.4 ns

0.5 0.5 0.7 ns

5.0 5.0 5.0 ns

3.0 3.0 3.0 ns

5.0 5.0 5.5 ns

7.0 7.0 7.5 ns

5.0 5.0 5.5 ns

Page 43

EPF8636A LE Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

LUT

t

CLUT

t

RLUT

t

GATE

t

CASC

t

CICO

t

CGEN

t

CGENR

t

C

t

CH

t

CL

t

CO

t

COMB

t

SU

t

H

t

PRE

t

CLR

4.0 4.0 4.0 ns

4.0 4.0 4.0 ns

0.8 1.0 1.1 ns

0.9 1.1 1.4 ns

FLEX 8000 Programmable Logic Device Family Data Sheet

Unit

2.0 2.3 3.0 ns

0.0 0.2 0.1 ns

0.9 1.6 1.6 ns

0.0 0.0 0.0 ns

0.6 0.7 0.9 ns

0.4 0.5 0.6 ns

0.4 0.9 0.8 ns

0.9 1.4 1.5 ns

1.6 1.8 2.4 ns

0.4 0.5 0.6 ns

0.4 0.5 0.6 ns

3

FLEX 8000

0.6 0.7 0.8 ns

0.6 0.7 0.8 ns

EPF8636A External Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max Min Max

t

DRR

t

ODH

1.0 1.0 1.0 ns

Altera Corporation 43

16.0 20.0 25.0 ns

Page 44

FLEX 8000 Programmable Logic Device Family Data Sheet

EPF8820A Internal Timing Parameters

EPF8820A I/O Element Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

IOD

t

IOC

t

IOE

t

IOCO

t

IOCOMB

t

IOSU

t

IOH

t

IOCLR

t

IN

t

OD1

t

OD2

t

OD3

t

XZ

t

ZX1

t

ZX2

t

ZX3

1.4 1.6 1.8 ns

0.0 0.0 0.0 ns

0.7 0.8 0.9 ns

1.7 1.8 1.9 ns

1.7 1.8 1.9 ns

1.0 1.0 1.0 ns

0.3 0.2 0.1 ns

1.2 1.2 1.2 ns

1.5 1.6 1.7 ns

1.1 1.4 1.7 ns

1.6 1.9 2.2 ns

4.6 4.9 5.2 ns

1.4 1.6 1.8 ns

1.4 1.6 1.8 ns

1.9 2.1 2.3 ns

4.9 5.1 5.3 ns

Unit

EPF8820A Interconnect Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max Min Max

t

LABCASC

t

LABCARRY

t

LOCAL

t

ROW

t

COL

t

DIN_C

t

DIN_D

t

DIN_IO

44 Altera Corporation

0.3 0.3 0.4 ns

0.3 0.3 0.4 ns

0.5 0.6 0.8 ns

5.0 5.0 5.0 ns

3.0 3.0 3.0 ns

5.0 5.0 5.5 ns

7.0 7.0 7.5 ns

5.0 5.0 5.5 ns

Page 45

EPF8820A LE Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

LUT

t

CLUT

t

RLUT

t

GATE

t

CASC

t

CICO

t

CGEN

t

CGENR

t

C

t

CH

t

CL

t

CO

t

COMB

t

SU

t

H

t

PRE

t

CLR

4.0 4.0 4.0 ns

4.0 4.0 4.0 ns

0.8 1.1 1.2 ns

0.9 1.1 1.5 ns

FLEX 8000 Programmable Logic Device Family Data Sheet

Unit

2.0 2.5 3.2 ns

0.0 0.0 0.0 ns

0.9 1.1 1.5 ns

0.0 0.0 0.0 ns

0.6 0.7 0.9 ns

0.4 0.5 0.6 ns

0.4 0.5 0.7 ns

0.9 1.1 1.5 ns

1.6 2.0 2.5 ns

0.4 0.5 0.6 ns

0.4 0.5 0.6 ns

3

FLEX 8000

0.6 0.7 0.8 ns

0.6 0.7 0.8 ns

EPF8820A External Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Unit

Min Max Min Max Min Max

t

DRR

t

ODH

1.0 1.0 1.0 ns

Altera Corporation 45

16.0 20.0 25.0 ns

Page 46

FLEX 8000 Programmable Logic Device Family Data Sheet

EPF81188A Internal Timing Parameters

EPF81188A I/O Element Timing Parameters

Symbol

A-2 Speed Grade A-3 Speed Grade A-4 Speed Grade

Min Max Min Max Min Max

t

IOD

t

IOC

t

IOE

t

IOCO

t

IOCOMB

t

IOSU

t

IOH

t

IOCLR

t

IN

t

OD1

t

OD2

t

OD3

t

XZ

t

ZX1

t

ZX2

t

ZX3

1.4 1.6 1.8 ns

0.0 0.0 0.0 ns

0.7 0.8 0.9 ns

1.7 1.8 1.9 ns

1.7 1.8 1.9 ns

1.0 1.0 1.0 ns

0.3 0.2 0.1 ns

1.2 1.2 1.2 ns

1.5 1.6 1.7 ns

1.1 1.4 1.7 ns

1.6 1.9 2.2 ns

4.6 4.9 5.2 ns

1.4 1.6 1.8 ns

1.4 1.6 1.8 ns

1.9 2.1 2.3 ns

4.9 5.1 5.3 ns

Unit

EPF81188A Interconnect Timing Parameters

Symbol