Additives & Instruments

A member of

Measure what you see.

micro-gloss

Manual

micro-gloss

Manual

Patent pending 260 020 398 E 1008

BYK-Gardner GmbH

Lausitzer Str. 8

D-825 38 Geretsried

Germany

Tel. 0-800-gardner

(0-800-4273637)

+49-8171-3493-0

Fax +49-8171-3493-140

www.byk.com/instruments

BYK - Ga rdner U SA

9104 Guilford Road

Columbia, MD 21046

USA

Phone 800-343-7721

301-483-6500

Fax 800-394-8215

301-483-6555

1

Dear customer,

thank you for having decided for a BYK-Gardn er

product. BYK-Gardner is committed to providing you

with quality products and services. We offer

complete system solutions to solve your problems

in areas of gloss and physical properties. As the

basis of our worldwide business , we strongly believe

in total customer satisfaction. Therefore, in addition

to our products, we offer many VALUE-ADDED

services:

· T echnical Sales Force

· T e chnical & Application Support

· Application and Technical Seminars

· Repair & Certification Service

BYK-Gardner is part of Altana AG and a direct

subsidiary of BYK-Chemie GmbH, a leading supplier

of additives for coatings and plastics. T ogether, we

offer complete and unique solutions for you, our

customer.

Thank you for your trust and confidence. If there is

anything we can do better to serve your needs, do

not hesitate to let us know.

Y our BYK-Gar dner Team

2

Table of content

T able of con tent

1. Syste m descr iption and De livery notes ............................................ 7

2. Power s upply..................................................................................... 9

2.1 Power supp ly ba tte ry-op e ra te d .................................................................. 9

2.2 Changing the battery ................................................................................. 10

2.3 External power supply .............................................................................. 10

3. Co n trols............................................................................................. 1 1

4. Getti ng st art ed ..................................................................................13

4.1 T urning on the unit and measuring ......................................................... 13

4.2 Navi gation ................................................................................................... 14

4.3 Change names/numbers .......................................................................... 15

4.4 Overview of main menu ............................................................................ 16

5. Calibrate ...........................................................................................17

5.1 Autodi agnosis ............................................................................................ 17

5.2 Calibrate ..................................................................................................... 18

5.2.1 Gloss ............................................................................................... 18

5.2.2 Thic kness (mic ro-T RI-gloss µ o nly) .............................................. 18

5.2.3 Ch ange cal.valu es .......................................................................... 19

5.2.4 Statu s ............................................................................................... 2 0

5.2.5 Sc ale Glos s ..................................................................................... 21

5.2.6 Sc ale Thic kness ............................................................................. 2 1

5.3 Calibrating standards ............................................................................... 22

5.4 Checking standard .................................................................................... 22

English

6. Meas ureme nt te chniques.................................................................23

6.1 Paints and v a rnishes , plastic s and similar materials .......................... 23

6.2 Anodized aluminum and other metal surfaces ..................................... 24

6.3 Measuremen t of film th ick nes s .............................................................. 2 5

7. Meas urement Mode s ........................................................................26

7.1 Sample mode ............................................................................................. 26

7.2 Statistics..................................................................................................... 2 7

7.2.1 Nu mber of me asu rements ....................................................................... 28

7.2.2 Display ......................................................................................................... 2 9

3

T able of con tent

7.2.3 Exit block .....................................................................................................30

8.2.4 Delete block ................................................................................................30

8.2.5 De lete meas urement ................................................................................. 3 0

7.3 Continuous ........................................................................................ 31

7.4 Basic mode.......................................................................................32

8 Geometr y/S ens or..............................................................................33

8.1 Geometry selection ....................................................................................33

8.2 Thickness Sensor selection ..................................................................... 33

8.3 Sensor-set ting Combi

......................................................................................................................34

9. Memory.............................................................................................3 5

9.1 Memory ........................................................................................................35

9.2 Se lect memory ........................................................................................... 35

9.3 Cre ate memory ........................................................................................... 3 6

9.4 De lete me mory ...........................................................................................3 6

9.5 Display memory ..........................................................................................36

10. Difference measurement and Pass/Fail ..........................................38

10.1 Difference ....................................................................................................38

10. 2 Measu re standard ...................................................................................... 38

10. 3 Se lect sta ndard .......................................................................................... 3 9

10. 4 Create standa rd .......................................................................................... 4 0

Define standard ....................................................................................................40

10.5 Change standard ........................................................................................41

10. 6 Delete s tan d a rd ..........................................................................................41

11. Setup................................................................................................. 42

11.1 Bluetooth®...................................................................................................42

11.2 Date/T ime .....................................................................................................42

11.3 Bee p e r..........................................................................................................42

11.4 Display time .................................................................................................42

11.5 Language .....................................................................................................43

11.6 Info................................................................................................................43

4

T able of con tent

12 . Interface............................................................................................44

12.1 Installation .................................................................................................. 45

13 . Stan dard s..........................................................................................4 6

14. Technical data ..................................................................................48

15 . Errors and wa rning m essa ges..........................................................50

16. Cleaning and maintenance ............................................................. 52

17. Service and Certification ................................................................53

Service ................................................................................................................. 53

Service Centers for BYK-Gardner products .................................................... 54

18 . Cop y r i g ht ..........................................................................................55

5

System description and Delivery notes

1. Sy stem descr iption an d Deli v er y notes

Measurement units of the micro-gloss family can be

used to determine the gloss level of paint coatings,

plastics, ceramics and metal surfaces. The microTRI-gloss µ additionally allows to measure the film

thickness of paint and coatings on magnetic (Fe)

and non-magnetic base metals (NFe).

Light is directed at the surface of the sample at a

defined angle and the reflected light is measured

photoelectrically (reflectometer).

Depending on the typical gloss level of the test

object, reflectometers that direct light onto the

surface at different angles (geometry) can be used.

Measurement units are equipped w ith standard

geometries of 20°, 60° or 85°. All three of these

geometries are integrated into th e micro-TRI-gloss.

Functions described in this manual in terms of

geometry selection are only available with the three

angle device.

In addition to measuring individual gloss values, it is

also possible to record, save and statistically

evaluate series of measurements consisting of up to

999 values.

The operate button and scroll wheel are used to

control the system. System operation is supported

by display messages (autodiagnosis and error

messages).

The measurement unit conforms to the standards

DIN 67530, ISO 2813, ASTM D 523 and BS 3900

Part D 5.

6

System description and Delivery notes

Instrument type:

micro-gloss 20° 4440

micro-gloss 60° 4442

micro-gloss 85° 4444

micro-gloss 45° 4454

micro-gloss 75° 4456

micro-TRI-gloss 4446

micro-TRI-gloss µ 4448

micro-gloss 60° S 4450

micro-TRI-gloss S 4452

Comes complete with:

Measurement device, Protective holder with

integrated calibration tile, Traceable certificate,

Software easy-link and USB driver on CD, USBcable, Bluetooth® adapter w ith driver on CD,

Operating manual on CD, Quick user guide and

Safety instructions, Battery, Carrying case.

micro-TRI-gloss µ delivery includes additionally

Fe and NFe zero standards.

7

System description and Delivery notes

Recommended acce ssories:

Checking standards for control of test equipment

for micro-gloss 20° 4422

for micro-gloss 60° 4462

for micro-gloss 85° 4487

for micro-gloss 45° 4458

for micro-gloss 75° 4459

for micro-TRI-gloss 4434

and micro-TRI-gloss µ

micro-gloss 60° S 4464

micro-TRI-gloss S 4438

mirror typ e, hi ghly re flective 4433

for 20°, 60° and 85°

8

2. Power supply

Before operating the instrument for the first time,

please read the operating instructions and pay

attention to the safety instructions in Chapter 1.

Unpack the device and check to make certain all

pieces ha ve been included w ith delivery (for scope of

delivery, see Section Delivery notes).

2.1 Power supply battery-operated

The battery must be placed in the measuring unit for

operation service. The device runs on one AA 1.5-V

alkaline or 1.2-V NiMH rechargeable battery .

Use only alkaline batteries or NiMH

rechargeables (AA /LR6)!

Depending on the exact brand, the capacity of each

battery is sufficient for about 10,000 measurements.

When the battery voltage falls below the required

minimum voltage in the course of ope ration, the

following message ap pears on the display

T o ensure that the unit is always ready for operation,

it is recommended to have a spare battery handy,

especially when p erforming measurements in the

field.

Power sup ply

Battery low!

9

Power sup ply

2.2 Changing t he batt ery

T o insert or change the battery open the battery

compartment. The easiest way to do this is by

turning the cover with a coin one-eighth of a rotation

to the left. Turn the device back around and allow

the old battery and the battery compartment cover

to slide into your hand.

Insert the new battery with the positive (top) end first

into the battery compartment and set the battery

Changing the ba ttery

2.3 External power supply

compartment cover in place again. Lock the cover

by turning it one-eighth of a rotation to the right.

The instrument can be operated and supplied at a

computer via USB-port. For the connection to the

PC use the USB- cable included in the delivery.

10

Please refer to the chapter Interface for installation

of the required software and drivers.

For power supply specification note the technical

data.

3. Controls

1

7

6

Contr ols

2

3

4

5

Measu rement unit and pr otective holder

1 Mode scroll wheel: used to turn the unit on and for menu selection

2 Display for user guidance and dis playing measurement values

3 Sign al lamp:

green: measurement active

red: error

green flashing: Blueto oth® connection active

4 Operate bu tton: used to activate measureme nts

5 Prote ctive holder with integrated calibration s tandard

6 Mark for the measurement aperture

7 USB interface for connecting to a PC

11

Contr ols

The basic system consists of the measuring device

and the p rotective holder .

The protective holder is used for calibration and to

store the measurement unit. Calibration is

performed inside the holder automatically at the

touch of a button. The gloss standard required for

this purpose is kept in the holder and is positioned

in such a manner that calibration is always

performed at the same point.

When the device is turned on inside the holder, it

performs a self-test (autodiagnosis ).

If you will not be using the measuring unit, please

store it in the protective holder. In this way the

measurement optics are protected from dirt and

dust and the calibration standard is always readily

available.

The operate button and scroll wheel are used to

control the system. Pressing the wheel turns the

unit on and causes a menu to be displayed. All

settings within the menus are made by turning and

pressing the wheel.

12

Pressing the operate button starts measurements or

performs functions that are displayed. In addition,

you can return from the various menus to mode with

the operate button. System operation is supported

by an autodiagnosis test, comments and error

messages. Meas urement values and comments

appear in the display.

4. Ge tting st arted

4.1 T ur ning on the unit a nd mea suring

T o turn on the unit, press the mode scroll wheel.

Information on the date and last certification appears

in the display. If the device was turned on in its

holder, the autodiagnosis test is performed (see the

section on Calibration).

Then the unit switches into the last measurement

mode to be selected.

Pressing operate initiates measurements.

The display of measurement results on the screen

may be broken down into the following elements:

A: When Difference meas urement is turned o n,

the name of the standard that is selected is

displayed here.

B: If Memory is selected, the memory area that

is selected appears at the top left and for

C: the sample name (block name).

D: If Statistics or Continuous is turned on, the

number of measurements performed or selected is

displayed here.

The measurement values appear in the lower part of

the display area. The size of the numbers depends

on whe ther St atistics or Difference measurement

has been activated and on the number of geometries

displayed. Depending on the measu rement mode, a

header line also appea rs for the measurement

values.

Getting started

13

Getting started

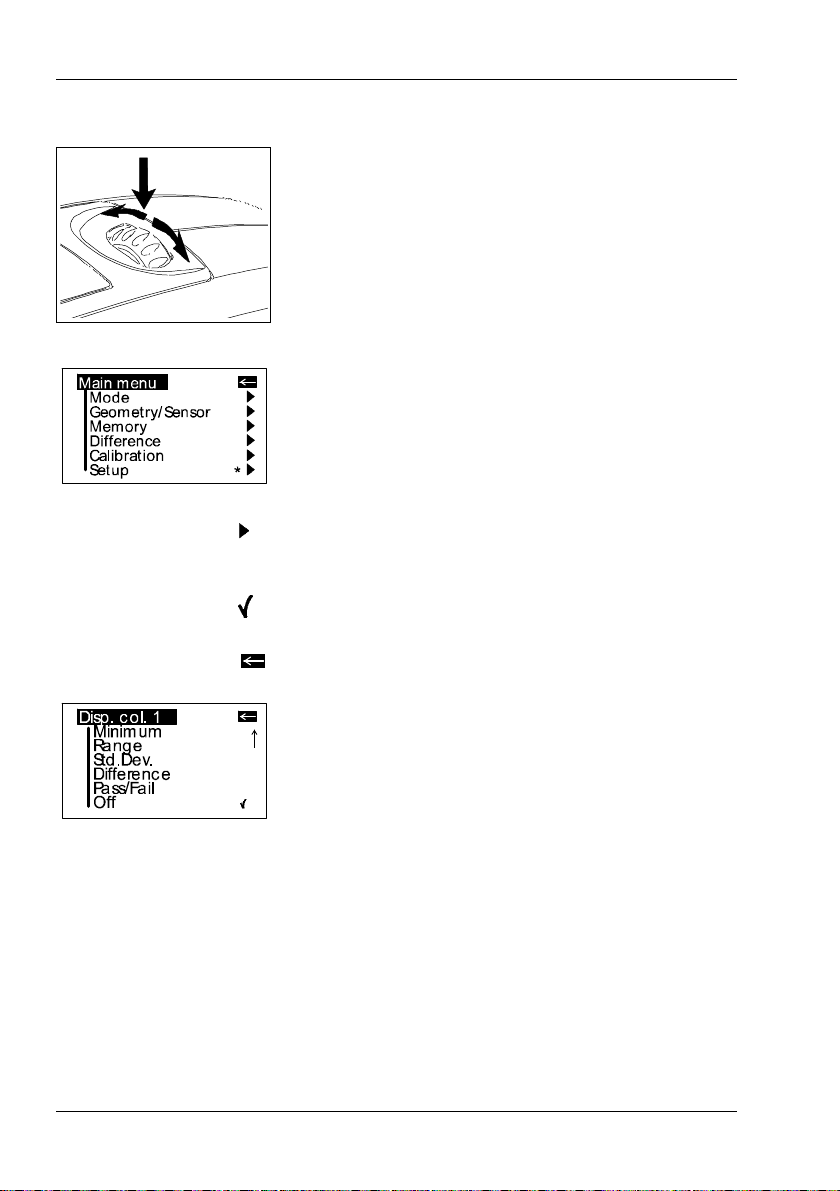

4.2 Nav iga tion

All control functions are controlled by the mode

scroll wheel. Pressing the wheel causes a menu to

appear in the display. Turning the wheel allows you

to move the black mark to the desired function and

to select or activate it by pressing the wheel.

What functions are displayed in the menu depends

on the settings in the main menu. The main menu is

the “central” level and can always be reached

quick ly.

Certain rules apply within the menus to make it

easier to navigate:

A black triangle to the right of a function indicates

that selecting this function will take you to a submenu.

A check mark on the right indicates that the function

in question has been activated.

Y ou can us e the arrow at the top right to switch the

display back by one level.

Arrows pointing up or down indicate that there are

other menu options above or below the part of the

menu that is visible. To reach these menu options,

simply turn the scroll wheel in the direction in which

the arrow is pointing.

Y ou can quickly switch back from the menus to the

measurement display by using the operate button.

In some cases this button also has another

function, but that will be indicated in the display (for

example Confirm -> operate).

14

4.3 Change names/numbers

For some functions, you can enter or change the

date or name. The arrow pointing upward marks the

position that can be changed. T o change the

character, turn the scroll wheel. When you press the

wheel, the arrow jumps to the next character.

After you have adjusted the last character or

number, confirm your input by pressing the wheel.

When you enter the name, the arrow jumps to the

first character. This allows you to correct any

inadvertent incorrect entries. Y ou can confirm the

name in these menus at any time with the operate

key.

Getting started

15

Getting started

4.4 Overview o f mai n menu

Mode

Sample mode

Statistics

Continous

Basic mode

Advanced mode

Geometry/Sensor

Measurement without sta tistical evaluation.

Multiple measurement with statistics.

Continuous measuring with adjustable interval.

Measuring without statistics, s aving and difference.

Reactivates all menues and functions when Basic

mode was activated.

Select geometry and thickness sensor if applicable.

Memory

Memory

Select memory

Create memory

Delete memory

Display memory

Difference

Difference

Measure standard

Select standard

Create stan dard

Delete stan dard

Changestandard

Calibration

Setup

The following can be used together s imultaneously:

• Memory with: Sample mode, Statistics, Continuous

• Difference with: Sample mode, Statistics

Memory functions:

Turn saving on/off.

Select memory area from list.

Enter up to 50 memory areas.

Delete memory content or memory name.

Recall of memory content (use scroll wheel).

Settings for difference mode:

Turn difference measurement on/off.

Measure a stand ard.

Select s tan dard (if s aved).

Enter up to 50 standards and limits for Pass/Fail.

Delete individual stan dards .

Enter/change limit values for Pass/Fail.

Calibrate, change cal. values, GU - % scale.

Bluetooth®, Date/Time, Beeper, Display time, Language,

Info

16

5. Calibrate

5.1 Autodia gnosis

Calibrate

The holder with the integrated glass standard is

used for calibration. Always keep the measurement

unit in the holder. This protects the measurement

optics and ensures that the standard is always at

hand.

If you have several devices of this type, you must

put the unit in the holder which belongs to the unit

(see the ser ial number).

Make certain that the standard is clean and

there are no cracks on it.

When you place the device in the holder, make

certain that it ships firmly into place.

Whenever you turn on the device in the holder, it first

performs a self-tes t. During this tes t, any ch ang es in

the measurement signal are tested against saved

calibration data. This allows for a long-term calibration

so that a new calibration is required only about once a

week. Beyond that, calibration is only necessary if

there are significant weather changes (see under 6.2).

It is recommended that you perform the self-test in the

holder regularly (every day).

The autodiagnosis generally takes about 2 seconds.

“Please clean standard” or “Please test standard”

may be displayed. For more information on

cleaning, see Chapter 17.

A message will appear in the display informing you

that the autodiagnosis has been completed

successfully.

In some cases, the system may suggest that you

repeat the calibration. The reason for this may be

changed ambient conditions. It is also possible,

however, that the standard still has small amounts

of residue left over from cleaning. This problem can

generally be alleviated by cleaning with a dry optical

cleaning cloth.

17

Calibrate

5.2 Calibrate

5.2.1 Gloss

Y ou s hould recalibrate the device if ambient

conditions have changed. This applies espe cially

when changing location if major changes in

temperature and relative humidity may be expected

as a result (for example inside/outside).

When moving from cold areas to w arm areas, there

is a danger of condensation. For this reason, after

there has been a change in ambient conditions, you

should wait for an appropriate amount of time to

allow the optical components to adjust before

calibrating and using the unit.

Use the path shown on the left side to reach the

Calibrate menu option.

T o begin calibration, press the scroll wheel.

The calibration process is performed automatically

for all three geometries. The saved calibration values

of the standard appear in the display.

The unit then returns to the selection menu

Calibration.

Y ou can use the path s how n on the left side to

reach the Calibrate Thickness option.

5.2.2 Thickness (micro-TRI-gloss µ only)

Choose the sensor (Fe, NFe) first.

In the display appears the menu for the calibration.

Put the instrument on the metal standard, according

to sensor selection Fe or NFe, and press operate.

18

5.2.3 Change cal. values

Calibrate

After the zero setting has been performed, the

display AIR will appear. To proceed with this, hold

the instrument in midair and press the operate

button.

The successful calibration is confirmed in the

display (OK). The instrument returns to the

selection menu Calibration.

Note:

The film thickness measurement is also influenced

by the basis metal. It is therefore advisable to

perform the zero calibration on the uncoated metal

which is used for the object to be measured.

In this case place the instrument on your original

substrate instead of on the supplied metal plate.

The gloss values of the calibration standard in the

holder included w ith delivery are saved in the

measuring device. During automatic calibration, this

data is assigned to the standard in the holder.

In some cases it will be necessary to enter data for

a new calibration standard, for example if the

previous standard has be en damaged or scratched.

To ensure exact calibration, only original

standards from the manufacturer should be

used.

Y ou can use the path s how n on the right side to

reach the Chang e cal.values menu option.

At three angle units, a selection menu will appear

for geometries. Select the desired geometry and

press the scroll wheel.

19

Calibrate

A warning message appears. You can cancel this

process by pressing the operate button.

If you press the scroll wheel, you will continue with

the process of changing calibration values.

In the next display you can enter new calibration

values.

After you have entered the n ew value, a war ning

message appears again in the display. You can

again abort the process with operate.

If you confirm the new value by pressing the scroll

wheel, the value will be accepted.

After you have changed all necessa ry values, you

should recalibrate the measu rement device as

usual.

5.2.4 Status

20

This menu item provides you with information on the

calibration status of the unit.

In particular, you can check here whether the s aved

calibration values match those of the holder. The

display also indicates if an error message was

generated as a result of the last autodiagnosis or

calibration. If this has happ ened, further information

is available under Section Errors and w arning

messages.

5.2.5 Scale Gloss

5.2.6 Scale Thickness

Calibrate

Y ou can set the scales of the measurement values

for gloss and thickness separately.

Y ou can us e the Scale menu option to switch back

and forth between Gloss Units and Reflectance (see

the Section on Practical measuring suggestions).

Move the mark to the desired entry and press mode.

A check mark identifies the Scale that is selected.

After you switch the Scale, the unit must not be

recalibrated.

Y ou can us e the Scale menu option to switch back

and forth between µm and mil. Move the mark to the

desired entry and press mode. A check mark

identifies the Scale that is selected.

21

Calibrate

5.3 Calibrating standards

T o ens ure exact calibration, only original standards

from the manufacturer should be use d.

These are calibrated against tested primary

standards. Their surface must not be touched and

must be protected against scratches. Due to

environmental influences, however, the values of

standards can change over the course of time even

if they are handled gently. For this reason, you

should have the calibration standards tested by the

manufacturer at regular intervals (we recommend

annually).

5.4 Checking standard

We recommend the regular use of a separate test

standard for control of test equipment. The

frequency of this verification depen ds on the

conditions of usage (for example monthly). The

gloss standards are integrated into an aluminum

guide in which the measurement device is

positioned exactly. Perform the measurement as

you would normally, for example in Basic mode. The

displayed measurement value must not deviate from

the value printed on the standard by more than one

unit. Otherwise you should check whether there is

dirt and dust on the high gloss standard in the

holder or test standard. If cleaning and recalibration

do not offer any improvement, please get in touch

with our Customer Service.

22

Measur ement techniques

6. Measurement techniques

In accordance with the standa rd, the reflectometer

value is related to a black glass standard at a

defined index of refraction (generally 1.567) which is

thus equal to 100 units.

Reflectometers are differentiated by the angle of

incidence of the illuminating mechanism.

Geometries are set in the standards at 20°, 60° and

85°.

6.1 Paints and varnishes, plastics and similar materials

The various geometries are distinguished according

to their fields of application as follows:

Semi-gloss surfaces are measured at a n angle of

incidence of 60° and should fall within a range from

10 to 70 gloss units.

Highly reflective surfaces with measurement values

exceeding 70 units in the 60° geometry should be

measured at 20°.

On the other hand, matte surfaces with less than 10

gloss units (at 60°) should be measured at the 85°

geometry.

In addition, specific measuring geometries are

defined in some industries, e.g. ceramic and plastic

film applications recommend 45° geo metry or paper

and vinyl housing facades use 75° geometry .

23

Measur ement techniques

6.2 Anodized aluminum and other metal surfaces

The measuring unit is equipped with an extended

measuring range for measuring samples with a very

high reflectance.

The reflectance of non-metallic surfaces increases

with the angle of incidence. The reflective properties of

metals do not always behave in this manner. Because

of double reflection, the light is partially reflected on

the coating and partially on the metal underneath. For

a complete understanding of the reflective properties

of such s urfaces , it is recommende d to meas ure them

at all geometries.

In addition to the reference to a black glass standard

(gloss units), it is also common in the area of metals

to relate the reflectometer value to the amount of

irradiated light and to express it as a % (reflectance).

Y ou can select this in the Scale menu.

Notes

Proper measurements are only possible on level

surfaces.

Measurements on dirty, scratched or otherwise

distorted areas of the test specimen are not meaningful except as a way of determining the degree of such

imperfections by means of a gloss measurement.

Since it cannot be assumed that the gloss capacity is

not con stant over the entire s urface of the tes t

specimen, the reflectometer value can be measured

at several different places and the standard deviation

can be determined.

If the sample exhibits structures or directionally

dependent gloss properties, the structural features

and the direction of the incident light should be

specified for the measurement in the test report.

Samples that must be measured several times over

the course of an examination (for example weathering

samples) should be marked accordingly to ensure

that the measurement is made at the same point

during repeated tests.

24

6.3 Measurement of film thickness

The film thickness sensor functions according to the

magnetic method (Fe) or the eddy current method

(NFe). Therefore, the measurement results can be

distorted by strong magnetic fields or electromagnetic radiation.

The measurement of film thickness is influenced by

the thickness and magnetic (Fe) or electrical (NFe)

properties of the basis metal.

The measurement results can thus be distorted by

such factors as the composition or heat treatment of

the substrate. It is therefore advisable to perform the

zero calibration on the uncoated metal which is

used for the object to be measured.

Surface roughness also influences the measurement of the coating thickness. T o reduce random

errors, multiple measurements are recommende d.

If the paint film thickness is to be measured using a

magnetic substrate coated with a non-iron

metal (e.g. zinc plated steel sheet), the following

must be noted:

• For the NFe setting, the thickness of the

substrate, i.e. of the non-magnetic coating, must be

at least 50 µm.

• With the Fe setting, the thickness of the nonmagnetic coating is included in the measurement

result.

Measur ement techniques

25

Measur ement Modes

7. Measurement Modes

Y ou can select different types of measurement in

the Mode menu. The mode that is activated is

identified by a check mark.

7.1 Sample mo de

Single measurements can be performed without

statistical evaluation in Sample mode.

The results can be saved and compared with a

standard (refer to Memory or Difference).

When Memory is turned on, a name is suggested

after every measurement. Y ou can confirm this

name directly or change it.

26

If you would like to delete the last measurement,

press the scroll wheel and select the appropriate

menu item.

7.2 Statistics

Measur ement Modes

Y ou can make multiple measurements with each

sample in Statistics mode. These measurements

will be evaluated statistically and displayed.

The results can be saved and compared with a

standard. These functions must be p reviously

activated (refer to Memory or Difference).

When Memory is turned on, a name is suggested

after all measurements of a sample (block). You can

confirm this name directly or change it.

When the Statistics function is turned on, additional

functions are available depending on the context

after you press the scroll wheel.

27

Measur ement Modes

Note:

(micro-TRI-gloss µ only)

When STA TISTICS is activated, all film thickness

values are stored in the Memory independently of

the sonde used.

In the case of an incorrect substrate or a high film

thickness, “Infi“ is written to the memory.

When the instrument is switched off, the last setting

remains active.

7.2.1Number of measurements

Y ou can adjust the number of measurements per

sample or per block with this option, from 2 - 99.

28

Y ou can find this value in the measurement display

by looking for “n=” after the forward slash. The

number of measurements (which increases by one

each time a measurement is performed) appears

before the slash.

7.2.2Display

Measur ement Modes

In the Statistics measurement display, you can

assign the following data freely to three columns:

Value:

Last value to be measured

Mean value:

Arithmetic mean of the sample (block).

Maximum:

Highest measurement value of the sample

Minimum:

Lowest measurement value of the sample

Range:

The difference between the maximum and minimum

value.

Std. D e v.:

The sta ndard de viation of the s ample

Difference*:

The difference between the sample and a target

value.

Pass/Fail* :

Pass is displayed if the sample value falls within the

spe cified limits, o r Fa il if it falls o uts ide .

Off:

Turns off the display of the selected column.

* To be able to use these functions, a standard must

be measured, created or selected. In particular, a

limit value must be defined.

29

Measur ement Modes

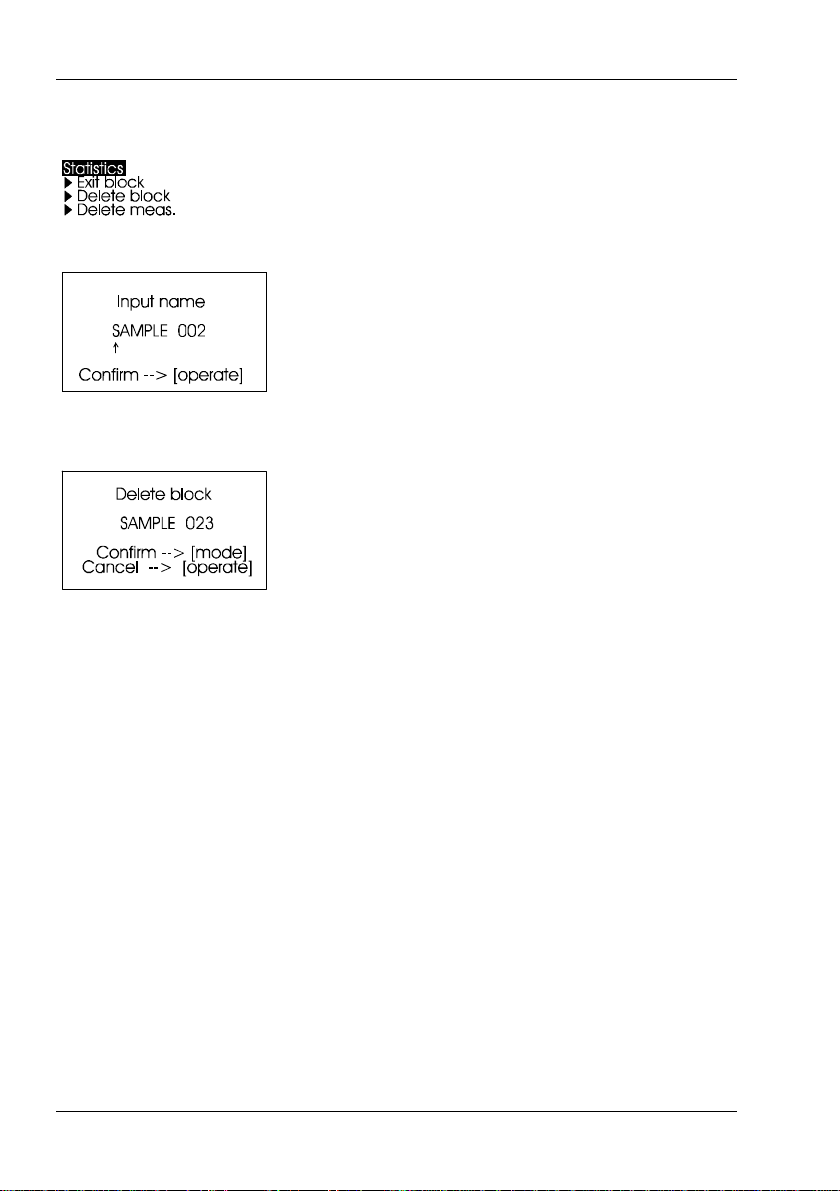

7.2.3Exit block

8.2.4Delete block

This function terminates the block before it reaches

the required number of measurements n. It is useful

if you have selected a high number of

measurements for n, for example in the case of

large samples.

If Save is turned on, a display appears to enter a

block name for the sample.

This function deletes the current block.

8.2.5 Delete measurement

This function deletes the last measurement value.

30

7. 3Contin uous

Measur ement Modes

Y ou can use this function to perform up to 99

measurements atan adjustable measurement

interval. This is helpful when you are covering large

samples and you want to evaluate the homogeneity

of the surface.

Activate Continuous under M ode from the Main

menu.

A screen appears for starting a new sequence.

T o start the measurement, press operate. The unit

now performs measurements up to 99 times at the

set interval. Measurement values are show n in the

display after each measurement.

Y ou can interrupt the continuous measurement by

pressing the operate button (hold it down briefly).

The number of measurements, t he mean value, the

minimum and the maximum appear in the display.

The Pause symbol on the left side indicates that

you can continue the sequence, therefore press the

operate b utton.

T o end the sequence, press mode.

For starting a new sequence, press operate again

If saving is activated, a screen appears at start of a

new sequence, which allows to enter a sample

name.

31

Measur ement Modes

7.4 Basic mode

The measu ring interval can be cha nged before a

sequence is started. Therefore press the mode

wheel to open the Continuous submenu.

The longest measu rement interval possible is 9

seconds, the shortest 0 seconds for continous

measuring. The interval slightly increases wh en

thickness sensor is activated.

The selection options are limited to the most

essential in Basic mode. This also greatly simplifies

operation in this mode.

Y ou can select geometry and thickness sensor and

perform calibration. In addition, all functions in the

Setup menu item are available.

Basic mode is useful if you want to interrupt a

series of measurements and quickly perform some

other measurements in the middle without leaving

the series of measurements.

32

Once these other measurements are complete, you

can use

to return to the point where you interrupted the

series of measurements.

8 Geometry/Sensor

8.1 Geometry selection

Geometry/Sensor

In this menu, you can select the geometry for the

gloss measurement, just as the sensor for the film

thickness measurement (at micro-TRI-gloss µ).

Choose Gloss Geometry from the Geometry/Sensor

menu.

Y ou can choose between the representation of one,

two or all three geometries in the display.

The currently set angle combination is indicated in

the Geometry menu by a check mark.

Select the desired combination with the scroll wheel

and then confirm by pressing mode.

When Save is turned on, switching the geometry

automatically causes the program to switch to the

appropriate predefined area of memory.

8.2 Thickness Sensor selection

The currently selected sensor is indicated in the

display by a check mark.

Off

The film thickness sensor is switched off.

Fe

Magnetic base metal (iron or steel)

NFe

Non-iron metal (e .g. aluminium)

33

Geometry/Sensor

Combi

When changing the substrate, the sensor will be

switched over automatically

Choose the desired sensor with the scroll wheel.

Press mode to confirm the desired selection.

The selected sensor is indicated in the display.

Note:

The measurement unit can be selected in µm or mil

for display (see section Calibration: Scale

Thickne ss ).

8.3 Sensor-setting Combi

When switching the Thickness setting to Combi,

the measurement will be run through in the

sequence Fe - NFe.

As the measurement takes place on a

ferromagnetic substrate, the procedure w ill be

finished directly after the Fe measurement.

With the measurement on a non-magnetic substrate

the sequence will go through and therefore lasts

somew hat longer .

Note:

When STA TISTICS is activated, all film thickness

values are stored in the Memory independently of

the sonde used.

In the case of an incorrect substrate or a high film

thickness, „Infi“ is written to the memory.

When the instrument is switched off, the last setting

remains active

34

9. Memory

9.1 Memory

Memory

T o s ave measurement values, you must activate the

Memory function before measuring or else select or

create a memory. Up to 999 measurements can be

stored. A fixed memory area is already created for

each geometry or combination (e.g. M60°). These

memory areas cannot be deleted. A total of 50

memory areas can be created.

The Memory function can be used for sample mode,

Statistics and Continuous measurements. The

layout of the memory is such that the measurement

mode and the standard can be changed within a

memory area, but not the geometry.

Y ou can use this function to turn saving on or off. A

check mark indicates if the function has been

activated.

Turning on Memory automatically selects the area

in memory that is predefined for the currently set

geometry (for example M20°60°).

9.2 Select memory

When you press operate to start a reading, you are

asked to enter a name for this memory.

All available areas of memory are listed in this

menu, beginning with the one that is predefined.

The number of measurements saved for each area in

memory is shown on the right.

Select the appropriate memory area with the scroll

wheel and activate the selection by pressing mode.

This automatically turns on Save and switches the

geometry if necessary (if the selected memory area

is defined for other geometries than what was

previously set).

35

Memory

9.3 Create memory

9.4 Delete memory

Users can set up their own memory areas with this

function. Select the required geometry before you

activate this function. Then you must enter the

name of a memory area. You can confirm the

suggested name directly with the operate button or

change it with the scroll wheel. After you confirm,

Save is automatically turned on.

This menu lists all memory areas that have been

created with the number of values stored in each

one.

Use the scroll wheel to move the mark to the

memory area you would like to delete and press the

wheel.

A menu appears in which you can decide whether

you would like to delete just the content of the

memory area or the entire memory area.

9.5 Display memory

36

For pre-defined memory areas, you can only delete

the measurement values.

Y ou can transfer data that has been saved to a PC

via the interface. The values can also be show n in

the display at any time.

The “Display memory” function opens a menu in

which all memory areas that have been created are

listed. Select the desired area of memory with the

scr oll w h ee l.

Memory

The values of the first measurement appear in the

display. The sample name is displayed in the

highlighted field.

Turning the wheel switches the display to the next

sample with its corresponding values.

Which values are displayed in the columns (for

example mean value, min., max.) depends on the

display currently selected for Statistics.

37

Difference measurement and Pass/Fail

10. Difference measur emen t and Pass/Fail

Y ou can compare the readings of samples with the

value of a previously measured or saved standard.

For saved standards, you can also display whether

the test specimen falls within the limits (Pass) or

outside (Fail).

Up to 50 standards can be saved. They are stored in

a separate area of memory. For each geometry you

can determine:

- A target value

- Maximum and minimum for Pass/Fail,

see Create s tandard or Change s tandard.

10.1 Difference

Y ou can use this menu option to turn Difference

measurement on or off. A check mark indicates if

the function is active.

When you turn on Difference, the last standard to be

used is automatically selected.

If no standard is available, choose the function

“Measure standar d“ or “Create standard“ to

continue.

10.2 Measure standard

38

We recommend to perform several readings on the

standard with Statistics turned on.

Memory must be activated to store the measured

standard. Otherwise it will be temporary hold until

another standard is measured.

Activate “Measure standard” a nd p erform the

measurement with operate. With memory on, a

window appe ars after the last reading where you can

enter the standard’s name.

If you inadvertently select a name that has already

been used, a message will appear in the display

and the arrow will jump back to the first position of

the name.

10.3 Select standard

Difference measurement and Pass/Fail

The measured s tandard values are s aved as the

target values. At the same time, Difference

measurement is turned on and the measured

standard is activated. If you want to define limit

values additionally , you can use the “Change

stand ard” function.

For measuring the samples continue by pressing

operate. The display shows the sample values and

difference to the target.

The Measure stand ard function can also be reached

directly from the measurement screen by pressing

mode.

If you want to compare samples without saving the

standard, use the Difference mode with Memory

switched off. A measured standard will be kept

temporary then, until you measure another one.

T o s elect an existing standard, use the arrow to

move the mark to Select standard and then press

the whee l.

The first standard appears in the display. The t arget

value, minimum and maximum are displayed. For

values that are not defined, 0.0 or 2000 is displayed.

The name of the standar d appears inverted a t the

top rig ht.

Turning the scroll wheel causes the next standard to

be displayed.

When you have selected the desired standard in the

display, activate it by pressing on the wheel.

A reference to the selected data will appear in the

display.

T o sta rt Difference measurement pres s “operate“.

39

Difference measurement and Pass/Fail

10.4 Create standard

Standards can also be saved by entering the target

and limit values with the scroll wheel. Move the

mark to “Create standard” and activate the function.

A display appears in which you must assign a name

for the new standard. If you inadvertently select a

name that has already been used, a message will

appear to this effect and the marker arrow will jump

back to the first position of the name. Confirm the

name with the operate button.

In the next step you can define the target and limit

values of your standard.

Define standard

With the three angle device, a menu first appears in

which you can select the geometry.

40

After that, the menu appears for selecting the target

value, mini mum and maximum.

Select the desired variable and press on the scroll

wheel.

Now you can adjus t the corresponding value.

After the last number is activated, the display jumps

back to the previous menu.

In this manner you can enter additional target and/or

limit values for the standard one after the other if

need be. After the entries are complete, Difference

measurement is turned on with the new standard.

10.5 Change standard

10.6 Delete standard

Difference measurement and Pass/Fail

Y ou can use this function to change target values

and limit values of saved standards. You can also

use it to define limit values subsequently (for

example for a measured standard). Use the scroll

wheel to move the mark to Change standard and

press the wheel.

All standards are listed one after the other in the

following menu. Select the desired standard and

press the scroll wheel.

In the next step you can define the target and limit

values as described above.

Use the selection wheel to move the mark to Delete

standard in the Difference menu and then press the

wheel.

The Delete stand ard menu appea rs. All saved

standards are listed in this menu.

If there are more standards than can be shown in

the display, arrows on the right edge of the display

will point to additional standards.

Use the scroll wheel to move the mark to the

desired standard and press the wheel.

The standard to be deleted is listed again in the

display. Confirm by pressing the mode scroll wheel.

The unit then reverts to the previous menu.

41

Setup

11. Setup

11 .1 Bluetooth®

1 1 .2 Date/Time

Y ou can make general settings in the Setup menu,

for example Langu age or Display time.

Y ou can us e this menu option to turn the

Bluetooth® function on or off. Use the scroll wheel

to move the mark to Bluetooth® and press the

wheel.

When Bluetooth® is turned on, a check mark

appears at the end of the line. Additionally, the

Bluetooth® symbol appears shortly in the start

screen when you switch on the instrument.

The unit contains an integrated clock. This makes

the date and time of the measur ement available for

data transfer to a PC. The date and time are not lost

even when the battery is changed. If you would like

to change the time setting, use the scroll wheel to

move the mark to Date/Time and then press mode.

The display for setting the date and time appears.

1 1.3 Beeper

1 1.4 Display time

42

Y ou can use this menu option to turn the beeper on

or off. Use the scroll wheel to move the mark to

Beeper and press the wheel.

When the beeper is turned on, a check mark

appears at the end of the line.

T o s ave electricity , the unit automatically turns off

after a certain amount of time. Yo u can determine

this time yourself with Display time.

11.5 Language

11 .6 Info

Setup

You can use this menu to select the display

language.

Use the scroll wheel to move the mark to the

desired language and press the wheel.

Y ou can use this menu option to find the following

information:

• C atalog N o.

• Serial No.

• Ver sion numbe r of the firmware

• Date of the last calibration

• Date of the last certification

43

Interface

12. Interface

The measurement device is equipped with an

interface that allows direct communication with a

PC.

Measurement data can be transferred from memory

or directly after each measurement.

The easy-link program is included with delivery

for this purpose. The transferred data are displayed

immediately in a test report.

For data transfer you can use the USB cable

included with delivery or the wireless c onnection via

the integrated Bluetooth® module.

If no USB cable is attached, the instrument

transfers the da ta via Bluetooth® . Therefore,

activate the Bluetooth® function in the Setup menu

of the instrument.

44

12.1 Installation

Interface

Bluet ooth® :

Please refer to the separate Bluetooth® Installation

Guide.

Software easy-link and USB drivers:

Insert the easy-link CD into the CD drive and run the

„setup.exe“ for installation of the program. Follow

the instructions on the screen.

After installation, the default directory of the

appropriate Excel Reports will be “...\bykware\easylink“.

As you connect the device to the USB port of the

computer, it is recognized by the system and the

hardware assistant opens:

1. Choose “Install from a list“ and click the button

“Next“. Then select the folder “U SB Driver“ from the

easy-link CD. The driver setup begins. Note that if a

window displays a choice of buttons to “Continue

Anyway“ or “Stop Ins tallation“ click on “Continue

Anyway“. Click the “Finish“ button to complete the

installation of the 1st driver.

2. After short time the hardware assistant opens for

installation of the 2nd dr iver. Co ntinue the

installation as described above by following the

instructions.

After the setup is completed for both drivers, open

the gloss-link report from the easy-link folder.

45

Standards

13. Standards

ISO 2813 Paints and varnishes - Determination of specular

gloss of non-metallic paint films at 20°, 60° and 85°

ASTM D 523 Stan dard Test Method for Specular Gloss

ASTM D 2457 Standard T est Method for Specular Gloss of Plastic

Films an d Solid Pla stics

DIN 67530 Reflektometer als Hilfsmittel zur Glanzbeurteilung an

ebenen Ans trich- und Kuns tstoffobe rflächen

(Reflectometer as a means for gloss ass essment of

plane surfaces of paint coatings and plastics)

BS 3900 - D5 Methods of test for paints. Measurement of specular

gloss of non-metallic paint films at 20°, 60° and 85°

JIS Z 8741 Method of Measure ment for Specular Gloss iness

ISO 7668 Anodized aluminium and aluminium alloys -

Measurement of specu lar reflectance and specular

gloss at angles of 20°, 45°, 60° or 85°.

BS 6161 - 12 Methods of test for anodic oxidation coatings on

aluminium and its alloys. Measurement of specular

reflectance and specular gloss at angles

of 20°, 45°, 60° or 85°.

46

Standards

ISO 2178 Non-magnetic coatings on magnetic substrates -

Measurement of coating thickness - Magnetic

method

ISO 2360 Non-condu ctive coatings on no n-magnetic electrically

conductive basis materials. Measurement of coating

thickness. Amplitude-sensitive eddy-current method.

ASTM B 499 Measurement of Coating Thicknesses by the

Magnetic Method: Nonmagnetic Coatings on

Magnetic Basis Metals

ASTM D 1400 Measurement of Dry Film Thickness of Nonmetallic

Coatings of Paint, Varnish, Lacquer , and Related

Products applied on a Nonmagnetic Metal Base

T ap pi T 480 S pecular gloss of pa per and paper board at 75°

47

T echnical data

14. Techn ical data

General techn ical data

T emperature range +15 °C to +40 °C (60°F to 104°F) for operation

- 10 °C to +60 °C (-14°F to 140°F) for storage

Rel. humidity Up to 85% non-condens ing

Mearurement unit:

Memory 999 measurements with date and time, in up to 50

memory areas

Difference measurement Memory for 50 references

Interface USB

Evaluation software easy-link, included

Power sup ply 1 Mignon A lkaline (AA/LR6) or rechargeable NiMH

Battery 1.5VDC, max. 0.1A

Rechargeable 1.2VDC, max. 0.1A

External power supply USB, 5VDC, max. 0.1A

Dimensions (WxLxH) 48 x 155 x 73 mm

Weight 400 g

Gloss measurem ent:

Measurement geometry 2 0° 60° 8 5° 45° 75°

Measurement ar ea ( mm) 10 x 10 9 x 15 5 x 38 9 x 1 3 7 x 24

Measurement range 0-2000GU 0-1000GU 0-160GU 0 – 180GU

Co lor s e ns it ivity in spectral adjustment to CIE luminosity function

(2°) under illuminant CIE-C

Accuracy

Range Repeatability Reproducibility

0 - 100 GU 0.2 GU 0.5 GU

100 -2000 GU 0.2 % 0.5 %

S - type units:

0 - 10 GU 0.1 GU 0.2 GU

0 – 140GU

48

Film thickness measurement:

Substrate Fe: magnetic, e.g. iron

NFe: non magnetic, e.g. aluminium

Sonde One point

Measurement range 0....500 µm (0 … 20 mil)

Accuracy ±(1.5µm +2%*)

*of measured value

Min. substrate thickness Fe: 0.20 mm (8 mil)

NFe: 0.05 mm (2 mil)

Specifications subject to change without notice.

T echnical data

49

Errors and warning mess ages

15. Errors and warning messages

Memory full Trans fer the content of memory to a PC and then

delete the contents of memory.

Refere nce memory full A maximum of 50 references can be saved. It may

be necessary to delete old references.

Y ou will also find an error number for the following messages in the Calibration/

Sta tus menu to provide support for diagnostics:

T olerance Generally occurs only with major changes in

Error 01 climatic or weather conditions. The deviation was

success fullycompensated for by calibration and

correct measurements are still possible. You should

still recalibrate the device as soon as it is operating

in normal climatic conditions again. How ever if a

change in climate cannot be considered as the

cause of the problem, you should check whether the

standard is clean.

Pleas e call Service Autodiagnosis has dete rmined an impermissible

Service (invalid) deviation in the measurement signal

that cannot be remedied by recalibrating.

Error 02 Generally occurs when there is a significant amount

of dirt or dust on the standard or optics. First try to

clean the standard. You should only have the optics

cleaned by ou r Customer Service department, for

example as part of a yearly recertification.

Error 03 Defect in the electronics or operating error. First

check whether the standard is clean and whether

the device is properly snapped into the holder.

Error 04 Defect in the lamp or electronics.

Error 05 Defect in the electronics.

Infi Wrong basis metal, measurement range

exceeded or calibration error; recalibrate, if

necessary .

50

Errors and warning mess ages

Error Thickness Operating error: improper ap plication, raising

before measurement is complete, or calibration

error . Repeat the pr ocedure.

If the error is show n repeatedly despite

correct operation and calibration, please contact

our customer se rvice department.

Please observe the instructions on cleaning standards in the section on

Calibration.

Fluctuations in measurement values

Was the same point on

the sample used for all

measurements?

Yes. It may help to test

the calibration with an

additional sta ndard if

one is available.

Calibration correct:

Is the test surface

completely even and

does the measur ing

device have good

contact with the

sample?

Yes: Device defective

Do not attempt to make any repairs yourself! If a malfunction occurs on your

measuring device, our Customer Service department will be happy to help you

as quickly as possible.

No. Check how high the deviations are on

the sample itself.

Calibration not correct:

Recalibrate and clean the standard if

necessary .

No:

In this case, major deviations are possible.

Please contact our Cu stomer S ervice

department.

51

Cleaning a nd maintena nce

16. Cleaning and maintenance

• Do not insert any objects into the measurement

aperture for cleaning. The instrument could get

damaged - a ffecting a pro per and s afe operatio n.

• The instrument housing is resistant to a number

of solvents, but cannot be guaranteed to withstand

all chemicals. Y ou should therefore use a soft,

moist cloth for cleaning. For cleaning excessive dirt,

use ethanol or cleaning alcohol. Do not use any

acetone!

• Cleaning standa rds

The accuracy of the measurement can be

significantly impacted by using dirty or damaged

standards.

Since the surfaces of the standards are highly

sensitive, cleaning must be undertaken with great

care.

T o clean standards, use a new lint-free cloth, dust-

free lens paper or an optical cloth.

Apply only slight pressure as you clean and make

certain there are no large particles stuck in the cloth

that could damage the surface. Do not us e any

acetone!

For dirt that is difficult to remove, use an optical

cloth dipped in liquid. Then wipe the surface with a

dry optical cloth.

Exact calibration is not possible unless the

standard is in perfect condition. If the condition of

the standard seems doubtful

because of its appearance or measurement errors,

we will be happy to check it for you.

52

17. Service and Cer tification

Service

Besides the repair of your instrument we offer the

following ad ditional ser vices:

First diagnosis on the telephone or by e-mail

Call us or send us an e-mail and we will try to solve

your problem. If this is not successful, please send

us the instrument for repair.

Preventive main tenance, calibrati on, an d

recertification

For precautionary reaso ns we re commend regular

preventive maintenance. We carry out this preventive

maintenance automatically when you send us your

instrument for maintenance and rec ertification. We

clean the optics, check all functions, test and, if

required, adjust the measured values by using

reference standards . Y ou will receive a certificate,

which includes the retraceability to international

standards.

Loaners

During the period of repair we furnish you with a

loaner on req uest an d availability.

Maintenance agreement

In case you want to make sure that the necessary

maintenance is being done on a regular basis and

on time, we recommend a maintenance agreement.

Extended warranty contracts

Furthermore, you can request an extended w arranty

contract for additional 12 months.

Service and Certification

Order ing infor ma tion:

SP-4440 Calibration service

SE-4440 Extended warranty

53

Service and Certification

Service Centers for BYK-Gardner products

Germany

BYK-Gardner GmbH

Lausitzer Strasse 8

82538 Geretsried

Germany

Phone:+49-8171-3493-0

Fax: +49-8171-3493-166

USA

BYK-Gardner USA

9104 Guilford Road

Columbia, MD 21046

USA

Phone:+1-301-483-6500

Fax: +1-301-483-6555

China

BYK-Gardner Shanghai Office

Room 1407, SIP AI PLA ZA

103, Cao Bao R oad

Shanghai 200233

P .R. C hina

Phone: +86-21 -6475-8570

Fax: +86-21-6475-7284

54

Brazil

BYK-Gardner La tin America

Rua das Aroeiras, 771

Bairro Jardim-Santo André-SP

CEP 09090-000

Brazil

Phone:+55-11-2147-1 199

Fax: +55-11-2147-1168

Copyright

18. Copyright

This instruction manual is an important part of this instrument. It co ntains essential information about setting up, placi ng in service and use. If you pass

the device on to another user , ple ase ensure that the instruction manual is

included with the instrume nt. The manual must be studied careful ly before

working with the equipment. Please contact your regional service office if

you have any questions or require additional information about the device.

The technology and fittings are based on state-of-the art optic and

electronic techno log y . New devel opments and innovati ons are co nstantly

being integrated into the equipment. Thus, the diagrams, dimensions, and

technical data used in this manual may have changed as a result of adapting

the device to new infor mation and improvements.

© Copyright 2010 B YK -Gardner GmbH

All righ ts reserv ed

No portion of the software, documentation or other accompanying materials

may be translated, modified, reproduced, copied or otherwise duplicated

(with the exception of a backup copy), or distributed to a third party, without

prior written authoriz ation from B YK -Gardner GmbH . In any case, this

requires the prior writte n consent of B YK -Gardner.

BYK -Gardner GmbH of fers no guarantee that the software wi ll functio n

without error or that the functions incorporated therei n can be executed in all

applications and combinations selected by you.

No liability other than as provided by law is assumed for direct or indirect

damage sustained in associa tion with the use o f the instrum ent, the software

or documentation.

BYK -G ardner GmbH reser ves the right to update the sof tware and written

documentation without prior notice .

55

260 020 398 E 1008

Loading...

Loading...