Additives & Instruments

A member of

Measure what you see.

LCM III

Manual

Betriebsanleitung

Mode d’emploi

Istruzioni d´uso

Table of contents

Section 1 Specifications ............... .................................... ................................... .................................... .............. 3

Section 2 General Information .................................. .......................................................... .................................. 5

2.1 Safety information ..................................... .... ... ... ... ... .......................................... ............................................... 5

2.1.1 Use of hazard information .......................................... .......................................... ..................................... 5

2.1.2 Precautionary labels ................................................................................................................................. 5

2.1.3 Chemical and Biological Safety ........................................ ... ... ... .... ... ........................................................ 5

2.2 Overview of product ........................................................................................................................................... 6

Section 3 Installation ............................................................................................................................................. 7

3.1 Unpack the instrument .................................. ... ... .......................................... ... .................................................. 7

3.2 Environment considerations ............................................. ... ... .... ... ..................................................................... 7

3.3 Power connections ....... ... .... ... ... .......................................... ... .... ... ..................................................................... 8

3.4 Connection ............. ... ... ... .... ... ....................................... ... ... ... .... ... ... ... ............................................................... 9

3.5 Cell compartments and cell adapter ................... ... ... .... .......................................... ... ... ... .... ... ......................... 10

3.5.1 Cell compartments and adapter .............................................................................................................. 10

3.5.2 Installation of the cell adapter .................................... ... .... ... ... ... .... ... ... ... ................................................ 11

Section 4 Start Up ................................................................................................................................................ 13

4.1 Power the instrument on and off ...................................................................................................................... 13

4.2 Language selection ................ ... ... .... ... ... ... .... ... ... ... .......................................... ................................................ 13

4.3 Self-Check ................ ... .............................................................................. ... ... ... .... ......................................... 13

4.4 Characteristics in continuous operation ........................................................................................................... 14

Section 5 Standard Operations .................... .......................... .......................... .......................... ......................... 15

5.1 Overview .......................................................................... ... ... .... ... ... ... ............................................................. 15

5.1.1 Tips for the use of the touch screen ..................................... ... ... .... ... ... ... ... .... ... ... ... .... ............................ 15

5.1.2 Use of the alphanumeric keypad ..... .... ... ................................................................................................ 15

5.1.3 Main Menu .............................................................................................................................................. 16

5.2 Instrument Setup mode ....................... ............................. ............................. ................................................... 16

5.2.1 Operator ID ............................................................................................................................................. 16

5.2.2 Sample ID ............................................................................................................................................... 17

5.2.3 Date and time .......................................................................................................................................... 18

5.2.4 Display and sound preferences ........................................... ... ... .... ... ... ... ... .... ... ...................................... 19

5.2.5 Power Management ................................................................................................................................ 19

5.2.6 PC and printer ......................................................................................................................................... 20

5.2.6.1 Printer setup ............................................................................................................................... 21

5.2.6.2 PC setup ..................................................................................................................................... 23

5.2.6.3 Print data .................................................................................................................................... 23

5.2.7 Password ................................................................................................................................................ 24

5.2.7.1 Deactivate a password ............................................................................................................... 25

5.3 Store, recall, send and delete data .................................................................................................................. 26

5.3.1 Auto/manual data storage ....................................................................................................................... 26

5.3.2 Recall stored data from the data log ....................................................................................................... 26

5.3.3 Send data from the data log .................................................................................................................... 27

5.3.4 Delete stored data from the data log ....................................................................................................... 28

5.4 Sampling and sample preparation ................................................................................................................... 29

1

Table of Contents

5.5 Color measurement ......................................................................................................................................... 30

5.5.1 Take a color measurement ..................................................................................................................... 31

5.5.1.1 Touch-sensitive areas on the measurement window .................................................................. 32

5.5.1.2 Parameter setup options ................................ ............. ............. ............ ............. .......................... 33

5.5.1.3 Change the color scale after a measurement .............................................................................33

5.5.2 Determine the Iodine color value ............................................................................................................ 34

5.5.3 Determine the Hazen color value (Pt-Co or APHA-method) ......................... ... .... ... ... ... .... ... ... ... ... .... ... ...34

5.5.4 Determine the Gardner color value ......................................................................................................... 35

5.5.5 Mineral oil color value (ASTM D 1500 and ISO 2049) ............................................ ... ... .... ... ... ................ 35

5.5.6 Determine the Saybolt color number (ASTM D 156) .............................................................................. 35

Section 6 Advanced Operations ............................................................... .......................................................... 37

6.1 System checks ................................................................................................................................................. 37

6.1.1 Instrument information .................. ... ... .......................................... .......................................................... 37

6.1.2 Upgrade of the instrument software ....................... .............................................. ................................... 38

6.1.3 Optical checks ..................... ... ... ....................................... ... .... ... ... ... .... ... ... ............................................. 38

6.1.3.1 Verification kit ................................... ... ... ... .... ... ... ... .... ... ... ... .... ... ................................................ 38

6.1.4 Output checks ..................................................... ... ....................................... ... .... ... ................................ 40

6.1.5 Lamp history ............................. .... ... ....................................................................................................... 40

6.1.6 Factory service ................. ... ... ... .... ... .......................................... ... .......................................................... 41

6.1.7 Service time ..................... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ... .... ................................... 41

6.1.8 Instrument backup ........................... ... .................................................................................................... 43

Section 7 Maintenance ........................................................................................................................................ 47

7.1 Cleaning requirements ..................................................................................................................................... 47

7.1.1 Housing and cell compartment ............................................................................................................... 47

7.1.2 Display ................... ... ... .... ... ... ....................................... ... ... .... ... ... .......................................................... 47

7.1.3 Cuvettes/sample cells ............................................ ....................................... ... .... ... ... ............................. 47

7.2 Insert or change of the battery ......................................................................................................................... 48

7.2.1 Information about using the battery ........... ... ... ... ... .... ... ....................................... ... ... ... .... ...................... 49

7.2.1.1 Recycle the lithium battery .......................................................................................................... 49

7.2.1.2 Optimal operation of the battery ................................................................................................. 50

7.2.1.3 Lifespan of the battery ...................... ... ... ... .... ... ... ... .... ... ... .......................................................... 50

7.2.1.4 Load the battery/Operating time ....................... ... ... .... ... ... ... .... ... ... ... ... ....................................... 50

7.3 Lamp replacement ........................................................................................................................................... 51

Section 8 Tr oubleshooting .............................................. .............................................................. ......................55

Index ...................................................................................................................................................................... 57

2

Section 1 Specifications

Specifications are subject to change without notice.

Performance specifications

Operating mode Color measurement

DIN 6162 Iodine color value

ISO 6271 Hazen color value

Colorimetric evaluation

Source lamp Gas-filled Tungsten (visible)

Wavelength range 400–700 nm

Wavelength accuracy ± 2 nm

Wavelength calibration Automatic

ISO 4630 Gardner color value

ASTM D 1209 Saybolt color value

ASTM D 1500 Mineral oil color value

Wavelength range for color

measurement

Photometric accuracy

Photometric linearity

Stray light > 3.0 Abs. at 500 nm with OG570/3

Data log 200 color measurements

Physical and environmental specifications

Width 220 mm (8.6 in.)

Height 135 mm (5.3 in.)

Depth 330 mm (12.9 in.)

Weight

Operating requirements 10–40 °C (50–104 °F), max. 80 % relative humidity (non-condensing)

Storage requirements –40–60 °C (-40–140 °F) max. 80 % relative humidity (non-condensing)

Additional technical data

Mains connection

Interfaces

Enclosure rating

400 to 700 nm

5 mAbs at 0.0 to 0.5 Abs

1% at 0.50 to 2.0 Abs

< 0.5 % to 2 Abs

< = 1 % at > 2 Abs with neutral glass at 546 nm

4.06 kg (8.95 Ibs) without battery

4.38 kg (9.66 Ibs) with battery

15 V- / 30 VA

Plug-in power supply unit: (100–240 V/50–60 Hz)

Use only screened cables with maximum length of 3 meters.

1 x USB type A

1 x USB type B

IP 41 with closed lid

IP 42 with Protective Cover in place

Protection Class Safety class II

3

Specifications

4

Section 2 General Information

2.1 Safety information

Please read this entire manual before unpacking, setting up or

operating this equipment. Pay attention to all danger, warning and

caution statements. Failure to do so could result in ser iou s injury to

the operator or damage to the equipment.

To make sure that the protection provided by this equipment is not

impaired, do not use or install this equipment in any manner other

than that specified in this

2.1.1 Use of hazard information

manual.

2.1.2 Precautionary labels

DANGER

Indicates a potentially or imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in

minor or moderate injury.

Important Note: Indicates a situation which, if not avoided, may

cause damage to the instrument. Information that requires special

emphasis.

Note: Information that supplements points in the main text.

Read all labels and tags attached to the instrument. Personal injury

or damage to the instrument could occur if not

if noted on the instrument, will be included with a danger or caution

statement in the manual.

observed. A symbol,

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after

12 August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC),

European electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no

charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories and all auxiliary items for proper disposal.

2.1.3 Chemical and Biological Safety

DANGER

Potential Chemical/ Biological Exposure Hazards. Handling

chemical samples, standards and reagents can be dangerous.

Users of this product are advised to familiarize themselves

with safety procedures and the correct use of chemicals, and

to carefully read all relevant Material Safety Data Sheets.

5

General Information

2.2 Overview of product

Normal operation of this instrument may involve the use of

hazardous chemicals or biologically harmful samples.

• The user must observe all cautionary information printed on the

original solution containers and safety data sheet prior to their use.

• All waste solutions must be disposed in accordance with local and

national law.

• The type of protective equipment must be selected according to

the concentration and amount of the dangerous substance at the

specific workplace.

The LCM III is a color measuring instrument for determin the color

values of transparent, optically clear liquids. The instrument comes

with a complete set of application programs and multi-language

support.

The LCM III can carry out an exact colorimetric evaluation in

conformity with ISO/ASTM standards with just a single

measurement and display the result in terms of traditional color

systems such as Iodine, Hazen or Gardner color numbers.

6

Section 3 Installation

WARNING

Electrical and Fire Hazards. Use only the provided power

supply. Only qualified personn el should conduct the tasks

described in this section of the manual.

3.1 Unpack the instrument

The LCM III comes packaged with the following items:

• LCM III

• Dust cover

• External power supply, including 4 adapter for EU, UK, USA

• cuvette/cell adapter Z

• LCM III user manual

Note: If any of these items are missing or damaged, contact the

manufacturer or a sales representative immediatly.

3.2 Environment considerations

The following conditions are necessary to make sure correct

instrument operation and accurate resu lts:

• Place the instrument firmly on an even surface. Do not push

and AUS/China

any objects under the instrument.

• Maintain an ambient temperature of 10 to 40 ºC (50 to 104 ºF)

for proper instrument operation.

• The relative humidity should be less than 80 %; moisture

should not condense on the instrument.

• Leave at least a 15 cm (6 in.) clearance at the top and on all

sides for air circulation to avoid overheating of electrical parts.

• Do not operate or store the instrument in extremely dusty,

damp or wet locations.

• Keep the surface of the instrument, the cell compartment and

all accessories clean and dry at all times. Splashes or spills on

and in the instrument should be cleaned up immediately (see

section 7.1 on page 47).

• After a continuous operating time of more than 24 hour without

switching off the instrument we recommend to perform a new

calibration with a distilled water cuvette/sample cell.

• After a continuous operating time of more than 7 days without

switching off the instrument we recommend to switch off an d on

the instrument to perform a new system check with filter

adjustment and lambda-calibration.

Important Note: Protect the instrument from temperature

extremes, including heaters, direct sunlight and other heat sources.

7

Installation

3.3 Power connections

Install the correct adapter plug on the supplied external power

supply (

Correctly mounted, both housing of power supply and plug are in

line. Plug the external power supply cord into the connector on the

back panel of the instrument, then plug the supply into a power

outlet (100–240 V~ / 50–60 Hz). Press the power switch on the

back of the instrument to initialize power (

Figure 1). Slide the adapter on until it "clicks" into position.

Figure 2 on page 9).

Figure 1 Power adapter

1 Power supply with EU adapter plug installed 3 USA adapter plug

2 UK adapter plug 4 AUS/China adapter plug

8

3.4 Connection

Installation

The LCM III has two USB interfaces as a standard feature, located

on the back of the instrument (

The USB Type A interface is used for communications with a

printer, USB memory stick or keyboard. A USB memory stick is

used to update instrument software.

The USB Type B interface is used for communications with a PC.

The optional Data Trans software must be installed on the PC for

this use.

A USB hub may be used to connect several accessories at a time.

Note: USB cables must not be longer than 3 meters (10 feet).

These USB interfaces enable data and graphics to be output to a

Printer and a PC and upgrade instrument software (see

section 6.1.2 on page 38).

Figure 2).

Figure 2 Interfaces

1 On/Off switch 4 Cover

2 USB type B 5 USB type A

3 Plug in power supply

9

Installation

3.5 Cell compartments and cell adapter

3.5.1 Cell compartments and adapter

The LCM III has two cell compartments (Figure 3). Only one

cuvette/sample cell type at a time can be used for a measurement.

Cell compartment #1

• 11-mm round cuvettes/sample cells

For measurements with 11 mm round cuvettes/sample cells in

cell compartment #1 insert the adapter Z into cell

compartment #2.

Cell compartment #2

Cell compartment #2 uses adapters to accommodate different

cuvette/sample cell types.

• 50 mm rectangular cuvettes/sample cells (can be inserted

directly into the cell compartment without using an adapter).

• 10 mm square cuvettes/sample cells (can be inserted with the

adapter Z)

Important Note: Be sure that the adapter Z is inserted proper into

the cell compartment. Press the adapter down until it snap into the

compartment.

Figure 3 Cell compartments

1 Cell compartment #1 2 Cell compartment #2

10

1 Adapter Z: 10 mm square cell adapter

Installation

Figure 4 Cell adapter Z

3.5.2 Installation of the cell adapter

1. Open the cell compartment.

2. Insert the adapter for measurements with the round

cuvette/sample cell (11 mm) and/or 10 mm square

cuvette/sample cell so the arrow on top of the adapter po int s to

the left (Figure 4) and the orientation tab fits the groove in the

compartment opening.

Note: The arrow on top of the adapter indicates the direction of the light

beam path.

11

Installation

12

Section 4 Start Up

4.1 Power the instrument on and off

1. Plug in to the power supply (laboratory analysis) or insert the

battery (field analysis).

2. The push-button switch on the back of the instrument switches

the instrument on (press for about 1 second) and off (press for

about 3 to 5 seconds). An acoustic signal confirms that the

instrument has been switched off.

Note: Do not turn the instrument off and on in rapid succession. Always

wait about 20 seconds before turning the instrument on again, otherwise

the electronic and mechanical systems will be damaged.

4.2 Language selection

The LCM III software includes several language options. The first

time the instrument is turned on, the language selection screen will

appear.

4.3 Self-Check

1. Select the desired language.

2. Press OK to confirm. The self-check will start automatically.

Changing the language setting

The instrument functions in the selected language until the option is

changed.

1. While turning the instrument on, touch the screen at any point

until the list for selecting a language appears (about

30 seconds).

2. Select the required language.

3. Press OK to confirm. The self-check will start automatically.

Each time the instrument is powered, a series of diagnostic tests

are performed automatically to make sure operation of major

system components.

This procedure, which takes approximately two minutes, checks the

system, lamp, filter adjustment, wavelength calibration and volt age.

Each test which functions correctly is confirmed with a check mark.

Note: For further error messages during self-check, see Section 8 on page

55.

13

Start Up

The Color Measurement Menu is displayed when diagnostics are

completed. Insert a cuvette/sample cell with distilled water to

calibrate.The calibration starts automatically when the LCM III

recognizes a 11 mm round vial in the cell compartment #1. For the

use of square cuvettes/sample cells in the cell compartment #2,

press Start to start the calibration.

Insert the sample cuvette/cell. For the use of 11 mm round vials the

measurement starts automatically. For the use of square

cuvettes/sample cells in the cell compartment #2, press Measure to

start the measurement.

See section 5.1.3 Main Menu on page 16 for a detailed description.

4.4 Characteristics in continuous operation

After a continuous operating time of more than 24 hour without

switching off the instrument we recommend to perform a new

calibration with a distilled water cuvette/sample cell.

After a continuous operating time of more than 7 days without

switching off the instrument we recommend to switch of f and on the

instrument to perform a new system check with filter adjustment

and lambda-calibration.

14

Section 5 Standard Operations

5.1 Overview

5.1.1 Tips for the use of the touch screen

The entire screen is touch-activated. T o make a selection, press the

screen with a fingernail, fingertip, pencil eraser or a stylus. Do not

press the screen with a sharp object, such as the tip of a ball

point

pen.

• Do not place anything on top of the screen, to prevent damage

or scratching on the screen.

• Press keys, words or icons to select them.

• Use scroll bars to move up and down long lists very quickly.

Press and hold the scroll bar, then move up or down to move

through the list.

• Highlight an item from a list by pressing it once. When the item

has been successfully selected, it will be displayed as reversed

text (light text on a dark background).

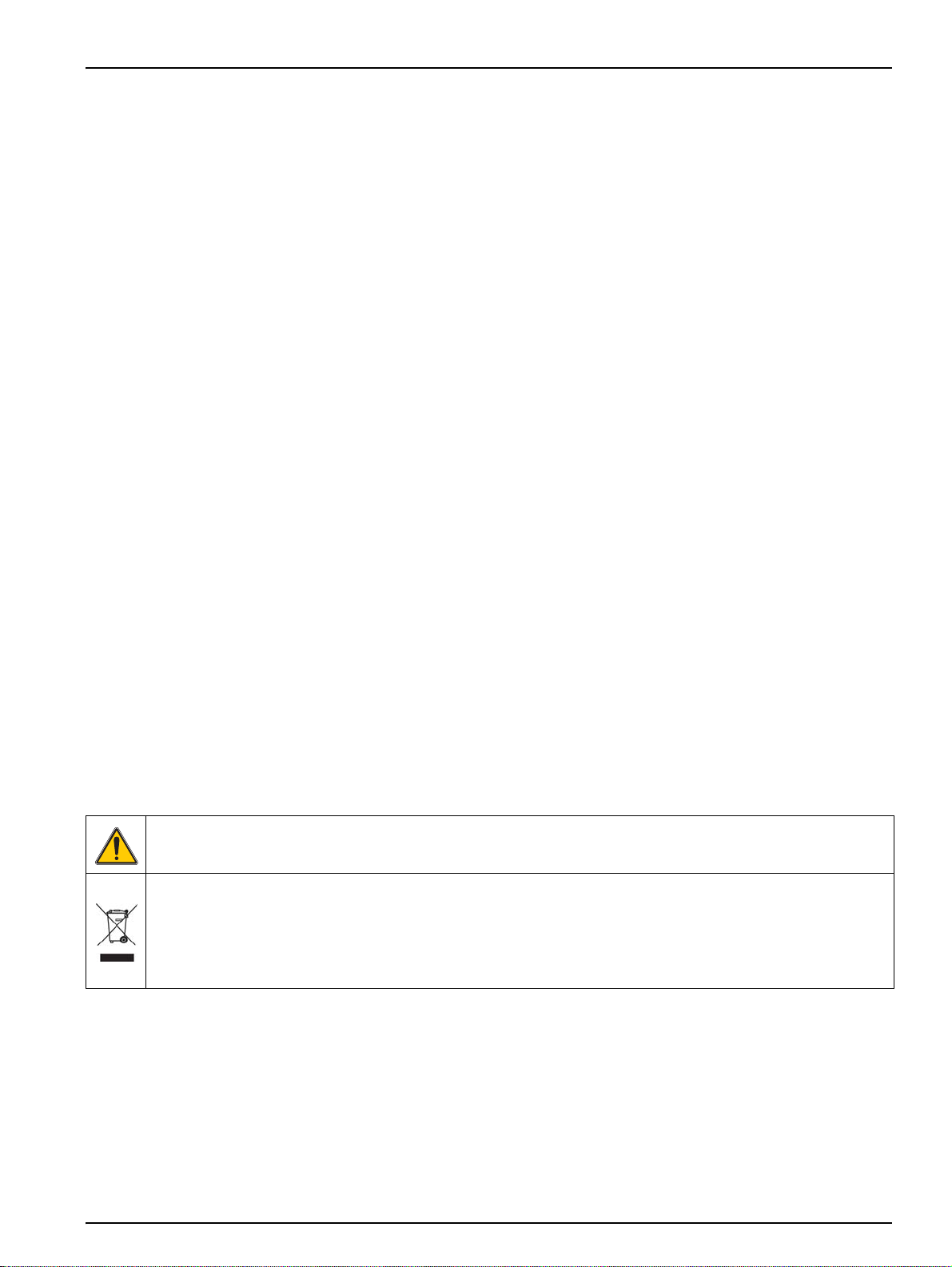

5.1.2 Use of the alphanumeric keypad

This display is used to enter letters, numbers and symbols as

needed when programming the instrument. Unavailable options are

disabled (grayed out). The icons on the right and left of the screen

are described in

The central keypad changes to reflect the selected entry mode.

Press a key repeatedly until the desired character appears on the

screen. A space can be entered by using the underscore on the

YZ_ key.

Note: A USB keyboard (with US keyboard layout) or a USB Barcode

handset scanner can be used for input.

Table 1 Alphanumeric keypad

Icon / key Description Function

ABC/abc Alphabetic

# % Symbols Punctuation, symbols and numerical sub- and superscripts may be entered.

123 Numeric For entering regular numbers.

CE Clear Entry Clear the entry.

Left Arrow Backspace

Right Arrow Advance

When entering alphabetic characters (ex. user-entered units), this key allows to

toggle between upper and lower case letters.

Moves back one position. This deletes the character previously entered in the new

position.

Moves to the next space in an entry when two adjacent characters occur on the

same key.

Table 1.

15

Standard Operations

5.1.3 Main Menu

A variety of modes may be selected from the Main Menu. Table 2

briefly describes each menu option.

Table 2 Main Menu options

Option Function

Color Measurement

System Checks

Recall Data Stored data can be recalled, filtered, sent to Printer, Memory stick or PC and deleted.

Instrument Setup

The COLOR MEASUREMENT mode is used to determine visual color values like Hazen,

Gardner and Saybolt

The system checks menu offers a number of options, including optical checks, output checks,

lamp history, instrument update, service time and instrument backup.

In this mode, user-specific or method-specifi c settings can be entered: Operator-ID, Sample-ID,

Date & Time, Display & Sound, PC & Printer, Password

5.2 Instrument Setup mode

5.2.1 Operator ID

1. Select Instrument Setup in the Main Menu.

A selection of configuration options appear.

Use this option to enter up to 30 sets of operator initials (up to five

characters each). Also the color can assigned for each Operator ID.

This feature helps record which operator measured each sample.

16

Standard Operations

1. Press Operator ID in the Instrument Setup.

2. Press New to enter a new Operator ID.

3. Use the alphanumeric keypad to enter a new Operator ID.

4. Press OK to confirm.

5. The display shows the selected Operator ID.

6. Press OK to return to Instrument Setup.

7. The selected Operator ID is activated.

5.2.2 Sample ID

Note: Press Delete to remove an Operator ID from the list.

Note: Alternatively , enter or change an Operator ID in measurement mode.

In the results screen, press Options>More>Instrument Setup or if an

Operator ID is already assigned, select the Operator ID symbol

immediately in the results screen.

Use this option to enter up to 100 Sample Identification tags (up to

13 characters each) into the instrument. Sample IDs can be used to

specify the sample location or other sample specific information.

1. Press Sample ID in the Instrument Setup.

2. Press New to enter a new Sample ID.

17

Standard Operations

3. Use the alphanumeric keypad to enter a new Sample ID.

Note: If a USB Barcode handset scanner is connected, Sample IDs

can also be scanned.

4. Press OK to confirm.

5. To number the Sample IDs sequentially (e.g. Inflow (01 etc.)),

select Add Number.

• Use the arrow keys to specify the first number of the

sequence.

5.2.3 Date and time

• Use the key between the arrow keys to enter the first

number of the sequence using the alphanume ric ke ypad.

6. Press OK to return to Instrument Setup.

7. The Sample ID is activated. Each Sample ID is automatically

numbered in ascending order after a measurement. The

number is shown in parentheses behind the Sample ID.

Note: To remove a Sample ID, highlight the ID and press Delete.

Note: A Sample ID can be entered or changed in measurement mode. In

the results screen, press Options>More>Instrument Setup. If a Sample

ID is already assigned, select the Sample ID symbol in the results screen.

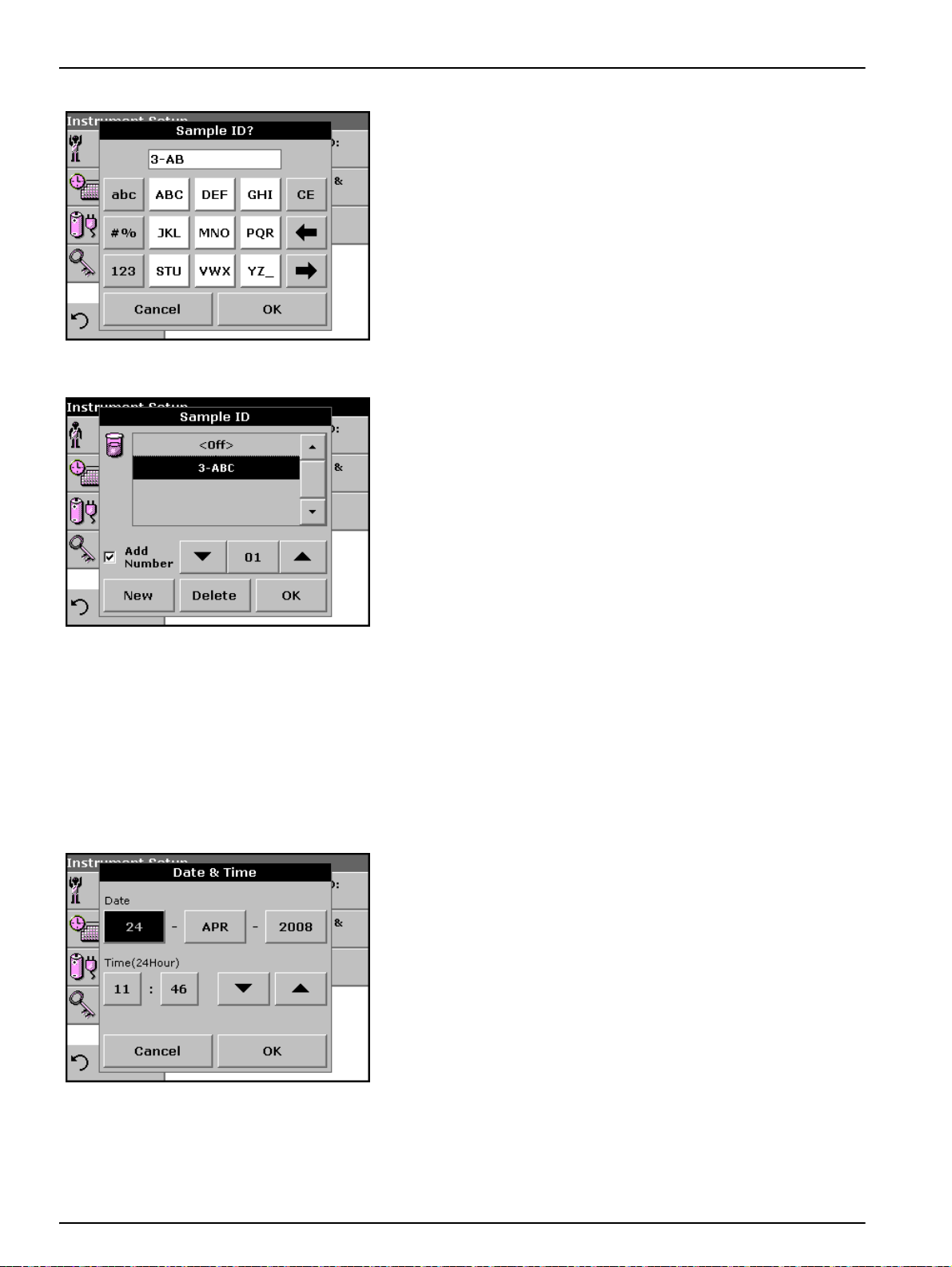

1. Press Date & Time in the Instrument Setup.

2. The date and time are subdivided over a number of fields.

Press the appropriate field and use the arrow keys to change

the value.

18

3. Press OK to return to Instrument Setup.

5.2.4 Display and sound preferences

1. Press Display & Sound in the Instrument Setup.

The following options will be displayed:

• Display Contrast—Adjusts the display brightness to suit

• Screen touch—Activates//Deactivates a short beep each time

• Reading done—Activates/Deactivates a sound when a

•Timer—Adjusts the length of the timer sound. Select Short or

2. Select Long to change the number of audio signals.

Standard Operations

lighting conditions.

the screen is pressed (Default:off).

reading is complete (Default: short beep every time a reading is

complete).

Long. Long beeps are recommended for noisy environments.

5.2.5 Power Management

Use the alphanumeric keypad to enter/specify the number of

audio signals (4–25).

Note: A high number of audio signals increases the duration of the

tones and a small number of audio signals reduces the duration of the

tones.

3. Press OK to confirm. The selected number of the audio signals

sounds as a corresponding acoustic signal.

4. Press OK to return to Instrument Setup.

The LCM III can run on mains or battery power.

Note: The battery is not part of the standard scope of delivery.

1. Select Power Management in the ”Instrument Setup“ menu.

The battery symbol indicates the charge status of the battery

in

%.

Note: The timer settings in the Power Management menu are only

active when the instrument is runn i n g on ba ttery power.

19

Standard Operations

2. Select one of the options under Standby mode to set the

length of the idle period that can elapse before the instrument

switches to the Standby mode when running on battery power.

Note: In standby mode, the backlighting of the screen is switched off.

Touching the display causes the lighting to switch on again.

3. Select one of the options under Auto off to set the length of the

idle period that can elapse before the instrument automatically

switches off when running on battery power.

After the instrument switches itself off automatically, you have to press the

push-button switch on the back of the instrument to start it again.

5.2.6 PC and printer

The LCM III is provided with 2 USB interfaces, which are located on

the back of the instrument (see

interfaces can be used for exporting data and graphics to a printer,

updating data and for data communication to a personal computer.

These interfaces can be used for the connection of a USB stick, an

external USB keyboard or a USB Barcode handset scanner.

Note: A USB hub may be used to connect several accessories at a time.

A USB memory stick is used to upgrade data, see section 6.1.2 on

page 38.

Important Note: A screened USB cable must not be longer than

3

m!

Table 3 USB connector

USB Interfaces Description

USB (Type B)

USB (Type A) This USB port can be used to connect a printer, a USB memory stick and keyboard.

This USB interface is only intended for the LCM III to PC connection (with installation of the Data

Trans Software).

Figure 2 on page 9). These

20

5.2.6.1 Printer setup

Standard Operations

1. Press PC & Printer in the Instrument Setup.

A list with information about the connections opens.

For reasons of compatibility, the printer language must be

HP

PCL 3.

1. Press Printer.

2. Press Setup to display the Printer Setup screen.

Printer Setup:

• Resolution: Font size

• Paper: Paper size

Note: If an optional Thermal Printer is connected, the function "Auto Send"

on/off is available.

21

Standard Operations

3. Select Auto-Send: On to send all measured dat a automatically

to the Thermal printer.

Note: The option Auto-Send is not available for any other printer (e.g. ink

jet printer).

4. Press Resolution to select the print quality.

Select between

• 100 dpi

• 150 dpi

• 300 dpi

5. Press OK to confirm.

Note: Press OK again to return to the Instrument Setup menu.

6. Press Paper to select the paper size.

Select between

• Letter

• Legal

• Executive

• A4

7. Press OK to confirm.

Note: Press OK again to return to the Instrument Setup menu.

22

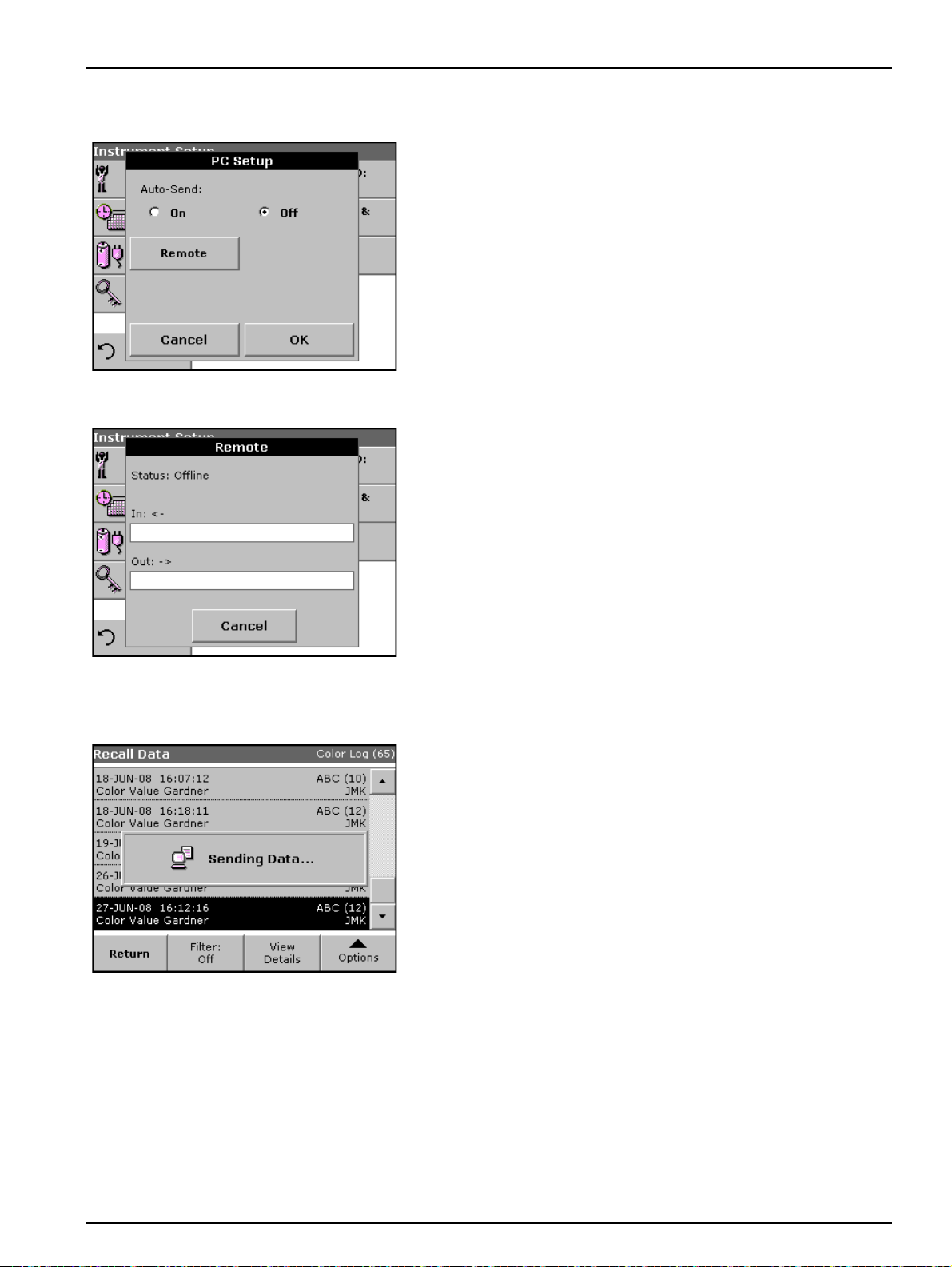

5.2.6.2 PC setup

Standard Operations

1. Press PC.

2. Press Setup to display the PC Setup screen.

3. With Auto-Send ON selection each measurement result will be

automaticly sent to a PC.

4. Select Remote to etablish a bi-directional PC connectio n to

send and receive commands and data (reserved for advanced

application).

5.2.6.3 Print data

1. Press Recall Data in the Main Menu.

2. Select the data source, where the data to be printed are stored.

3. A list is displayed. Data can be filtered. For more information

see 5.3.2 Recall stored data from the data log on page 26.

4. Press the Printer icon.

5. Highlight Single point or Filtered data or All data and press

OK to confirm.

6. Sending Data is displayed until the data have been printed.

23

Standard Operations

5.2.7 Password

The Password menu contains a variety of security settings to

control access to various functions. For example, prevent

unauthorized changes to stored programs or instrument

configurations.

1. Press Password in the Instrument Setup menu.

2. In order to highlight the Security List assign a password. Press

Set Password.

3. Use the alphanumeric keypad to enter a new Password (up to

10 characters each) and press OK to confirm.

The access to the Security List is activated.

4. Press Security List to lock various functions for unauthorized

users.

24

5.2.7.1 Deactivate a password

Standard Operations

5. Highlight the desired functions to control.

6. Confirm the Security List with OK to return to the Password

menu.

7. Press On to highlight the new settings of the Security List.

8. Enter the new Password again to confirm.

9. Press OK to return to Instrument Setup.

Note: The alphanumeric keypad to the Password inquiry appears when a

user tries to reach a locked setting.

1. Press Password in the Instrument Setup.

2. Use the alphanumeric keypad to enter the former Password

and press OK to confirm.

3. Press Off to deactivate the settings of the Security List.

4. Press OK to return to Instrument Setup.

Note: Use this function to delete the former Password or to enter a new

one.

25

Standard Operations

5.3 Store, recall, send and delete data

The Data Log will store up to 200 color measurments taken in the

Color Measurements modes.

A complete record of the analysis is stored, including the Date,

Time, Results, Sample

5.3.1 Auto/manual data storage

The data storage parame ter indicates whether dat a are to be stored

automatically or manually (in which case the user has to decide

which data to store).

ID and Operator ID.

1. Press Store: On/Off in the Options menu.

•Store On setting: All measurement data are stored

•Store Off setting: No measurement data are stored.

Note: When the instrument memory (data log) is full, the oldest data are

automatically deleted allowing the new data to be stored.

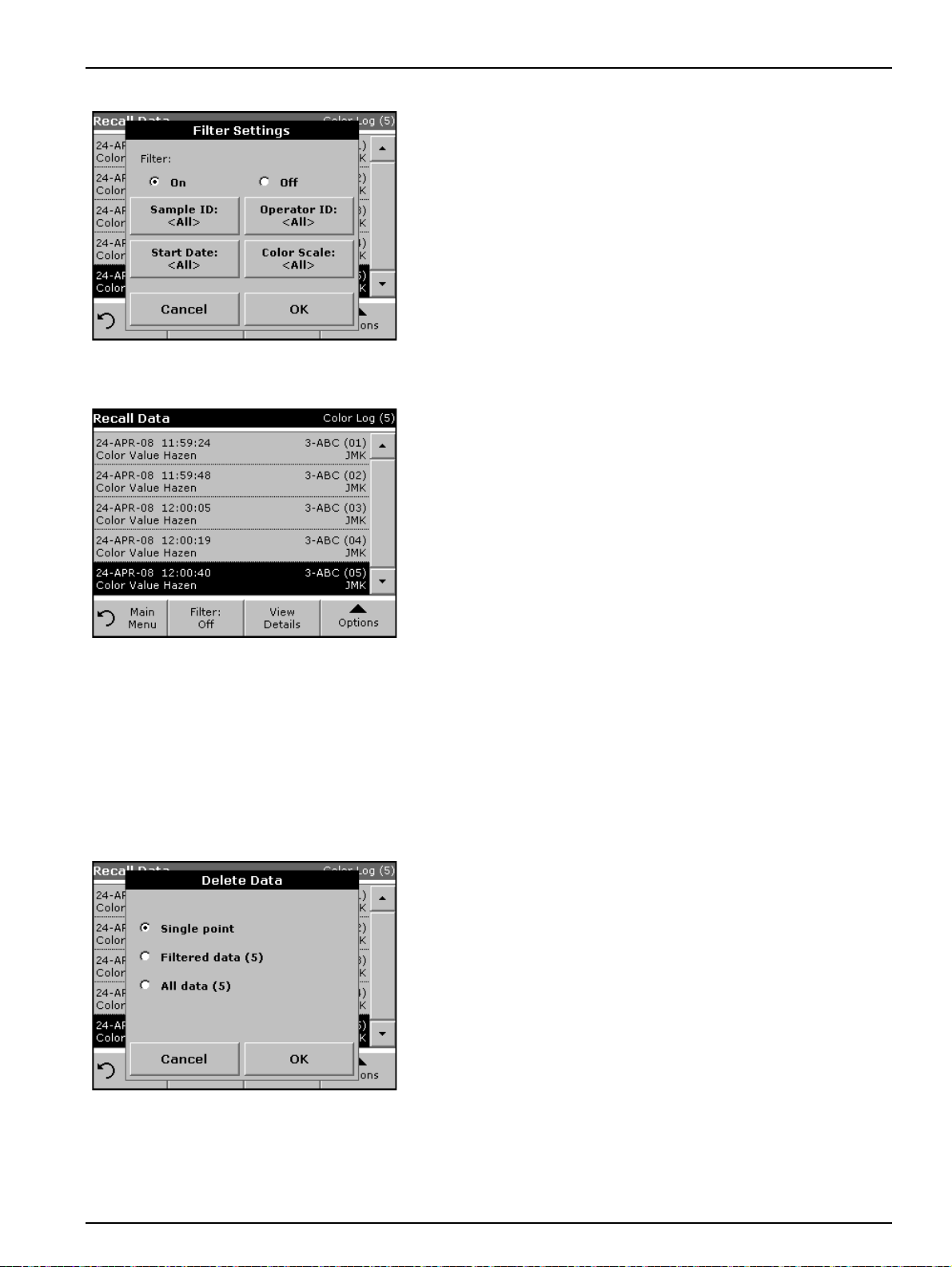

5.3.2 Recall stored data from the data log

1. Press Recall Data in the Main Menu.

2. Press Data Log.

A listing of the stored data is displayed.

3. Press Filter: On/Off.

automatically.

However, this setting can be changed to Store On in the

result display through Configuration. The reading currently

shown in the display is then stored.

26

Standard Operations

4. The function Filter Settings is used to search for specific

items.

5. Highlight On to turn on the filters to select data by

• Sample ID

• Operator ID

• Start Date

• Color Scale

or any combination of the four.

6. Press OK to confirm the selection. The selected items are

listed.

7. Press View Details to get more information.

5.3.3 Send data from the data log

8. Turn on the filter to select data by Color Scale.

Data is sent from the data log as CSV (Comma Separated Value)

files through a USB memory stick to a file named DATALOG. The

file can then be processed using a spreadsheet program. The file

name will be formatted as:

DLYear_Month_Day_Hour_Minute_Second. CSV.

To send data to a Printer, see section 5.2.6.3 on page 23.

1. Plug in the USB device (Figure 2 on page 9).

2. Press Recall Data from the Main Menu. Press Options and

then the PC & Printer icon.

3. Select the data to send to the memory stick and press OK.

Note: The number in parenthesis is the total number of data sets

assigned to this selection.

To send measurement data to a PC:

The optional Data Trans software must be installed on the PC for

the subsequent to process for meas u re m en t da ta.

27

Standard Operations

1. Press PC & Printer in the Instrument Setup.

2. Select PC.

3. Press Setup to display the PC Setup screen.

For further installation instructions, refer to the Data Tr ans user

manual.

4. Select Auto-Send: On to send all measured dat a automatically

to the PC.

Note: If Auto-Send: Off is selected, the "PC & Printer" key must be

pressed, in order to send data to the PC.

The remote function is only for monitoring the data transfer.

5.3.4 Delete stored data from the data log

1. Press Recall Data in the Main Menu.

2. Press Data Log, then Options>Delete.

3. Highlight Single Point or Filtered data or All data and press

OK to confirm.

Note: The number in parentheses is the total number of data sets

assigned to this selection.

28

5.4 Sampling and sample preparation

Take a representative sample from the product you want to

measure in accordance with DIN EN ISO 15528 (or ASTM

D3925-02).

If the material shows any visual haziness, remove the haze by

either filtration, centrifugation, heating, ultrasonic treatment or

suitable means.

Heat partly solid samples before measuring in order to dissolve the

solid material in the liquid. The preparation must not cause any

chemical changes in the sample.

Make sure that during the measurement are no bubbles in the

sample.

There are three cuvette/sample cell types available for color

measurement with the LCM III, differing by material (glass, PS and

PMMA) and path length (10 mm,11 mm and 50 mm). Fill the

cuvette/sample cell to approximately 2 cm. The light beam passes

through the cuvette/sample cell around 0.5 cm to 1.5 cm above the

base of the cuvette/sample cell.

The program calculates and displays Iodine, Hazen, Gardner,

Saybolt, Klett and ASTM D 1500 color values automatically, taking

into account the cuvette/sample cell type.

Standard Operations

A dry thermostat is available for the 11 mm disposable round glass

cuvettes/sample cells. The dry thermostat heats the

cuvettes/sample cells to any temperatur e be tween ambiant and

150 °C.

Important Note: The samples must be clear and free of turbidities.

If products in paste or solid form cannot be measured directly, the

product must be melted before being transferred to the

cuvettes/sample cells. Make sure the cuvettes/sample cells do not

contain any air bubbles.

• Always hold the cuvette/sample cell close to the top, to make

sure that there are no fingerprints in the measurement zo ne of

the cuvette/sample cell. Use suitable transfer pipettes to

introduce samples into the cuvettes/sample cells.

• Slowly add samples to the cuvettes/sample cells cells to make

sure air bubbles do not form on the cuvette/sample cell wall

and in the sample. Air bubbles will cause false readings.

• If air bubbles are entrapped, remove them by heat, vacuum,

ultrasonic treatment or other suitable means.

• Clean the outside of the cuvettes/sample cells thoroughly

before inserting them in the cell compartment.

Important Note: Before using disposable cuvettes/sample cells

made by PS (Polystyrene) or PMMA (Polymethyl methacrylate) be

sure that the cuvettes/sample cells will not be destroyed by

samples, otherwise the cell compartment can be damaged.

29

Standard Operations

5.5 Color measurement

Proper sample preparation is extremely importa nt for accurate color

measurement. To make sure an accurate measurement is taken,

refer to the following sample preparation guidelines:

• Always clean the glass cuvettes/sample cells immediately after

use.

• Only use optically preferred samples for measurement. Make

sure the cuvette/sample cell are clean and show no signs of

opaqueness.

• Slowly fill the liquid into the cuvette/sample cell to prevent air

bubbles in the sample.

• Refer to section 5.4 on page 29 for more sample and sampling

preparation information.

The Color Measurement mode is used to determine absolute color

values in the Hazen or Gardner.

The LCM III uses an independent calibration data set for each type

of cuvette/sample cell size (11 mm round vial and 50 mm

rectangular cells).

It is possible to calibrate the instrument with one, two or three types

of cuvettes/sample cells and to use these different cuvette/sample

cell types in parallel.

For the use of the 10 mm square cuvette/sample cell and 11 mm

round vials it is necessary to insert the adapter Z into the cell

compartment #2. For measurements with 50 mm rect angular

cuvettes/sample cells please remove the adapter.

The cell compartment #1 has an automatically cell detection. For

use of the 11 mm round vial in the cell compartment #1 the

measurement starts automatically.

For the use of square cuvettes/sample cells in the cell compartment

#2, press Start or Measure to start the measurement.

30

5.5.1 Take a color measurement

Standard Operations

1. Press Color Measurement.

2. Insert a cuvette/sample cell with distilled water to calibrate.

Important Note: Carried out the calibration always very carefully,

as a faulty calibration can cause inaccurate results to be obtained.

3. The calibration starts automatically when the LCM III

recognizes a 11 mm round vial in the cell compartment #1.

For the use of square cuvettes/sample cells in the cell

compartment #2, press Start to start the calibration.

4. The type of cuvette/sample cell and the actual progress of

calibration is shown in a seperat window.

5. After the calibration is done the screen shows an empty

measurement window. In the upper right corner of the window

the selected cuvette/sample cell size is displayed. The middle

button changes to Measure.

31

Standard Operations

6. Insert the sample cuvette/cell.

For the use of 11 mm round vials the measurement starts

automatically.

For the use of square cuvettes/sample cells in the cell

compartment #2, press Measure to start the measurement.

7. The result of the color calculation is displayed.

Note: The control bar displayed on the right of the displayed result

shows the relationship of the measurement result to the measuring

range.

8. For the next measurement, remove the cuvette/sample cell and

insert the next sample cuvette/cell or press Measure to

measure the same sample again.

5.5.1.1 Touch-sensitive areas on the measurement window

On the screen are touch-sensitive areas where the user has

immediate access to special software options.

Figure 5 Touch-sensitive areas on the measurement window

1 Open Operator ID to change or add operator ID

(see section 5.2.1 on page 16 )

2 Open Sample ID to change or add sample ID

(see section 5.2.2 on page 17)

3 Open Select Color Scale and select scale for

display (see section 5.5.1.3 on page 33)

4 Change the displayed color scale to the next color

system which is selected in the Operator ID color

scale list for display. (see section 5.5.1.3 on page

33)

5 Change Date & Time (see section 5.2.3 on page

18)

6 Open Power Management to indicate the charge

status of the battery in %. (see section 5.2.5 on

page 19)

32

5.5.1.2 Parameter setup options

Table 4 Stored programs options

Options Description

More For further Options

Store: On

With the STORE ON setting, all measurement data are stored automatically. With the STORE OFF

setting, no measurement data are stored.

Standard Operations

Press Option for Parameter Setup.

Send Data To send data to a printer, computer or USB memory stick (Type A)

Color Scale Select the color scale

Send Data To send data to a printer, computer or USB memory stick (Type A)

Color Scales for

Operator ID

Configure the color scale for the display and for print.

5.5.1.3 Change the color scale after a measurement

1. Press the touch-sensitive area 3, e.g. Color Value Hazen.

33

Standard Operations

2. A list of all color scales is displayed.

3. Select the required scale .

4. Press OK to confirm.

5. The current result of the actual reading and all further

measurements will be displayed in the selected color scale.

5.5.2 Determine the Iodine color value

DIN 6162 defines the Iodine color value as mg of iodine per 100 mL

of potassium iodide solution. Color matching with the Iodine color

determines the depth of color of clear liquids like solvents,

plasticisers, resins, oils and fatty acids, whose color is similar to

that of a solution of iodine and potassium iodide of the same

thickness.

For iodine color values of less than or approximately 1, the

determination of the Hazen value according to DIN-ISO 6271 is to

be preferred. Sampling and preparation are described in section

on page 29.The Iodine value can be accurately determined using

an 11 mm round glass cuvette/sample cell.

5.5.3 Determine the Hazen color value (Pt-Co or APHA-method)

The Hazen color value (ISO 6271, also known as "AHPA-method "

or Platinum-Cobalt Scale) is defined as mg of platinum per 1 litre of

solution. The Hazen parent solution is composed of 1.246 g of

potassium hexachloroplatinate (IV) and 1.00 g of cobalt(II)chloride

dissolved in 100 ml of hydrochloric acid and filled up to 1000 ml with

distilled water.

The Hazen-color scale is used to evaluate the colors of nearly

water-clear products. It has narrower gradations in the light yellow

range than the Iodine scale and extends to water-clear color casts.

5.4

34

Note: Samples with Hazen values between 50 and 1000 can be measured

with sufficient accuracy in 10 mm square and 11 mm round

cuvettes/sample cells. Hazen values below 50 are measured in 50 mm

cuvettes/sample cells. Hazen values below 10 are only be measured with

the 50 mm cuvette/sample cell used for calibration, because nearly

water-clear products can easily give faulty measuring results due to

cuvette/sample cell tolerances.

5.5.4 Determine the Gardner color value

The Gardner color value is defined in DIN-ISO 4630.The lighter

Gardner color values (1 to 8) are based on

potassium-chloroplatinate solutions, while the darker ones (9 to 18)

are based on solutions of iron(III)chloride, cobalt(II)chloride and

hydrochloric acid. The LCM III can determine Gardner values at all

cuvette/sample cell path lengths (only values 0 to 4 in 50 mm

cuvettes/sample cells).

The 10 mm and 11 mm cuvettes/sample cells provide sufficient

accuracy.

5.5.5 Mineral oil color value (ASTM D 1500 and ISO 2049)

The mineral oil color scale is used to evaluate the color of mineral

oil products such as lubricating oils, fuel oil, diesel fuel and paraf fin.

The color scale starts at color value 0 for water-white, non-colored

oils and ends at 8 for very dark brown oils. Substances are visually

evaluated in multiples of 0.5 (0.5; 1.0; 1.5 etc.).The LCM III displays

the results in multiples of 0.1. For samples whose color value is

higher than 8,*** is displayed.

Standard Operations

Note: Because of the intensive color of the ASTM D 1500 color value, it is

calculated only for 11 mm round or 10 mm square cuvettes/sample cells.

No calculation is carried out for the 50 mm path length.

5.5.6 Determine the Saybolt color number (ASTM D 156)

The Saybolt color scale is used to evaluate refined oil products

such as petrol and kerosene, as well as for petroleum waxes and

pharmaceutical white oils.

The Saybolt color properties are comparable to those of the Hazen

scale (APHA). The Saybolt color scale starts at color number +30

(lightest color , equivalent to approximate ly 8 to 10 Hazen) and ends

at -16 (strongest color, equivalent to approximately 350 Hazen).

Note: The measurements can be carried out with 10 mm, 11 mm or 50 mm

cuvette/sample cell path lengths. A longer path length increases the degree

of accuracy associated with the measurements (50 mm recommended).

35

Standard Operations

36

Section 6 Advanced Operations

6.1 System checks

1. Press System Checks in the Main Menu.

The System Checks menu contains instrument information and

various performance tests.

6.1.1 Instrument information

1. Press Instrument Information in the System Checks menu.

2. The model, serial number and software version are displayed.

37

Advanced Operations

6.1.2 Upgrade of the instrument software

1. Go to http://www.hach-lange.com

2. Select the country and go to Download>Software.

3. Enter LCM III in ”Search for documents“.

4. Locate the appropriate download and follow the prompts for

saving the file(s) to the USB memory stick or to the PC.

5. Unpack the ZIP file and save the files to the USB mem ory st ick .

6. Press Instrument Update in the System Checks menu.

7. Connect the USB memory stick to the USB interface (type A)

on the instrument, see section 3.4 on page 9.

8. Press OK. The link is established automatically and the

software is updated.

6.1.3 Optical checks

6.1.3.1 Veri fication kit

9. Press OK to return to the System Checks menu.

Note: When the instrument software has been updated, a prompt to restart

the instrument is displayed.

1. Press Optical Checks in the System Checks menu.

The Optical Checks menu for checking the wavelength accuracy,

stray light and photometric accuracy.

An test filter set (Verification Kit) containing four precision glass

filters, target values and instructions is available as an aid for

carrying out comprehensive in-house instrument checks.

The Verification Kit is desig ned for periodic monitoring of scattered

light, photometric accuracy and the wavelength accuracy of the

spectrophotometers.

38

When results exceed allowable tolerances (given in the quality

control certificate to the test record), contact the manufacturer.

Advanced Operations

1. Press Nominal Values.

2. Press Edit.

An automatic menu guidance queries values (filters,

wavelength, nominal values and tolerances) given in the quality

control certificate, to the following specifications:

• Stray Light

• Photometrical accuracy

• Wavelength accuracy

3. Press OK when all values are entered and the overview is

displayed.

4. Press Verification.

5. Insert the adapter Z (Figure 4 on page 11) in

cell compartment #2.

39

Advanced Operations

6. Remove any cuvettes/sample cells from the cell compartment

and press Start.

7. Insert the different filter in the given order one after the other.

Press Next after inserting a filter.

6.1.4 Output checks

6.1.5 Lamp history

After the last measurement the results are displayed.

8. Press PC & Printer icon to send the data to a USB memory

stick, PC or to a printer.

The files will be stored automatically as CSV file (Comma

Separated Value). The file name will be formatted as

“Verification.csv“.

If a printer is connected a test printing of the current screen will be

printed.

The Lamp History menu provides the amount of time that the lamp

has been on (Hours).

40

6.1.6 Factory service

Advanced Operations

After a lamp is replaced, the display of the total operating time is

reset to 0.

1. Press Lamp History in the System Checks menu.

2. Press Reset VIS and the Visible Lamp will be reset.

3. Press OK to return to System Checks.

The Factory Service menu is password protected. This menu is not

intended for customer use.

6.1.7 Service time

In order to make sure a regular inspection, an automatic memory

reference for the service times can be entered. After switching the

instrument on this memory reference will be activated and indicated

at the appropriate time.

1. Press Service Time in the System Checks menu.

2. Select On and then Last Service to enter the date of the last

inspection.

3. Press OK to confirm.

41

Advanced Operations

4. Select Next Service to determine a specific period of time up to

the next inspection.

5. Press OK to confirm.

If the next service is due, the message "Next service is due!" is

displayed after switching on the instrument.

6. Press OK to return to the Main Menu.

Contact the manufacturer to arrange an appointment for the next

service.

42

6.1.8 Instrument backup

Advanced Operations

Before the next service date the Instrument Backup men u offers

the possibility to store all programs, measuring data, Operator ID,

Sample ID, passwords and all adjustable data on a USB stick.

1. Press Instrument Backup in the System Checks menu.

2. Connect the USB memory stick (section 3.4 on page 9).

3. Press Store to start a Backup.

Note: If the USB stick is not connected, the message "Please insert USB

Memory" is displayed. Connect a USB stick, in order to store the data.

Press OK to confirm and press Store again.

Note: If the Backup was already stored before, the message "Data already

exists. Overwrite?" is displayed. Press OK to overwrite the dat a.

43

Advanced Operations

If the file was stored the message Instrument Backup is stored to

USB stick will be displayed.

4. Press OK to return to the System Checks menu.

Restore backup data:

Important Note: All current data will be overwritten when restoring

the Backup file!

1. Press Instrument Backup in the System Checks menu.

2. Connect the USB memory stick containing the Backup

(section 3.4 on page 9).

3. Press Restore to pass back the data.

Note: If the USB stick is not connected, the message "Please insert USB

Memory" is displayed. Connect a USB stick, in order to store the data.

Press OK to confirm and press Restore again.

44

Advanced Operations

4. Press OK to confirm after the message “Instrument Backup

from S/N XXXXXXX. Restore?“ is displayed.

5. After the backup start the instrument again.

45

Advanced Operations

46

Section 7 Maintenance

7.1 Cleaning requirements

7.1.1 Housing and cell compartment

CAUTION

Potential Chemical, Biological Eye and Skin Hazards.

Only qualified personnel should conduct the tasks described

in this section of the manual.

Important Note: Remove any cuvettes/sample cells that are still in

the instrument and dispose of cuvettes/sample cells or its contents

using an approved disposal method.

CAUTION

Potential Pinch, Eye, Burn and Chemical Hazards.

Always disconnect power from the instrument before

attempting any cleaning operations.

Important Note: Under no circumstances should the instrument,

display or the accessories be cleaned with solvents such as white

spirit, acetone, etc.

• Clean the enclosure, cuvette/sample cell compartments and all

accessories with a soft damp cloth. A mild soap solution can

also be used. Do not get excess water in the cuvette/sample

cell compartments. Do not insert a brush or sharp object into

Cell Compartment #1 to avoid damaging the mechanical

components.

7.1.2 Display

7.1.3 Cuvettes/sample cells

• Dry the cleaned parts carefully with a soft cotton cloth.

• Take care not to scratch the display. Do not touch the screen

with ball pens, pencils or similar pointed objects.

• Clean the display with a soft, lint-free and oil-free cotton cloth.

Diluted window cleaner liquid can also be used.

CAUTION

Potential Chemical/ Biological Exposure Hazards.

Use proper laboratory practices whenever there is a risk of

chemical exposure.

1. After performing a procedure, clean glass cuvettes/sample cells

2. Afterwards, rinse the cuvettes/sample cells several times with

Important Note: Glass cuvettes/sample cells that have been used

for organic solvents (such as chloroform, benzene, toluene, etc.)

must be rinsed with acetone before being treated with cleaning

agents. In addition, another rinse with acetone is necessary as a

final treatment step before the cuvettes/sample cells are dried.

with cleaning agents.

tap water and then thoroughly with deionized water.

47

Maintenance

7.2 Insert or change of the battery

1. Remove the cuvette from the cell compartment.

2. Switch the instrument off.

3. Unplug the power cord.

4. Turn the instrument over carefully and place it on a soft surface.

5. Use a screwdriver or a coin to remove the screw from the

cover.

6. Remove the cover and place it to one side.

CAUTION

For quality and safety reasons, only the manufacturer’s lithium

batteries (LZV551) should be used for this instrument. Use of

non-instrument-specific battery types may impair the

functioning of and/or damage the instrument electronics by

overloading them, or depending on battery types can even

result in fire or explosion hazards.

7. Carefully push the battery from right to left into the

compartment, with the labeled face upward.

48

8. Push in the battery so that the contacts of the instrument can

be plugged into the socket of the battery.

Important Note: Take care that the battery contacts are always

clean. Soiled contacts can result in contact heating and voltage

drop, interfering with the proper operation of the

spectrophotometer.

9. Use a screwdriver or a coin to replace the screw securing the

cover.

10. Carefully stand the instrument upright.

11. Plug in power supply again – the Instrument is now ready for

use. The battery charges up.

7.2.1 Information about using the battery

7.2.1.1 Recycle the lithium battery

A lithium battery allows the LCM III to be used as a portable

instrument.

Maintenance

Disposal: At the end of their lifespan, batteries should be returned

to the manufacturer to ensure that they are disposed of properly.

Please return the batteries individually, in a plastic bag or the

original packaging, to the manufacturer (information about th e

charge status of the battery can be found in the "Instrument Setup”

menu under

CAUTION

Pay special attention to the following information for the

Lithium battery pack:

• Do not short-circuit the contacts.

5.2.5 Power Management on page 19).

• Keep the battery away from fire.

• Do not expose the battery to temperatures above 60 °C (such

temperatures may occur , for example, in a car lef t in the sun, or

in direct sunlight).

• Take care that the battery does not become wet.

• Take care that the battery is not exposed to impacts, blows, etc.

Do not drop it. Do not step on it by accident.

49

Maintenance

7.2.1.2 Optimal operation of the battery

• Do not take the battery apart or modify it in any way.

• The performance of the battery decreases with the

temperature.

The battery is charged automatically when the plug-in power supply

on the back of the instrument is connected and is plugged into a

mains socket (100–240 Volt/50–60 Hz).

7.2.1.3 Lifespan of the battery

7.2.1.4 Load the battery/Operating time

CAUTION

Use only the manufacturer's specified external power supply

to operate the instrument and charge the internal lithium

battery pack. The specified power supply and it's plug shape,

it voltage rating (12 V, 2 A) and it's electromagnetic

characteristics are critical to assur ing the LCM III's

performance and the safety of the user.

Important Note: We advise charging the battery at an ambient

temperature between 10 °C and 30 °C, as this is the range in which

it can be most effectively charged to 100 %.

The battery has a limited lifespan. The more it is used, the more its

capacity is reduced. If a fully charged battery only allows the

instrument to be used for a relatively short time, replace th e battery

with a new one.

Note: Y ou need not run down the battery completely before recharging it. If

you recharge the battery when it still has some residual charge, this does

not reduce its capacity!

The time required to charge a newly installed battery is about

3.5

hours.

50

Operating time of a fully charged battery:

Charge: If a battery is charged to 100 % capacity, and the user

carries out 10 measurements per day, and the instrument is left on

after each measurement for the full 15 minutes before it

automatically switches off, the battery can be used for 6 to 7 days

before it needs recharging.

7.3 Lamp replacement

Maintenance

CAUTION

To avoid a possible electric shock, disconnect the instrument

from the power source before servicing the lamp.

1. Remove the cuvette from the cell compartment.

2. Switch the instrument off.

3. Unplug the power cord.

WARNING

Burn Hazard. Wait until the lamp cools down. Contact with the

hot lamp can cause burns.

4. Turn the instrument over carefully and place it on a sof t surface.

5. Use a screwdriver or a coin to remove the screw from the

6. Remove the cover and place it to one side.

7. If there is a battery in the instrument, push it out and put it to

cover.

one side too, see section 7.2.1 on page 49.

8. Use a screwdriver (slotted or cross-headed) to remove the

screws from the lamp fitting.

51

Maintenance

WARNING

Burn Hazard. Wait until the lamp cools down. Contact with the

hot lamp can cause burns.

9. Lift the lamp fitting carefully.

10. Put both screws to one side.

11. Push up on the pressure spring.

52

12. Remove the halogen lamp complete with the plug panel.

Maintenance

13. Carefully unplug the halogen lamp from the plug panel.

Important Note: Hold the lamp by the fitting only. Avoid touching

the glass, as substances on the skin can bake onto the lamp bulb

and thus accelerate the aging process of the lamp.

14. Plug a new halogen lamp to the panel.

15. Insert the halogen lamp with the half rounded part pointing

down.

16. Press the plug with slight pressure into the direction of the

halogen lamp and push the pressure spring down, so that it will

engage.

17. Carefully insert the lamp fitting again.

18. Use a screwdriver (slotted or cross-headed) to replace the

screws to secure the lamp fitting.

19. Put the battery back in place, see section 7.2.1 on page 49.

20. Use a screwdriver or a coin to screw the back cover to the

instrument.

21. Carefully stand the instrument upright.

22. Plug in the power supply.

23. Reset the Lamp History, see section 6.1.5 on page 40.

53

Maintenance

54

Section 8 Troubleshooting

Problem/Display screen Likely Cause Action

Please insert adapter Z.

Color = ***

Error

Selfcheck stopped.

Please check the lamp.

Please close the lid.

Error [xx]

Error

Selfcheck stopped.

Please remove the cuvette.

Please close the lid.

Error

Selfcheck stopped.

Hardware error.

Error [x]

Error

Too much ambient light!

Move device into shade

or close the lid!

For measurements with 11 mm round

cells the adapter Z is required.

Sample coloring outside the measuring

range.

Self-Check Test stops while starting the

instrument

Self-Check Test stops while starting the

instrument

Electronic defect

The instrument sensors detects too

much ambient light.

Insert the adapter Z into cell

compartment #2.

Press OK.

Dilute the sample or select appropriate

color scale.

Check the lamp and replace, if

necessary.

Close the lid.

Press Start Again.

Remove the cuvette/sample cell from

the cell compartment.

Press OK.

Contact the manufacturer or a sale s

representative and indicate the error

number

Reduce ambient light. (Avoid direct sun

light.)

Close the lid.

55

Troubleshooting

56

Index

A

Alphanumeric keypad .............................................. 15

APHA-method

ASTM D 1500

ASTM D 156

Audio signals

.......................................................... 34

.......................................................... 35

............................................................ 35

........................................................... 19

C

Cell adapter Z ...........................................................11

Color Measurement

Cuvettes/cells

................................................. 16

.......................................................... 47

D

Data

deleting

recalling

sending

storing

Date and Time

DIN 6162

DIN-ISO 2049

DIN-ISO 4630

DIN-ISO 6271

Display

Display and Sound

Disposal

..................................................26, 28, 29

.......................................................26, 29

........................................................26, 29

..........................................................26, 29

......................................................... 18

.................................................................. 34

.......................................................... 35

.......................................................... 35

.......................................................... 34

...............................................................15, 47

................................................... 19

..................................................................... 6

F

Factory Service ........................................................ 41

Filter Settings

........................................................... 27

G

Gardner color value ................................................. 35

H

Hazard Information .................................................... 5

Hazen color value

.................................................... 34

I

Instrument Backup .............................................43, 44

Instrument Information

Instrument Setup

Interfaces

Internet

Iodine color value

.............................................................9, 20

..................................................................... 38

............................................. 37

..................................................... 16

..................................................... 34

L

Lamp, see VIS-Lamp

Language

................................................................. 13

M

Main Menu ............................................................... 16

Maintenance

Mineral oil color value

............................................................ 47

.............................................. 35

O

Operator ID

deleting

Optical Checks

Output Checks

Overview of Product/Function

.............................................................. 17

......................................................... 38

......................................................... 40

.................................... 6

P

Password ................................................................. 24

activating

........................................................... 24

deactivating

PC and Printer

Printer Setup

Printing data

Programm overview

....................................................... 25

.............................................20, 21, 23

............................................................ 21

............................................................. 23

................................................. 16

R

Recall Data .............................................................. 16

S

Safety Information ...................................................... 5

Sample ID

Sample preparation

Sampling

Saybolt color number

Security List

Self-Check

Send Data

Service Time

Software

Spezifications

Stored Data

System Check

System Checks

................................................................ 17

creating

deleting

.............................................................. 17

.............................................................. 18

.................................................. 29

.................................................................. 29

............................................... 35

............................................................. 24

............................................................... 13

................................................................ 27

............................................................ 41

................................................................... 38

............................................................. 3

.............................................................. 26

....................................................13, 41

........................ 16, 37, 38, 40, 41, 43

T

Timer ........................................................................ 19

Touch Screen

Touch-sensitive area

Troubleshooting

........................................................... 15

................................................ 32

....................................................... 55

U

Unpacking the instrument .......................................... 7

Update

..................................................................... 38

V

Verification Kit .......................................................... 38

VIS-Lamp

Lamp Control

Lamp History

..................................................... 40

57

58

Inhaltsverzeichnis

Kapitel 1 Technische Daten .............................................. ...... .......... .......... ......... .......... .......... ......... .......... ........... 3

Kapitel 2 Allgemeine Informationen ...................... ............................................................. .................................. 5

2.1 Sicherheitshinweise ........................................................................................................................................... 5

2.1.1 Bedeutung von Gefahrenhinweisen .......................................................................................................... 5

2.1.2 Warnetiketten ............................................................................................................................................ 5