Additives & Instruments

A member of

Measure what you see.

cloud-runner

Manual

cloud-runner

Manual

Patent pen ding 270 021 236 E 1010

BYK-Gardner GmbH

Lausitzer Str. 8

D-82538 Geretsried

Germany

T el. 0-800-gardn er

(0-800-427363 7)

+49-8171-3493-0

Fax +49-8171-3493-140

ww w .byk.com/instruments

BYK - Gardner USA

9104 Guilford Road

Columbia, MD 21046

USA

Phone800-343-7721

301-483-6500

Fax 800-394-8215

301-483-6555

1

Dear customer,

thank you for having decided for a BYK-Gardn er

product. BYK-Gardner is committed to providing you

with quality products and services. We offer

complete system solutions to solve your problems

in areas of gloss and physical properties. As the

basis of our worldwide business , we strongly believe

in total customer satisfaction. Therefore, in addition

to our products, we offer many VALUE-ADDED

services:

· T echnical Sales Force

· T e chnical & Application Support

· Application and Technical Seminars

· Repair & Certification Service

BYK-Gardner is part of Altana AG and a direct

subsidiary of BYK-Chemie GmbH, a leading supplier

of additives for coatings and plastics. T ogether, we

offer complete and unique solutions for you, our

customer.

Thank you for your trust and confidence. If there is

anything we can do better to serve your needs, do

not hesitate to let us know.

Y our BYK-Gar dner Team

2

T able of contents

T able of conten ts

1. Saf ety instr uct ions ............................................................................. 5

2. Syste m descr iption and De livery notes ...........................................11

Storage structure ................................................................................................ 11

3. Power s upply....................................................................................14

3.1 Rechargea ble b a ttery p ac k ...................................................................... 14

3.2 Docking station power supply ................................................................. 15

3.3 Charging the rechargeable battery ......................................................... 15

4. Controls.............................................................................................16

5. Getti ng st art ed ..................................................................................1 8

5.1 T urning the unit on and measuring ......................................................... 18

5.2 Display of mea su reme n t res ults ............................................................. 2 0

6. Te sting t he ins trum ent......................................................................21

7. Menu opera tion ................................................................................22

7.1 Navi gati on................................................................................................... 22

7.2 Overview of main menu ............................................................................ 23

7.3 Changing names and numbers ............................................................... 24

8. Measur e ............................................................................................2 5

8.1 Measure ...................................................................................................... 25

Interrupt Checkzone ........................................................................................... 27

Parameter Info .................................................................................................... 27

End Test Series ................................................................................................... 27

8.2 ME MORY..................................................................................................... 28

8.3 Orga nizer ....................................................................................................... 2 9

8.4 Memory with Para meter Inpu t ................................................................. 3 1

9 Configuration.................................................................................... 33

9.1 Number of Mea sure ments ....................................................................... 3 4

9.2 Scanlength ................................................................................................. 3 4

9.3 Angles ......................................................................................................... 3 4

9.4 Scale s ......................................................................................................... 3 5

3

T able of contents

10. A dvanc ed Confi guration....................................................................3 6

10.1 Interrupt .......................................................................................................36

10.2 Input Para meter 2, 3 and Comment .........................................................36

10.3 Input ID .........................................................................................................36

10.4 Input Checkzone .........................................................................................36

11. Memor y.............................................................................................37

11.1 Configuration New ......................................................................................37

11.2 Configuration Change ................................................................................38

11.3 Configuration Delete ..................................................................................38

11.4 Data Vie w.....................................................................................................39

11.5 Data Delete ..................................................................................................40

12. Setup................................................................................................. 41

12.1 Beeper..........................................................................................................41

12.2 Confirm with mode .....................................................................................41

12.3 Language .....................................................................................................41

12.4 Info................................................................................................................42

12.5 Date / Time ...................................................................................................42

12.6 Display Time ................................................................................................42

13 . Installation of s oftwa re..................................................................... 43

14 . Interface............................................................................................4 4

15. Technical Data.................................................................................. 45

16 . Info and Err or m essa ges ..................................................................4 7

17. Cleaning and maintenance ............................................................. 51

18. Service and Certification ................................................................53

19. Copyright ..........................................................................................55

4

1. Safety instru ctions

• Before operating the instrument the first time,

• If you use the unit and accessories properly,

• This product is equ ipped with safety features.

• No claims of product liability or warranty can be

• Keep these instructions for future reference.

Safety instructions

please read the operating instructions and take

particular notice of the safety instructions.

there are no hazards to fear .

Nevertheless, read the safety war nings carefully

and use the product only as described in these

instructions to avoid accidental injury or damage.

honored if the device is not operated in

accordance with the operating instructions.

• If you pass this instrument to somebody else,

make sure to include these instructions.

5

Safety instructions

The following symbols and terms are used.

This symbol warns of the danger of injury.

This symbol warns of the danger of injury caused by

electricity .

This sign points out add itional information.

DANGER

The term DANGER warns of pos sible severe

injuries and da nger to life.

WA RNING

The term WARNING warns of injuries and severe

material damage.

CAUTION

The term CAUTION warns of slight injuries or

damage.

6

Safety instructions

DA NGE R injur ies poss ible

• Defects and extraordinary loads

If safe operation can no longer be presumed,

shut down the device and secure it against

unintended operation.

The device must be presumed unsa fe to operate:

• if visible damage is evident

• if the instrument is no longer working

• if it has been stored for long periods under

adverse conditions

• after hars h treatment during shipping.

• Safety advices for batteries: Do not crush or

dismantle, do not heat or incinerate, do not

immerse in any liquid. This may cause explosion

or release harmful substances.

• Do not perform any repairs on the unit yourself.

The unit must be opened by trained

professionals only. Please contact our customer

service department in such cases.

• The measu rement device may be disconnected

from any power source as follows:

a) by removing the rechargeable battery pack

Docking station:

a) by disconnecting the plug from the docking

station or from

b) the mains socket.

Please make certain that the power supply plug is

easily accessible. Use only the power supply

included with delivery.

7

Safety instructions

• When working with the batteries make certain

there is no short circuit on the contacts. Metallic

objects must not come in contact with the bare

contacts.

WARNING severe materi al damag e

• The measurement unit consists of sensitive

optical and electronic precision parts. Prevent it

from being dropped, bumped or shaken!

• Avoid exposure to continuous hu midity and

condensation. A void splashing with water ,

chemicals or other liquids.

• Please use only accessories that are available

for the unit.

• Only devices that meet the requirements for low

voltage safety may be connected to the

interface.

8

Safety instructions

CAUTION material d amag e

• Do not allow any foreign objects to get into the

measur ement opening .

• Do not expose the unit to direct sunlight for

extended periods of time. Do not store it in a hot

or dusty environment. Use the instrument case

for storage.

• Recharg eable Li-Ion battery packs: Do not

charge at temperatures below 0°C. The allowable

discharge temperature range is -20 to +60°C.

Please refer to the charging instructions in

section „Power Supply“.

• D o not us e a ny a c e tone for clea ning the

unit! The unit housing is resistant to many

solvents. For cleaning you should use a soft,

moist cloth. Excessive dirt and dust can be

removed with ethanol or cleaning alcoho l.

• In case you intend not to use the instrument for

a longer period of time, take out the batteries.

Addit onal infor mation on use:

• You will find the technical data for all system

components on the res pective manufacturer’s

plates and in the section T echnical Data

• Batteries are special waste and must therefore

not be disposed of with household trash. Make

certain to observe the disposal instructions of the

battery or rec hargea ble battery manufacture r.

9

System description and Delivery notes

2. System description an d Deli v er y notes

Please read the instruction manual before using the

instrument and note the safety instructions.

The instrument simulates visual evaluation under

different obse rving angles and ch aracterizes clouds /

mottles by their size and visibility.

The measurement system consists of the portable

measurement device, docking station and the

smart -char t progr am.

Depending on the application, the system can be

used in various ways, from single measurements in

R & D up to routine quality control procedures (e.g.

automobile).

In order to guarantee a flexible data analysis, it is

essential to allocate the data to a clearly defined

object (identification).

10

The so-called “Organizer” file clearly defines the

object to be measured. The Organizer needs to be

created in the smart-chart software and defines the

measurement s equence ( sampling proce dure). This

file is transferred to the instrument then to guide the

user d uring measur ement.

Storage structure

System description and Delivery notes

The saved results are transferred to the PC and

displayed as a QC report.

The data is saved in a database for further analysis

over time. Pre-prepared test reports in the smartchart software assist in analyzing the data.

Each measurement series contains a header and

the individual measurements with name (test zon e)

and measured values.

In the header, up to 5 par ameters can be defined for

object identification. Parameters 1 to 3 are defined

in the Organizer file, parameters 4 and 5 can be

entered before storage in the data base.

Additionally, date and time of the measurement are

stored.

This structure determines the data organization in

the instrument and in the data base. In addition to

using Organizers, i. e. definition of parameters

before

the measurements, parameters and test

zones can also be entered during the

measu rements . See cha pter “Memo ry”.

11

System description and Delivery notes

Application hints:

Measurement task

1. Single measurements, e.g.

occasiona l sample-measurements

2. Objects with several test zones.

T est sequ ence / identifikation can be

standardized, e.g. automobile or addon parts

3. Regular test series. Test

sequence / identifikation can be

standardized, e.g. batch control

4. Occasional test series. Test

sequence / identifikation can not be

standardized, e.g. projects

Recommendation

- Me nu “Meas ure“ > “MEM ORY“.

- Transfer results to smart-chart.

- Generate Organizer in smartchart and transfer it to the

instrument.

- T ake readings, see chapter 8.3.

- Transfer results to smart-chart

and store in data base.

- Data analysis smart-chart.

see 2.

- Generate new Memory (chapter

Memory, Config. New).

- T ake readings, see chapter 8.2.

- Transfer results to smart-chart.

12

System description and Delivery notes

cloud-runner AM-6350

Comes complete with:

Mottling meter with pr otective cover, Reference tile

with certificate, smart-chart software on CD,

Docking station with USB cable, 2 rechargeable LiIon battery packs, Operating manual, Carrying case.

Acces sories and Replacements:

Reference Tile AM-6353

Docking S tation AM-6351

Battery Pack AM-6349

smart-chart sofware AW-4831

13

Power sup ply

3. Power supply

Before operating the instrument for the first time,

please read the operating manual and take

particular notice of the Safety Instructions. Unpack

the instrument and check the delivery for

completeness (See chap ter “Delivery Notes”).

Powering the ins trument

The measurement unit is operated with the

Rechargeable

batt ery pack

3.1 Rechargeable battery pack

rechargeab le battery pack included w ith delivery.

T o place the instrumen t in service, the rechargeab le

battery pack must be inserted until it locks in place.

The battery pack can only be attached when it is in

the correct position.

When inserting the battery pack, ensure that its

contacts are aligned with those of the instrument.

See adjace nt figure.

The capacity of the rechargeable battery pack

included with de livery is sufficient for about 1000

measurements. When the voltage of the battery

pack falls below the requ ired operating voltage in the

course of operation, the following messag e appea rs

on the display:

“Low Battery!”

14

Note: To ensure uniform utilization, the rechargeble

battery packs should be exchanged regularly

between instrument and docking station (weekly

recommended).

3.2 Docking station power supply

Power is supplied to the docking station through the

external power supply unit. Connect the external

power supply unit to the docking station. Connect

the appropriate end of the power connection line to

the power supply unit and the plug end of the power

connection line to the pow er outlet after verifying

that the specifications of the power supply unit

match the power source in terms of current and

voltage.

3.3 Ch arg i n g t h e rech arg eab l e bat tery

The rechargeable battery pack included with delivery

may be charged in the docking station. Charging

time for an empty battery pack is aprox. 2 hours.

Please note chapter “Safety Instructions”!

1. Battery pack in the instrument:

The lithium ion rechargeable battery will begin

charging immediately upon insertion of the

instrument into the docking station. To do this,

power must be supplied to the docking station

through the correspo nding power s upply unit.

Insert the measurement unit into the docking station

as show n in the neighboring illustration.

2. Battery pack on docking station:

A second charging shaft is located behind the shaft

for the instrument. Insert the second battery pack

here for charging, so it will be handy at any time to

replace the other battery when it is discharged.

Power sup ply

1 2

Charging indicator for:

1: additional battery pack

2: ins trument

Indication light:

green:ready

red: charging

15

Contr ols

4. Controls

2

1

3

7

4

5

6

Measur ement unit

1 Mode scroll wheel: Menu selection

2 Display for user guidan ce and meas urement values

3 Signal lamp

4 Operate button: Turn on, measurement and confirmation of menu items.

5 Measur ement aperture

6 Cover

7 Opening for hand strap

16

Contr ols

The basic system consists of the measurement

device and the docking station.

The docking station is used to exchange data and

to charge the rechargeable battery pack.

When the unit is not in use, place it in the docking

station. In this way the rechargeable battery pack

will be charged and the instrument will always be

ready for measurements.

The operate button and scroll wheel are used to

control the system. Pressing “operate“ turns the unit

on and causes a menu to be displayed. All settings

within the menus are made by turning the wheel and

pressing “operate”.

Pressing the o perate button performs

measurements or runs selected functions. System

operation is supported by an autodiagnosis test,

comments and error messages. Measurement

values and comments appear in the display.

17

Getting started

5. Getting st arted

5.1 Turning the unit on a nd mea suring

Turn the instrument on by pressing the operate

button.

If the operate button is depressed while switching

the unit on, a reference to the firmware appears

along with the date of the last certification.

The unit then switches to the last measurement

mode to be selected.

If no measurement mode has been previously

selected, the main menu appears. For the first

steps, select MEMORY under the “Measure” menu.

T o perform a measurement, press and hold the

operate b utton.

Move the instrument evenly and slow ly over the

sample surface.

18

During the measurement, the following information

appears in the display:

The upper bar shows the progress of the

measurement, while the arrow shows the scan

direction. The two lower bars provide information

about the status of the memory and battery

capacity.

Getting started

After completing a measurement, a signal is heard

and the measurement results are displayed.

Performing the measuremen t requires so me

practice. The following error messages a re

especially likely to occur during the first trials.

A warning signal is heard and the light diode flashes

at a rapid rate. At the same time, a message

appears in the display indicating the type of error:

Speed

Y ou have moved the measurement unit too quickly

or unevenly over the s ample. Confirm this

information by pressing the operate button and

repeat the measurement.

Scan length

The required scan length has not been reached

completely .

Repeat the meas urement, moving the device until a

short audio confirmation is heard.

Small areas can be measured by moving the

instrument back and forth.

Direction

The scan direction was changed.

Confirm the message by pre ssing “opera te” and

repeat the measurement.

19

Getting started

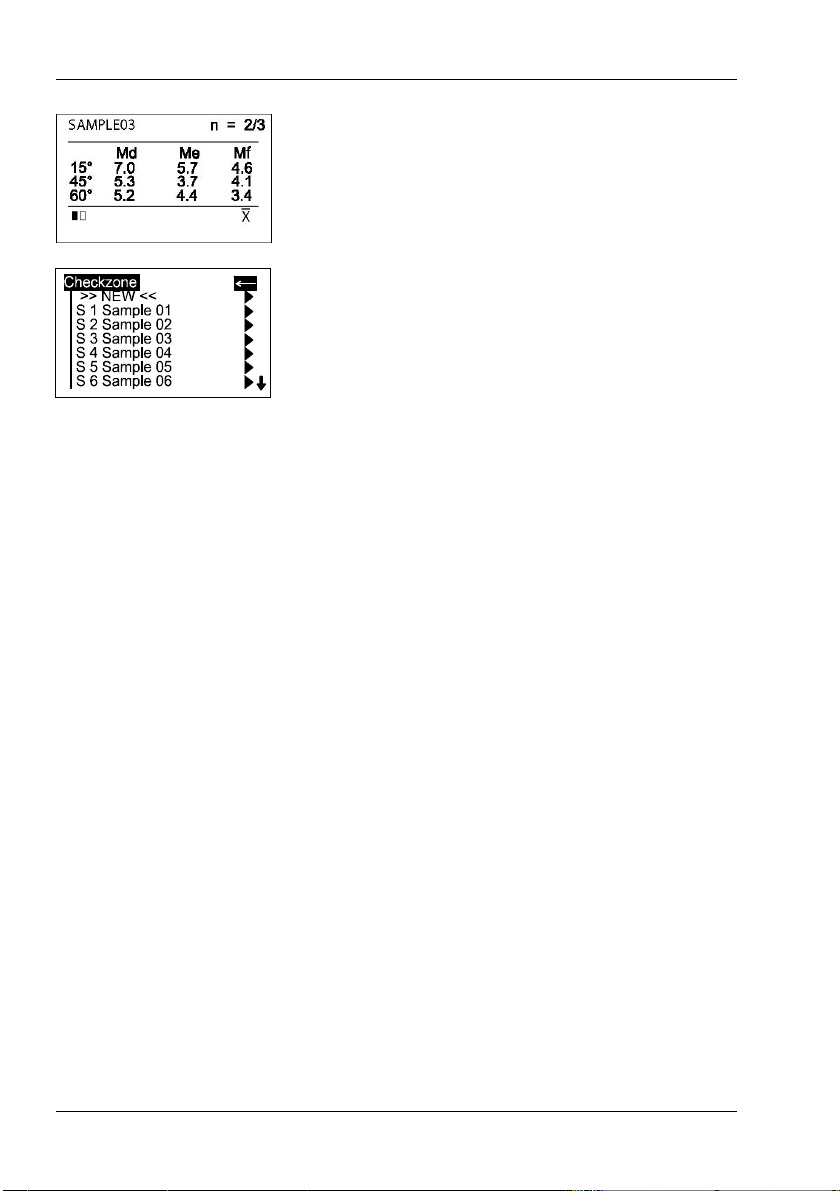

5.2 Display of measurement results

The measurement resu lts displayed w ill vary

A B

C

depending on the options selected in the

Configuration (see chapter 9, 10). Displayed results

may be broken down into the following elements:

A: Name of the measured sample or checkzone.

B: The number of performed and predefined

measurements (e.g. 2 of 3). The statistic function is

activate if the predefined number of measurements

is greater than 1.

C: The black rectangle shows the active page of the

display. You can access the second page by turning

the scroll wheel. If only one page is active, only one

rectangle is shown.

The measurement values appear in the lower part of

the display area.

Pressing the operate button now , the values will

disappear and the number of readings is increas ed

by one. Or, if a sample is finished, the name of the

next checkzone/sample will be displayed.

20

T o exit the measurements, press the scroll wheel. A

menu for deleting, interrupt or ending the series

appears. Use the scroll wheel to move the cursor to

“End T es t Series” and press operate. The display

switches to the Measure menu after a request for

confirmation.

6. Testing the instrument

Due to the measurement principle, calibration of the

equipment is not necessary. It is recommended,

however, to check the functionality of the instrument

at regular intervals (abou t once every 3 months). The

reference tile include d with delivery is provided for

this purpose.

Select the “Standard” in the Measure menu. The

configuration of this organizer is fixed and cannot be

changed.

The unit then switches to the measurement mode.

Place the instrument on the test tile as shown

above and perform three measurements.

If the values measured on the re ference tile are

within the printed tolerance range, the re quirements

are met.

If the mean value is not within the desired tolerance

range, try carefully cleaning the test tile. If this

produces no improvement, please con tact our

Customer Service department.

Reference tile:

T o ensure a precise instrument test, only original

test tiles from the manufacturer should be used.

Their surface must not be touched and must be

protected against scratches . Due to environmental

influences, however, the values of test tiles can

change over the course of time even if they are

handled gently. For this reason, have the test tiles

checked by the manufacturer at regular intervals

(annual checks are recommended). For cleaning the

test tile refer to chapter 17.

T es ting the instrument

21

Menu operation

7. Menu operation

7.1 Navigation

*

All functions are controlled by the mode scroll wheel

and the operate button.

Pressing the operate button or the scroll wheel

causes a menu to appear in the display. Turning the

wheel allows you to move the cursor to the desired

function. Select or activate the function by pressing

the operate button.

The following symbols can be found througho ut the

menus to aid navigation:

A black triangle to the right of a function indicates

that selecting this function will open a sub-menu.

The arrow at the top right is used to move back one

level within the menu system.

A check mark on the right indicates that the function

in question has been activated.

In submenus which require a selection, the actual

setting is indicated by a dot.

The star guides you to the Language menu.

22

Menu operation

7.2 O verview of mai n men u

Measure

MEMORY Default memory for single measurements

MY MEMORY User-defined memory (appears only if

generated under “Memory” menu)

Standard T o verify the device function on the test panel

My Model Measurement with Organizer (appears only if

loaded from PC)

Memory

Config. New Create a ne w memory

Config. Change Change the settings of a memory

Config. Delete Delete a memory

Data View View measured data of a memory

Data Delete Delete measured data

Setup Cha nge the language, date/time and switch-

off time; activate audio s ignal and

confirmation by scroll wheel.

23

Menu operation

7.3 Changing names a nd numbers

For some functions, you can enter or change the

date or name. The triangle pointing upw ard marks

the item that can be changed. T o change the

character, turn the scroll wheel. When you press

the scroll wheel, the arrow jumps to the next

charac ter .

After you have adjusted the last character, confirm

your input by pressing the operate key.

A confirmation message appears which allows you

to save the settings or change incorrect entries. Use

“Cancel” to exit the function without making any

changes.

24

8. Measure

8.1 Measure

Measure

For beginning a new test series, select Measure

from the Main Menu. The Measure menu offers a list

of names to identify the new test series

(Parameter1). Individual entries can be added to t he

list.

Two types of test procedures can be differenciated

by a symbol in front of the names:

Memories:

generated in the instrument, allow to input

identification parameters during measurement

procedure.

Organizer:

down loaded from the smart-cha rt softwar e, offer a

predefined test proced ure for user guida nce and

identification.

A virgin instrument contains only two entries in the

menu, which can not be deleted:

MEMORY - for simple measurement of samples.

Standard - for checking the instrument on the test

tile (see chapter 6)

Select a desired item from the list to start the test

series and perform the measurements according to

section 5.

Differences between the measurement procedures

will be explained in chapter 8.2 to 8.4.

25

Measure

T o exit a measurement series, press the scroll

wheel. A menu a ppears for deleting, interrupt and

ending the series:

Delete Last

Deletes the last measurement within a

checkzone.There is no ad ditional warning before the

deletion.

Delete Checkzone

Deletes the entire last checkzone. There is no

additional warning before the deletion.

Delete T est Series

Deletes the entire measurement series. A

confirmation display app ears before final deletion.

26

Interr upt Che ck zone

Parameter Info

End Test Series

Measure

This function allows you to exit a checkzone/sample

before reaching the pr eset number of measurements

or to skip a checkzone. Then you can continue the

measurement series with the next checkzone.

If Interrupt is not activated in the Configuration menu

(Chapt. 9) or the Configuration of the selected

Organizer, a message will be displayed.

Gives you an information about the selected

parameters of the sample.

Ends the entire measurement series. A confirmation

display appears. The instrument returns to the

Measure menu.

If Interrupt is not activated in the Configuration, a

message will be displayed in the case that the test

series is not finished yet.

Note:

Only complete series can be saved, i.e. you can

exit series only by deletion.

27

Measure

8.2 MEMOR Y

This is a memory with default settings for single

measurements on samples.

The settings can be changed for individual needs,

e.g. scale selection, statistics or scan length.

For further information pleas e refer to cha pter

“Configuration”.

Changes in the configuration are only possible if no

measurement data are s aved under the de sired

memory name. Before you change the configuration,

first backup the stored data and then delete them.

28

8.3 Organizer

Measure

An organizer file defines a test sequence for user

guidance, e. g. for measuring a car body with

several checkzones. These files can be generated

with the smart-chart software.

If no Organizer is loaded in the device, one must be

trans ferred from a PC.

Once an Organizer is selected, a menu appears for

Parameter 2 of the Organizer. Colors are listed as

an example of this in the menu to the side. After you

have selected the appropriate color, a selection

menu appear s for Parameter 3.

The illustrated example featu res automotive paint

line s.

If “Input Comment” is activated in the Organizer ,

you are prompted to enter ad ditional information.

If “Input ID” is activated in the Organizer , you are

prompted to enter a code, e.g. the vehicle ID.

Upon definition of all parameters, the following

measurement series is identified and the instrument

goes into measurement mode.

29

Measure

The name of the checkzone to be measured first,

appears on the left side of the display.

The number of performed and predefined

measurements (e.g. 2 of 3) appear in the upper right

corner.

Once the number of measurements for the

checkzone is reached, a double audio signal is

heard.

The display shows the results of the measurement

and indicates that the measurement of the

checkzone is complete (e.g.3/3).

Pressing briefly the operate button allows the next

checkzone to appear in the display.

The instrument is ready for the next measurement.

30

Once all checkzones have been measured, the

instrument returns to the Measure menu.

8.4 Memo ry w ith Parameter I np ut

By using the internal memory function of the

instrument, measurement series and samples/

checkzones can be identified by individual names

during the test procedure.

Therefore, input options of the menu item Advanced

Configuration nee d to be activated for the desired

memory.

Y ou can us e the existing MEMORY in the

instrument or create another memory name

(Parameter 1). For more information about cha nge of

configuration please refer to s ection Configuration.

Select a memory for which Input Parameter 2, 3,

Input Comment or Input ID are activated. A menu

appears to assign a name.

If there are preexisting names for this memory, they

are shown in a list for selection. The >>NEW<<

option opens another menu with a list of all names

available in the instrument. Here, the menu item

>>NEW<< opens an input mask which allows you

to create a new designation.

Enter the name by using the scroll wheel. When

finished, press the operate button.

A confirmation display appears which allow s to verify

that the entered data is correct.

Next, a selection menu may appear to enter an

additional para meter. Proceed a s des cribed above.

Measure

If a memory is selected that already contains

measurements, the test series can be continued.

A display appears to confirm this. By selecting No,

a new test series will be started.

The device goes to the measurement mode, you

can start taking readings.

31

Measure

Once you have reached the prese t number of

measurements (n = ...), you might be prompted to

enter a name for the checkzone (“Input Checkzone”

aktivated).

Proceed by entering the name of the checkzone as

described above for the parameters.

If “Input Checkzone” is deac tivated, the instrument

automatically assigns the name SAMPLE 01 and

then increments this name.

To exit the test series, presss the scroll wheel and

activate End T est Series.

32

9 Configuration

Configuration

For every memory, specific settings can be made

that affect the test procedure an d the evaluation of

the data.These s ettings are individually definable in

the Memory menu:

Config New

for a new memory

Config Change

for an existing memory

Once a memory is selected, the menu with the

various configuration items appears.

The complete contents of the menu are shown in

the neighboring illustration.

The current settings are displayed on the right side

next to the black triangles.

To exit the menu, scroll the cursor to

and press the operate button.

A display appears to confirm the changes.

33

Configuration

9.1 Number of Measurements

This function allows selection of the numbers of

readings to be taken per sample. If the number is

greater than 1, the measurements are statistically

evaluated. Turning the scroll wheel adjusts the

number while pressing it shifts the decimal place

one further over. Press ing operate completes the

process and a confirmation display appears.

9.2 Scanlength

The scanlength is adjustable between 10 and 100

cm in 1 cm steps to your individual needs. The little

black triangle shows the position to be adjusted.

Turn the mode wheel to adjust or press the wheel to

proceed to the next position. Pressing operate

completes the process and a confirmation display

appears.

Y ou can enter the scanlength alternatively by

pressing the operate button and by moving the

instrument over the surface to be scanned. Keep

the operate button pressed until the desired length

is reached. Then release the operate button. The

scanlength is displayed and you can confirm it by

press ing operate again.

9.3 Angles

34

Note:

Using a short scanlength will result in strong

statistical skewing of measurement values for large

mottle sizes (for minimum scan length please see

also under 9.4).

Three angles may be selected for the display of the

measurement results.

Select the desired angle and press the operate

button. A checkmark indicates the selected

angle(s).

9.4 Scales

Configuration

Eight scales may be selected for the display of the

measurement results.

Following scales are available:

Mottle S pe ctrum: Md...Mi

The measurement sign al is filtered into 6 different

ranges, which represent a s pecific range of mottle

sizes.

Mottle Ch art: T, M

a two-dimens ional evaluation of small and large

mottles.

T exture: a measure for mottles smaller ~ 25mm

Mottling: a measure for mottles larger ~ 25mm

Select the desired scale and press the operate

button.

Note:

Depending on the mottle size, a minimum scan

length is requ ired for measurement of:

Md to Mi 75 cm

Md to Mh 42 cm

Md to Mg 23 cm

Md to Mf 13 cm

Md to Me 10 cm

M 23 cm

35

Advanced Configuration

10. A dvan ced Configuration

10 .1 Interr upt

If statistic is activated in the configuration of the

selected memory (n > 1), you can interrupt a

checkzone (sample) before reaching the preset

number of meas urements.

10.2 I n put Parameter 2, 3 and Comment

When active, these parameters allow to assign

individual names for identification of a new test

series.

10 .3 Input ID

When this function is active, you can enter an

identification code e.g. vehicle ID number for each

new test series.

10 .4 Input Checkz one

When active, you can enter a des ignation for every

sample during a test series. When deactivated, the

instrument automatically assigns sample names

incrementally, beginning with SAMPLE 01.

36

11. Memory

1 1. 1 Configur ation New

Memory

In the Memory menu you can create new memories

with a configuration according to specific needs

(e.g. scales, statistics). Also, the configuration of

existing memories can be changed. Memories

which are no longer needed, will be deleted with the

function “Config Delete”.

Additionally, the menu allows to recall or delete a

measured test series.

After selecting this menu item, you will be prompted

to enter a name for the new Memory (Parameter 1).

Enter a name by using the scroll wheel. When

finished, press the “operate” button.

A display appears to check and confirm the entries.

The next step allows to copy the configuration from

an existing Memory or Organizer. Select the desired

entry from the list.

A menu will then appear with the copied

configuration for the new Memory .

T o change the settings, refer to chapter 9 and 10.

T o exit the menu, activate the arrow at the top of the

list. A confirmation display appears to complete the

creation of a new memory. The display now returns

to the Memory menu.

37

Memory

1 1 .2 Configura tion C hange

This function allows to modify the configuration of an

existing memory. A menu appears with a list of the

existing memories and organizers.

Select the desired memory.

A menu then appears listing the configuration of the

selected memory. T o change the settings, refer to

chapter 9 and 10.

T o exit the menu, activate the arrow at the top of the

menu.

Note: Changes to the settings of Organizer files are

not permitted. If an Organizer is selected, a warning

message w ill appear.

The configuration can only be changed if no

readings are s aved in the selected memory . Before

changing, first backup the readings and then delete

the data.

1 1 .3 Configuration D elete

38

The delete function opens the s election menu for the

memories wh ich are present.

Select the memory to be deleted.

A display appears to confirm the deletion process.

The instrument returns to the Memory menu.

Note: Deletion of a memory that contains

measurement data is not permitted.

If necessary, use the Data Delete function described

at the end of this chapter.

Deletion of an Organizer is only permitted if its

corresponding lock-function is deactivated in the

smart- chart s oftwa re (o rgan izer prote cted ).

11.4 Data V iew

Memory

Y ou can use this function to display all

measurement series stored in the instrument.

First, the selection menu for existing memories will

be shown.

Select the desired memory to recall its contents. If

the selected memory is identified by additional

parameters, further menus w ill appear:

Select Parameter 2.

Select Parameter 3.

As appropriate, select Comment and ID accordingly.

Finally, select the measurement series itself under

date and time.

The measurement values appear in the display.

Press the operate button to display the next

checkzo ne.

The numbers at the upper left of the display

represent the displayed/existing checkzone

numbers.

The checkzone name is displayed just below.

If more measurement data is present than can be

displayed, an arrow will appear on the right edge of

the display. Scroll down to view the remaining data.

Pressing the scroll will exit this display. The

instrument returns to the Memory menu.

39

Memory

11.5 Data Delete

This function deletes a desired test series stored in

the instrument.

Select the memory containing the data to be

deleted.

For the following selection of parameters and the

measurement series itself, please proceed as

described in the previous pa ragraph, Data View .

After selecting the desired test series, a display

appears to con firm the deletion.

The instrument returns to the Memory menu.

Note:

Measurement data of Organizers may only be

deleted if its corresponding lock-function is

deactivated in the smart-chart software(Organizer

protected).

40

12. Setup

12 . 1 Beeper

12 .2 Confirm with m ode

Setup

In the Setup menu you find functions to adjust the

following general settings of the instrument:

This menu option turns the beeper on or off. Use the

scroll wheel to move the cursor to Beeper and press

“operate”.

When the beeper is activated, a checkmark appears

at the end of the line.

Setting a checkmark on this option, activates the

function to select menu items by pressing the scroll

wheel too.

12 .3 Language

You can use this menu to select the display

language.

If a foreign language is activated actually, you

allways can find the language settings by following

the symbol in the menus.

*

Use the scroll wheel to move the cursor to the

desired language and press the operate key.

41

Setup

12.4 Info

12.5 Date / T ime

12.6 Display Time

This menu displays the following information about

the device:

• Catalog no

• Serial no

• Firmware version

• Free memory capacity

• Battery capacity

• Date of last certification

The unit contains an integrated clock. This makes

the date and time of the measur ement available for

data transfer to a PC. The date and time are not lost

even when the battery is changed. If necessary,

adjust the data by using the scroll wheel.

T o s ave energy, the unit automatically turns off after

a certain amount of time. You can determine what

this time is by specifying a switch off time between

15 and 99 seconds.

42

13. Installation of software

Before you install the software, make sure your

computer meets the following system requirements:

• Operating system: Windows® XP SP3 or higher

• Excel® version: 2003 incl. VBA

• Memory: min. 1GB

• Hard disk capacity: min 100 MB

• Monitor resolution: min 1280 x 1024 Pixel or higher

• Disk drive: CD-ROM or DVD

• Interface : Free U SB-Po rt

• Microsoft .NET Framework 3 .5 SP1

Running setup:

During installation full administrator rights are

necessary . You might need to contact your IT

support for this purpose.

After inserting the CD in the CD-ROM or DVD drive

Windows® starts the installation automatically. If

this is not the case, please run the file „install.exe“

in the main directory of the CD.

Follow the setup instructions on the screen.

Y ou are allowed to install and use the software on

up to two computers.

After successful installation the software can be

started via Start – Programs – BYK-Gardner –

smart-chart.

Installation of softw are

Note:

If you experience a limited functionality of the QCreports, please check the security settings of the

macro-function in Excel and set the level to

med iu m.

*Mi cros oft Wi ndows and E xcel ar e tradem arks of Mi cros oft C orp oration

43

Interface

14. In terface

Connecting the measurement unit to a PC

Data transfer to and from the measurement unit

takes place through the docking station. It contains

the USB interface connecting the instrument with a

PC.

The connection point for the USB cable is located

on the back of the docking station. Plug in the cable

included with delivery.

T o transfer data, the instrument must be inserted

into the docking station.

The data transfer itself takes place with the smartchart program, which is included with delivery .

Set up the computer and additional instruments as

described in the corresponding manuals. T o transfer

data, the connection cable must be connected to a

USB port. For the position and assignment of the

socket, please refer to your computer manual.

44

T echnical Data

15. Technical Data

General tech nical d ata:

T emperature range 10°C to 40°C (+50°F to 104°Foperation)

0°C to 60°C (+32°F to 140°F storage)

Rel. humidity up to 85% at 35°C (95°F), non-condensing

Measurement unit:

Application:

Clou d s ize Md 6 to 13 mm

Me 1 1 to 24 mm

Mf 19 to 42 mm

Mg 33 to 72 mm

Mh 57 to 126 mm

Mi 100 to 200 mm

Repeatability 5% or > 0.5 (standard deviation)

Reproducibility 8% or > 0.8 (standard deviation)

Object curvature > 500 mm

Scanlength 10 to 100 cm, selectable in 1cm steps

Smallest sample size 35 mm x 150 mm

Resolution 25 points / cm

Measuring Time < 4 sec.

Memory 1 000 reading s

Interface USB 1.1

Languages English, French, German, Italian, Japanese,

Portuguese,Spanish

Light Source White Power LED

Power sup ply rechargeable battery pack, approx. 1500 readings

Dimensions (WxLxH) 55 x 150 x 110 mm (2.2 x 5.9 x 4.3 in)

Weight 650 g (1.5 lbs.)

45

T echnical Data

Docking station:

Power sup ply 5 VDC; 2.5 A

Dimensions (WxLxH) 130 x 160 x 85mm (5.1 x 6.3 x 3.4 in)

Weight 450 g (1 lbs.)

External power supply:

Power sup ply Input: 100-240 VAC; 50/60 Hz; 800 mA

Output: 5 VDC; 4.0 A

Dimensions (WxLxH) 95 x 55 x 35mm (3.7 x 2.2 x 1.4 in)

Weight 320 g (0.7 lbs.)

46

16. Info and Error me ssages

Error

If an error occurs while using the instrument, the

display will indicate the error type.

Confirm the error by pressing the the operate button.

Repeat the process or the entry.

In the upper right corner, an additional number is

shown for service purposes.

Info

Informative displays always appear when deviceinternal settings or limits are reached or exceeded.

Confirm the message by pressing the the operate

button.

Info and error mess ages

47

Info and error mess ages

Error Messages

Identifies an interna l error . Load a firmware u pdate.

When in doubt, call the Customer Service

department.

The measurement unit was moved across the

sample too fast. The measurement is invalid and

must be repeated.

The operate key wa s releas ed before the full

scanlength was rea ched. Perform a new

measurement.

Day or month falls outside the valid range of 1 - 31

or 1 - 12. Repeat the entry.

Appears whe n the number of measurements in

“Memory-Config Change” is set to a value less than

1 or greater than 20. Repeat the setting with a value

between 1 and 20.

48

The specified year falls outside the valid range from

2000 to 2100. Please repeat the input with a valid

year.

Info and error mess ages

Error Messages

While adjusting the Display Time, you entered a

value outside the valid range from 15 - 99. Please

repeat the entry w ith a valid value.

Appears w hen the maximum number of

measurement series is reached for the selected

memory area.

No more free memory capacity available. Delete

measurement series w hich are no longer required.

Appears w hen you have measured 100 che ckzones

with one memory area. Create a new memory area

and continue your measurements.

When attempting to measure an Organizer near the

end of memory capacity, the instrument can detect,

based on the Organizer structure, that memory will

be exhausted before the en d of the measurement

series. It then generates this error before the

measurement b egins.

49

Info and error mess ages

Informa tion

The setting option “Interrupt” for the selected

memory is not activated or not allowed (Organizer).

Warning message indicating that measurement

values are present in the memory selected for

deletion.

Y ou can only assign a maximum of 100 sample

names per memory. That number has be en reached.

Y ou can only assign a maximum of 500 names for

Parameter 2 per memory. Tha t number has been

reached.

Y ou can only assign a maximum of 20 names for

Parameter 3 per memory. Tha t number has been

reached.

50

Y ou have ass igned an already existing name while

filing a memory area.

Y ou have attempted to change the settings of an

Organizer. Organizers cann ot be changed.

Y ou have attempted to delete a protected Organizer.

This notice appears when 95 % of the device

memory is filled.

17. Cleaning and maintenance

• Before cleanig, the instrument and accessories

must be disconnected from the power supply as

described in the safety instructions.

• Do not insert any objects into the measurement

aperture for cleaning. The instrument could get

damaged - a ffecting a pro per and s afe operatio n.

• Do not use any acetone! The instrument

housing is resistant to a number of solvents, but

cannot be guaranteed to withstand all chemicals.

Y ou should therefore use a soft, moist cloth for

cleaning. For cleaning excessive dirt, use

ethanol or cleaning alcohol.

• A cleaning mat to clean the unit’s wheels is

situated on top of the reference tile’s cover.

Therefore, roll the wheels several times over the

mat and then over a cleen sheet of paper. Dirt

will stick to the mat and can be removed with

clear water.

Cleaning a nd maintena nce

51

Cleaning a nd maintena nce

Cleaning the test tile

• Do not use any acetone!

The accuracy of the measurement can be

significantly impacted by using a dirty or

damaged test tile.

Since the surface of the test tile is highly

sensitive, cleaning must be undertaken with

great care.

T o clean the test tile, use a new lint-free cloth,

dust-free lens paper or an optical cloth.

Apply only slight pressure as you clean and

make certain there are no large particles stuck in

the cloth that could damage the surface.

For dirt that is difficult to remove, use an premoistened optical cloth. Then wipe the surface

with a dry optical cloth.

If the condition of the test tile seems doubtful

because of its appeara nce or measurement

errors, we will be happy to check it for you.

52

18. Service and Cer tification

Service

Besides the repair of your instrument we offer the

following ad ditional ser vices:

First diagnosis on the telephone or by e-mail

Call us or send us an e-mail and we will try to solve

your problem. If this is not successful, please send

us the instrument for repair.

Preventive main tenance, calibrati on, an d

recertification

For precautionary reaso ns we re commend regular

preventive maintenance. We carry out this preventive

maintenance automatically when you send us your

instrument for maintenance and rec ertification. We

clean the optics, check all functions, test and, if

required, adjust the measured values by using

reference standards . Y ou will receive a certificate,

which includes the retraceability to international

standards.

Loaners

During the period of repair we furnish you with a

loaner on req uest an d availability.

Maintenance agreement

In case you want to make sure that the necessary

maintenance is being done on a regular basis and

on time, we recommend a maintenance agreement.

Extended warranty contracts

Furthermore, you can request an extended w arranty

contract for additional 12 months.

Order ing infor ma tion:

SE-6350 extended warranty

Service and Certification

53

Service and Certification

Service Centers for BYK-Gardner products

Germany

BYK-Gardner GmbH

Lausitzer Strasse 8

82538 Geretsried

Germany

Phone:+49-8171-3493-0

Fax: +49-8171-3493-166

USA

BYK-Gardner USA

9104 Guilford Road

Columbia, MD 21046

USA

Phone:+1-301-483-6500

Fax: +1-301-483-6555

China

BYK-Gardner Shanghai Office

Room 1407, SIP AI PLA ZA

103, Cao Bao R oad

Shanghai 200233

P .R. C hina

Phone: +86-21 -6475-8570

Fax: +86-21-6475-7284

54

Brazil

BYK-Gardner La tin America

Rua das Aroeiras, 771

Bairro Jardim-Santo André-SP

CEP 09090-000

Brazil

Phone:+55-11-2147-1 199

Fax: +55-11-2147-1168

Copyright

19. Copyright

This instruction manual is an important part of this instrument. It co ntains essential information about setting up, placi ng in service and use. If you pass

the device on to another user , ple ase ensure that the instruction manual is

included with the instrume nt. The manual must be studied careful ly before

working with the equipment. Please contact your regional service office if

you have any questions or require additional information about the device.

The technology and fittings are based on state-of-the art optic and

electronic techno log y . New devel opments and innovati ons are co nstantly

being integrated into the equipment. Thus, the diagrams, dimensions, and

technical data used in this manual may have changed as a result of adapting

the device to new infor mation and improvements.

© Copyright 2010 B YK -Gardner GmbH

All righ ts reserv ed

No portion of the software, documentation or other accompanying materials

may be translated, modified, reproduced, copied or otherwise duplicated

(with the exception of a backup copy), or distributed to a third party, without

prior written authoriz ation from B YK -Gardner GmbH . In any case, this

requires the prior writte n consent of B YK -Gardner.

BYK -Gardner GmbH of fers no guarantee that the software wi ll functio n

without error or that the functions incorporated therei n can be executed in all

applications and combinations selected by you.

No liability other than as provided by law is assumed for direct or indirect

damage sustained in associa tion with the use o f the instrum ent, the software

or documentation.

BYK -G ardner GmbH reser ves the right to update the sof tware and written

documentation without prior notice .

55

270 021 236 E 1010

Loading...

Loading...