Page 1

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL –

ALLISON 4TH GENERATION CONTROLS

DIAGNOSTIC TROUBLE CODES (DTC)

W elcome to the TS3989EN T roubl eshooting Manual. We make every effort to keep our service information current

and accurate. Because of the time lag involved with writing and printing processes, the transmission TCM may

report a code that has not yet been added to this document. If you encounter a code that is not yet in this

publication, please call Allison Transmission.

Go to the Table of Contents

PREFACE

Copyright © 2008 Allison Transmission, Inc.

Page 2

Page 3

2008 OCTOBER

Troubleshooting

TS3989EN

Manual

Allison Transmission

VOCATIONAL MODELS

3000 VOCATIONAL MODELS

3000 HS 3500 RDS B 300(P)(R)

3000 RDS 3500 EVS B 400(P)(R)

3000 EVS T 200

3000 MH T 300

3000 PTS

3000 TRV

3200 SP 3500 SP 3700 SP

3200 TRV

4000 VOCATIONAL MODELS

4000 EVS 4500 EVS 4700 EVS 4800 EVS B 500

4000 HS 4500 HS 4700 RDS B 500P

4000 MH 4500 RDS 4700 OFS B 500R

4000 RDS 4500 SP B 500PR

4000 TRV 4500 TRV T 425

T 450

Allison Transmission, Inc.

P.O. Box 894 Indianapolis, Indiana 46206-0894

www.allisontransmission.com

Printed in USA Copyright © 2008 Allison Transmission, Inc.

Page 4

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

FOREWORD — How to Use This Manual

This manual provides troubleshooting information for the 3000 and 4000 Product Families Transmissions. Service

Manuals SM4013EN and SM4014EN, plus Parts Catalogs PC2150EN and PC2456EN may be used in co njunction

with this manual.

This manual includes:

• Description of the 3000 and 4000 Product Families Allison 4

• Description of the electronic control system components.

• Description of diagnostic codes, system responses to faults, and troubleshooting.

• Wire, terminal, and connector repair information.

Specific instructions for using many of the available or required service tools and equipment are not included in

this manual. The service tool manufacturer will furnish instructions for using the tools or equipment.

Additional information may be published from time to time in Service Information Letters (SIL) and will be

included in future revisions of this and other manuals. Please use these SILs to obtain up-to-date information

concerning Allison Transmission products.

This publication is revised periodically to include improvements, new models, special tools, and procedures. A

revision is indicated by a new date on the title page and in the lower left corner of the rear cover. Check with your

Allison Transmission service outlet for the currently applicable publication. Additional copies of this publication

may be purchased from authorized Allison Transmission service outlets. Look in your telephone directory under

the heading of Transmissions — Truck, Tractor, etc.

TH

Generation Electronic Control system.

T ake time to review the Table of Contents and the manual. Reviewing the Table of Contents will aid you in quickly

locating information.

NOTE: Allison Transmission is providing for service of wiring harnesses and wiring harness components as

follows:

• Repair parts for the internal wiring harness and for wiring harness components attached to the

shift selector will be available through the Allison Transmission Parts Distribution Center (PDC).

Use the P/N from your appropriate parts catalog or from Appendix E in this manual. Allison

Transmission (AT) is responsible for warranty on these parts.

• Repair parts for the external harnesses and external harness components must be obtained from

St. Clair Technologies Inc. (SCTI). SCTI provides parts to any Allison customer or OEM and is

responsible for warranty on these parts. SCTI recognizes AT, manufacturers, and SCTI part

numbers. SCTI provides a technical HELPLINE at 519-627-1673 (Wallaceburg). SCTI will have

parts catalogs available. The SCTI addresses and phone numbers for parts outlets are:

St. Clair Technologies, Inc.

920 Old Glass Road

Wallaceburg, Ontario, N8A 4L8

Phone: 519-627-1673

Fax: 519-627-4227

St. Clair Technologies, Inc.

Calle Damanti S/N Col

Guadalupe—Guaymas

Sonora, Mexico 85440

Phone: 011-526-2222-43834

Fax: 011-526 2222-43553

ii Copyright © 2008 Allison Transmission, Inc.

Page 5

3000/4000 PRODUCT FAMILIES 4TH GENERATION ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

IMPORTANT SAFETY NOTICE

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings and cautions

used in this manual. These warnings and cautions advise against using specific service

procedures that can result in personal injury, equipment damage, or cause the equipment to

become unsafe. These warnings and cautions are not exhaustive. Allison Transmission could

not possibly know, evaluate, or advise the service trade of all conceivable procedures by which

service might be performed or of the possible hazardous consequences of each procedure.

Consequently, Allison Transmission has not undertaken any such broad evaluation.

Accordingly, ANYONE WHO USES A SER VICE PROCEDURE OR T OOL WHICH IS NOT

RECOMMENDED BY ALLISON TRANSMISSION MUST first be thoroughly satisfied

that neither personal safety nor equipment safety will be jeopardized by the service procedures

used.

Also, be sure to review and observe WARNINGS, CAUTIONS, and NOTES provided by the

vehicle manufacturer and/or body builder before servicing the Allison transmission in that

vehicle.

Proper service and repair is important to the safe and reliable operation of the equipment. The

service procedures recommended by Allison Transmission and described in this manual are

effective methods for performing troubleshooting operations. Some procedures require using

specially designed tools. Use special tools when and in the manner recommended.

The WARNINGS, CAUTIONS, and NOTES in this manual apply only to the Allison

transmission and not to other vehicle systems which may interact with the transmission. Be

sure to review and observe any vehicle system information provided by the vehicle

manufacturer and/or body builder at all times the Allison transmission is being serviced.

WARNINGS, CAUTIONS, AND NOTES

Three types of headings are used in this manual to attract your attention:

WARNING!

CAUTION:

NOTE: Is used when an operating procedure, practice, etc., is essential to highlight.

Is used when an operating procedure, practice, etc., which, if not correctly followed,

could result in injury or loss of life.

Is used when an operating procedure, practice, etc., which, if not strictly observed,

could result in damage to or destruction of equipment.

Copyright © 2008 Allison Transmission, Inc. iii

Page 6

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

TRADEMARKS USED IN THIS MANUAL

The following trademarks are the property of the companies indicated:

• Allison DOC

• DEXRON

®

• LPS

• Loctite

• MagiKey

• Teflon

• TranSynd

Cleaner is a registered trademark of LPS Laboratories.

TM

is a trademark of General Motors Corporation.

®

is a registered trademark of General Motors Corporation.

®

is a registered trademark of the Loctite Corporation.

®

is a registered trademark of NEXIQ Technologies, Inc.

®

is a registered trademark of the DuPont Corporation.

TM

is a trademark of Castrol Ltd.

SHIFT SELECTOR TERMS AND DISPLAY INDICATIONS

Shift selector terms and displays are represented in this manual as follows:

• Button Names — ↑, ↓, “display mode”, MODE, etc.

• Transmission Ranges — D (Drive), N (Neutral), R (Reverse), 1 (First), 2 (Second), etc.

• Displays — “o, L”; “o, K”, etc. (Display occurs one character at a time.)

iv Copyright © 2008 Allison Transmission, Inc.

Page 7

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

TABLE OF CONTENTS

Page

FOREWARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

IMPORTANT SAFETY NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

WARNINGS, CAUTIONS, AND NOTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

TRADEMARKS USED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

SHIFT SELECTOR TERMS AND DISPLAY INDICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

SECTION 1. GENERAL DESCRIPTION

1–1. TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–1

1–2. TRANSMISSION CONTROL MODULE (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–3

1–3. SHIFT SELECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

A. Pushbutton Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

B. Lever Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

1–4. THROTTLE POSITION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

1–5. SPEED SENSORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–7

1–6. CONTROL MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–8

1–7. WIRING HARNESSES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–12

A. External Wiring Harness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–12

B. Internal Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–14

1–8. VEHICLE INTERFACE MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–16

1–9. AUTODETECT FEATURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–16

A. Retarder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–17

B. Oil Level Sensor (OLS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–17

C. Throttle Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–17

D. Engine Coolant Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–18

1–10. TRANSID (TID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–18

1–11. SPECIAL ELECTRONIC/ELECTRICAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–19

SECTION 2. DEFINITIONS AND ABBREVIATIONS

2–1. CHECK TRANS LIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–1

2–2. ALLISON TRANSMISSION DIAGNOSTIC TOOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–5

2–3. ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–7

Copyright © 2008 Allison Transmission, Inc. v

Page 8

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

TABLE OF CONTENTS (cont’d)

Page

SECTION 3. BASIC KNOWLEDGE

3–1. BASIC KNOWLEDGE REQUIRED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3–2. USING THE TROUBLESHOOTING MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3–3. SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–4. IMPORTANT INFORMATION IN THE TROUBLESHOOTING PROCESS. . . . . . . . . . . . . . . . 3–2

3–5. BEGINNING THE TROUBLESHOOTING PROCESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

3–6. TCM DIAGNOSTIC PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

3–7. RESTTING OF TCM PARAMETERS TO SUPPORT ENGINE UPDATE. . . . . . . . . . . . . . . . . . 3–6

3–8. RESETTING TCM AUTOSELECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3–9. HYDRAULIC OPERATION DURING ELECTRICAL INTERRUPTION. . . . . . . . . . . . . . . . . . 3–6

SECTION 4. WIRE CHECK PROCEDURES

4–1. TESTING FOR OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND. . . . . . . 4–1

4–2. TESTING AT TRANSMISSION FEEDTHROUGH CONNECTOR FOR INTERNAL

HARNESS OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND . . . . . . . . . . 4–3

SECTION 5. FLUID CHECK PROCEDURES

5–1. OIL LEVEL SENSOR (OLS) INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5–2. ELECTRONIC FLUID LEVEL READING (SHIFT SELECTOR) . . . . . . . . . . . . . . . . . . . . . . . . 5–3

A. Fluid Level Reading Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

5–3. ELECTRONIC FLUID LEVEL CHECK (ALLISON DOC™ FOR PC–SERVICE TOOL) . . . . . 5–5

A. Fluid Level Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

5–4. COLD CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

A. Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

B. Cold Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

5–5 HOT CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–7

A. Hot Check Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–7

5–6 KEEPING FLUID CLEAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–8

A. Foreign Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–8

5–7 FLUID RECOMMENDATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–8

vi Copyright © 2008 Allison Transmission, Inc.

Page 9

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

TABLE OF CONTENTS (cont’d)

Page

SECTION 6.DIAGNOSTIC TROUBLE CODES (DTC)

6–1. DIAGNOSTIC CODE MEMORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–1

6–2. CODE READING AND CODE CLEARING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–2

6–3. DIAGNOSTIC CODE RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–3

6–4. SHIFT SELECTOR DISPLAYS RELATED TO ACTIVE CODES . . . . . . . . . . . . . . . . . . . . . . . .6–4

6–5. DIAGNOSTIC CODE LIST AND DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–4

6–6. DIAGNOSTIC CODE TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–14

A. Beginning the Troubleshooting Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–14

B. Solenoid Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–14

C. Diagnostic Code Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–14

SECTION 7. INPUT AND OUTPUT FUNCTIONS

7–1. INPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–1

7–2. OUTPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–3

SECTION 8. GENERAL TROUBLESHOOTING OF PERFORMANCE COMPLAINTS

APPENDICES

A. IDENTIFICATION OF POTENTIAL CIRCUIT PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

B. MEASURING CLUTCH AND RETARDER PRESSURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

C. SOLENOID AND CLUTCH CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

D. WIRE/CONNECTOR CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–1

E. CONNECTOR PART NUMBERS, TERMINAL PART NUMBERS, . . . . . . . . . . . . . . . . . . . . . . .E–1

TOOL PART NUMBERS, AND REPAIR INSTRUCTIONS

F. THROTTLE POSITION SENSOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F–1

G. WELDING ON VEHICLE/VEHICLE INTERFACE MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . G–1

H. HYDRAULIC SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H–1

J. 3000 AND 4000 PRODUCT FAMILIES WIRING SCHEMATIC. . . . . . . . . . . . . . . . . . . . . . . . . . J–1

K. SOLENOID RESISTANCE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K–1

L. EXTERNALLY-GENERATED ELECTRONIC INTERFERENCE. . . . . . . . . . . . . . . . . . . . . . . . .L–1

M. DIAGNOSTIC TREE—3000 AND 4000 PRODUCT FAMILIES HYDRAULIC SYSTEM . . . . M–1

N. ALLISON DOC™ FOR PC–SERVICE TOOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N–1

P. INPUT/OUTPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P–1

Q. THERMISTOR TROUBLESHOOTING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Q–1

R. SAE J1939 COMMUNICATION LINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R–1

Copyright © 2008 Allison Transmission, Inc. vii

Page 10

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

NOTES

viii Copyright © 2008 Allison Transmission, Inc.

Page 11

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

SECTION 1—GENERAL DESCRIPTION

1–1. TRANSMISSION

The Allison 4th Generation Controls feature closed-loop clutch control to provide superior shift quality over a

wide range of operating conditions. The 3000 and 4000 Product Families transmissions configurations can be

programmed to have up to six forward ranges, neutral, and one reverse range. The 3700 SP, 4700 RDS, 4700/

4800 EVS, 4700/4800 SP, and 4700 OFS have up to seven forward ranges and one reverse.

Figure 1–1 is a block diagram of the basic system inputs and outpu t s.

SHIFT SELECTOR

MODE SWITCH

SPEED SENSORS

THROTTLE POSITION SENSOR

RETARDER MODULATION

VEHICLE/ENGINE

COMMUNICATION LINKS

RANGE AND

TCM

DISPLAY

DIAGNOSTIC PRESSURE SWITCH

VIM

INPUTS OUTPUTS

Figure 1–1. Transmission Control Module

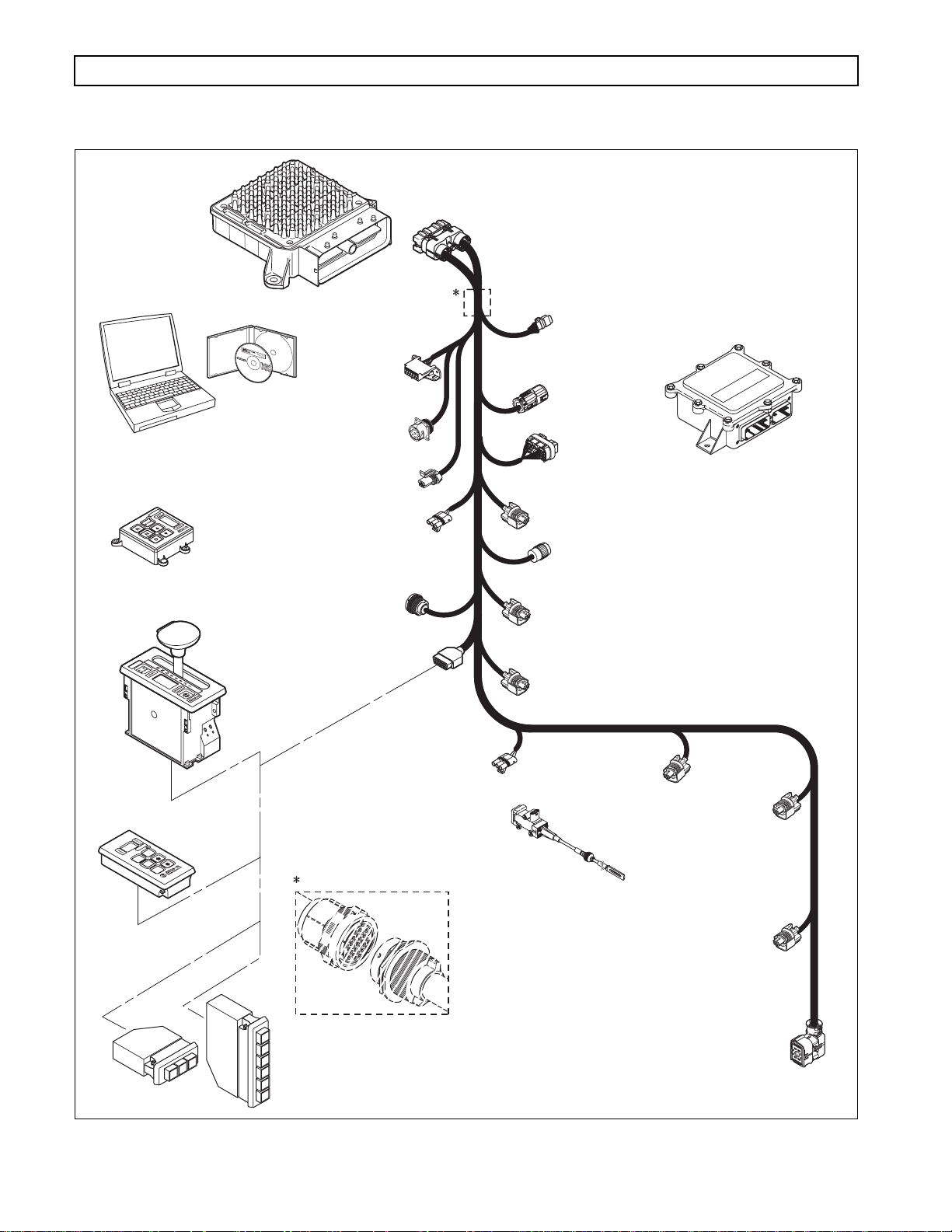

Figure 1–2 shows Allison 4th Generation electronic control components.

th

Allison 4

Generation Controls consist of the following elements:

• Remote 12V or 12/24V Max Feature Sealed Transmission Control Module (TCM)

• Remote Pushbutton or Lever Shift Selector

• Optional Secondary Shift Selector

OIL LEVEL SENSOR

SOLENOIDS

TEMPERATURE SENSOR

(SUMP/RETARDER)

FILTER LIFE

SWITCH (PS2)

V09074.00.00

NOTE:

• Throttle Position Sensor (TPS) or electronic engine throttle data or PWM signal

• Engine, Turbine, and Output Speed Sensors

• Control Module (Electro-Hydraulic Valve Body)

• Wiring Harnesses

• Vehicle Interface Module (VIM)

• Autodetect Feature

• TransID Feature

• Optional Retarder Controls

• Optional Engine Coolant Temperature Input

• Filter Life Switch (PS2)

• All external harnesses are OEM supplied.

• The VIM is an OEM option.

Copyright © 2008 Allison Transmission, Inc. 1–1

Page 12

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

TRANSMISSION

CONTROL

MODULE

(TCM)

ALLISON DOC™

FOR PC - SERVICE TOOL

COMPACT

PUSHBUTTON

SELECTOR

DIAGNOSTIC

TOOL

CONNECTOR

DEUTSCH 9-PIN

DIAGNOSTIC TOOL

CONNECTOR

SCI (J1587)

CONNECTOR

(OPTIONAL)

RE TARDER

MODULATION

REQUEST (RMR)

CONNECTOR

J1939

CONNECTOR

VIW

CONNECTOR

(OPTIONAL)

VIM

CONNECTOR

RE TARDER ACCUMULATOR

CONNECTOR

(3000 PRODUCT FAMILY 7-SPEED)

VEHICLE

INTERFACE

MODULE

(VIM)

ORTRANSFER CASE CONNEC T

REMOTE LEVER

SELEC TOR

REMOTE

PUSHBUTTON

SELEC TOR

R

STRIP PUSHBUTTON

SHIFT SELEC TORS

(EUROPEAN

OEM)

.

SENSOR HARNESS

CONNECTOR (OPTIONAL)

SHIFT

SELEC TOR

CONNECTOR

THROTTLE POSITION

SENSOR (TPS)

CONNECTOR

THROTTLE

MODE

N

D

POSITION

SENSOR (TPS)

OUTPUT

SPEED SENSOR

CONNECTOR

RE TARDER TEM P.

SENSOR CONNECTOR

SPEED SENSOR

CONNECTOR

(4000 PRODUCT

TURBINE

FAMI

LY)

ENGINE

SPEED

SENSOR

CONNECTOR

Bulkhead Connector (Optional)

RE TARDER “PCS5”

SOLENOID

CONNECTOR

1

2

R

N

D

3

D

NOTE: Illustration is not to scale. Actual harness

N

conguration may dier from this illustration.

R

20-WAY

TRANSMISSION

FEEDTHROUGH

HARNESS

CONNECTOR

V09274.01.00A

Figure 1–2. Typical Allison 4th Generation Control Components

1–2 Copyright © 2008 Allison Transmission, Inc.

Page 13

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

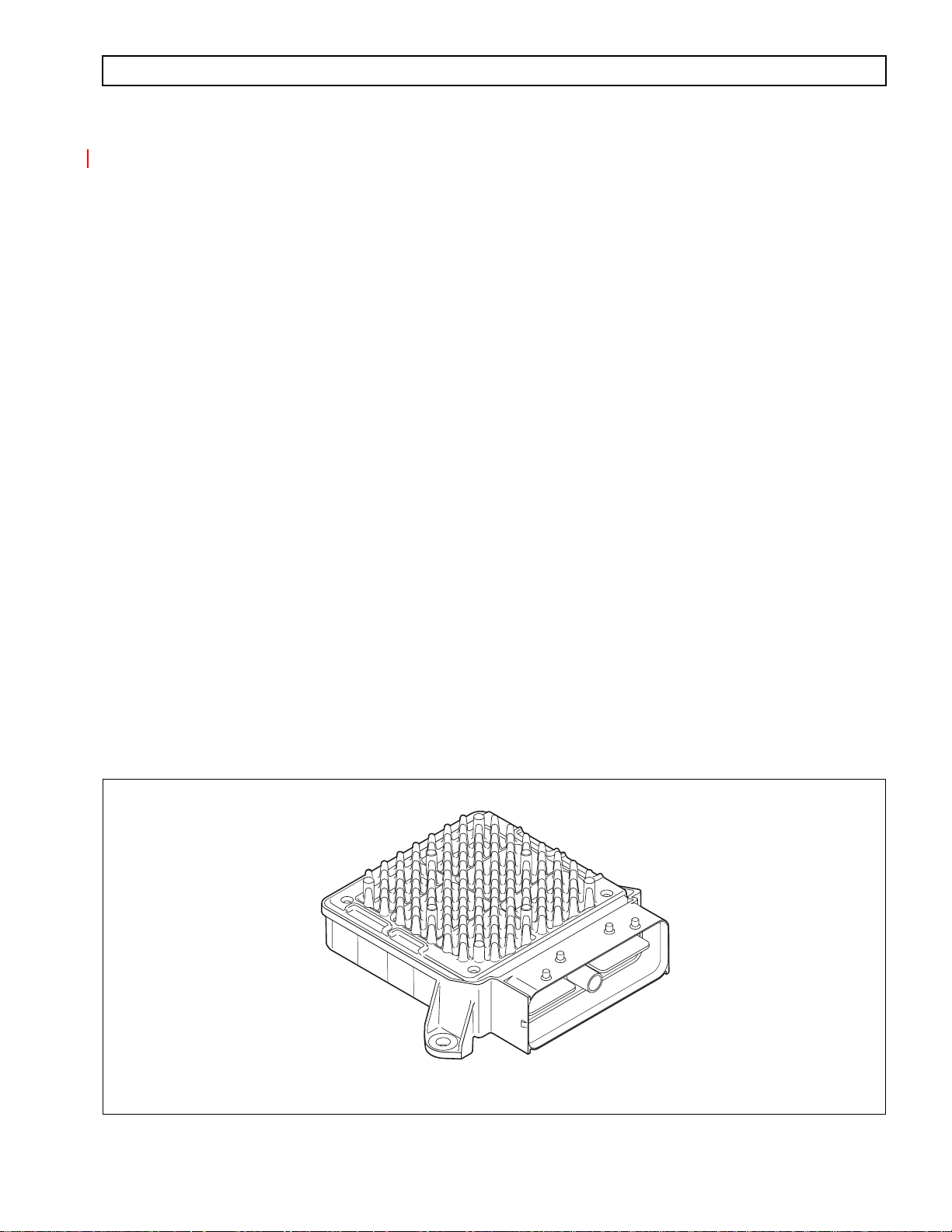

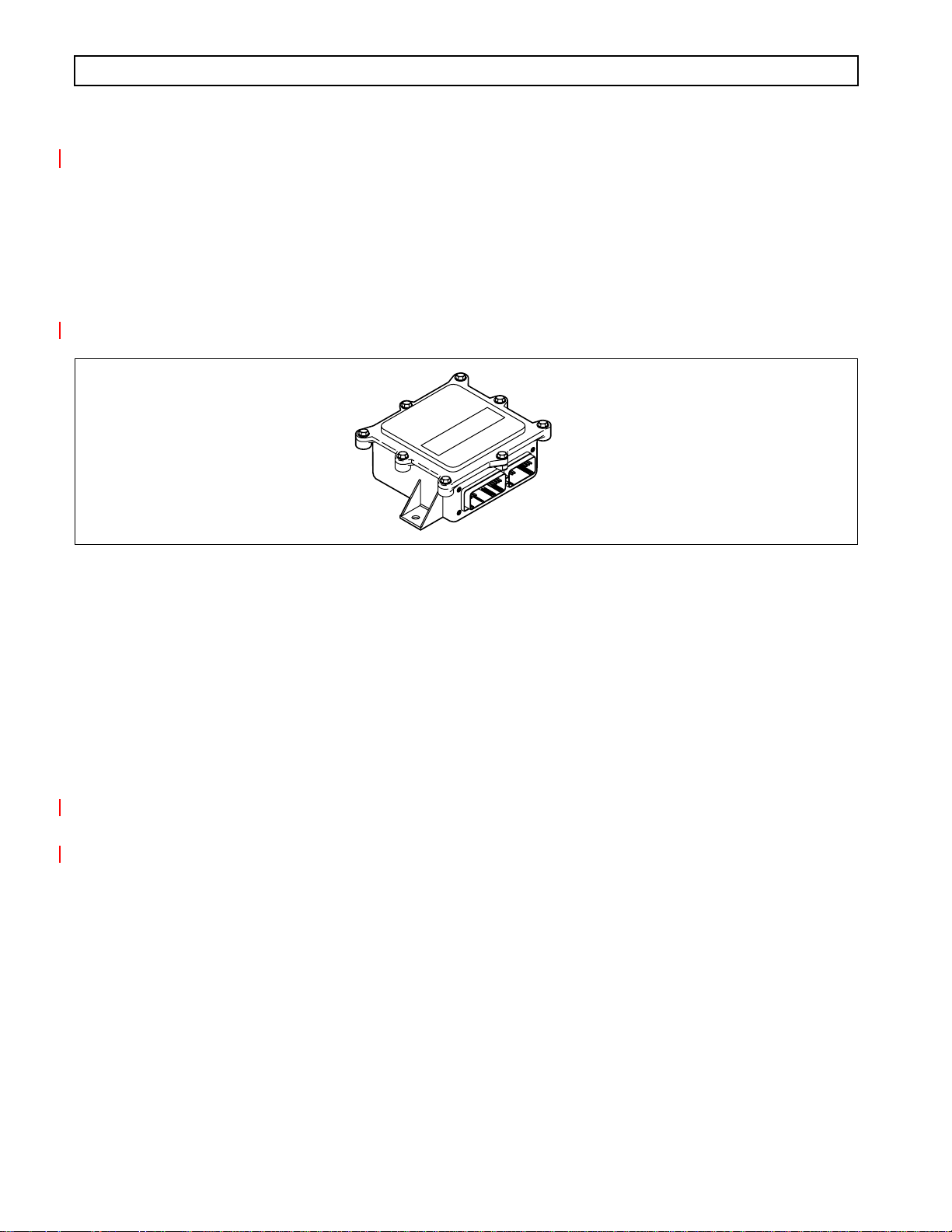

1–2. TRANSMISSION CONTROL MODULE (TCM)

The electronic control of the transmission is performed by a microcomputer. The microcomputer is an independent

controller and is referred to as a Transmission Control Module (TCM). TCMs are available in both 12V and 12/24V

configurations to match the configuration of the vehicle electrical system.

The TCM (Figure 1–3) contains the microcomputer which is the brain of the control system. The TCM receives

and processes information defining:

• Shift selector

• Throttle position

• Sump/retarder temperature

• Pressure switch state

• Engine speed

• Turbine speed

• Transmission output speed.

The TCM uses the information to:

• Control transmission solenoids

• Supply system status

• Provide diagnostic information.

Each TCM has a date code laser etched on the outer case of the TCM. This is the date when the TCM passed final

testing. This date is commonly used to denote the change configuration level of the TCM. It is normal for the TCM

date displayed electronically to be a few days prior to the date shown on the label.

V09005.00.00

Figure 1–3. Transmission Control Module (TCM)

Copyright © 2008 Allison Transmission, Inc. 1–3

Page 14

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

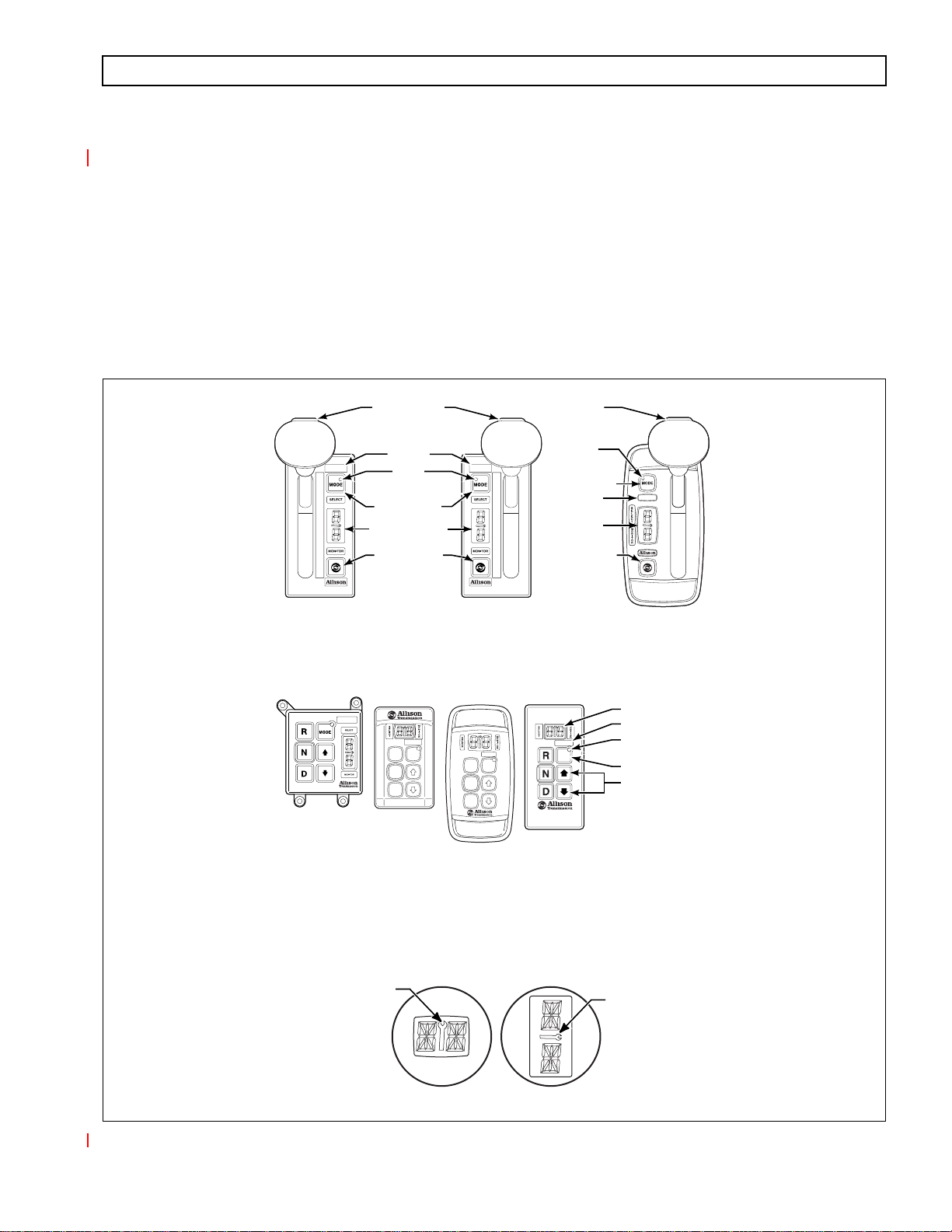

1–3. SHIFT SELECTOR

Pushbutton and lever shift selectors for the Allison 4th Generation Series are remote mounted from the TCM and

communicate to the TCM via the J1939 communications data link. All shift selectors except the strip-type

pushbutton have a dual digit vacuum fluorescent (VF) display and a mode indicator (LED). During normal

transmission operation, illumination of the LED indicator shows that a secondary or special operating condition

has been selected by pressing the MODE button. During diagnostic display mode, illumination of the LED

indicator shows that the displayed Diagnostic Trouble Code (DTC) is active. Display brightness is regulated by the

same vehicle potentiometer that controls dash light display brightness. More information on both types of shift

selectors is continued below.

A. Pushbutton Shift Selector (Figure 1–4)

There are three full-function pushbutton shift selectors and a strip pushbutton shift selector. Strip

pushbutton shift selectors are used primarily by non-North American OEMs. A full-function shift

selector has a MODE button and diagnostic display capability through the dual digit vacuum

fluorescent (VF) display. The strip pushbutton shift selector does not have a MODE button,

diagnostic capability, or adjustable illumination. The full-function pushbutton shift selector has

six (6) pushbuttons which are R (Reverse), N (Neutral), D (Drive), ↓ (Down), ↑ (Up), and MODE.

Manual forward range downshifts and upshifts are made by pressing the ↓ (Down) or ↑ (Up) arrow

buttons after selecting D (Drive). The N (Neutral) button has a raised lip to aid in finding it by touch.

The MODE button is pressed to select a secondary or special operating condition, such as

ECONOMY shift schedule. Diagnostic information is obtained by pressing the ↑ (Up) and ↓ (Down)

arrow buttons at the same time.

The strip pushbutton shift selector has either three or six range selection positions as shown in

Figure 1–4. When a strip pushbutton shift selector is used, diagnostic information must be obtained

by using the Allison DOC™ For PC–Service Tool, or a customer-supplied remote display.

1–4 Copyright © 2008 Allison Transmission, Inc.

Page 15

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

B. Lever Shift Selector (Figure 1–4)

The lever shift selector can have as many as six forward range positions (seven for the 7-speed

models), as well as R (Reverse) and N (Neutral). There is a hold override button which must be

pressed and held in order to move between certain selector positions. The hold override button must

be pressed when shifting between R, N, and D. The hold override button is released when the desired

selector position is reached. The selector lever can be moved freely between D and the numbered

forward ranges without pressing the hold override button. The lever selector can be chosen with the

lever on the left side or on the right side and with the R (Reverse) position toward the front or toward

the rear of the selector. Diagnostic and oil level (if sensor is present) information is obtained from the

LED display by pressing the “display mode” button.

1

2

3

4

5

D

N

R

SIX-SPEED,

LEFT-HAND

LEVER SELECTOR

HOLD OVERRIDE

BUTTON

MODE ID

MODE

INDICATOR

(LED)

MODE BUTTON

DIGITAL DISPLAY

DISPLAY MODE

DIAGNOSTIC

BUTTON

MODE

R

N

D

R

N

D

6

*

5

4

3

2

1

SEVEN-SPEED,

RIGHT-HAND

LEVER SELECTOR

MODE

R

N

D

HOLD OVERRIDE

BUTTON

MODE

INDICATOR

(LED)

MODE BUTTON

MODE ID

DIGITAL

DISPLAY

*

DISPLAY MODE

DIAGNOSTIC

BUTTON

MODE

CONTOURED

BEZEL

DIGITAL DISPLAY

MODE ID

MODE

INDICATOR (LED)

MODE BUTTON

Push simultaneously

to enter diagnostic

mode and fluid

level check

*

PUSHBUTTON SELECTORS

*NOTE:

The first number displayed in the digital display is the highest forward range available and second

number is range attained in selected position.

Visually confirm that the range selected was attained. If display is flashing, shift is inhibited.

SERVICE ICON

SERVICE ICON

Location of service icon on vertical and horizontal digital display

Figure 1–4. Typical Allison 4th Generation Shift Selectors

Copyright © 2008 Allison Transmission, Inc. 1–5

V11058.00.00

Page 16

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

1–4. THROTTLE POSITION SENSOR (Figure 1–5)

The Throttle Position Sensor (TPS) can be mounted to the engine, chassis, or transmission. The TPS contains a pul l

actuation cable and a potentiometer. One end of the cable is attached to the engine fuel lever and the other, inside a

protective housing, to the TPS potentiometer. Output voltage from the TPS is directed to the TCM through the

external harness. The voltage signal indicates the throttle position and, in combination with other input data,

determines shift timing.

A

Figure 1–5. Throttle Position Sensor (Without Mounting Brackets)

B

C

THROTTLE POSITION SENSOR

V00628

1–6 Copyright © 2008 Allison Transmission, Inc.

Page 17

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

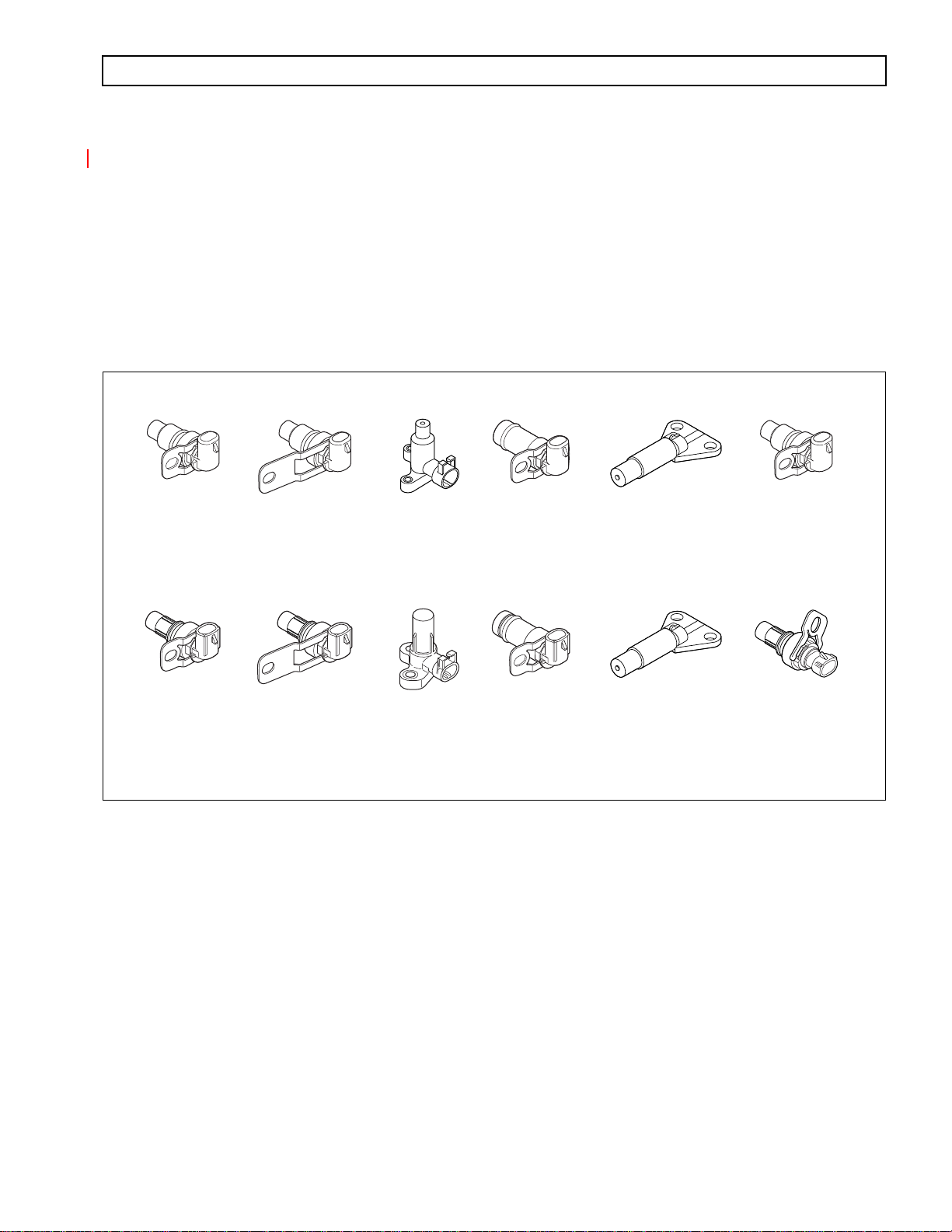

1–5. SPEED SENSORS (Figure 1–6)

Three speed sensors—engine speed, turbine speed, and output speed—provide information to the TCM. The

engine speed signal is generated by ribs on the shell of the torque converter pump. The turbine speed signal is

generated by the rotating-clutch housing spline contours. The output speed signal is generated by a toothed

member attached to the output shaft (except for the 3000 Product Family 7-speed models, where the toothed

member is the transfer case idler gear). The speed ratios between the various speed sensors allow the TCM to

determine if the transmission is in the selected range. Speed sensor information is also used to control the timing of

clutch apply pressures, resulting in the smoothest shifts possible. Hydraulic problems are detected by comparing

the speed sensor information for the current range to that range’s speed sensor information stored in the TCM

memory.

FORMER (BEFORE JANUARY, 2006)

3000 AND 4000

PRODUCT FAMILIES

ENGINE

(EXTERNAL)

3000/4000

PRODUCT FAMILIES

ENGINE

(EXTERNAL)

4000

PRODUCT FAMILY

TURBINE

(EXTERNAL)

4000

PRODUCT FAMILY

TURBINE

(EXTERNAL)

3000

PRODUCT FAMILY

TURBINE

(INTERNAL)

3000

PRODUCT FAMILY

(EXCEPT 7-SPEED)

RETARDER OUTPUT

(EXTERNAL)

CURRENT (JANUARY, 2006)

3000

PRODUCT FAMILY

TURBINE

(INTERNAL)

3000

PRODUCT FAMILY

(EXCEPT 7-SPEED)

RETARDER OUTPUT

(EXTERNAL)

Figure 1–6. Speed Sensors

3000

PRODUCT FAMILY

7-SPEED OUTPUT

(INTERNAL)

3000

PRODUCT FAMILY

7-SPEED OUTPUT

(INTERNAL)

3000 AND 4000

PRODUCT FAMILIES

OUTPUT (EXTERNAL),

4000 PRODUCT FAMILY

RETARDER

3000 AND 4000

PRODUCT FAMILIES

OUTPUT (EXTERNAL),

4000 PRODUCT FAMILY

RETARDER

V09819.00.00

Copyright © 2008 Allison Transmission, Inc. 1–7

Page 18

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

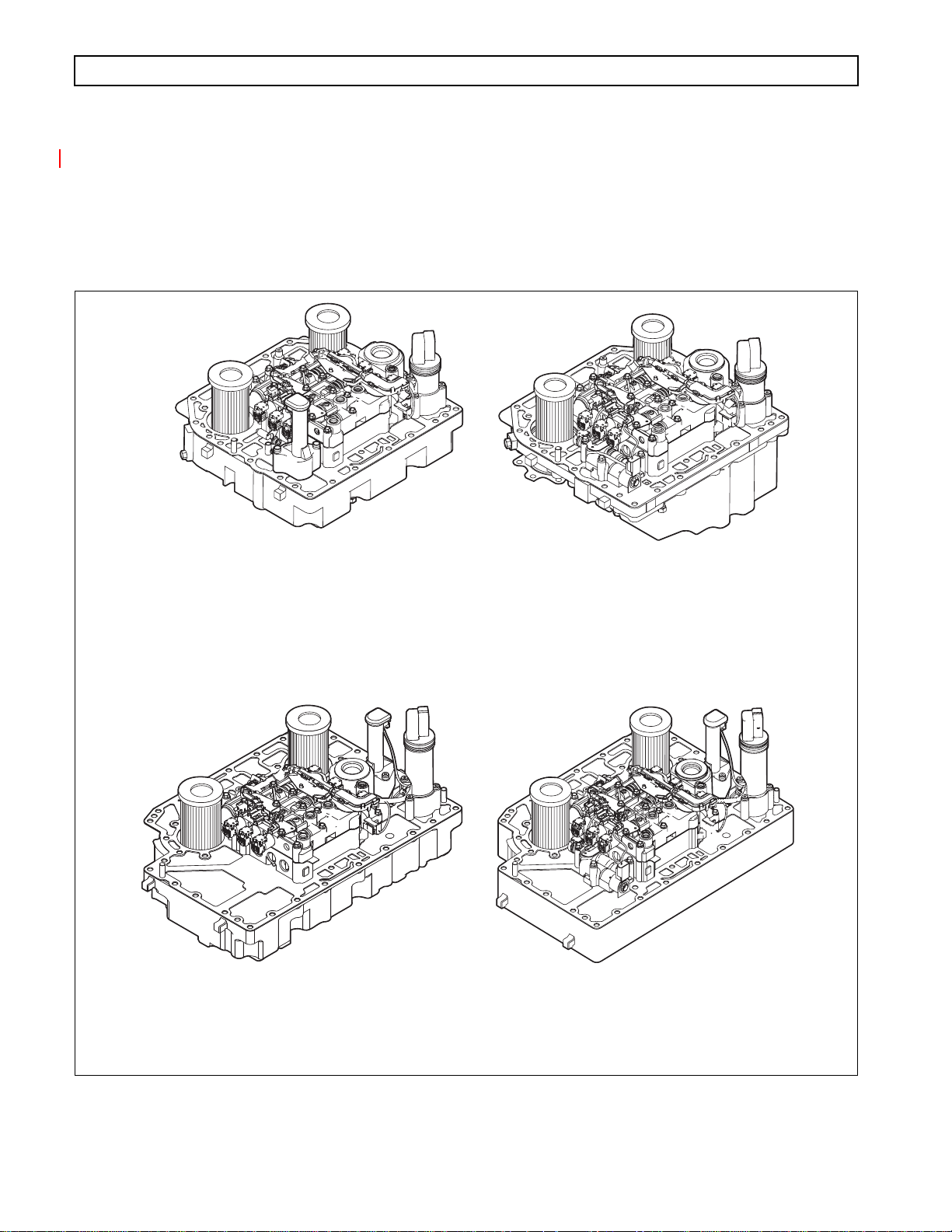

1–6. CONTROL MODULE (Figures 1–7 and 1–8)

The Allison 4

body assembly , which are mounted to an aluminum channel plate. The TCM issues commands to various solenoids

in the two valve bodies to govern fluid flow to the clutches (including torque converter clutch). The solenoids

produce an output pressure that is proportional to current from the TCM. Hence, the solenoids are referred to as

pressure control solenoids (PCS).

th

Generation Series transmission control module contains a main body assembly and solenoid valve

6-SPEED

3000 PRODUCT FAMILY

CONTROL MODULE

6-SPEED

4000 PRODUCT FAMILY

CONTROL MODULE

7-SPEED

3000 PRODUCT FAMILY

CONTROL MODULE

7-SPEED

4000 PRODUCT FAMILY

CONTROL MODULE

Figure 1–7. Allison 4th Generation Control Modules

1–8 Copyright © 2008 Allison Transmission, Inc.

V09276.00.00

Page 19

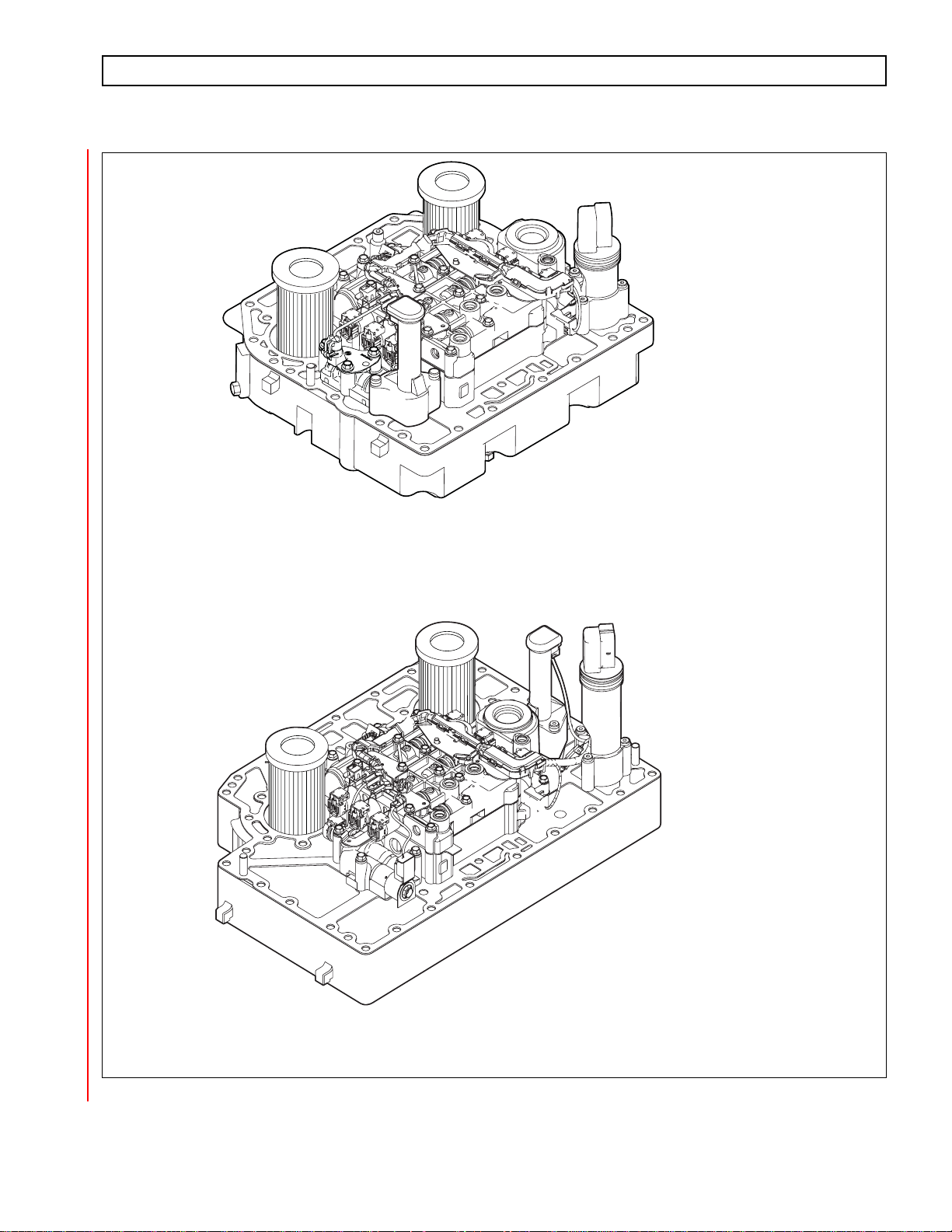

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

6-SPEED W/PROGNOSTICS

3000 PRODUCT FAMILY

CONTROL MODULE

6-SPEED W/PROGNOSTICS

4000 PRODUCT FAMILY

CONTROL MODULE

Figure 1–8. Allison 4th Generation Control Mudules with Prognostics

Copyright © 2008 Allison Transmission, Inc. 1–9

V09276.00.00.A

Page 20

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

The main valve body assembly contains the following:

• Main pressure regulator valve

• Control main regulator valve

• Converter flow valve

• Lube regulator valve

• Converter regulator valve

• Exhaust backfill valve

• Two latching logic valves

• On/Off solenoid SS1.

The solenoid valve body assembly contains the following:

• Pressure control solenoid MAIN MOD

• PCS1 (A trim)

• PCS2 (B trim)

• PCS3 (C trim)

• PCS4 (D trim)

• TCC (lockup)

• Diagnostic pressure switch PS1

• Filter Life Switch (PS2)

• Five solenoid regulator valves

• One diagnostic valve.

The low valve body assembly (in 3000 and 4000 Product Families 7-speed mod els) contains solenoid PCS6 (C6)

and one ON/OFF solenoid SS2 (C6 enable). Refer to the appropriate service manual for valve locations.

The Allison 4

in improved cooler flow and reduced pump losses when throttle position and output speed is low. The Allison 4

th

Generation controls system includes a main modulation solenoid. Modulated main pressure results

th

Generation Controls TCM commands the main mod solenoid ON when all of the following conditions are

simultaneously met:

• Sump temperature is greater than –80ºC (–112ºF) and less than 150ºC (302ºF).

• Engine speed less than 1200 rpm in all ranges except neutral. There are no restrictions on engine speed

in neutral.

• Throttle percentage less than 15 percent in reverse, low (7-speed), first, or second range. Main mod may

be commanded ON in neutral at any throttle position.

• Output speed is less than 250 rpm in neutral, reverse, low (7-speed), first, or second range.

• The PTO input to the TCM indicates the PTO is OFF.

• Shift not in progress.

The TCM may activate the main mod solenoid for improved clutch control and transmission response during other

unusual operating situations.

A temperature sensor (thermistor) is located in the internal wiring harness. Changes in sump fluid temperature are

indicated by changes in sensor resistance, which changes the signal sent to the TCM. Refer to the chart in

Appendix Q.

The oil level sensor (OLS) is a float type device mounted on the control module channel plate. The OLS senses

transmission fluid level by electronically measuring the buoyancy forces on the float. The sensor operates on

1–10 Copyright © 2008 Allison Transmission, Inc.

Page 21

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

5VDC supplied by the TCM. The oil level sensor is available on any 3000 and 4000 Product Families

transmissions except the 3000 7-speed transmissions.

The diagnostic pressure switch PS1 is mounted on the solenoid valve body assembly and performs the following

two functions:

• When the C5 clutch is filled, PS1 senses the PCS2 solenoid regulator valve position to verify proper C3

clutch control in reverse, neutral, and first range.

• When the C5 clutch is exhausted, as in second through sixth ranges, PS1 verifies the position of the C1

and C2 latch valves.

The turbine speed sensor is mounted on the control module for the 3000 Product Family transmissions. The turbine

speed sensor is directed at the rotating-clutch housing. The turbine speed sensor on the 4000 Product Family

transmission is located on the outside of the main housing.

A. Control System Prognostics Operation and Display

The Prognostics Package includes the following functions:

• Oil Life Monitor

• Filter Life Monitor

• Transmission Health Monitor

Use the Allison DOC™ For PC–Service Tool to review the current status of any of these functions

and a history of indicator resets. Use the Allison shift selector to review the current status of any of

these functions, provided the function being checked is in its specific display mode. See the selector

information section for that procedure.

When a specified threshold is detected for any of the prognostic functions, the SERVICE TRANS

indicator (an open-ended wrench icon located between the range select and range monitor digits in

the Allison shift selector) illuminates to alert the operator . The lamp strategy for the icon varies, either

flashing, or steady, to indicate to the operator which function detected the threshold value was

reached.

NOTE: Failure to attend to a service condition indicated by an illuminated lamp and then reset the SERVICE

TRANS indicator within a defined operating period results in illumination of the CHECK TRANS

light and an active Diagnostic Trouble Code (DTC)—indicating the increased probability that the

service condition will develop into a more serious condition.

B. Filter Life Valve Body

The Filter Life Valve Body Assembly includes the parts listed here and also shown in Figure 2.

• Filter Life Valve Body

• Filter Life Valve

• Return Spring

• Valve Stop

• Retaining Clip

• Pressure Switch 2 (Filter Life)

• M6 x 45 Long Screws (4)

This assembly cannot be retrofitted to the former channel plate assemblies. Make sure all updates

listed in this section and all other requirements are met prior to using the Prognostics features.

Copyright © 2008 Allison Transmission, Inc. 1–11

Page 22

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

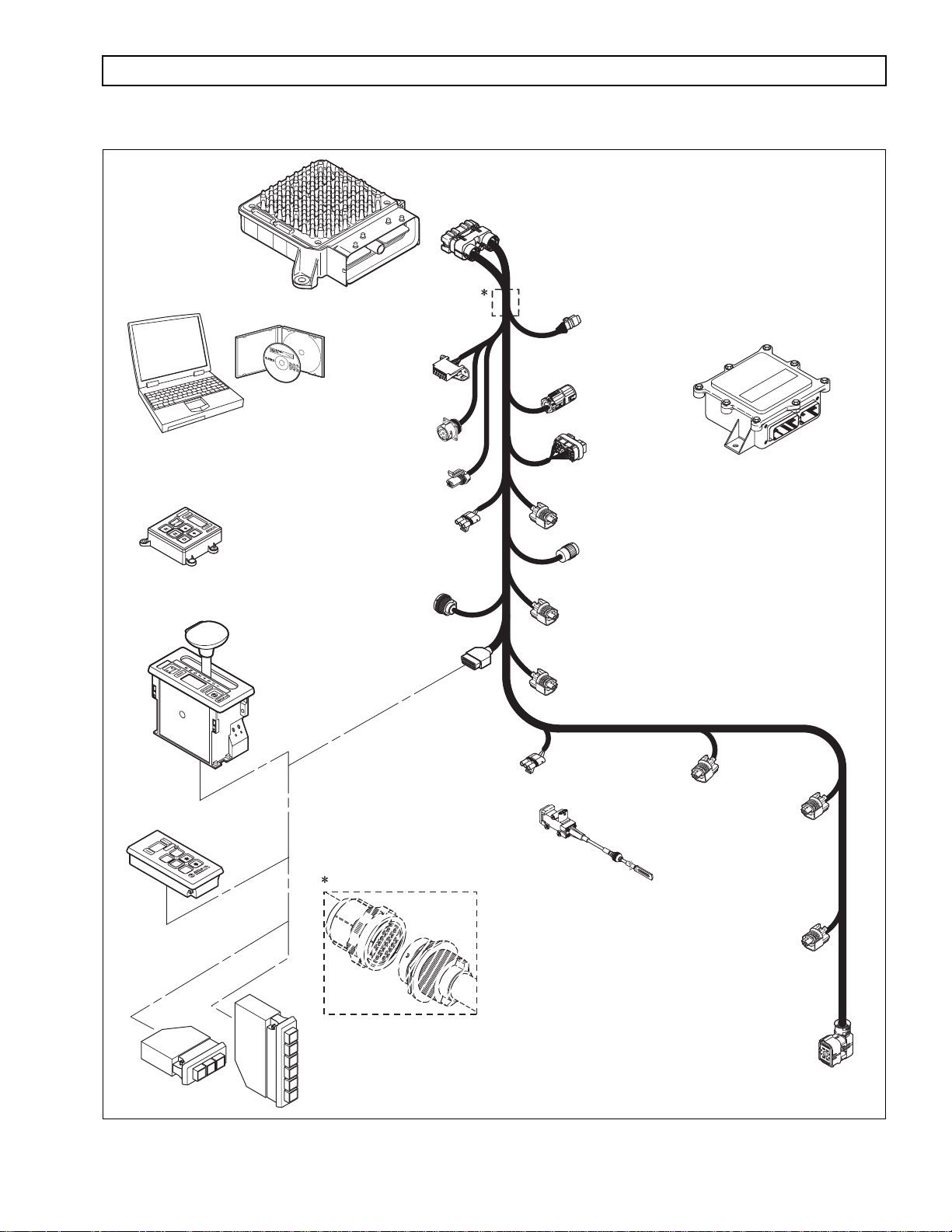

1–7. WIRING HARNESSES

A. External Wiring Harness (Figure 1–9)

The TCM uses a single 80-way connector, which is used to receive input from the following:

Transmission TPS Diagnostic tool connector

Engine Vehicle interface module (VIM) Retarder

Turbine Retarder control module Retarder temperature sensor

Output speed sensor Shift selector Accumulator

Filter life switch (PS2)

Many harnesses will include a bulkhead fitting to separate cab and chassis components. Also, many

different styles and materials for harnesses are likely to be encountered.

NOTE: Allison Transmission is providing for service of wiring harnesses and wiring harness components as

follows:

• Repair parts for the internal wiring harness and for wiring harness components attached to the

shift selector will be available through the Allison Transmission Parts Distribution Center (PDC).

Use the P/N from your appropriate parts catalog or from Appendix E in this manual. Allison

Transmission is responsible for warranty on these parts.

• Repair parts for the external harnesses and external harness components must be obtained from

St. Clair Technologies Inc. (SCTI). SCTI provides parts to any Allison customer or OEM and is

responsible for warranty on these parts. SCTI recognizes Allison Transmission, manufacturers,

and SCTI part numbers. SCTI provides a technical HELPLINE at 519-627-1673 (Wallaceburg).

SCTI will have parts catalogs available. The SCTI addresses and phone numbers for parts

outlets are:

St. Clair Technologies, Inc.

920 Old Glass Road

Wallaceburg, Ontario, Canada N8A 4L8

Phone: 519-627-1673

Fax: 519-627-4227

St. Clair Technologies, Inc.

Calle Damanti S/N Col

Guadalupe—Guaymas

Sonora, Mexico 85440

Phone: 011-526 2222-43834

Fax: 011-526-2222-43553

• SCTI is the source for external harness repair parts.

1–12 Copyright © 2008 Allison Transmission, Inc.

Page 23

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

TRANSMISSION

CONTROL

MODULE

(TCM)

ALLISON DOC™

FOR PC - SERVICE TOOL

COMPACT

PUSHBUTTON

SELECTOR

DIAGNOSTIC

TOOL

CONNECTOR

DEUTSCH 9-PIN

DIAGNOSTIC TOOL

CONNECTOR

SCI (J1587)

CONNECTOR

(OPTIONAL)

RE TARDER

MODULATION

REQUEST (RMR)

CONNECTOR

J1939

CONNECTOR

VIW

CONNECTOR

(OPTIONAL)

VIM

CONNECTOR

RE TARDER ACCUMULATOR

CONNECTOR

(3000 PRODUCT FAMILY 7-SPEED)

VEHICLE

INTERFACE

MODULE

(VIM)

ORTRANSFER CASE CONNEC T

REMOTE LEVER

SELEC TOR

REMOTE

PUSHBUTTON

SELEC TOR

MODE

R

N

D

STRIP PUSHBUTTON

SHIFT SELEC TORS

(EUROPEAN

OEM)

N

D

SENSOR HARNESS

CONNECTOR (OPTIONAL)

SELEC TOR

CONNECTOR

SHIFT

THROTTLE POSITION

SENSOR (TPS)

CONNECTOR

THROTTLE

POSITION

SENSOR (TPS)

OUTPUT

SPEED SENSOR

CONNECTOR

RE TARDER TEM P.

SENSOR CONNECTOR

SPEED SENSOR

CONNECTOR

(4000 PRODUCT

TURBINE

FAMI

LY)

ENGINE

SPEED

SENSOR

CONNECTOR

Bulkhead Connector (Optional)

RE TARDER “PCS5”

SOLENOID

CONNECTOR

1

2

R

3

D

NOTE: Illustration is not to scale. Actual harness

N

conguration may dier from this illustration.

R

20-WAY

TRANSMISSION

FEEDTHROUGH

HARNESS

CONNECTOR

V09274.01.00A

Figure 1–9. Typical 4th Generation Electronic Controls External Wiring Harnesses

Copyright © 2008 Allison Transmission, Inc. 1–13

Page 24

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

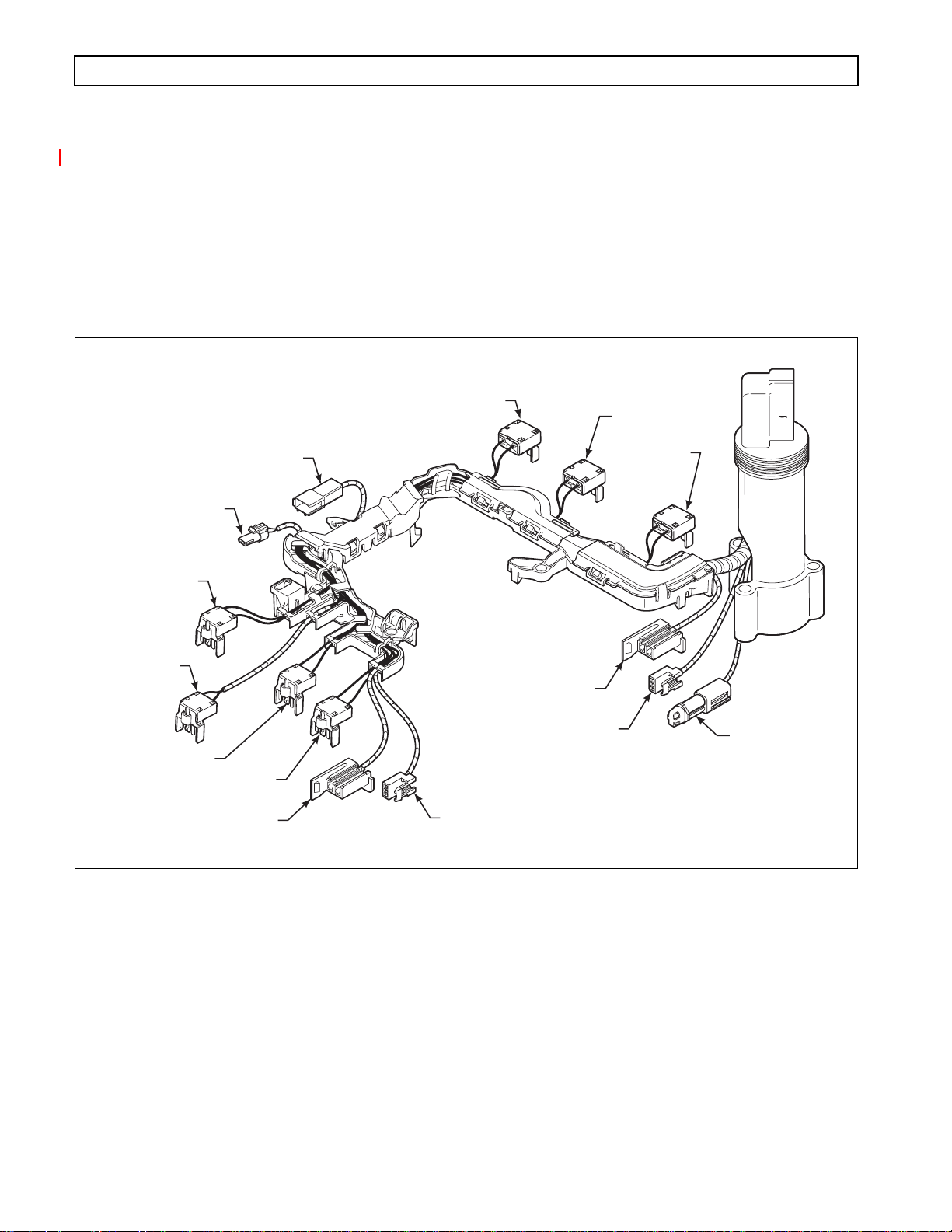

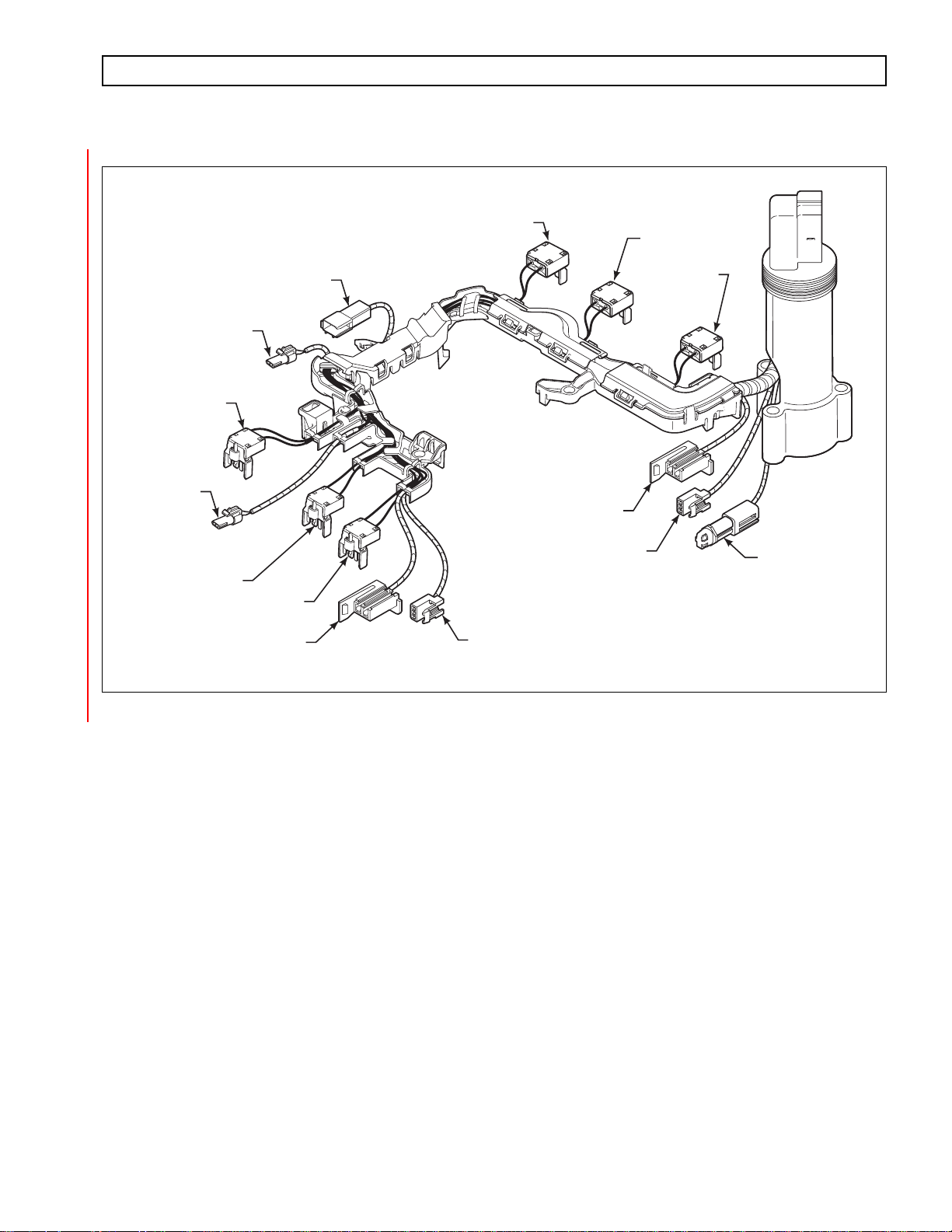

B. Internal Wiring Harness (Figure 1–10)

The internal wiring harness provides connection between the following:

• External harness

• Pressure control and shift solenoids

• Oil level sensor

• Diagnostic pressure switch

• Temperature sensor

• Turbine speed sensor.

PS1 DIAGNOSTIC

PRESSURE SWITCH

NT1 TURBINE

SPEED SENSOR

(3000 ONLY)

MAIN MOD

PCS6

(C6, 7-SPEED)

PCS4 (C4)

PCS3 (C3\C5)

(3000 AND 4000 PRODUCT

FAMILIES 7-SPEED C6 ENABLE)

SS2

TCC (LOCKUP)

OIL LEVEL SENSOR

OIL LEVEL SENSOR

(3000, EXCEPT 7-SPEED)

SS1

ON/OFF

(4000 ONLY)

PCS1 (C1)

PCS2 (C2/C3)

OIL

TEMPERATURE

SENSOR

V09251.00.00

Figure 1–10. Allison 4th Generation Internal Wiring Harness

1–14 Copyright © 2008 Allison Transmission, Inc.

Page 25

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

PS1 DIAGNOSTIC

PRESSURE SWITCH

NT1 TURBINE

SPEED SENSOR

(3000 ONLY)

MAIN MOD

PS2

FILTER LIFE

PCS4 (C4)

PCS3 (C3\C5)

SS2

(3000 AND 4000 PRODUCT

FAMILIES 7-SPEED C6 ENABLE)

TCC (LOCKUP)

OIL LEVEL SENSOR

OIL LEVEL SENSOR

(3000, EXCEPT 7-SPEED)

SS1

ON/OFF

(4000 ONLY)

PCS1 (C1)

PCS2 (C2/C3)

OIL

TEMPERATURE

SENSOR

V09251.00.00.A

Figure 1–11. Allison 4th Generation Inter nal Wiring Harness with Prognostics

Copyright © 2008 Allison Transmission, Inc. 1–15

Page 26

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

1–8. VEHICLE INTERFACE MODULE (Figure 1–12)

The vehicle interface module (VIM) provides relays, fuses, and connection points for interface with the output side

of the vehicle electrical system. VIMs are available for both 12V and 24V electrical systems. The VIM for 12V

systems uses all 12V relays. The VIM for 24V systems has all 24V relays. Refer to the appropriate parts catalog for

the transmission assembly number that you are servicing for detailed parts information. Refer to Pages D–15 and

D–16 for VIM wire number and terminal information.

Some OEMs may provide their own equivalent for the VIM which performs the same functions as the VIM shown

in Figure 1–12.

V00631.02

Figure 1–12. Vehicle Interface Module (VIM)

1–9. AUTODETECT FEATURE

Autodetect is active on the first 25 engine starts and, in the case of throttle source detection logic, may continue

past 25 ignition cycles until a valid source is determined (details follow in A through D below). Autodetect takes

place within the first 30 seconds of each engine start monitored. Autodetect searches for the presence of the

following transmission components or data inputs in the priority listed:

Retarder Present, Not Present

Oil Lever Sensor (OLS) Present, Not Present

Throttle TPS, J1587, J1939 *

Engine Coolant Temperature Sensor, J1939, J1587

* No Throttle Autodetect with MY09

Even after autodetect has been completed, it can be reset to monitor an additional group of engine starts. Reset may

be necessary if a device known to be present is not detected or if an autodetectable component or sensor was added

after the initial vehicle build. Reset is accomplished by using Allison DOC™ For PC–Service Tool. To use the

Allison DOC™ For PC–Service Tool, select “RESET AUTODETECT” to search for all four devices. Select

“RESET AUTODETECT RETARDER” to search for a retarder only. Selecting “RESET ADAPTIVE SHIFT

PARAMETERS” will not reset autodetect logic.

The Allison DOC™ For PC–Service Tool can also be used to override autodetect and manually enter the

component or sensor to be recognized by the TCM by changing appropriate “customer modifiable constants”

(CMC). The four items above are the only CMCs that are autodetectable. Other CMCs can be changed at any time

TM

and are not related to autodetect. Consult the Allison DOC

related to Allison 4

th

Generation Controls CMC. Additional details for each of the four autodetectable features are

User’s Guide, GN3433EN, for, detailed instructions

given below.

1–16 Copyright © 2008 Allison Transmission, Inc.

Page 27

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

A. Retarder

Autodetect searches for the presence of pressure control solenoid 5 (PCS5) to the retarder during the

first 35 engine ignition cycles. Retarder autodetect will countdown for a maximum of 35 ignition

cycles while recording detections of a retarder. A retarder will be identified as present and the ret arder

autodetect logic will stop once it is detected for three consecutive ignition cycles. If the ignition cycle

counter completes the 35 cycles before there are three consecutive detections of a retarder, the

software will log that there is no retarder and the retarder autodetect logic will stop. If the autodetect

logic is not satisfied during the first 35 engine starts, the retarder is not detected and will not function

on subsequent engine starts.

If a retarder is present but is not detected by autodetect, the retarder will not

WARNING:

function. Be sure to determine that the retarder is functioning properly

immediately after the 35

PCS5 solenoid for an open, short-to-ground, or short-to-battery condition. Use

the Allison DOC™ For PC–Service Tool to reset retarder autodetect or to

manually select the presence of the retarder after the PCS5 circuit is repaired.

th

engine start. If the retarder is not functioning, test

B. Oil Level Sensor (OLS)

NOTE: If an OLS is known to be present but has not been detected, a possible cause is that the transmission

fluid level is too low. Determine the fluid level before beginning the OLS troubleshooting.

Oil level sensor autodetect will countdown for a maximum of 25 engine starts while recording

detections of an OLS. The TCM monitors the OLS input voltage on wire 116. OLS input voltage

must exceed a predetermined level for the TCM to record a detection. Additionally, OLS detection

must occur within 12.5 seconds on any given engine start. An OLS will be identified as present and

the OLS autodetect logic will stop once it is detected during any single engine start.

If the engine start counter completes 25 cycles before the TCM records one detection of an OLS, the

software will log that there is no OLS present and the OLS autodetect logic will stop. Then the TCM

concludes that no OLS is present.

No OLS diagnostics take place until the OLS is detected. Frequently test for the presence of oil level

diagnostics if the transmission is known to contain an OLS. If an OLS is known to be present, but has

not been detected, troubleshooting the OLS circuit is required. After the OLS circuit is repaired, reset

autodetect or manually select the OLS function using the Allison DOC™ For PC–Service Tool.

C. Throttle Source

Throttle autodetect will increment a counter for a throttle source on each engine start during which

the possible throttle source is detected. When the counter for any of the sources indicates five

consecutive detections, the software will set a “confidence flag” to indicate that this is an available

throttle source. Multiple throttle sources can be detected on a single engine start and multiple

confidence flags can be set. There is no limit to the number of engine starts for autodetection of the

throttle source until a confidence flag is set for a source. Once a confidence flag is set for any one of

the sources, a counter begins to countdown for 15 additional engine starts. During the entire

autodetect period, the software will use the highest priority source as the throttle source if multiple

sources are detected before any confidence flags are set. Once a confidence flag is set, that source is

used as the source for the throttle signal. When the countdown period is complete, the software will

use the highest priority throttle source having a confidence flag set and the autodetect logic will stop.

Copyright © 2008 Allison Transmission, Inc. 1–17

Page 28

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

D. Engine Coolant Temperature

Engine coolant temperature sensor autodetect will countdown for a total of 25 engine starts while

recording detections of engine coolant temperature sources. A “confidence flag” will be set once a

source is detected for five consecutive engine starts. Multiple sources detected before a confidence

flag is set or multiple confidence flags will result in the highest priority source being used as the

engine coolant temperature source. Multiple sources can be detected on a single engine start cycle.

1–10. TRANSID (TID)

The TransID feature enables the TCM to recognize various transmission hardware configurations and select an

appropriate software calibration. However, if a matching calibration does not exist in memory, the TCM registers a

DTC. Furthermore, TID only works when the controller and transmission have the same generation controls. Thus,

TID will not allow an Allison 4

TID allow a WTEC III ECU to recognize a transmission with Allison 4

The TCM senses the transmission configuration using TID wire 176. In initial versions of Allison 4

Controls, wire 176 is connected to high side driver 1 (HSD1), wire 111, in the internal wiring harness. HSD1

supplies power to PCS6 and MAIN MOD solenoids. This wiring configuration is designated TID A.

th

Generation TCM to recognize a transmission with WTEC III controls, nor will

th

Generation Controls.

th

Generation

Whenever a TID level change is to be made, the new TID level calibration will be added to the PROM Calibration

Configurator System (PCCS) before the change (s) is (are) made in production to the transmissions. All TCMs

programmed and sold after that date will be loaded with the new TID calibration. These TCMs will contain

calibrations for the new level transmission and all previous TID levels and will automatically load the correct

calibration for the transmission based on the TID signal sensed by Autodetect during the first 25 engine starts.

1–18 Copyright © 2008 Allison Transmission, Inc.

Page 29

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

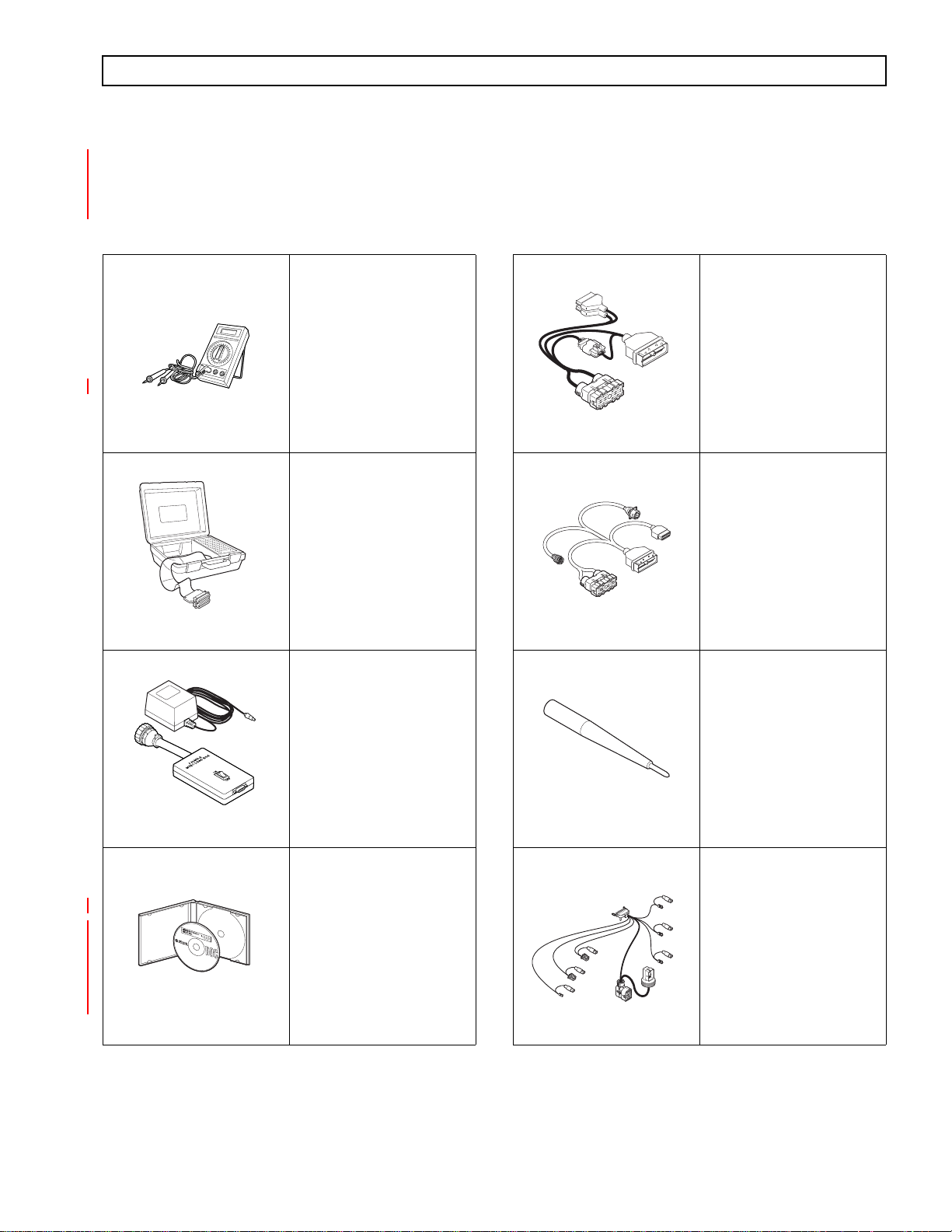

1–11. SPECIAL ELECTRONIC/ELECTRICAL TOOLS

All tools listed are essential for overhaul, maintenance, and/or recalibration of the 3000 and 4000 Product Families

electronic and electrical systems. The tools listed below are available for purchase from SPX/Kent-Moore.

Table 1–1. Essential Tools

3 4 of 9 D I G I T A L M U L T I M E T E R

40

50

100

500

200

300

300

900

400

600

2

5

7

200

500

300

600

400

500

500

700

600

x

COM

abcde

A

xyz ab

10 A

abcde

xyz ab

m

ultim

eter

J 39700

J 34520-A

Digital

Volt/Ohmmeter

J 39700

Univeral Breakout Box

TCM Breakout

Harness Adapter

NOTE: Used with J 39700.

J 47275

J 47276

“T” Breakout and TCM

Reflashing Harness

J 47276

J 47277

Terminal Probe

J 42455-A

J 47275

Load Box

NOTE: J 47277 is now

included in the J 39197-A

Kit.

J 42455-A

J 47277

J 44950

Allison DOC™ For

PC–Service Tool

NOTE: J 44950 is

superseded for each new

release of Allison DOC™

For PC–Service Tool

*

NOTE: 4000 Product Family

*

*

3000 and 4000 Product

Families Breakout Harness

V09224.01.00

J 44950

J 47279

Copyright © 2008 Allison Transmission, Inc. 1–19

Page 30

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

Table 1–1. Essential Tools (cont’d)

J 47943

J 39197-A

J 47943-A

or

J 47943

DPA4 (Plus) USB

Translator Device Kit

J 39197

or

J 39197-A

Jumper Kit

NOTE: J 47277 Terminal

Probe is now included in

the J 39197-A Kit.

Table 1–2. Available Tools

J 47949-A

or

J 47949

GMLAN Cable

J 47949

J 38125-12A

Terminal Remover

(80-way connector)

GM P/N: 12094429

J 38125-12A J 47139

J 47139 (Former)

63811-6000 (Current)

Crimper

1–20 Copyright © 2008 Allison Transmission, Inc.

Page 31

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

SECTION 2—DEFINITIONS AND ABBREVIATIONS

2–1. CHECK TRANS LIGHT

When the TCM detects a serious fault, the CHECK TRANS light (usually located on the vehicle instrument panel)

illuminates and action is automatically taken to protect operator, vehicle, and the transmission. A Diagnostic

Trouble Dode (DTC) will nearly always be registered when the CHECK TRANS light is on; however, not all

DTCs will turn on the CHECK TRANS light. Codes related to the CHECK TRANS light are detailed in the

diagnostic trouble code chart (refer to Section 6).

Illumination of the CHECK TRANS light indicates that a condition was detected that requires service attention.

Operation may or may not be restricted. Even when operation is restricted, the vehicle can be operated to reach a

service assistance location. Depending upon the cause for the CHECK TRANS light illumination, the TCM may or

may not respond to shift selector requests. The transmission may be locked in a range. That range will be shown on

the shift selector display. Both upshifts and downshifts may be restricted when the CHECK TRANS light is

illuminated. Seek service assistance as soon as possible.

Each time the engine is started, the CHECK TRANS light illuminates briefly and then goes off. This momentary

lighting shows the light circuit is working properly. If the light does not come on during engine start, request

service immediately.

A. Oil Life Monitor (OM)

The display message, seen in Allison DOC™ For PC–Service Tool or the Allison shift selector,

indicates the calculated remaining life of the transmission fluid. This value is based on the established

life for the required baseline fluid, and is continuously adjusted for the cumulative effects of

operating parameters such as operating time, retarder operation, output shaft revolutions, and shift

frequency.

OM Display: The selector display is a two-digit number, showing the percentage of fluid life

remaining. New fluid is displayed as 99 percent. Minimum value displayed is 00 percent. Allison

DOC™ For PC–Service Tool displays from 100 percent down to minus (–) 100 percent.

OM TRANSMISSION SERVICE Condition: The SERVICE TRANS indicator illuminates when

transmission fluid needs to be changed. This occurs when the remaining fluid life is approximately 1

percent. The indicator is lit upon each initialization of the TCM, and remains on for approximately 1–

2 minutes after the first selection of a drive range, until service is performed and the indicator is reset.

Failure to perform maintenance and reset the SERVICE TRANS indicator within a specified period

results in the illumination of the CHECK TRANS light and DTC P0897, Transmission Fluid

Deteriorated, being set. P0897 indicates the remaining fluid life has reached 1 percent.

OM Reset: The function may be reset by one of the following methods:

NOTE: Prognostic information can only be reset in the higher of two shift schedules, if applicable.

• Message over the SAE J1939 communication interface.

• With the ignition ON and the engine OFF, shift between N D N D N R N, pausing briefly (less

than 3 seconds) between shifts, to reset the value displayed on the shift selector to 99 percent.

• Display the Oil Life Monitor information and press and hold the MODE button of the Allison

shift selector for 10 seconds.

• Reset by using the specific Action Request in the Allison DOC™ For PC–Service Tool .

The SERVICE TRANS indicator illuminates briefly following a reset to acknowledge the reset was

successful.

Copyright © 2008 Allison Transmission, Inc. 2–1

Page 32

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

Allison DOC™ For PC–Service T ool may be used to enable a Customer Modifiable Constant (CMC)

within the Prognostics CMC Group to restrict reset to the service tool only. If resets are restricted to

the service tool, the selector will not be able to reset the function.

OM History: A historical record of the last 6 resets, including mileage at the time of each reset, may

be viewed using the Allison DOC™ For PC–Service Tool .

NOTE: Required calendar-based fluid change intervals are not monitored by this function and those intervals

remain applicable to all vehicle installations in addition to the above.

B. Filter Life Monitor (FM)

Filter Life Monitor indicates when the filters require changing. The display message indicates the

operating status of the transmission main filter, based on the measured pressure drop across the filter.

The Prognostics pressure switch is activated when fluid exiting the main filter drops below a predetermined pressure. Both the main and lube filters must be changed when the SERVICE TRANS

indicates the main filter should be changed. The differential pressure limit is verified for a period of

time to make sure there is no false filters change indication. This feature is not functional until

transmission sump temperatures are between 40º–150ºC (105–302ºF). This feature is not available

with 7-speed transmission models.

FM Display: An acceptable filter life status is displayed as OK in the shift selector; an unacceptable

filter life status is displayed as LO. Allison DOC™ For PC–Service To ol indicates the Filter Life

Monitor expired as YES or NO.

FM TRANSMISSION SERVICE Condition: Once the programmed threshold for maximum filter

pressure drop has been observed and verified, a DTC P088A, Main Filter Deteriorated, sets to

indicate the filter has reached the end of its designed life. The SERVICE TRANS icon flashes up to 2

minutes at key on after D (Drive) is selected. The indicator illuminates and flashes upon each TCM

initialization, continuing to flash for 1–2 minutes after the first selection of a drive range, until service

is performed and the indicator is reset.

Failure to perform maintenance and reset the monitor after a calibration-defined number of warnings

results in the illumination of the CHECK TRANS light. When the CHECK TRANS has been

illuminated for this purpose, the TCM registers DTC P088B, Very Deteriorated Filter.

FM Reset: The feature resets automatically when the control main fluid filter has been changed and

the pressure drop across the filter no longer exceeds the threshold value. The lube filter must be

changed with the main filter.

The SERVICE TRANS indicator illuminates briefly following a reset to acknowledge the reset was

successful.

Manual resets may also be performed by one of the following methods:

• With the ignition ON and the engine OFF, shift between N R N R N D N to reset the value

displayed on the shift selector to OK.

• Display the Filter Life Monitor information and press and hold the MODE button of the Allison

shift selector for 10 seconds.

• Message over the SAE J1939 communication interface.

NOTE: The Filter Life Monitor triggers the SERVICE TRANS icon following a reset if the Filter Life

indicator switch reopens.

2–2 Copyright © 2008 Allison Transmission, Inc.

Page 33

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

Allison DOC™ For PC–Service T ool may be used to enable a CMC (Customer Modifiable Constant)

within the Prognostics CMC Group to restrict reset to the service tool only. If resets are restricted to

the service tool, the selector will not be able to reset the function.

FM History: Use the Allison DOC™ For PC–Service Tool to display the amount of transmission

operation from the initial service indication until the service reset.

NOTE: Required calendar-based filter change intervals are not monitored by this feature and remain

applicable to all vehicle installations in addition to the above.

C. Operation of Filter Life Valve and Pressure Switch (PS2)

Pressure Switch 2 (PS2), also known as the Filter Life Switch, is used to monitor the pressure

difference between main pressure before the filter and lockup clutch pressure as a method to monitor

the main filter for excessive filter restriction. See Figure 1.

When the main filter is in an unrestricted state and lockup clutch pressure is applied, the switch is

depressurized and in its Normally closed (NC) position which completes a circuit between wire 118

and analog returns wire 158. Allison DOC™ For PC–Service Tool shows PS2 EXHAUSTED. The

Filter Life Valve is de-stroked off the return spring in this condition because lockup pressure is high

enough to keep main pressure (before the filter) from stroking the valve.

When the main filter gets excessively restricted by debris, lockup pressure drops. The Filter Life

Valve strokes because of the higher main pressure (before the filter). This acts on the other end of the

Filter Life Valve, compressing the return spring and allowing control main pressure through the valve

to PS2, which pressurizes the switch. This opens the PS2 and voltage is sensed on wire 118. Allison

DOC™ For PC–Service Tool shows PS2 PRESSURIZED.

Copyright © 2008 Allison Transmission, Inc. 2–3

Page 34

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

MAIN CIRCUIT FILTER

FILTER LIFE VALVE

MAIN PRESSURE

(BEFORE FILTER)

PUMP

SUCTION FILTER

EX

SUMP

FILTERED

MAIN

FILTER LIFE VALVE HYDRAULIC SCHEMATIC

Figure 2–1. Filter Life Valve Hydraulic Schematic

D. Transmission Health Monitor (TM)

MAIN

FLOW

PS 2

EX

CONTROL MAIN

TCC FLOW

FILTERED

MAIN

LUBE

V11111.00.00

The display message, seen in Allison DOC™ For PC–Service T ool or the Allison shift selector,

identifies clutch life status, as determined by monitored changes and the calculated running clearance

of the transmission clutches C1, C2, C3, C4, and C5.

TM Display: An acceptable clutch life status is displayed as OK in the shift selector; an unacceptable

clutch life status is displayed as LO. The specific clutch or clutches causing the LO display cannot be

identified using the shift selector display. Allison DOC™ For PC–Service Tool displays clutch

condition as OK or NOT OK for each clutch, C1 through C5. Allison DOC™ For PC–Service Tool

displays NA until transmission shifts are adapted.

TM TRANSMISSION SERVICE Condition: The SERVICE TRANS indicator illuminates,

indicating the need for clutch maintenance. This occurs when the remaining clutch life reaches

2–4 Copyright © 2008 Allison Transmission, Inc.

Page 35

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

approximately 10 percent or the running clearance exceeds a maximum value, which may indicate a

non-wear-related issue. The indicator illuminates upon each initialization of the TCM, and remains on

during vehicle operation until service is performed and the indicator is reset. Additional

troubleshooting is required to make sure clutches require replacing.

TM Reset: This feature resets itself automatically after maintenance/repair is done to correct the

condition that caused the warning for excessive clutch clearance. If necessary, the indicator can be

manually reset using the Allison DOC™ For PC–Service Tool diagnostics program. After a number

of warnings occur from the SERVICE TRANS indicator without correcting the condition, the

CHECK TRANS light illuminates and DTC P2789, Clutch Adaptive Learning at Limit, activates.

TM History: Use the Allison DOC™ For PC–Service T o ol to display the amount of transmission

operation from the initial service indication until the service reset.

2–2. ALLISON TRANSMISSION DIAGNOSTIC TOOL

Allison DOC™ (Diagnostic Optimized Connection) For PC–Service Tool is a PC-based diagnostic tool for use

with 3000 and 4000 Product Families transmissions. The Allison DOC™ For PC–Service Tool is a full-feature

diagnostic software application supporting the Allison 4

own PC, it will allow the technician to acquire data from the transmission’s control system and through the use of

embedded troubleshooting manuals, conduct systematic troubleshooting of transmission complaints.

th

Generation Control System. When installed on the user’s

Basic Features

Allison DOC™ For PC–Service Tool uses a Windows

• User selected views of multiple transmission parameters

• Active and historical diagnostic trouble codes (DTCs)

• Graphical instrument panel view of transmission parameters

• Strip chart function

• User configurable Snapshot function

• User configurable Print function

• Code driven links to embedded Allison 4

• Reprogramming capability (available after satisfying Allison Transmission training certification

th

requirements)

• Demo Mode which allows the user to practice the program without being connected to a vehicle

• New animated screen by screen help support (found in Help, V ideo-based training materials, Allison

DOC™ For PC–Service To ol Training Videos)

• Application Configuration—This menu function serves as the platform for three different features:

(1) General tab, which allows the user to select language (English only at this time), and unit of measure.

(2) TCM Reprogramming tab, used to enable the reprogramming capability of the Allison DOC™ For

PC–Service Tool .

(3) Update Application tab, which provides access to a URL containing minor updates for the diagnos-

tic tool to support changes in the various transmission control systems.

• Data Bus Viewer allows the user to capture (see and save) the raw data transmitted on the various

vehicle data buses supported by Allison DOC™ For PC–Service Tool (J 1939 and J 2284)

• Printed user’s manual and laminated Job Aid Card

• Adobe

• Microsoft

Acrobat Reader® bundled on the CD for reading the Troubleshooting Manual

Media Player bundled on the CD for displaying various and updated training videos

(available from the application Help menu).

style graphical user interface (GUI) and includes:

Generation Control System Troubleshooting Manuals

Copyright © 2008 Allison Transmission, Inc. 2–5

Page 36

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

PC Platform Definition

Allison DOC™ For PC–Service Tool V7.x.x has been tested with and is known to operate on PCs with the

following configurations*:

• Microsoft Windows XP® Professional, Wind ows 2000 (SP4 or later) Professional, and Windows

Vista™ Home Basic (or better)

NOTE: In order to install and run Allison DOC for PC–Service Tool V7.x.x on Windows Vista™, the user

must have full administrator privileges and must have the User Acount Control feature turned OFF.

• 20 GB Hard Drive (40 GB or greater recommended)

• 600 MB free hard drive space required to install the program (after software installation, the operating

system requires sufficient free hard disk dpace to run the program)

• 1 GHz (or greater) 32-bit (x86) or 64-bit (x64) processor

• 512 MB of RAM system memory (1 GB recommended)

• One available USB port—USB 1.1 (USB 2.0 recommended)

• 16x CD-ROM (48x or greater recommended)

• Full administrative privileges are required to install, update, and run Allison DOC™ For PC–Service

Tool

• Internet connection capability with Internet Explorer® 5.0.1 or greater.

NOTE: A broadband Internet connection is highly recommended for receiving updates and file

downloads.

• Windows Media® Player is installed by default

• Adobe® Acrobat Reader® is installed by default

NOTE: Error messages, sudden disconnections, and poor performance are some of the results users will

experience if Allison DOC

For PC-Service Tool V7.x.x is installed on PCs that do not meet one or

more of the above specifications.

NOTE: For the latest requirements, please refer to www.allisontransmission.com/Service/Electronic

(Diagnostic) Tools/Requirements or the latest revision of Service Information Letter 12-TR-07, Rev. A.

2–6 Copyright © 2008 Allison Transmission, Inc.

Page 37

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

2–3. ABBREVIATIONS

A/N Assembly Number

ABS Anti-lock Brake System—OEM-provided means to detect and prevent wheel stoppage to

enhance vehicle handling. Retarder and engine brakes will not apply when ABS is active.

Amp Unit of electrical current

API Application Program Interface

AT Allison Transmission

C1...C6 Clutch 1....Clutch 6

CAN Controller Area Network—A network for all SAE J1939 communications in a vehicle

(engine, transmission, ABS, etc.)

CIN Calibration Identification Number

CMC Customer Modified Constant

CPA Connector Position Assurance

CT Closed Throttle

DCE Direction Change Enable

DMM Digital Multimeter

DNA Does Not Adapt—Adaptive shift control is disabled

DNS DO NOT SHIFT—Refers to the DO NOT SHIFT diagnostic response during which the

CHECK TRANS light is illuminated and the transmission will not shift and will not

respond to the Shift Selector

DOC Diagnostic Optimized Connection

DPA Dearborn Protocol Adapter

DTC Diagnostic Trouble Code

DVOM Digital Volt/Ohmmeter

ECM Engine Control Module

EMI ElectroMagnetic Interference

FBO F eature Based Ordering

FCC Federal Communications Commission

FM Filter Life Monitor

GPI General Purpose Input—Input signal to the TCM to request a special operating mode or

condition

GPO General Purpose Output—Output signal from the TCM to control vehicle components

(such as PTOs, backup lights, etc.) or allow a special operating mode or condition

GUI Graphical User Interface

HSD High Side Driver

J1587 Engine/transmission serial data communications link

J1939 High-speed vehicle serial data communications link

Copyright © 2008 Allison Transmission, Inc. 2–7

Page 38

3000 AND 4000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

2–3. ABBREVIATIONS (cont’d)

LED Light-Emitting Diode—Electronic device used for illumination

LRTP Low Range Torque Protection

LSD Low Side Driver

MB Mega Byte

NNC Neutral No Clutches—Neutral commanded with no clutches applied

NVL Neutral Very Low—The TCM has sensed turbine speed below 150 rpm when output speed

is below 100 rpm and engine speed is above 400 rpm when N (Neutral) was selected. This

is usually caused by a dragging C1 or C3 clutch or a failed turbine speed sensor. NVL is

attained by turning D solenoid “ON” (in addition to E solenoid) and the C4 and C5

clutches are applied to lock the transmission output.

OEM Original Equipment Manufacturer—Maker of vehicle or equipment

Ohm Unit of electrical resistance

OL Over Limit or Oil Level—For Over Limit see “”. Indicates Oil Level is being displayed

on a shift selector

OLS Oil Level Sensor—Electronic device (optional) on control module for indicating

transmission fluid level

OM Oil Life Monitor

PC Personal Computer

PCCS PROM Calibration Configurator System

PCS Pressure Control Solenoid

PLR Primary Lock Reinforcement (Connector)

P/N Part Number

PROM Programmable Read Only Memory

PSS Primary Shift Selector—Main shift selector in a two-selector control system.

PTO Power Takeoff

PWM Pulse Width Modulation

RELS Reduced Engine Load at Stop

RFI Radio Frequency Interference