Page 1

AT-LX3800U

Multi-Service

Transport System

LightExplorer™

Installation and Maintenance

Guide

613-50549-00 Rev. C

Page 2

Copyright © 2005 Allied Telesyn, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesyn, Inc.

Microsoft and Internet Explorer are registered trademarks of Microsoft Corporation. Netscape Navigator is a registered

trademark of Netscape Communications Corporation. All other product names, company names, logos or other designations

mentioned herein are trademarks or registered trademarks of their respective owners.

Allied Telesyn, Inc. reserves the right to make changes in specifications and other information contained in this document

without prior written notice. The information provided herein is subject to change without notice. In no event shall Allied Telesyn,

Inc. be liable for any incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits,

arising out of or related to this manual or the information contained herein, even if Allied Telesyn, Inc. has been advised of,

known, or should have known, the possibility of such damages.

Page 3

Electrical Safety and Emissions Standards

This product meets the following standards.

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved of by the manufacturer or the FCC, can void your right to operate

this equipment.

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

RFI Emissions FCC Class A, EN55022 Class A, EN61000-3-2, EN61000-3-3, VCCI

Class A, C-TICK, CE

Immunity EN55024

Electrical Safety EN60950 (TUV), UL 60950 (

Laser Safety EN60825

CULUS

)

3

Page 4

Laser Warnings

Caution

- Using controls, making adjustments to performance, or performing procedures other than

those specified herein may result in hazardous radiation exposure.

- The protection provided by the equipment may be impaired if the equipment is used in a

manner not specified by Allied Telesyn.

- Do not remove the cover from the unit or change any of the internal cables or wiring. Only

an authorized Allied Telesyn service technician should make repairs to this device.

- The TX and RX multiplexing ports contain embedded Class IIIb lasers operating in Class I

compliance. Do not make any modifications to the unit that would override the safeguards

that maintain the Class I compliance.

- The laser light used by the multiplexing ports and SFP modules is invisible. Standard

safety precautions (e.g. avoid looking directly into a fiber optic port) should always be

observed when installing or maintaining this product.

Pluggable Transceivers

For continued compliance with the above laser safety standards, use only UL recognized or other

safety agency certified Class 1 small form-factor pluggable (SFP) transceivers. The following SFP

transceiver models are available from and supported by Allied Telesyn:

AT-SPSX

AT-SPLX10

AT-SPLX40

AT-SPZX80

AT-SPZX80/1470

AT-SPZX80/1490

AT-SPZX80/1510

AT-SPZX80/1530

AT-SPZX80/1550

AT-SPZX80/1570

AT-SPZX80/1590

AT-SPZX80/1610

Refer to the Allied Telesyn web site, www.alliedtelesyn.com, or an authorized Allied Telesyn sales

representative for a current list of supported SFP modules for this unit.

4

Page 5

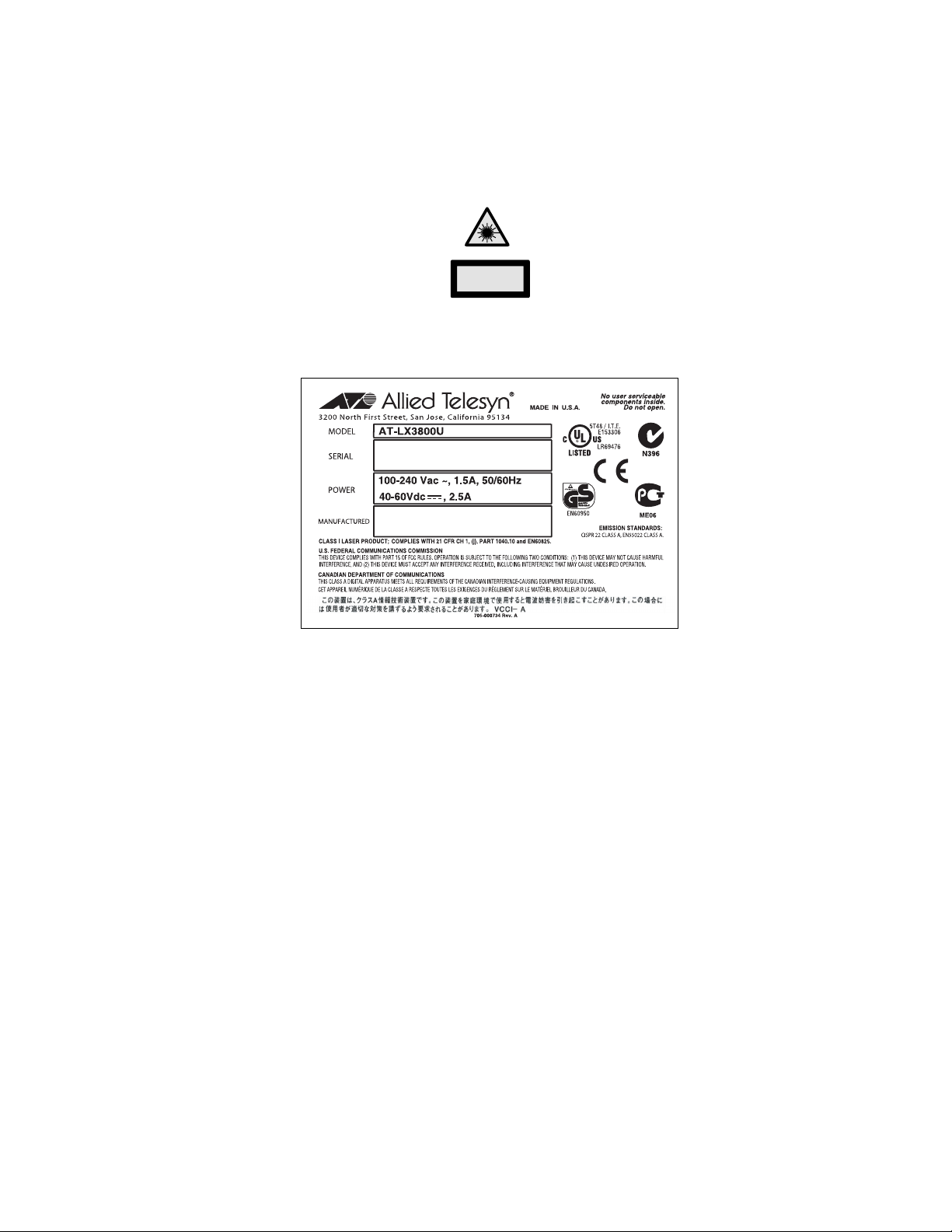

Product Labels

This label, located on the front panel of the unit, indicates the device is a Class 1 laser device.

CLASS 1

LASER PRODUCT

This label is located on the bottom panel of an AT-LX3800U Multi-Service Transport System.

5

Page 6

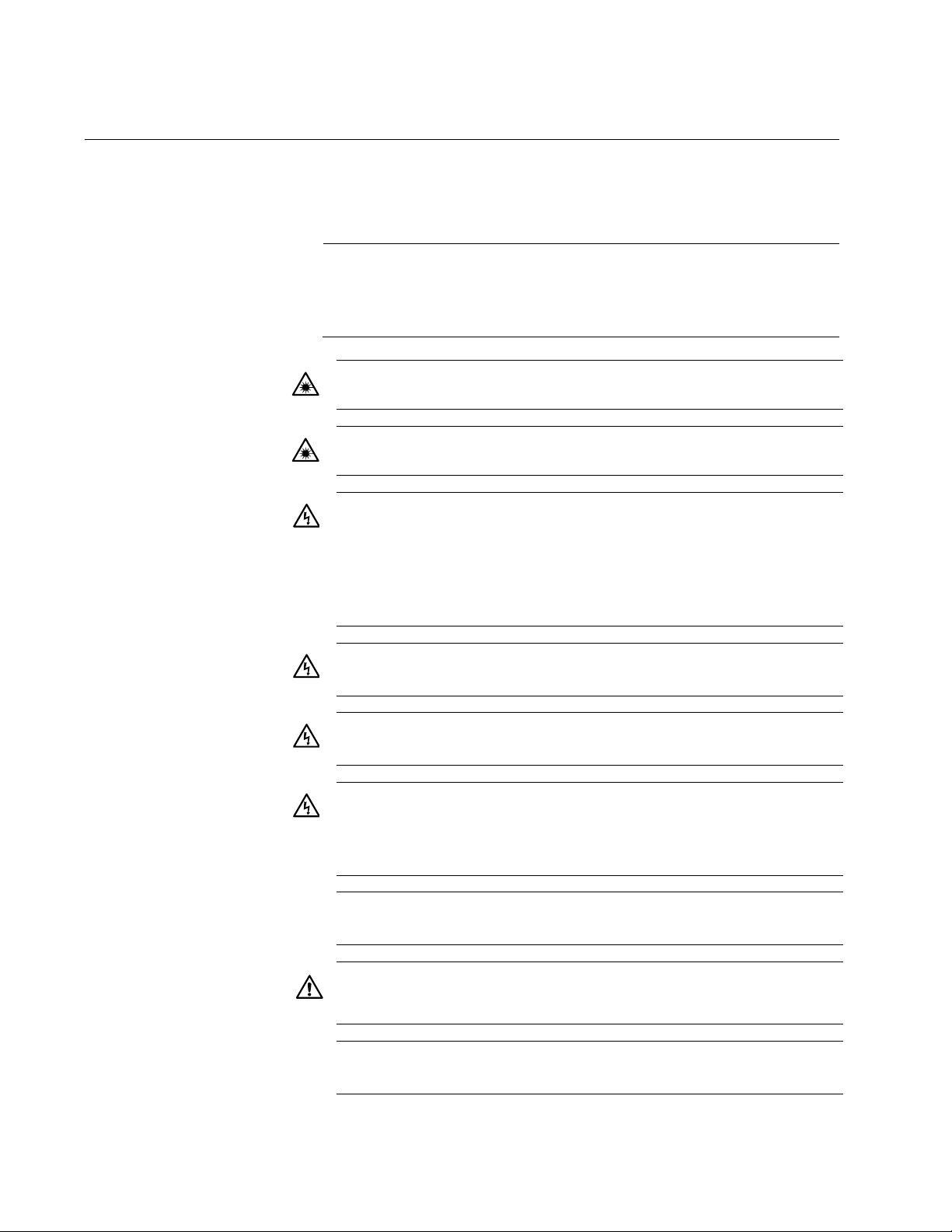

Translated Safety Statements

Important: Appendix C contains translated safety statements for installing this equipment. When

you see the , go to Appendix B for the translated safety statement in your language.

Wichtig: Anhang C enthält übersetzte Sicherheitshinweise für die Installation dieses Geräts. Wenn

Sie sehen, schlagen Sie in Anhang B den übersetzten Sicherheitshinweis in Ihrer Sprache nach.

Importante: El Apéndice C contiene mensajes de seguridad traducidos para la instalación de este

equipo. Cuando vea el símbolo , vaya al Apéndice B para ver el mensaje de seguridad traducido

a su idioma.

Important : L'annexe C contient les instructions de sécurité relatives à l'installation de cet

équipement. Lorsque vous voyez le symbole , reportez-vous à l'annexe B pour consulter la

traduction de ces instructions dans votre langue.

Importante: l’Appendice C contiene avvisi di sicurezza tradotti per l’installazione di questa

apparecchiatura. Il simbolo , indica di consultare l’Appendice B per l’avviso di sicurezza nella

propria lingua.

Важно: Приложение C содержит переведенную инструкцию по безопасности при установке

данного устройства. Если Вы встретите , перейдите к Приложению B для получения

переведенной инструкции по безопасности.

6

Page 7

Contents

Preface ................................................................................................................................................................................ 13

Safety Symbols Used in this Document................................................................................................................................ 14

Where to Find Web-based Guides ....................................................................................................................................... 15

Contacting Allied Telesyn ..................................................................................................................................................... 16

Online Support ..............................................................................................................................................................16

Email and Telephone Support....................................................................................................................................... 16

Returning Products........................................................................................................................................................16

Sales or Corporate Information .....................................................................................................................................16

Management Software Updates....................................................................................................................................16

Chapter 1: Overview ..........................................................................................................................................................17

System Description...............................................................................................................................................................18

Line Card Descriptions .........................................................................................................................................................20

AT-LX3801 Blank Slot Covers.............................................................................................................................................. 22

LEDs.....................................................................................................................................................................................23

Line Card LEDs ............................................................................................................................................................. 23

System LEDs.................................................................................................................................................................27

Management Connections....................................................................................................................................................29

Terminal Port................................................................................................................................................................. 29

10/100Base-TX Ethernet Port .......................................................................................................................................29

AT-LXPWR Power Supply Module .......................................................................................................................................30

AT-LXPWR/AC Power Supply.......................................................................................................................................30

AT-LXPWR/DC Power Supply.......................................................................................................

Power Connectors ................................................................................................................................................................32

AC Power Connector.....................................................................................................................................................32

DC Power Connector .................................................................................................................................................... 32

Topologies ............................................................................................................................................................................33

................................31

Chapter 2: Installation .......................................................................................................................................................37

Reviewing Safety Precautions..............................................................................................................................................38

Selecting a Site for the Chassis............................................................................................................................................42

TX and RX Fiber Optic Cable Specifications........................................................................................................................ 43

Unpacking the Chassis.........................................................................................................................................................44

Installing the Power Cord Retaining Clip (AC Power Supply Only) ......................................................................................45

Installing the AT-LX3800U Chassis in a Rack ......................................................................................................................47

Installing an AT-LX3811/x Line Card .................................................................................................................................... 50

Installing an SFP Transceiver in a Line Card .......................................................................................................................53

Installing an AT-LX3801 Blank Slot Cover............................................................................................................................ 55

Cabling the Chassis..............................................................................................................................................................57

Connecting the Fiber Optic Cables to a Line Card ........................................................................................................57

Connecting the Fiber Optic Cables to the TX and RX Ports..........................................................................................58

Powering On an AC Powered System..................................................................................................................................60

Wiring and Powering On a DC Powered System ................................................................................................................. 63

Starting a Local Management Session .................................................................................................................................66

Starting a Remote Management Session.............................................................................................................................68

Warranty Registration........................................................................................................................................................... 70

Chapter 3: Troubleshooting ..............................................................................................................................................71

PA or PB LED for the System is Off or Flashing...................................................................................................................71

RDY LED on a Line Card is Off ..................................................................................................

RDY LED on a Line Card is Flashing ................................................................................................................................... 72

..........................................72

7

Page 8

Contents

Line Card Tributary Side (SFP) RX and TX LEDs are Off ....................................................................................................72

Line Card Line Side RX and TX LEDs are Flashing Green or Off ........................................................................................73

Appendix A: Technical Specifications .............................................................................................................................75

Physical Specifications .........................................................................................................................................................75

Environmental Specifications................................................................................................................................................75

Power Specifications.............................................................................................................................................................75

Optical Specifications............................................................................................................................................................76

Safety and Electromagnetic Emissions Certifications...........................................................................................................77

Standards .............................................................................................................................................................................77

DIN-8 RS-232 Terminal Port Pinouts....................................................................................................................................77

10/100Base-TX Port Pinouts ................................................................................................................................................78

Appendix B: Cleaning Fiber Optic Connectors ...............................................................................................................79

Using a Cartridge-Type Cleaner ...........................................................................................................................................80

Using a Swab........................................................................................................................................................................82

Appendix C: Translated Safety Statements ....................................................................................................................85

8

Page 9

Figures

Figure 1. AT-LX3800U System Front Panel........................................................................................................................ 19

Figure 2. Back Panel of an AT-LX3800U System Ordered with an AC Power Supply Installed .........................................19

Figure 3. Back Panel of an AT-LX3800U System Ordered with a DC Power Supply Installed ........................................... 19

Figure 4. AT-LX3811/x Line Card........................................................................................................................................20

Figure 5. AT-LX3801 Blank Slot Cover................................................................................................................................22

Figure 6. Line Card LEDs ....................................................................................................................................................23

Figure 7. System LEDs........................................................................................................................................................27

Figure 8. AT-LXPWR/AC Power Supply..............................................................................................................................30

Figure 9. AT-LXPWR/DC Power Supply..............................................................................................................................31

Figure 10. AC Power Connector and On/Off Switch............................................................................................................ 32

Figure 11. DC Terminal Block.............................................................................................................................................. 32

Figure 12. Standard Point-to-Point Configuration................................................................................................................ 33

Figure 13. Regeneration Configuration Using the Internal Loopback Feature ....................................................................34

Figure 14. Loop-type Backbone Topology...........................................................................................................................35

Figure 15. Power Cord Retaining Clip .................................................................................................................................45

Figure 16. Power Cord Retaining Bracket ...........................................................................................................................45

Figure 17. Inserting the Retaining Clip into the Retaining Bracket ......................................................................................45

Figure 18. Retaining Clip Properly Installed in the Bracket .................................................................................................46

Figure 19. Removing Plastic Feet from the Chassis............................................................................................................47

Figure 20. Rack-Mount Bracket Configurations...................................................................................................................47

Figure 21. Mounting the AT-LX3800U Chassis in a 19-inch Rack ...................................................................................... 48

Figure 22. Removing the Dust Covers.................................................................................................................................50

Figure 23. Location of Alignment Guides.............................................................................................................................51

Figure 24. Inserting the Line Card.......................................................................................................................................51

Figure 25. Tightening the Captive Screws...........................................................................................................................52

Figure 26. Removing the Dust Plug from the SFP Port.......................................................................................................53

Figure 27. Installing an SFP Transceiver in a Line Card .......................................................................

Figure 28. Location of Alignment Guides.............................................................................................................................55

Figure 29. Installing the Blank Slot Cover............................................................................................................................56

Figure 30. Tightening the Captive Screws...........................................................................................................................56

Figure 31. Removing the Dust Plug from the SFP...............................................................................................................57

Figure 32. Connecting a Fiber Optic Cable to the SFP .......................................................................................................58

Figure 33. Removing the Dust Plugs from the TX and RX Ports.........................................................................................58

Figure 34. Connecting the TX and RX Cables..................................................................................................................... 59

Figure 35. On/Off Switch in Off Position..............................................................................................................................60

Figure 36. Power Cord Retaining Clip in the Up Position....................................................................................................60

Figure 37. Plugging in the AC Power Cord..........................................................................................................................61

Figure 38. Securing the Power Cord with the Retaining Clip...............................................................................................61

Figure 39. On/Off Switch in On Position..............................................................................................................................62

Figure 40. Positive, Frame Ground, and Negative Terminals..............................................................................................63

Figure 41. Wire Stripping Specification................................................................................................................................64

Figure 42. Connecting the Stripped Wire............................................................................................................................. 64

Figure 43. Connecting the Local Management Cable to the Terminal Port.........................................................................66

Figure 44. AT-S65 Main Menu............................................................................................................................................. 67

Figure 45. Connecting a Cable to the 10/100Base-T Port...................................................................................................68

Figure 46. DIN-8 RS-232 Connector and Port Pin Layouts.................................................................................................77

Figure 47. 10/100Base-TX Connector and Port Pinouts .....................................................................................................78

Figure 48. Ferrule in an SC Connector Plug........................................................................................................................79

Figure 49. Unclean and Clean Ferrule..........................................................................................

Figure 50. Cartridge Cleaner ...............................................................................................................................................80

..............................54

....................................... 79

9

Page 10

Figures

Figure 51. Rubbing the Ferrule Tip on the Cleaning Surface ..............................................................................................80

Figure 52. Lint-Free and Alcohol-Free Swabs .....................................................................................................................82

Figure 53. Cleaning a Recessed Ferrule.............................................................................................................................82

10

Page 11

Tables

Table 1. Safety Symbols .....................................................................................................................................................14

Table 2. AT-LX3811/x Line Cards ......................................................................................................................................20

Table 3. RDY LED ..............................................................................................................................................................23

Table 4. Tributary Side TX and RX LEDs ........................................................................................................................... 24

Table 5. Line Side TX and RX LEDs ..................................................................................................................................25

Table 6. Line Side Sync LED ..............................................................................................................................................27

Table 7. System LEDs ........................................................................................................................................................27

Table 8. Optical Power per Channel for Line Ports with Optical MUX/DEMUX Losses Included .......................................76

Table 9. Power Budget Per Channel ..................................................................................................................................76

Table 10. DIN-8 RS-232 Terminal Port Pinouts ..................................................................................................................77

Table 11. 10/100Base-TX Port Pinouts (MDIX Mode Only) ...............................................................................................78

11

Page 12

Tables

12

Page 13

Preface

This guide contains instructions on how to install an AT-LX3800U MultiService Transport System and contains the following sections:

“Safety Symbols Used in this Document” on page 14

“Where to Find Web-based Guides” on page 15

“Contacting Allied Telesyn” on page 16

13

Page 14

Preface

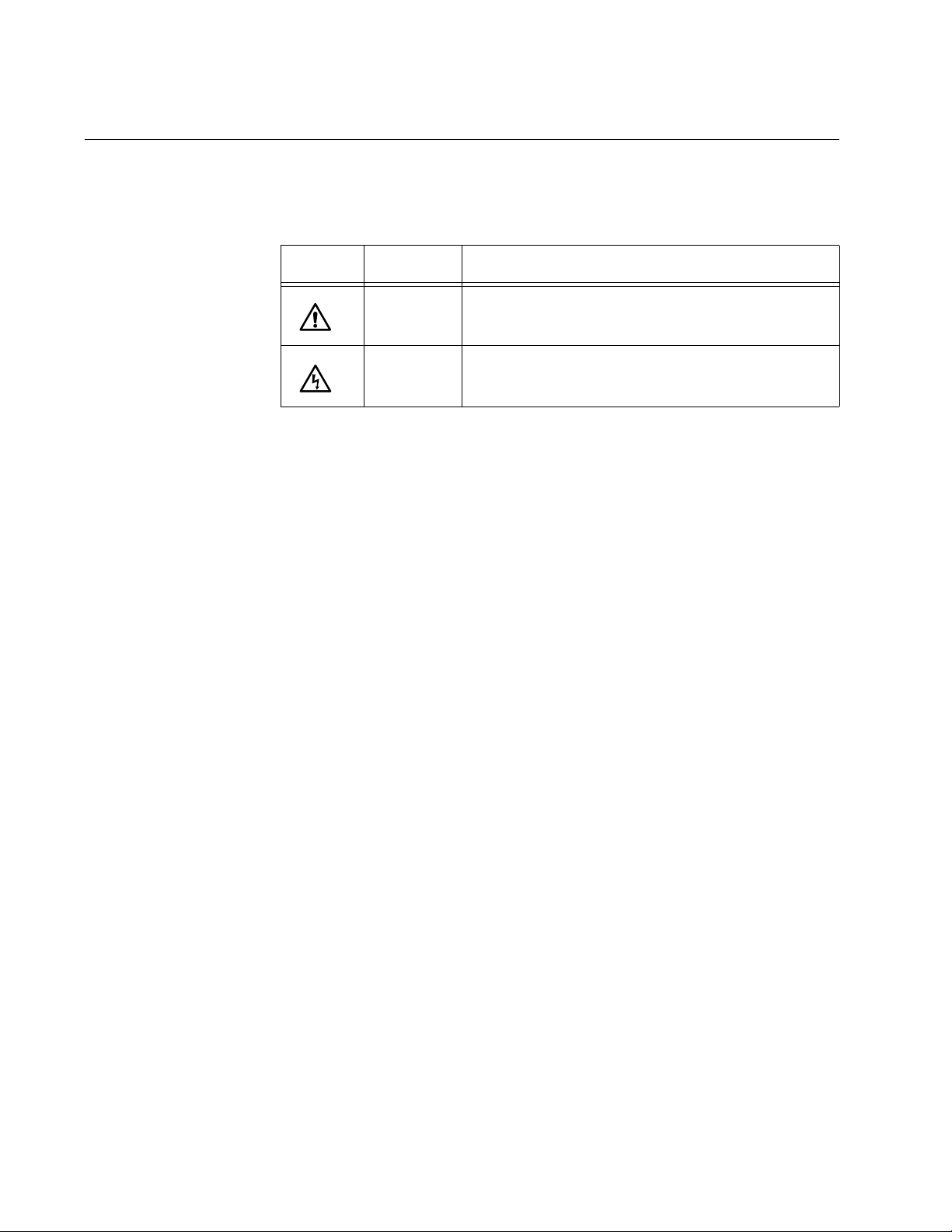

Safety Symbols Used in this Document

This document uses the safety symbols defined in Table 1.

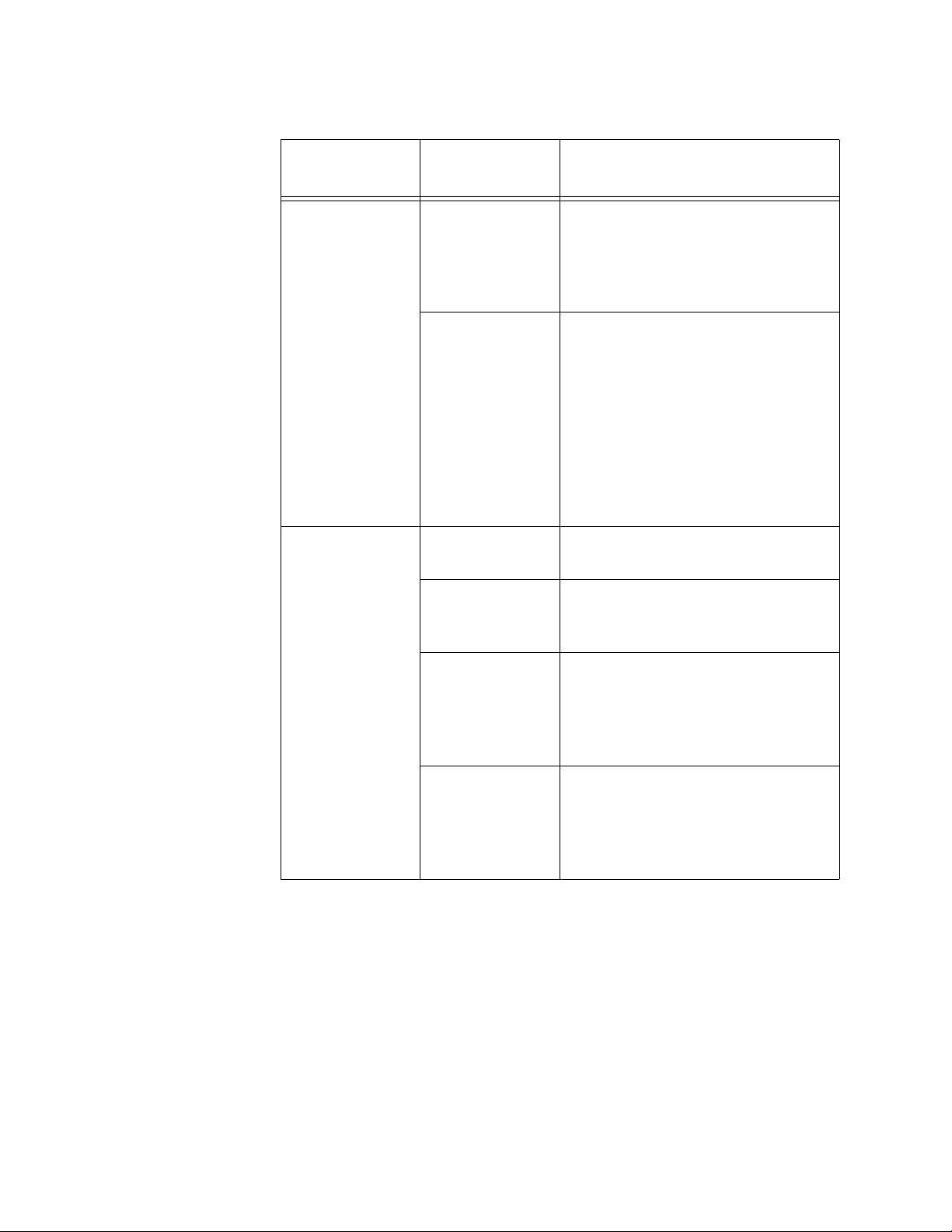

Table 1. Safety Symbols

Symbol Meaning Description

Caution Performing or omitting a specific action may

result in equipment damage or loss of data.

Warning Performing or omitting a specific action may

result in electrical shock.

14

Page 15

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Where to Find Web-based Guides

The installation and user guides for all Allied Telesyn products are

available in portable document format (PDF) on our web site at

www.alliedtelesyn.com. You can view the documents online or download

them onto a local workstation or server.

15

Page 16

Preface

Contacting Allied Telesyn

This section provides Allied Telesyn contact information for technical

support as well as sales and corporate information.

Online Support You can request technical support online by accessing the Allied Telesyn

Knowledge Base: http://kb.alliedtelesyn.com. You can use the

Knowledge Base to submit questions to our technical support staff and

review answers to previously asked questions.

Email and

Telephone

Support

Returning

Products

Sales or

Corporate

Information

Management

Software Updates

For Technical Support via email or telephone, refer to the Support &

Services section of the Allied Telesyn web site: www.alliedtelesyn.com.

Products for return or repair must first be assigned a return materials

authorization (RMA) number. A product sent to Allied Telesyn without an

RMA number will be returned to the sender at the sender’s expense.

To obtain an RMA number, contact Allied Telesyn Technical Support

through our web site: www.alliedtelesyn.com.

You can contact Allied Telesyn for sales or corporate information through

our web site: www.alliedtelesyn.com. To find the contact information for

your country, select Contact Us -> Worldwide Contacts.

New releases of management software for our managed products are

available from either of the following Internet sites:

Allied Telesyn web site: www.alliedtelesyn.com

Allied Telesyn FTP server: ftp://ftp.alliedtelesyn.com

16

If you prefer to download new software from the Allied Telesyn FTP server

from your workstation’s command prompt, you will need FTP client

software and you must log in to the server. Enter “anonymous” for the user

name and your email address for the password.

Page 17

Chapter 1

Overview

The AT-LX3800U Multi-service Transport System aggregates up to eight

multi-rate services into a single fiber optic link using small form-factor

pluggable (SFP) transceivers.

This chapter contains the following sections:

“System Description” on page 18

“Line Card Descriptions” on page 20

“AT-LX3801 Blank Slot Covers” on page 22

“LEDs” on page 23

“Management Connections” on page 29

“AT-LXPWR Power Supply Module” on page 30

“Power Connectors” on page 32

“Topologies” on page 33

17

Page 18

Chapter 1: Overview

System Description

The AT-LX3800U Multi-service Transport System has the following

features:

An eight-slot chassis with integrated management module

One preinstalled AT-LXPWR/AC or AT-LXPWR/DC power supply in

the PWR A slot in the rear, with one expansion slot for an optional

redundant power supply unit. Both slots support any combination of

AC and DC power supplies.

Eight preinstalled AT-LX3801 Blank Slot Covers

Standard rack mounting or standalone

Eight AT-LX3811/x Multi-Service Line Cards available with industry

standard small form-factor pluggable (SFP) transceiver slots

Data rates from 100 MB to 2.5 GB

Numbered and color-coded system labels and line cards to eliminate

line card installation errors

Six LEDs per line card and four system LEDs

One RS-232 terminal port for local management

One 10/100Base-TX Ethernet port for remote management

Preinstalled AT-S65 management software for remote or local

management

The AT-LX3800U chassis is available with either an AC or a DC power

supply preinstalled.

18

Page 19

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Figure 1 shows the front panel of the AT-LX3800U system.

RS-232 Terminal Port

Line Card Slots

1 2 3 4 5 6 7 8

AT-LX3801 AT-LX3801 AT-LX3801 AT-LX3801 AT-LX3801 AT-LX3801AT-LX3801 AT-LX3801

10/100Base-T Port

Figure 1. AT-LX3800U System Front Panel

Figure 2 shows the back panel of an AC-powered system.

RX and TX Ports

AT-LX3800U

8

LASER PRODUCT

100 10

RESET

CLASS 1

10/100Base-TX

TX RX

LINE

TERMINAL

RS-232

122

FT

CO

PA

PB

AT-LXPWR/AC

AT-LXPWR/DC

AC Power Supply

FOR CENTRALIZED DC

POWER CONNECTION,

INSTALL ONLY IN A

RESTRICTED ACCESS

LOCATION

DC Power Supply

40-60VDC

ON

100-240VAC~

PWR A

PWR B

Figure 2. Back Panel of an AT-LX3800U System Ordered with an AC

Power Supply Installed

Figure 3 shows the back panel of a DC-powered system.

ON

PWR A

PWR B

Figure 3. Back Panel of an AT-LX3800U System Ordered with a DC

Power Supply Installed

470

704

19

Page 20

Chapter 1: Overview

Line Card Descriptions

The AT-LX3800U chassis can contain up to eight AT-LX3811/x line cards,

numbered and color-coded for insertion in the corresponding numbered

slot in the chassis, as described in Table 1.

Table 1. AT-LX3811/x Line Cards

Model Wavelength

AT-LX3811/1 1470 1

AT-LX3811/2 1490 2

AT-LX3811/3 1510 3

AT-LX3811/4 1530 4

AT-LX3811/5 1550 5

AT-LX3811/6 1570 6

AT-LX3811/7 1590 7

AT-LX3811/8 1610 8

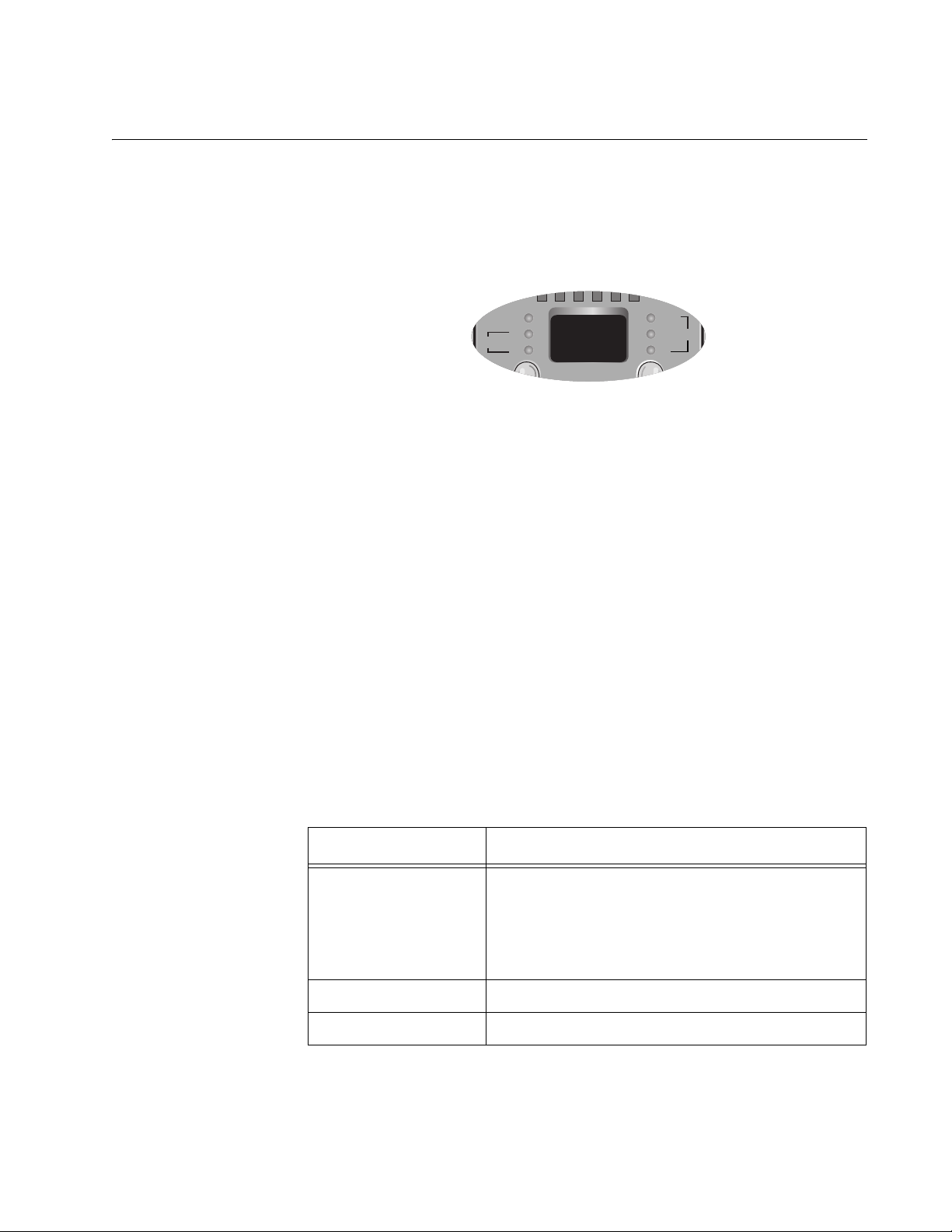

Figure 4 shows a sample AT-LX3811/x line card.

Slot

Number

20

AT-LX3811/8

RDY

TRIB

TX

RX

SYNC

TX

LINE

SFP

RX

123

Figure 4. AT-LX3811/x Line Card

Note

The RDY LED on the line card flashes and the AT-S65 management

software displays an error if a line card is inserted in the wrong slot.

Page 21

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

The line cards are hot swappable into and out of the system. Each line

card can only be used in its dedicated slot.

Each AT-LX3811/x line card contains one SFP transceiver slot.

To install an AT-LX3811/x line card, refer to “Installing an AT-LX3811/x

Line Card” on page 50.

21

Page 22

Chapter 1: Overview

AT-LX3801 Blank Slot Covers

The AT-LX3800U chassis is shipped with eight AT-LX3801 Blank Slot

Covers in place. The blank slot cover protects the fiber optic connectors

on the backplane from becoming dirty, and helps maintain proper air flow

through the chassis. A blank slot cover is shown in Figure 5.

AT-LX3801

176

Figure 5. AT-LX3801 Blank Slot Cover

Note

Allied Telesyn strongly recommends that a blank slot cover be

inserted in any slot that does not contain a functioning line card.

To install a blank slot cover that was removed from the chassis, refer to

“Installing an AT-LX3801 Blank Slot Cover” on page 55.

22

Page 23

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

SFP

SYNC

TX

RX

LINE

RDY

TX

RX

TRIB

LEDs

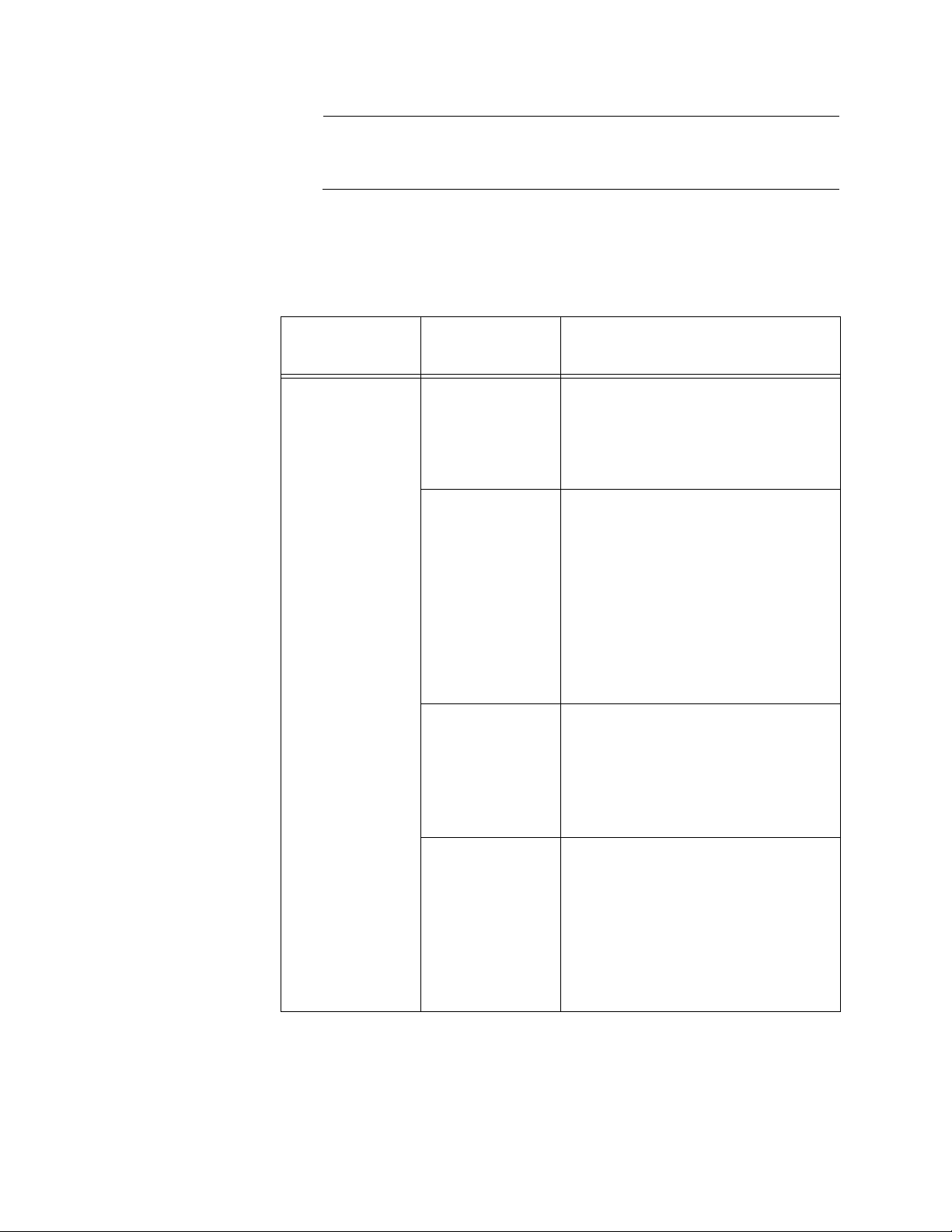

The AT-LX3800U provides two groups of LEDs, one group for each line

card and one group for the system.

Line Card LEDs Each line card has six LEDs, as shown in Figure 6.

Figure 6. Line Card LEDs

The line card LEDs include a RDY (Ready) LED that provides information

about the overall operation of the line card, and two groups marked TRIB

and LINE. The TRIB LEDs provide information about the tributary side of

the line card (the operation of the SFP), and the LINE LEDs display

information about the line side of the line card (the operation of the RX and

TX Wavelength Division Multiplexing (WDM) ports).

124

The LEDs are described in the following tables:

The RDY LED is described in Table 2.

The tributary side TX and RX LEDs are described in Table 3 on

page 24.

The line side TX and RX LEDs are described in Table 4 on page 25.

The line side Sync LED is described in Table 5 on page 27.

Table 2 describes the RDY LED on the tributary side.

Table 2. RDY LED

State Description

Flashing green Power is on, but the card is in the wrong slot.

Note that when a new version of the AT-S65

management software is being downloaded, the

RDY LED may flash on all line cards until the

downloading is complete.

Solid green Power is on and the card is in the correct slot.

Off The line card is not receiving any power.

23

Page 24

Chapter 1: Overview

Note

When you install or reinstall a line card, the AT-S65 management

software recognizes this change within 20 seconds.

The operation of the tributary side TX and RX LEDs is affected by the

status of the Missing Link feature in the AT-S65 management software.

Table 3 describes the TX and RX LEDs on the tributary side.

Table 3. Tributary Side TX and RX LEDs

Missing Link

State

TX and RX

State

Enabled TX: Solid green

RX: Solid green

TX: Off or

flashing green

RX: Solid green

TX: Flashing

green

RX: Off

Description

The SFP port has established a

link with its local end node as well

as with its corresponding end

node connected to the remote

system.

The SFP port is receiving packets

or a link signal from its local end

node but has not established a link

with its corresponding remote end

node connected to the remote

system.

Or, the port was manually disabled

using the AT-S65 software, but is

still receiving packets or a link

signal from its local end node.

The SFP port has not established

a link with its local end node. It is

receiving packets or a link signal

from its corresponding remote end

node connected to the remote

system.

24

TX: Off

RX: Off

No SFP is installed.

Or, the port was manually shut

down using the AT-S65

management software and the

local end node connected to the

port was powered off.

Or, the cable to the SFP port was

disconnected.

Page 25

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Table 3. Tributary Side TX and RX LEDs (Continued)

Missing Link

State

TX and RX

State

Disabled TX: Solid green

RX: Solid green

TX: Solid green

RX: Off

TX: Off

RX: Solid green

TX: Off

RX: Off

Description

The SFP port has established a

link with its end node.

The SFP port is transmitting

packets or a link signal but has not

established a link to its local end

node.

The port was manually shut down

using the AT-S65 management

software, but is still receiving

packets or a link signal from its

local end node.

No SFP is installed.

Or, the port was manually shut

down using the AT-S65

management software and the

end node connected to the port

was powered off.

Or, the cable to the SFP port was

disconnected.

The operation of the line side TX and RX LEDs is affected by the status of

the Missing Link feature in the AT-S65 management software. Table 4

describes the line side TX and RX LEDs.

Table 4. Line Side TX and RX LEDs

Missing Link

State

Enabled TX: Solid green

TX and RX

State

RX: Solid green

Description

The line port has established a link

with its corresponding end node

connected to the remote system.

TX: Off

RX: Off

The line port is not receiving or

sending packets.

Or, the port was manually shut

down using the AT-S65

management software while the

port was not receiving packets or a

signal.

25

Page 26

Chapter 1: Overview

Table 4. Line Side TX and RX LEDs (Continued)

Missing Link

State

TX and RX

State

Enabled TX: Flashing

green

RX: Off

TX: Off

RX: Flashing

green

Disabled TX: Solid green

RX: Solid green

TX: Flashing

green

RX: Off

Description

The line port has not established a

link with its corresponding end

node on the remote system and

the line port is not receiving

packets or a signal.

The local SFP port has not

established a link with its

corresponding local end node.

Or, the line port is not receiving

packets or a signal.

Or, the port was manually shut

down using the AT-S65

management software while the

port was receiving packets or a

signal.

The line port has established a link

with the remote line port.

The line port has not established a

link with the remote line port.

TX: Off

RX: Flashing

green

TX: Off

RX: Off

The port was manually shut down

using the AT-S65 management

software but is still receiving

packets or a link signal from its

remote end node.

The port was manually shut down

using the AT-S65 management

software.

Or, the optical cable to the remote

line port is disconnected.

26

Page 27

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

CLASS 1

LASER PRODUCT

100 10

10/100Base-TX

RS-232

TERMINAL

FT

CO

PA

PB

RESET

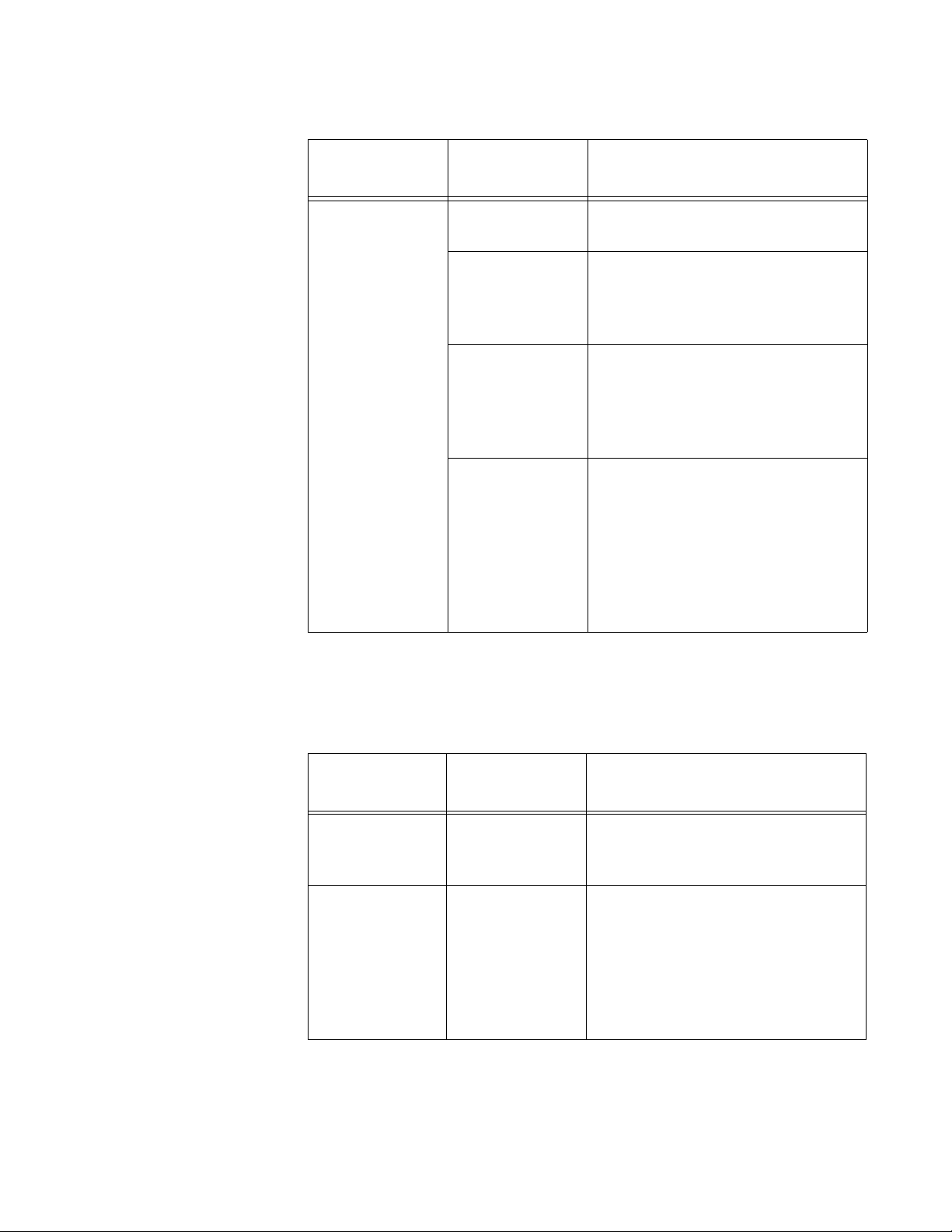

Table 6 describes the line side Sync LED.

Table 5. Line Side Sync LED

State Description

Fast flashing green The RX path signal is synchronized.

Slow flashing green The TX path signal is synchronized.

Solid green Both the RX and TX path signals are

synchronized.

Off No activity.

System LEDs To the right of the RS-232 terminal port are four system LEDs, as shown in

Figure 7 and described in Table 6.

125

Figure 7. System LEDs

Table 6. System LEDs

LED Definition State Description

FT Fault Solid red System fault.

CO Console Solid green User is logged in to the system

through the RS-232 terminal port.

Flashing green A management software update is

being downloaded through the

RS-232 terminal port.

PA Power supply

Solid green Normal operation.

slot A

Fast flashing green The output of the power supply in slot

A is not OK.

Slow flashing green The operation of the power supply in

slot A is normal but one or two fans

have failed.

27

Page 28

Chapter 1: Overview

LED Definition State Description

Table 6. System LEDs (Continued)

PB Power supply

slot B

Solid green Normal operation.

Fast flashing green The output of the power supply in slot

B is not OK.

Slow flashing green The operation of the power supply in

slot B is normal but one or two fans

have failed.

28

Page 29

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Management Connections

The AT-LX3800U chassis provides two management connections to the

preinstalled AT-S65 management software:

RS-232 terminal port for local (out-of-band) management

10/100Base-TX Ethernet port for remote management using Telnet

Terminal Port You can use the terminal port to establish a local (out-of-band)

management session with the chassis to configure parameters and also

view information about the operating of the system and line cards. You

establish a local management session with the switch by connecting either

a terminal, or a personal computer with a terminal emulation program, to

the port.

The terminal port has a DIN-8 style connector. A management cable is

supplied with the chassis.

10/100Base-TX

Ethernet Port

The terminal port is set to the following specifications:

Baud rate: 115200 bps

Data bits: 8

Parity: None

Stop bits: 1

You can use the AT-S65 management software to change the terminal

port settings.

You can also manage the AT-LX3800U chassis from any workstation on

your network through the 10/100Base-TX Ethernet port using Telnet.

29

Page 30

Chapter 1: Overview

AT-LXPWR Power Supply Module

The AT-LX3800U chassis is shipped with one AT-LXPWR power supply

preinstalled in slot A, and one empty slot (B) for an optional redundant

power supply (RPS). Two power supply versions, AC and DC, are

available for the AT-LX3800U chassis, as described below. Both slots

support any combination of AC and DC power supplies.

When two power supplies are installed, one of them works in standby

mode while the other one provides full power to the chassis. If one power

supply fails, the remaining power supply provides all the power to the

system, preventing a system failure.

AT-LXPWR/AC

Power Supply

The AT-LXPWR/AC power supply is shown in Figure 8.

AT-LXPWRAC

ON

100-240V

AC

~

126

Figure 8. AT-LXPWR/AC Power Supply

For information about installing an AT-LXPWR/AC power supply, consult

the documentation that is shipped with the unit.

30

Page 31

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

AT-LXPWR/DC

Power Supply

The AT-LXPWR/DC power supply is shown in Figure 9.

AT-LXPWR/DC

FO

R

C

E

NT

R

P

A

O

LIZ

W

E

E

R

D

CO

D

C

N

N

IN

E

S

TA

L

L O

R

N

E

LY

S

TR

I

C

TED

A

LO

CA

TION

40-60VDC

CT

IO

N

,

IN

A

CCES

S

ON

700

Figure 9. AT-LXPWR/DC Power Supply

For information about installing an AT-LXPWR/DC power supply, consult

the documentation that is shipped with the unit.

31

Page 32

Chapter 1: Overview

ON

Power Connectors

The AT-LX3800U chassis is available with one of two power supply

options: AC or DC.

AC Power

Connector

DC Power

Connector

The AC power supply in an AT-LX3800U chassis has an On/Off switch, as

shown in Figure 10.

AT-LXPW

RAC

ON

100-240V

A

C

~

On/Off Switch

AC Power Connector

PWR A

471

Figure 10. AC Power Connector and On/Off Switch

The DC power supply in an AT-LX3800U chassis has a DC terminal block,

as shown in Figure 11.

32

706

Figure 11. DC Terminal Block

For information about wiring a DC power supply refer to “Wiring and

Powering On a DC Powered System” on page 63.

Page 33

Topologies

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

The AT-LX3800U chassis can be configured for multiple network

topologies. The following figures show several possible configurations.

Figure 12 shows two AT-LX3800U systems linked to multiple devices.

Video

Server

Video

Server

Ethernet

Switch

Ethernet

Switch

Ethernet

Switch

AT-LX3800U

TX

RX

AT-LX3800U

Fibre

Channel

Fibre

Channel

ATM

Switch

Video

Server

RX

TX

Video

Server

Ethernet

Switch

Ethernet

Switch

Ethernet

Switch

Channel

Fibre

Channel

ATM

Switch

Fibre

Figure 12. Standard Point-to-Point Configuration

33

Page 34

Chapter 1: Overview

The AT-LX3800U system is capable of fully regenerating, retiming, and

reshaping each tributary service. This allows for configurations which

extend services beyond the limits of the point-to-point configuration, as

shown in Figure 13.

Site B

Regeneration Location

Site A

AT-LX3800U

TX

RX

RX

AT-LX3800U

TX

Site C

RX

AT-LX3800U

TX

TX

AT-LX3800U

RX

Figure 13. Regeneration Configuration Using the Internal Loopback

Feature

For more information about using the AT-S65 software to set up this type

of topology, refer to Chapter 5, “Line Card Modes of Operation” in the

AT-S65 Management Software User’s Guide.

34

Page 35

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Figure 14 illustrates a loop-type backbone topology.

Backbone

Switch

Switch

Backbone

AT-LX3800U AT-LX3800U

TX

RX

TX

RX

TX

RX

AT-LX3800U

RX

TX

AT-LX3800U

AT-LX3800U

TX

RX

AT-LX3800U

RX

TX

TX

RX

TX

RX

AT-LX3800UAT-LX3800U

Backbone

Switch

Backbone

Switch

Figure 14. Loop-type Backbone Topology

35

Page 36

Chapter 1: Overview

36

Page 37

Chapter 2

Installation

This chapter contains the following installation information for the

AT-LX3800U chassis:

“Reviewing Safety Precautions” on page 38

“Selecting a Site for the Chassis” on page 42

“TX and RX Fiber Optic Cable Specifications” on page 43

“Unpacking the Chassis” on page 44

“Installing the Power Cord Retaining Clip (AC Power Supply Only)” on

“Installing the AT-LX3800U Chassis in a Rack” on page 47

“Installing an AT-LX3811/x Line Card” on page 50

page 45

“Installing an SFP Transceiver in a Line Card” on page 53

“Installing an AT-LX3801 Blank Slot Cover” on page 55

“Cabling the Chassis” on page 57

“Powering On an AC Powered System” on page 60

“Wiring and Powering On a DC Powered System” on page 63

“Starting a Local Management Session” on page 66

“Starting a Remote Management Session” on page 68

“Warranty Registration” on page 70

37

Page 38

Chapter 2: Installation

Reviewing Safety Precautions

Please review the following safety precautions before you begin to install

the chassis or any of its components.

Note

When you see the

Safety, and Emission Information” on page 77 for translated safety

statements.

Warning: Class 1 Laser product.

Warning: Do not stare into the laser beam.

Warning: To prevent electric shock, do not remove the cover. No

user-serviceable parts inside. This unit contains hazardous

voltages and should only be opened by a trained and qualified

technician. To avoid the possibility of electric shock, disconnect

electric power to the product before connecting or disconnecting

the LAN cables.

, go to Appendix C, ”Translated Electrical,

1

2

3

Warning: Do not work on equipment or cables during periods of

lightning activity.

Warning: Power cord is used as a disconnection device. To deenergize equipment, disconnect the power cord.

Warning: Class I Equipment. This equipment must be earthed.

The power plug must be connected to a properly wired earth

ground socket outlet. An improperly wired socket outlet could

place hazardous voltages on accessible metal parts.

Pluggable Equipment. The socket outlet shall be installed near

the equipment and shall be easily accessible.

Caution: Air vents must not be blocked and must have free

access to the room ambient air for cooling.

Warning: Operating Temperature. This product is designed for a

maximum ambient temperature of 40° degrees C.

4

8

7

5

9

6

38

Page 39

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

All Countries: Install product in accordance with local and

National Electrical Codes.

Warning: As a safety precaution, install a circuit breaker with a

minimum value of 15 Amps between the equipment and the DC

power source.

Always connect the wires to the LAN equipment first before you

connect the wires to the circuit breaker. Do not work with HOT

feeds to avoid the danger of physical injury from electrical shock.

Always be sure that the circuit breaker is in the OFF position

before connecting the wires to the breaker.

Warning: Do not strip more than the recommended amount of

wire. Stripping more than the recommended amount can create

a safety hazard by leaving exposed wire on the terminal block

after installation.

12

10

11

Warning: When installing this equipment, always ensure that the

frame ground connection is installed first and disconnected last.

13

Warning: Check to see if there are any exposed copper strands

coming from the installed wire. When this installation is done

correctly there should be no exposed copper wire strands

extending from the terminal block. Any exposed wiring can

conduct harmful levels of electricity to persons touching the

wires.

This system works with positive grounded or negative grounded

DC systems.

Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect

that overloading of circuits might have on overcurrent protection

and supply wiring. Appropriate consideration of equipment

nameplate ratings should be used when addressing this

concern.

14

23

15

39

Page 40

Chapter 2: Installation

Caution: Risk of explosion if battery is replaced by an incorrect

type. Replace only with the same or equivalent type

recommended by the manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

Attention: Le remplacement de la batterie par une batterie de

type incorrect peut provoquer un danger d’explosion. La

remplacer uniquement par une batterie du même type ou de

type équivalent recommandée par le constructeur. Les batteries

doivent être éliminées conformément aux instructions du

constructeur.

A tray cable is required to connect the power source if the unit is

powered by centralized DC power. The tray cable must be a UL

listed Type TC tray cable and rated at 600 V and 90 degrees C,

with three conductors, minimum 14 AWG.

Warning: Mounting of the equipment in the rack should be such

that a hazardous condition is not created due to uneven

mechanical loading.

24

27

26

Warning: This unit might have more than one power cord. To

reduce the risk of electric shock, disconnect all power cords

38

32

40

39

before servicing the unit.

If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater

than the room ambient temperature. Therefore, consideration

should be given to installing the equipment in an environment

compatible with the manufacturer’s maximum rated ambient

temperature (Tmra).

Caution: Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the

equipment is not compromised.

Warning: Reliable earthing of rack-mounted equipment should

be maintained. Particular attention should be given to supply

connections other than direct connections to the branch circuits

(e.g., use of power strips).

Warning: Circuit breaker is used as a disconnection device. To

de-energize equipment, shut down the circuit breaker and then

disconnect the input wire.

40

Page 41

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Warning: This unit might have more than one power source. To

reduce the risk of electric shock, disconnect all power sources

before servicing the unit.

41

Page 42

Chapter 2: Installation

Selecting a Site for the Chassis

Observe the following requirements when you choose a site for the

chassis:

If you plan to install the chassis in an equipment rack, check to be sure

that the rack is safely secured and that it will not tip over. Devices in a

rack should be installed starting at the bottom, with the heavier devices

near the bottom of the rack.

If you are installing the chassis on a table, be sure that the table is

level and secure.

The power outlet for the chassis should be located near the unit and

should be easily accessible.

The site should provide easy access to the ports on the front of the

chassis. This arrangement will make it easy for you to connect and

disconnect cables as well as to view the LEDs.

To allow proper cooling of the chassis, air flow around the unit and

through its vents should be unrestricted.

Do not place objects on top of the chassis.

Do not expose the chassis to moisture or water.

Make sure that the site is a dust-free environment.

Use dedicated power circuits or power conditioners to supply reliable

electrical power to the device.

42

Page 43

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

TX and RX Fiber Optic Cable Specifications

The TX and RX ports require 9µ single mode fiber (SMF) cable with a

simplex SC/UPC connector.

Note

For information about the fiber optic cabling specifications for the

line cards, refer to the SFP installation instructions.

43

Page 44

Chapter 2: Installation

Unpacking the Chassis

To unpack the chassis, perform the following procedure:

1. Remove all components from the shipping package.

2. Make sure that the following components are included in the package.

If any item is missing or damaged, contact your Allied Telesyn sales

representative for assistance.

One AT-LX3800U chassis with preinstalled Ac or DC power

Note

Store the packaging material in a safe location. You must use the

original shipping material if you need to return the unit to Allied

Telesyn.

supply

Two rack-mount brackets

Eight flathead Phillips rack-mount bracket screws

Power cord (AC models only; Americas, EU, Australia, and

UK only)

AC power cord retaining clip (AC models only)

Management cable with DIN-8 connector for local

management connection

Documentation CD

Warranty card

3. Place the AT-LX3800U chassis on a level, secure surface.

44

Page 45

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Installing the Power Cord Retaining Clip (AC Power Supply Only)

To install the power cord retaining clip on an AC powered system, perform

the following procedure:

1. Locate the power cord retaining clip, as shown in Figure 15.

Figure 15. Power Cord Retaining Clip

2. Locate the retaining bracket on each side of the AC power connector

on the back of the chassis, as shown in Figure 16.

AT-LXPWRAC

O

N

100-240VAC

~

PWR A

Bracket

473

Figure 16. Power Cord Retaining Bracket

3. With the “u” of the clip facing up, press the sides of the clip toward the

center and insert the short ends into the holes in the retaining bracket,

as shown in Figure 17.

AT-LXPWRAC

O

N

100-240VAC

~

PWR A

474

Figure 17. Inserting the Retaining Clip into the Retaining Bracket

45

Page 46

Chapter 2: Installation

4. Verify that the retaining clip is in the correct position, as shown in

Figure 18.

AT-LXPWRAC

O

N

100-240VAC

~

PWR A

Figure 18. Retaining Clip Properly Installed in the Bracket

46

Page 47

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Installing the AT-LX3800U Chassis in a Rack

The chassis is shipped with two rack-mount brackets. To mount the

chassis in a rack, perform the following procedure:

1. Place the chassis upside down on a level, secure surface.

2. Using a flathead screwdriver, remove the plastic feet from the bottom

of the chassis, as shown in Figure 19.

Figure 19. Removing Plastic Feet from the Chassis

3. Turn the chassis right side up.

4. Install a bracket on one side of the chassis using a Phillips screwdriver

and four of the rack-mount screws included with the unit. There are two

ways that you can attach the brackets to the chassis: so that it extends

forward from the rack, or flush with the front of the rack, as shown in

Figure 20.

136

801

8

8

8

AT-LX3800U

A

T-LX3801

C

L

A

S

L

S

A

S

1

E

R

P

R

O

D

U

C

T

100 10

RESET

10/100Base-TX

TX

LINE

RX

TERMINAL

FT

C

O

PA

RS-232

PB

8

AT-LX3800U

AT-LX380

1

TX

LINE

RX

C

L

A

S

L

S

A

S

1

E

R

P

R

O

D

U

C

T

100 10

TERMINAL

10/100Base-TX

FT

C

O

PA

RS-232

PB

RESET

Figure 20. Rack-Mount Bracket Configurations

5. Repeat step 4 to attach the remaining bracket to the other side of the

chassis.

47

Page 48

Chapter 2: Installation

7

6. Mount the chassis in a 19-inch rack using appropriate screws (not

supplied), as shown in Figure 21.

3801

AT-LX3801

8

8

AT-LX3800U

CL

ASS 1

LA

SE

R PRODUCT

100 10

RE

SET

10/100Base-TX

TX

LINE

RX

TERMINAL

F

T

C

O

P

A

RS-232

P

B

13

Figure 21. Mounting the AT-LX3800U Chassis in a 19-inch Rack

Warning: To prevent electric shock, do not remove the cover. No

user-serviceable parts inside. This unit contains hazardous

voltages and should only be opened by a trained and qualified

technician. To avoid the possibility of electric shock, disconnect

electric power to the product before connecting or disconnecting

the LAN cables.

3

Warning: Do not work on equipment or cables during periods of

lightning activity.

4

48

Warning: Power cord is used as a disconnection device. To de-

energize equipment, disconnect the power cord.

5

Warning: Class I Equipment. This equipment must be earthed.

The power plug must be connected to a properly wired earth

ground socket outlet. An improperly wired socket outlet could

place hazardous voltages on accessible metal parts.

6

Pluggable Equipment. The socket outlet shall be installed near

the equipment and shall be easily accessible.

7

Caution: Air vents must not be blocked and must have free

access to the room ambient air for cooling.

Warning: Operating Temperature. This product is designed for a

maximum ambient temperature of 40° degrees C.

8

9

Page 49

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect

that overloading of circuits might have on overcurrent protection

and supply wiring. Appropriate consideration of equipment

nameplate ratings should be used when addressing this

concern.

23

Warning: Mounting of the equipment in the rack should be such

that a hazardous condition is not created due to uneven

mechanical loading.

27

If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater

than the room ambient temperature. Therefore, consideration

should be given to installing the equipment in an environment

compatible with the manufacturer’s maximum rated ambient

temperature (Tmra).

38

Caution: Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the

equipment is not compromised.

39

Warning: Reliable earthing of rack-mounted equipment should

be maintained. Particular attention should be given to supply

connections other than direct connections to the branch circuits

(e.g., use of power strips).

40

49

Page 50

Chapter 2: Installation

Installing an AT-LX3811/x Line Card

To install an AT-LX3811/x line card, perform the following procedure:

Note

The AT-LX3811 line cards are numbered and color-coded for

insertion in the corresponding numbered and color-coded slot in the

chassis. The RDY LED on the line card flashes green and the

AT-S65 management software displays an error if a line card is

inserted in the wrong slot.

1. Remove the AT-LX3811/x line card from its shipping package and

store the package in a safe place.

You must use the original package if you need to return the unit to

Allied Telesyn.

2. Select the slot in the AT-LX3800U chassis that corresponds to the

number of the line card you want to install.

3. Remove any AT-LX3801 Blank Slot Cover from the slot.

Keep the blank slot cover in a safe area in case you remove the line

card. The blank slot cover protects the fiber optic connectors on the

backplane from becoming dirty, and helps maintain proper air flow

through the chassis.

4. Remove the dust caps from the fiber optic connectors at the back of

the line card, as shown in Figure 22.

173

50

Figure 22. Removing the Dust Covers

Page 51

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

RDY

TX

RX

TRIB

SYNC

TX

RX

LINE

3

4

5

6

S

FP

SYNC

TX

R

X

LINE

RDY

TX

RX

TRIB

AT-LX3811/3

SFP

SYNC

TX

RX

LINE

RDY

TX

RX

TRIB

AT-LX3811/4

TR

IB

R

TRIB

SYN

C

TX

RX

LINE

AT-LX3811/8

SFP

SYNC

TX

RX

LINE

RDY

TX

RX

TRIB

SFP

SYNC

TX

RX

LINE

RDY

TX

RX

TRIB

AT-LX3811/6

5. Locate the left and right alignment guides in the slot, as shown in

Figure 23.

Alignment Guides

138

Figure 23. Location of Alignment Guides

6. Align the back edge of the line card with the left and right alignment

guides.

7. Slide the line card into the slot that corresponds to the line card

number, as shown in Figure 24, until the faceplate is flush with the

front. (See “Line Card Descriptions” on page 20 for a list of the line

cards and their corresponding slot numbers.)

139

Figure 24. Inserting the Line Card

51

Page 52

Chapter 2: Installation

2

3

4

5

6

SFP

SYNC

TX

RX

LIN

E

R

DY

TX

RX

TRIB

AT-LX3811/3

SFP

SYNC

TX

R

X

LINE

R

DY

TX

RX

TR

IB

AT-LX3811/4

TRIB

RD

R

TR

IB

SYNC

TX

RX

LIN

E

SFP

S

YNC

TX

RX

LINE

R

DY

TX

R

X

TRIB

AT-LX3811/6

SFP

SYN

C

TX

R

X

LINE

R

DY

TX

R

X

TRIB

AT-LX3811/5

8. Use a Phillips head screwdriver to tighten the captive screws on the

line card, as shown in Figure 25.

140

Figure 25. Tightening the Captive Screws

Note

Always tighten the captive screws to secure the line card to the

chassis. This helps ensure that the fiber optic connectors at the back

of the line card are securely connected to the backplane.

9. Repeat this procedure to install additional line cards.

52

Page 53

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

3

4

5

SFP

SYNC

TX

RX

LINE

RDY

TX

RX

TRIB

AT-LX3811/3

SFP

SYNC

TX

RX

LINE

RDY

TX

RX

TRIB

AT-LX3811/4

TRIB

SFP

SYNC

TX

RX

LINE

RDY

TX

RX

TRIB

AT-LX3811/5

Installing an SFP Transceiver in a Line Card

To install an SFP transceiver in a line card, perform the following

procedure:

Note

The transceiver can be hot swapped; you do not need to power off

the chassis to install an SFP transceiver. However, always remove

the cables before removing the SFP.

Note

You must install the transceiver before you connect cables to it.

1. Remove the SFP from its shipping container and store the packaging

material in a safe location.

Note

An SFP transceiver can be damaged by static electricity. Be sure to

observe all standard electrostatic discharge (ESD) precautions,

such as wearing an antistatic wrist strap, to avoid damaging the

transceiver.

2. Remove the dust plug from the SFP port, as shown in Figure 26.

Figure 26. Removing the Dust Plug from the SFP Port

Store the dust plug in a safe location for possible use later.

3. Locate the label on the transceiver and turn it so that the label is on the

top and the alignment groove is on the bottom.

53

Page 54

Chapter 2: Installation

3

4

5

S

FP

SYNC

TX

RX

LINE

RD

Y

TX

R

X

TRIB

AT-LX3811/3

SFP

SY

NC

TX

RX

LINE

RDY

TX

RX

TRIB

AT-LX3811/4

TRIB

SYNC

TX

RX

LINE

S

FP

S

YN

C

TX

R

X

LINE

RDY

TX

R

X

TRIB

AT-LX3811/5

RD

Y

TX

RX

TRIB

AT

4. Slide the SFP into the slot in the line card, as shown in Figure 27.

144

Figure 27. Installing an SFP Transceiver in a Line Card

For information about cabling the SFP, refer to “Connecting the Fiber

Optic Cables to a Line Card” on page 57.

54

Page 55

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

RDY

TX

RX

TRIB

SYNC

TX

RX

LINE

Installing an AT-LX3801 Blank Slot Cover

The AT-LX3801 Blank Slot Cover protects the fiber optic connectors on

the backplane from becoming dirty, and helps maintain proper air flow

through the chassis.

Note

Allied Telesyn strongly recommends that a blank slot cover be

inserted in any slot that does not contain a functioning line card.

To install a blank slot cover, perform the following procedure:

1. Remove the AT-LX3801 Blank Slot Cover from its shipping package

and store the package in a safe place.

You must use the original package if you need to return the unit to

Allied Telesyn.

2. Select the slot in the AT-LX3800U chassis where you want to install

the blank slot cover.

3. If an AT-LX3811/x line card is installed in the slot, do the following:

a. Disconnect the cables from the SFP in the line card.

b. Reinstall the SFP port dust cap.

c. Remove the line card from the slot.

4. Locate the left and right alignment guides in the slot, as shown in

Figure 28.

Alignment Guides

138

Figure 28. Location of Alignment Guides

5. Align the back edge of the blank slot cover with the left and right

alignment guides.

55

Page 56

Chapter 2: Installation

3

4

5

6

S

FP

SYNC

TX

R

X

LIN

E

R

DY

TX

RX

TRIB

AT-LX3811/3

SFP

SYNC

TX

RX

LIN

E

RDY

TX

RX

TRIB

AT-LX3811/4

TR

IB

RD

R

TR

IB

FP

SY

NC

TX

RX

LIN

E

AT-LX3801

S

FP

SYNC

TX

R

X

LINE

RDY

TX

RX

TRIB

AT-LX3811/6

3

4

5

6

SFP

SYNC

TX

RX

LINE

R

DY

TX

RX

TRIB

AT-LX3811/3

SFP

SYNC

TX

R

X

LIN

E

RDY

TX

R

X

TRIB

AT-LX3811/4

TR

IB

R

TRIB

SYNC

TX

RX

LINE

SFP

SYNC

TX

RX

LINE

RDY

T

X

RX

TRIB

AT-LX3811/6

AT-LX3801

6. Slide the blank slot cover into the slot, as shown in Figure 29, until the

faceplate is flush with the front.

142

Figure 29. Installing the Blank Slot Cover

7. Use a Phillips head screwdriver to tighten the captive screws, as

shown in Figure 30.

Figure 30. Tightening the Captive Screws

Note

Always tighten the captive screws to secure the blank slot cover to

the chassis. This helps ensure that the fiber optic connectors on the

backplane are covered by the blank slot cover connectors.

8. Repeat this procedure to install additional blank slot covers.

56

Page 57

Cabling the Chassis

3

4

5

SFP

SYNC

TX

R

X

LINE

R

DY

TX

R

X

TRIB

AT-LX3811/3

S

FP

SYNC

TX

RX

LIN

E

R

DY

TX

R

X

TRIB

AT-LX3811/4

TRIB

SYNC

TX

R

X

LINE

SFP

SYNC

TX

RX

LINE

R

DY

TX

RX

TRIB

AT-LX3811/5

RDY

TX

RX

TR

IB

AT

Perform the following procedures to connect the fiber optic cables to the

tributary ports of the line cards and the line (WDM) ports of a device.

AT-LX3800U Multi-Service Transport System Installation and Maintenance Guide

Connecting the

Fiber Optic

Cables to a Line

Card

To connect a fiber optic cable to a line card, perform the following

procedure:

Warning: Class 1 Laser product.

Warning: Do not stare into the laser beam.

1

2

1. Remove the dust plug from the SFP in the line card, as shown in

Figure 27.

145

Figure 31. Removing the Dust Plug from the SFP

Note

For information about the proper cable type, refer to the installation

instructions you received with your SFP.

Note

Before you install the cable in SFP, verify that the optical power input

to the SFP is within the SFP transceiver’s dynamic range.

57

Page 58

Chapter 2: Installation

3

4

5

SFP

SYNC

TX

RX

LINE

RD

Y

TX

RX

TRIB

AT-LX3811/3

S

FP

SYNC

TX

RX

LINE

RDY

TX

RX

TRIB

AT-LX3811/4

TRIB

S

YNC

TX

RX

LINE

S

FP

SYNC

TX

R

X

LIN

E

RDY

TX

R

X

TRIB

AT-LX3811/5

RD

Y

TX

R

X

TRIB

A

2. Connect the fiber optic cable to the SFP, as shown in Figure 32.

146

Figure 32. Connecting a Fiber Optic Cable to the SFP